Patents

Literature

119results about How to "Avoid influence of measurement results" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

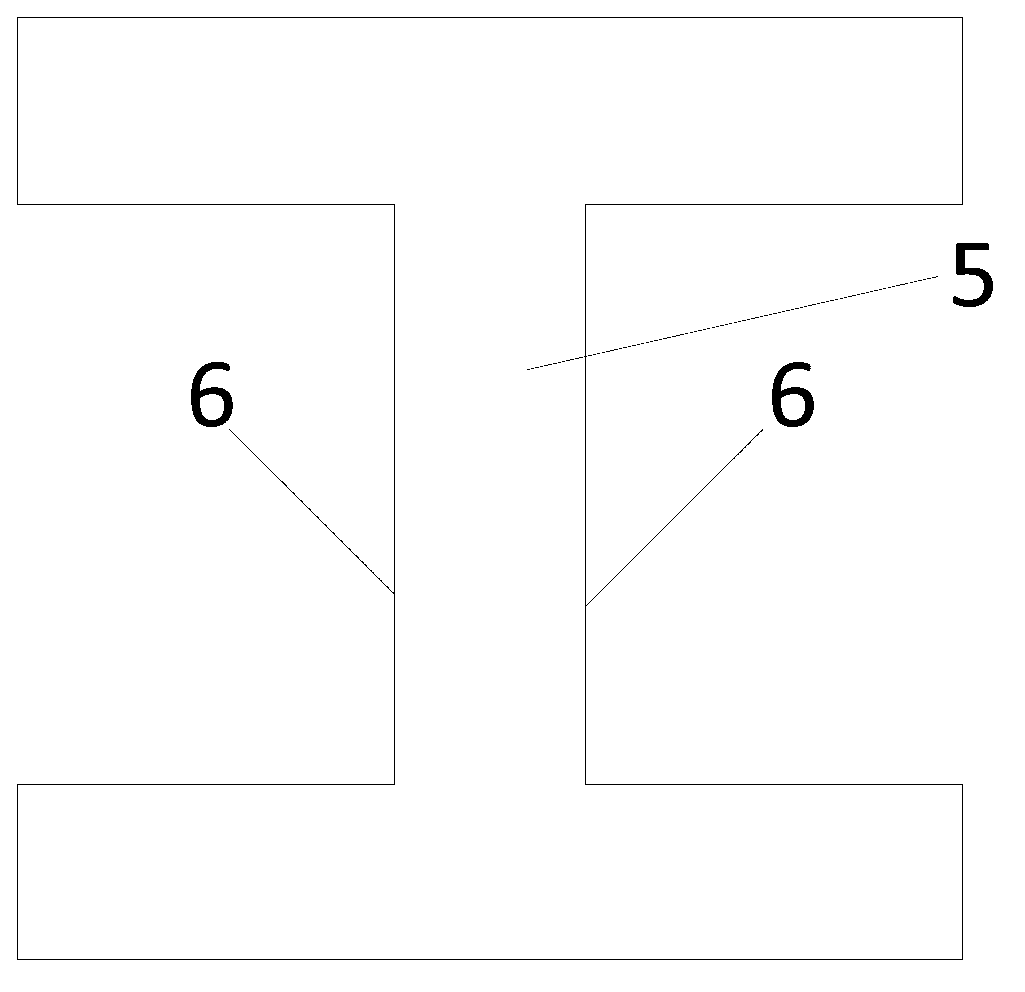

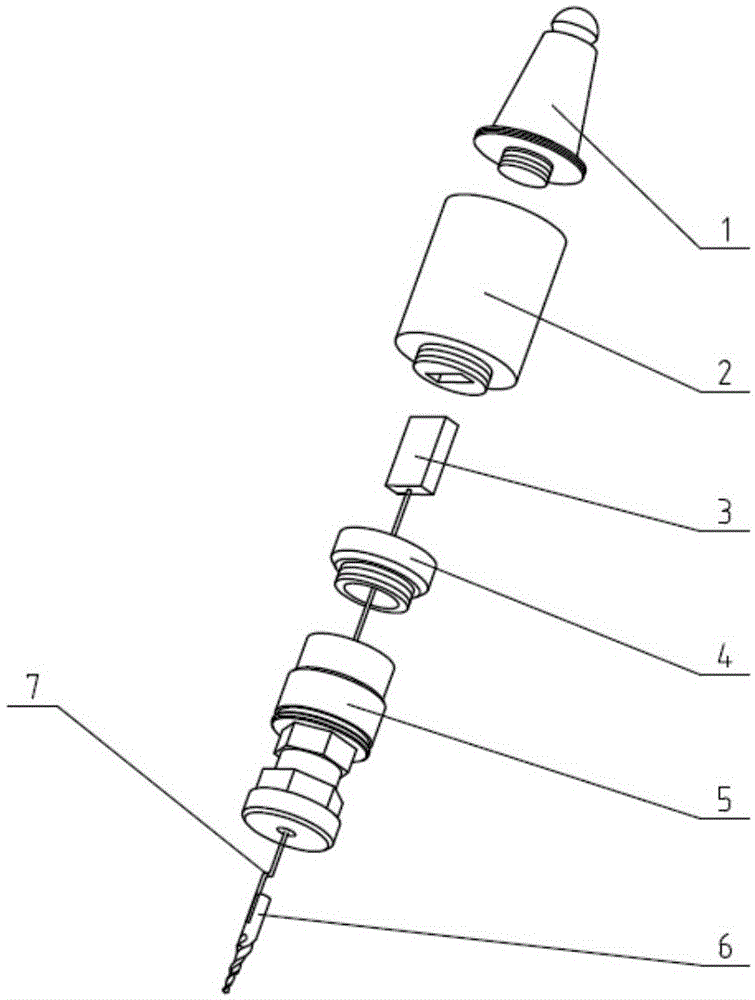

Vertebra support ranging device

PendingCN107374752AAvoid measurement errorsEasy to pull outDiagnosticsSurgeryVertebraResistance wire

The invention provides a vertebra support ranging device which comprises probing rods and a resistance wire. Each probing rod comprises a rod body and a probe, wherein the rod bodies are prepared from an insulation material, and the resistance wire and the probes are separated by the rod bodies. The probing rods comprise the first probing rod and the second probing rod. The resistance wire is arranged between the first probing rod and the second probing rod in a penetrating mode. By means of the principle of a slide rheostat, the distance between vertebra supports is measured; meanwhile, by means of an electronic display screen, the distance value can be directly read easily and conveniently.

Owner:SECOND AFFILIATED HOSPITAL SECOND MILITARY MEDICAL UNIV

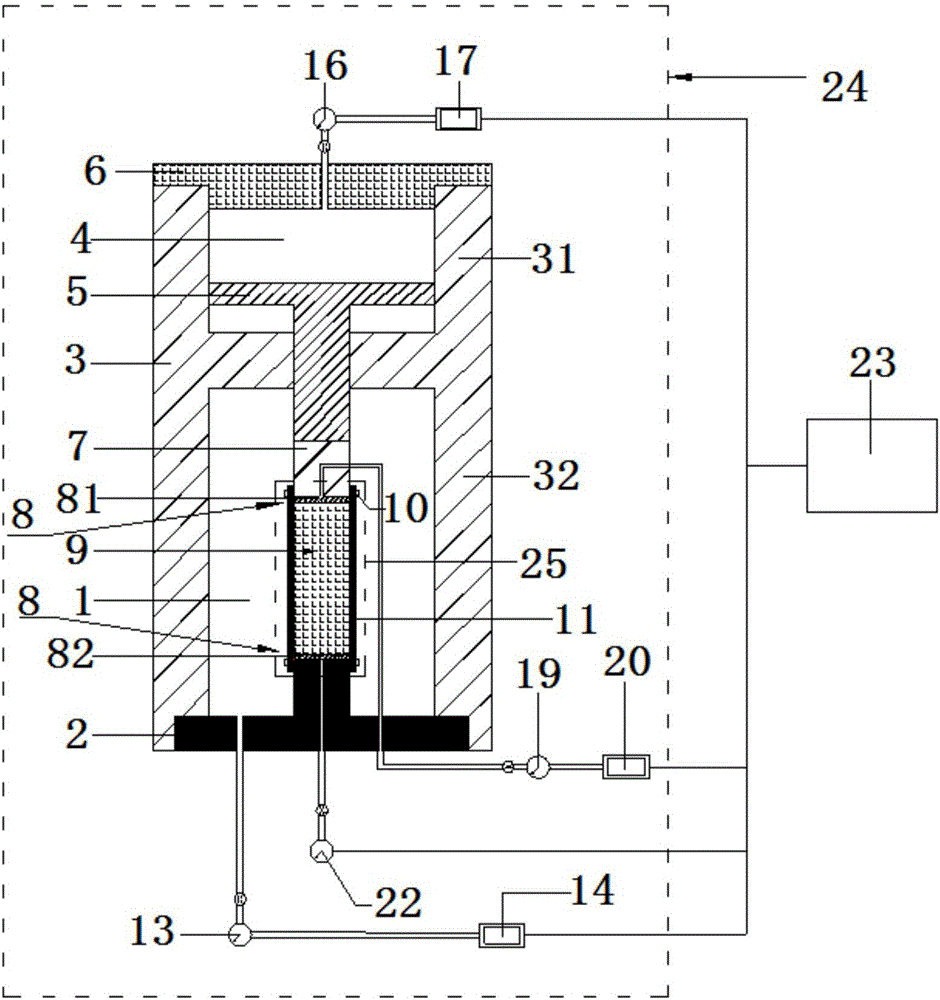

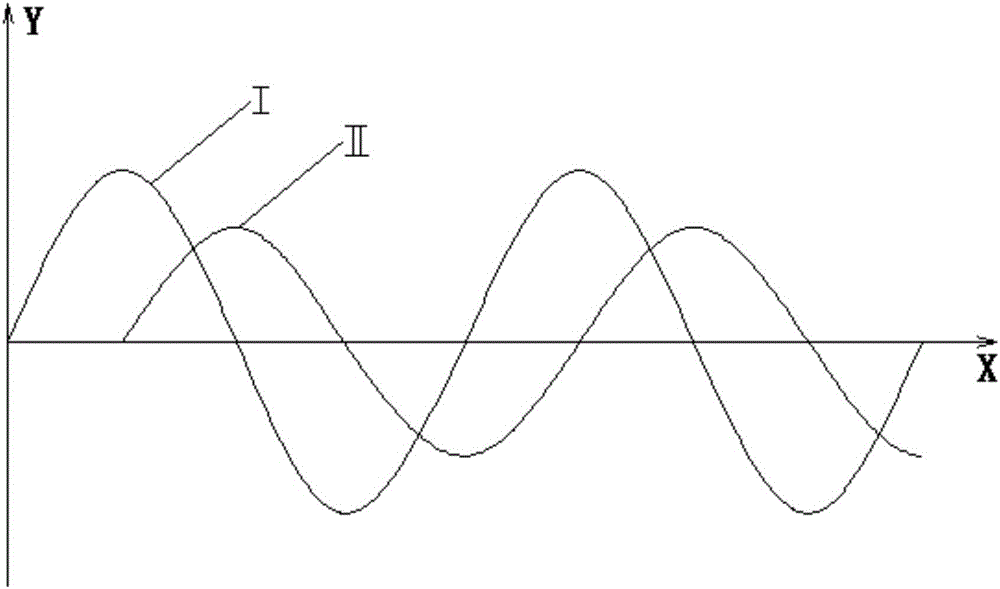

Method for measuring permeability of ultra-low permeability rocks under tri-axial stress effect

InactiveCN106290118AEasy to measureSimulate Triaxial Stress StatePermeability/surface area analysisAxial pressureStressed state

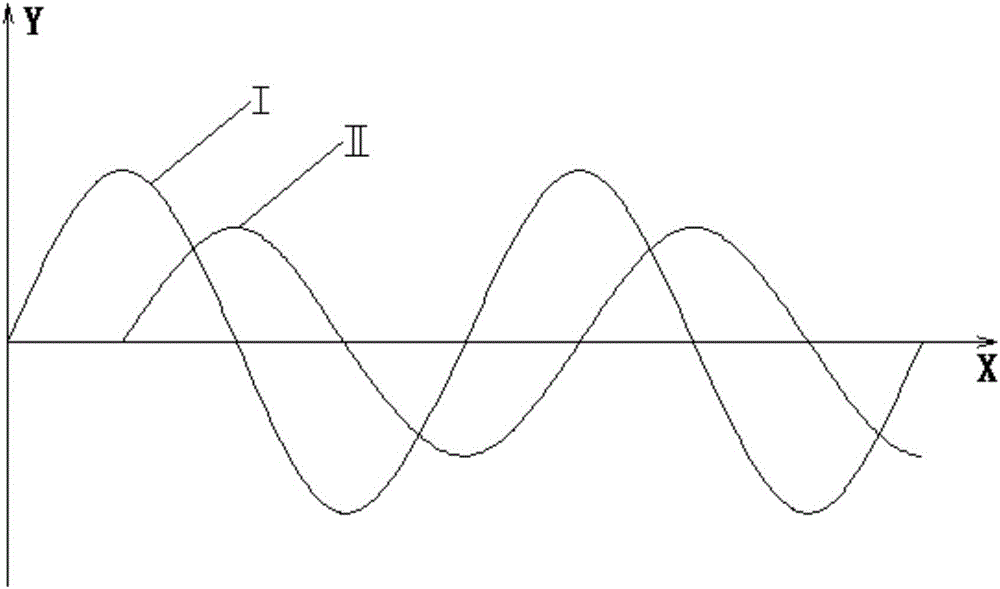

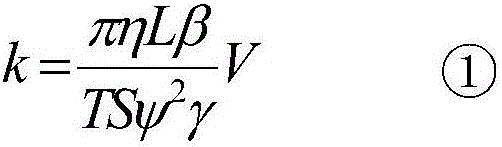

The invention discloses a method for measuring permeability of ultra-low permeability rocks under a tri-axial stress effect. The method comprises the following steps of: selecting an ultra-low permeability rock, and preparing a test sample; wrapping water permeable liner plates at the upper end and the lower end of the test sample and the test sample between an upstream porous pressure cushion block and confining pressure chamber base by using a rubber sleeve; applying confining pressure and axial pressure to the test sample to a given value, simultaneously applying permeation pressure to the test sample, and saturating the test sample; after the osmotic pressure saturation of the test sample, applying a sinusoidal pressure wave with a known amplitude and a known frequency to the test sample, recording a downstream pore pressure wave situation, and transmitting the data to a data measurement and acquisition system in real time; changing the confining pressure and the axial pressure, measuring the permeability by using a waveform correlation method, analyzing the permeability of the test sample under different confining pressure and axial pressure situations, and obtaining the permeability under different confining pressure and axial pressure conditions. By adopting the method for measuring the permeability of the ultra-low permeability rocks under the tri-axial stress effect, the weaknesses of the prior art that the measurement precision is poor, only the confining pressure can be provided, and the stress state of the deep rock under the tri-axial stress effect cannot be actually simulated can be overcome.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

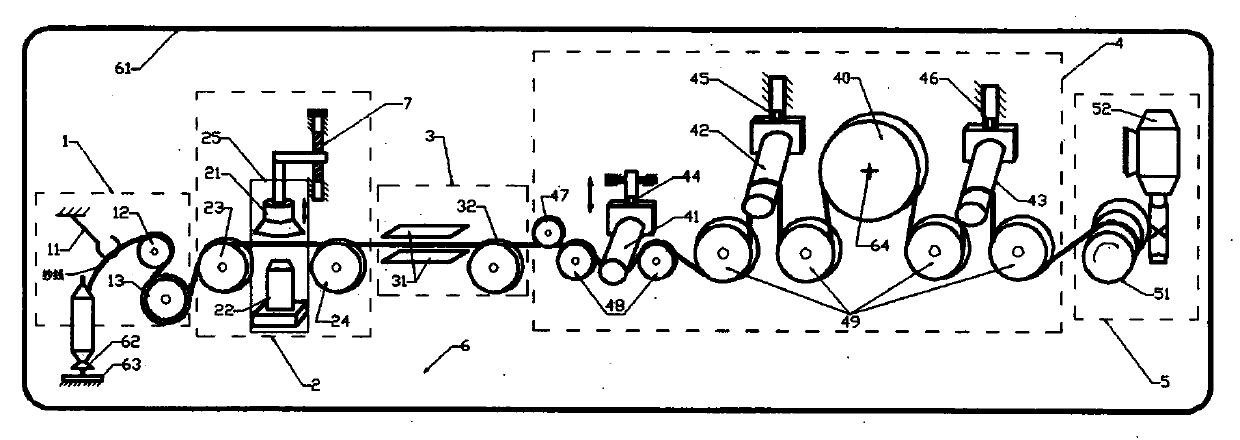

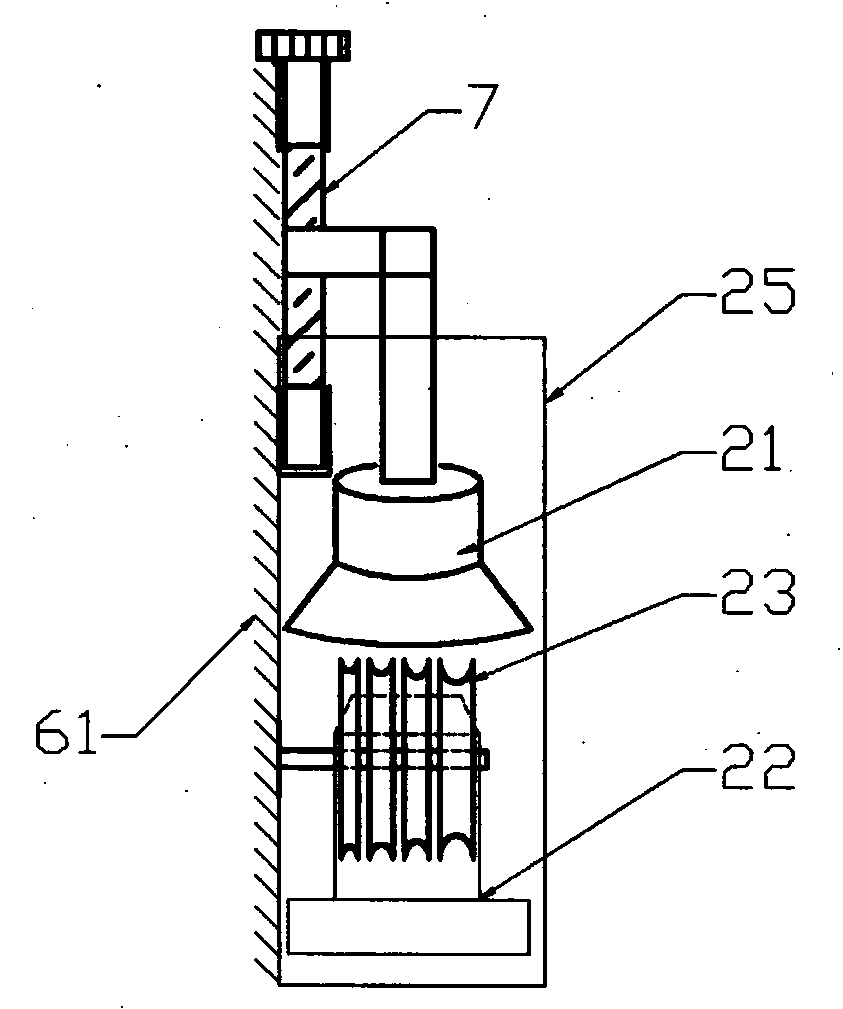

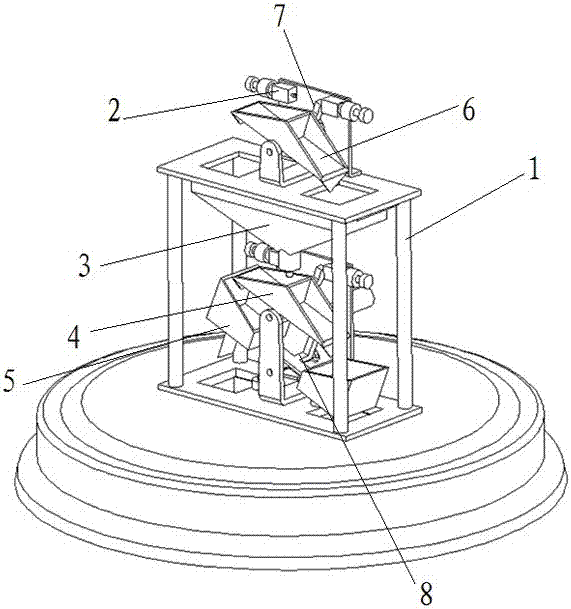

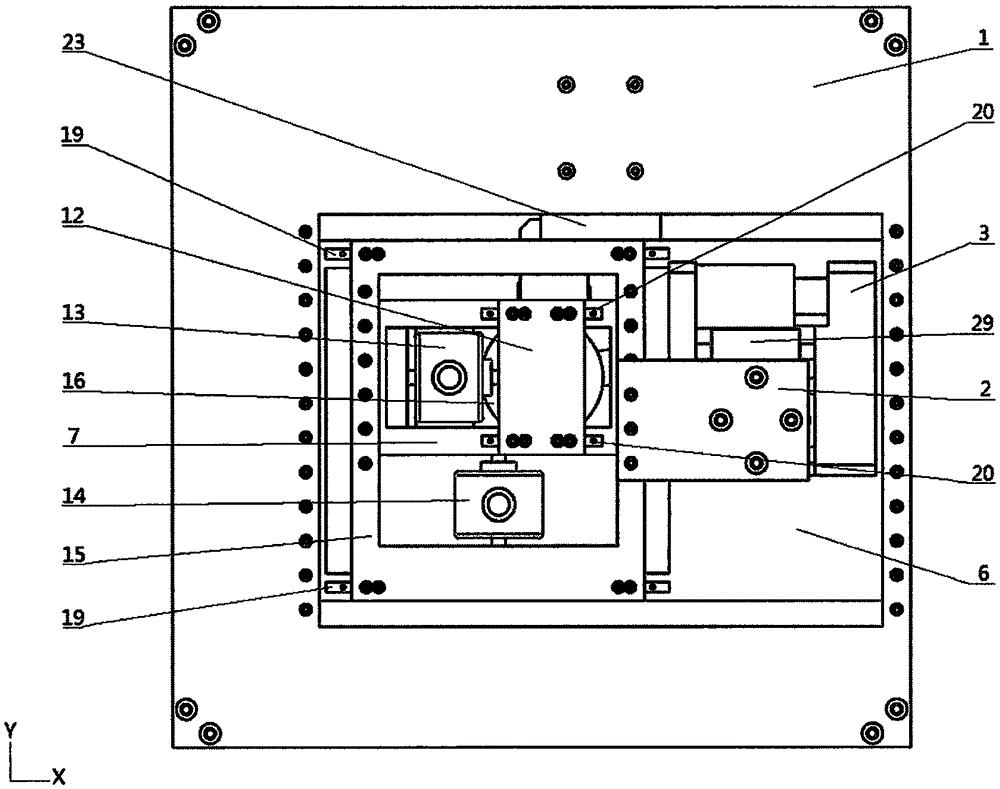

Device and method for measuring curvature, friction, evenness and hairiness of yarn in combined mode

InactiveCN103727976ASmall footprintLow costMaterial analysis by optical meansMaterial strength using steady bending forcesYarnCapacitance

The invention relates to a device and method for measuring curvature, friction, evenness and hairiness of yarn in a combined mode. The device is composed of a yarn guiding mechanism, a hairiness measuring mechanism, an evenness measuring mechanism, a force measuring mechanism, a dragging and winding mechanism and a bottom plate assembly and is further composed of a corresponding form and force signal collecting, driving control and processing system and a computer. The method for achieving the device comprises the steps that yarn is guided through the yarn guiding mechanism, and the yarn is dragged through the dragging and winding mechanism; the hairiness measuring mechanism is used for horizontally supporting the yarn and extracting the surface hairiness of the yarn, and the hairiness index is obtained through the processing system; a capacitance plate of the evenness measuring mechanism is used for obtaining the evenness of the yarn; a bending mechanism, composed of a pressing needle and double carrier rollers, of the force measuring mechanism is used for bending the yarn, and then the yarn anti-bent strength is obtained; a friction roller of the force measuring mechanism rubs with the yarn, the tension of the yarn before being input into the friction roller and the tension of the yarn after being input into the friction roller are obtained, and then the yarn friction coefficient is obtained. The device and method have the advantage of combining optics, electrics and mechanics measurement.

