An industrial camera fill light control method and system

A technology for industrial cameras and control systems, applied in the parts of TV systems, TVs, color TVs, etc., can solve the problems of the brightness of the lamp group cannot be maintained stable, the wiring is complicated, and there is no consideration, and achieves low power consumption, Simple wiring and stable brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

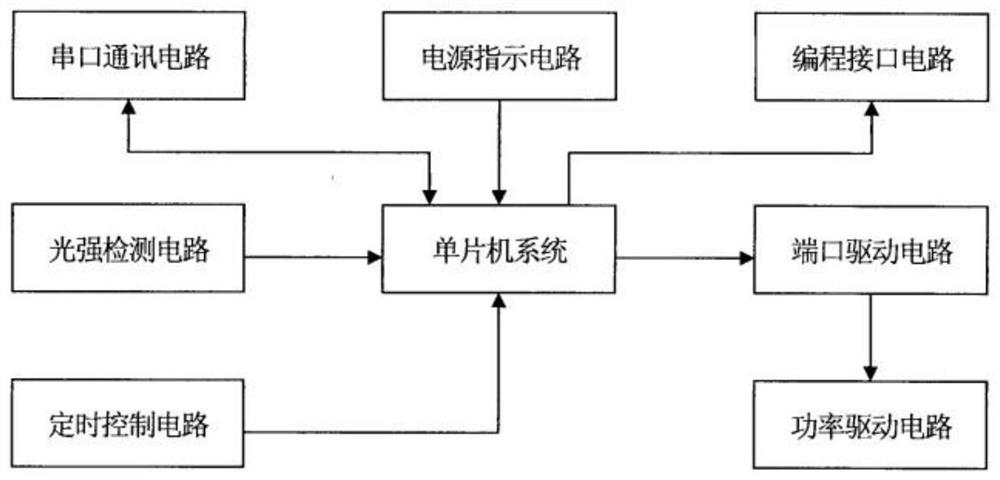

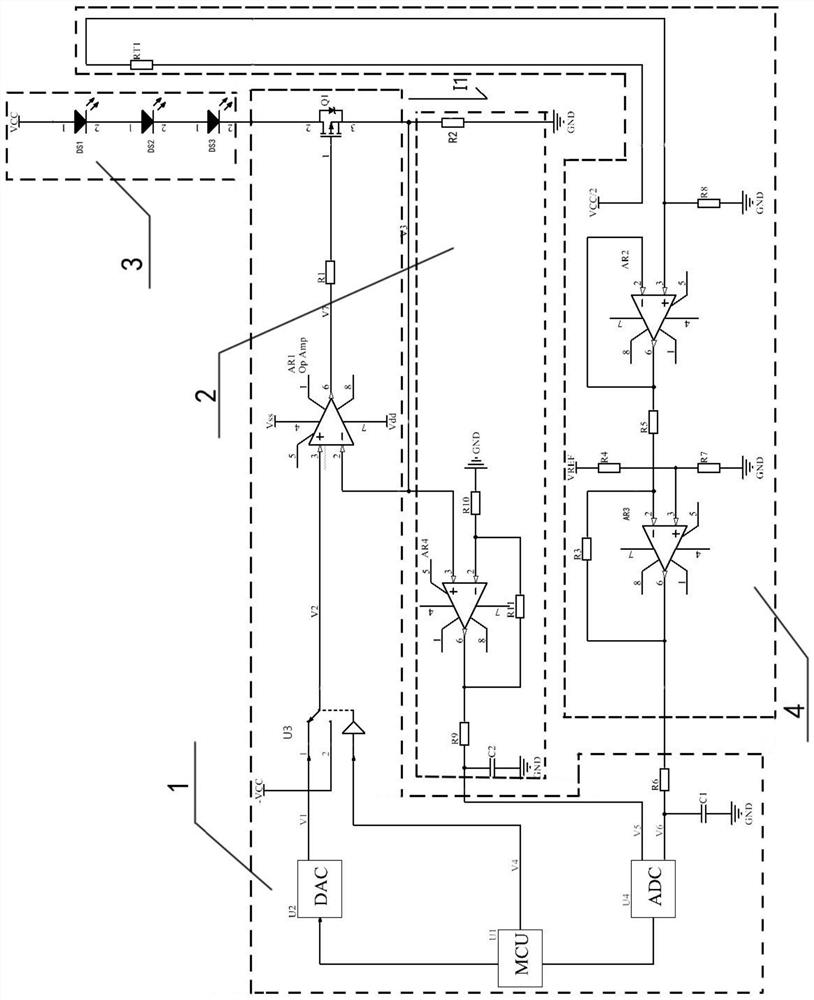

[0038] Such as Figure 3-6 As shown, the industrial camera supplementary light control system provided by this embodiment includes: a control circuit module 1, which is used to control the complete machine; a current correction / acquisition module 2, which is connected to the control circuit module connection; the thermistor voltage amplification module 4, which is connected to the control circuit module 1; the lamp group module 3, which is connected to the control circuit module 1.

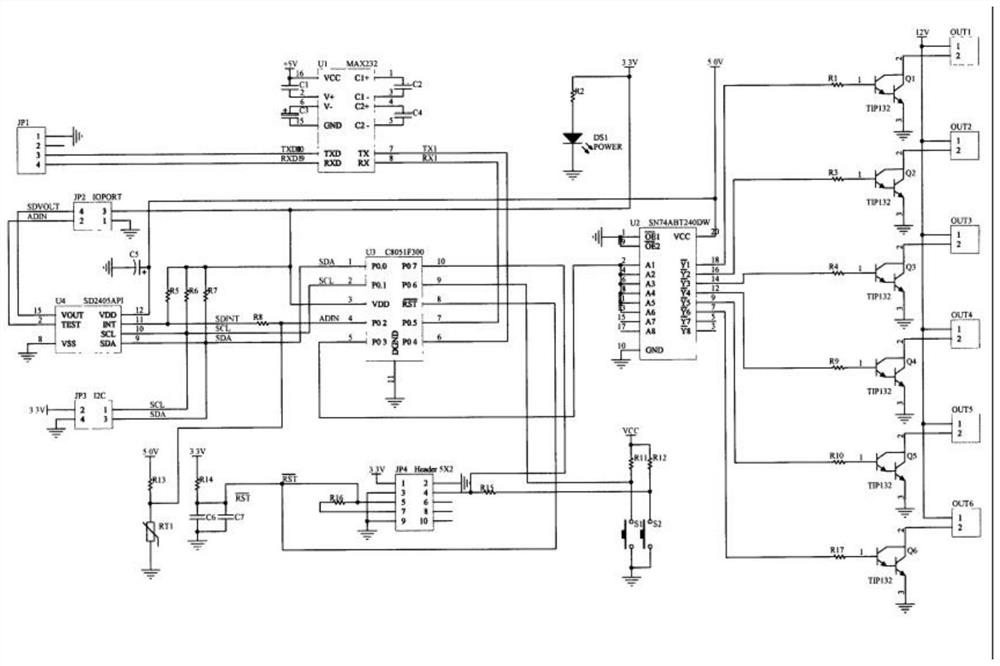

[0039]The control circuit module 1 includes a microcontroller MCU, a digital-to-analog conversion module DAC, an analog-to-digital conversion module ADC, an analog switch U3, a power supply-VCC, a power supply Vss, a power supply Vdd, an operational amplifier AR1, a resistor R1, a MOS tube Q1, a resistor R6, capacitor C1, microcontroller MCU are respectively connected with the input end of the digital-to-analog conversion module DAC, the output end of the analog-to-digital conversion module ADC an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com