Thermal flow sensor

A thermal flow sensor technology, applied in the direction of mass flow measurement devices, etc., can solve the problems of low precision and poor signal output stability, and achieve the effects of improving work efficiency, low price, and ensuring measurement accuracy and measurement stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

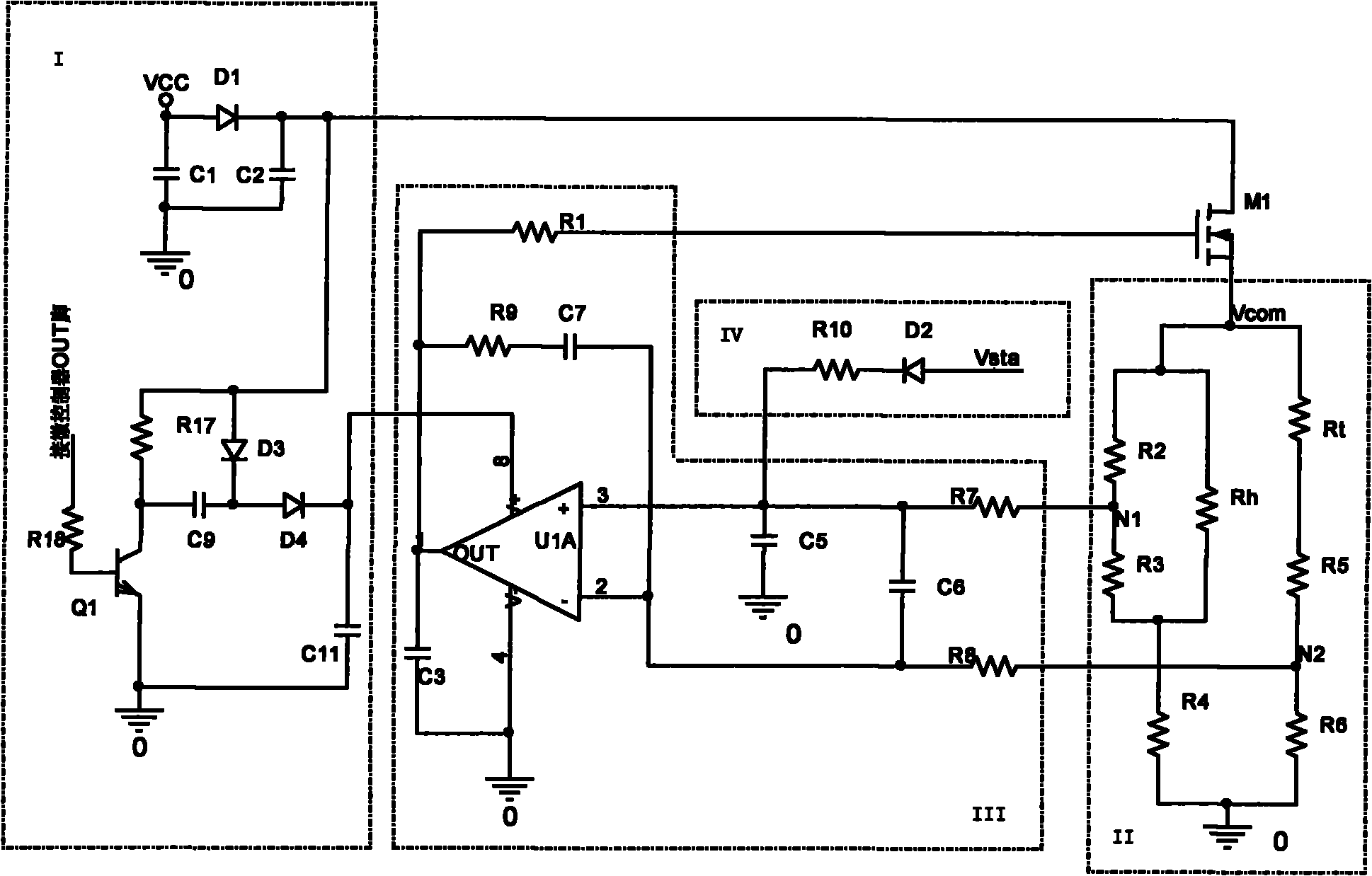

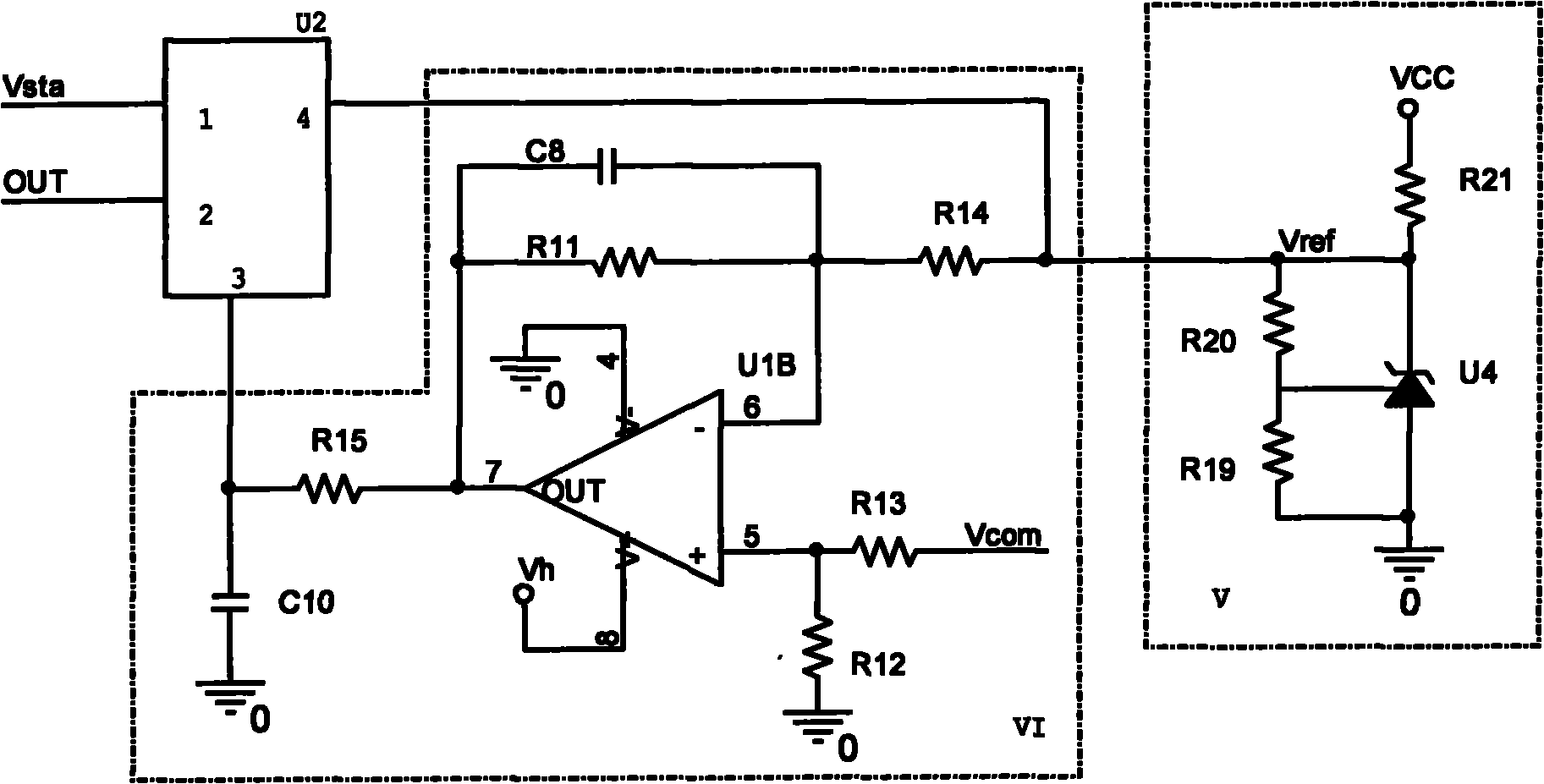

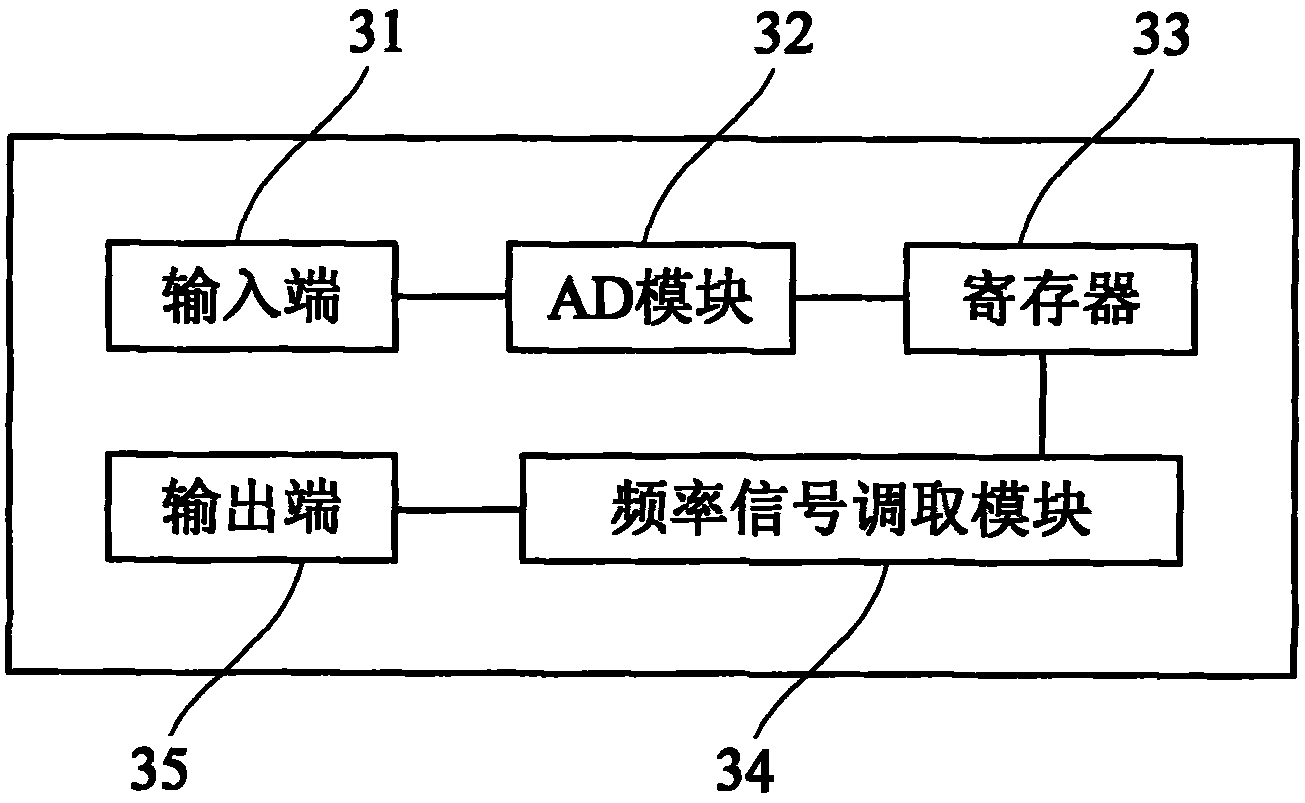

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings. In order to facilitate the understanding of the present invention, the thermal flow sensor of the present invention is now divided into a pre-stage part and a post-stage part according to the functional distinction of each circuit. The pre-stage part is used to sense the current air mass flow rate and provide original information for the post-stage part. The post-stage part is used to complete the processing of the output signal of the pre-stage part, and complete the conditioning, filtering, conversion and output of the signal. The connection mentioned in the present invention specifically refers to a direct or indirect electrical connection between circuits or between circuits and components or components.

[0028] Firstly, the pre-stage part of the thermal flow sensor of the present invention will be described. It reflects the flow rate through the degree of heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com