Owner:DONGHUA UNIV

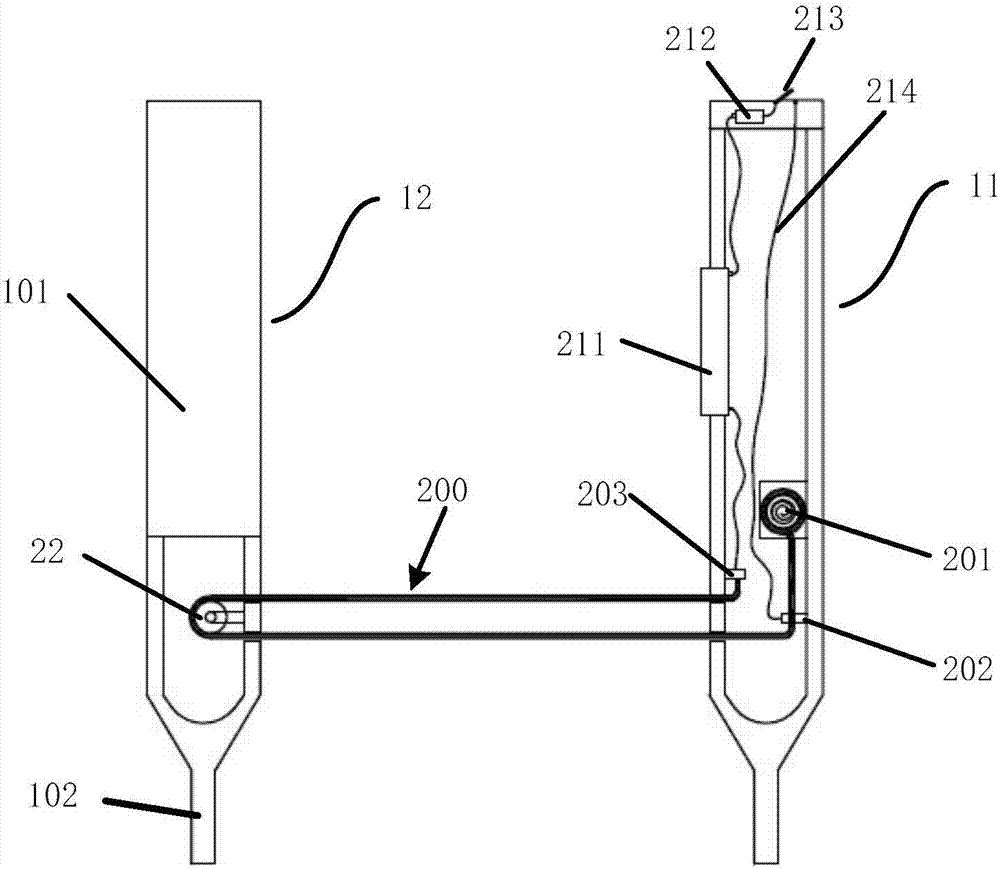

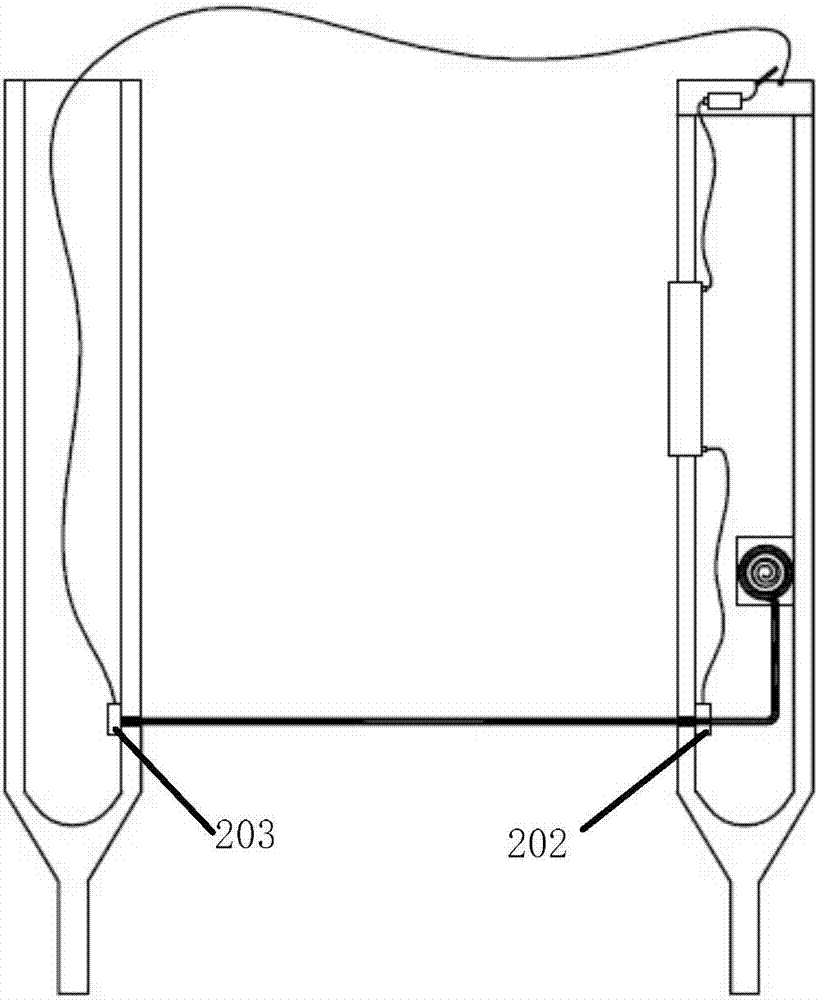

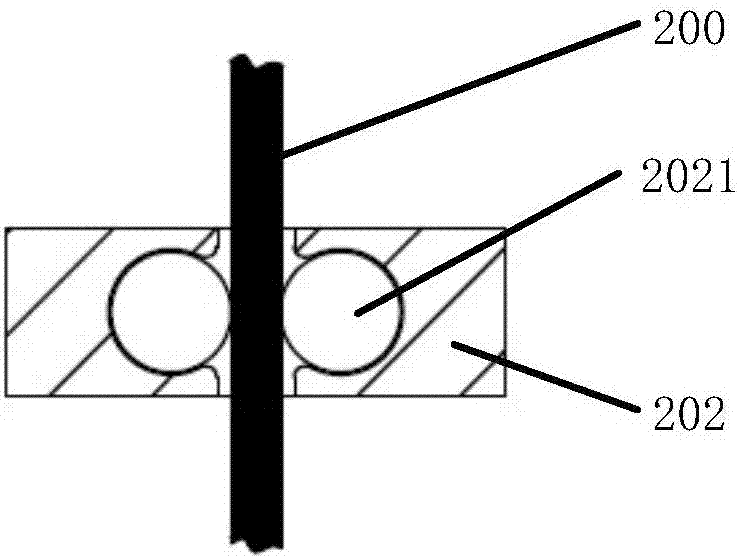

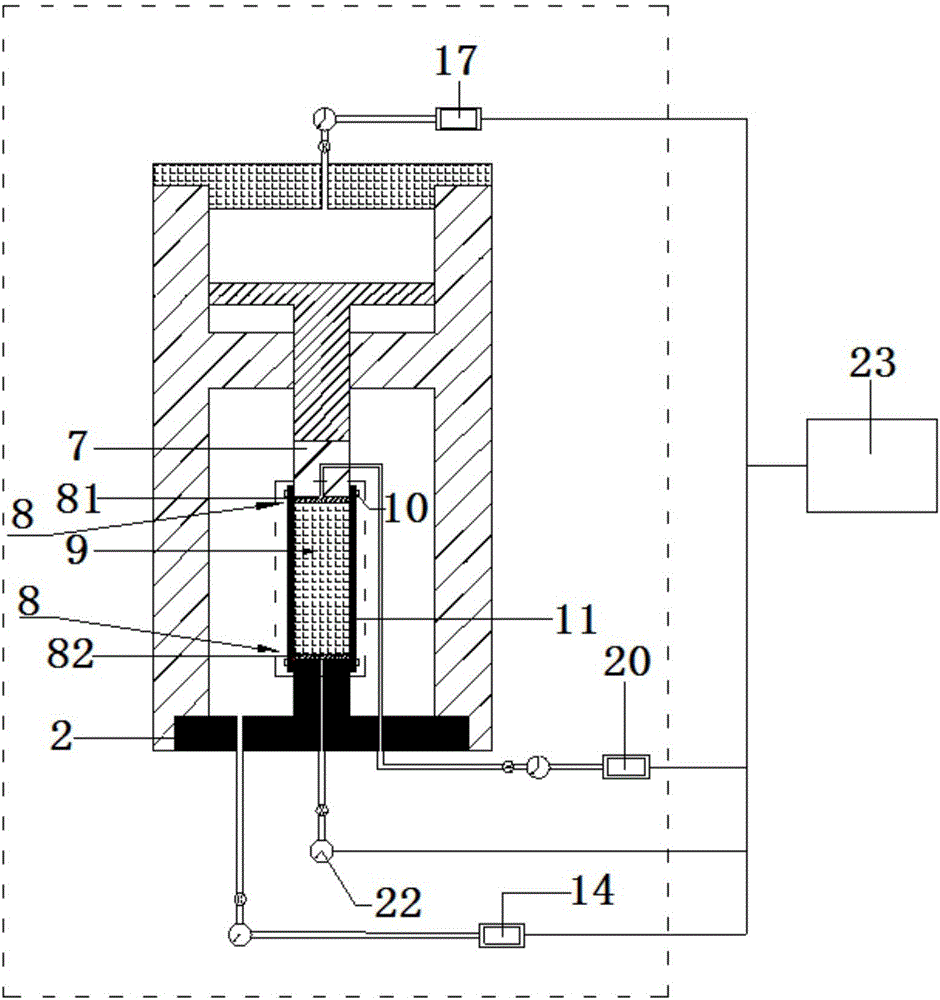

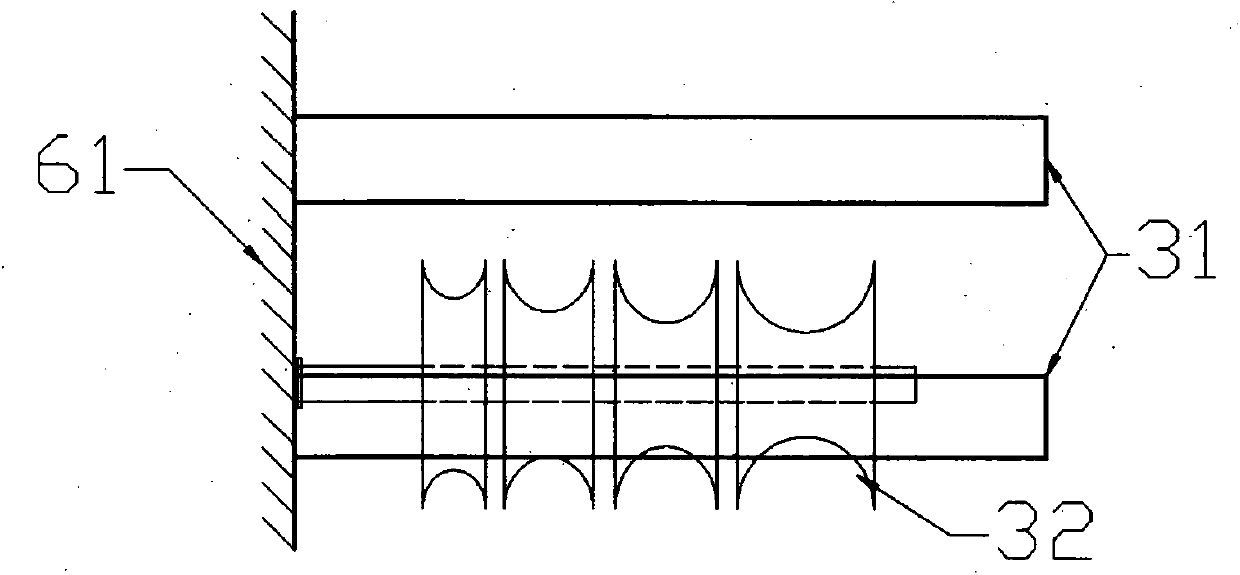

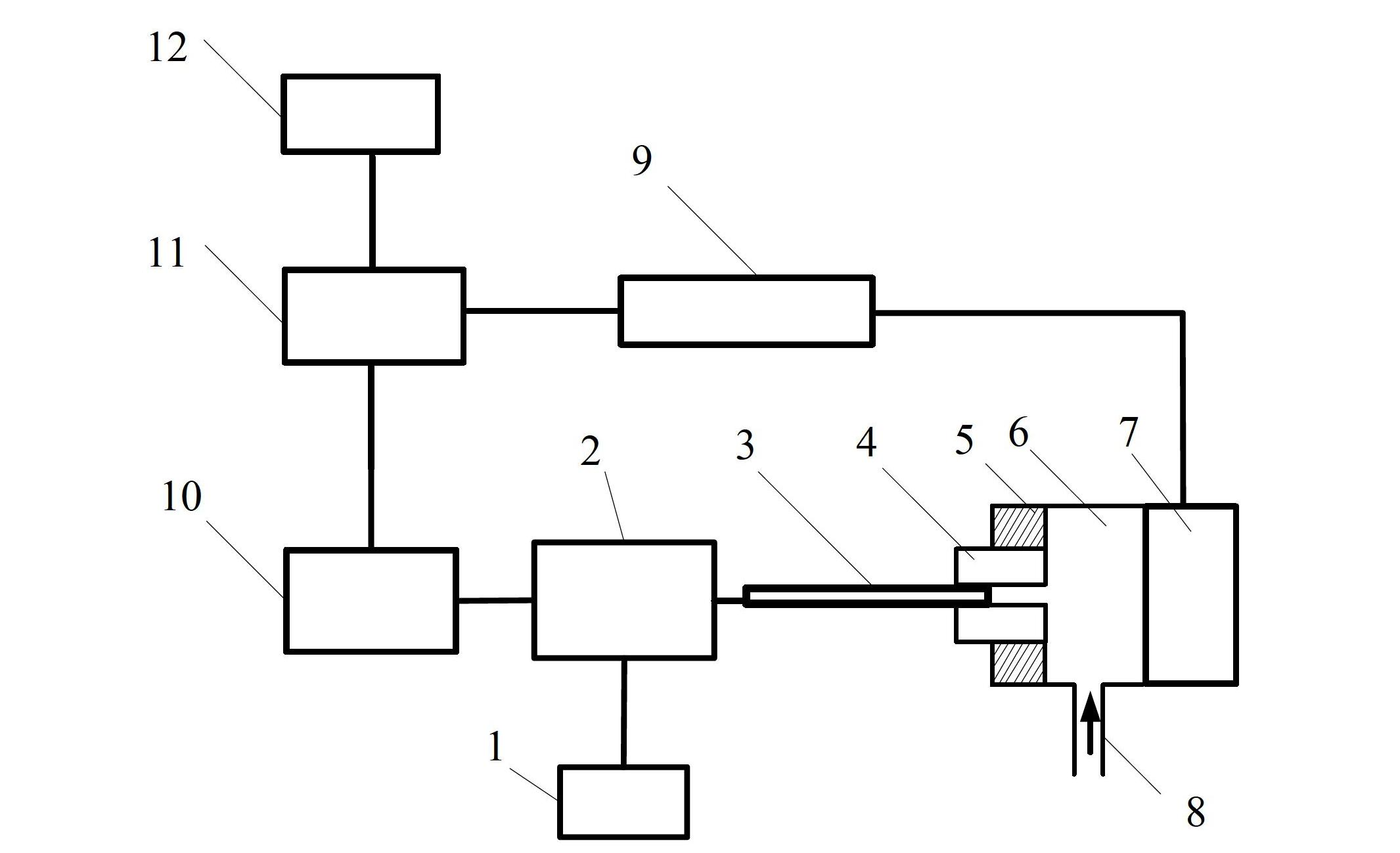

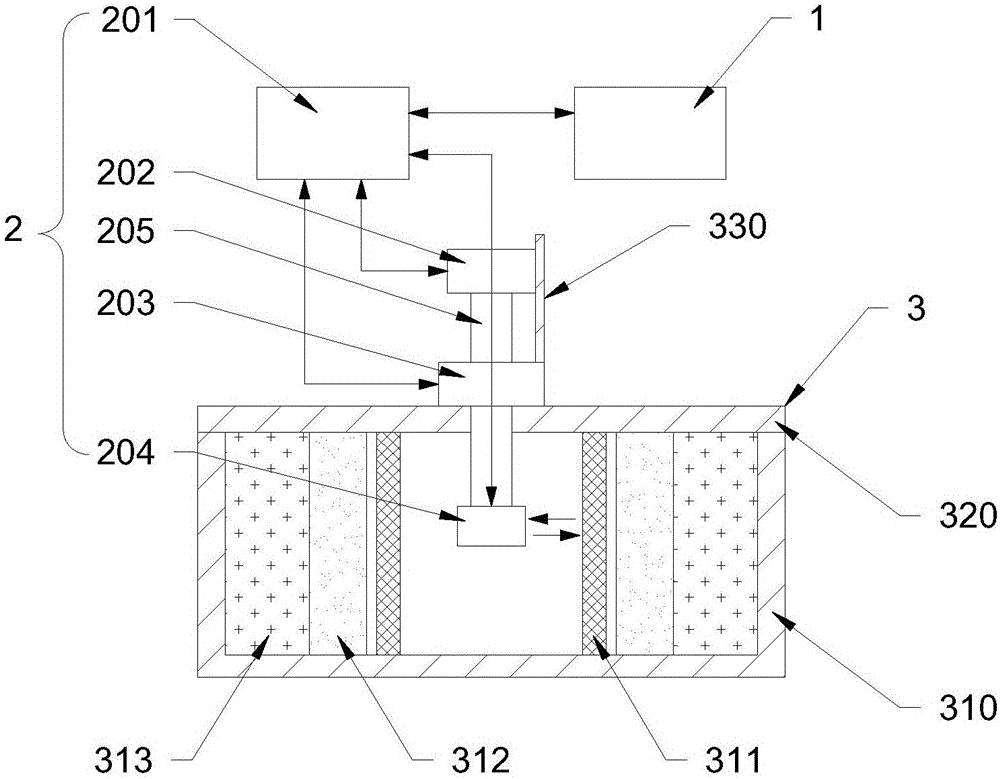

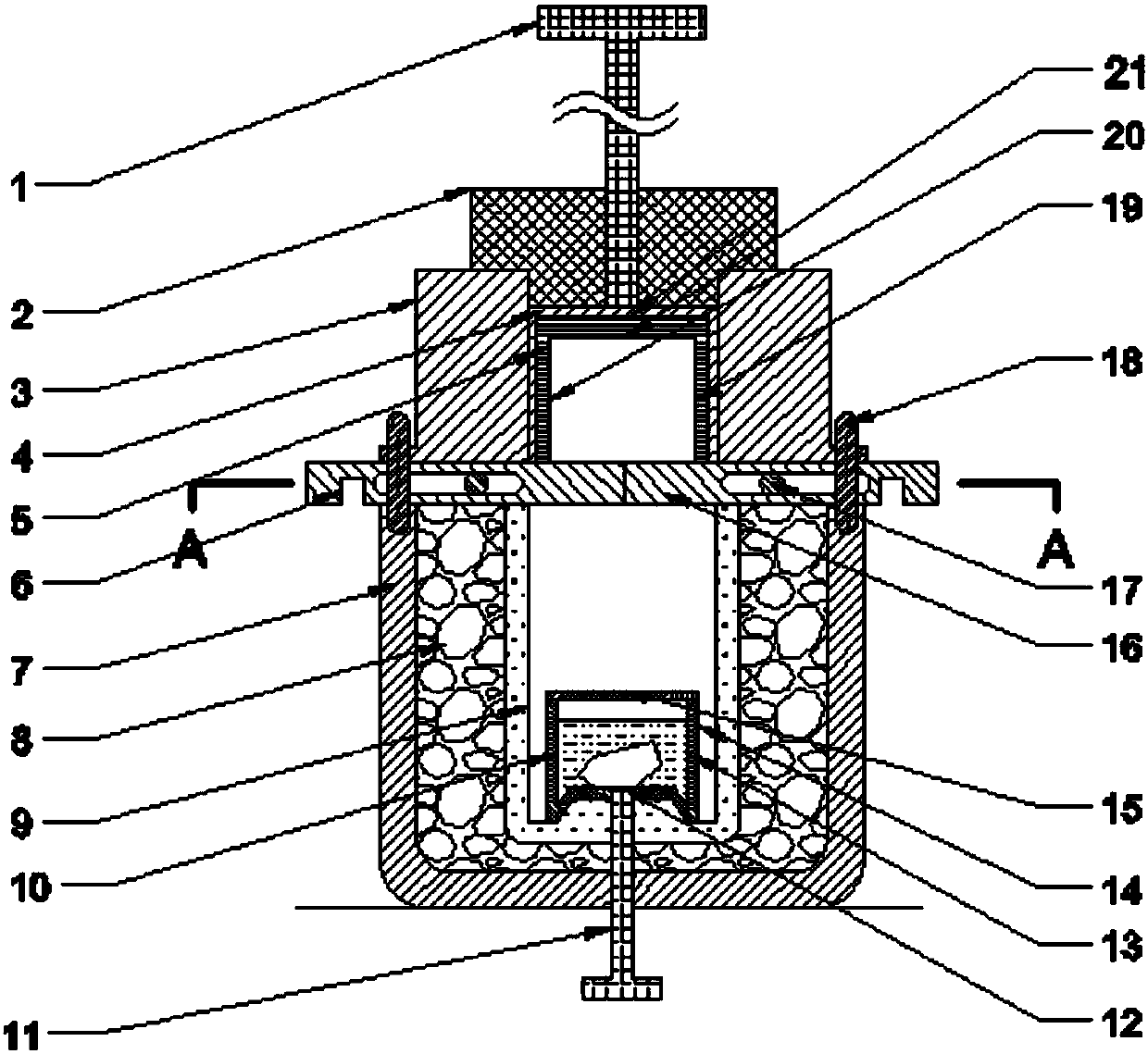

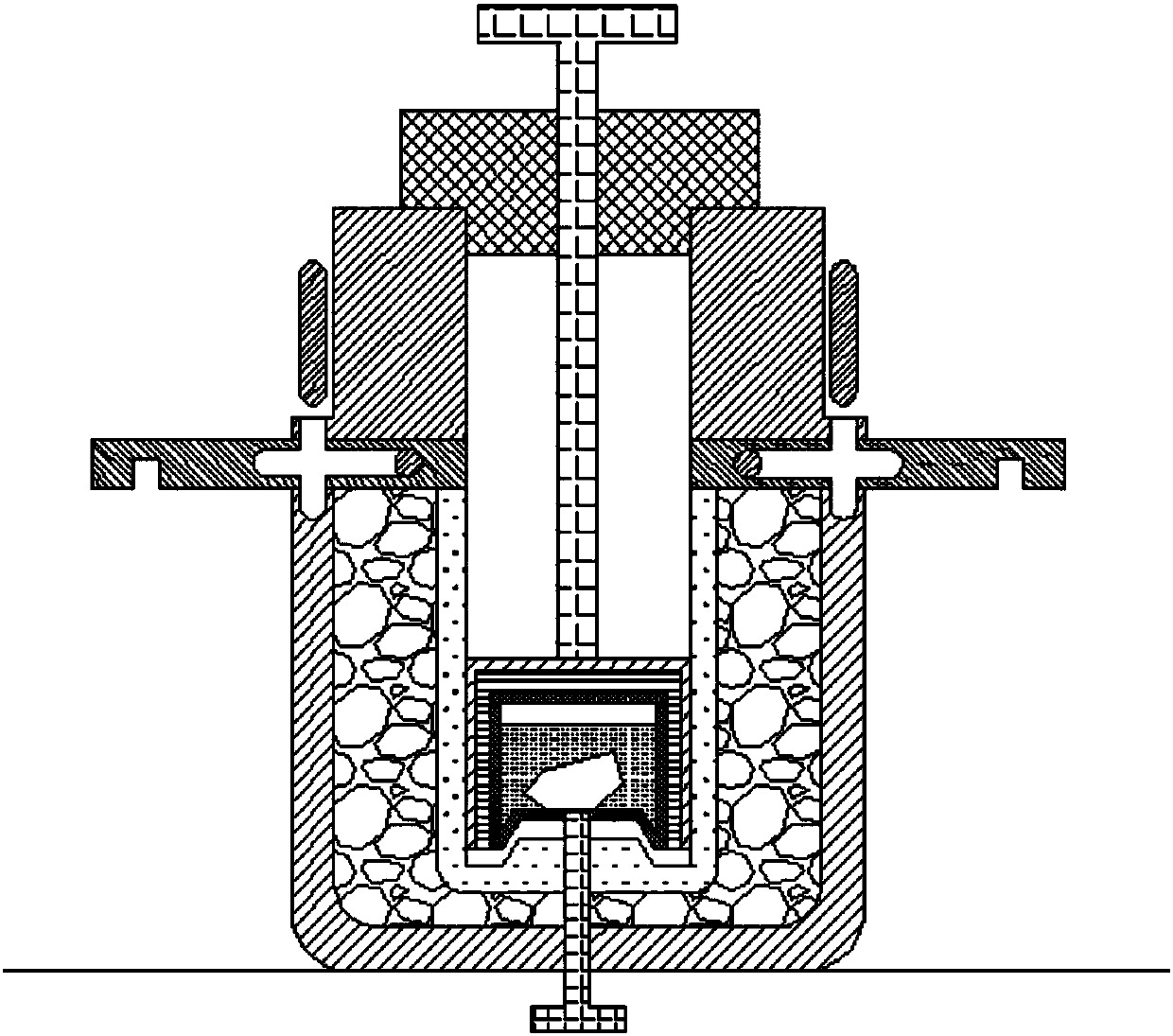

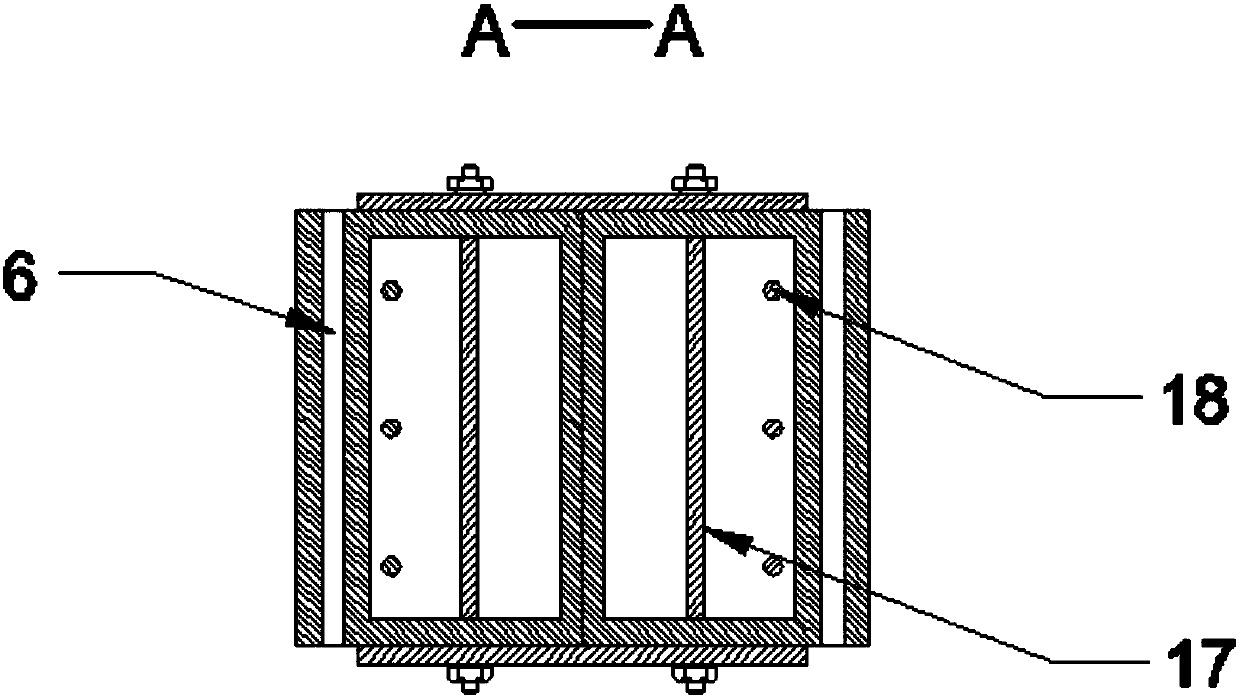

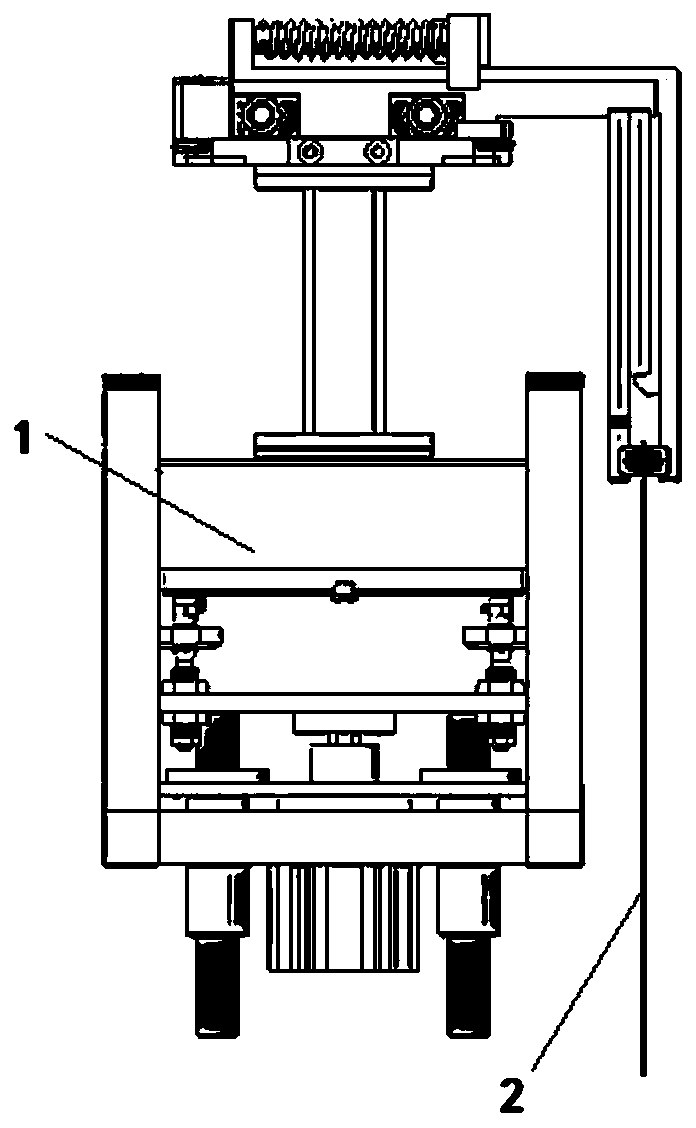

Device for measuring permeability of ultra-low permeability rocks under action of triaxial stress

PendingCN106323841AEasy to measureSimulate Triaxial Stress StatePermeability/surface area analysisPressure systemAxial pressure

