Hybrid-range FBG (fiber bragg grating) strain and crack sensor for concrete material package

A concrete and sensor technology, applied in the field of sensors, can solve the problems that sensors cannot meet the monitoring requirements, limit the measurement strain range, and the difference in strain results, etc., and achieve the effect of increasing the effective working range, overcoming relatively large influence, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

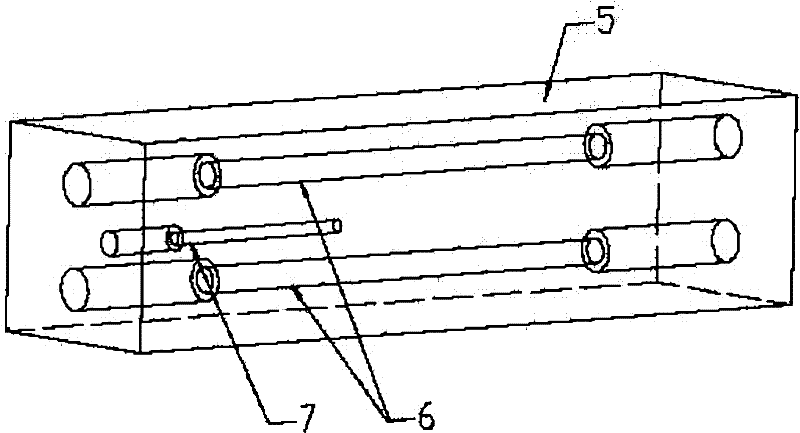

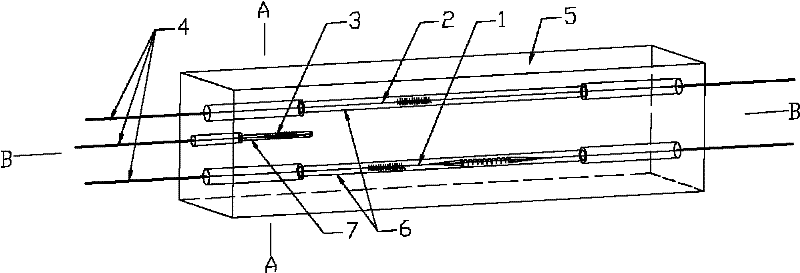

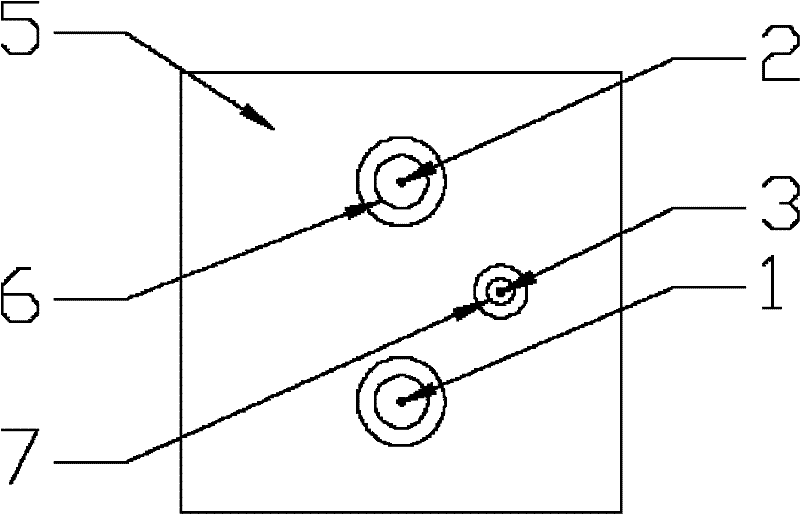

[0017] The structure of the fiber grating strain sensor is as follows: figure 2 with image 3 As shown, the strain sensor includes a spring fiber grating 1, a pure fiber grating 2, a prefabricated concrete encapsulation structure 5, two through grooves 6, a temperature sensing groove 7, a temperature sensor 3 and an armored optical cable 4. First, respectively embed the spring fiber grating and pure fiber grating connected to the spring into two through grooves, and then use glue to consolidate one end of the spring fiber grating and pure fiber grating with the concrete package structure where they are located, and finally fix the spring fiber grating connected to the spring. Apply a certain level of tensile prestress to the grating and pure fiber grating, and then consolidate the other ends of the two groups of fiber gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com