Patents

Literature

405 results about "Mass flow sensor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A mass (air) flow sensor (MAF) is a sensor used to determine the mass flow rate of air entering a fuel-injected internal combustion engine. The air mass information is necessary for the engine control unit (ECU) to balance and deliver the correct fuel mass to the engine. Air changes its density with temperature and pressure. In automotive applications, air density varies with the ambient temperature, altitude and the use of forced induction, which means that mass flow sensors are more appropriate than volumetric flow sensors for determining the quantity of intake air in each cylinder.

Flow sensor

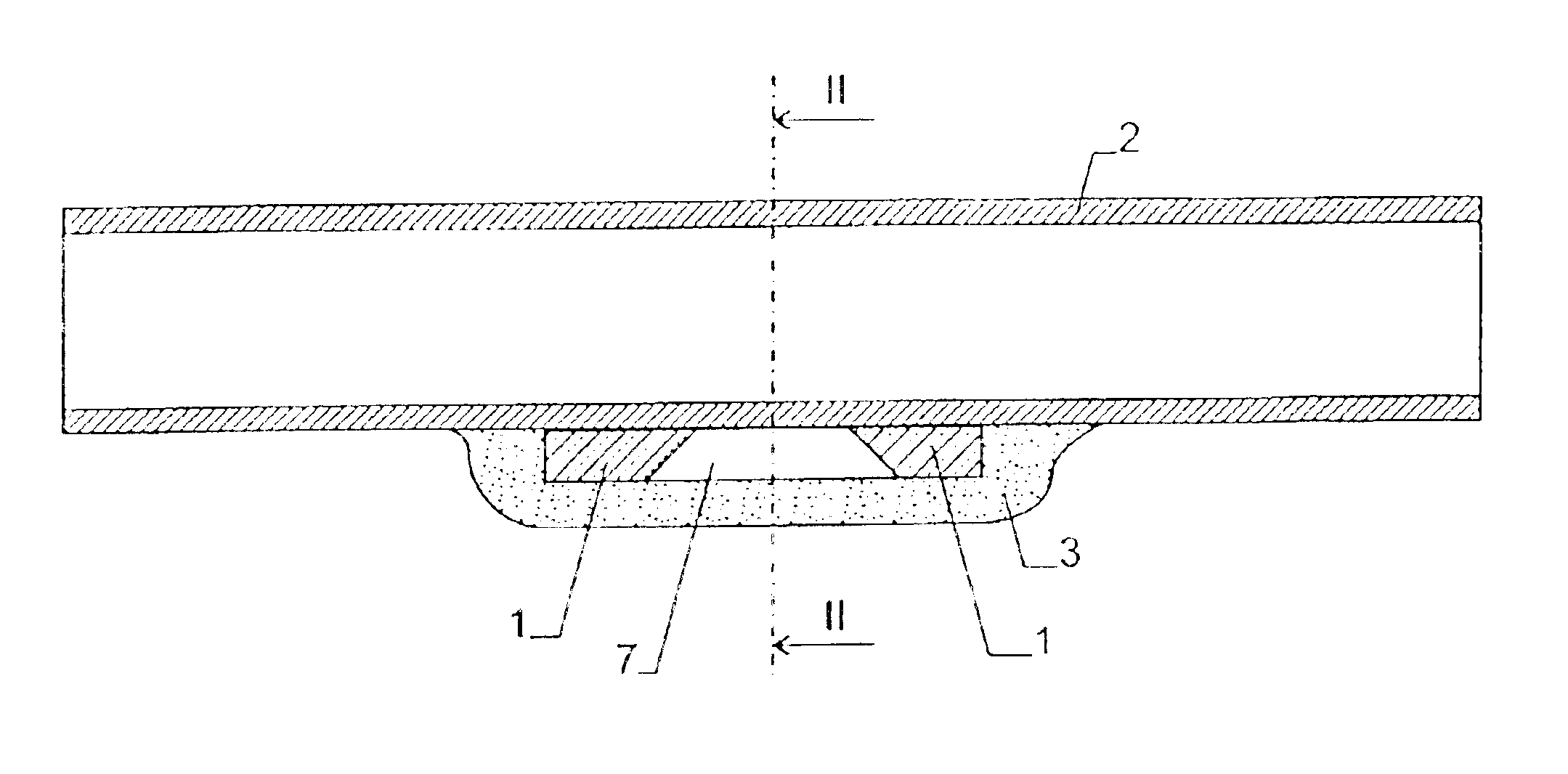

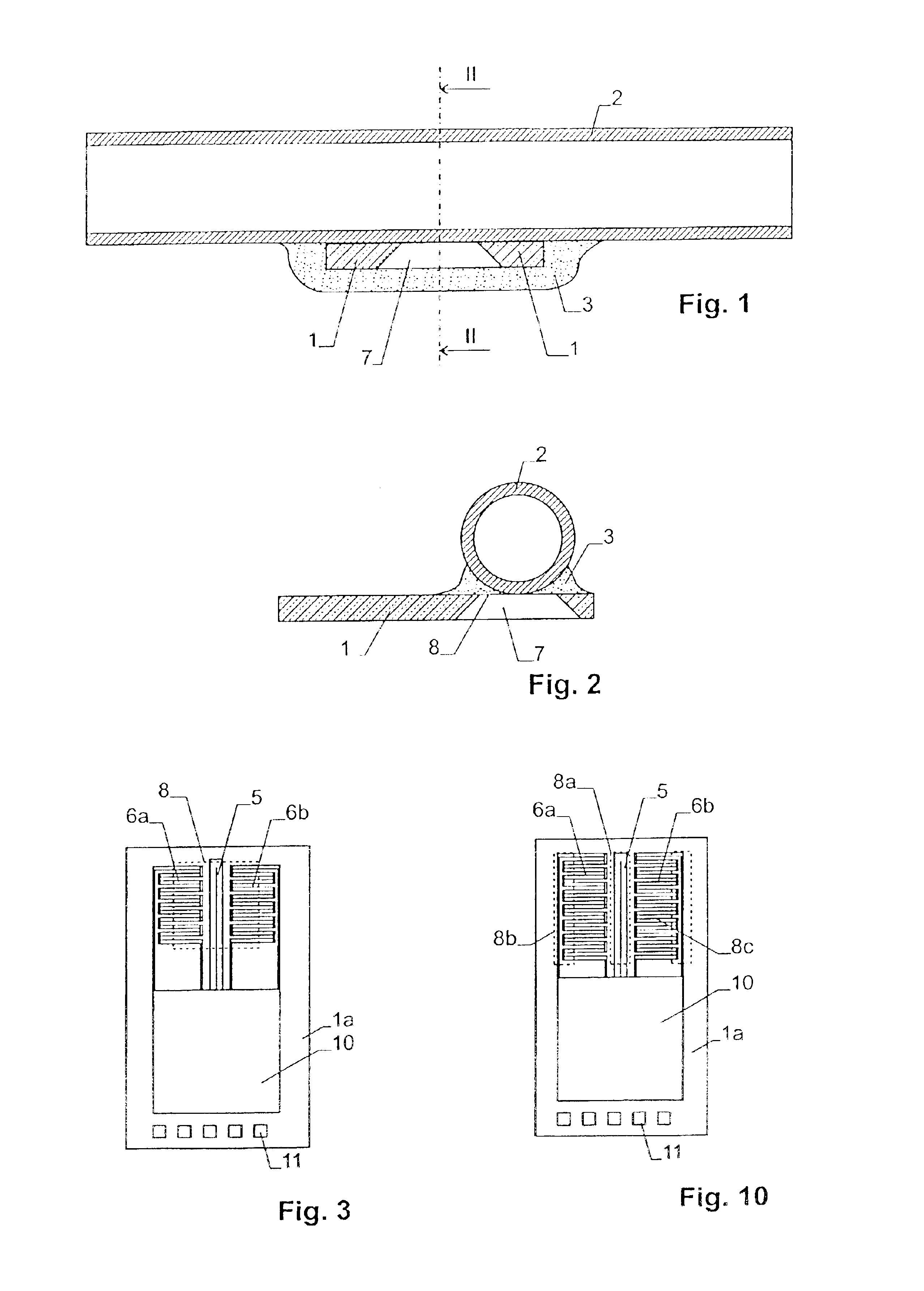

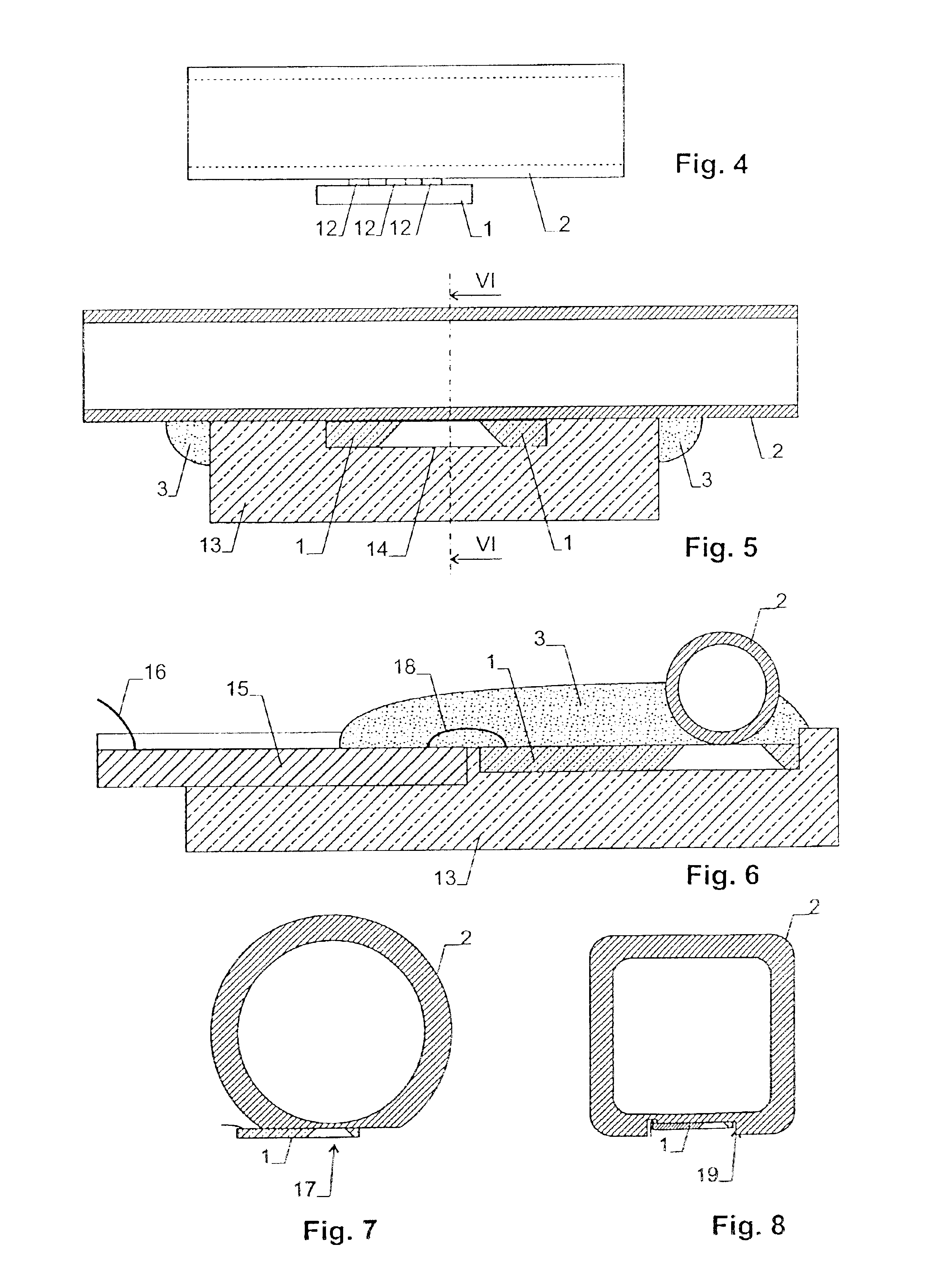

The flow sensor comprises a semiconductor device (1) on which a heat source and, symmetrically thereto, two temperature sensors are arranged. The semiconductor device (1) is arranged on an exterior side of a tube section (2), and a liquid, the flow velocity of which has to be measured, is led through the tube section (2). The temperature sensors and the heat source are in thermal contact with the exterior side of the tube section (2). It has been found that such an assembly allows to carry out flow measurements with high accuracy and sensitivity.

Owner:SENSIRION HLDG

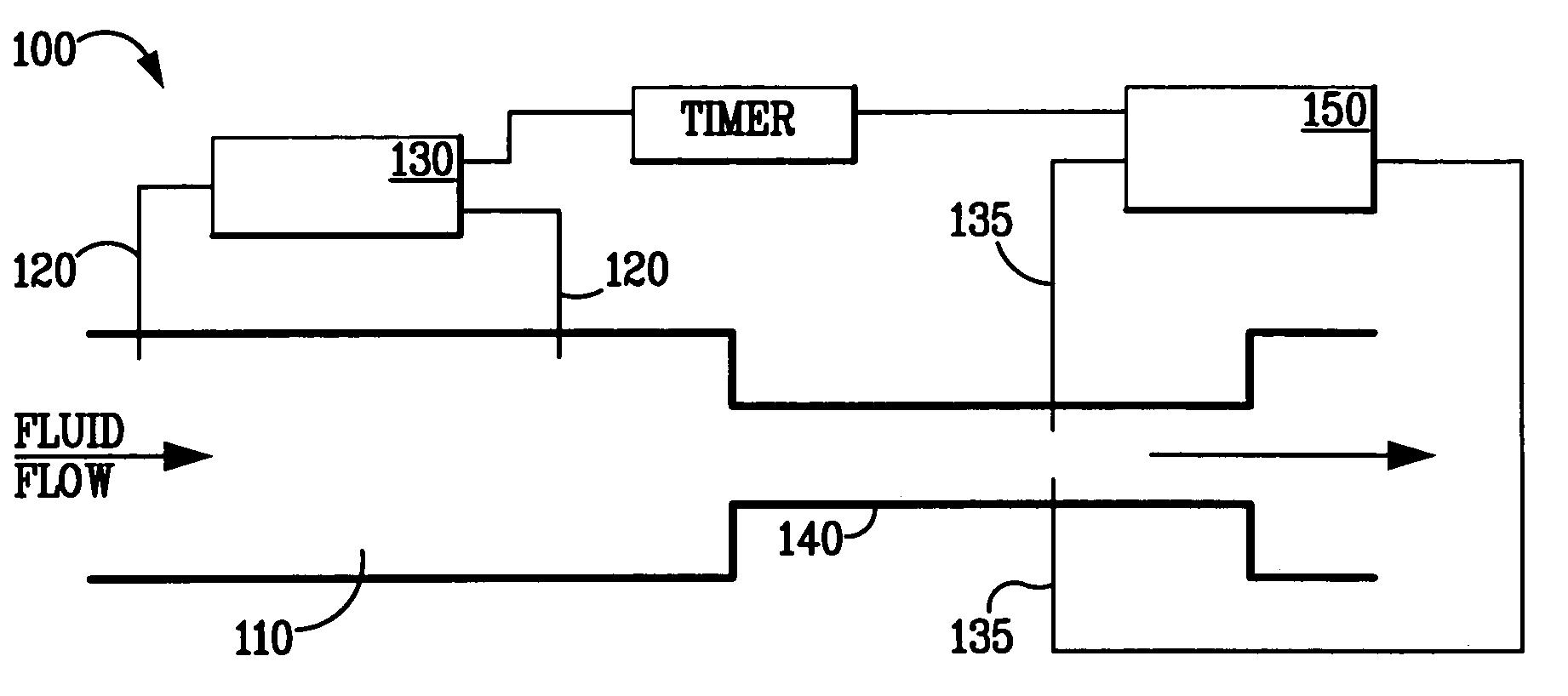

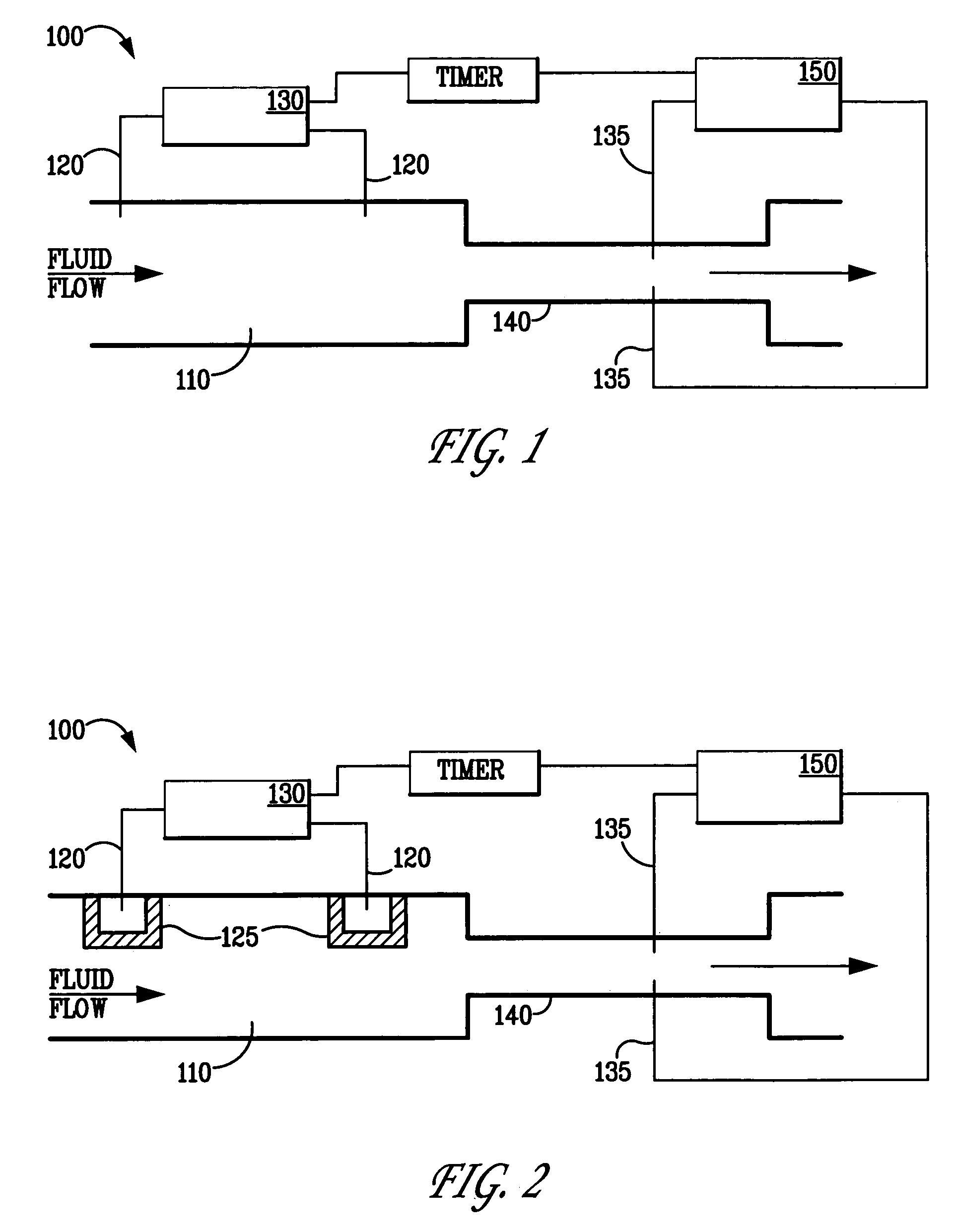

Mass flow sensor and methods of determining mass flow of a fluid

ActiveUS6912918B1Prevent leakageAvoid radiationVolume/mass flow by dynamic fluid flow effectSpecific gravity measurementSonificationUltrasonic beam

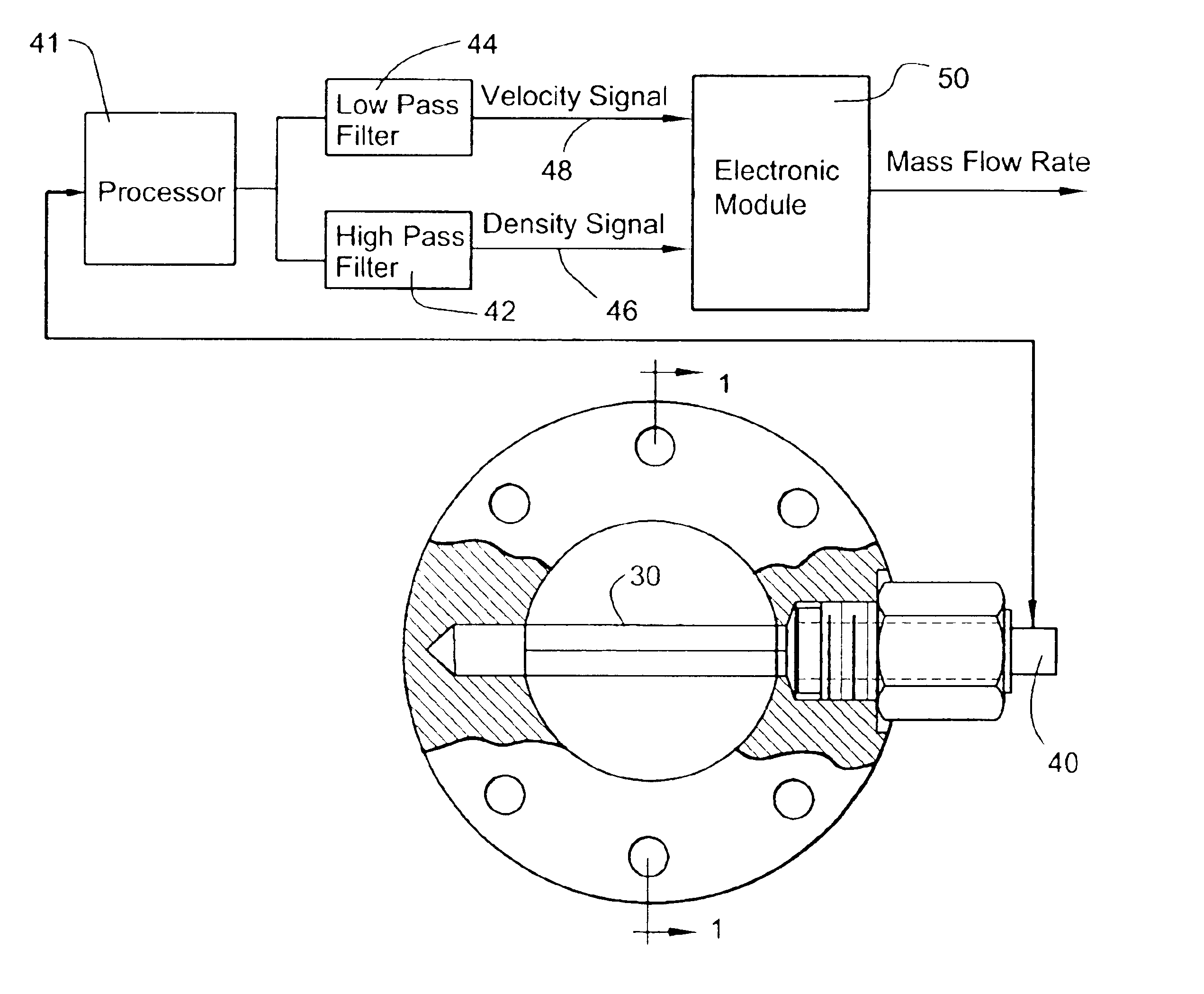

The mass flow rate sensor includes a waveguide disposed in a flow passage having a bluff body facing in an upstream direction. Waves are pulsed along the waveguide for interaction with the fluid. A receiver is coupled to the waveguide to detect a propagated wave and provides a first output signal proportional to the transit time of the propagated wave for determining fluid density. The receiver also provides a second output signal proportional to the shedding frequency of vortices from the waveguide to determine velocity. An electronics module calculates mass flow rate from the velocity times density times area of the flow passage and a constant. In other forms, the velocity is ascertained by transmitting an ultrasonic beam through the shedding vortices to determine vortex frequency which is proportional to velocity.

Owner:BAKER HUGHES INC

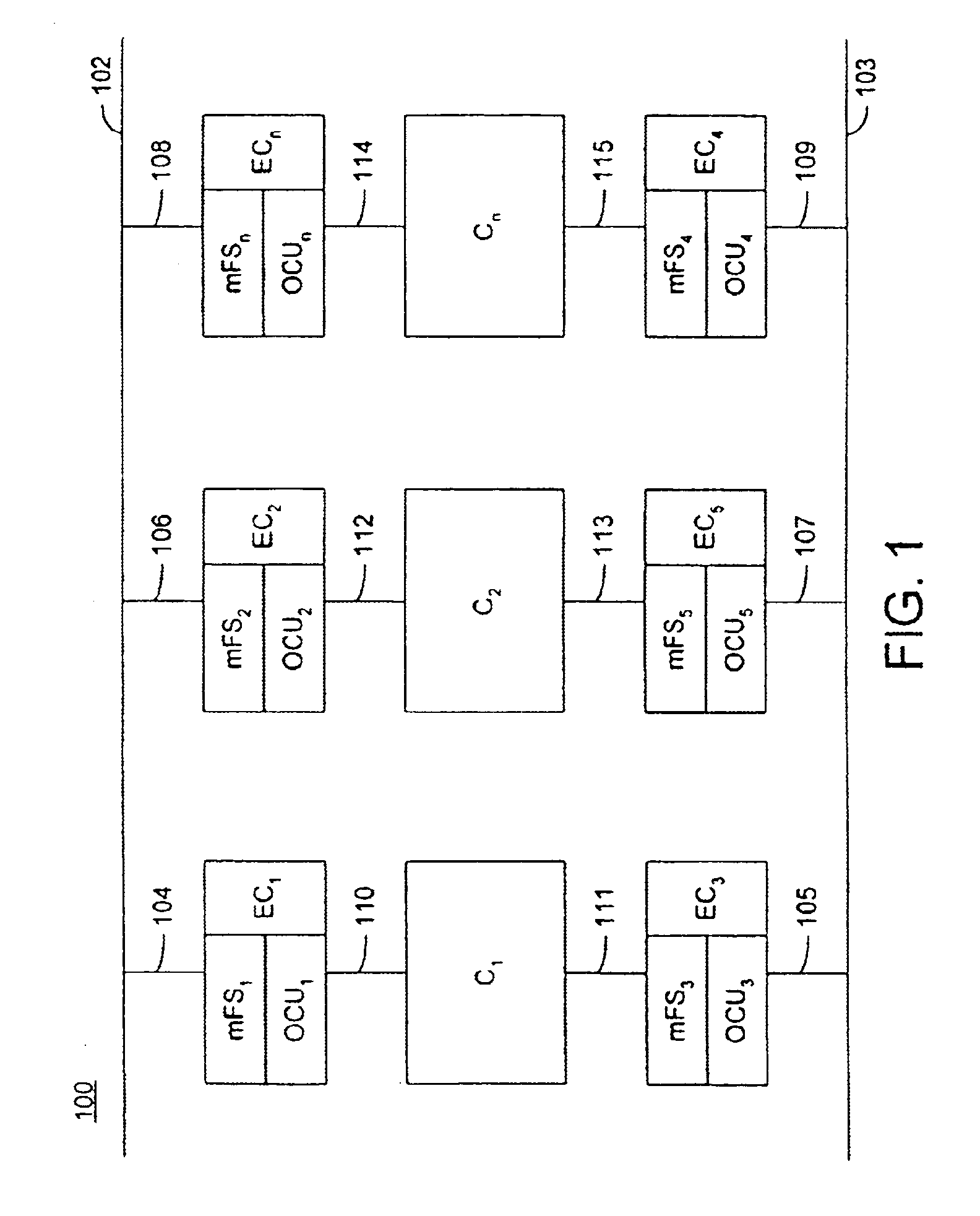

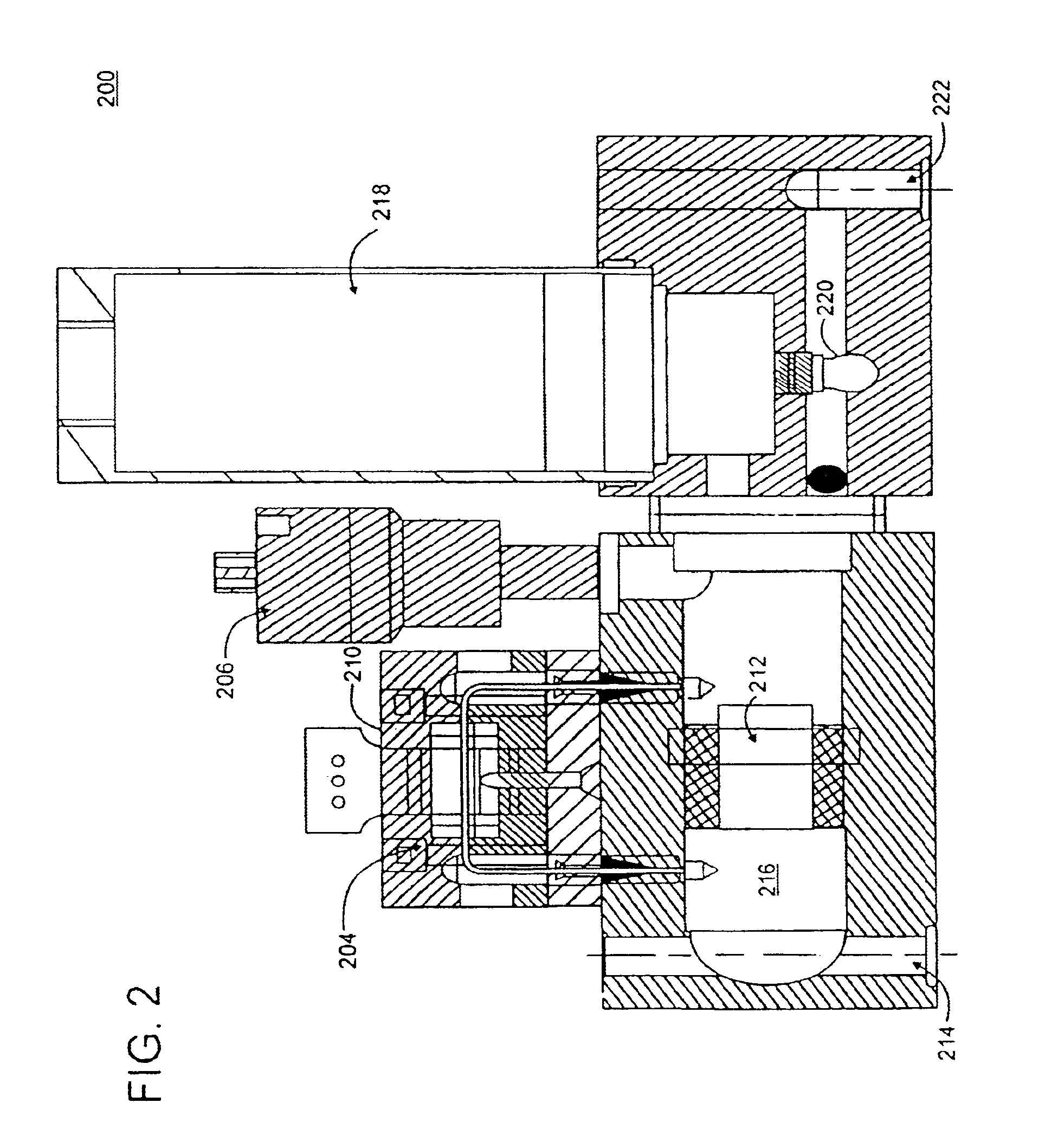

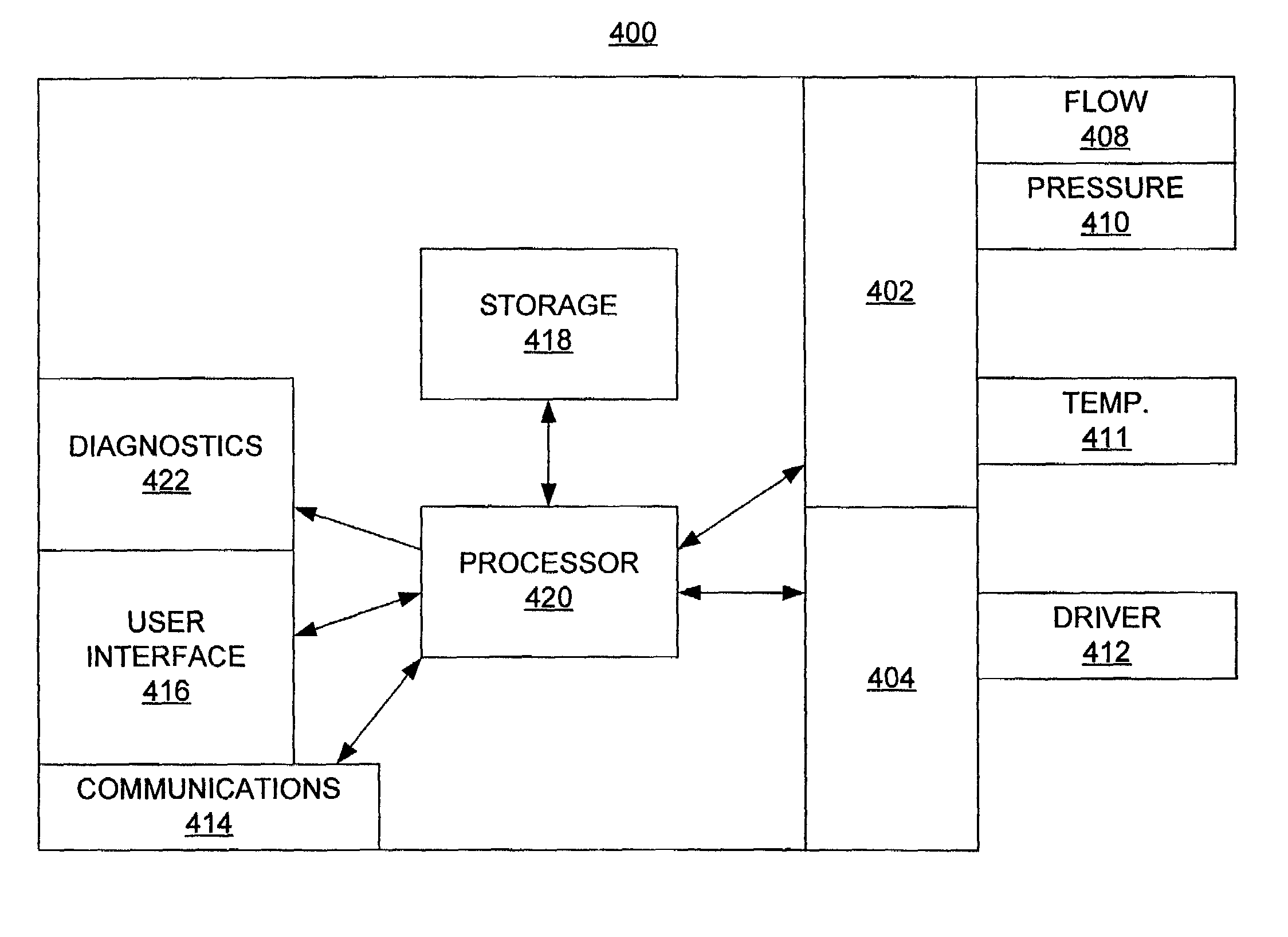

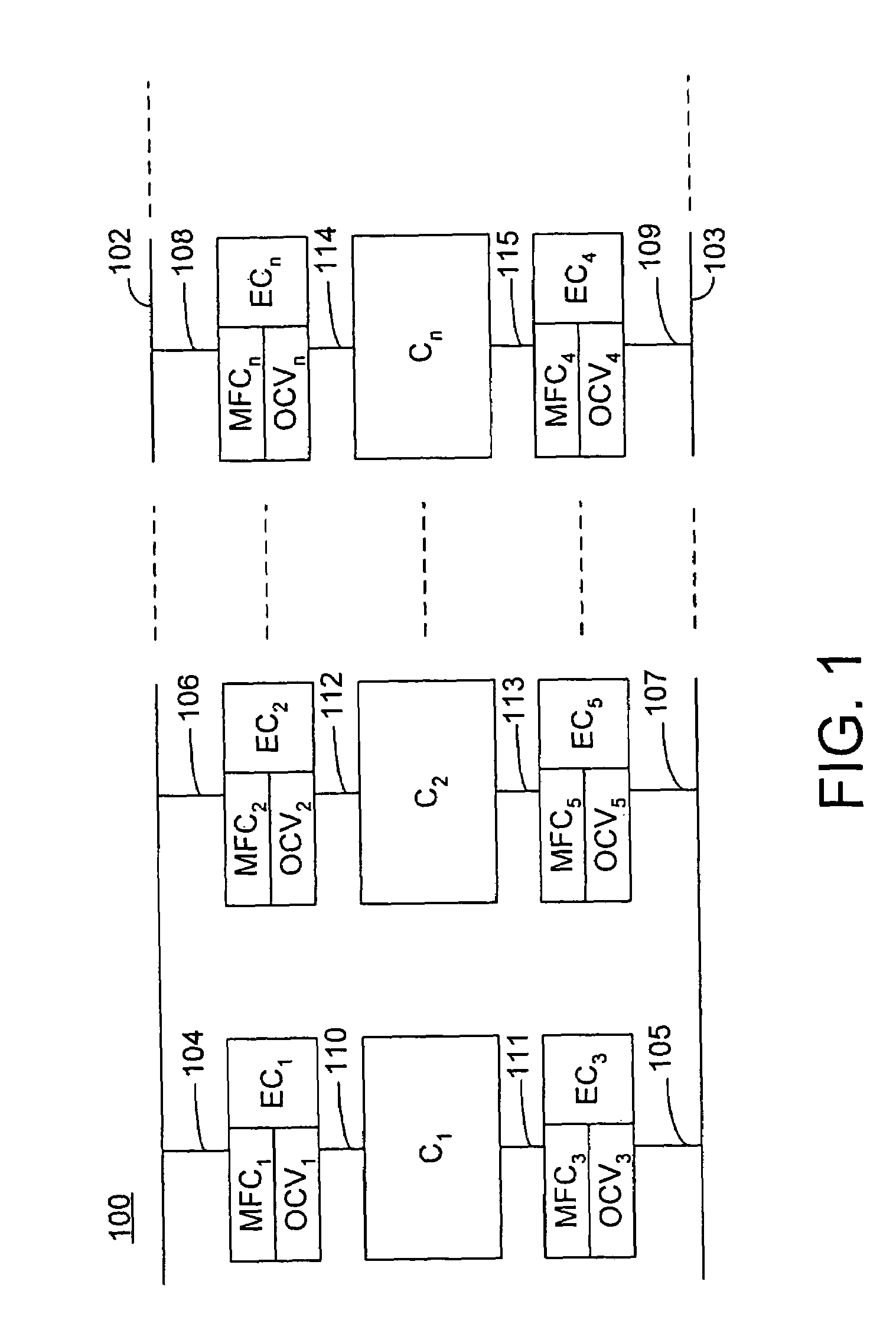

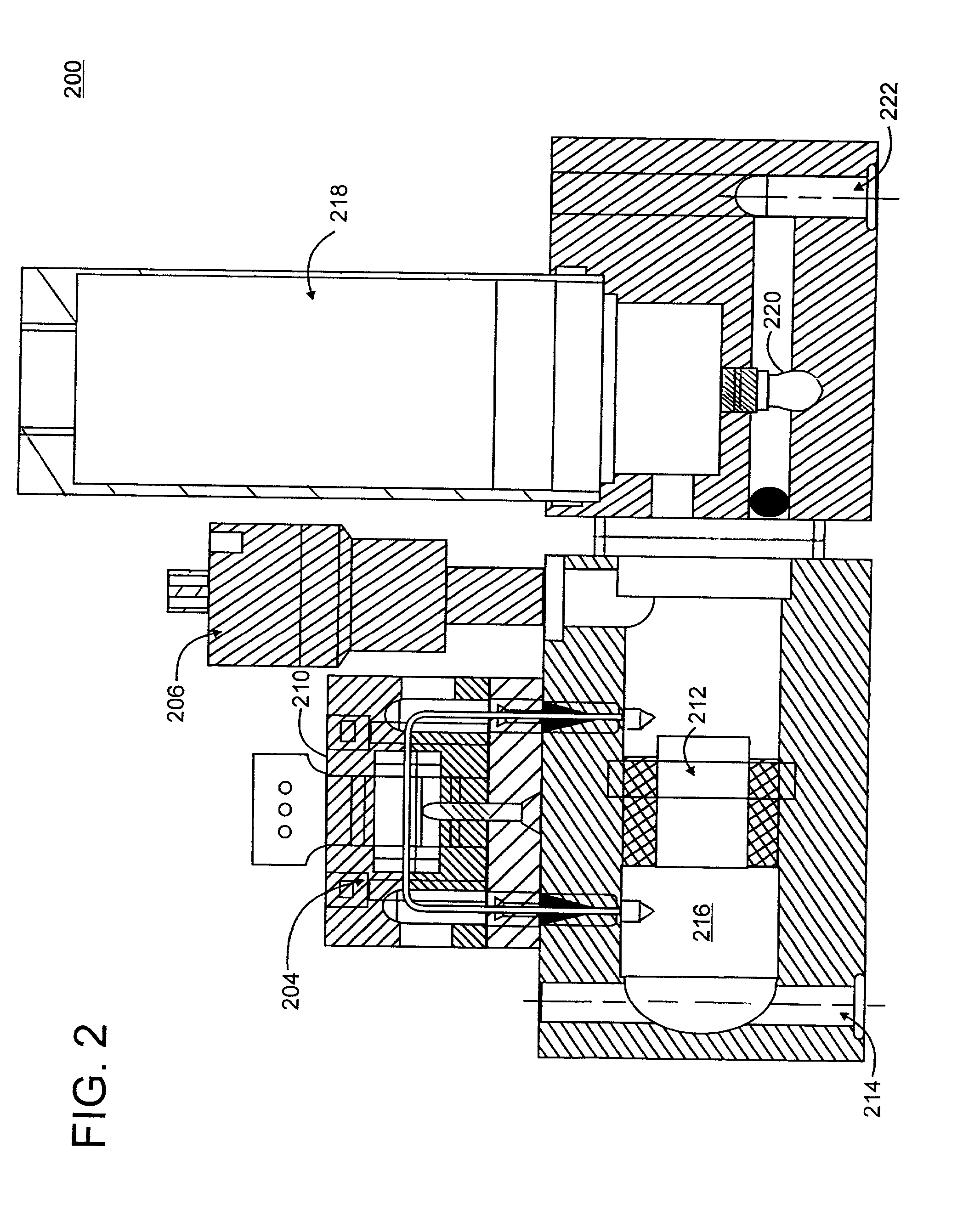

Apparatus and method for self-calibration of mass flow controller

InactiveUS6948508B2Testing/calibration apparatusFluid pressure measurementEngineeringMass flow sensor

A mass flow controller includes a mass flow sensor and a calibrator configured to perform a self-calibration on the mass flow controller. The calibrator generates flow measurements that are used as “standards” and flow measurements from the mass flow sensor are correlated to flow measurements from the calibrator.