The invention discloses a device for measuring the permeability of ultra-low permeability rocks under the action of triaxial stress, relating to the field of rock mechanics testing in the geotechnical engineering technique. The device comprises a data acquisition and processing system and a triaxial pressure system, wherein the triaxial pressure system comprises a confining pressure chamber, an axial pressure chamber, a testing chamber, a confining pressure closed loop servo metering pump, an axial pressure closed loop servo metering pump and an osmotic pressure closed loop servo metering pump; an axial pressure chamber cylinder barrel is connected to the upper end of a confining pressure chamber cylinder barrel and is fixedly sealed and connected with the confining pressure chamber cylinder barrel into a whole by bolts; the data acquisition and processing system is arranged outside the triaxial pressure system and is connected on the triaxial pressure system by the confining pressure closed loop servo metering pump, the axial pressure closed loop servo metering pump and the osmotic pressure closed loop servo metering pump respectively. The device overcomes the defects that the prior art has poor measurement accuracy, can only provide confining pressure and can not really simulate the stress state of the deep rock mass under the action of triaxial stress.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

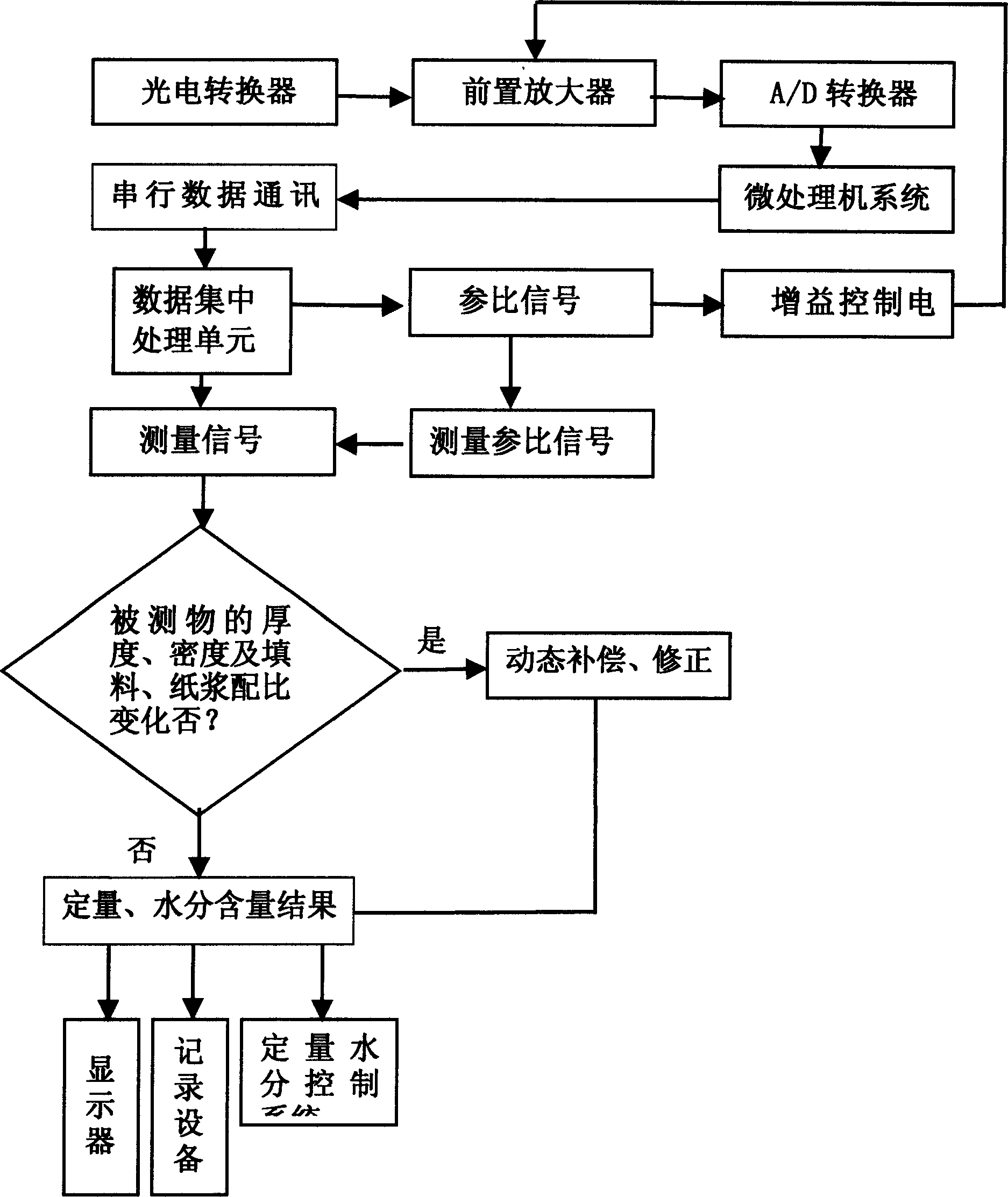

Near infrared quantitative water content measurement method for paper

ActiveCN1800825AEnables real-time process detectionNo radioactive contaminationColor/spectral properties measurementsAudio power amplifierEngineering

The quantitative moisture measurement method for near infrared paper comprises: modulating the infrared light into near infrared lights with different wavelength and arranged as chronological order to reflect with a reflector to the emission integral semisphere to reflect and cross the paper to focus on a optical-electrical converter, sending the converted electric signal to microprocessor for pretreatment; then, transmitting into a data centralized processing unit to recognize and divide into reference signal with one path to control front amplifier and another path as the reference signal and measurement signal; calculating in the processing unit to obtain quantitative moisture content. This invention realizes online measurement with high accuracy and low cost.

Owner:西安力源光电科技有限责任公司

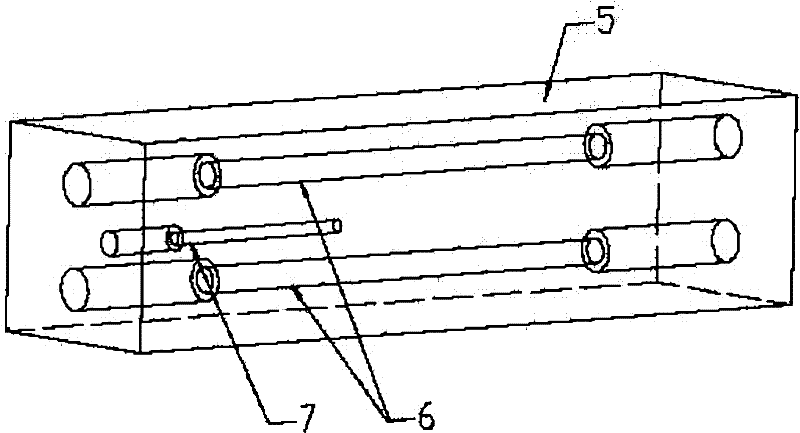

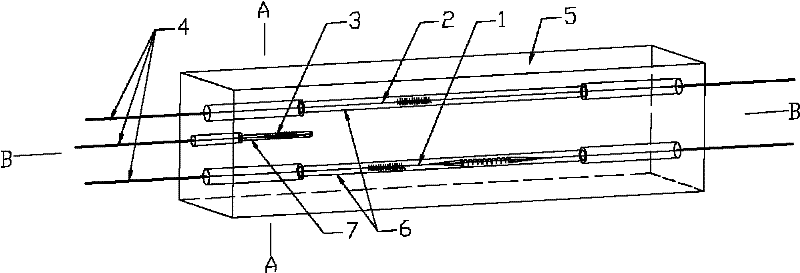

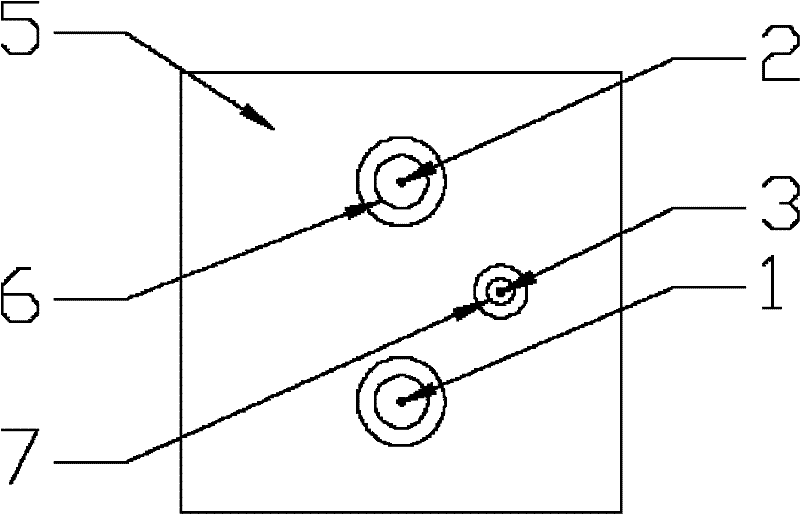

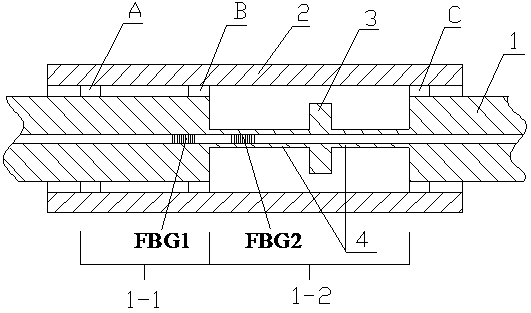

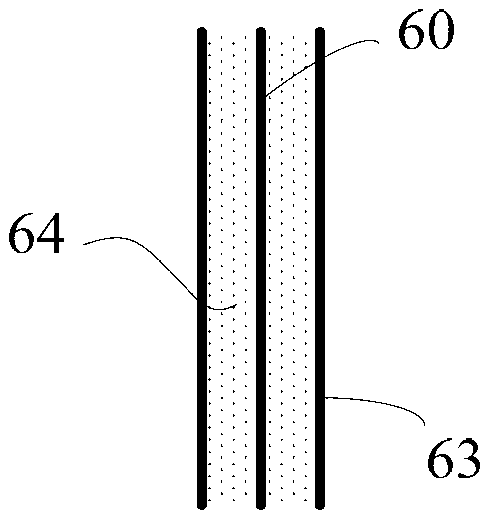

Hybrid-range FBG (fiber bragg grating) strain and crack sensor for concrete material package

InactiveCN102243066AAdd temperature compensationIncrease effective lengthUsing optical meansGratingAdhesive

The invention discloses a hybrid-range FBG (fiber bragg grating) strain and crack sensor for a concrete material package. The sensor comprises a pre-cast concrete material package structure, a spring FBG firmly combined with a micro spring, a pure FBG, a temperature sensor, two penetration grooves, a temperature sensing area and an armored optical cable. Firstly, the pure FBG and the spring FBG firmly combined with the micro spring are embedded in the two penetration grooves, then, one segment of two groups of the FBG is firmly combined with a die through a high-performance adhesive, a tension pre-stress is applied on the two groups of the FBG, and then, the other end of each one of the two groups of the FBG is firmly combined, the temperature sensor is embedded in the package structure, and finally, the armored optical cable is used for connecting the two groups of the led out FBG and the temperature sensor. The hybrid-range FBG strain and crack sensor is suitable for structural health monitoring in various concrete structures of civil engineering, is simple in technology, convenient to arrange, high in accuracy and wide in range, and can monitor internal strain and cracks in overall process of destroying the concrete structure by pulling and pressing.

Owner:DALIAN UNIV OF TECH

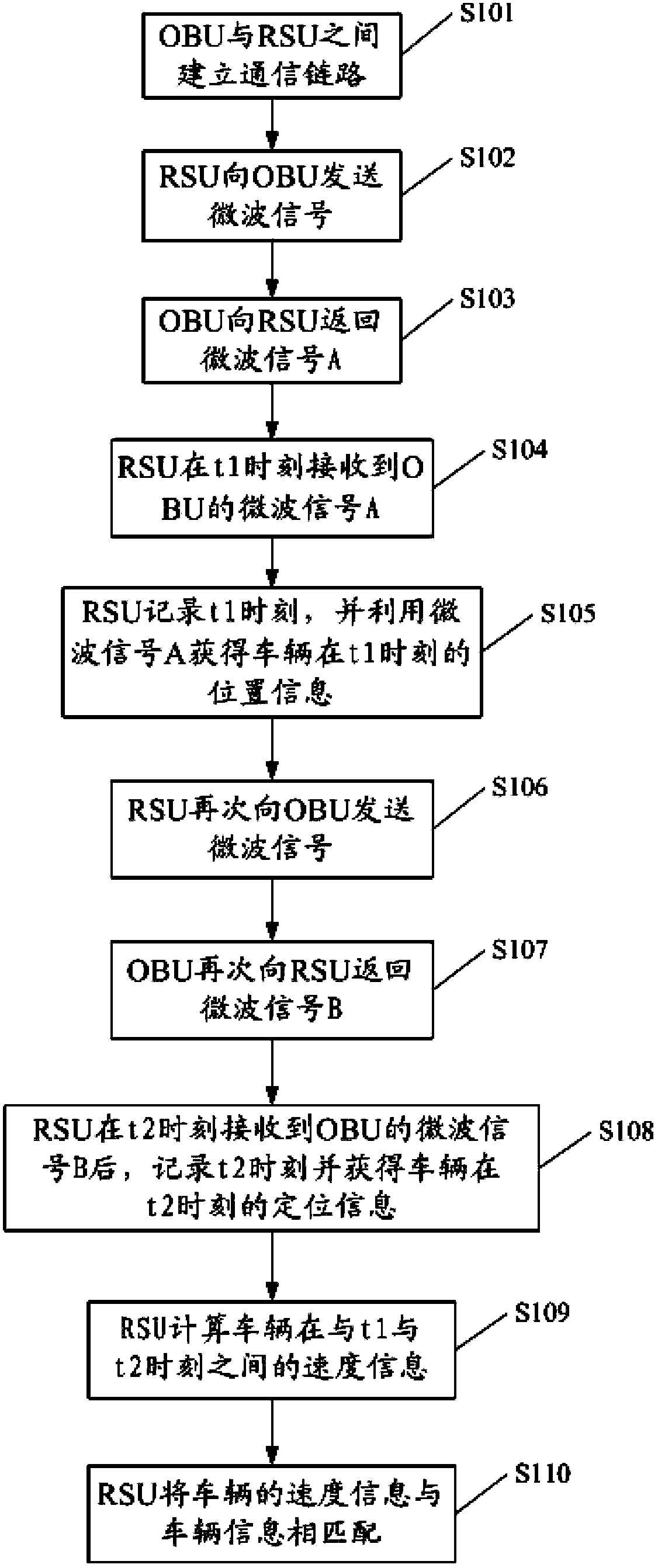

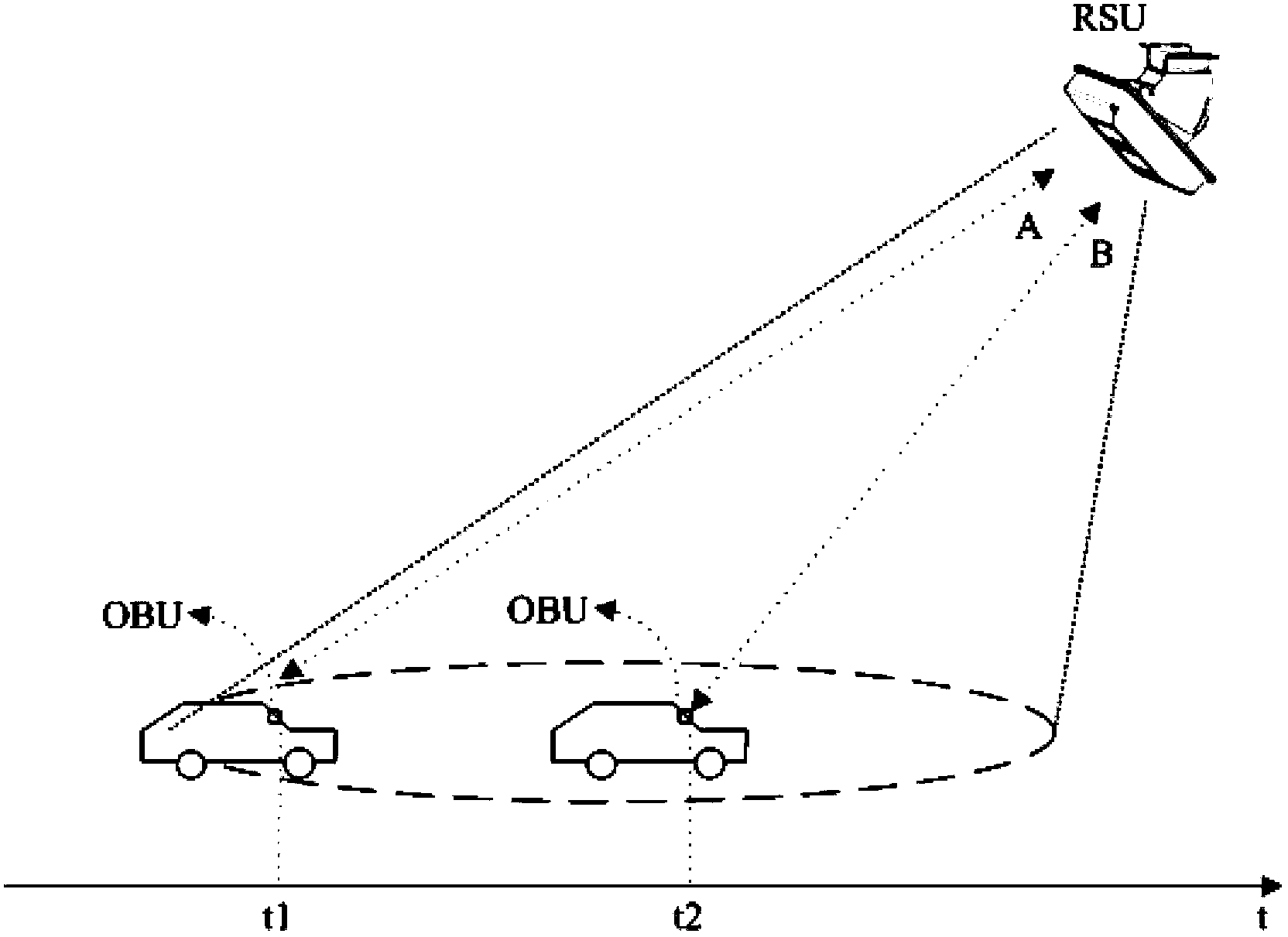

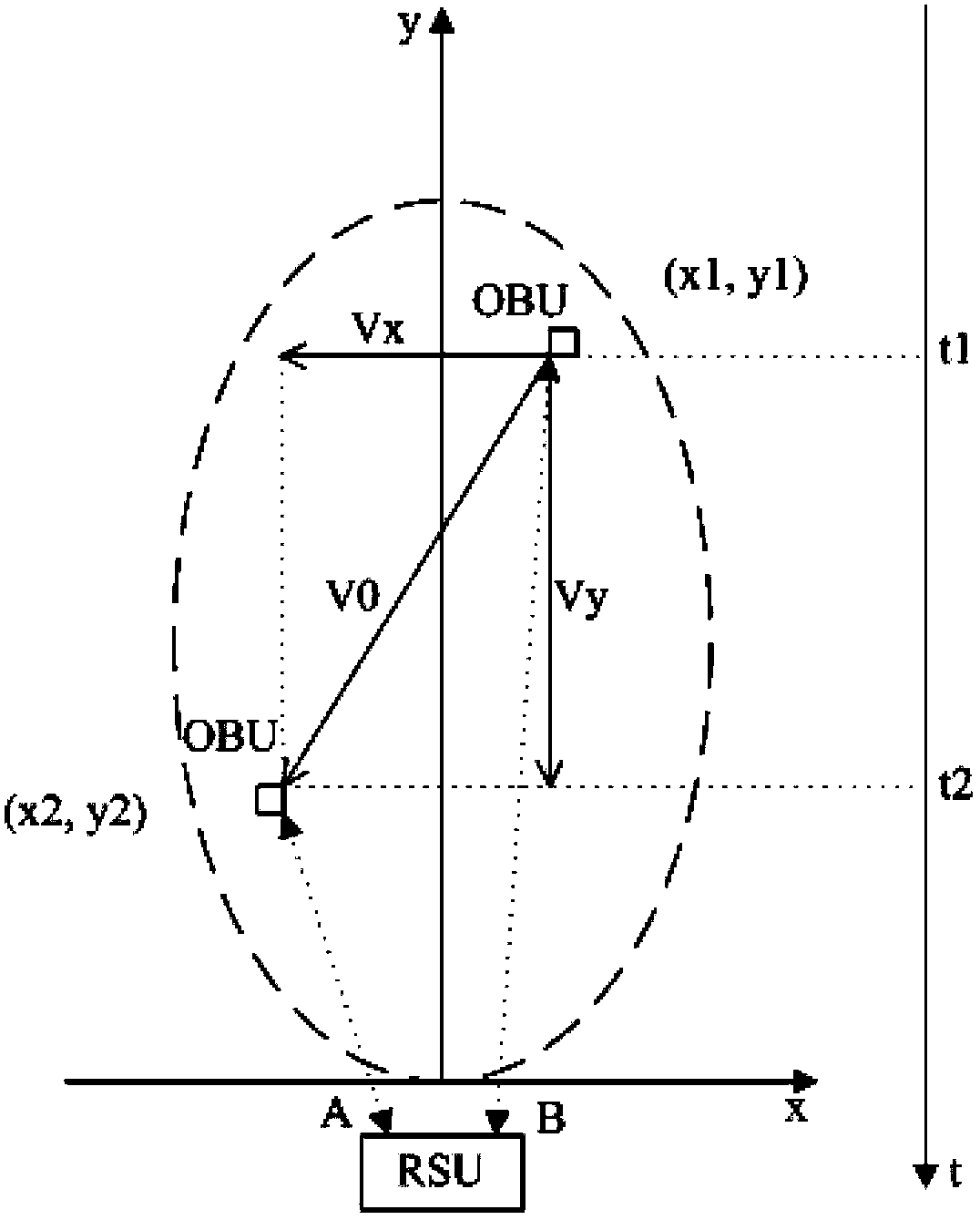

DSRC-based vehicle speed measuring method and device, and DSRC application system

ActiveCN103514746AExtended functional scopeExpand the scope of useTicket-issuing apparatusRoad vehicles traffic controlEngineeringMicrowave signals

The invention discloses a DSRC-based vehicle speed measuring method and device, and a DSRC application system. The method comprises the following steps: a RSU is used to receive a plurality of microwave signals sent by a vehicle through an OBU, wherein at least one microwave signal carries the vehicle information of the vehicle, at least two microwave signals correspond to a t1 moment and a t2 moment respectively, and the time interval between the t1 moment and the t2 moment is t0; the RSU is used to acquire the positioning information of the vehicle at the t1 moment according to the microwave signal of the t1 moment, and acquire the positioning information of the vehicle at the t2 moment according to the microwave signal of the t2 moment; and the RSU is used to calculate the distance information of the vehicle between the t1 moment and the t2 moment by utilizing the positioning information of the t1 moment and the positioning information of the t2 moment of the vehicle, and calculate the speed information of the vehicle between the t1 moment and the t2 moment according to the distance information and the time interval t0. According to the invention, the vehicle speed measuring process can be simplified, the vehicle can be positioned accurately, and functions of existing DSRC equipment can be extended.

Owner:SHENZHEN GENVICT TECH

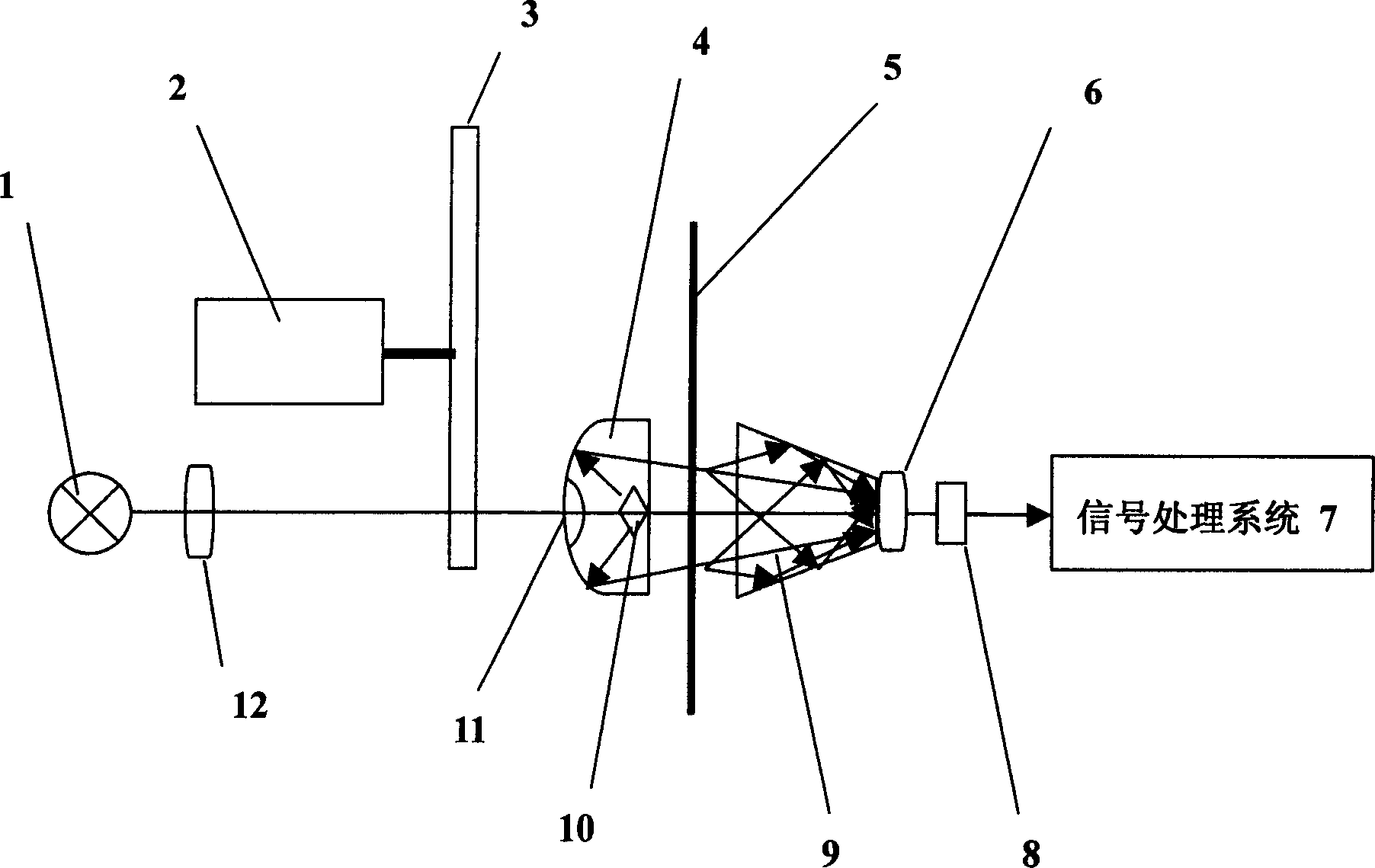

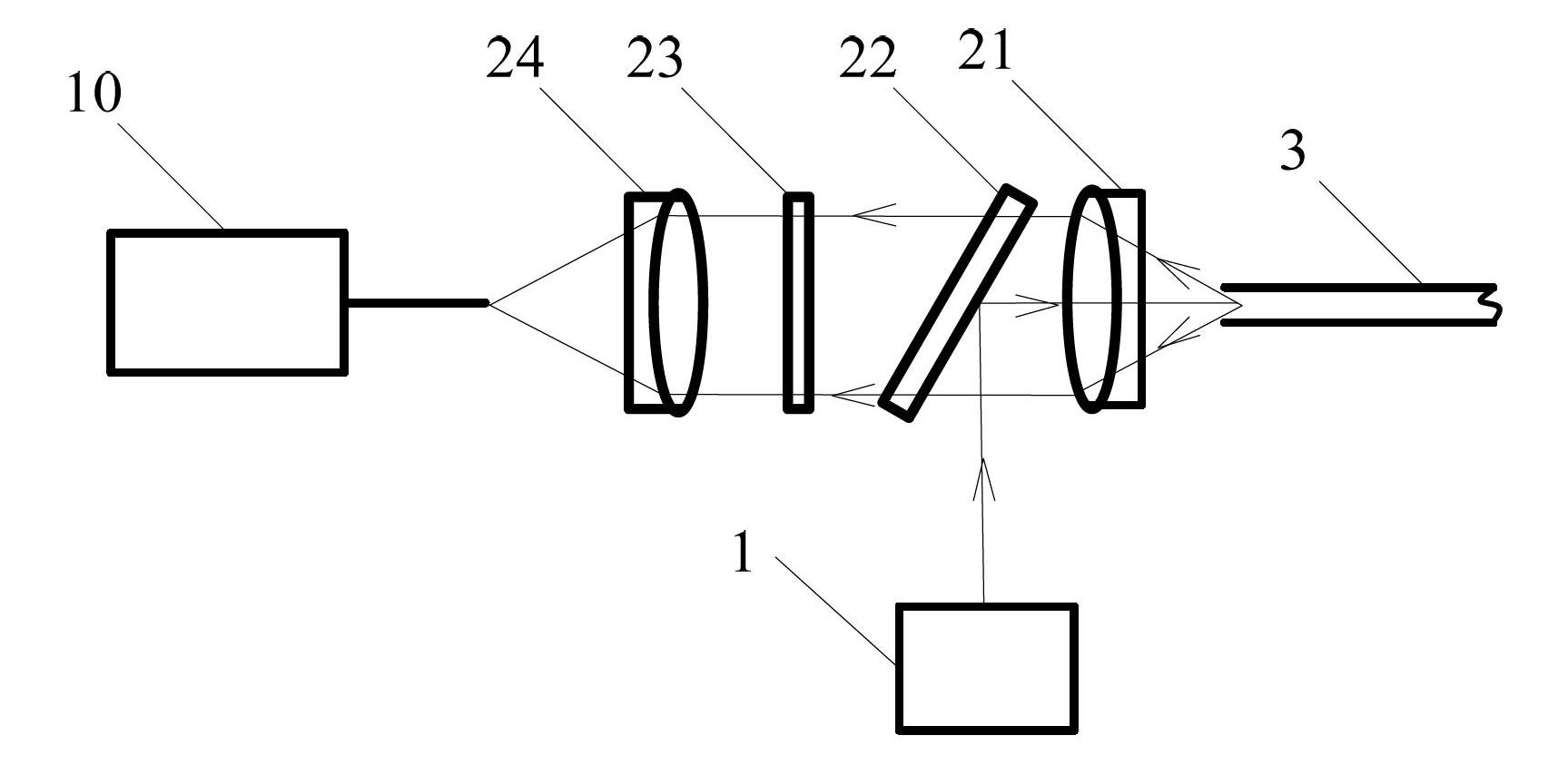

System for removing Raman spectral scattering background noise

ActiveCN102680451AAvoid influence of measurement resultsPracticalRaman scatteringGas analysisSignal generator

The invention discloses a system and a method which are based on a vibrating charger and cooperate with a lock phase amplifier to remove the background noise produced by a capillary tube and the like in gas Raman scattering. The invention includes a vibrator and a lock phase amplification method. The vibration generated by the vibrator drives the gas in the glass capillary tube to produce tiny waves, consequently, the number of gas molecules in the capillary tube is changed, and a gas molecule Raman scattering signal which is fluctuated at fixed frequency is obtained. By means of the reference frequency provided by a signal generator, the lock phase amplifier extracts the gas molecule Raman scattering signal fluctuated at the frequency from a total Raman scattering signal. The invention overcomes the affection of background scattering noise on a measuring result in the process of Raman gas analysis and testing, and solves the defect that various systems cannot thoroughly remove background noise. The gas Raman scattering detection system provided by the invention has a simple structure, is convenient to operate, and is highly practical.

