Patents

Literature

159results about How to "To achieve temperature compensation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pressure sensor calibration method with temperature compensation function

ActiveCN103837300ATo achieve temperature compensationImprove detection accuracyFluid pressure measurementCurve fittingEngineering

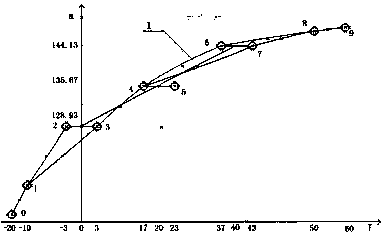

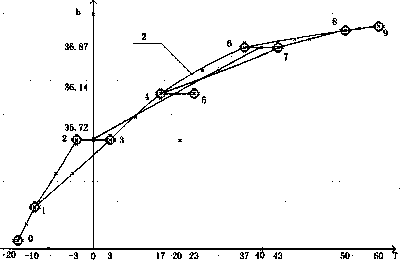

The invention discloses a pressure sensor calibration method with a temperature compensation function. According to the method, a zero drifting value and a sensitivity drifting value of a pressure sensor are measured at normal temperature and other temperature points, different pressures at the normal temperature and AD values corresponding to the pressures are stored in a pressure parameter table of the pressure sensor, then a zero drifting value and a sensitivity drifting value of the pressure sensor in a full-temperature range are obtained through a curve fitting method when the pressure sensor works, through calculation, the pressure AD values of the sensor at any temperature are converted into AD values at normal temperature, and finally compensated pressure measuring values are obtained according to the parameter table. According to the method, important parameters, namely the zero drifting values and the sensitivity drifting values of the pressure sensor are directly used, and the calibrated pressure sensor is high in precision and is easy to operate.

Owner:CHENGDU QIANJIA TECH CO LTD

Optical fiber raster vibration sensor of tunable matching filtering demodulation

ActiveCN1752729ASolve wavelength demodulationSolve temperature problemsSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansVibration amplitudeFrequency spectrum

The invented optical-fibre grating vibration sensor is characterized by that it utilizes a demodutation grating and a sensing grating and makes them be series-connected together, and respectively makes them be stuck on a main beam and an auxiliary beam, two beams are made of identical material and have identical heat expansion coefficient, so that their central wavelengths can be synchronously shifted with temperature, therefore they have automatic temperature compensation function so as to implement matching filter demodutation. Said invention utilizes the detection of light intensity change of sensing grating reflecting light to monitor the parameters of vibration frequency and vibration amplitude of monitored body, finally utilizes computer or single-chip computer to make analysis and processing of body vibration frequency spectrum.

Owner:WUHAN WUTOS

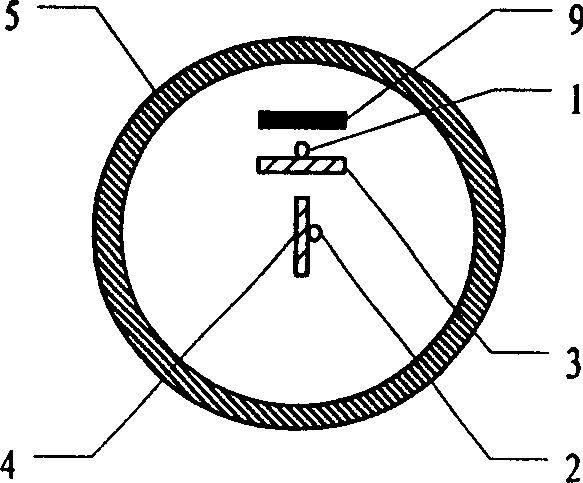

Optical fiber grating soil pressure sensing method

InactiveCN101413836AGuaranteed Linear VariationEasy to connect in seriesForce measurement by measuring optical property variationUsing optical meansCircular discGrating

The invention belongs to an optical fiber grating earth pressure sensing method. The method is characterized in that: a bearing disc (1) is connected with a cylindrical cavity shell (6), the cylindrical cavity shell (6) is connected with a disc cover (11); the bottom end of the cylindrical cavity shell (6) is provided with two wedge-shaped blind holes (12), and two fixed legs (5) are wedged into the two wedge-shaped blind holes (12); the fixed legs (5) are provided with fixed splints (13) and buffer splints (14) respectively, the fixed splints (13) are fixed at the two ends of a force measurement grating (9), the buffer splints (14) are fixed at the two ends of a temperature compensation grating (8), after the force measurement grating (9) and the temperature compensation grating (8) are connected in series, the two ends of the connected force measurement grating (9) and the temperature compensation grating (8) are connected with an input / output optical fiber (7) by a grating port (10), wavelength values of the force measurement grating (9) and the temperature compensation grating (8) are measured by an optical fiber grating demodulator, and then a true value of the earth pressure is obtained by subtracting the wavelength value of the temperature compensation grating (8) from the wavelength value of the force measurement grating (9). The method has the advantages of high sensitivity, anti-electromagnetic interference, good stability and being capable of monitoring landslide mass deformation, subgrade settlement, tunnel roof deformation and bridge deformation for a long time.

Owner:CHANGAN UNIV

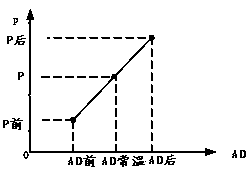

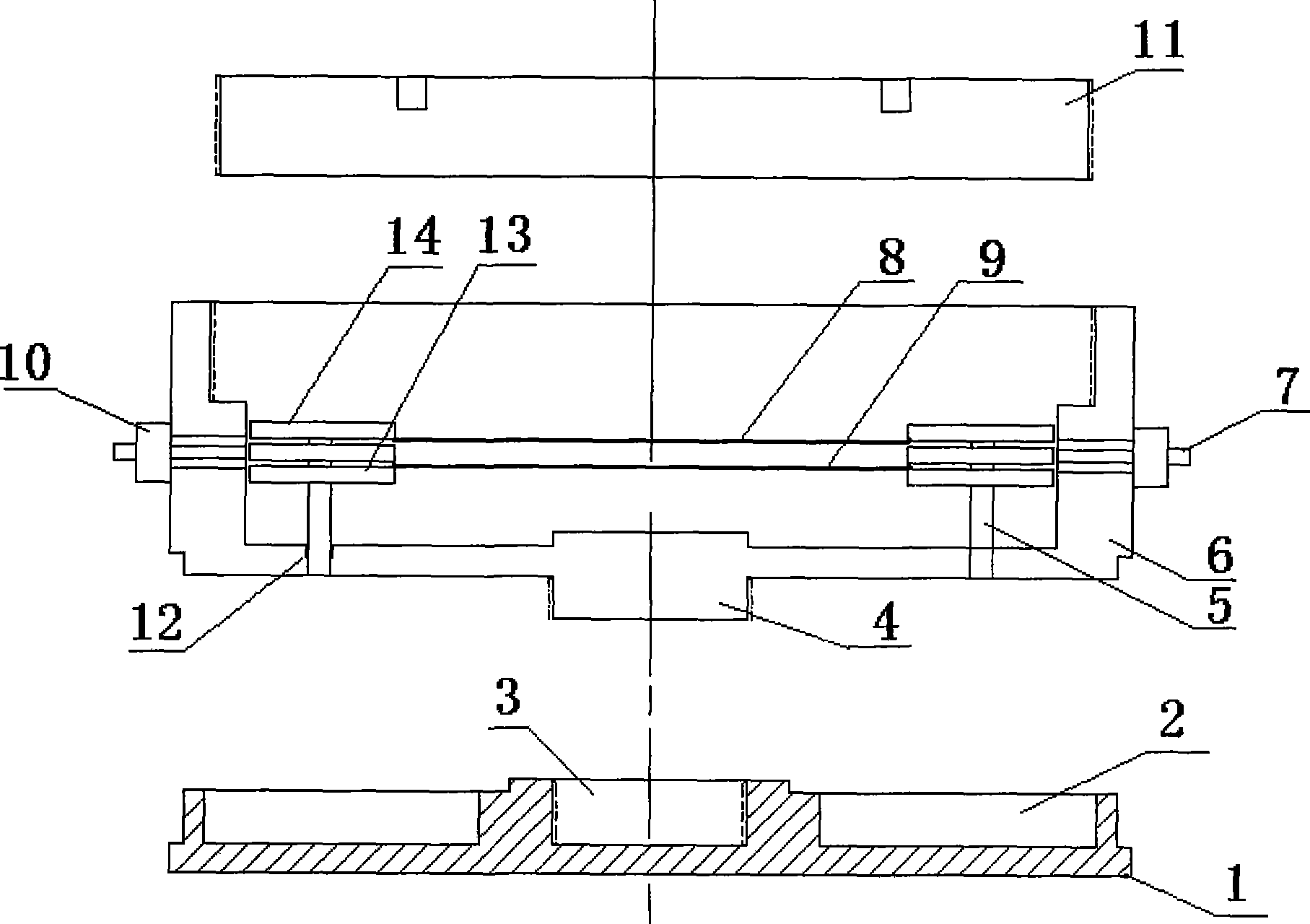

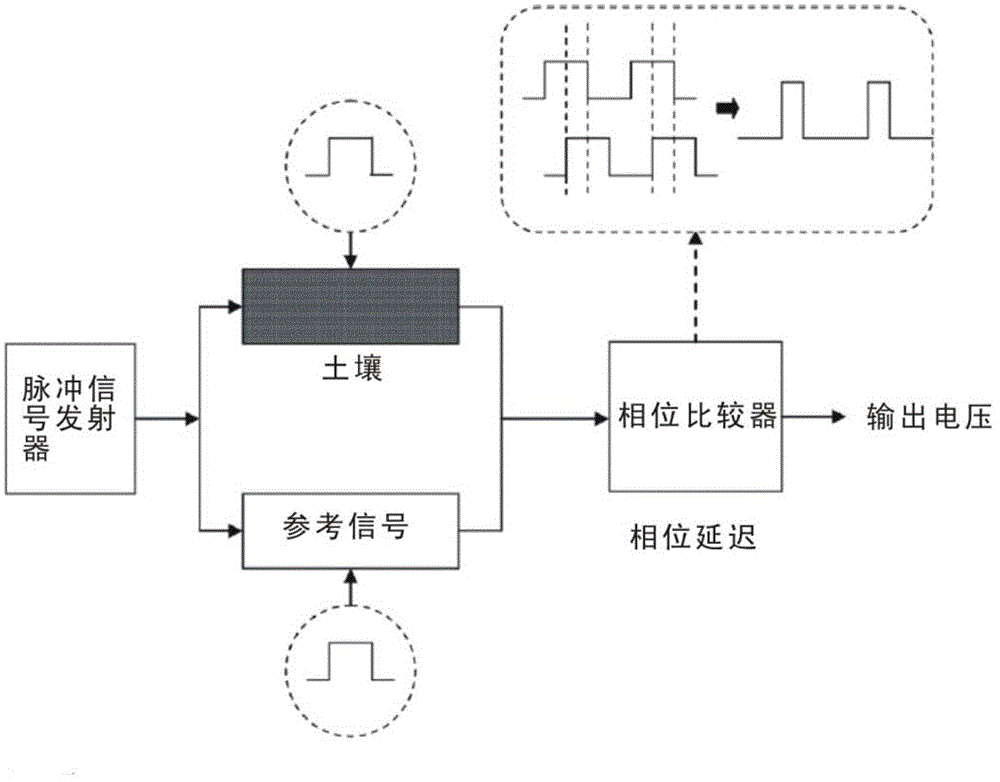

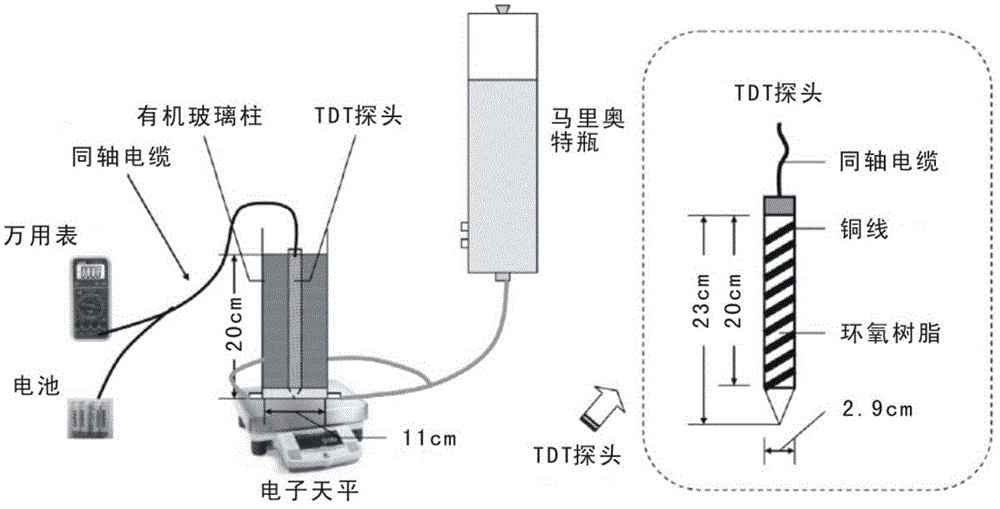

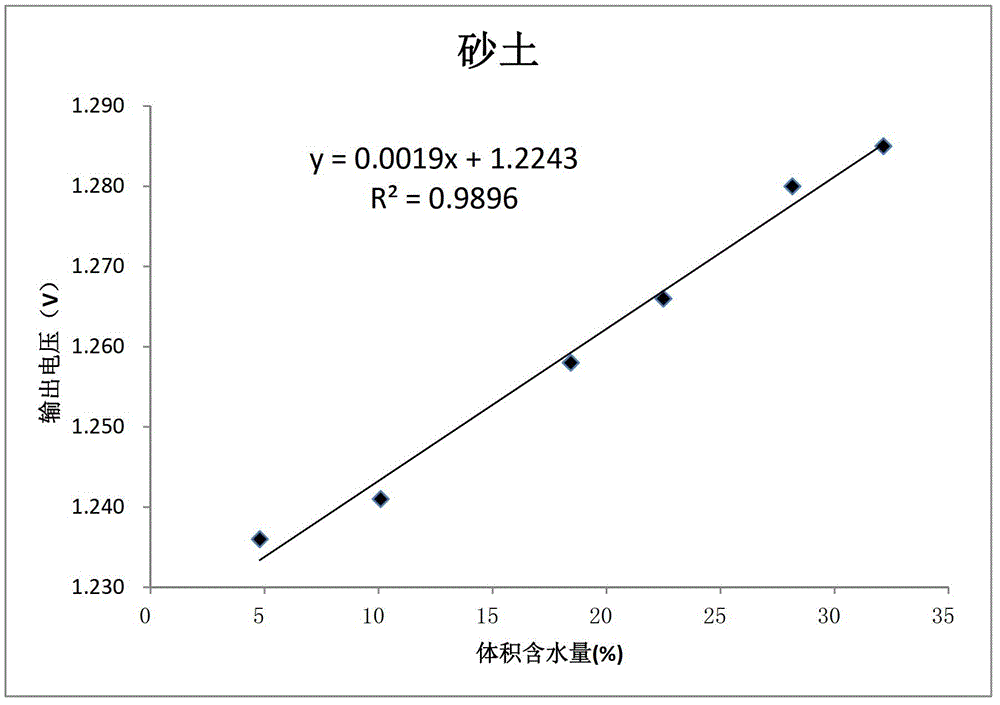

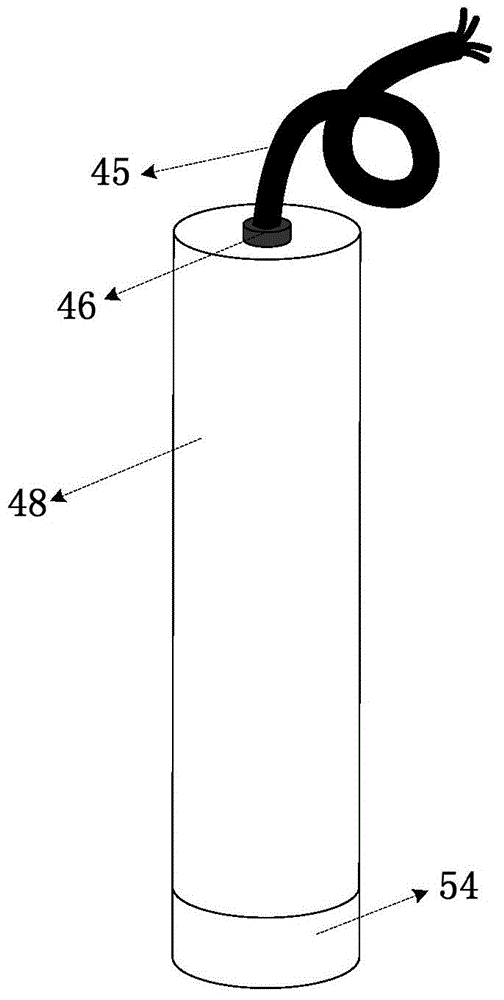

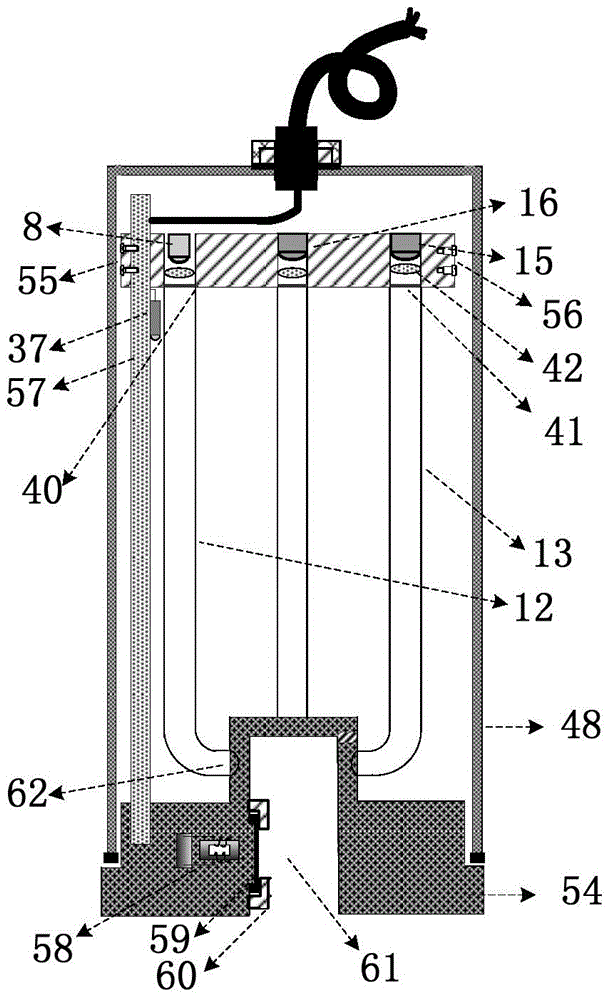

Soil moisture sensor calibration device and method based on time domain transmission technology

InactiveCN102944577ATo achieve temperature compensationMaterial analysis by electric/magnetic meansEpoxyTransmission technology

The invention discloses a soil moisture sensor calibration device and method based on a time domain transmission technology(TDT). A sensor probe mainly consists of a built-in circuit board, a coaxial cable, a copper line and epoxy resin. The calibration device mainly consists of a multimeter, a battery, an organic glass column, an earth pillar, a TDT sensor, an electronic balance, a Marriott bottle (Markov bottle) and an artificial climatic box. According to the calibration method disclosed by the invention, different soil textures can be calibrated to obtain a calibration curve and a relevant parameter as well as obtain a temperature calibration curve so as to better realize temperature compensation. The parameter obtained with the calibration method disclosed by the invention has an important meaning on TDT soil moisture sensor performance evaluation, subsequent perfection and development and practical application.

Owner:SUZHOU NANZEE SENSING TECH

Two-channel optical fiber method and sensor for measuring turbidity

ActiveCN104596990AImprove accuracyImprove water resistanceScattering properties measurementsTransmissivity measurementsPhysicsScattered light

The invention discloses a two-channel optical fiber method and two-channel optical fiber sensor for measuring turbidity. The method is characterized in that a detection mode adopting double light sources, four laser beams and four photo-electricity is adopted, and the double different-wavelength light sources can be alternately lightened by an optical measuring module, so that 90-degree scattered lights and transmission lights can be alternately measured; a temperature measuring module is used for collecting temperature signals of water; a signal adjusting module is used for processing collected turbidity signals and temperature signals; a data processing module is used for calculation and treatment so that turbidity values and a temperature values are generated, and the in-site collecting data are transmitted to an upper computer. The different-wavelength light sources are simultaneously measured so that the stray light impact on turbidity measurement is eliminated; the external impact on the light signals is avoided through optical fiber transmission, thus the method has the high-temperature and high-pressure resisting performances and the anti-electromagnetic interference performance; temperature compensation is performed on the measured turbidity values so as to improve the measurement precision of turbidity. In-site online detection for the turbidity values is realized by the method, thus the method is high in sensitivity, excellent in linearity, low in cost and easy to carry and install, and the method is applied to narrow detection space and occasions where detected liquid is limited in capacity.