Owner:MKS INSTR INC

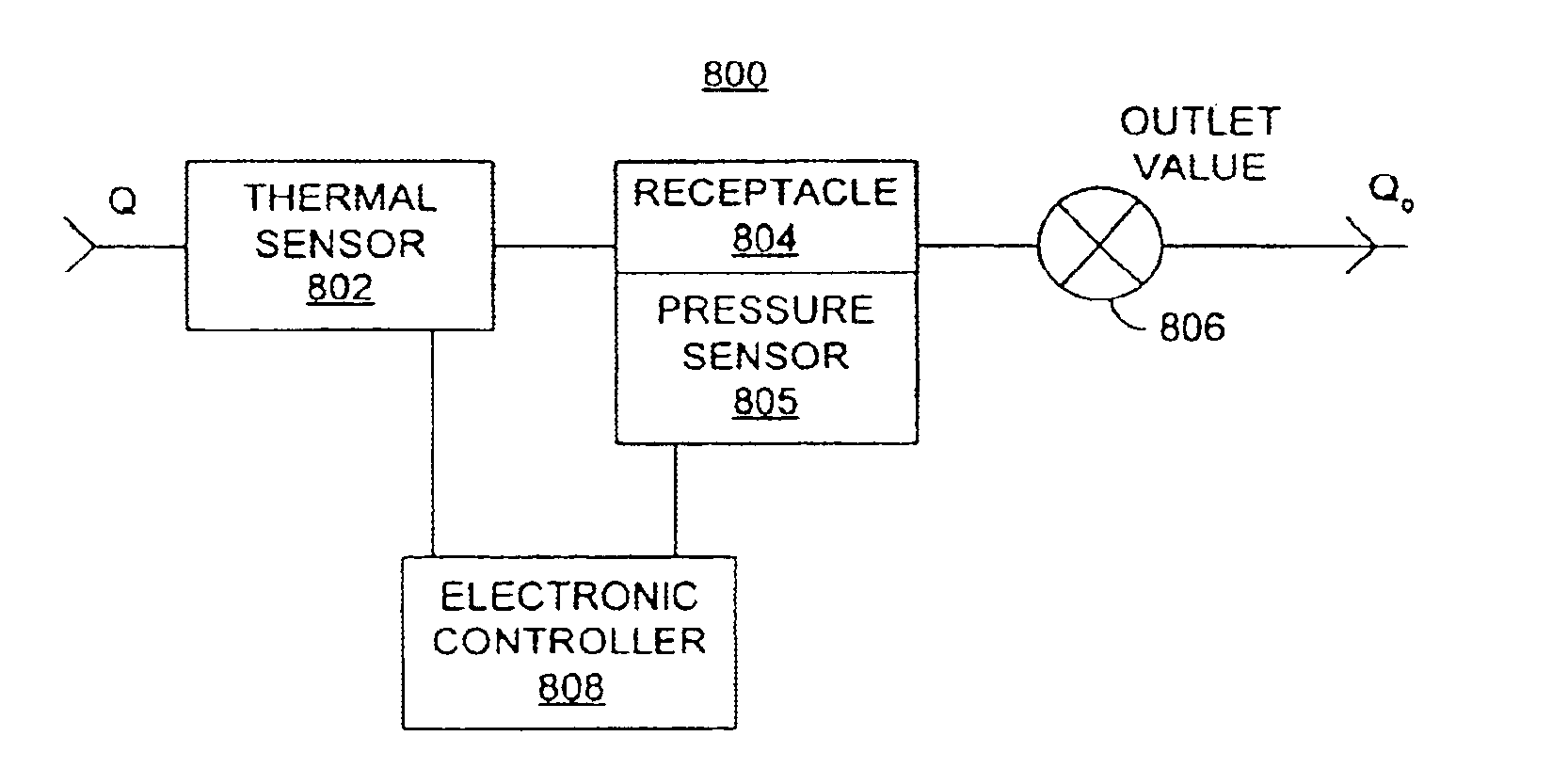

Apparatus and method for calibration of mass flow controller

InactiveUS7136767B2Testing/calibration apparatusVolume flow proportion measurementDifferentiatorEngineering

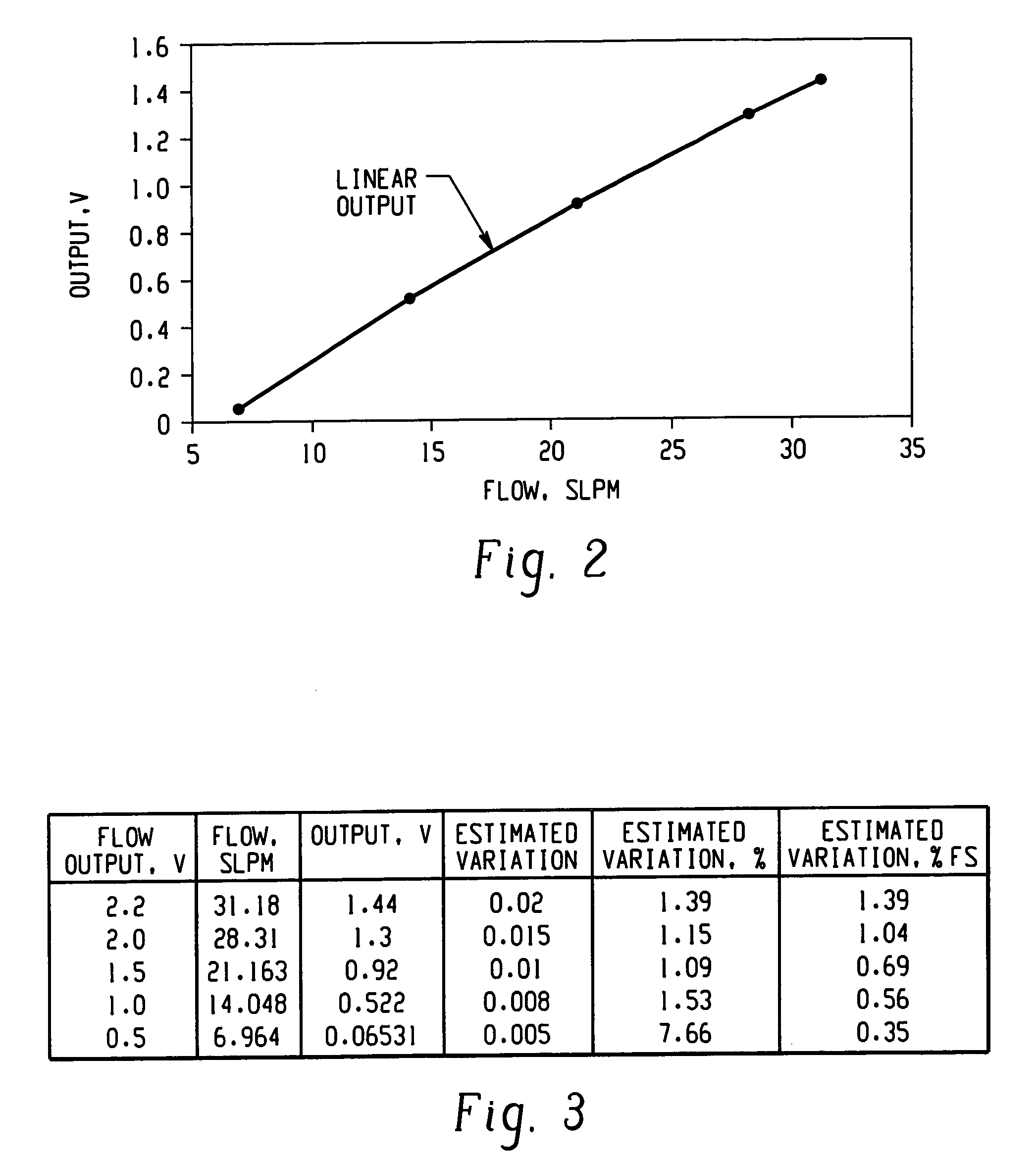

A mass flow sensor calibrator employs a variable-flow fluid source, a receptacle of known volume, and a pressure differentiator. The variable-flow fluid source supplies gas at varying rates to the mass flow sensor being calibrated and at proportional rates to a receptacle of known volume. A pressure differentiator computes the time derivative of gas flow into the receptacle of known volume and, from that, the actual flow into the receptacle. Given the actual flow, the proportionate flow into the mass flow sensor may be determined and the flow signal from the mass flow sensor correlated to the actual flow.

Owner:MKS INSTR INC

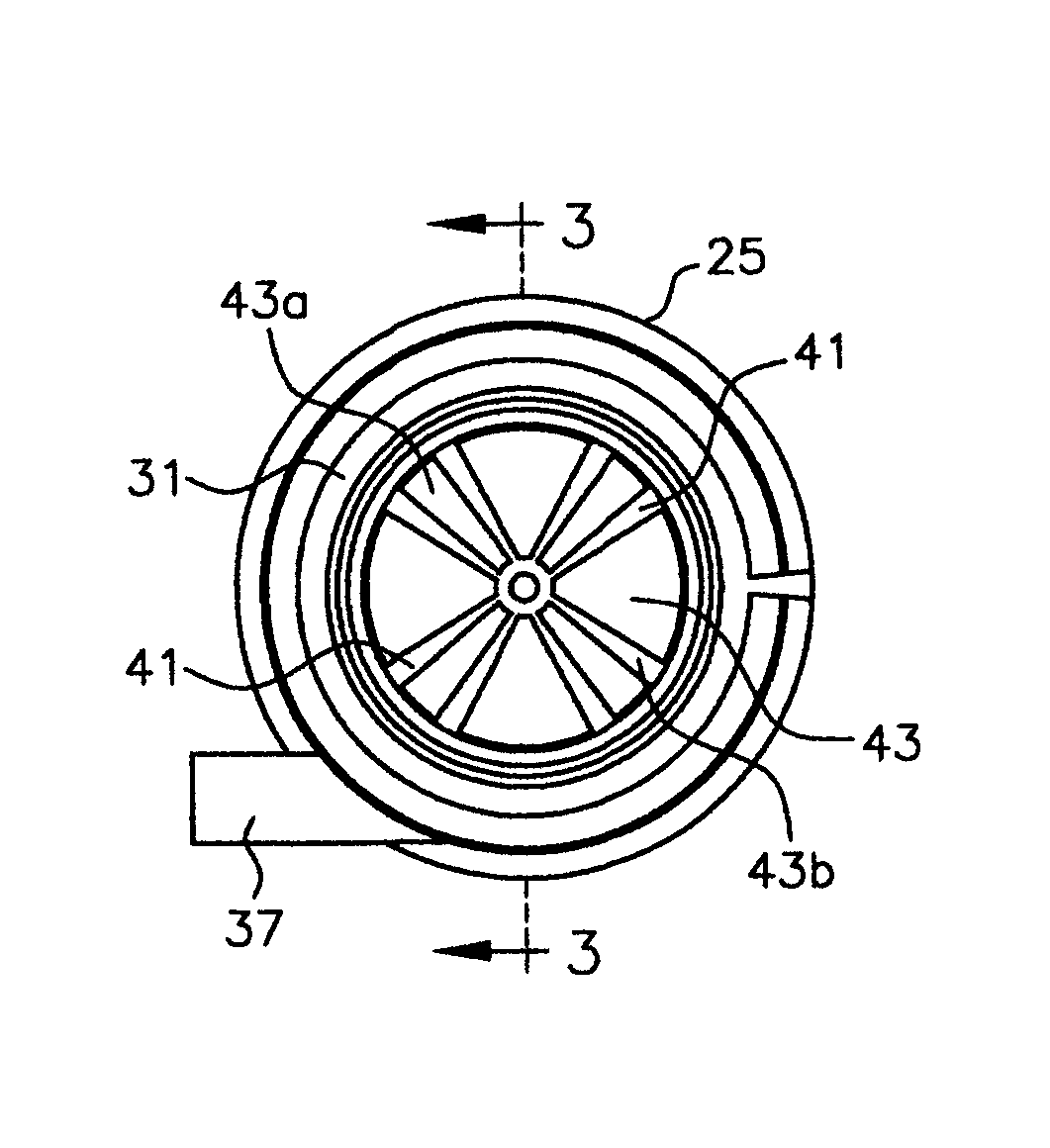

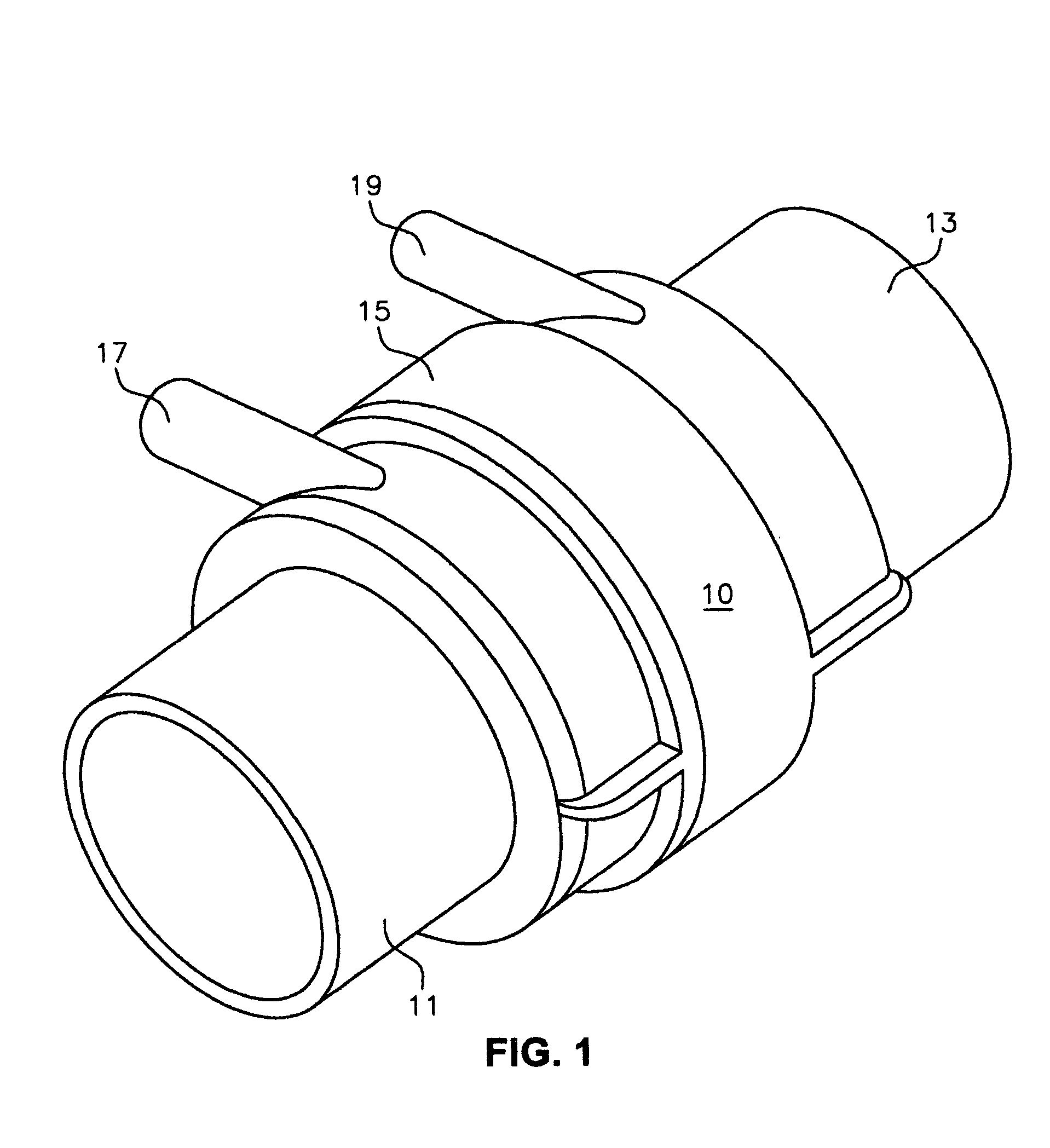

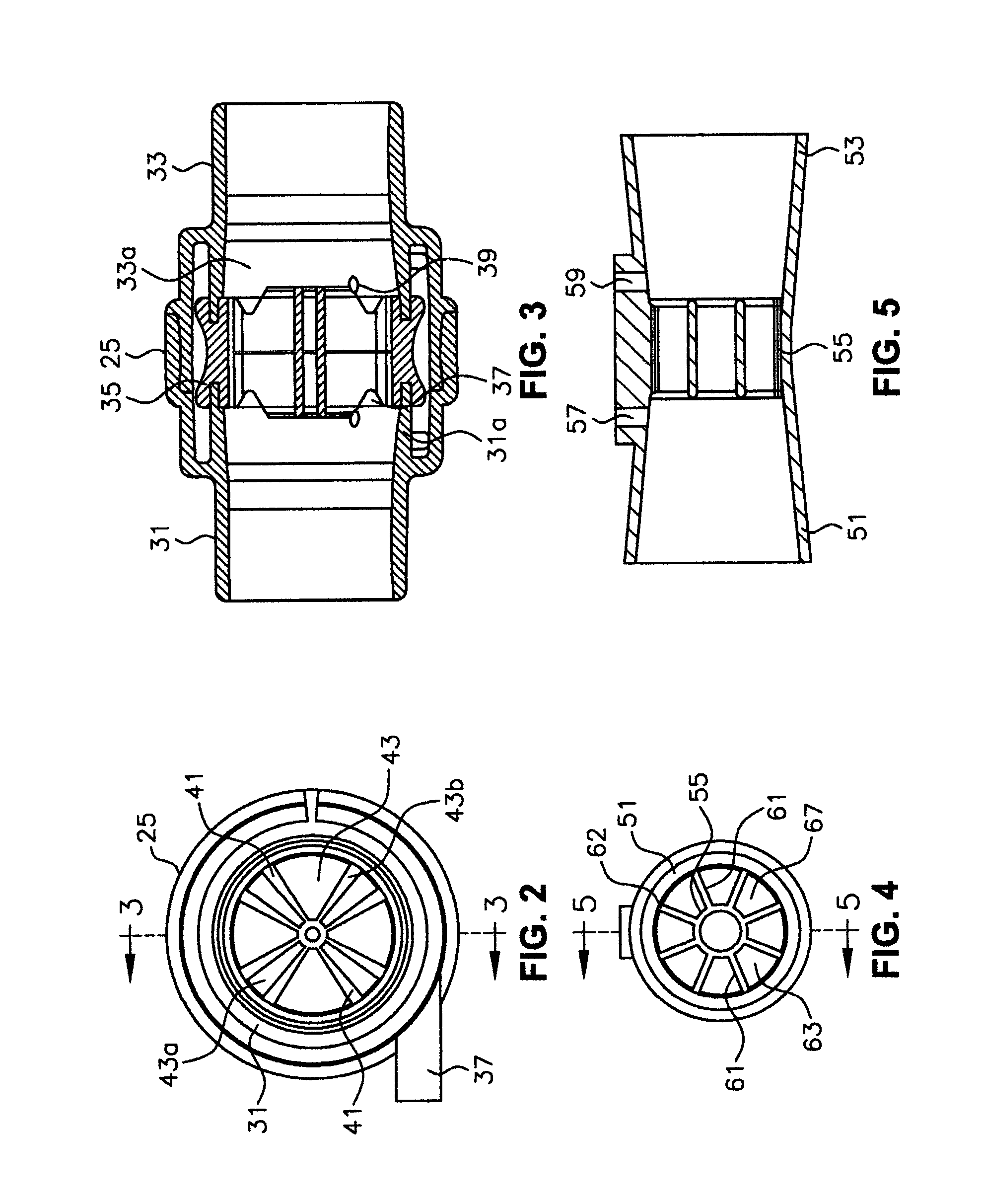

Flow sensor with integrated delta P flow restrictor

A high mass flow sensor device having a flow restrictor formed by a body having a generally cylindrical shape with an upstream end and a downstream end separated by a center portion having pressure taps proximate the junction of the ends with the center portion. Flow passes from upstream to downstream. The upstream end has a decreasing tapering inner surface for contact with the flow and the downstream end having an increasing tapering inner surface for contact with the flow. A center portion has radial and axial restrictor elements positioned forming axial openings in the path of flow through the center portion. The restrictor elements having tapered leading edges. One opening is formed by a central tube having a predetermined diameter and the remaining openings are radially extending members supporting the central tube, each of the radially extending members having substantially the same cross-sectional area as the central tube.

Owner:RESPIRONICS

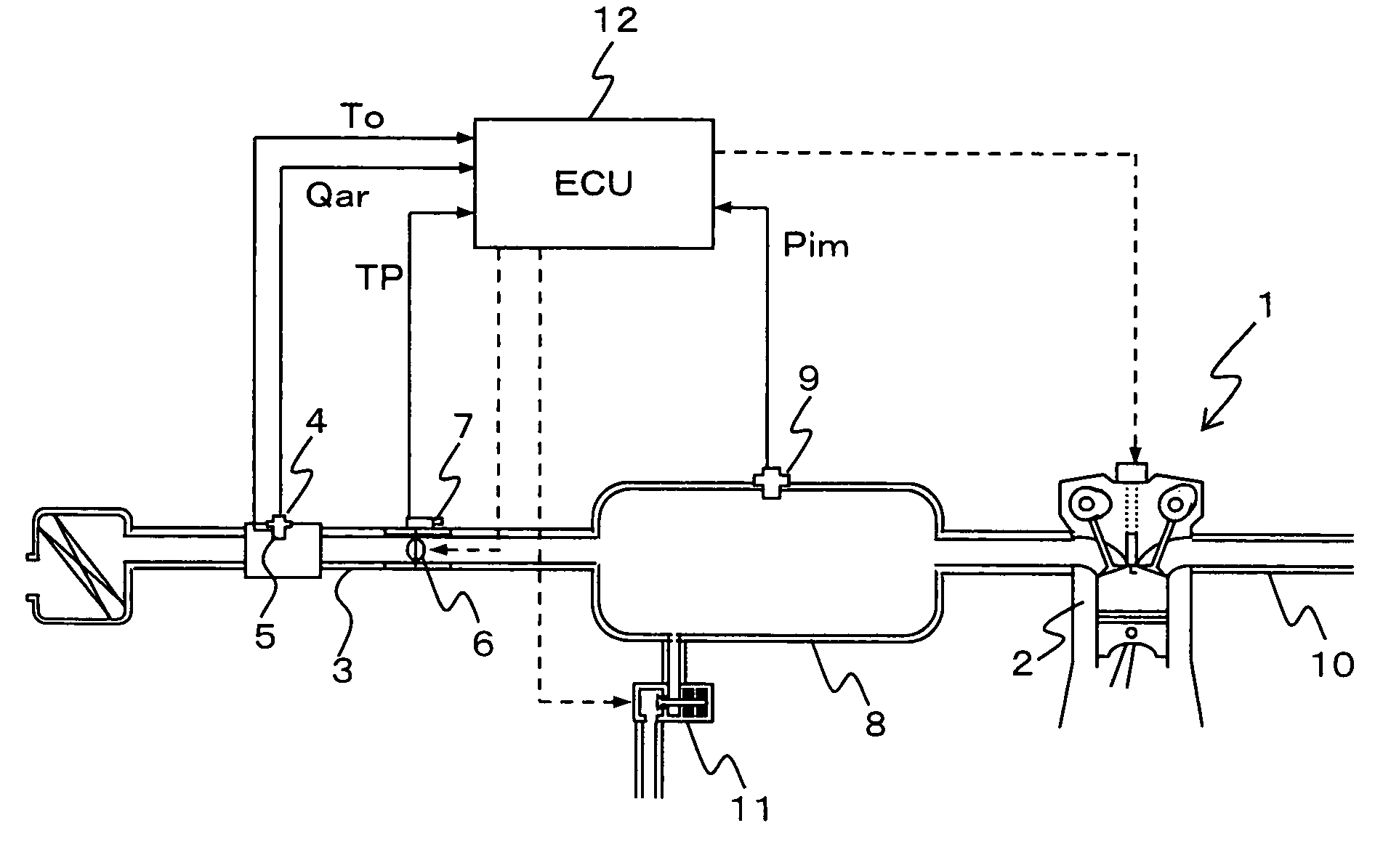

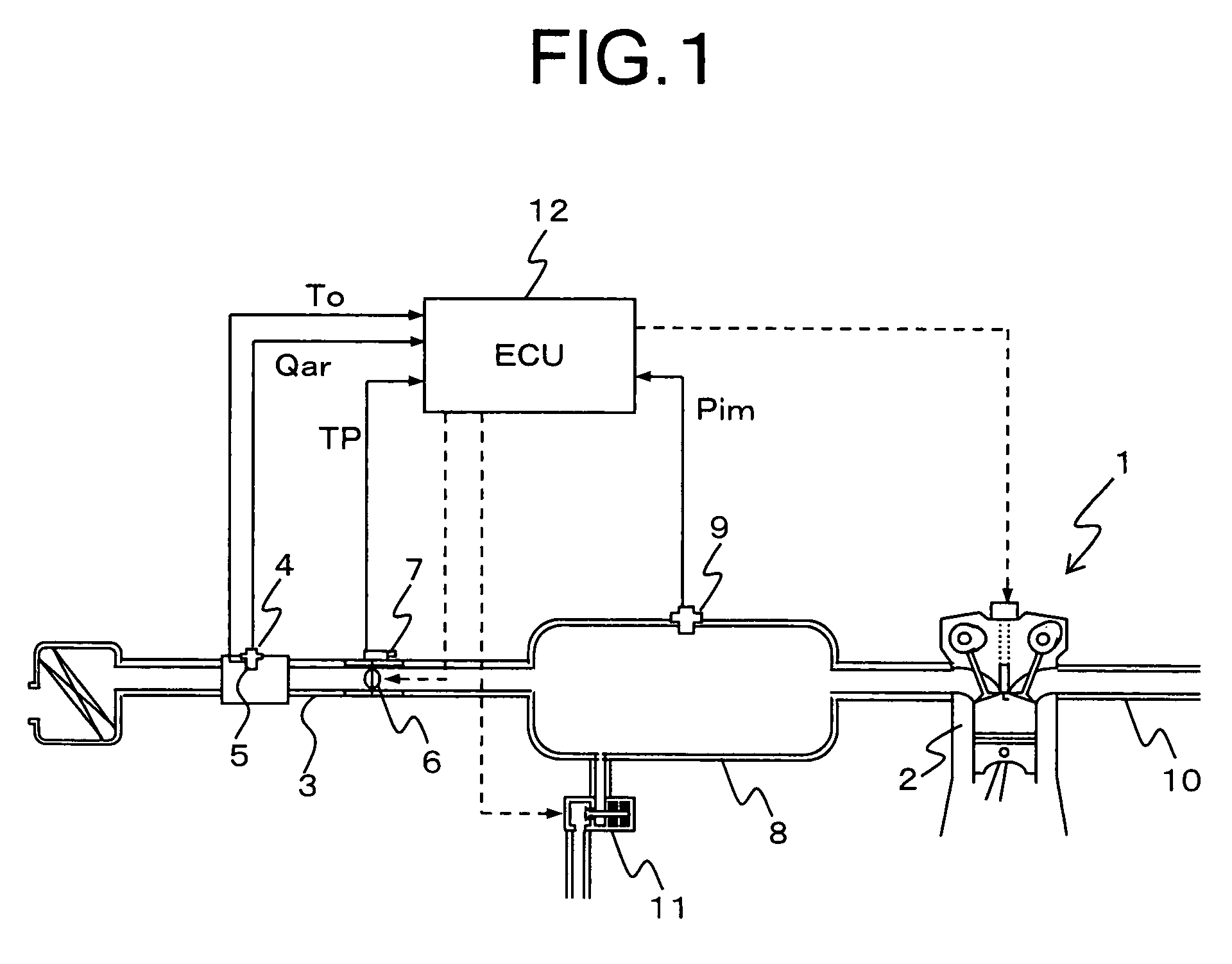

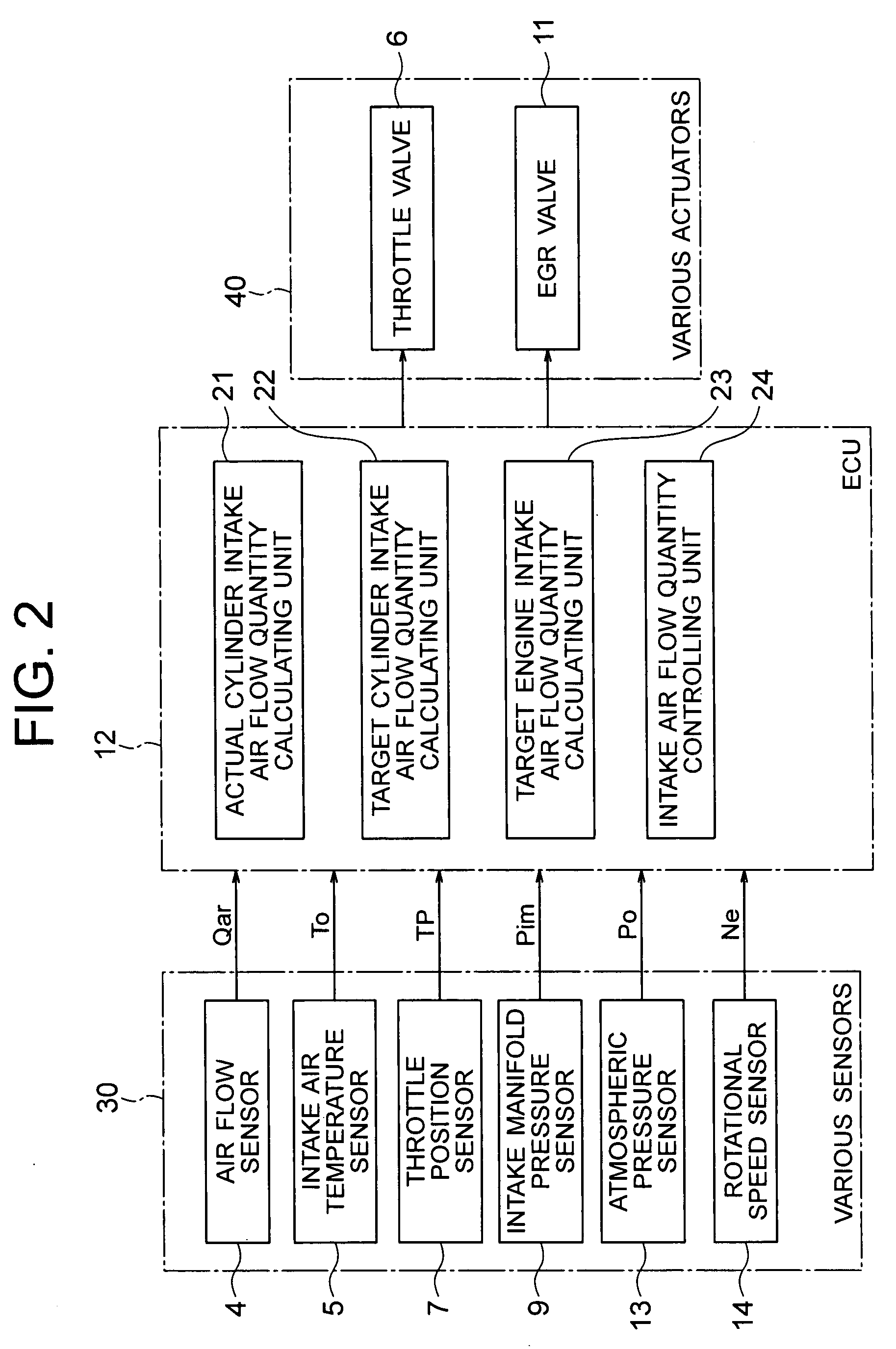

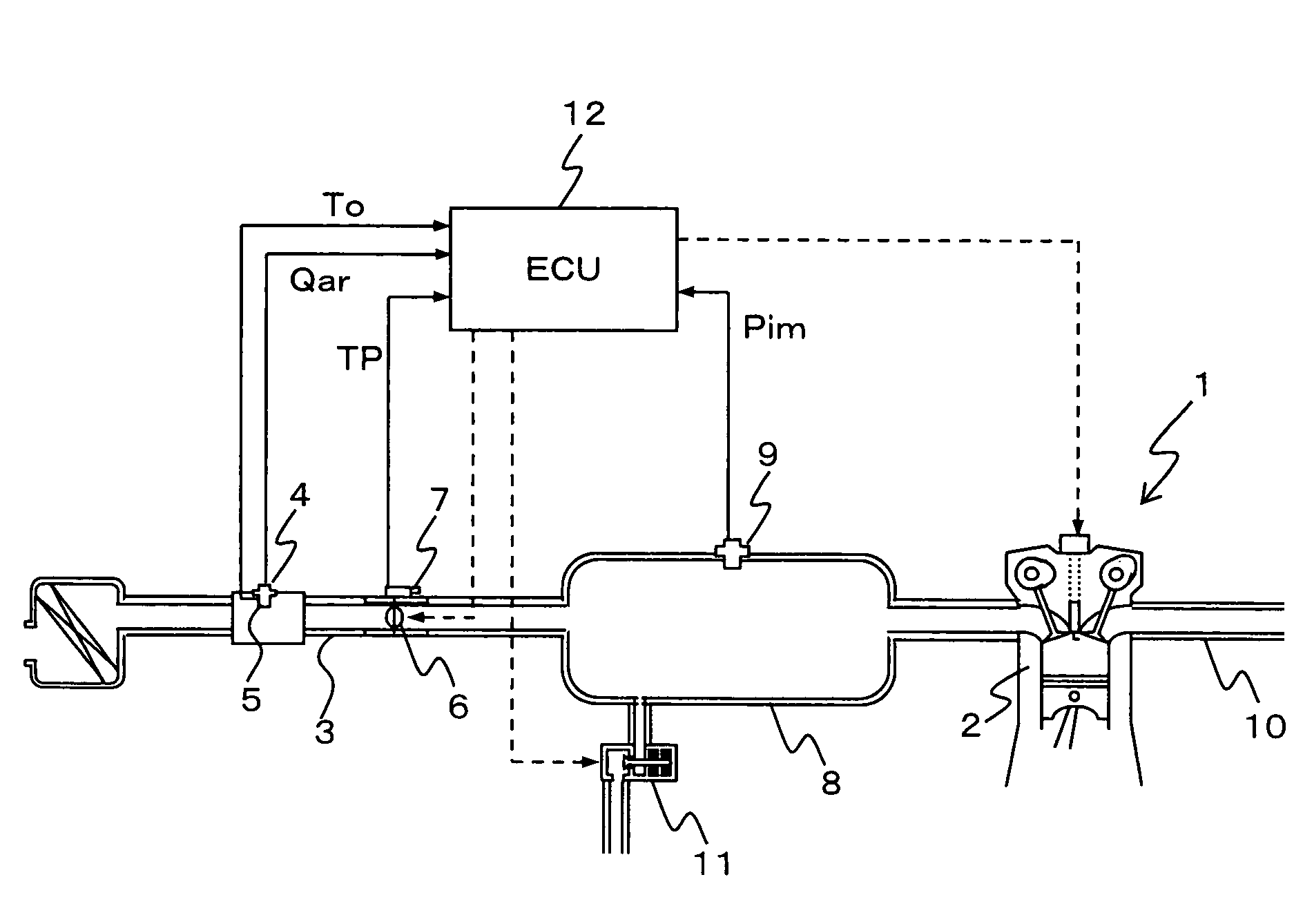

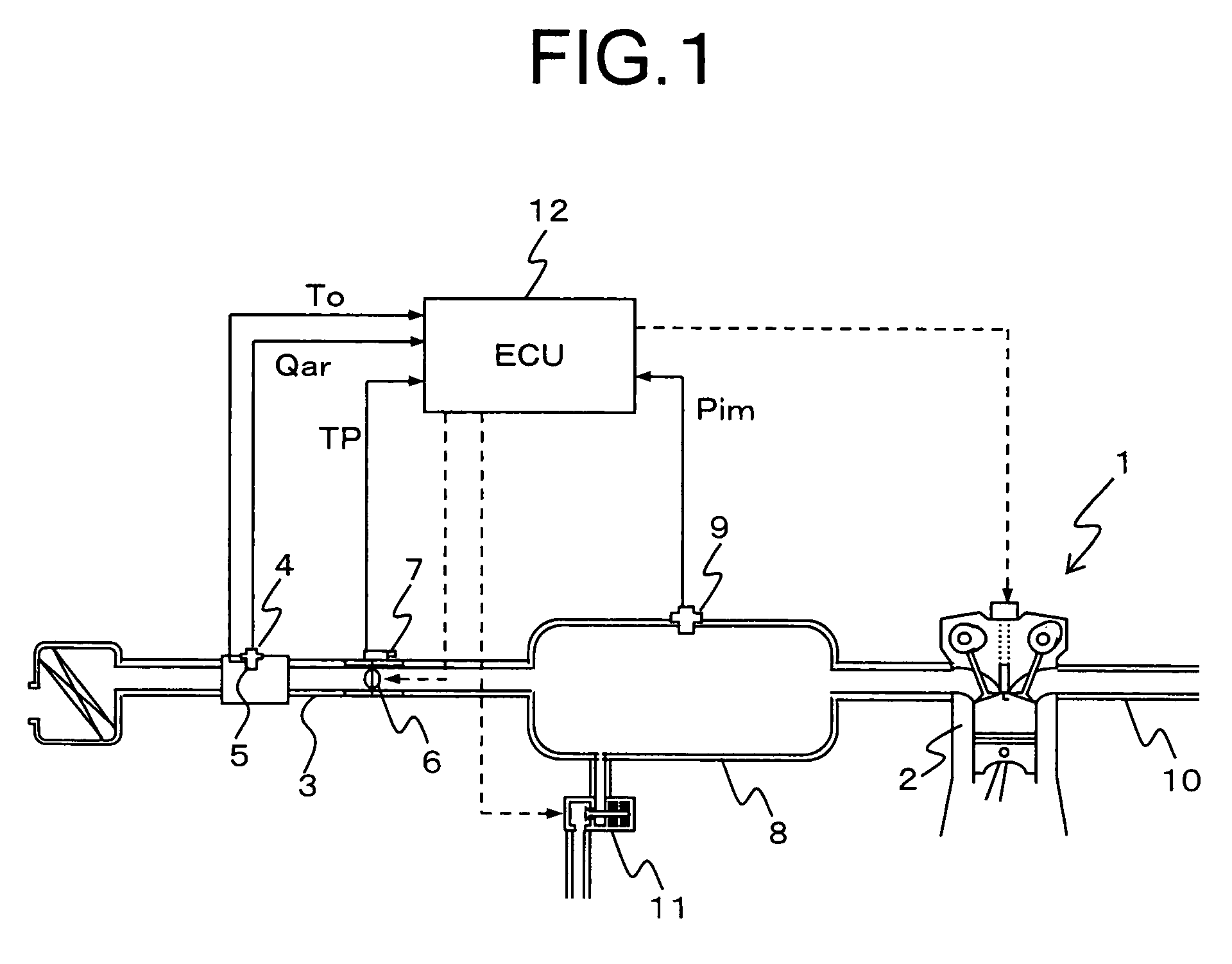

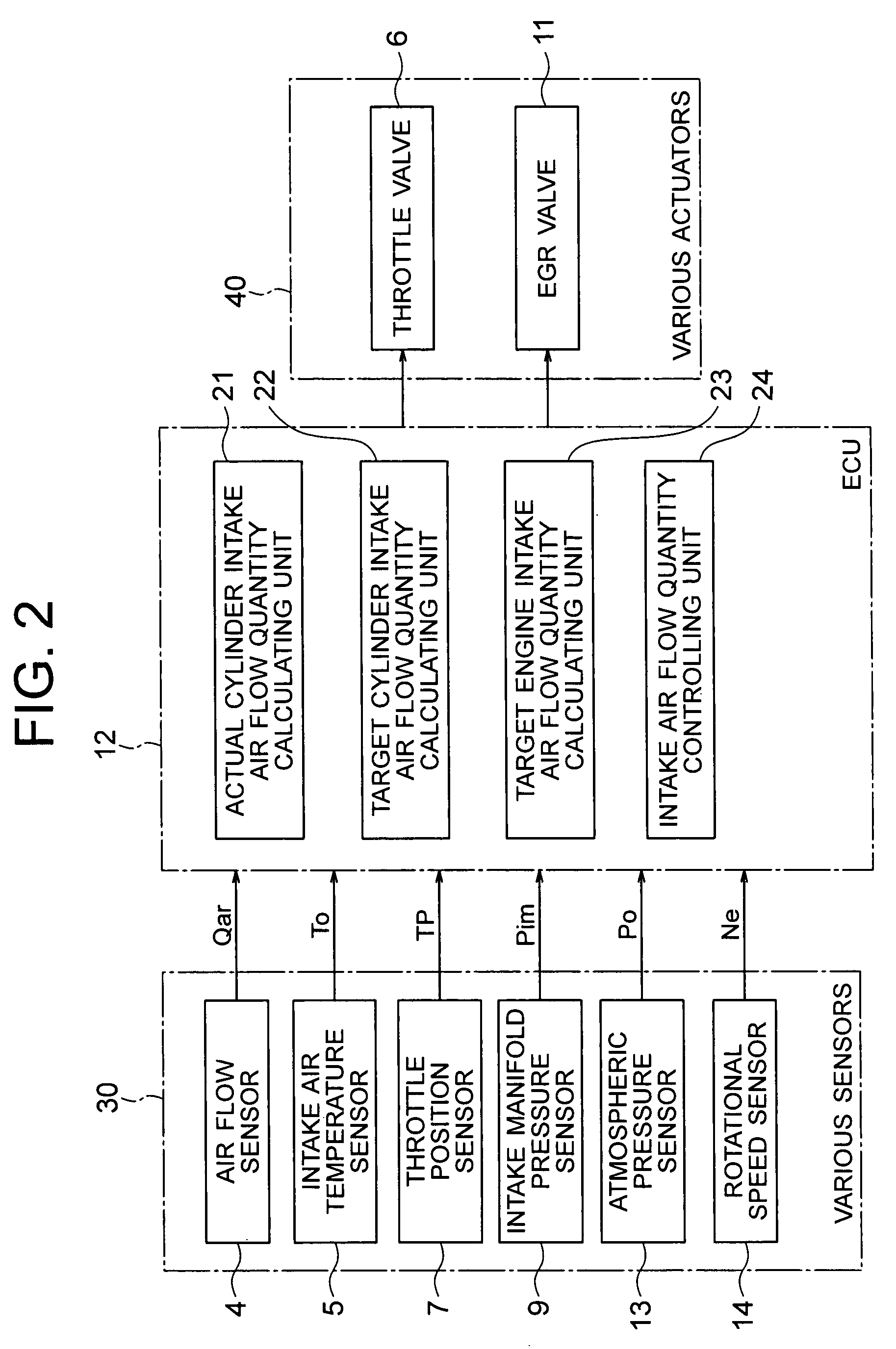

Control device for internal combustion engine

ActiveUS20080127938A1Reduce in quantityShort calculation timeElectrical controlInternal combustion piston enginesResponse delayThrottle opening

Provided is a control device for an internal combustion engine, which is provided to allow a throttle opening degree to be controlled in accordance with a target engine intake air flow quantity even during transitional operation. The actual cylinder intake air flow quantity calculating unit (21) calculates a response delay model for an intake system from a volumetric efficiency equivalent value (Kv) calculated from a rotational speed (Ne) of an engine (1) and an intake manifold pressure (Pim), an intake pipe volume (Vs), and a displacement (Vc) of each of cylinders (2), and calculates an actual cylinder intake air amount (Qcr) from an actual engine intake air amount (Qar) obtained from an air flow sensor (4) and the response delay model. The intake air flow quantity controlling unit (24) controls the throttle opening degree (TP) in accordance with the target engine intake air amount (Qat).