Owner:HUAZHONG UNIV OF SCI & TECH +1

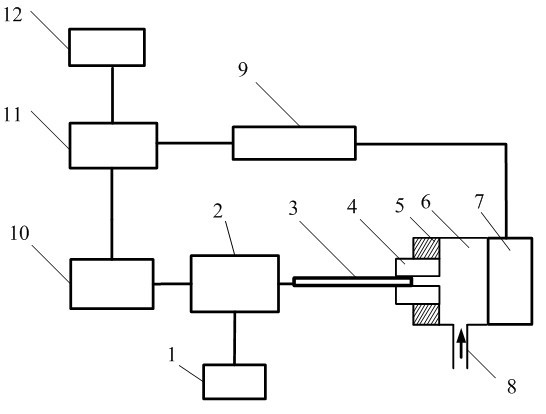

Quasi-distributed fiber sensor capable of measuring temperature and vibration simultaneously and manufacturing method

ActiveCN103323143ASmall sizeAvoid influence of measurement resultsSubsonic/sonic/ultrasonic wave measurementThermometers using physical/chemical changesVibration measurementGrating

Provided is a quasi-distributed fiber sensor capable of measuring the temperature and vibration simultaneously. The fiber sensor comprises common single mode fibers and a protective casing. The inner wall of the protective casing is welded with the outer walls of the common single mode fibers. The common single mode fiber between a first welding position and a second welding position forms a temperature correction section, and a first Bragg grating is arranged on the temperature correction section. The common single mode fiber between the second welding position and a third welding position forms a vibration measurement section, a vibration amplification block is arranged in the middle of the vibration measurement section, and the two sides of the vibration measurement section are provided with two vibrating beams respectively; a second Bragg grating is arranged on the vibrating beam between the vibration amplification block and the temperature correction section; the first Bragg grating differs from the second Bragg grating in central wavelength. The quasi-distributed fiber sensor has the technical advantages that the size of a device is greatly shortened, adaptability of the sensor for installation positions is improved, influences on measuring results caused by the thermal expansion effect of the sensor are avoided, the structure is simple, and the application range is wide.

Owner:成都塔科光电技术有限公司

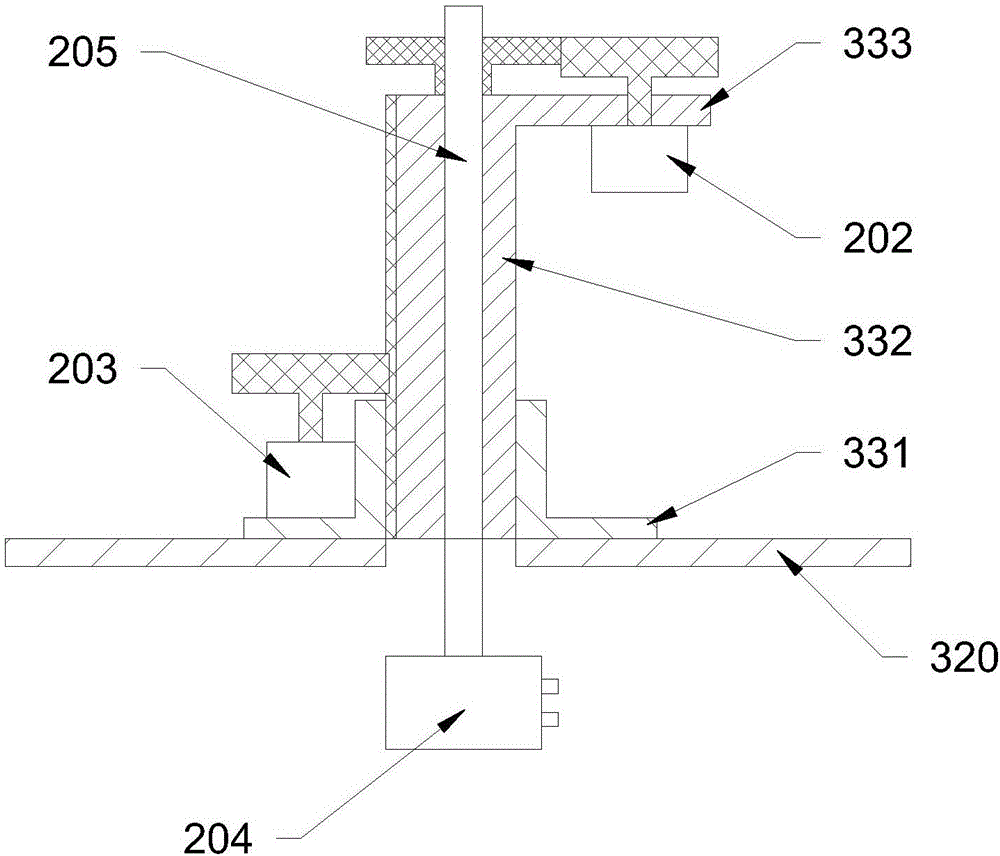

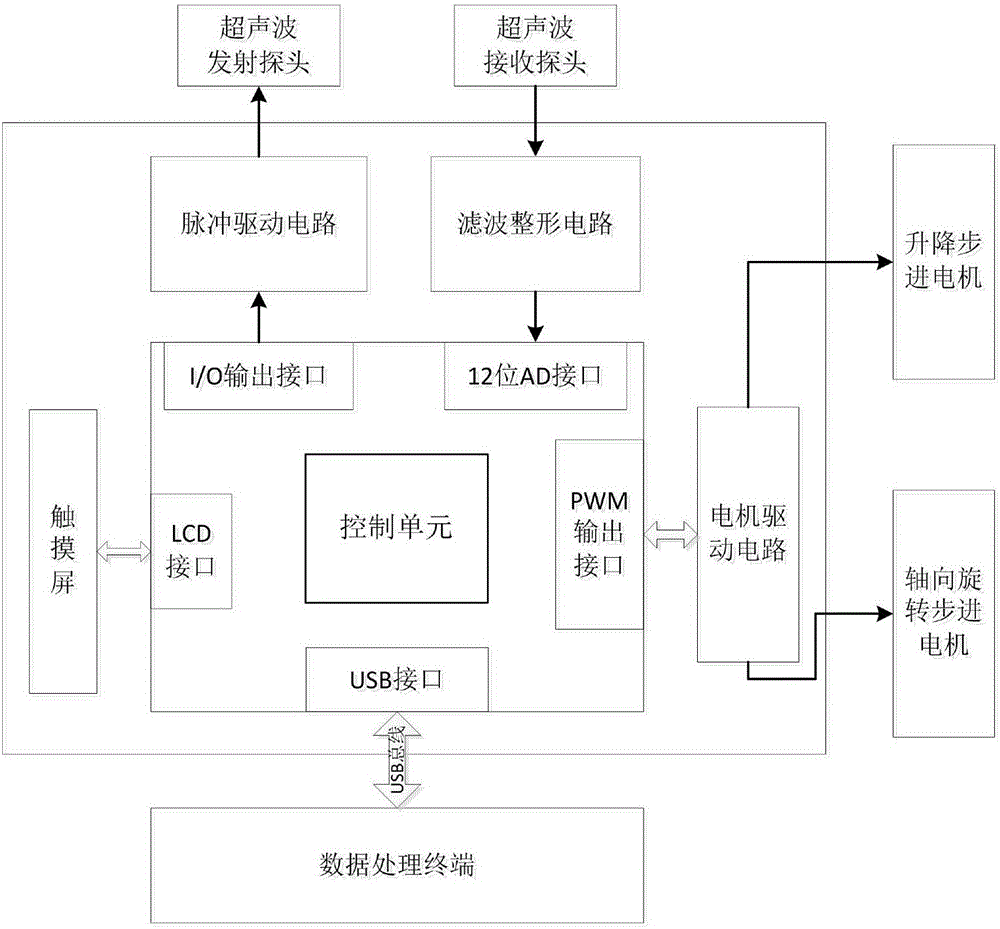

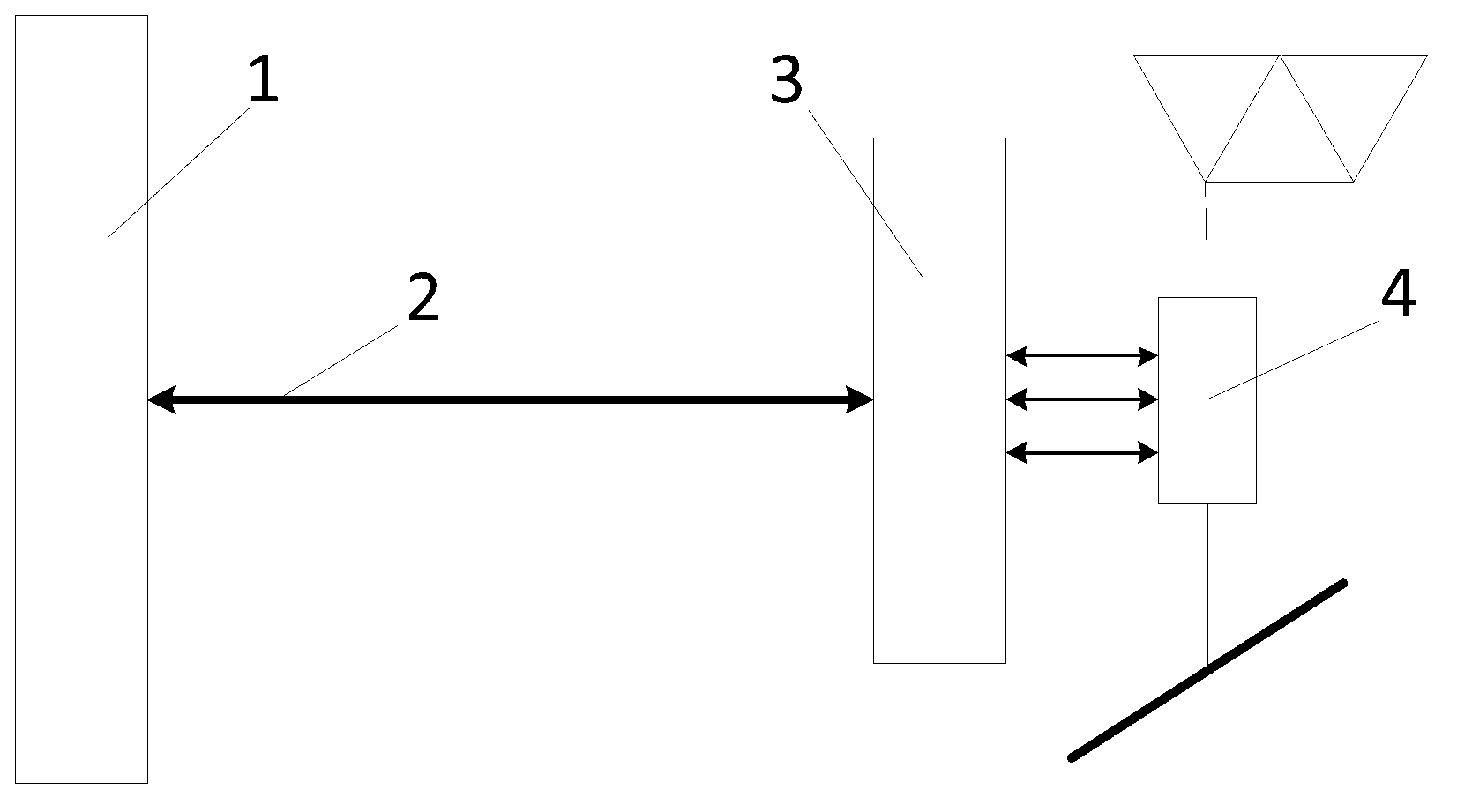

System and method to detect the crack width between the cement outside drivepipe and the drivepipe

ActiveCN106595538AAccurate measurementAvoid influence of measurement resultsConstructionsUsing subsonic/sonic/ultrasonic vibration meansFrequency spectrumData acquisition

The invention discloses a system and method to detect the crack width between the cement outside a drivepipe and the drivepipe. The method comprises the following steps: inputting the already known parameters of a to-be-measured model into a data processing terminal and setting the emission frequency of the ultrasonic waves and the emission cycle; then placing the to-be-measured model into a model container; filling the drivepipe with liquid until it is full; covering the top cover onto the model container; setting the detection position and the detection azimuth angle through the adjustment of the rotation of the axial rotation stepping motor and the hoisting stepping motor through the data processing terminal; controlling the emission of the ultrasonic probe and the reception of the echo by the data processing terminal through the data acquisition control module; carrying out fast Fourier transform on the waveform data of the echo by the data processing terminal to seek the frequency data of the echo signal; and then using the spectral information of the reflected wave in the drivepipe resonance transmission window to establish an inversion objective function; and through the improved differential evolution algorithm, obtaining the minimum value of the objective function so as to obtain the crack width between the cement outside the drivepipe and the drivepipe. Tested by experiment, the maximum relative average error between the actual value and the measured value is less than 0.178 mm.

Owner:YANGTZE UNIVERSITY

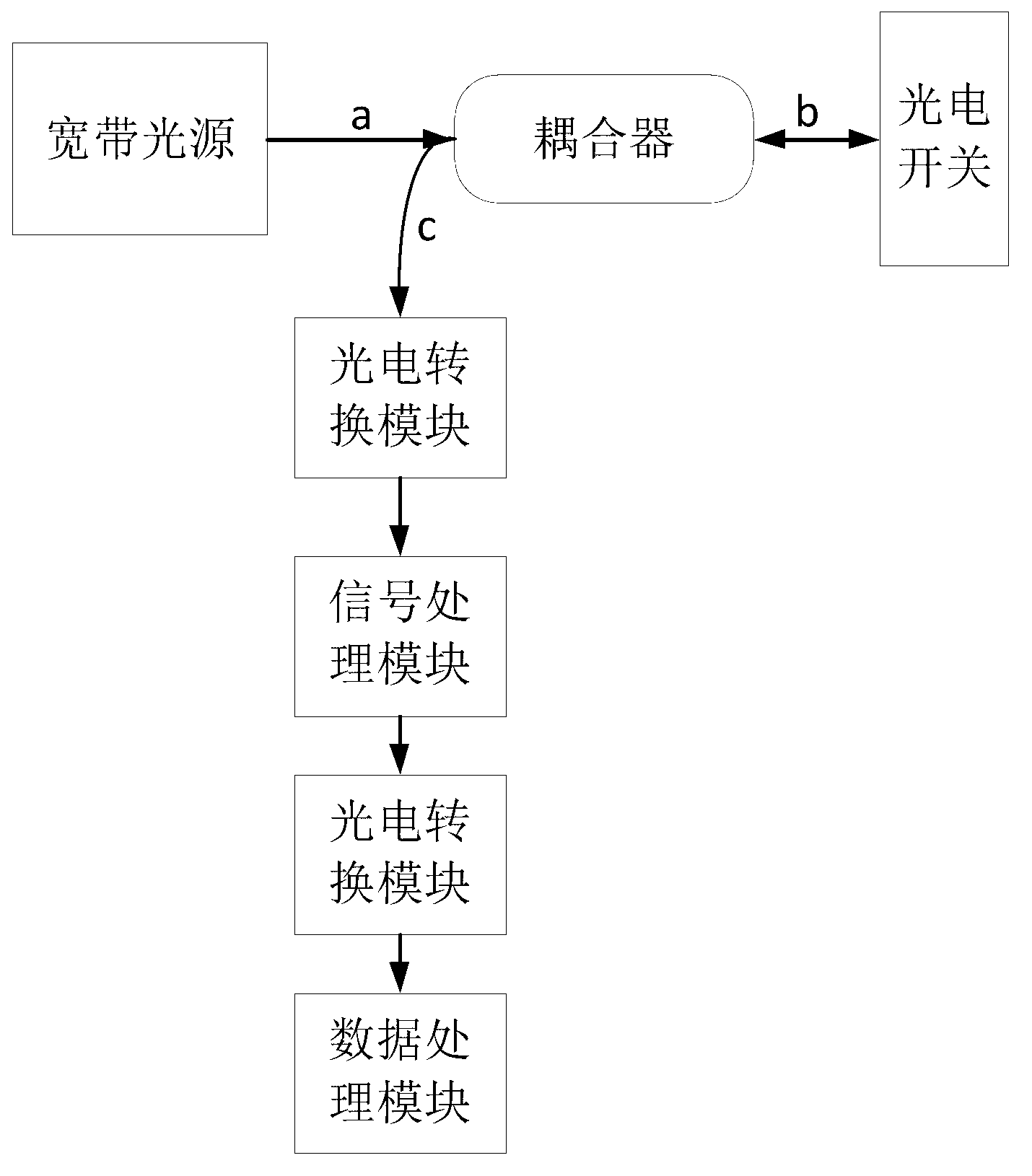

Ice coating detection device for cable

InactiveCN103076070AImprove corrosion resistanceStable chemical propertiesUsing optical meansWeighing apparatusFiberGrating

The invention relates to a weight detection device, in particular to an ice coating detection device for a cable. The ice coating detection device comprises a fiber grating wavelength modulator, an optical divider and a fiber grating weighing sensor, wherein the fiber grating wavelength modulator is connected with the optical divider through a signal transmission optical cable; the optical divider is connected with the fiber grating weighing sensor through a signal transmission optical cable; the upper end of the fiber grating weighing sensor is fixedly suspended, and the lower end of the fiber grating weighing sensor is connected with the cable; an elastic body is arranged in the middle of the fiber grating weighing sensor; the elastic body is provided with the fiber grating sensor; a broadband light source is arranged in the fiber grating wavelength modulator; the broadband light source is transmitted to the fiber grating sensor through a signal transmission optical cable; the fiber grating sensor is used for transmitting a wavelength signal of reflected light of the broadband light source to the fiber grating wavelength modulator; and the fiber grating wavelength modulator is used for obtaining the weight change of the cable according to a received wavelength signal. Due to the adoption of the ice coating detection device, the ice coating condition of the cable can be effectively detected.

Owner:YANTAI RAYTRON TECH

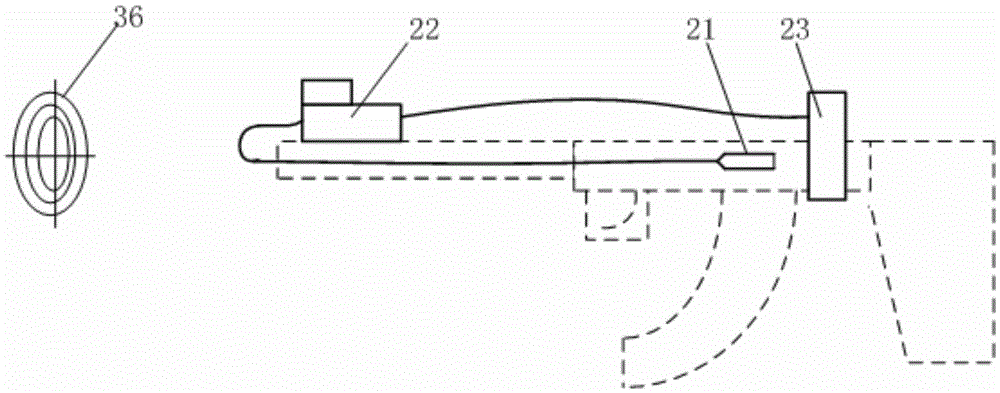

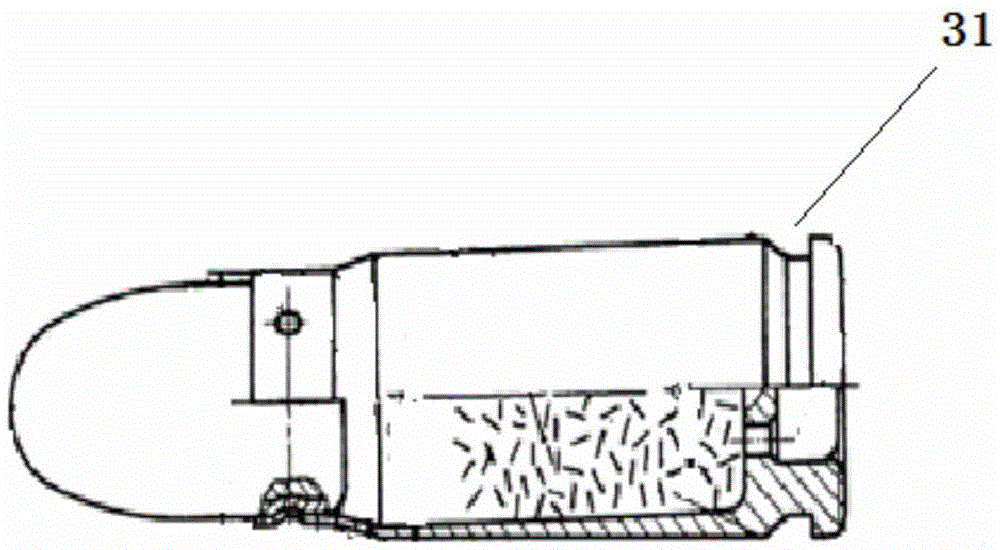

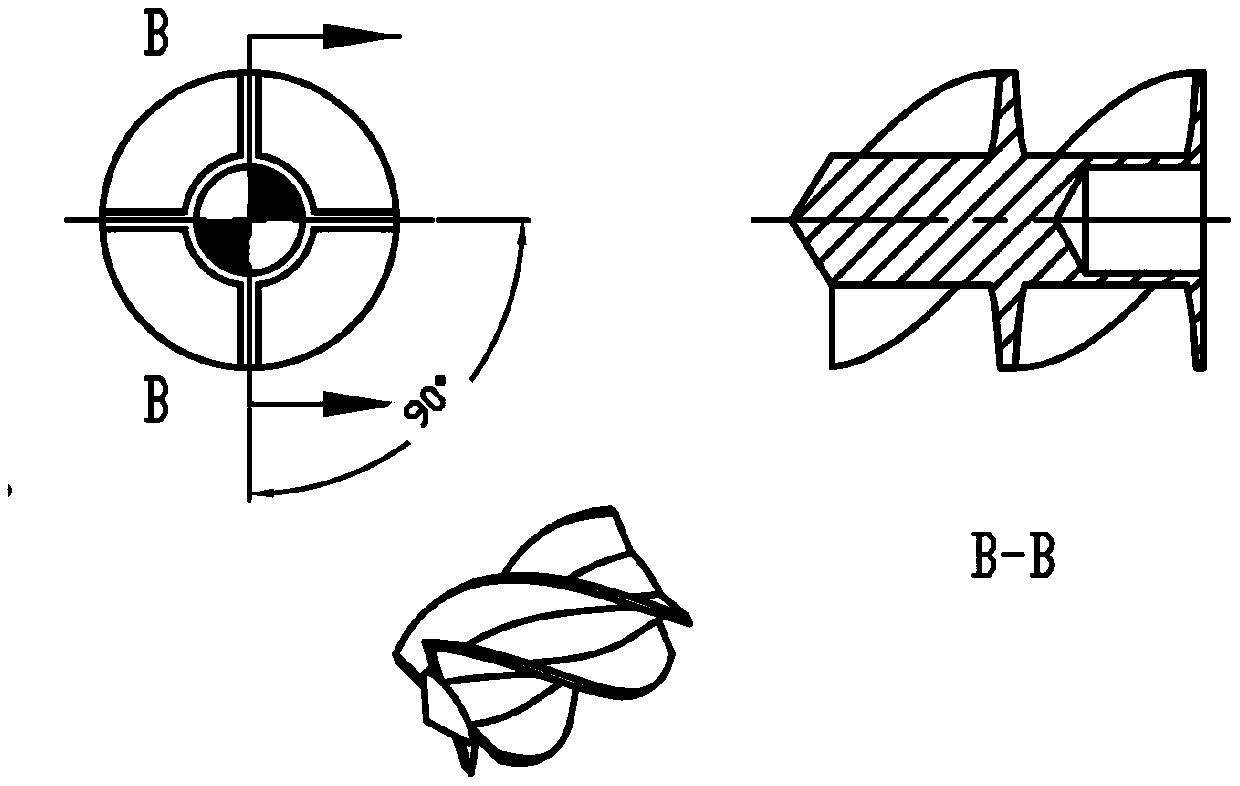

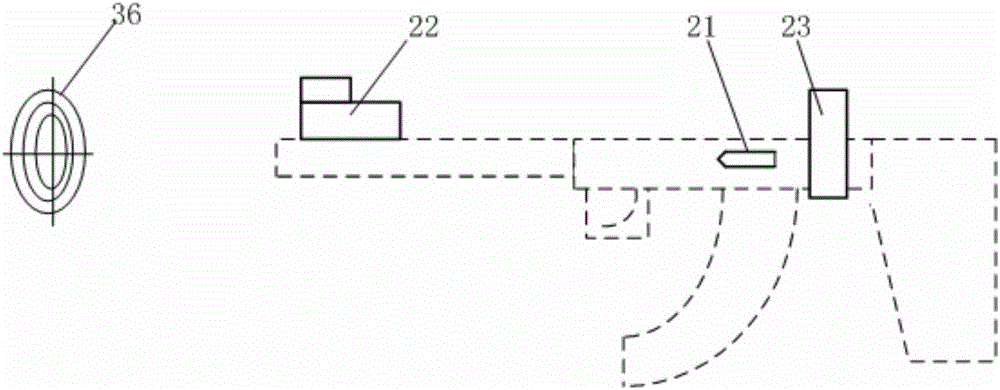

Piezoelectric type synchronizing signal trigger and compact type shooting auxiliary training system

InactiveCN105486169AChange Bad Shooting HabitsEasy to acceptTraining adaptationElectricityControl theory

The invention discloses a piezoelectric type synchronizing signal trigger and a compact type shooting auxiliary training system. The synchronizing signal trigger comprises a cartridge case, a tail sleeve, a percussion base, a piezoelectric unit and a piezoelectric unit support, wherein the piezoelectric unit is fixed to the piezoelectric unit support; and a gun firing pin drives the percussion base to knock the piezoelectric unit to generate a trigger signal. A target scoring unit of the shooting auxiliary training system compares image data with standard target image date for solution, so that the aiming ring number during the shooting process is obtained, the ring number during the generation of the trigger signal is displayed on the target scoring unit and the target is reported through sound. The compact type shooting auxiliary training system is similar to a live ammunition target shooting process, and is more acceptable for shooters, the problem that shooters develop bad shooting habits due to the situation that other simulated training devices have relatively large difference with live ammunition target shooting is solved, and the purpose of training while inspection and correction is achieved.

