Patents

Literature

48results about How to "Accurate temperature compensation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

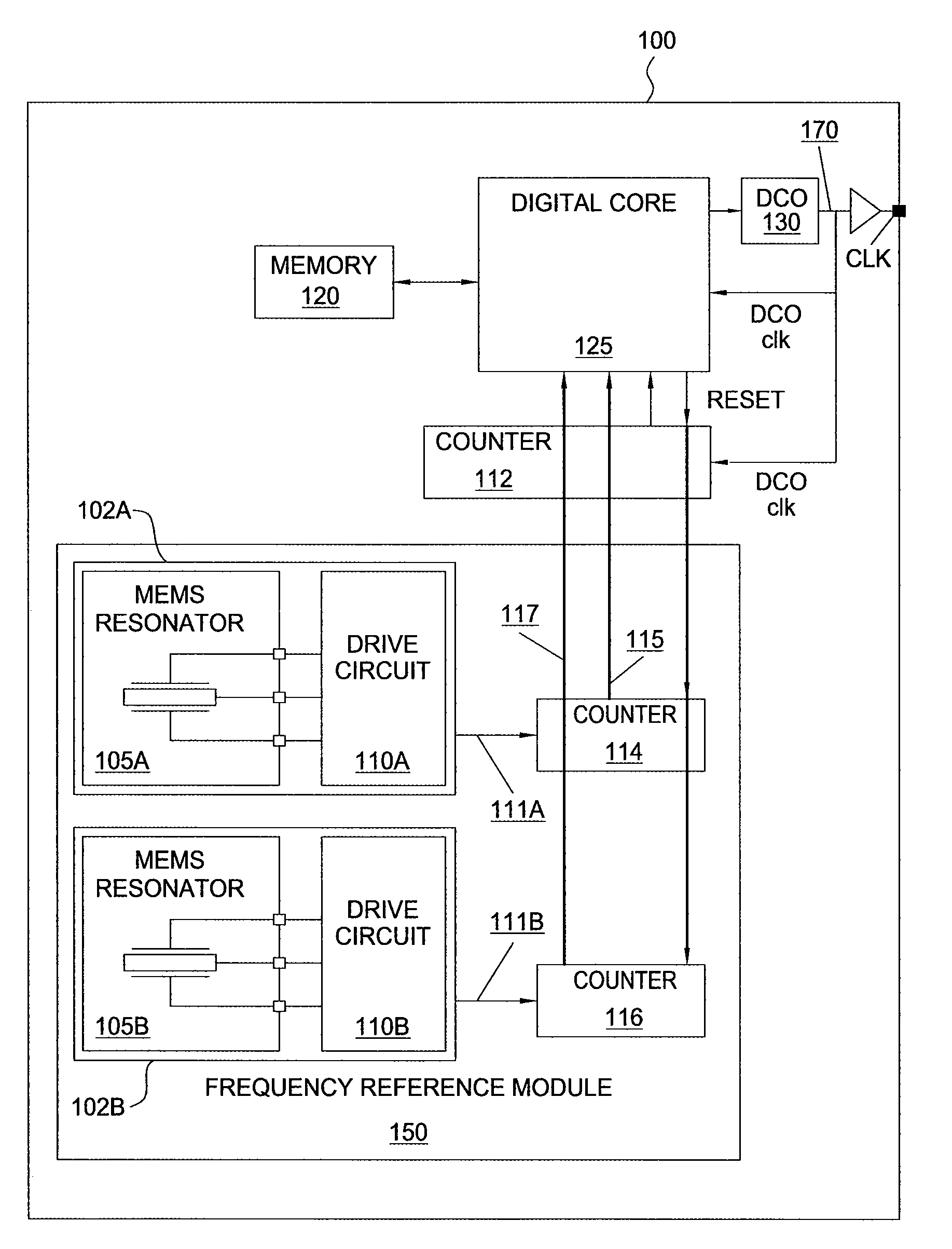

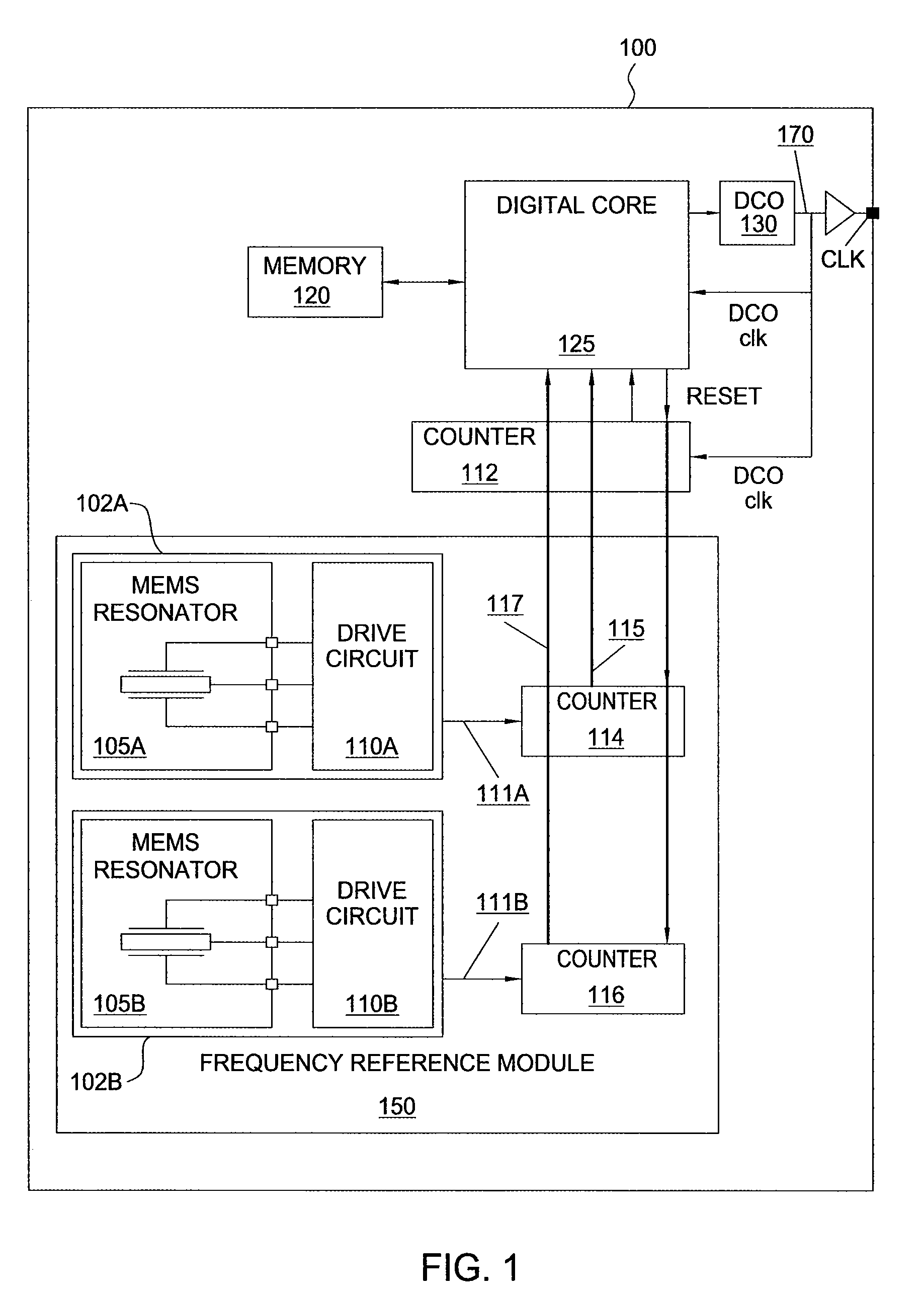

Dynamic temperature compensation for a digitally controlled oscillator using dual MEMS resonators

ActiveUS7545228B1Accurate temperature compensationThermometer detailsPiezoelectric/electrostriction/magnetostriction machinesDigital controlled oscillatorComputer science

A method for generating a temperature-compensated timing signal that includes counting, within an update interval, a first number of oscillations of a first micro-electromechanical (MEMS) resonator, a second number of oscillations of a second MEMS resonator and a third number of oscillations of a digitally controlled oscillator (DCO), computing a target DCO count based on the first number and second number of oscillations, computing a loop error signal based on the target DCO count and the third number of oscillations, and modifying an output frequency of a temperature-dependent (DCO) timing signal based on the loop error signal. The duration of the update interval may also be modified based on temperature conditions, and the update interval may also be interrupted and the output frequency immediately adjusted, if a significant temperature change is detected. Thus, dynamic and precise temperature compensation is achieved that accommodates constant, slowly changing, and rapidly changing temperature conditions.

Owner:SITIME

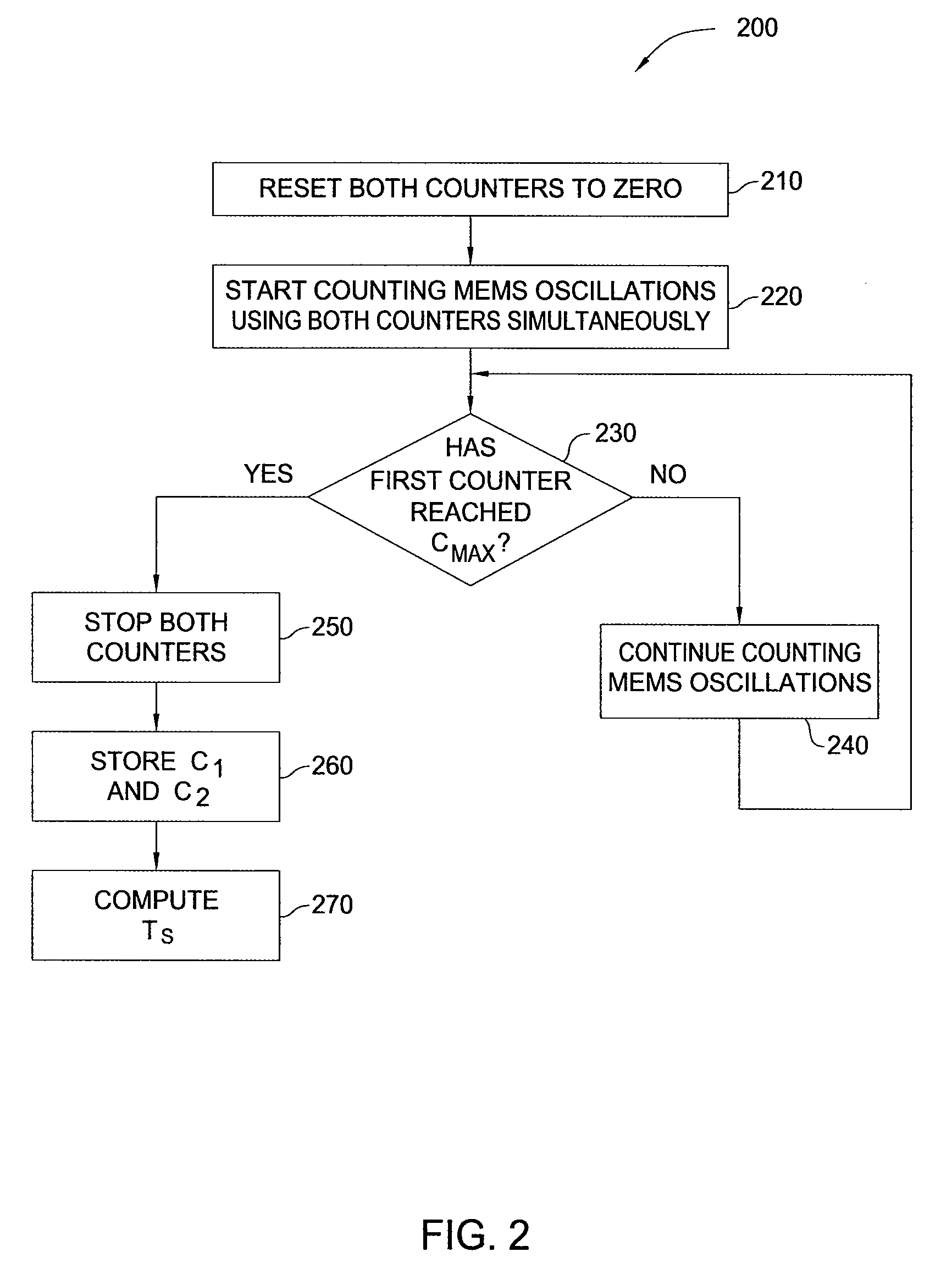

Air conditioner control method and air conditioner

ActiveCN104879876AImprove use comfort performanceEasy to useMechanical apparatusSpace heating and ventilation safety systemsControl theory

Owner:HAIER GRP CORP +1

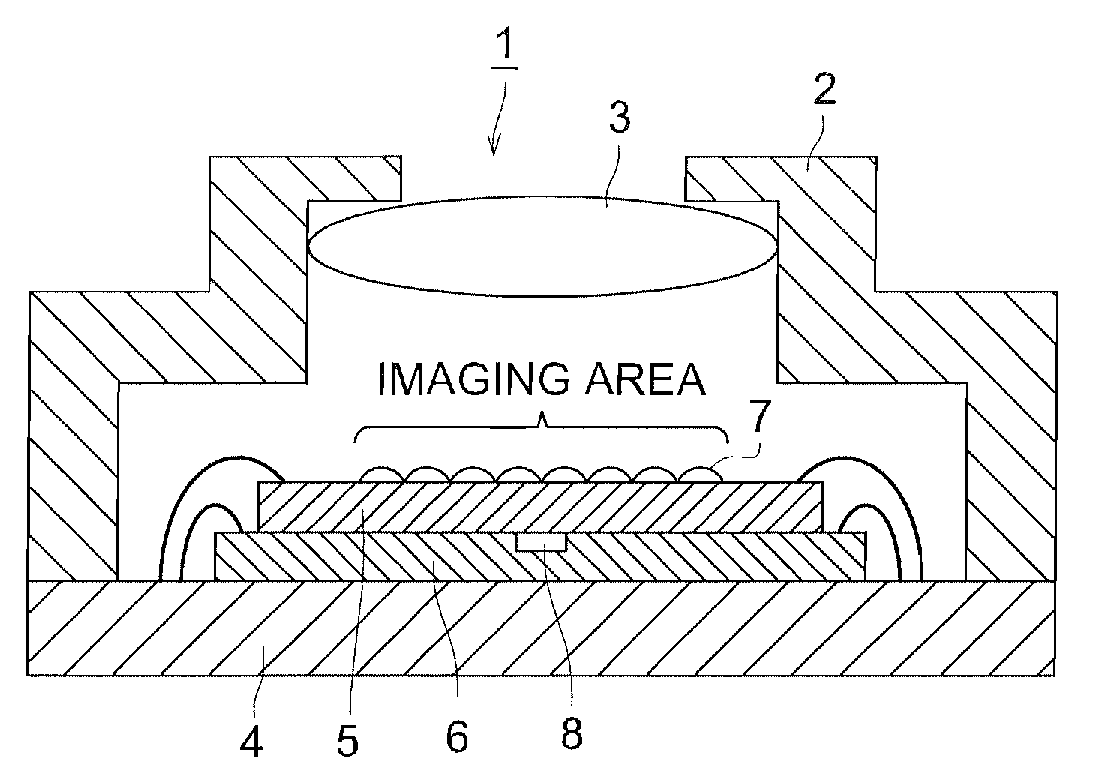

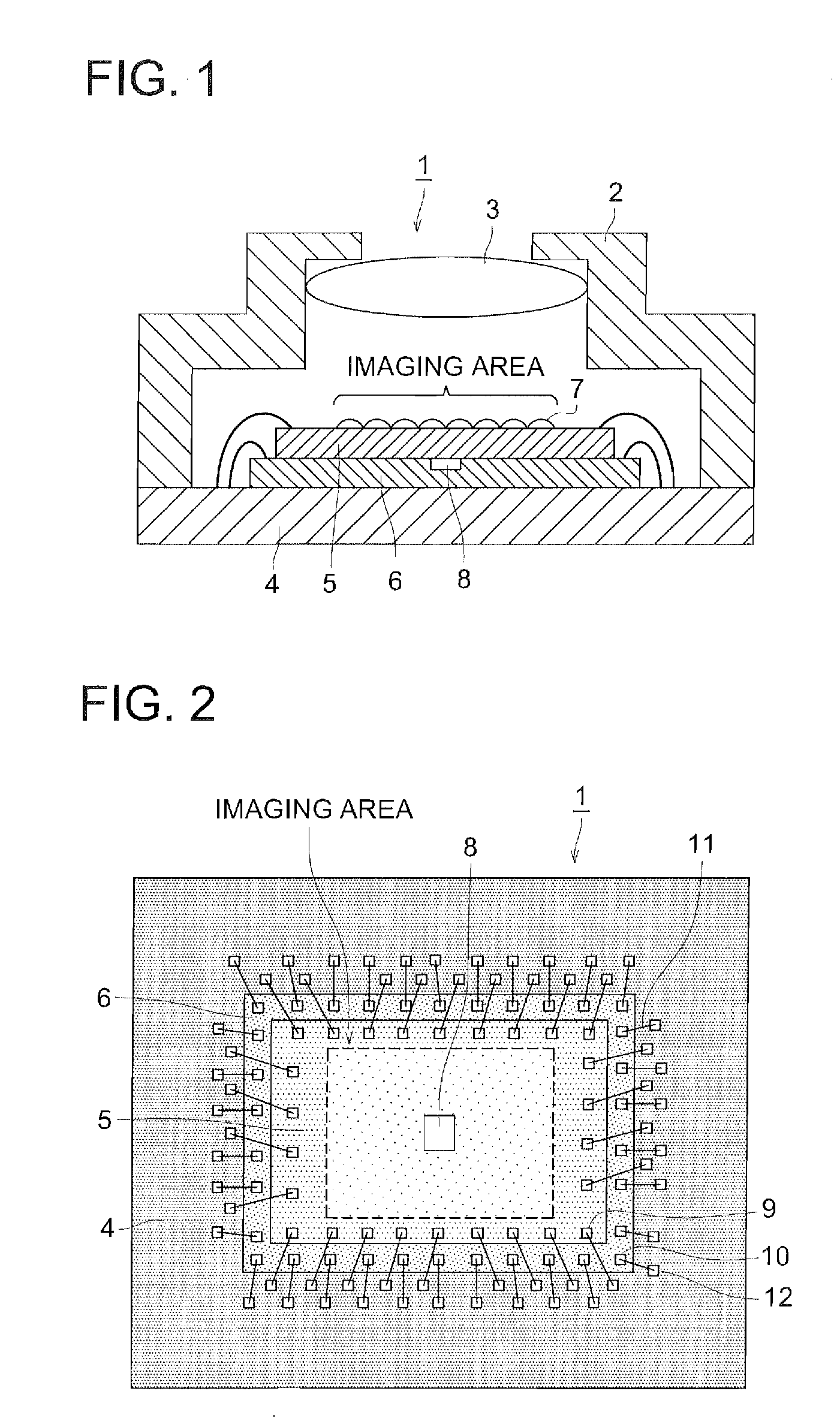

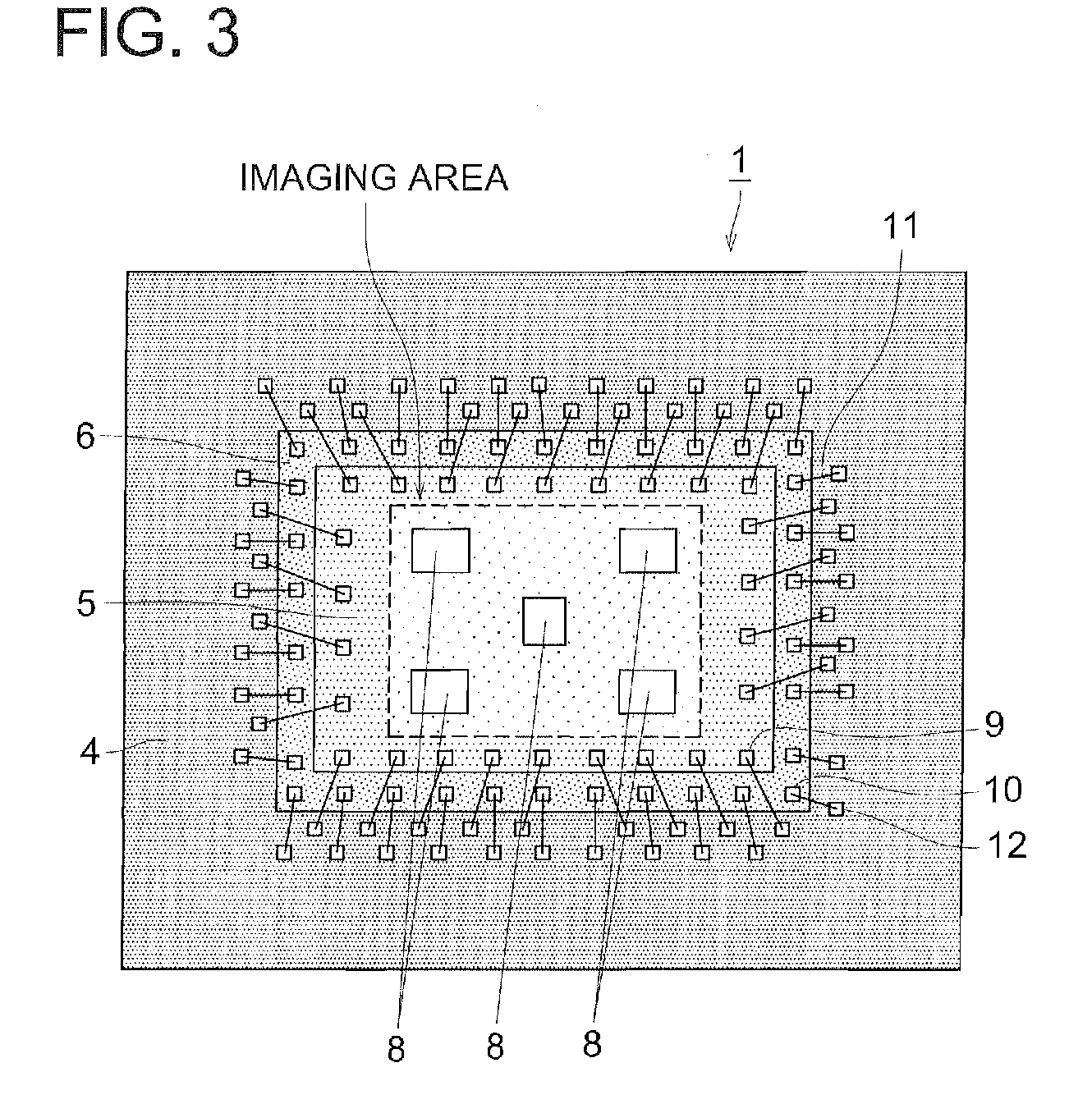

Imaging device

InactiveUS20090140125A1Reduce manufacturing costImaging can be minimizedThermometer detailsTelevision system detailsImaging equipmentElectric signal

The present invention provides an imaging device where the temperature of an imaging area of the imaging device is accurately detected to perform precise temperature compensation and the imaging device can be minimized as a whole. This imaging device is characterized in that the device includes: the imaging element (5) for converting incident light into an electric signal; a signal processing chip (6) mounted by being stacked with the imaging element (5); and a temperature sensor (8) integrated into the signal processing chip (6) close to the imaging element (5) in a state where the imaging element (5) and the signal processing chip (6) are stacked.

Owner:KONICA MINOLTA INC

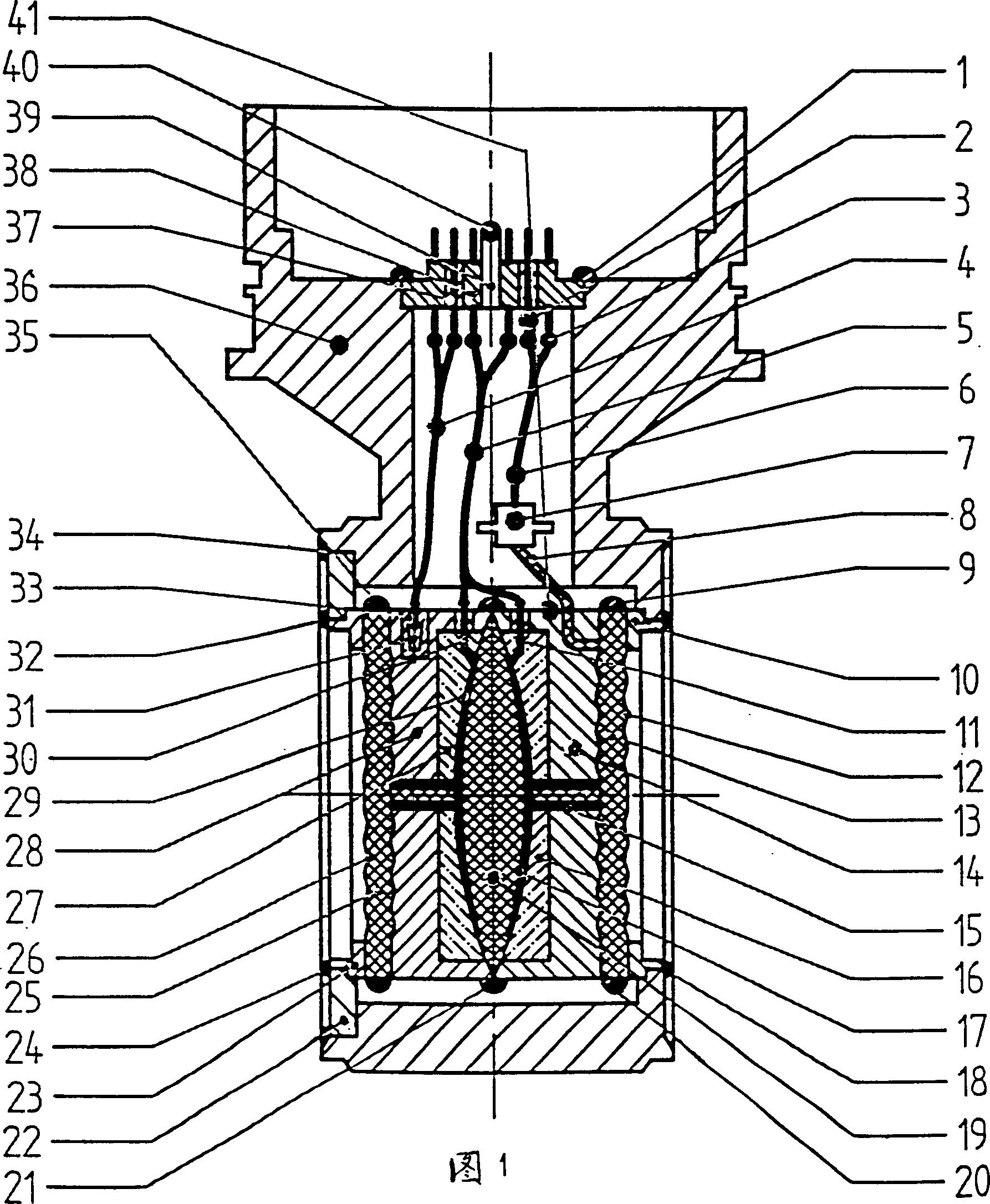

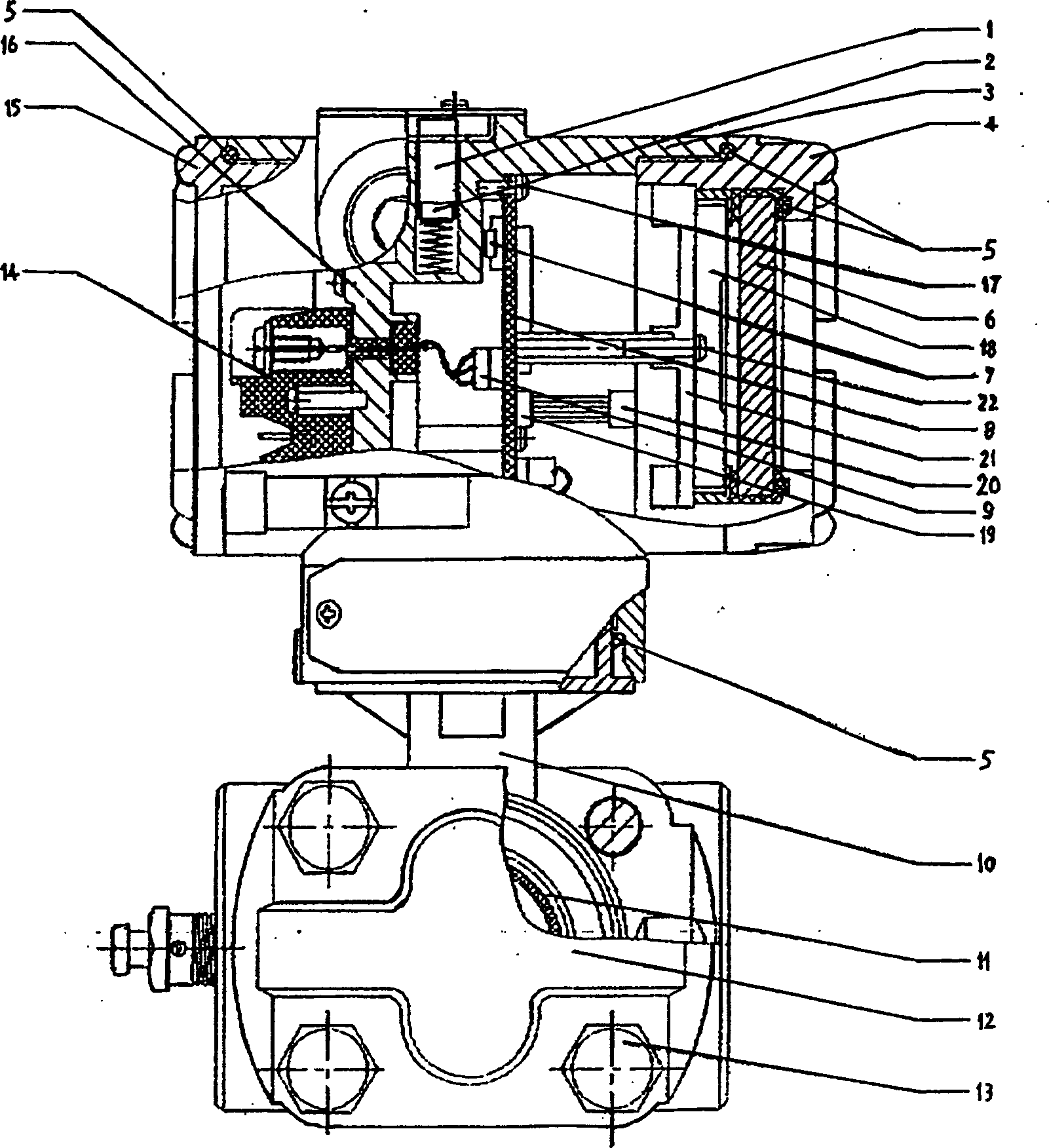

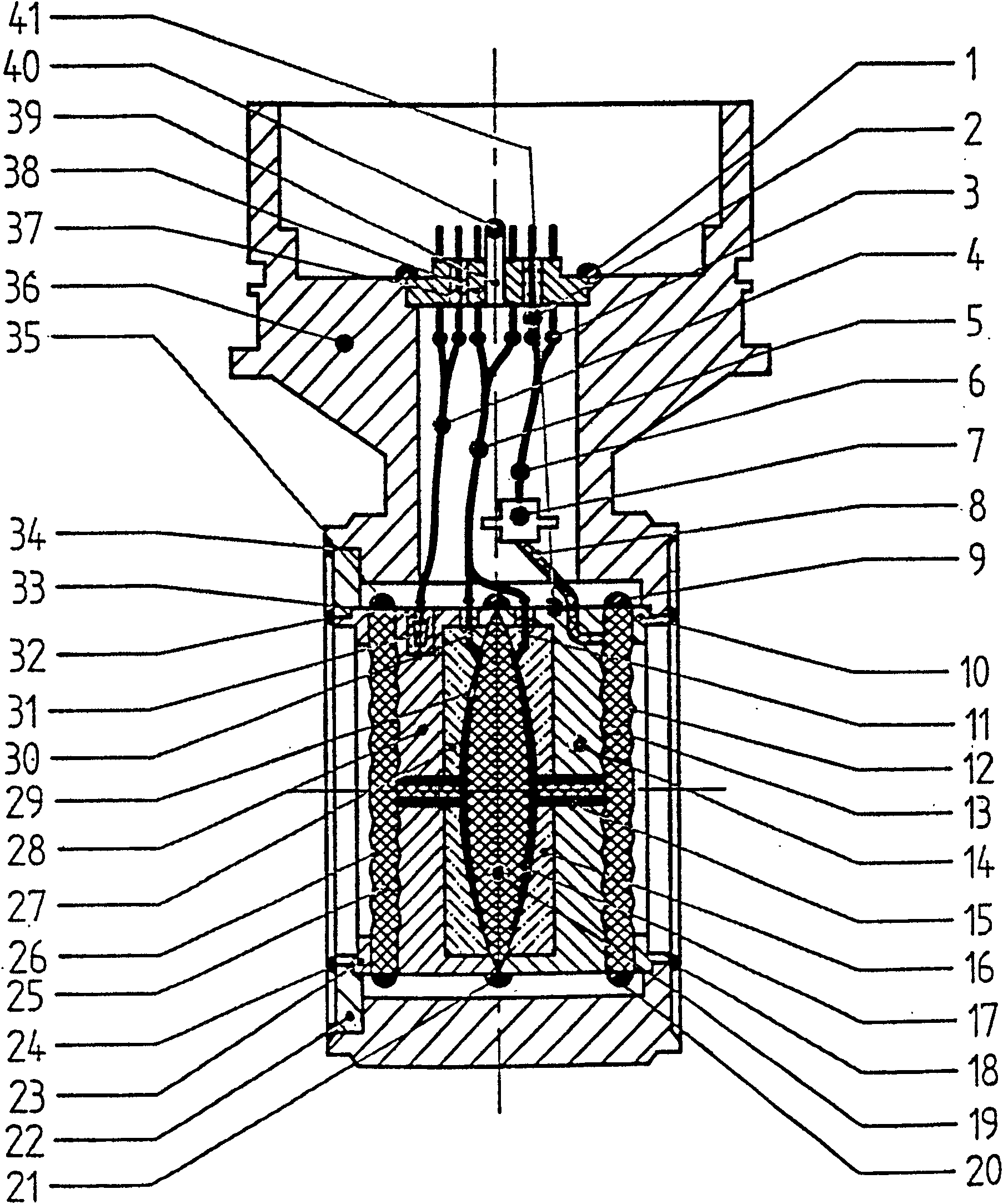

Multi-parameter sensor for measuring differential pressure/pressure/temp

ActiveCN1869599ASmall and exquisite appearanceReduce weightFluid pressure measurement using ohmic-resistance variationFluid pressure measurement using elastically-deformable gaugesDifferential capacitancePetroleum

The invention discloses a multi-parameter sensor for measuring differential pressure / pressure / temperature, characterized in that there is a differential capacitance bellows differential pressure sensor packed combination in a casing; pressure resistance type static pressure sensor, detecting sensor and medium temperature digital output high-accuracy integrated temperature sensing chip are used to detect differential pressure, pressure, and temperature parameters. And it has characters of small and exquisite, lightweight, and easy to manufacture by routine process. On this basis, various manufactured transducers of different functions can be widely applied to chemical departments, petroleum departments, metallurgy departments, power stations, etc, for detecting pressure, level, differential pressure, flow and other basic thermal parameters of liquid, gas and steam, and can posses multiple compensating properties and very good development space.