Owner:MITSUBISHI ELECTRIC CORP

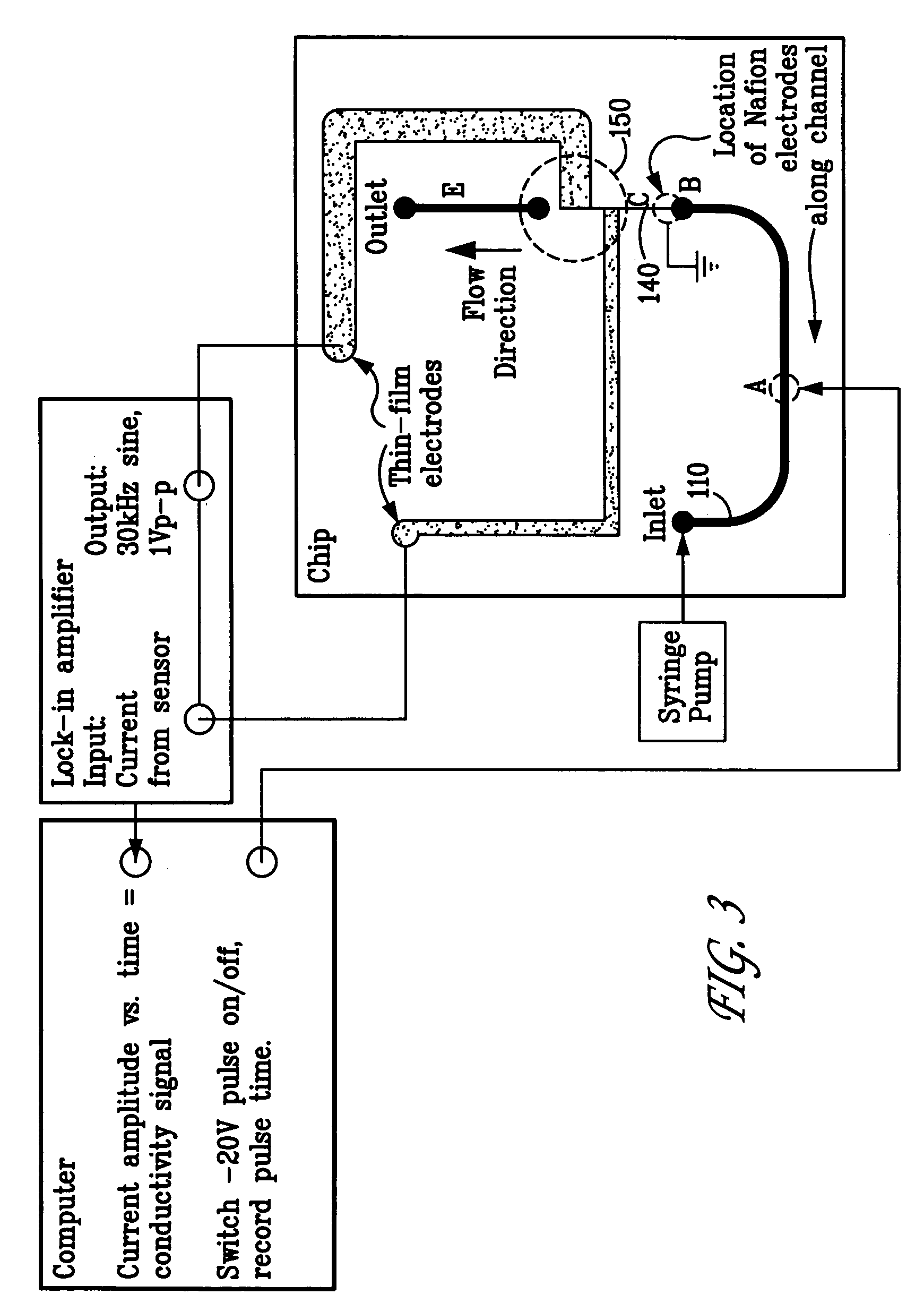

Composition pulse time-of-flight mass flow sensor

InactiveUS7225683B2Increase heat transfer rateHigh sensitivityVolume/mass flow by electromagnetic flowmetersElectrolysisSolvent

Owner:SANDIA NAT LAB

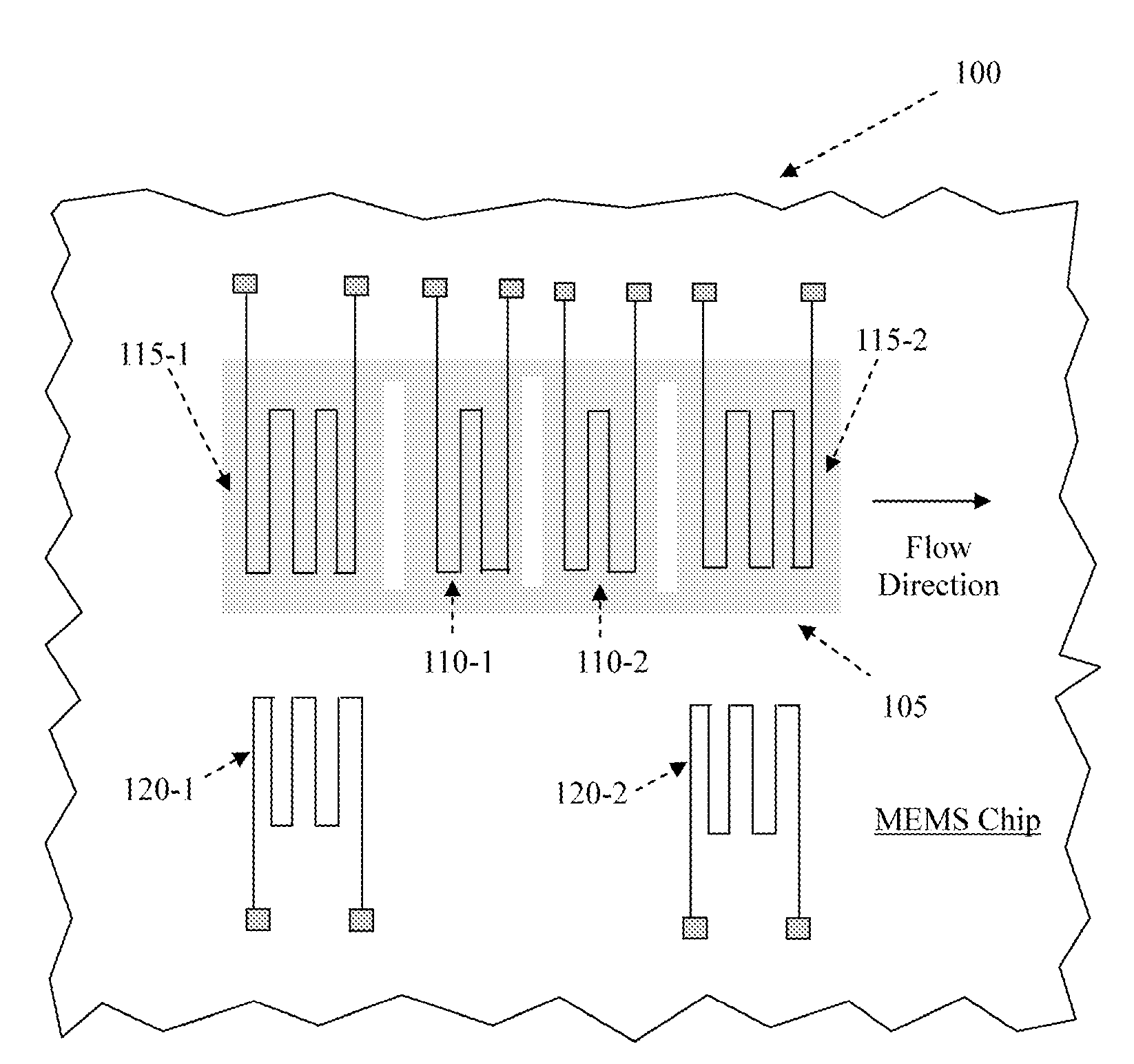

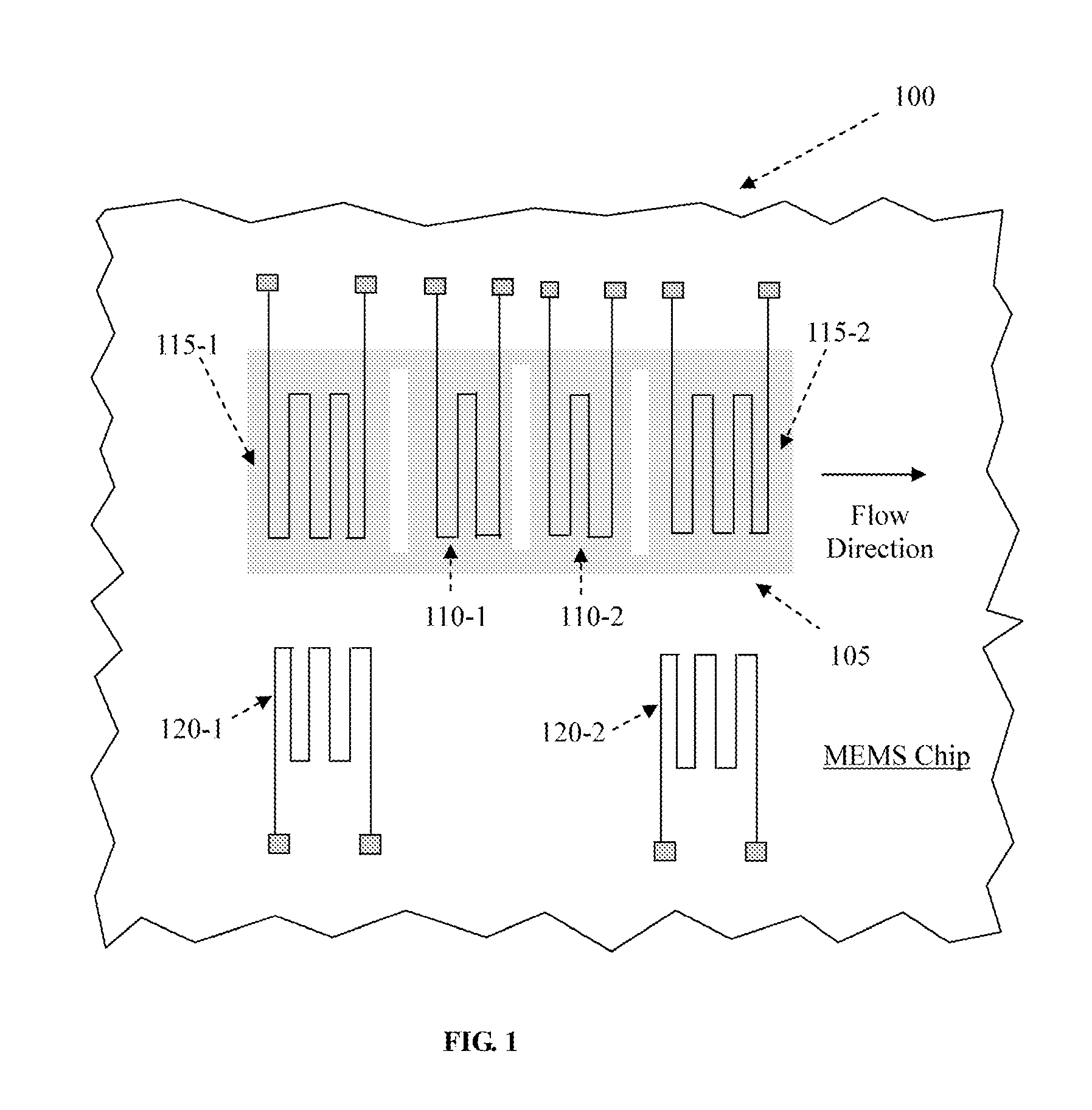

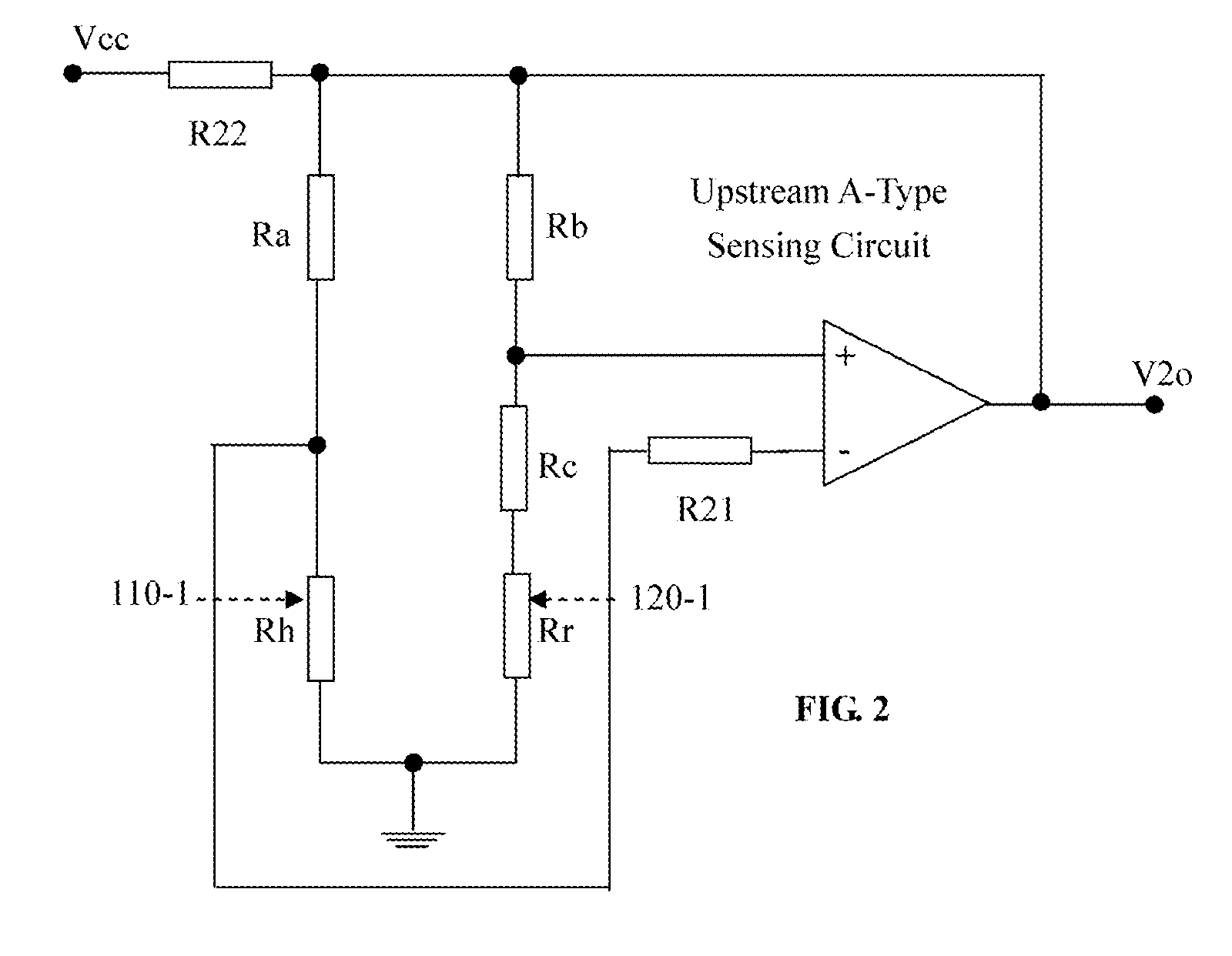

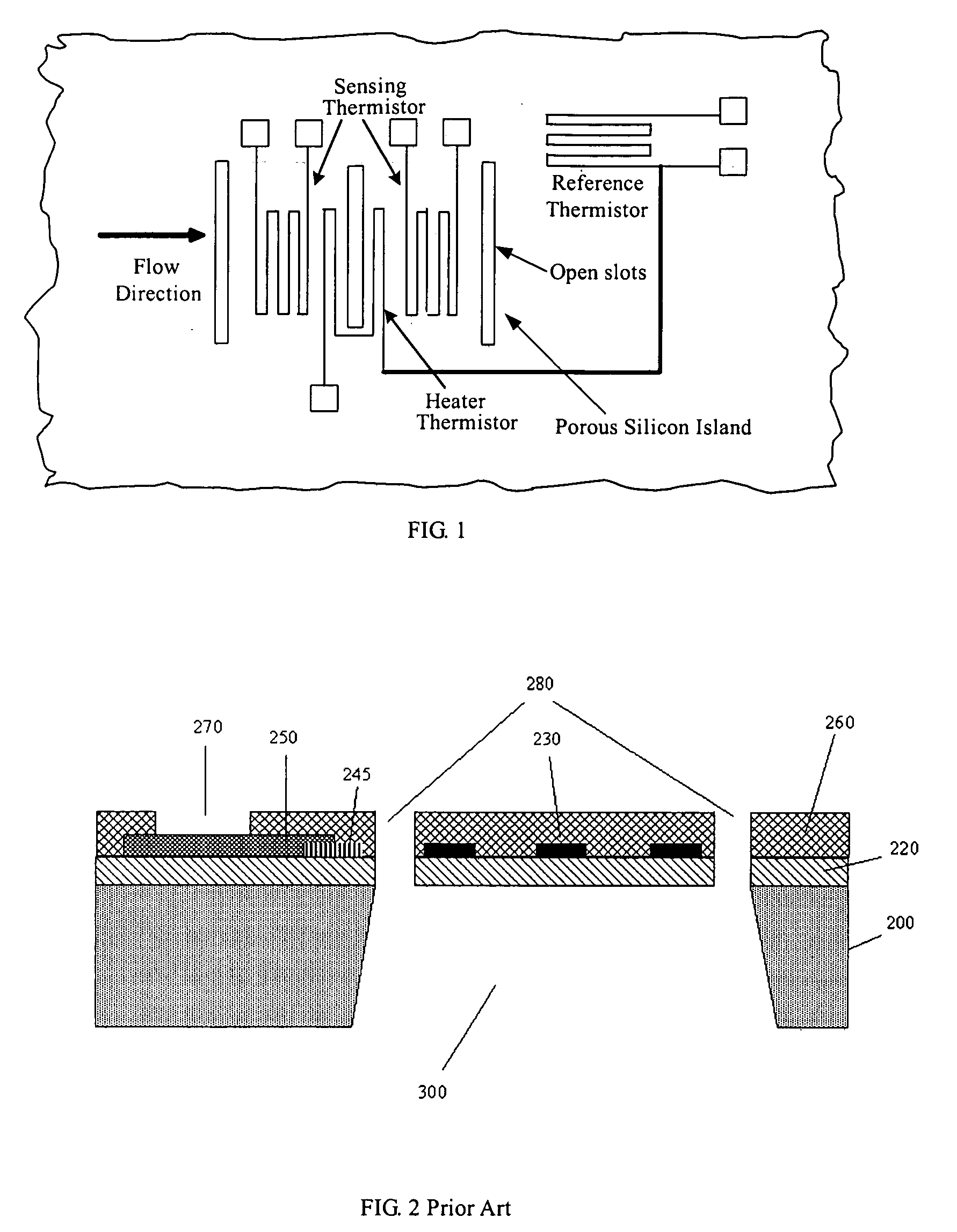

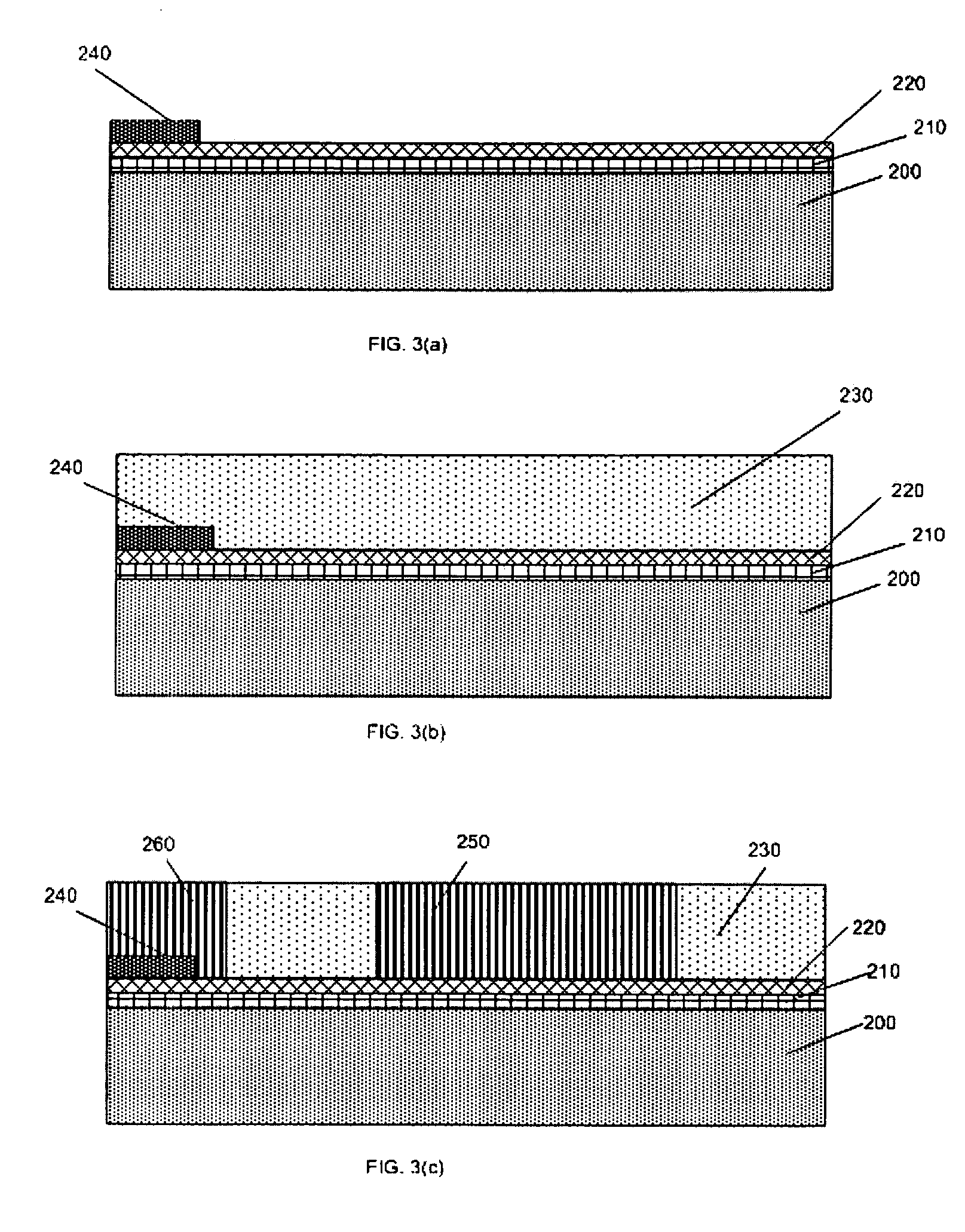

Integrated micromachined thermal mass flow sensor and methods of making the same

ActiveUS20090164163A1Accurate flowIncrease speedTesting/calibration apparatusVolume/mass flow by thermal effectsEngineeringP type silicon

An integrated mass flow sensor is manufactured by a process of carrying out a micro-machining process on an N or P-type silicon substrate with orientation <100>. This mass flow sensor comprises an upstream thin-film heater, an downstream thin-film heater, and a pair of thin-film heat sensing elements, and a thermally isolated membrane for supporting the heaters and the sensors out of contact with the substrate base. This mass flow sensor is operated with three sets of circuits, a first circuit for measuring a flow rate in a first range of flow rates, a second circuit for measuring a flow rate in a second range of flow rates, and a third circuit in a differential configuration for measuring a flow rate in said first range of flow rates or said second range of flow rates, to significantly increase range of flow rate measurements and provide an optional for concentration measurement, while maintains a high degree of measurement accuracy.