Owner:高文武

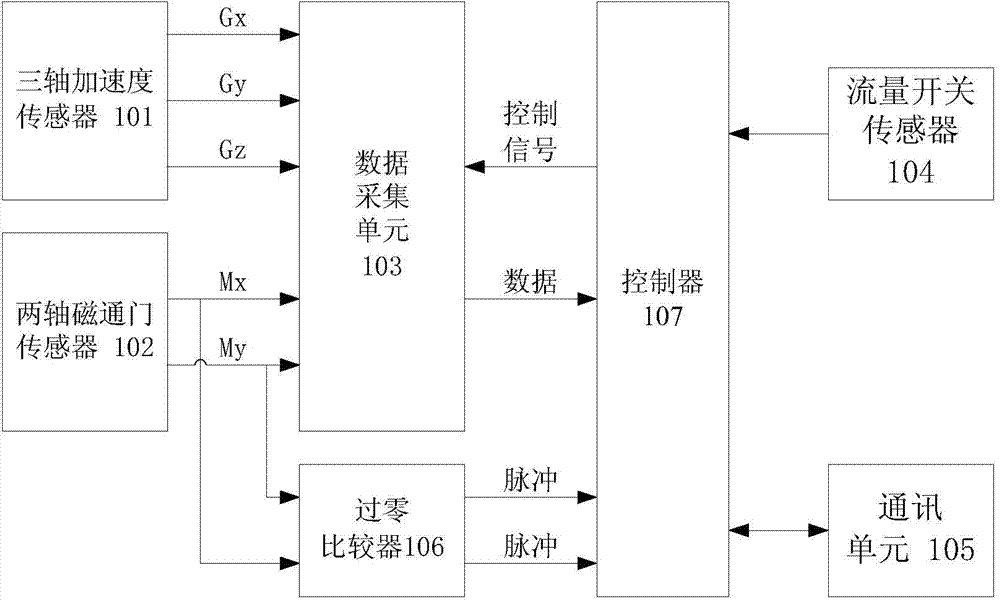

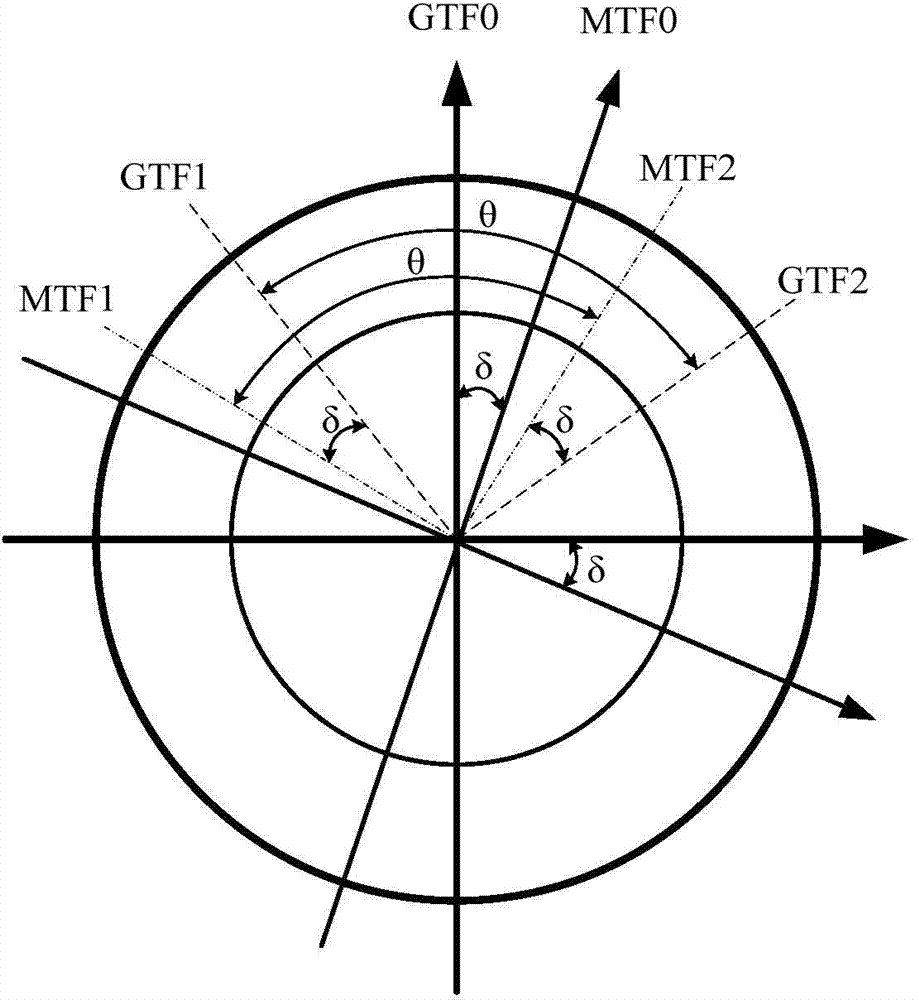

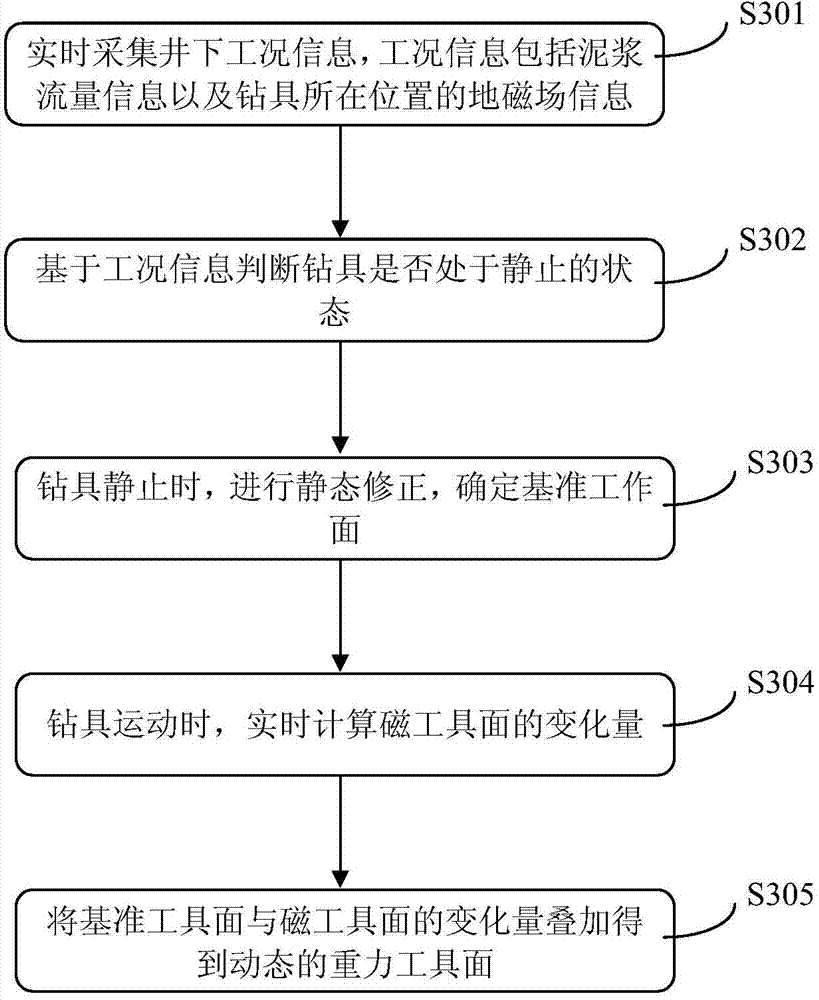

Angle position measurement method and system

The invention discloses an angle position measurement method and system. The method includes: collecting downhole condition information in real time; judging whether a drilling tool is in a static state or not on the basis of rotating speed determined by mud flow information and geomagnetic field information or gravity field information; when the drilling tool is static, calculating well deviation and a static gravity tool surface and a static magnetic tool surface of the drilling tool, and determining a benchmarking tool surface to be the static gravity tool surface or the static magnetic tool surface; when the drilling tool is dynamic, calculating variation of the magnetic tool surface; subjecting the variation of the benchmarking tool surface and the magnetic tool surface to superposition calculation to a dynamic gravity tool surface of the drilling tool and determining the angle position of the drilling tool. The gravity tool surface of the drilling tool is measured in real time by relative change of a rotating magnetic field, magnetic interference is monitored, affect of magnetic inference on measurement results can be avoided, and the angle position of the drilling tool is accurately measured.

Owner:CHINA PETROCHEMICAL CORP +1

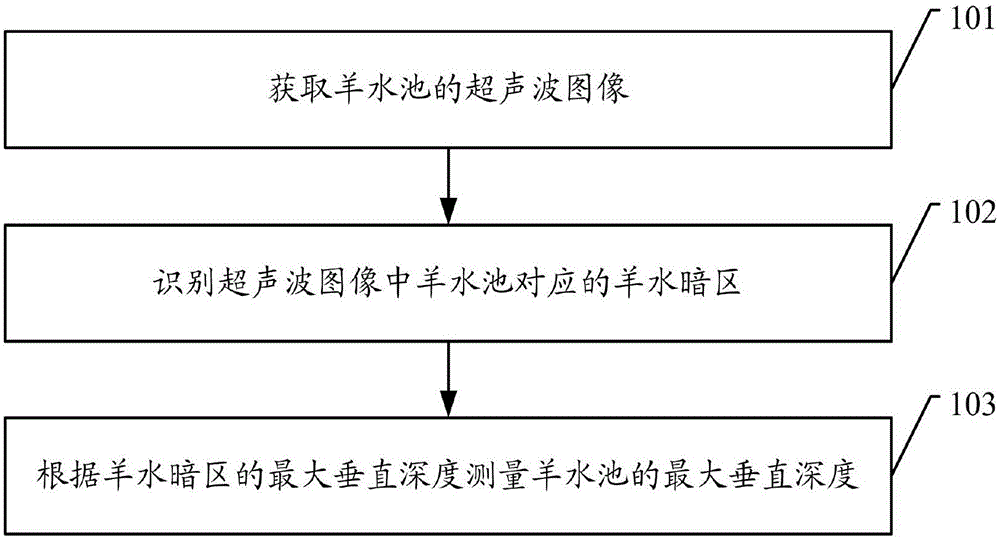

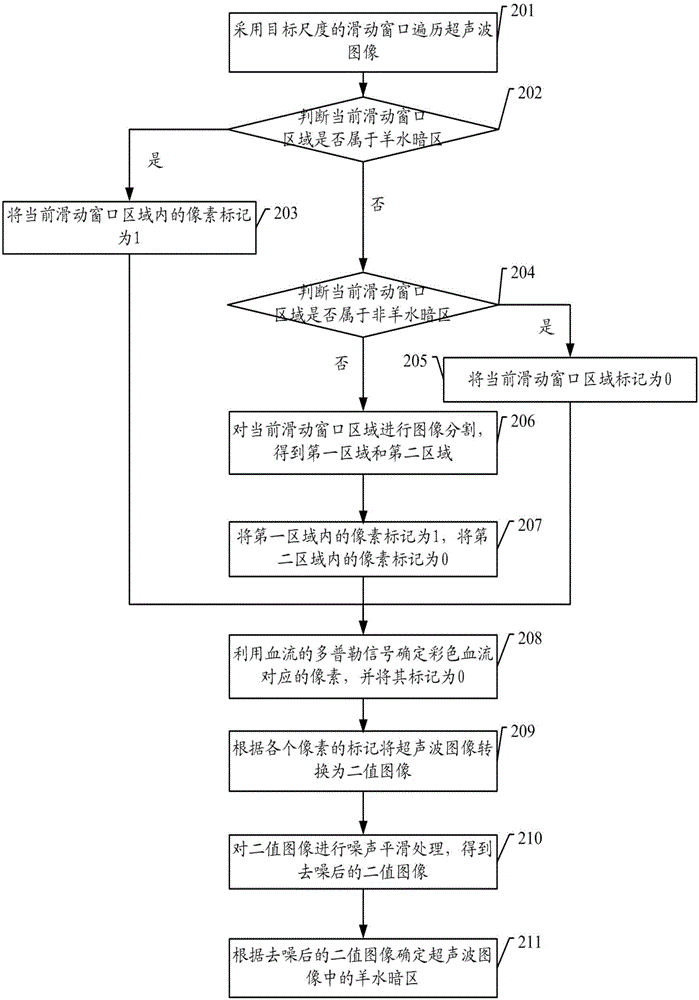

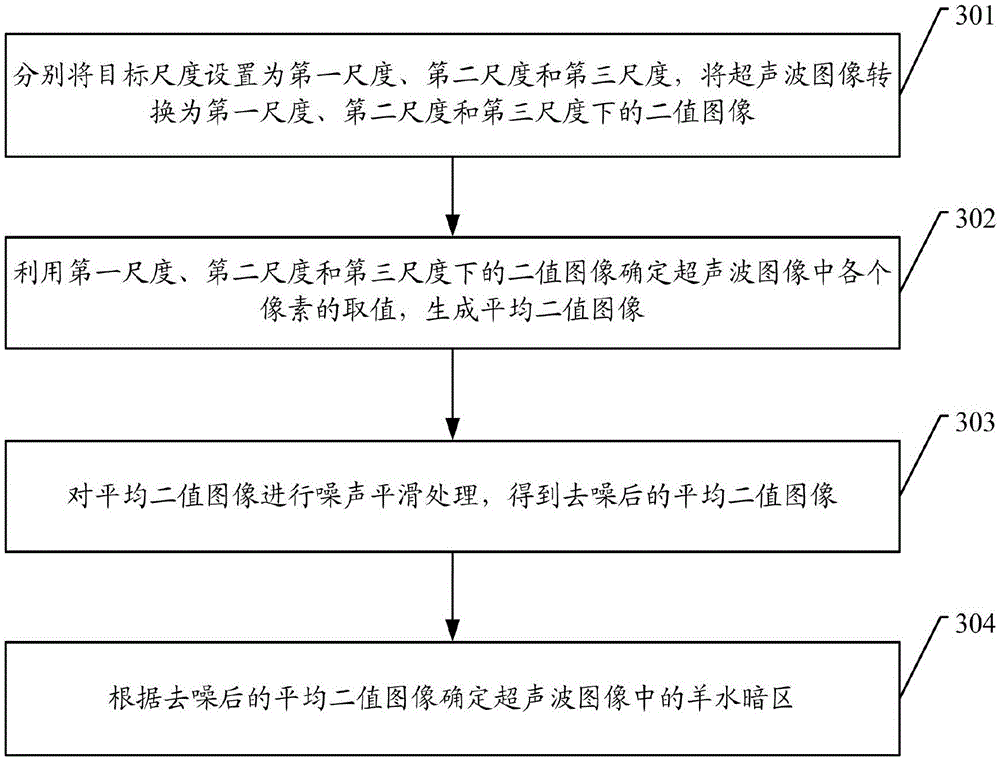

Ultrasound image processing method and device, ultrasonic diagnosis device and storage medium

ActiveCN107518920AImprove accuracyAvoid influence of measurement resultsImage enhancementImage analysisImaging processingAmniotic fluid volume

The embodiment of the invention discloses an ultrasound image processing method and device, an ultrasonic diagnosis device and a computer readable storage medium, and relates to the field of image processing. The ultrasound image processing method and device, the ultrasonic diagnosis device and the computer readable storage medium are used for avoiding an impact which human factors have on a measurement result of the amniotic fluid volume as much as possible and improving the correctness of an amniotic fluid detection result and are beneficial to misdiagnosis reduction. The method comprises the steps that an ultrasound image of an amniotic fluid pocket is obtained; an amniotic fluid opaque area corresponding to the amniotic fluid pocket in the ultrasound image is identified; the largest vertical depth of the amniotic fluid pocket is measured according to the largest vertical depth of the amniotic fluid opaque area.

Owner:SONOSCAPE MEDICAL CORP

Optical fiber current sensing system

InactiveCN103308745AEasy to assembleSimple and convenient on-site installation processCurrent/voltage measurementThermometers using physical/chemical changesElectrical conductorPhotovoltaic detectors

The invention provides an optical fiber current sensing system which comprises a photoelectric detector, a signal processing unit, as well as a light source, a Y-shaped wave guide, a 45-degree welding point, a strip-shaped waveguide modulator, a polarization maintaining optical fiber and an optical fiber current sensing device which are sequentially connected with one another, wherein the Y-shaped wave guide is provided with a first branching end, a second branching end and a combining end, and is used for converting a light beam which is received from the light source through the first branching end into a linearly polarized light, receiving the light beam which is returned from the optical fiber current sensing device and carries the conductor current information from the combining end, and outputting from the second branching end; and the photoelectric detector is used for detecting the intensity of interference light outputted from the second branching end of the Y-shaped wave guide, converting the light intensity information into an electric signal, and transmitting to the signal processing unit. The optical fiber current sensing system adopts a double-waveguide structure, the polarization performance of a light path can be improved due to the Y-shaped wave guide, and the optical phase can be modulated due to the strip-shaped waveguide modulator, so that the light path has the advantages of being simple in structure and high in light path polarization stability.

Owner:XUNDI SCI & TECH HUBEI PROV

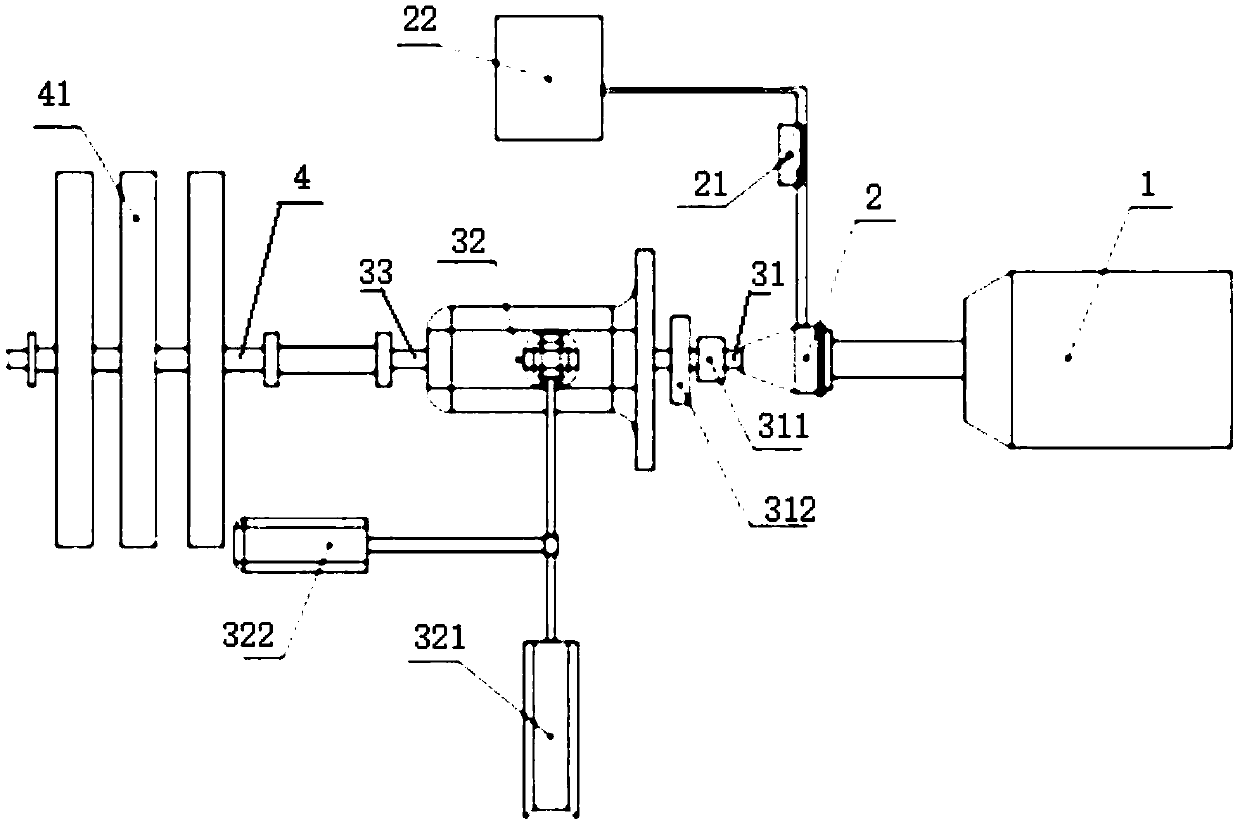

Device for testing starting and shifting performance of vehicle and method

PendingCN109540543AAchieve launch shift performanceAvoid influence of measurement resultsVehicle testingData acquisitionDrive motor

The invention relates to a vehicle inspection device and a method, and provides a device for testing the starting and shifting performance of a vehicle and a method to solve the problem that the starting and shifting performance testing of an existing transmission lacks a special detection device. The device for testing the starting and shifting performance of the vehicle comprises a transmission,a driveshaft which is connected to the output shaft of the transmission, a drive motor which is connected to the input shaft of the transmission via an electromagnetic clutch, a data acquisition processor, and an operation controller. The transmission comprises a transmission body, a shift selecting manipulator and a shifting manipulator. The shifting manipulator is provided with a force sensor.The input shaft of the transmission is provided with a rotating speed encoder and an inertia disk. The driveshaft is provided with an inertia wheel set. The electromagnetic clutch is connected to a power source via a neutral position switch. The neutral position switch is provided at a neutral light of the transmission body. The speed encoder and the force sensor are respectively and electricallyconnected to the data acquisition processor. The drive motor, the shaft selecting manipulator, and the shifting manipulator are respectively electrically connected to the operation controller.

Owner:XIAN FASHITE AUTOMOBILE TRANSMISSION CO LTD

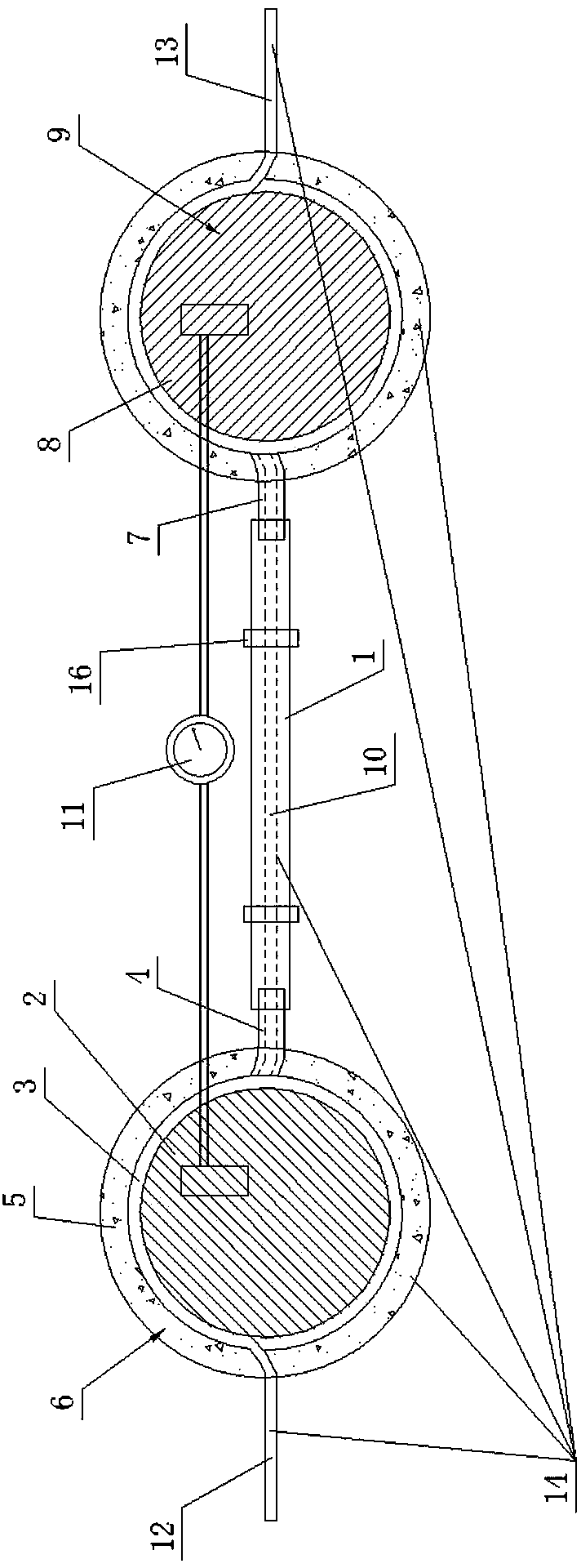

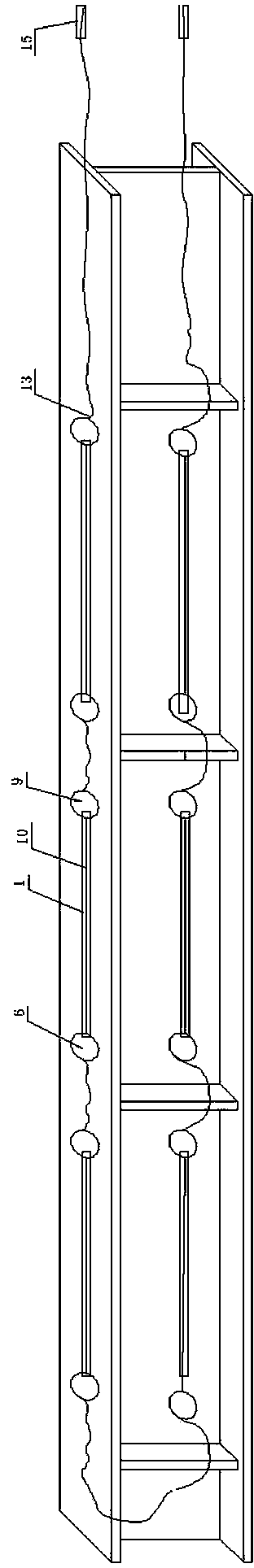

Method for installing distributed sensing optical fibers used for monitoring strain of steel structure

