Patents

Literature

69results about How to "Guaranteed measurement stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

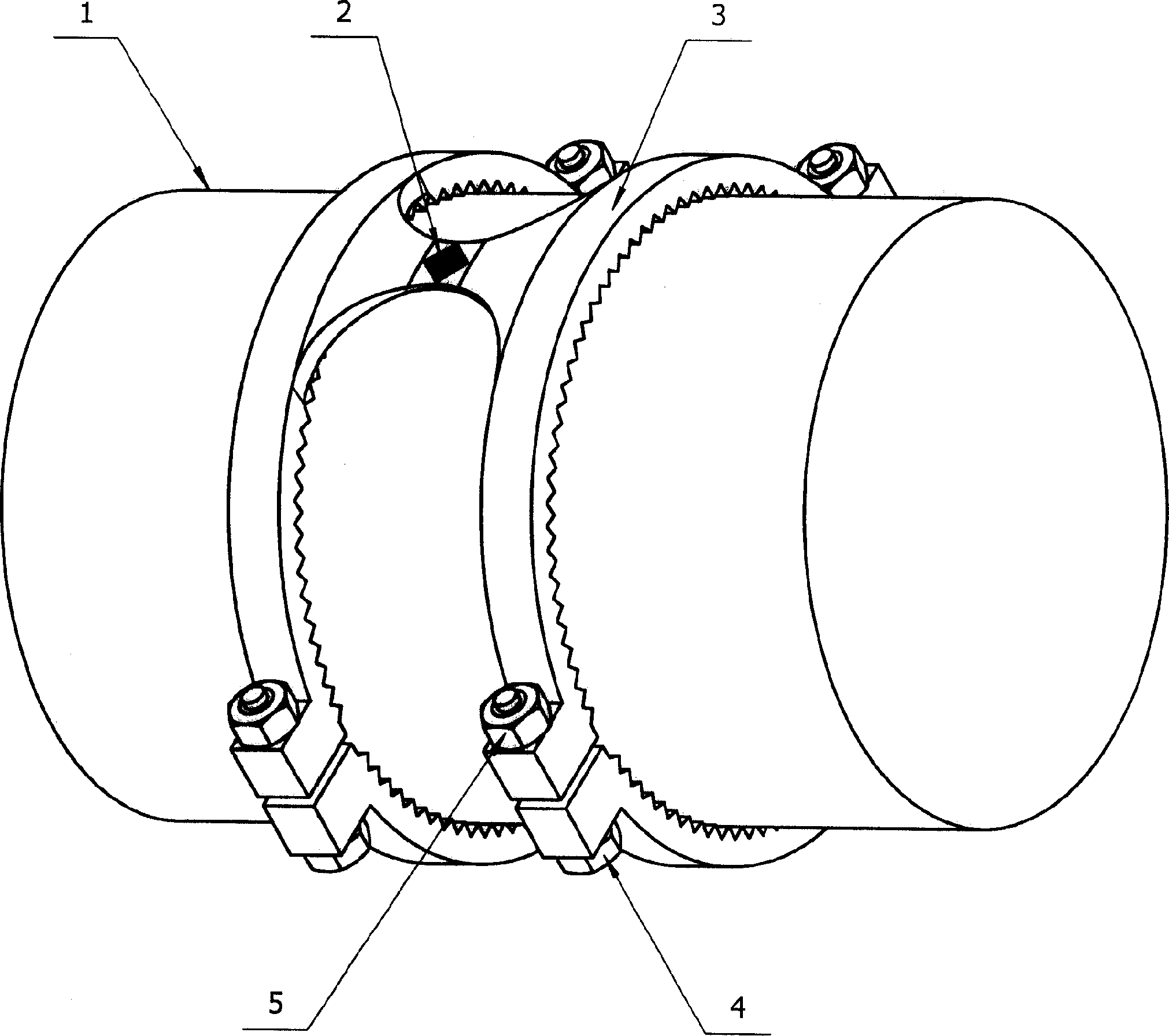

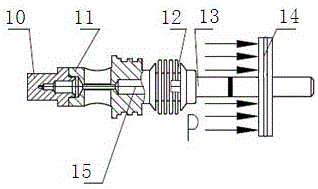

Clamp ring type torque sensor

InactiveCN1752725AEasy to detectAvoid insufficient clamping forceWork measurementTorque measurementElastomerDrive shaft

The present invention relates to a clamp ring type torque sensor for obtaining drive shaft torque. Said sensor adopts semi-ring design, and said sensor can be quickly clamp-mounted on the drive shaft only by utilizing holt and nut. When the torque is received by drive shaft, the shearing deformation which is directly proportional to the torque on the drive shaft can be transferred to the sensor elastic body on which a strain foil is stuck so as to obtain the torque signal of said drive shaft. Said invention also provides the design method of said sensor elastic body.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

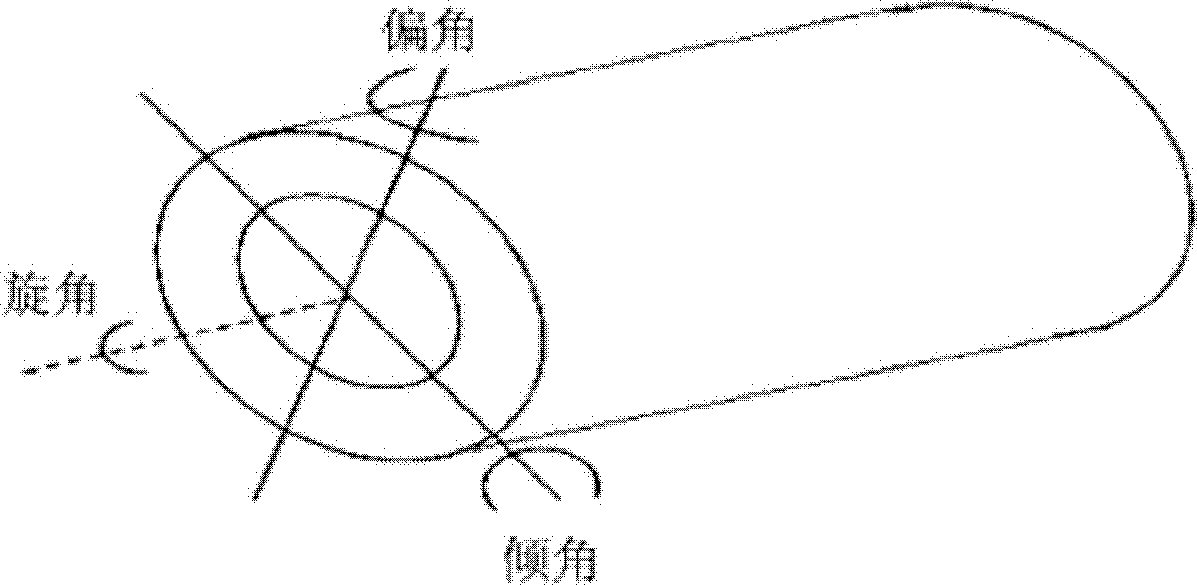

Measuring method of tunnel shield posture

InactiveCN101684731AGuaranteed measurement accuracyGuaranteed measurement stabilityTunnelsTheodolitesTheodolitePrism

The invention provides a measuring method of tunnel shield posture, comprising the following steps: 1. respectively arranging a theodolite, a prism, a front ruler and a rear ruler; 2. calculating the design coordinates of the front ruler and the rear ruler according to the design coordinates of the head part and the tail part of a shield machine and the relative position among the front ruler, the rear ruler and the shield machine, and calculating the design included angles alphafront of the prism, the theodolite and the front ruler and the included angles alpharear of the prism, the theodolite and the rear ruler; 3. using the theodolite to respectively measure the included angles betafront of the prism, the theodolite and the front ruler and the included angles betarear of the prism, thetheodolite and the rear ruler; 4. according to the design coordinates of the front ruler and the rear ruler and the coordinates of the theodolite, calculating the distance Sfront between the front ruler and the theodolite and the distance Srear between the rear ruler and the theodolite; 5. calculating the plane deviation of the front ruler and the rear ruler; 6. and according to the plane deviation of the front ruler and the rear ruler, calculating the plane deviation of the head part and the tail part of the shield machine in horizontal direction. The invention improves measurement precision, simplifies measurement process and greatly saves engineering cost.

Owner:SHANGHAI MECHANIZED CONSTR GRP

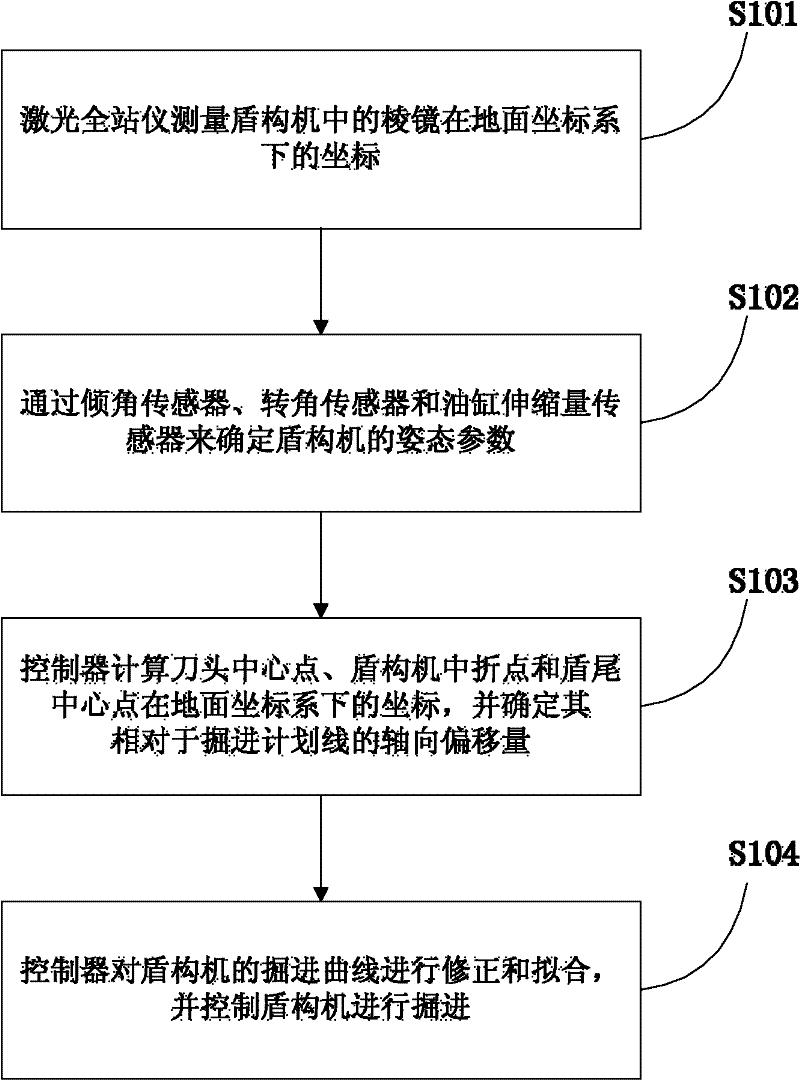

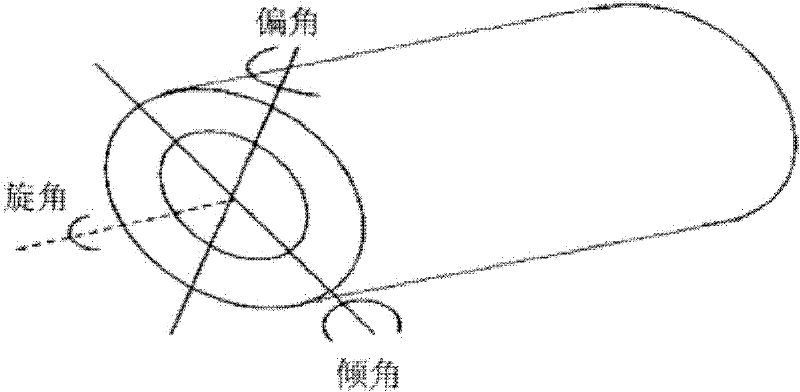

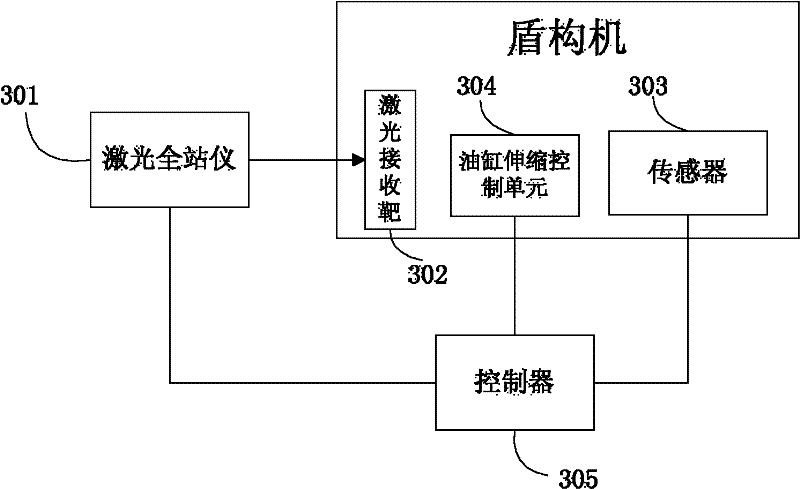

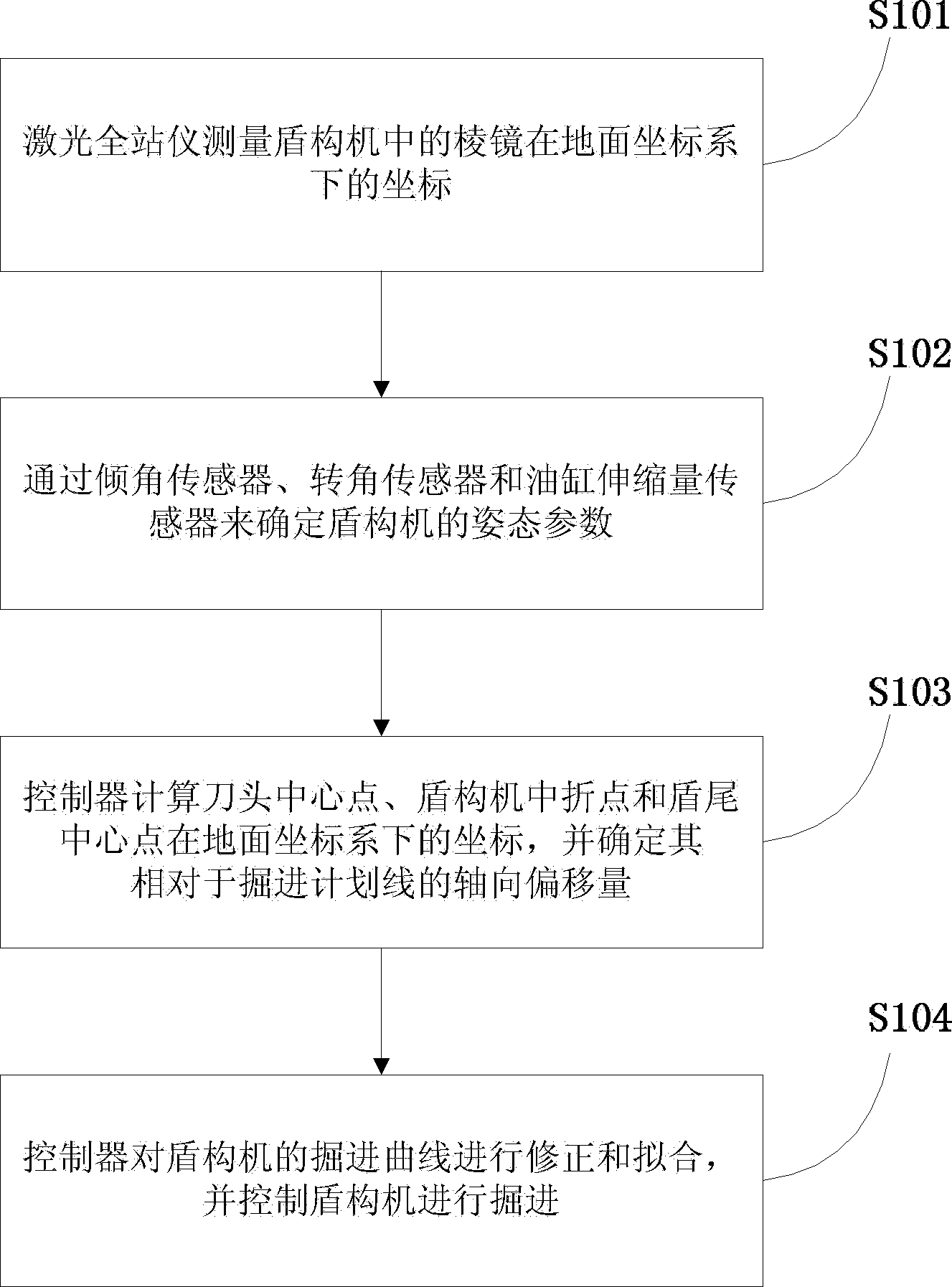

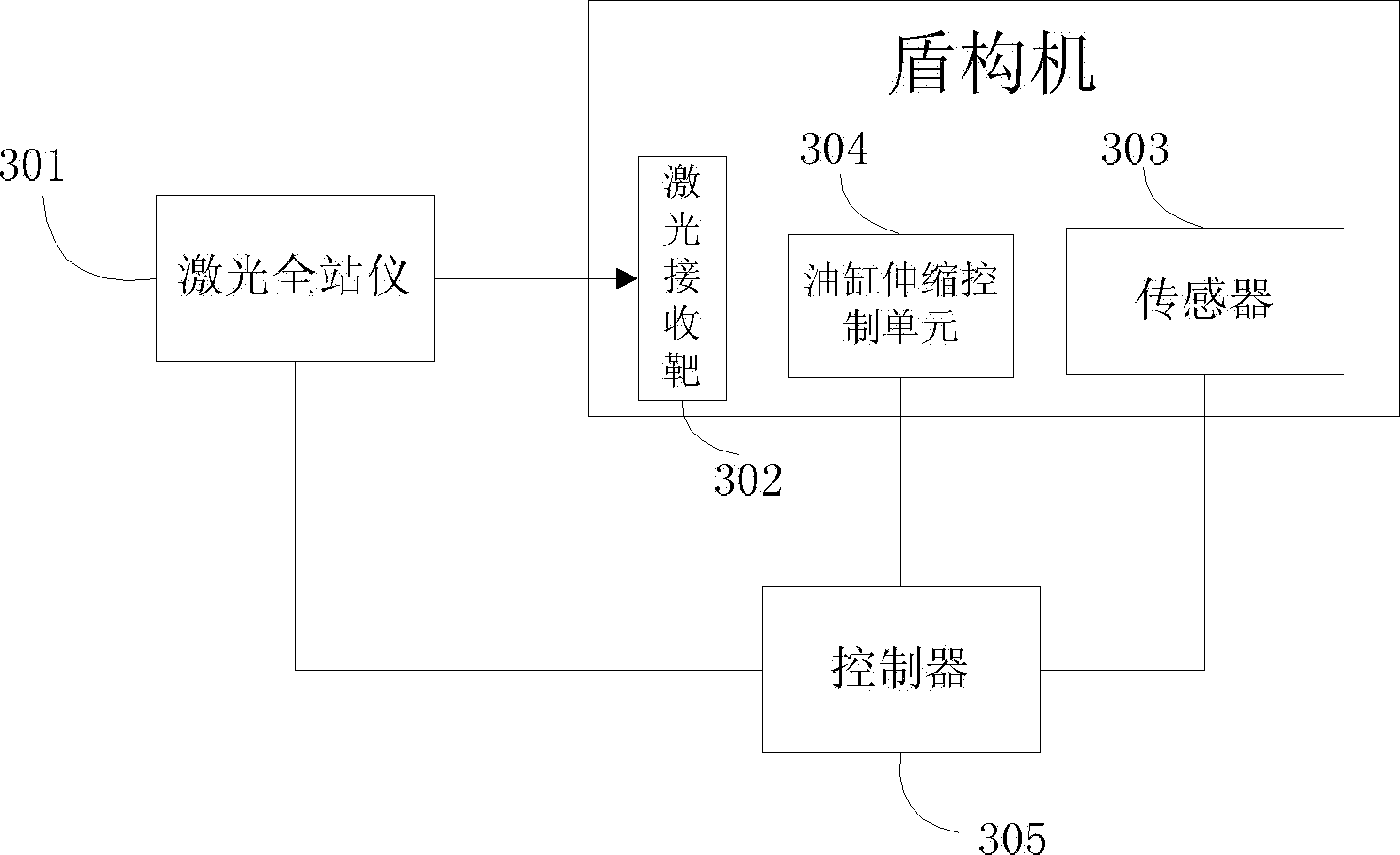

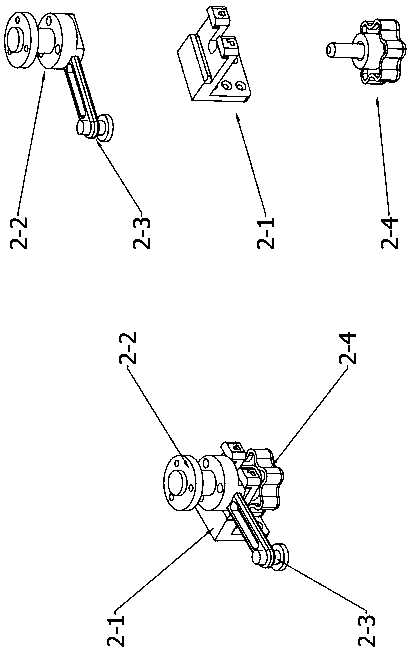

Laser-oriented control system and method for shield machine

InactiveCN102518445AHigh degree of automationImprove construction efficiencyTunnelsControl systemTotal station

The invention discloses a laser-oriented control system and method for a shield machine. The method comprises the following steps: measuring the coordinate of a prism under a ground coordinate system in the shield machine by a laser total station instrument; determining the attitude parameter of the shield machine by a laser receiving target and a sensor; calculating the coordinates of a tool bit centre point, a middle folding point of the shield machine and a shield tail centre point under the ground coordinate system by a controller; determining the axial offset amount of the tool bit centre point, the middle folding point of the shield machine and the shield tail centre point relative to a tunneling plan line; revising and fitting the tunneling curve of the shield machine by the controller; and controlling the shield machine to tunnel by the controller. According to the technical scheme disclosed by the invention, the degree of automation and the construction efficiency of the traditional control survey system are greatly improved on the premise of guaranteeing the measurement precision and stability, and the engineering expenditure can be greatly saved.