Owner:CHINA AGRI UNIV

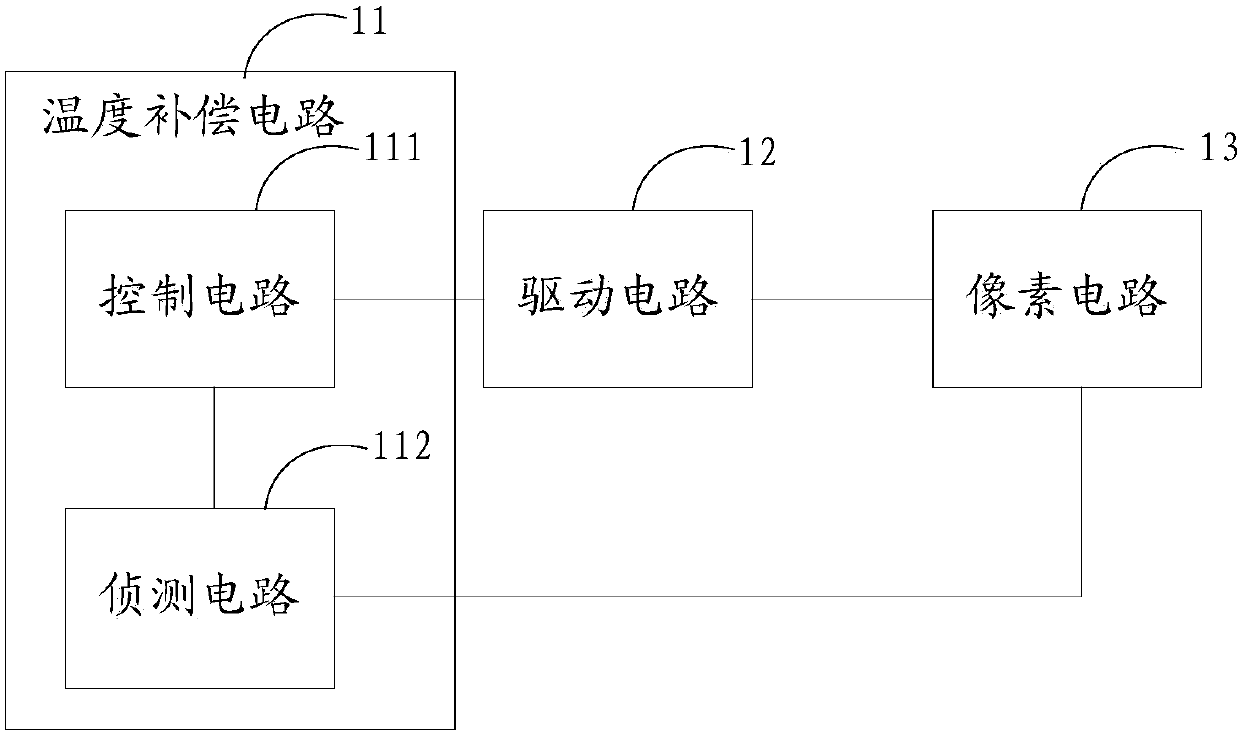

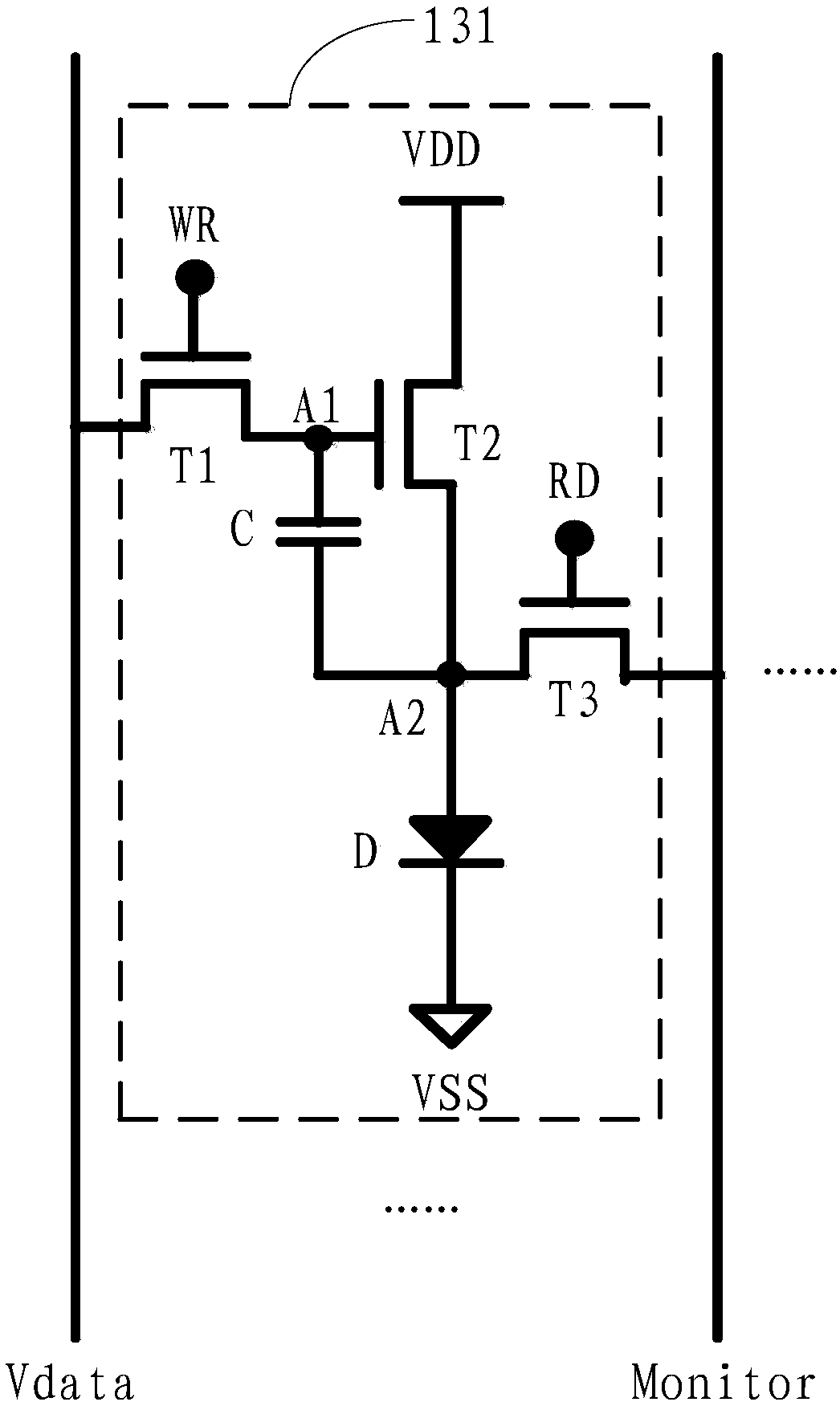

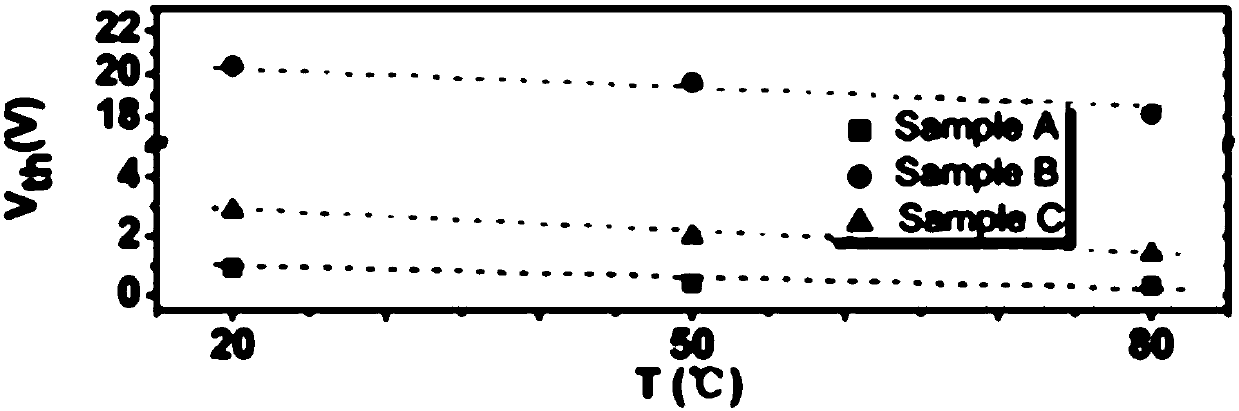

Temperature compensation circuit and method applied to display panel and display panel

ActiveCN107731160AExtended service lifeTo achieve temperature compensationStatic indicating devicesCurrent thresholdCurrent compensation

The invention discloses a temperature compensation circuit and method applied to a display panel and the display panel. The display panel includes a control circuit, a driving circuit, a detection circuit, and a pixel circuit. The detection circuit is used for obtaining a current threshold voltage of a switch tube in a pixel circuit. The control circuit obtains a current voltage difference betweenthe current threshold voltage and initial threshold voltage, a current compensation gain matched the current voltage difference is obtained in preset associated data of a voltage difference and a compensation gain, and the current compensation gain is used to control the driving circuit to drive the pixel circuit. Through the above mode, the temperature compensation of the display panel can be realized without an additional temperature sensor, and thus the service life of the display panel is prolonged.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

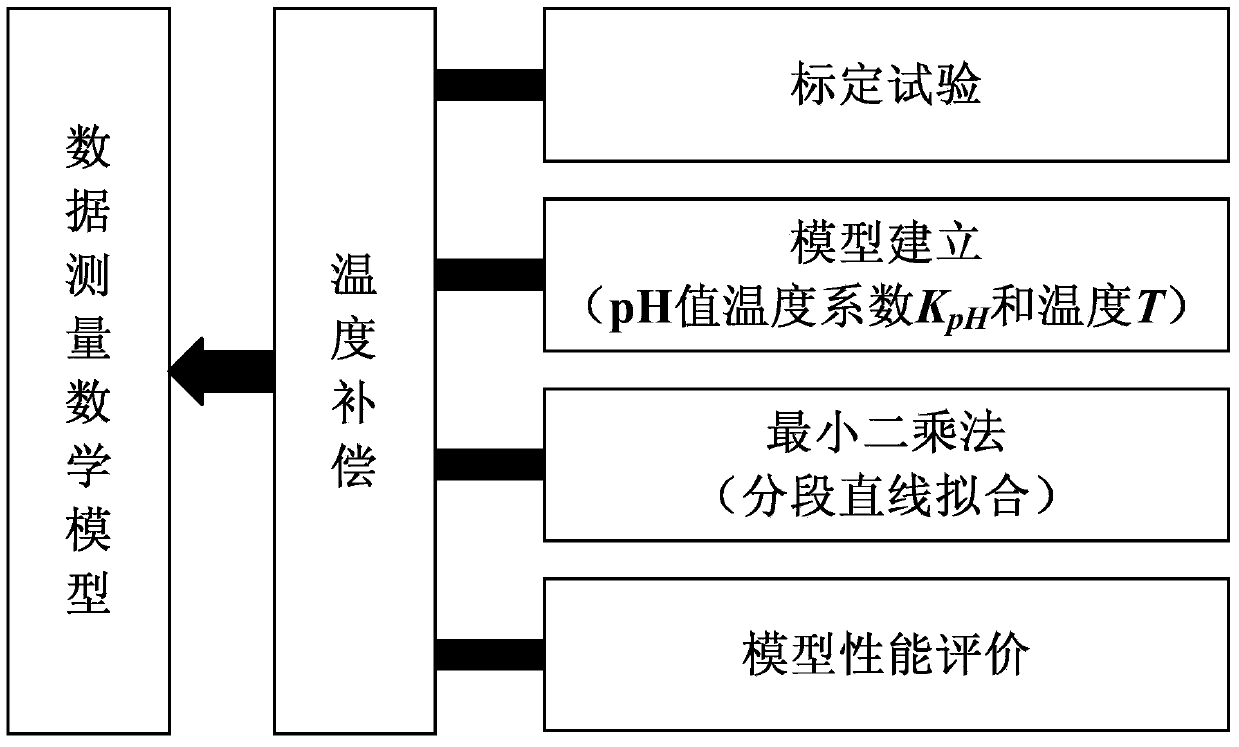

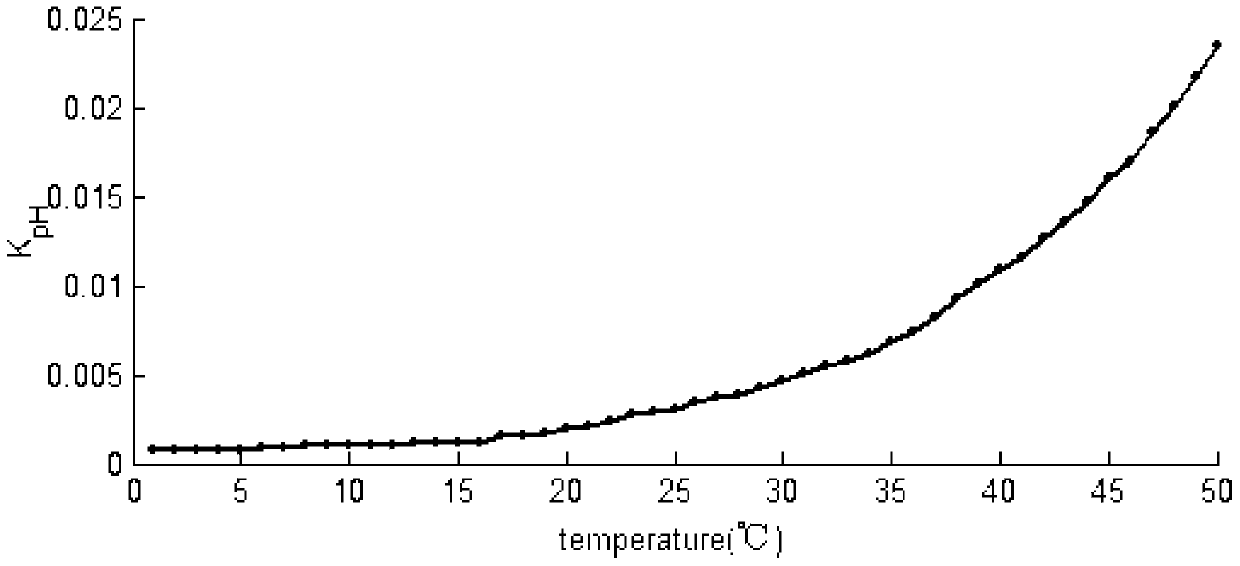

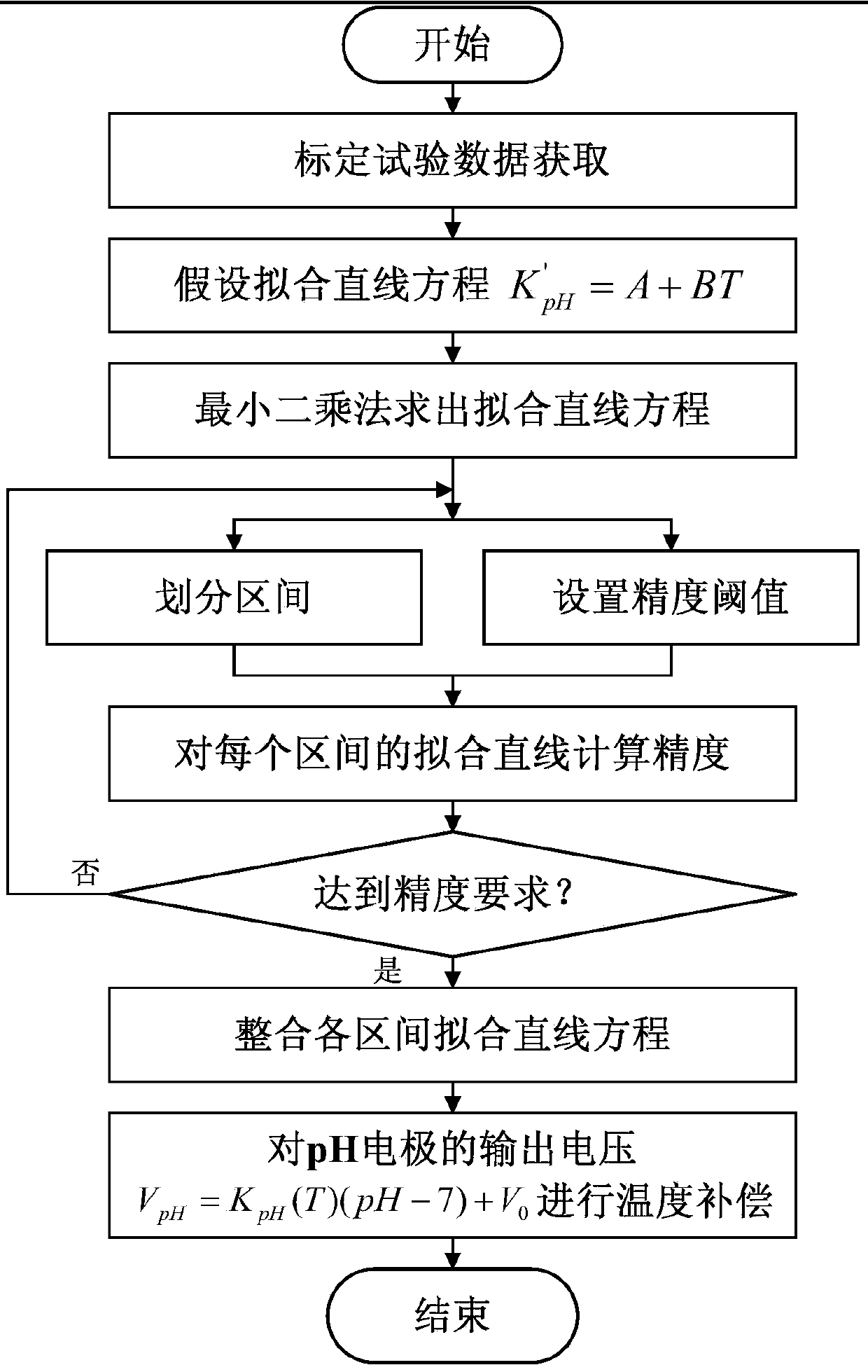

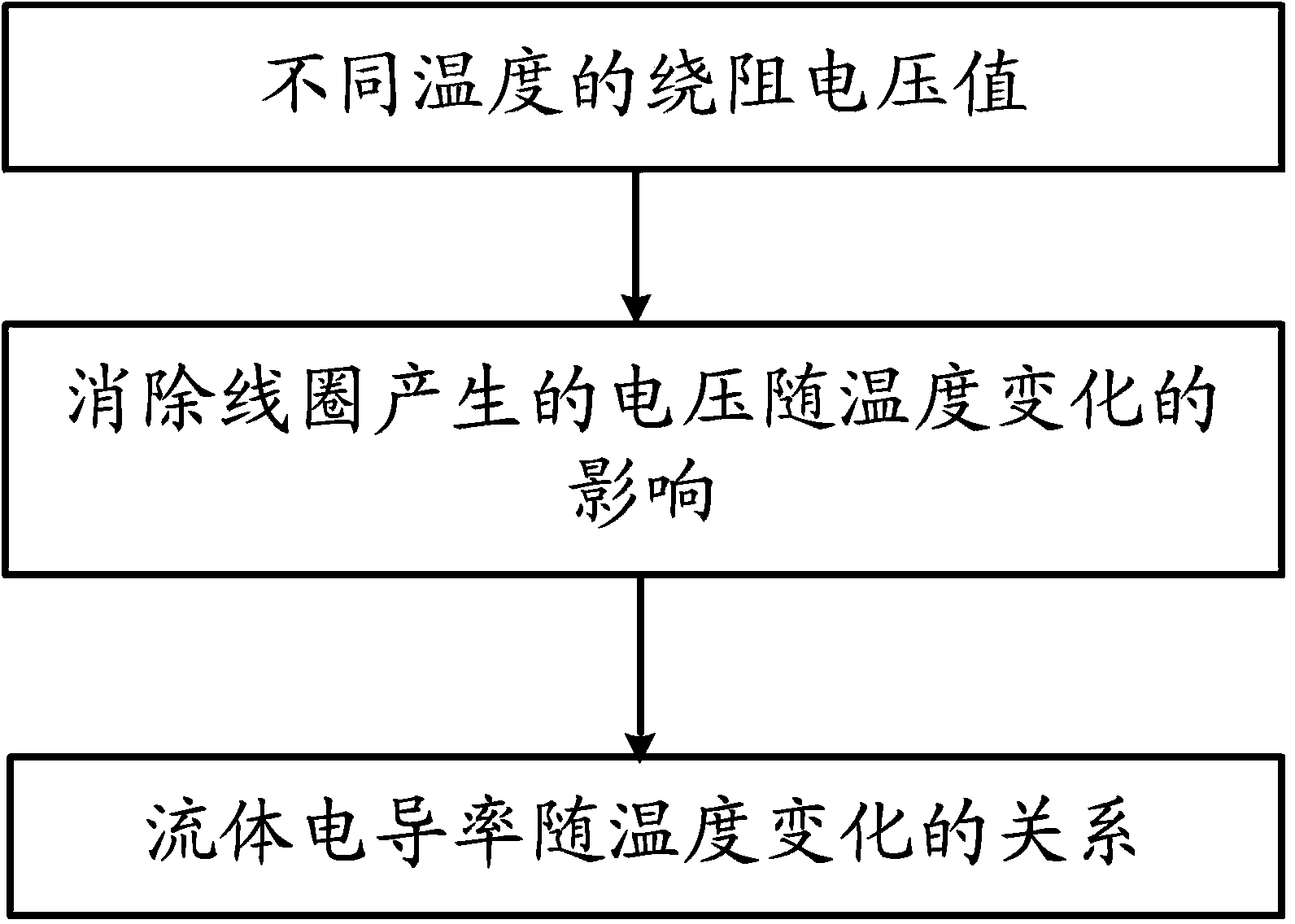

Small-signal sectional fitting temperature compensation method of water quality sensor

ActiveCN104181214AImprove Acquisition AccuracyTo achieve temperature compensationMaterial electrochemical variablesMathematical modelData acquisition

The invention discloses a small-signal sectional fitting temperature compensation method of a water quality sensor, relates to the technical field of small signal processing, and in particular relates to a sectional fitting method which can realize a fitting effect for improving the measure accuracy, reducing the measure data conversion error and fitting a nonlinear curve to improve the measure precision. The method comprises the following steps of establishing a mathematic model by adopting a sectional linear fitting method, dividing a pH temperature coefficient KpH calibration curve into a plurality of intervals, fitting a corresponding linear equation by adopting a least square method, calculating the linear fitting precision, re-dividing the intervals to perform the fitting if the precision is lower than a threshold value until the precision meets the requirement, and further realizing the temperature compensation. A simple, rapid and precise mathematic model is adopted, so that the data acquisition accuracy can be effectively improved.

Owner:SOUTH CHINA AGRI UNIV

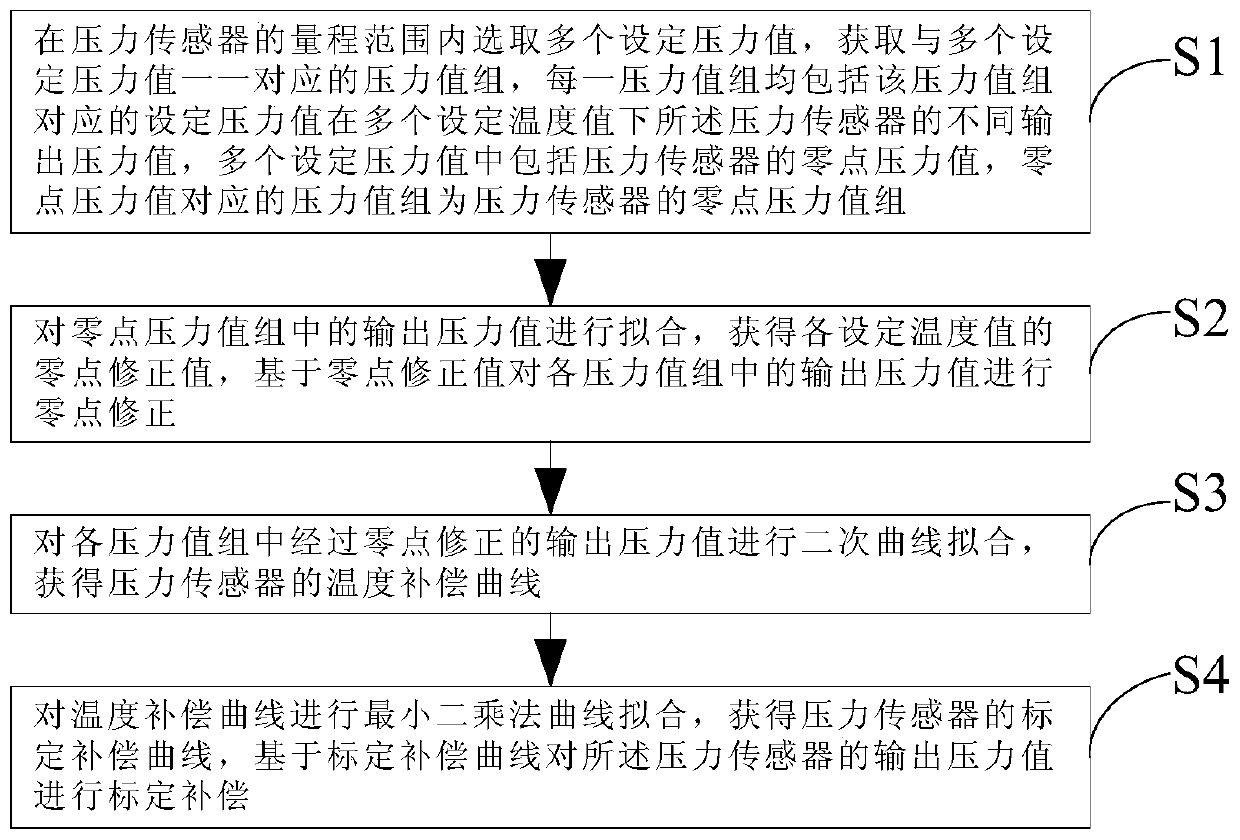

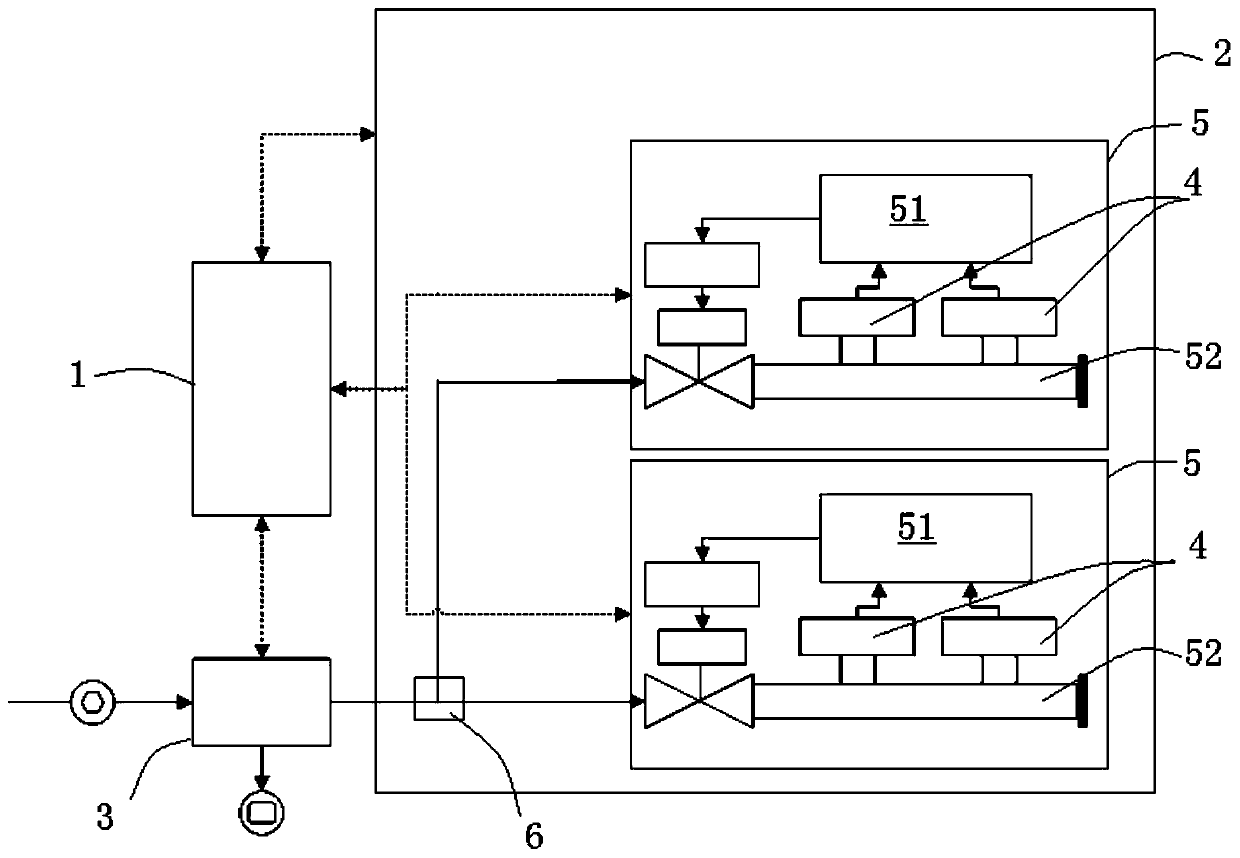

Compensation method and system of pressure sensor

ActiveCN110553786ATo achieve temperature compensationHigh compensation accuracyFlow control using electric meansFluid pressure measurementControl theoryForce sensor

The invention provides a compensation method and system of a pressure sensor. The method comprises the steps of s1, selecting a plurality of set pressure values in the measuring range of a pressure sensor, obtaining the corresponding pressure value sets, each pressure value set comprising different output pressure values under the set temperature value, and the pressure value set corresponding tothe zero pressure value being the zero pressure value set of the pressure sensor; s2, fitting the output pressure values to obtain zero-point correction values of the set temperature values, and performing zero-point correction on the output pressure values in the pressure value groups based on the zero-point correction values; s3, performing quadratic curve fitting on the output pressure value subjected to zero correction to obtain a temperature compensation curve; and s4, performing least square method curve fitting on the temperature compensation curve to obtain a calibration compensation curve of the pressure sensor, and performing calibration compensation on the output pressure value based on the calibration compensation curve. The pressure sensor compensation method and system provided by the invention are high in compensation precision, low in system resource consumption and short in calibration period.

