Closed-loop temperature compensation method and device for clock crystal oscillator

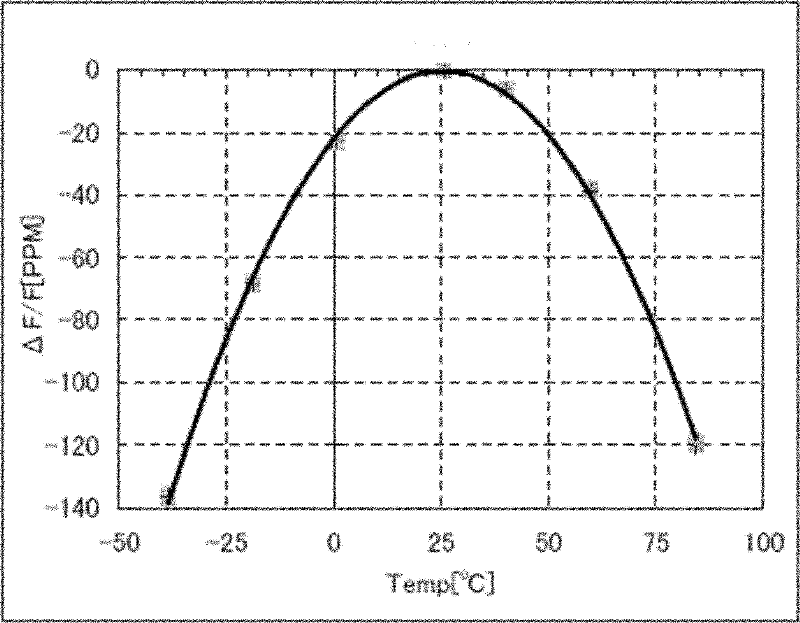

A technology of crystal oscillator and temperature compensation, applied in power oscillators, electrical components, etc., can solve the problems of inaccurate compensation results and inability to guarantee compensation results, and achieve the effects of low cost, accurate temperature compensation, and small system volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

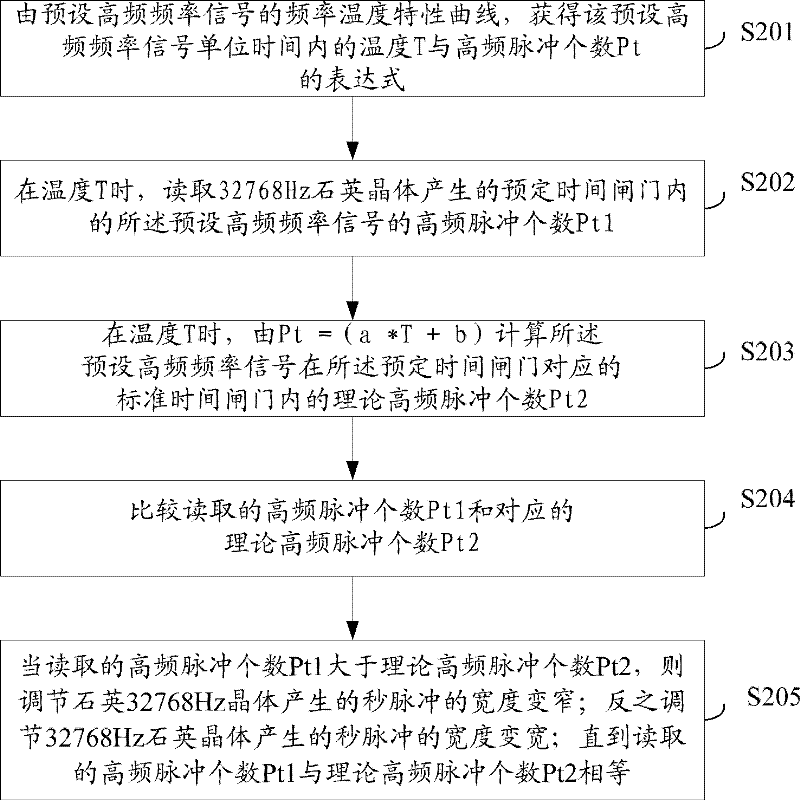

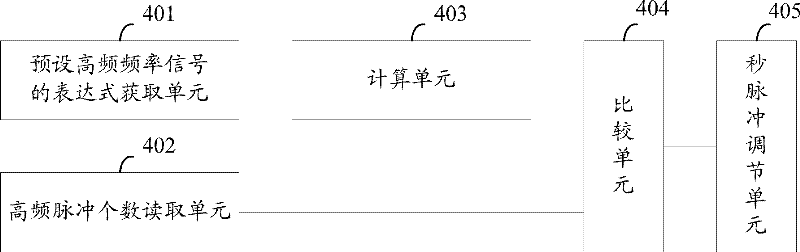

Method used

Image

Examples

Embodiment Construction

[0039] In order to enable those skilled in the art to better understand and implement the technical solution of the present invention, several technical terms related to the present invention are introduced below.

[0040] Quartz crystal oscillator: It is a resonant device made by using the piezoelectric effect of a quartz crystal (crystal of silicon dioxide). Its basic composition is roughly: cut a thin slice (abbreviated as a wafer) from a quartz crystal at a certain azimuth angle. , it can be square, rectangular or circular, etc.), coat its two corresponding surfaces with a silver layer as electrodes, solder a lead on each electrode and connect it to the pin, plus the package shell A quartz crystal resonator is formed, referred to as a quartz crystal or crystal oscillator for short.

[0041] 32768Hz quartz crystal is often used as a clock crystal.

[0042] In order to make the above objects, features and advantages of the present invention more comprehensible, specific imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com