Owner:BEIJING INFORMATION SCI & TECH UNIV

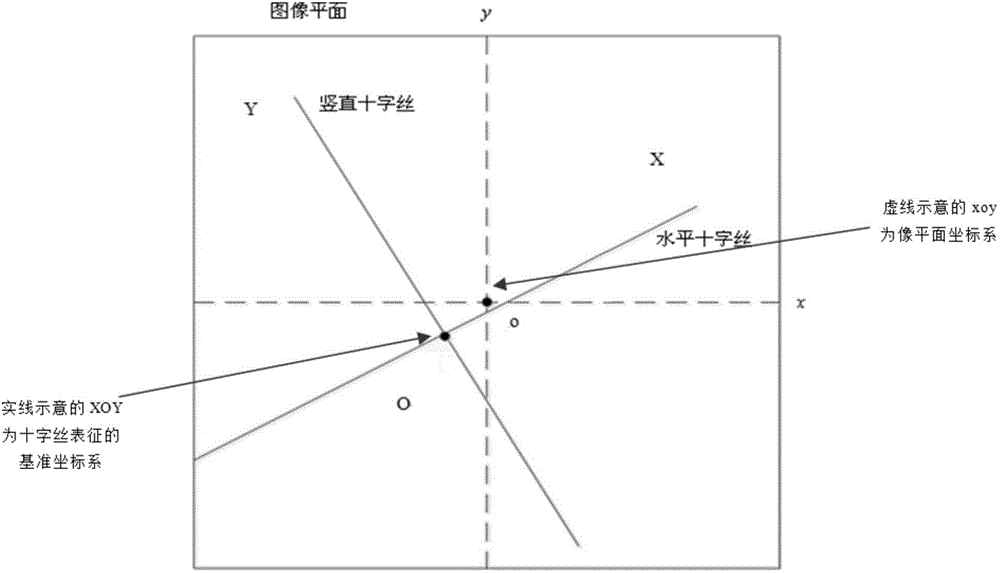

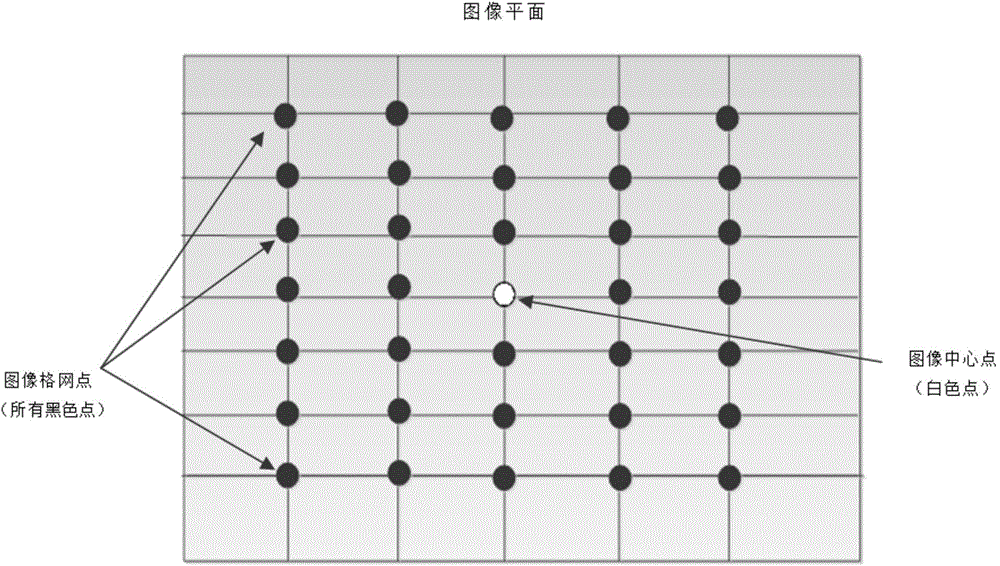

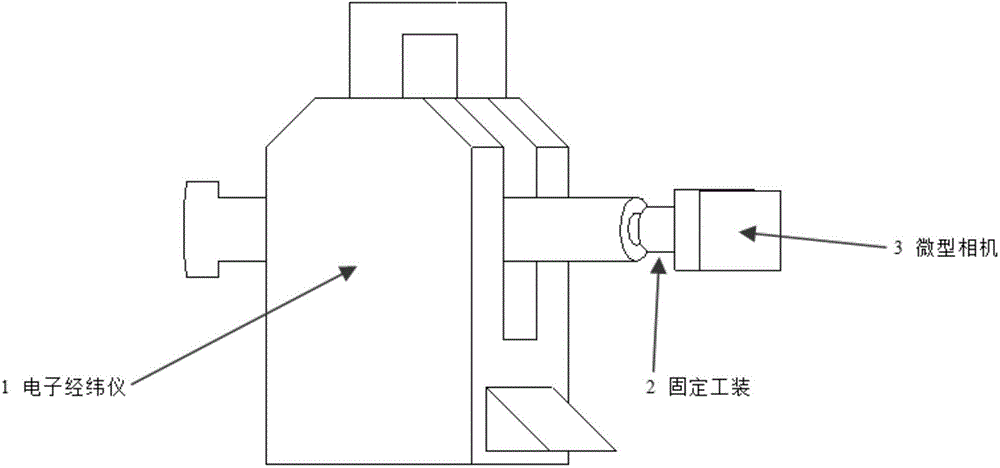

Automatic theodolite collimation method based on image recognition

The invention discloses an automatic theodolite collimation measurement method based on image recognition. A measurement device of the method comprises an electronic theodolite internally provided with a drive motor, a miniature measurement camera and a fixed fixture, wherein the automatic collimation measurement of the electronic theodolite is guided by the miniature measurement camera, a transformational relation between an image plane coordinate system and a theodolite eyepiece reticule observation coordinate system and a relation between an electronic theodolite deflection angle quantity and a miniature measurement camera pixel quantity when a focal length is in a collimation observation state are calibrated, and collimation return light and an electronic theodolite eyepiece reticule and a deviation relation are automatically extracted until collimation is achieved. According to the automatic theodolite collimation measurement method adopted by the invention, an image recording and analyzing method is used for replacing a conventional human eye observation method, so that the measurement stability in the case of long-term measurement is ensured, and the measurement work efficiency is increased.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

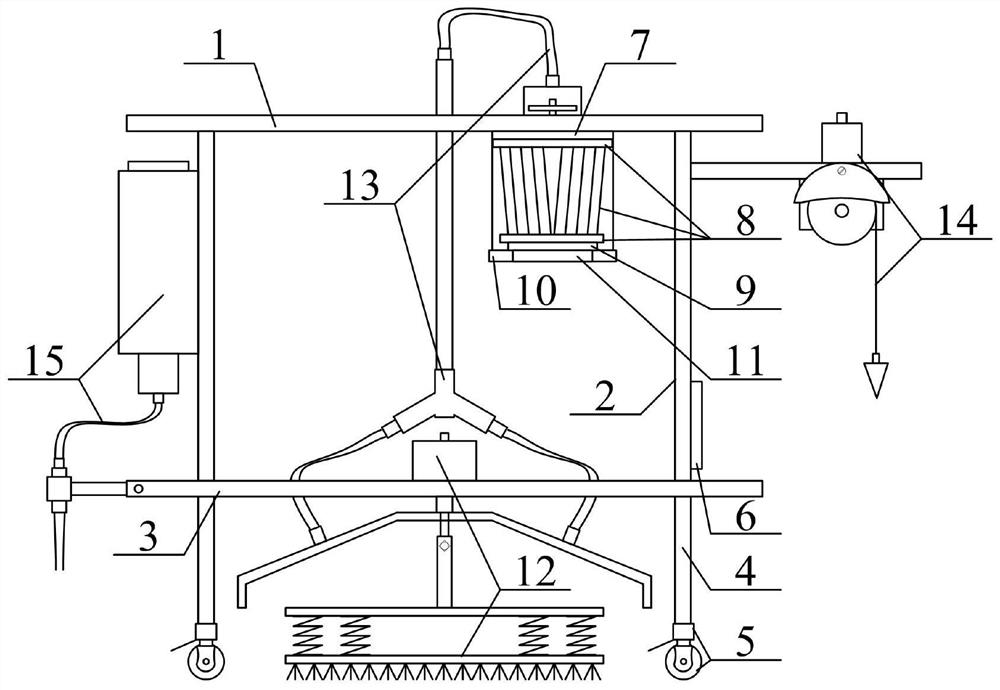

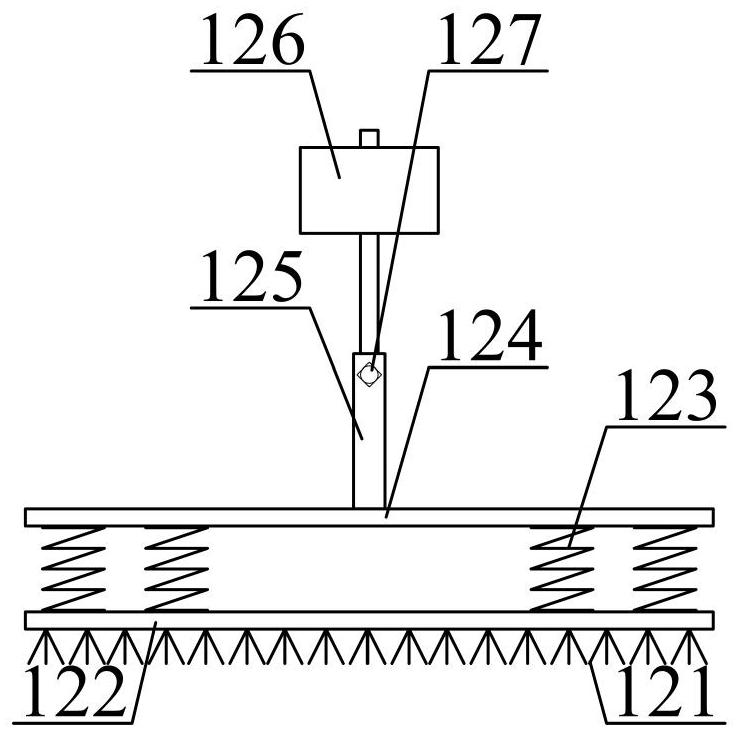

Temperature detecting and self-cleaning cooling device for arc fuse wire additive manufacturing

InactiveCN110181146AGuaranteed measurement accuracyGuaranteed measurement stabilityAdditive manufacturing apparatusRadiation pyrometryClosed loopEngineering

The invention relates to a temperature detecting and self-cleaning cooling device for arc fuse wire additive manufacturing. The device comprises a printing device, a printing welding system, a machinetool moving system, a welding gun head, a non-contact type infrared thermometer, a cooling system, a self-cleaning system, and a central control system; the device is simple in structure, the temperature measuring position is accurate, accurate detection and control of interlayer-temperature of overlaying coatings obtained through equal arc additive manufacturing can be achieved, closed loop control is achieved, the forming size precision and quality of the arc additive manufacturing can be improved, the protection and cleaning of the temperature measuring device can be considered, the measuring precision or stability of the temperature measuring device can be ensured, equipment long-term continuous running is ensured while the printing efficiency is improved, in addition, the control over the printing layer temperature of a printing part is considered, the defect of the heat conduction manner and the cooling manner is overcome, a cooling system is used for rapidly cooling to determine continuous operation of a large structural part printing process, the printing intermittent cooling time is greatly shortened, and the printing efficiency is greatly improved.

Owner:宁波中星新材料研究院有限公司

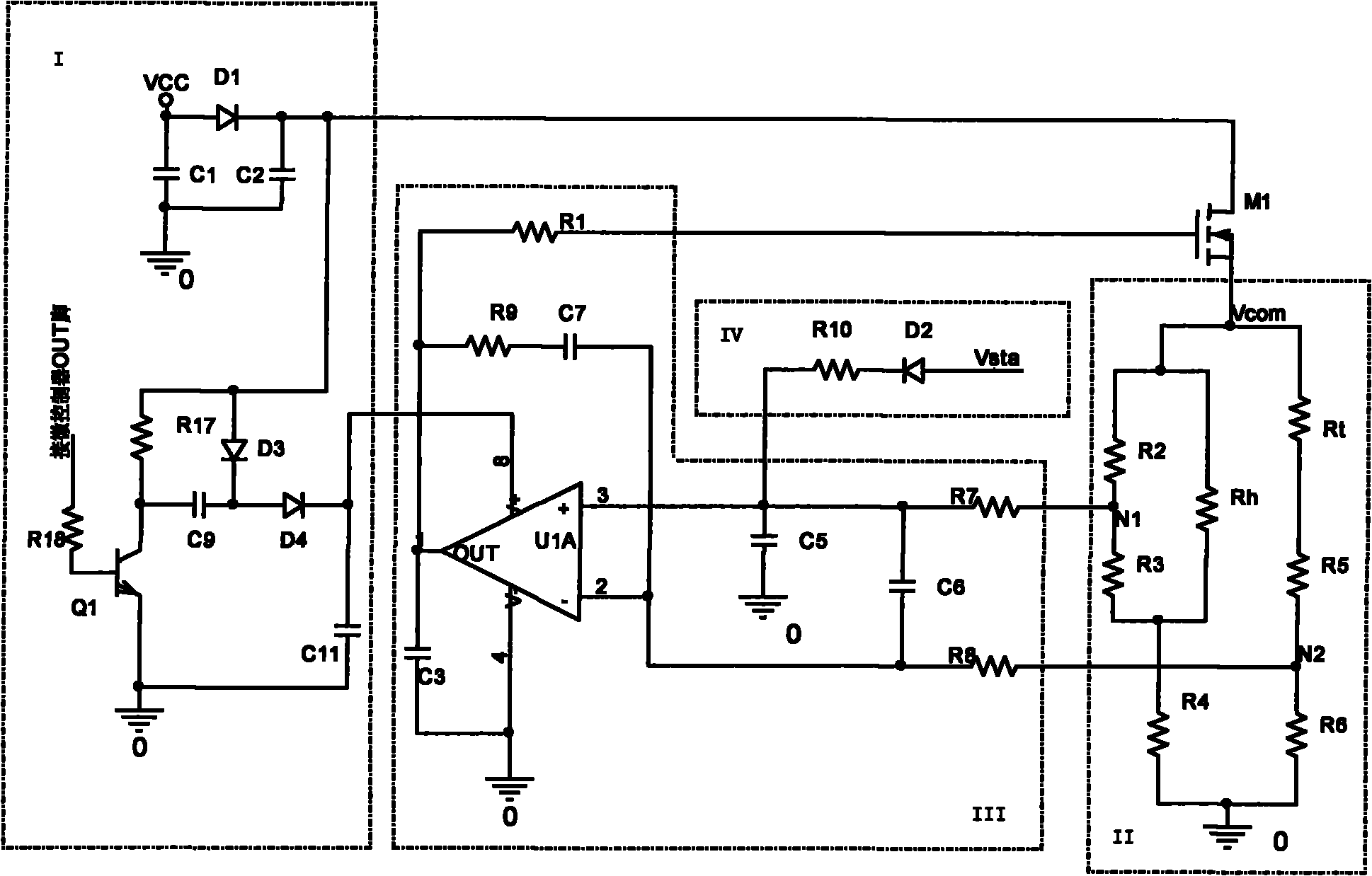

Thermal flow sensor

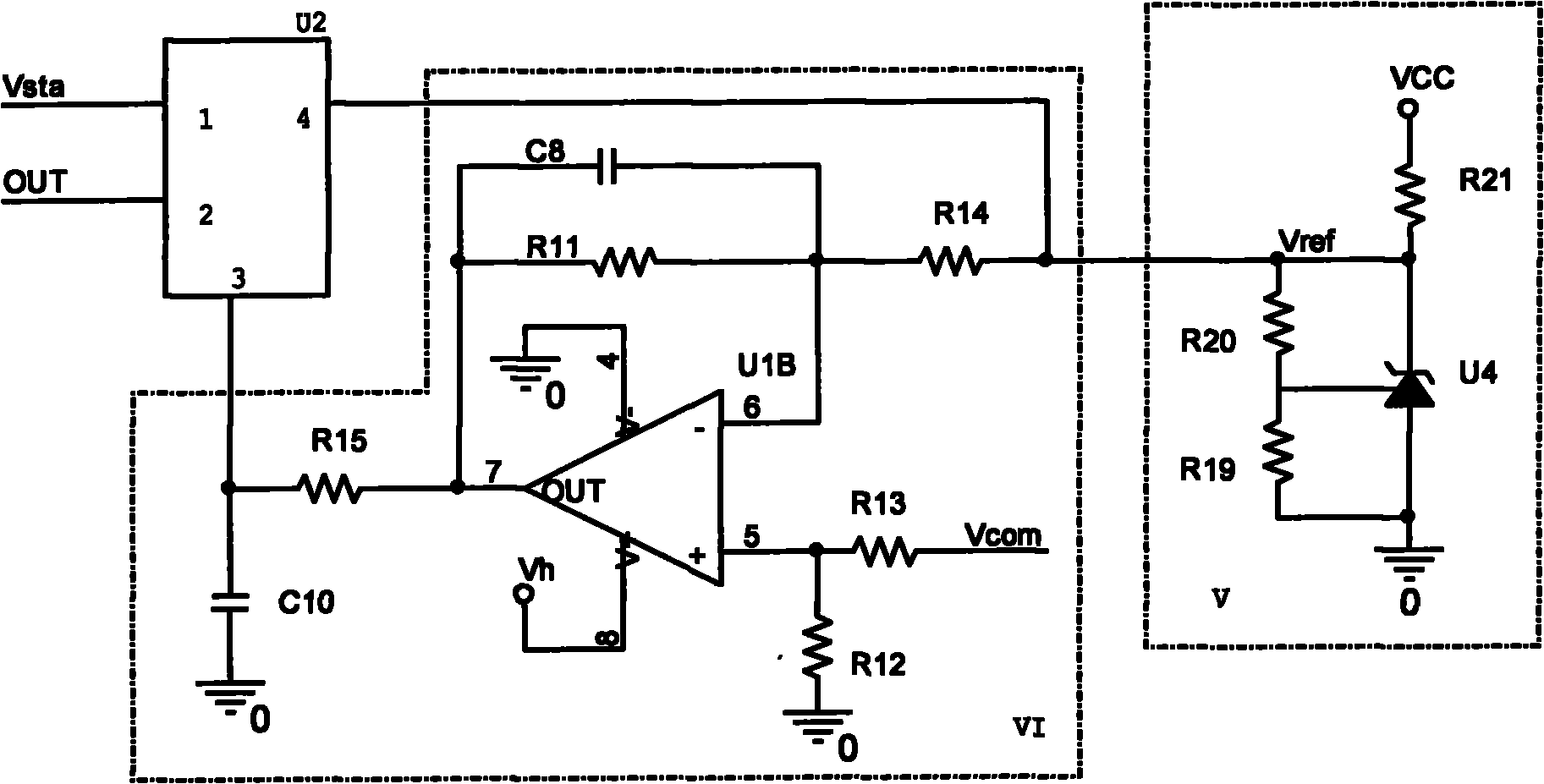

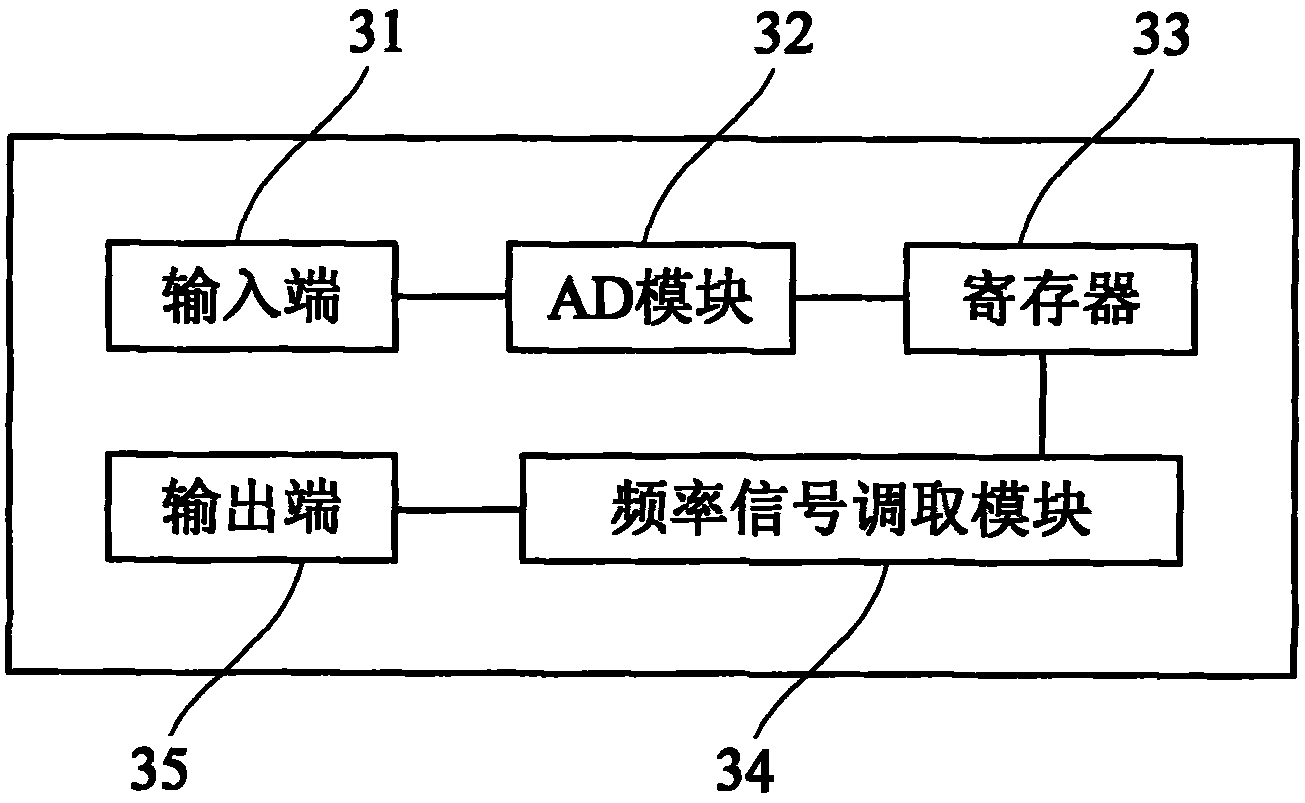

InactiveCN101995279AFacilitates temperature compensationAccurate responseMass flow measurement devicesMicrocontrollerField-effect transistor

The invention provides a thermal flow sensor, comprising a power circuit, a field-effect tube, a Wheatstone bridge, an operational amplifier circuit and a microcontroller, wherein the drain of the field-effect tube is connected with the power circuit; the Wheatstone bridge comprises two bridge arms on which a heating resistor and a temperature sensitive resistor are respectively arranged, and the common point of the two bridge arms is connected with the source electrode of the field-effect tube and serves as a detecting voltage output point reflecting the current air mass flow; the operational amplifier circuit is respectively connected with the intermediate nodes of the two arms of the Wheatstone bridge, and the output end of the operational amplifier circuit is connected to the grid electrode of the field-effect tube to adjust the current flowing through the heating resistor by controlling the current flowing out from the source electrode of the field-effect tube and ensure that the surface temperature of the heating resistor remains stable; and the input end of the microcontroller is connected with the source electrode of the field-effect tube and used for processing the detecting voltage of the source electrode of the field-effect tube and outputting a frequency signal showing the current air mass flow. The thermal flow sensor has the advantages of high precision, and strong stability.