InactiveCN103376067AAccurate measurementGuaranteed production accuracyUsing optical meansOptical fiber connectorEngineering

The invention discloses a method for installing distributed sensing optical fibers used for monitoring strain of a steel structure. The method includes the following steps that a plurality of optical fiber distribution monomers (14) are manufactured, wherein each optical fiber distribution monomer (14) comprises two magnetic bonding ends, a strain monitoring optical fiber section (10), a front section signal transmission optical fiber section (12) and a rear section signal transmission optical fiber section (13); the optical fiber distribution monomers (14) are sequentially connected in series, and optical fiber connectors are welded at the front end of the front section signal transmission optical fiber section (12) of the headmost optical fiber distribution monomer (14) and the rear end of the rear section signal transmission optical fiber section (13) of the backmost optical fiber distribution monomer (14) respectively; then the optical fiber distribution monomers (14) which are connected in series are fixed on the steel structure to be monitored, and then the two optical fiber connectors of the optical fiber distribution monomers (14) which are connected in series are connected to a test instrument. The method for installing the distributed sensing optical fibers is rapid, comprehensive and accurate.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

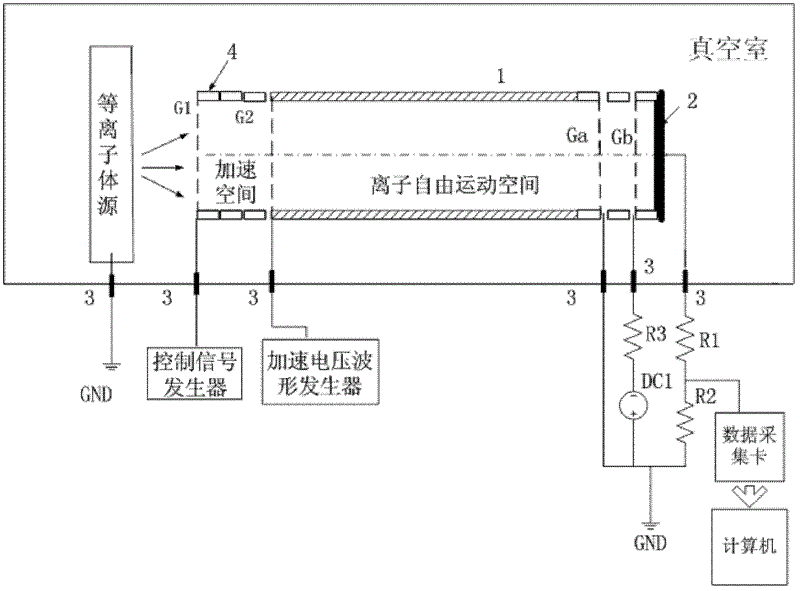

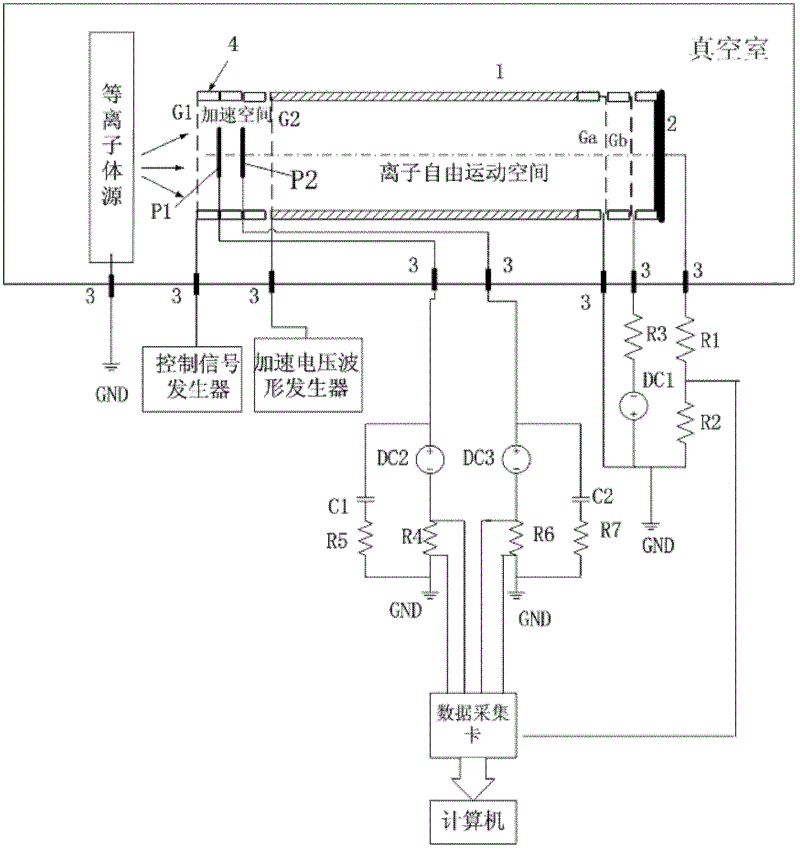

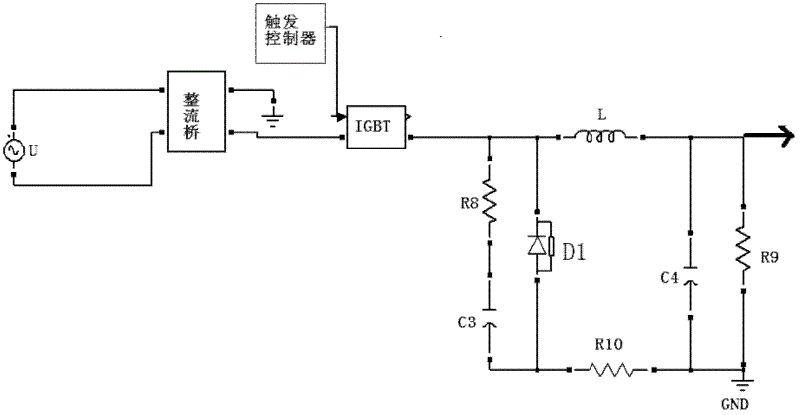

Device and method for detecting ion current of vacuum discharge plasma

ActiveCN102623287ARapid disconnectionSimple methodElectric discharge tubesNegative potentialWave shape

The invention discloses a device and a method for detecting ion current of vacuum discharge plasma, which belong to the technical field of plasma diagnosis. The device and the method are mainly characterized in that a grid mesh applied with negative potential is used for controlling the plasma. The device for detecting the ion current of the vacuum discharge plasma is structurally characterized in that the control grid mesh is arranged at the front end of a cylindrical object, an accelerating electrode and a collection plate are arranged at two ends of a pipe, a first grid mesh and a second grid mesh are sequentially mounted in the front of the collection plate, a plasma source and the pipe are positioned in a vacuum chamber, the control grid mesh is connected with a control signal generator, and the accelerating electrode is connected with an accelerating voltage waveform generator. The device and the method have the advantages that 1) space transmission characteristics of the discharge plasma can be conveniently analyzed; 2) an optional section of plasma can be measured; 3) on and off of the plasma can be controlled by means of applying proper barrier potential; and 4) the device is simple in structure and high in measuring precision and interference resistance, and the strength of the ion current can be effectively detected.

Owner:BEIJING JIAOTONG UNIV

Rock specific heat capacity measuring device and measuring method

PendingCN107621479AAccurately measure temperature changesHigh measurement accuracyMaterial heat developmentPhysicsSpecific heat

The invention discloses a rock specific heat capacity measuring device. The rock specific heat capacity measuring device comprises a lower housing, a heating layer, a sample cup, a first galvanic couple group, a heat insulating plate, a cooling cup, a second galvanic couple group and an upper housing, wherein the heating layer for heating the sample cup is arranged inside the lower housing; the sample cup is movably arranged on the heating layer; the first galvanic couple group is arranged on the inner wall of the sample cup; the heat insulating plate is movably arranged on the top of the lower housing; the upper housing is arranged on the top of the heat insulating plate; the cooling cup is arranged inside the upper housing; a cooling cup heat insulating layer is arranged on the outer part of the cooling cup; the second galvanic couple group is arranged on the inner wall of the cooling cup. During cooling, the heat insulating plate is opened, so that the upper housing internally communicates with the lower housing, the sample cup is separated from the heating layer, and the sample cup is sleeved by the cooling cup. The device is simple in structure, is convenient to operate, is high in applicability, is precise in measuring, and has relatively high use and popularization value.

Owner:CHANGAN UNIV

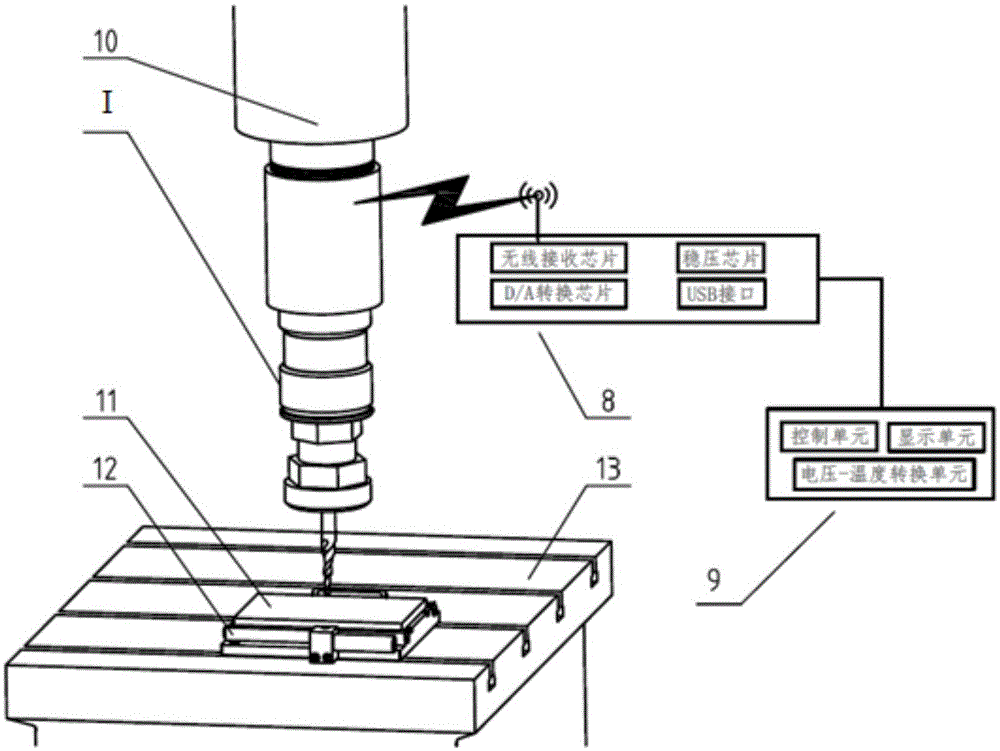

Wireless temperature measuring system and method for carbon fiber composite drilling

ActiveCN105150273AAvoid damageAvoid influence of measurement resultsThermometers using electric/magnetic elementsUsing electrical meansVIT signalsCarbon fiber composite

The invention belongs to the field of mechanical detection, and relates to a wireless temperature measuring system and method for carbon fiber composite drilling. The system comprises a wireless temperature measuring tool handle unit, a man-machine interaction parameter setting and measuring result displaying unit and a wireless signal receiving unit connected with the man-machine interaction parameter setting and measuring result displaying unit. The temperature measuring method comprises the steps that the wireless temperature measuring tool handle unit is assembled at first; the installed wireless temperature measuring tool handle unit is connected with a machine tool spindle, the sampling frequency is set, required technological parameters are set, and a machine tool is started; and an A / D conversion chip of a wireless signal transmitting unit conducts data collection on weak electric signals converted by a thermocouple. According to the wireless temperature measuring system and method, no damage is caused to the machine tool spindle, no special workpiece is needed, and all data of transient temperature changes in the whole carbon fiber composite drilling process on any technological conditions can be obtained. The temperature measuring system is simple and reliable. According to the temperature measuring method, the test cycle is shortened, and the test cost is lowered.

Owner:DALIAN UNIV OF TECH

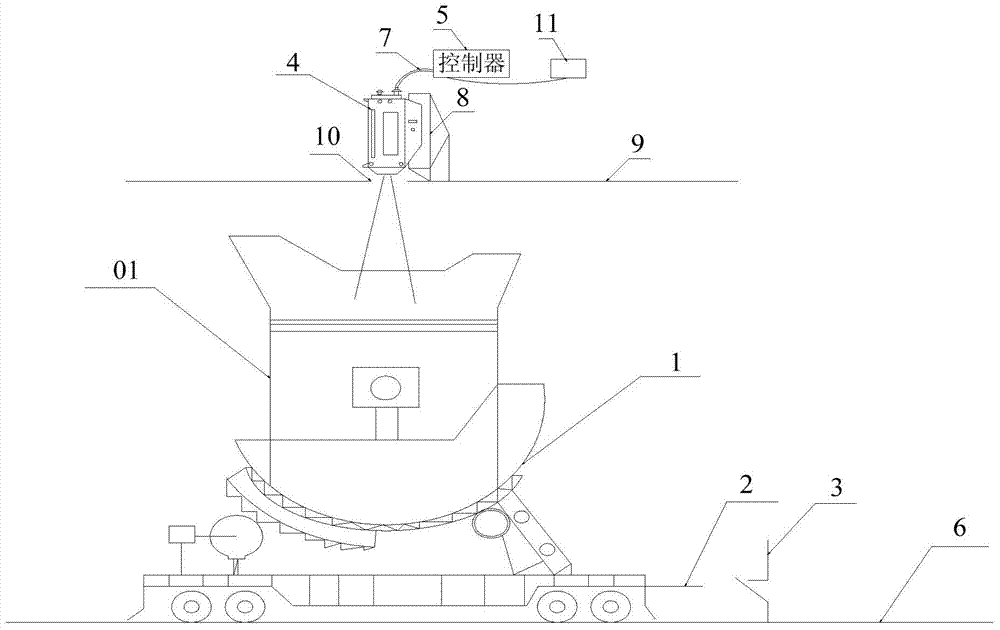

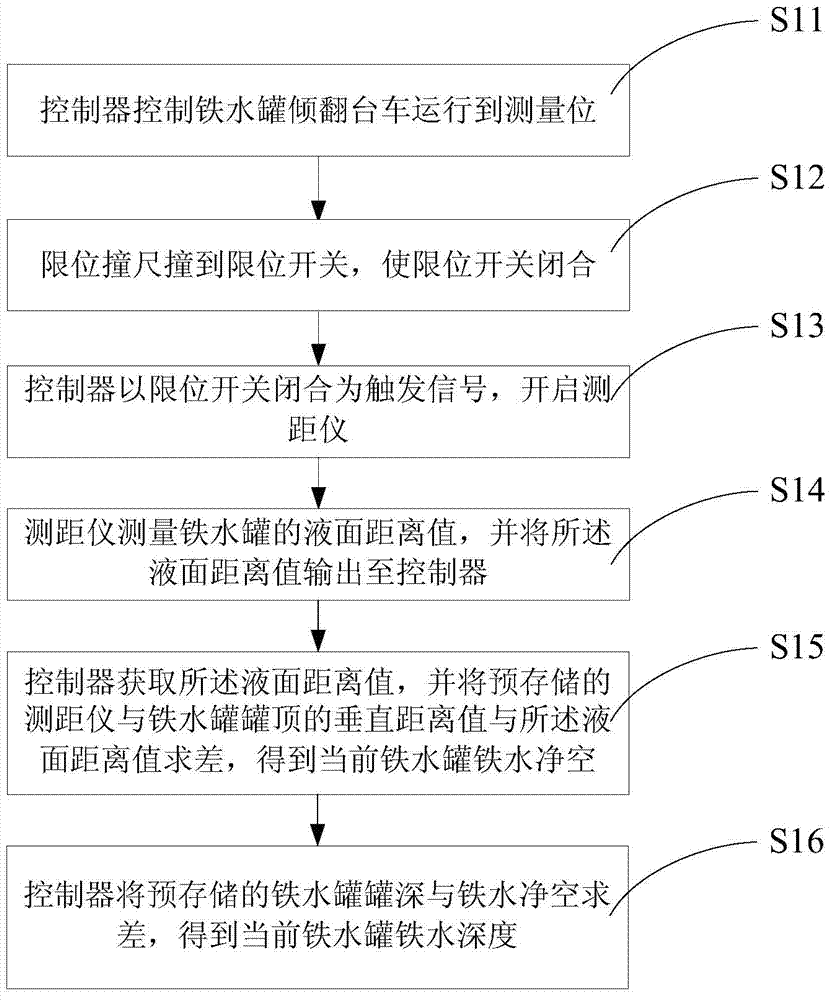

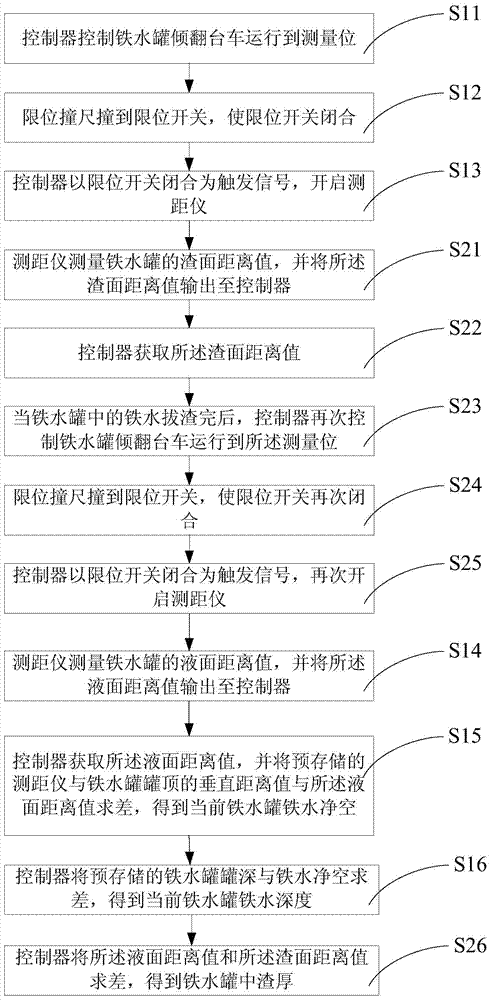

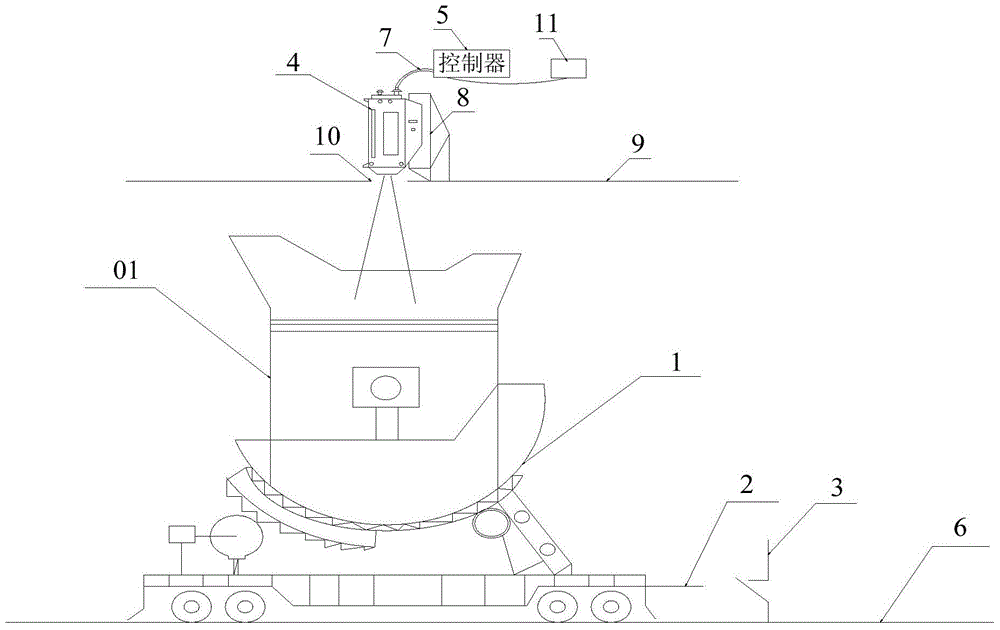

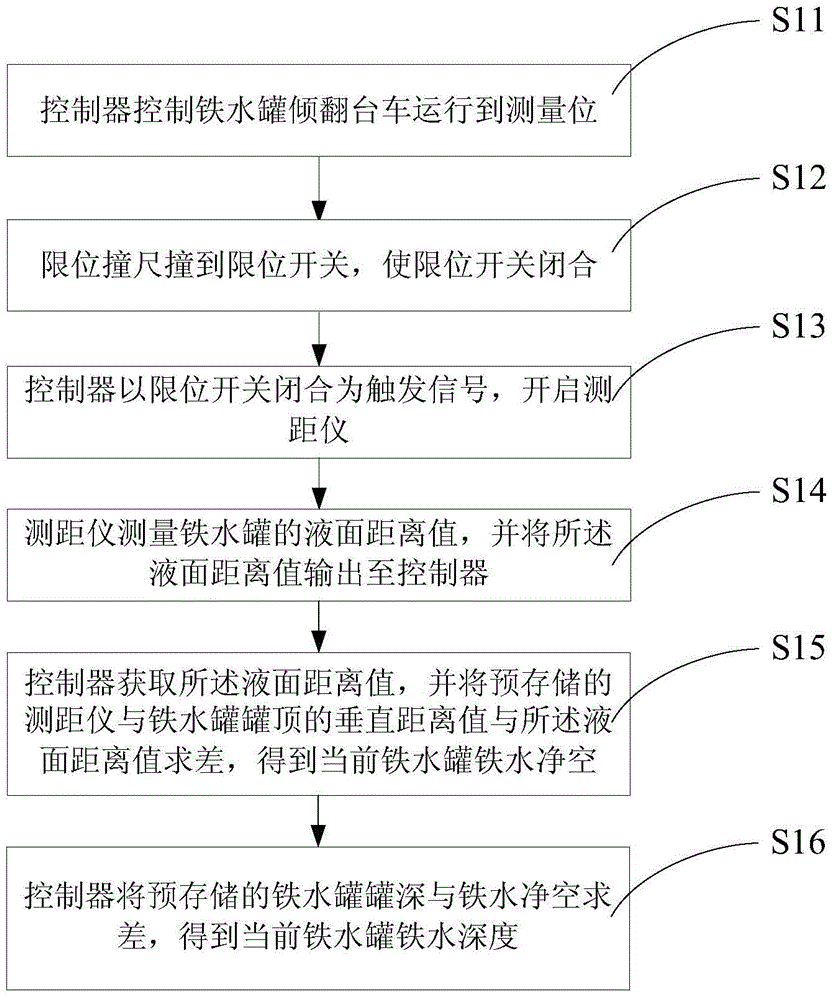

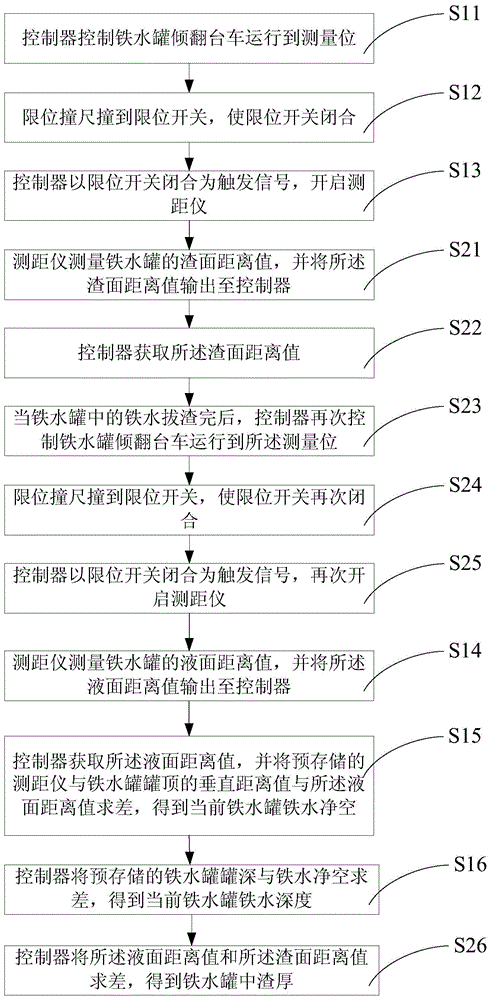

Method and device for measuring depth of hot metal in hot metal bottle

ActiveCN103884400AReduce measurement errorAccurate insertion depthMachines/enginesLevel indicatorsObservational errorMeasuring instrument

The invention provides a method and device for measuring the depth of hot metal in a hot metal bottle. The device comprises a hot metal bottle tipping trolley, a limiting striker, a limiting switch, a distance measuring instrument and a controller. The method comprises the steps that the controller controls the hot metal bottle tipping trolley to move to a measurement position, the closing of the limiting switch serves as a triggering signal, the distance measurement instrument is controlled to measure the vertical distance between the distance measurement instrument and the liquid level in the hot metal bottle after slagging-off of the hot metal in the hot metal bottle, the difference between the vertical distance measured and the vertical distance between the distance measurement instrument and the top of the hot metal bottle is obtained, then the headroom of the hot metal in the hot metal bottle currently is obtained, and finally the difference between the known depth of the hot metal bottle and the headroom of the hot metal is obtained to further obtain the depth of the hot metal in the hot metal bottle currently. Due to the adoption of the technical method that the depth of the hot metal in the hot metal bottle is obtained by measuring the headroom of the hot metal in the hot metal bottle after slagging-off of the hot metal directly, the influence of slag thickness on a measurement result is effectively avoided, and the hot metal depth measurement error is reduced due to the fact that the measurement accuracy of the distance measurement instrument is far higher than that of manual visual measurement of the headroom.