Owner:BEIJING SEVENSTAR FLOW CO LTD

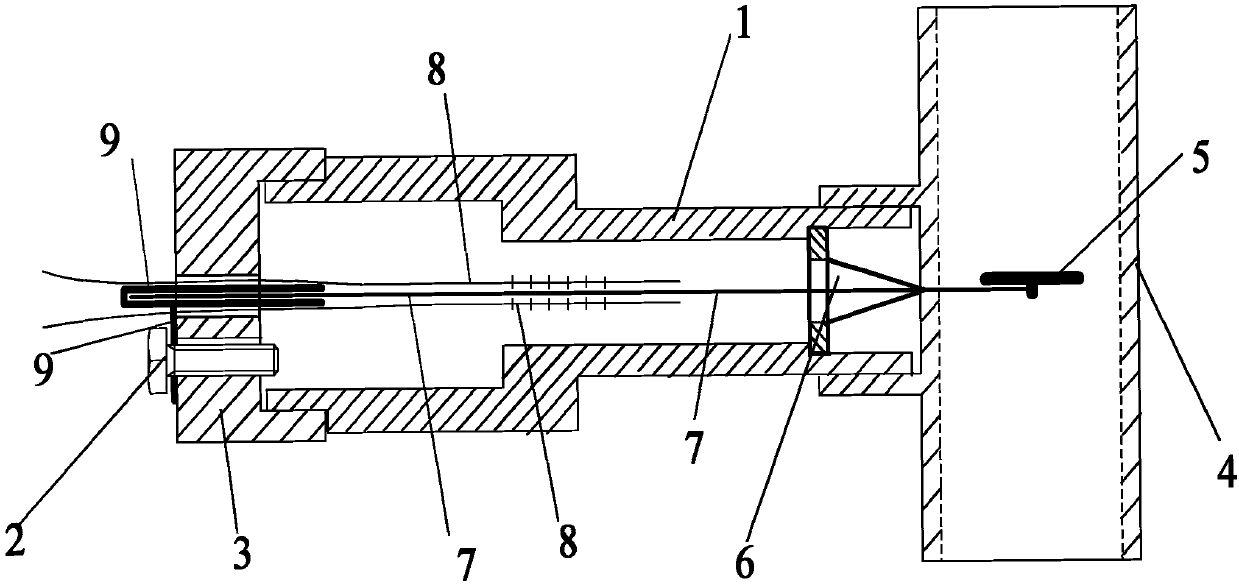

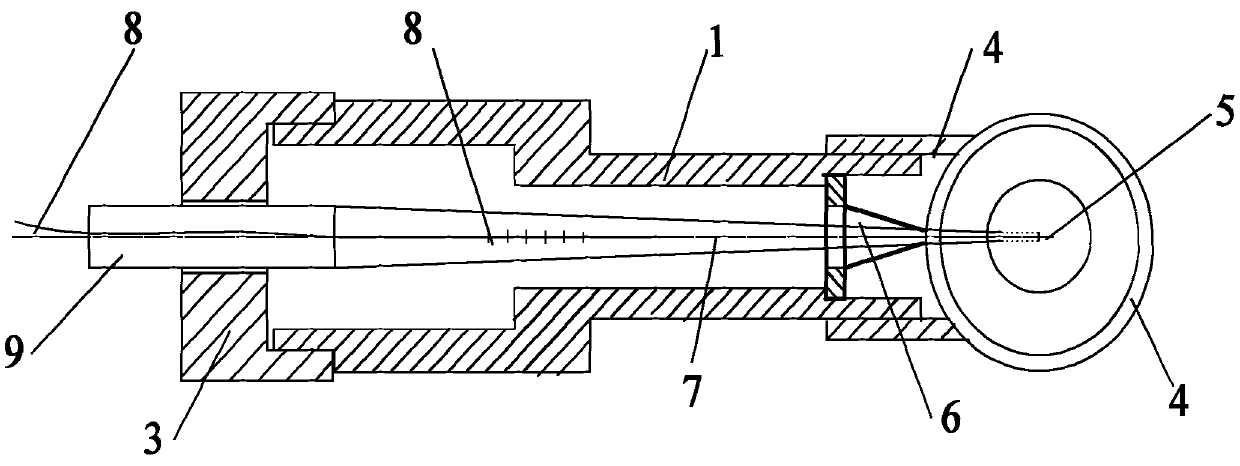

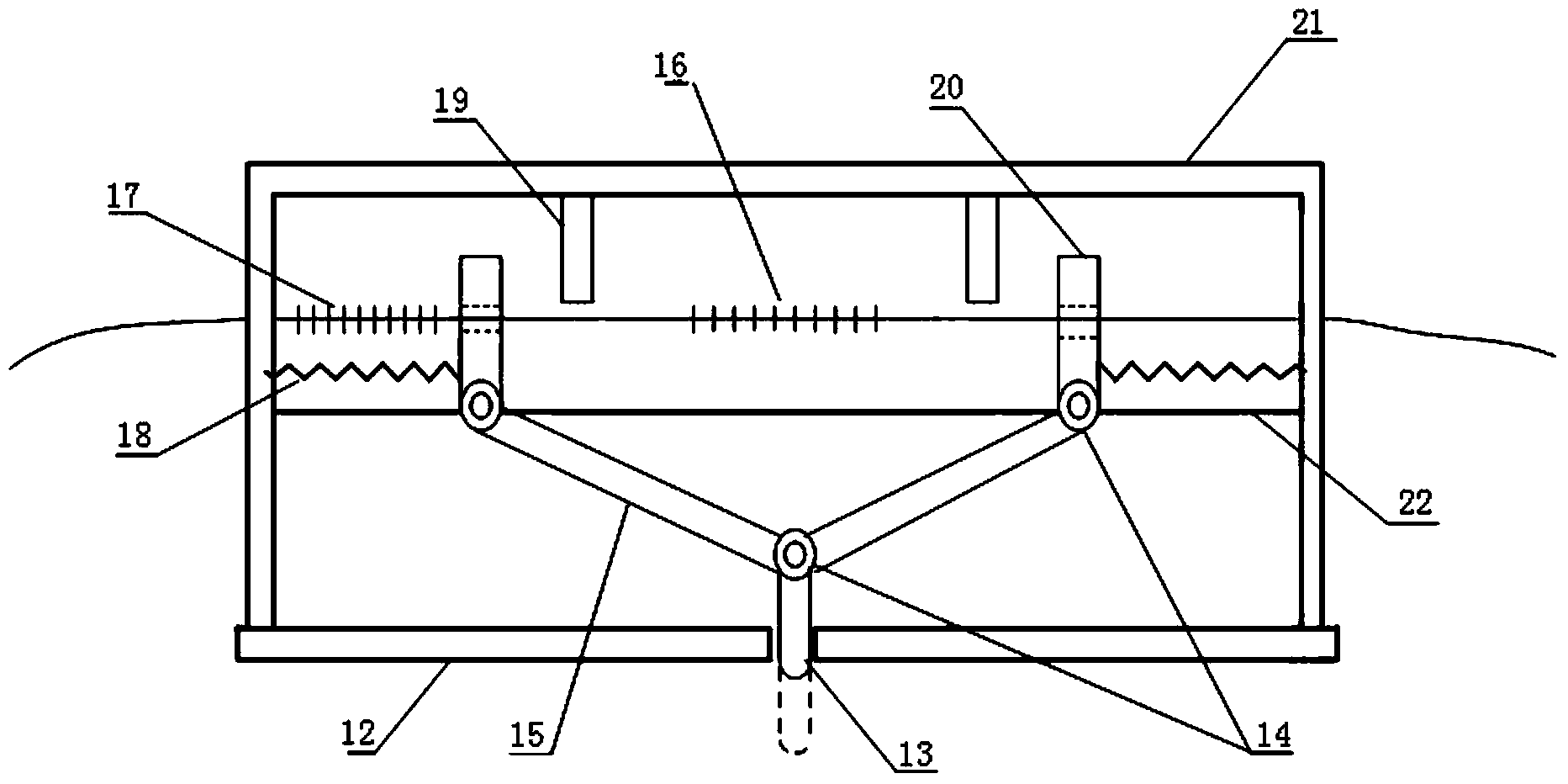

Target fiber grating rheometer

InactiveCN101995485AThere is no hidden danger of electric sparksSimple structureFluid speed measurementGratingElectromagnetic interference

The invention relates to a target fiber grating rheometer, which has small measurement volume, high precision, good waterproof property and electromagnetic interference resistance, and can perform real-time monitor in different environments such as pipeline, crack and the like. The target fiber grating rheometer comprises a casing, one end of which is connected with a measurement joint and the other end of which is provided with an end cover; the end cover is equipped with a fixed metal sheet which is connected with a cantilever beam, the cantilever beam is provided with a measurement grating, the measurement grating is connected with fibers passing through the end cover; the end of the cantilever beam is provided with a metal target sheet arranged inside the measurement joint, and the cantilever beam is provided with a sealing device.

Owner:SHANDONG UNIV

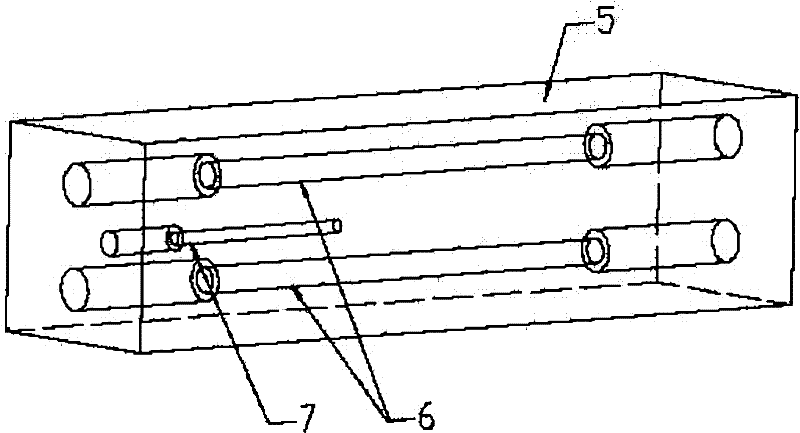

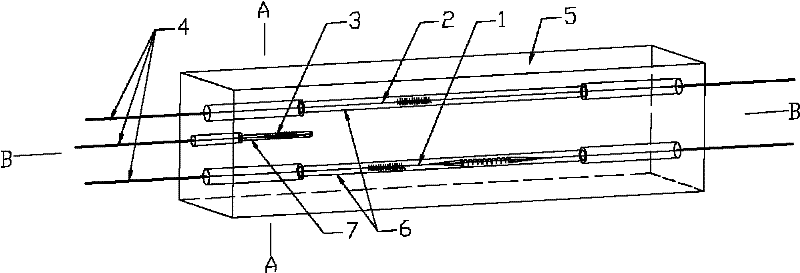

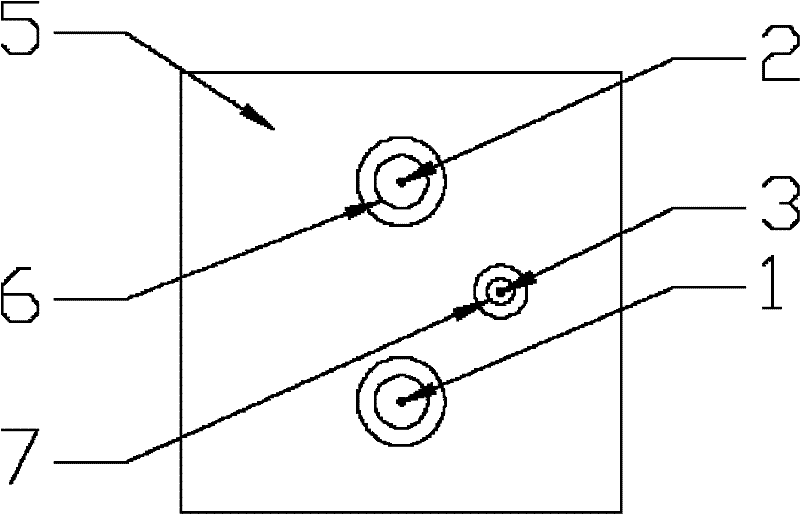

Hybrid-range FBG (fiber bragg grating) strain and crack sensor for concrete material package

InactiveCN102243066AAdd temperature compensationIncrease effective lengthUsing optical meansGratingAdhesive

The invention discloses a hybrid-range FBG (fiber bragg grating) strain and crack sensor for a concrete material package. The sensor comprises a pre-cast concrete material package structure, a spring FBG firmly combined with a micro spring, a pure FBG, a temperature sensor, two penetration grooves, a temperature sensing area and an armored optical cable. Firstly, the pure FBG and the spring FBG firmly combined with the micro spring are embedded in the two penetration grooves, then, one segment of two groups of the FBG is firmly combined with a die through a high-performance adhesive, a tension pre-stress is applied on the two groups of the FBG, and then, the other end of each one of the two groups of the FBG is firmly combined, the temperature sensor is embedded in the package structure, and finally, the armored optical cable is used for connecting the two groups of the led out FBG and the temperature sensor. The hybrid-range FBG strain and crack sensor is suitable for structural health monitoring in various concrete structures of civil engineering, is simple in technology, convenient to arrange, high in accuracy and wide in range, and can monitor internal strain and cracks in overall process of destroying the concrete structure by pulling and pressing.

Owner:DALIAN UNIV OF TECH

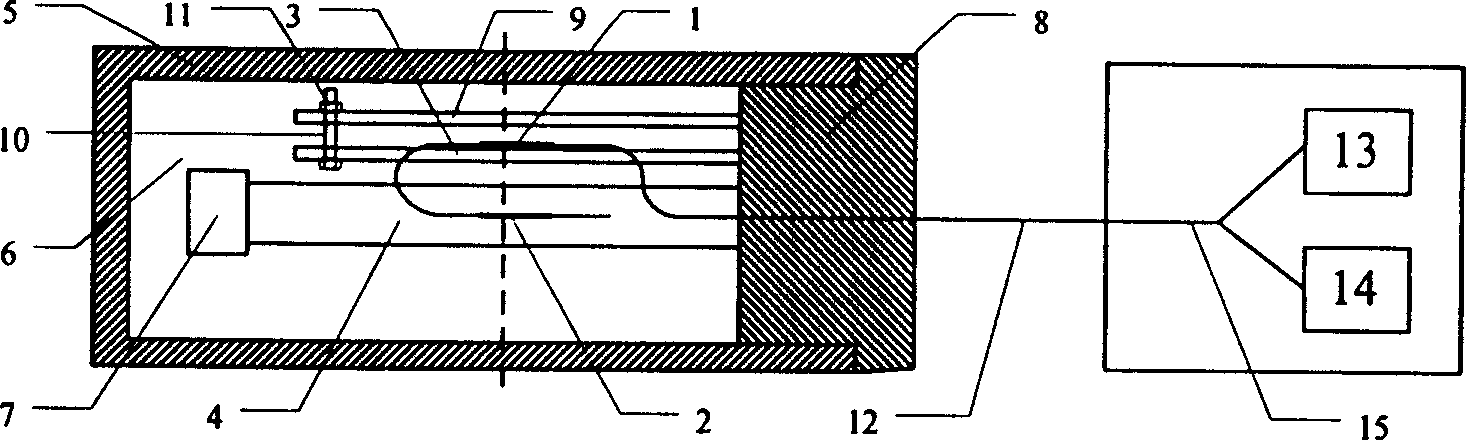

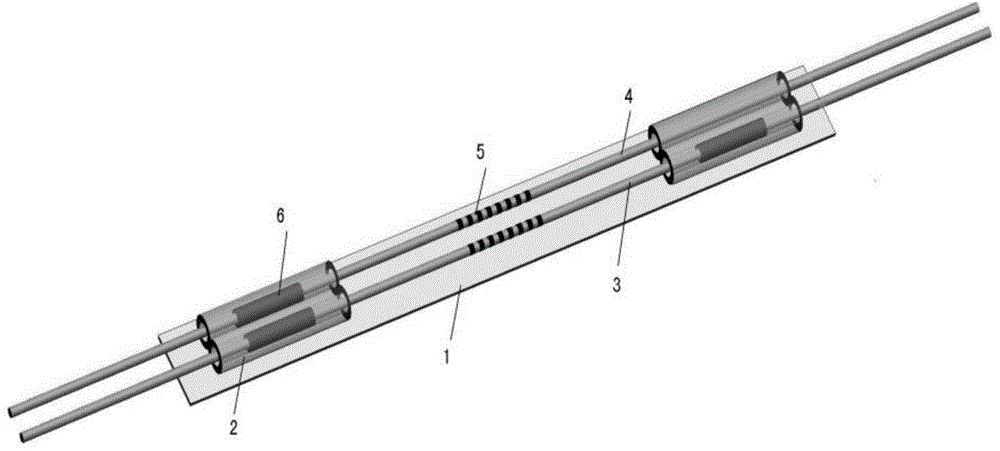

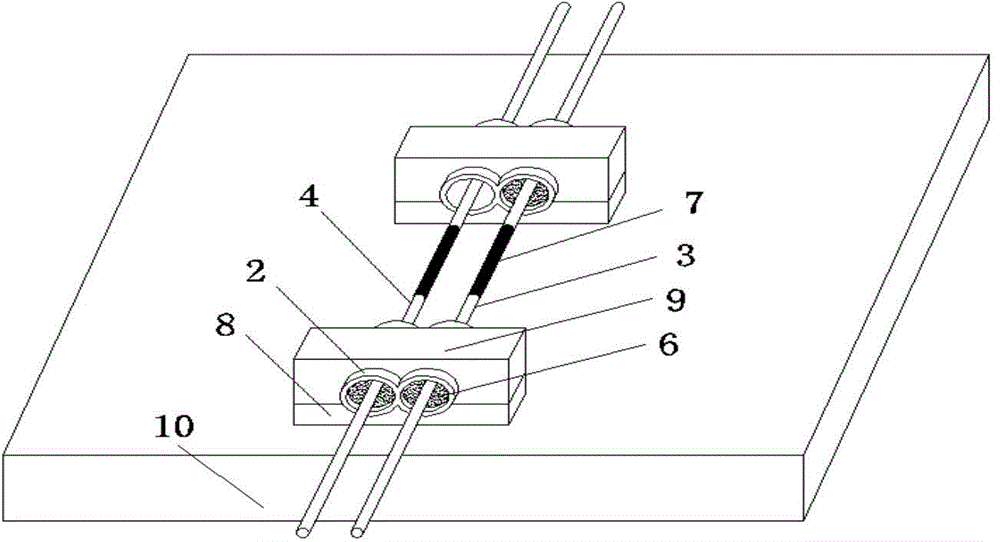

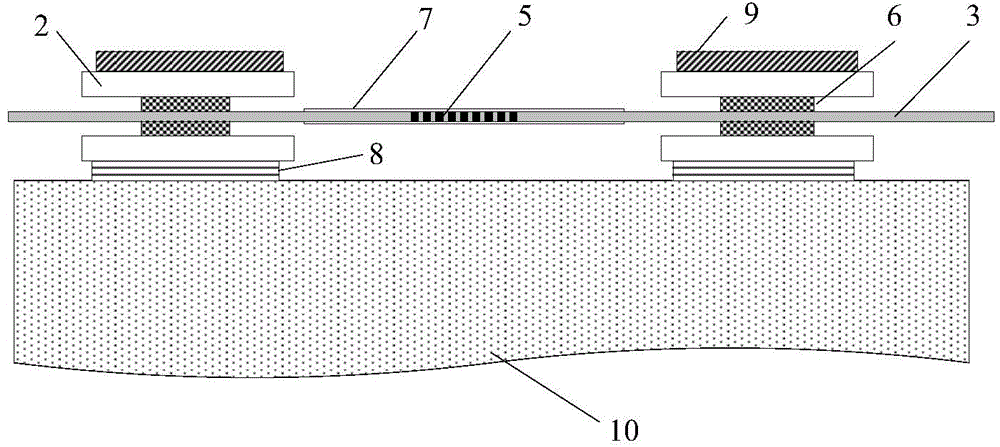

Fiber bragg grating high-temperature stress testing device and mounting method of device

InactiveCN104596434ASolving High Temperature Degradation ProblemsEnable high temperature strain measurementUsing optical meansTemperature stressFiber

The invention relates a fiber bragg grating high-temperature stress testing device applied to a structural heat test radiation heat environment and a mounting method of the fiber bragg grating high-temperature stress testing device. The device comprises a stress sensing optical fiber (3) which is equipped with a fiber bragg grating (5), two 8-shaped quartz tubes (2) and a temperature reference optical fiber (4), wherein the temperature reference optical fiber (4) is the same as the stress sensing optical fiber (3); the stress sensing optical fiber (3) and the temperature reference optical fiber (4) respectively pass through the two 8-shaped quartz tubes (2) to be parallel; the stress sensing optical fiber (3) is integrally fixed to the two 8-shaped quartz tubes (2) through fixing materials (6); the temperature reference optical fiber (4) is only integrally fixed to one 8-shaped quartz tube (2), and the other end of the temperature reference optical fiber (4) is suspended. With the adoption of the device, the temperature of degeneration of the fiber bragg grating at high temperature is solved; the device is applicable to the heat test environment at the temperature close to 1000 DEG C and achieves the high-temperature stress measurement of a composite material structural part.

Owner:BEIJING INST OF STRUCTURE & ENVIRONMENT ENG +1

Three-dimensional touch panel

ActiveCN105426005AReduce thicknessHigh precisionInput/output processes for data processingPressure sensitivePhysics

The invention provides a three-dimensional touch panel. The three-dimensional touch panel comprises an insulation dielectric layer, a touch electrode layer and a pressure-sensitive electrode layer, wherein the touch electrode layer and the pressure-sensitive electrode layer are respectively positioned at two opposite sides of the insulation dielectric layer; the touch electrode layer comprises multiple sets of insulated and staggered touch electrodes and is used for detecting the position of a touch signal; the pressure-sensitive electrode layer comprises at least one pressure-sensitive electrode correspondingly arranged with at least one part of the touch electrodes and is used for detecting the pressure of the touch signal; the touch electrode correspondingly arranged with the pressure-sensitive electrode is also used for performing temperature compensation of the pressure-sensitive electrode; and the temperature compensation manner includes a positive and negative temperature coefficient material series manner, a value reduction manner and a Wheatstone bridge manner. The three-dimensional touch panel provided by the invention has the advantages of being high in detection precision, light, thin and the like.