Owner:SHANGHAI JIECHENG MACHINERY & MOTOR +1

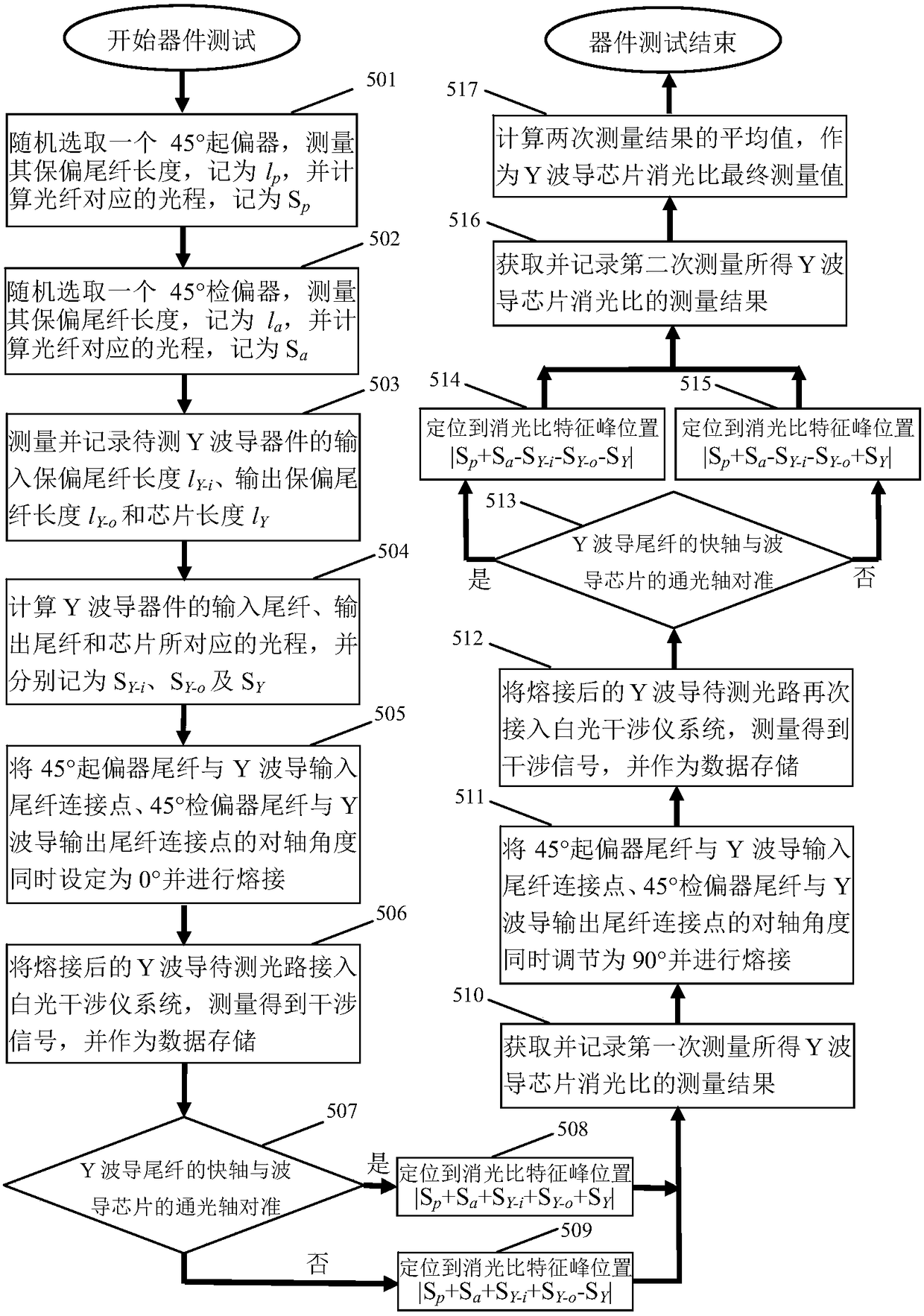

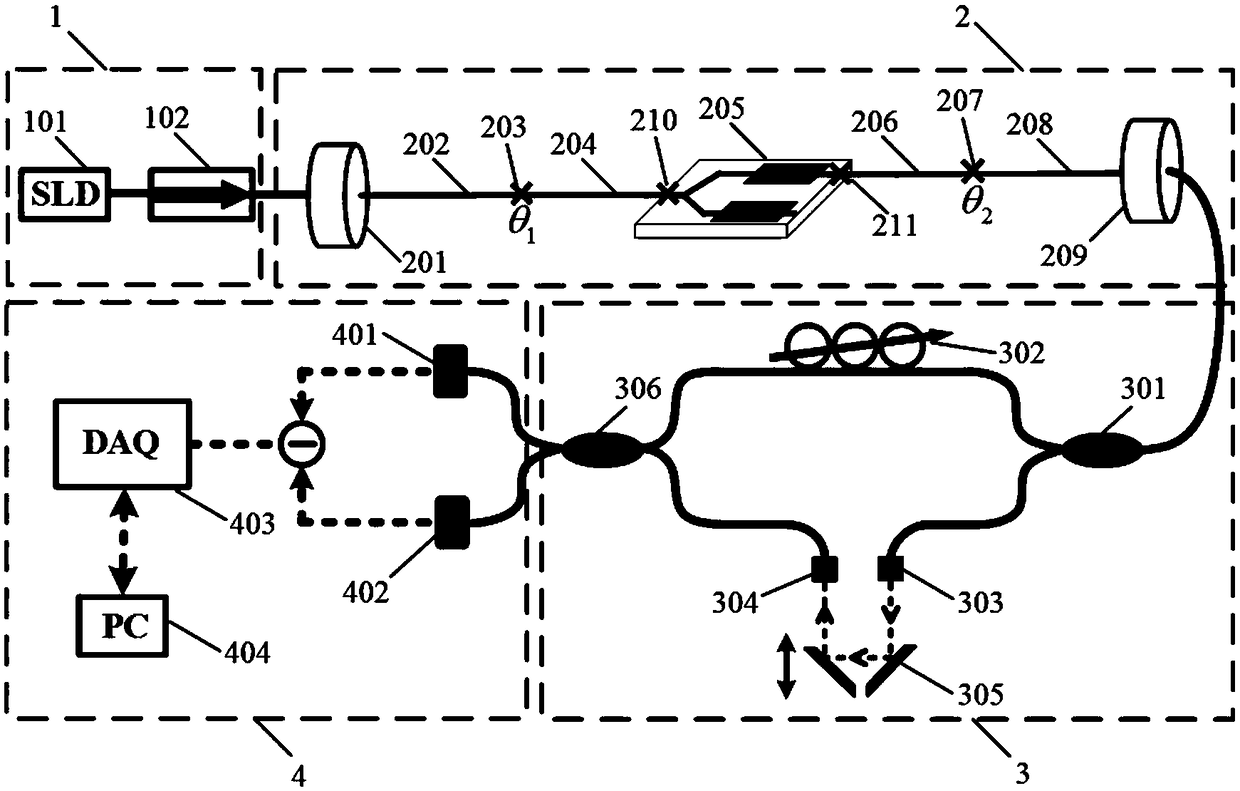

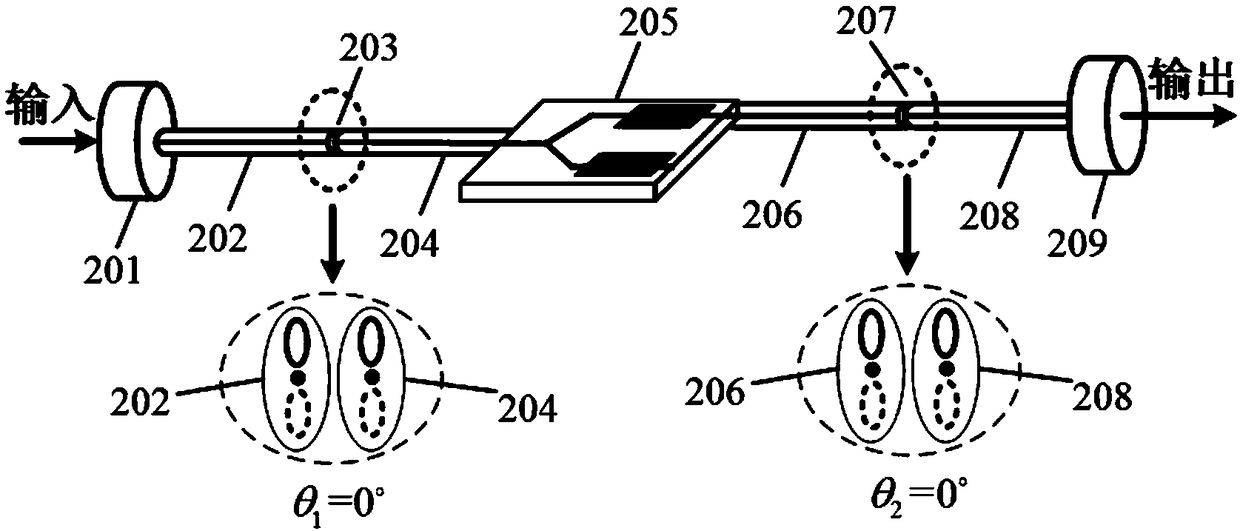

Method for improving measuring accuracy of polarization performance of Y waveguide device

ActiveCN108106817ARealize high-precision measurementEliminate measurement errorsTesting optical propertiesFiberObservational error

The invention provides a method for improving the measuring accuracy of the polarization performance of a Y waveguide device. The method comprises the following steps: firstly, connecting an input polarization-maintaining tail fiber of a Y waveguide to be measured with a polarization-maintaining tail fiber connecting point of a polarizer, setting the countershaft angle of the output polarization-maintaining tail fiber of the Y waveguide and the polarization-maintaining tail fiber connecting point of a polarization analyzer to be 0 degree, obtaining a polarization parameter measurement result for the first time; simultaneously adjusting the countershaft angles of the two connecting points to be 90 degrees, so as to obtain a second measurement result; and finally, calculating the average value of the two measurement results as the final measurement value. According to the measuring method, a measuring optical path structure does not need to be changed, and the measuring method is simpleand effective, and easy to realize. The measurement error caused by the self structure and performance defect of a polarizer and a polarization analyzer in an optical path to be measured is eliminated, so that the measurement accuracy is further improved. The method can be widely applied to high-precision measurement of parameters such as extinction ratio of a Y waveguide device chip.

Owner:HARBIN ENG UNIV

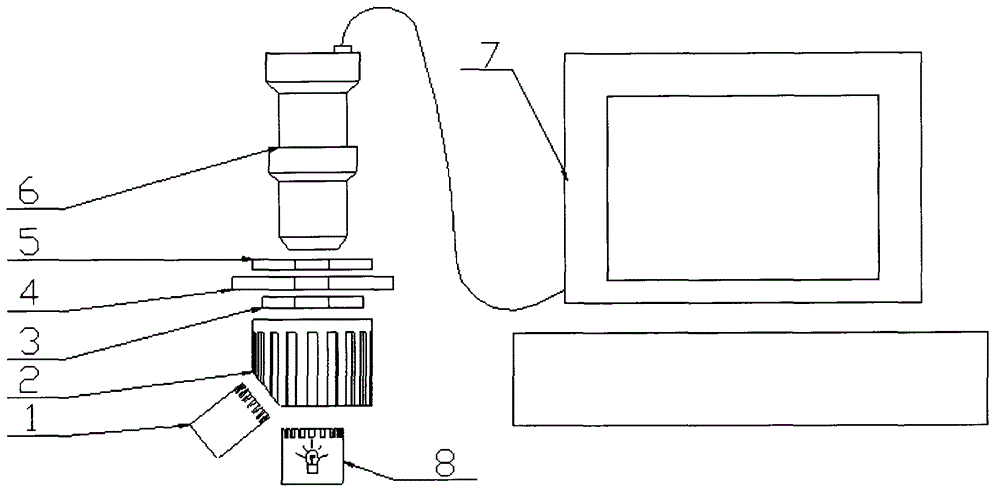

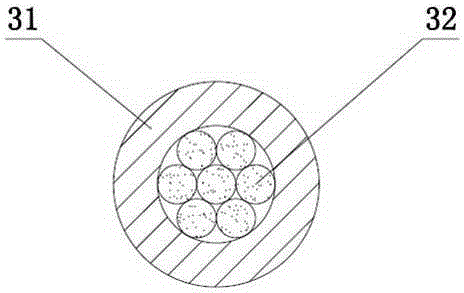

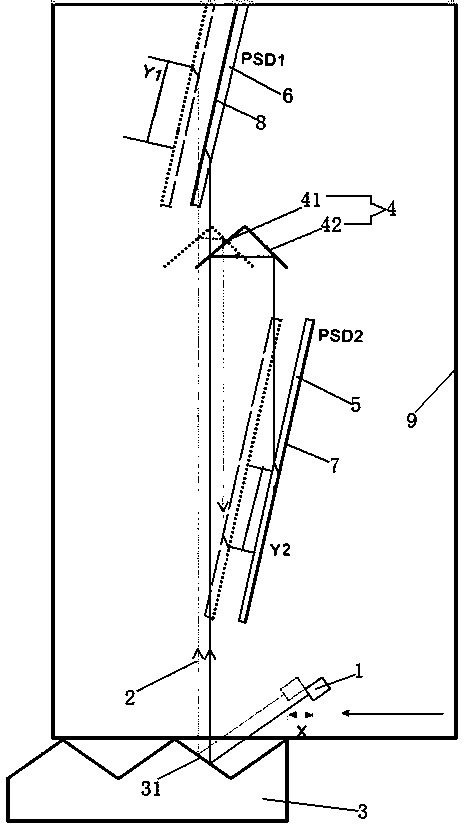

Nanoparticle measurement device and method

InactiveCN102879318AGuaranteed measurement accuracyGuaranteed measurement stabilityIndividual particle analysisMeasurement deviceLaser beams

The invention discloses a nanoparticle measurement device and method. The nanoparticle measurement device comprises a sample cell which is horizontally arranged, wherein a charge coupled device (CCD) microscope is arranged above the sample cell; the CCD microscope is connected with a computer; a semiconductor laser is arranged below the sample cell; and an inclined angle of 10 to 80 degrees is formed between the semiconductor laser and the sample cell. According to the nanoparticle measurement device and method, the semiconductor laser is arranged on the CCD microscope, and a certain inclined angle is formed between the semiconductor laser and the sample cell, so that the nanoparticles in the sample cell generate dynamic scattered light spots under irradiation of laser beams, the particle size and particle size distribution of the particles from dozens of nanometers to several nanometers are measured according to the Brownian motion equation proposed by Einstein; and therefore, the measurement precision and stability can be guaranteed, the production cost can be greatly reduced, and the nanoparticle measurement device is simple in structure and easy to popularize and use.

Owner:NANJING LONGBOW INST OF SCI & TEACHING APP

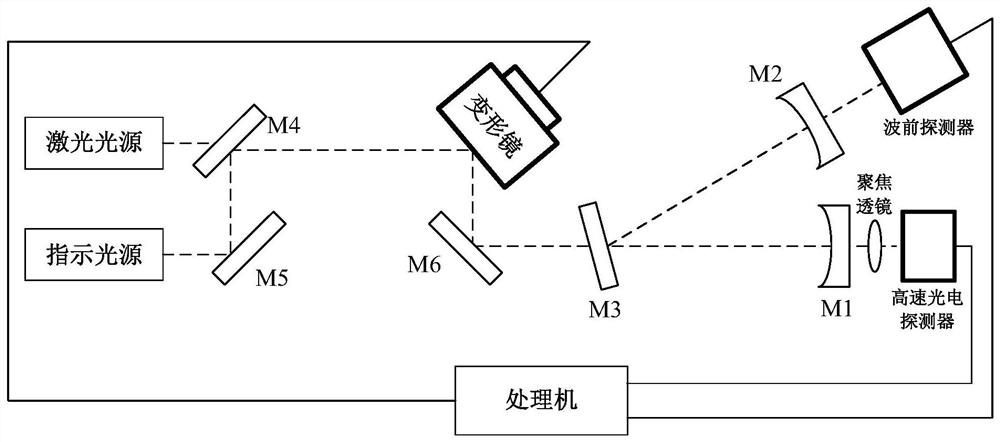

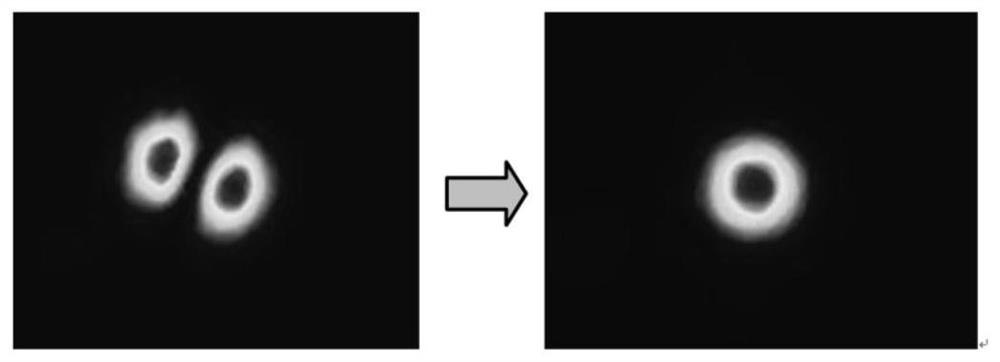

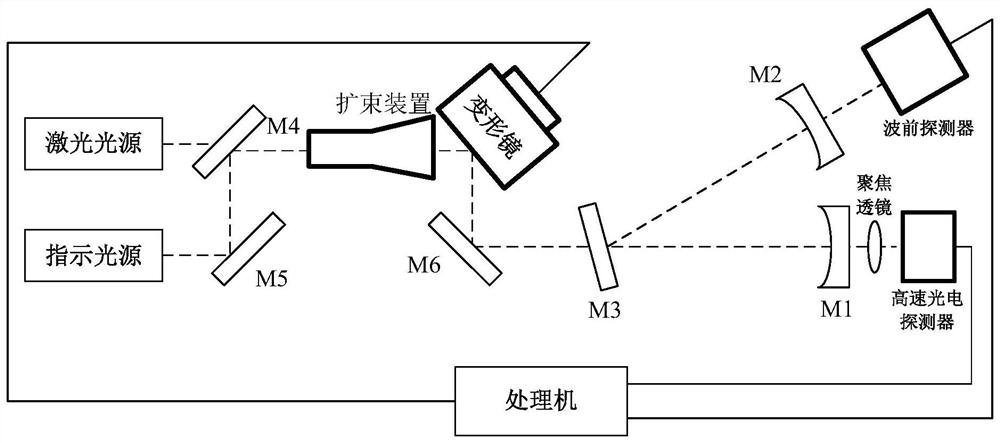

Optical cavity ring-down adaptive optical active transverse mode matching method

PendingCN113310902AImprove matching accuracyGuaranteed measurement accuracyScattering properties measurementsColor/spectral properties measurementsOptical cavityLight beam

The invention relates to an optical cavity ring-down adaptive optical active transverse mode matching method. An operation mode in a ring-down cavity is actively intervened by using an adaptive optical beam control technology, the mode coupling efficiency of a fundamental transverse mode in the ring-down cavity is effectively ensured, and active transverse mode matching is realized. The active transverse mode matching mode can effectively ensure the measurement precision and stability of the cavity ring-down technology. Meanwhile, in the application of film system parameter measurement, the method allows the use of an expanded beam to obtain the average result of a film system to be measured in the large aperture at one time; and compared with a traditional point measurement mode, the method can increase the measurement aperture, reduce the error caused by the randomness of a point measurement selection position, and obtain a measurement result closer to the actual working state of the film system.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

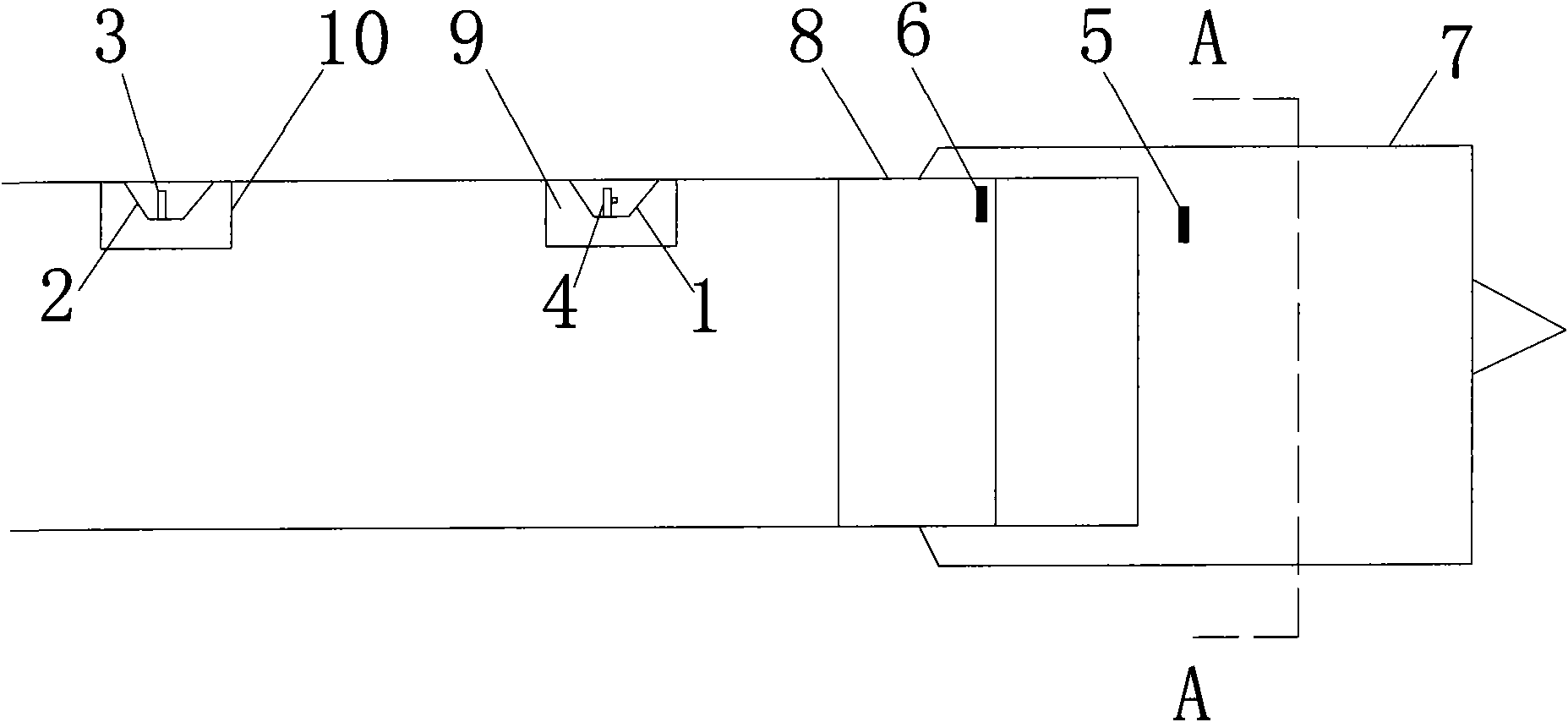

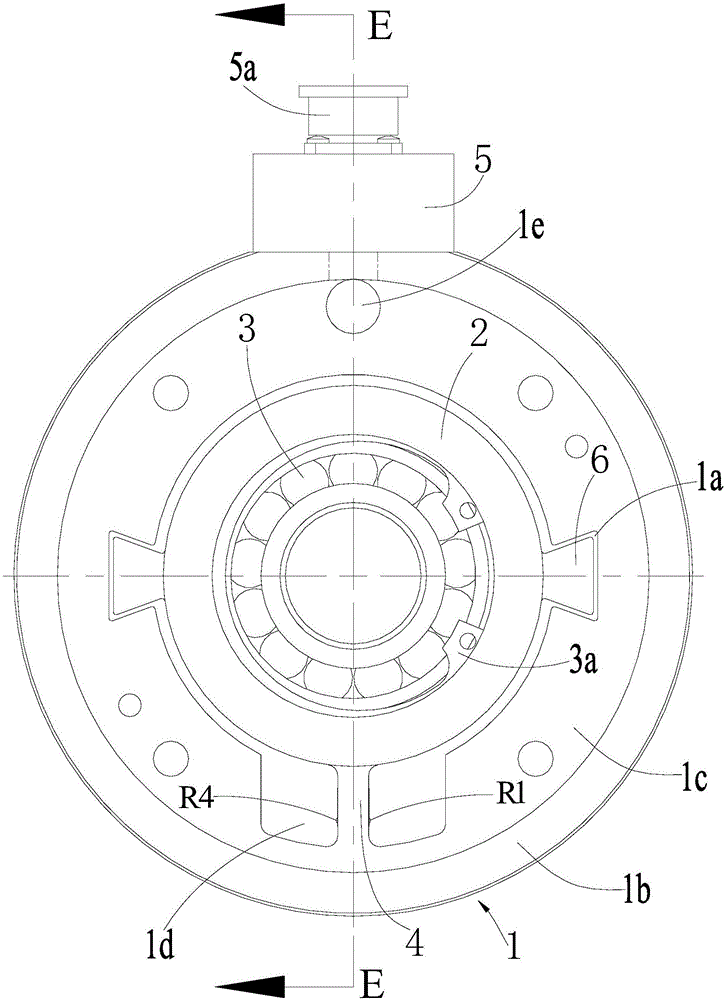

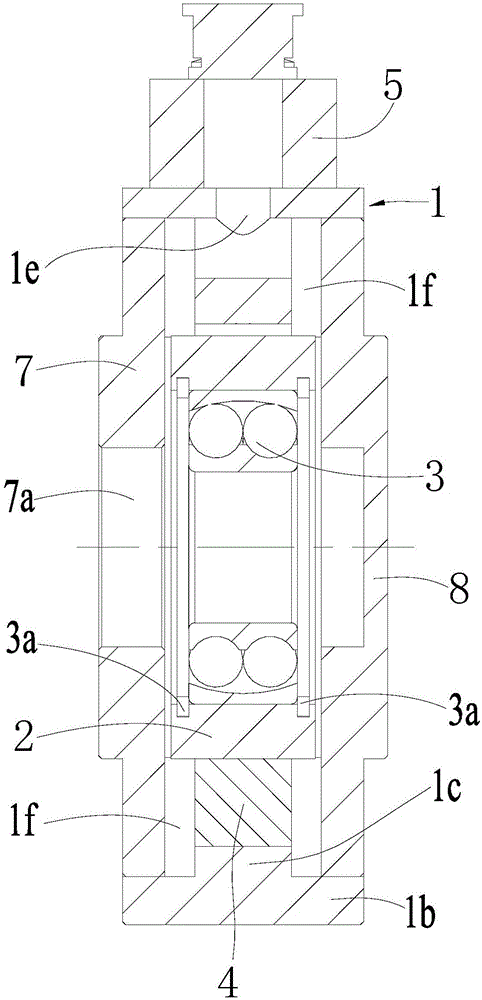

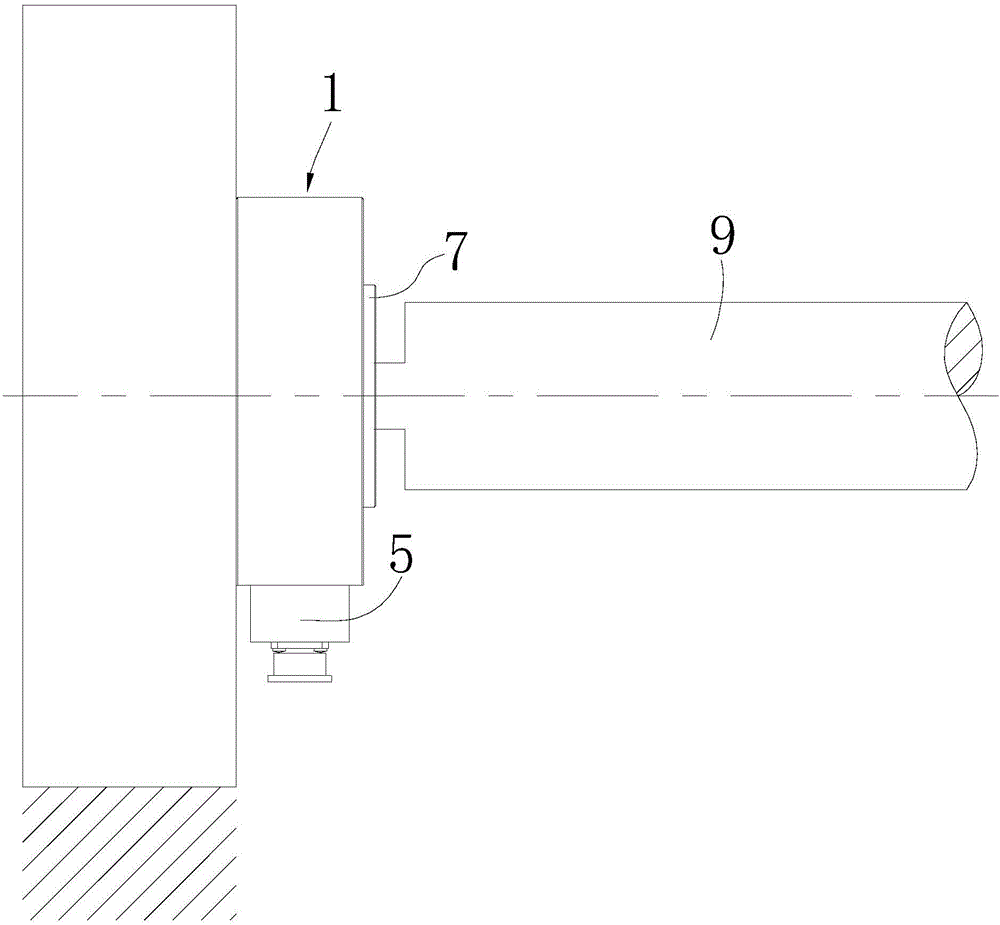

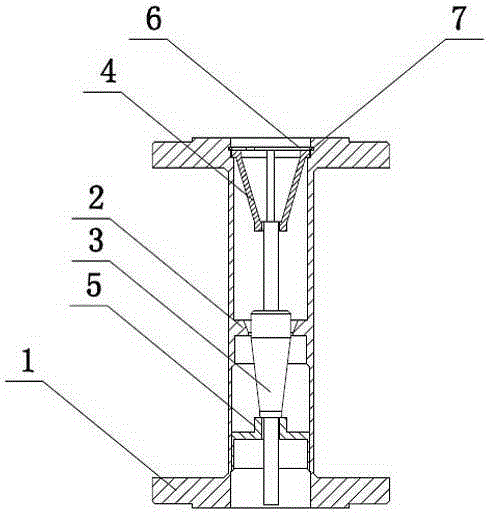

Through shaft type tension sensor

InactiveCN106525313AEasy to useGuaranteed measurement accuracyForce measurementTension measurementIsosceles trapezoidZero temperature