Owner:LAIWU IRON & STEEL GRP

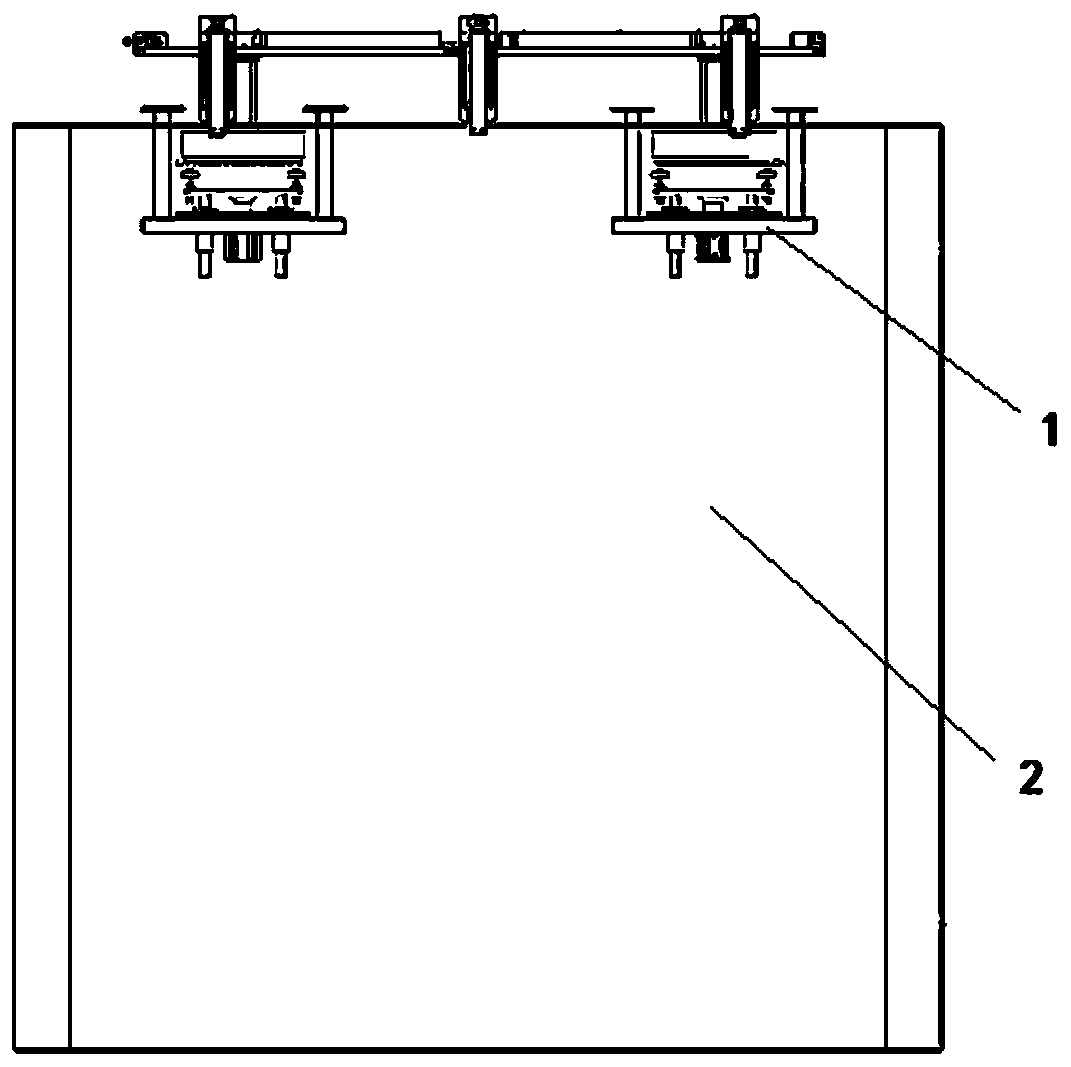

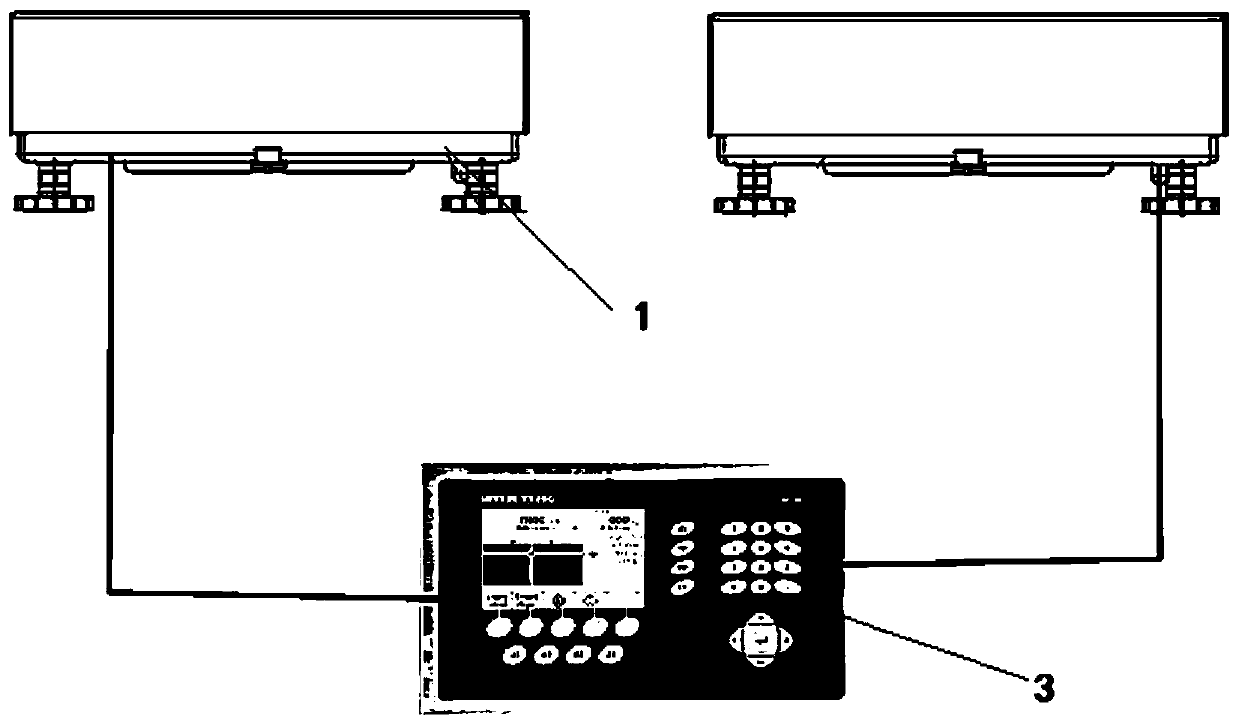

TFT glass BOD process rapid dynamic weighing system and weighing method

InactiveCN111579035AGuaranteed rangeEliminate the effects ofGlass severing apparatusSpecial purpose weighing apparatusWeight changeProcess engineering

The invention relates to a TFT glass BOD process rapid dynamic weighing system. The system comprises two groups of weighing devices and a plc, wherein one group of weighing devices are arranged at a no-load weighing station and used for measuring the weight of a transport trolley, the other group of weighing devices is arranged at a load weighing station and is used for measuring the weights of the transport trolley and the weighing glass, each group of weighing devices comprises two high-precision measuring scales, and the two high-precision measuring scales jointly complete weight measurement. A TFT glass BOD process rapid dynamic weighing method comprises steps that the weight of the transport trolley is measured firstly, then the weight of the transport trolley and the weight of the weighing glass are measured, and the weight of the weighing glass is obtained by taking a difference value; in the weighing process, a weight change curve of a current weight value of the weighed objectmeasured in real time is drawn, the sampling frequency is calculated by more than 200 milliseconds, previous data with large fluctuation is avoided, and whether weighing is completed is judged according to the data whether weight change curve change is in the stable stage, so the plc can conveniently calculate to obtain accurate weighing data at the first time.

Owner:IRICO

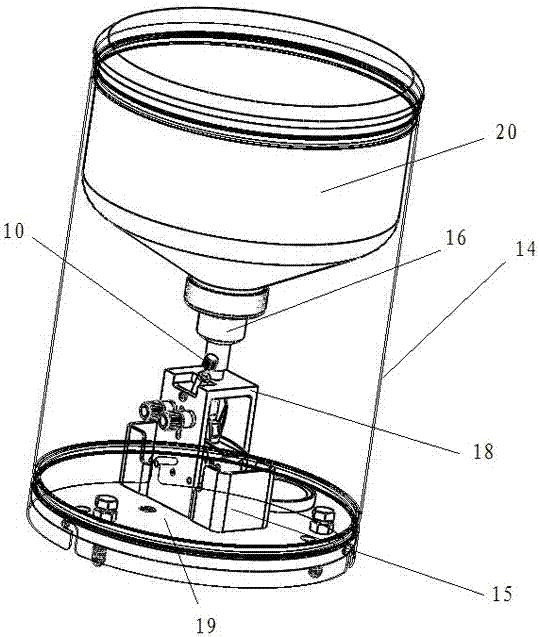

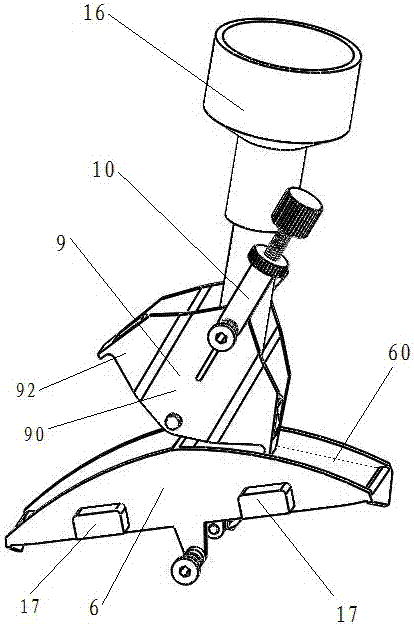

Method for changing water volume by adjusting gravity center of upper tipping bucket

ActiveCN107991723AAccuracy adjustableAvoid influence of measurement resultsRainfall/precipitation gaugesWater volumeWater flow

The invention relates to a method for changing water volume by adjusting the gravity center of an upper tipping bucket. The upper tipping bucket is arranged above a tipping bucket of a tipping-bucket-type rain sensor; rotating shafts of the upper tipping bucket and the tipping bucket are parallel to each other, and are on the same vertical surface; an adjusting screw rod is arranged on the upper tipping bucket movably; the position of the adjusting screw rod in the upper tipping bucket is changed to change the gravity center position of a combined body formed by the upper tipping bucket and the adjusting screw rod. The method has the advantages that the gravity center of the combined body formed by the upper tipping bucket and the adjusting screw rod is changed through change of the position of the adjusting screw rod in the upper tipping bucket, the weight of water flowing into the tipping bucket from the upper tipping bucket is further changed, and accordingly, measurement accuracy is adjusted.

Owner:福州小草科技有限公司

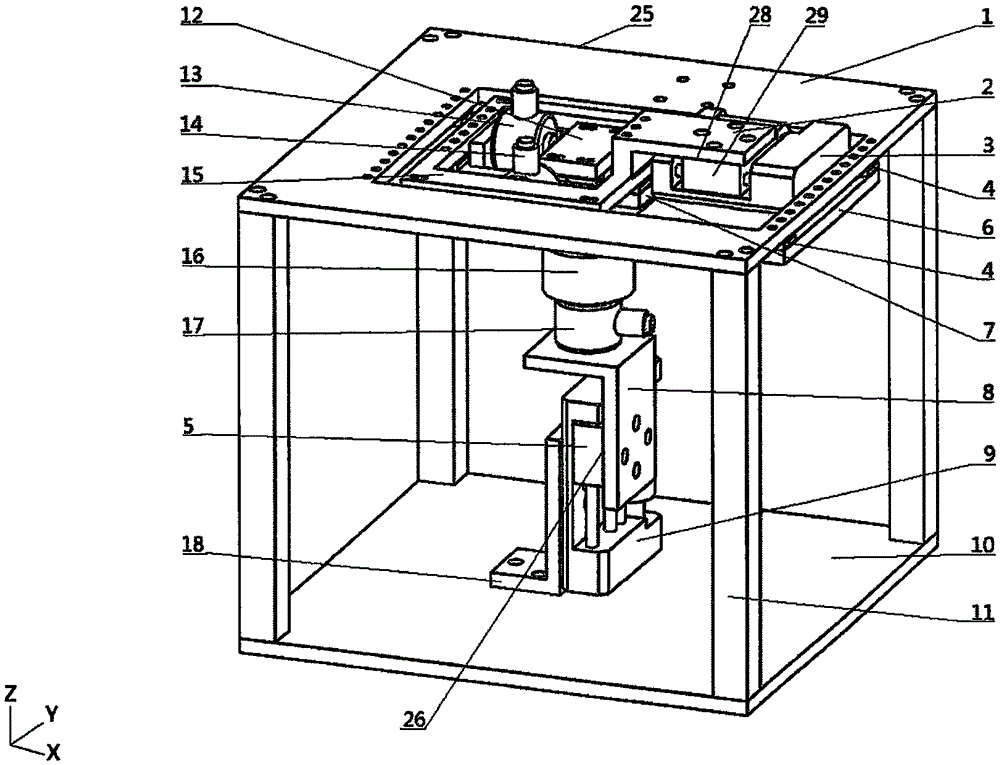

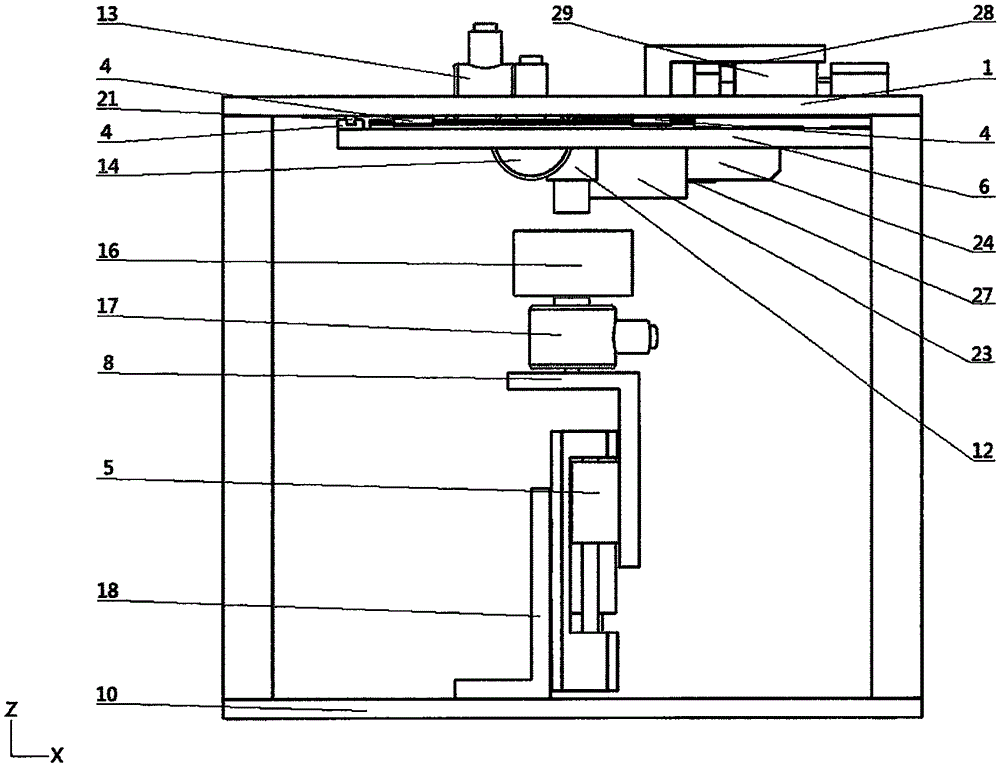

Measuring device of biological soft tissue mechanical properties

ActiveCN105527174AGuaranteed accuracyReduce interactionMaterial strength using steady shearing forcesElectric machineryEngineering

The invention belongs to a measuring device of biological soft tissue mechanical properties. The measuring device comprises a machine frame, wherein a motor seat and a Z-axis automatic slide table mechanism are arranged on a bottom plate of the machine frame; a Z-axis sensor is arranged on the Z-axis automatic slide table mechanism; an object carrying container is arranged on the Z-axis sensor; a Y-axis automatic slide table mechanism and a Y-axis driving guide rail are arranged under an upper plate of the machine frame; a Y-axis driving plate is linked under the Y-axis driving guide rail; the Y-axis automatic slide table mechanism is connected with the Y-axis driving plate; an X-axis driving guide rail and an X-axis automatic slide table mechanism are arranged on the Y-axis driving plate; the X-axis automatic slide table mechanism is connected with an X-axis driving plate; a Y-axis driven guide rail is arranged under the X-axis driving plate; a Y-axis driven plate is linked under the Y-axis driven guide rail; an X-axis driven guide rail is arranged on the Y-axis driven plate; an upper shearing platform is linked on the X-axis driven guide rail; a Y-axis sensor is arranged between the X-axis driving plate and the Y-axis driven plate; an X-axis sensor is arranged between the upper shearing platform and the Y-axis driven plate. The measuring device has the advantages that the structure is light and ingenious; the accuracy is high; the operation is convenient; the portability is realized.

Owner:ZHENGZHOU UNIV

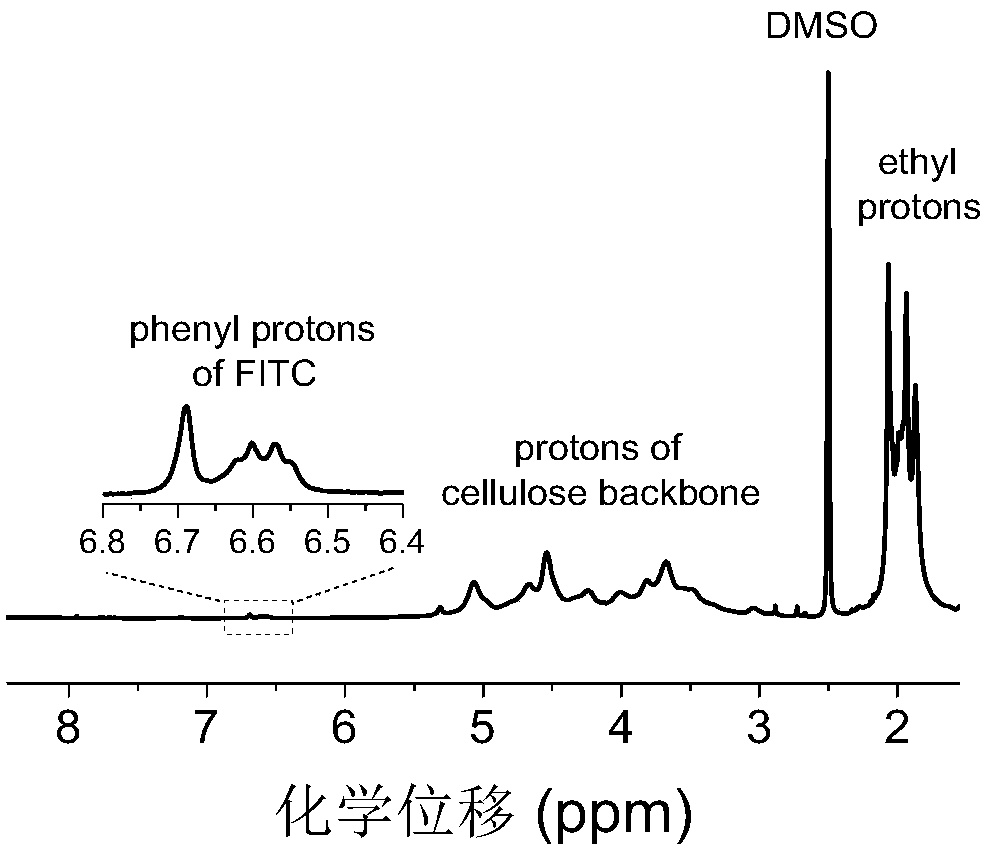

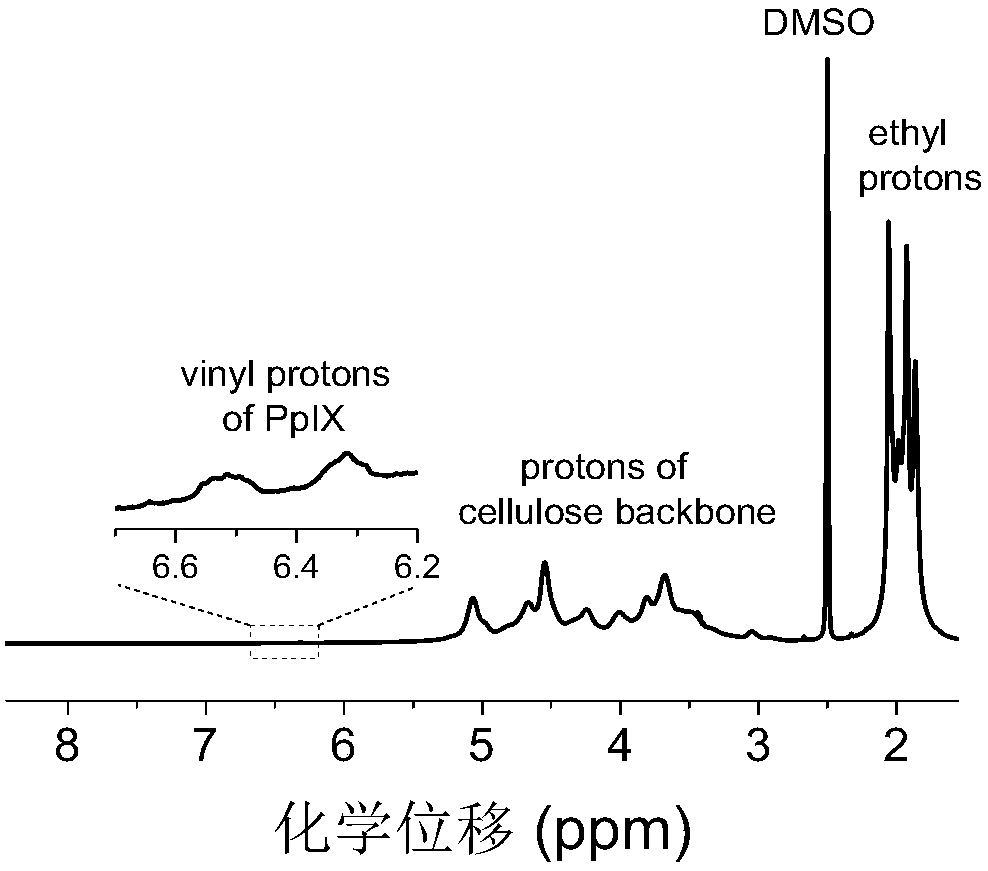

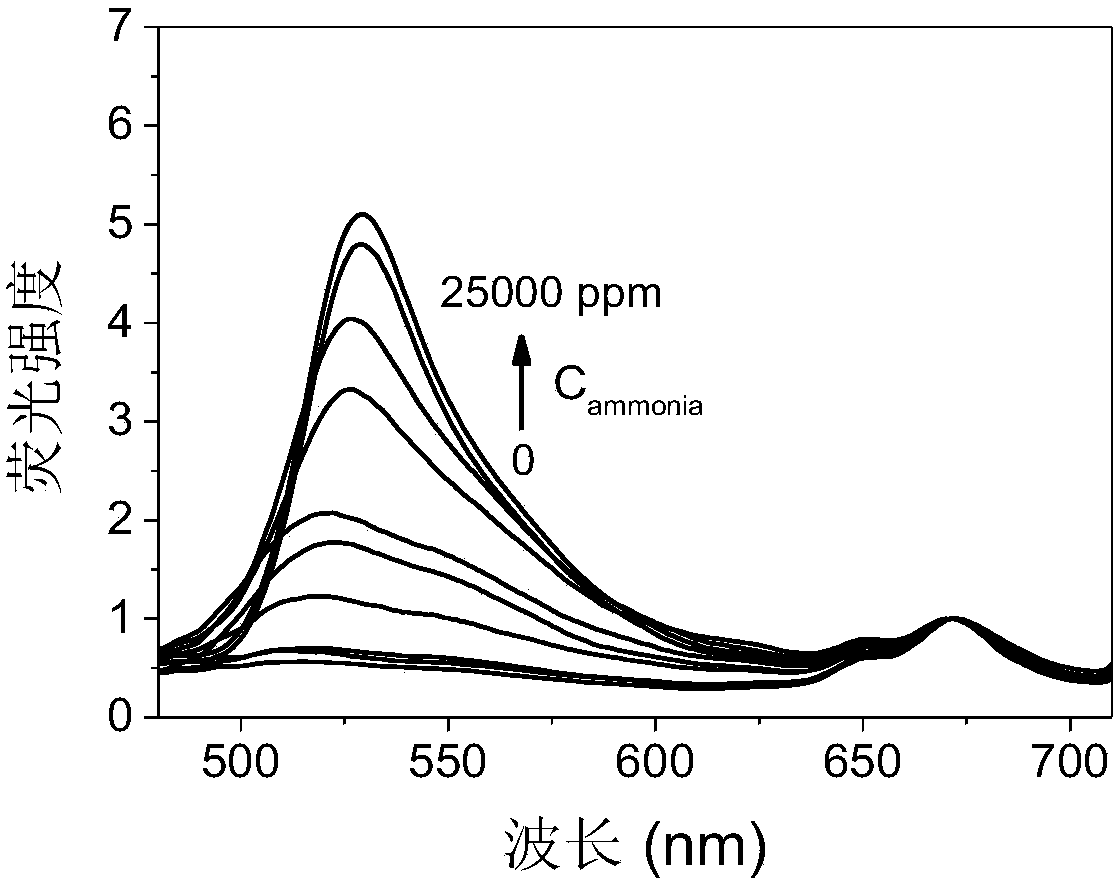

Dual-emitting cellulose-based fluorescent material, preparation method and applications thereof

ActiveCN109111913AGood biocompatibilityEasy to processFlexible coversWrappersCelluloseInternal standard

The invention discloses a dual-emitting cellulose-based fluorescent material, a preparation method and applications thereof, wherein the dual-emitting cellulose-based fluorescent material has good biocompatibility and good workability, and comprises two classes of fluorophores, wherein one class of the fluorophores are responsive to biogenic amines so as to be used as indicators, and the other class of the fluorophores are not responsive to biogenic amines so as to be used as internal standard substances. The invention further discloses a method for detecting biogenic amines, wherein the dual-emitting cellulose-based fluorescent material is used, and the biogenic amine is detected according to the change of the ratio of the fluorescence intensities of the two classes of the fluorophores and the change of the fluorescent color of the cellulose-based fluorescent material, and during the detecting, the ratio of the fluorescence intensities of the two classes of the fluorophores produces the visible color change along with the increase of the concentration of the biogenic amine so as to achieve the visual detection of biogenic amine.