Owner:TPK TOUCH SOLUTIONS (XIAMEN) INC

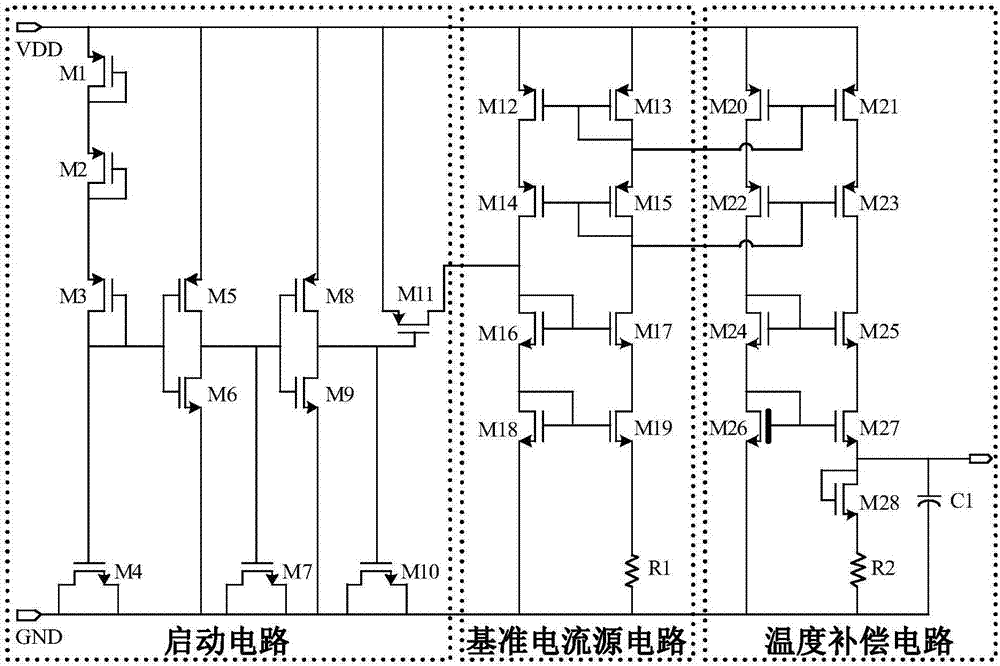

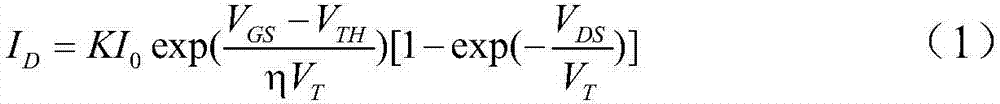

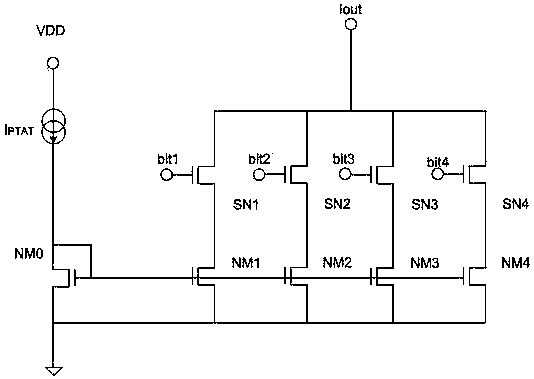

Full common gate common source reference voltage source

ActiveCN107066015ASuppress noiseReduce layout areaElectric variable regulationElectricityReference current

The invention provides a full common gate common source reference voltage source. The full common gate common source reference voltage source includes a start circuit, a reference current source circuit and a temperature compensation circuit which are connected between a power supply VDD and a ground in parallel; the starting circuit, the reference current source circuit and the temperature compensation circuit are successively connected; an output end of the start circuit is connected to the reference current source circuit, and the start circuit is used for providing start current in power-on of the power supply and allowing a reference voltage source to break away from a degeneration bias point; an output end of the reference current source circuit is connected to the temperature compensation circuit, a common source common gate current mirror is used to improve the power supply voltage rejection ratio and the voltage regulation factor, and the reference current source circuit is used for generating the reference current; and the temperature compensation circuit is used for generating low temperature drift reference voltage, the common source common gate current mirror is used to duplicate current from the reference current source circuit, and the output voltage of the temperature compensation circuit is the output voltage Vref of the reference voltage source. The full common gate common source reference voltage source is an ultra-low power consumption full cascode reference voltage source, and can suppress power source noise well.

Owner:GUILIN UNIV OF ELECTRONIC TECH

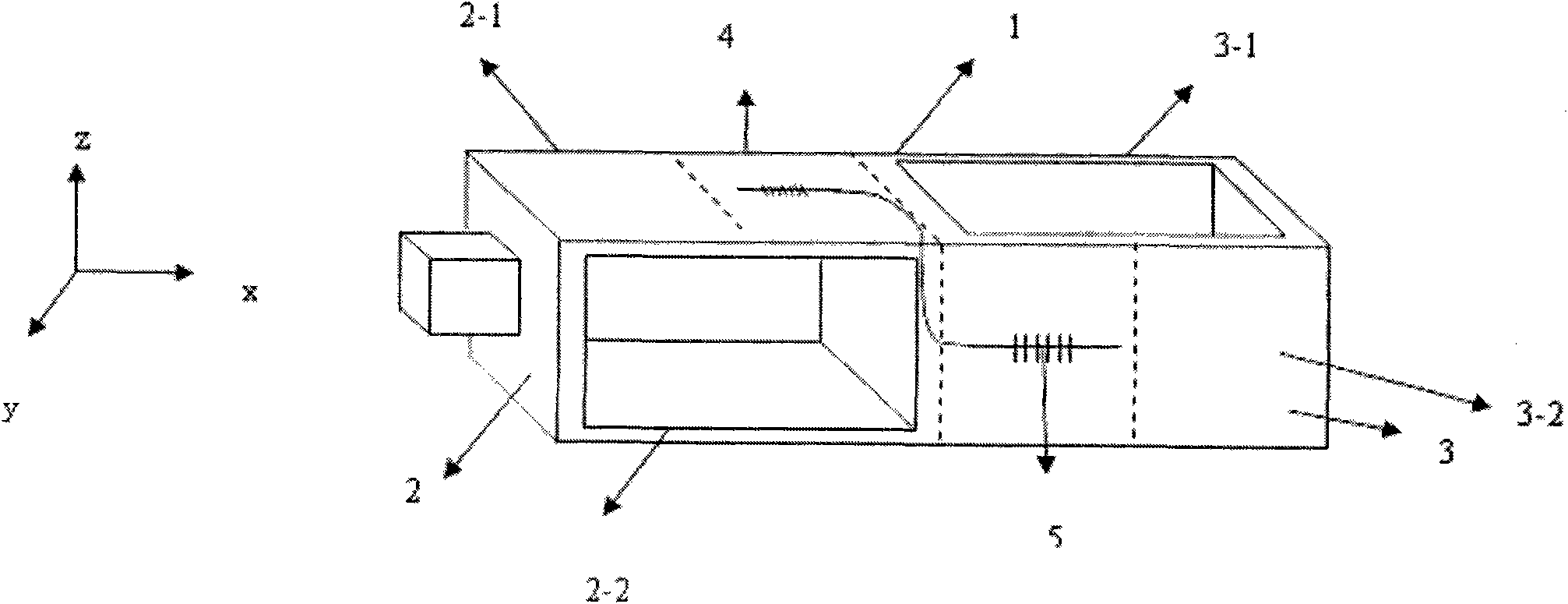

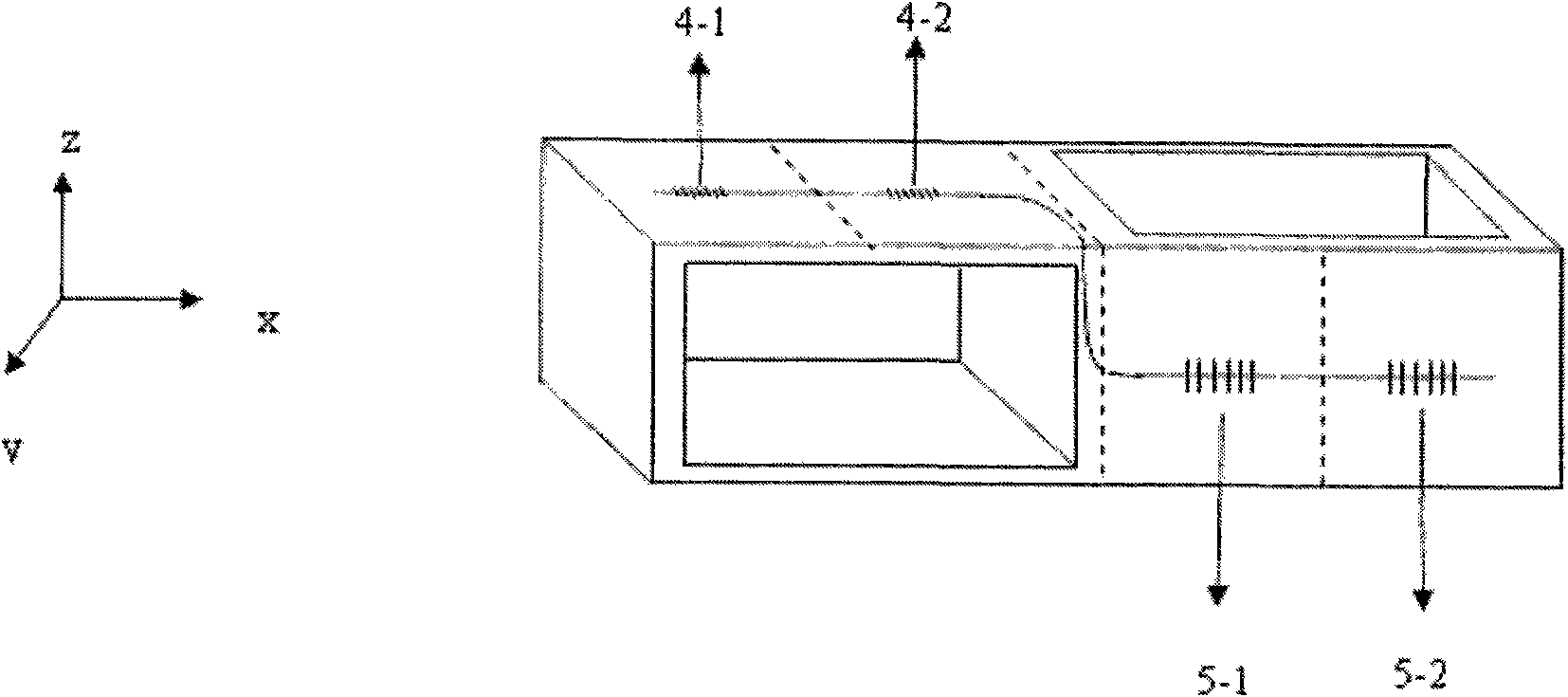

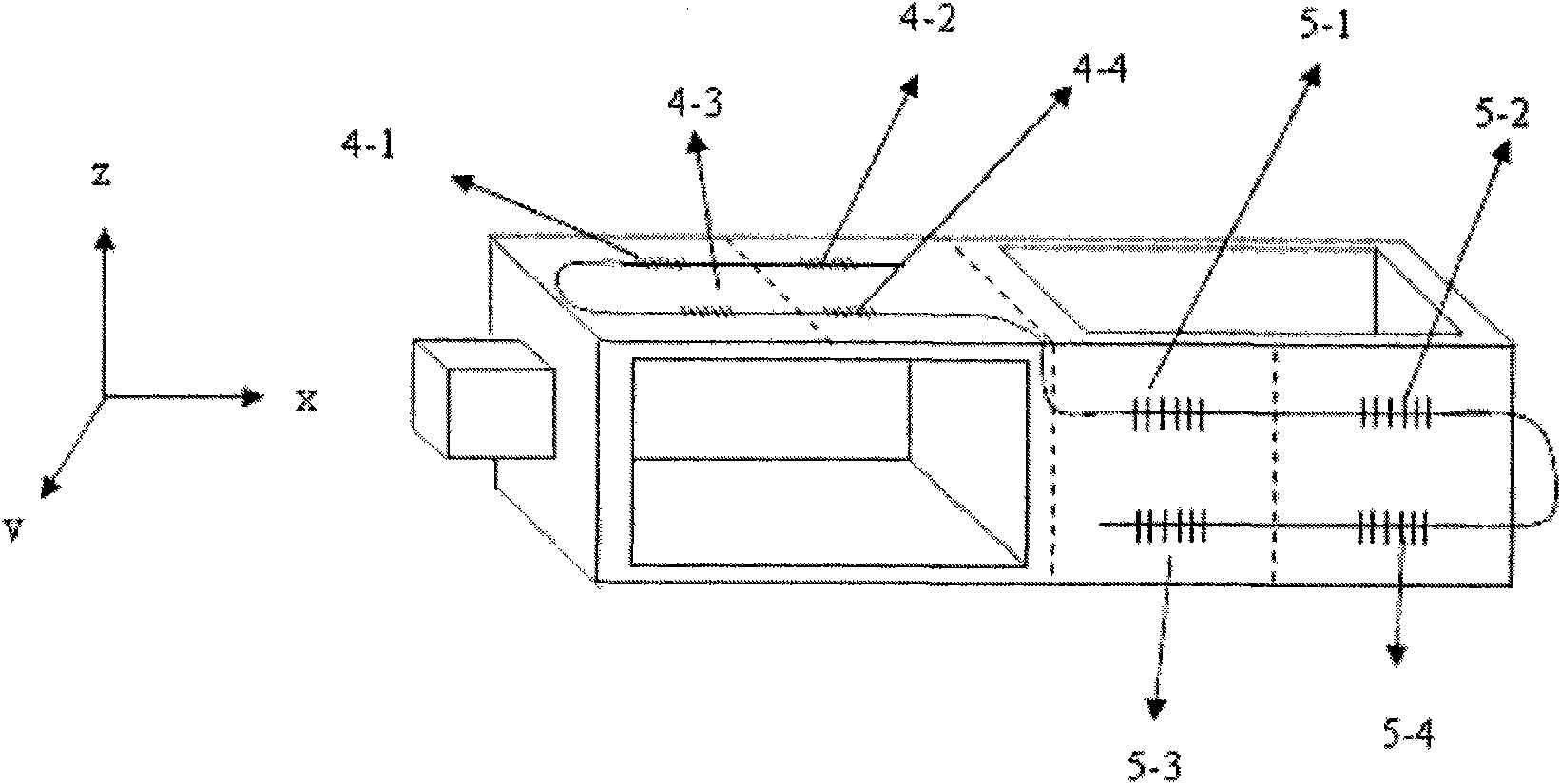

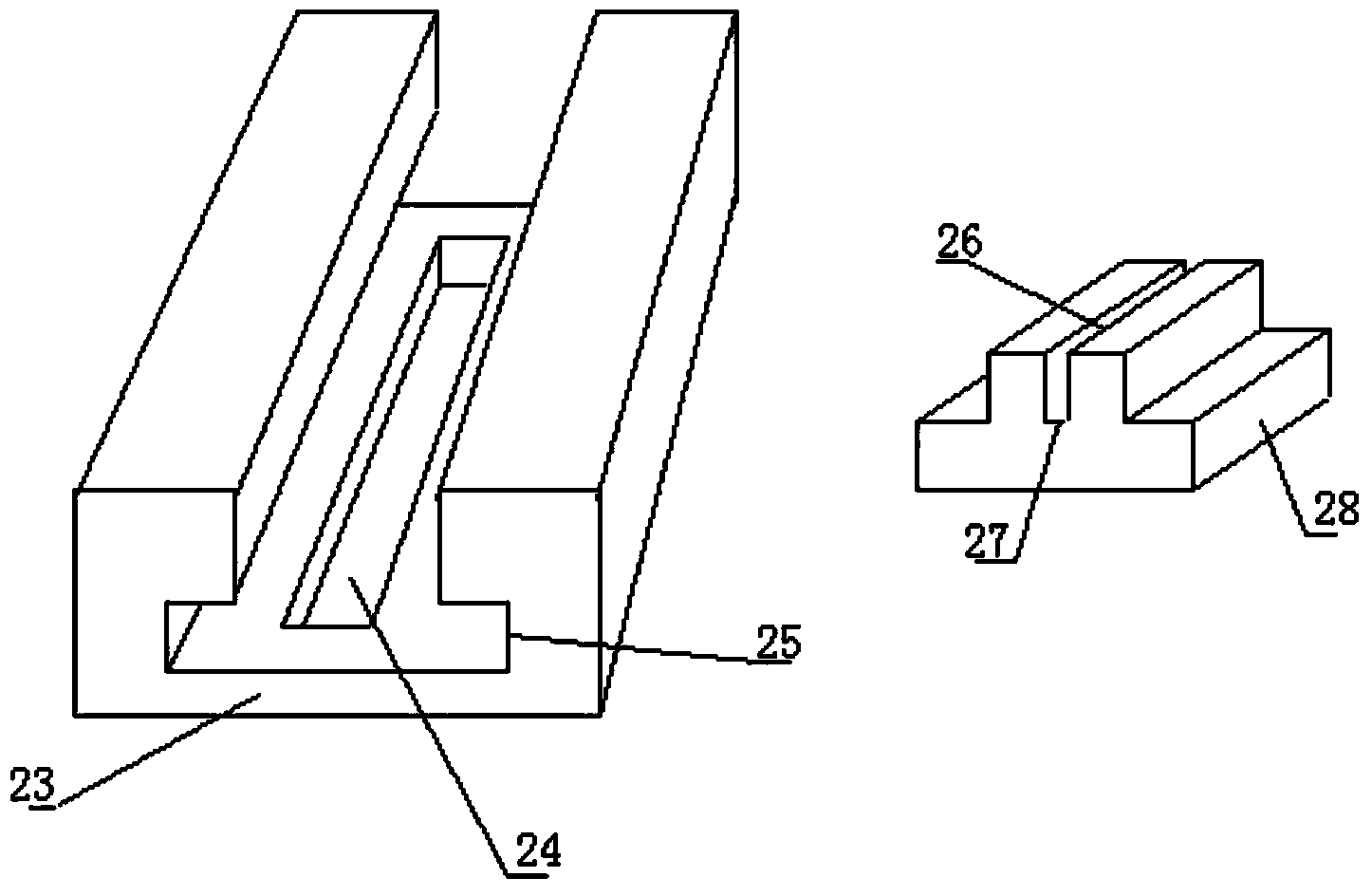

Temperature self-compensating fiber grating rod force sensor and using method thereof

InactiveCN101975632ASimple structureWith anti-electromagnetic interferenceForce measurement by measuring optical property variationUsing optical meansFiberGrating

The invention relates to a fiber grating rod force sensor and a using method thereof. The force sensor is characterized in that: rectangular hollow rectangular frames of two associated parallel girders smoothly move and are vertically and fixedly connected; a first fiber grating strain sensor is adhered to a plane of the first associated parallel girder parallel to the rectangular hollow rectangular frames; a second fiber grating strain sensor is adhered to a plane of the second associated parallel girder parallel to the rectangular hollow rectangular frames; and the first fiber grating strain sensor and the second fiber grating strain sensor are connected in series. The sensor has the characteristics of anti-electromagnetic interference, high precision, quick dynamic response, small volume, light weight, simple structure and the like, and also has reliability, stability and simpleness. In addition, the temperature self-compensating fiber grating rod force sensor has relatively low cost, is applied to narrow space, and is subjected to temperature compensation when measuring the stress of an elastic element.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

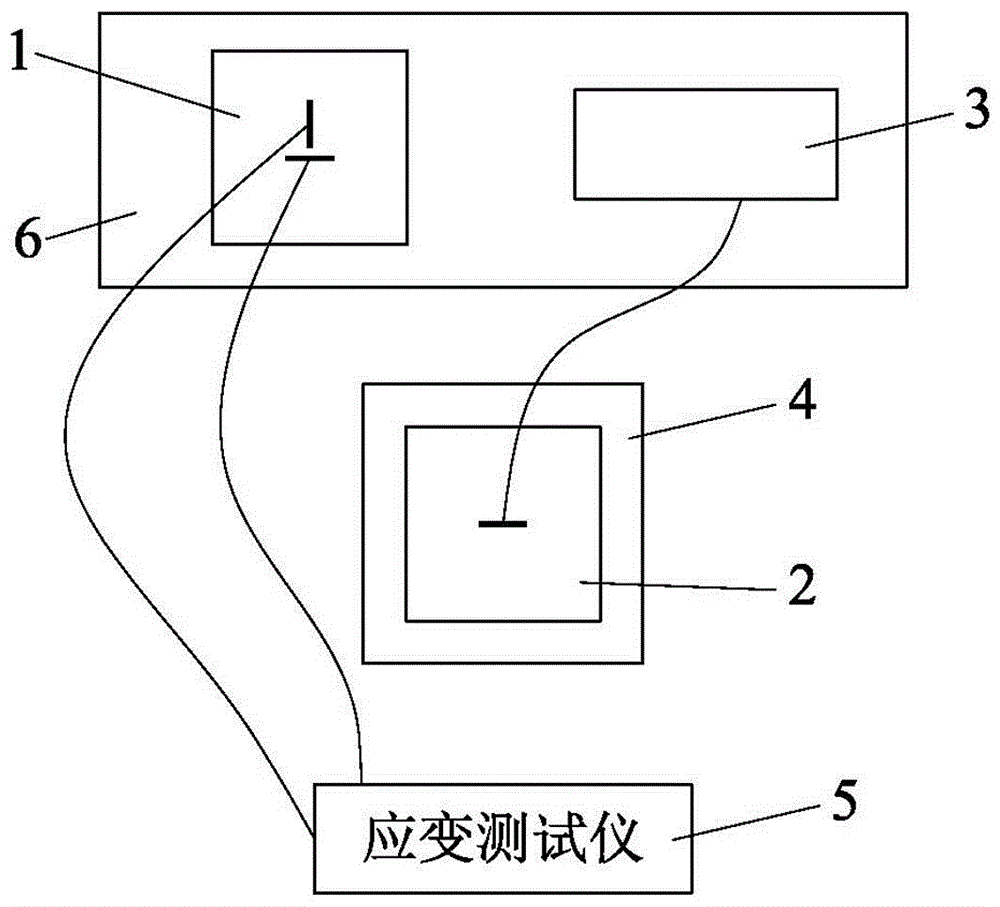

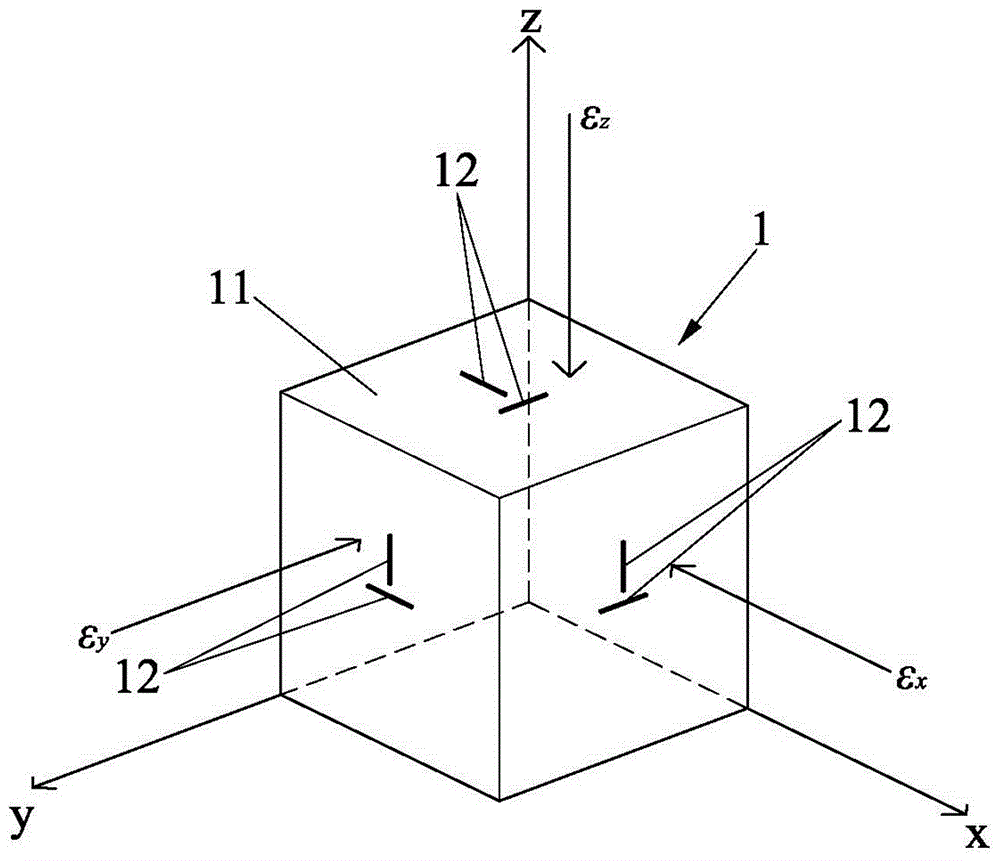

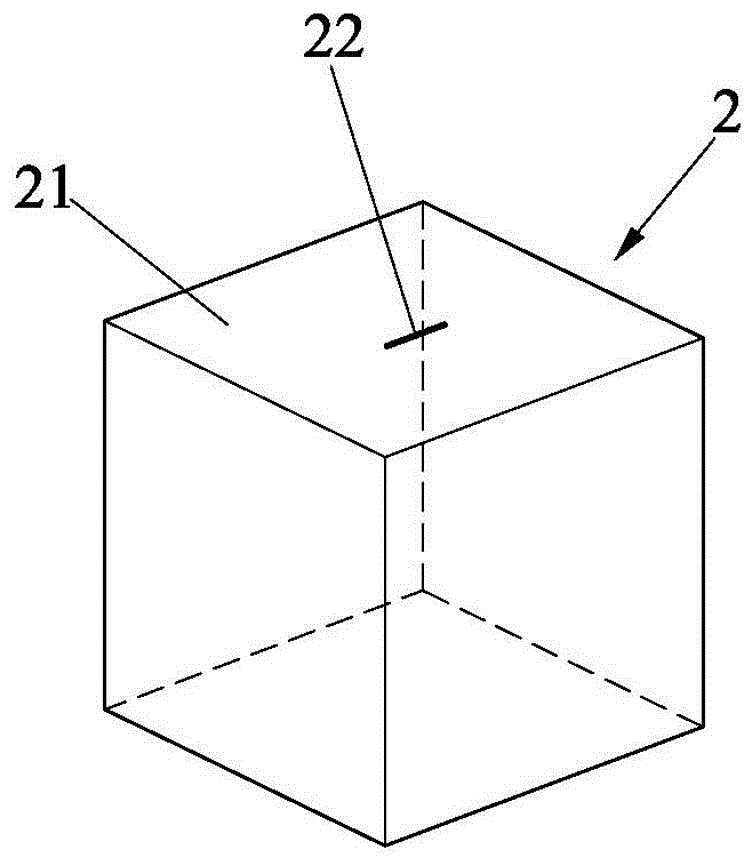

Measuring system and method for concrete non-load internal stress in concrete structure

InactiveCN106771102AImprove test accuracyEliminate the effects ofMaterial testing goodsTester deviceRebar

The invention relates to a measuring system and method for a concrete non-load internal stress in a concrete structure. The system comprises a metal block sensor, a temperature compensation block, a temperature sensor, a temperature heating box and a strain tester, wherein the metal block sensor and the temperature sensor are buried in to-be-measured concrete; the temperature compensation block is placed in the temperature heating box and is located on the to-be-measured concrete; the metal block sensor comprises a metallic lumpish test block; at least three mutually vertical strain gages are adhered to the test block; the temperature compensation block comprises a metallic lumpish compensation block; one temperature strain gage is adhered to the compensation block; the strain gages and the temperature strain gage are connected with the strain tester in the manner of 1 / 4 bridging; the poisson ratio and coefficient of linear expansion of the test block and the compensation block are similar to those of the concrete; the temperature sensor is connected with the temperature heating box. According to the invention, the influences of inner temperature change of the concrete in early period of the concrete and different rebar reinforcement ratios on the internal concrete stress can be avoided and the test precision is higher.