Owner:SHANGHAI AUTOMATION INSTRAION CO LTD

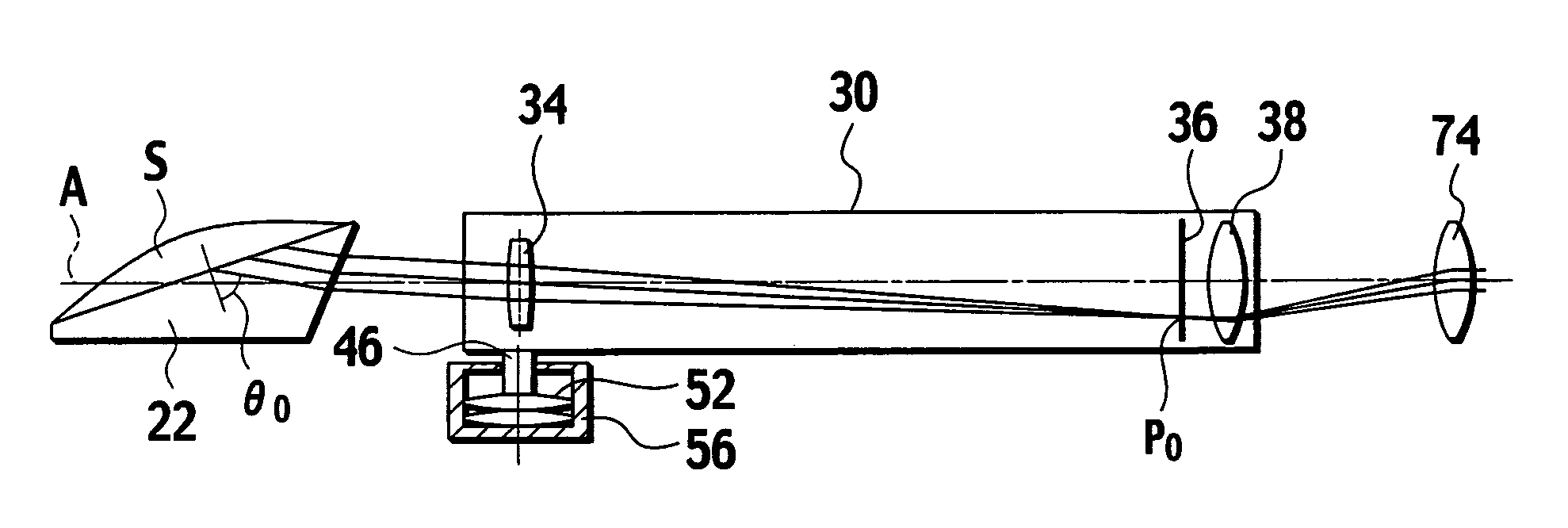

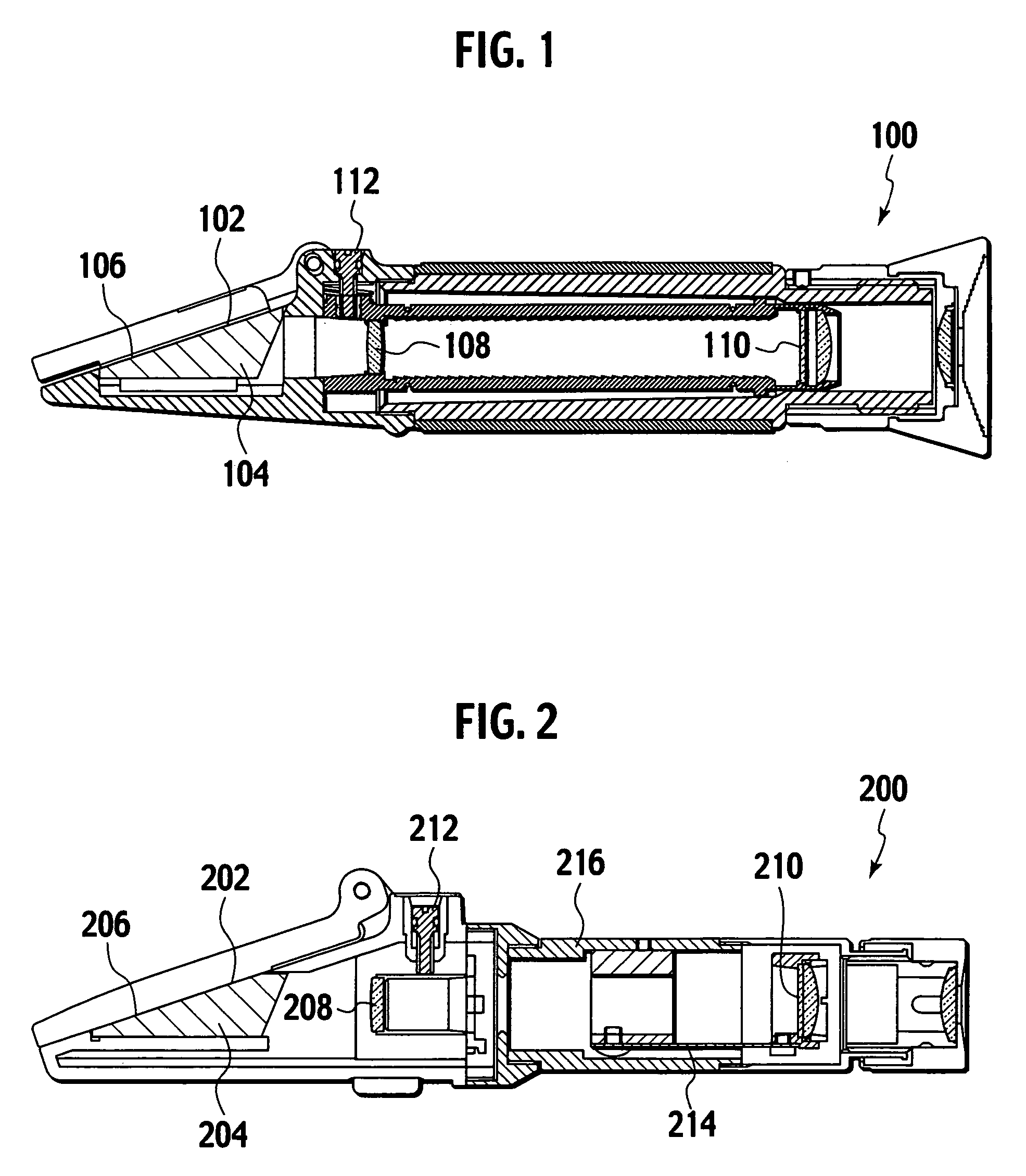

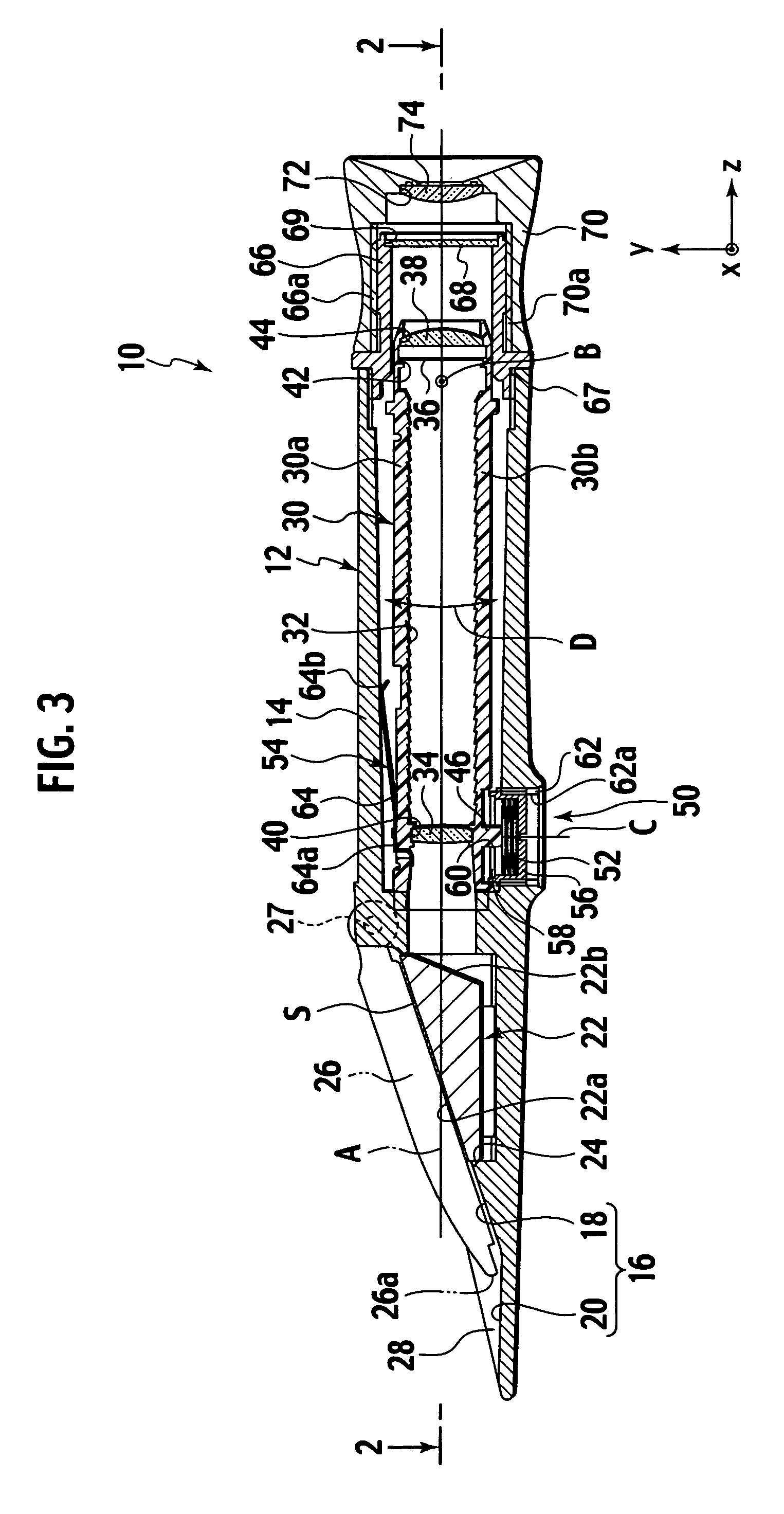

Portable refractometer

InactiveUS7369221B2Accurate temperature compensationFatty/oily/floating substances removal devicesPhase-affecting property measurementsRotational axisPrism

A portable refractometer is provided that includes a lens barrel having a lens barrel axis. A prism is secured to one end of the lens barrel, the prism having an entry face that provides a boundary surface between the prism and a substance to be measured. A tube shaped optical chassis is inside the lens barrel, and is rotatably supported about a predetermined rotational axis perpendicular to the lens barrel axis. An objective lens is arranged in the optical chassis, and is positioned in relation to the optical chassis. An optical scale is arranged inside the optical chassis, at the focal point of the objective lens. A mover moves the objective lens relatively in relation to the optical scale in response to changes in temperature by turning the optical chassis about the rotational axis.

Owner:ATAGO

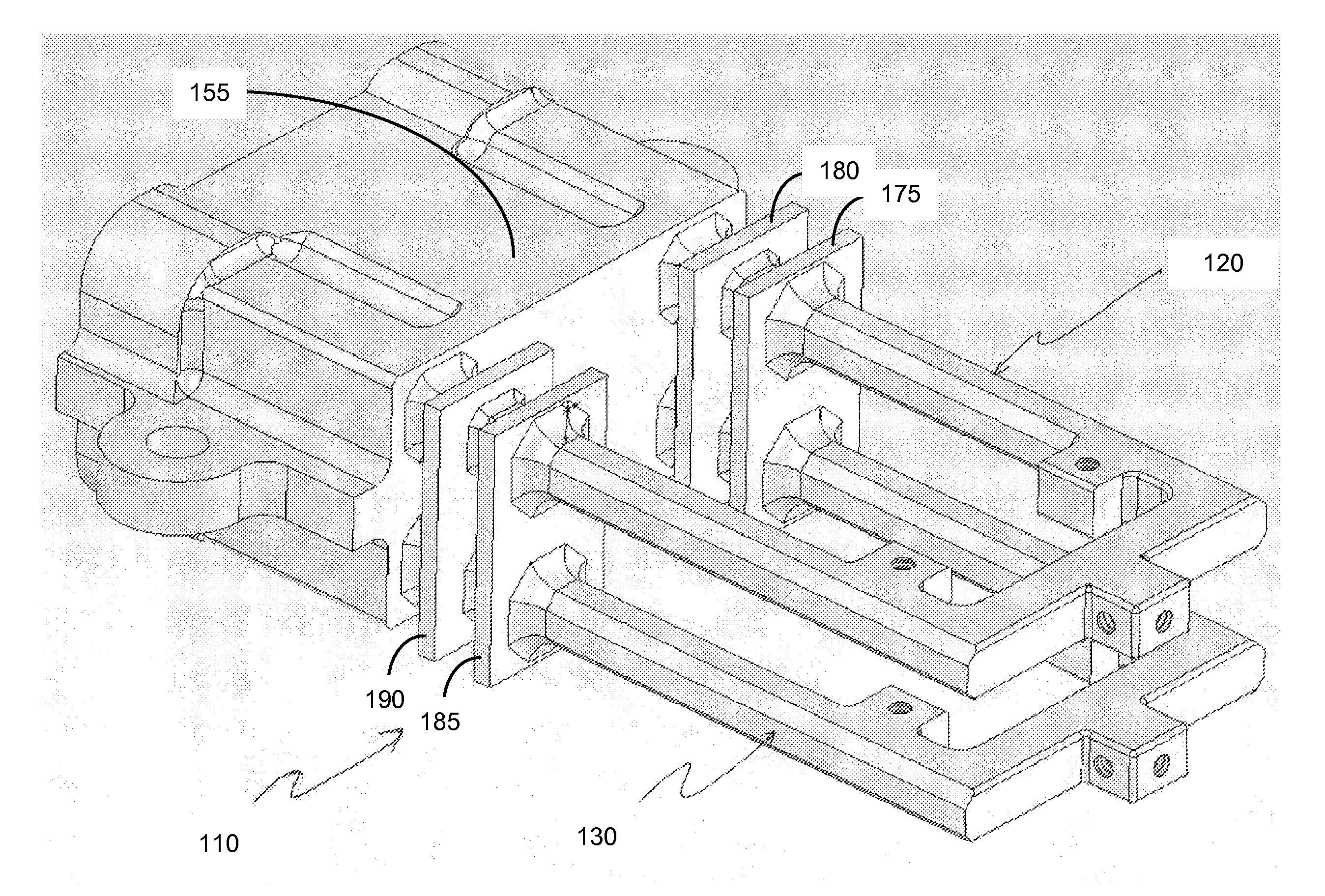

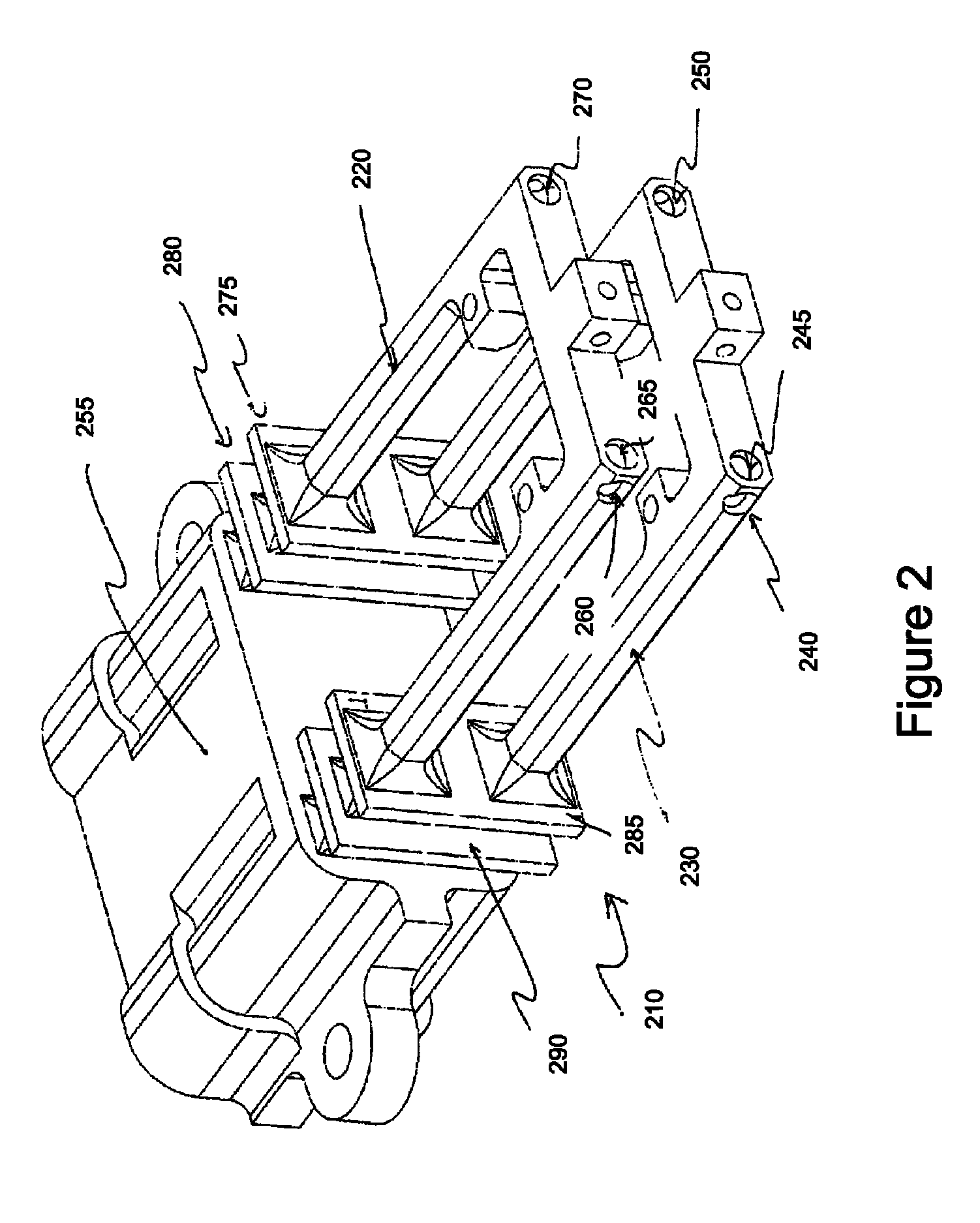

Methods of manufacturing and temperature calibrating a coriolis mass flow rate sensor

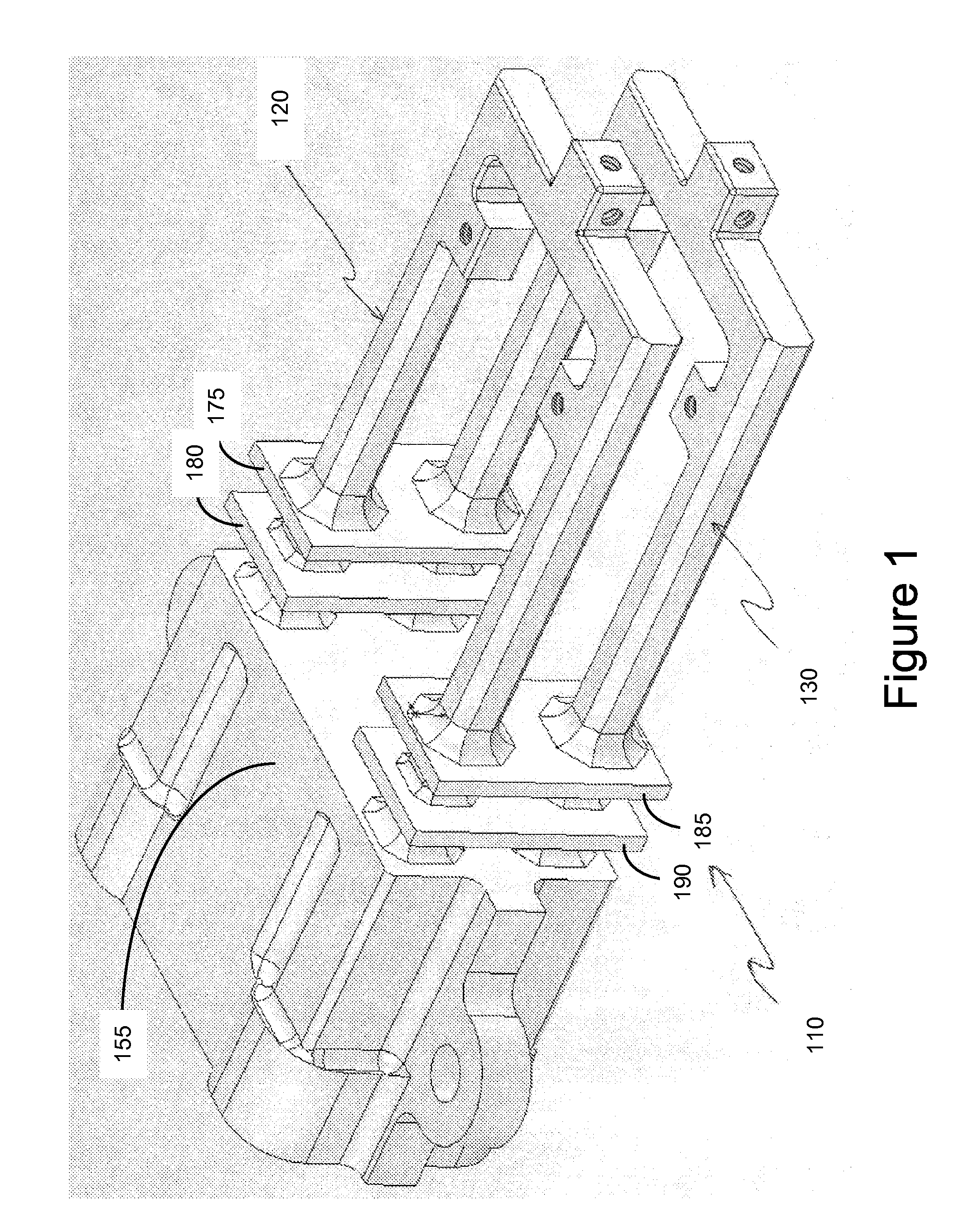

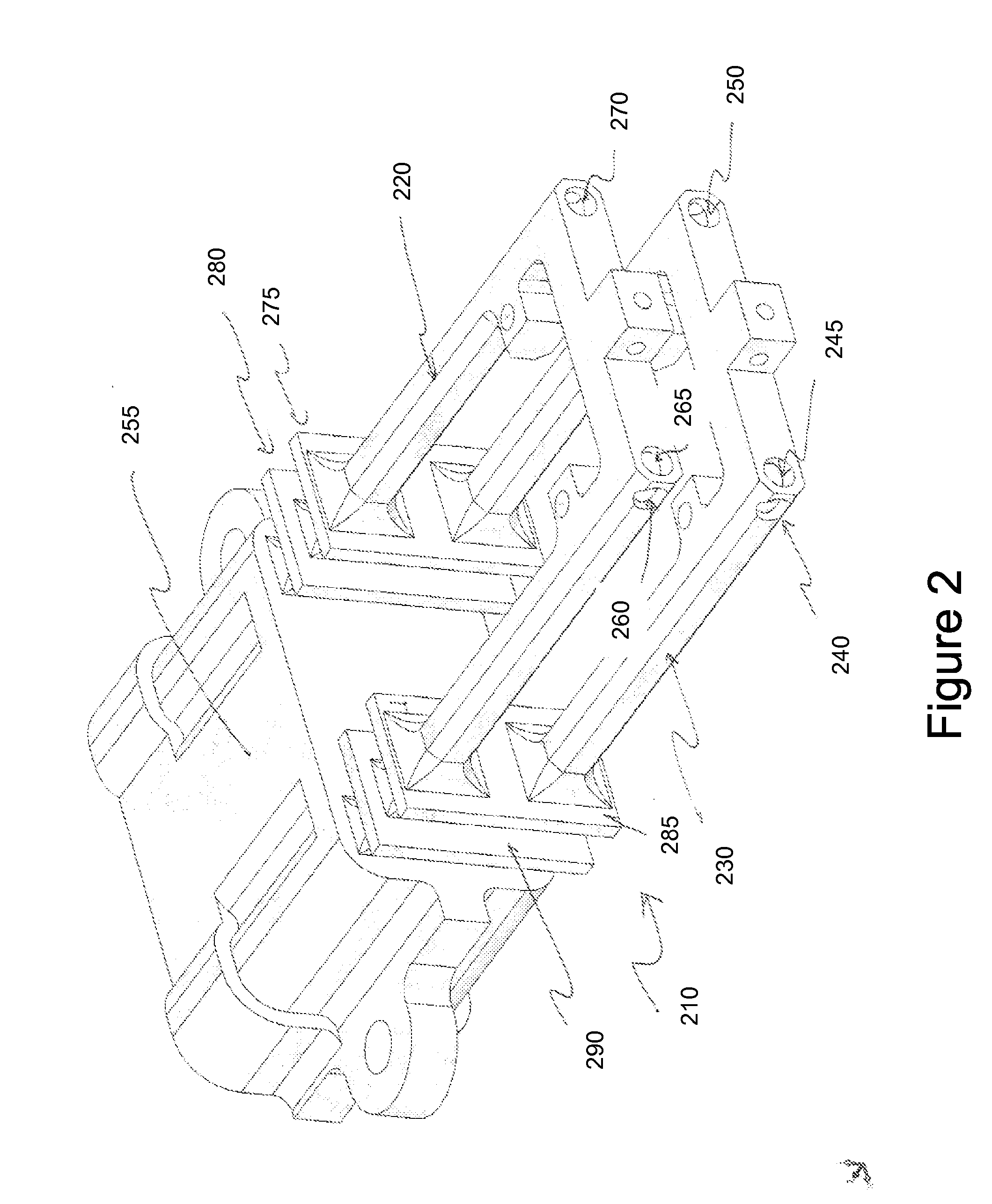

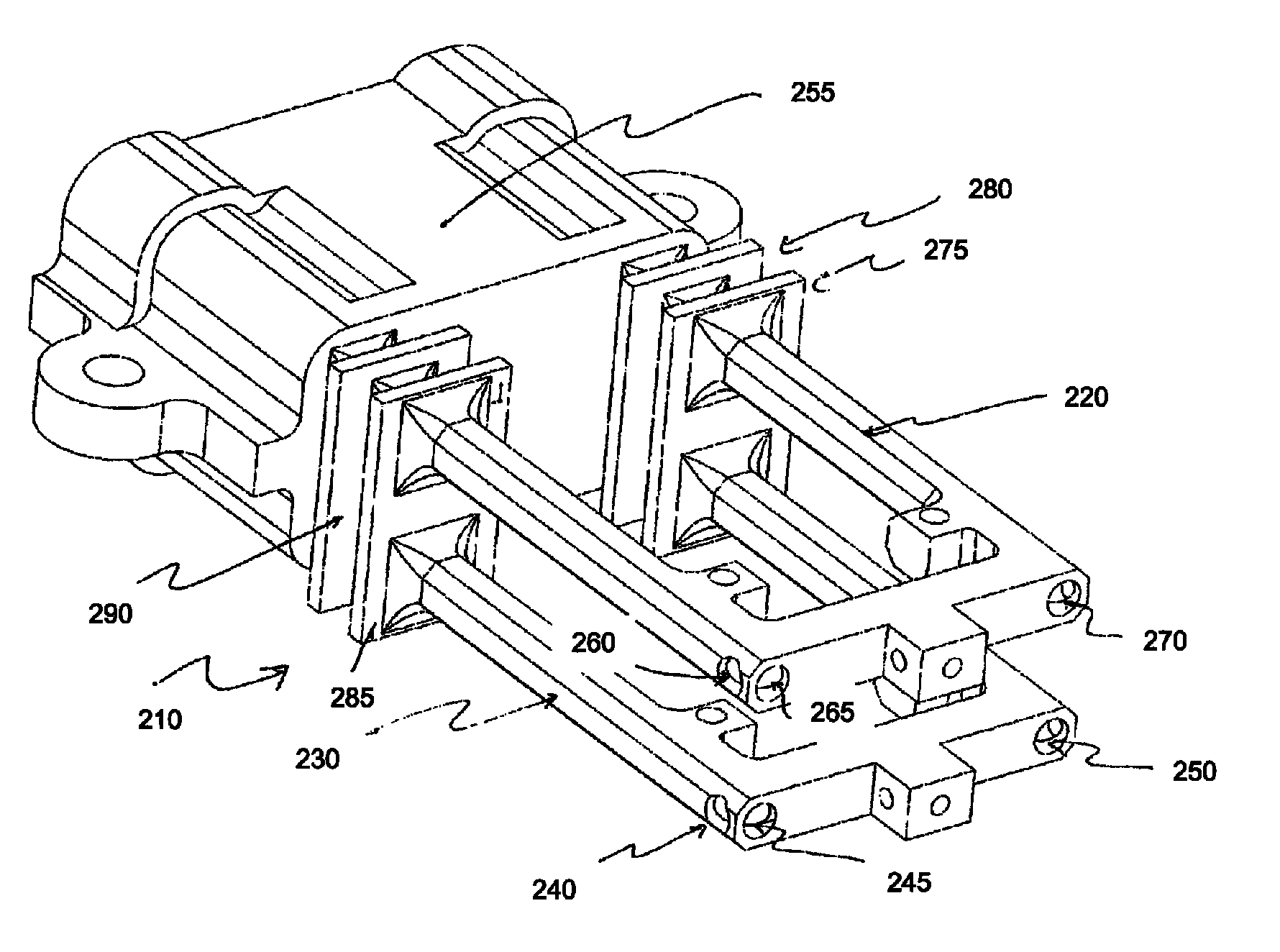

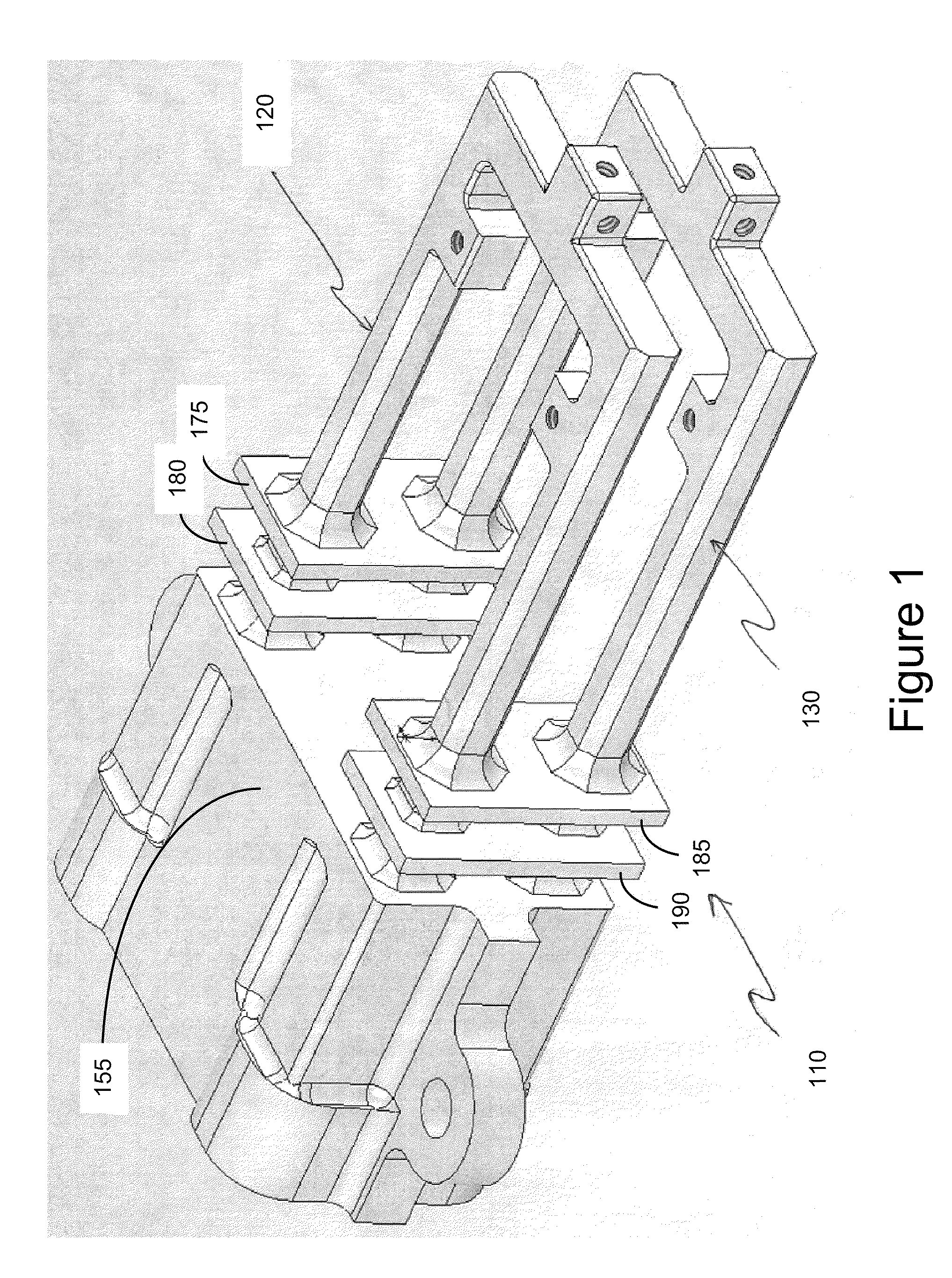

ActiveUS20110197650A1Small diameterAccurate temperature compensationCylinder headsCylindersEngineeringMass flow sensor

A subassembly of a Coriolis flowmeter is fabricated from a single monolithic piece of elastic polymeric material. The subassembly includes two flow-sensitive members and a base integrally connected to the two flow-sensitive members. The two flow-sensitive members include straight sections, and are substantially similar and parallel to each other. Flow passages are drilled along the straight sections of the two flow-sensitive members, and drilled entrances are sealed using the elastic polymeric material. A temperature sensor is fixedly attached to a flow-sensitive member for measuring a temperature of the flow-sensitive member and communicating the temperature to a metering electronics. The metering electronics determines a calibrated flow rate of fluid flowing through the Coriolis flowmeter that accounts for the temperature.

Owner:MALEMA ENG

Methods of manufacturing and temperature calibrating a coriolis mass flow rate sensor

ActiveUS8404076B2Small diameterAccurate temperature compensationCylinder headsCylindersEngineeringMass flow sensor

A subassembly of a Coriolis flowmeter is fabricated from a single monolithic piece of elastic polymeric material. The subassembly includes two flow-sensitive members and a base integrally connected to the two flow-sensitive members. The two flow-sensitive members include straight sections, and are substantially similar and parallel to each other. Flow passages are drilled along the straight sections of the two flow-sensitive members, and drilled entrances are sealed using the elastic polymeric material. A temperature sensor is fixedly attached to a flow-sensitive member for measuring a temperature of the flow-sensitive member and communicating the temperature to a metering electronics. The metering electronics determines a calibrated flow rate of fluid flowing through the Coriolis flowmeter that accounts for the temperature.

Owner:MALEMA ENG

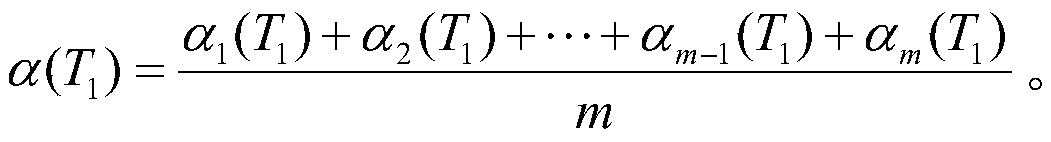

High-precision sulfur hexafluoride gas density relay

ActiveCN103456561ALight in massTo achieve temperature compensationElectric switchesSulfur hexafluorideElectrical performance

The invention discloses a high-precision sulfur hexafluoride gas density relay which is good in shock resistance, high in precision, good in electrical performance, and long in service life. The high-precision sulfur hexafluoride gas density relay comprises a signal control part and an indicating value displaying part which are arranged in a shell body, wherein the signal control part and the indicating value displaying part are relatively independent, the indicating value displaying part comprises a display bourdon tube, a display end base, a machine core and a pointer, one end of the display bourdon tube is welded on a base, the other end of the display bourdon tube is welded on the display end base, and the shell body is an airtight air chamber and is filled with sulfur hexafluoride gas used for temperature compensation; the signal control part comprises a control bourdon tube, the base, a control end base, a plurality of signal generators and a signal adjusting mechanism, one end of the control bourdon tube is fixed on the base, the other end of the control bourdon tube is fixed on the control end base, the signal adjusting mechanism is arranged on the control end base, and the signal generators are installed on the base and are triggered to move by the signal adjusting mechanism.

Owner:SHANGHAI ROYE ELECTRICAL CO LTD

Miniaturized intelligent differential pressure / pressure transmitter

ActiveCN1796957AEasy to produceGood adjustment functionFluid pressure measurement using capacitance variationCapacitanceDifferential pressure

The invention discloses a small intelligent differential pressure / pressure transducer, where there is an electronic box sealed and fixed at the upper part of a sensor component, the lower part of the sensor component provided with pressurized seal ring is fixed with a pressure flange component, the sensor component is provided with a capacitance differential pressure sensor and a temperature sensor under a chamber, there is a group of protective rings and welded rings outside the two sensors, there are terminals in the left cavity of the electronic box, the top end of the left cavity is provided with a magnetic button, there is a printed circuit board (PCB) in the right cavity of the electronic box, and the PCB is mounted with dry reed tube and connected with a display. It can be widely applied to the departs such as chemical, petroleum, metallurgy and circuit boards, for measuring the thermal basic parameters such as pressures, liquid levels and differential pressures of liquids, gases and steams.

