Ultralarge-diameter-ratio asynchronous rolling mill and plate rolling method

A technology of asynchronous rolling mill and ultra-large diameter, which is applied in the direction of metal rolling, metal rolling, metal rolling stand, etc., and can solve the problems of reducing the warpage of the strip after rolling, large friction force of the rolling mill, and unfavorable biting , to achieve the effect of enhancing the shearing effect, reducing the rolling force, and improving the plastic deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to further illustrate the technical solution of the present invention, the present invention will be further described below through examples.

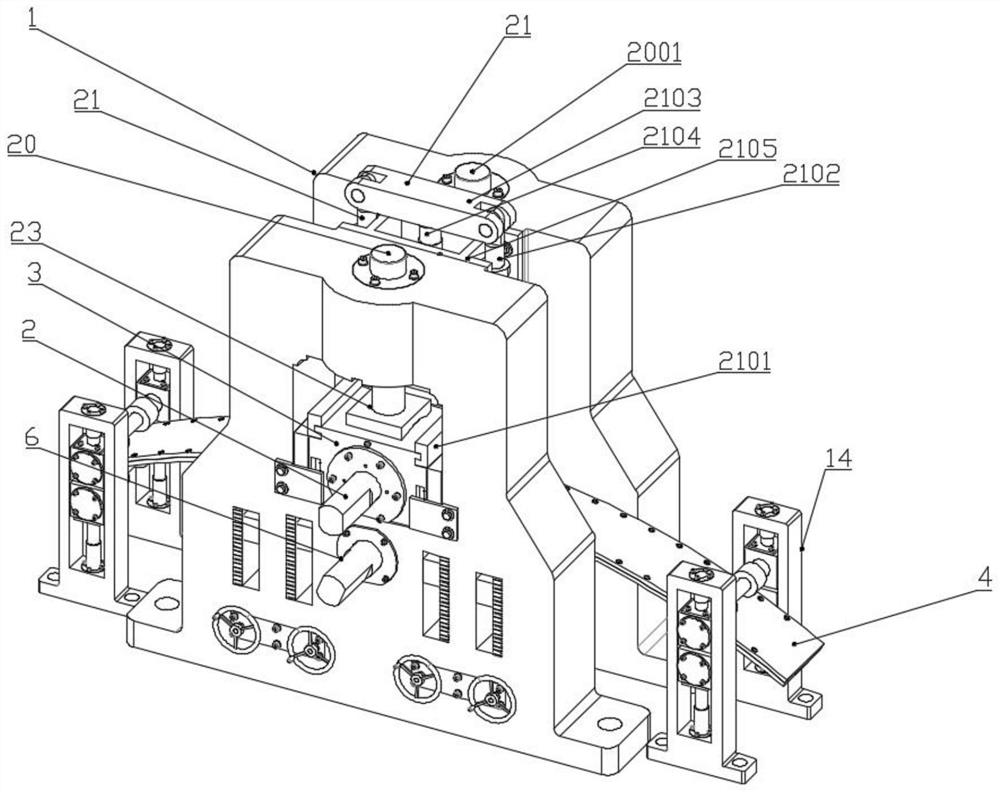

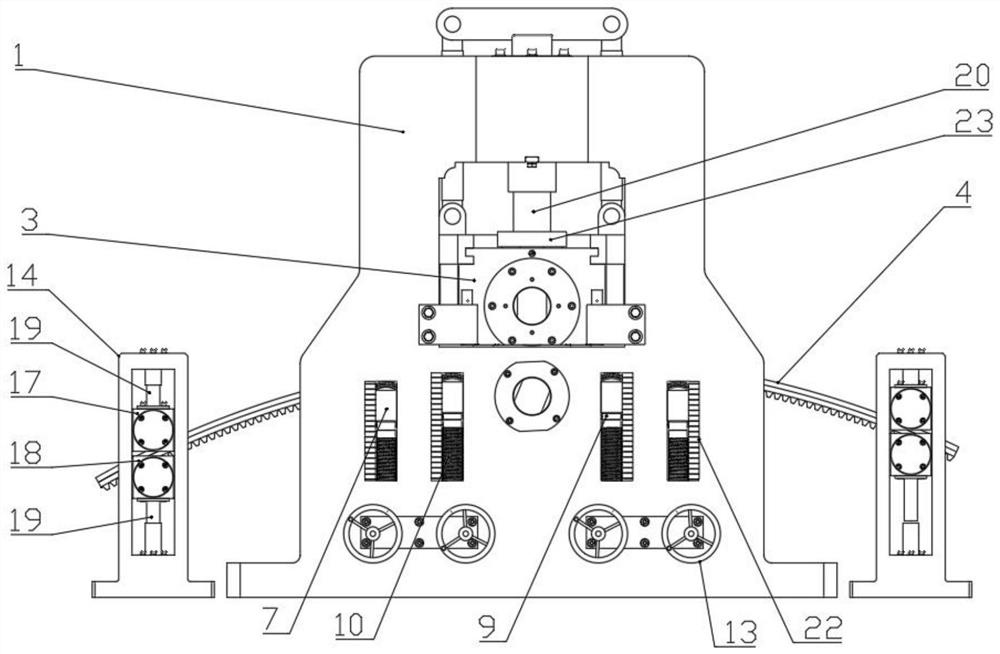

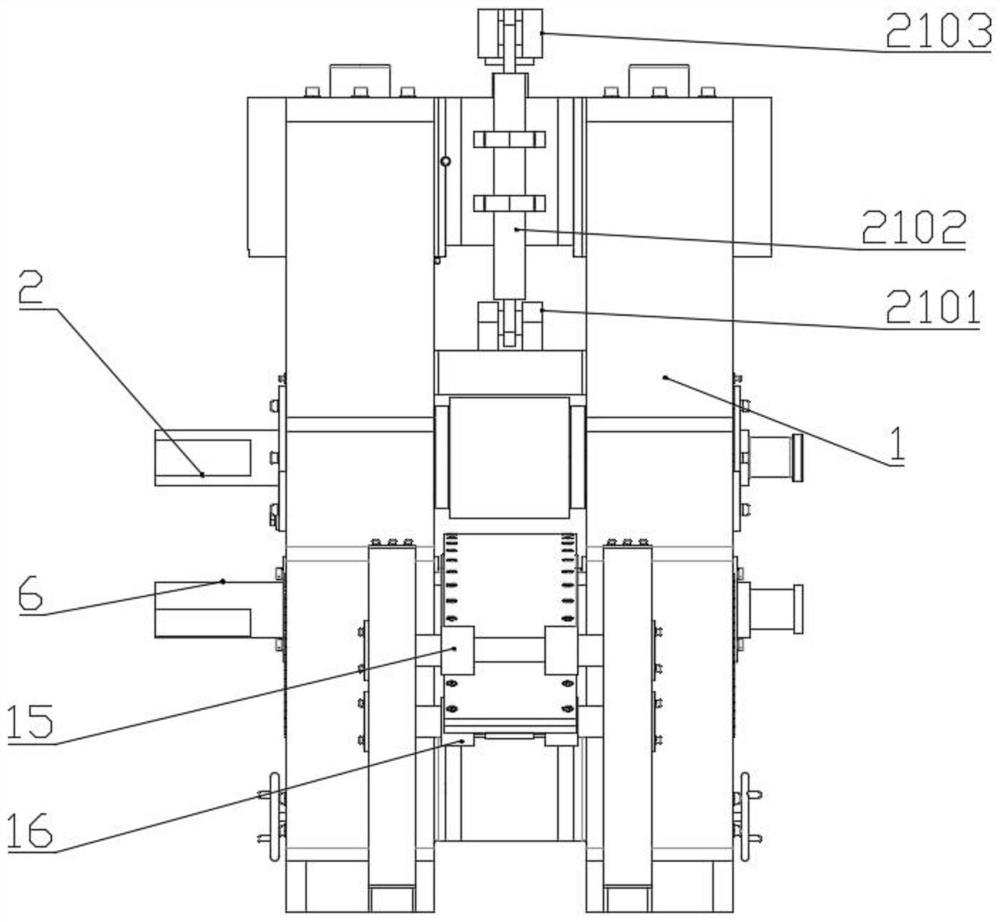

[0048] Such as Figure 1 to Figure 13 As shown, an asynchronous rolling mill with a super large diameter ratio is characterized in that it includes a rolling mill stand 1, a pressing device 20, a balancing device 21, an upper roll system and an arc-shaped plate device;

[0049] The lower width of the rolling mill stand 1 is greater than the upper width of the rolling mill stand 1;

[0050] The depressing device 20 includes two depressing hydraulic cylinders 2001;

[0051] The balance device 21 includes a lower balance beam 2101, a balance pull rod 2102, an upper balance beam 2103, a balance hydraulic cylinder 2104 and a connecting frame 2105, and the two balance beam pull rods 2102 are respectively connected with the upper balance beam 2103 and the lower balance beam 2101 with pins, The balance hydraulic cylinder 210...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com