Mass-flow sensor with a molded flow restrictor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016]The particular values and configurations discussed in these non-limiting examples can be varied and are cited merely to illustrate at least one embodiment and are not intended to limit the scope thereof.

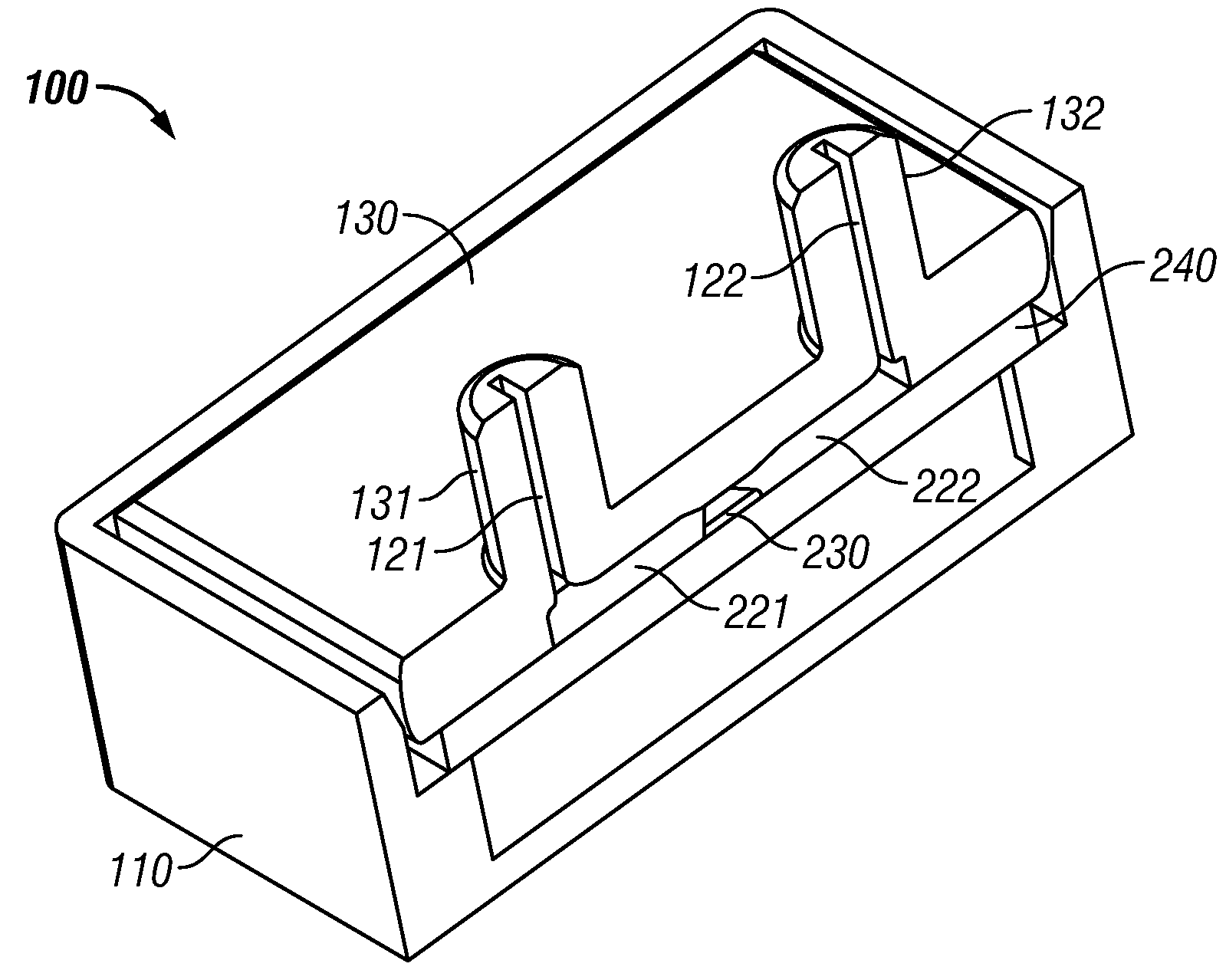

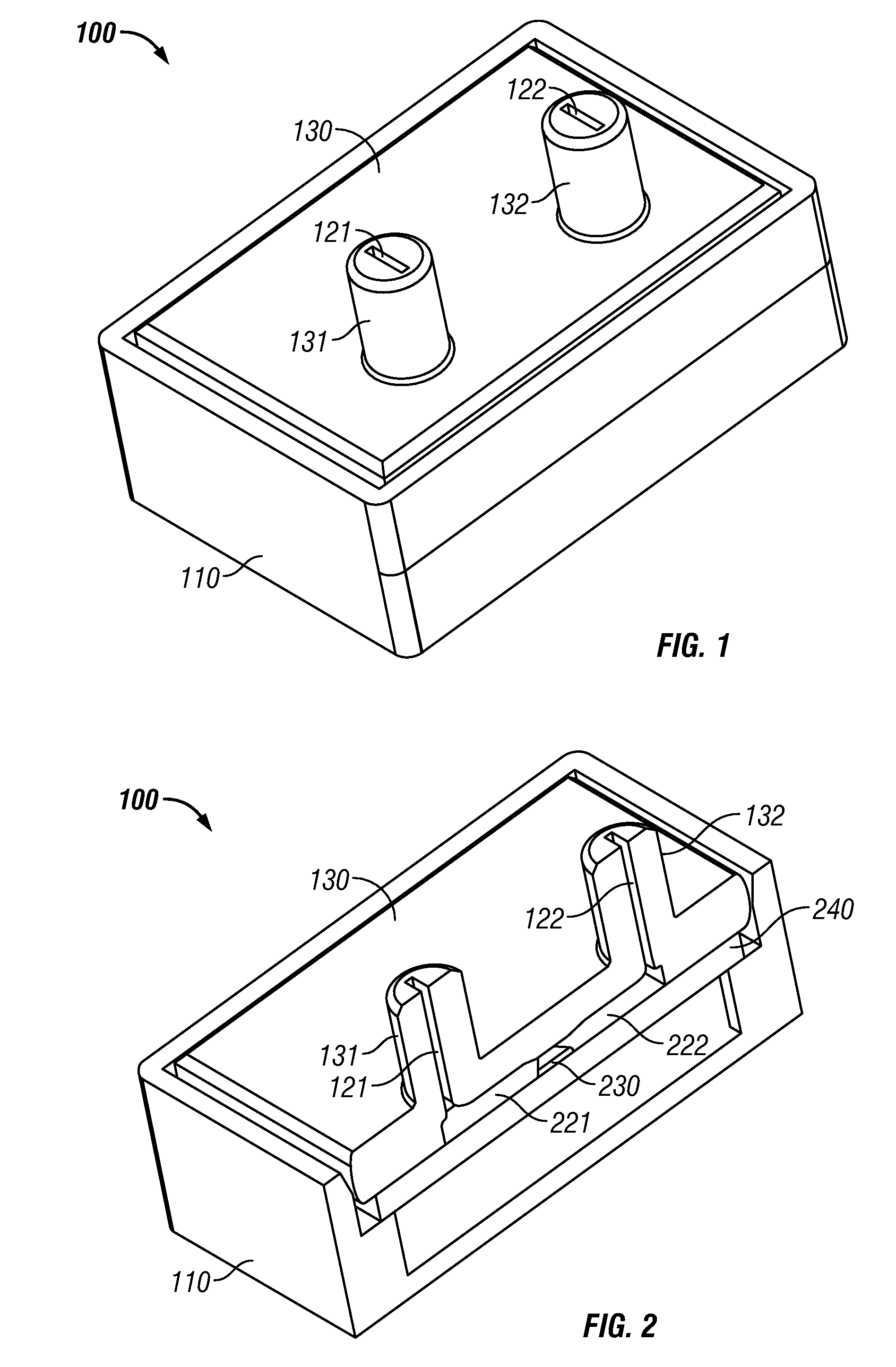

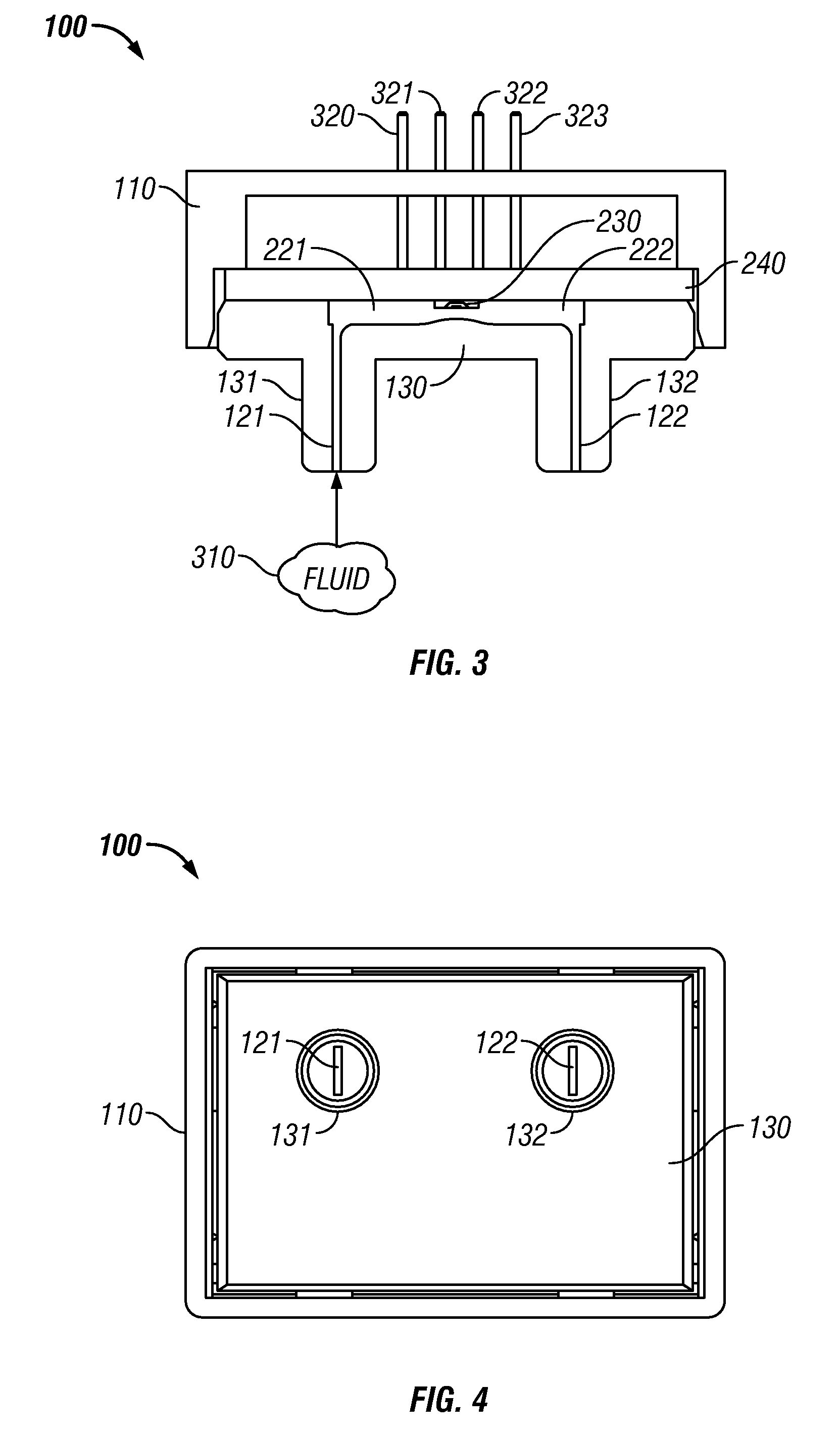

[0017]FIG. 1 illustrates a general perspective view of a mass-flow sensing apparatus 100, which can be adapted for use in implementing a preferred embodiment. The mass-flow sensing apparatus 100 can include a body 110 and flow tube 130 which can be fitted with ports 131 and 132 having restrictors 121 and 122, so that a fluid enters restrictor 121, flows through flow channel 221 and 222 as depicted in FIG. 2 and exits the restrictor 122. Note that as utilized herein the term “fluid” can refer to a gas and / or a liquid. Thus, the high mass-flow sensing apparatus 100 can be utilized in a flow system (not shown) for measuring a flow rate of the fluid. Note that the embodiments discussed herein generally relate to an airflow sensing system. It can be appreciated, however, that such e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com