Replaceable high-anti-fatigue fiber grating strain sensor

A strain sensor and optical fiber strain technology, which is applied to instruments, optical devices, measuring devices, etc., can solve the problems of non-replacement and difficult maintenance of optical fiber strain sensors, and achieve the effect of avoiding sensor failure, accurate temperature compensation, and prolonging use time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0035] In order to achieve the purpose of the present invention, in some embodiments of a replaceable high-fatigue fiber grating strain sensor,

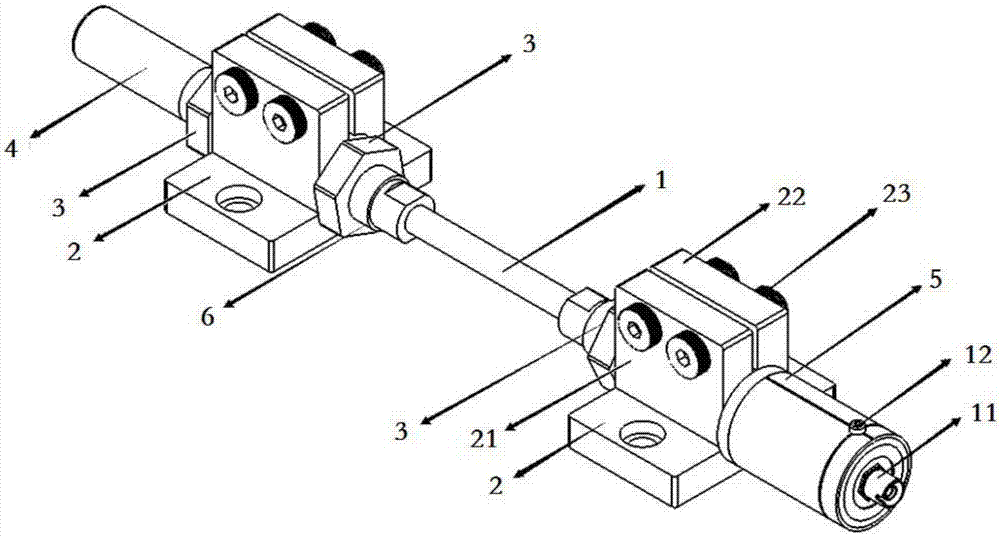

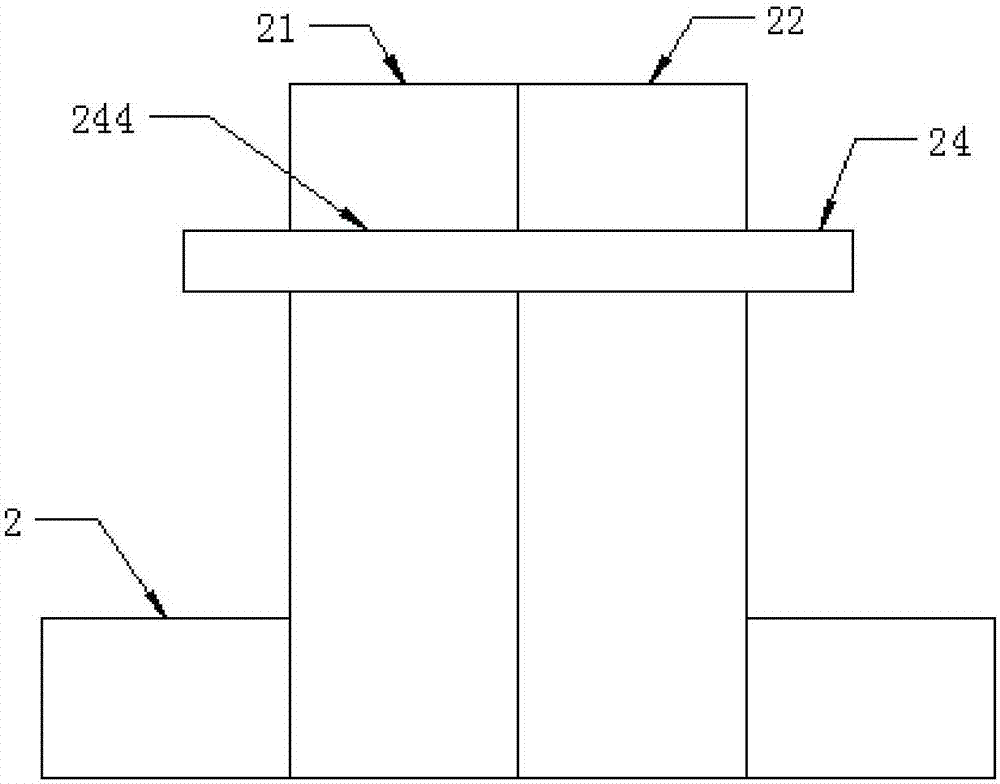

[0036] like figure 1 As shown, a replaceable high-fatigue fiber grating strain sensor includes: a central sensing element 1 , an anchor assembly, two sensor bases 2 arranged in pairs, and a position adjusting element 3 .

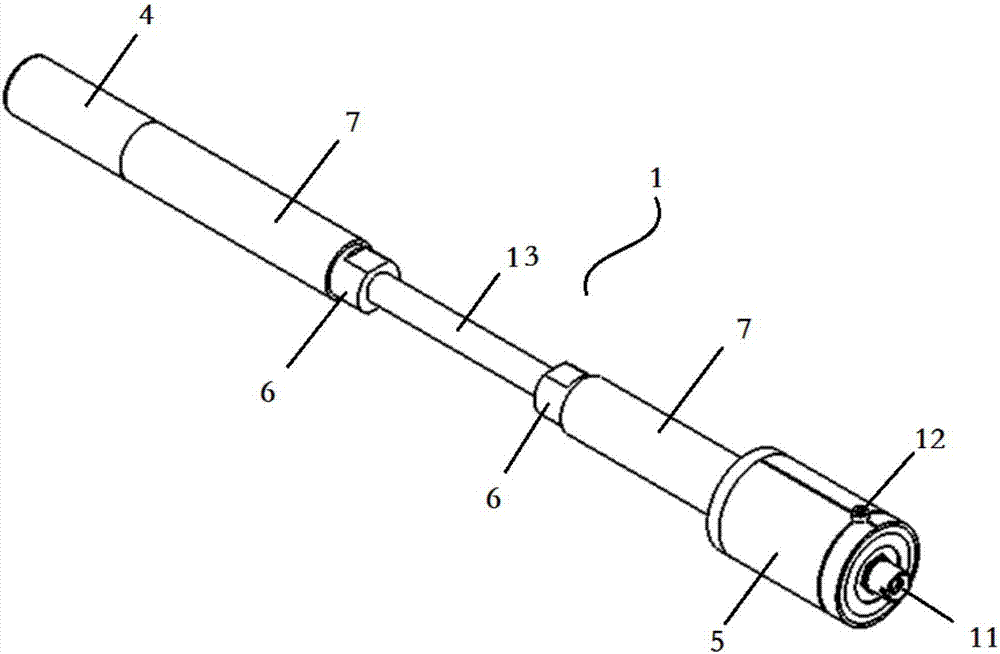

[0037] like figure 2 As shown, the central sensing element 1 is a sensing element 13 compounded with fiber gratings, and an optical fiber quick interface 11 is connected to the output end of the central sensing element 1 .

[0038] The anchoring assembly includes a tail anchoring cylinder 4, an end anchoring cylinder 5 and an outer anchor 6 of the anchor head. The outer anchor member 6 of the anchor head is sleeved in the middle area of the central sensing member.

[0039...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com