Double-rack six-roller UCM leveling and double cold reduction unit for production of tinned substrate

A technology of tin-plated substrate and secondary cold rolling, applied in the direction of metal rolling stands, metal rolling mill stands, rolls, etc., can solve the problems of unclean dew condensation, poor shape and lack of production strip steel plate, etc. , to achieve the effect of emulsion barrier and anti-condensation, reducing unit rolling force and improving rolling stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

[0027] The present invention will be further described below in conjunction with implementation examples and accompanying drawings, but the present invention is not limited.

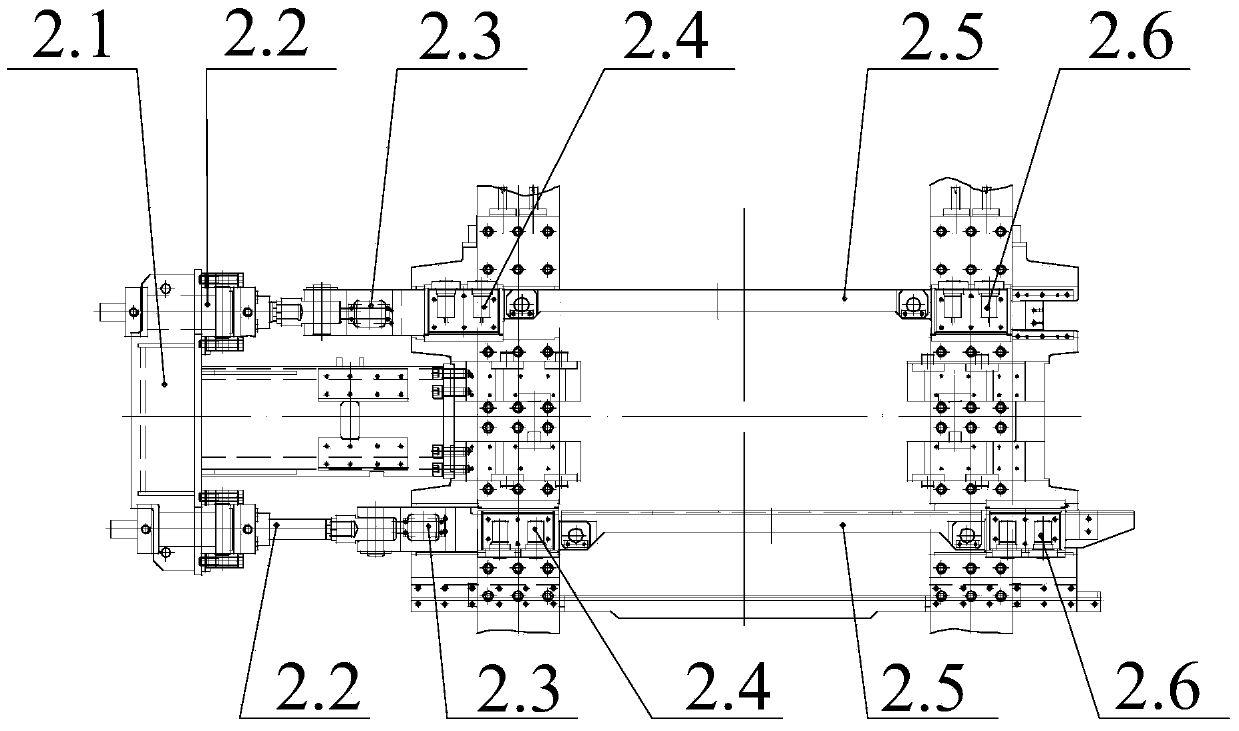

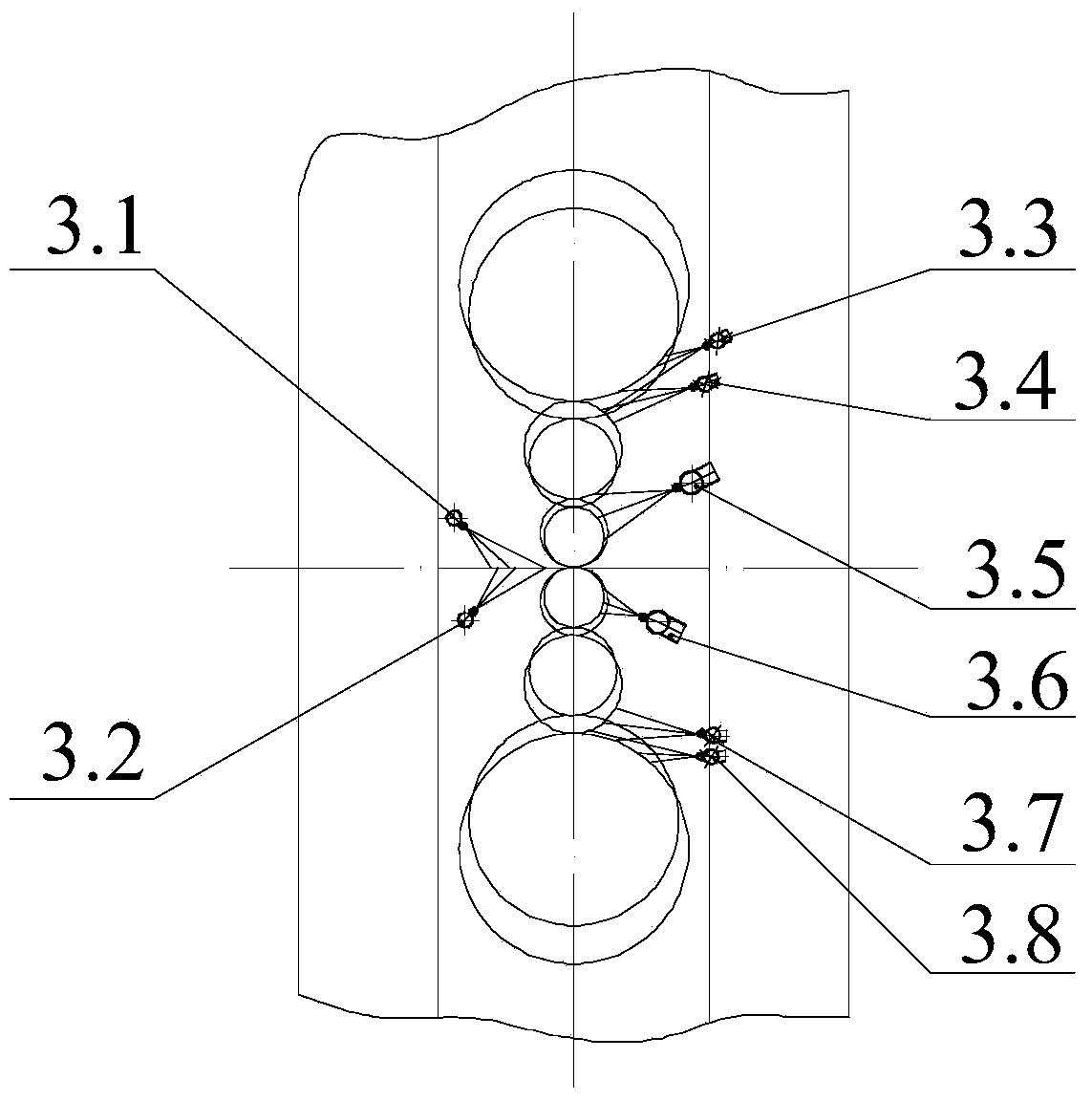

[0028] (1) The No. 1 and No. 2 stands of the two-stand six-roll UCM pass-through and secondary cold-rolling unit are all six-roll UCM.