Owner:M TECH INSTR HLDG

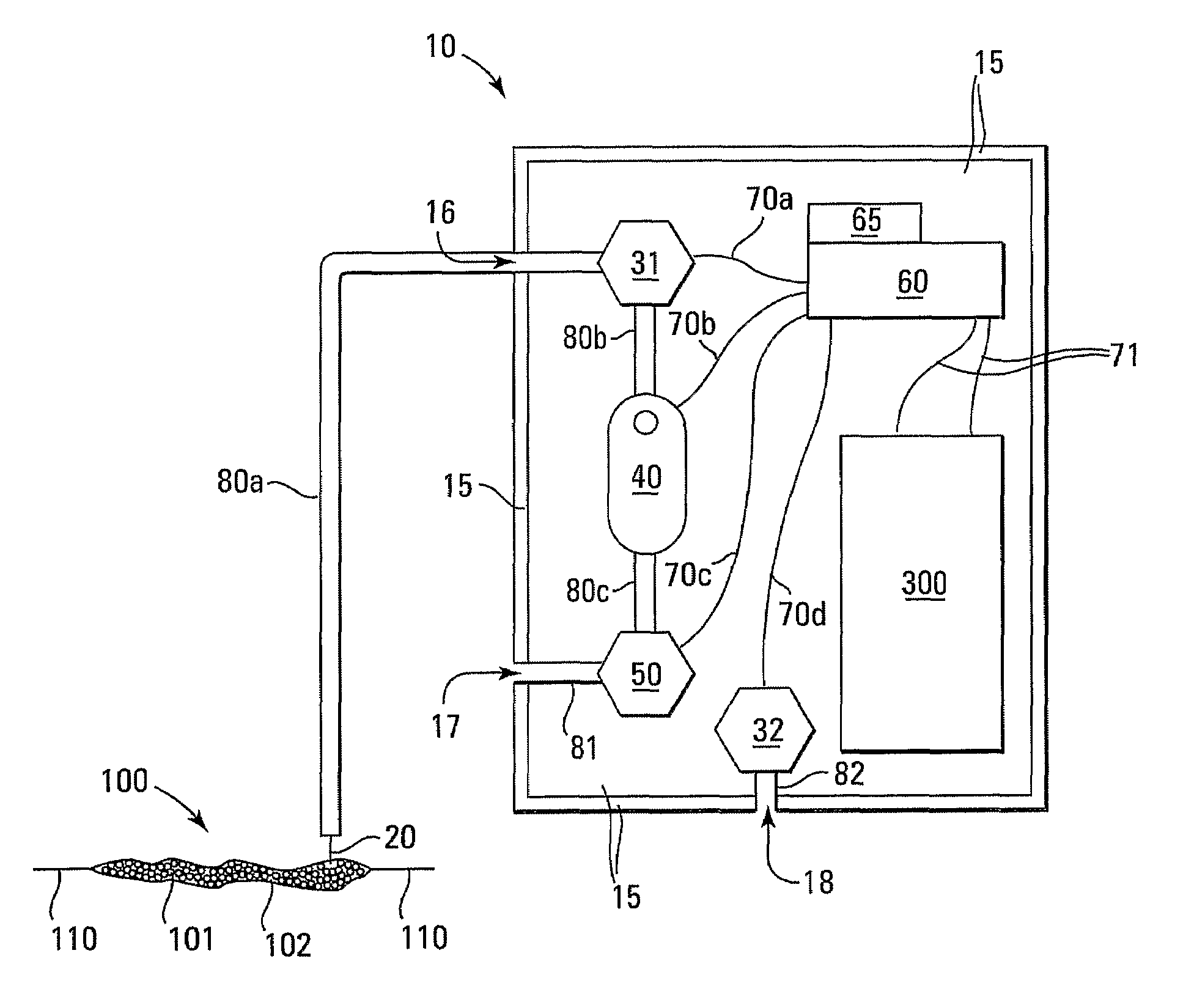

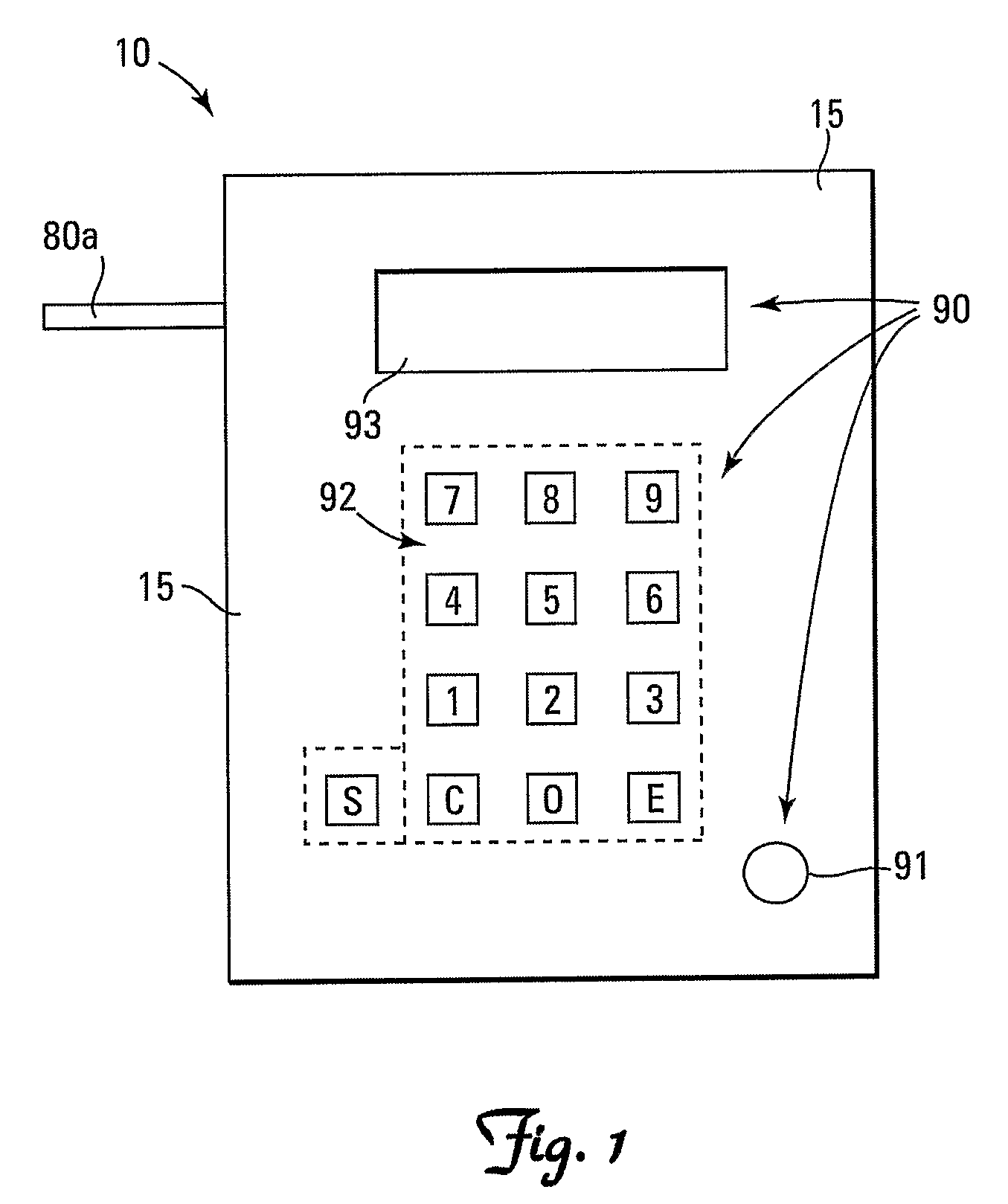

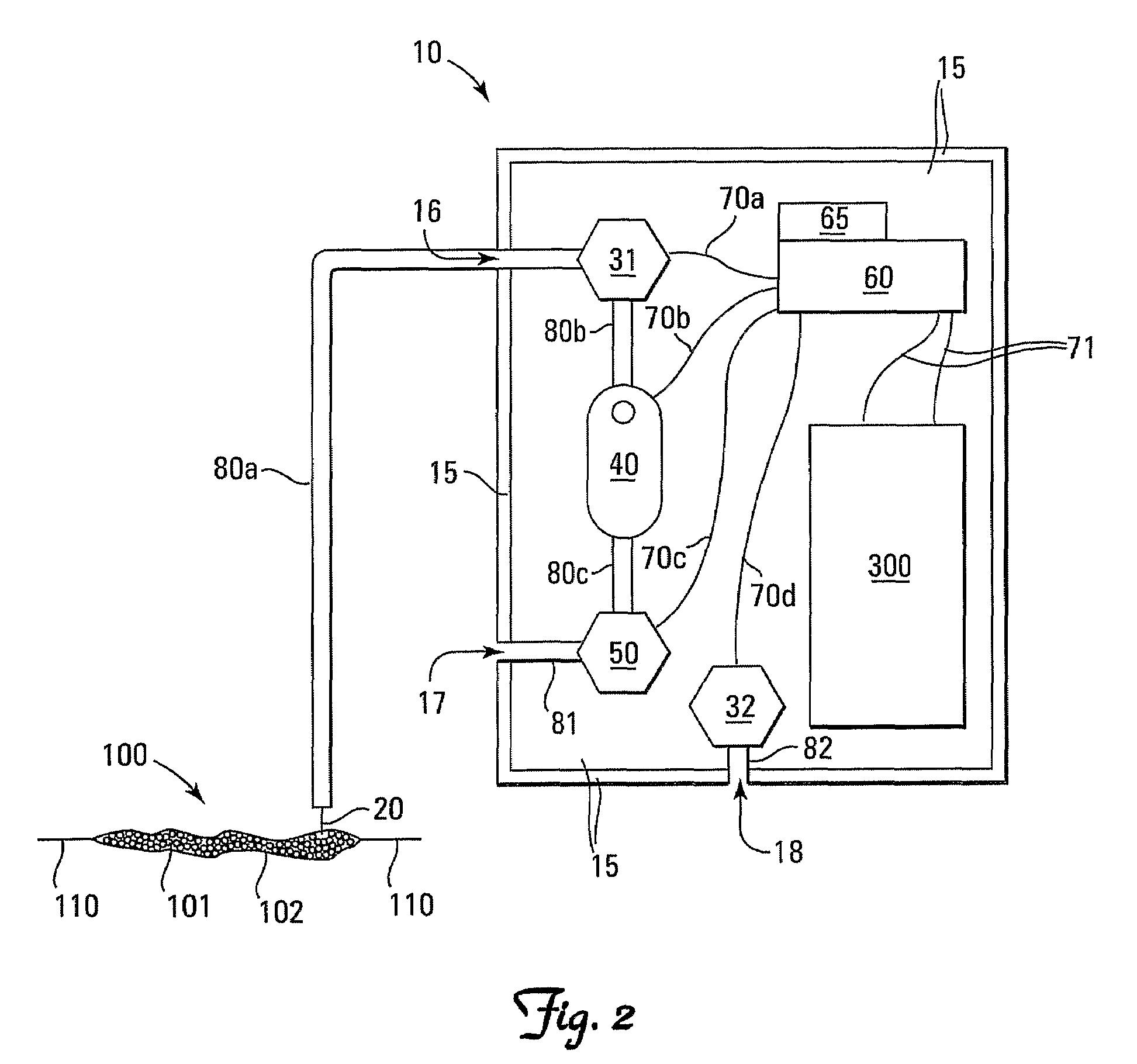

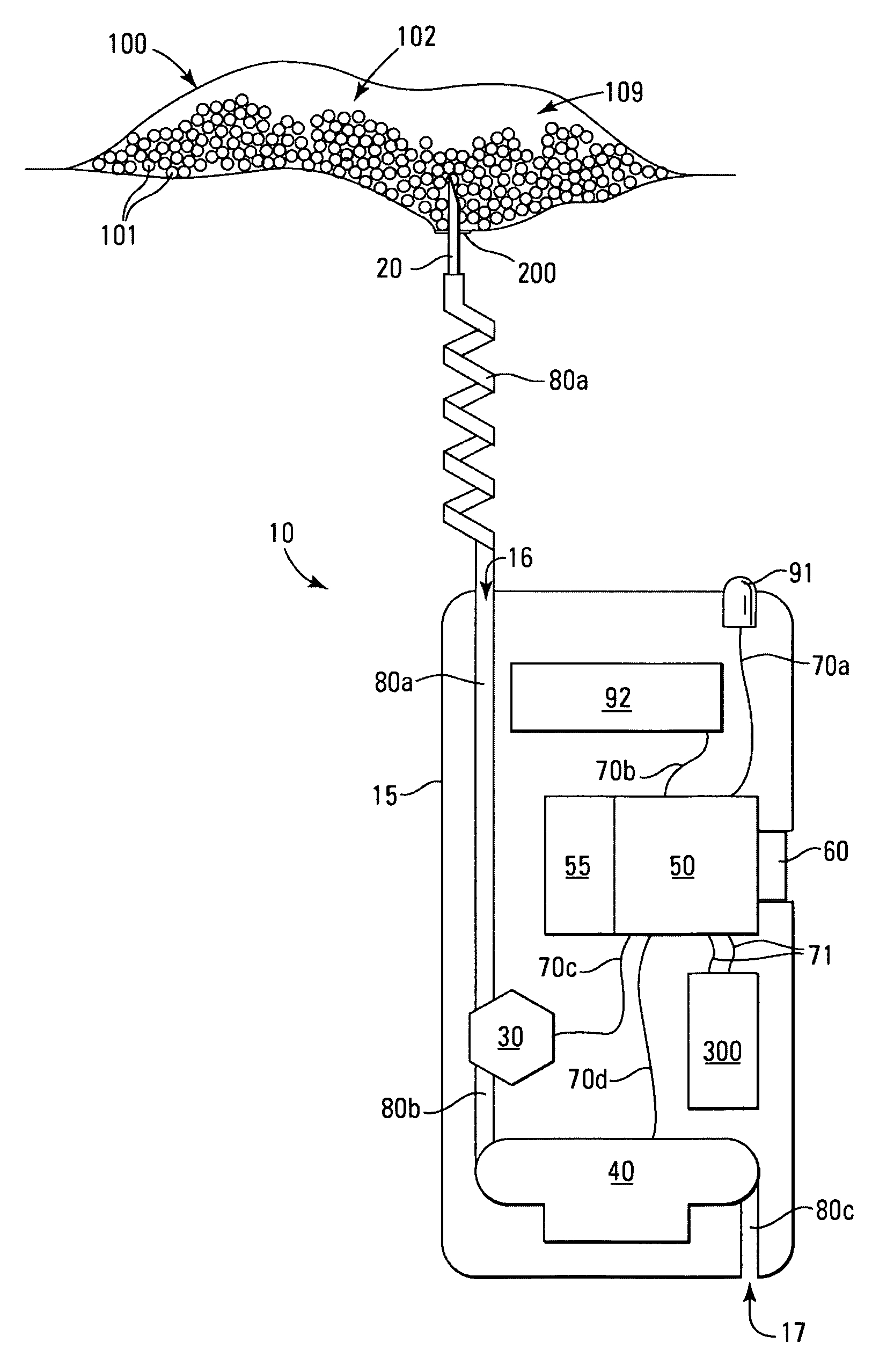

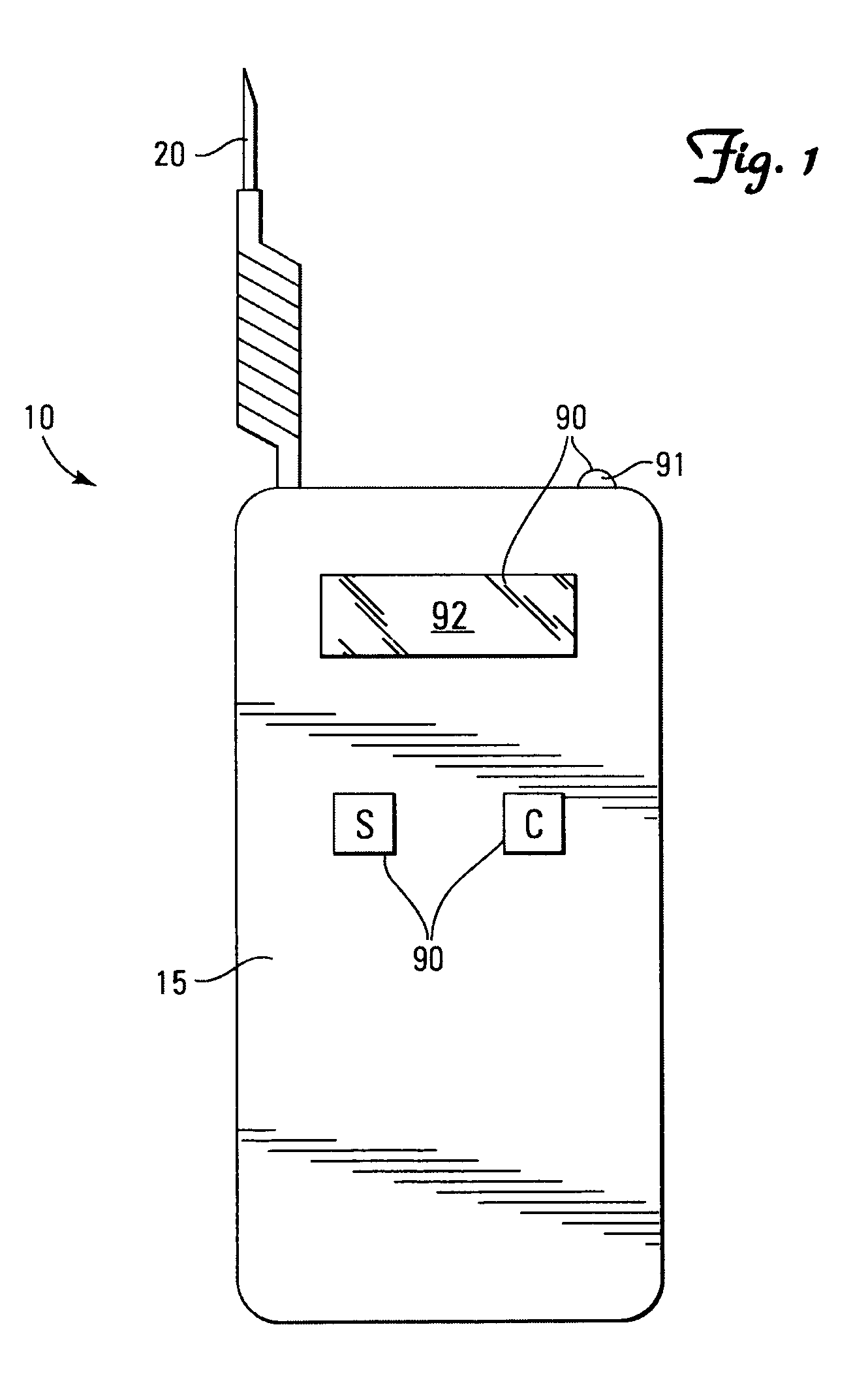

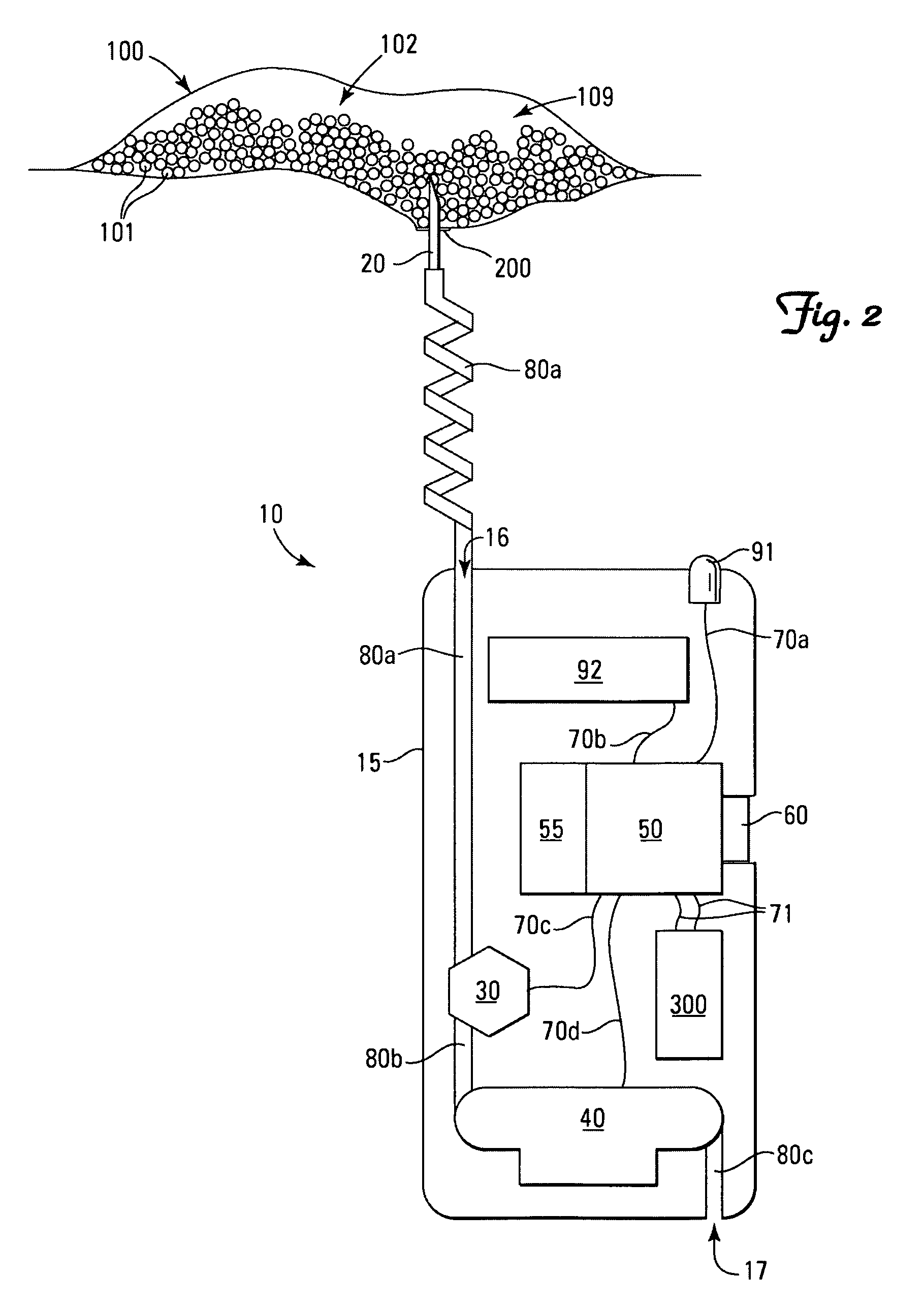

Instrument and method for detecting and reporting the size of leaks in hermetically sealed packaging

An instrument for detecting leaks in a hermetically sealed package. The instrument includes (i) a hollow needle, (ii) a mass flow rate sensor in sealed fluid communication with the lumen defined by the hollow needle, and (iii) a vacuum pump. The vacuum pump is in fluid communication with the lumen defined by the needle for evacuating gas from the hermetically sealed package, and in fluid communication with the mass flow rate sensor for directing mass flow from the evacuated package into operable contact with the mass flow rate sensor so as to permit sensing of any continuing mass flow from the evacuated package. The instrument may further include an oxygen sensor, also in sealed fluid communication with the lumen defined by the hollow needle for analyzing the oxygen concentration of the gas within the hermetically sealed package.

Owner:MODERN CONTROLS

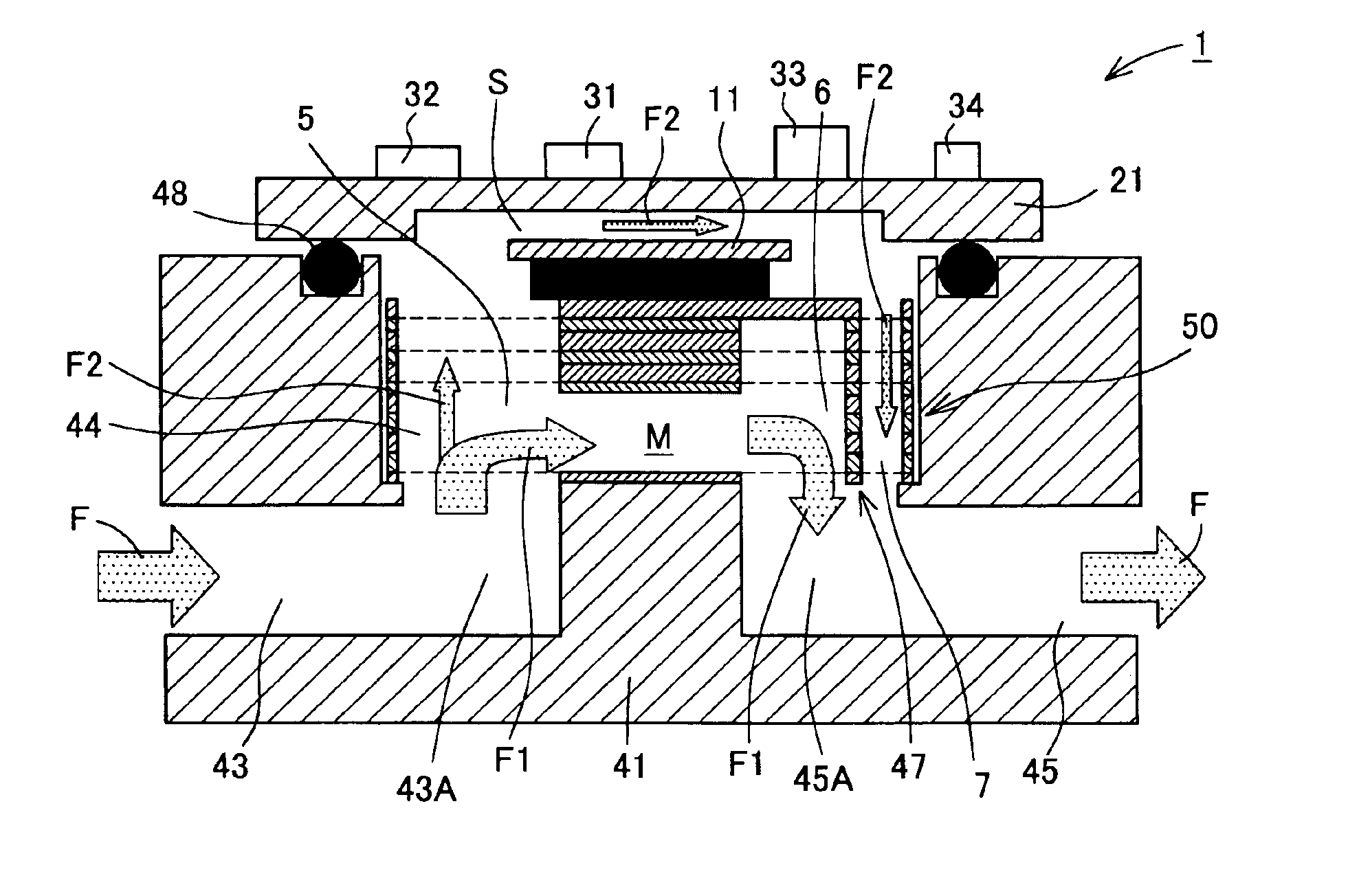

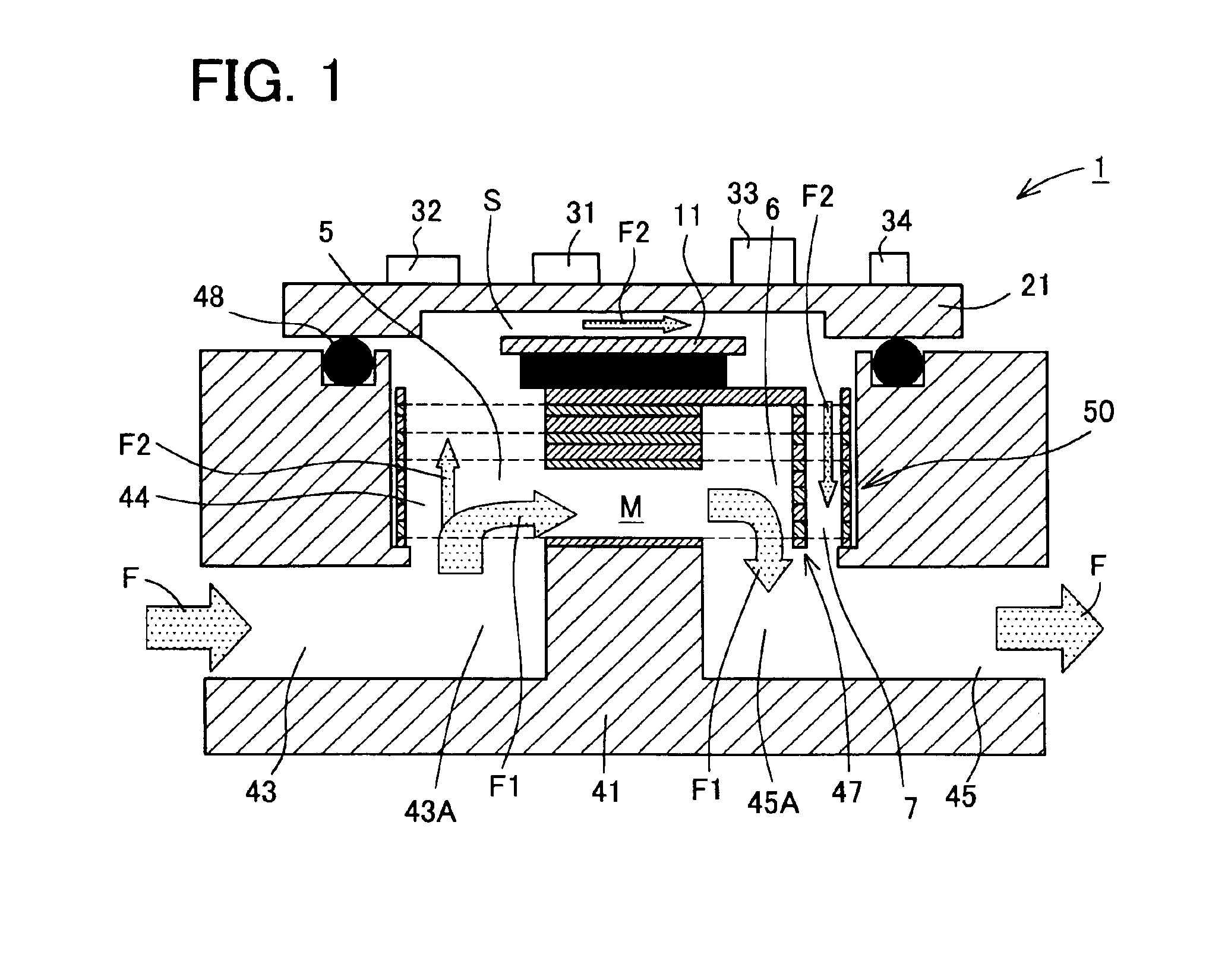

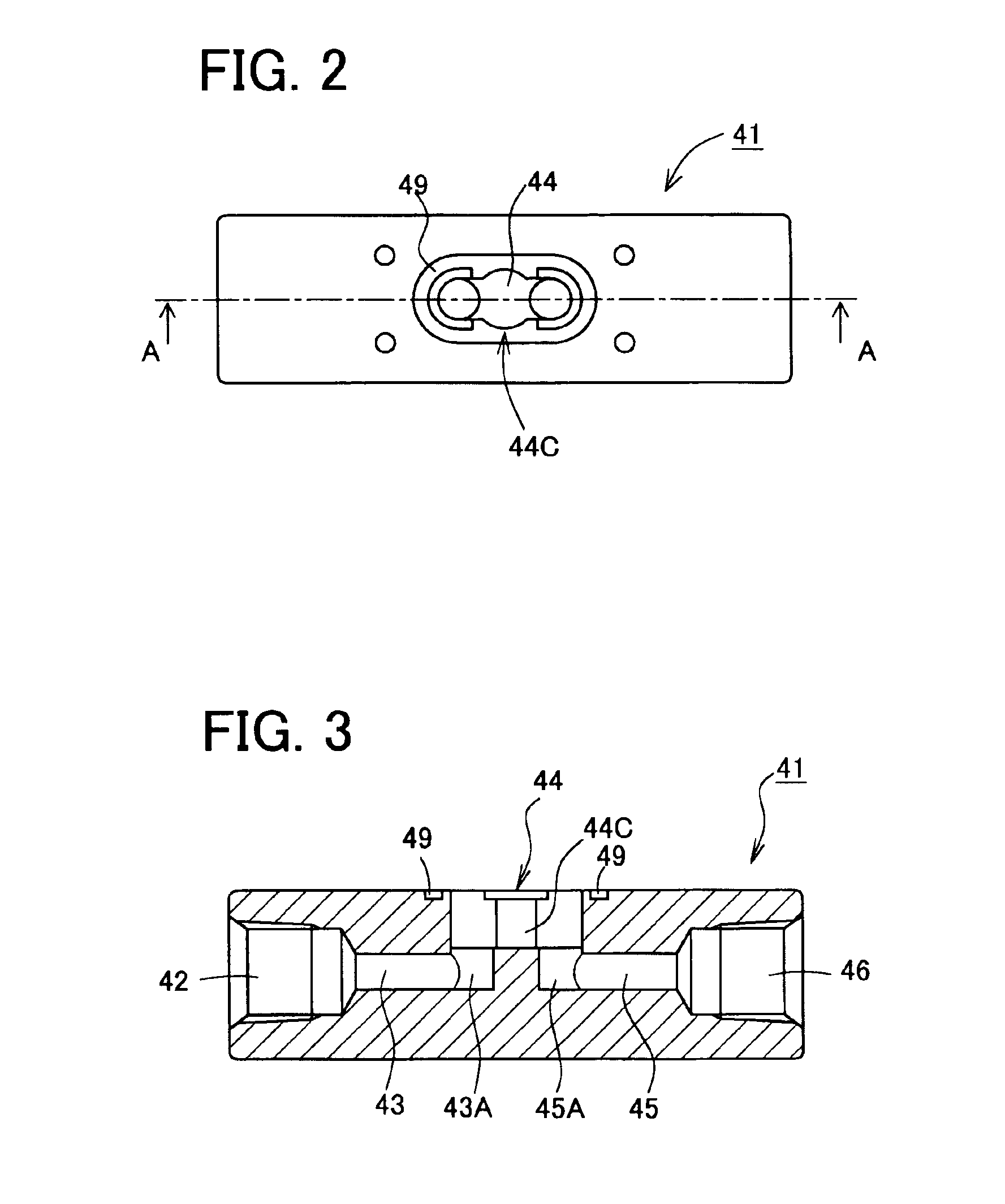

Thermal mass flow rate sensor including bypass passageways and a sensor passageway having similar entrance effects

ActiveUS7107834B2Type accurateCalibrationVolume/mass flow by thermal effectsVolume flow proportion measurementEngineeringBypass ratio

A sensing apparatus for use in a mass flow rate sensor for measuring a fluid flow rate includes a main conduit for containing a fluid flow, and a sensor passageway for tapping a portion of the fluid flow from the main conduit at a first location, and returning the portion of the fluid flow to the conduit at a second location. At least one bypass passageway, which may be provided in the form of a tube, is positioned in the main conduit between the first and second locations, and the bypass passageway is provided with non-negligible entrance effects that are substantially equal to entrance effects of the sensor passageway, so that a bypass ratio of the apparatus remains constant. A mass flow rate sensor of the present disclosure accurately measures any type of gas but only requires calibration in only one reference gas.

Owner:MKS INSTR INC

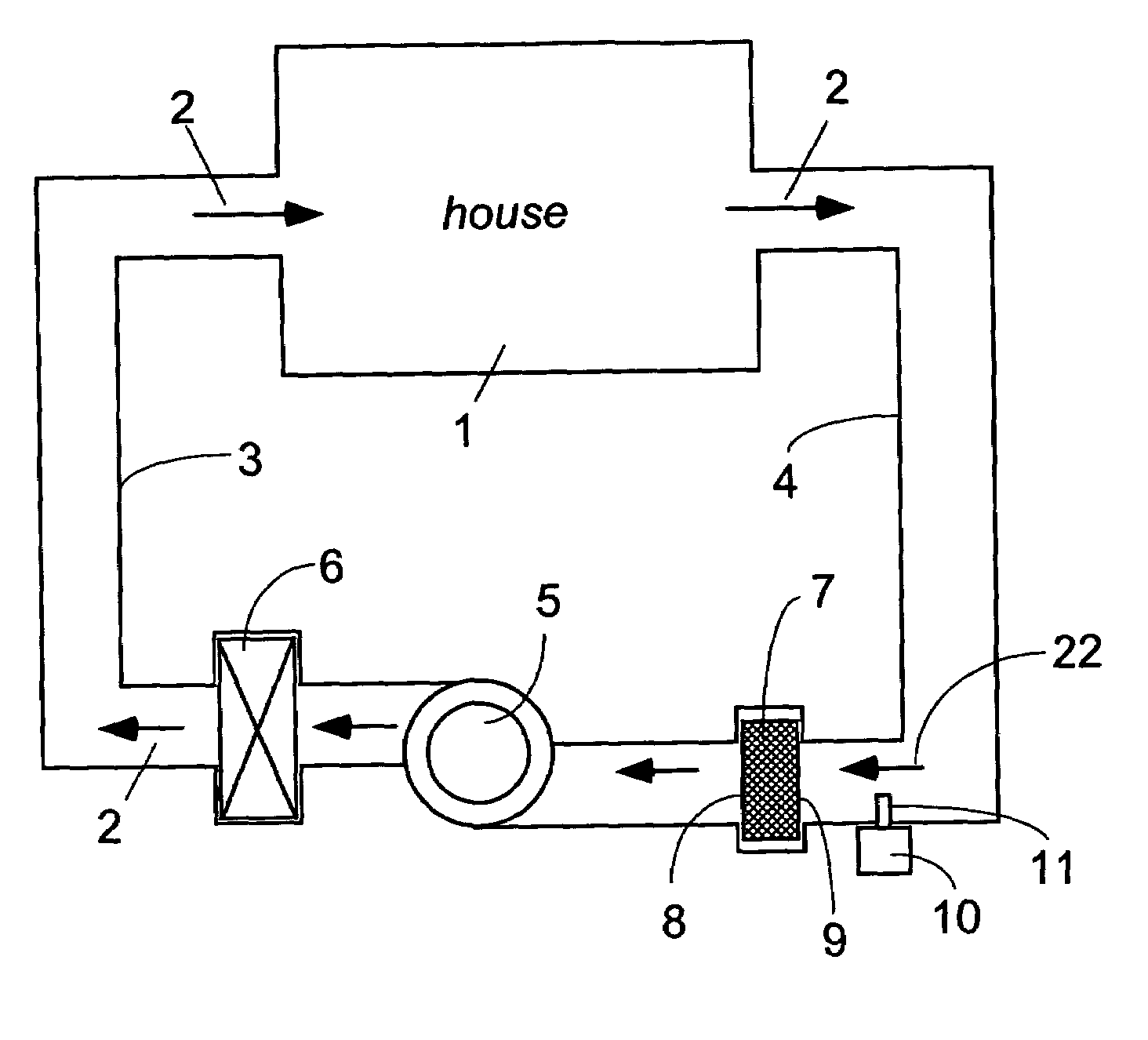

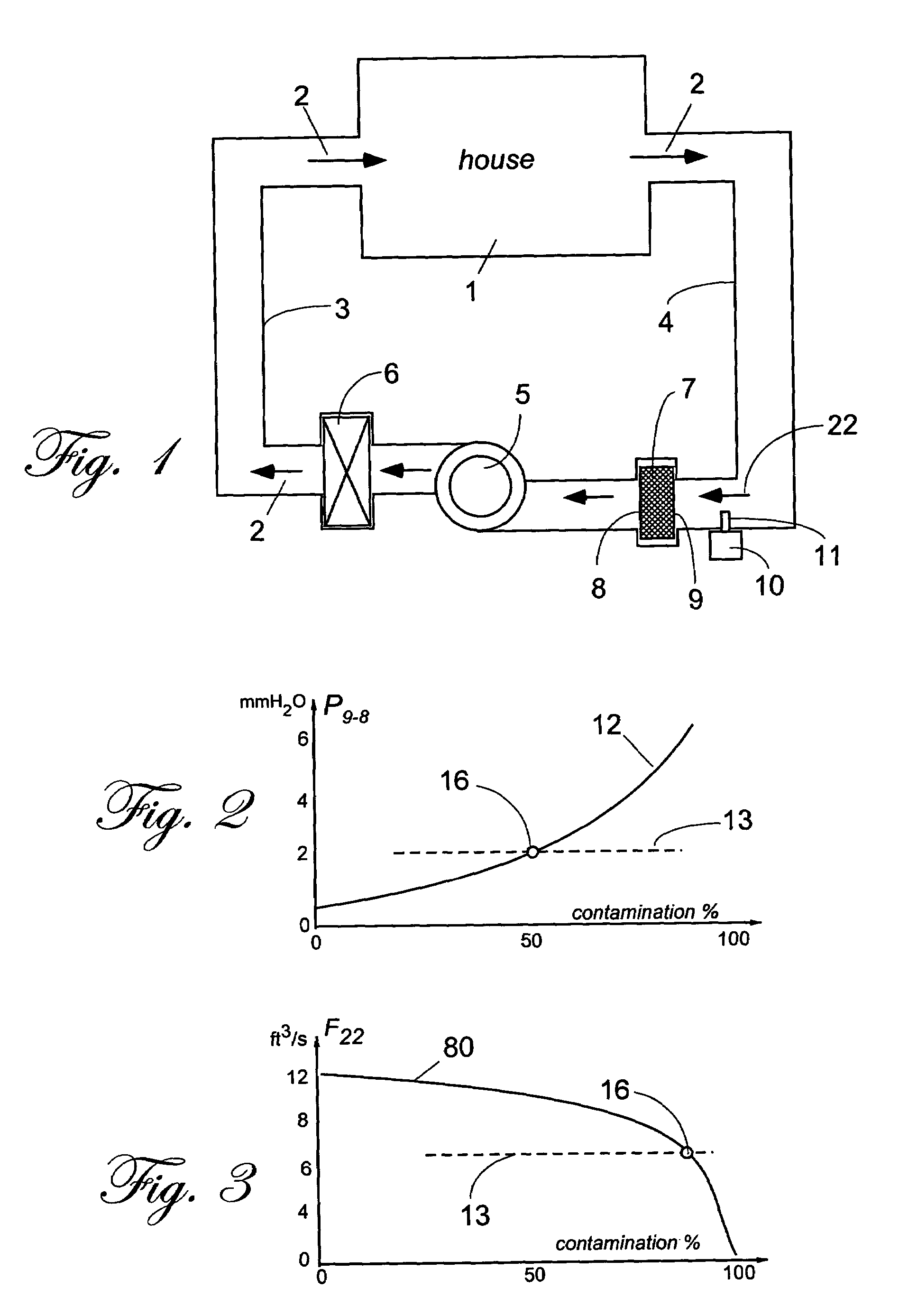

Clogging detector for air filter

The detector for monitoring decrease in air flow rate due to air filter clogging. It is based on combination of three essential components: the air flow sensor, a threshold detector and an indicator. The air flow sensor is built in form of a novel thermo-anemometer which contains a thermistor, a heating element, and a thermal insulator. Temperature of the sensor is maintained above the air temperature by a constant value by means of an electronic servo circuit. The threshold detector is implemented either in a hardware or software. A novel design of a thermo-anemometer (closely related to a hot wire anemometer) automatically compensates for variations in the air temperatures. The thermo-anemometer triggers the threshold circuit when air flow rate drops below a preset level. For reduction of power consumption, the detector may employ two additional sensors: one is for detection of the blower operation and the other is a presence detector to enable the alarm in presence of people to perceive the alarm. The device automatically calibrates itself upon installation of a new or cleaned air filter. The applications include residential and commercial air conditioners, air heaters, internal combustion engines, vacuum cleaners and other systems where air filters are employed.

Owner:CLEAN ALERT

Control device for internal combustion engine

ActiveUS7441544B2Short calculation timeImprove accuracyElectrical controlInternal combustion piston enginesResponse delayThrottle opening

Provided is a control device for an internal combustion engine, which is provided to allow a throttle opening degree to be controlled in accordance with a target engine intake air flow quantity even during transitional operation. The actual cylinder intake air flow quantity calculating unit (21) calculates a response delay model for an intake system from a volumetric efficiency equivalent value (Kv) calculated from a rotational speed (Ne) of an engine (1) and an intake manifold pressure (Pim), an intake pipe volume (Vs), and a displacement (Vc) of each of cylinders (2), and calculates an actual cylinder intake air amount (Qcr) from an actual engine intake air amount (Qar) obtained from an air flow sensor (4) and the response delay model. The intake air flow quantity controlling unit (24) controls the throttle opening degree (TP) in accordance with the target engine intake air amount (Qat).

Owner:MITSUBISHI ELECTRIC CORP

Thermal flow sensor having sensor and bypass passages

InactiveUS6886401B2Stably producing measurement outputVolume/mass flow by thermal effectsVolume flow proportion measurementMechanical engineeringMass flow sensor