The invention provides a through shaft type tension sensor. The through shaft type tension sensor is characterized in that a bearing bracket is arranged in a shell; self-aligning bearings are arranged in the bearing bracket; two lugs are arranged outside the bearing bracket; the section shapes of the lugs are any one of isosceles trapezoid, large semicircle, half waist circle and half oval; two matched clamp slots and a strain beam connected with the bearing bracket and the shell are formed in the shell; resistance strain gauges R1-R4 are arranged on the strain beam; the section shape of the strain beam is rectangular; an output interface is arranged outside the shell and is communicated with the interior of the shell; a control circuit comprises the resistance strain gauges R1-R4, a zero temperature compensation resistor Rt, a zero output compensation resistor Rz, an input consistency compensation resistor Ri, two parallel sensitivity output compensation resistors RL and two parallel sensitivity temperature compensation resistors Rb; a power line and an output signal line of the control circuit are laid in the shell and are connected with the output interface; inner and outer side plates are arranged at the two axial sides of the shell. The sensor has high precision, good stability and long service life.

Owner:安徽中航电子科技发展有限公司

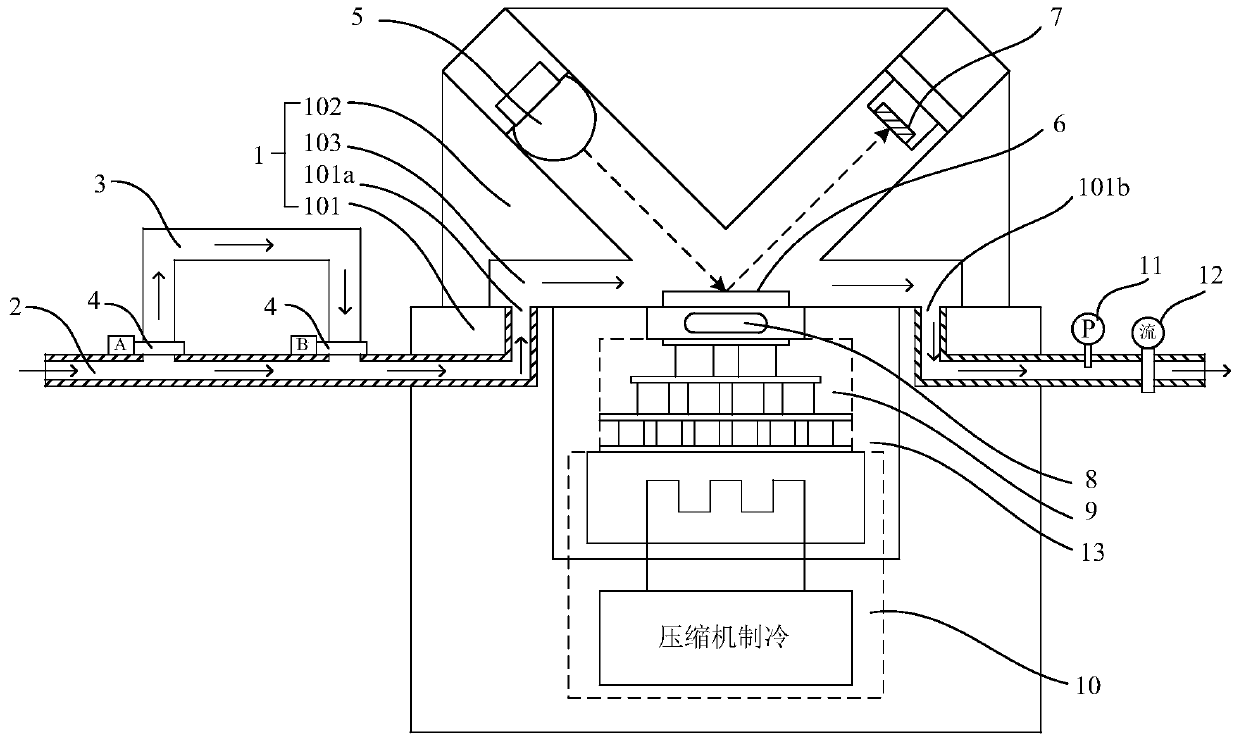

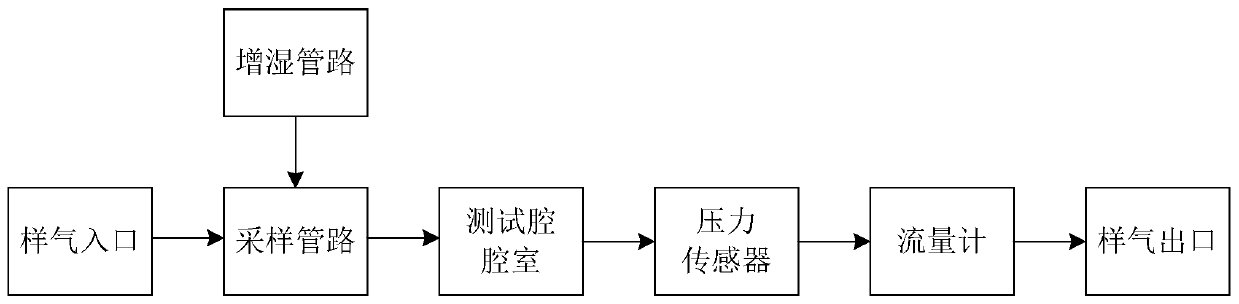

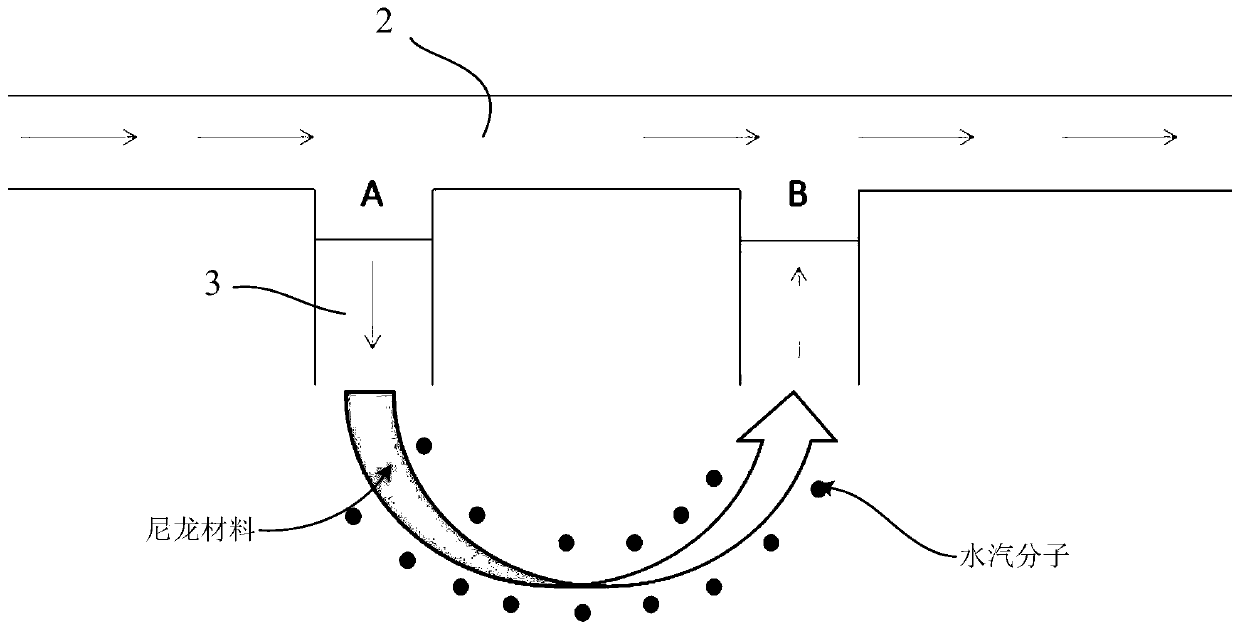

Chilled-mirror dew-point hygrometer capable of quickly measuring extremely low dew point

InactiveCN111044567AImprove accuracyImprove stabilityMaterial moisture contentMirror reflectionControl system

The invention relates to the field of dew point temperature measurement, and particularly relates to a chilled-mirror dew-point hygrometer capable of quickly measuring an extremely low dew point. Thechilled-mirror dew-point hygrometer comprises a gas path system, a light path system, a refrigerating system and a control system, wherein the gas path system comprises a test cavity, a sampling pipeline and an auxiliary humidifying unit, the auxiliary humidifying unit comprises a humidifying pipeline and an electromagnetic valve, and two ends of the humidifying pipeline are connected to two openings of the sampling pipeline; the light path system comprises a transmitting light source, a mirror surface and a photosensitive receiver, the mirror surface is located in the test cavity, the transmitting light source irradiates the mirror surface, and reflected light is received by the photosensitive receiver; the refrigerating system comprises a semiconductor refrigerator and a compressor refrigerator for performing pre-refrigeration treatment on the semiconductor refrigerator, the cold end of the semiconductor refrigerator is connected to the bottom of the mirror surface, and the hot end of the semiconductor refrigerator is mounted on an evaporator of the compressor refrigerator; and the control system is electrically connected with the gas path system, the light path system and the refrigerating system. The chilled-mirror dew-point hygrometer can measure an extremely low dew point, and is high in measurement speed, high in accuracy and high in stability.

Owner:NO 63837 TROOPS PLA +1

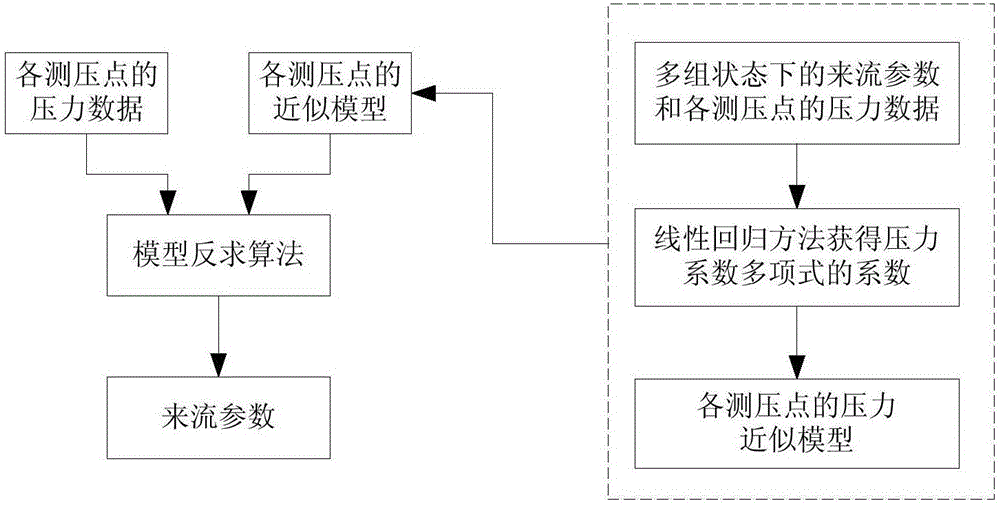

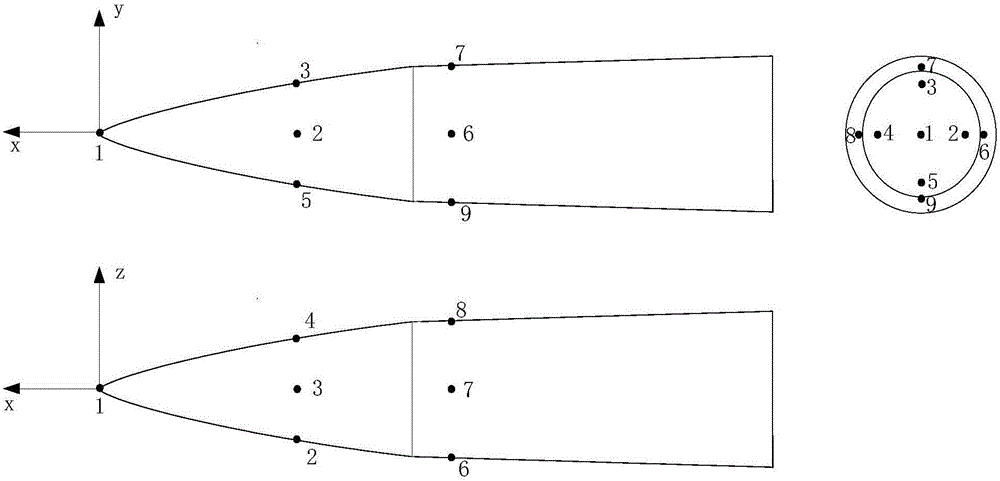

Incoming flow parameter determining method applicable to appearance of body of revolution

ActiveCN106844896AMeet the precision requirementsGuaranteed measurement stabilityDesign optimisation/simulationSpecial data processing applicationsNumerical fittingBack calculation

Provided is an incoming flow parameter determining method applicable to an appearance of a body of revolution. The method comprises the steps of 1, building a surface pressure approximation model applicable for the appearance of the body of revolution, wherein firstly a surface pressure computational formula is determined, and surface pressure is expressed as a sum of a product of incoming flow dynamic pressure qc and a pressure coefficient Cpi and incoming flow static pressure p infinity; then a polynomial form is adopted to express the pressure coefficient Cpi, and polynomial factors are a flight attack angle alpha, a sideslip angle beta and an incoming flow pressure ratio R; finally the factors in the polynomial are obtained through numerical fitting, regression or a least square method to surface measuring point pressure of the body of revolution in multiple sets of states; 2, obtaining the surface measuring point pressure of the body of revolution in a flight experiment, conducting back calculation according to the surface measuring point pressure combining the approximation model, and accordingly obtaining an incoming flow parameter. According to the incoming flow parameter determining method applicable for the appearance of the body of revolution, the model can be used for an embedded air data system, and the prediction accuracy of the system can be effectively improved.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

Metal rotor flowmeter with rectification function

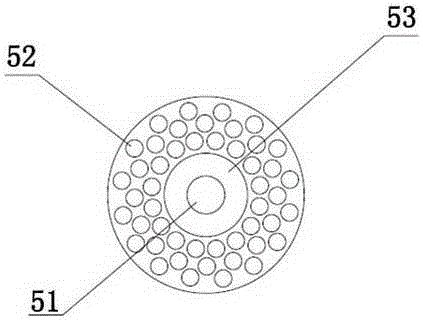

InactiveCN105258751ALower requirementIncrease the scope of application of working conditionsVolume/mass flow by mechanical effectsVolume meteringVena contracta diameterCurrent limiting

The invention discloses a metal rotor flowmeter with a rectification function. The metal rotor flowmeter comprises a pipe body, a rotor sleeve, a rotor, an upper stop and a lower stop. A guiding hole allowing the rotor to extend therein is arranged at the center of the lower stop, the periphery of the guiding hole is provided with at least one ring of a plurality of sieving apertures enclosing a circumference, and a heightening boss is additionally arranged between the guiding hole and somewhere nearby the ring of the sieving apertures. According to the invention, a dense grid plate structure with multiple small circular holes in uniform circumferential distribution is employed, under the condition that the accumulated flow passage area of all the small holes is not decreased, current stabilization effect is applied on a fluid, when the fluid passes through such throttling members as a bend, a valve, a reducing pipe and the like, instability is caused to the flow field of the fluid due to the effect of the throttling members, and after passing through a porous current-limiting orifice plate, the fluid is rectified again, such that the requirement of the metal rotor flowmeter for a straight pipe segment is lowered, and the working condition adaptation scope of the metal rotor flowmeter is enlarged under the condition that the measurement stability is enhanced.

Owner:ZHEJIANG DIYUAN INSTR

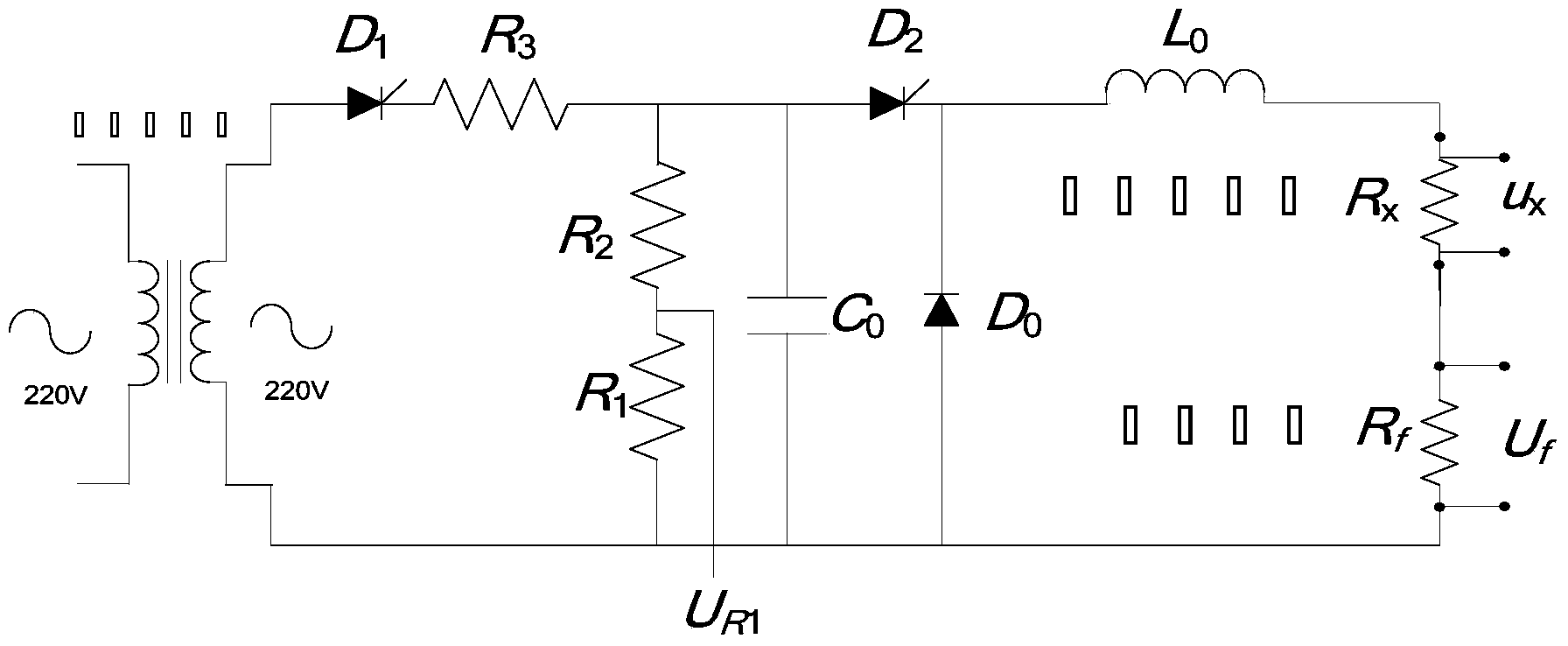

Novel topology loop for measuring breaker loop resistance and measuring method of novel topology loop

The invention relates to a novel topology loop for measuring breaker loop resistance and a measuring method of the novel topology loop. The novel topology circuit comprises a capacitor charging loop, a capacitor discharging loop, a measuring loop and a thyristor control loop. The novel topology circuit specially comprises a test power source, an isolation transformer, a current-limiting resistor, a capacitor, a vibration inductor, a breaker resistor, a measuring resistor, a detected breaker resistor and a standard resistor, wherein the isolation transformer is connected with the test power source. The method comprises the steps that the test power source charges the capacitor, and the thyristor control loop controls the connection and disconnection of the charging and discharging loop; the capacitor carries out discharging on an RLC loop composed of the vibration inductor, the detected breaker resistor and the standard resistor, a pulse current source no less than 100 A is generated, the voltage at the two ends of the detected breaker and the standard resistor is measured to be calculated, and the resistance value of the detected breaker loop is obtained through calculation. The novel topology loop is simple in structure, easy to achieve and good in economical efficiency, the detecting device becomes smaller while the measuring precision is guaranteed, and the novel topology circuit is convenient to carry.