Owner:SHANGHAI AUTOMATION INSTRAION CO LTD

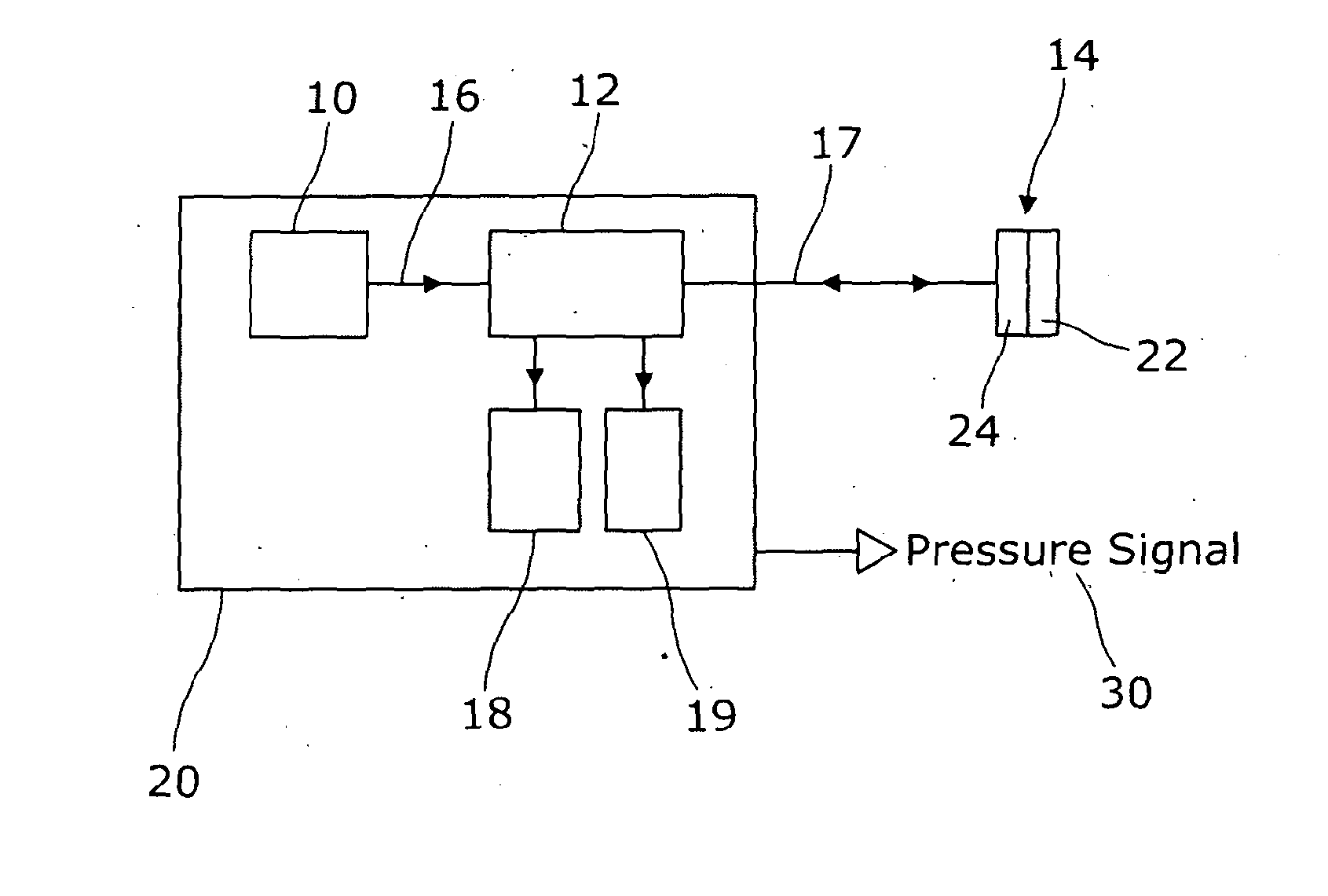

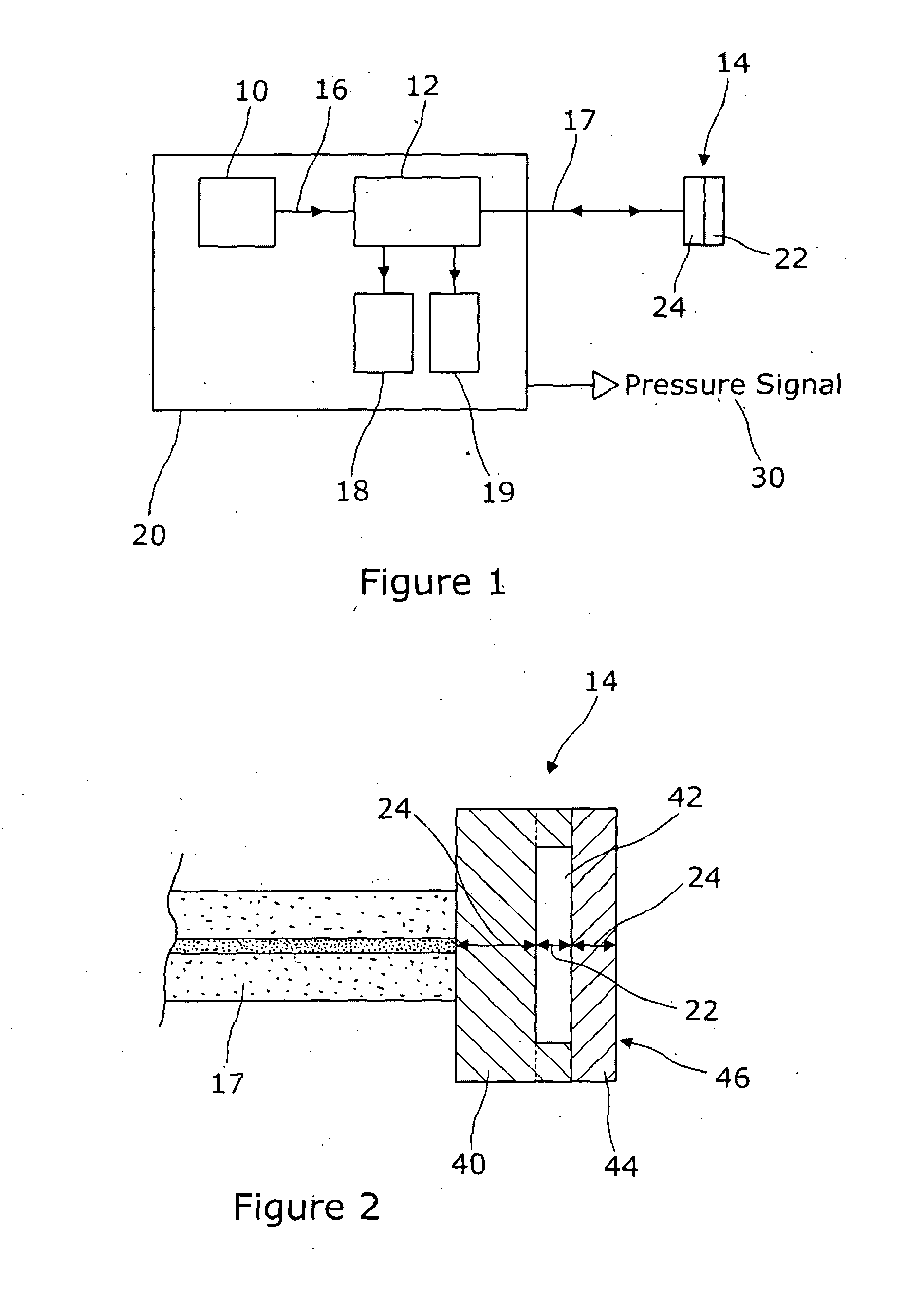

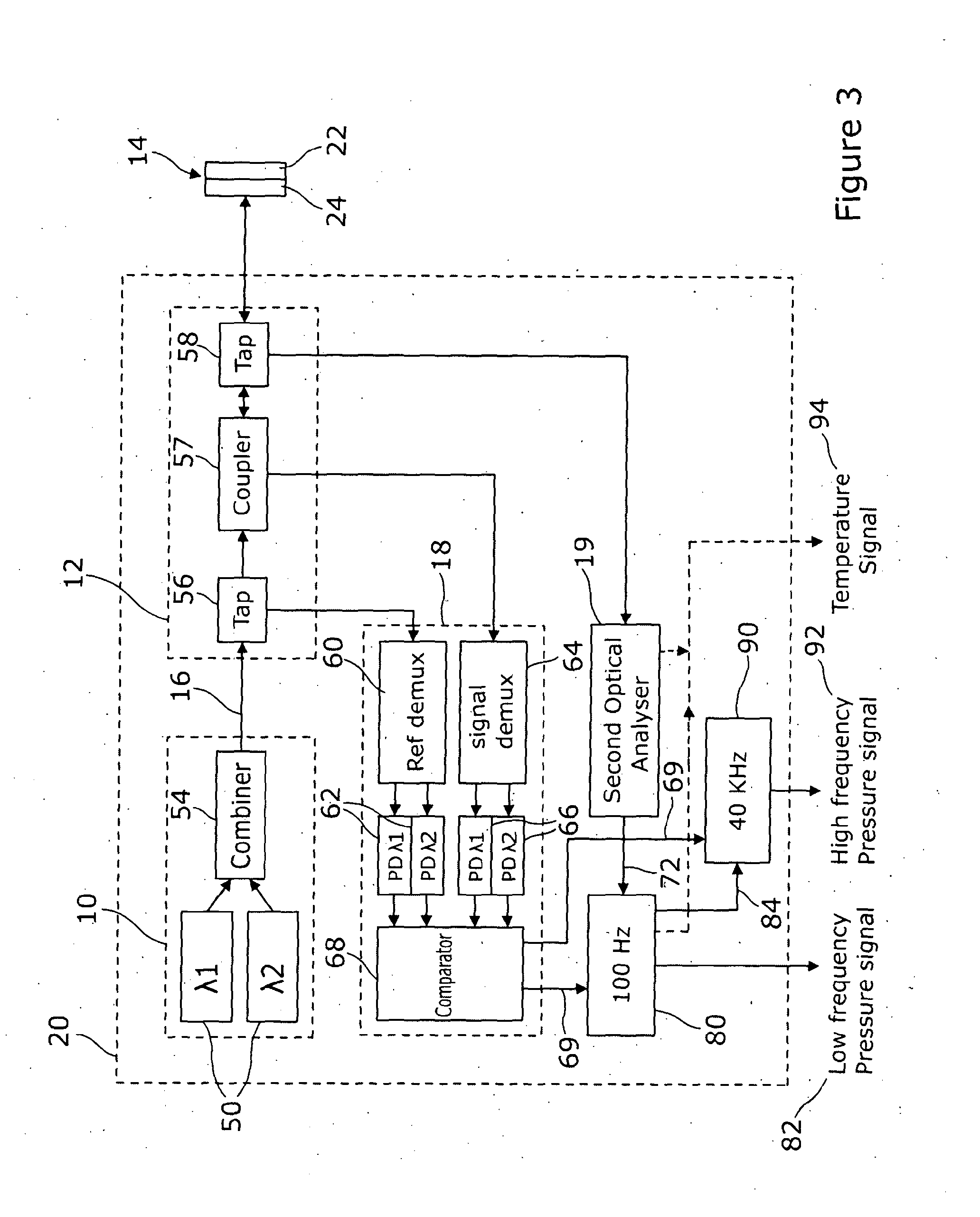

Optical pressure sensor

ActiveUS20150020599A1Accurate temperature compensationFacilitates temperature compensationOptical measurementsFluid pressure measurement by electric/magnetic elementsOptical cavityPressure sense

An optical pressure sensor is disclosed having a pressure sensing optical cavity. A temperature sensing optical cavity at the sensor head is used by an interrogator to correct a pressure signal for effects of temperature. The optical cavities may be, for example, Fabry Perot cavities in the sensor head.

Owner:OXSENSIS

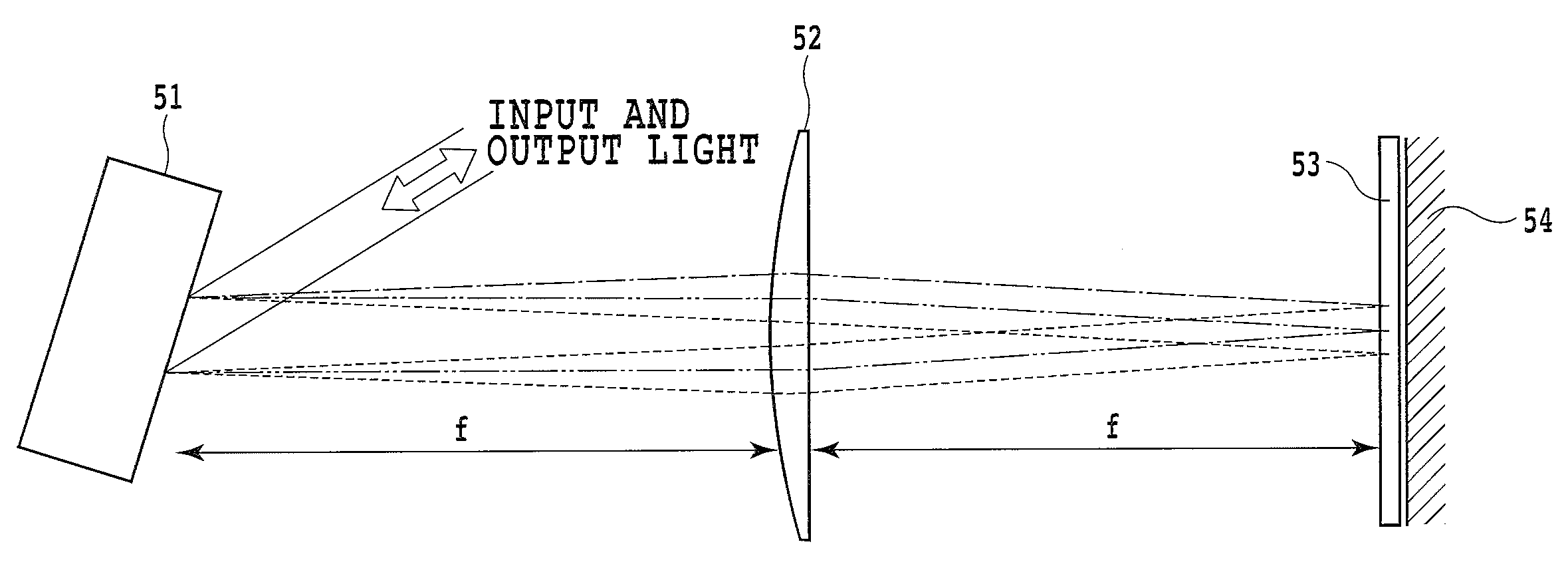

Optical signal processing device

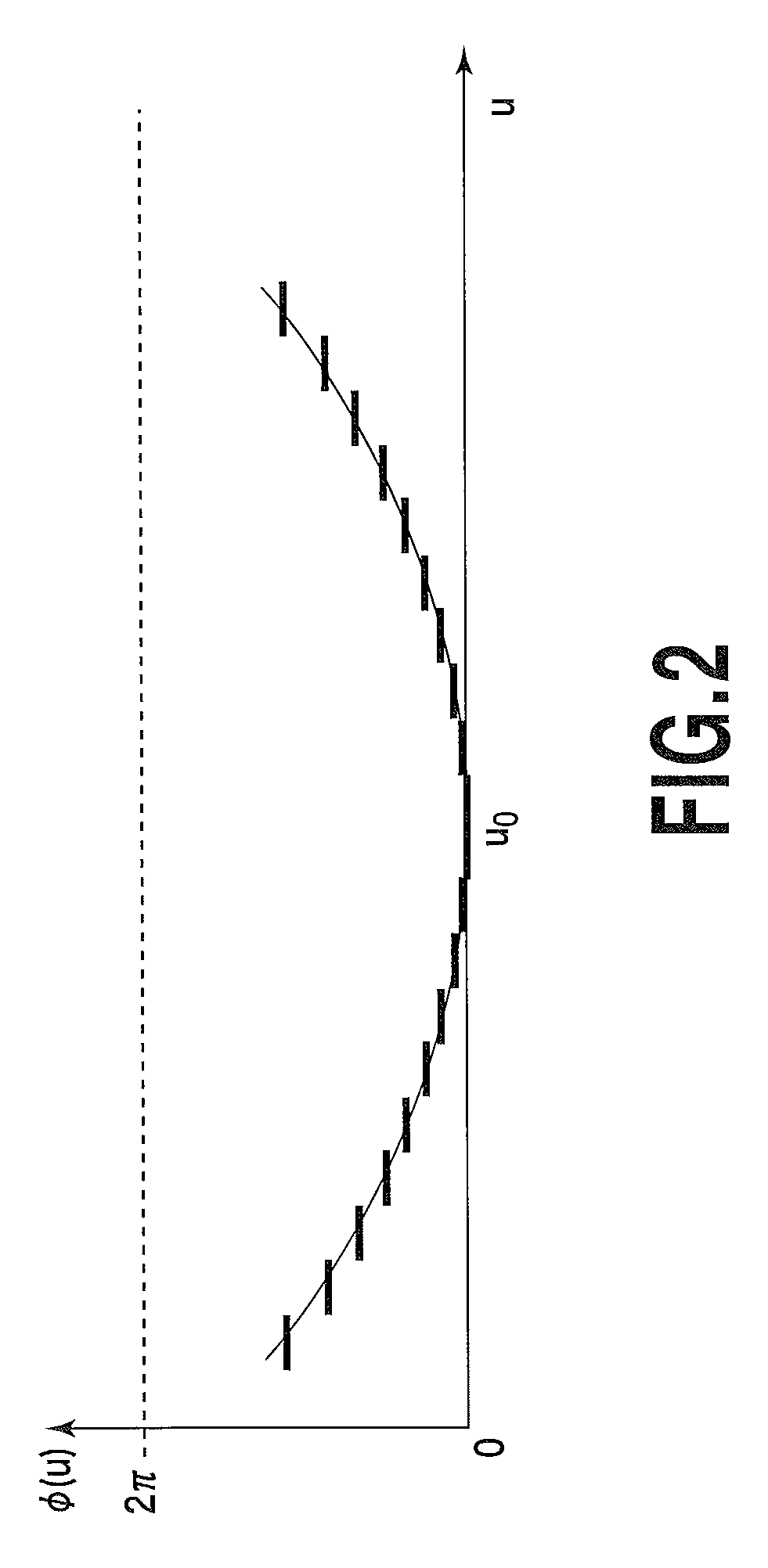

ActiveUS20100316385A1Accurate temperature compensationSimple and low-cost methodWavelength-division multiplex systemsOptical light guidesAthermalizationDirect control

A conventional optical signal processing device had a disadvantage where the temperature dependency of the spectroscopic characteristics of a spectroscopic element causes a deteriorated performance. In order to solve the temperature dependency, there has been a method to form a plurality of grooves for dividing a core on the array waveguide of the AWG. However, this method cannot avoid an excess loss and causes a high manufacture cost. By directly controlling the modulation characteristic profile formed by an element device of a spatial light modulator, athermalization can be achieved in a simpler and low-cost manner. This consequently provides a remarkable reduction of the light coupling loss in the spatial optical system of the optical signal processing device. More accurate temperature compensation can be realized that copes with an actual behavior of the device to a temperature fluctuation, including causing factors of a complicated temperature fluctuation of the optical system.

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

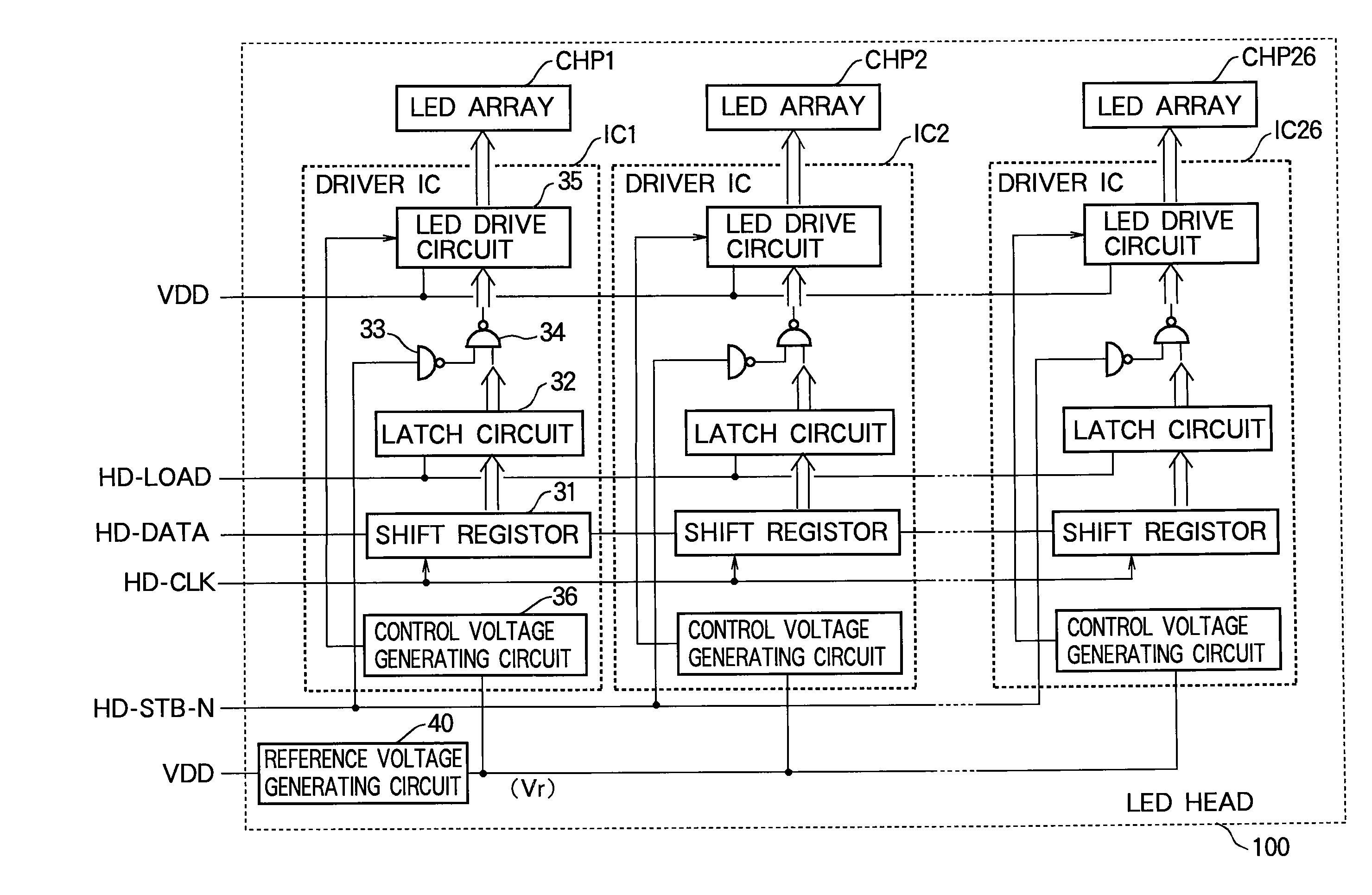

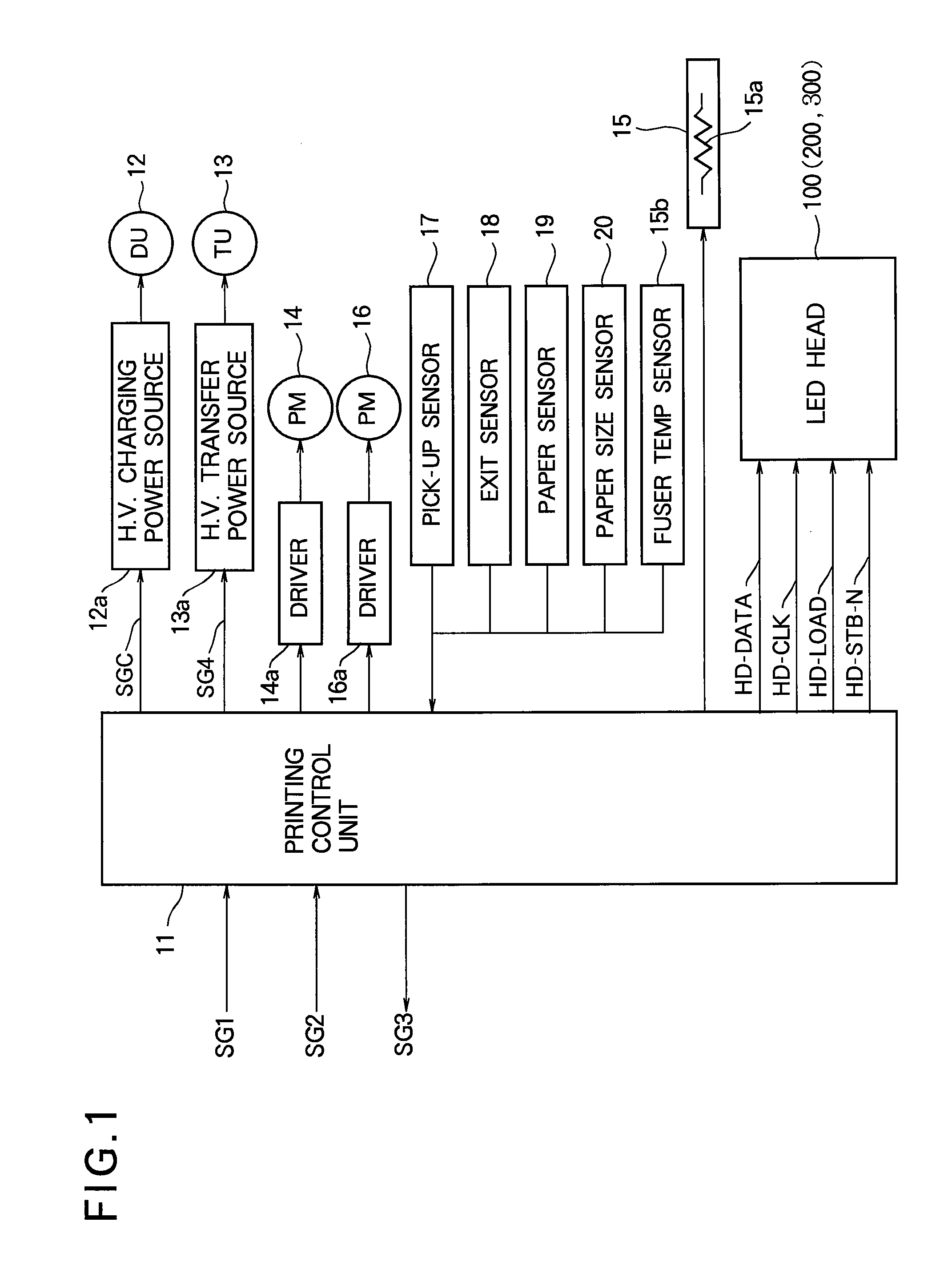

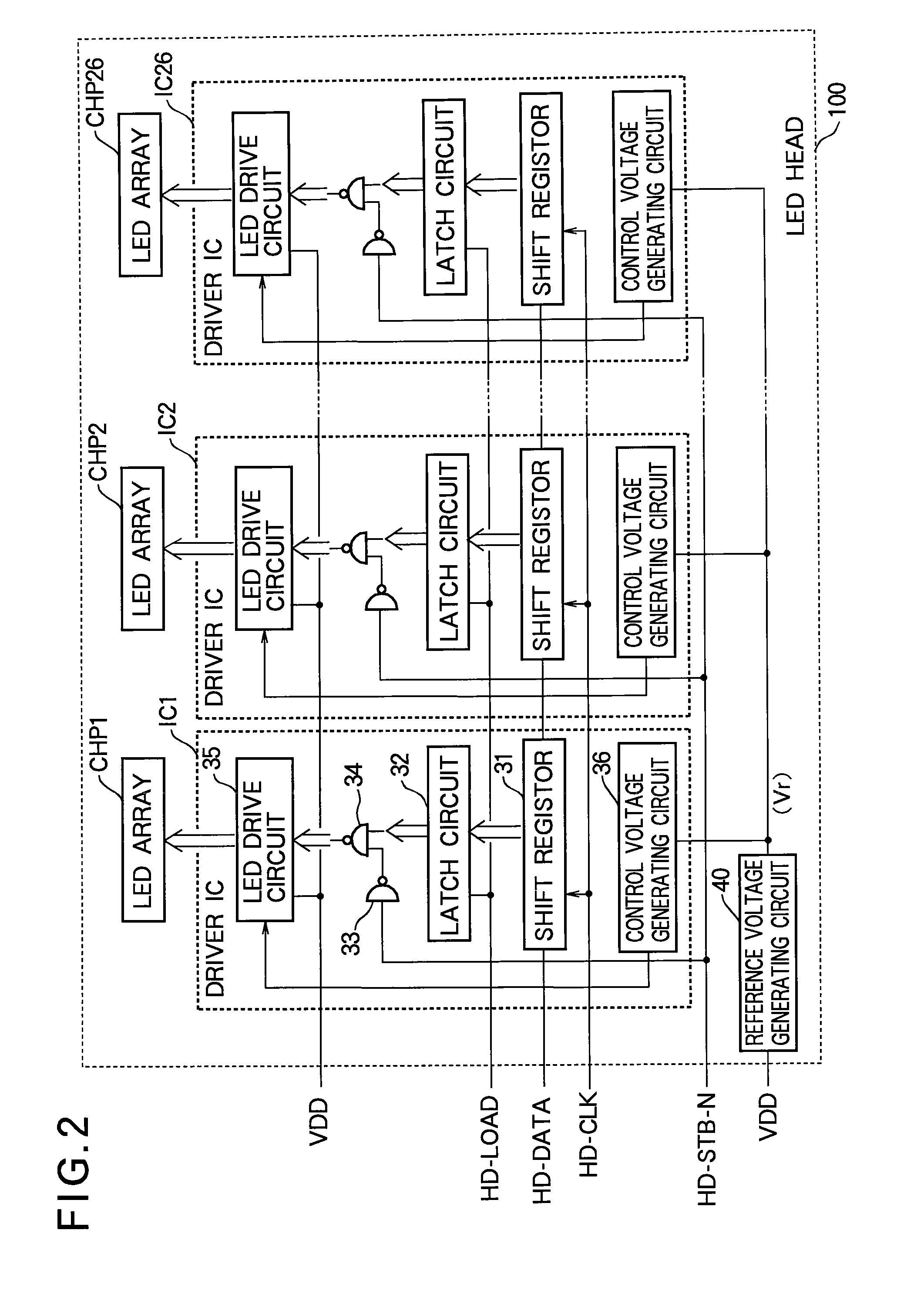

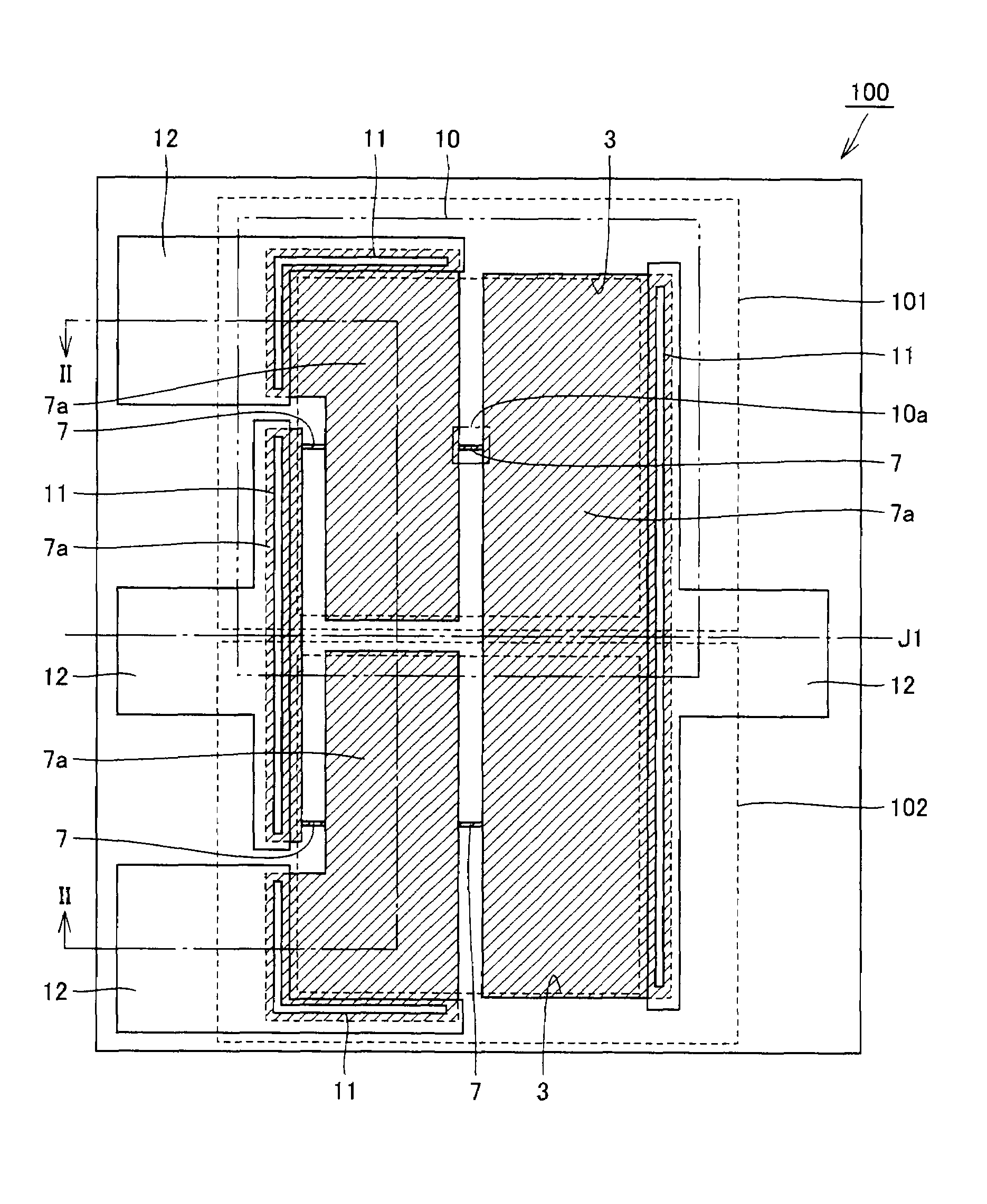

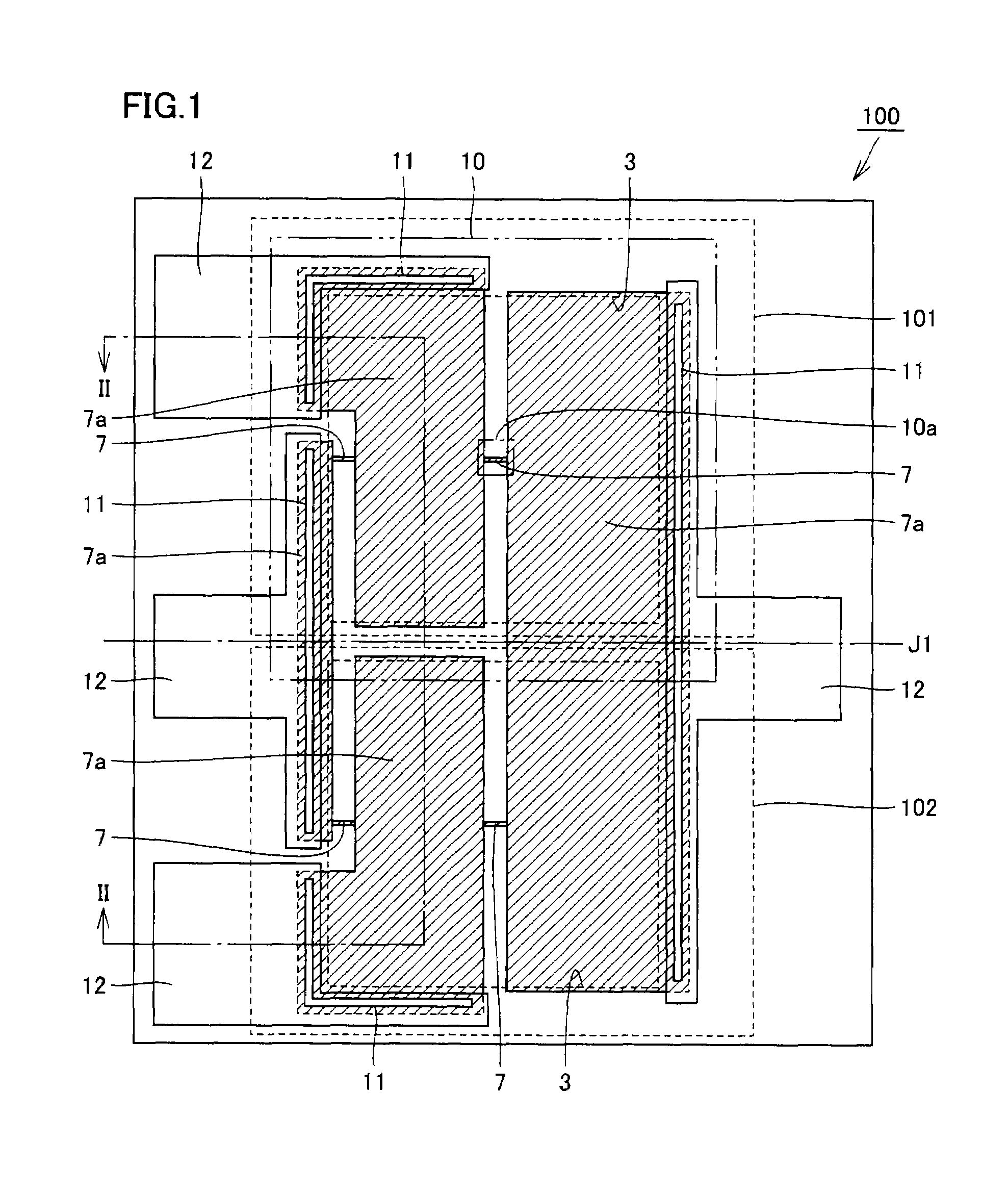

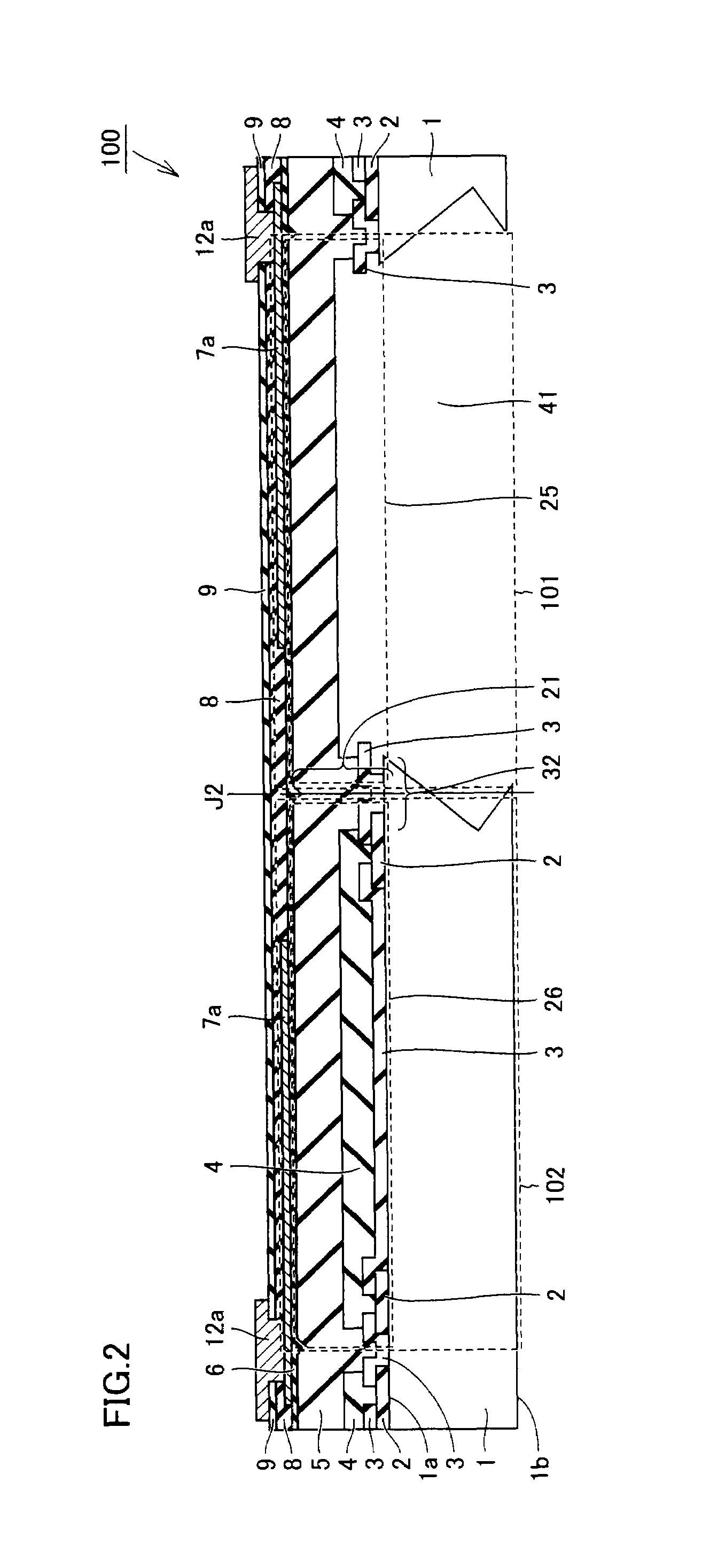

Driving circuit and apparatus, and image forming apparatus

ActiveUS20110193924A1Consistent qualityAccurate temperature compensationRecording apparatusElectrical apparatusDriven elementVoltage reference

A driving circuit includes a reference voltage generating circuit and a driver circuit. The driver circuit drives a driven element at a level determined by the reference voltage output by the reference voltage generating circuit. The reference voltage generating circuit includes a regulating section that generates a regulated voltage, a temperature compensation section that applies a temperature compensation to the regulated voltage to compensate for the temperature characteristics of the driven element, and a voltage amplifying section that amplifies the resulting temperature compensated voltage to generate the reference voltage, thereby supplying a reference voltage high enough to avoid noise effects.