Owner:XIAMEN UNIV OF TECH

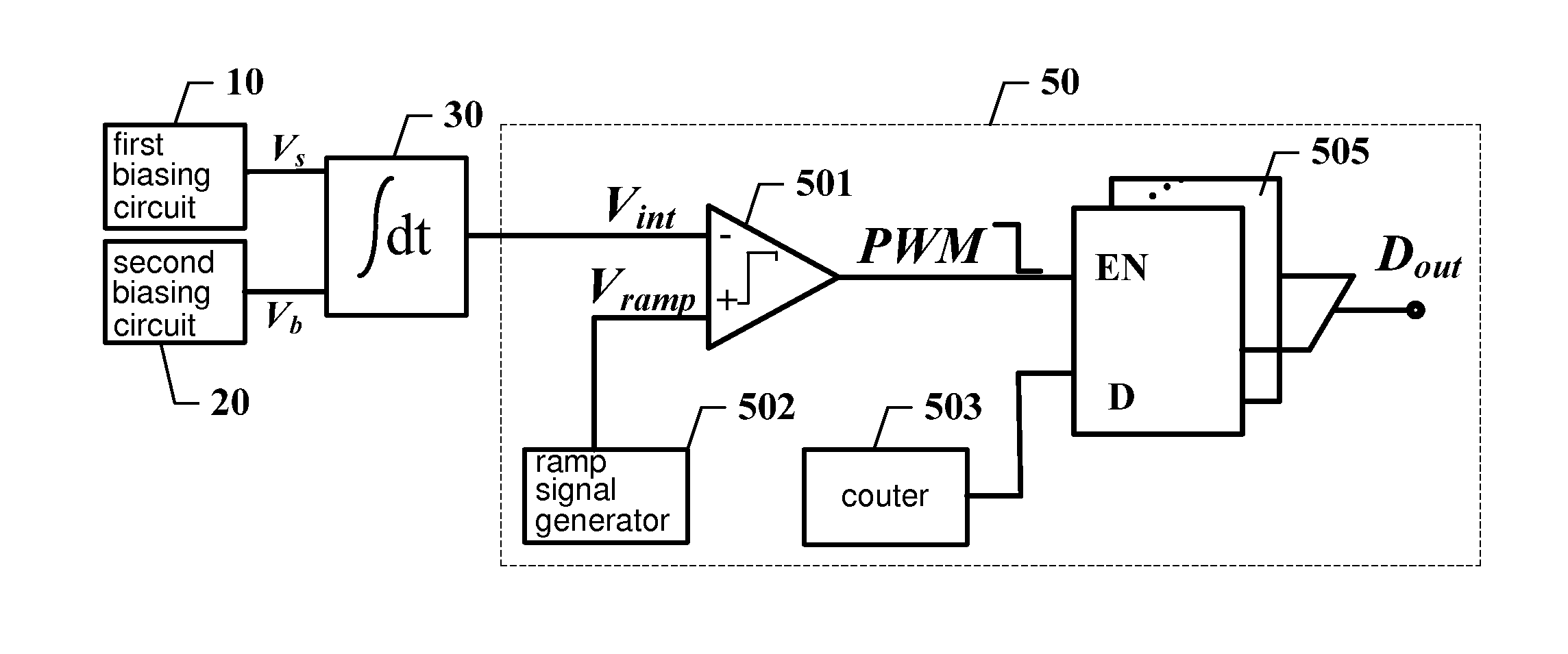

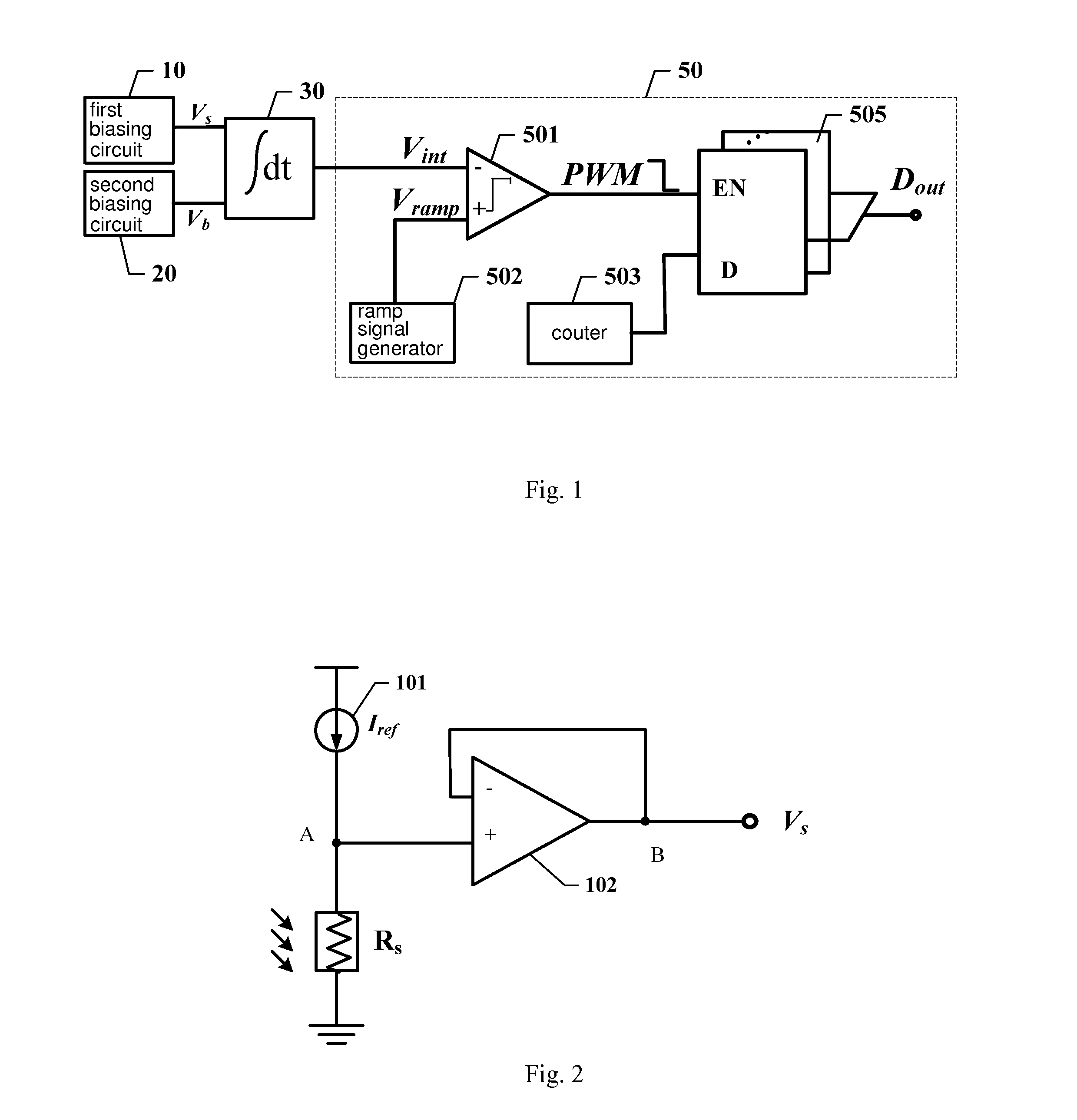

Readout circuit for uncooled infrared focal plane array

ActiveUS20150192472A1Improve dynamic rangeReduce chip areaTelevision system detailsMaterial analysis by optical meansIntegratorAnalog to digital conversion

A readout circuit for an uncooled infrared focal plane array includes: a first biasing circuit for generating a detection output signal; a second biasing circuit for generating a first reference output signal; a first integration circuit; and an analog-to-digital circuit including: a ramp signal generating circuit for generating a ramp signal according to a second reference microbolometer of a third biasing circuit. In the readout circuit, subtracting and amplifying the detection output signal and the first reference output signal are provided by the integrator at an analog domain, while ratio counting is provided by an analog-to-digital converter during analog-to-digital conversion. Furthermore, a column level integrated readout channel utilizes only one reference microbolometer, and the chip level ramp signal generator also utilizes only one reference microbolometer. Therefore, a chip area is further saved, and noise sources are decreased.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

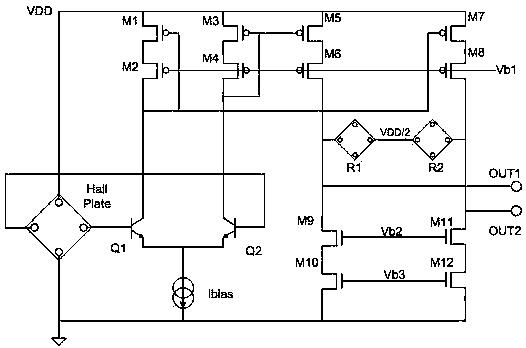

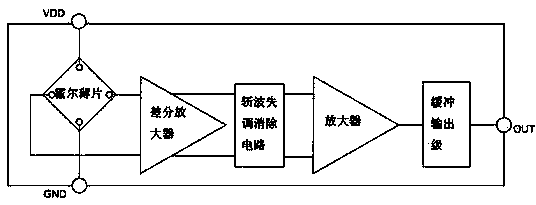

Magnetic sensitivity temperature compensation circuit and programmable linear Hall sensor chip

ActiveCN106153084AHigh sensitivityChange sensitivityConverting sensor output electrically/magneticallyPhysicsDifferential amplifier

The invention discloses a magnetic sensitivity temperature compensation circuit and a programmable linear Hall sensor chip. The magnetic sensitivity temperature compensation circuit comprises a Hall sheet and a differential amplifier, the Hall sheet senses a magnetic field signal, converts the magnetic field signal into a Hall voltage signal and outputs the Hall voltage signal to an input end of the differential amplifier, the magnetic sensitivity temperature compensation circuit further comprises a chopped wave offset cancellation circuit and an amplifier connected to output ends OUT1 and OUT2 of the differential amplifier, the amplifier is connected onto a signal output end of the chopped wave offset cancellation circuit, the Hall voltage signal amplified by the amplifier is outputted through an output port OUT on a buffer output stage, the differential amplifier is a gain adjustable differential amplifier, a tail current source Ibias of the differential amplifier is in direct proportion to the absolute temperature, and load resistors R1 and R2 on the differential amplifier both use load resistors in the same shape and material with the Hall sheet. Through the principle, the sensitivity of the Hall sheet is subjected to temperature compensation, so that the sensitivity of the chip is guaranteed not to change with the temperature.

Owner:CROSSCHIP MICROSYST

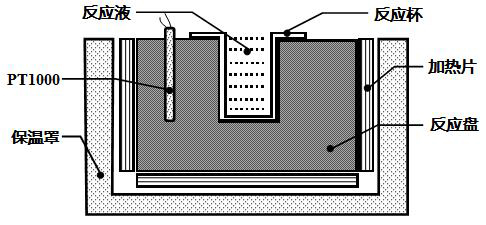

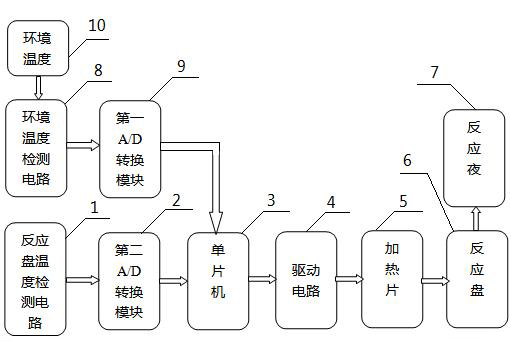

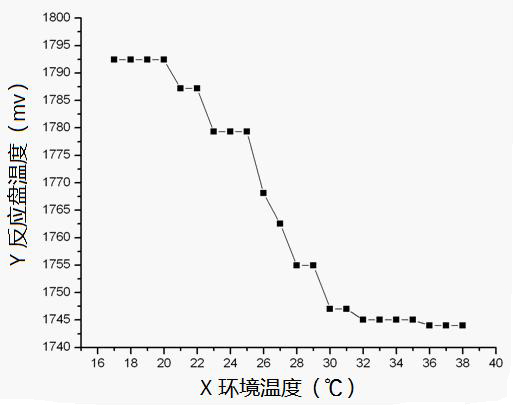

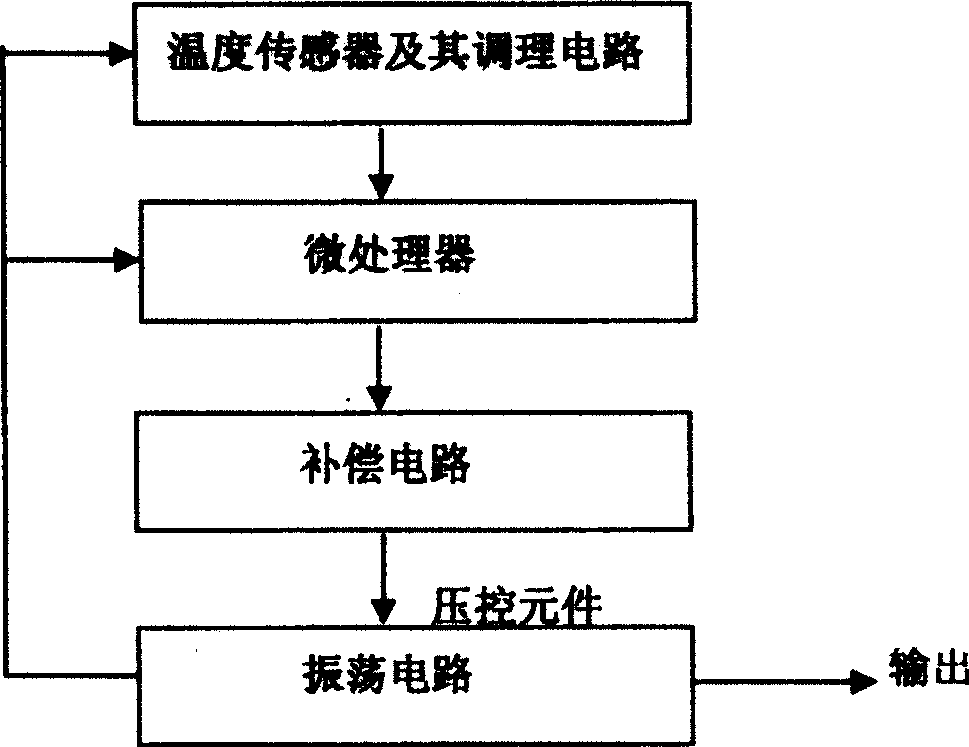

Temperature control system with environment temperature compensating function

InactiveCN102368163AImprove environmental adaptabilityHigh precisionThermometers using electric/magnetic elementsAuxillary controllers with auxillary heating devicesMicrocontrollerTemperature control

The invention discloses a temperature control system with an environment temperature compensating function. According to change of an environment temperature, the system actively changes a temperature of a reaction disc, and compensates influence of the environment temperature to a reaction solution temperature. The system comprises a reaction disc temperature detection circuit used for detecting a reaction disc temperature. The reaction disc temperature detection circuit connects with a one-chip microcomputer through a first A / D conversion module. The one-chip microcomputer connects with a drive circuit. The drive circuit connects with a heating plate. The heating plate is provided around the reaction disc. The reaction disc is embedded with a reaction cup and heats reaction solution in the reaction cup. The system also comprises an environment temperature detection circuit used for detecting the environment temperature. The environment temperature detection circuit connects with the one-chip microcomputer through a second A / D conversion module. According to the temperature control system of the present invention, requirements of high precision, fast response and good stability of temperature by a biochemistry analyzer are satisfied, and environmental adaptability of a device is improved.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH

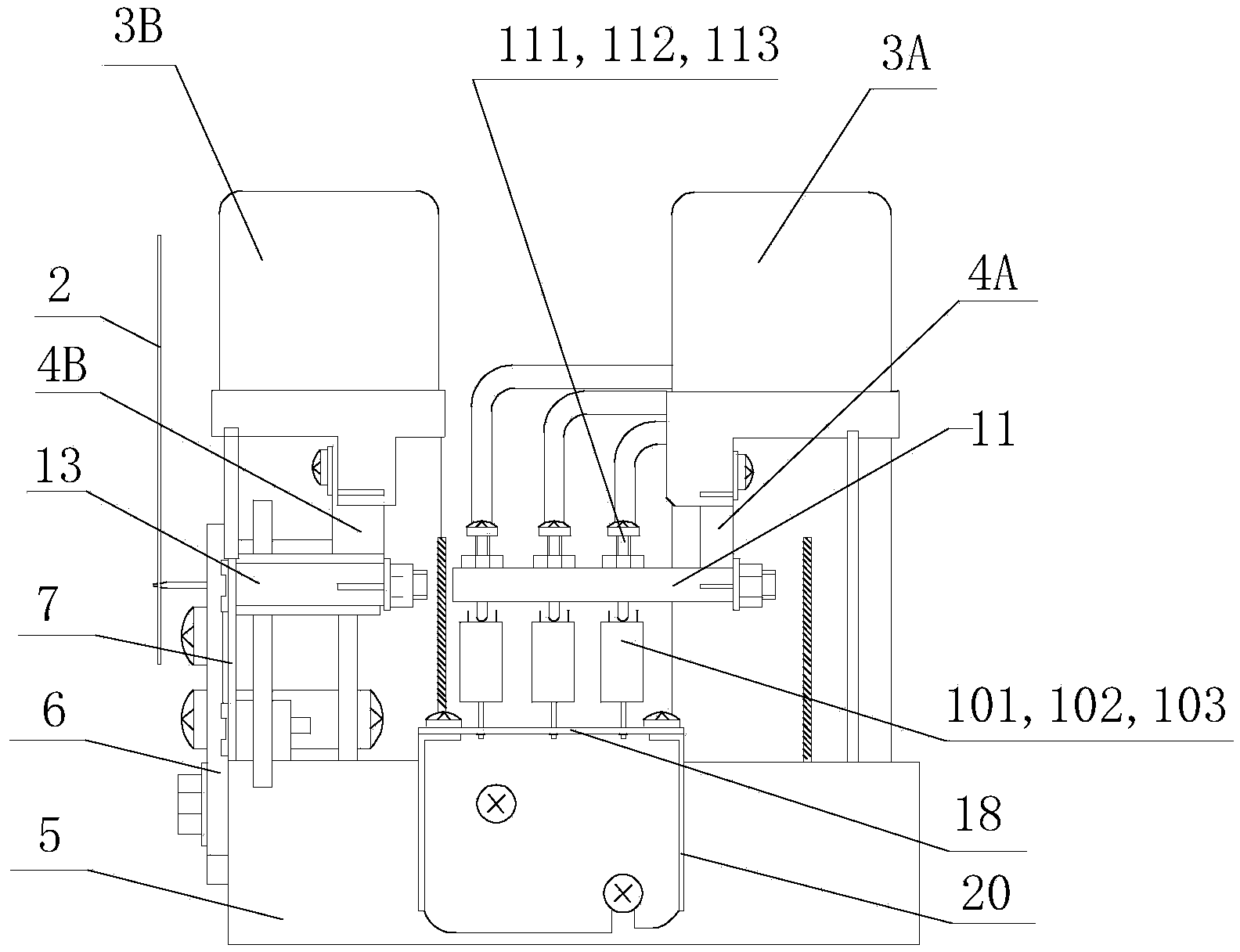

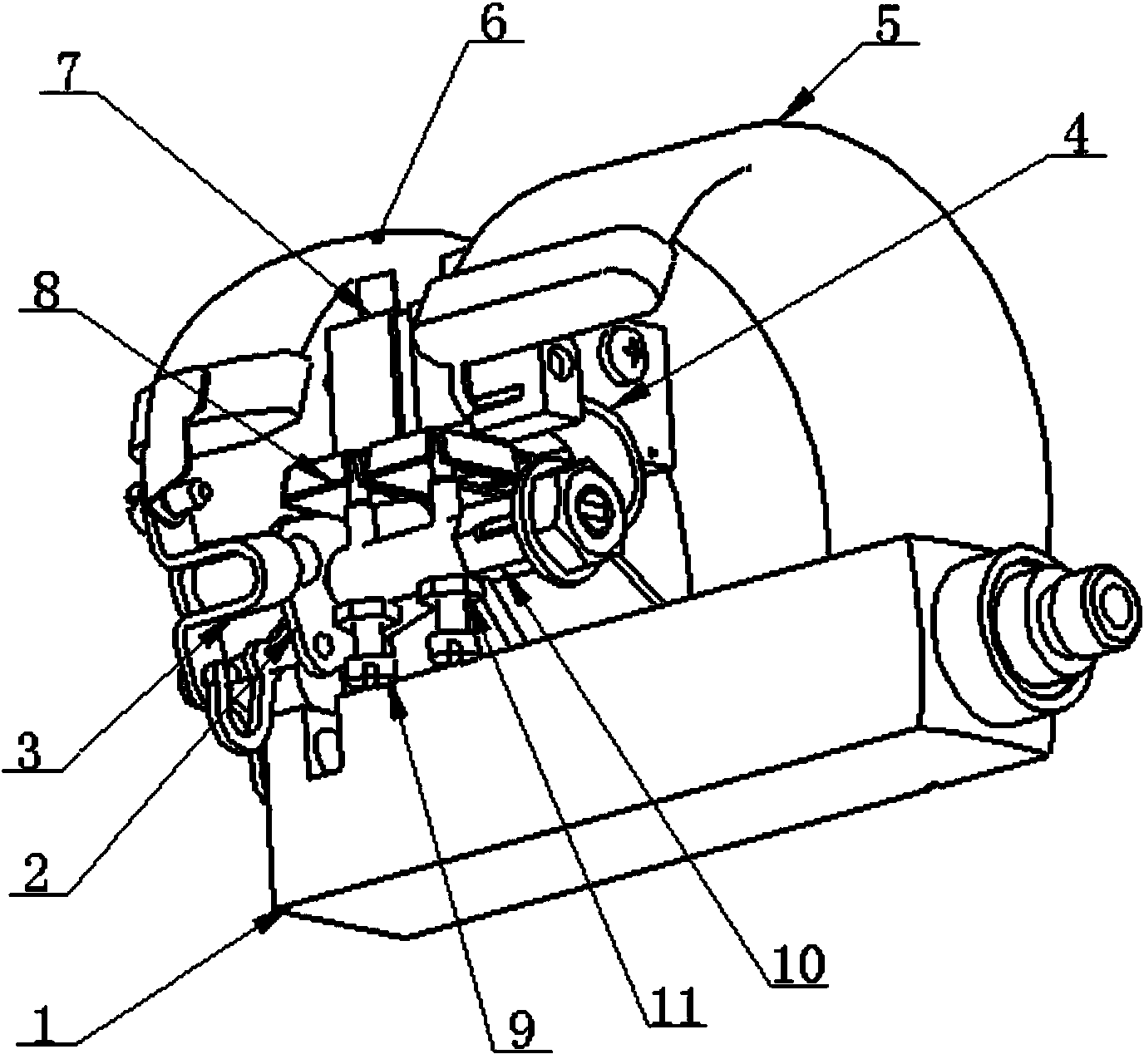

High-precision sulfur hexafluoride gas density relay

ActiveCN103456561ALight in massTo achieve temperature compensationElectric switchesSulfur hexafluorideElectrical performance

The invention discloses a high-precision sulfur hexafluoride gas density relay which is good in shock resistance, high in precision, good in electrical performance, and long in service life. The high-precision sulfur hexafluoride gas density relay comprises a signal control part and an indicating value displaying part which are arranged in a shell body, wherein the signal control part and the indicating value displaying part are relatively independent, the indicating value displaying part comprises a display bourdon tube, a display end base, a machine core and a pointer, one end of the display bourdon tube is welded on a base, the other end of the display bourdon tube is welded on the display end base, and the shell body is an airtight air chamber and is filled with sulfur hexafluoride gas used for temperature compensation; the signal control part comprises a control bourdon tube, the base, a control end base, a plurality of signal generators and a signal adjusting mechanism, one end of the control bourdon tube is fixed on the base, the other end of the control bourdon tube is fixed on the control end base, the signal adjusting mechanism is arranged on the control end base, and the signal generators are installed on the base and are triggered to move by the signal adjusting mechanism.