Owner:STATE GRID CORP OF CHINA +2

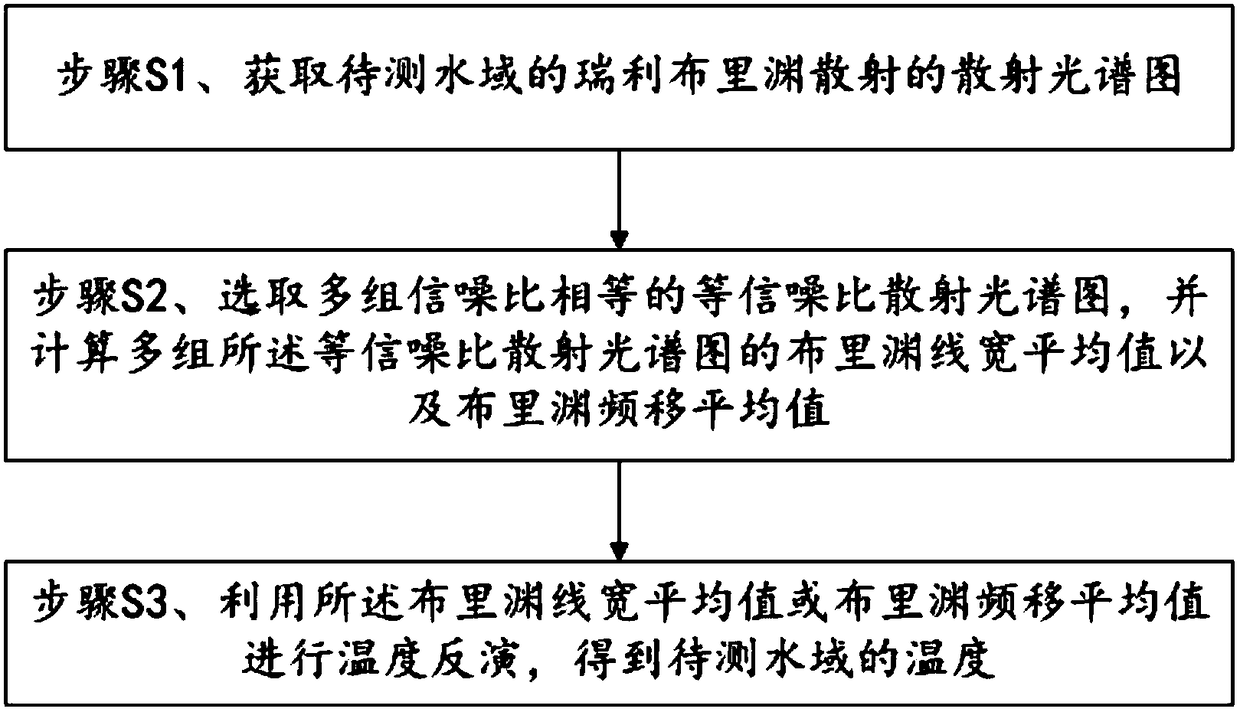

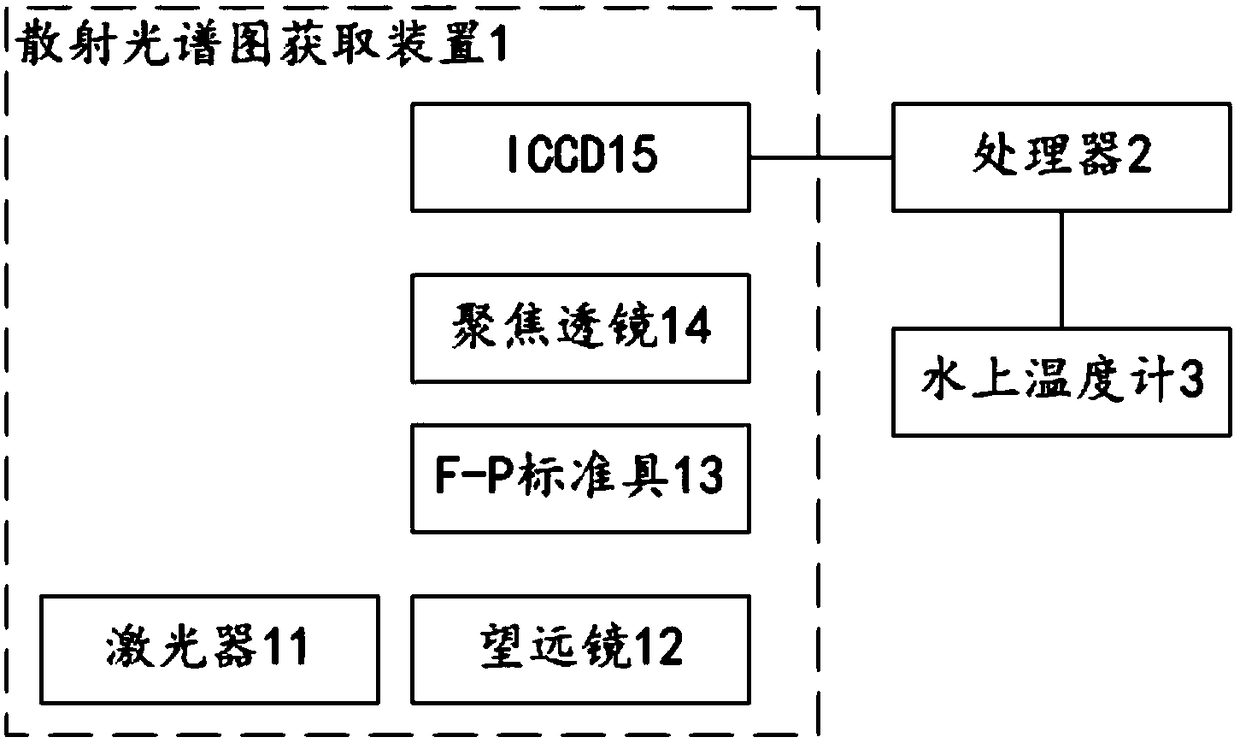

Underwater temperature remote-sensing measurement method and system

ActiveCN109060166AHigh measurement accuracyGuaranteed measurement stabilityThermometers using physical/chemical changesSignal-to-noise ratio (imaging)Line width

The invention discloses an underwater temperature remote-sensing measurement method. The method comprises the steps that S1, a scattering spectrogram of Rayleigh-Brillouin scattering of a to-be-measured water area is acquired; S2, multiple groups of equal-signal-to-noise-ratio scattering spectrograms with equal signal-to-noise ratios are selected, and a Brillouin line width average value and a Brillouin frequency shift average value of the multiple groups of equal-signal-to-noise-ratio scattering spectrograms are calculated; and S3, the Brillouin line width average value or the Brillouin frequency shift average value is utilized to perform temperature retrieval, and the temperature of the to-be-measured water area is obtained. The underwater temperature remote-sensing measurement method has high precision and high instantaneity.

Owner:EZHOU INST OF IND TECH HUAZHONG UNIV OF SCI & TECH +1

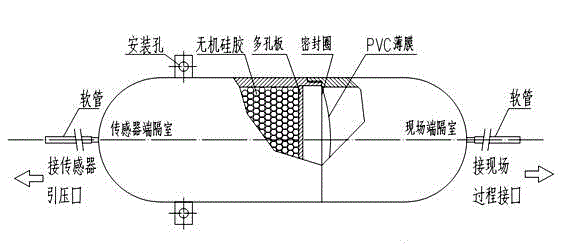

PCB (printed circuit board) micro-pressure sensor isolation box

InactiveCN104359610AGuaranteed measurement accuracy and stabilityExtended service lifeFluid pressure measurement using ohmic-resistance variationPrinted circuit boardAccuracy and precision

The invention provides a PCB (printed circuit board) micro-pressure sensor isolation box. A sealing anticorrosion micro-pressure transfer medium is arranged in the isolation box which is isolated into two spaces, a PCB micro-pressure sensor is connected to one side of the isolation box, and a measured medium is connected to the other side of the isolation box. By the arrangement, the harmful medium measured is prevented from directly contacting with the PCB micro-pressure sensor, the problem about adaptability of the PCB micro-pressure sensor under the micro-pressure measuring conditions of moisture, dust and corrosive gas is solved, the measuring accuracy and stability of products are guaranteed, and service life is greatly prolonged.

Owner:CRRC ZIYANG CO LTD

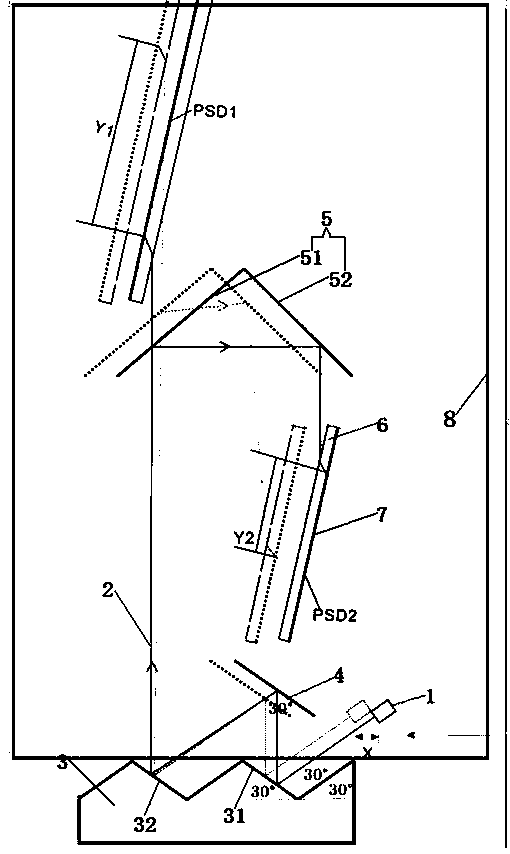

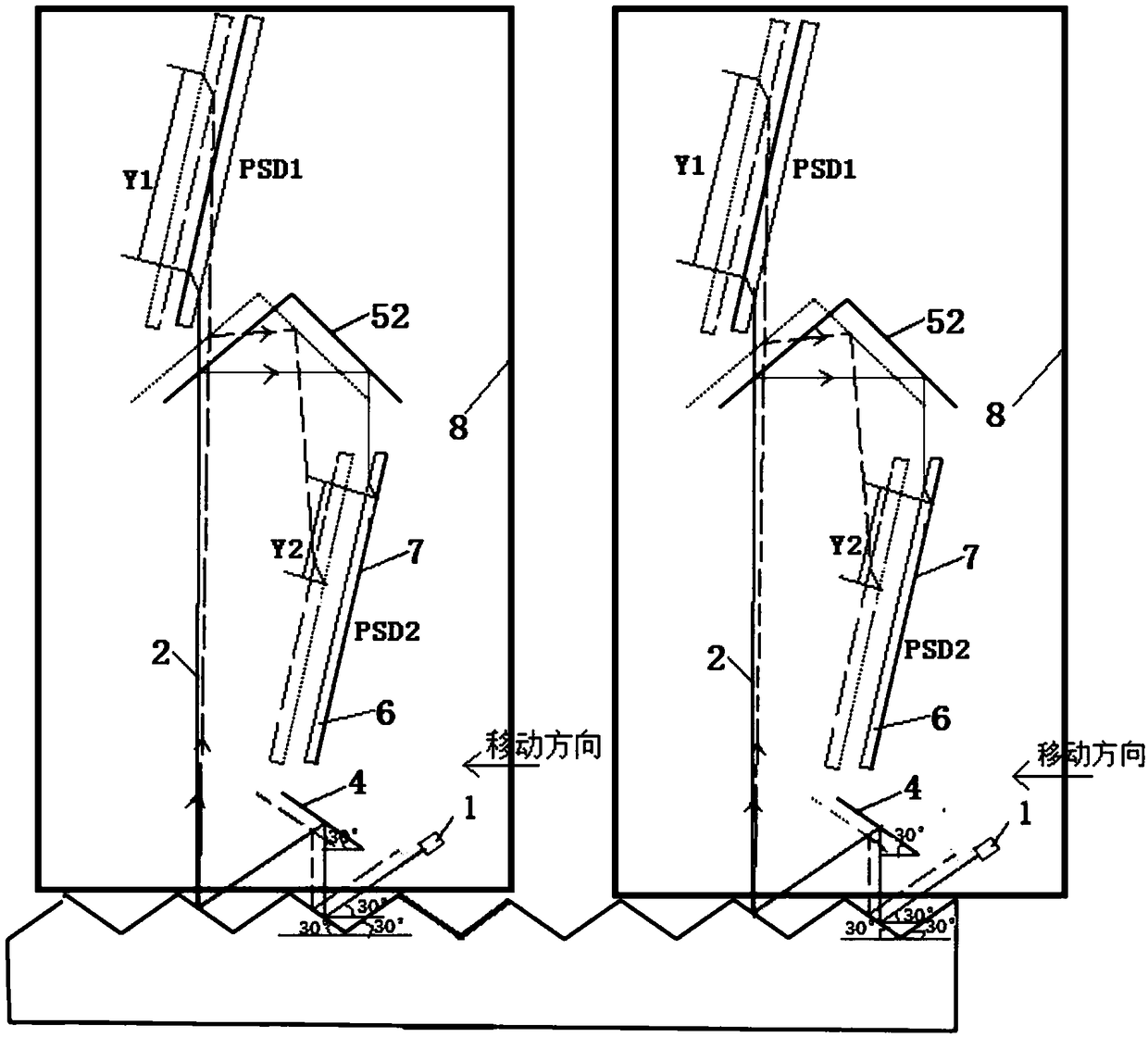

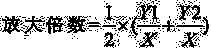

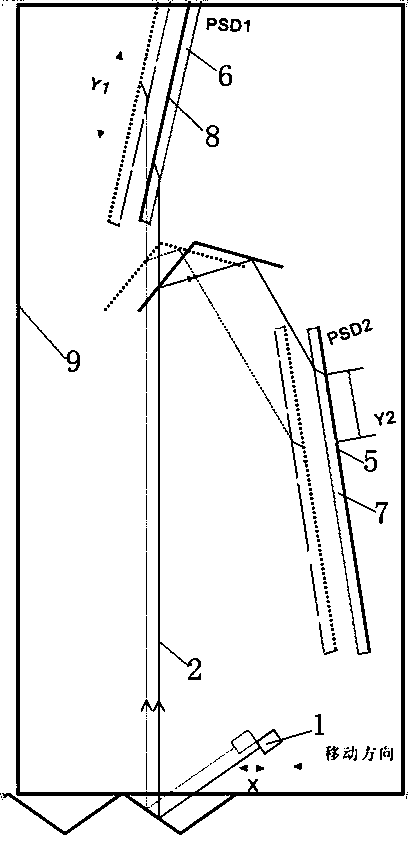

Novel displacement sensor with refractors and measuring method thereof

PendingCN109443219AHigh magnificationHigh measurement accuracyUsing optical meansPhotovoltaic detectorsOptoelectronics

The invention provides a novel displacement sensor with refractors and a measuring method thereof. The novel displacement sensor with the refractor comprises the components of a reflector which is used for receiving a laser beam that is reflected from a first reflecting surface of a triangular wave reflector, makes the laser beam be reflected to a second reflecting surface of the triangle wave reflector in a measuring process in which the laser beam is incident into the same first reflecting surface; and a spectroscope set which comprises a spectroscope and a light reflector, wherein the spectroscope and the light reflector are arranged in a certain included angle therebetween, and furthermore the laser beam which is reflected by the second reflecting surface of the triangle wave reflectoris incident to the spectroscope. Partial laser beam is reflected by the spectroscope and the light reflector and is incident to one refractor and is refracted and incident to a photoelectric detector, and the other partial laser beam is transmitted through the spectroscope and is incident into the other refractor for refraction and incidence into the photoelectric detector. According to the displacement sensor, through arranging the refractors, the measuring precision of the displacement sensor can be improved.