Owner:OKI DATA CORP

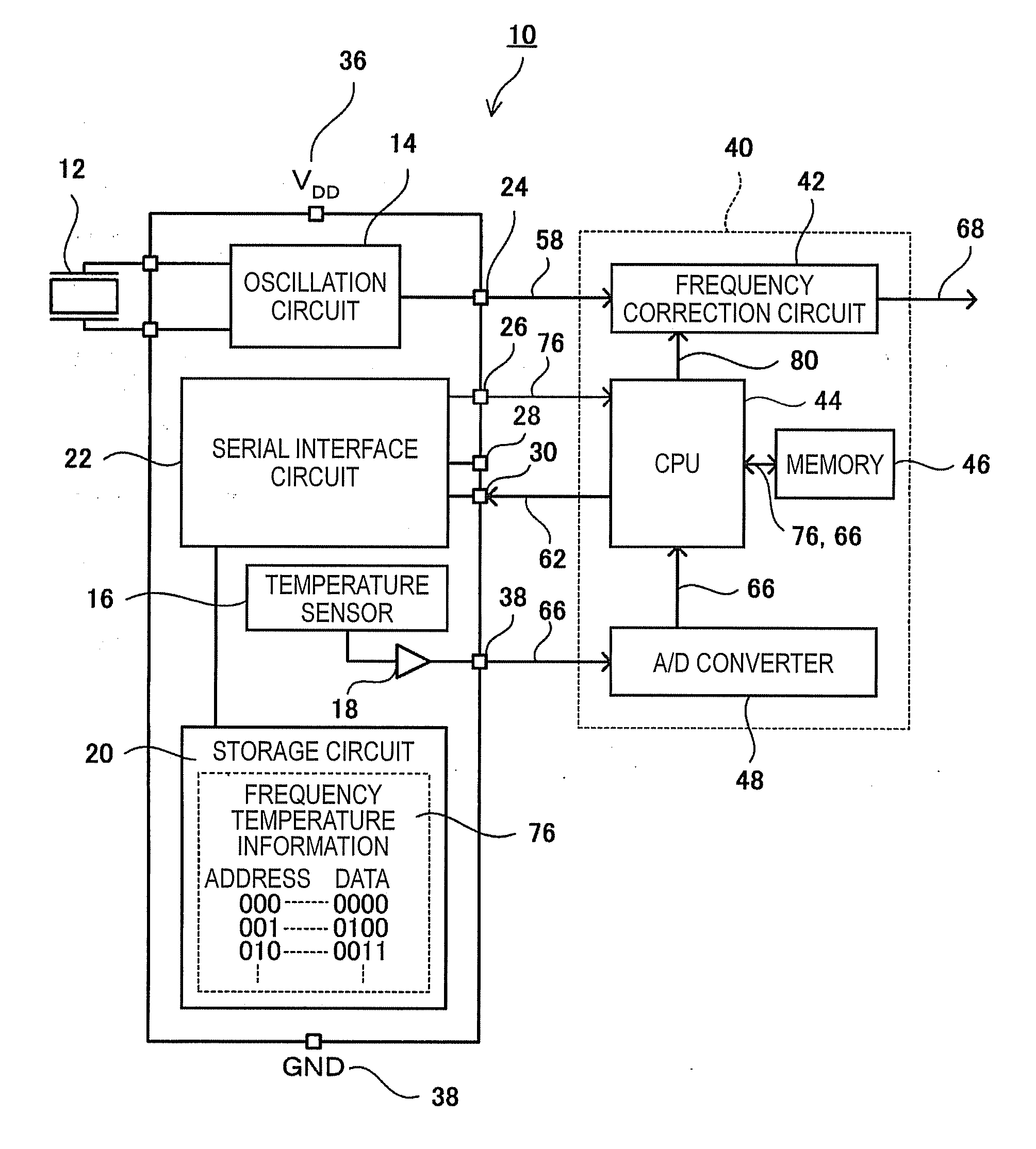

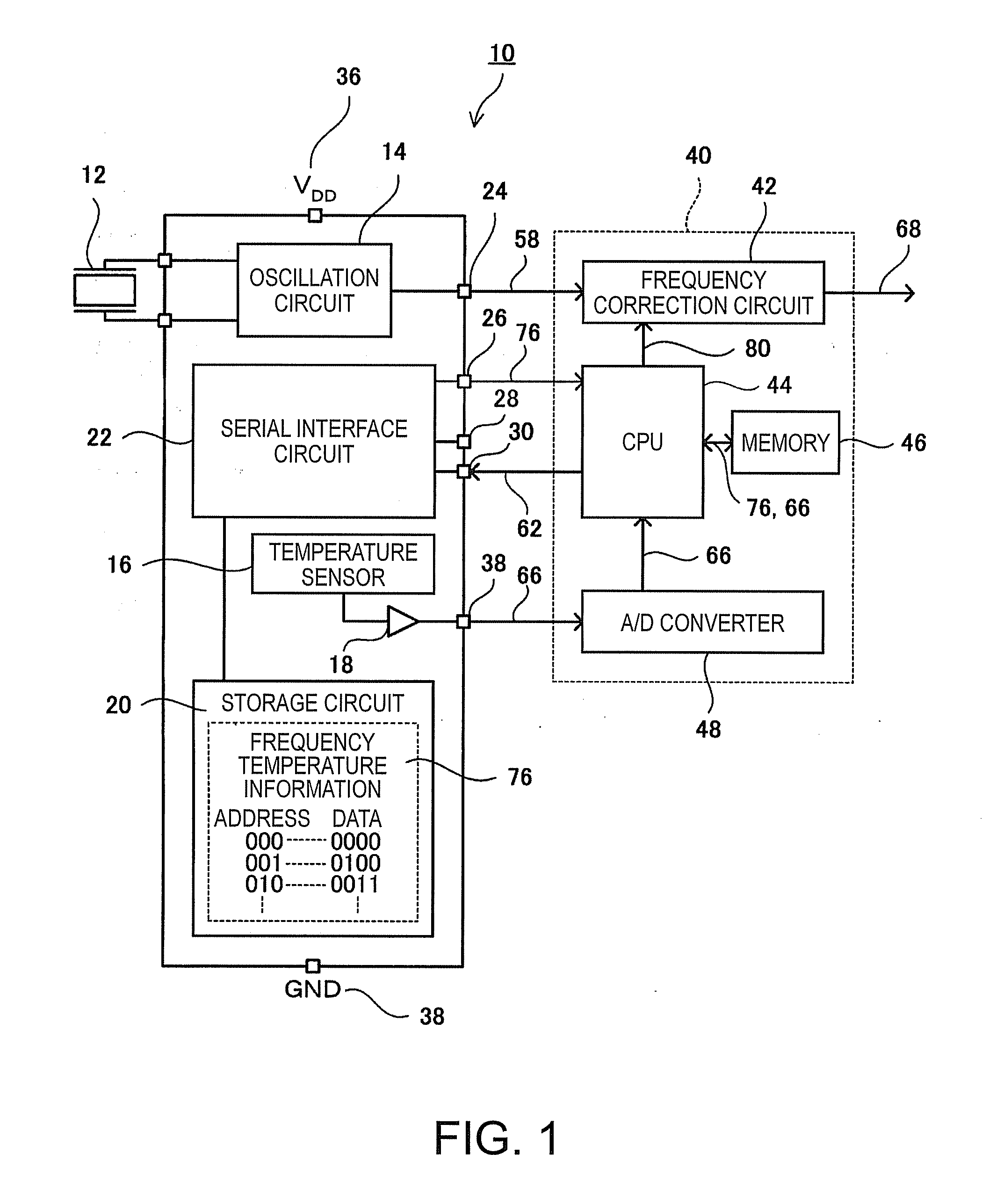

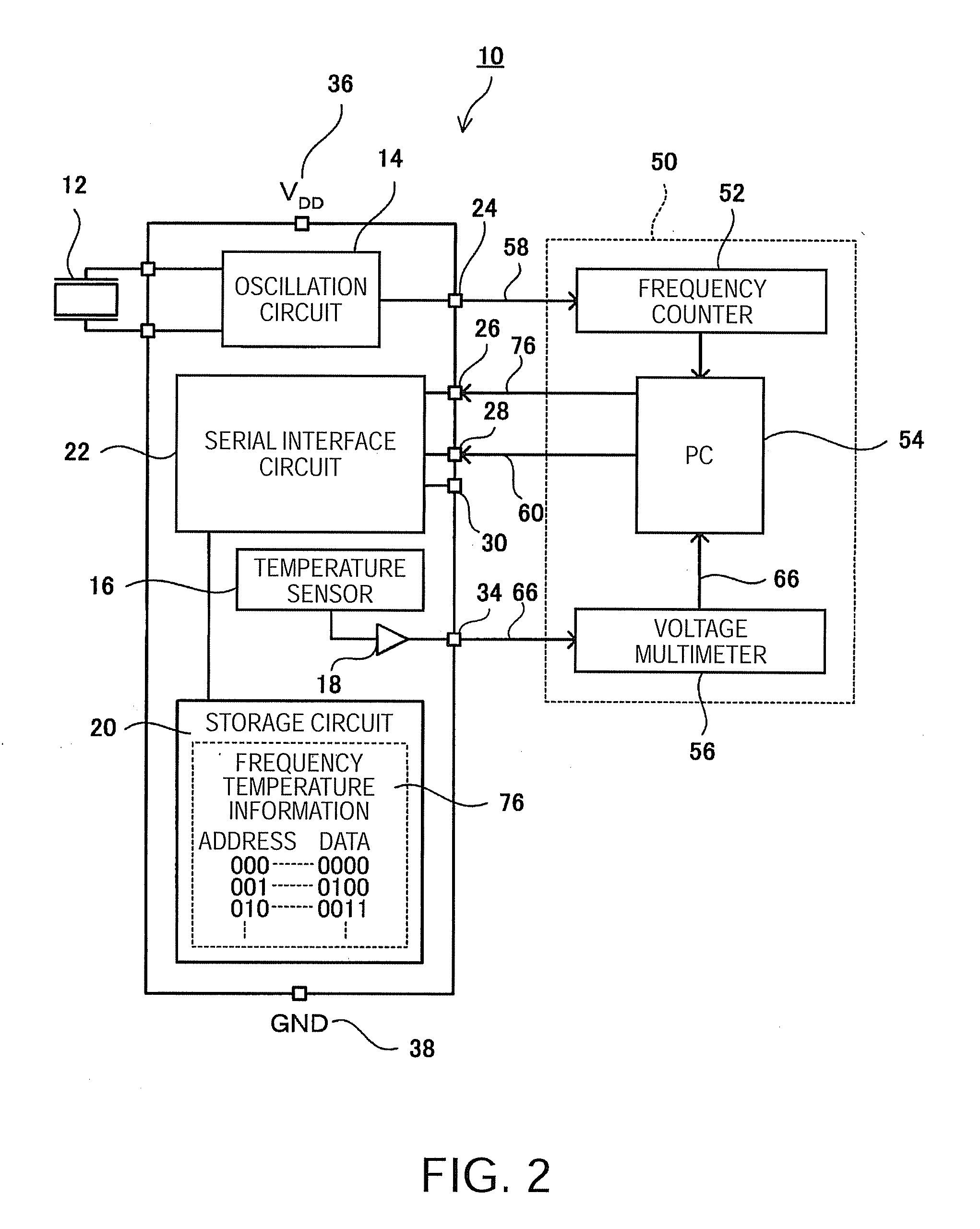

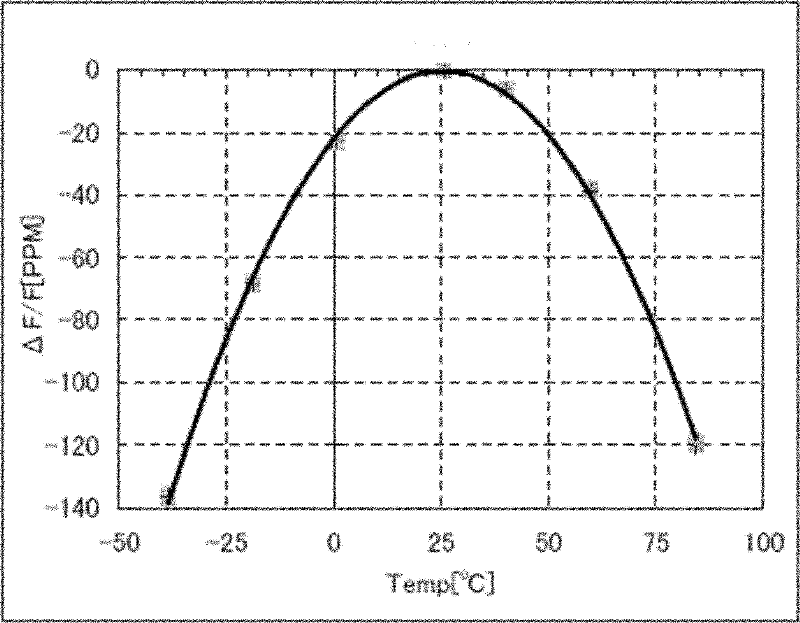

Temperature compensation method for piezoelectric oscillator, and piezoelectric oscillator

InactiveUS20110121909A1Accurately calculateAccurate temperature compensationRadiation pyrometryTemperatue controlHysteresisAcoustics

A temperature compensation method for a piezoelectric oscillator including a piezoelectric vibrator having a frequency temperature characteristic with a hysteresis characteristic, and an oscillation circuit which oscillates the piezoelectric vibrator and outputs an oscillation signal, wherein, to a temperature compensation circuit which can calculate a quantity of temperature compensation using frequency temperature information indicating a temperature characteristic of an oscillation frequency of the piezoelectric vibrator and temperature information of the piezoelectric vibrator at the time of oscillation of the oscillation signal, the oscillation signal and the frequency temperature information are outputted, includes: calculating, as the frequency temperature information, an intermediate value between elevated-temperature frequency temperature information of the piezoelectric vibrator that is generated in the case where ambient temperature of the piezoelectric vibrator is elevated, and lowered-temperature frequency temperature information of the piezoelectric vibrator that is generated in the case where the ambient temperature is lowered.

Owner:SEIKO EPSON CORP

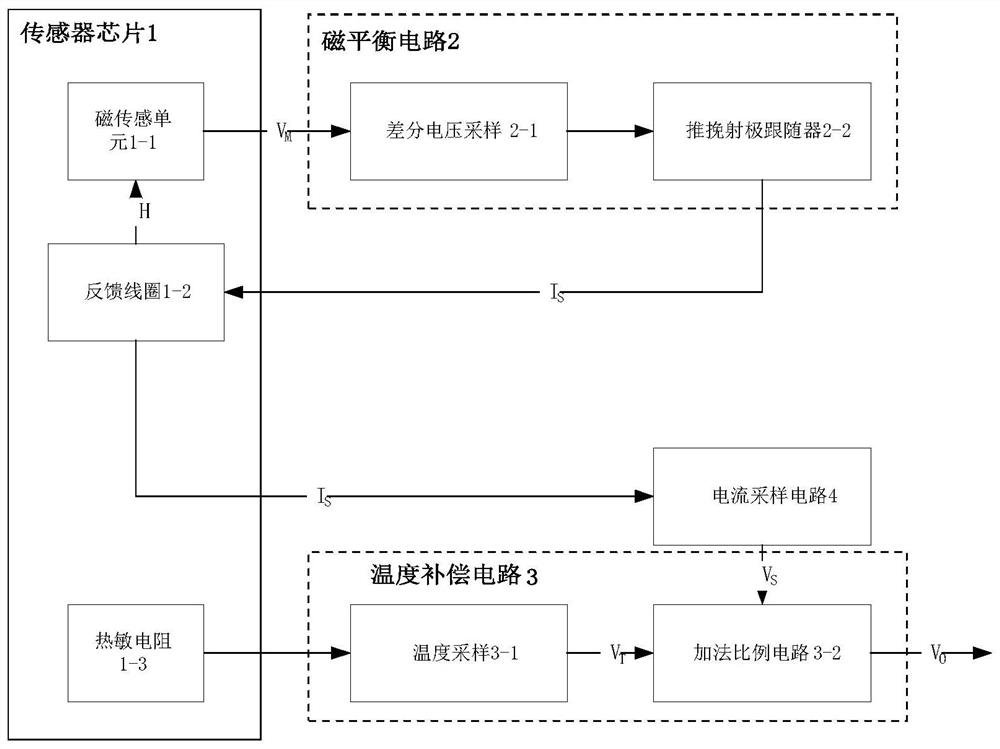

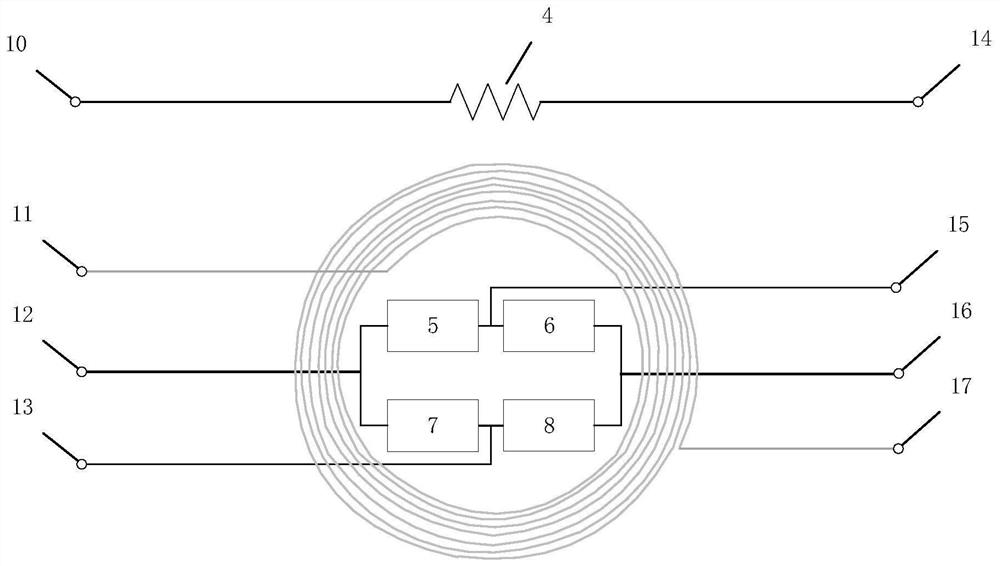

Magnetic sensing chip, closed-loop feedback current sensor and preparation method of closed-loop feedback current sensor

PendingCN111650428AReduce volumeReduce weightCurrent/voltage measurementVoltage/current isolationSignal processing circuitsClosed loop feedback

The invention discloses a magnetic sensing chip, a closed-loop feedback current sensor and a preparation method of the closed-loop feedback current sensor. The closed-loop feedback current sensor includes a shell; the magnetic sensing chip and the signal processing circuit are arranged in the shell, the magnetic sensing chip comprises a magnetic sensing unit composed of magneto-resistor elements and a feedback coil arranged above the magnetic sensing unit, the feedback coil is of a planar spiral line structure formed by etching a conductive material, and the spiral line plane is perpendicularto the sensitive direction of the magnetic sensing unit; the signal processing circuit comprises a magnetic balance circuit and a current sampling circuit, and the magnetic sensing chip is connected with a power supply through an input terminal and connected with the magnetic balance circuit through an output terminal; the magnetic balance circuit is connected with the feedback coil and provides current for the feedback coil, so that the feedback coil generates a feedback magnetic field; the current sampling circuit is connected with the feedback coil and collects and outputs a current signalof the feedback coil. According to the closed-loop feedback current sensor, the magneto-resistor elements and the feedback coil are integrated in the magnetic sensing chip, so that the size and the weight of the closed-loop feedback current sensor are reduced.