Owner:SHANGHAI ROYE ELECTRICAL CO LTD

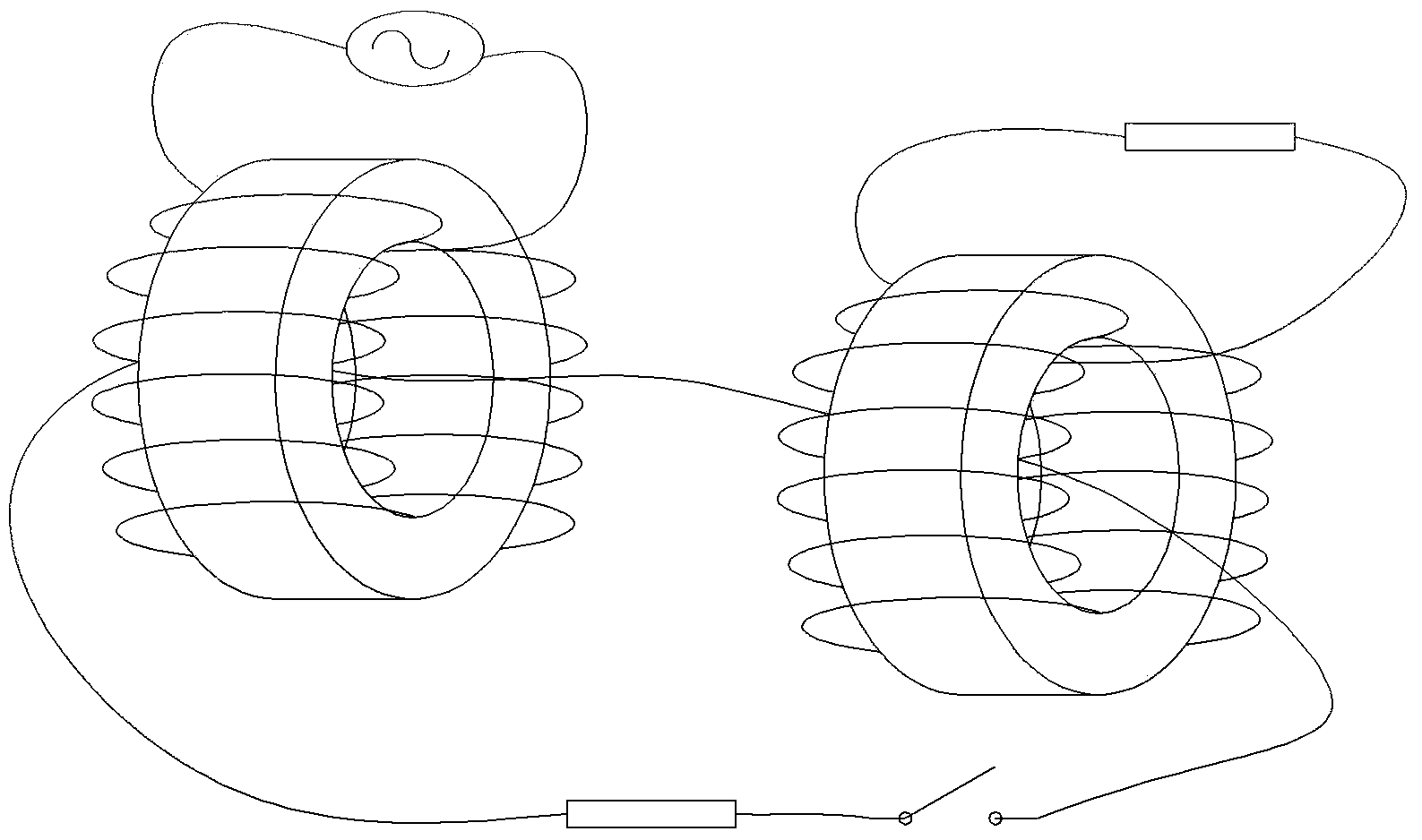

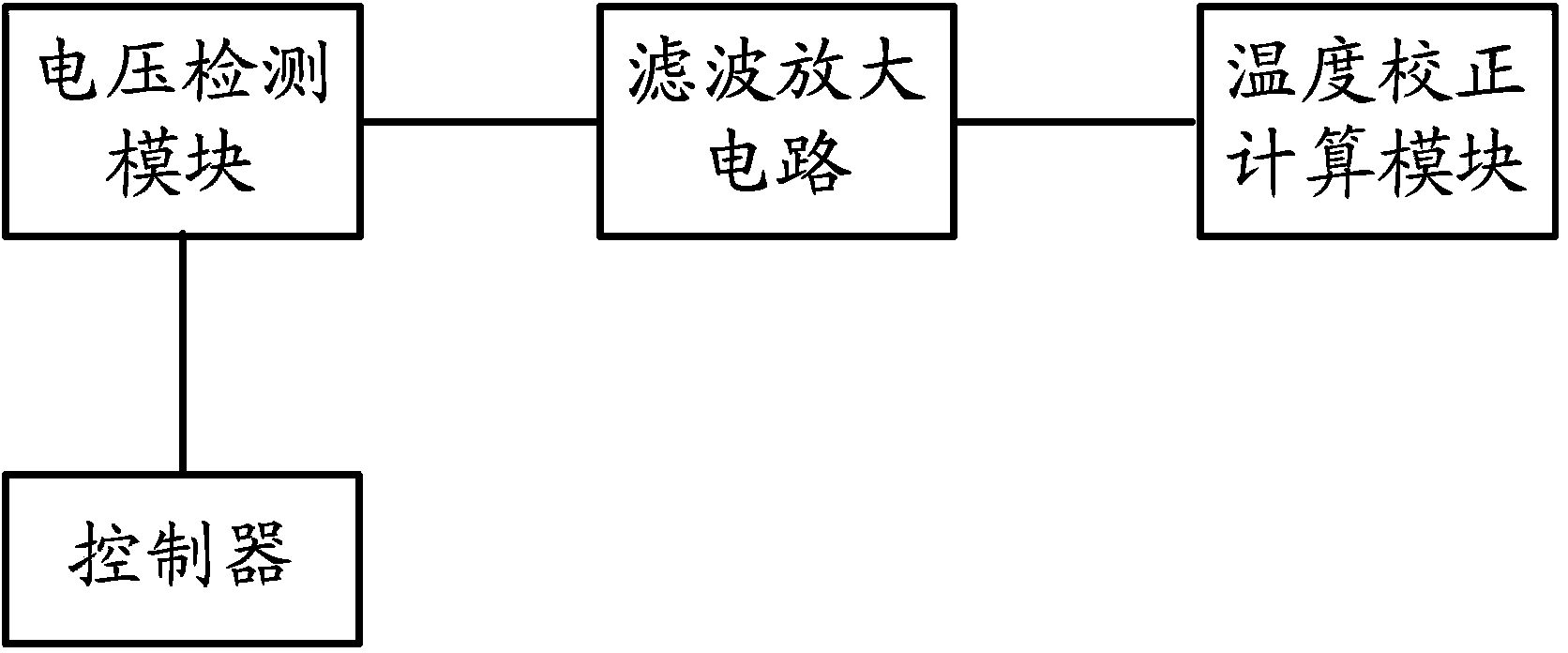

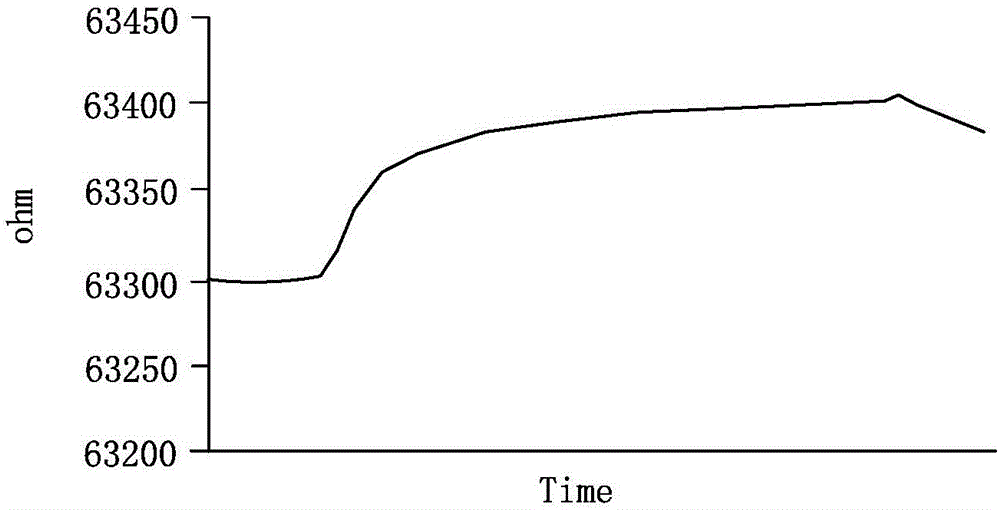

Fluid conductivity sensor, and device and method for measuring fluid conductivity

ActiveCN103412009ATo achieve temperature compensationGuaranteed measurement accuracyFluid resistance measurementsMaterial resistanceElectrical resistance and conductanceFluid conductance

The invention discloses a fluid conductivity sensor, and a device and a method for measuring fluid conductivity, and relates to the field of wireline logging. The method comprises the following steps: detecting voltage values of the two ends of a receiving resistor at different temperatures when no fluid passes to obtain multiple groups of first voltage values; inverting a relationship between induced voltages generated at the two ends of the receiving resistor by a transmitting coil and temperature variation according to the relationship between the multiple groups of first voltage values and temperature variation; detecting the voltage values of the two ends of the receiving resistor at different temperatures when fluid to be monitored passes to obtain multiple groups of second voltage values; calculating to obtain a relationship between the fluid conductivity and temperature variation according to the relationship between the induced voltages generated at the two ends of the receiving resistor by the transmitting coil and temperature variation and the multiple groups of second voltage values. Due to the design that a winding is connected in parallel with the fluid conductivity sensor and a matched circuit is provided, temperature compensation of the sensor is realized, and measuring accuracy of the coil type fluid conductivity sensor under a high-temperature environment is guaranteed.

Owner:CHINA NAT OFFSHORE OIL CORP +1

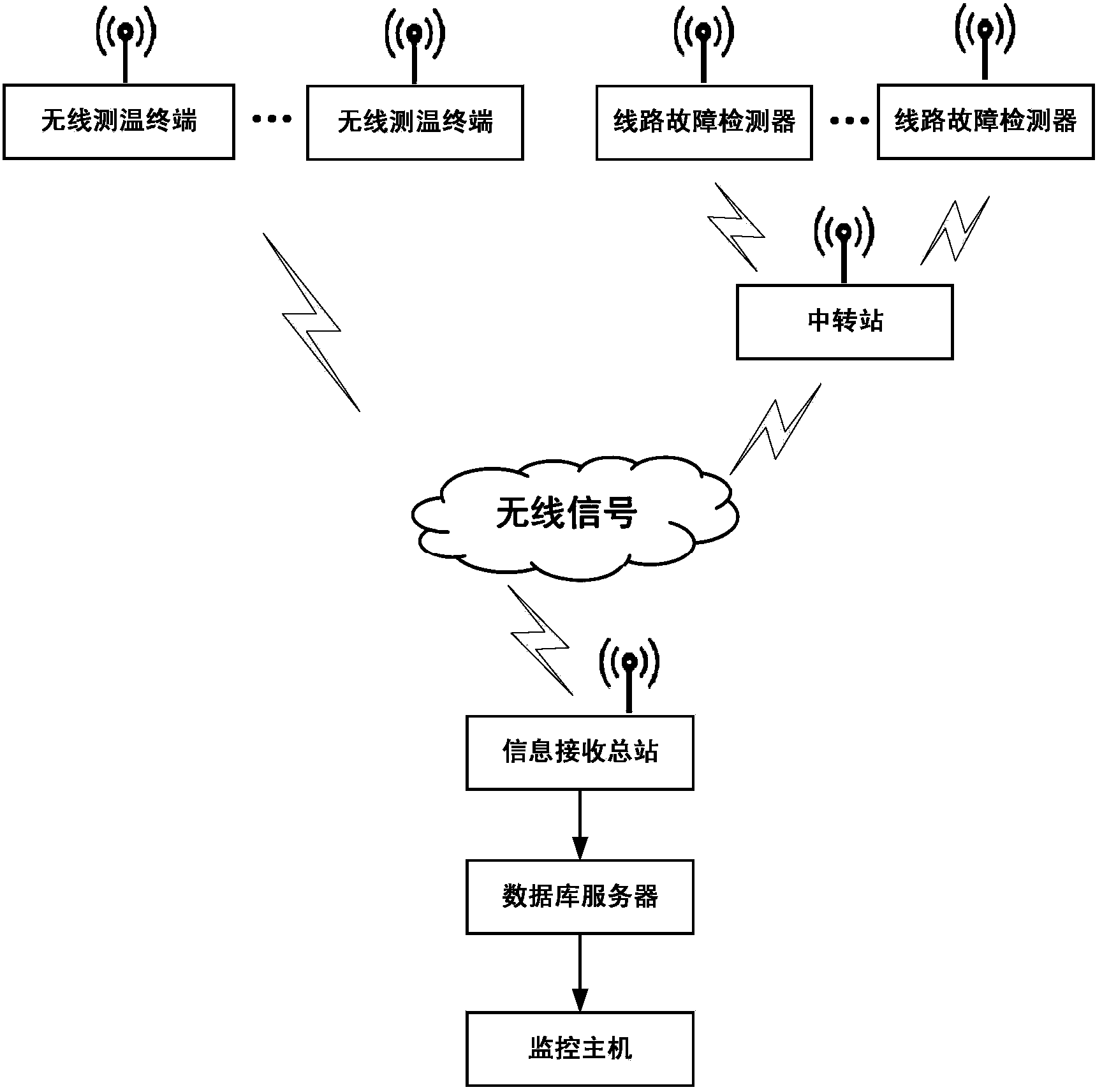

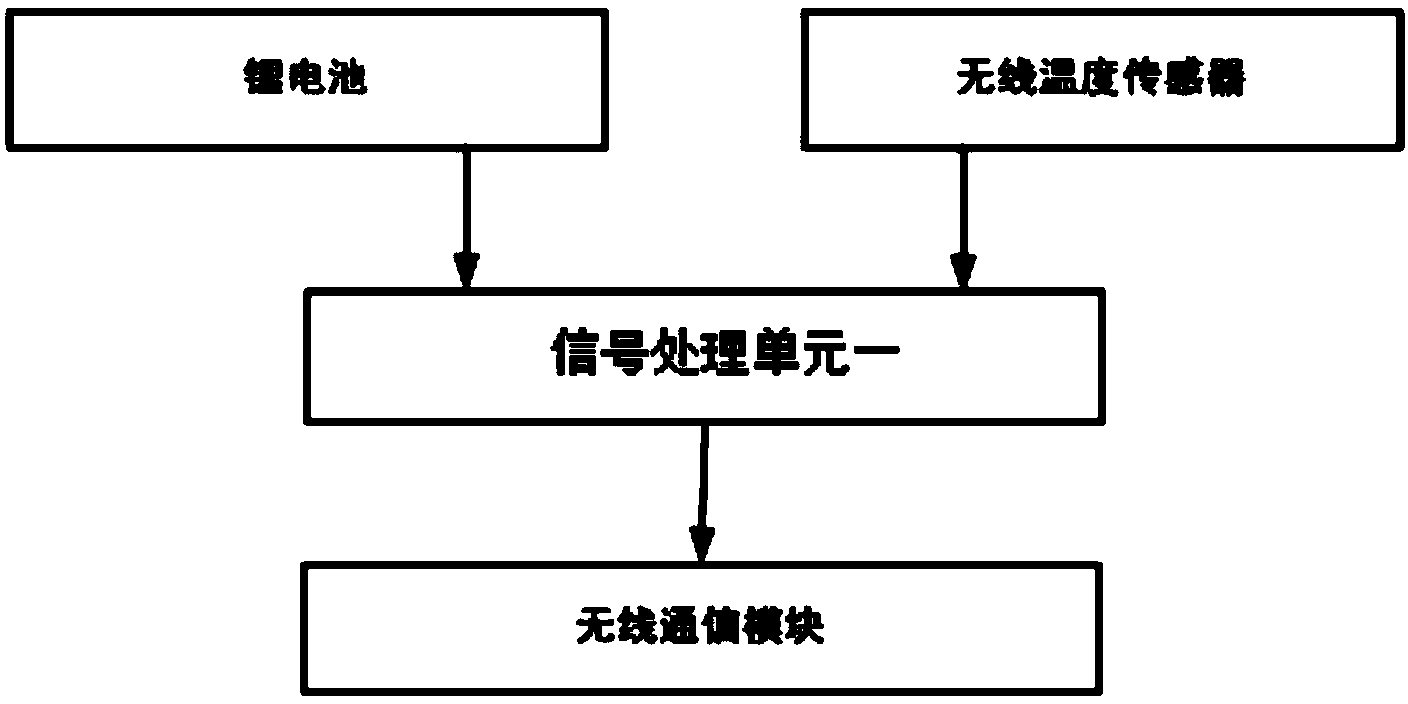

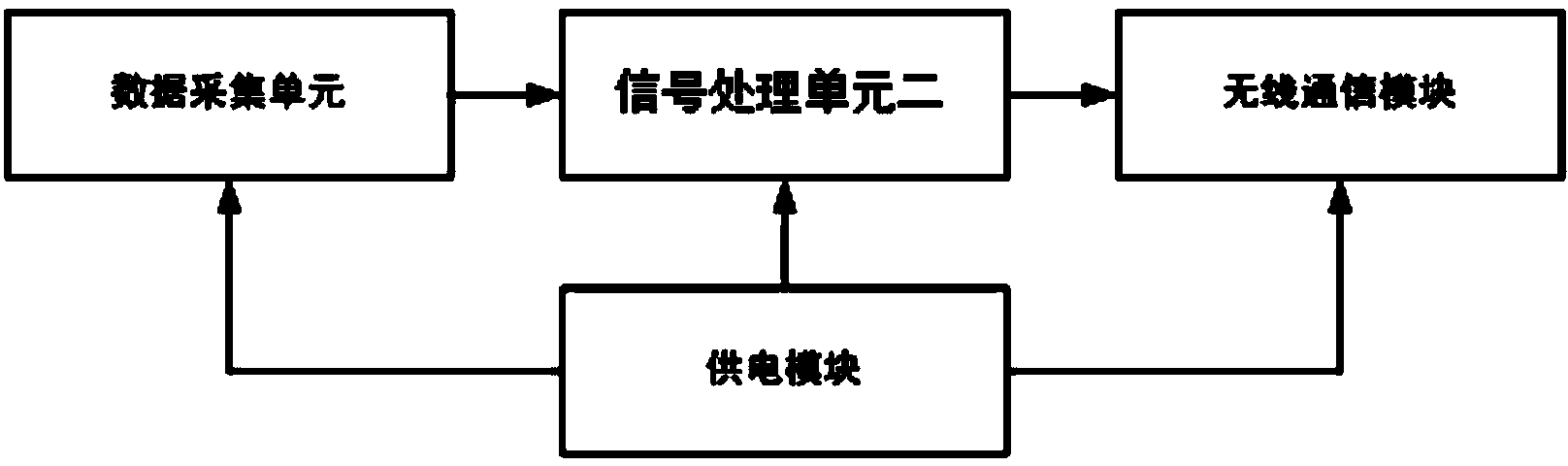

Power equipment and transmission line malfunction comprehensive online monitoring system

InactiveCN104316839AImprove signal anti-interference abilityTo achieve temperature compensationFault locationInformation technology support systemDatabase serverMonitoring system

The invention discloses a power equipment and transmission line malfunction comprehensive online monitoring system which comprises a wireless temperature measuring terminal, a line malfunction detector, a transfer station, an information receiving main station, a database server and a monitoring host. The wireless temperature measuring terminal is wirelessly connected with the information receiving main station through a built-in wireless communication module, the line malfunction detector is wirelessly connected with the information receiving main station through a built-in wireless communication module and the transfer station, and the information receiving main station is connected with the database server which is connected with the monitoring host. The system can monitor and upload power equipment temperature rise standard exceeding and transmission line ground fault information in real time, quickly locate line fault sections and fault branches, shorten fault clearing time and improve safety and reliability of power equipment and transmission lines.

Owner:ANSHAN POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER COMPANY +1

High-sensitivity fiber grating acceleration sensor

PendingCN108982916ASuppress lateral sensitivityHigh sensitivitySubsonic/sonic/ultrasonic wave measurementAcceleration measurementFiberGrating

The invention provides a high-sensitivity fiber grating acceleration sensor, which belongs to the technical field of vibration monitoring. The high-sensitivity fiber grating acceleration sensor comprises a measurement substrate A or a measurement substrate B, a rigid beam and a balance spring, wherein the balance position of the rigid beam is basically parallel with the measurement substrate A orbasically vertical to the measurement substrate B; one end of the rigid beam is hinged with a frame body fixedly connected with the measurement substrate A or the measurement substrate B through a rotating shaft, and the other end of the rigid beam is fixed with a mass block; one side of the rigid beam or the mass block is provided with the balance spring for enabling the rigid beam to be in a balance position; one side or two sides of the rigid beam is or re provided with one or two fiber gratings; and when the measurement substrate A or the measurement substrate B vibrates along with a monitored piece, the fiber grating can directly sense the vibration information of the rigid beam. The sensor sensitivity is improved obviously, the transverse sensitivity of the acceleration sensor can beeffectively suppressed, and the high-sensitivity fiber grating acceleration sensor has the advantages of simple structure, durability, not easy damage, small dynamic errors, accurate measurement, high sensitivity, high accuracy and high efficiency.