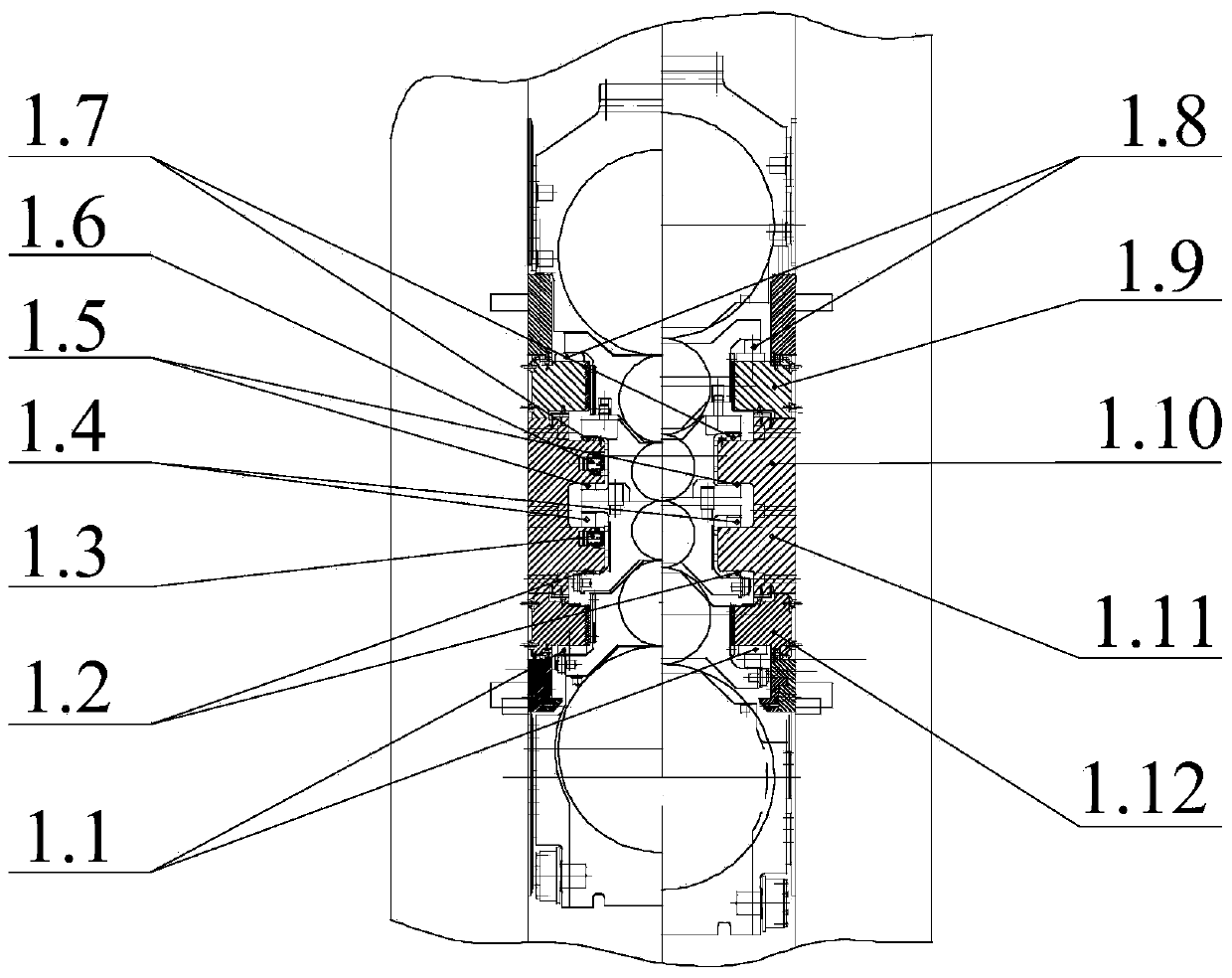

[0029] figure 1 It is a schematic diagram of the window and roll bending block of the two-stand six-high UCM skin pass and secondary cold rolling mill. Frame No. 1 or No. 2 includes upper back-up roll, lower back-up roll, upper middle roll, lower middle roll, upper work roll, lower work roll, lower middle roll bending cylinder 1.1, lower work roll forward bending cylinder 1.2, lower working roll side pushing cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com