Owner:珠海多创科技有限公司

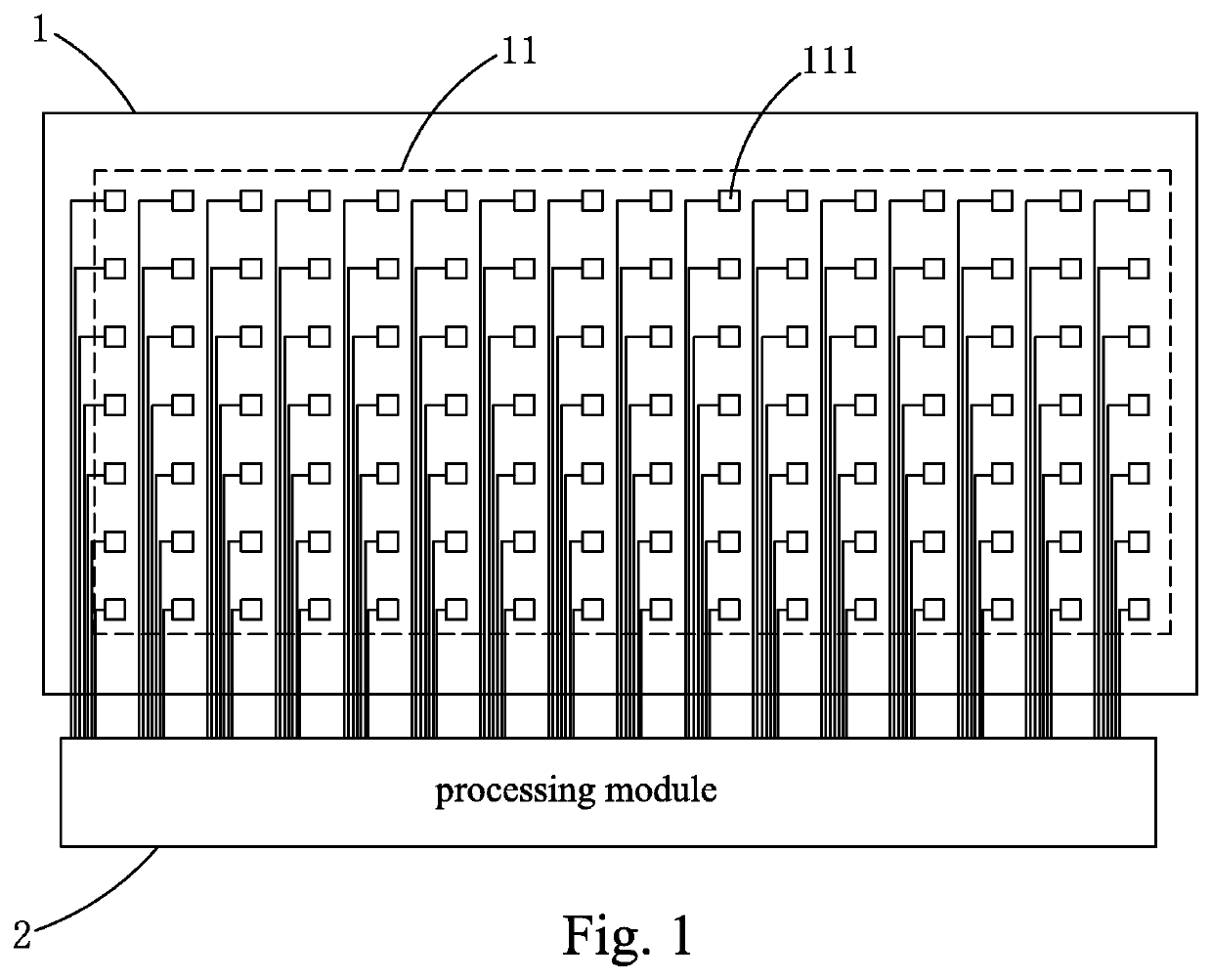

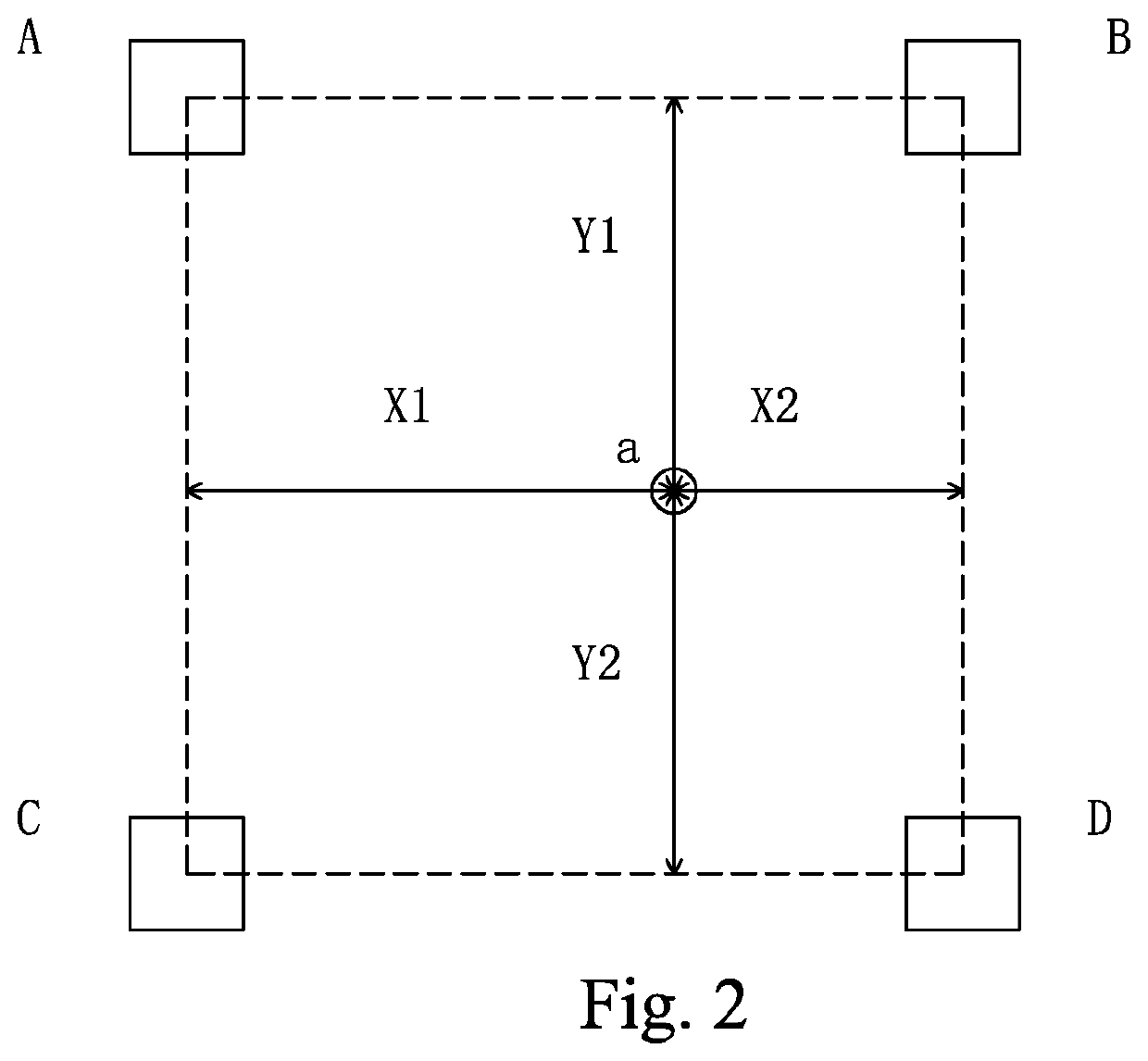

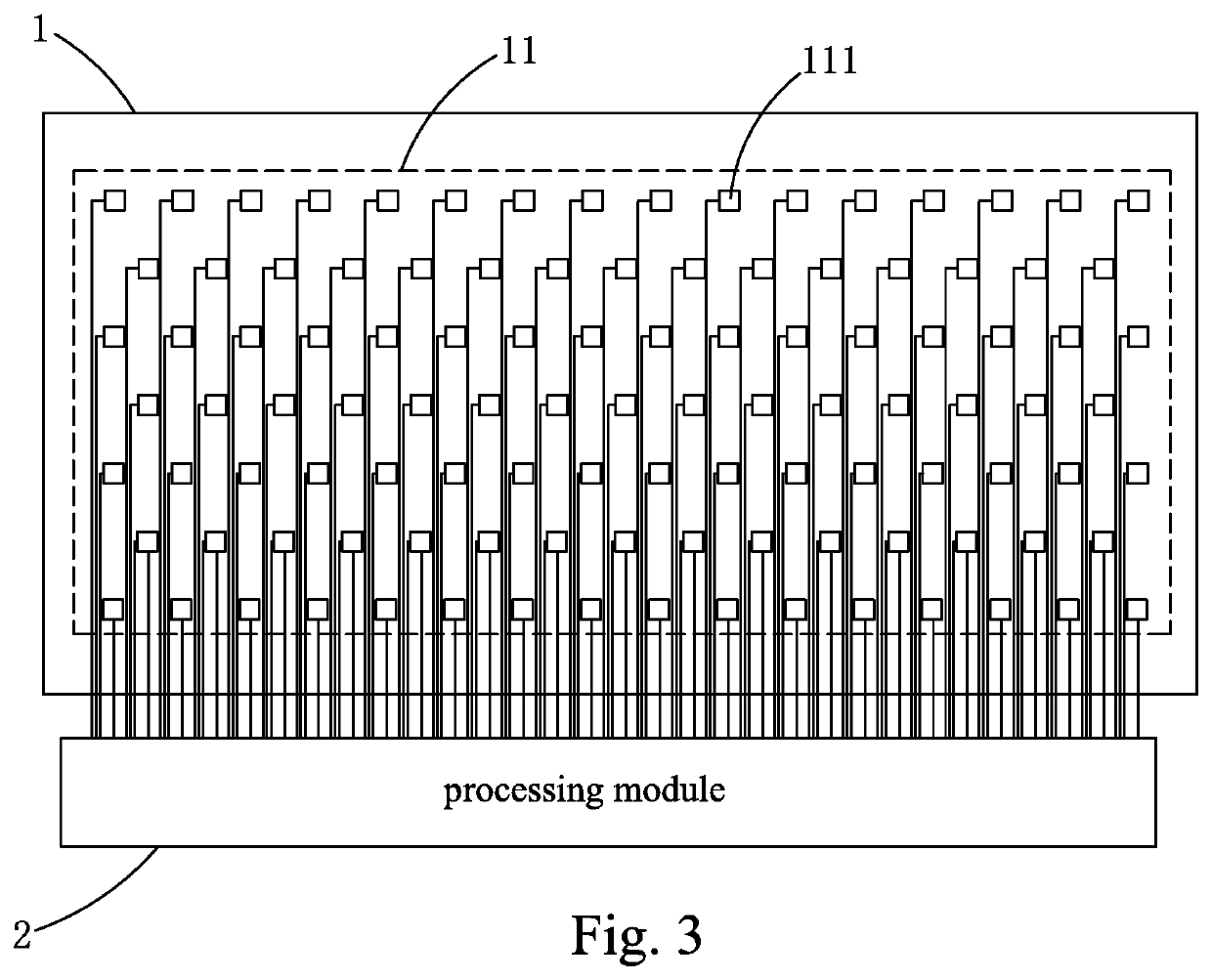

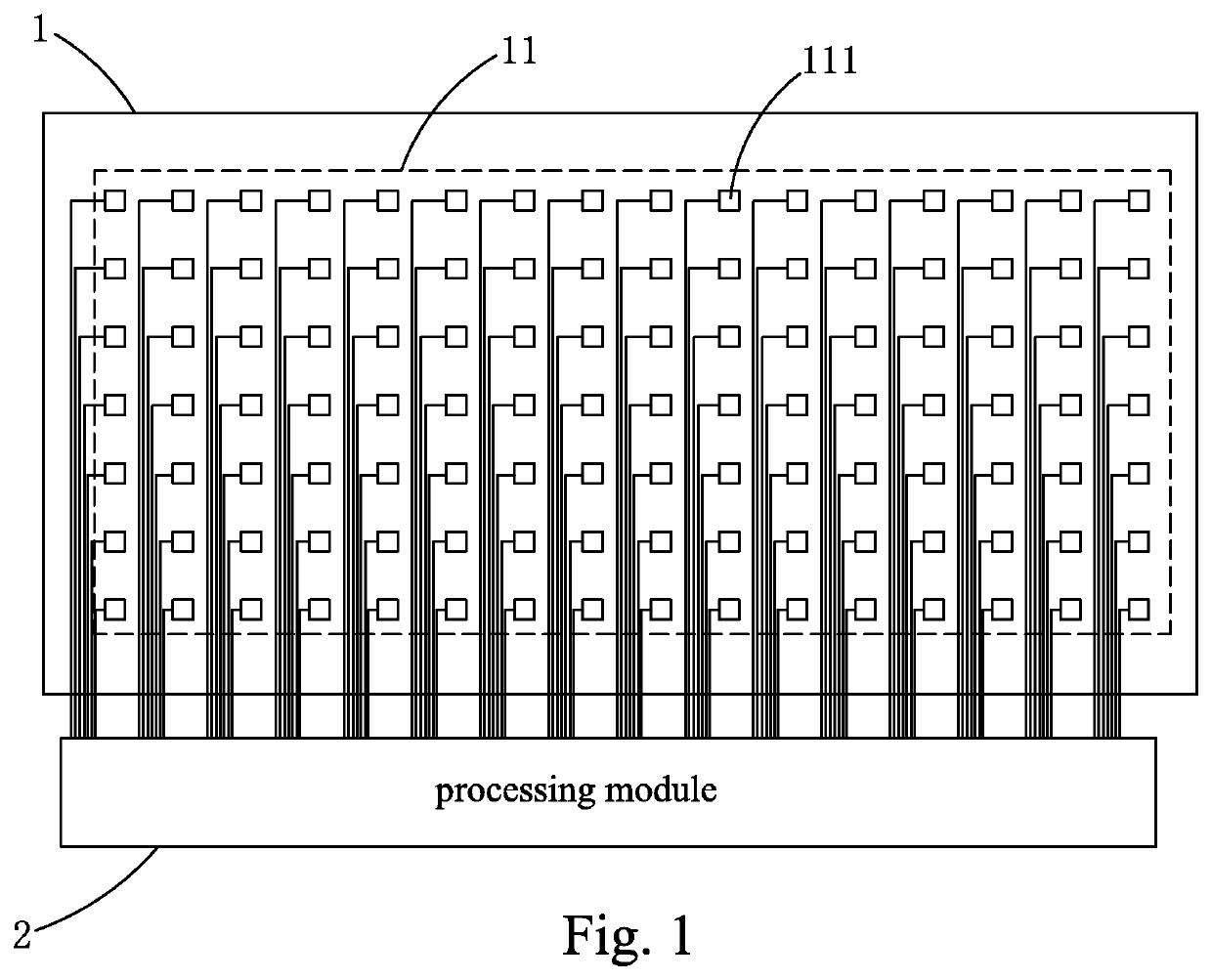

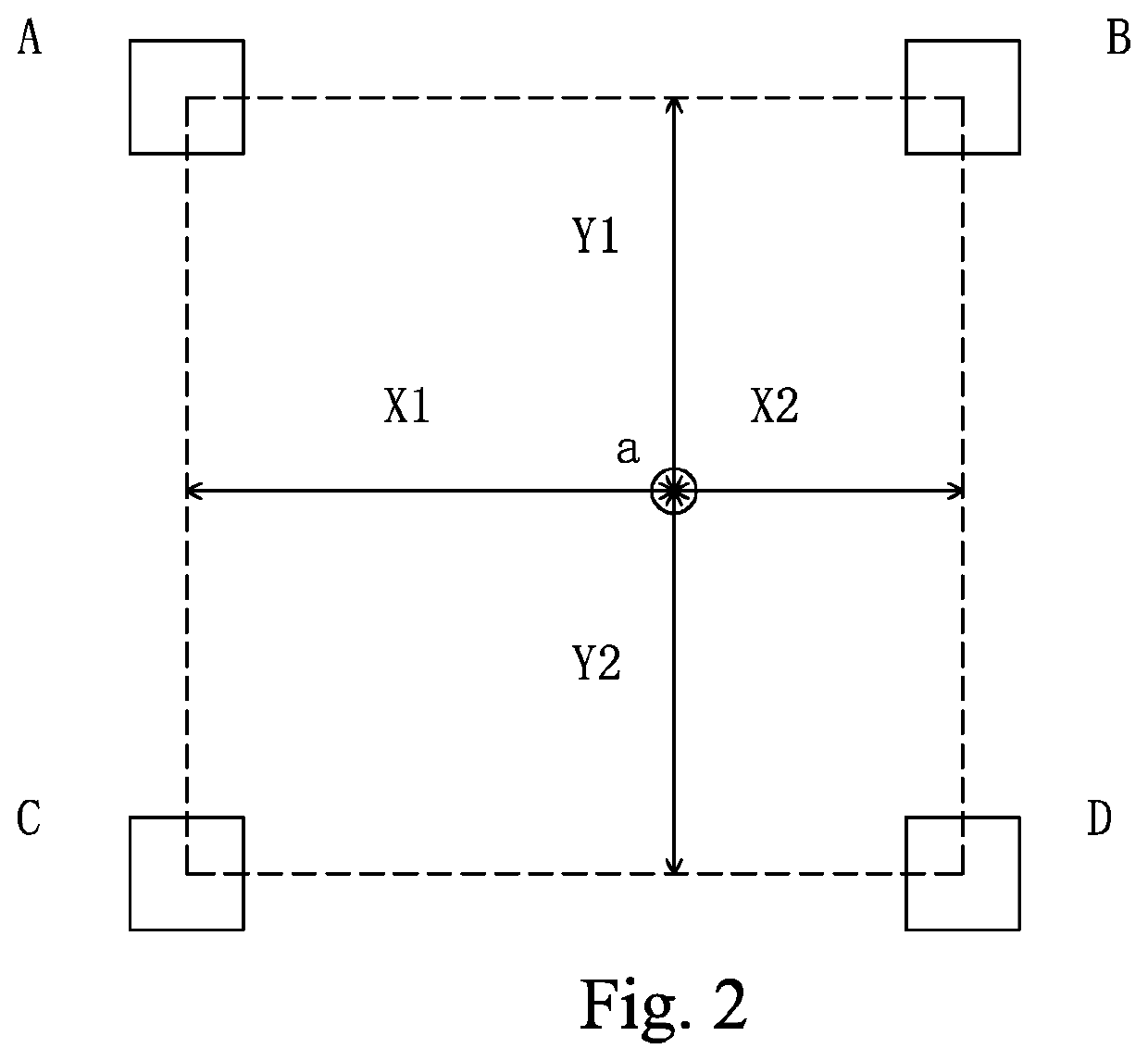

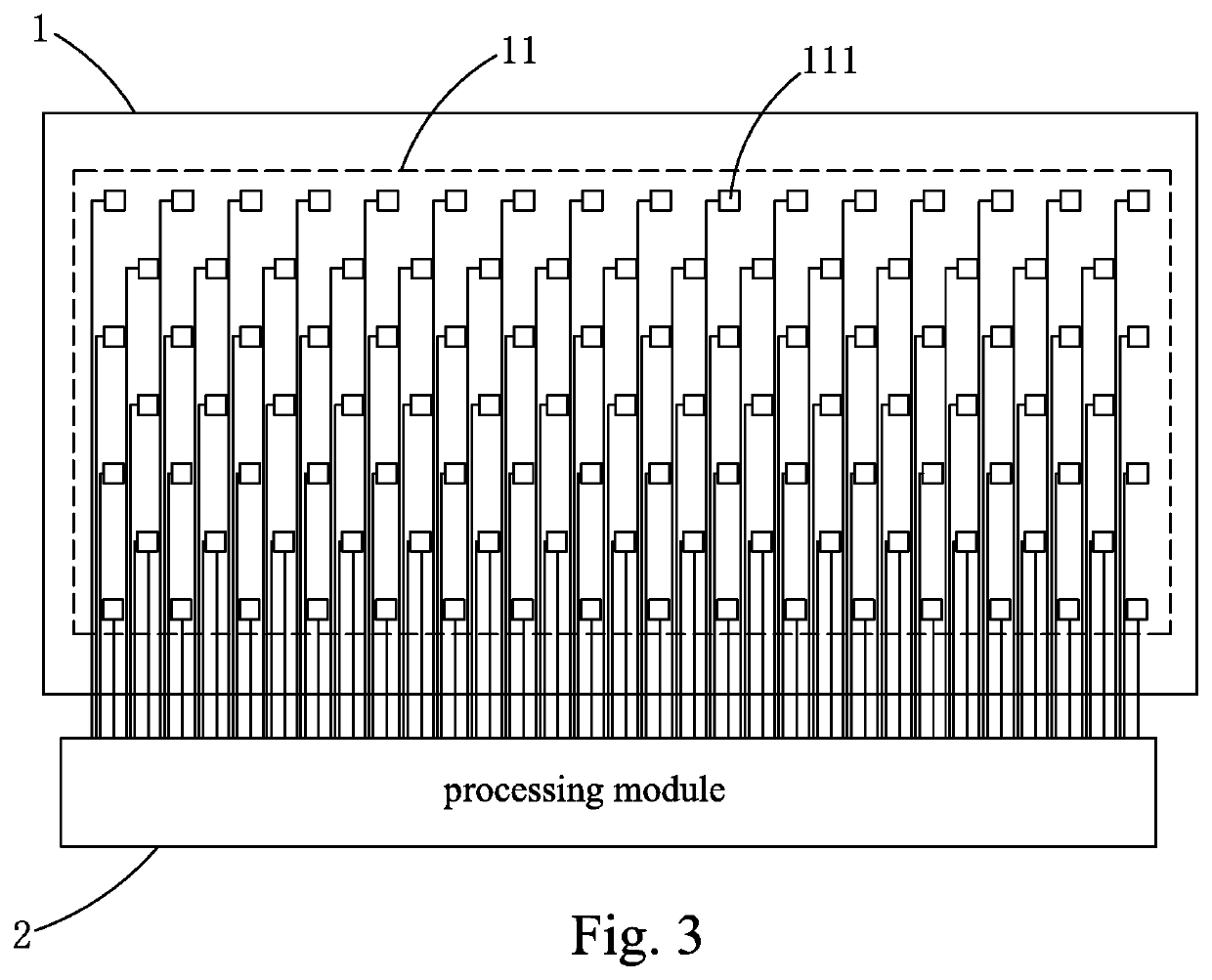

OLED panel temperature compensation system and OLED panel temperature compensation method

ActiveUS20190378454A1Accurately and effectively compensated for temperatureAccurate temperature compensationThermometer detailsStatic indicating devicesData signalEngineering

The invention provides an OLED panel temperature compensation system and method. The system comprises an OLED panel and a processing module connected to the OLED panel, the OLED panel is disposed with a temperature sensor layer of a plurality of temperature sensors on one side or inside; when performing temperature compensation, the temperature sensor detects the temperature of the location and transmits to the processing module, the processing module receives and processes the initial data signals of the plurality of sub-pixels to obtain the to-be-displayed brightness of the plurality of sub-pixels, and receives and processes the temperatures from the plurality of temperature sensors to obtain the temperatures of the plurality of sub-pixels, and generates and outputs compensation data signals corresponding to the plurality of sub-pixels according to the to-be-displayed brightness and temperature of the plurality of sub-pixels. The OLED panel is thus accurately and effectively compensated for temperature.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

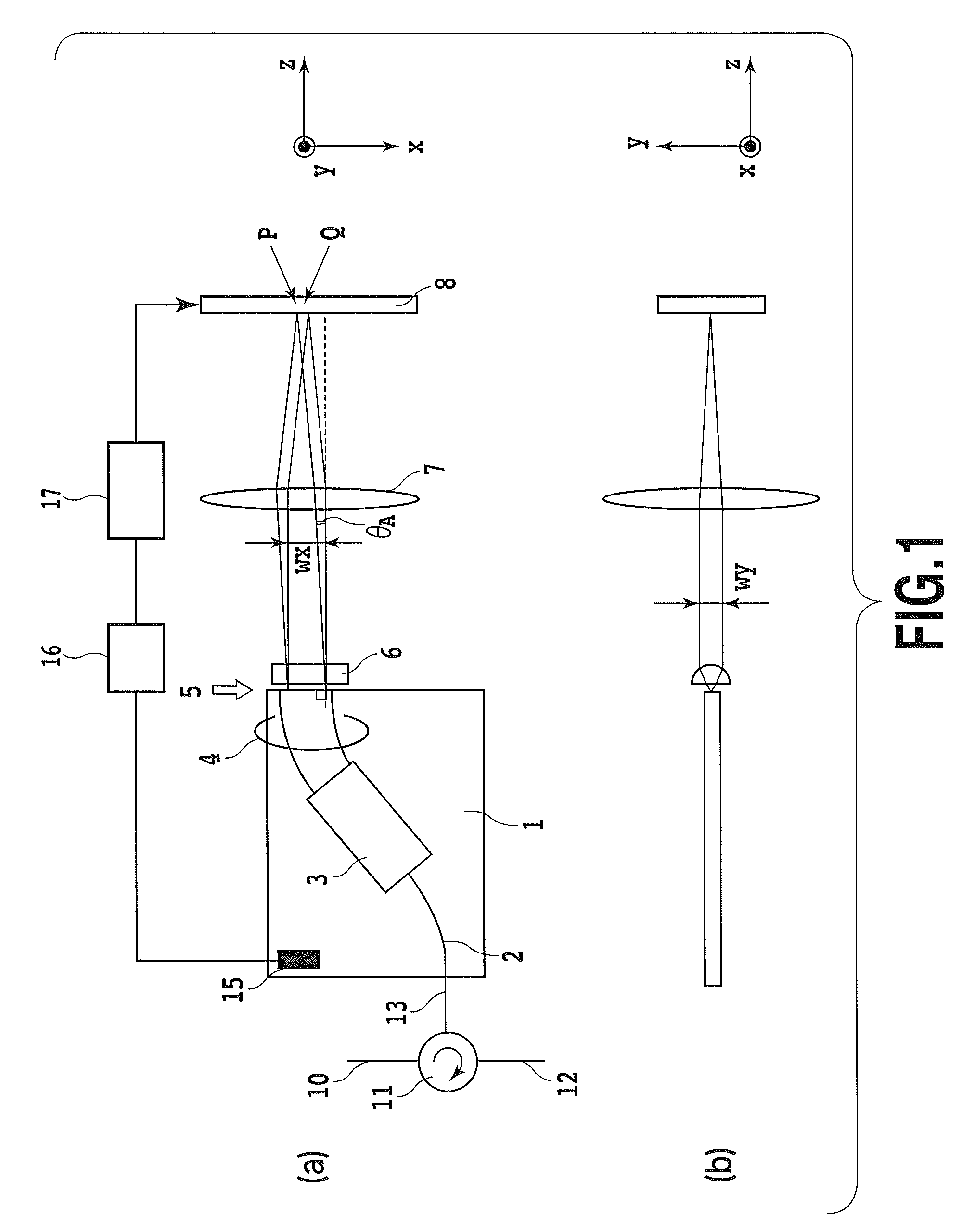

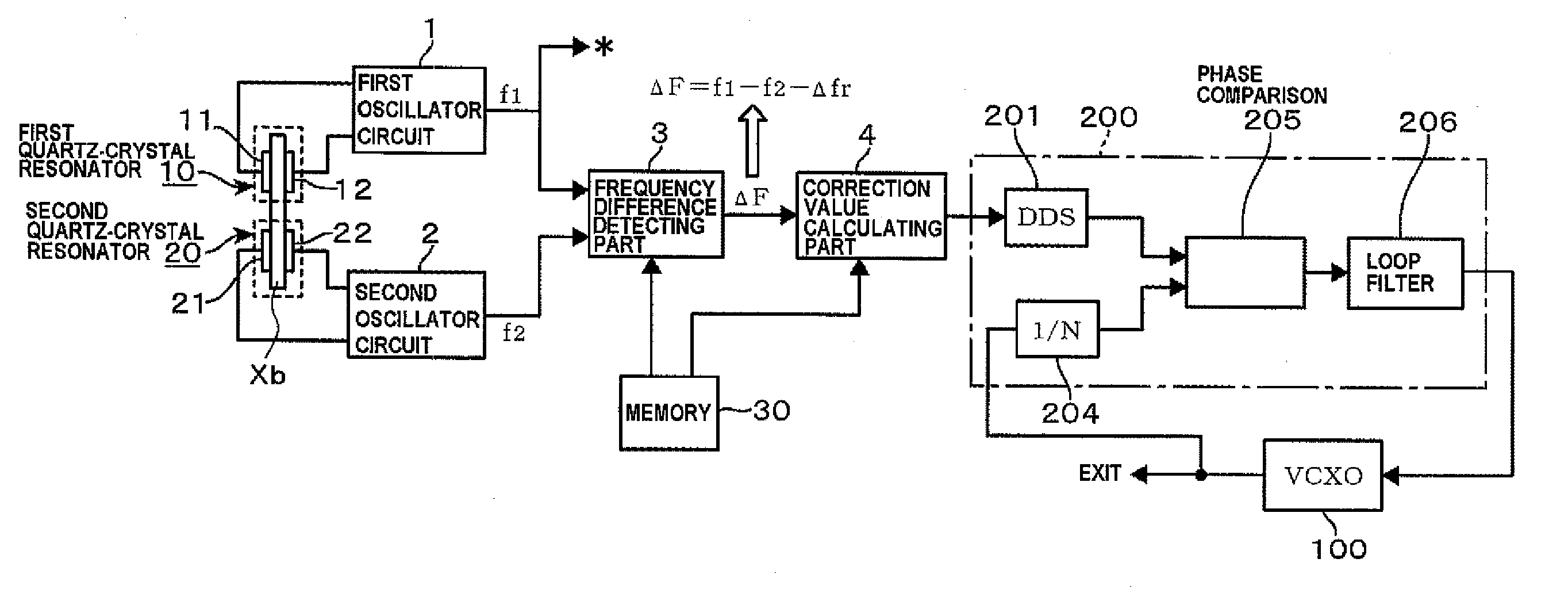

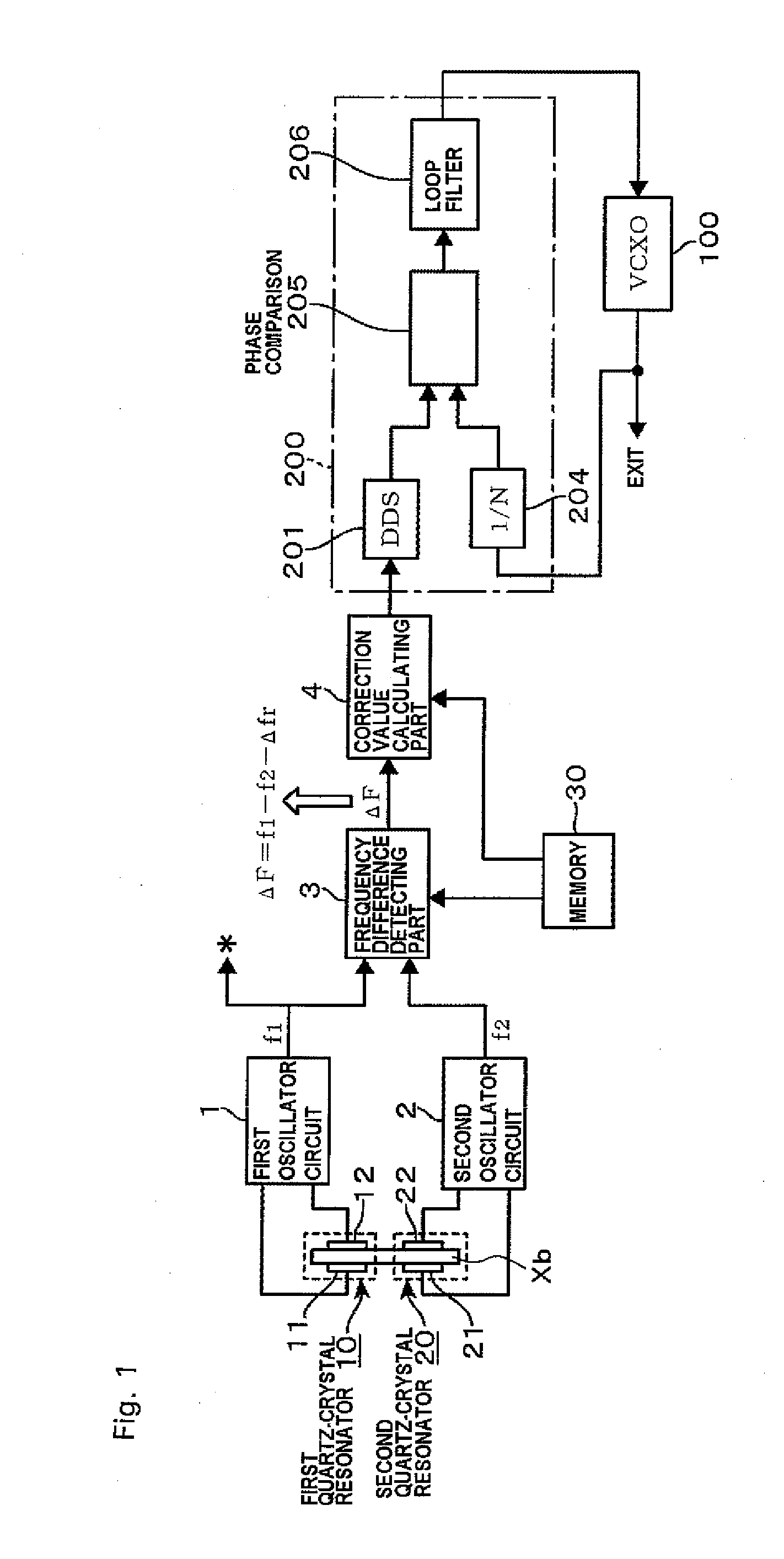

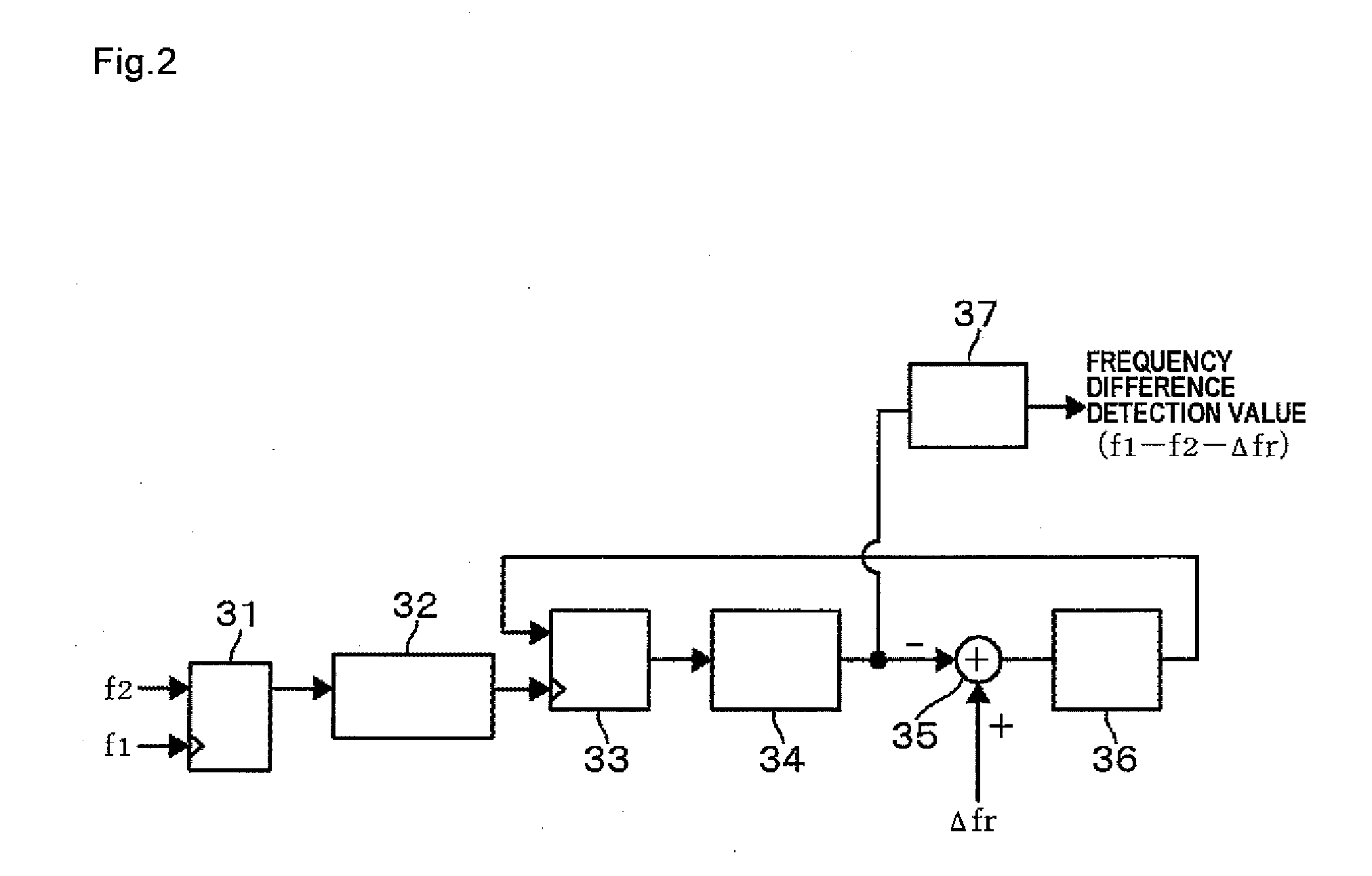

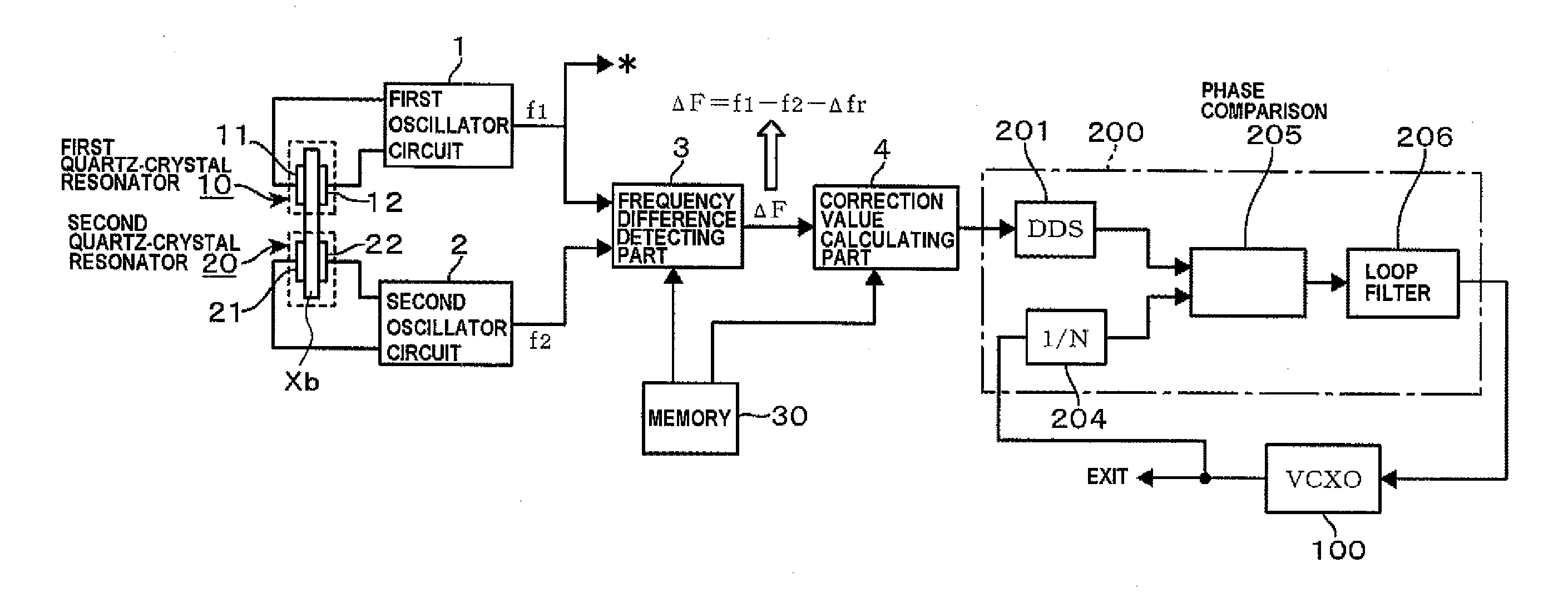

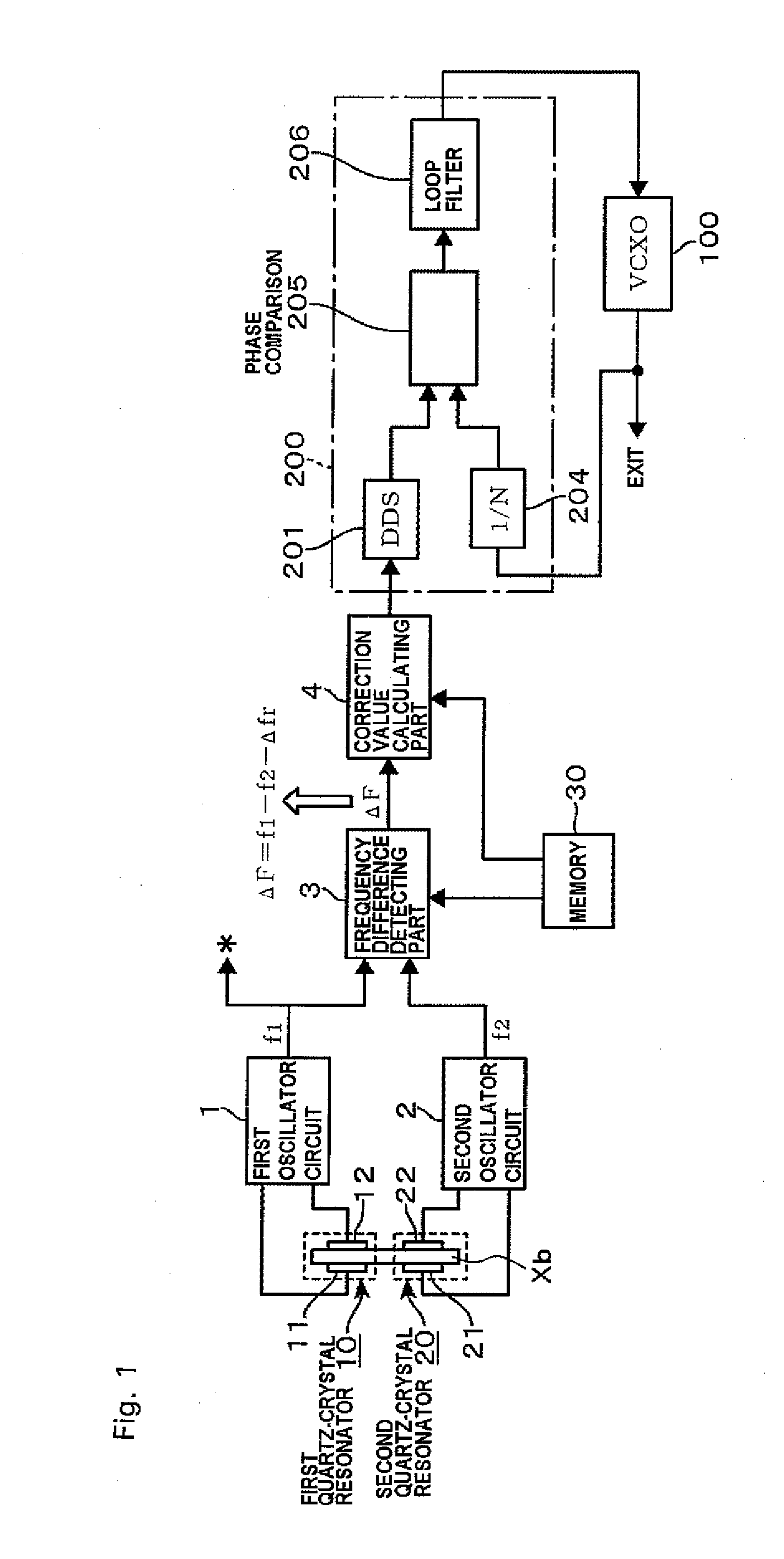

Oscillation device

ActiveUS20120194280A1Increase temperatureAccurate temperature compensationPulse automatic controlGenerator stabilizationQuartz crystal resonatorAtomic physics

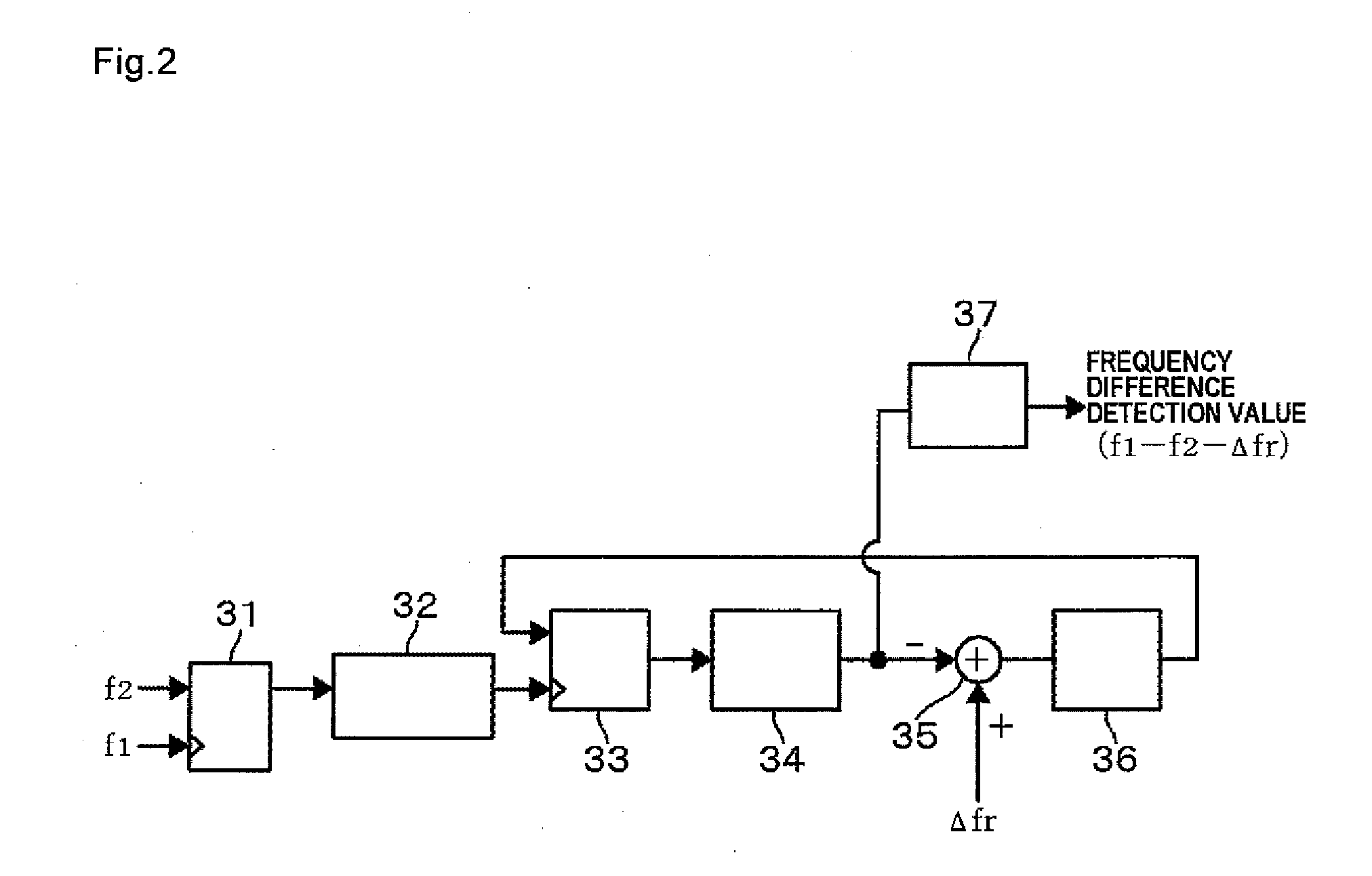

An oscillation device capable of highly accurate temperature compensation of an output frequency is provided. The oscillation device includes: first and second oscillator circuits oscillating first and second quartz-crystal resonators with overtones respectively; a frequency difference detecting part finding a value corresponding to a difference value between values corresponding to differences between f1 and f1r and between f2 and f2r, where f1 and f2 are oscillation frequencies of the first and second oscillator circuits, and f1r and f2r are oscillation frequencies of the first and second oscillator circuits at a reference temperature; and a correction value obtaining part which, based on the value corresponding to the difference value and a relation between the value corresponding to the difference value and a frequency correction value of the oscillation frequency f1, obtains the frequency correction value of f1, wherein the output frequency is corrected based on the found frequency correction value.