Owner:SHIJIAZHUANG TIEDAO UNIV

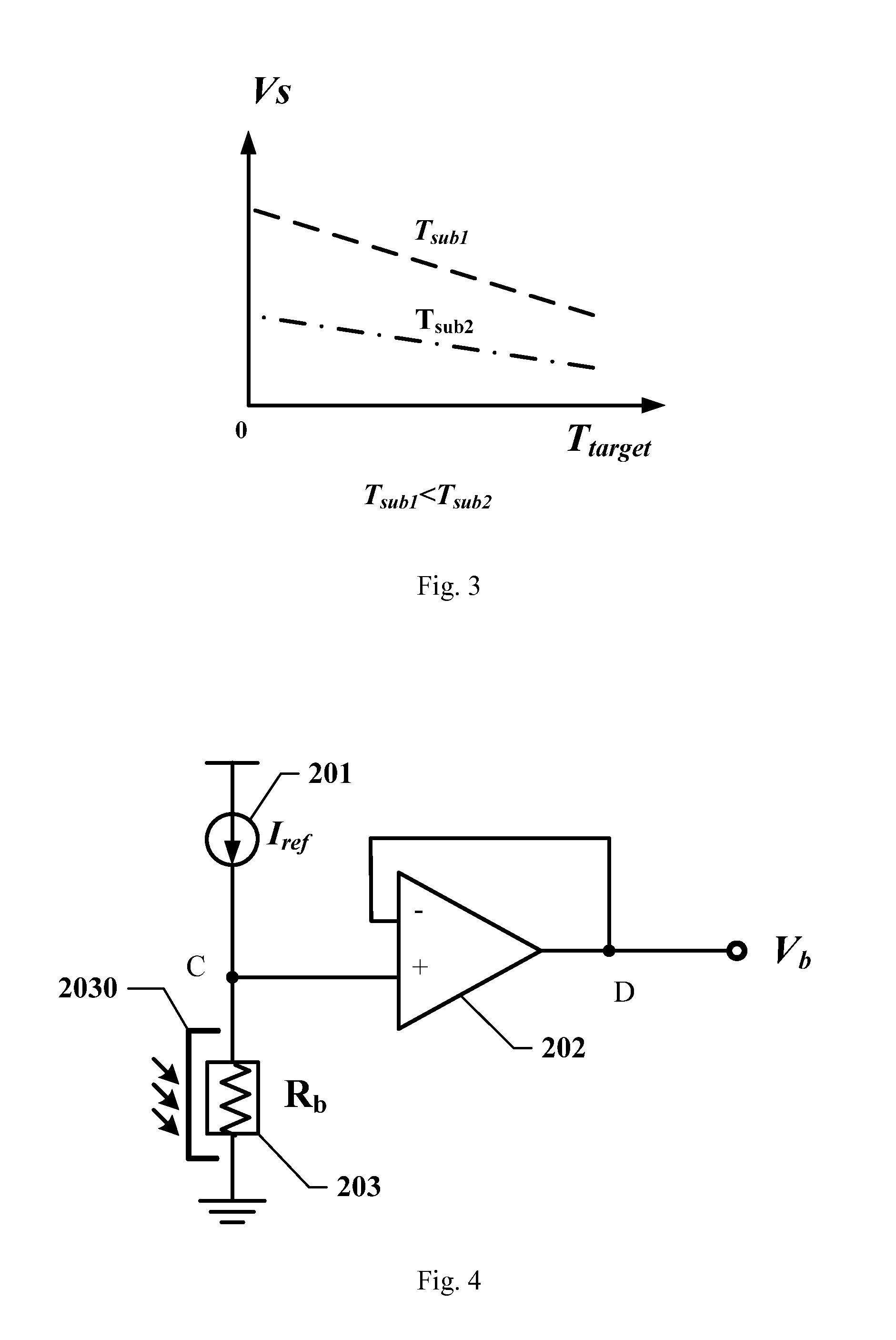

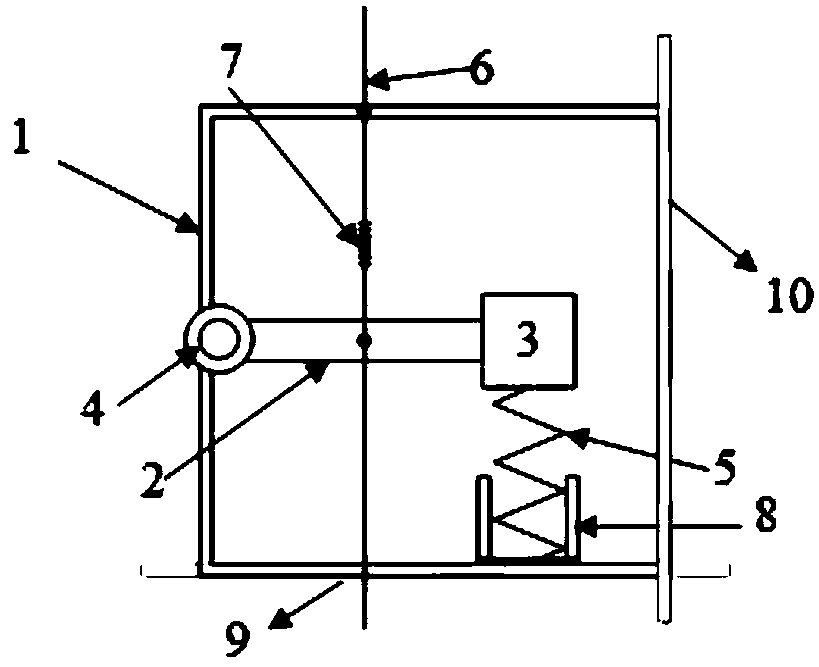

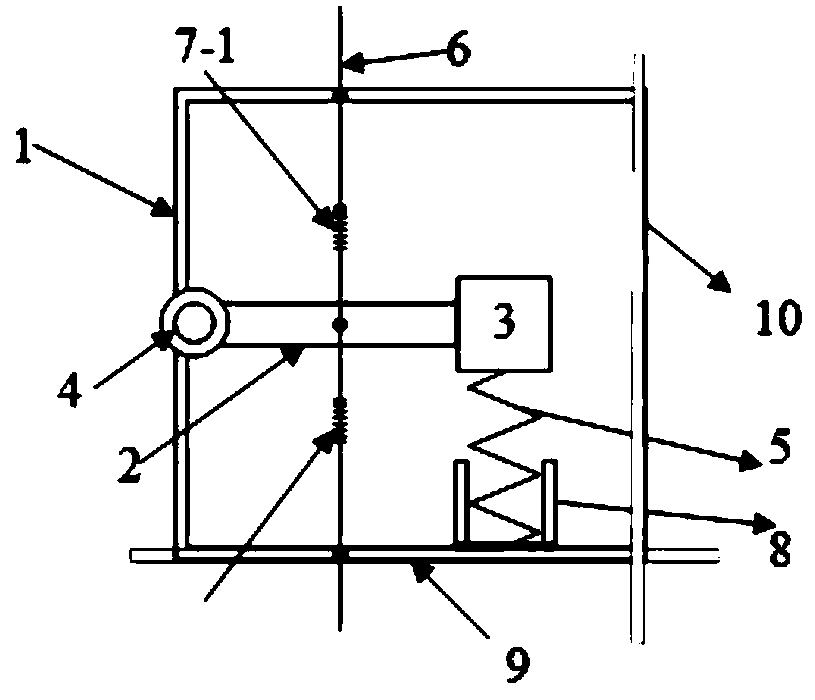

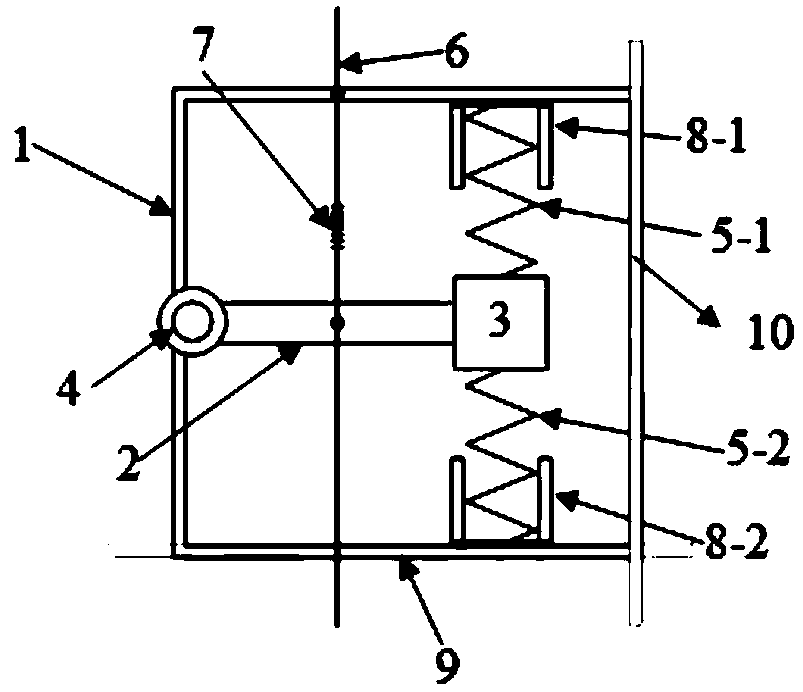

A pressure sensing apparatus

ActiveCN105115633AAccurate detectionGood pressure sensing sensitivityForce measurement using piezo-resistive materialsInput/output processes for data processingElectrical resistance and conductanceNegative temperature

The invention provides a pressure sensing apparatus including a pressure sensing layer which further includes a plurality of pressure sensing units. Each pressure sensing unit comprises at least one kind of positive temperature coefficient materials and at least one kind of negative temperature coefficient materials. The pressure sensing unit detects resistance variation generated after the pressure sensing layer is pressed. The negative temperature coefficient materials are used for compensating for changes of resistance values due to temperatures after the positive temperature coefficient materials are pressed so as to making the pressure sensing apparatus to be insensitive to the temperatures.

Owner:TPK TOUCH SOLUTIONS (XIAMEN) INC

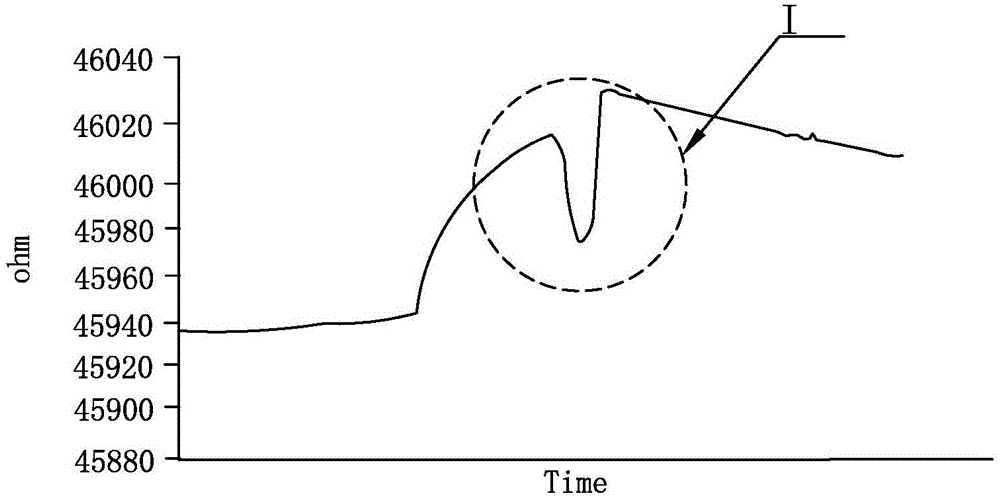

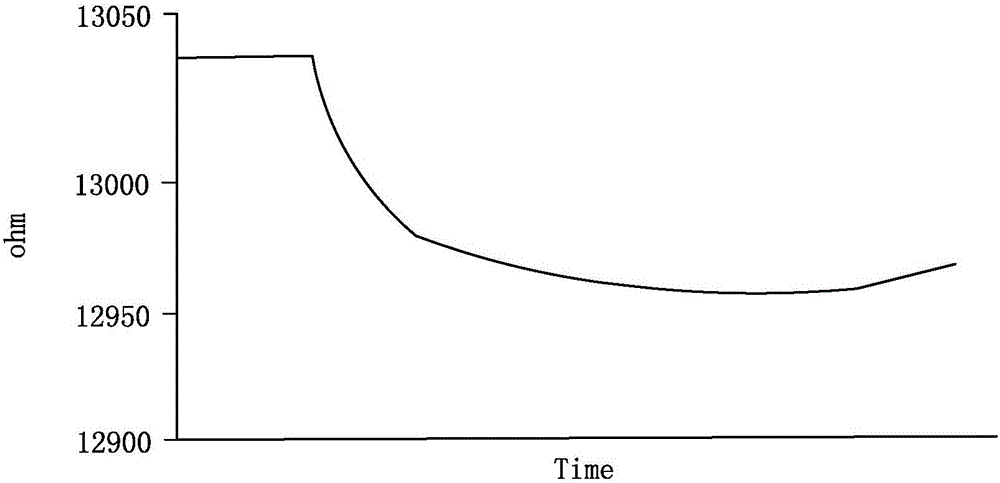

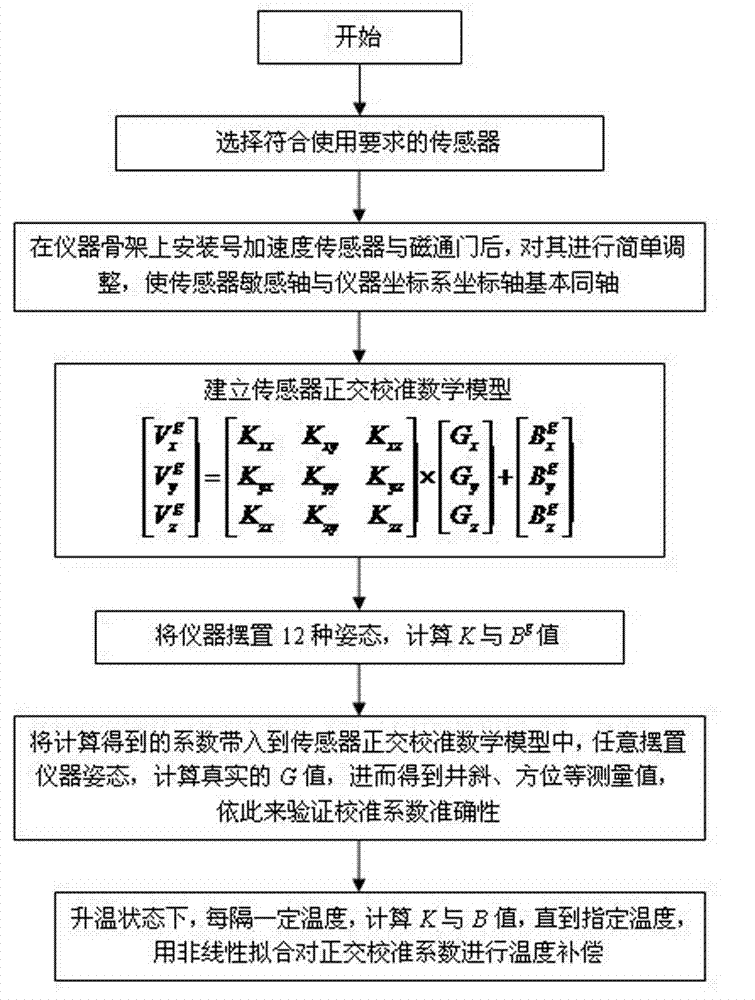

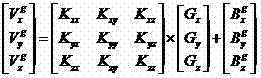

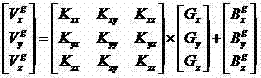

Sensor orthogonal calibration method for oil drilling measurement

ActiveCN102954804AReduce workloadTo achieve temperature compensationMeasurement devicesOil drillingEnvironmental geology

The invention discloses a sensor orthogonal calibration method for oil drilling measurement. The method comprises the following steps of: selecting an acceleration sensor and a flux gate which conform to use requirements, arranging the acceleration sensor and the flux gate on an instrument framework, and simply regulating to enable the coordinate axes of an instrument coordinate system to be basically coaxial with the sensing shaft of the sensor; then arranging instruments into 12 specific gestures according to an established mathematical model, so as to obtain orthogonal calibration coefficients of the sensor; calculating one group of orthogonal calibration coefficients at an temperature interval under a heating state till the specific temperature; carrying out temperature compensation on orthogonal calibration coefficients by utilizing nonlinear fitting; and enabling the calibrated sensing shaft of the sensor to be accurately coaxial with the coordinate axes of the instrument coordinate system by virtue of software. By utilizing the method, the calibrated sensing shaft of the sensor is accurately coaxial with the coordinate axes of the instrument coordinate system by virtue of software, thermal compensation is realized, and the original instrument calibration method is improved.

Owner:SCHLUMBERGER JHP OILFIELD TECH SHANDONGCO

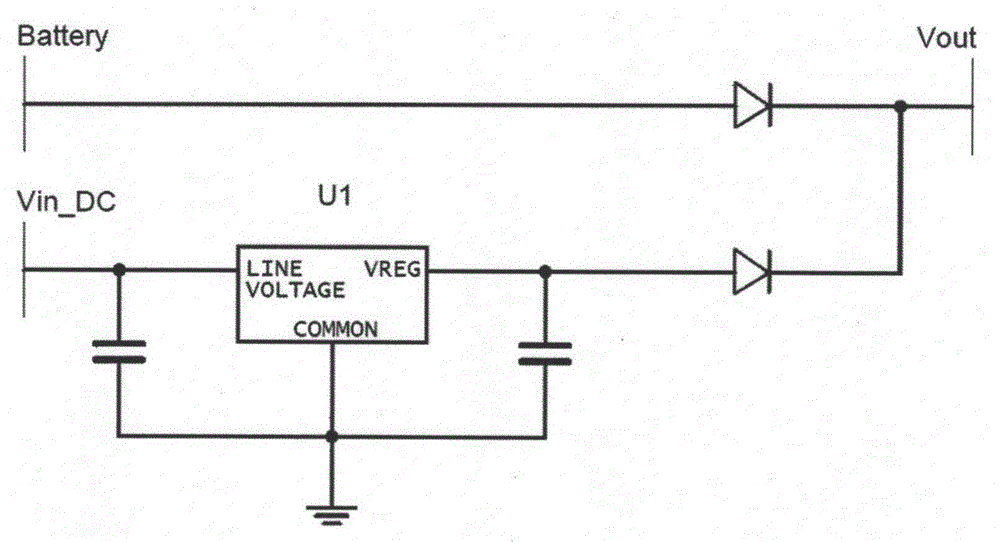

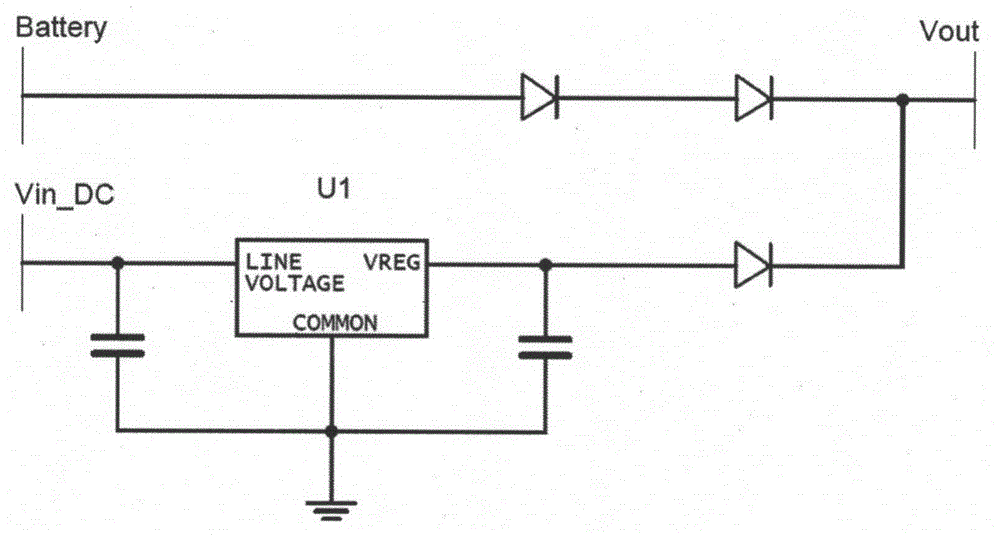

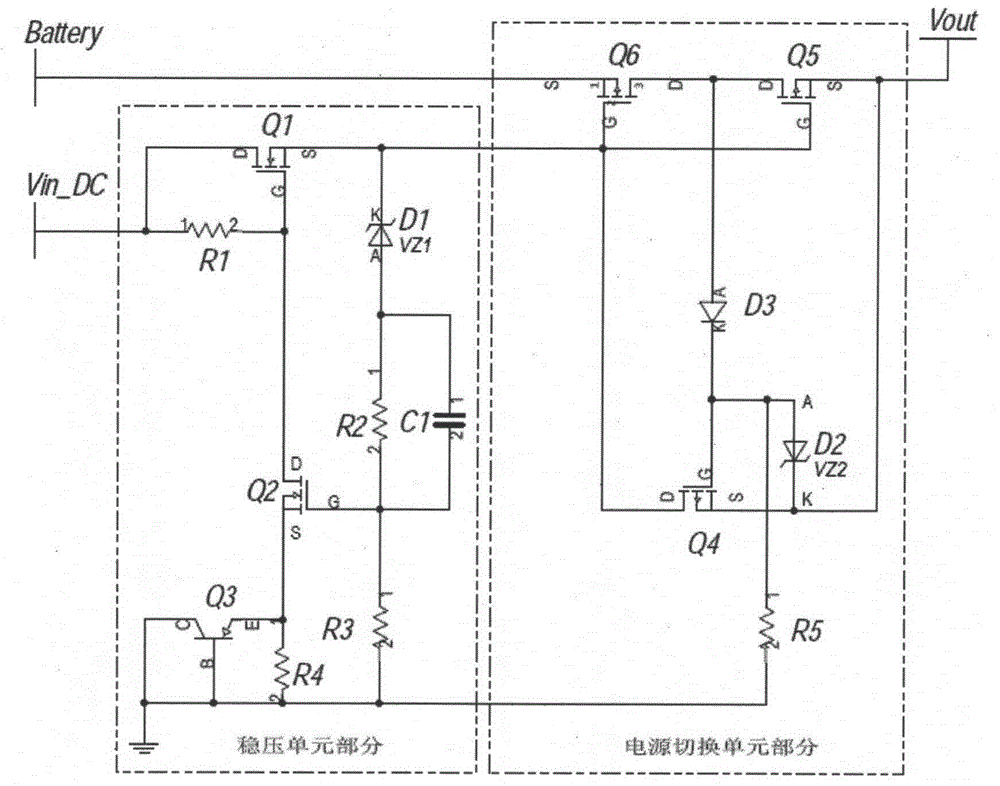

Self-switching voltage stabilizing circuit of power supply

InactiveCN104022647AImprove efficiencyFlexible designDc-dc conversionElectric variable regulationMOSFETField-effect transistor

The invention relates to a self-switching voltage stabilizing circuit of a power supply. The self-switching voltage stabilizing circuit comprises a voltage stabilizing unit part and a power supply switching unit, wherein an external power supply voltage input end is connected with the voltage stabilizing unit part, the voltage stabilizing unit part is connected with a power supply voltage output end through the power supply switching unit part, and the power supply switching unit part is also connected with a backup power supply positive input end. The self-switching voltage stabilizing circuit has advantage of being designed by adopting split elements and devices, so that the design is relatively flexible, an appropriate MOSFET (metal oxide semiconductor field effect transistor) is selected, a voltage stabilizing circuit with high input voltage can be designed, for example a voltage stabilizing circuit with the input voltage of 8V to 60V can be designed; meanwhile, the MOSFET is relatively high in efficiency, and the voltage stabilizing circuit with relatively large output current under the same size can be designed.

Owner:SHANGHAI XIELIN ELECTRONICS

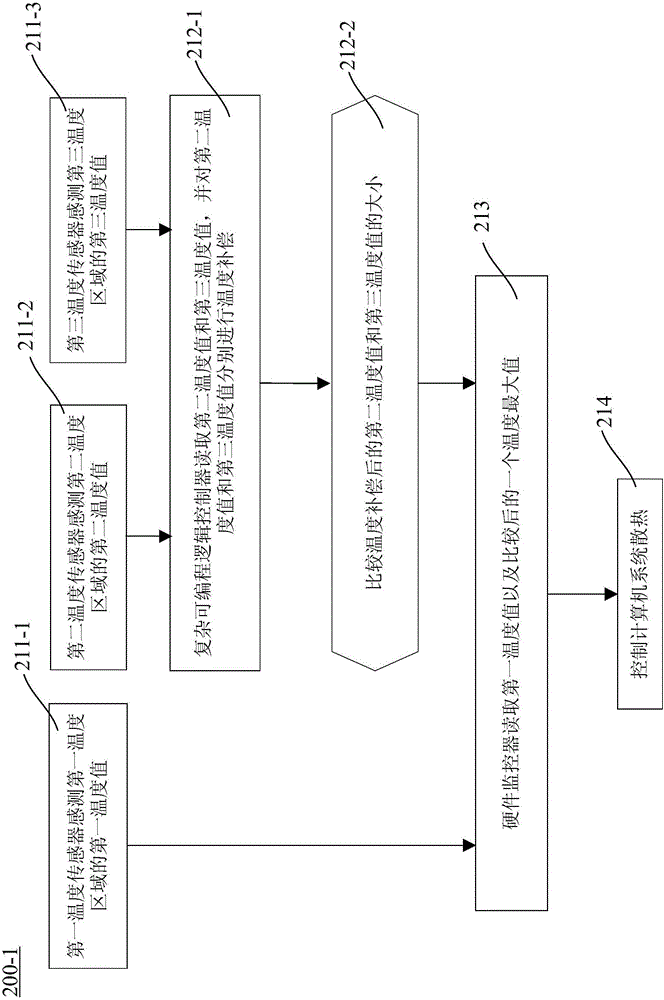

Server, hardware monitor system and the method of the same

InactiveCN106445780ATo achieve temperature compensationImprove cooling effectDigital data processing detailsHardware monitoringComputer hardwareProgrammable logic controller

The invention discloses a server, a hardware monitor system and the method of the server, the hardware monitor system. The server, the hardware monitor system and the method of the server, the hardware monitor system includes a first temperature value of a first temperature area is sensed through a first temperature sensor, and a second temperature value of a second temperature area is sensed through a second temperature sensor, and the second temperature value is read through a complex programmable logic controller. The complex programmable logic controller makes a temperature compensation to the second temperature value. A hardware controller reads the first temperature value and the second temperature value after temperature compensation, and controls the heat dissipation of a computer system according to the first temperature value and the second temperature value after temperature compensation. The server, the hardware monitor system and the method of the server, the hardware monitor system has the advantages of achieving temperature compensation of different temperature sensors and solving the problem that the temperature values of different temperature areas cannot be compensated alone in temperature in the prior art through sensing the temperature values of different temperature areas by a plurality of sensors, and through reading and updating the temperature values by the complex programmable logic controller.