Owner:BEIFANG UNIV OF NATITIES

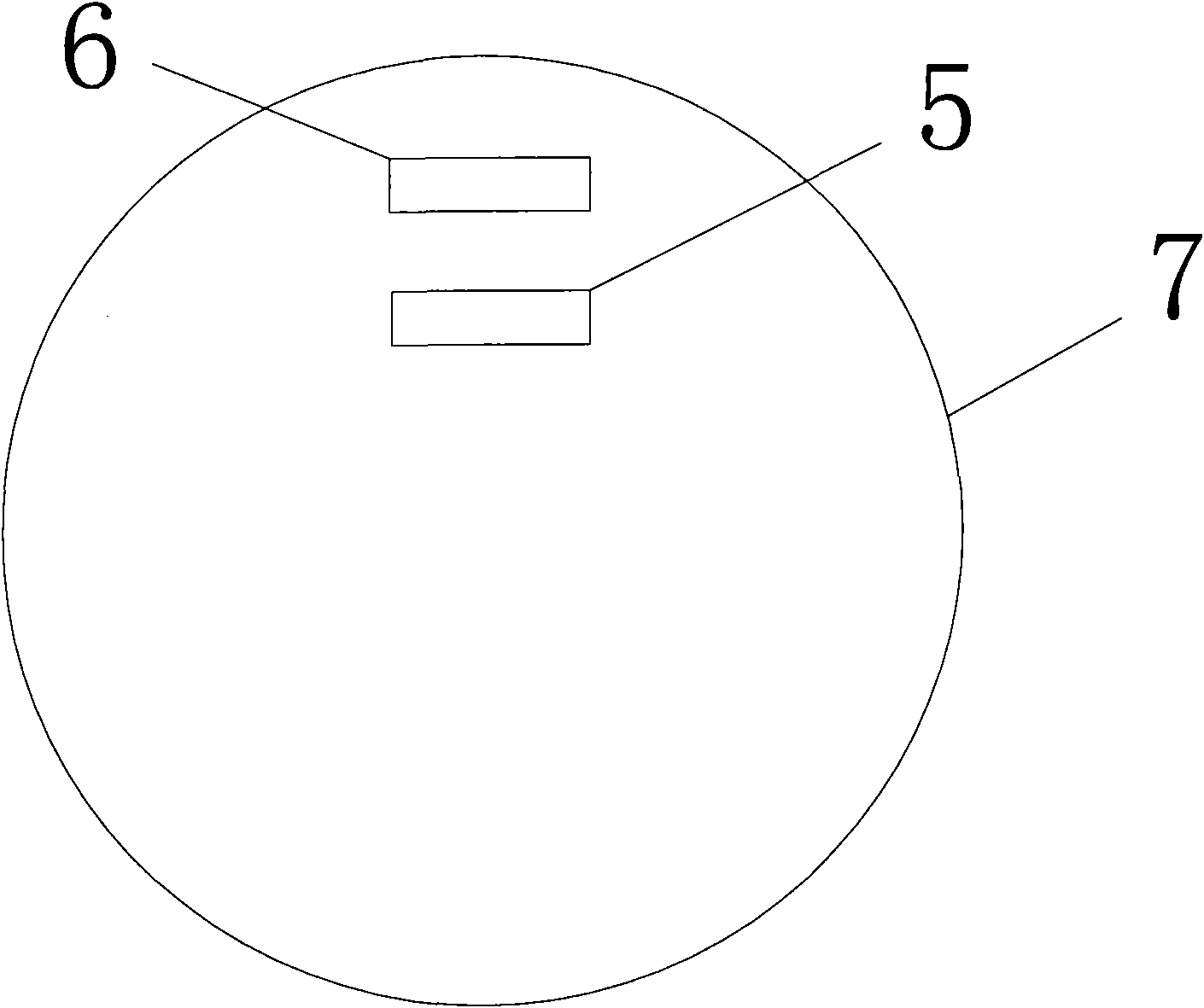

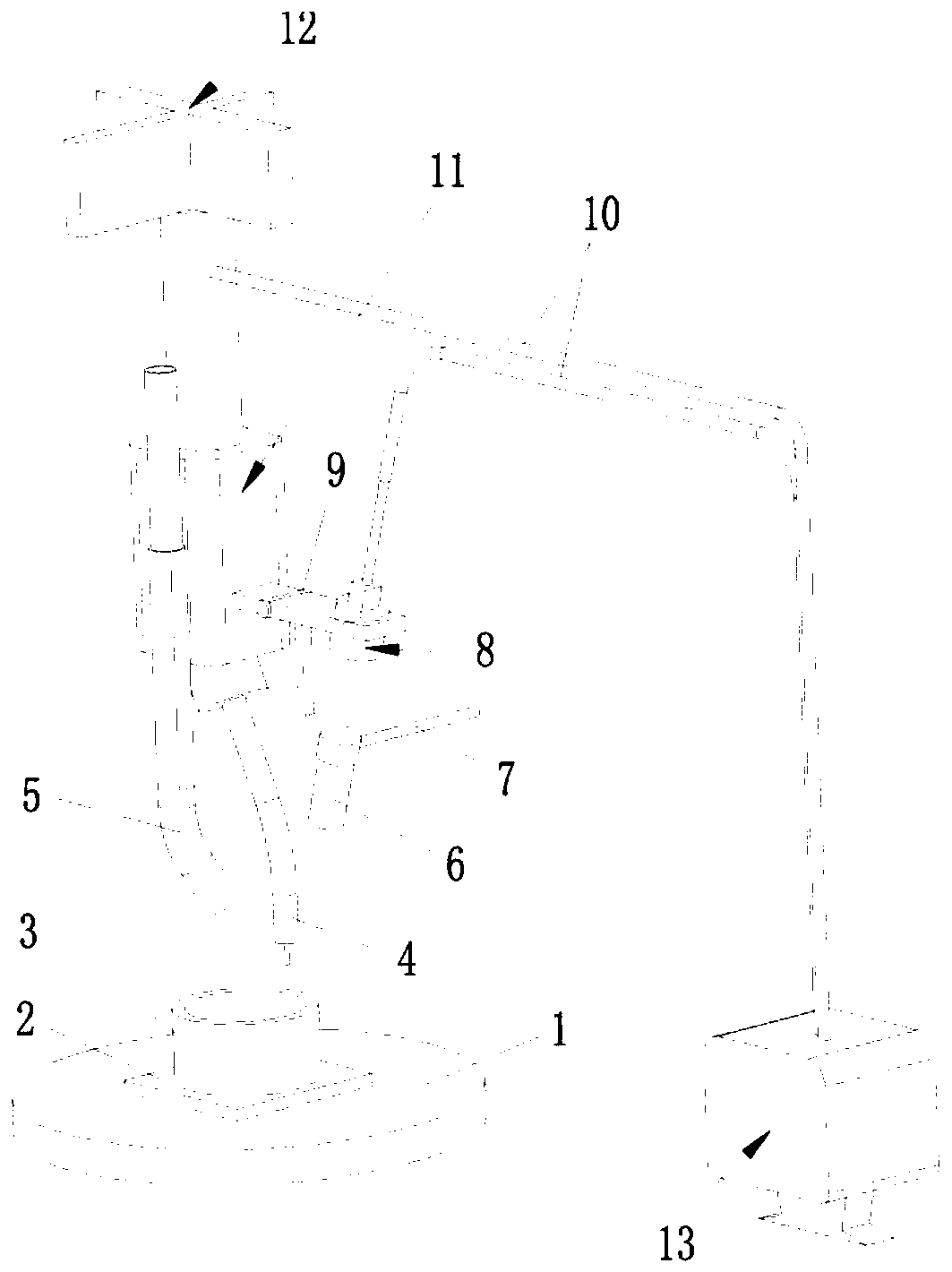

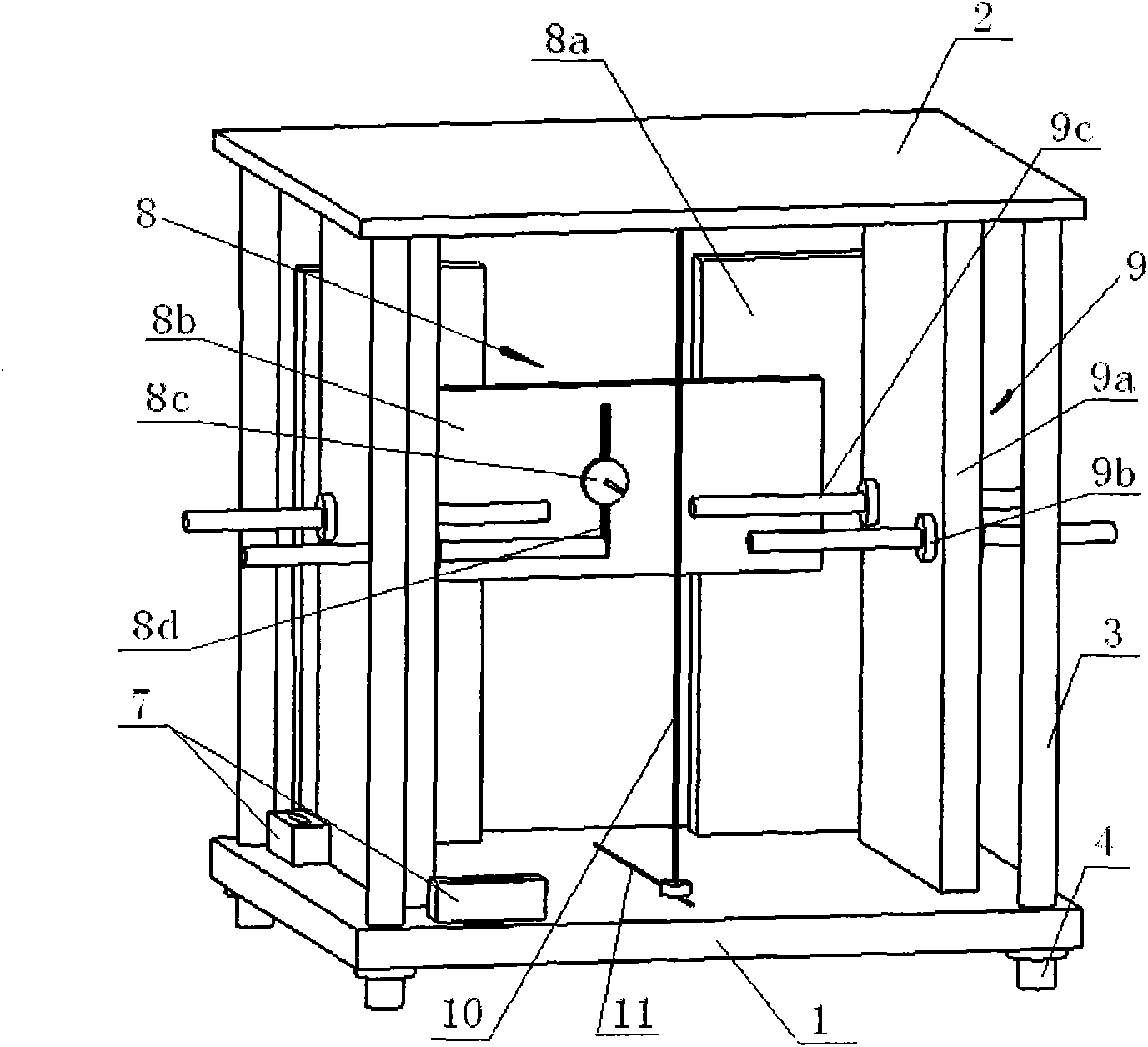

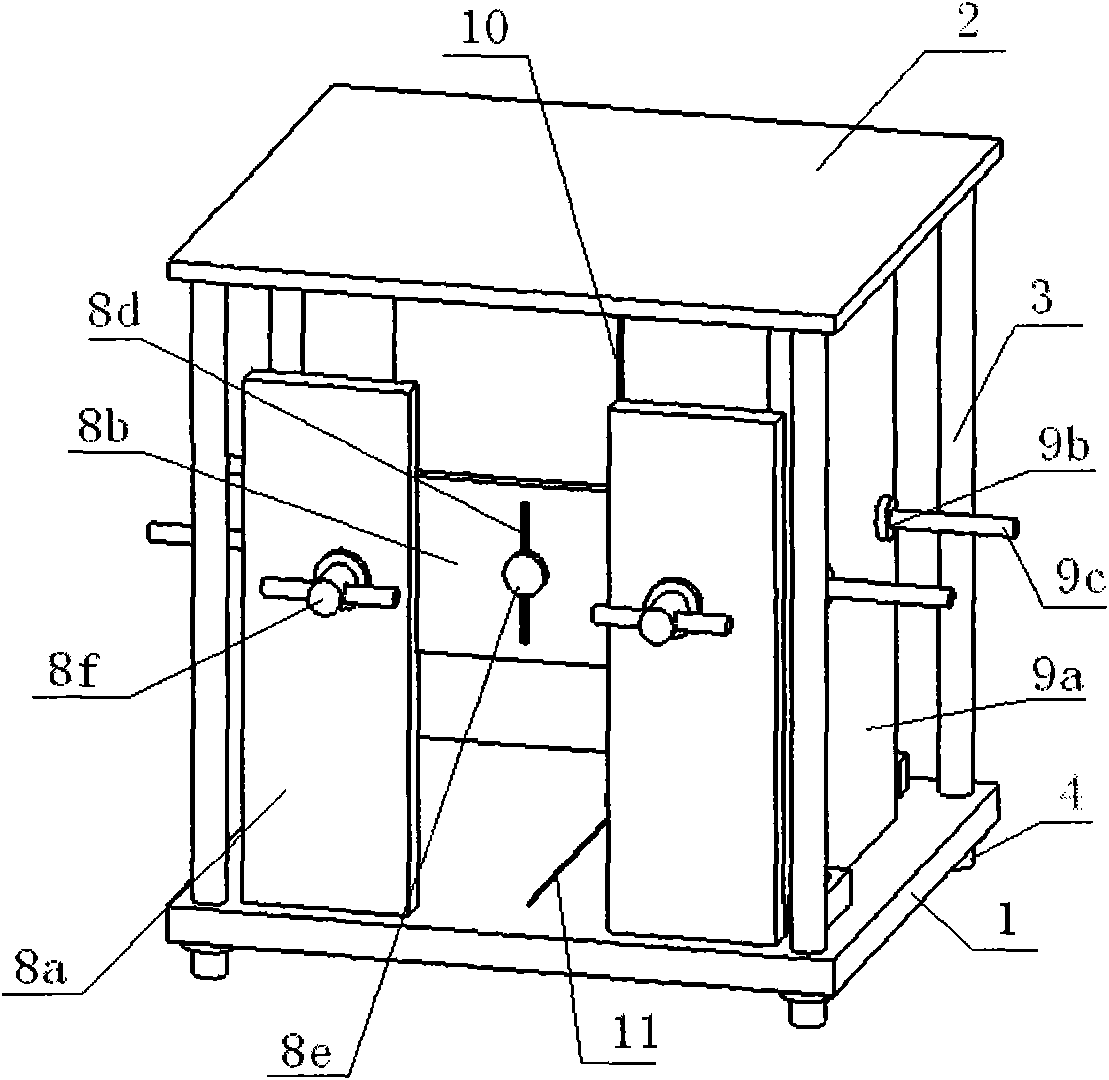

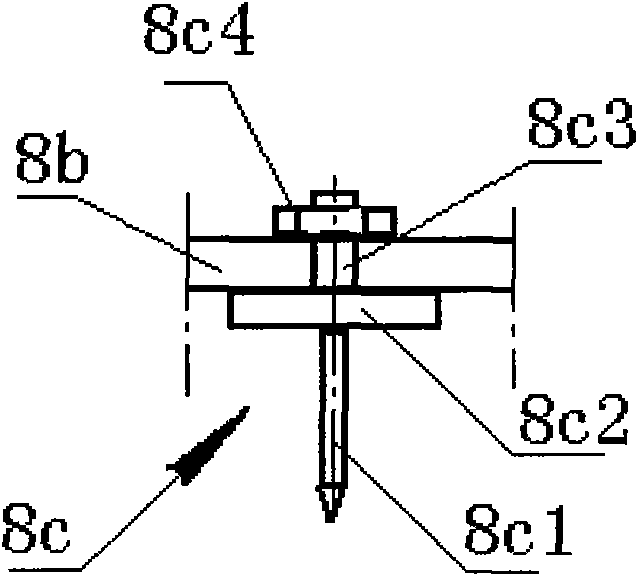

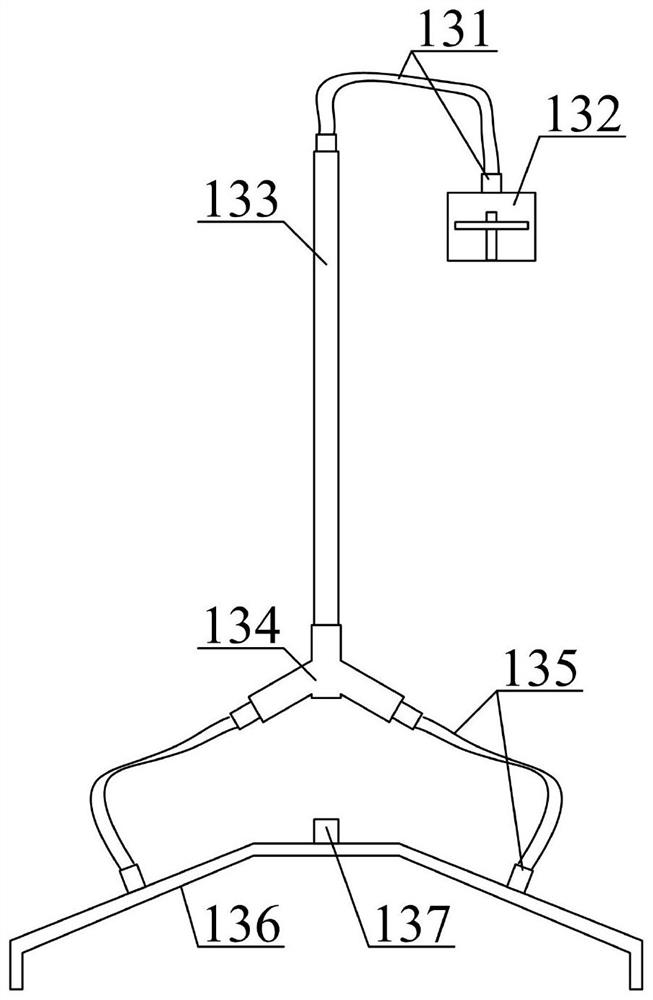

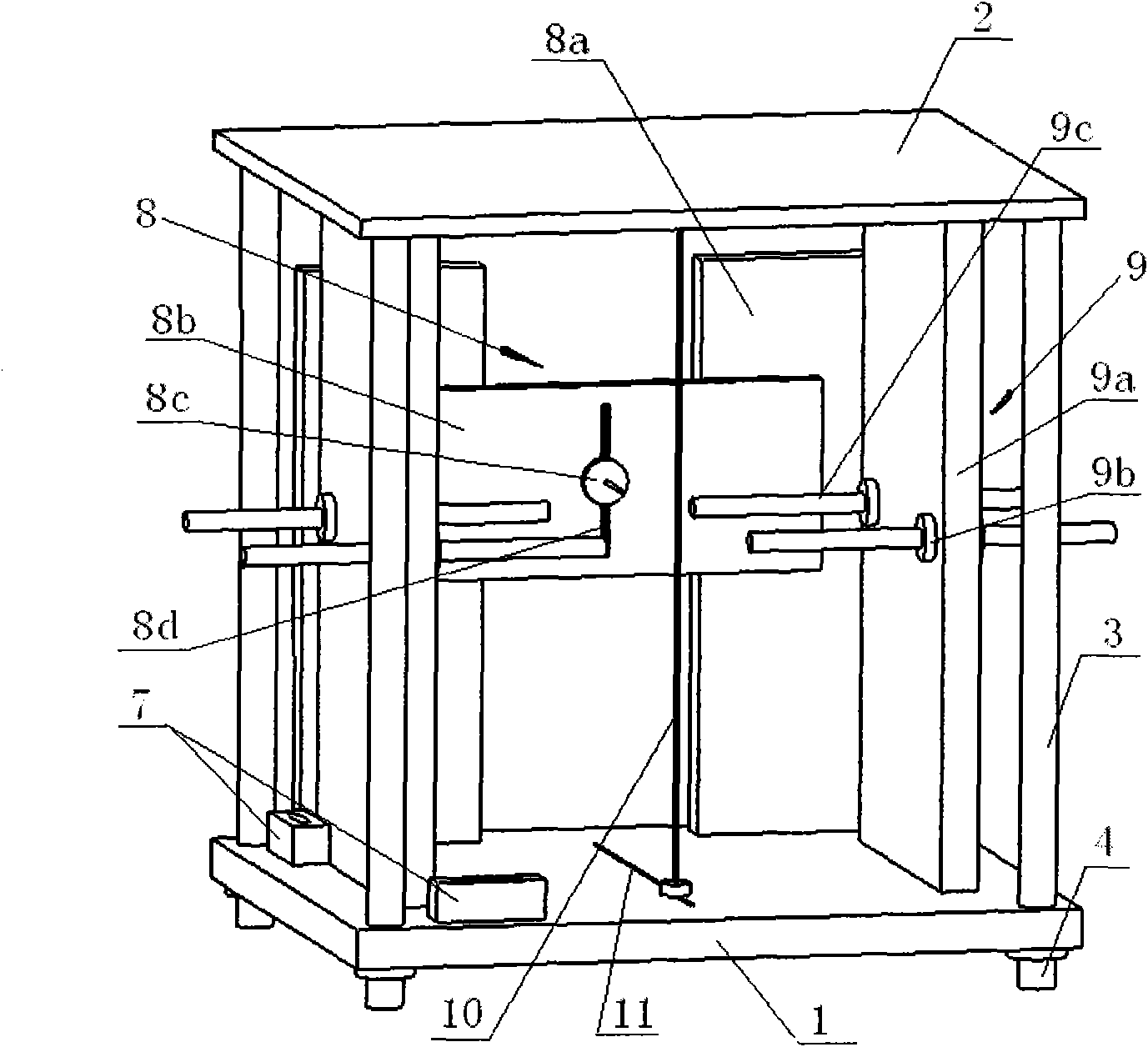

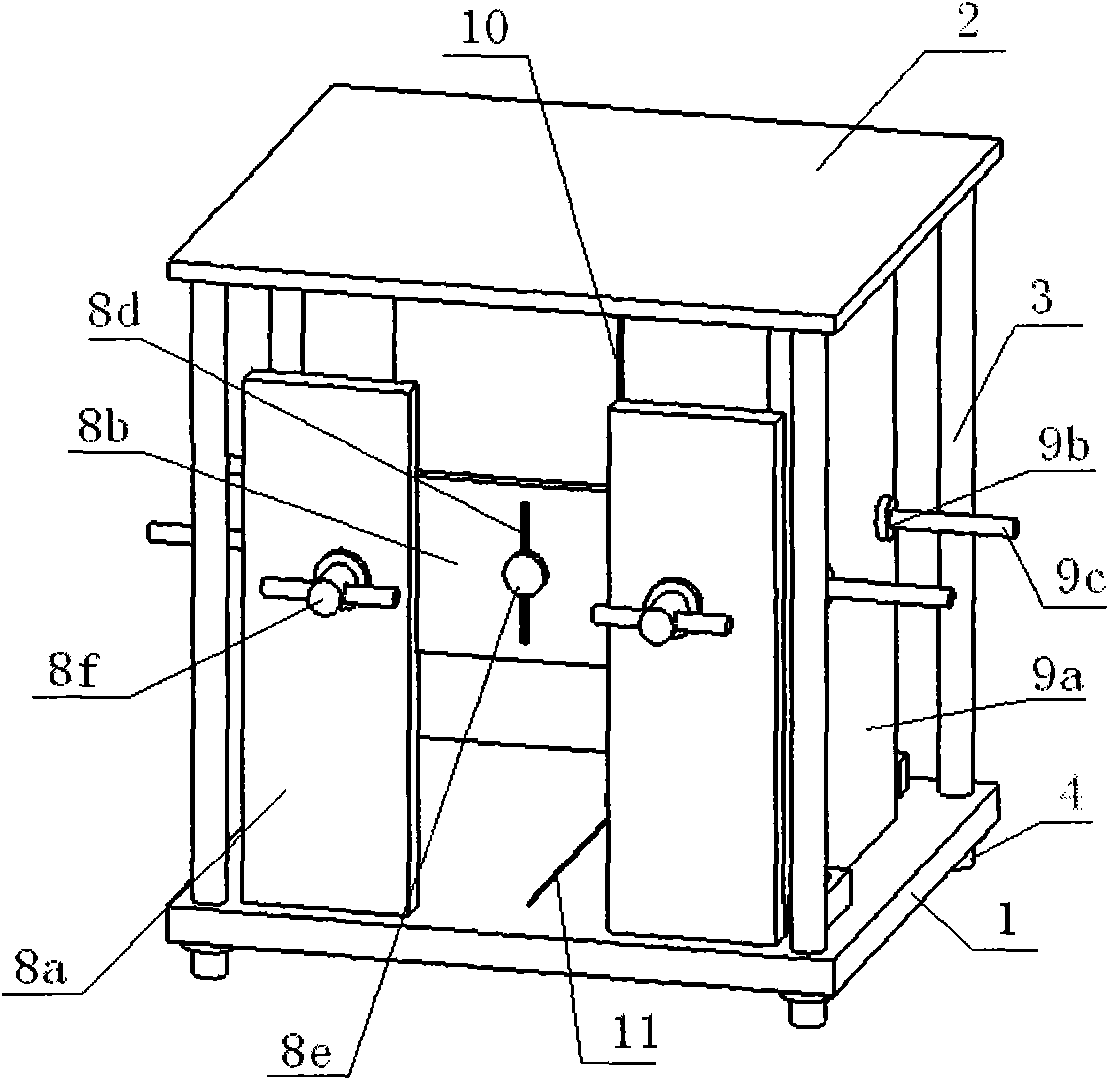

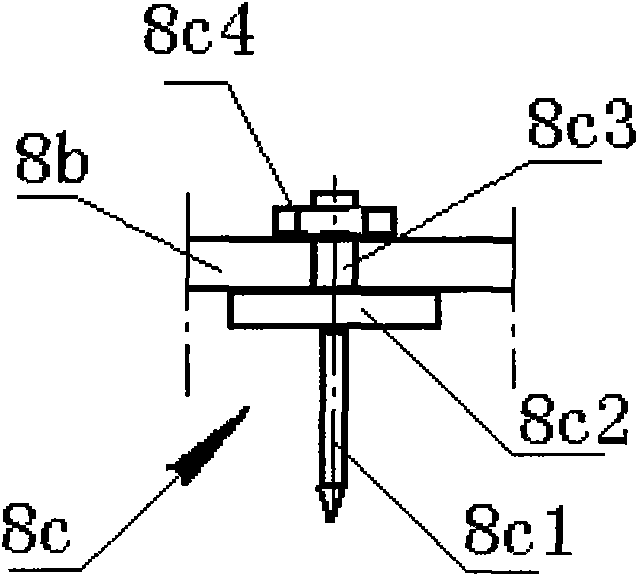

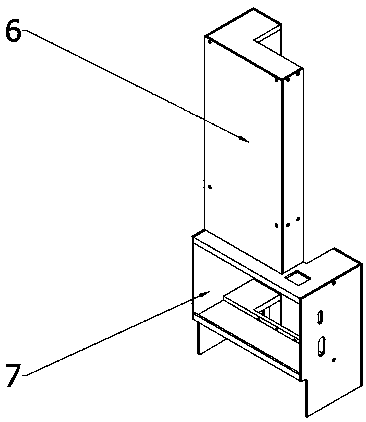

Flutter model center of gravity positioner

ActiveCN102323007ARelatively small errorSmall discreteStatic/dynamic balance measurementAviationGravity center

The invention belongs to aviation measurement technology, and relates to a flutter model center of gravity positioner. The flutter model center of gravity positioner is characterized by comprising a bearing framework, two level meters (7), a center of gravity positioning assembly (8), two model spacing assemblies (9) and a center of gravity locating lever (10). The flutter model center of gravitypositioner has the characteristics of a small error of a measured value and small discreteness. By utilizing a static balance principle and a model spacing device to restricting degree of freedom of model rotation, by utilizing the center of gravity locating lever to substitute a plumb, measurement stability is effectively guaranteed.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

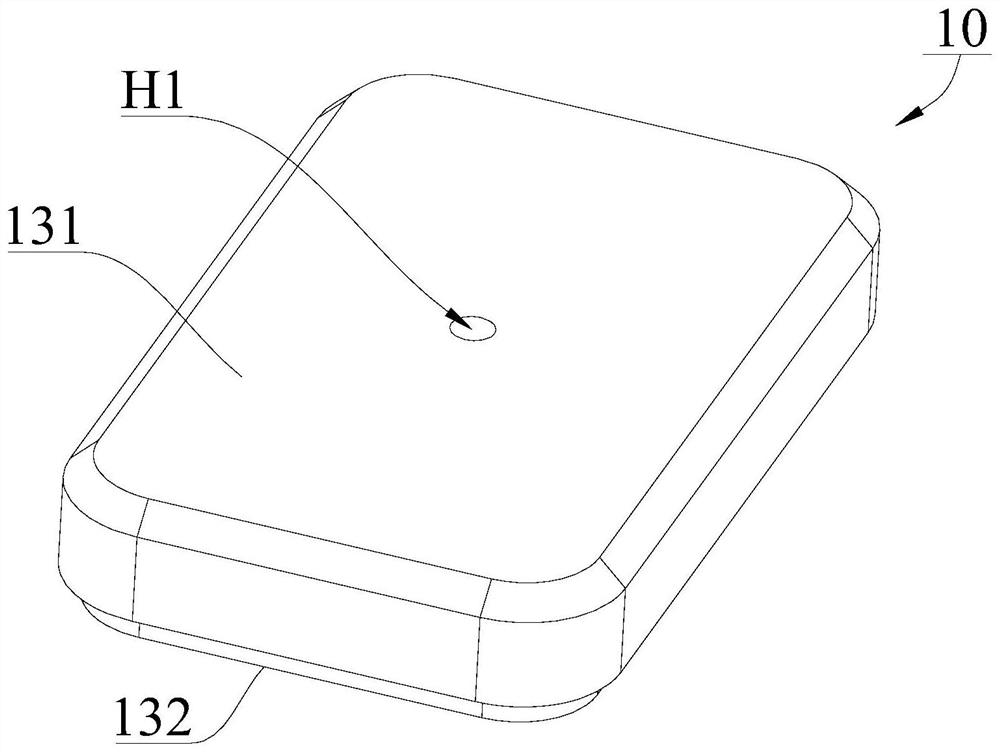

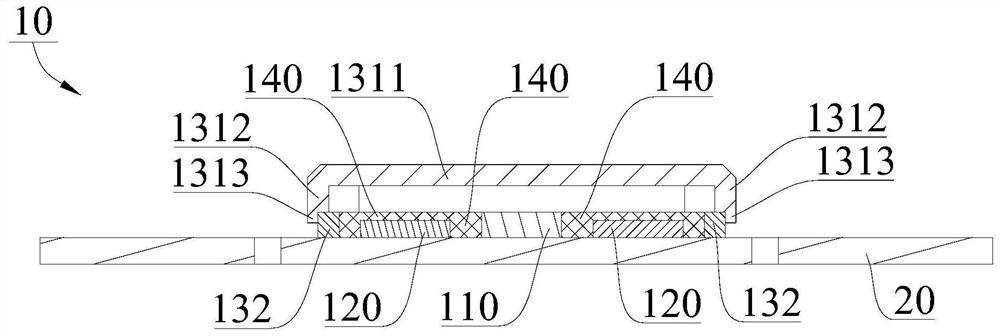

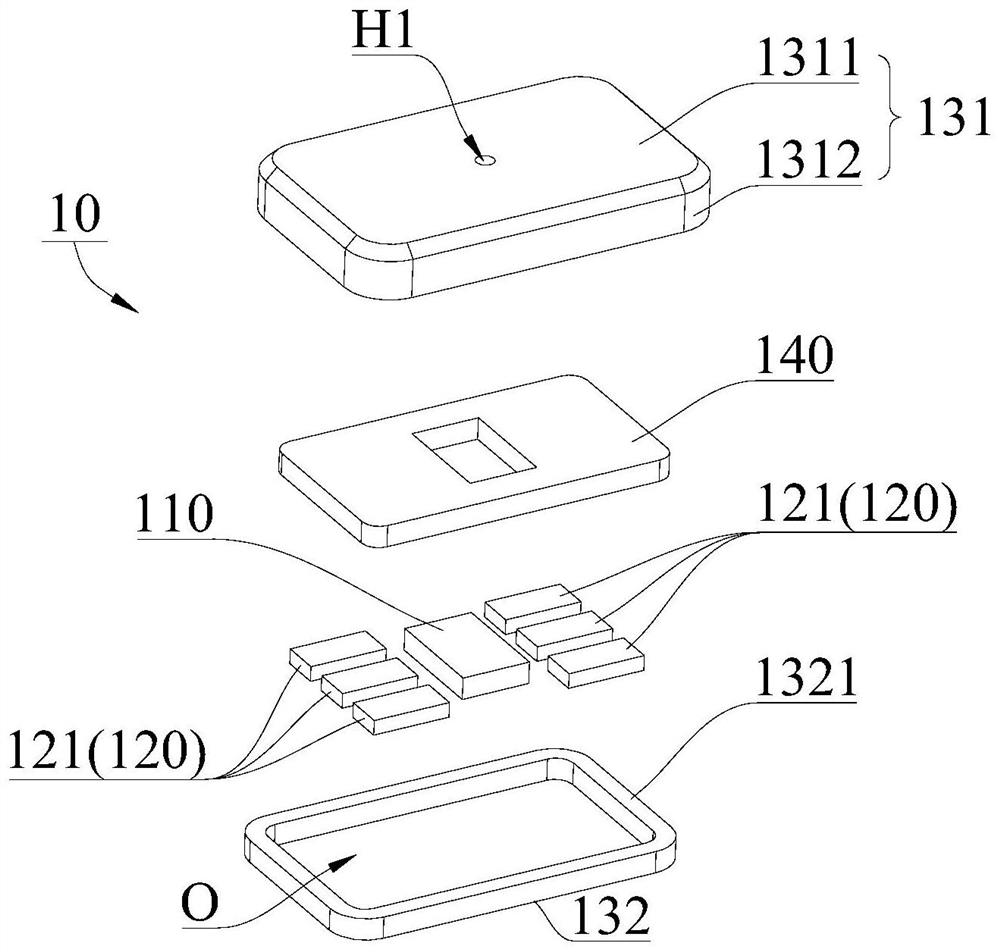

Inertia measurement module, flight control inertia measurement assembly and aircraft

PendingCN112429270AIncrease working temperatureShorten warm-up timeAircraft components testingFlight vehicleInertial measurement unit

The invention relates to an inertial measurement module, a flight control inertial measurement assembly and an aircraft, and the inertial measurement module comprises an inertial measurement unit which is used for measuring the inertial parameters of a moving object; an electric heating piece, which is arranged side by side with the inertia measurement unit at an interval, and is used for exchanging heat with the inertia measurement unit; a packaging structure which is used for packaging the inertial measurement unit and the electric heating piece inside; and a heat-conducting medium which isfilled in a gap between the inertial measurement unit and the electric heating piece and does not cover the top surface of the inertial measurement unit. The working temperature of the inertial measurement unit in the inertial measurement module can be maintained in an optimal state, and the pressure borne by the inertial measurement unit is small, so that the measurement accuracy and reliabilityof the inertial measurement unit are improved.