Owner:CKD

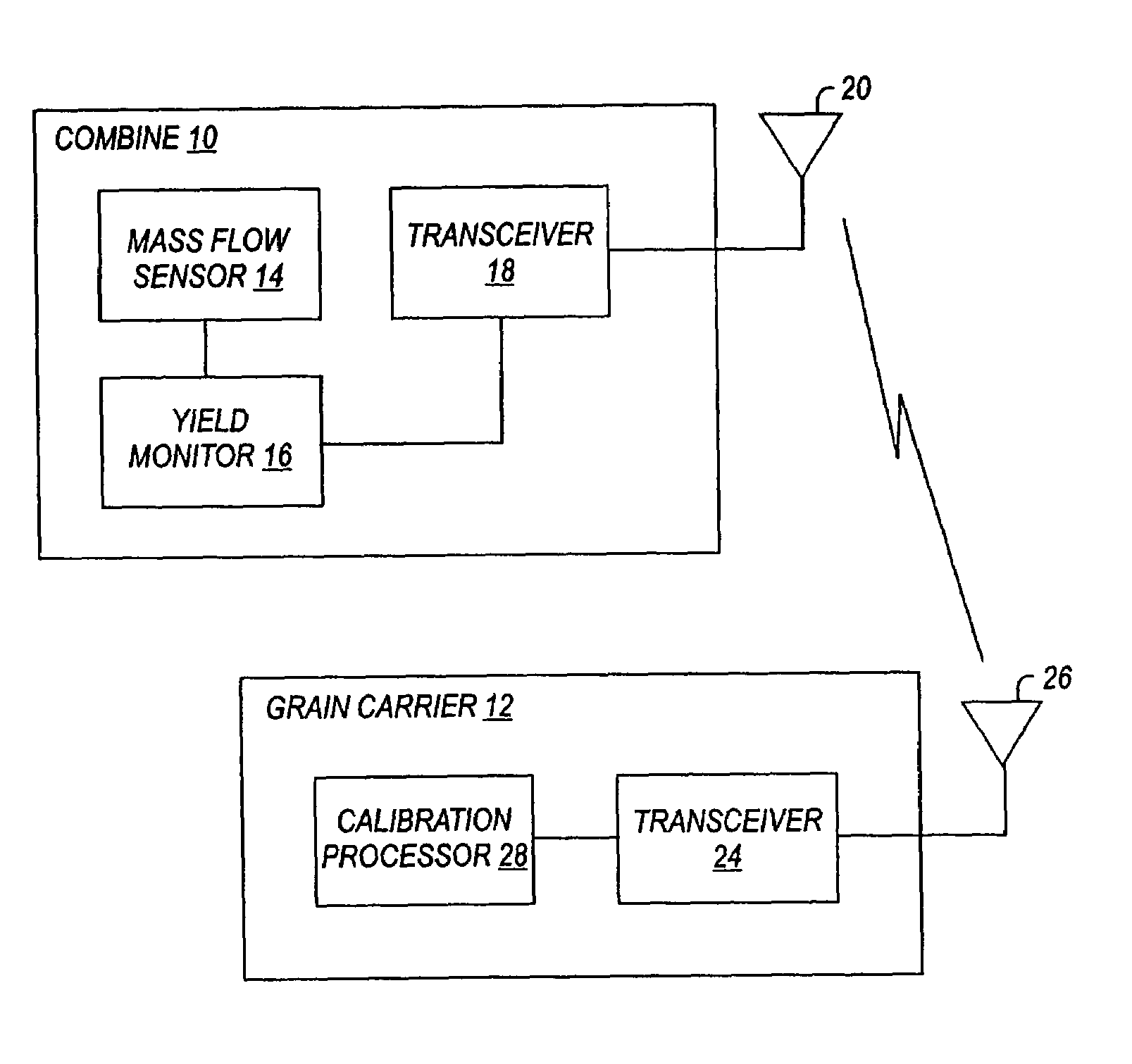

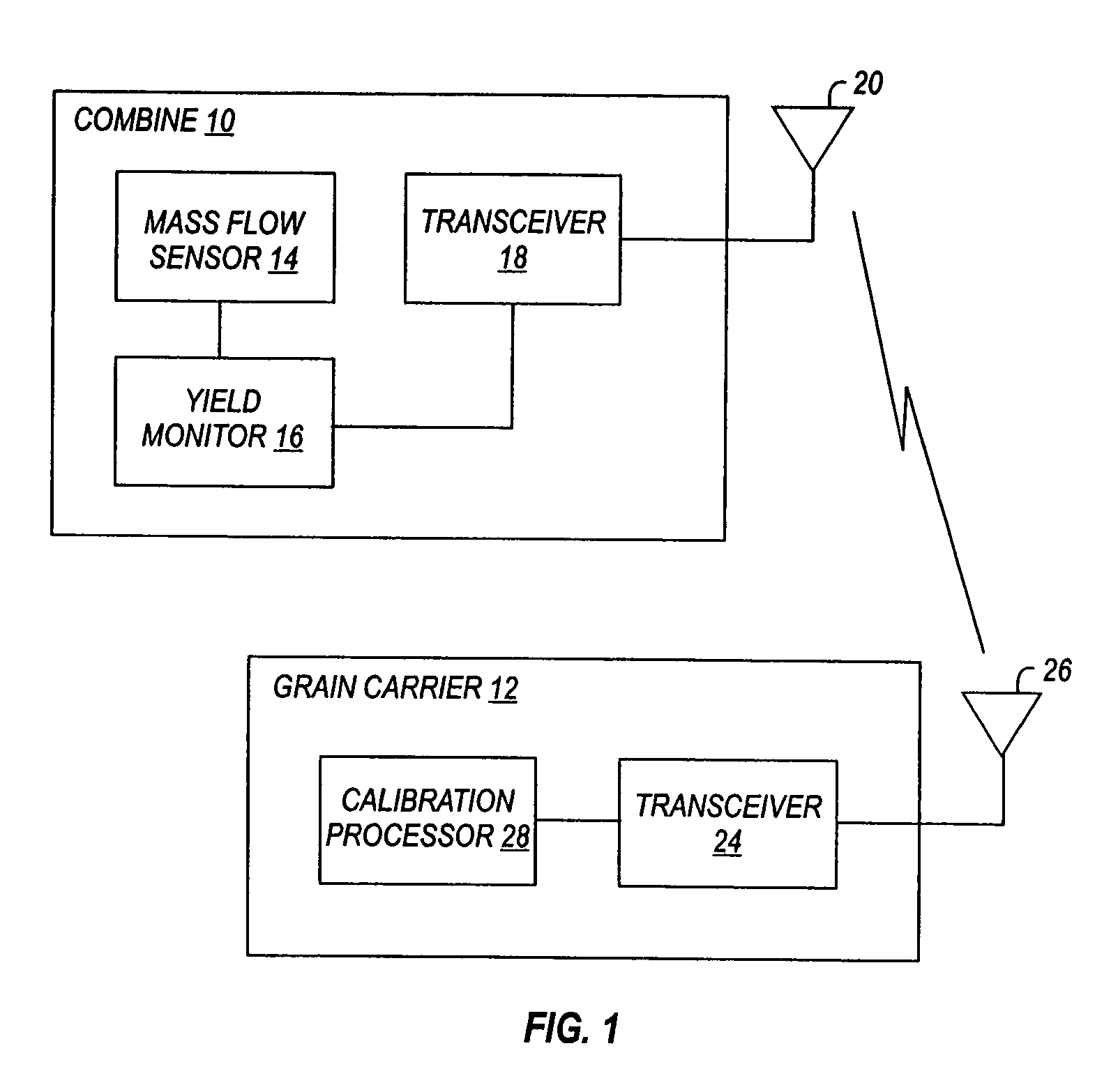

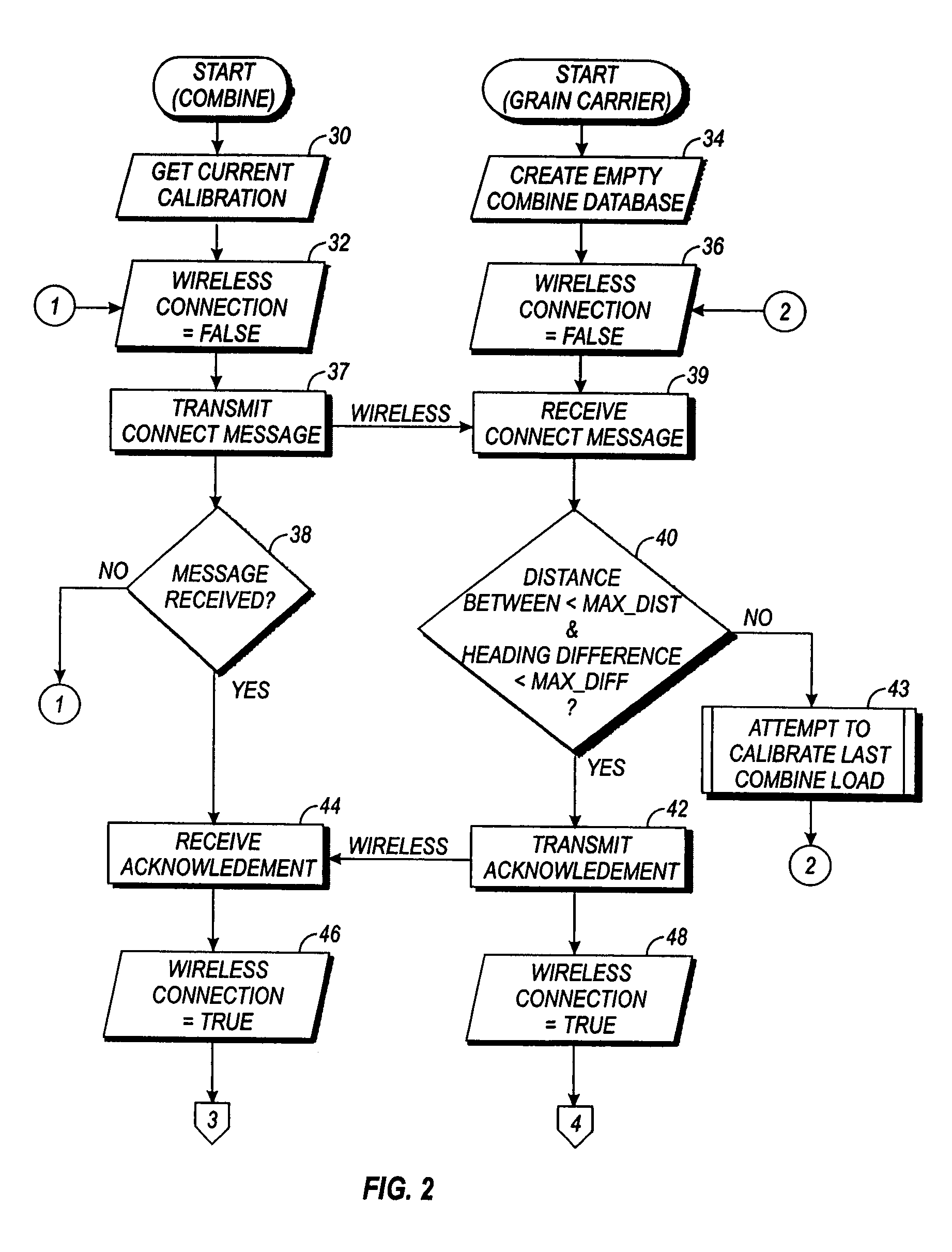

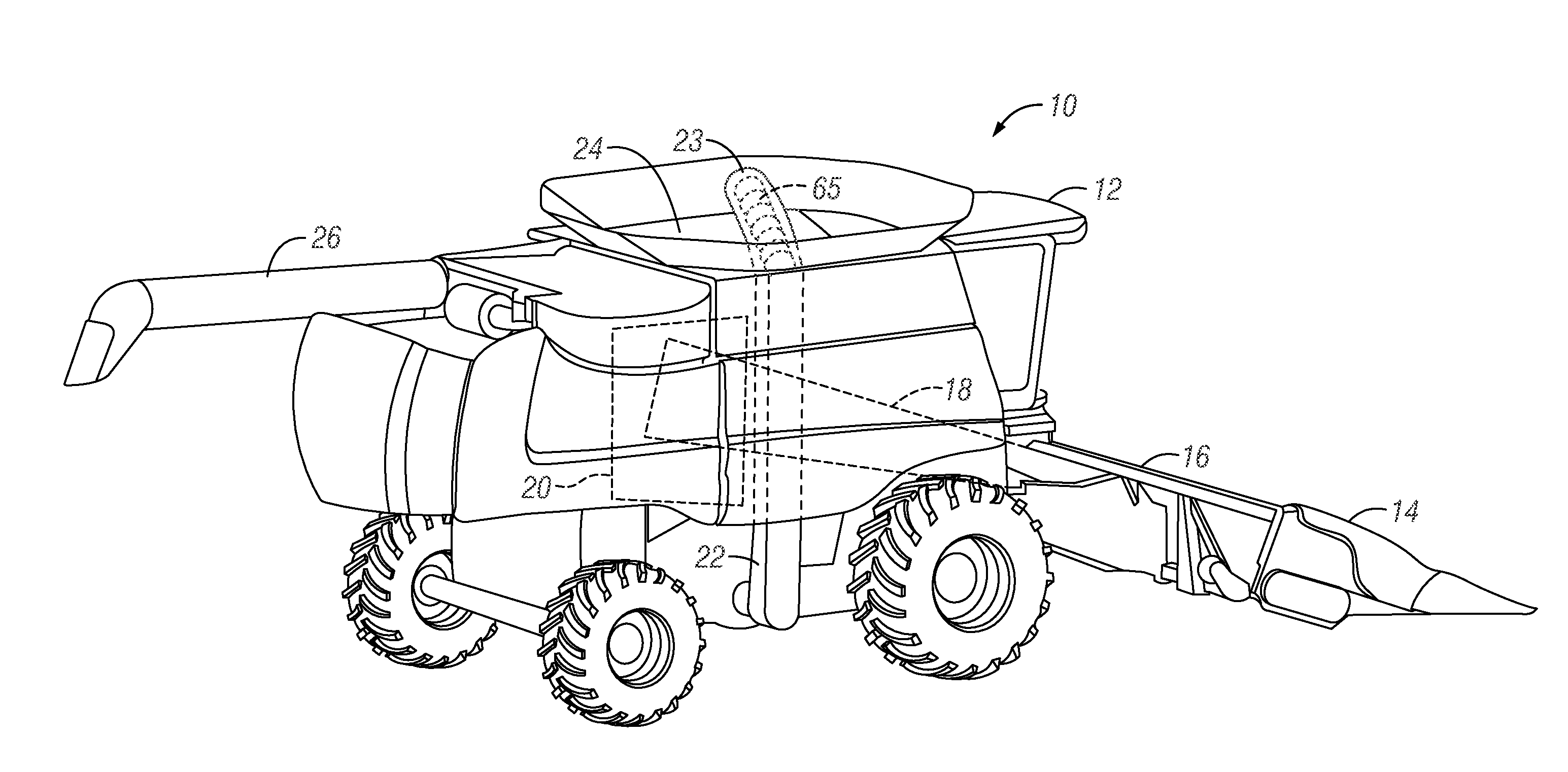

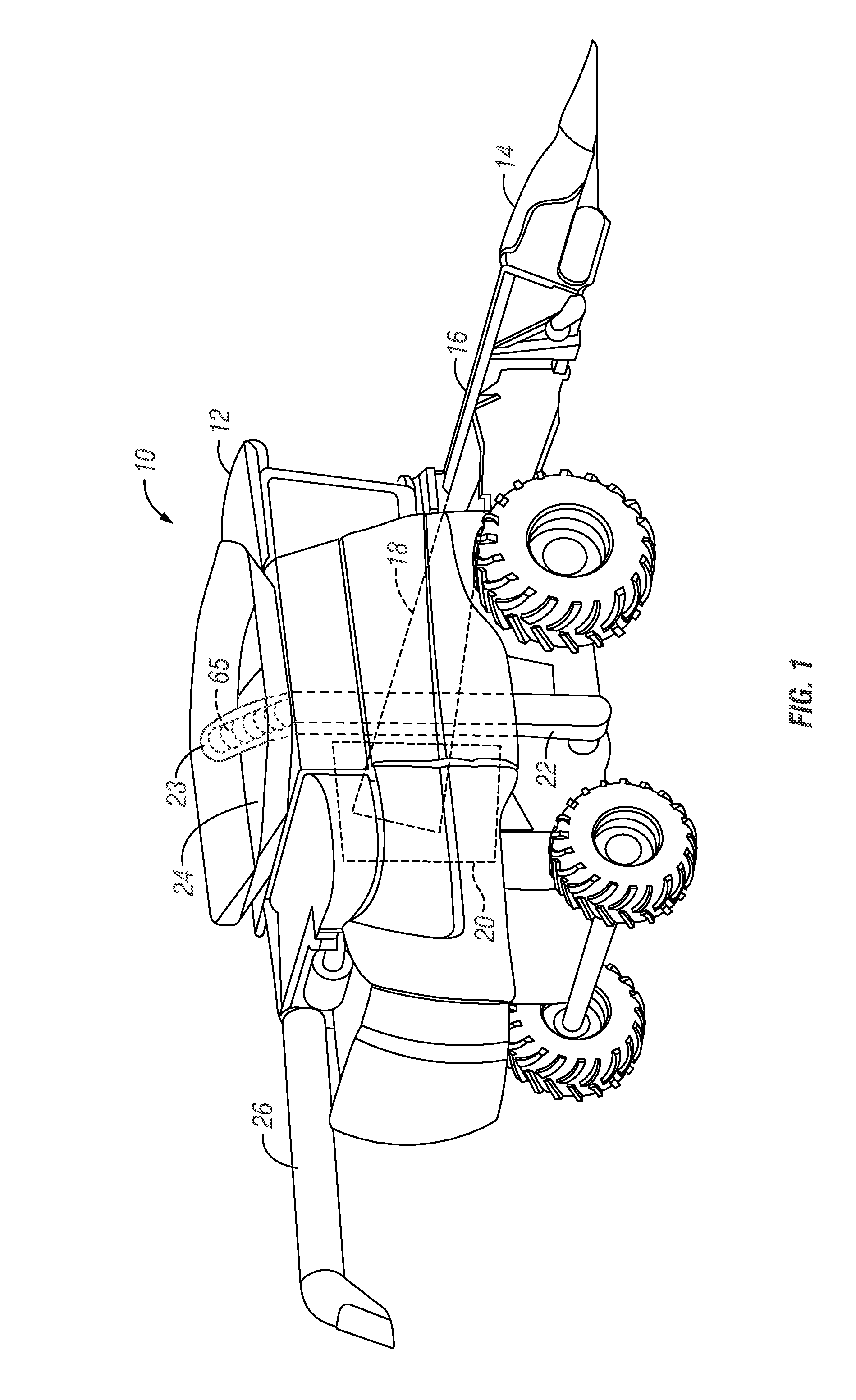

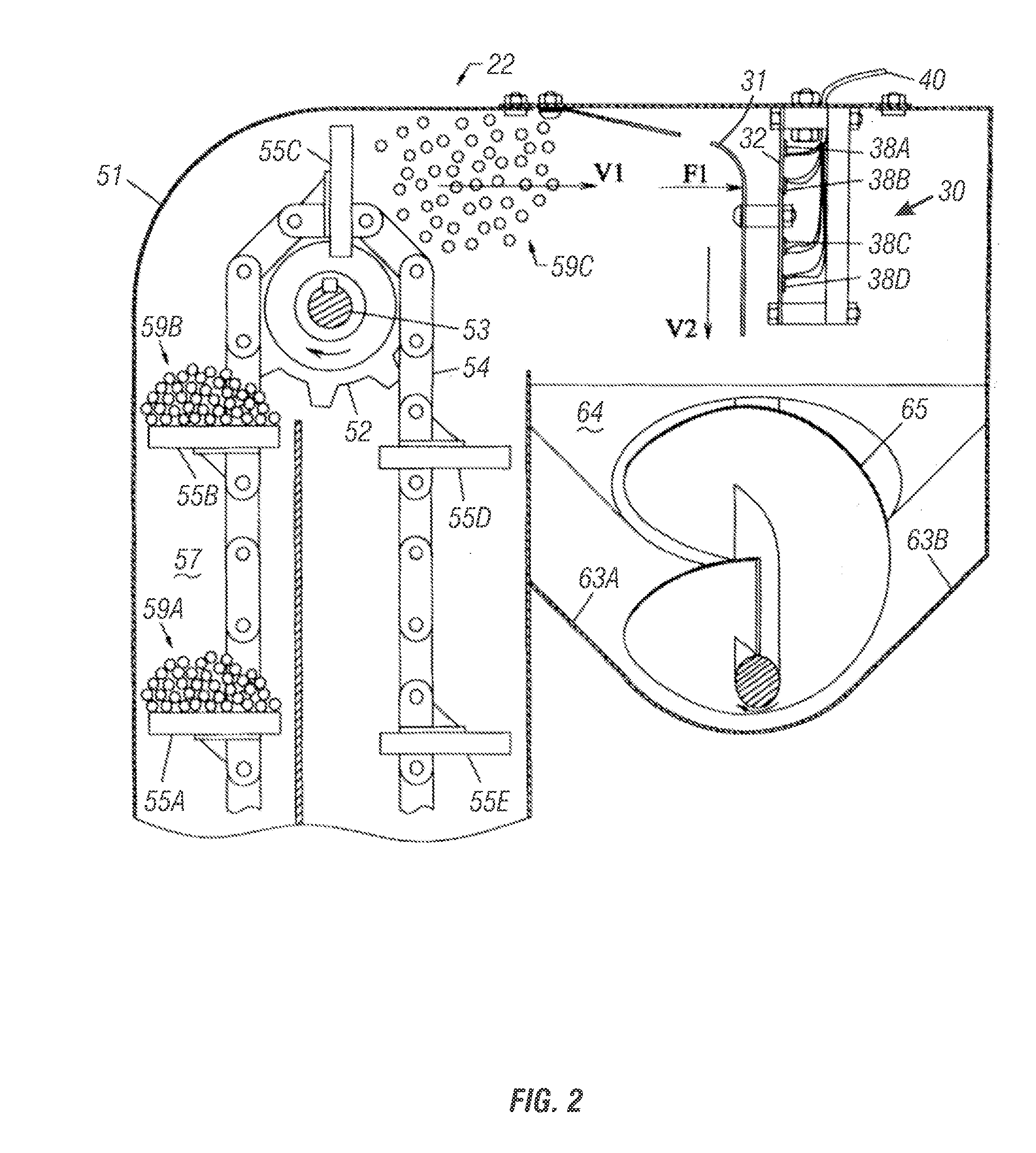

Automatic mass-flow sensor calibration for a yield monitor

A system and method is provided for remotely and automatically calibrating a mass-flow sensor in a yield monitor of a combine. The invention uses a wireless communication device installed on a combine and a remote wireless communication device installed on a grain carrier or truck carrier. Once an actual weight is obtained, calibration information is sent to the combine to calibrate the mass-flow sensor.

Owner:DEERE & CO

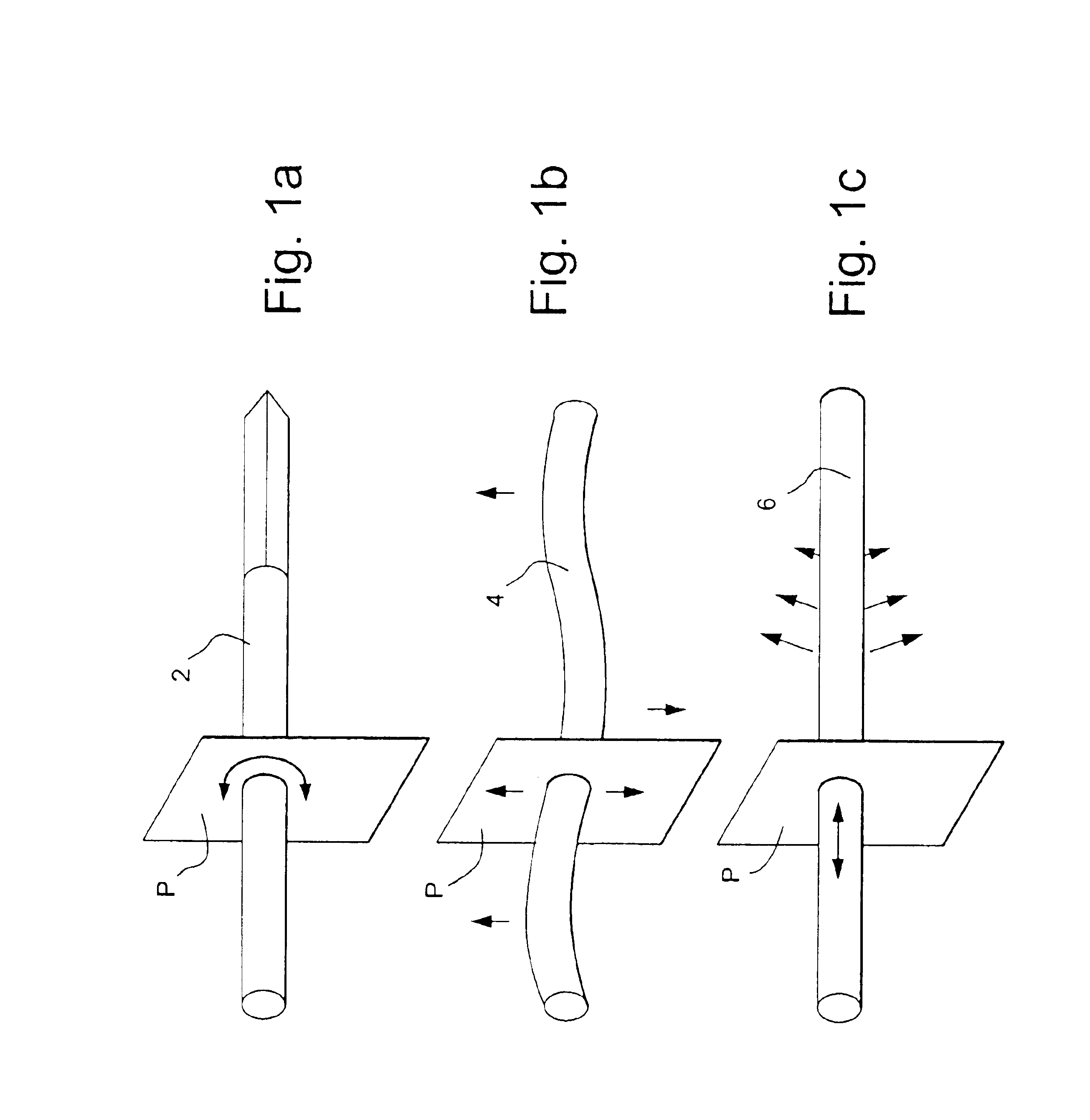

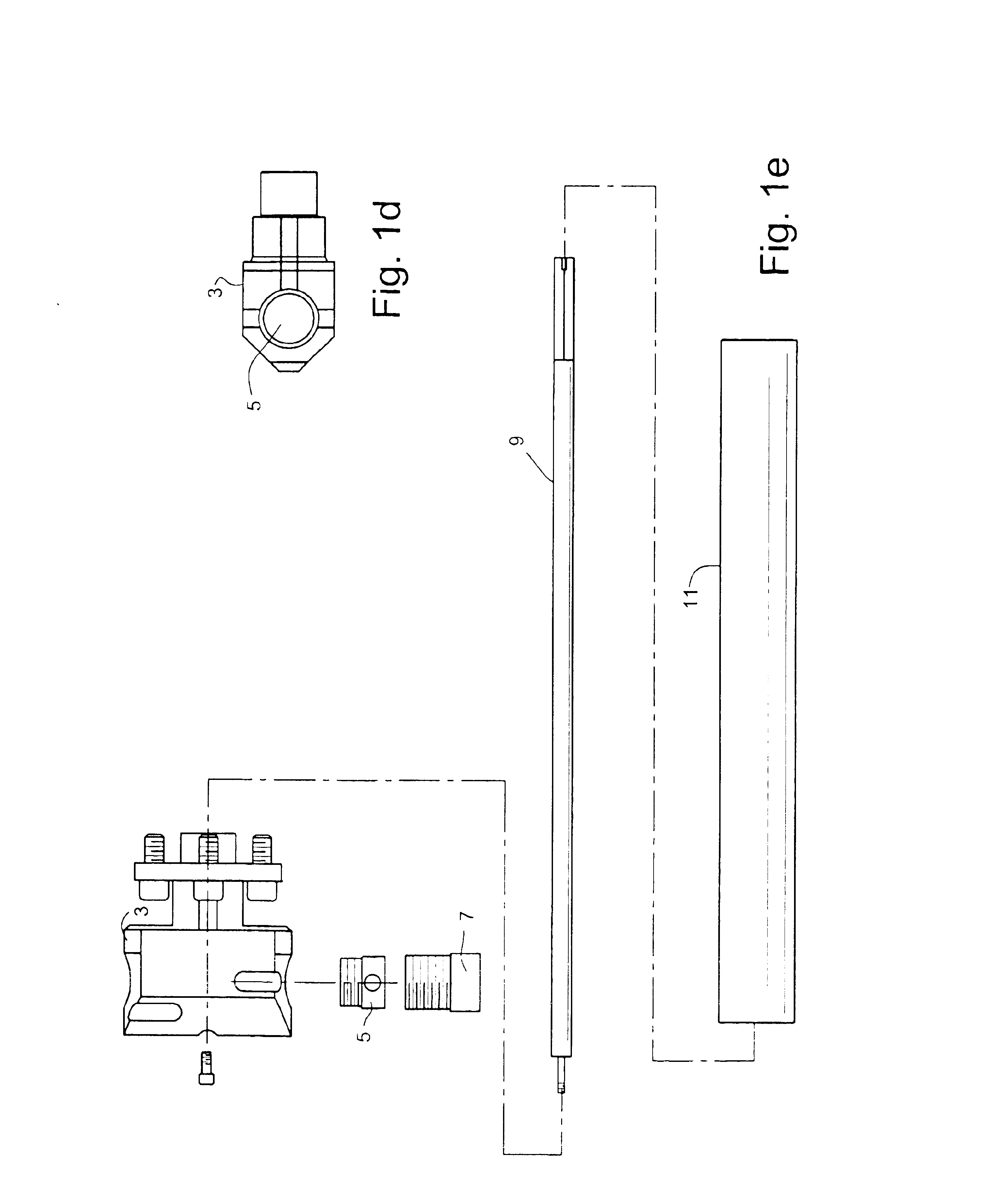

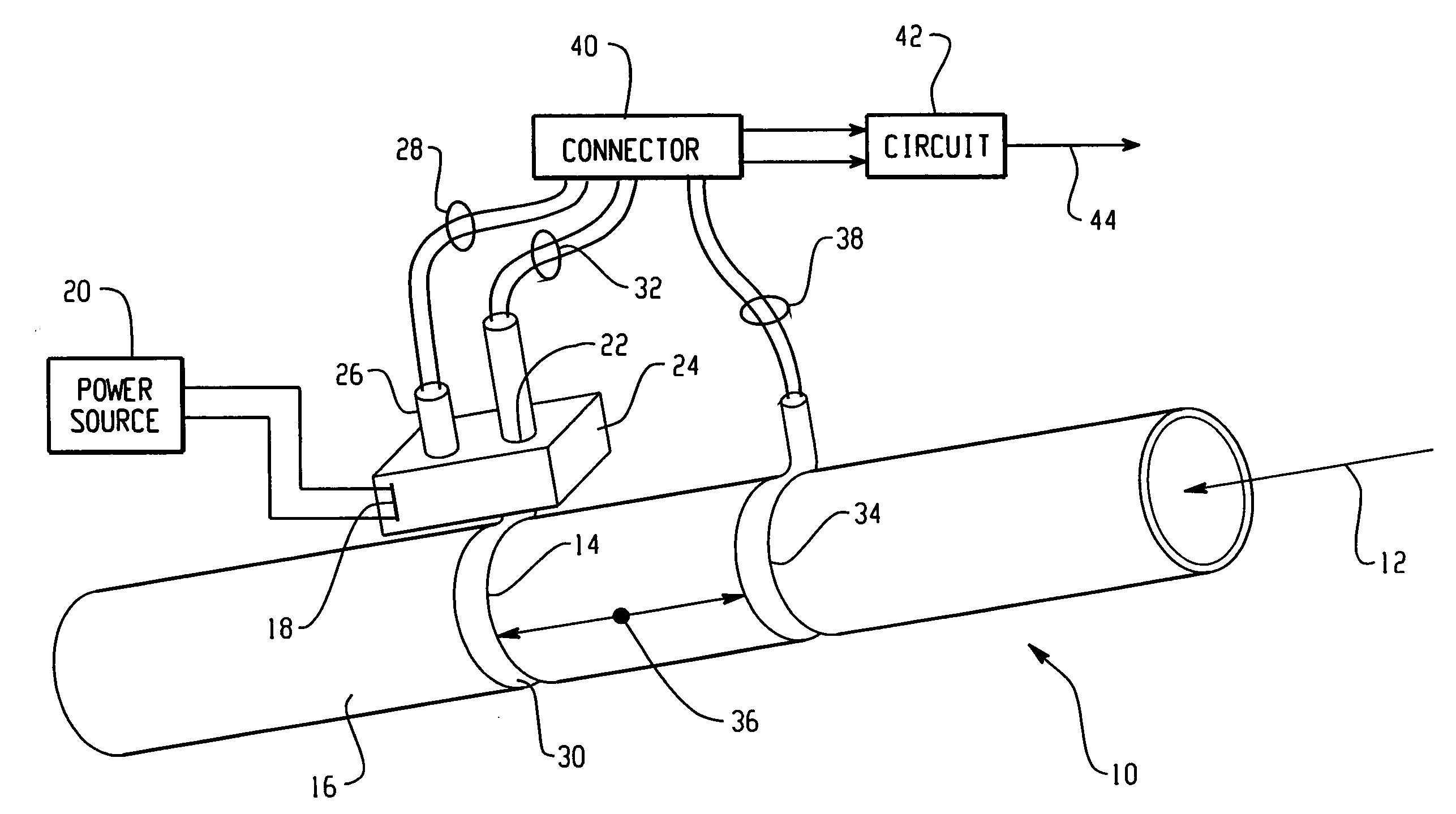

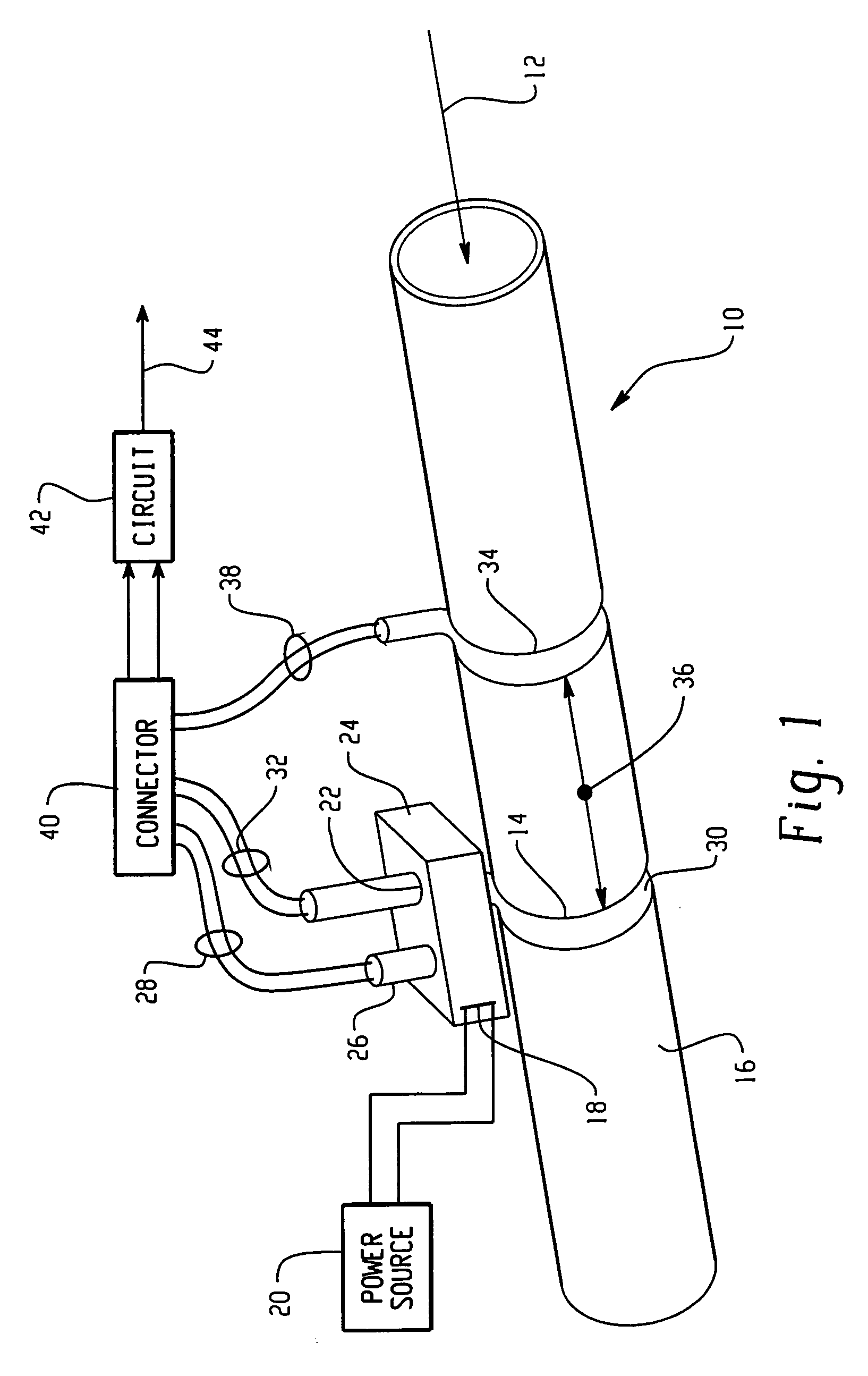

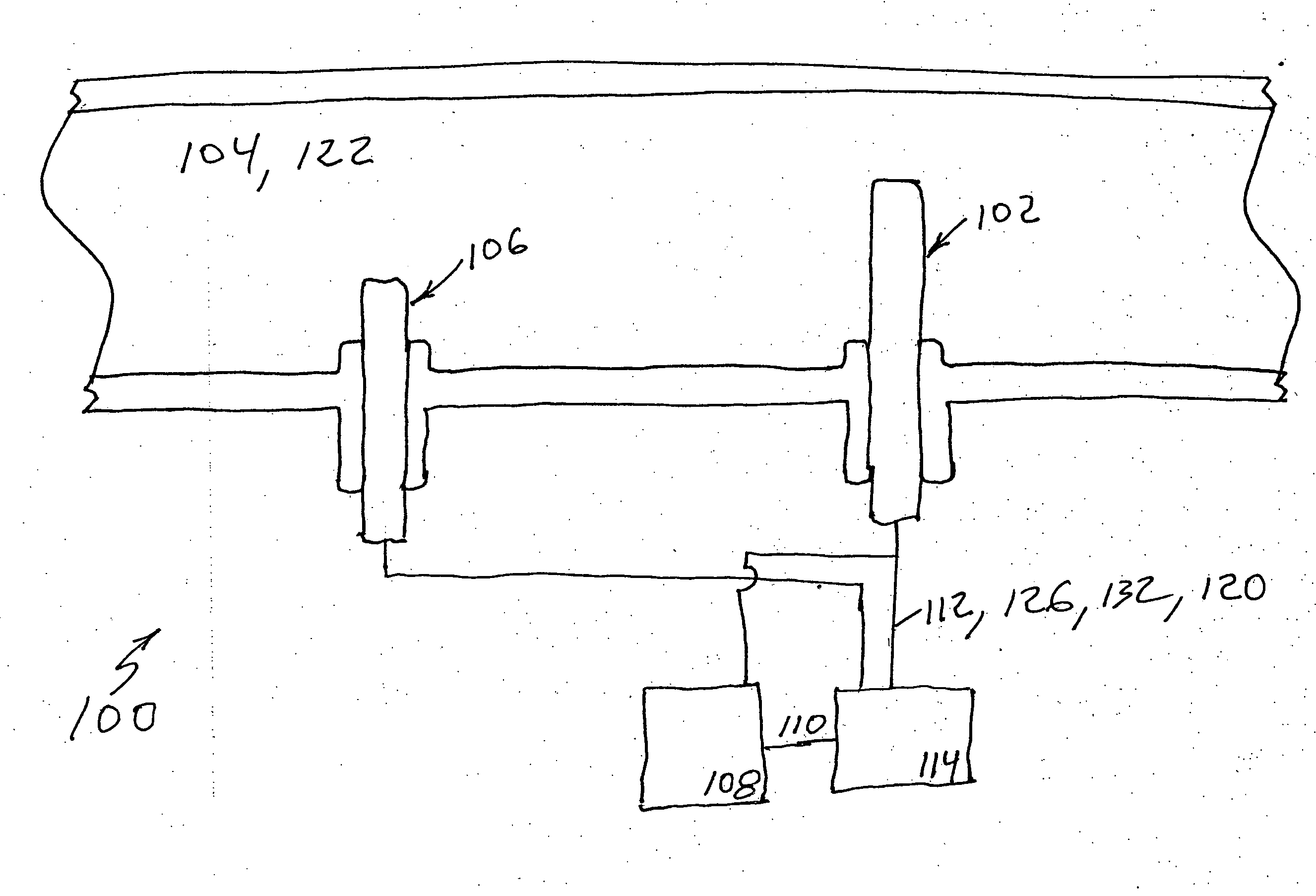

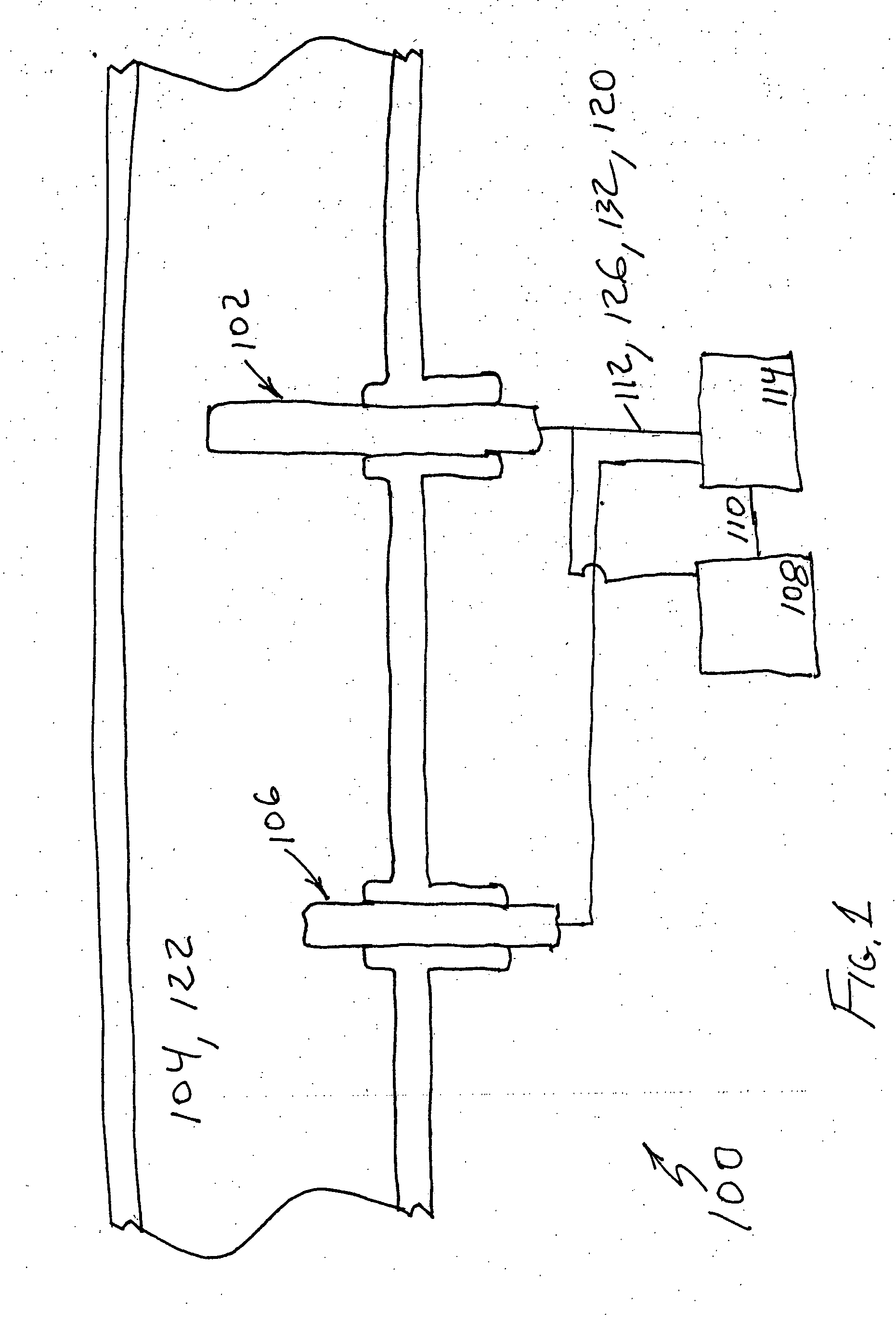

Sensor and method of measuring mass flow non-intrusively

A non-intrusive sensor for measuring mass flow of a medium flowing through a tube comprises: a probe having a predetermined length disposed along an external wall of the tube; a heater for heating the probe at a first point along the length thereof; a first temperature measuring device disposed at the first point for measuring a temperature of the probe and for generating a first signal Th representative thereof; a second temperature measuring device disposed at a second point along the length of the probe for measuring another temperature of the probe and for generating a second signal Tt representative thereof; a third temperature measuring device disposed along the external wall of the tube a distance away from the probe for measuring an ambient temperature and for generating a signal Ta representative thereof; and circuitry coupled to the first, second and third temperature measuring devices for generating a mass flow signal based on a ratio of temperature differential signals (Th−Ta) / (Tt−Ta). A counterpart method is also disclosed.