Owner:INVENTEC PUDONG TECH CORPOARTION +1

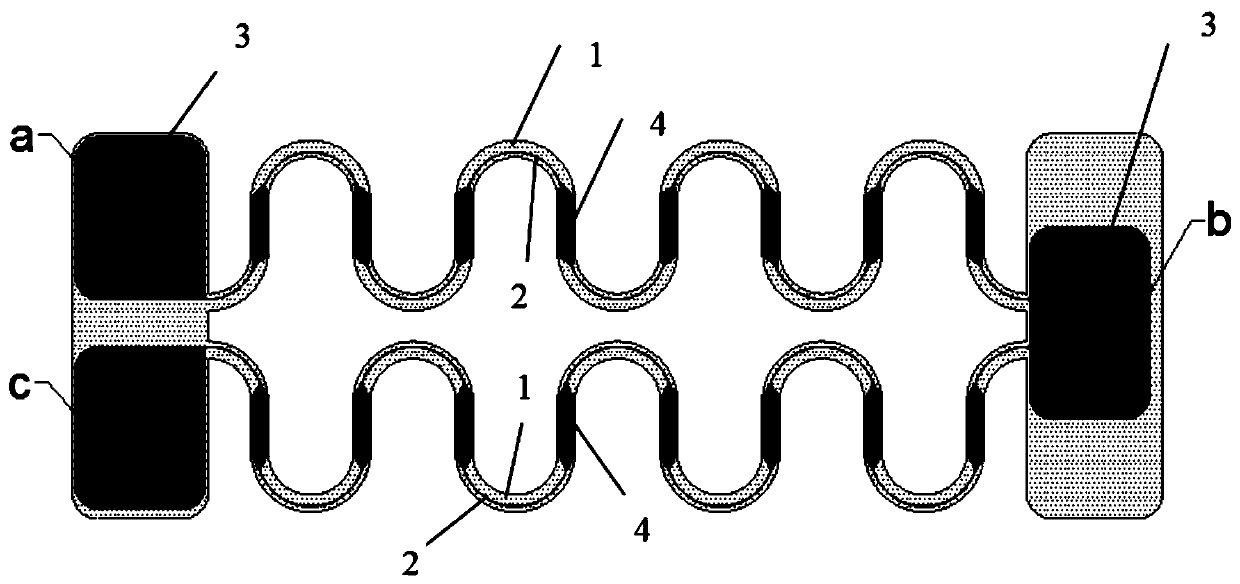

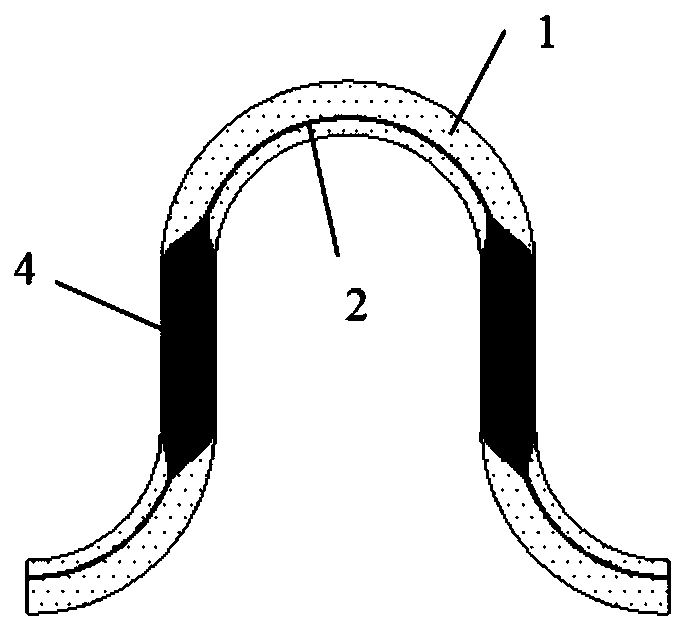

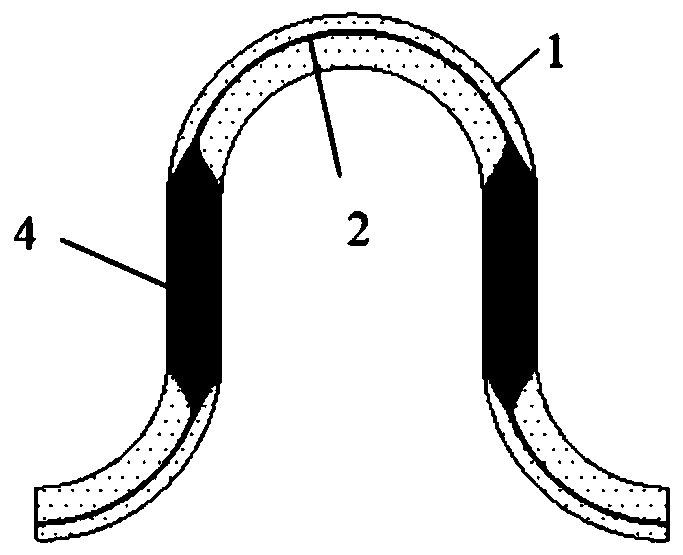

Resistance-type strain sensor and strain measurement method

ActiveCN109883316ATo achieve temperature compensationRealize the difference in the amount of resistance changeElectrical/magnetic solid deformation measurementElectrical resistance and conductanceStrain sensor

The invention provides a resistance-type strain sensor and a strain measurement method. The strain sensor can automatically perform temperature compensation during a strain measurement process, and meanwhile improves the sensitivity of strain measurement. The strain sensor comprises strain resistors and a substrate; the strain resistors are fixed on the substrate. The strain sensor is characterized in that the substrate is made from insulating material and is of a curved structure, the substrate at least comprises two rows arranged in parallel, and the end parts are separately connected with apasting end; one ends of the strain resistors on the two-row substrate are connected in series to achieve temperature compensation during a strain measurement process; the axle wires of the strain resistors on the two-row substrate are positioned at different positions of the substrate, to achieve the differences between the resistance variations during the strain measurement process. When in strain measurement, a lead is lead out from each of the two electrical ends of the strain resistors connected in series and the serially connected part in the resistance-type strain sensor to a half bridge measurement circuit and calibrated, and the measurement half bridge outputs voltage to acquire the strain of the substance under test.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

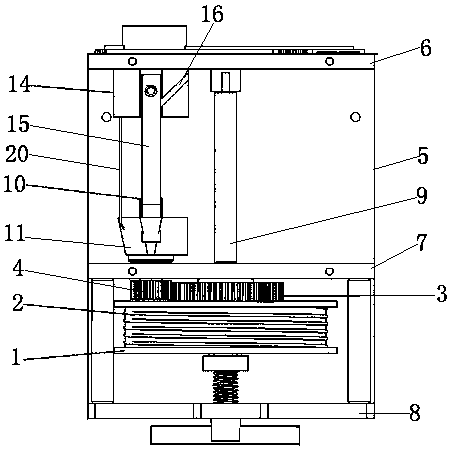

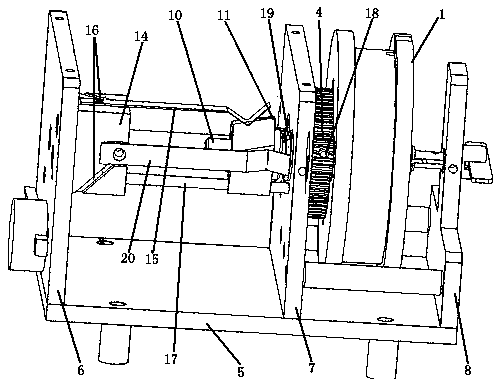

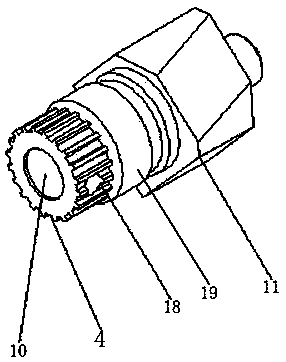

Mine-used large-range fiber grating passive roof bed separation sensor

The invention discloses a mine-used large-range fiber grating passive roof bed separation sensor, which comprises a shell, a wire rope roller mechanism and a fiber grating strain mechanism, and is characterized in that the fiber grating strain mechanism comprises a second gear, a precision screw rod with one end fixed with the second gear and rotating along with the second gear, a bevel slider with a bevel surface, a strain gauge fixing square block, and a fiber grating strain gauge, wherein the bevel slider sleeves the precision screw rod and can axially move along the screw rod; the strain gauge fixing square block is fixed on a front bearing support frame, and the position of the strain gauge fixing square block is corresponding to that of the bevel slider; and one end of the fiber grating strain gauge is fixed by the strain gauge fixing square block and the other end is a free end contacted with the bevel surface of the bevel slider and capable of sliding relatively, and a fiber grating is attached to the fiber grating strain gauge. The circular motion of the roller pulled by the wire rope changes to the axial motion of the bevel slider on the precision rod, the wavelength of the fiber grating changes, and real-time online dynamic roof bed separation monitoring can be realized.

Owner:山东道宽智能科技有限公司 +1

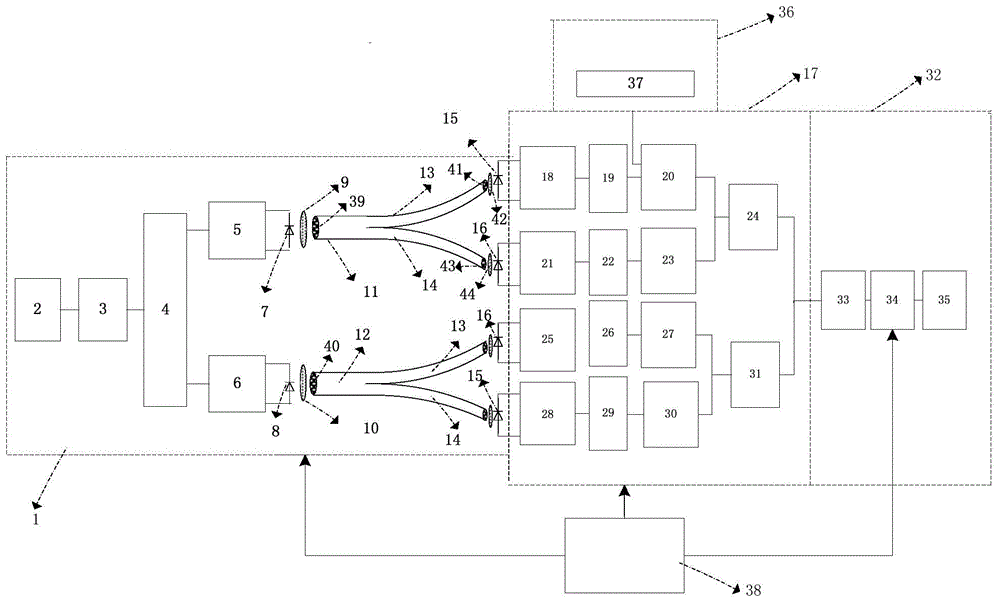

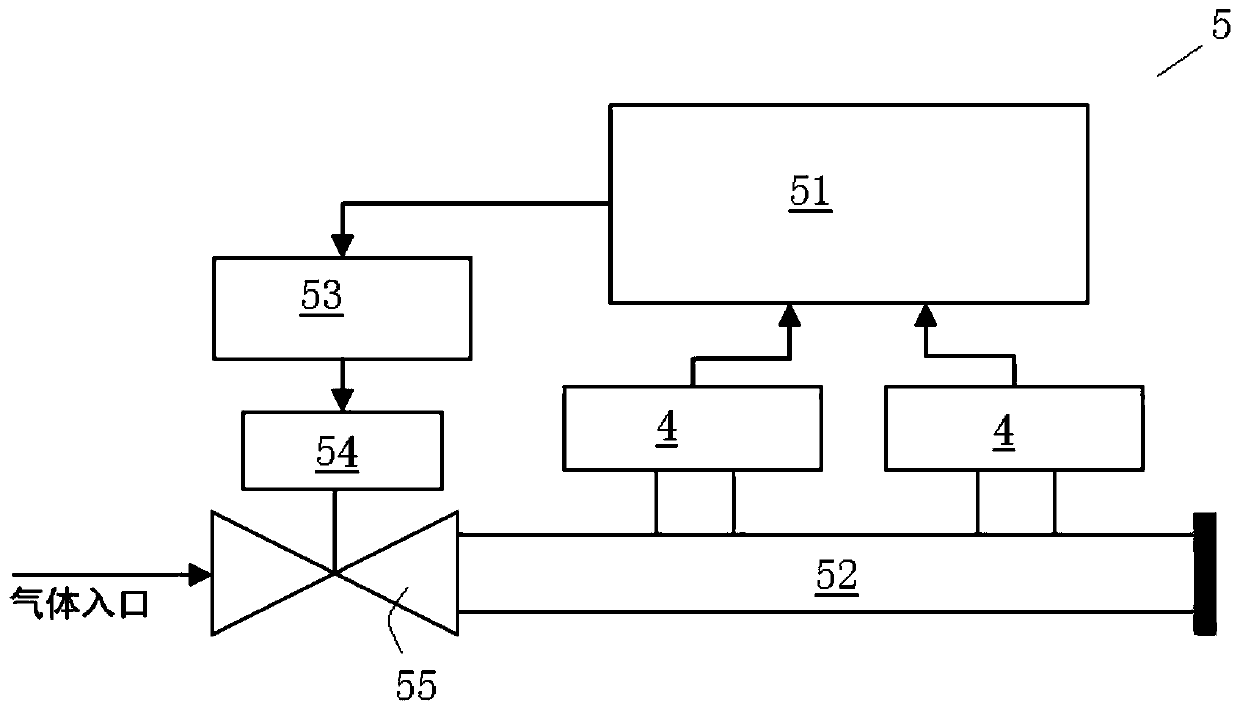

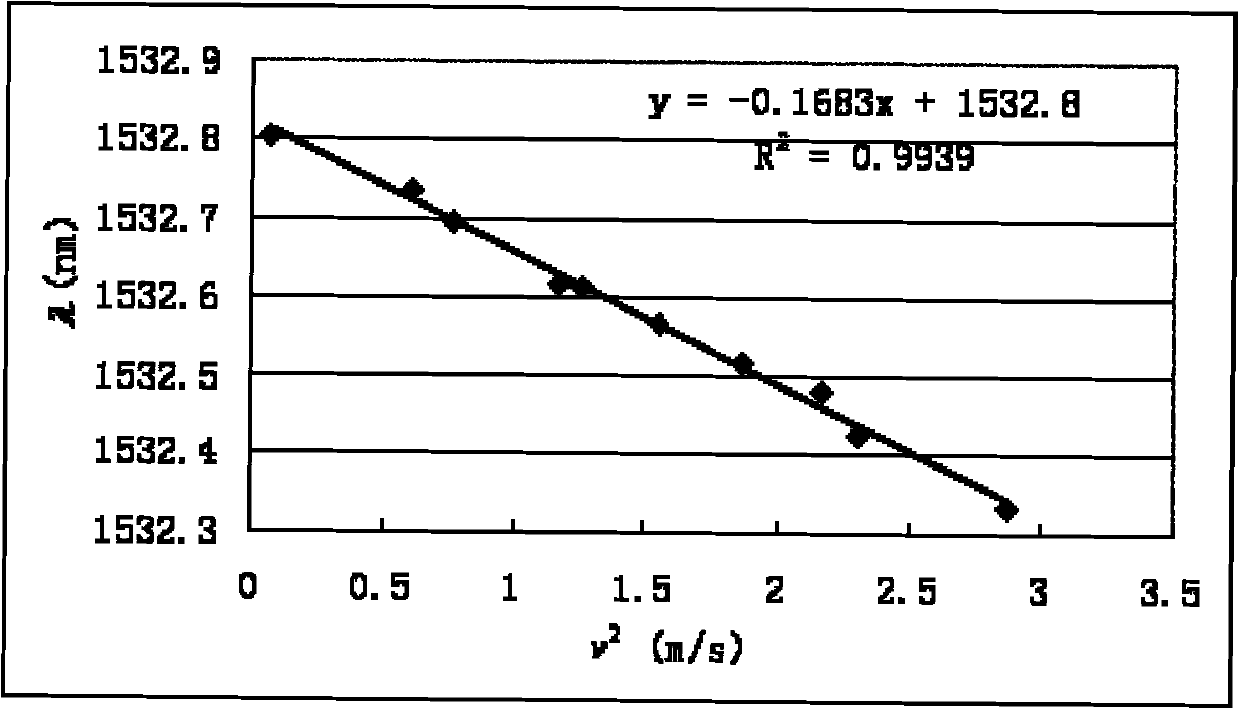

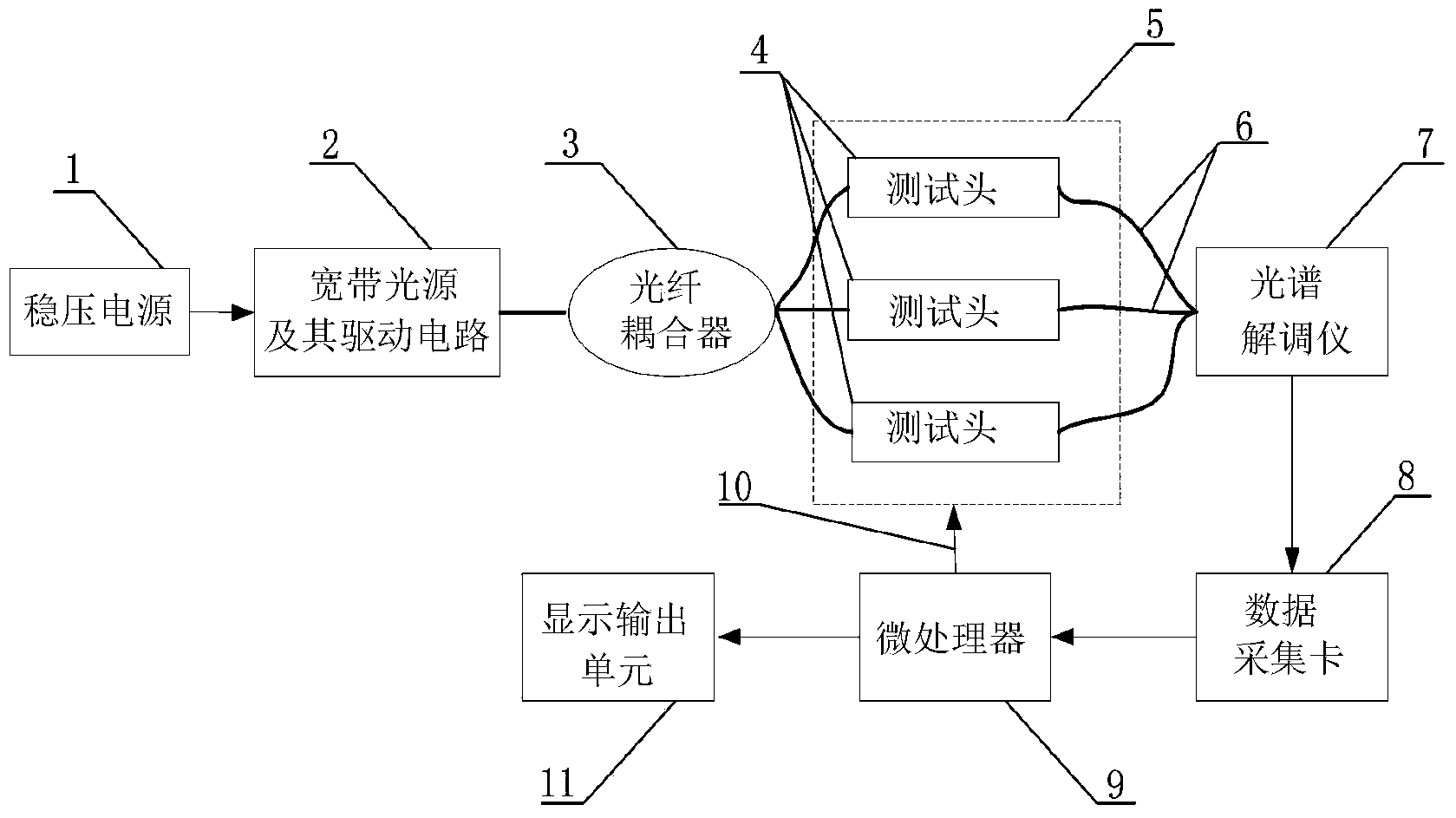

Novel optical pulse-taking instrument system

The invention discloses a novel optical pulse-taking instrument system which comprises a voltage-stabilized source, a broadband light source, a drive circuit of the broadband light source, an optical fiber coupler, optical fiber measuring heads, a pneumatic pressure control device, transmission optical fibers, a spectrum demodulator, a data acquisition card, a microprocessor, control signals and a display output unit. Output light signals of the broadband light source are coupled through the optical fiber coupler to the transmission optical fibers; after passing through the measuring heads, the light signals are received through the spectrum demodulator, and received wavelength shift signals are acquired through the data acquisition card and transmitted to the microprocessor; the microprocessor drives a pneumatic control circuit to exert different action forces to the three measuring heads through the output control signals, and the mode of three-finger pulse taking operation in traditional Chinese medicine is simulated; meanwhile, a series of acquired wavelength shift signals are amplified, filtered and separated through the microprocessor, sent to the display output unit and the signals are used for output of pulse wave signals. The novel optical pulse-taking instrument system has the advantages of being simple in structure, high in sensitivity and free of electromagnetic interference, a measuring device is good in sealing performance, and temperature compensation can be achieved.

Owner:TIANJIN UNIV

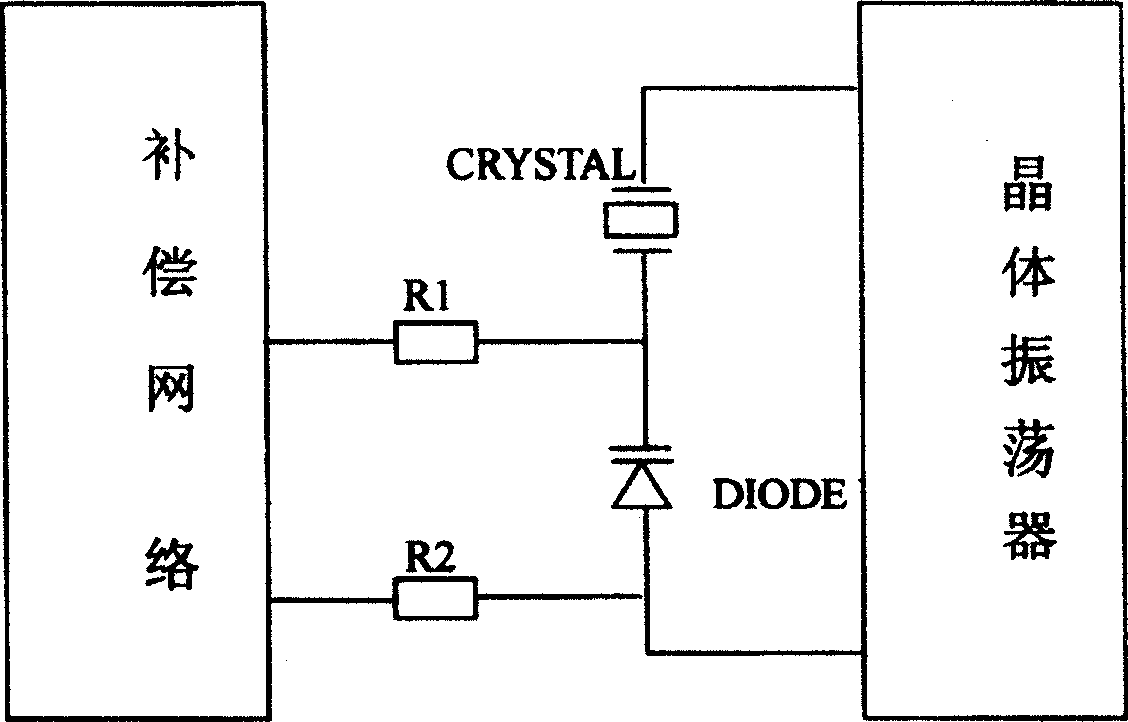

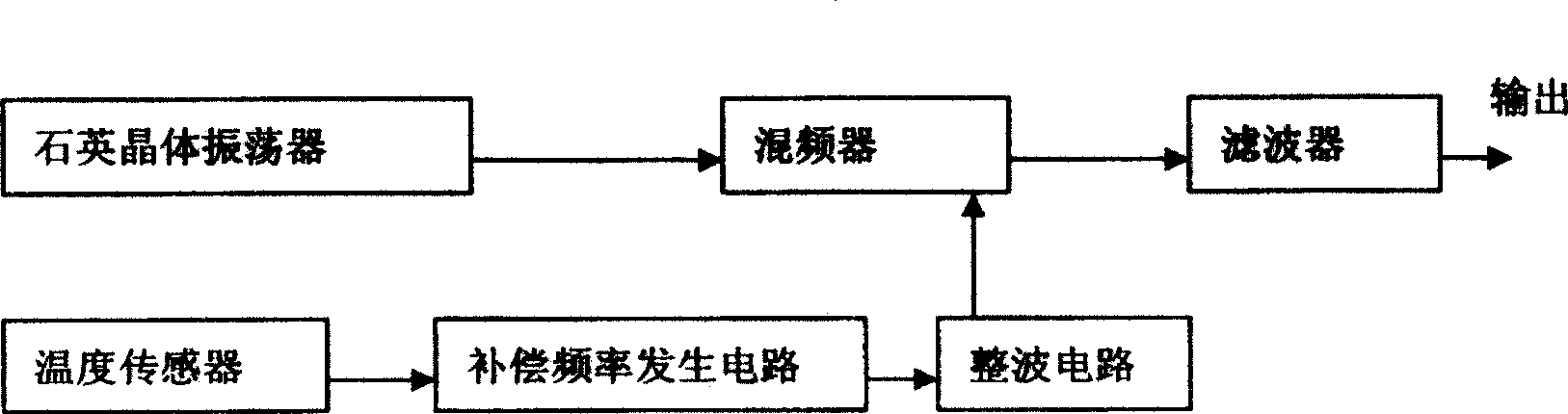

Temperature-compensating method for quartz crystal oscillator

InactiveCN100471035COvercoming phase jitterTo achieve temperature compensationOscillations generatorsPhase noiseWave shape

A temperature compensation method for quartz crystal oscillator, the temperature sensor and compensation frequency generation circuit producing a compensation frequency signal having equal absolute value and opposite sign with the deviation frequency value produced by uncompensated quartz crystal oscillator, said compensation frequency signal mixed and outputted with the uncompensated frequency signal after wave shaping, obtaining compensated frequency signal after filtering by filter, said invention has low phase noise and can make effective temperature compensation to high frequency overtone quartz crystal oscillator.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com