Owner:BEIJING AIRLANGO TECH CO LTD

Laser-oriented control system and method for shield machine

InactiveCN102518445BHigh degree of automationImprove construction efficiencyTunnelsControl systemTotal station

The invention discloses a laser-oriented control system and method for a shield machine. The method comprises the following steps: measuring the coordinate of a prism under a ground coordinate system in the shield machine by a laser total station instrument; determining the attitude parameter of the shield machine by a laser receiving target and a sensor; calculating the coordinates of a tool bit centre point, a middle folding point of the shield machine and a shield tail centre point under the ground coordinate system by a controller; determining the axial offset amount of the tool bit centre point, the middle folding point of the shield machine and the shield tail centre point relative to a tunneling plan line; revising and fitting the tunneling curve of the shield machine by the controller; and controlling the shield machine to tunnel by the controller. According to the technical scheme disclosed by the invention, the degree of automation and the construction efficiency of the traditional control survey system are greatly improved on the premise of guaranteeing the measurement precision and stability, and the engineering expenditure can be greatly saved.

Owner:BEIJING INFORMATION SCI & TECH UNIV

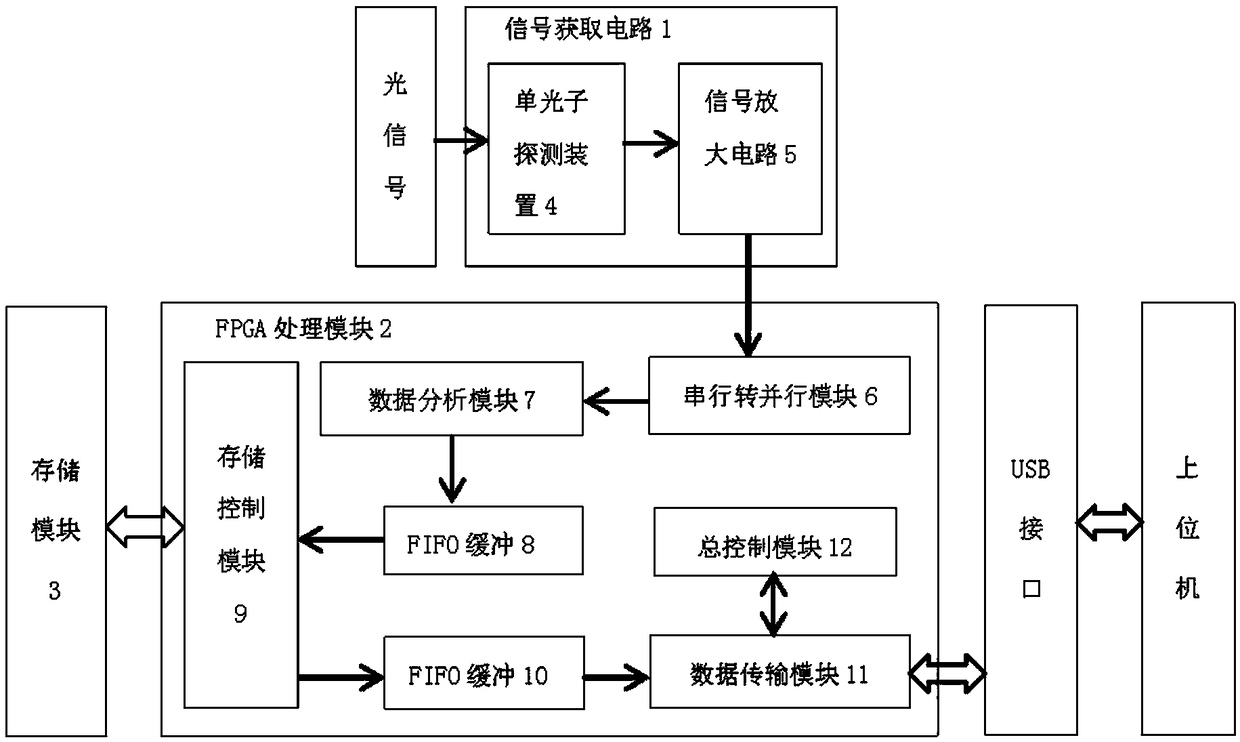

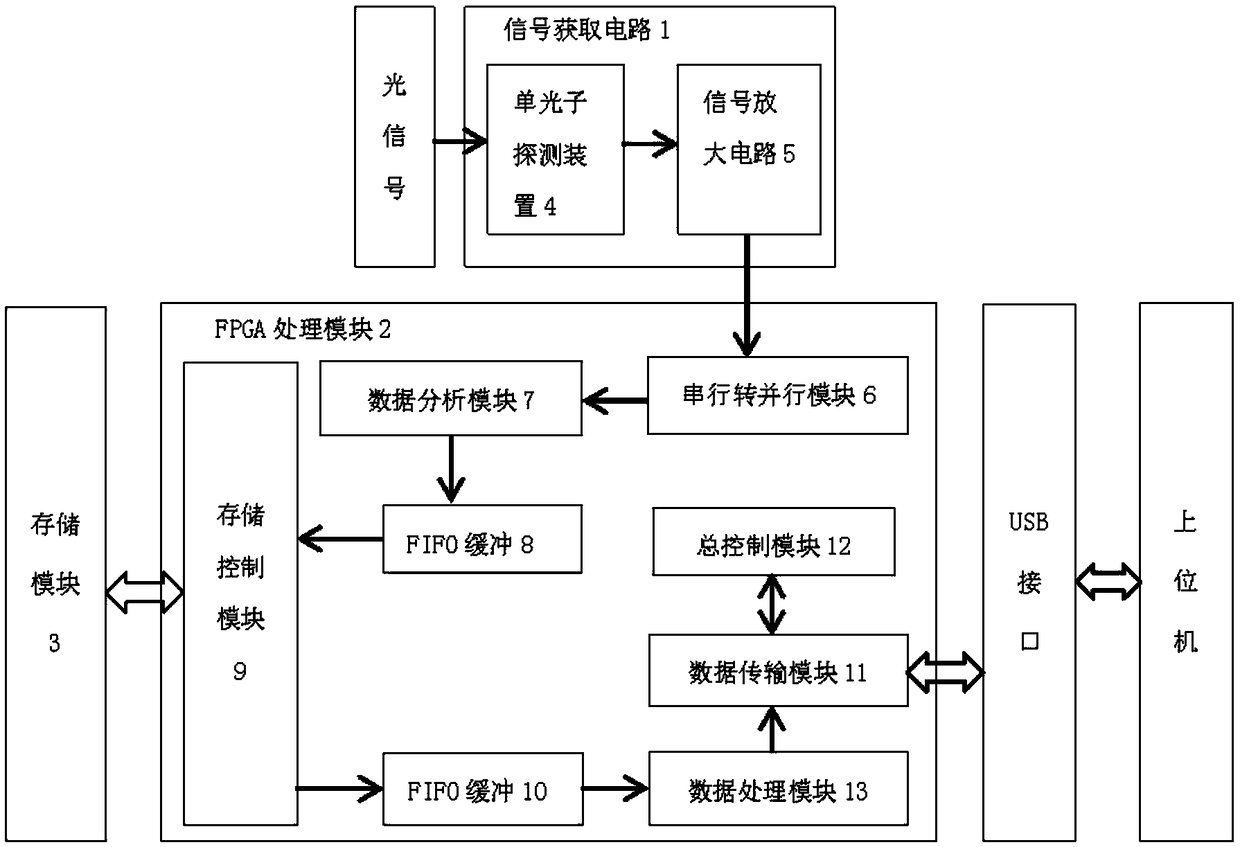

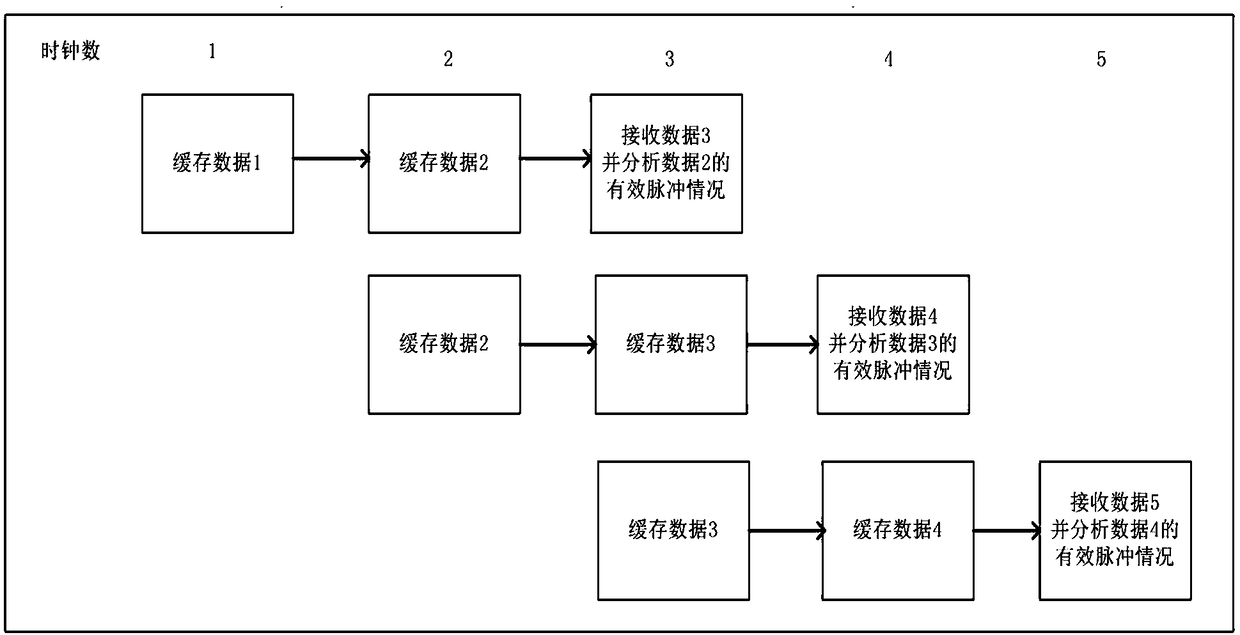

Single photon pulse arrival time detecting device

The invention discloses a single photon pulse arrival time detecting device. The device comprises a signal acquisition circuit, an FPGA processing module and a storage module. A single photon detecting device and a signal amplifying circuit convert an optical signal into a digital pulse signal which is collected by the FPGA processing module. In the acquisition of the single photon pulse signal, aserial-to-parallel conversion method is adopted to reduce the operating frequency of a data analysis module, the collected pulse data is analyzed by means of an assembly line, a multi-stage circuit simultaneously processes the data to achieve acquisition, analysis and storage, and the device greatly shortens the clock cycle required for the work, reduces the time taken for the entire process, andgreatly improves the efficiency.

Owner:HEFEI UNIV OF TECH

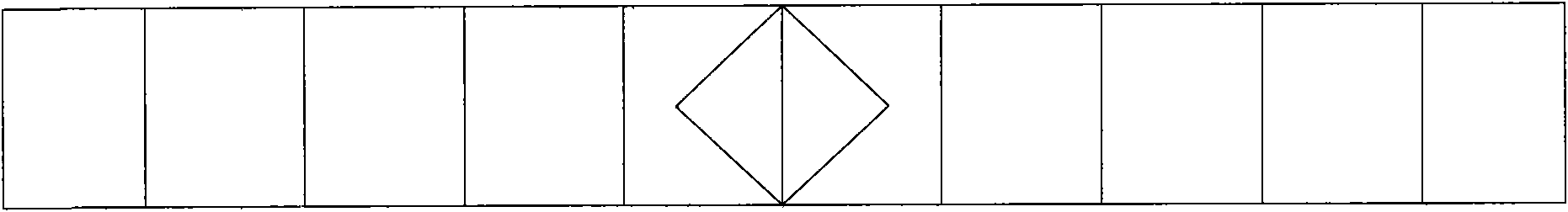

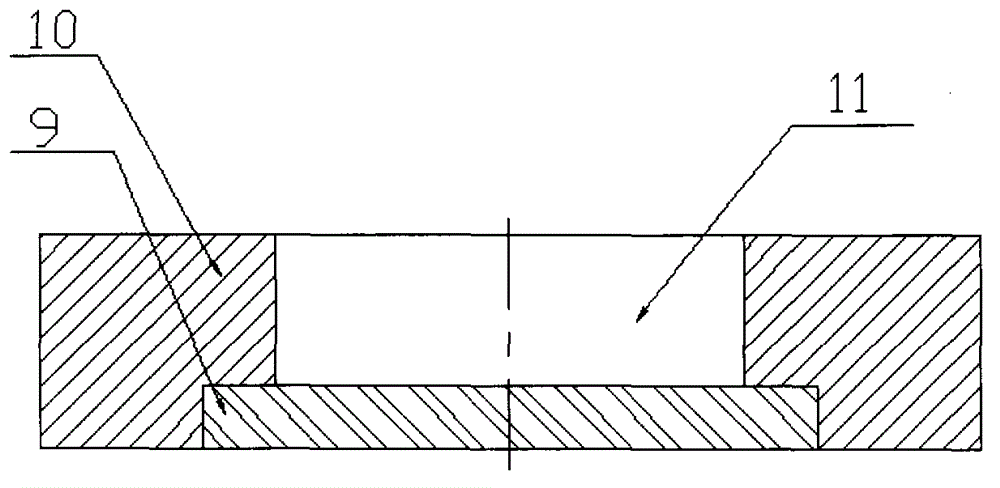

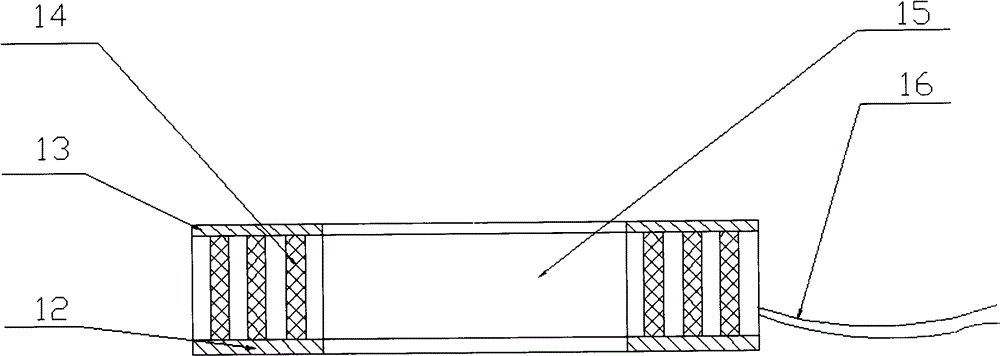

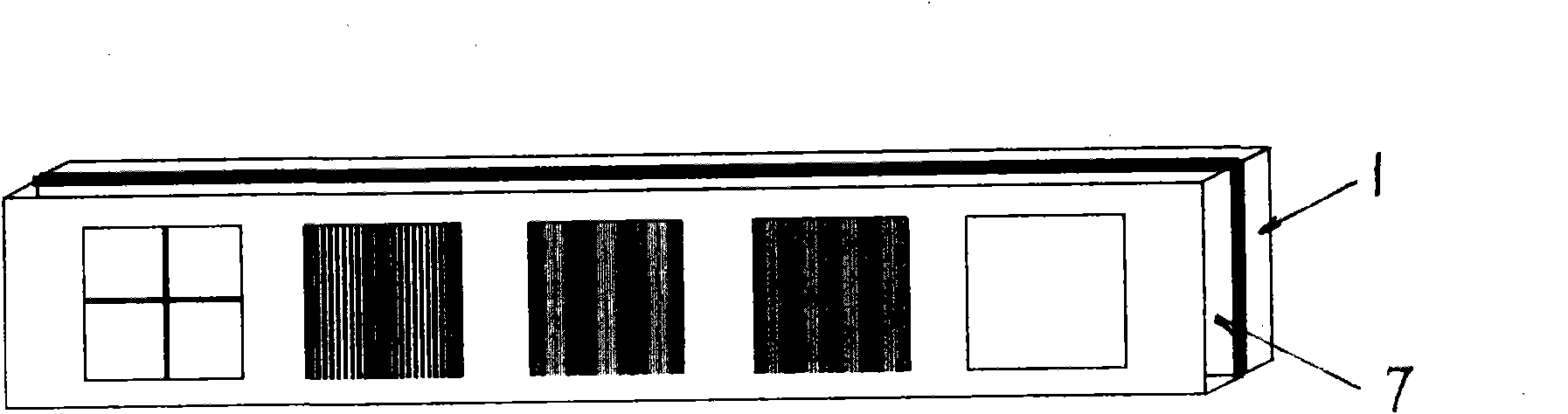

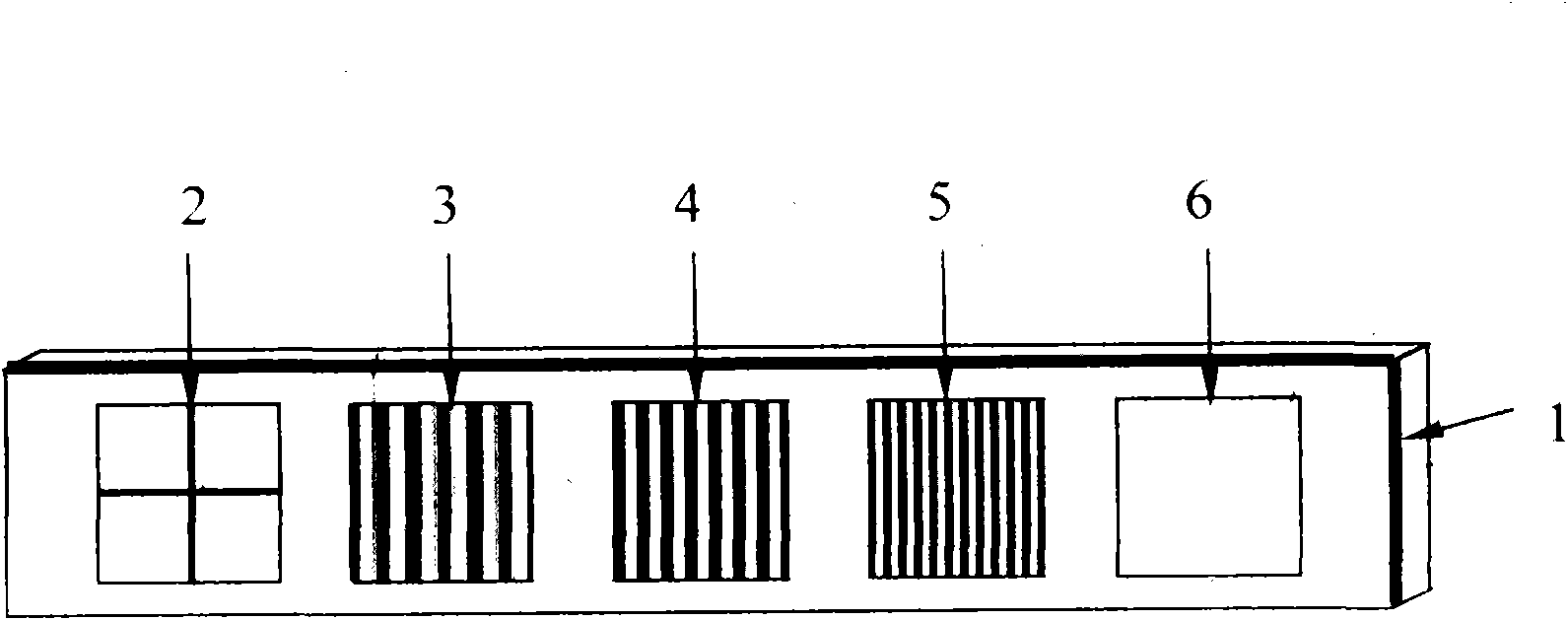

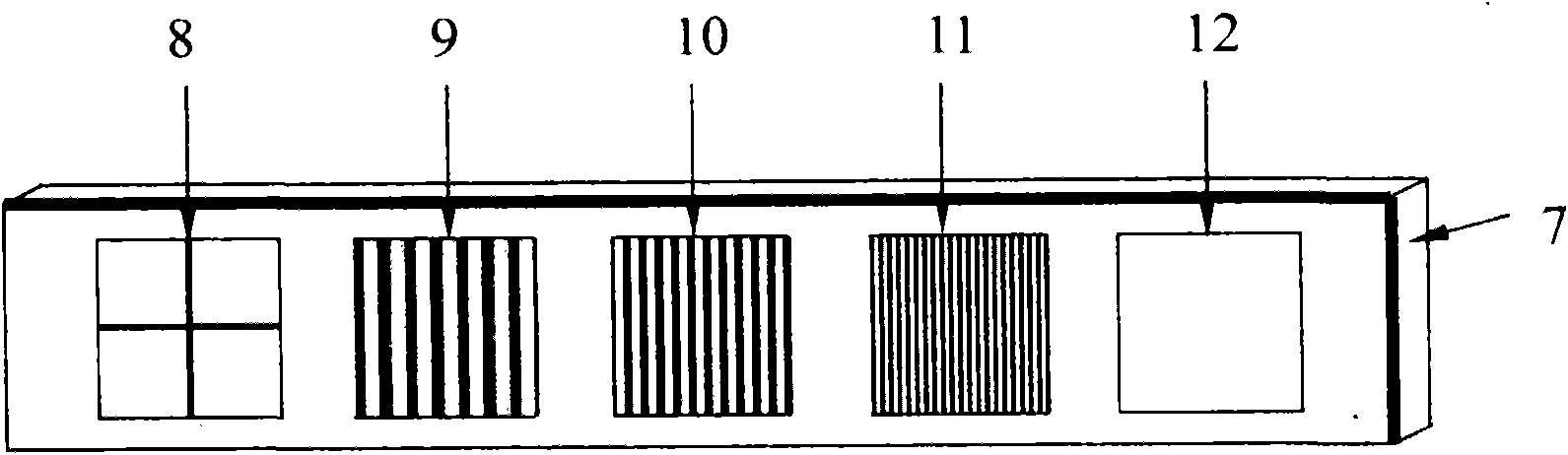

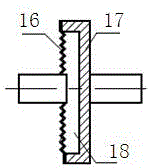

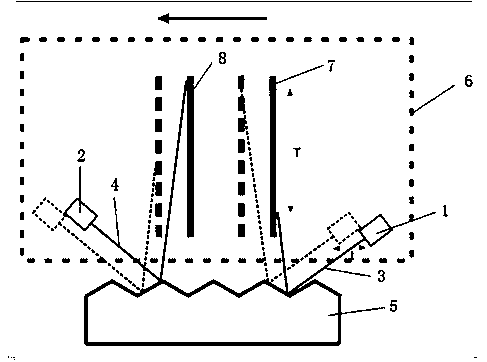

Stacked-gate sine stripe projection phase shifting grating

InactiveCN102141644AGuaranteed measurement accuracyGuaranteed measurement stabilityDiffraction gratingsUsing optical meansGratingThree dimensional measurement