Owner:ROSEMOUNT AEROSPACE

Blower for combustion air

InactiveUS7223094B2Work lessContinuous suctionFuel supply regulationAir supply regulationImpellerCombustion

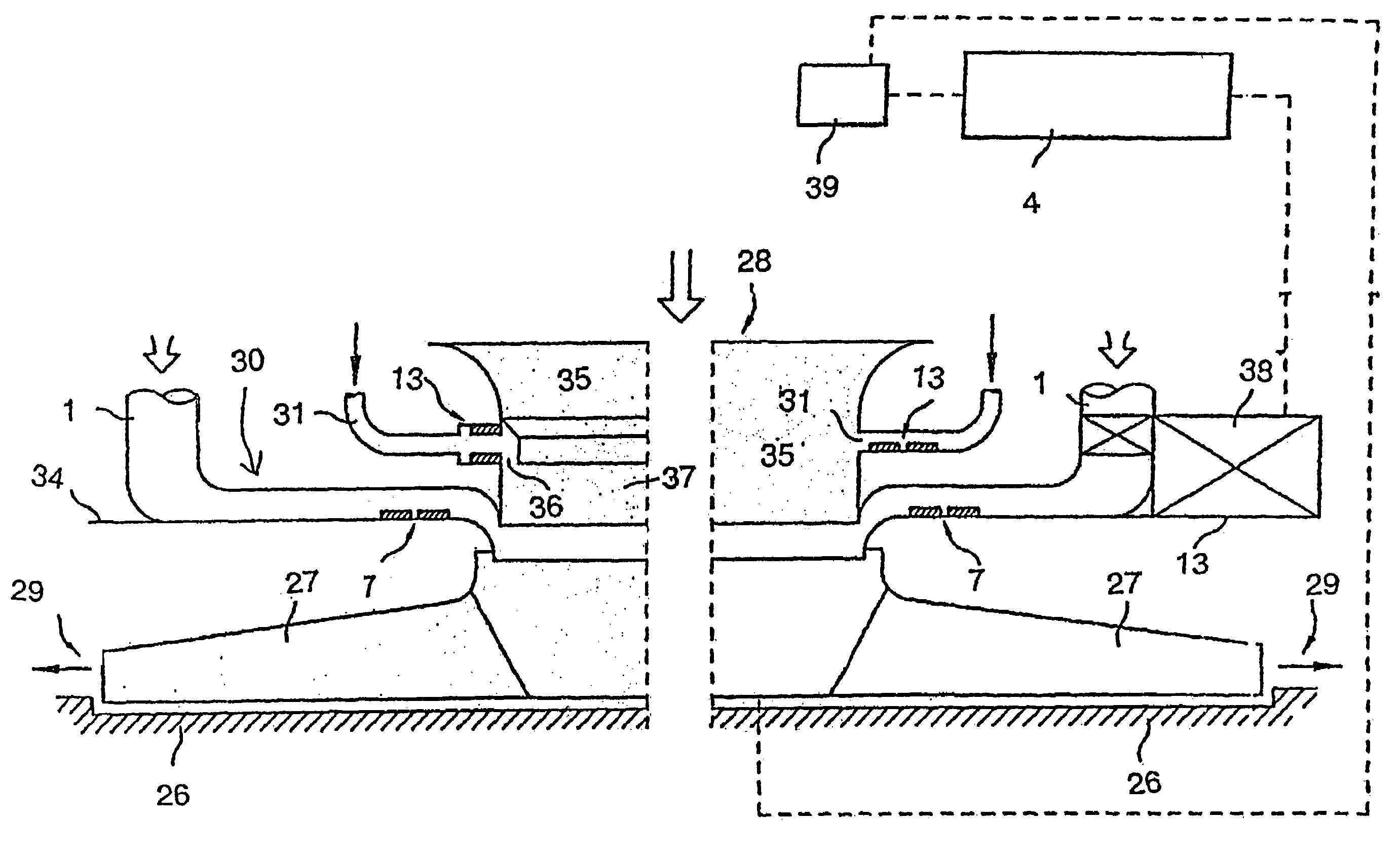

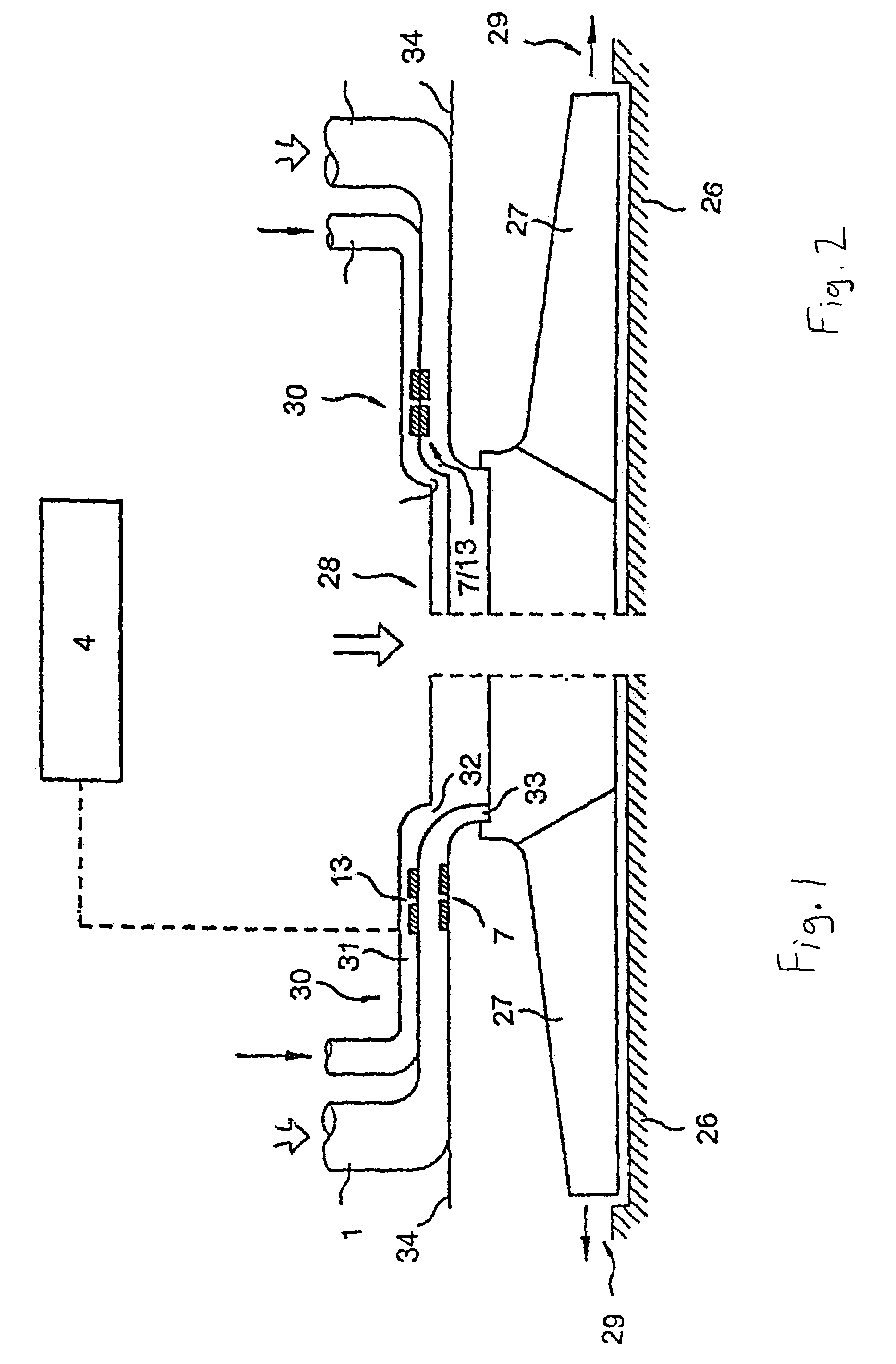

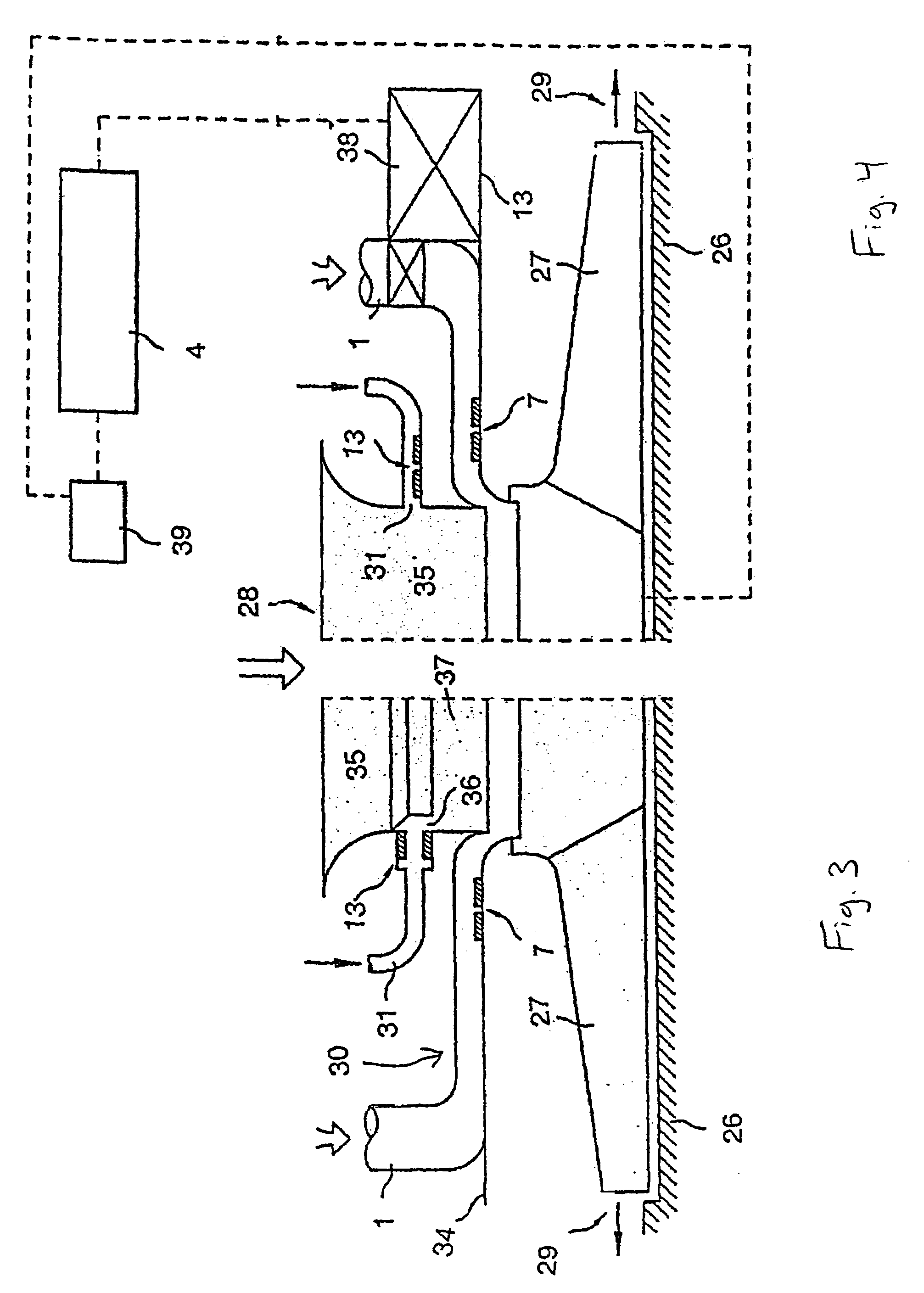

A blower for combustion air in a wall / floor furnace is provided that includes a blower housing (26), and blower wheel (27), with an air inlet (28) and an air outlet (29), and with a fuel feeder line (1) for fuel, wherein a mass current sensor (13) for determining the air mass current is located on the air inlet (28), which is functionally connected with a data processing device (4) and sends signals to the data processing device for calculation of a ratio of combustion medium to combustion air in dependence on a desired heating capacity.

Owner:EBM PAPST LANDSHUT

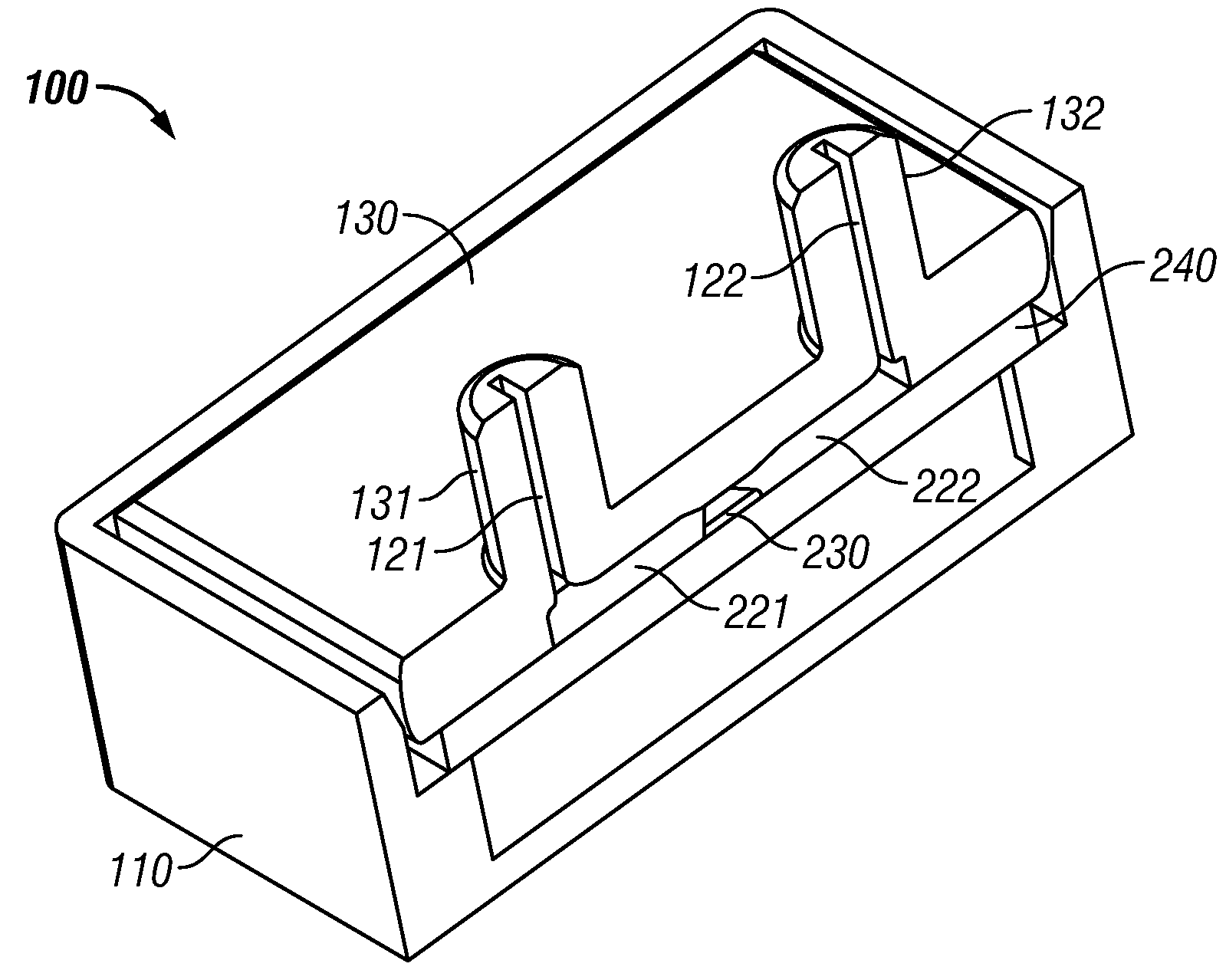

Automatic compensation for the effect of grain properties on mass flow sensor calibration

ActiveUS20150168187A1Minimize changesMowersVolume/mass flow by dynamic fluid flow effectEngineeringGrain moisture

A yield monitor system is configured to determine how the calibration characteristics of a grain mass flow sensor on an individual combine are affected by grain moisture content and / or other grain parameters which can be measured instantaneously or periodically by the yield monitor system or its operator, or which can be observed by the operator, or which can be determined from other reference information, such as maps of where different grain varieties or hybrids were planted. Other systems, methods, and apparatuses are also provided.

Owner:LEADER TECH

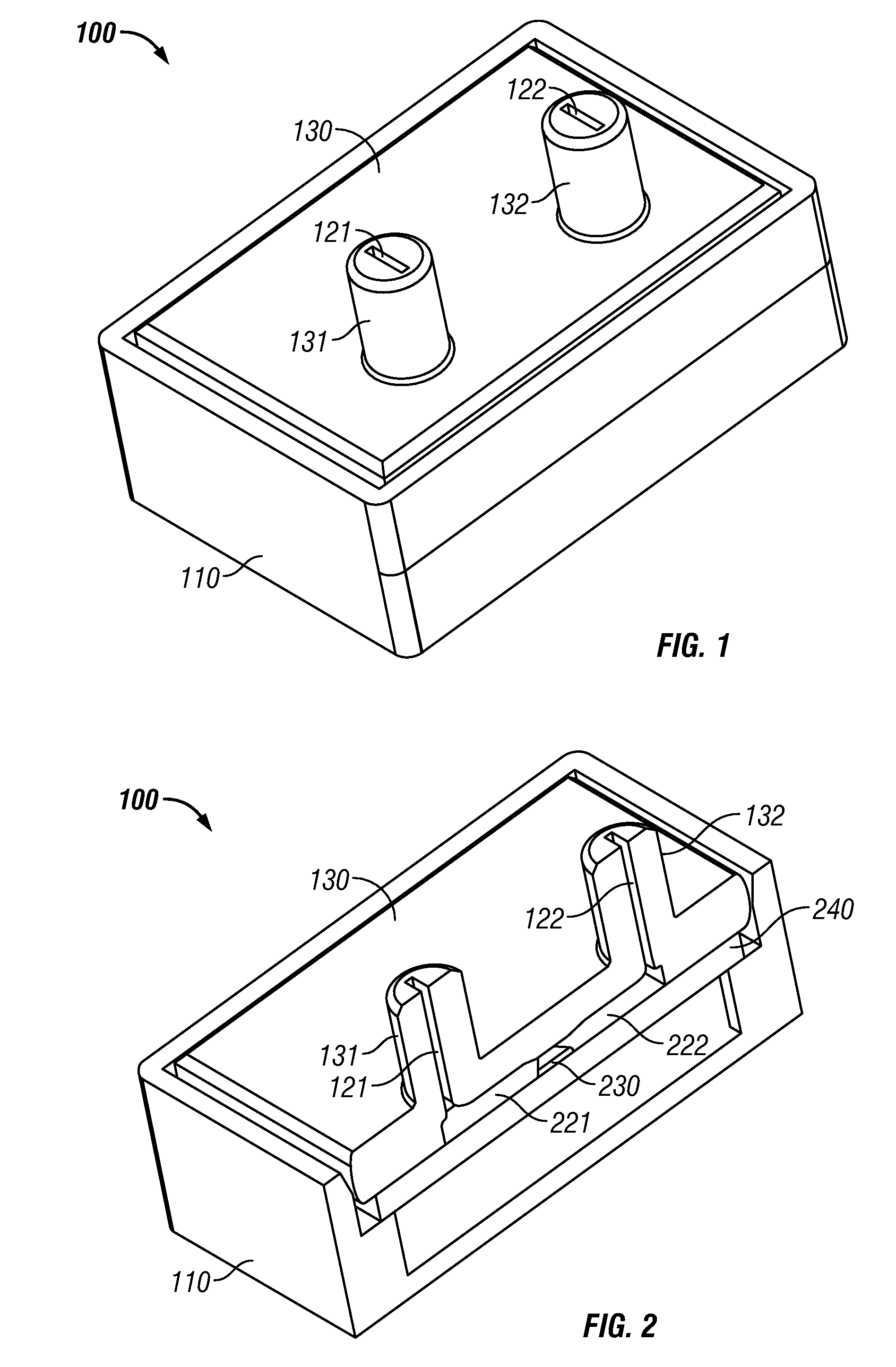

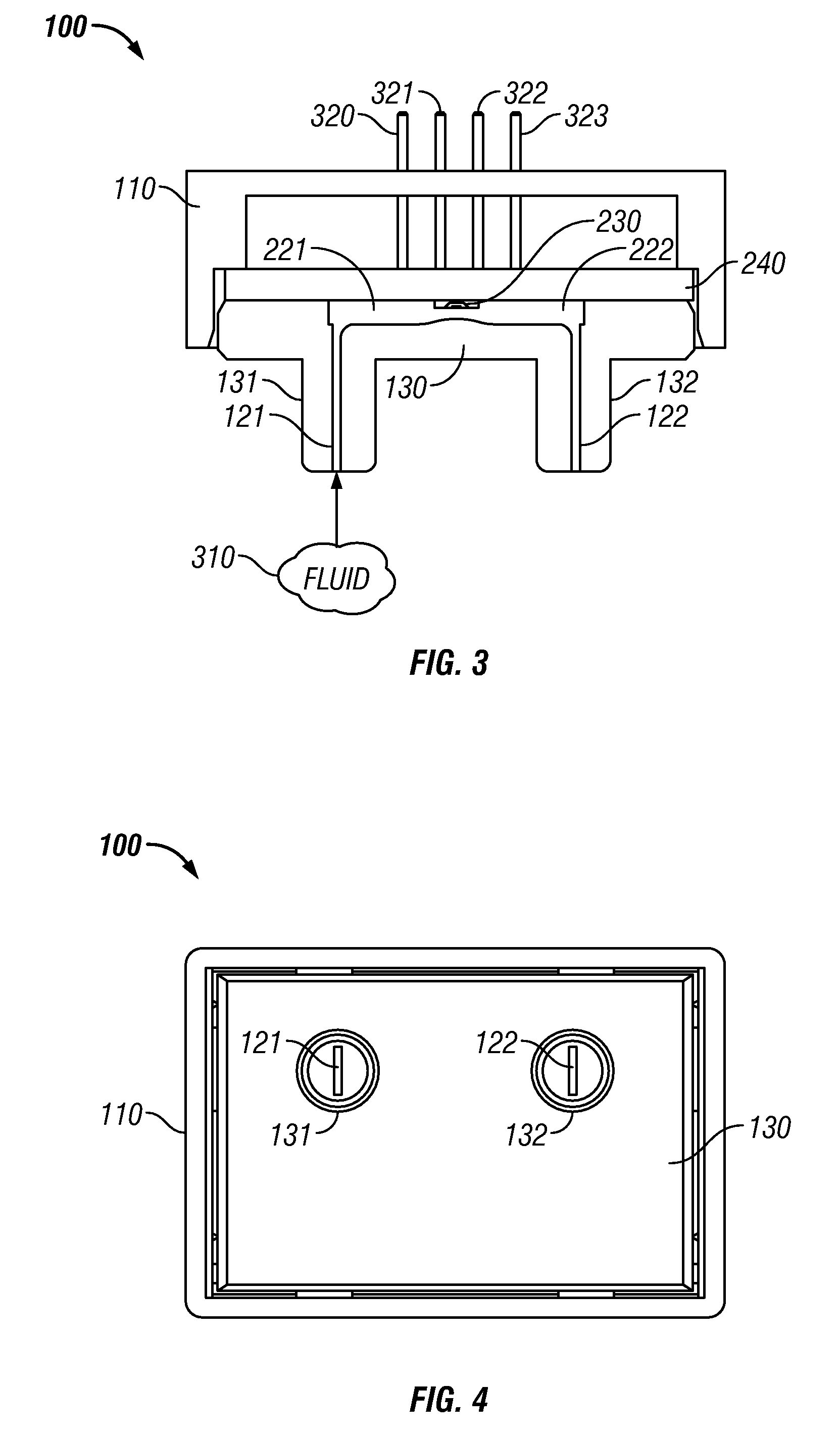

Mass-flow sensor with a molded flow restrictor

InactiveUS7631562B1Improve Sensing PerformanceReduce flow turbulenceVolume/mass flow by thermal effectsVolume meteringEngineeringMass flow sensor

A high mass-flow sensing apparatus and method of forming the same, comprising a flow tube bypassed in a flow path defined by a flow channel, through which a fluid flows. A flow sensor can be disposed in the flow tube for measuring a flow rate of the fluid in the flow channel. A set of narrow rectangular flow restrictors can be molded into the flow tube and adjacent to the flow sensor. Each flow restrictor can include several rectangular cutouts that are molded into upstream and / or downstream portions of the flow tube in order to limit the flow rate of the fluid across the flow sensor. The flow restrictors can laminarize the flow rate of the fluid in the flow tube and thereby reduce flow turbulence and lead to optimal sensing performance of the flow sensor.

Owner:HONEYWELL INT INC

Mass-flow sensor heating element protection method and apparatus

A heating element protection apparatus for a mass-flow sensor may include a heating element disposed in a gas, a gas temperature sensor disposed in the gas to sense a temperature of the gas, a slope detector to measure a slope of the temperature as power is supplied to the heating element, and a heating element controller to supply power to the heating element to replace heat dissipated by the gas. The heating element controller may detect a temperature of the heating element and may supply power to the heating element based on the heating element temperature and the gas temperature, and the power may be switched off for a predetermined period of time if a magnitude of the slope is greater than a reference magnitude.

Owner:VOLVO LASTVAGNAR AB +1

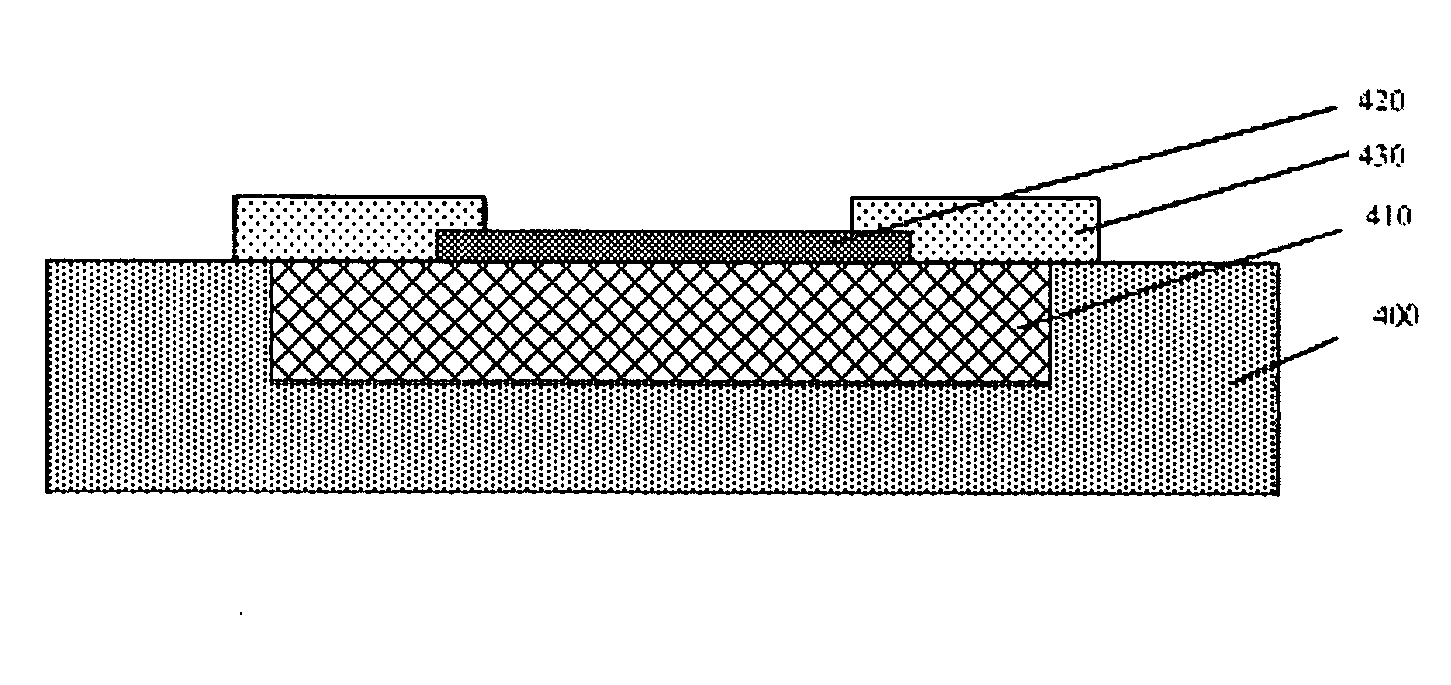

Micromachined Thermal Mass Flow Sensor With Self-Cleaning Capability And Methods Of Making the Same

ActiveUS20090158859A1Improve performanceRobust self-cleanedLiquid surface applicatorsVolume/mass flow by thermal effectsForeign matterThermal isolation

The current invention generally relates to Micro Electro Mechanical Systems (MEMS) thermal mass flow sensors for measuring the flow rate of a flowing fluid (gas / liquid) and the methods of manufacturing on single crystal silicon wafers. The said mass flow sensors have self-cleaning capability that is achieved via the modulation of the cavity of which the sensing elements locate on the top of the cavity that is made of a silicon nitride film; alternatively the sensing elements are fabricated on top of a binary silicon nitride / conductive polycrystalline silicon film under which is a porous silicon layer selective formed in a silicon substrate. Using polycrystalline silicon or the sensing elements as electrodes, an acoustic wave can be generated across the porous silicon layer which is also used for the thermal isolation of the sensing elements. The vibration or acoustic energy is effective to remove foreign materials deposited on top surface of the sensing elements that ensure the accuracy and enhance repeatability of the thermal mass flow sensing.

Owner:M TECH INSTR HLDG

Instrument and method for measuring the volume of a hermetically sealed variable volume and pressure conforming container

An instrument and method for measuring the volume of a hermetically sealed, variable volume, pressure conforming container. The instrument includes a needle, a vacuum pump, a mass flow rate sensor and an integrator. The needle has a lumen operable for sealingly perforating a container and thereby placing the lumen of the needle in fluid communication with a retention chamber defined by the container. The vacuum pump evacuates the gaseous content from the retention chamber through the lumen defined by the needle and past a mass flow rate sensor for sensing mass flow rates pulled through the lumen and transmitting corresponding mass flow rate signals over time to the integrator. The integrator is programmed to integrate the received mass flow rate signals over time through achievement of an evacuated retention chamber to generate a total mass value, and calculate a volume from the total mass value employing the Ideal Gas Law.

Owner:MODERN CONTROLS

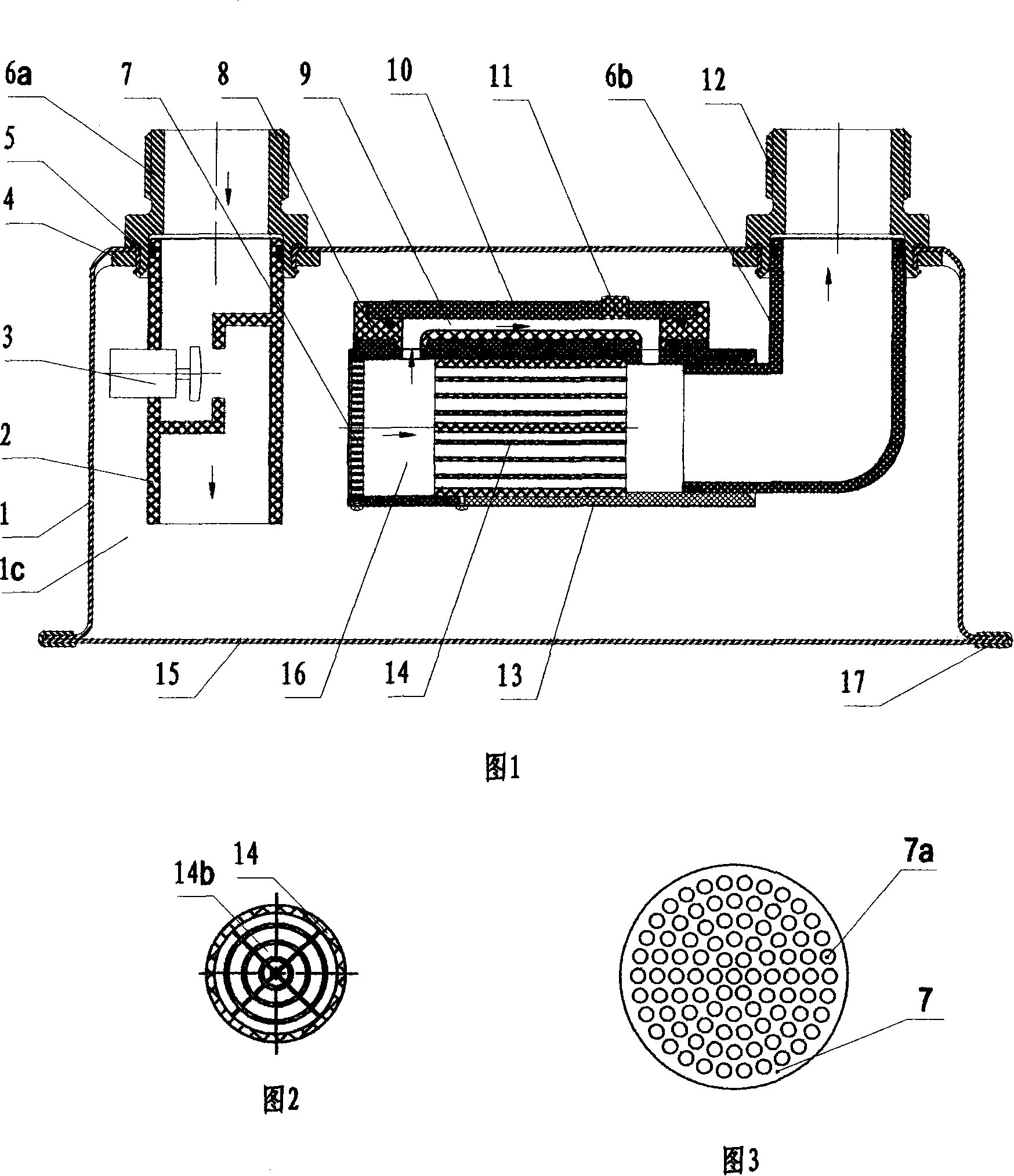

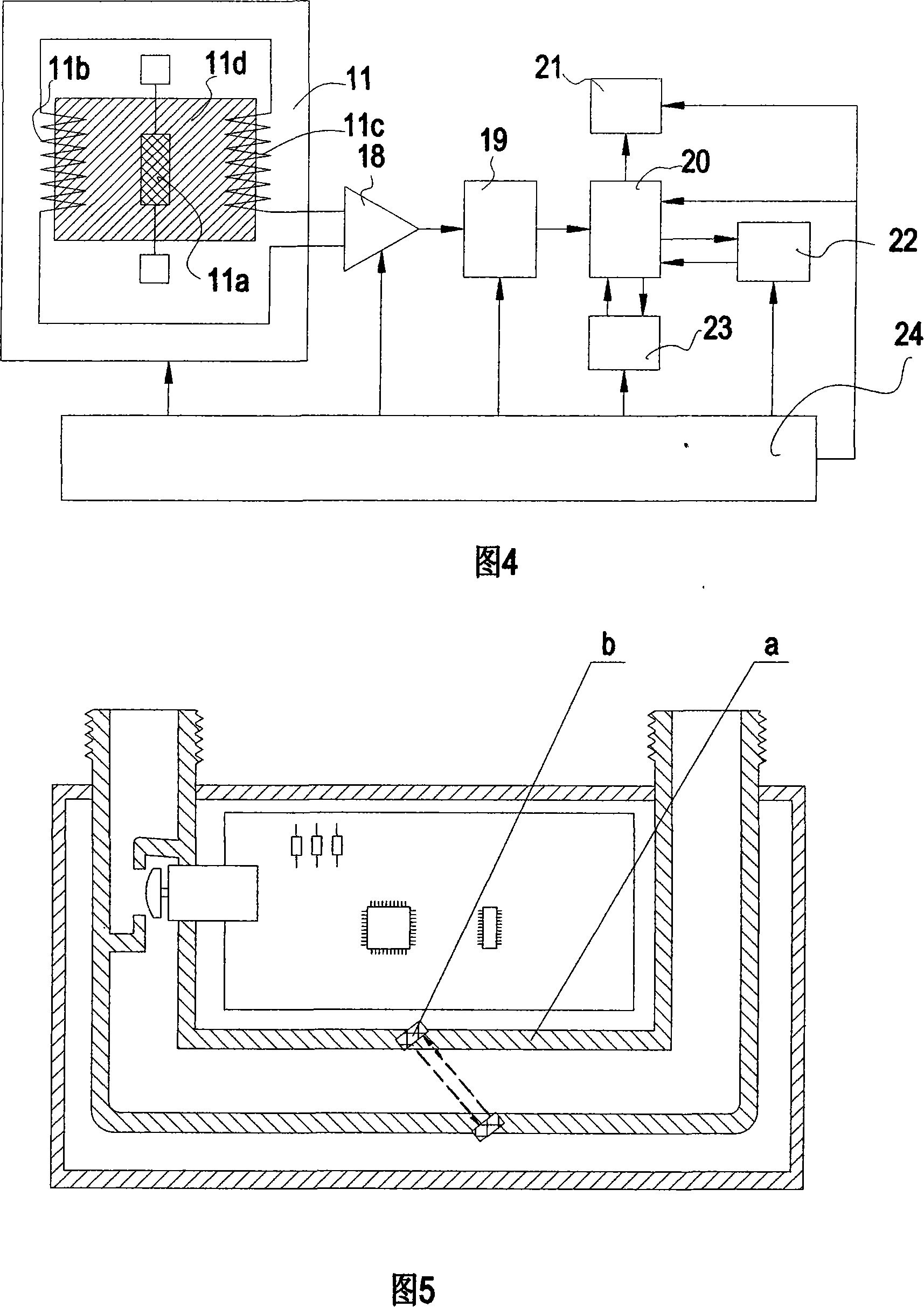

High frequency Coriolis mass flowmeter digital signal processing system

ActiveCN103278203AReduce power consumptionReduce the impactDirect mass flowmetersDigital signal processingOperational capabilities

The invention relates to a high frequency Coriolis mass flowmeter digital signal processing system. The high frequency Coriolis mass flowmeter digital signal processing system comprises a DSP chip, a first signal conditioning module, a second signal conditioning module, a constant flow source, a Pt100 platinum resistor, a first ADC, a second ADC, a third ADC, an analog driver module, an external expansion FLASH module, a PWM output module, a current output module, an external expansion UART module, an HART modulation module, a man-machine interface module, a power down protection module and software. For signal processing of a high frequency Coriolis mass flow sensor, a TMS320C6726 chip with the strong operational capability and the high processing speed is used as a core processor, and the high frequency Coriolis mass flowmeter digital signal processing system is invented. Based on the zero-cross detection algorithm and DTFT algorithm, the high frequency Coriolis mass flowmeter digital signal processing system solves the problem that the algorithm cannot guarantee real-time performance after sampling frequency of high frequency sensor signals is increased.

Owner:HEFEI UNIV OF TECH

Electronic gas meter for mass and flow

InactiveCN101126652AImprove accuracyEasy to collectVolume meteringIndirect mass flowmetersGas meterProcess engineering

The utility model discloses an electronic mass flow gas meter; an airtight cavity is arranged in the casing of the gas meter. The gas pipelines in the casing are divided into an independent gas inlet pipe, and a flow testing tube and gas outlet pipe, which are connected together. The gas inlet and outlet pipes are respectively connected with the gas outlet and inlet interfaces of the casing. The lower end of the flow testing tube is connected with the gas outlet pipe and horizontally suspended inside the casing. A main flow airway and a bypass airway are arranged in the flow testing tube; wherein, a by-passing device is arranged in the main flow airway and arranged between the two through holes for communicating the bypass airways. The cross-sectional area of the bypass airway is smaller than that of the main flow airway, and a signal sensing module of thermal mass flow sensors is arranged on the inner wall of the bypass airway for detection. The utility model can carry out mass flow measurement of the passing gas, and can prevent the dust in the gas from attaching to the sensing element, thus improving the measuring accuracy and service life of the gas meters.

Owner:CHONGQING QIANWEI SCI & TECH GRP +1

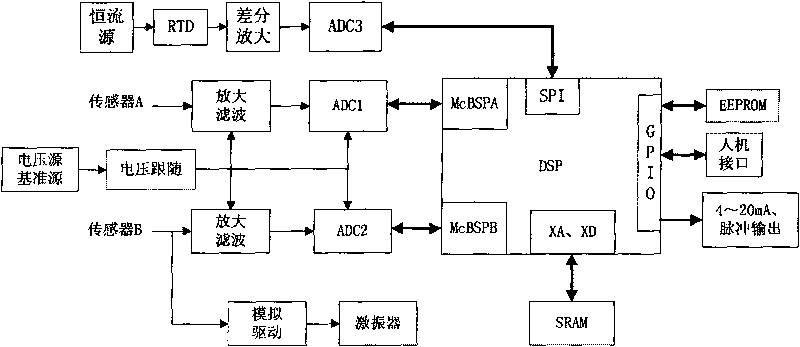

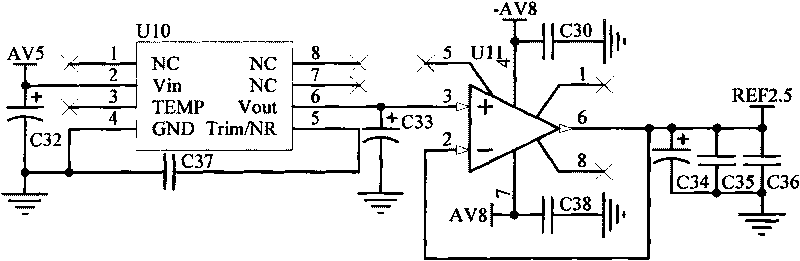

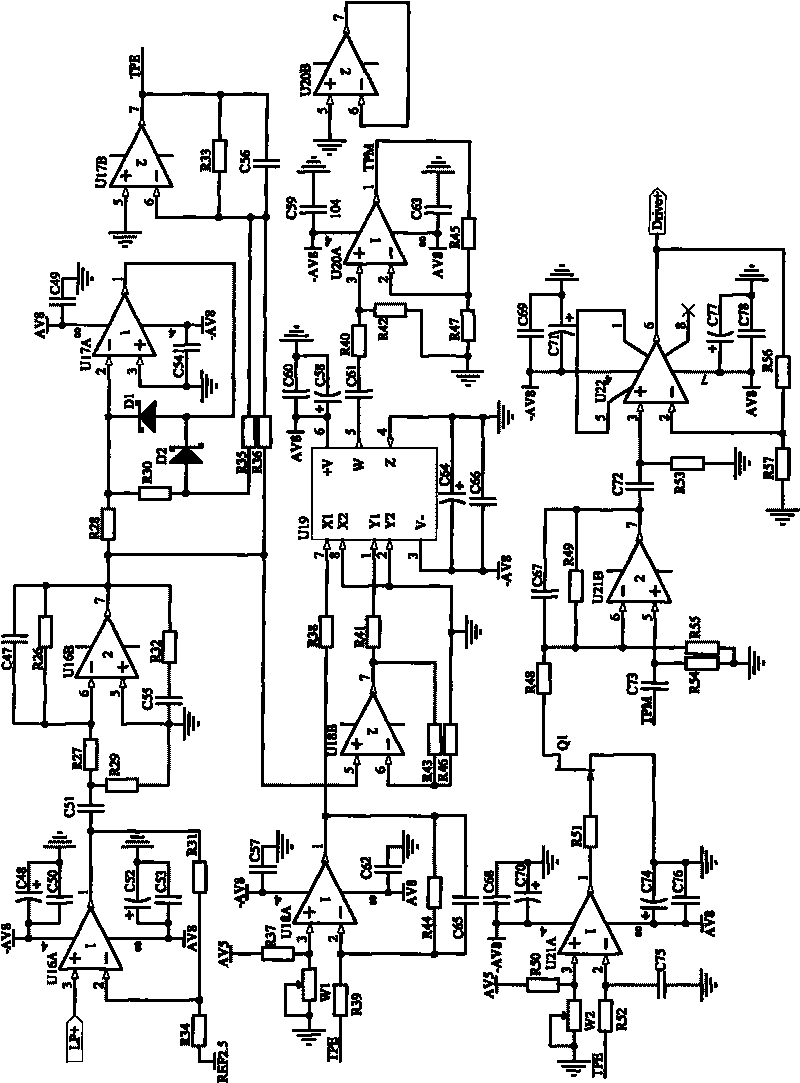

Coriolis mass flow transmitter based on DSP

ActiveCN101706299AImprove calculation accuracyShorten convergence timeVolume variation compensation/correction apparatusDirect mass flowmetersDigital signal processingPhase difference

The invention relates to the field of flow detection, and provides a Coriolis mass flow transmitter based on DSP, which comprises an amplifying filter circuit, an analog-to-digital converter 1, an analog-to-digital converter 2, a voltage reference source, a voltage follower, a current source, a difference amplifier, an analog-to-digital converter 3, a simulation driver module, a digital signal processor DSP minimum system, an expanding SRAM, an expanding EEPROM, a man-machine interface, 4-20mA current output and pulse output, a power module and a software. The simulation driver module stimulates a vibration exciter in the Coriolis mass flow transmitter so as to lead a flow tube to vibrate with natural frequency. Two magnetoelectric sensors positioned at two sides of the flow tube output two ways of sine-wave signals which are amplified and filtered by two ways of conditioning circuits with same parameter, then respectively and simultaneously sampled by two analog-to-digital converters with same model, and converted in digital value, and delivered to DSP by two multichannel buffered serial ports of the DSP. DSP adopts digital filter to eliminate the noise of the signals, is self-adaptive to a lattice notch filter to calculate the frequency, and then adopts the DTFT algorithm taking negative frequency into account to calculate to phase difference, thus obtaining the mass flow finally.