Owner:NIHON DEMPA KOGYO CO LTD

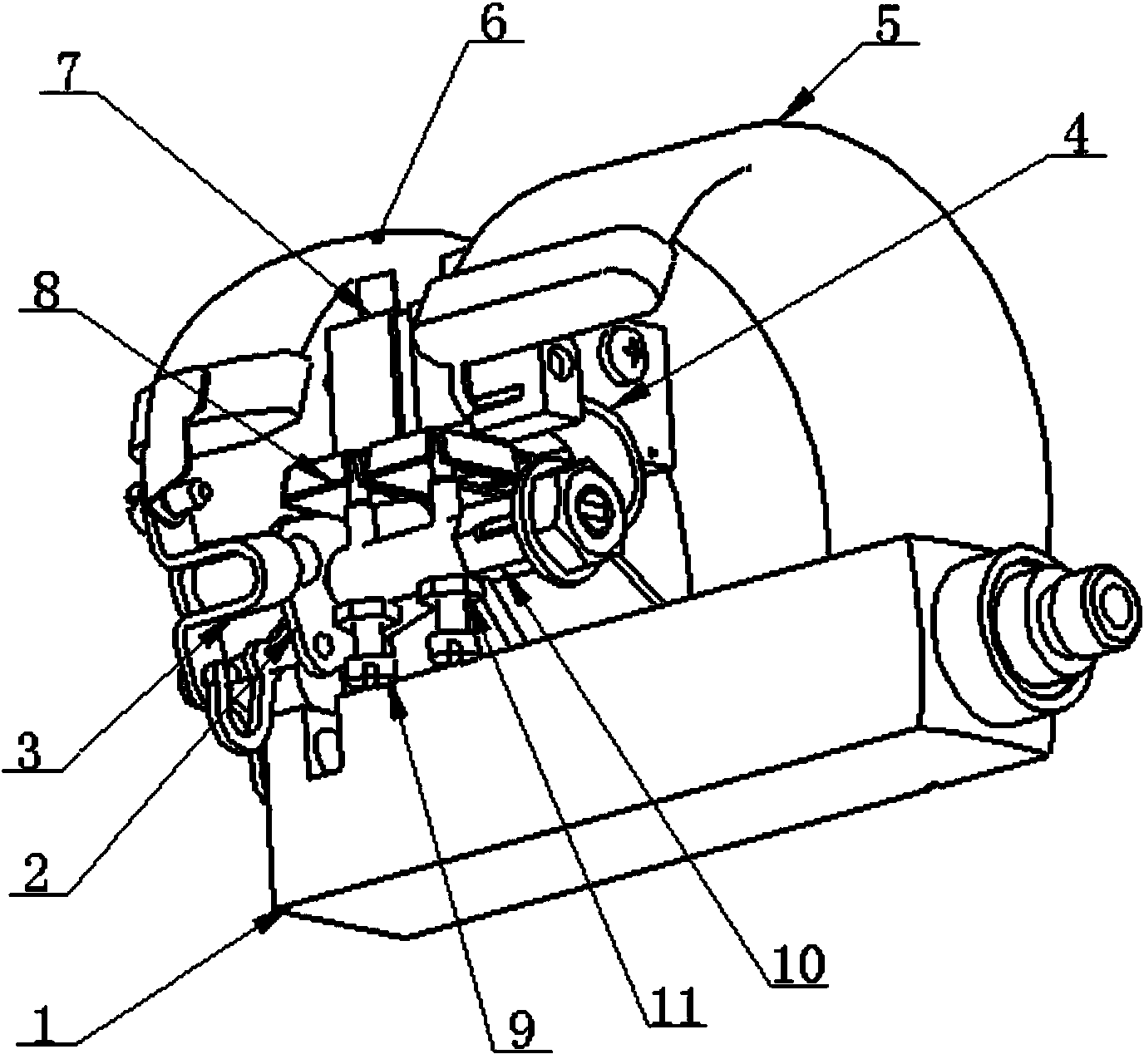

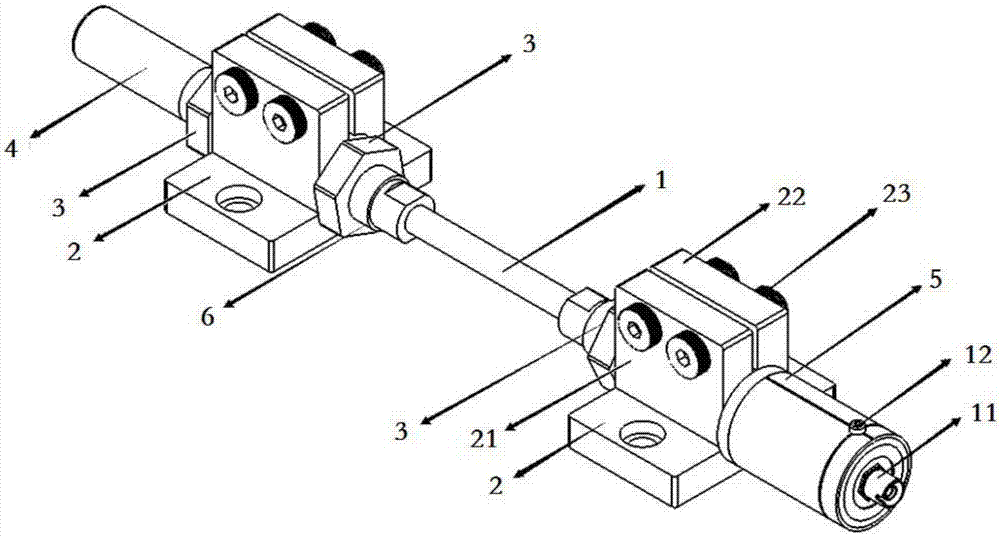

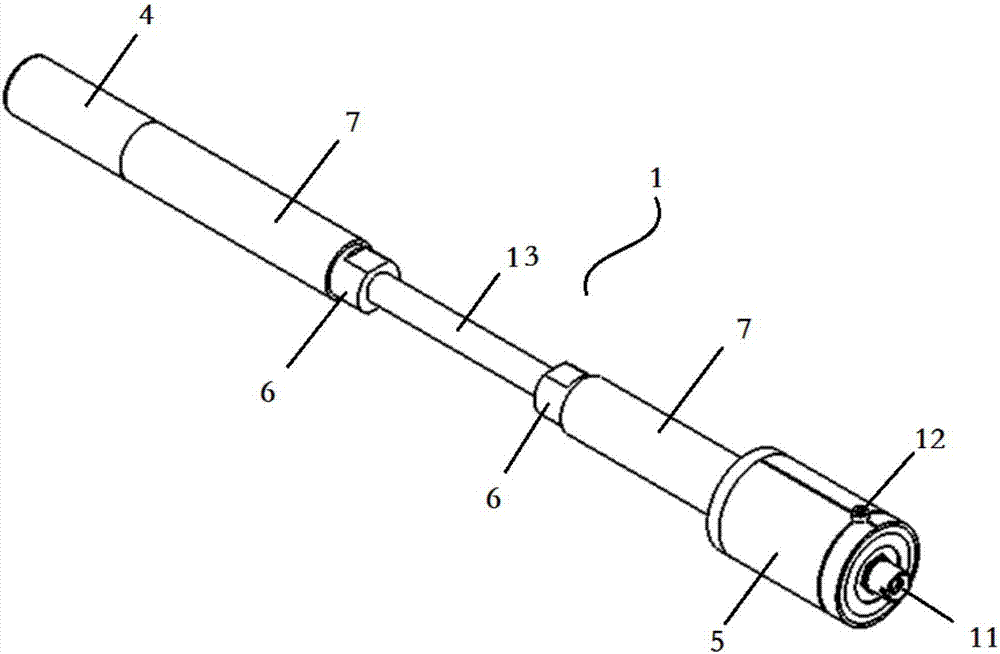

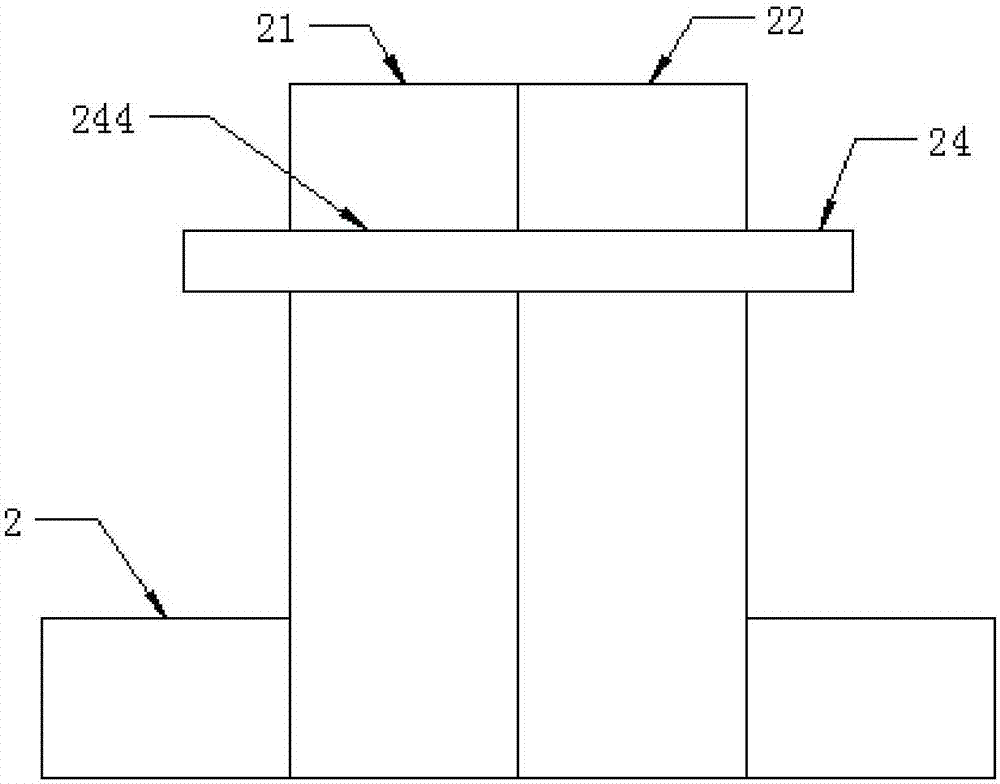

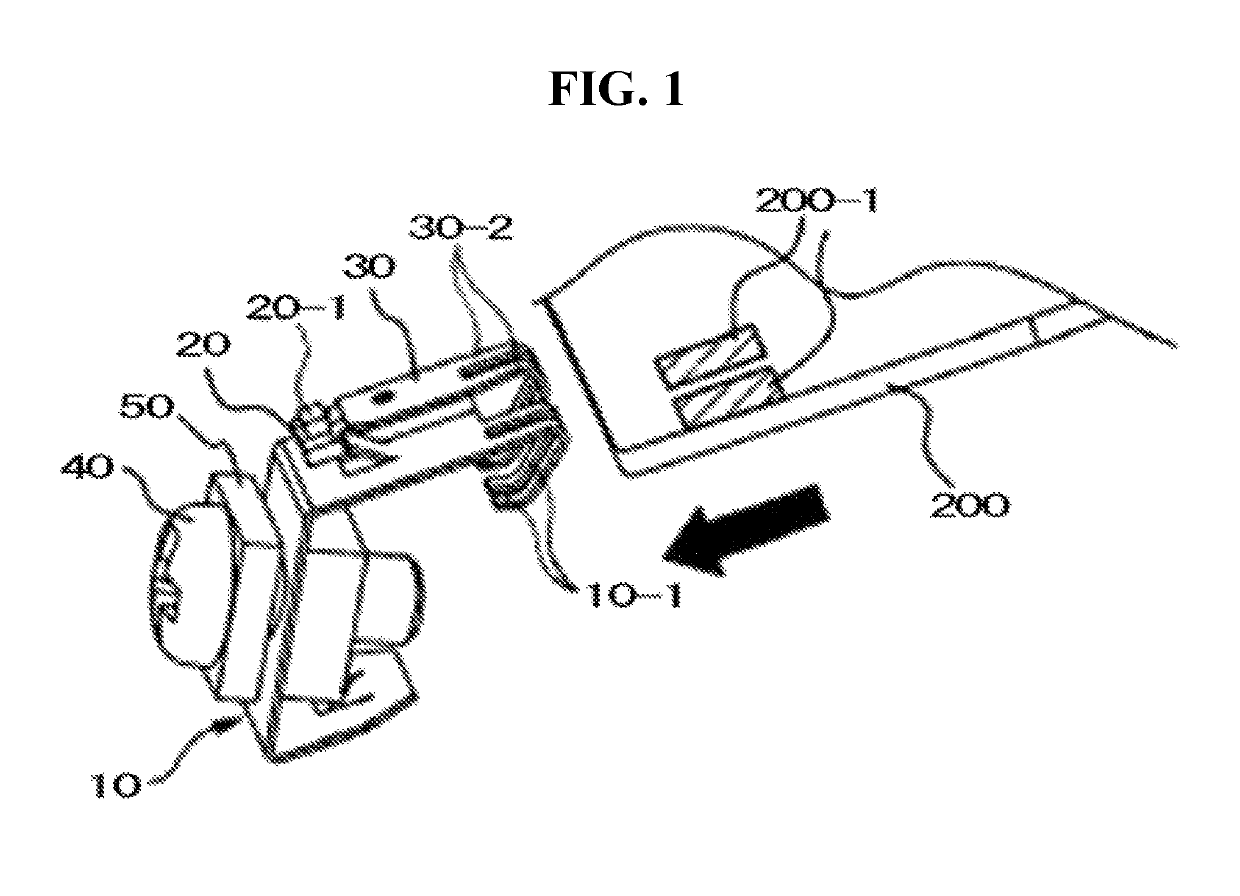

Replaceable high-anti-fatigue fiber grating strain sensor

The invention discloses a replaceable high-anti-fatigue fiber grating strain sensor comprising a central sensing element, an anchoring assembly, two sensor bases arranged in pair, and a position adjusting element. A quick fiber port is connected to the output terminal of the central sensing element. The anchoring assembly consists of a tail anchoring cylinder, an end anchoring cylinder and an anchor head; the tail anchoring cylinder sleeves the tail of the central sensing element; the end anchoring cylinder sleeves the end portion of the central sensing element; and the anchor head is arranged in the middle area of the central sensing element in a sleeve manner. The two sensor bases arranged at the surface of a to-be-measured object are used for fixing the two ends of the central sensing element; each sensor base is provided with a through hole; and the central sensing element passes through the through holes. The position adjusting element arranged at the central sensing element is used for adjusting the position of the central sensing element. On the basis of the design way of separation of the central sensing element with the sensor bases, replacement or maintenance of the central sensing element can be realized conveniently; and with the unique packaging process, the sensor structure has the better anti-fatigue performance.

Owner:ZHIXING S&T

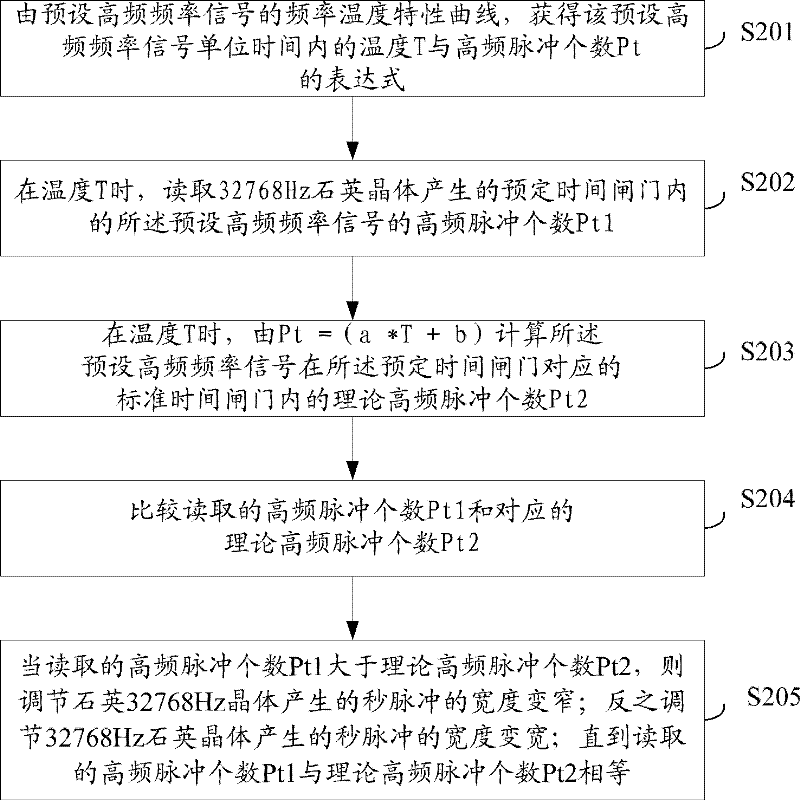

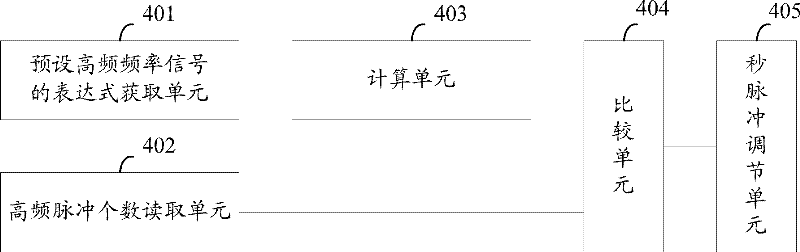

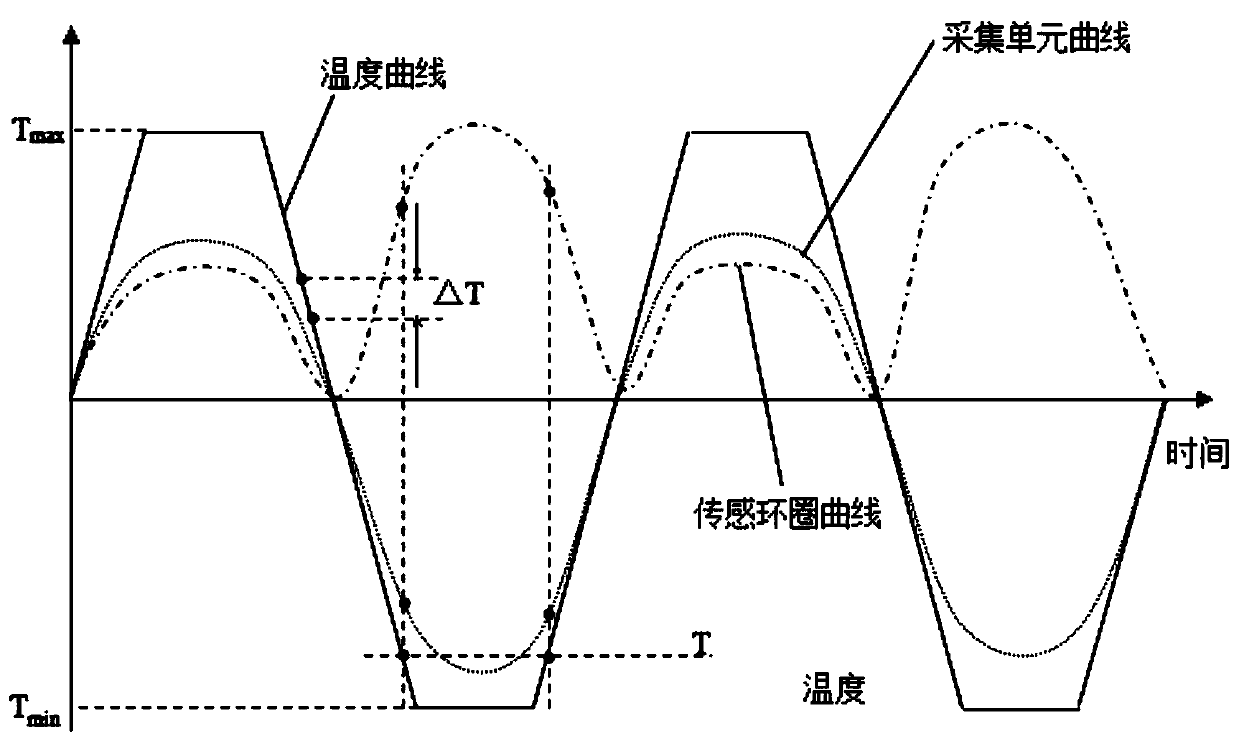

Closed-loop temperature compensation method and device for clock crystal oscillator

ActiveCN102545778ALow costAccurate temperature compensationOscillations generatorsCurve shapePhysics

The invention provides a closed-loop temperature compensation method and a closed-loop temperature compensation device for a clock crystal oscillator. A second pulse of a 32768Hz quartz crystal is continuously corrected by using an accurate high-frequency quartz crystal until the number of high-frequency pulses of a high-frequency pulse signal which is read in a time gate generated by the 32768Hz quartz crystal is equal to that of the high-frequency pulses which are theoretically accurate. Because the 32768Hz quartz crystal can be calibrated at any temperature, the frequency offset of the 32768Hz quartz crystal caused by temperature difference is compensated. In a closed-loop temperature compensation mode which is provided by the embodiment of the invention, the frequency temperature characteristic curve shape of a clock crystal is unrelated, and consistency is not required. Therefore, by adoption of a temperature soft compensation method provided by the invention, accurate temperature compensation can be realized. The cost of the temperature soft compensation method is low, and the size of a corresponding system is small.

Owner:苏州银河龙芯科技有限公司

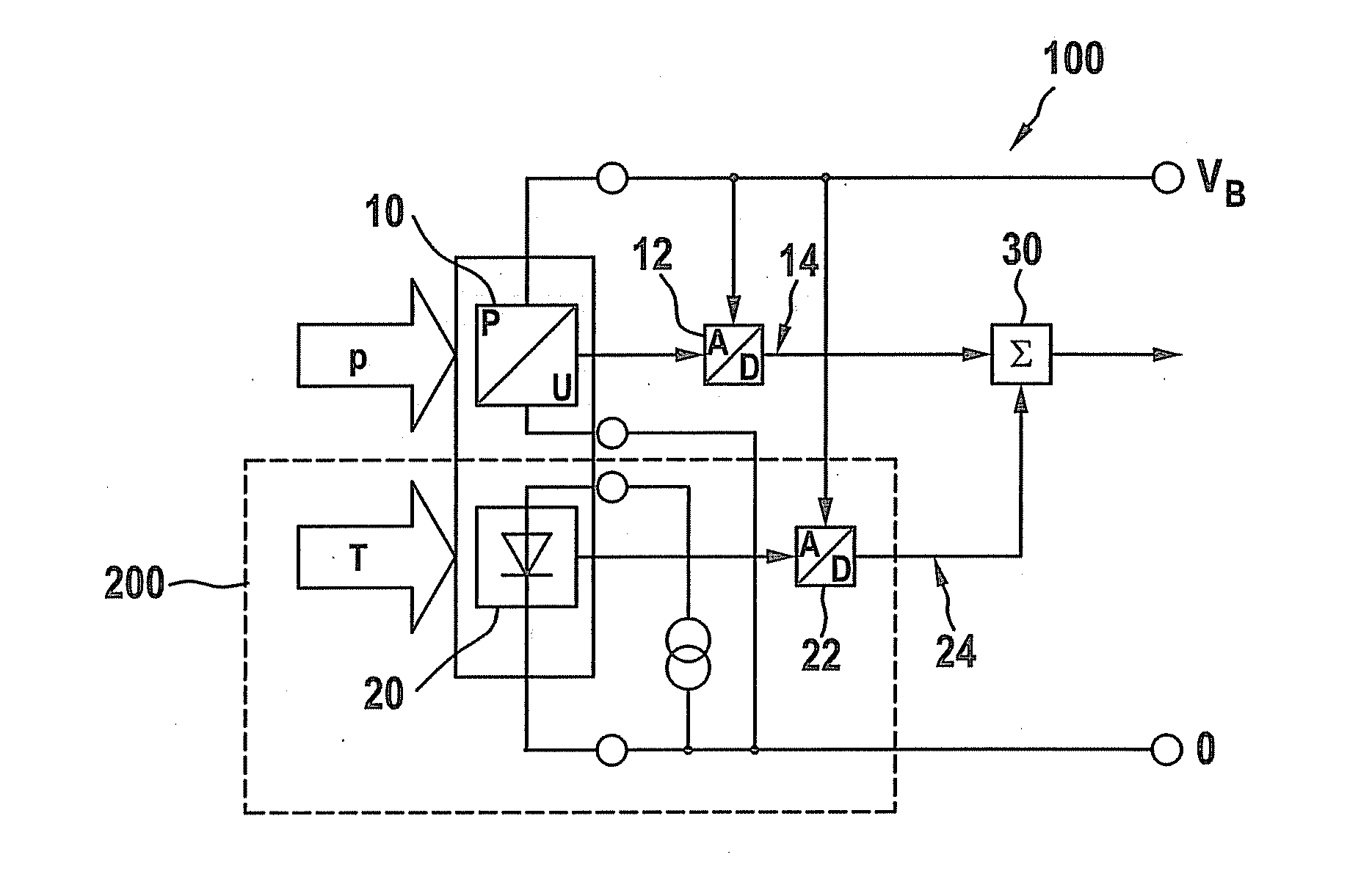

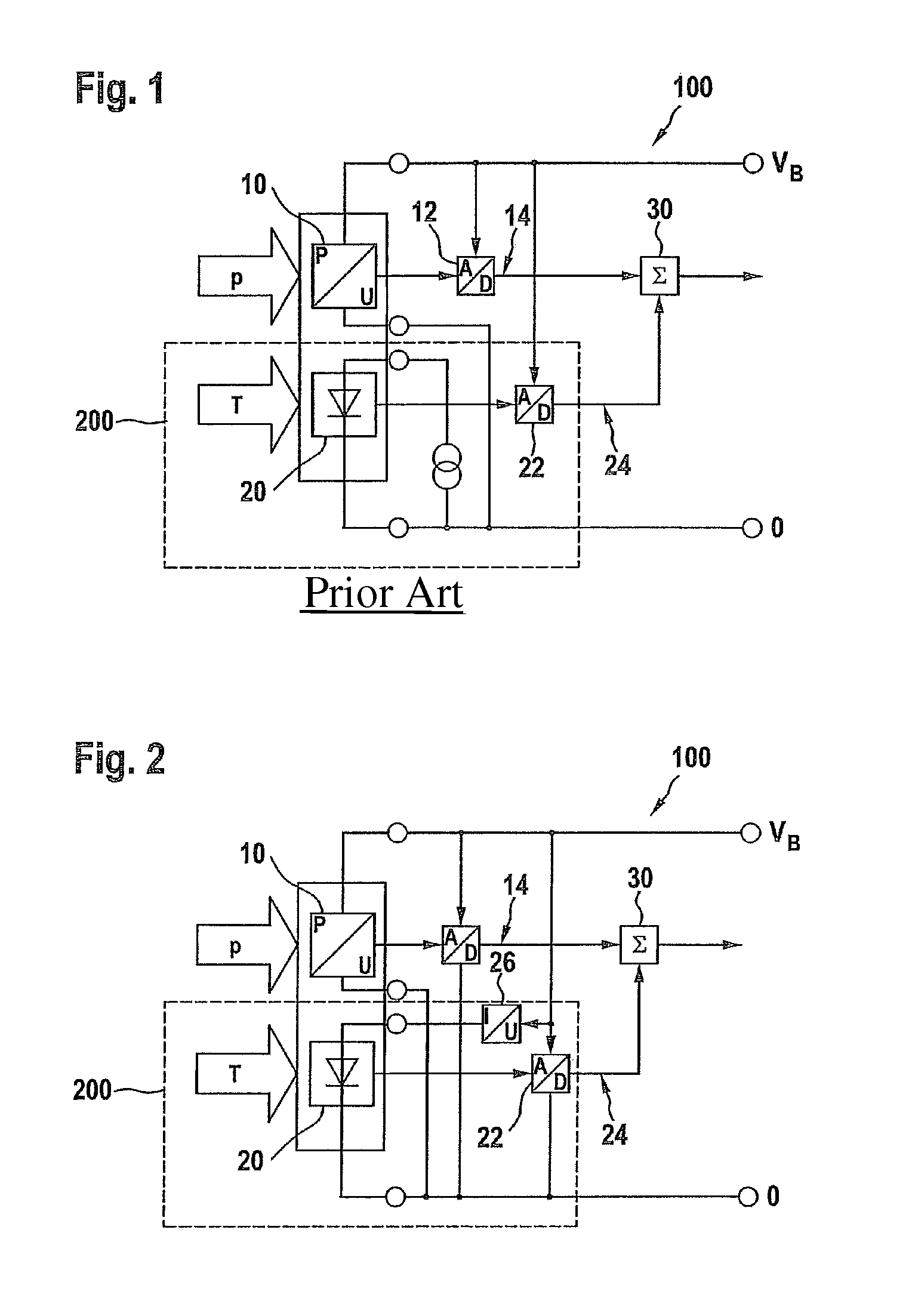

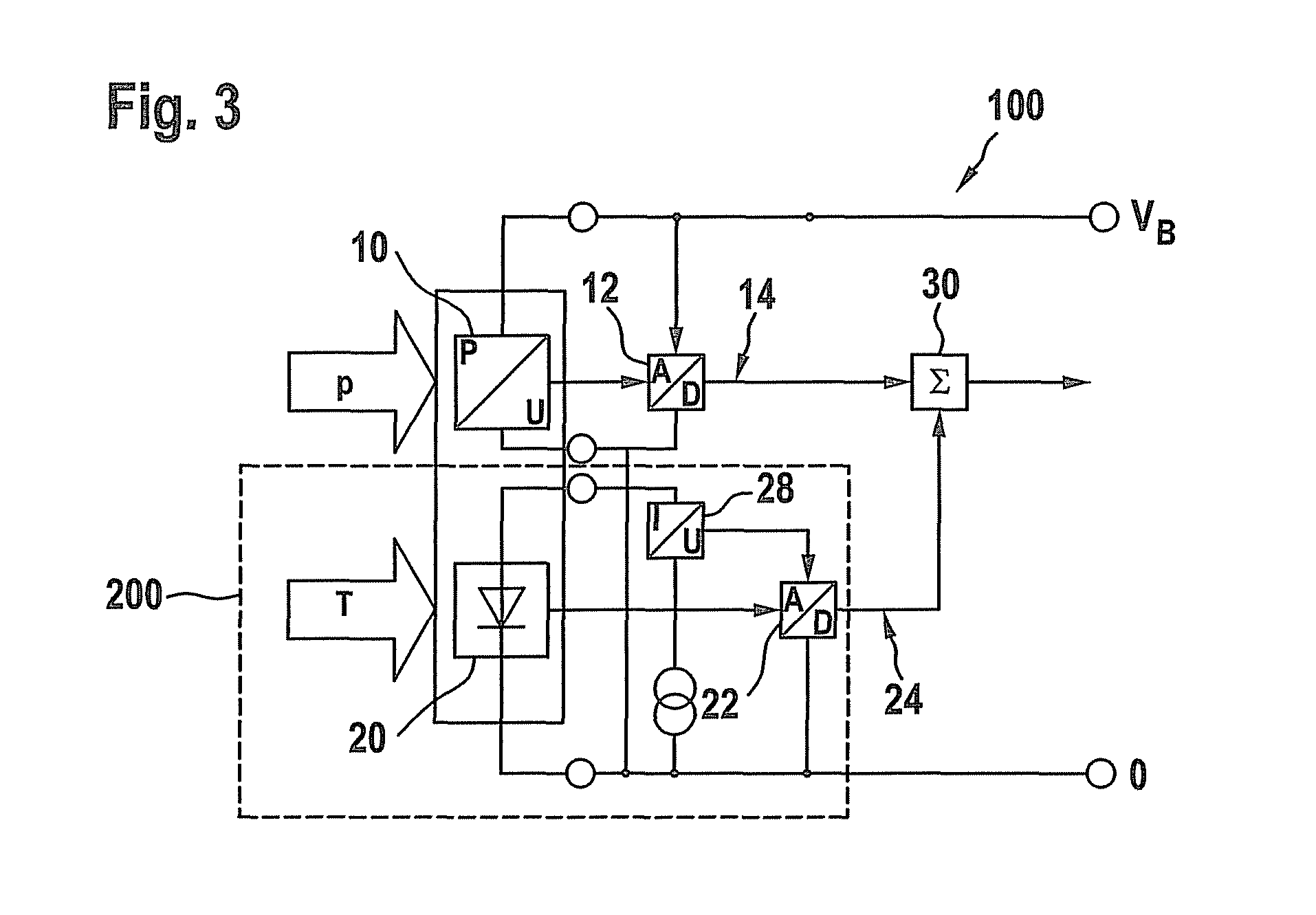

Temperature detection device having a diode and an analog-digital converter

ActiveUS8992080B2Minimize impactAccurate temperature compensationThermometer detailsThermometer with A/D convertersConvertersA d converter

A temperature detection device includes a diode and an analog-digital converter. An output voltage signal of the diode is applicable to an input of the analog-digital converter. The temperature detection device is adapted for the purpose of coupling a reference voltage of the analog-digital converter and the diode current of the diode such that effects of variations of the reference voltage or the diode current on the digital output signal of the analog-digital converter are partially or completely suppressed.

