Metal mask plate preparation method

A metal mask and metal film technology, which is applied in the coating process of metal materials, the photoengraving process of the pattern surface, and the originals used for optical mechanical processing, etc., can solve the problems of large opening size and poor accuracy, and achieve The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

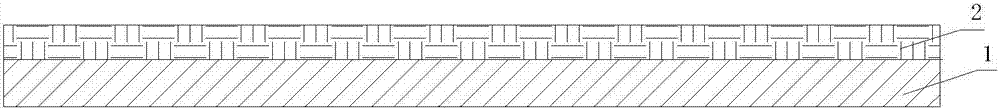

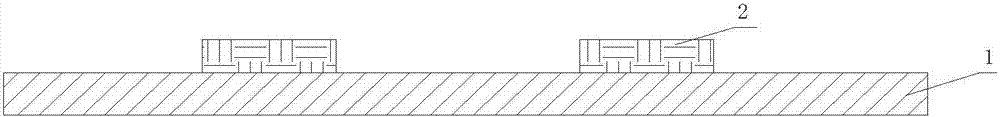

[0019] Such as figure 2 As shown, this embodiment relates to a method for preparing a metal mask, preferably, the metal mask is a precision metal mask; specifically, the method includes the following steps:

[0020] In step S1, a substrate 100 is provided. In an embodiment of the present invention, the substrate 100 can be a flexible substrate or a rigid substrate (such as a glass substrate, etc.), as long as the material of the substrate 100 can facilitate subsequent formation of organic substrates. The film 101 can be peeled off from the substrate 100, such as Figure 3a structure shown.

[0021] Step S2, forming a layer of organic film 101 on the substrate 100, since the step of forming the organic film 101 on the substrate 100 is not the focus of the improvement of the present invention, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com