Owner:GOLDCARD HIGH TECH

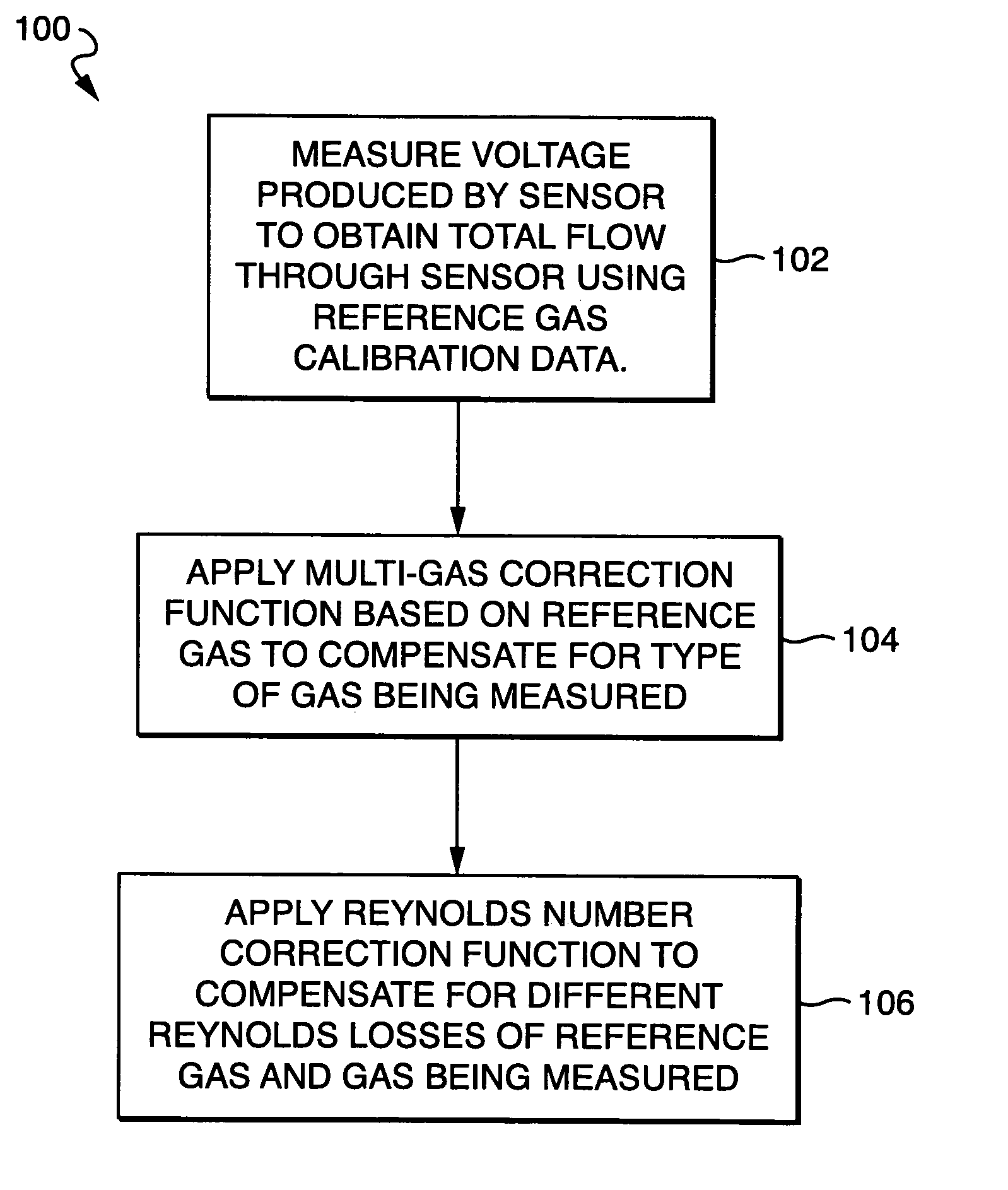

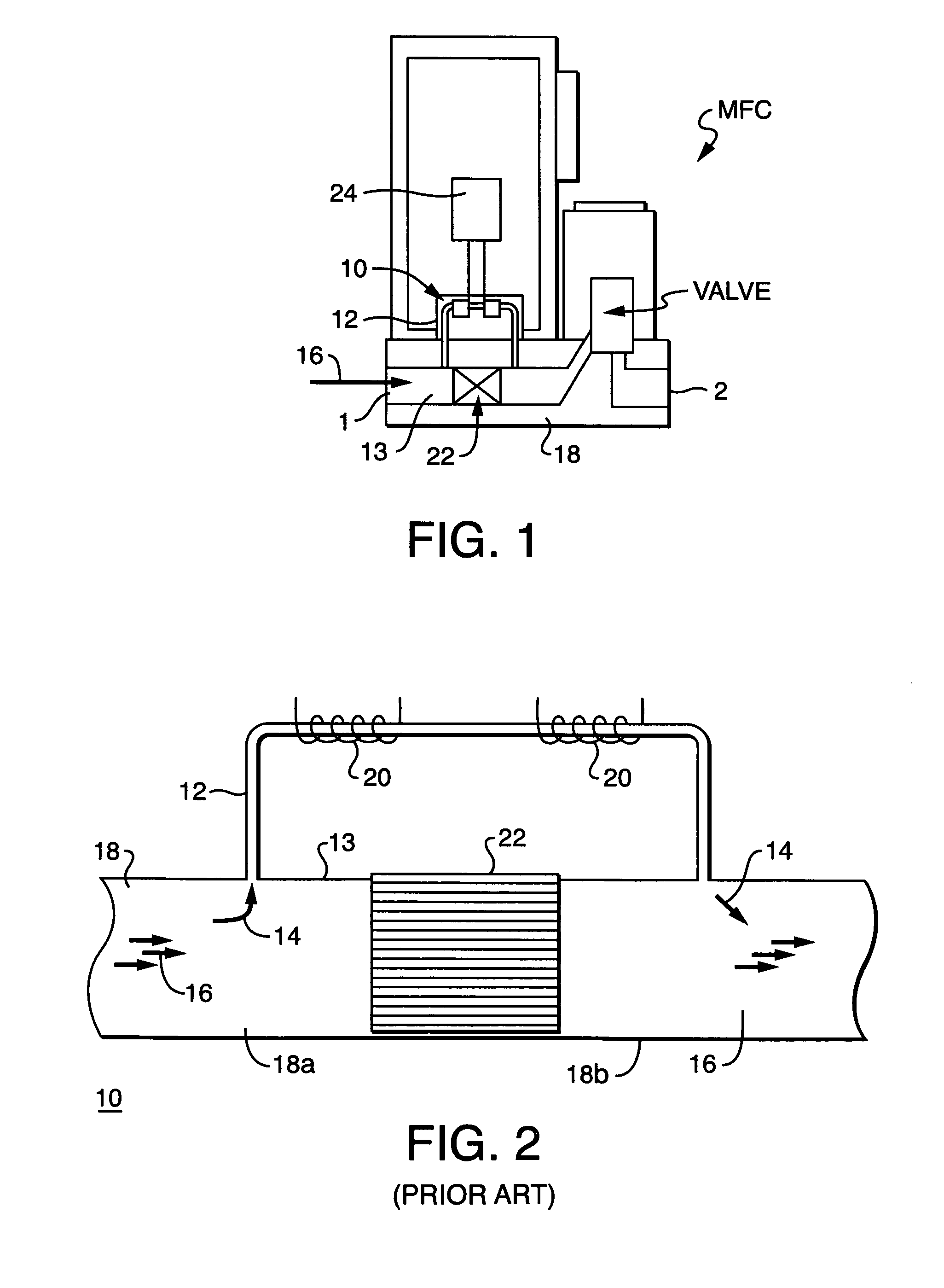

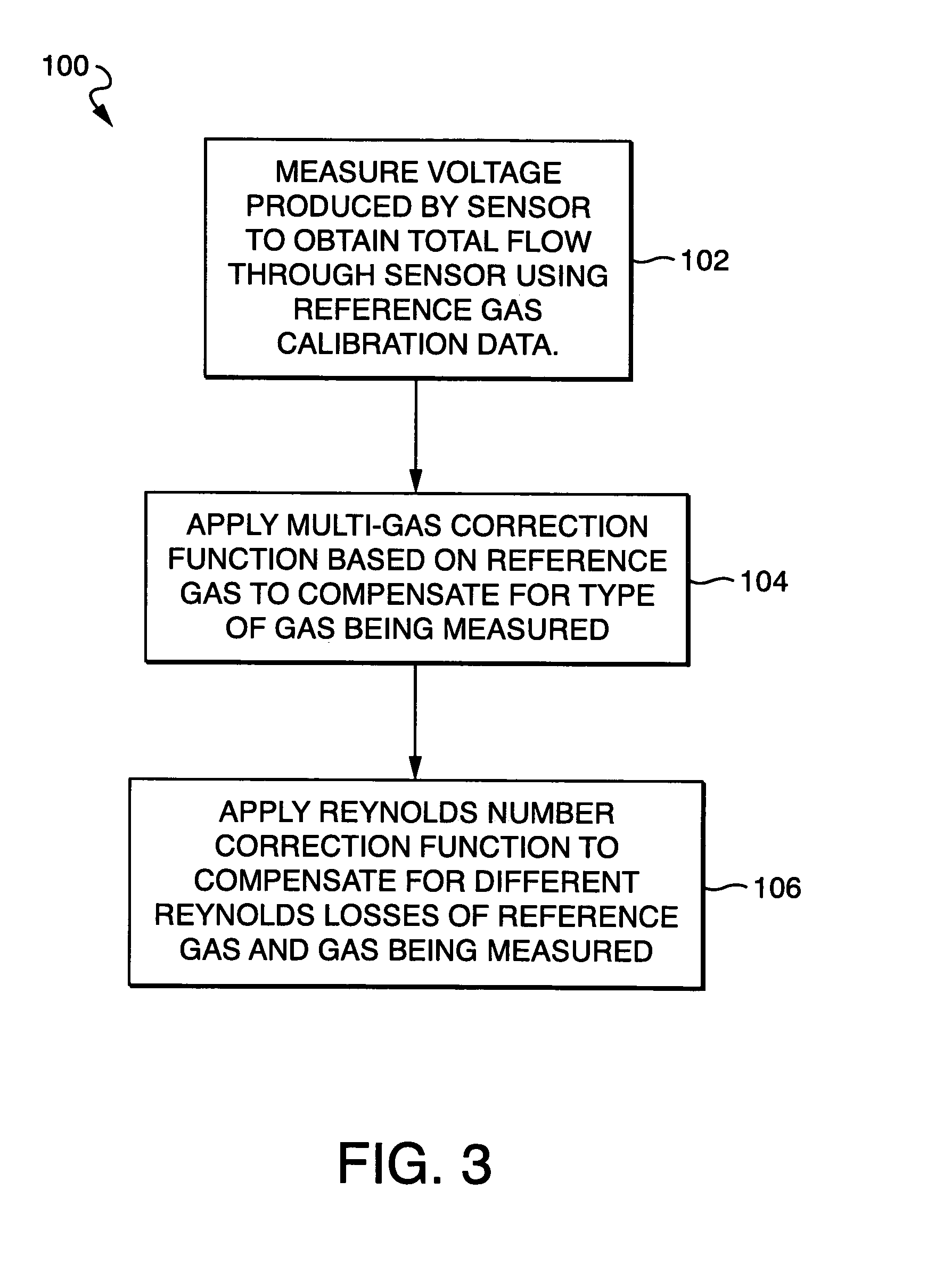

Reynolds number correction function for mass flow rate sensor

ActiveUS7000463B1Volume/mass flow by thermal effectsVolume flow proportion measurementBypass ratioMass flow sensor

A mass flow rate sensor uses a Reynolds number correction function to compensate for errors in a bypass ratio of the sensor for all gases, based on the fact that all bypass errors are functions of Reynolds number. The sensor includes a sensor tube and a bypass tube dividing flow, wherein a bypass ratio of the sensor equals a total flow rate through the sensor divided by a flow rate through just the sensor tube. Heater elements heat an upstream portion and a downstream portion of the sensor tube, and a circuit is connected to the heater elements for producing a voltage based upon a difference in resistance between the heater elements. The voltage is calibrated based on known flow rates of a reference gas, and the flow rate through the sensor is based upon the calibrated voltage multiplied by a multi-gas correction function and a Reynolds number correction function.

Owner:MKS INSTR INC

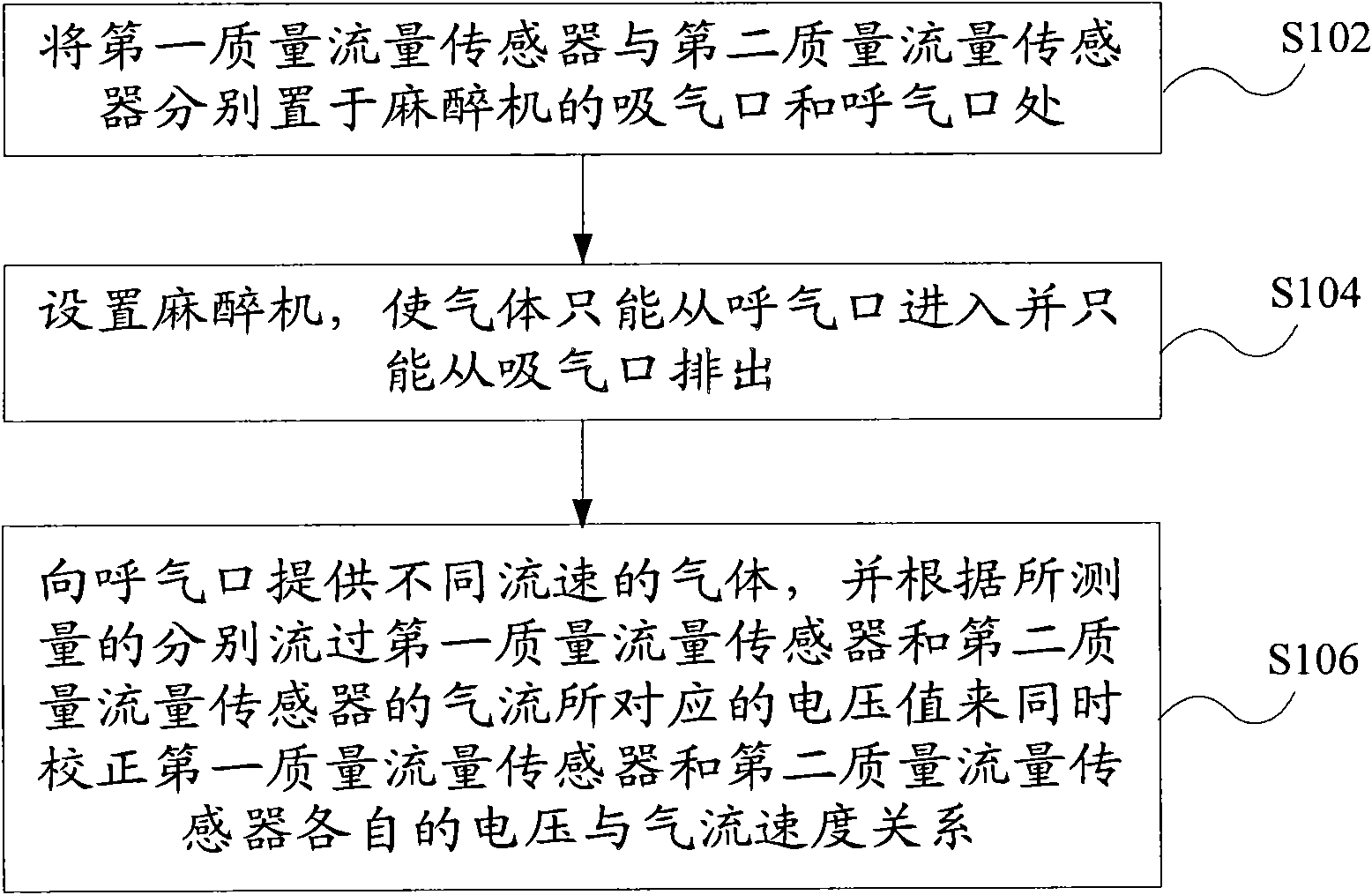

Method for correcting relation of voltage and airflow speed of mass flow sensor

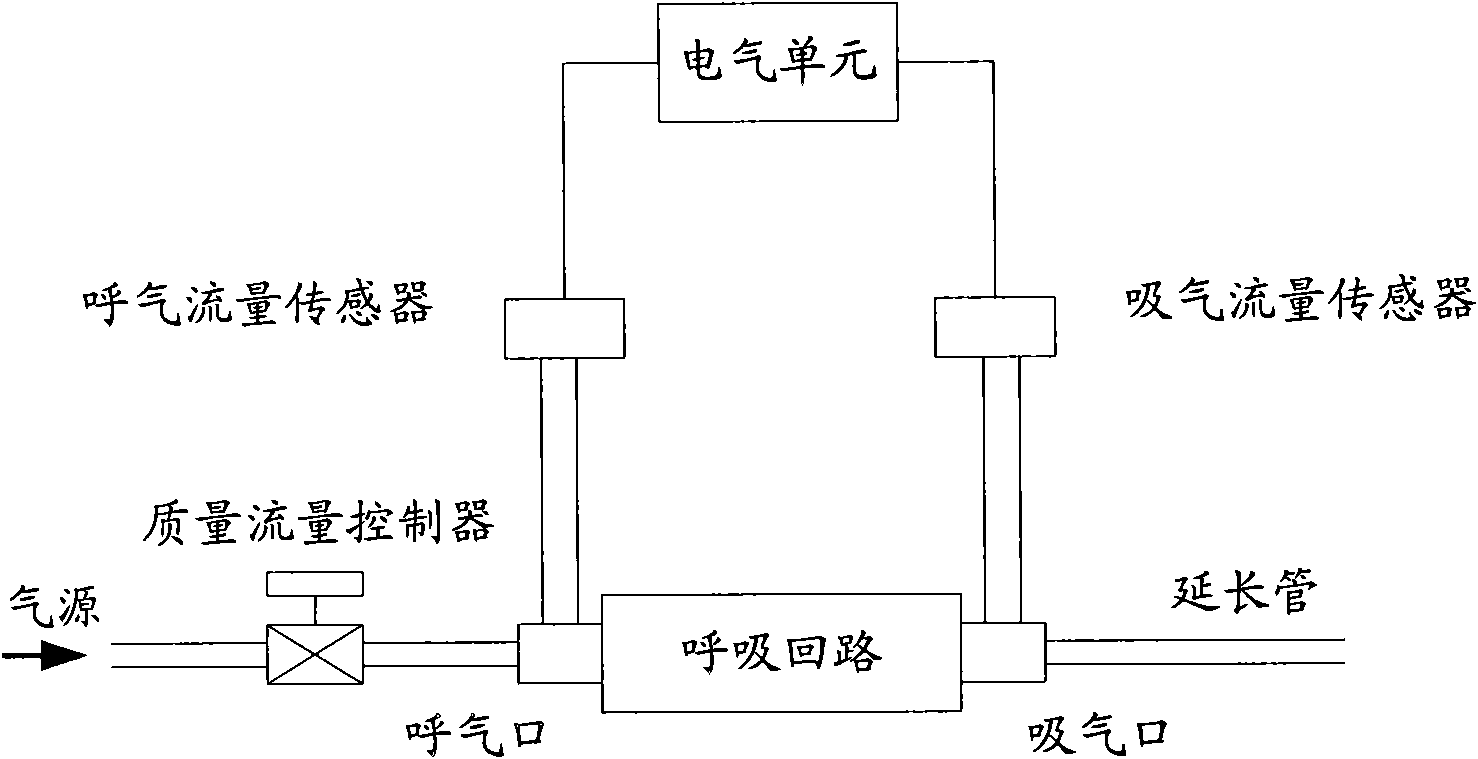

InactiveCN101614575AOvercome damageOvercoming Curve Offset IssuesRespiratorsTesting/calibration apparatusEngineeringMass flow sensor

The invention provides a method for correcting a relation of voltage and airflow speed of a mass flow sensor. The method comprises the following steps: step one, placing a first mass flow sensor and a second mass flow sensor at an air suction port and an exhalation port of an anesthesia machine respectively; step two, setting the anesthesia machine so that the air can enter only from the exhalation port and can be exhausted only from the air suction port; and step three, providing gas of different flow speeds to the exhalation port, and synchronously correcting respective relation of the voltage and the airflow speed of the first mass flow sensor and the second mass flow sensor according to the voltage value corresponding to the measured airflow flowing through the first mass flow sensor and the second mass flow sensor respectively. Therefore, compared with separate correction, by adopting the method of the invention, the correction can keep better consistency, and the correction precision can be improved; and simultaneously, the correction method is simplified, unnecessary workload is reduced, and the correction efficiency is improved.

Owner:BEIJING AEONMED

Heated Hot-Film Air-Mass Sensor

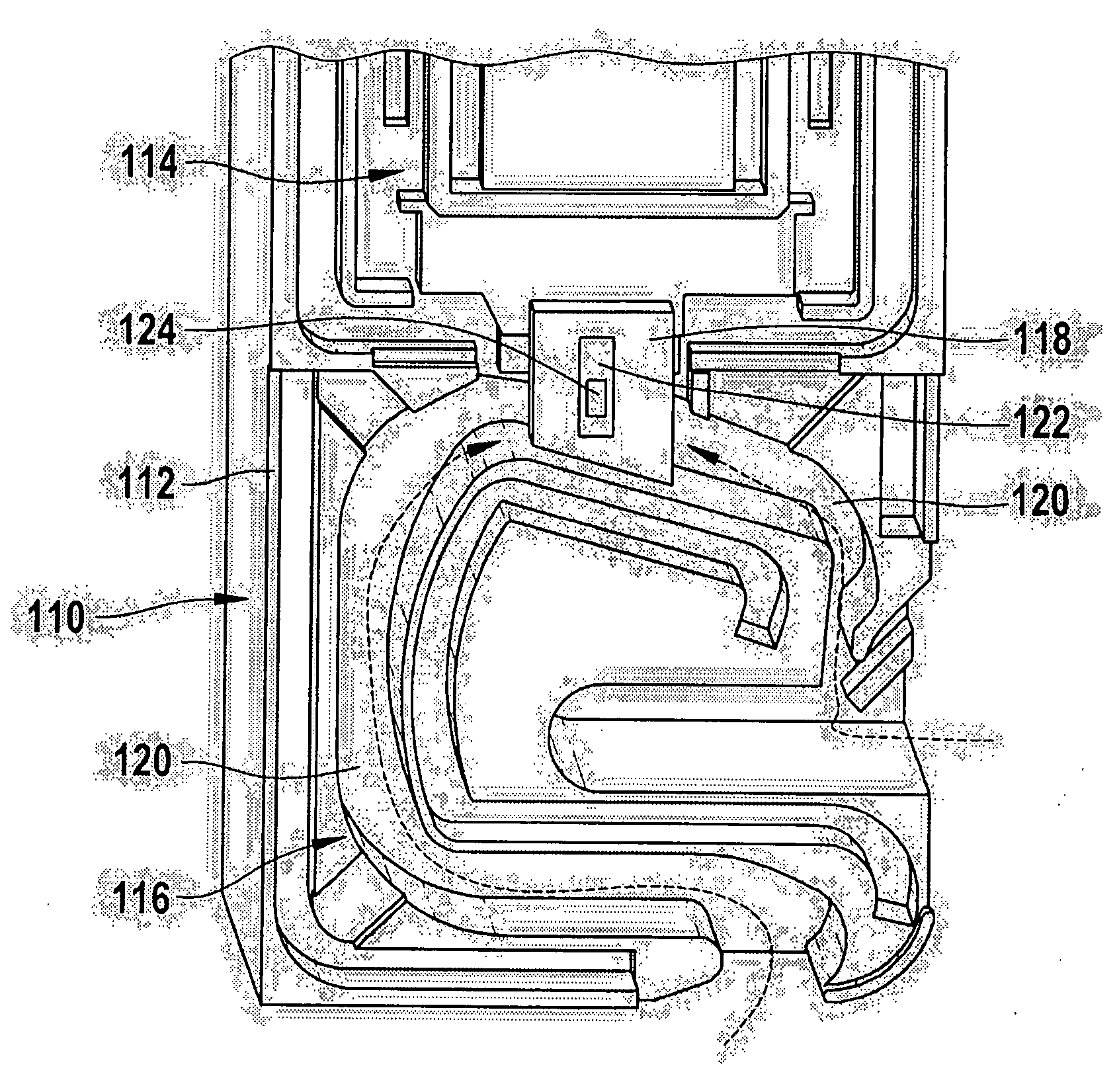

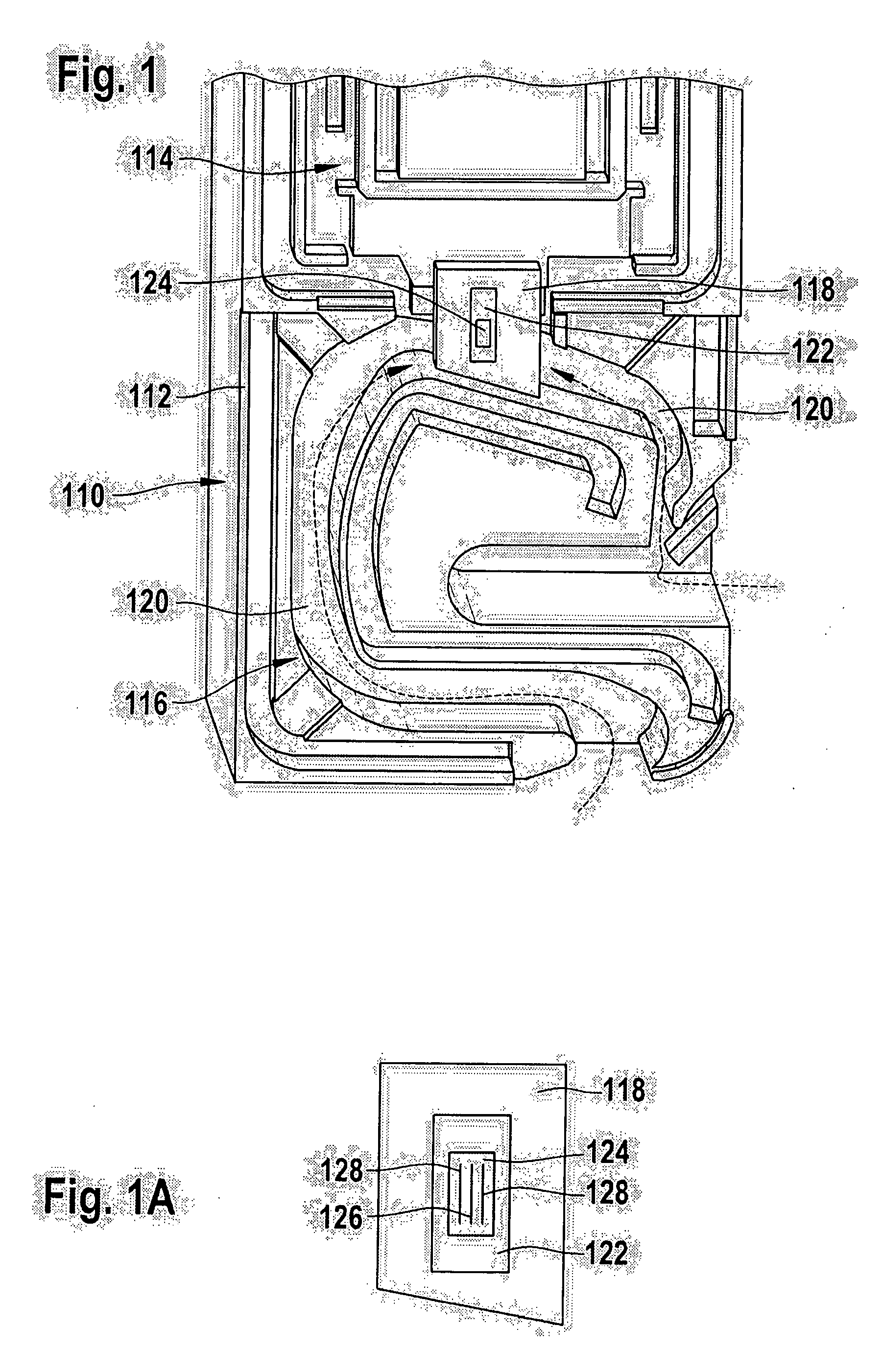

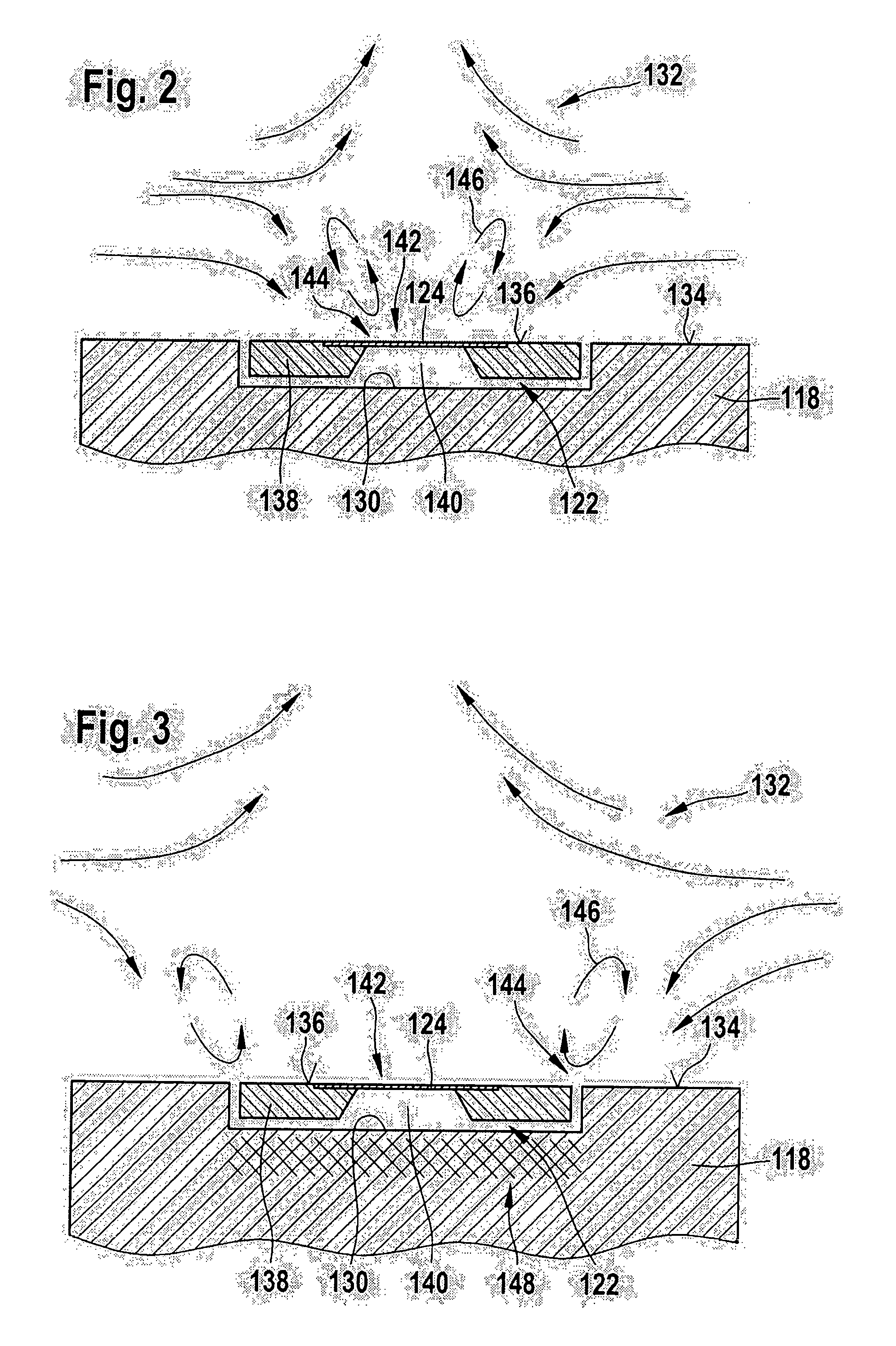

ActiveUS20090211355A1Contamination of the surface of the sensor chip is minimizedMinimize contaminationPrinted circuit assemblingElectrical controlCombustionTwo temperature

To determine air mass flows, especially for controlling internal combustion engines, a hot-film air-mass sensor is provided, which may be used especially for sensing air mass flows in the intake tract of an internal combustion engine. The hot-film air-mass sensor has a sensor chip having a sensor frame and a sensor diaphragm having at least one heating element and at least two temperature sensors. Furthermore, the hot-film air-mass sensor has a chip carrier for mounting the sensor chip, as well as at least one additional heating element. The sensor chip is able to be heated up using the at least one additional heating element, which is inserted into the chip carrier. Compared to the usual devices, the hot-film air-mass sensor has a lower susceptibility to contamination, especially by oil films.