Owner:ROBERT BOSCH GMBH

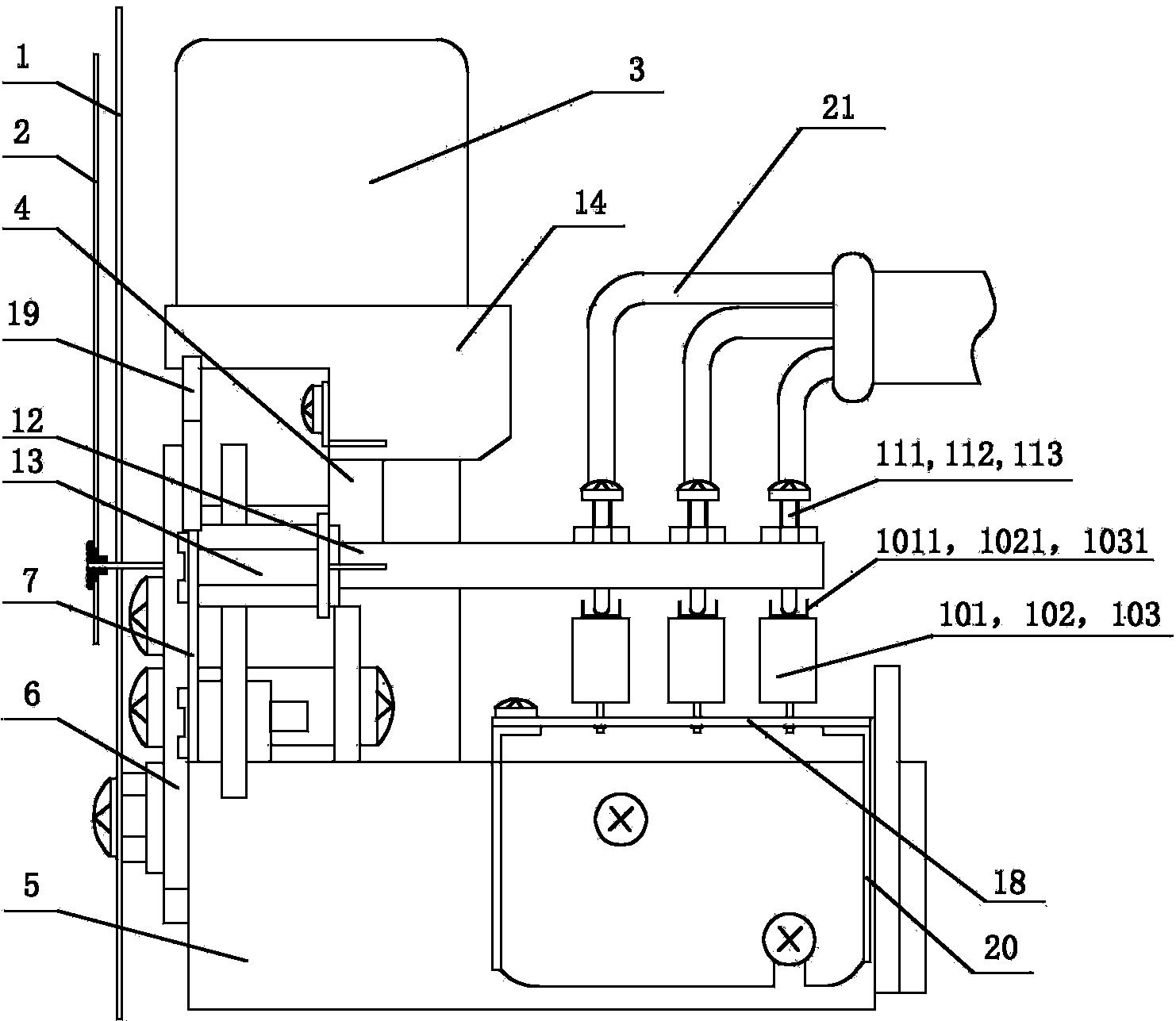

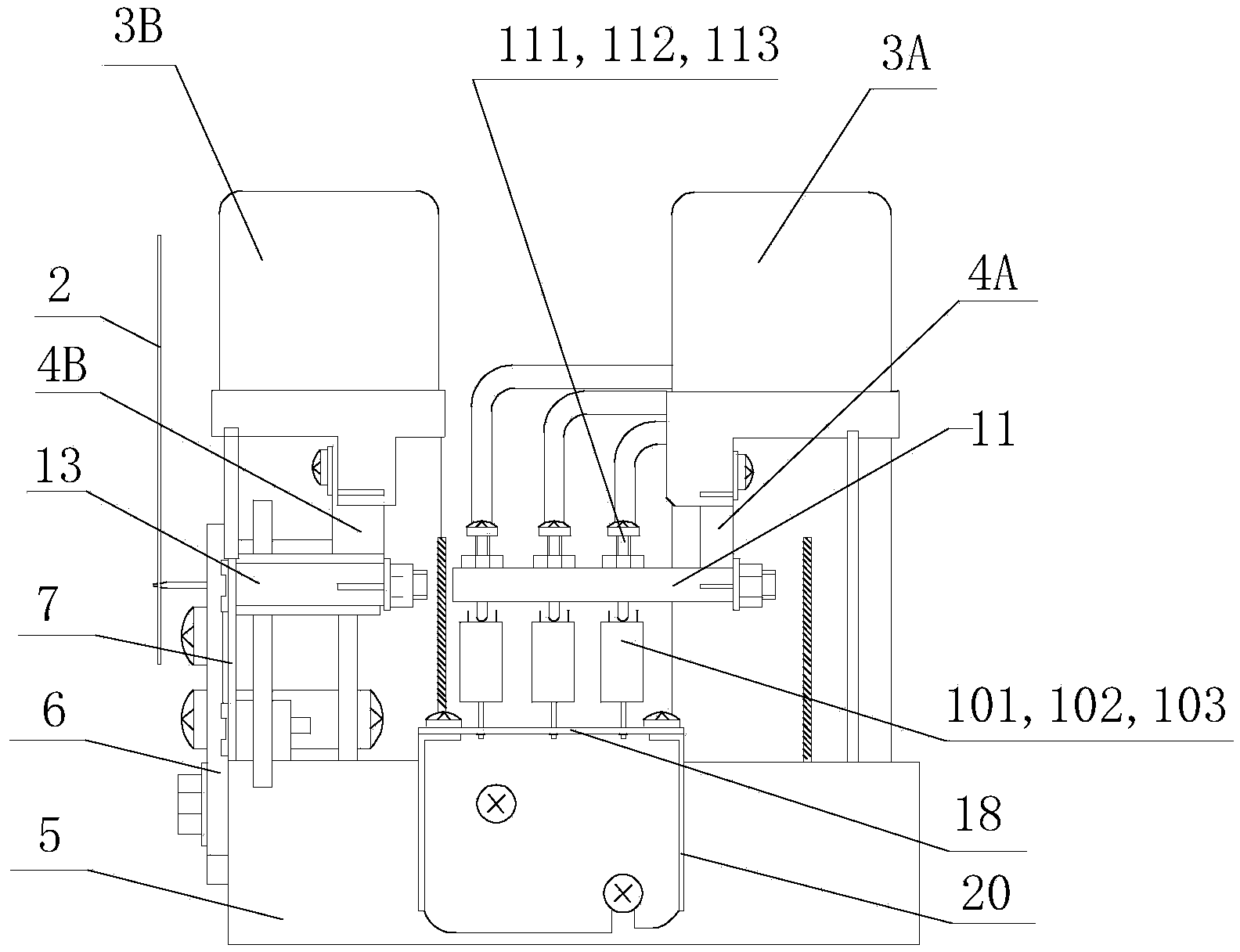

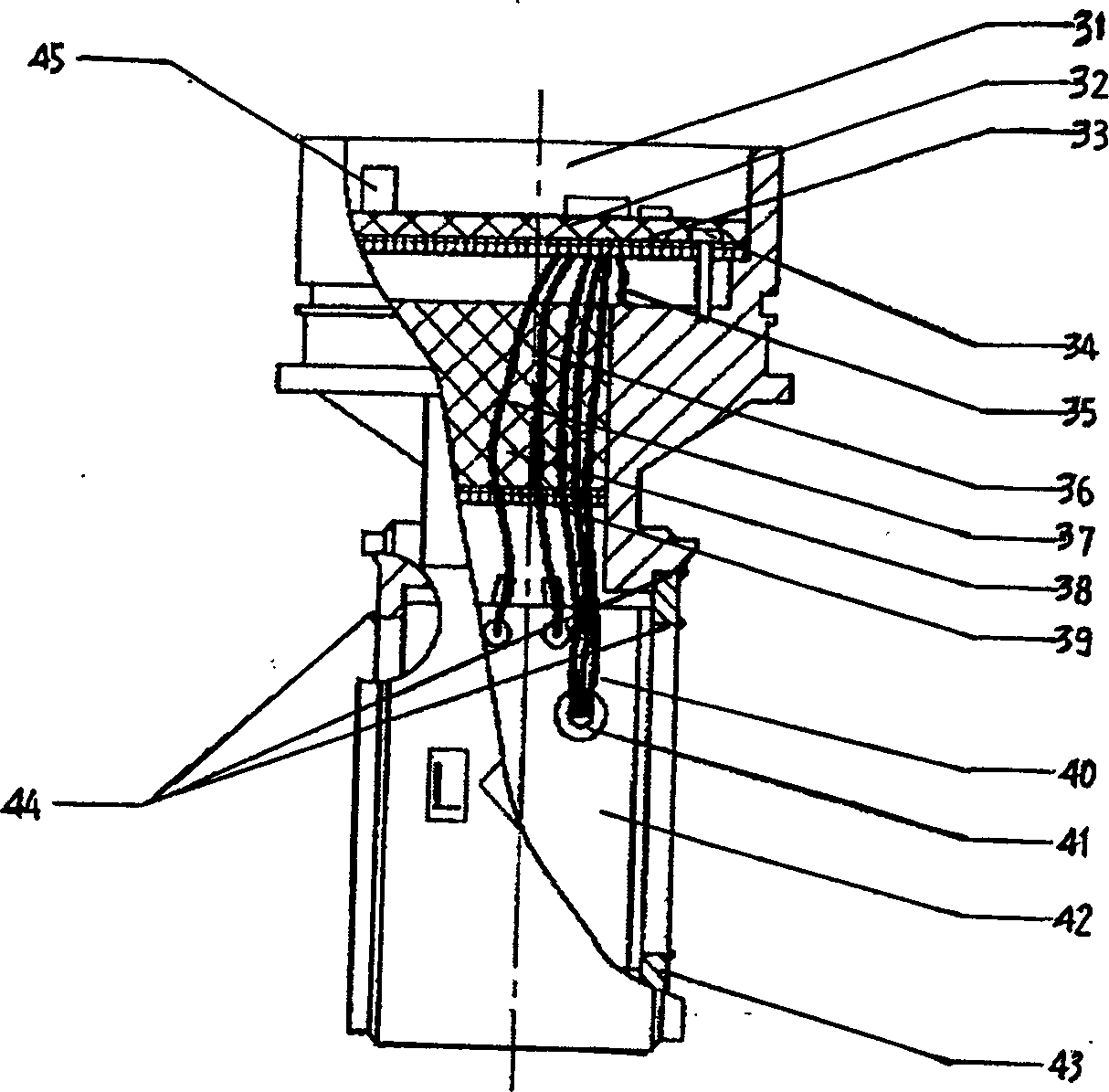

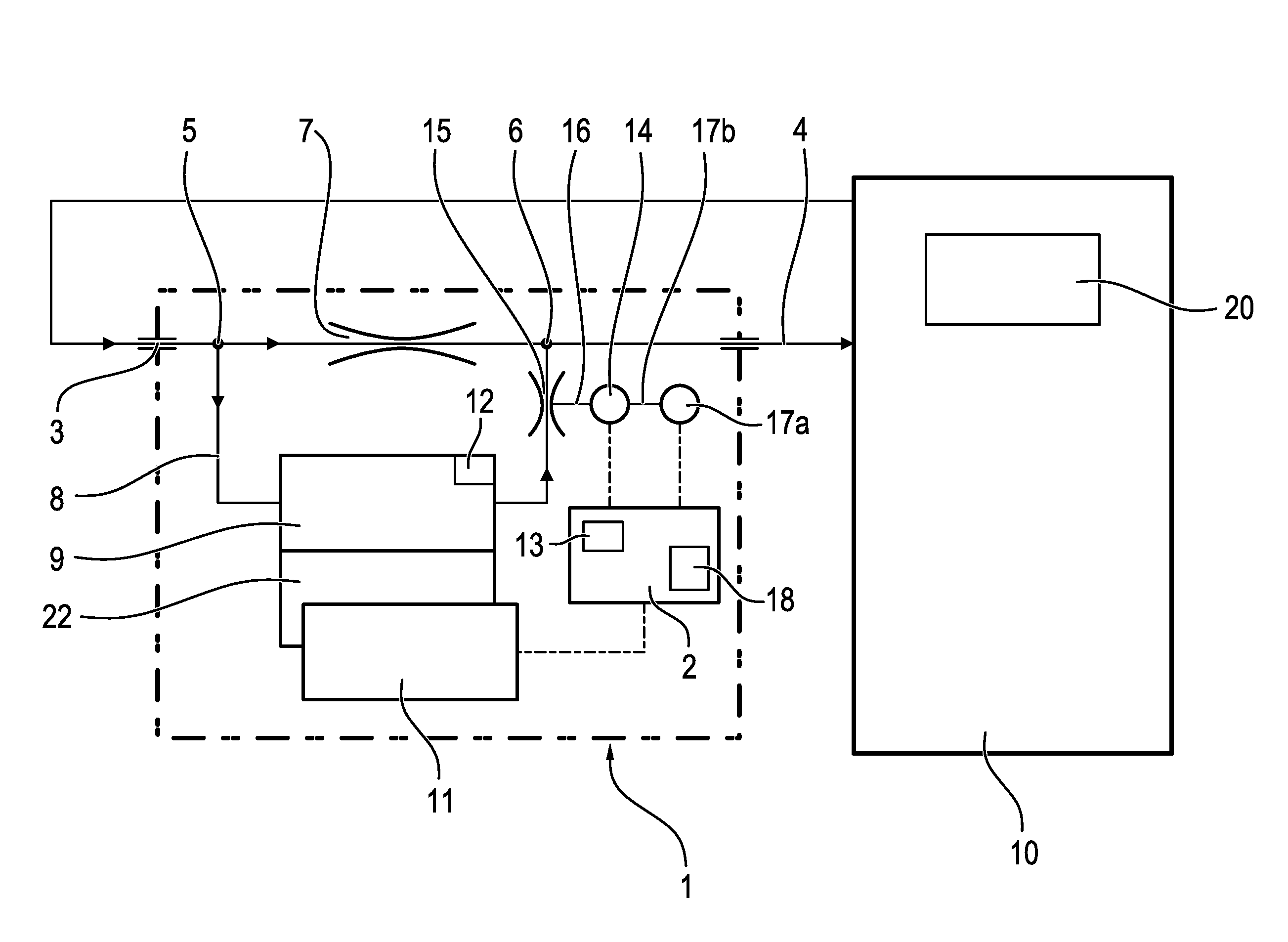

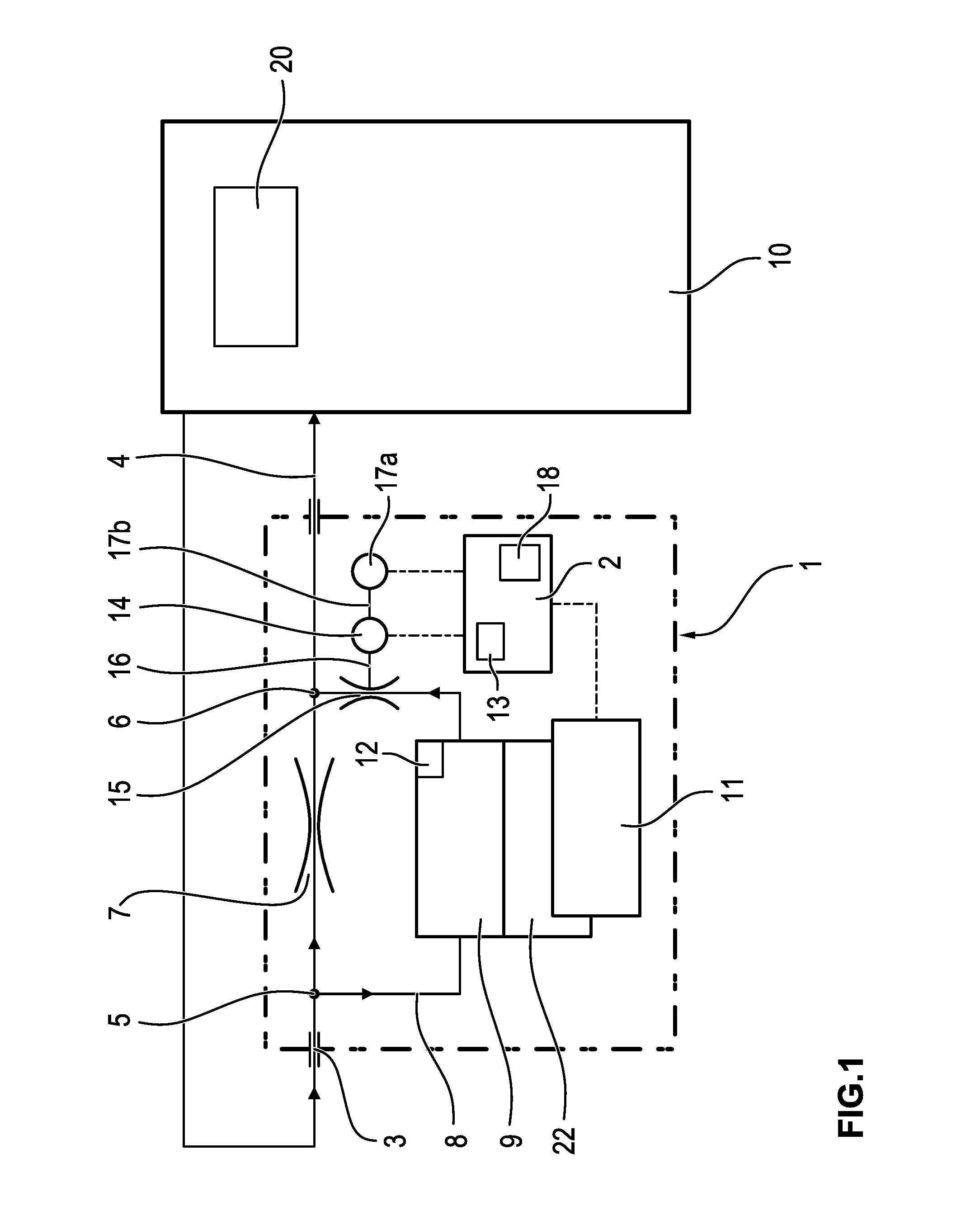

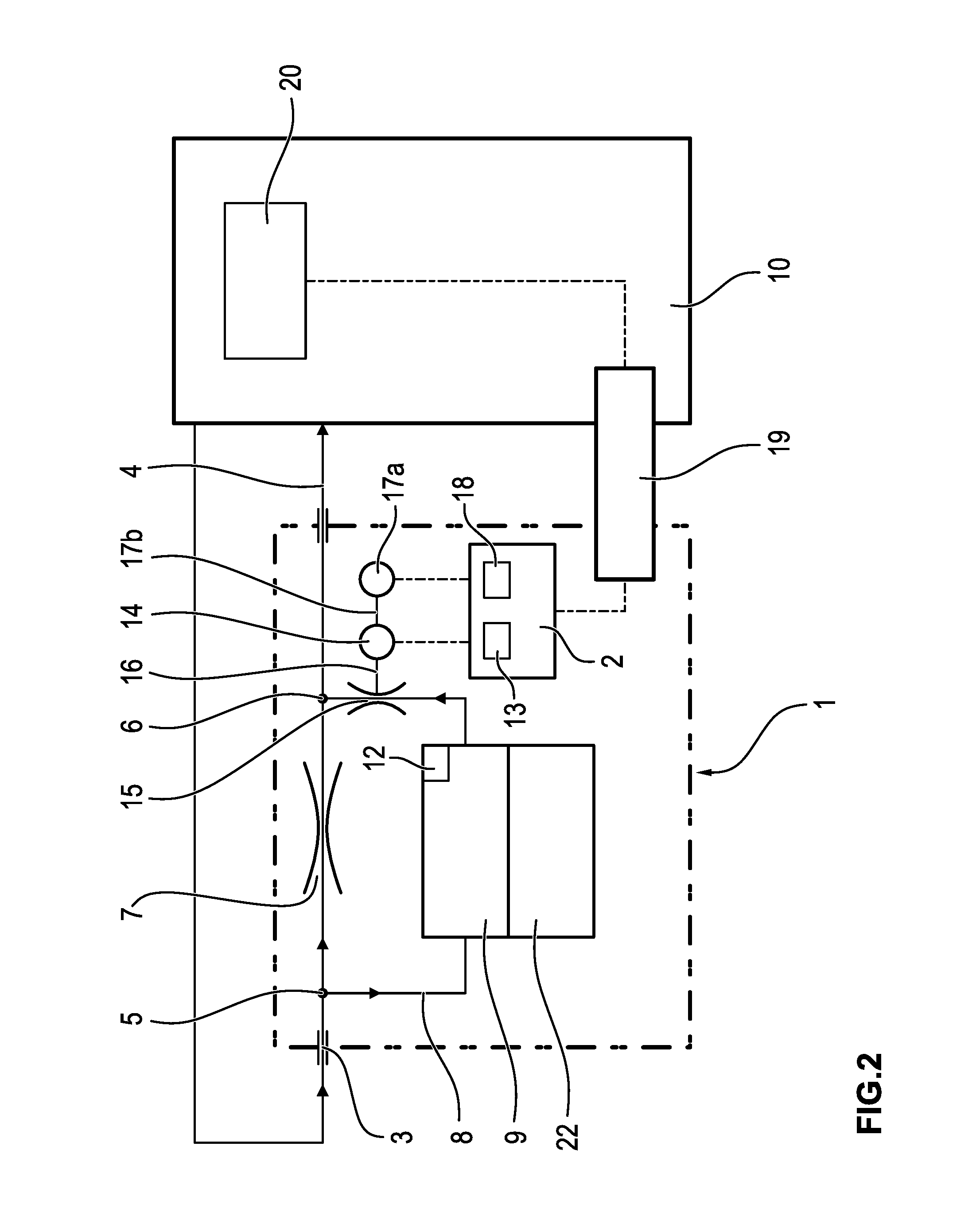

Anesthetic dispensing device

ActiveUS20160193441A1Accelerate evaporationIncrease in anesthetic concentrationRespiratorsMedical devicesControl signalAnesthetic gases

An anesthetic dispensing device (1), to which a carrier gas stream is fed for enriching with anesthetic, has the gas stream split into two partial gas streams, one of which flows through a bypass channel (7) unchanged and the other of which is fed to an evaporation chamber (9), where the partial gas stream is saturated with anesthetic. In a mixing point (6), both partial gas streams are mixed to form an anesthetic gas stream, which leaves the anesthetic dispensing device through the anesthetic gas outlet (4). A control unit (2) is provided that is configured to generate a control signal for an electric motor drive (14) for adjusting the valve opening of the valve element (15) on the basis of a concentration of the anesthetic in the anesthetic gas needed at the anesthetic gas outlet (4) and at least one temperature-specific correction factor.

Owner:DRAGERWERK AG

Semiconductor pressure sensor and manufacturing method thereof

InactiveUS20100218611A1High precision temperature compensationRemove the change in resistance valueFluid pressure measurement using ohmic-resistance variationFluid pressure measurement using elastically-deformable gaugesEngineeringForce sensor

A semiconductor pressure sensor includes a silicon substrate, an active gauge resistance forming portion having a first diaphragm and a first gauge resistance formed on the silicon substrate, and a dummy gauge resistance forming portion for temperature compensation having a second diaphragm and a second gauge resistance, formed on the substrate. The first diaphragm of the active gauge resistance forming portion and the second diaphragm of the dummy gauge resistance forming portion for temperature compensation are formed of a common polysilicon film. The polysilicon film has an anchor portion to be connected to the substrate. The first and second diaphragms have mutually identical or symmetrical structures and the first and second gauges have mutually identical or symmetrical structures. Accordingly, a semiconductor pressure sensor capable of highly accurate temperature compensation and manufacturing method thereof can be provided.

Owner:MITSUBISHI ELECTRIC CORP

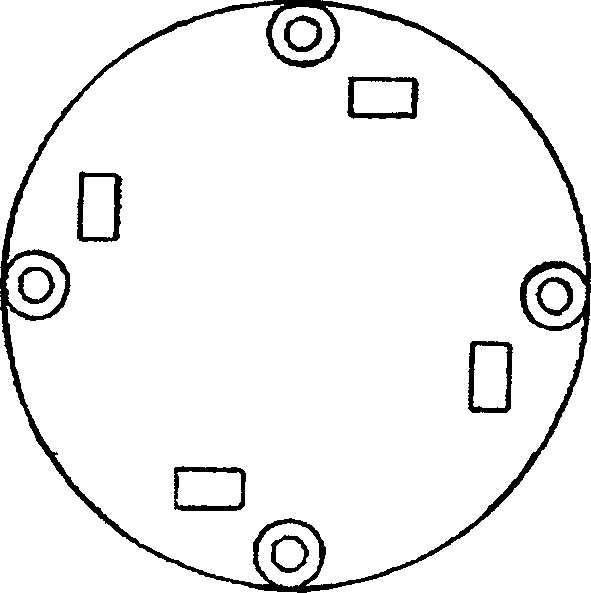

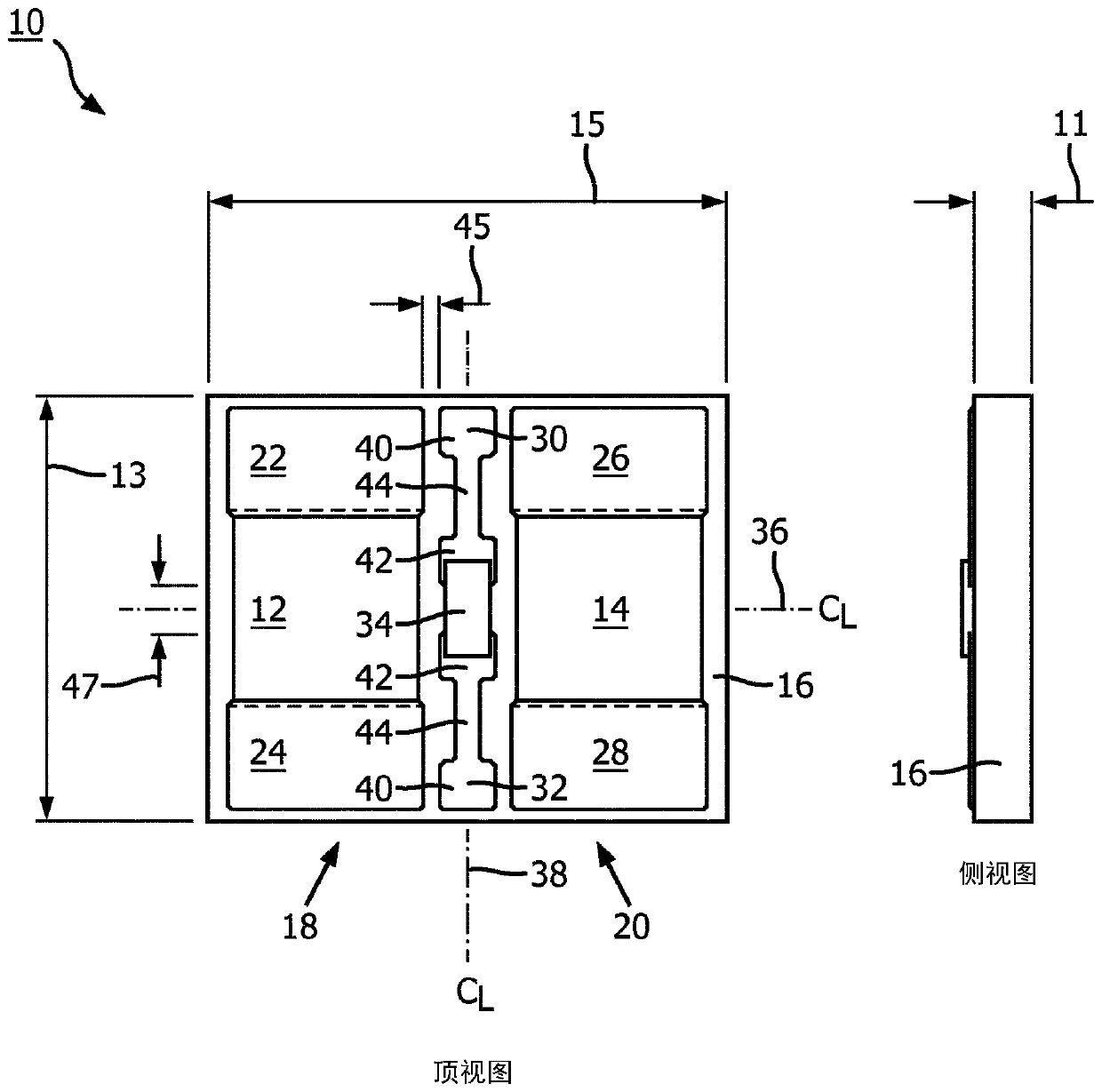

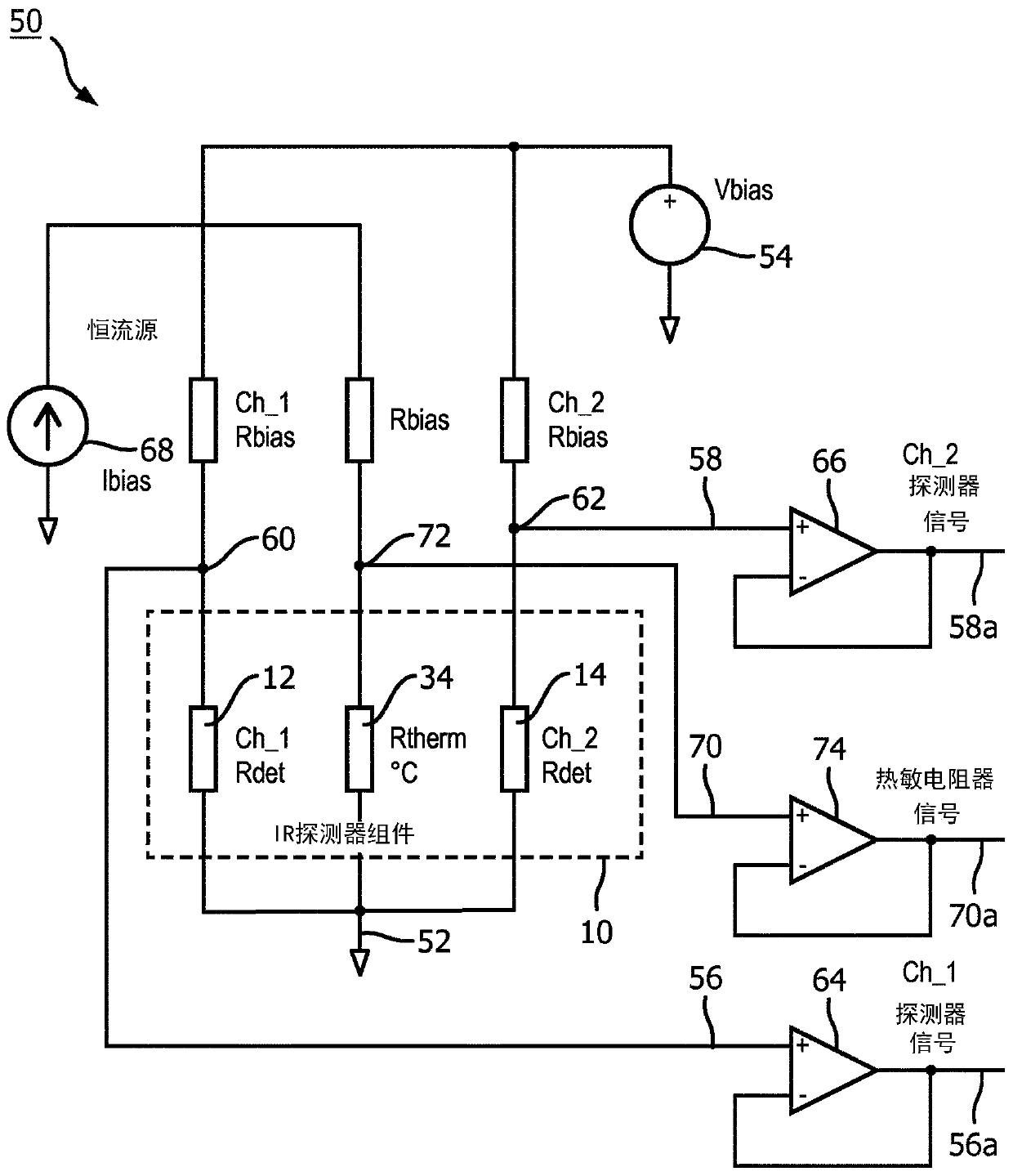

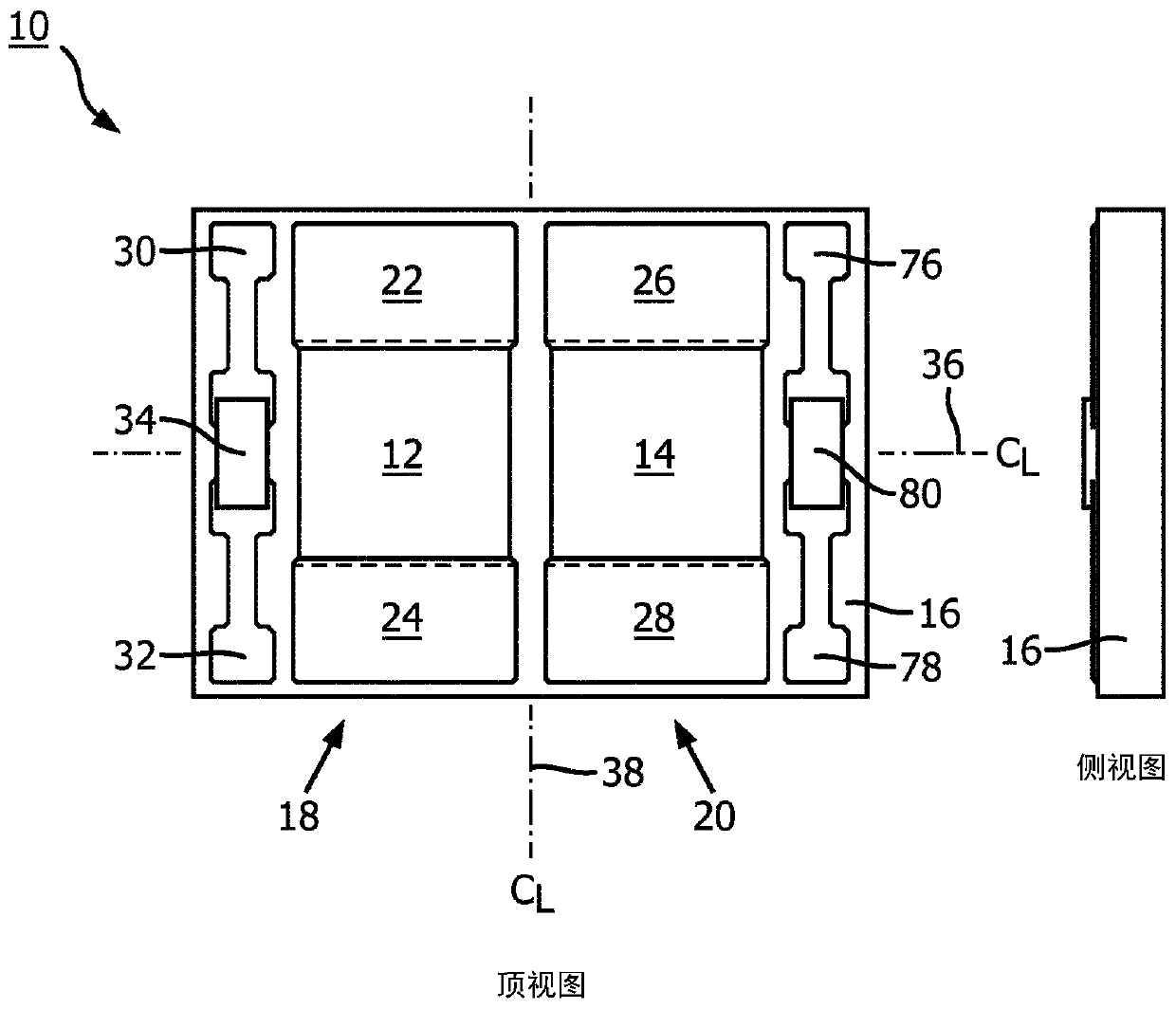

Infrared detector assembly with integrated temperature sensing, gas measurement apparatus and method

PendingCN111164414AEliminate driftAccurate measurementMaterial analysis by optical meansDiagnostic recording/measuringHeat lossesThermistor

A method of making an infrared detector assembly (10) with integrated temperature sensing comprises forming at least one IR sensitive element (12,14) on a substrate (16), and forming conductive electrode pads (22,24,26,28,30,32) for (a) an IR sensitive element and (b) at least one thermistor (34) on the substrate. The conductive electrode pads and the IR sensitive element are in a centerline symmetrical configuration in which the conductive electrode pads and the IR sensitive element, taken together, are centerline symmetrical about at least one axis (36,38) in a plane of the infrared detectorassembly, wherein the centerline symmetrical configuration is operable to reduce a thermal lag time between a temperature of the at least one thermistor and a temperature of the IR sensitive elementduring temperature transients. Each of first and second thermistor conductive electrode pads (30,32) has two pad end portions (40,42) spaced from each other and joined via a pad mid-portion (44) thatcomprises a thermal loss reduction member.

Owner:KONINKLJIJKE PHILIPS NV

Oscillation device

ActiveUS8581671B2Increase temperatureAccurate temperature compensationPulse automatic controlGenerator stabilizationQuartz crystal resonatorAtomic physics

Owner:NIHON DEMPA KOGYO CO LTD

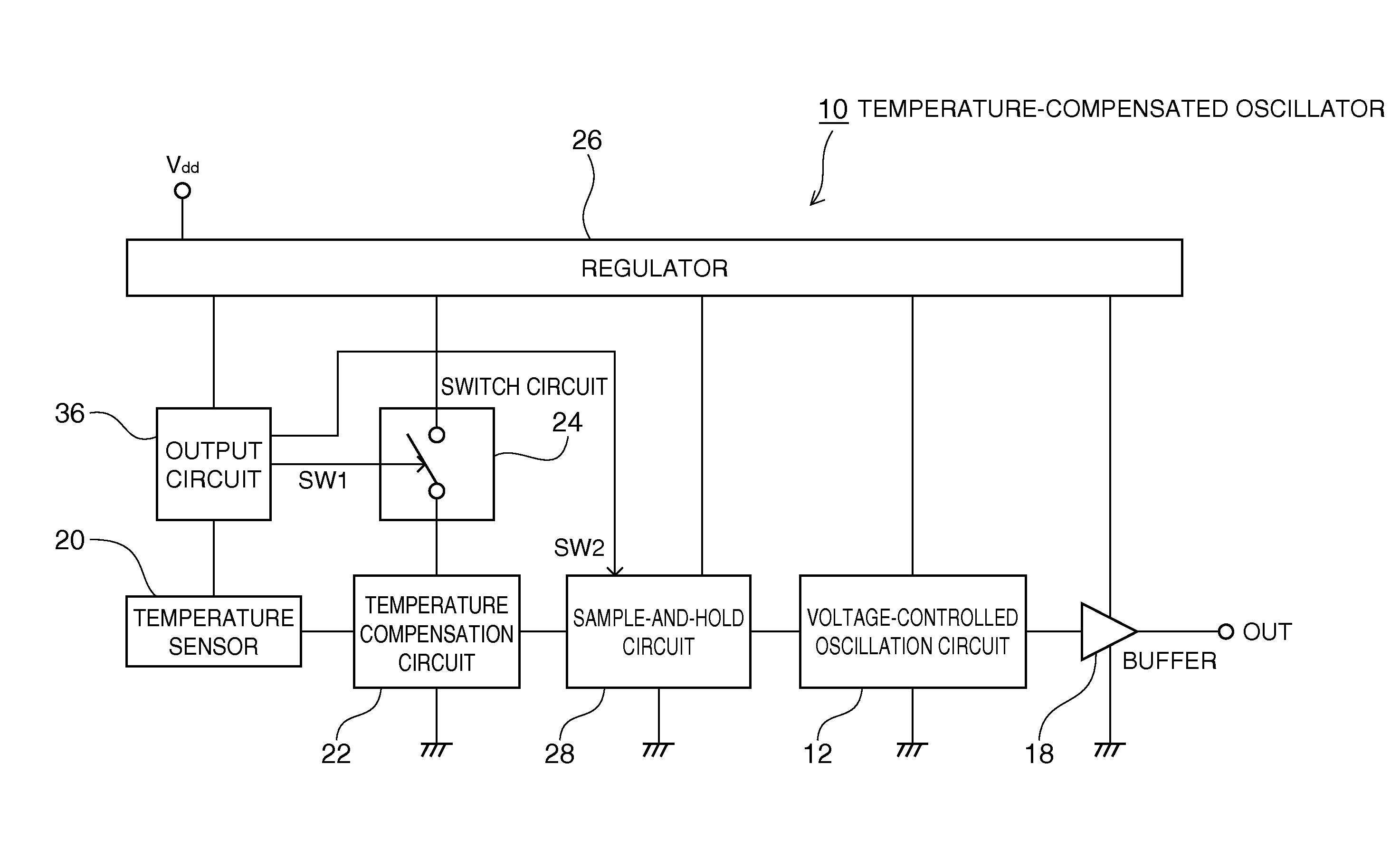

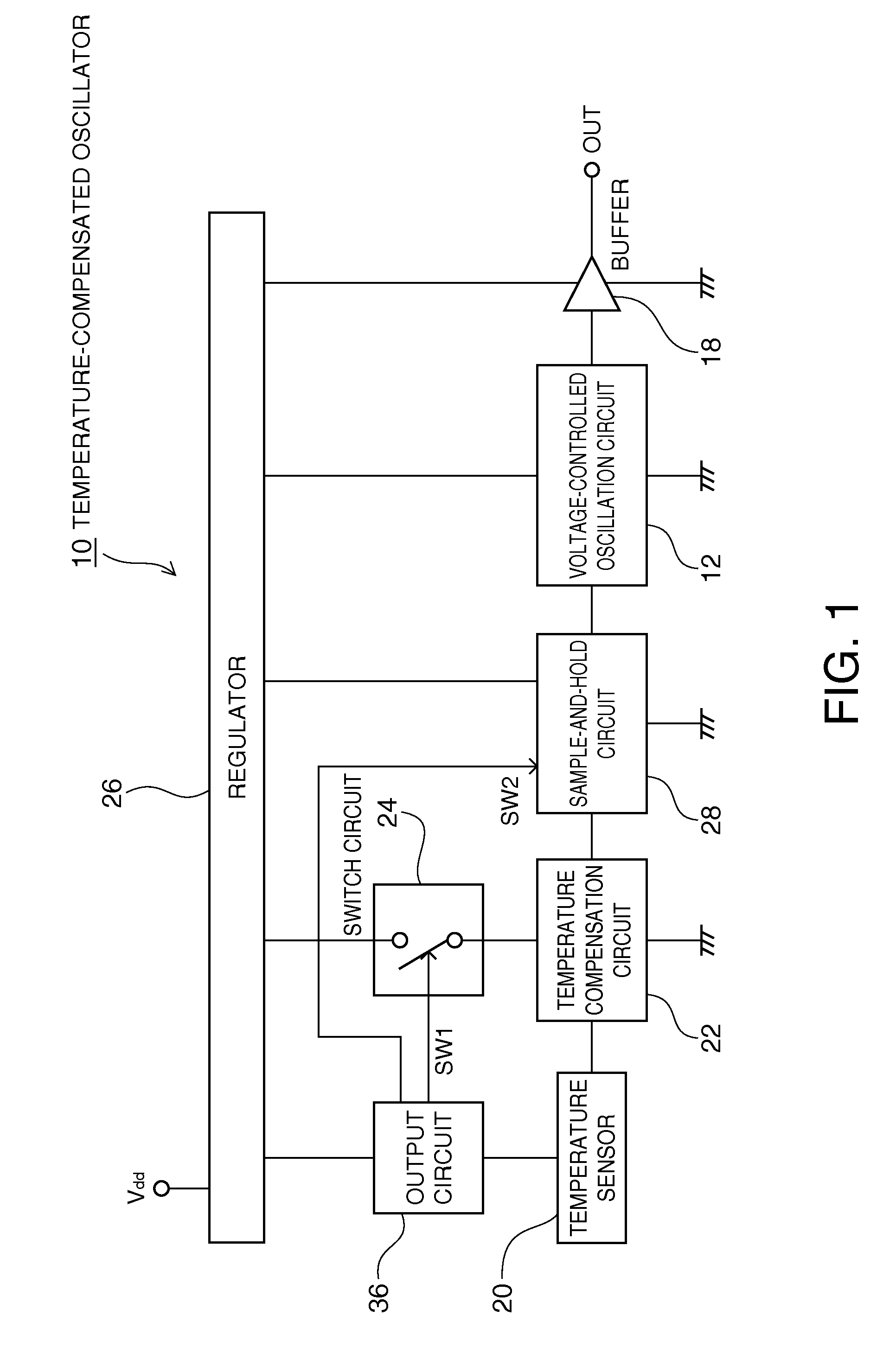

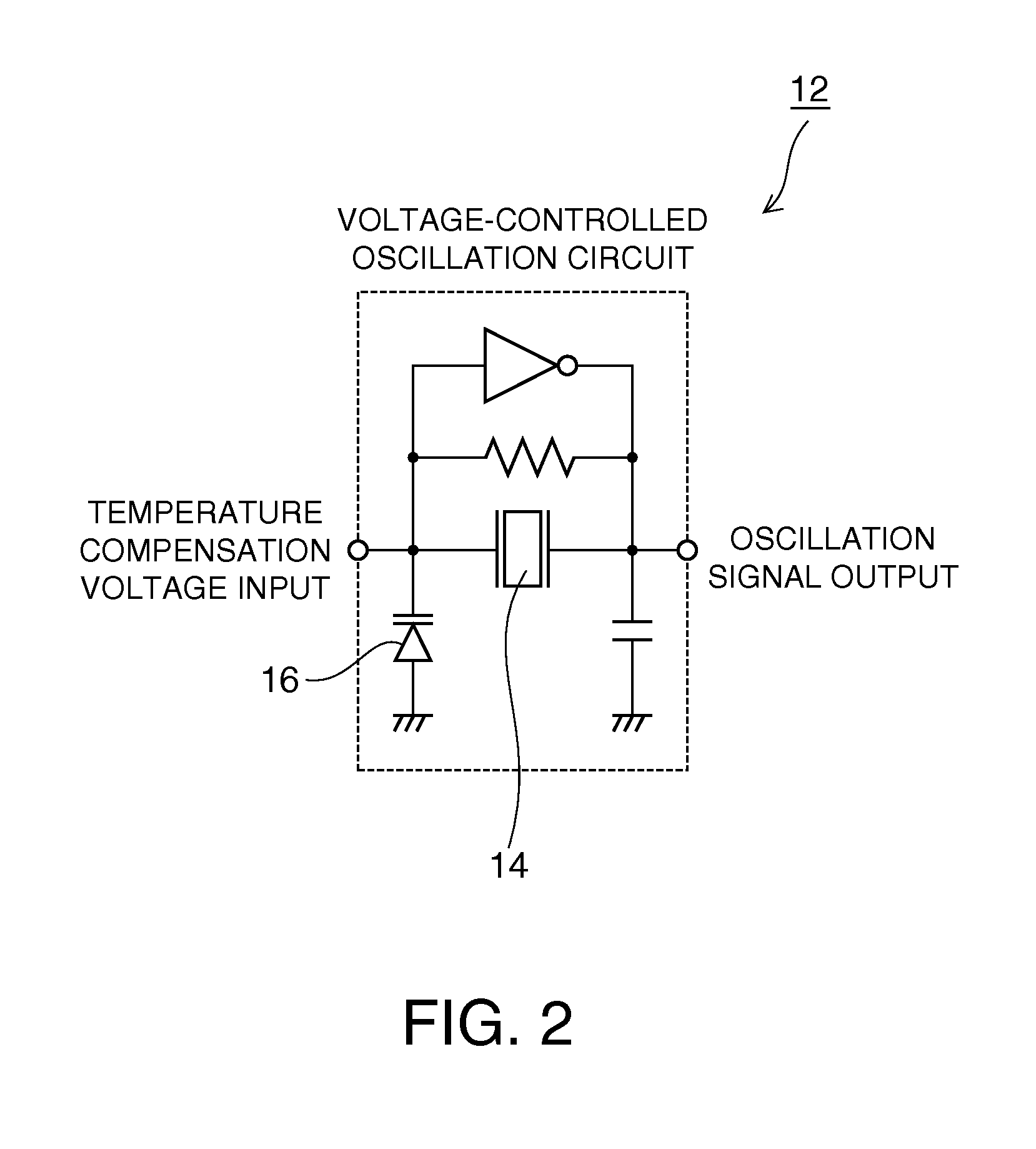

Temperature-compensated oscillator and electronic device

InactiveUS8680933B2Simple configurationReduce power consumptionGenerator stabilizationOscillations generatorsSignal onVoltage reference