The invention relates to a stacked-gate sine stripe projection phase shifting grating, belonging to an optical three-dimensional measurement technology. A first cross-shaped calibration, a first rectangular calibration and rectangular gratings A, B and C with different periods are arranged on a first grating glass substrate of a coating, a second cross-shaped calibration, a second rectangular calibration and rectangular gratings A', B' and C' with different periods are arranged on a second grating glass substrate of the coating, the first grating glass substrate of the coating and the second glass substrate of the coating are laminated into a whole, the first cross-shaped calibration and the second cross-shaped calibration are aligned and positioned, the first rectangular calibration and the second rectangular calibration are aligned and positioned, the rectangular gratings A, B and C are respectively laminated with the rectangular gratings A', B' and C', the grating stripe directions of all the rectangular gratings are mutually parallel, and the grating period is 40-100wires / mm. By applying the grating provided by the invention, structured light projection light intensity stripe sine distribution is realized, and the grating provided by the invention has the characteristics of simple structure, easiness in grating engraving, low processing cost, high contrast ratio, high measurement accuracy and good stability.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

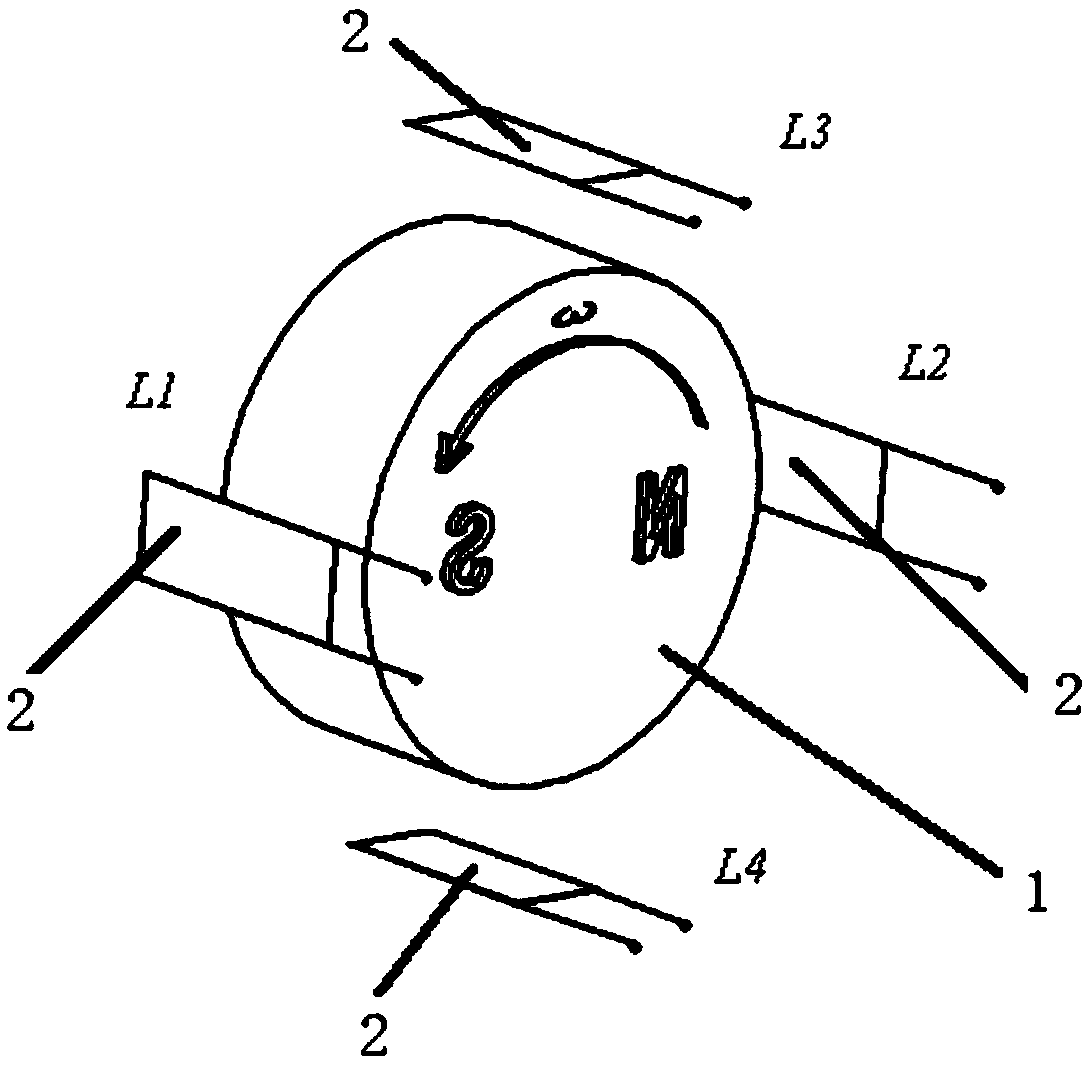

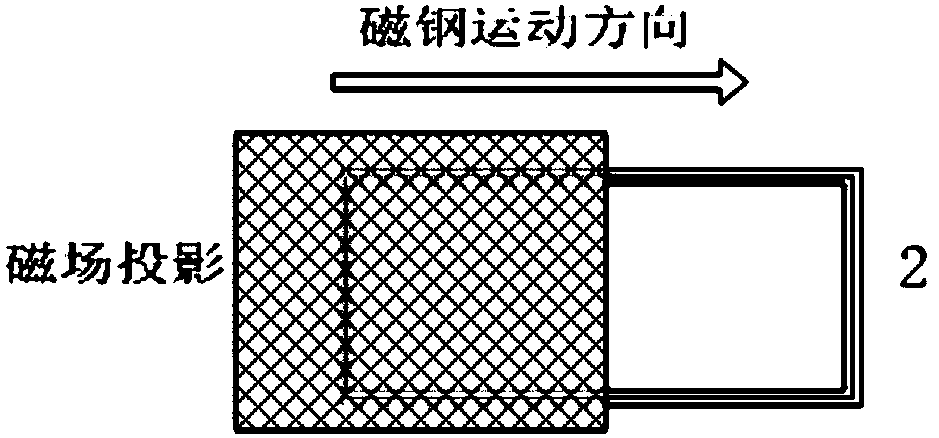

Dynamically tuned gyroscope and angular position sensor thereof

PendingCN108195365AGuaranteed accuracyGuaranteed stabilityRotary gyroscopesGyroscopeElectromagnetic interference

The invention discloses a dynamically tuned gyroscope and an angular position sensor thereof. The angular position sensor comprises at least two electromagnetic induction coils fixed relative to the position of a gyroscope, wherein the electromagnetic induction coils are arranged in the circumferential direction of a magnetic steel rotor, the two oppositely-arranged electromagnetic induction coilsare symmetrically relative to the rotation axis of the magnetic steel rotor, the magnetic steel rotor generates a sinusoidal changing magnetic field during the rotation, each electromagnetic induction coil is positioned in the sinusoidal changing magnetic field, and the wiring terminals of each electromagnetic induction coil are connected to voltage treatment and acquisition equipment. With the angular position sensor of the present invention, the anti-electromagnetic-interference capability is improved, the angular position measurement range is expanded, and the linearity of the output signal is increased, such that the angular position measurement accuracy, the range and the performance stability of the gyroscope are ensured.

Owner:CHINA AEROSPACE STANDARDIZATION INST

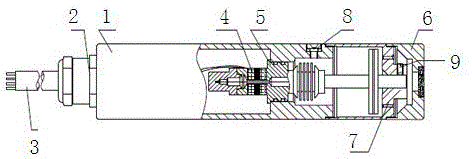

High precision vibrating wire type micro-pressure sensor

ActiveCN106092425ASmall structureThere is no need to consider the problem that a higher natural frequency cannot be obtainedFluid pressure measurement using elastically-deformable gaugesVibrating wireEngineering

The invention discloses a high precision vibrating wire type micro-pressure sensor comprising a housing, a cable joint connected with a cable, an induction coil, a micro-pressure sensitive part, an inner plugging cover provided with a central hole, and a permeable part. One end of the housing is connected with the cable joint, and the other end of the housing is connected with the permeable part. The induction coil, the micro-pressure sensitive part, and the inner plugging cover are disposed in the housing, and are sequentially connected together. The micro-pressure sensitive part comprises an upper end, a main body, a corrugated pipe, a lower end, a vacuum diaphragm capsule, and a steel wire. The upper end, the main body, the corrugated pipe, and the lower end are sequentially connected together, and are used to form a sealed cavity body. The steel wire is disposed in the sealed cavity body, and the vacuum diaphragm capsule is connected with the lower end. The micro-pressure sensitive part is disposed in the housing in a packaged manner, and the micro-pressure sensitive part is prevented from damaging caused by external influences. The stability of the sensor is improved, and a problem of inability of realizing extreme micro-pressure and high precision is solved. By combining the flexible stainless steel corrupted pipe with the vacuum diaphragm capsule, precision of measured values is improved.

Owner:NANJING NARI GROUP CORP +1

Multifunctional real-time detection device for road and bridge concrete structure

InactiveCN112709180AEasy to cleanAvoid Inaccurate Visual InspectionMechanical depth measurementsRoad cleaningArchitectural engineeringVisual inspection

The invention provides a multifunctional real-time detection device for the road and bridge concrete structure; the device comprises a cross beam, supporting frames, a rack, a moving rod, moving trundles, a control panel, a dust collection box, a dust collection core, supporting pipes, a cleaning box cover and an exhaust net, and the cross beam is transversely connected to the upper end between the supporting frames through bolts; the longitudinal lower ends of the supporting frames are connected to the left side and the right side of the upper portion of the rack through bolts. Through arrangement of cleaning bristles, a cleaning disc, a buffer spring, a rotating disc, a dismounting pipe, a cleaning motor and a quick dismounting bolt, cleaning of the surfaces of roads and bridges is facilitated, real-time detection is facilitated, the cleaning motor drives the dismounting pipe to rotate, and the rotating disc drives the cleaning disc to rotate through the buffer spring; therefore, the surface of the road bridge can be cleaned through the cleaning bristles, inaccurate visual inspection caused by dust coverage is avoided, cracks or cracks on the surface of the road bridge can be clearly determined, and marking and repairing are facilitated.

Owner:YANCHENG INST OF TECH

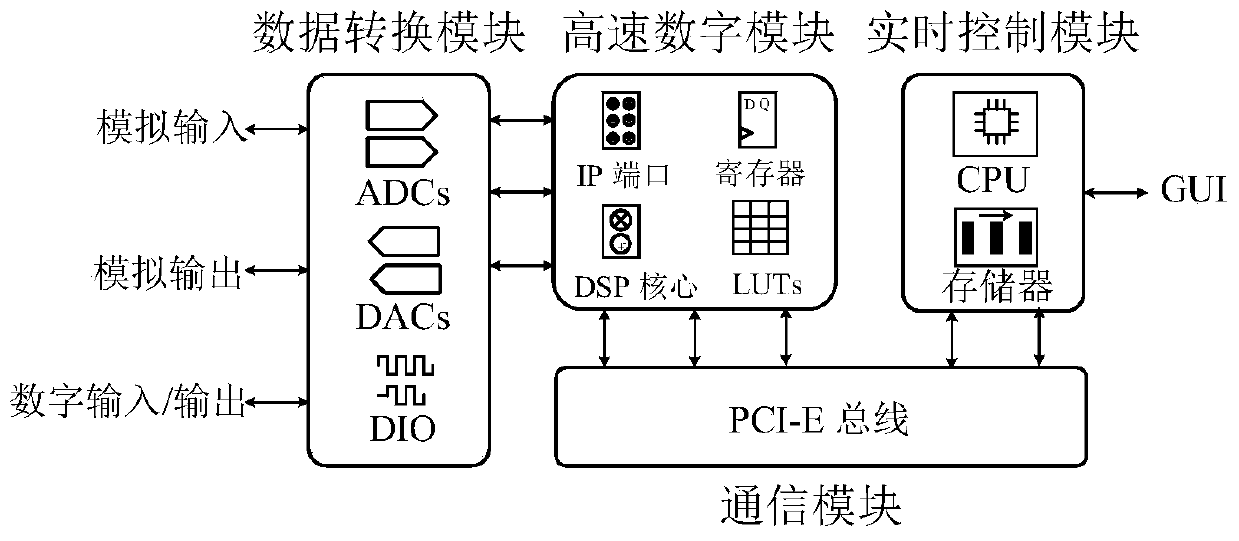

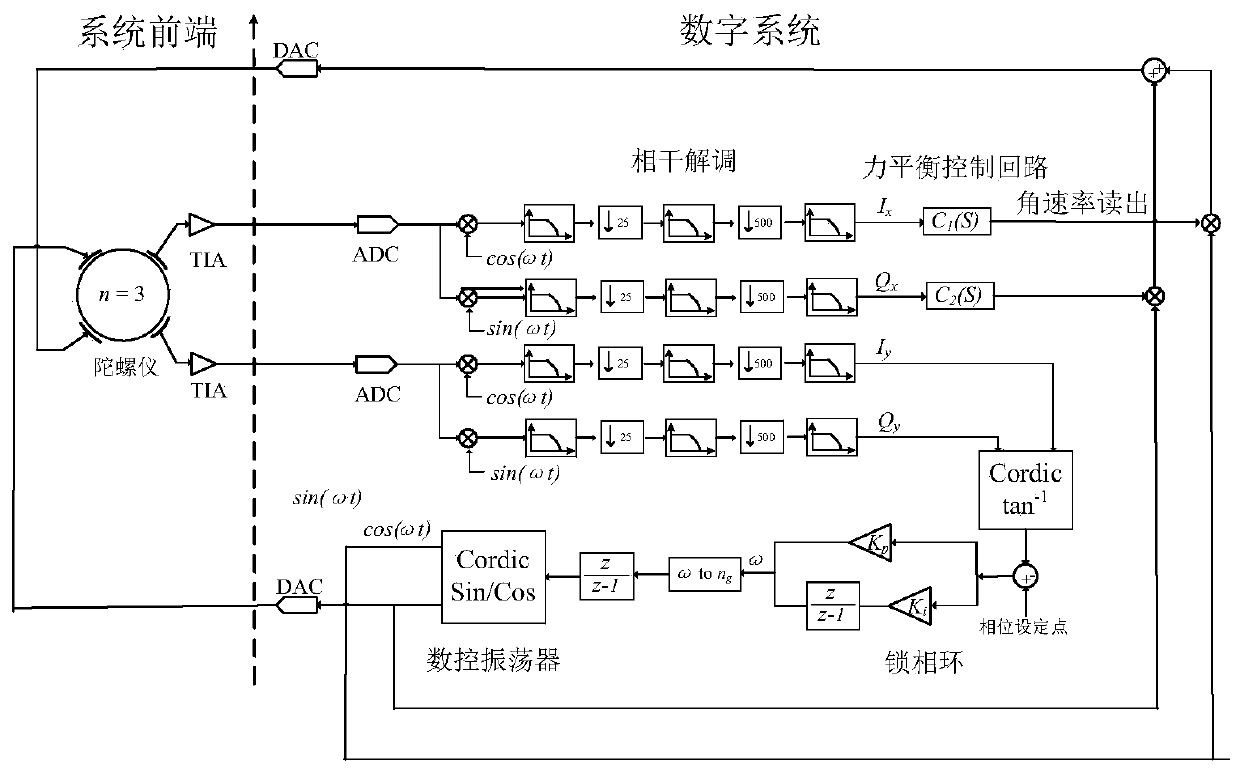

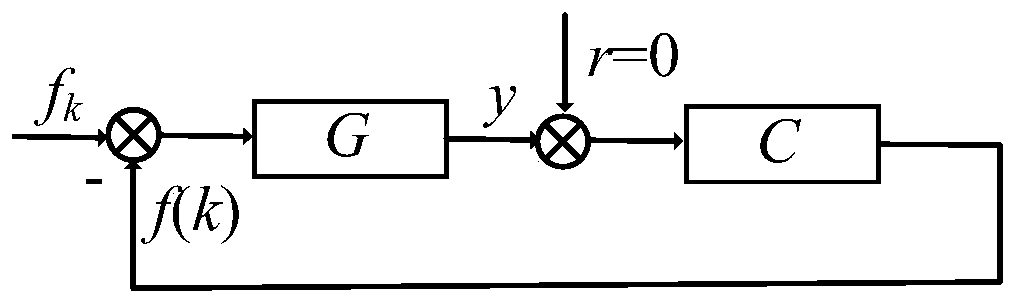

High-dynamic force balance control method of MEMS (micro-electro-mechanical system) resonant gyroscope

ActiveCN110440779AGuaranteed measurement accuracy and stabilityExtended dynamic range and measurement bandwidthSpeed measurement using gyroscopic effectsGyroscopes/turn-sensitive devicesAnti jammingControl variable

The invention discloses a high-dynamic force balance control method of an MEMS (micro-electro-mechanical system) resonant gyroscope. The method approximately comprises steps as follows: firstly, an augmentation form of a gyroscope resonant model is obtained and serves as a calculation model of an MPC (model predictive controller); then, the optimal balance force sequence is calculated in real timeat each sampling moment under the condition that balance force output constraint of the controller is met , and a first value of a vector of the sequence is taken as a controlled variable of the nextmoment. Such cycle calculation is performed, and finally, one optimal balance force sequence can be obtained, so that output of the gyroscope resonant model approaches a resonant output given value,coriolis force is counteracted, and force balance is realized. Accurate control of amplitude and frequency of the MEMS resonant gyroscope can be realized, accurate modal drive is provided for the gyroscope, and measurement accuracy and stability of the gyroscope are guaranteed. Meanwhile, the dynamic range and the measurement bandwidth of the gyroscope are enlarged, linearity and anti-jamming capability of scale factors are improved, and the sensitivity and the overall performance of the MEMS resonant gyroscope are improved.

Owner:OCEAN UNIV OF CHINA

Flutter model center of gravity positioner

ActiveCN102323007BRelatively small errorSmall discreteStatic/dynamic balance measurementAviationEngineering

The invention belongs to aviation measurement technology, and relates to a flutter model center of gravity positioner. The flutter model center of gravity positioner is characterized by comprising a bearing framework, two level meters (7), a center of gravity positioning assembly (8), two model spacing assemblies (9) and a center of gravity locating lever (10). The flutter model center of gravitypositioner has the characteristics of a small error of a measured value and small discreteness. By utilizing a static balance principle and a model spacing device to restricting degree of freedom of model rotation, by utilizing the center of gravity locating lever to substitute a plumb, measurement stability is effectively guaranteed.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

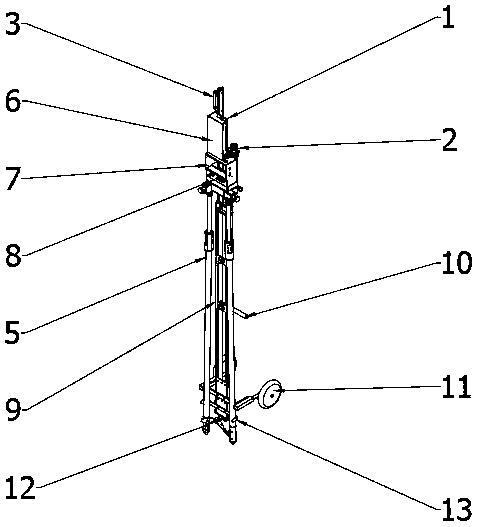

Ruler and instrument integrated installing frame for leveling

PendingCN108332019AEasy to store separatelyEasy to transportHeight/levelling measurementStands/trestlesEngineering

The invention discloses a ruler and instrument integrated installing frame for leveling, wherein the ruler and instrument integrated installing frame is simple and convenient to operate and capable ofimproving the installing efficiency and enhancing practicability. A vertical long-strip-shaped ruler base (1) is arranged, and a level instrument installing base (2) and a dragging handle (3) are fixed to the top end of the ruler base (1). The middle portion of the ruler base (1) is rotationally connected with an auxiliary foot stand (5) through a vertical rotation shaft (4). The part, above therotation shaft (4), of the ruler base (1) is provided with a battery bin (6), an electronic handbook bin (7) and an L-shaped level device bin (8), and the part, below the rotation shaft (4), of the ruler base (1) is provided with a vertical handle (9) and a transverse handle (10). Movable trundles (11), a limiting frame (12) and a ruler pad installing base (13) are arranged at the lower portion ofthe ruler base (1).

Owner:大连晶硕机械有限公司

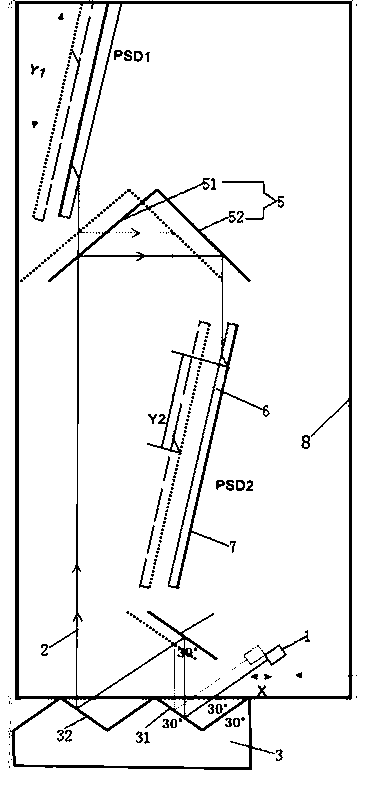

Differential displacement sensor with refractor and measuring method thereof

PendingCN109084692ARealize continuous displacement measurementEfficient measurementUsing optical meansBeam splitterPhotovoltaic detectors

The invention provides a differential displacement sensor with a refractor and a measuring method thereof. The displacement sensor comprises a laser beam, a beam splitter group, and a processing system, wherein the laser beam is incident on a reflecting surface of a triangular wave reflector; the beam splitter group comprises a beam splitter and a reflector which are arranged at an angle, the laser beam reflected by the reflecting surface of the triangular wave reflector is incident on the beam splitter, wherein a part of the laser beam is reflected by the beam splitter and the reflector and then incident on the refractor 1, and the other part of the laser beam is transmitted through the beam splitter and then incident on the refractor 2; the processing system is configured to calculate adisplacement change value of the measured object according to a change amount of the incident position of the laser beam received by a photodetector 1 and a photodetector 2. The differential displacement sensor with a refractor reduces the angle at which the laser is incident on the photodetector by providing the refractor 1 and the refractor 2, thereby improving the measurement accuracy of the displacement sensor.

Owner:BEIFANG UNIV OF NATITIES

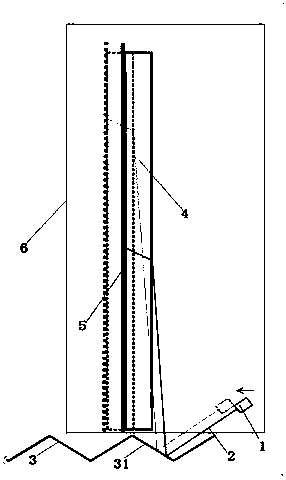

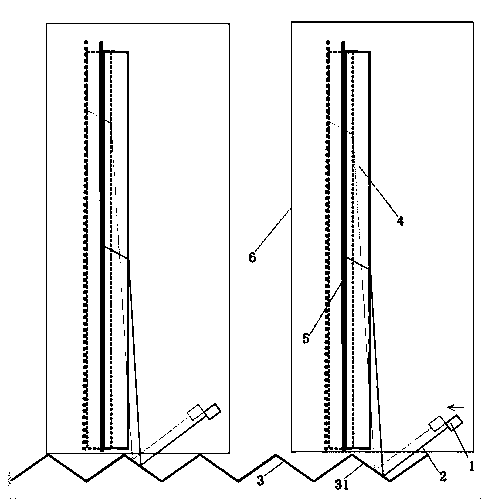

Refractive displacement sensor and measuring method thereof

PendingCN109084691AHigh magnificationHigh measurement accuracyUsing optical meansPhotovoltaic detectorsOptoelectronics

The invention provides a refractive displacement sensor and a measuring method thereof. The displacement sensor comprises a triangular wave reflector, a laser source, a refractor, a photoelectric detector, and a processing system. The triangular wave reflector comprises at least one reflecting surface which is sequentially distributed along the moving direction; the laser source is used for emitting a laser beam, and the laser beam is incident on one reflecting surface of the triangular wave reflector; the refractor is used for receiving a laser beam reflected by the reflecting surface, and refracting the received laser beam; the photoelectric detector is used for receiving the laser beam refracted by the refractor and measuring the incident position of the laser beam; and the processing system is used for calculating the displacement change value of a detected object according to the incident position change amount of the laser beam received by the photoelectric detector. According tothe refractive displacement sensor and the measuring method thereof, the angle of the laser incident to the photoelectric detector can be reduced while the amplification factor of the displacement sensor is increased by arranging a refractor, so that the measurement precision of the displacement sensor is improved.

Owner:BEIFANG UNIV OF NATITIES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com