Owner:ROBERT BOSCH GMBH

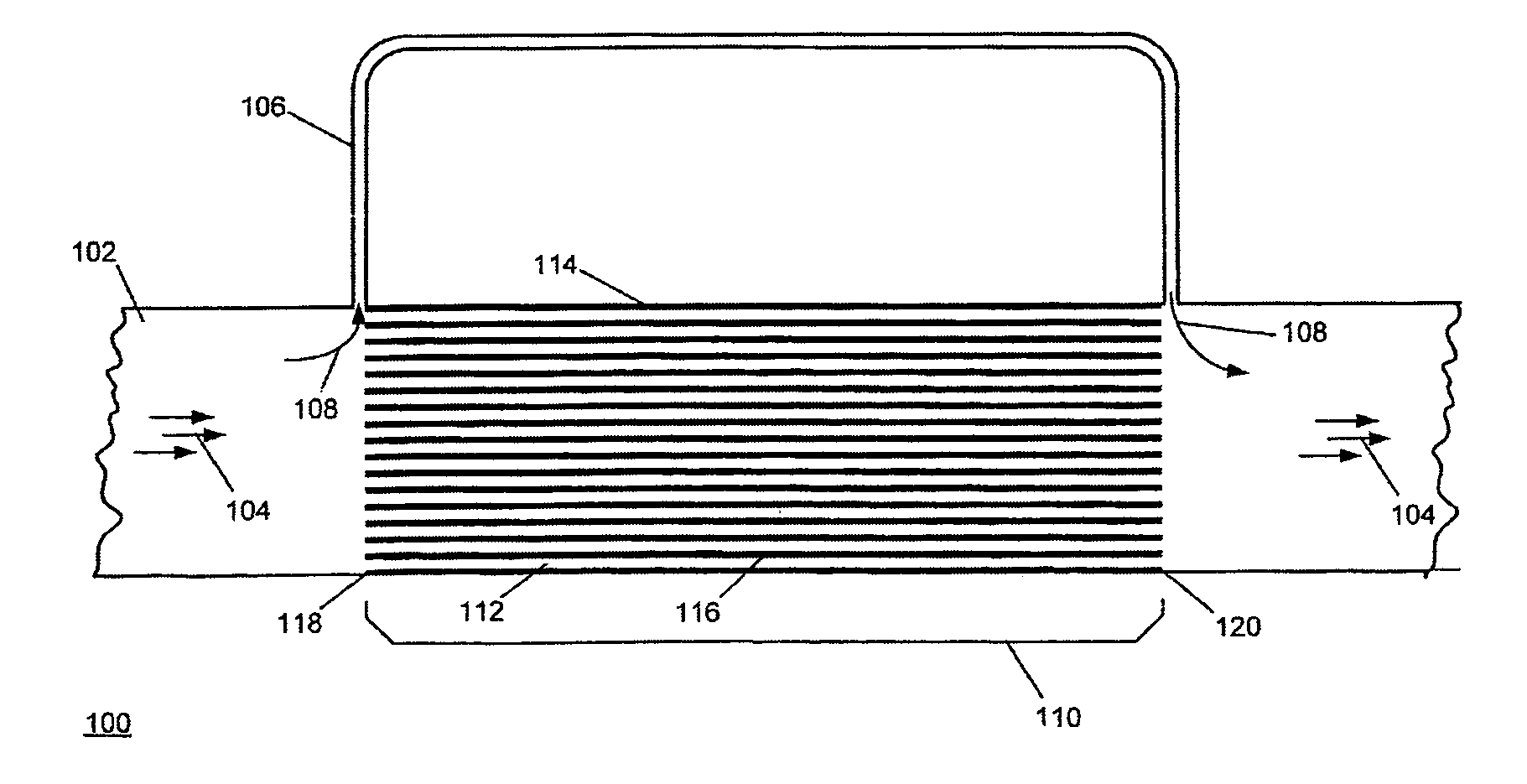

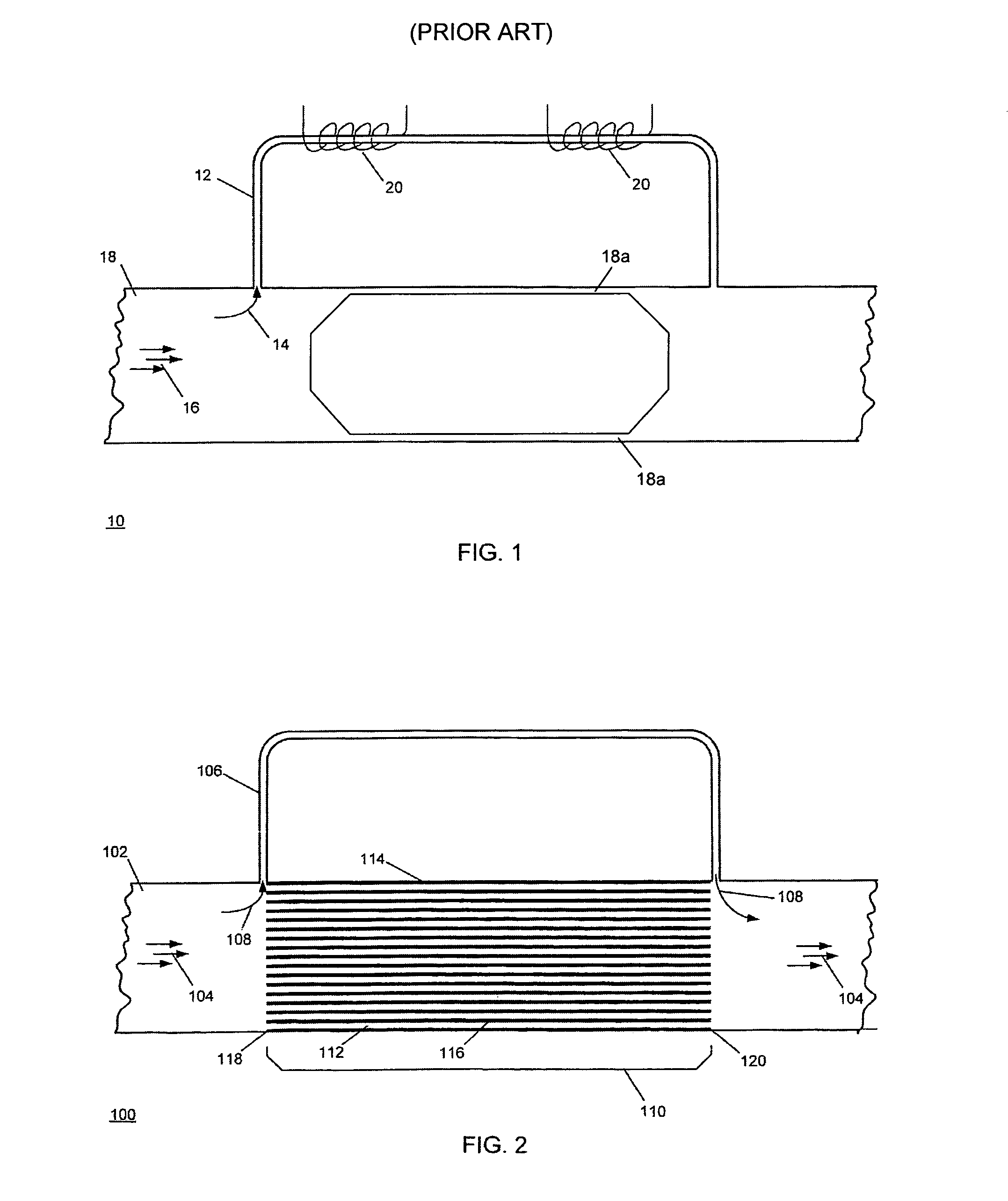

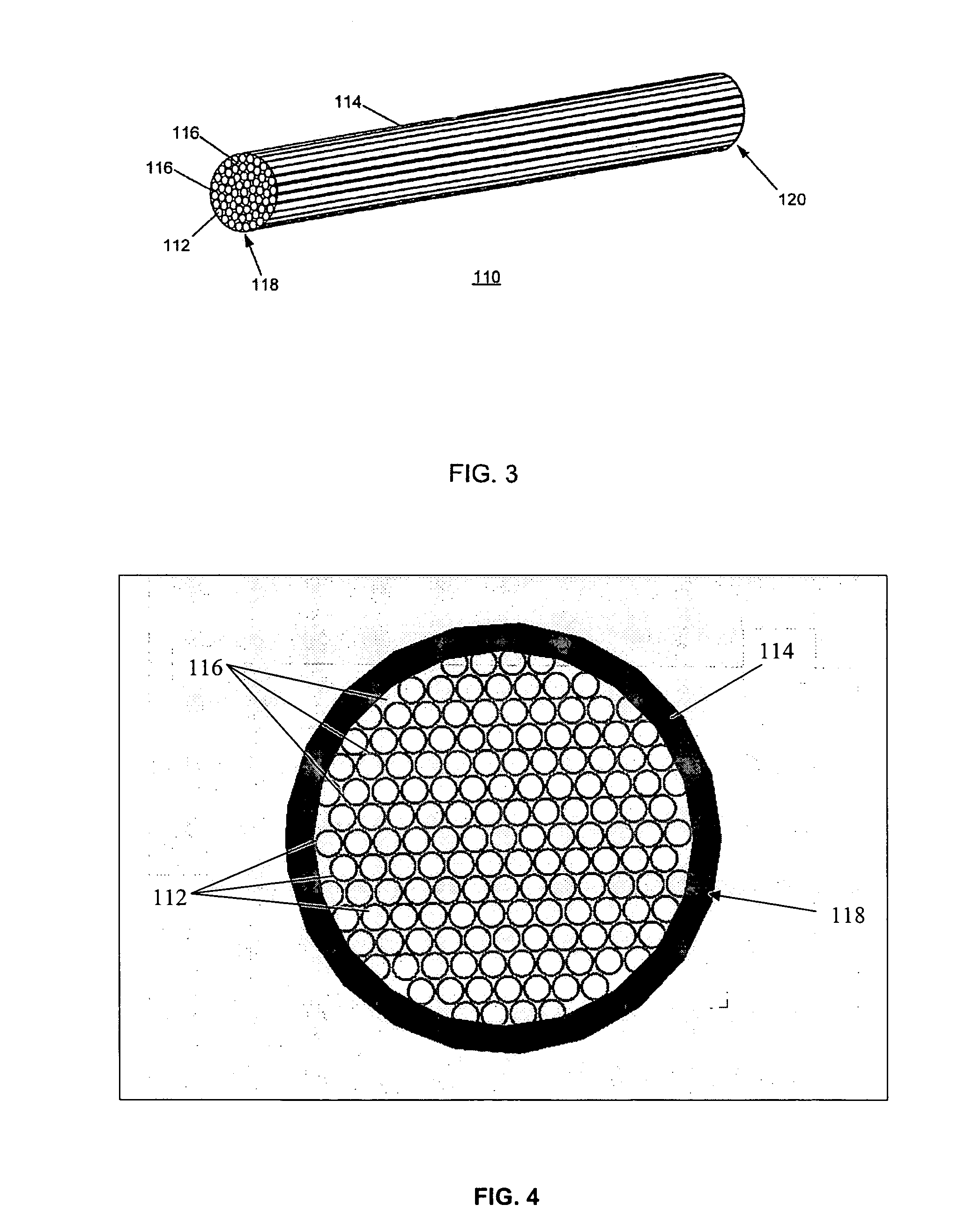

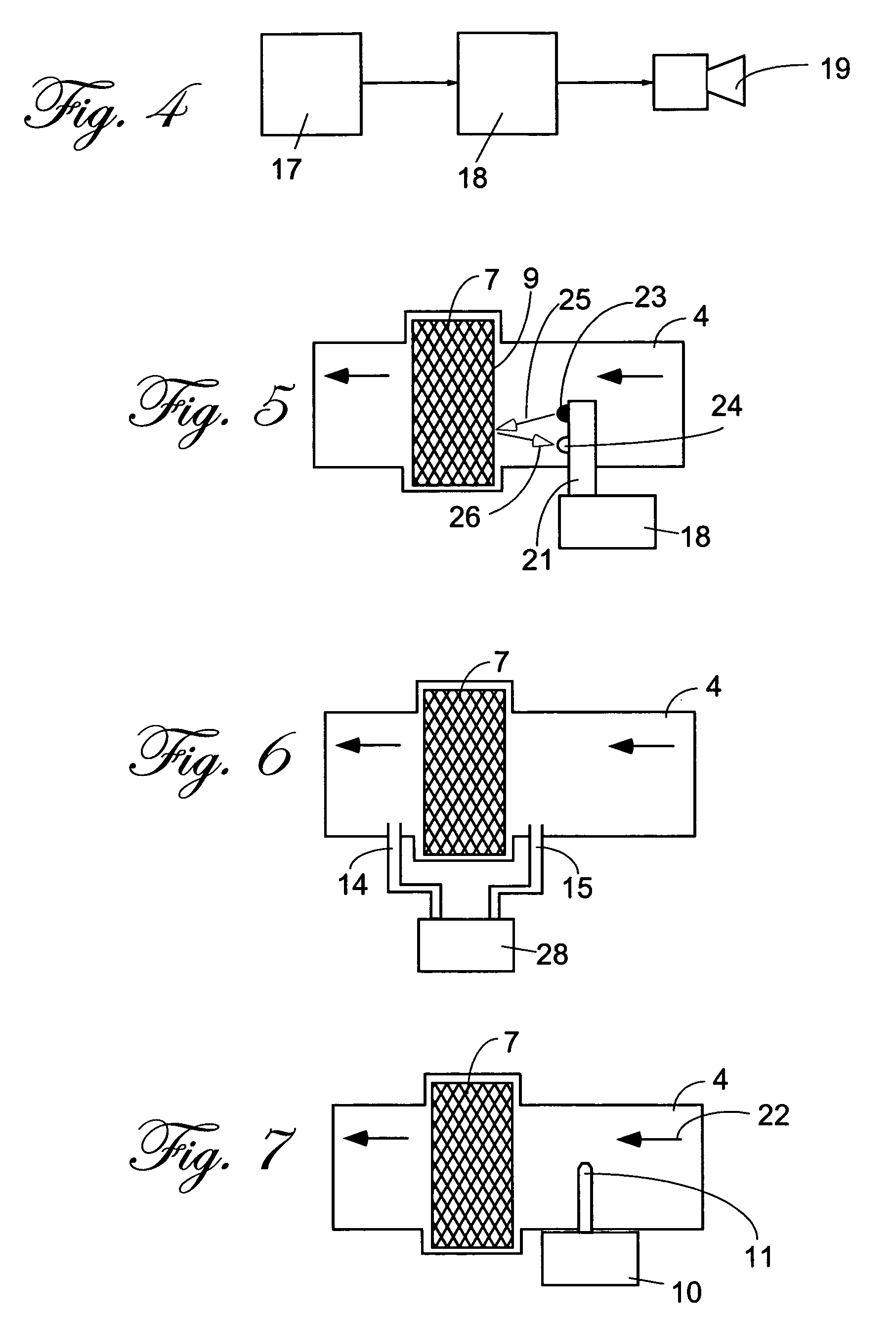

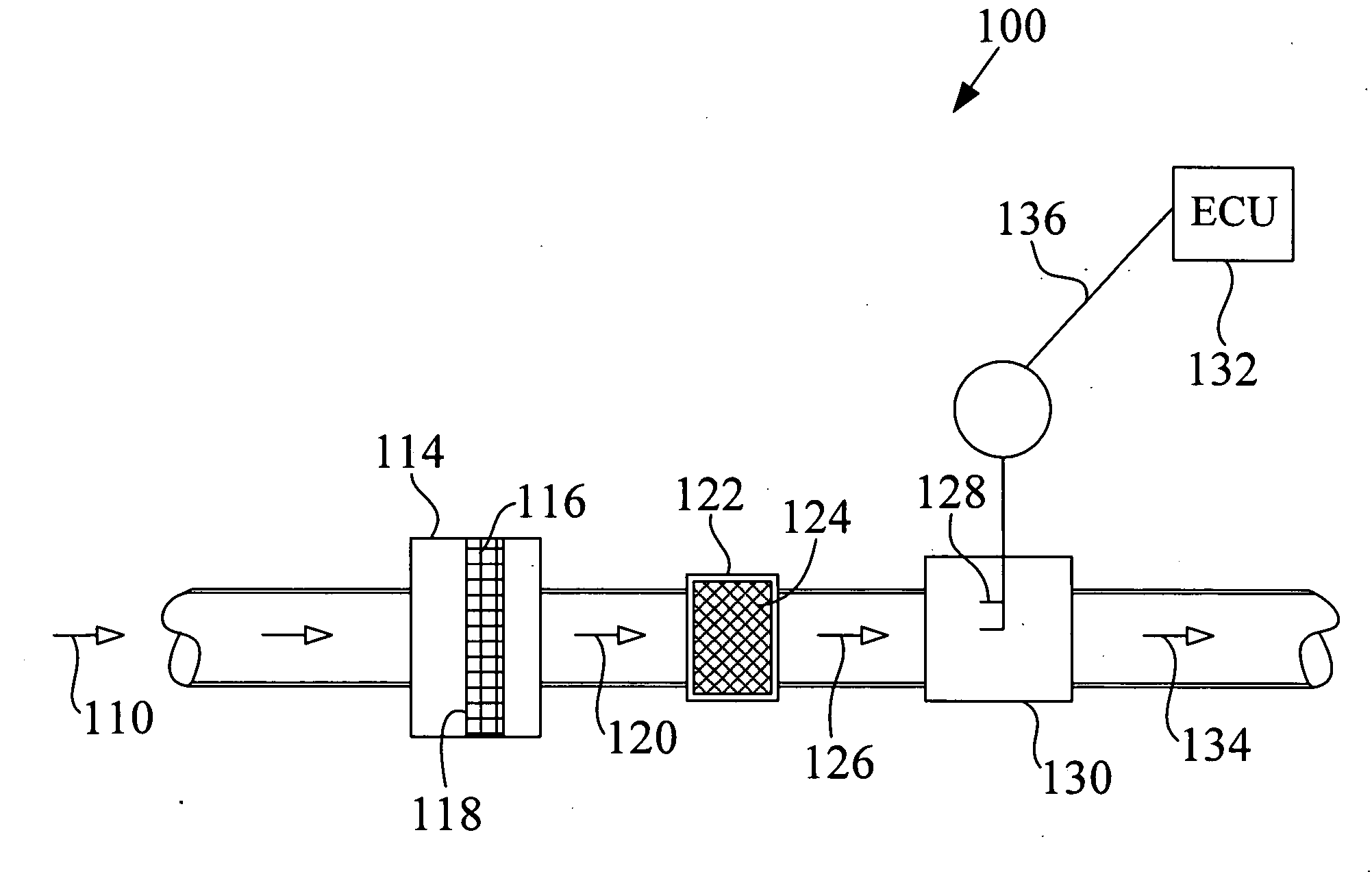

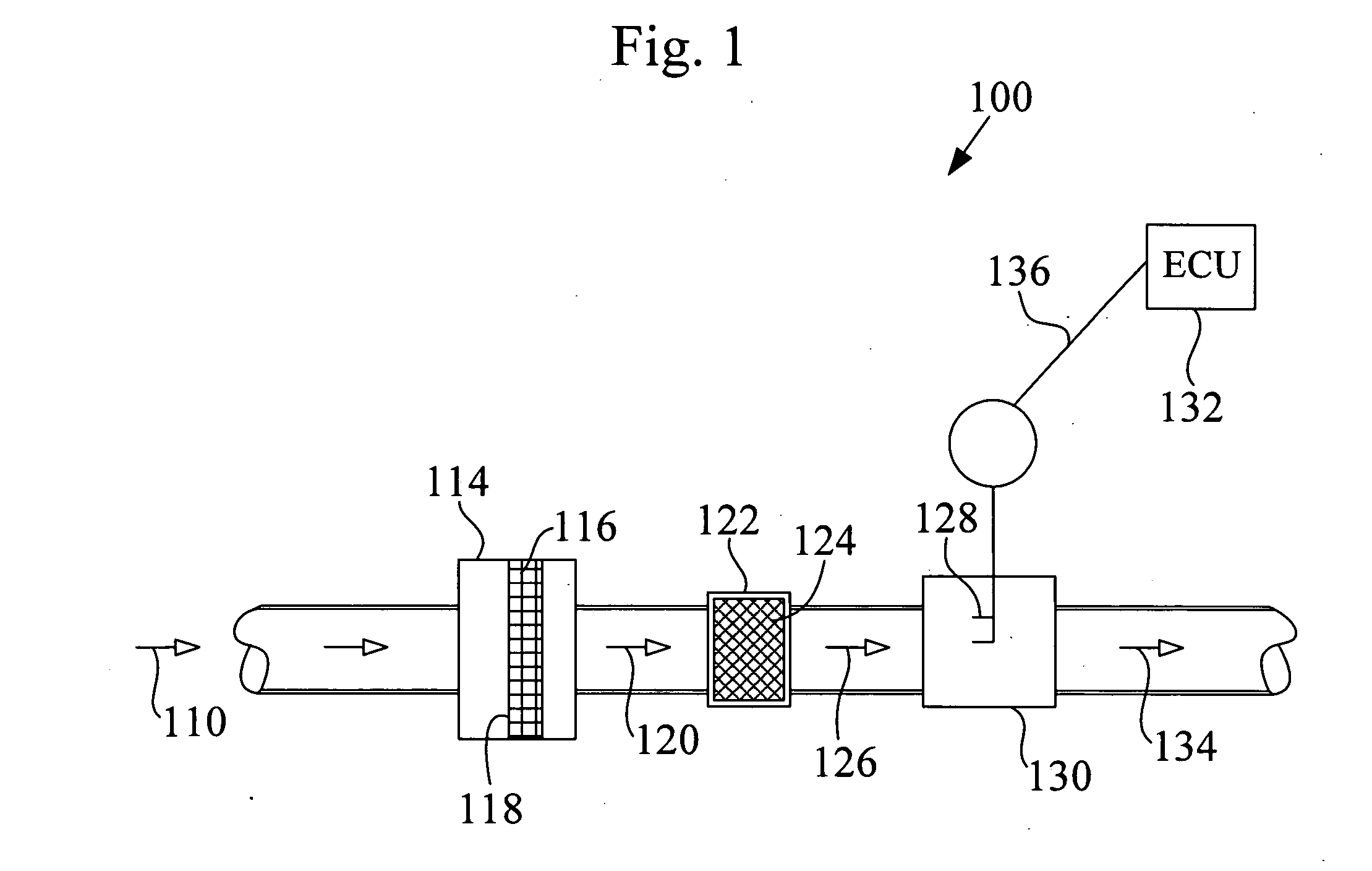

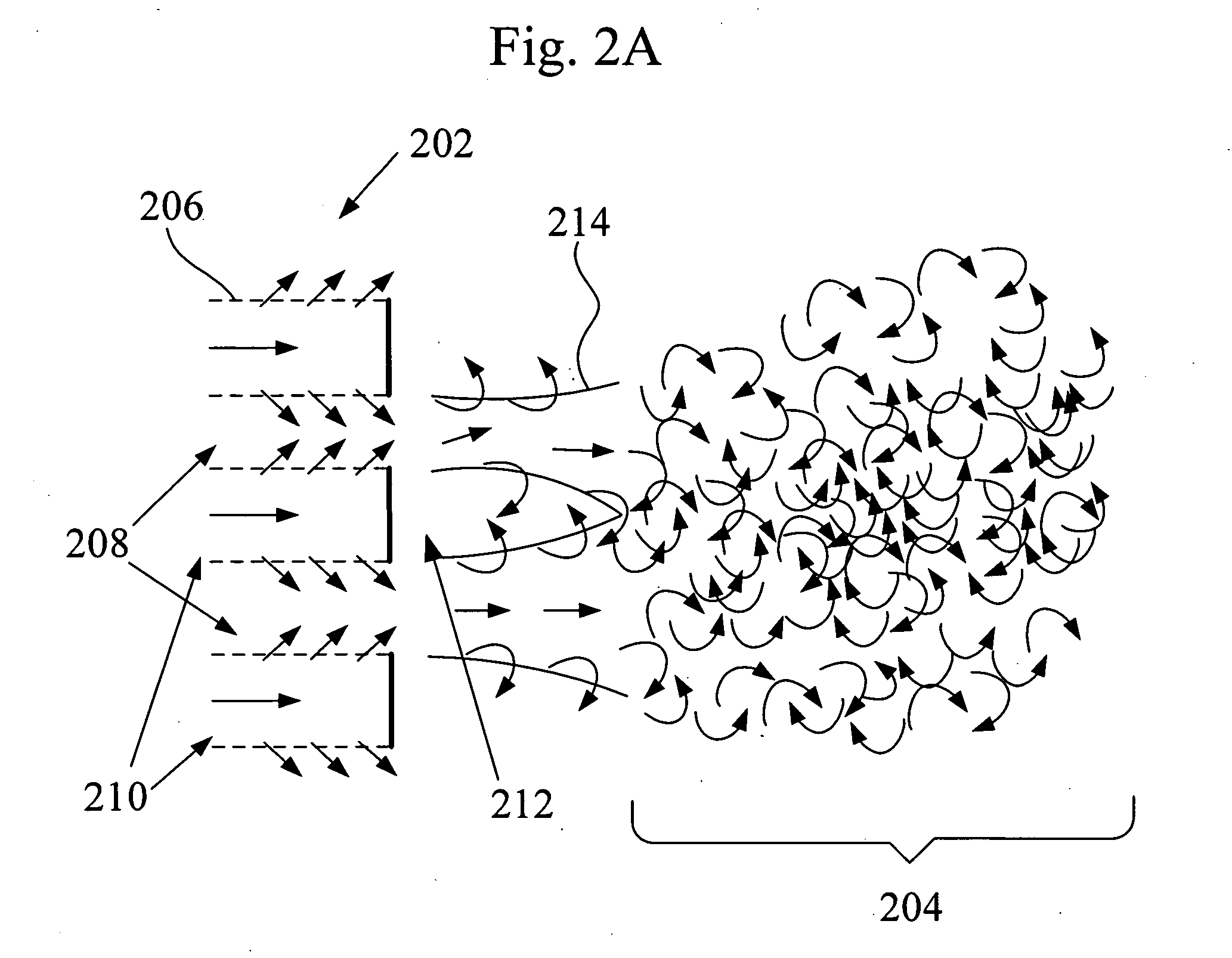

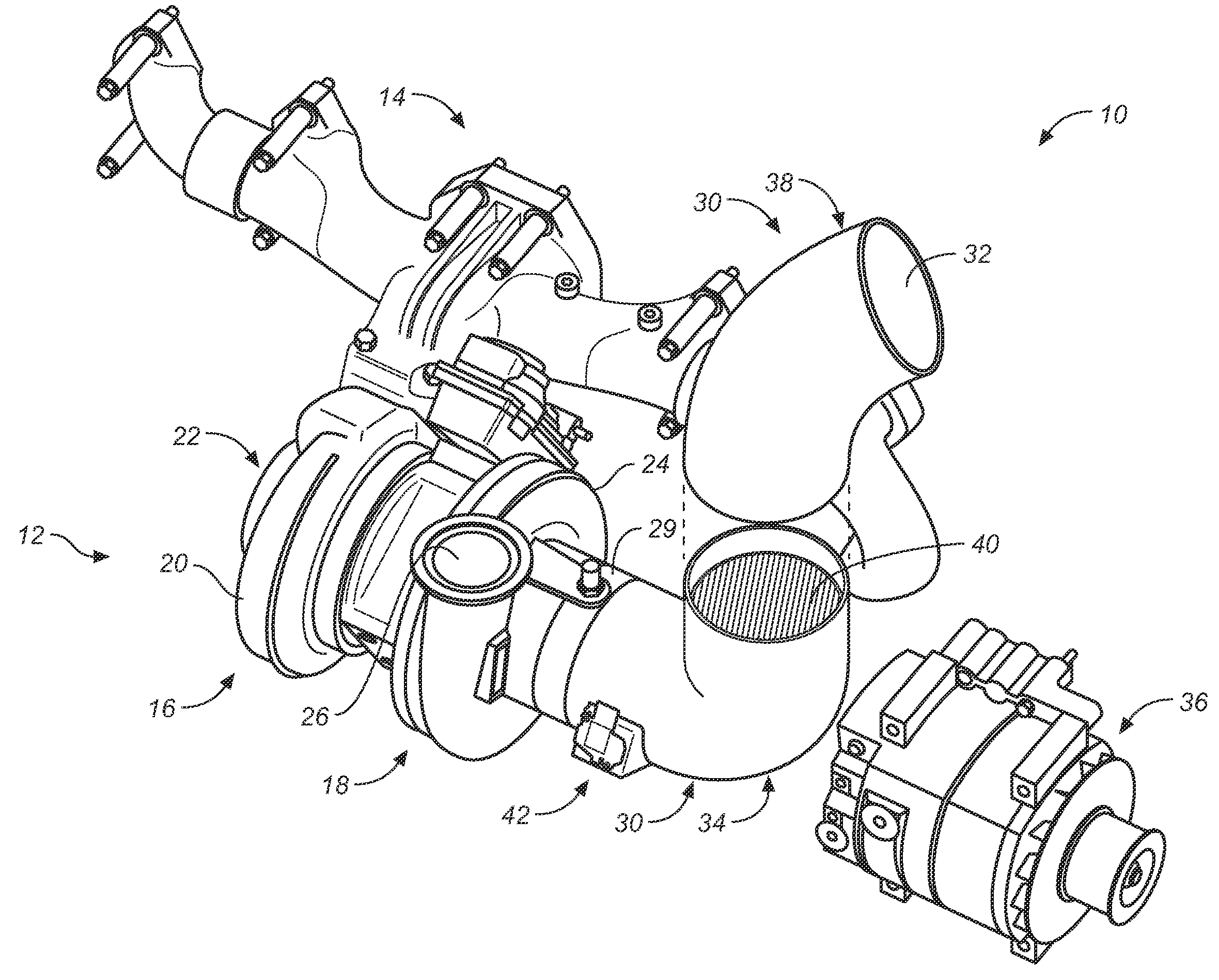

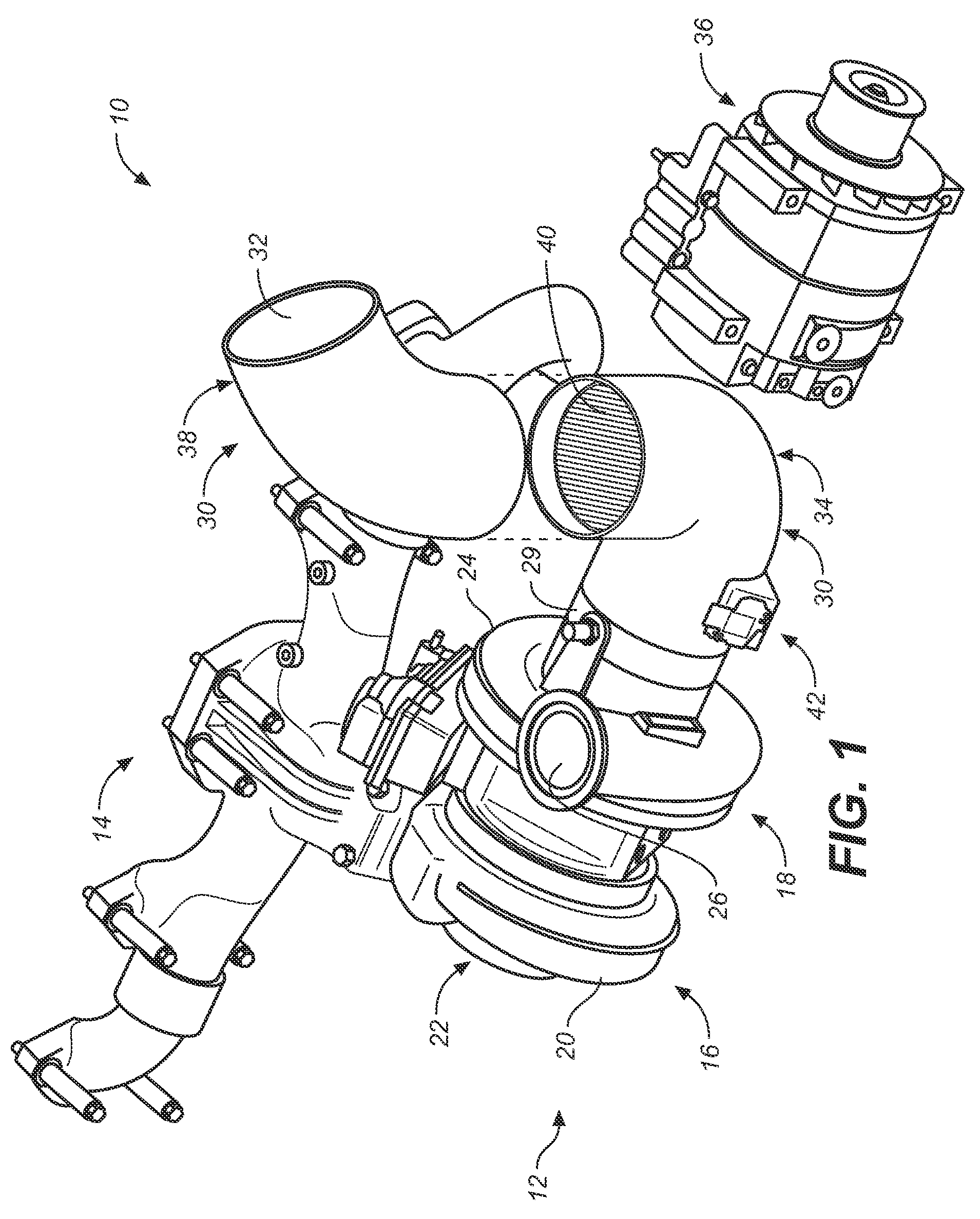

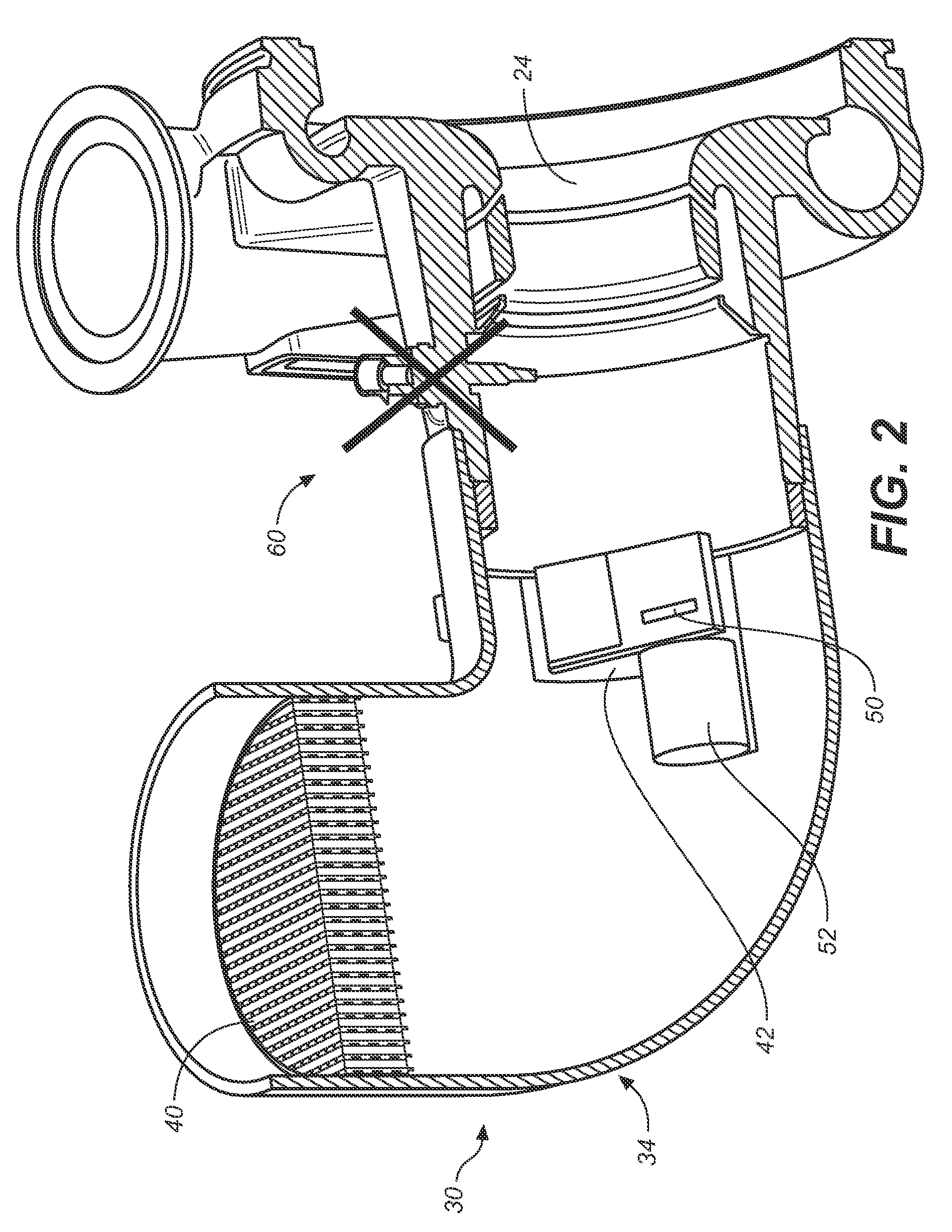

Flow vortex suppression apparatus for a mass air flow sensor

ActiveUS20100269583A1Reduce air turbulenceReduce turbulenceCombination devicesAuxillary pretreatmentFiberEngineering

In various aspects of the invention a flow vortex suppression apparatus for use in an air intake duct having a mass air flow sensor is disclosed. The flow vortex suppression apparatus includes an air flow permeable fibrous vortex dispersive media installed into the air duct in a position upstream of the mass flow sensor and configured to occlude the air duct such that air flow in the duct is constrained to pass through the vortex dispersive media. The vortex dispersive media is configured and adapted to diffuse vortices and reduce air turbulence of an air stream entering the mass flow sensor, thereby reducing variations and noise in a flow measurement signal from the mass air flow sensor.

Owner:MANN HUMMEL GMBH

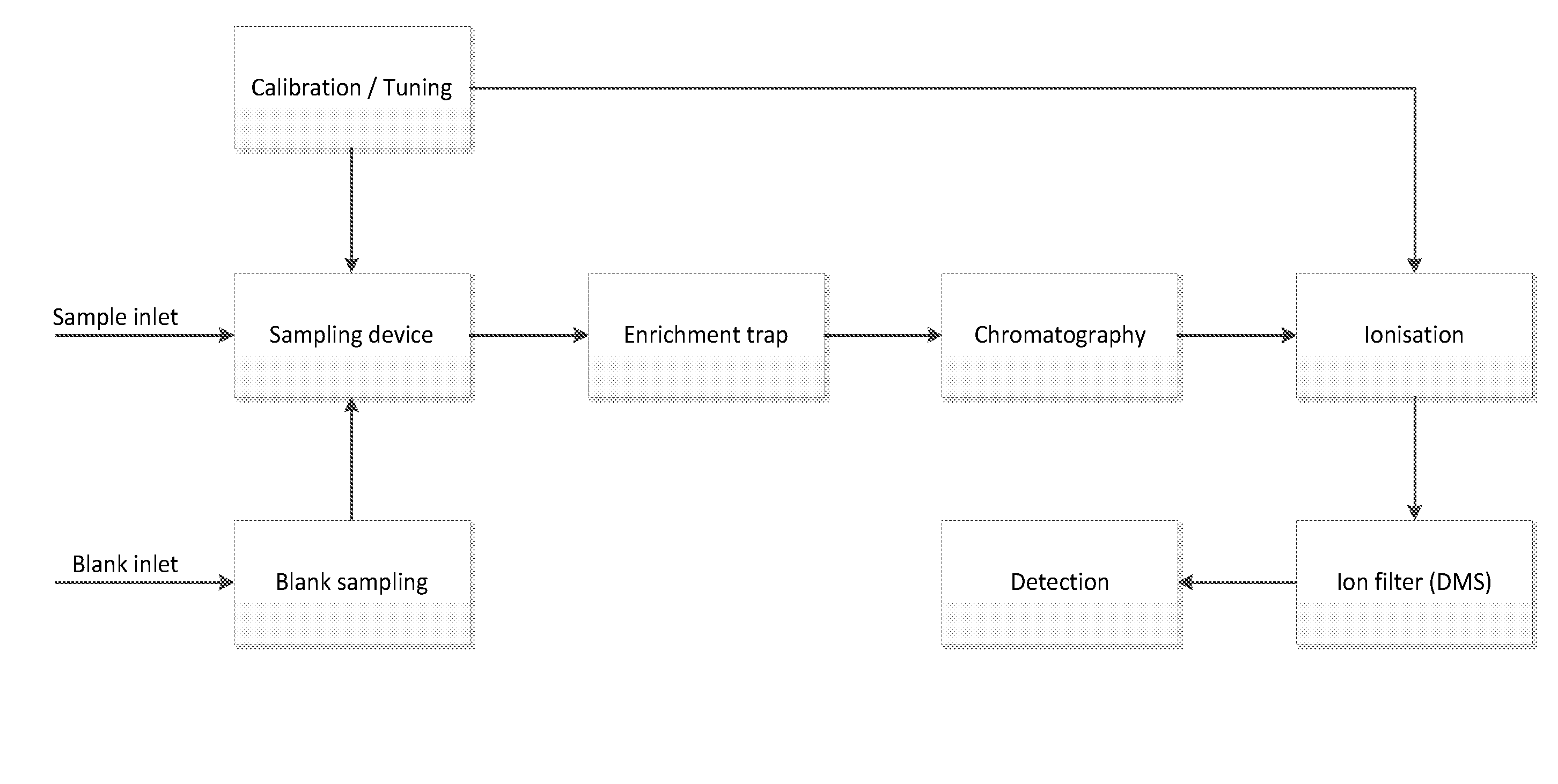

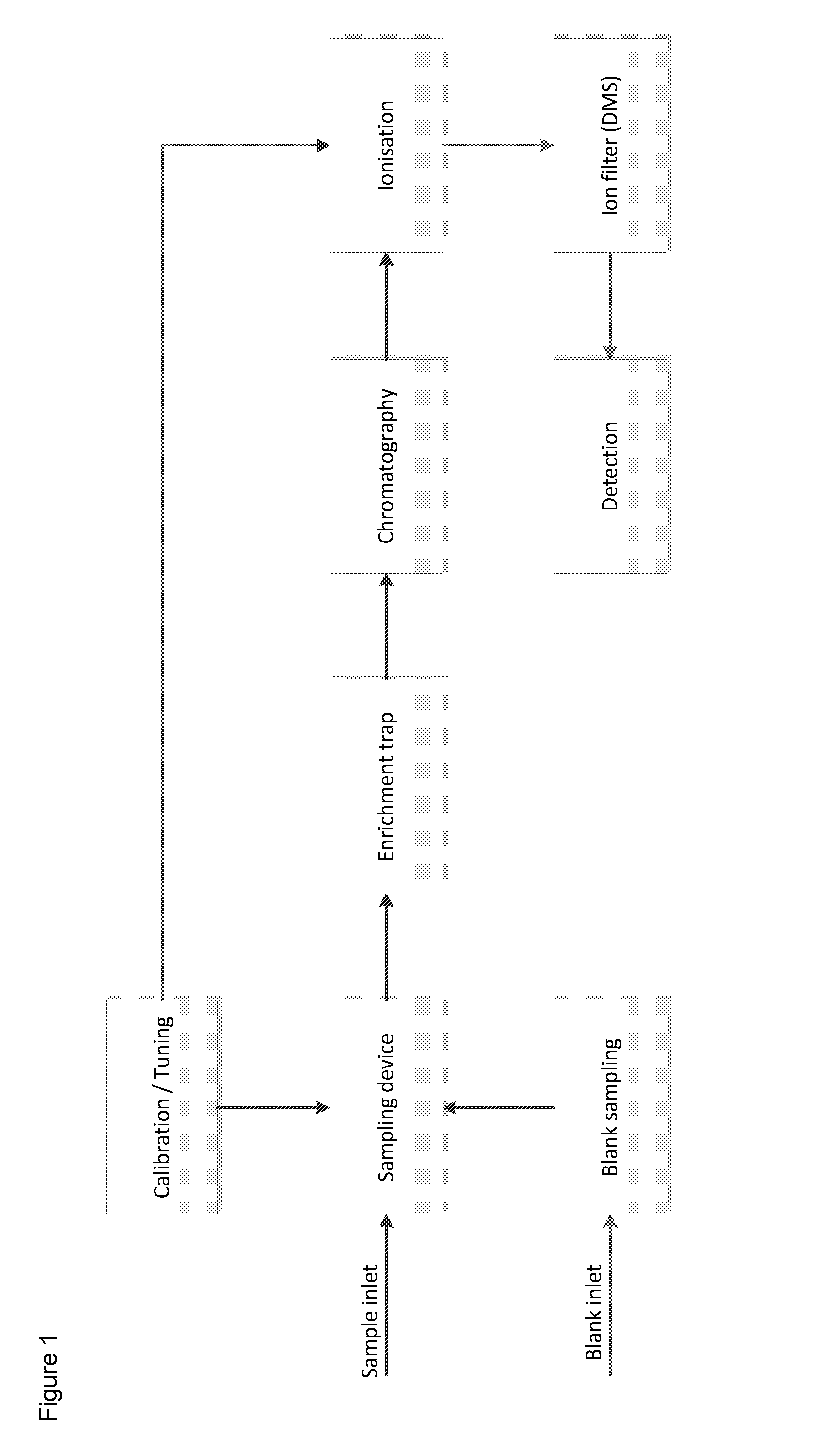

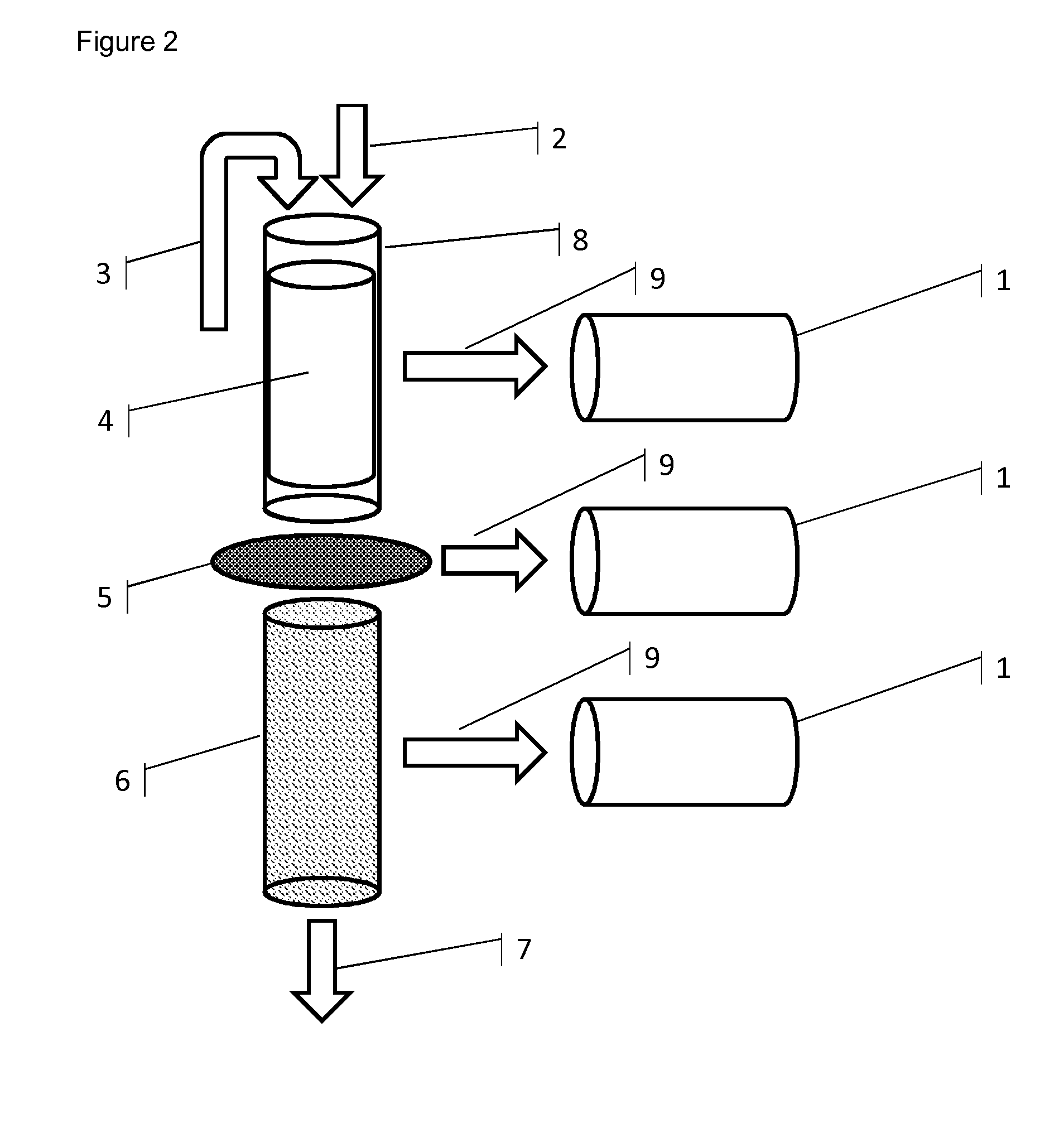

Flow regulating system and monitoring device comprising said flow regulating system for the detection of air borne analytes

InactiveUS20120329166A1Easy to detectComponent separationVolume/mass flow by thermal effectsAnalyteGas phase

Owner:PROVTAGAREN

Mass air flow sensor adaptor

InactiveUS20090241683A1Low costInternal combustion piston enginesVolume/mass flow measurementCombustionExternal combustion engine

Mass air flow sensing for internal combustion engines. In one aspect, a sensor adaptor for use in an internal combustion engine includes an inlet housing including an approximately 90-degree elbow and directing air within the inlet housing to the internal combustion engine in an airflow direction. A mass air flow sensor is coupled to the housing at a location after the 90-degree elbow with respect to the airflow direction and senses the air flowing within the inlet housing.

Owner:CUMMINS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com