A temperature-compensated oscillator includes a temperature sensor, a temperature compensation circuit, a voltage-controlled oscillation circuit adapted to output an oscillation signal on which temperature compensation is performed based on the temperature compensation voltage, an output circuit adapted to output an ON / OFF signal based on a relationship between variation of the detected-temperature voltage output by the temperature sensor and a reference voltage, a switch circuit adapted to supply the temperature compensation circuit with electrical power in response to the ON / OFF signal, and a sample-and-hold circuit adapted to be switched between a state of outputting the temperature compensation voltage to the voltage-controlled oscillation circuit while holding the temperature compensation voltage output by the temperature compensation circuit, and a state of outputting the temperature compensation voltage held to the voltage-controlled oscillation circuit while cutting the connection to the temperature compensation circuit in response to the ON / OFF signal.

Owner:SEIKO EPSON CORP

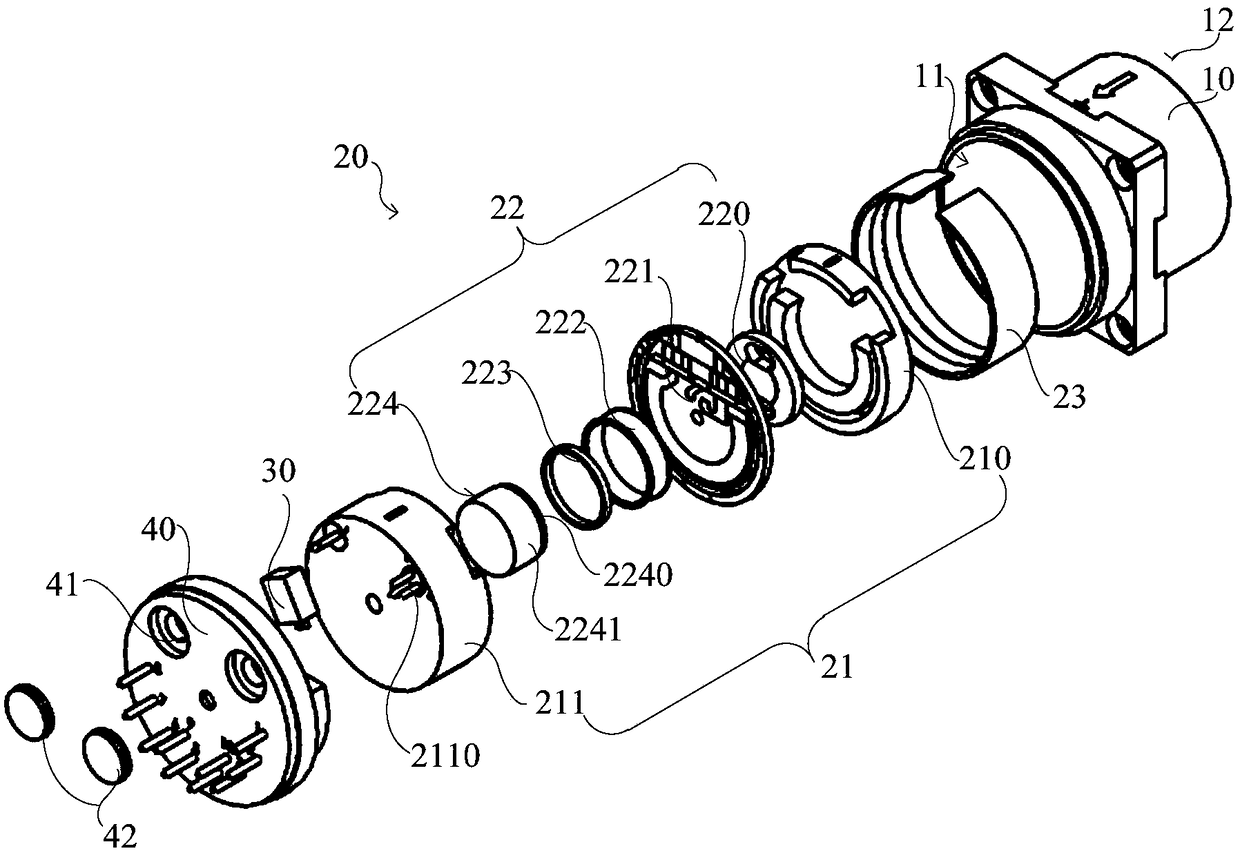

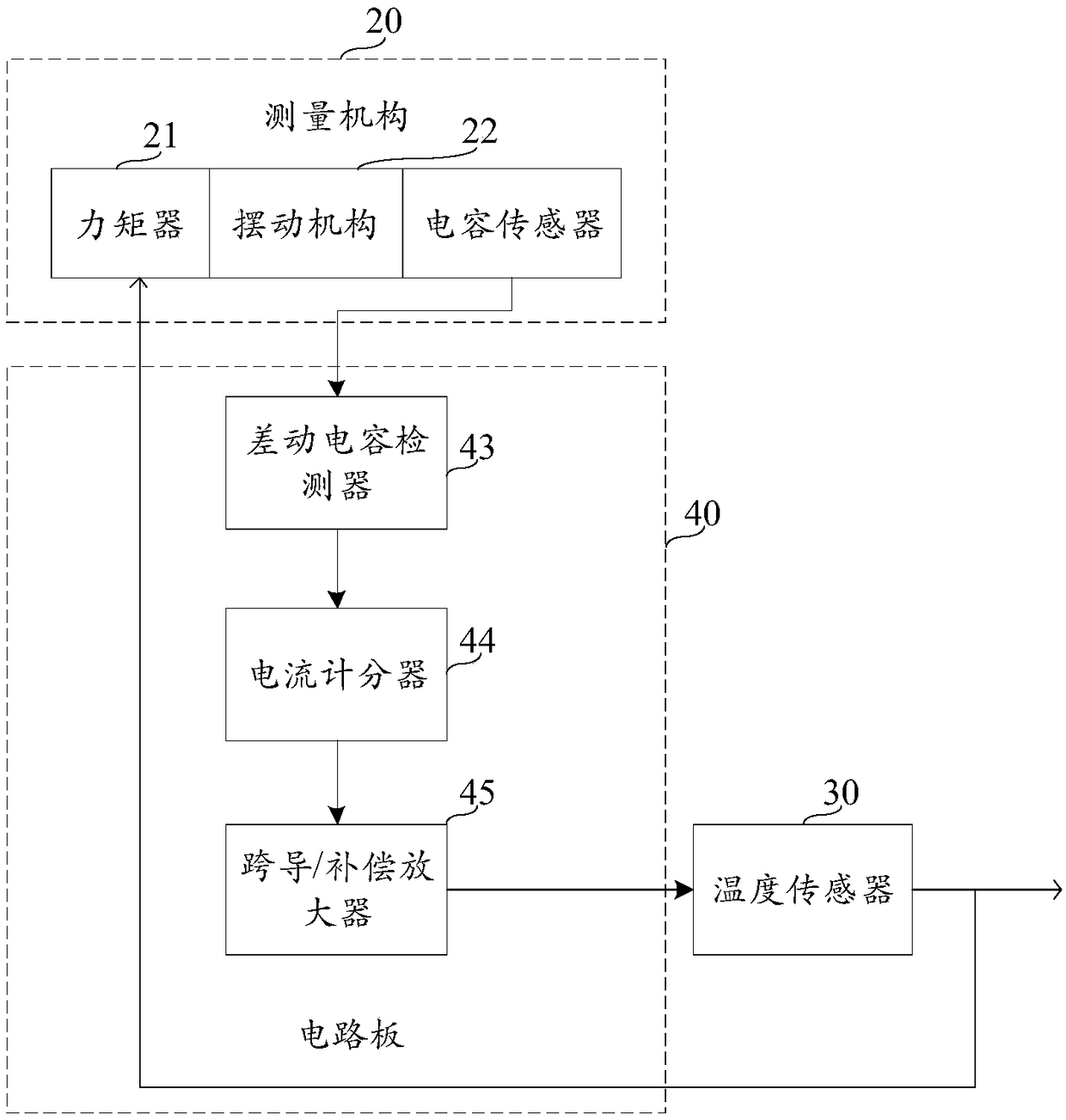

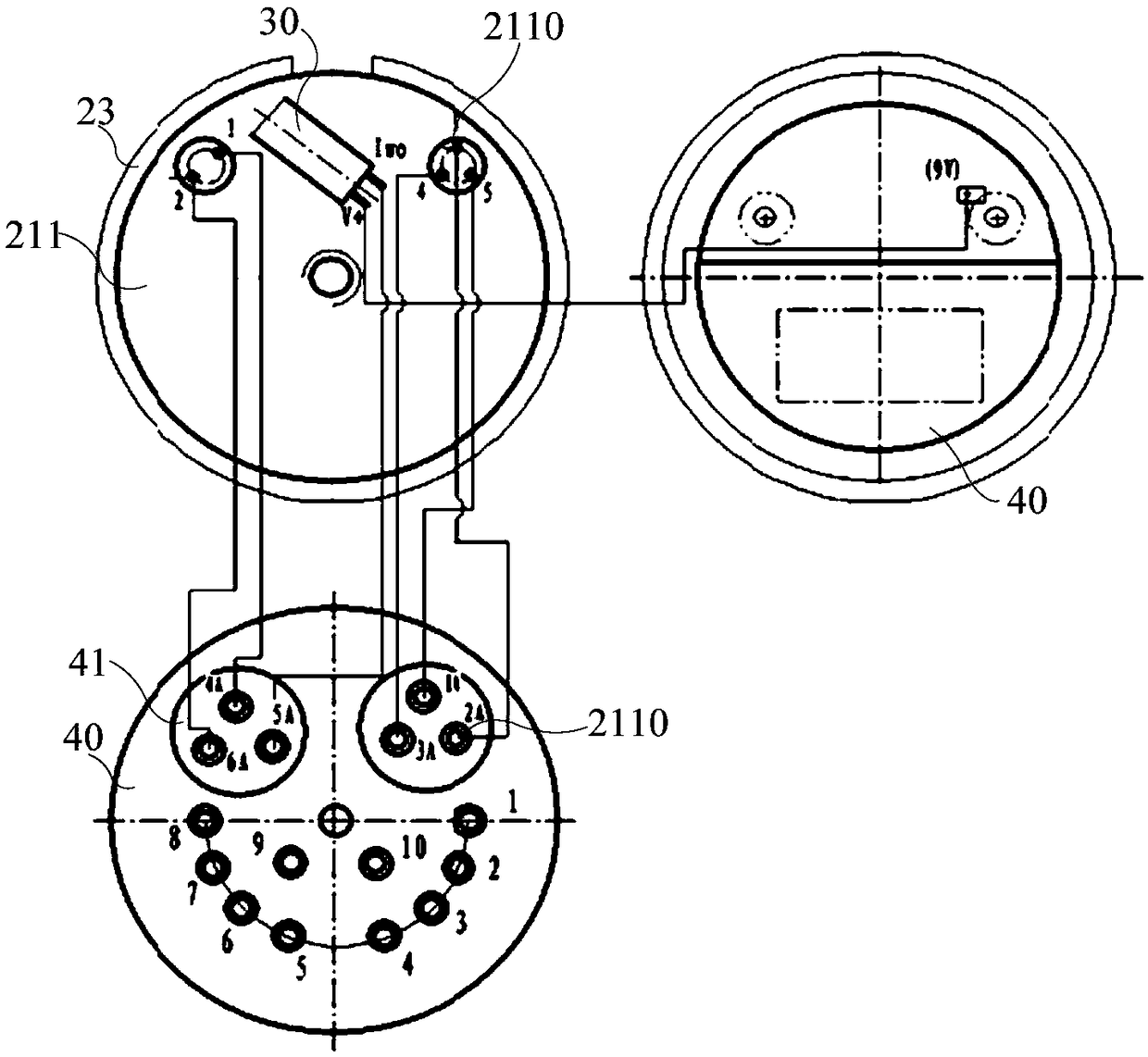

Accelerometer

InactiveCN109239402AHigh measurement accuracyAccurate measurementAcceleration measurementAccelerometerBiochemical engineering

The embodiment of the invention provides an accelerometer comprising a shell, a measurement mechanism, a temperature sensor and a circuit board, wherein an opening is formed in one end of the shell, and the other end of the shell is a closed end; the measurement mechanism is arranged in the shell, and fixedly connected with the shell; the temperature sensor is arranged on one side, far away from the closed end, of the measurement mechanism; the circuit board is arranged on one side, far away from the closed end, of the temperature sensor, and connected with the opening. According to the accelerometer provided by the embodiment of the invention, the temperature sensor is arranged in the accelerometer, the temperature in the accelerometer can be accurately measured, the accurate temperaturecompensation can be provided for acceleration measured by the accelerometer, and the measurement accuracy of the accelerometer can be improved.

Owner:AVIC SHAANXI HUAYAN AERO INSTR

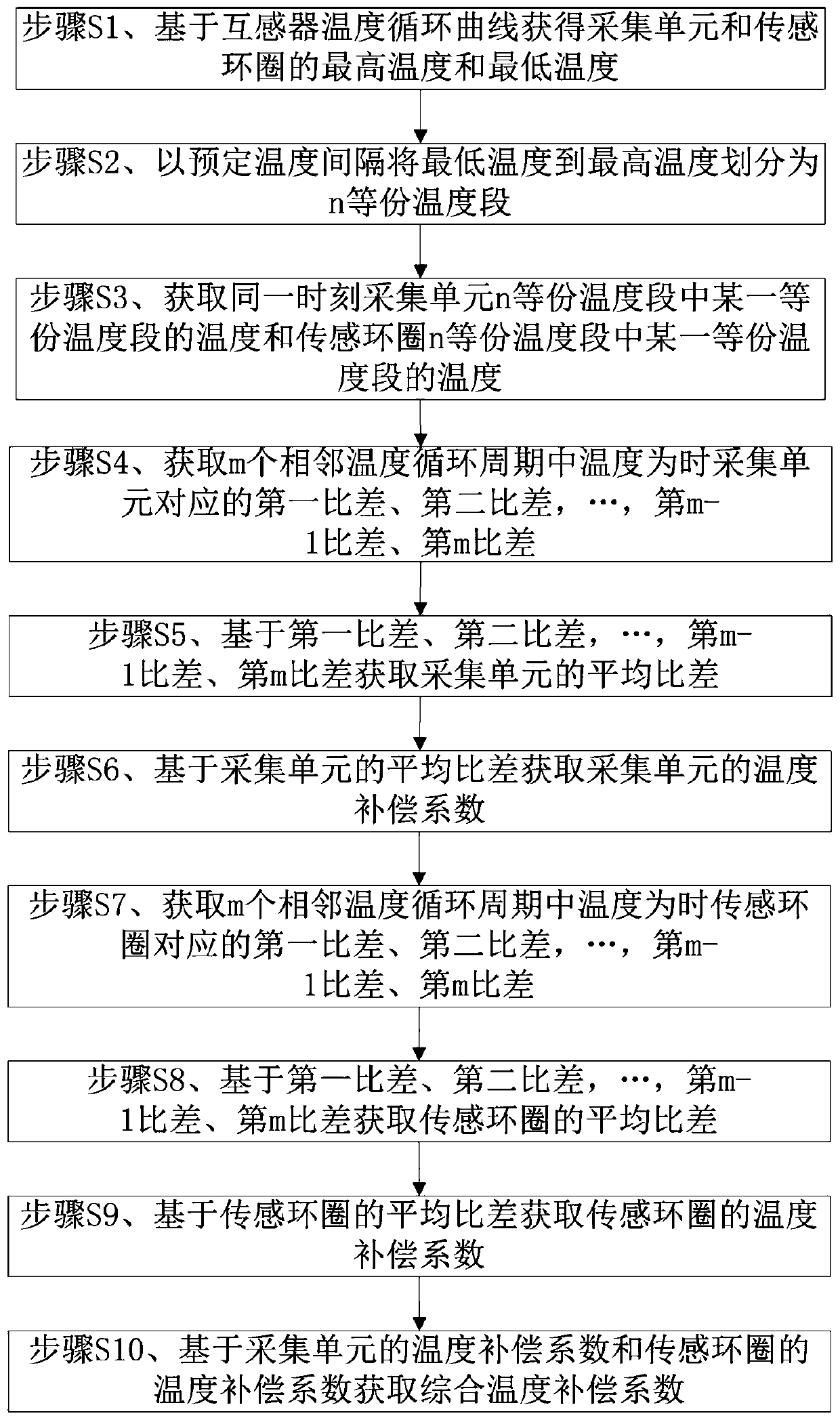

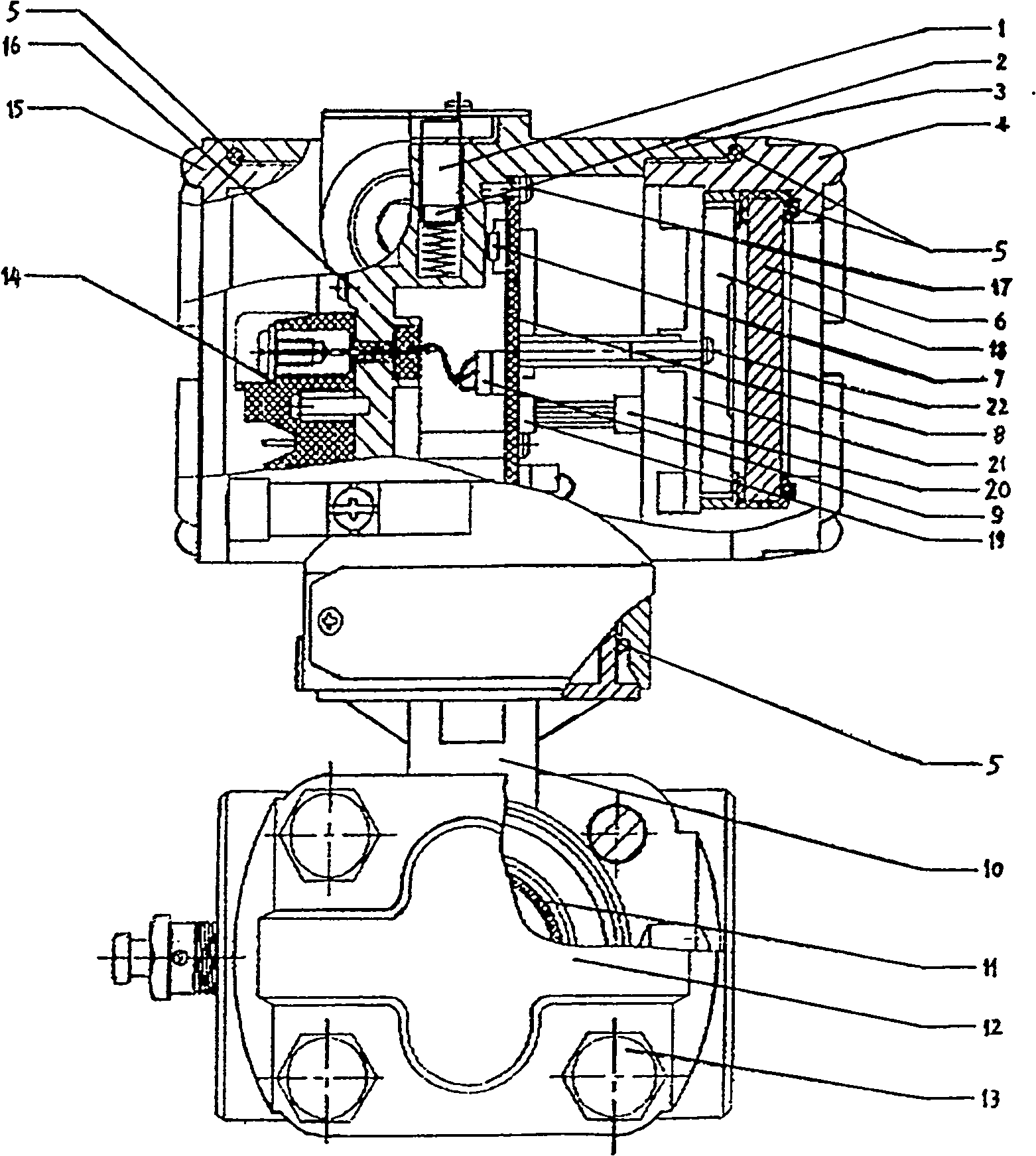

Method for precise temperature compensation of optical fiber current transformer

InactiveCN110988452AOvercoming Compensation Error ProblemsAccurate temperature compensationCurrent/voltage measurementVoltage/current isolationPhysicsEngineering

The invention provides a method for precise temperature compensation of an optical fiber current transformer. The method comprises the following steps: obtaining the highest temperature and the lowesttemperature of an acquisition unit and a sensing ring; dividing the temperature from the lowest temperature to the highest temperature into n equal temperature sections at a preset temperature interval; acquiring the temperature of the acquisition unit and the temperature of the sensing ring at the same moment; acquiring a first ratio difference, a second ratio difference-an (m-1) th ratio difference and an mth ratio difference corresponding to the acquisition unit when the temperature in m adjacent temperature cycle periods is T1; acquiring a temperature compensation coefficient of the acquisition unit; obtaining a first ratio difference, a second ratio difference-an (m-1) th ratio difference and an mth ratio difference corresponding to the sensing ring when the temperature is T2 in m adjacent temperature cycle periods; obtaining a temperature compensation coefficient of the sensing ring; obtaining comprehensive temperature compensation coefficients. According to the technical scheme, the technical problem that in the prior art, the temperature compensation effect is not ideal due to the fact that temperature fields of a sensing ring and an acquisition unit in an optical fiber current transformer are inconsistent is solved.

Owner:BEIJING AUTOMATION CONTROL EQUIP INST

Miniaturized intelligent differential pressure / pressure transmitter

ActiveCN100416250CEasy to produceGood adjustment functionFluid pressure measurement using capacitance variationCapacitanceDifferential pressure

The invention discloses a small intelligent differential pressure / pressure transducer, where there is an electronic box sealed and fixed at the upper part of a sensor component, the lower part of the sensor component provided with pressurized seal ring is fixed with a pressure flange component, the sensor component is provided with a capacitance differential pressure sensor and a temperature sensor under a chamber, there is a group of protective rings and welded rings outside the two sensors, there are terminals in the left cavity of the electronic box, the top end of the left cavity is provided with a magnetic button, there is a printed circuit board (PCB) in the right cavity of the electronic box, and the PCB is mounted with dry reed tube and connected with a display. It can be widely applied to the departs such as chemical, petroleum, metallurgy and circuit boards, for measuring the thermal basic parameters such as pressures, liquid levels and differential pressures of liquids, gases and steams.

Owner:SHANGHAI AUTOMATION INSTRAION CO LTD

OLED panel temperature compensation system and OLED panel temperature compensation method

ActiveUS10748478B2Accurate temperature compensationThermometer detailsStatic indicating devicesData signalEngineering

The invention provides an OLED panel temperature compensation system and method. The system comprises an OLED panel and a processing module connected to the OLED panel, the OLED panel is disposed with a temperature sensor layer of a plurality of temperature sensors on one side or inside; when performing temperature compensation, the temperature sensor detects the temperature of the location and transmits to the processing module, the processing module receives and processes the initial data signals of the plurality of sub-pixels to obtain the to-be-displayed brightness of the plurality of sub-pixels, and receives and processes the temperatures from the plurality of temperature sensors to obtain the temperatures of the plurality of sub-pixels, and generates and outputs compensation data signals corresponding to the plurality of sub-pixels according to the to-be-displayed brightness and temperature of the plurality of sub-pixels. The OLED panel is thus accurately and effectively compensated for temperature.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

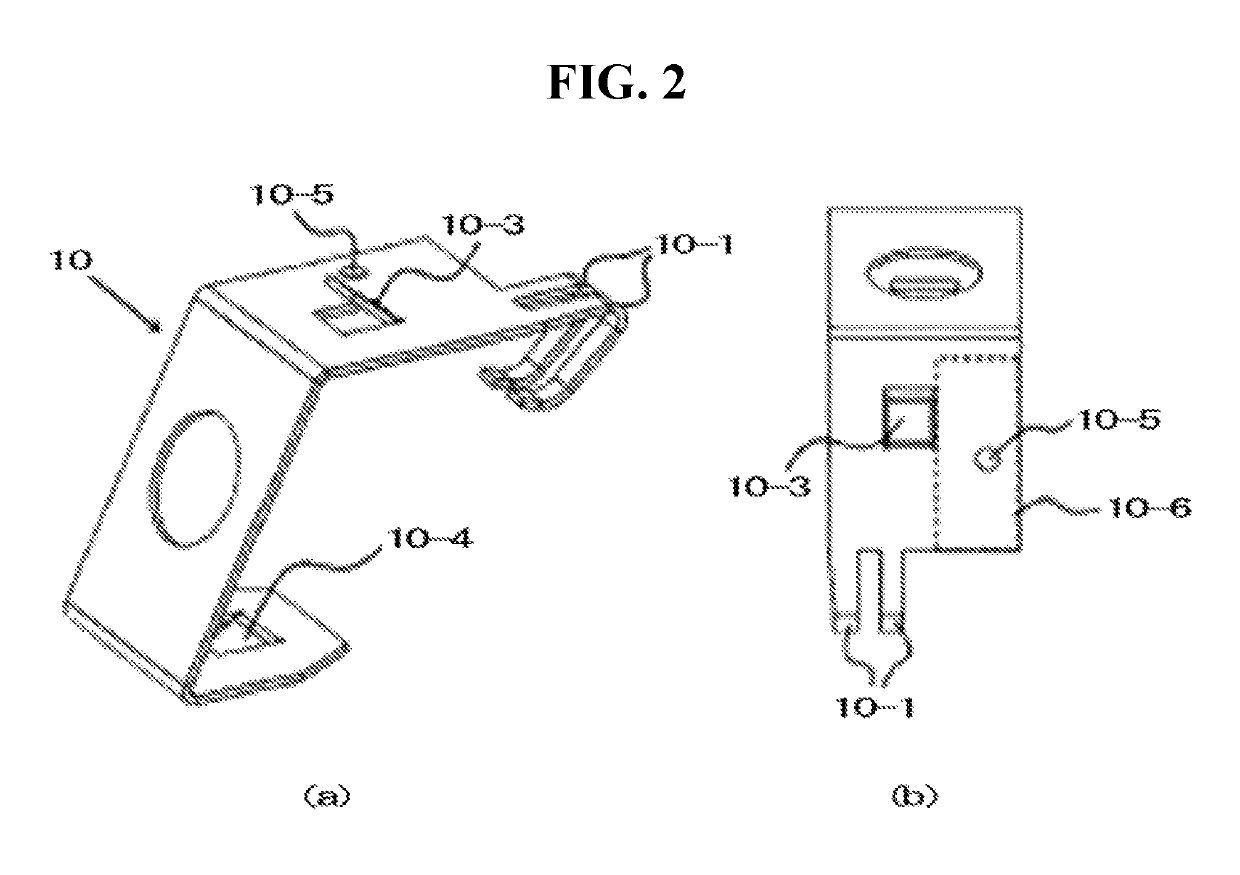

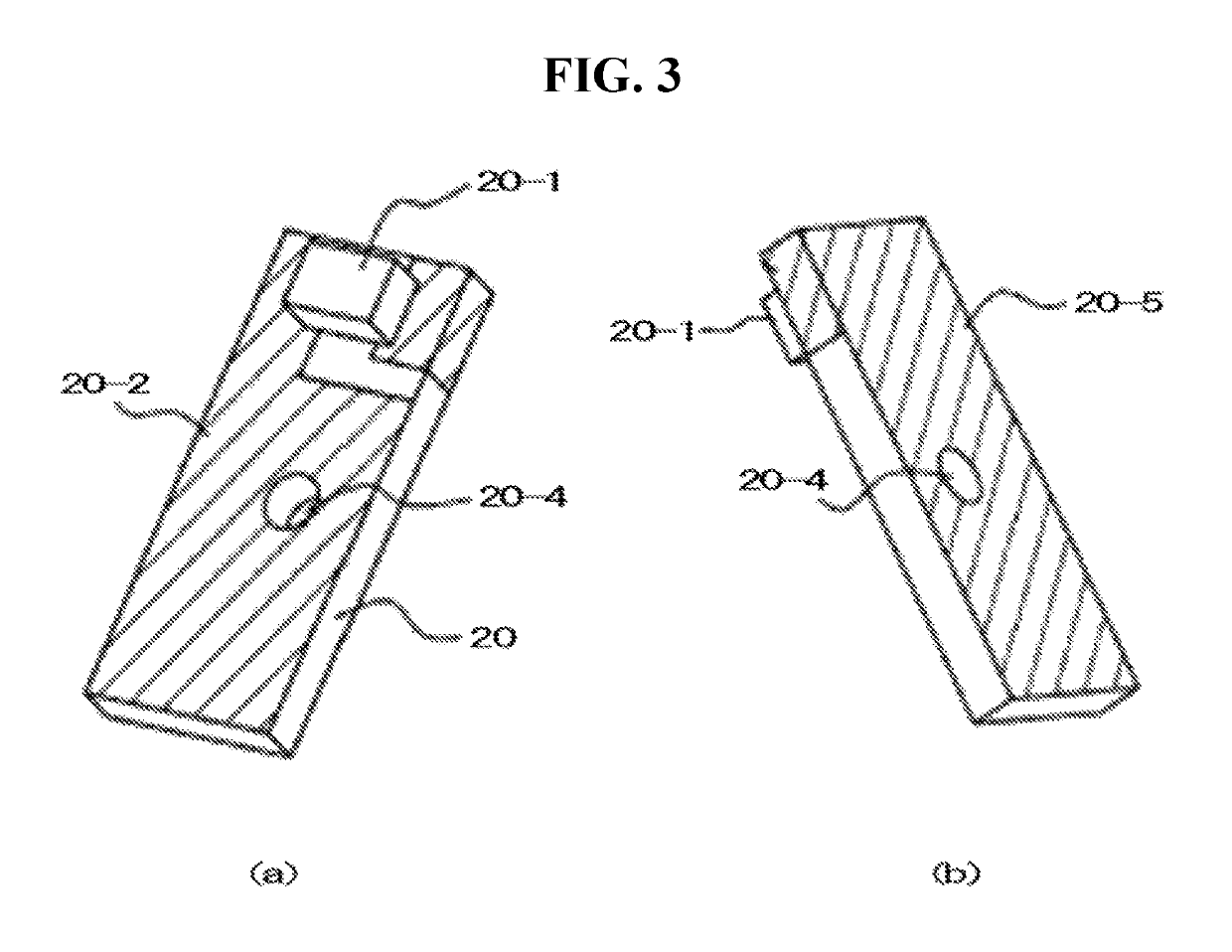

Terminal board for temperature compensation of thermocouple

ActiveUS10281339B2Simple structureAccurate temperature compensationThermometer detailsThermometers using electric/magnetic elementsEngineeringTerminal unit

The present invention provides a terminal board for temperature compensation of a thermocouple, the terminal board comprising: -shaped terminal unit for connecting a compensation lead wire of the thermocouple to a PCB contact terminal connected to a control circuit of a circuit board so as to allow accurate temperature compensation of the thermocouple, the terminal unit having a pair of curved connection pins; a small-sized compensation sensor PCB which has a chip type temperature sensor for compensation at one end of the upper side thereof, an upper soldering surface which is soldered to a sensor pin unit for electrically connecting an output of the temperature sensor for compensation, and a lower soldering surface which is soldered to the terminal unit; and an L-shaped sensor pin unit for soldering the compensation sensor PCB together with the terminal unit, the sensor pin unit having a pair of rounded connection pins for contact-connection of the output of the temperature sensor for compensation to the temperature compensation sensor of the circuit board.

Owner:AUTONICS

Multi-parameter sensor for measuring differential pressure/pressure/temperature

ActiveCN100545583CEasy to upgradeAccurate Static Pressure CompensationFluid pressure measurement using ohmic-resistance variationThermometers using electric/magnetic elementsDifferential pressureEngineering

The invention discloses a multi-parameter sensor for simultaneous measurement of differential pressure, pressure and temperature. The piezoresistive static pressure sensor and the high-precision integrated temperature measurement chip that detects the digital output of the sensor itself and the temperature of the medium in contact with it. The three sensors are used to detect various parameters such as differential pressure, pressure, and temperature. It has the characteristics of small and exquisite appearance, light weight, and is easy to manufacture by conventional methods. Transmitters with different functions manufactured on this basis can be widely used in chemical industry, petroleum, metallurgy, power station and other departments to measure the pressure, liquid level, differential pressure, flow and other thermal engineering basics of liquid, gas and steam. parameters, can have a variety of compensation characteristics, and has a good development space.

Owner:SHANGHAI AUTOMATION INSTRAION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com