Owner:INST OF CHEM CHINESE ACAD OF SCI

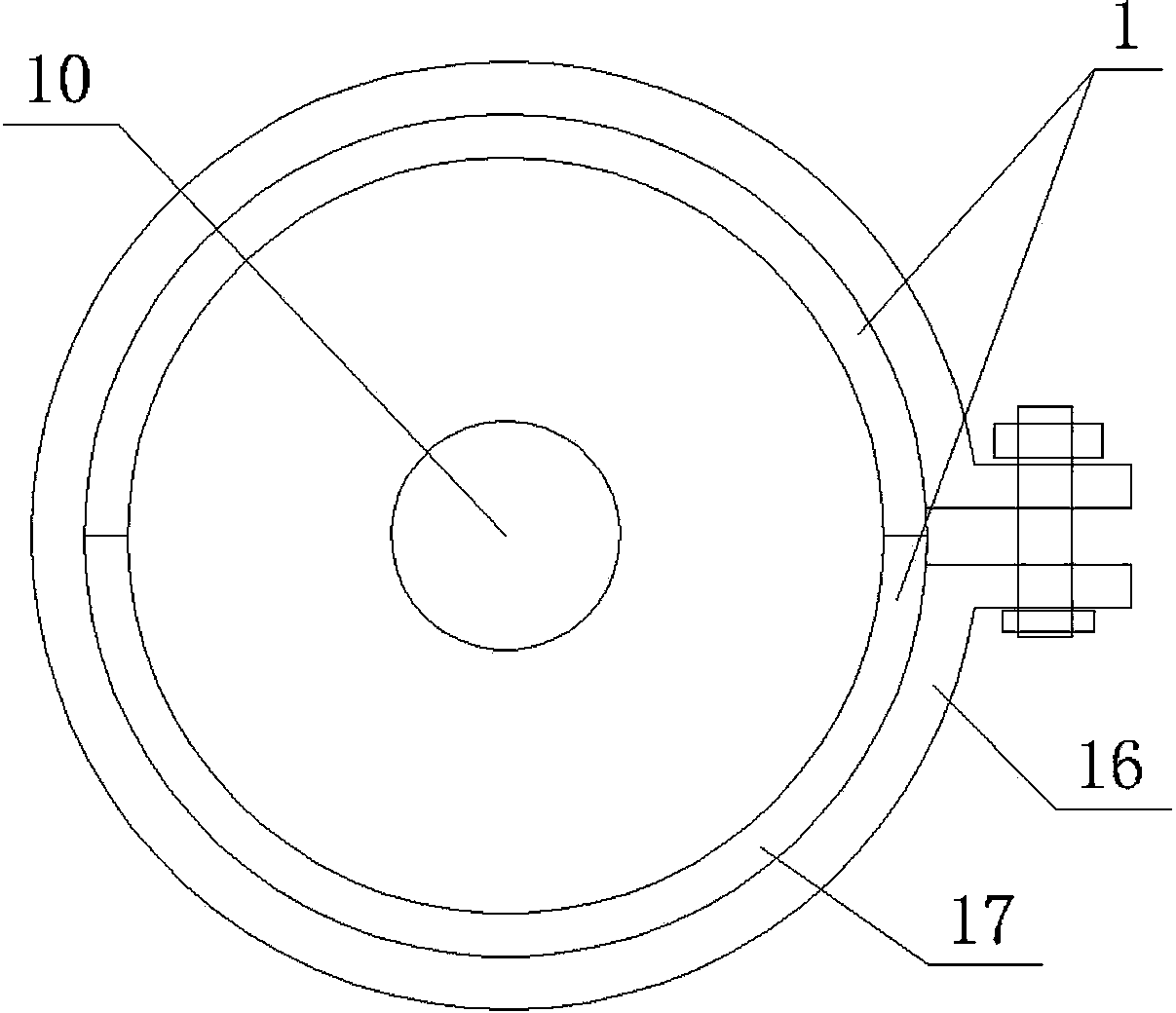

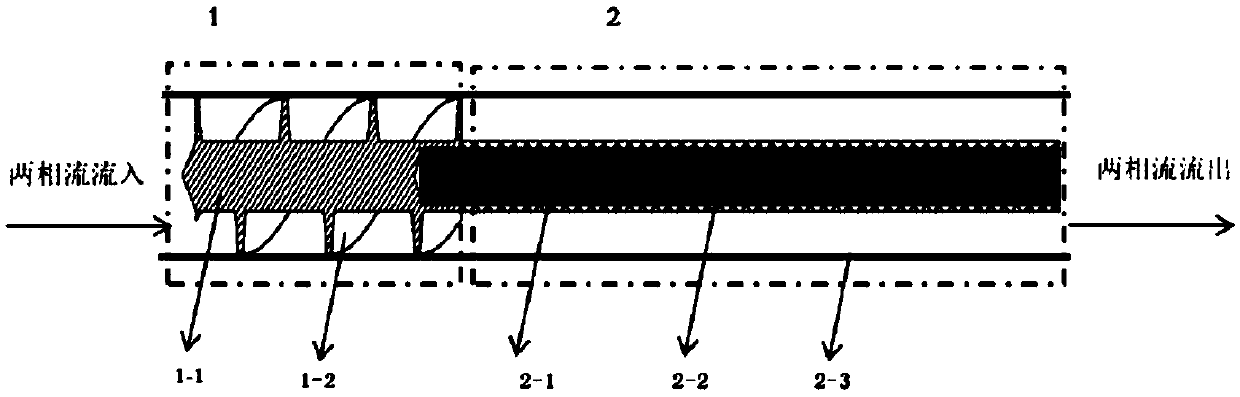

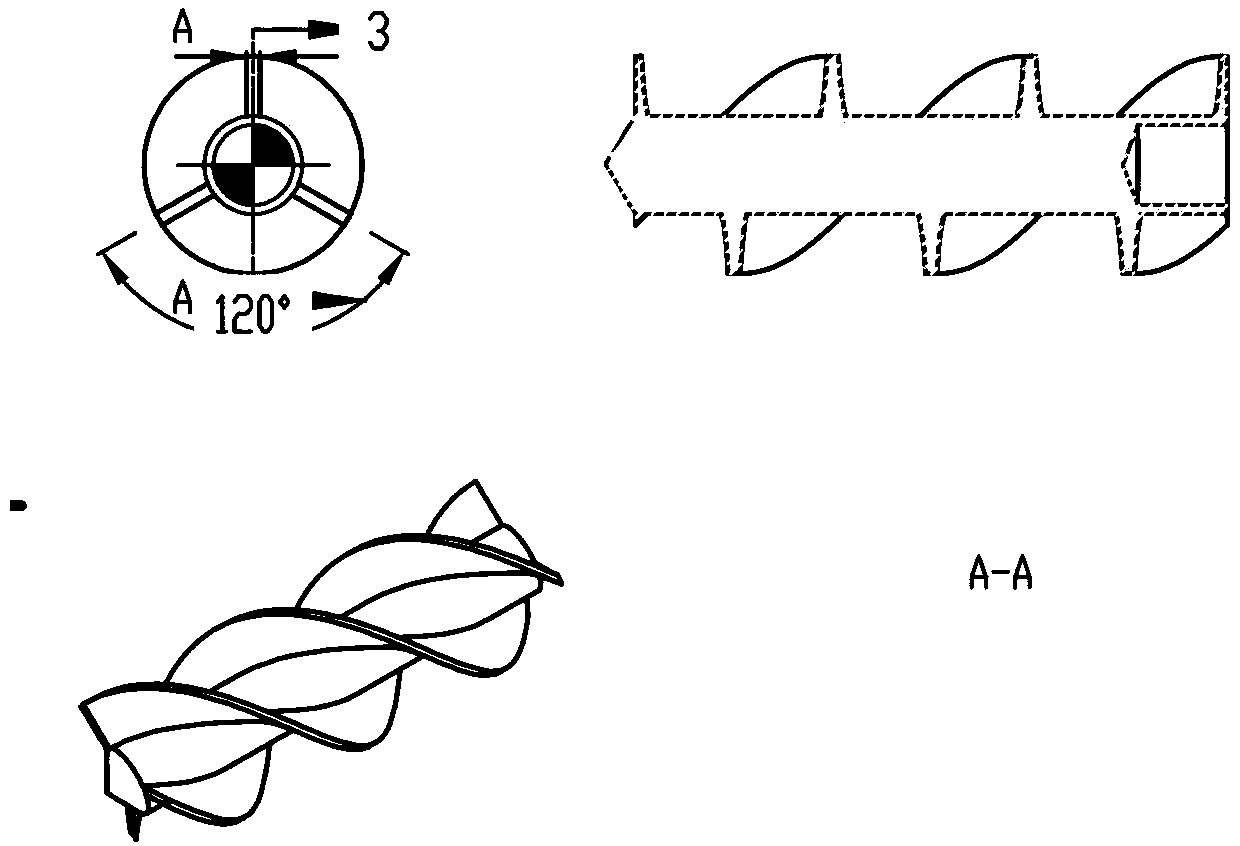

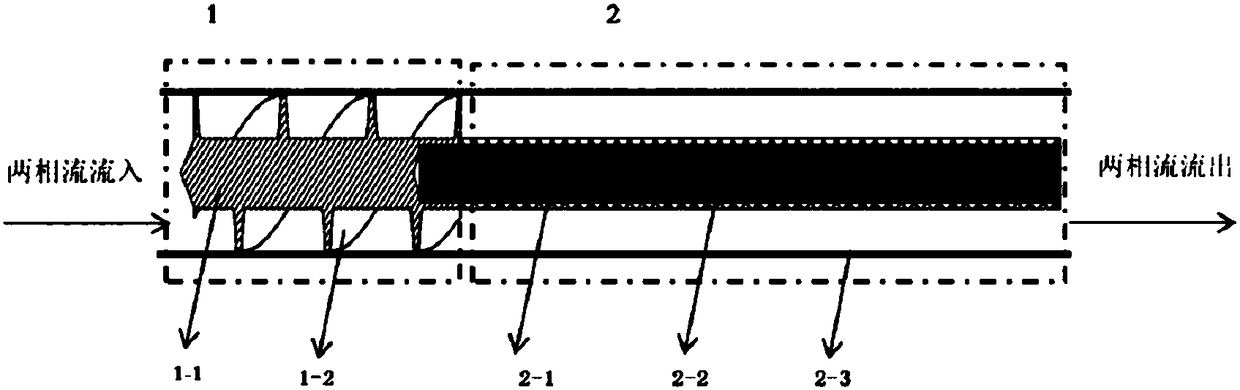

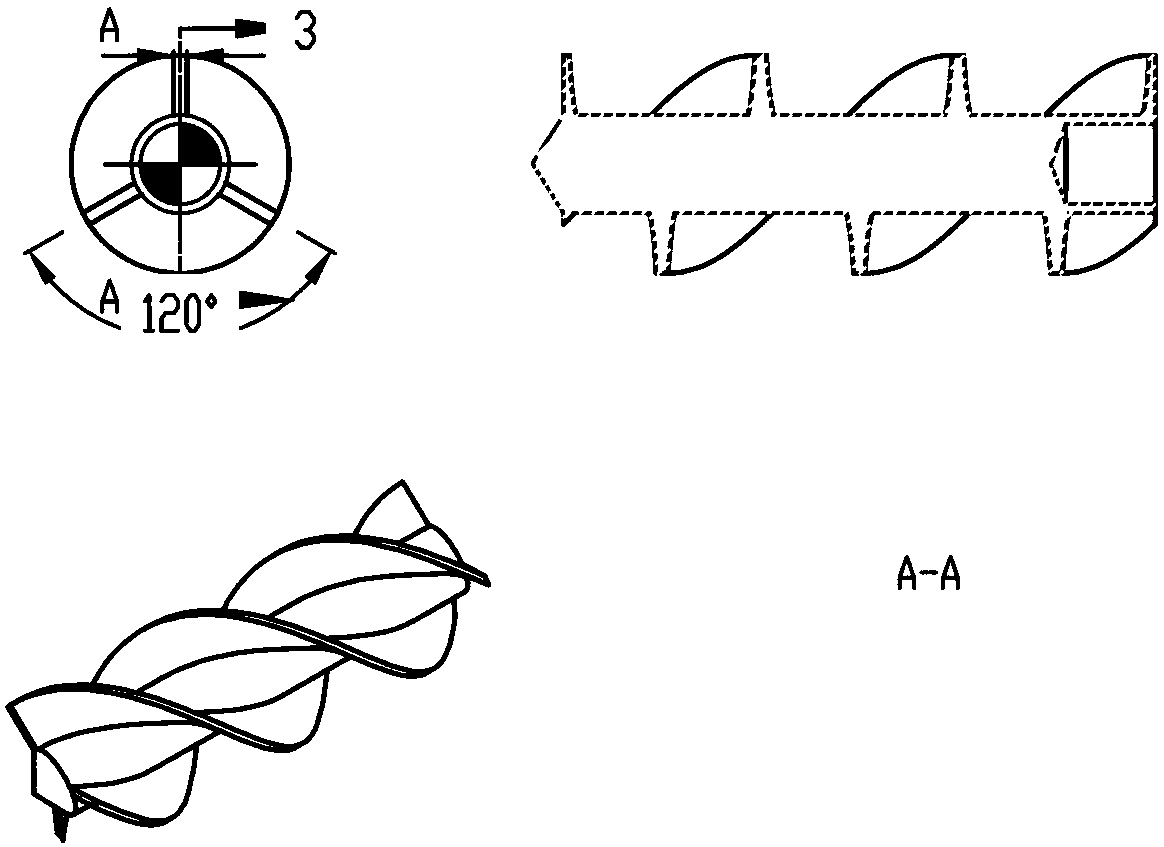

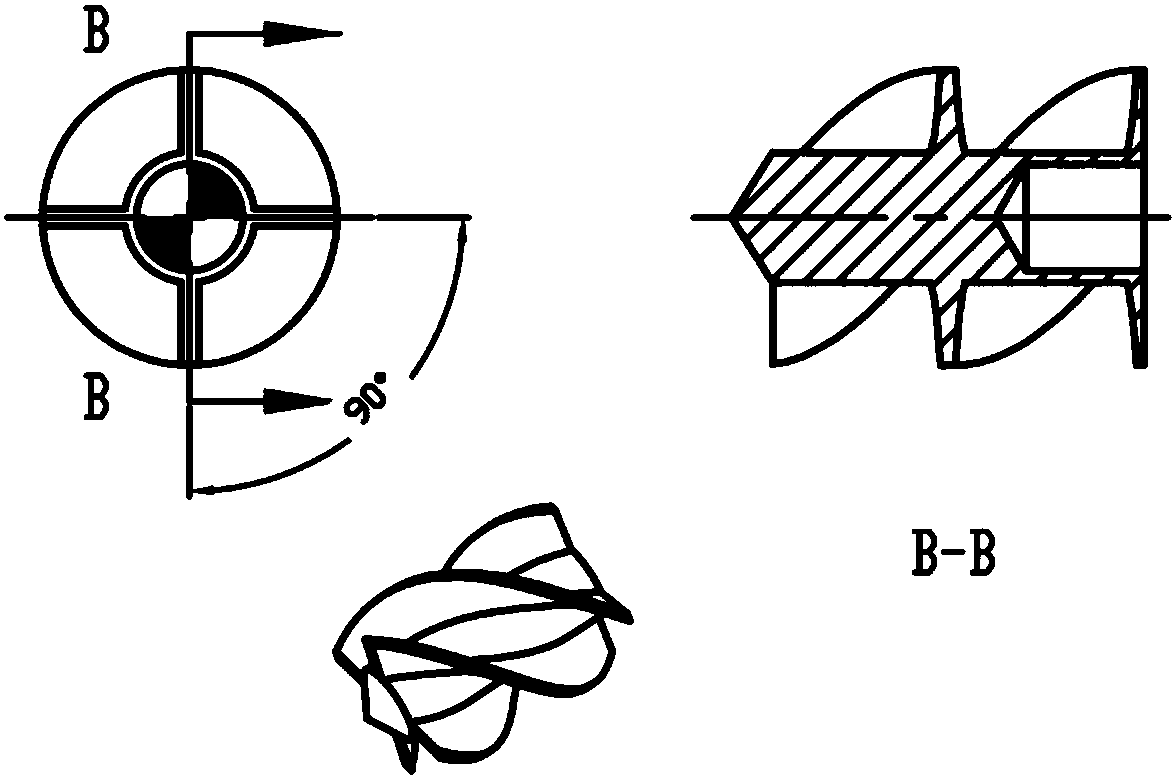

Multi-blade capacitor device with phase separation function of swirling flows for measuring moisture content

InactiveCN109613074AChange mobilityAvoid influence of measurement resultsMaterial capacitanceCapacitanceSpiral blade

The invention relates to a multi-blade capacitor device with a phase separation function of swirling flows for measuring the moisture content, which comprises a swirling flow phase separation unit anda capacitance measuring unit. The device is characterized in that: the swirling flow phase separation unit comprises a spiral blade support rod, and two or more spiral blades and an outer tube wall distributed on the outer circumference of the spiral blade support rod; the capacitance measuring unit comprises a metal inner core, an insulating layer and an outer metal tube wall covering the outercircumference of the metal inner core; the water-facing surface of the spiral blade support rod is streamlined. The multi-blade capacitor device has a good distribution effect of gas-liquid phase separation and does not depend on two-phase flow pattern, and can reliably measure the moisture content through the capacitor unit.

Owner:TIANJIN UNIV +1

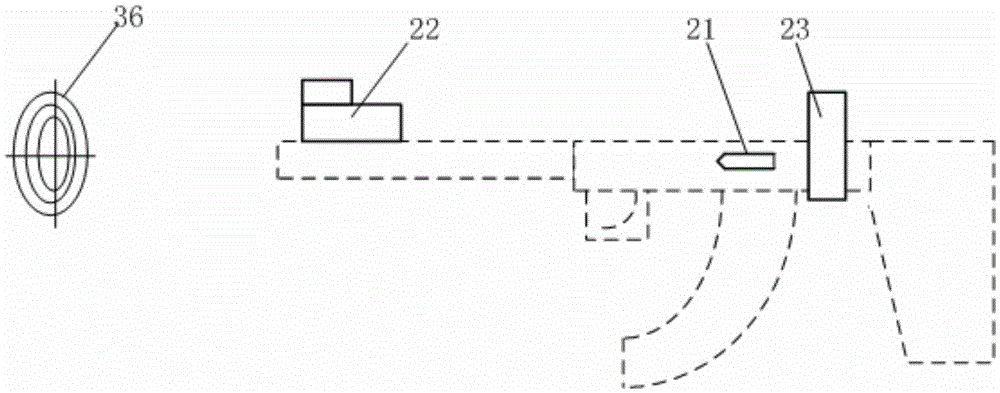

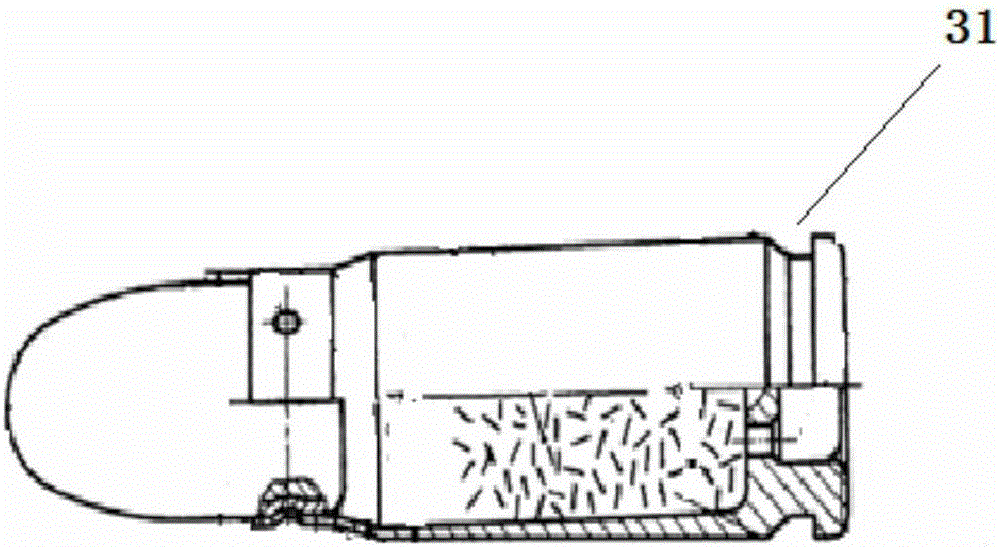

Compact type shooting training aid system

The invention discloses a compact type shooting training aid system. The compact type shooting training aid system comprises sights, a simulation bullet mounted in a bore, a scoring unit mounted on a shooter or a gun body and a target arranged far from the shooter, wherein the simulation bullet comprises at least one hollow coil arranged in a bullet shell and a corresponding moving magnet moving to and fro, the moving magnet penetrates through the corresponding hollow coil when a gun firing pin hits the simulation bullet, and the hollow coil is driven to produce a triggering signal. The image of the simulation bullet at the triggered moment is obtained by combining an embedded computer technology and a high-precision imaging technology. The shooting process of the compact type shooting training aid system is similar to and as vivid as a real bullet shooting process. The compact type shooting training aid system is more easily accepted by the shooter, changes the phenomenon that other training simulating devices help the shooter develop poor shooting habit due to large difference with real bullet shooting, and achieves the purpose of simultaneously training, checking and correcting.

Owner:高文武

Multi-blade eddy flow phase-splitting capacitor water content measuring device

InactiveCN108426925AAvoid influence of measurement resultsAvoid influenceMaterial capacitancePhase splittingMeasurement device

The invention relates to a multi-blade eddy flow phase-splitting capacitor water content measuring device. The multi-blade eddy flow phase-splitting capacitor water content measuring device comprisesan eddy flow phase-splitting segment and a capacitor measuring segment; the eddy flow phase-splitting segment comprises a spiral blade support rod, more than two spiral blades distributed on the periphery of the spiral blade support rod, and an external tube wall; and the capacitor measuring segment comprises a metal inner core, and an insulating layer and an external metal tube wall which are used for coating the periphery of the metal inner core.

Owner:TIANJIN UNIV +1

A method and device for measuring the depth of molten iron in a molten iron tank

ActiveCN103884400BReduce measurement errorAccurate insertion depthMachines/enginesLevel indicatorsSlagMeasuring instrument

The invention provides a method and device for measuring the depth of hot metal in a hot metal bottle. The device comprises a hot metal bottle tipping trolley, a limiting striker, a limiting switch, a distance measuring instrument and a controller. The method comprises the steps that the controller controls the hot metal bottle tipping trolley to move to a measurement position, the closing of the limiting switch serves as a triggering signal, the distance measurement instrument is controlled to measure the vertical distance between the distance measurement instrument and the liquid level in the hot metal bottle after slagging-off of the hot metal in the hot metal bottle, the difference between the vertical distance measured and the vertical distance between the distance measurement instrument and the top of the hot metal bottle is obtained, then the headroom of the hot metal in the hot metal bottle currently is obtained, and finally the difference between the known depth of the hot metal bottle and the headroom of the hot metal is obtained to further obtain the depth of the hot metal in the hot metal bottle currently. Due to the adoption of the technical method that the depth of the hot metal in the hot metal bottle is obtained by measuring the headroom of the hot metal in the hot metal bottle after slagging-off of the hot metal directly, the influence of slag thickness on a measurement result is effectively avoided, and the hot metal depth measurement error is reduced due to the fact that the measurement accuracy of the distance measurement instrument is far higher than that of manual visual measurement of the headroom.

Owner:LAIWU IRON & STEEL GRP

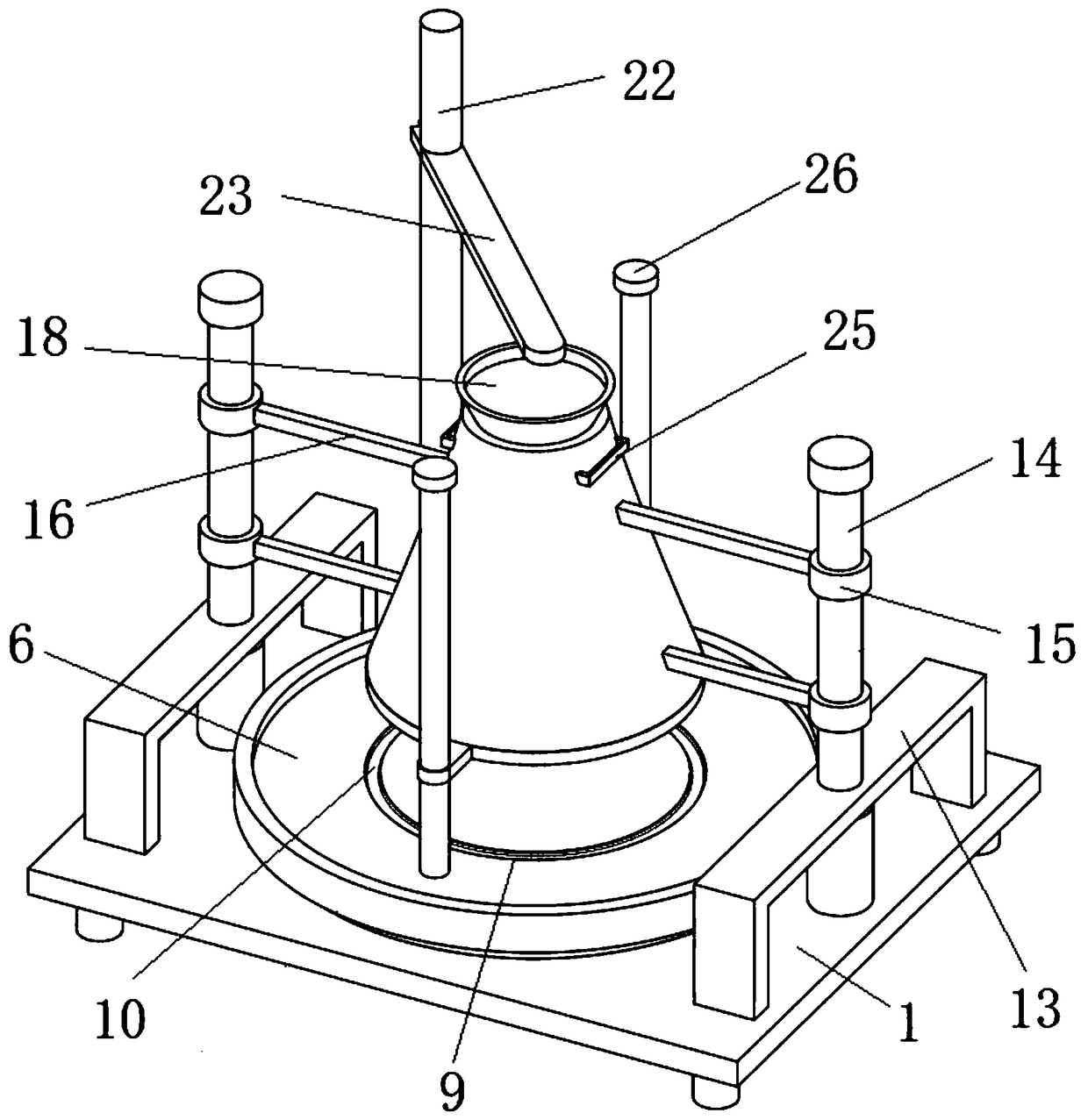

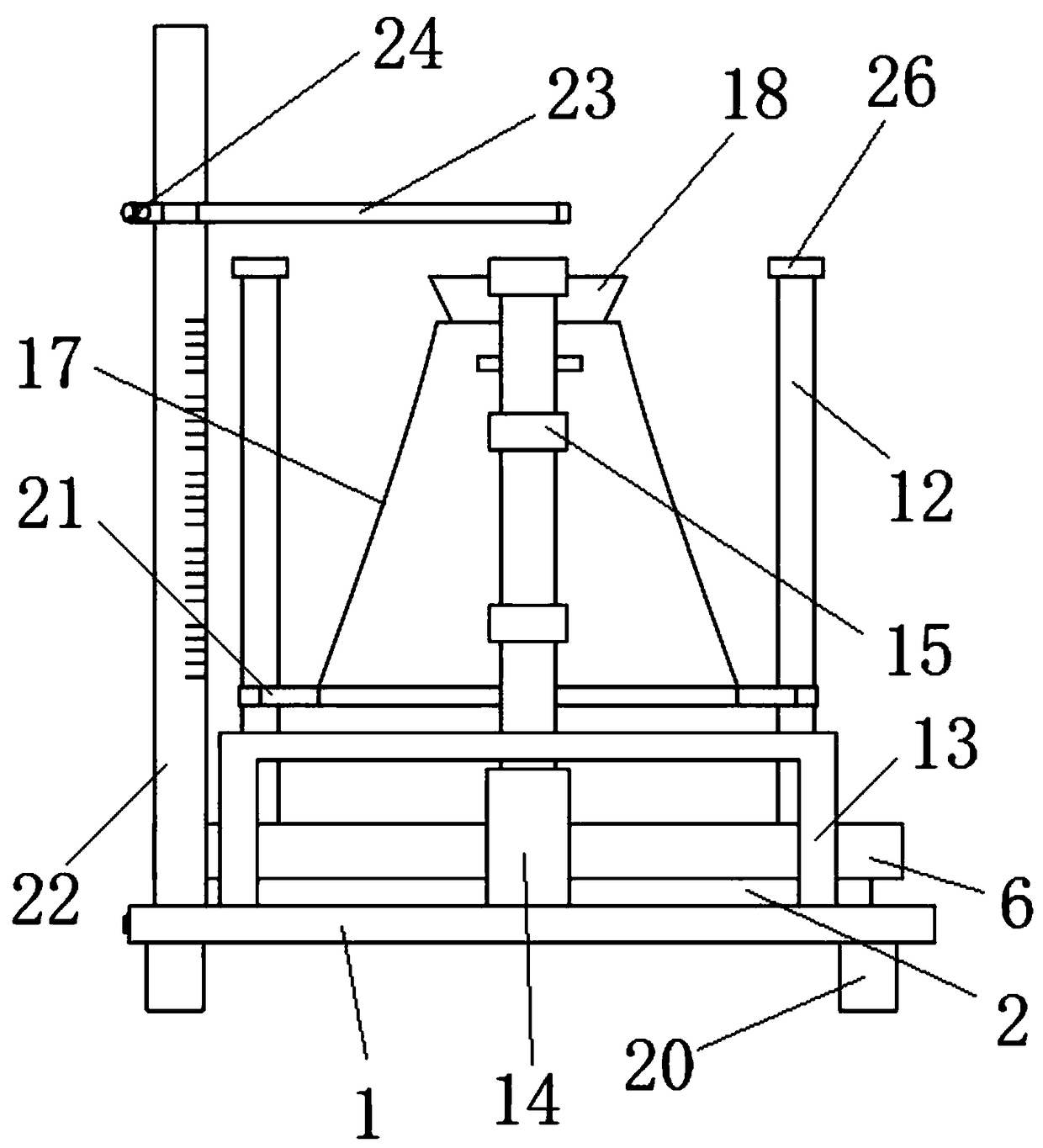

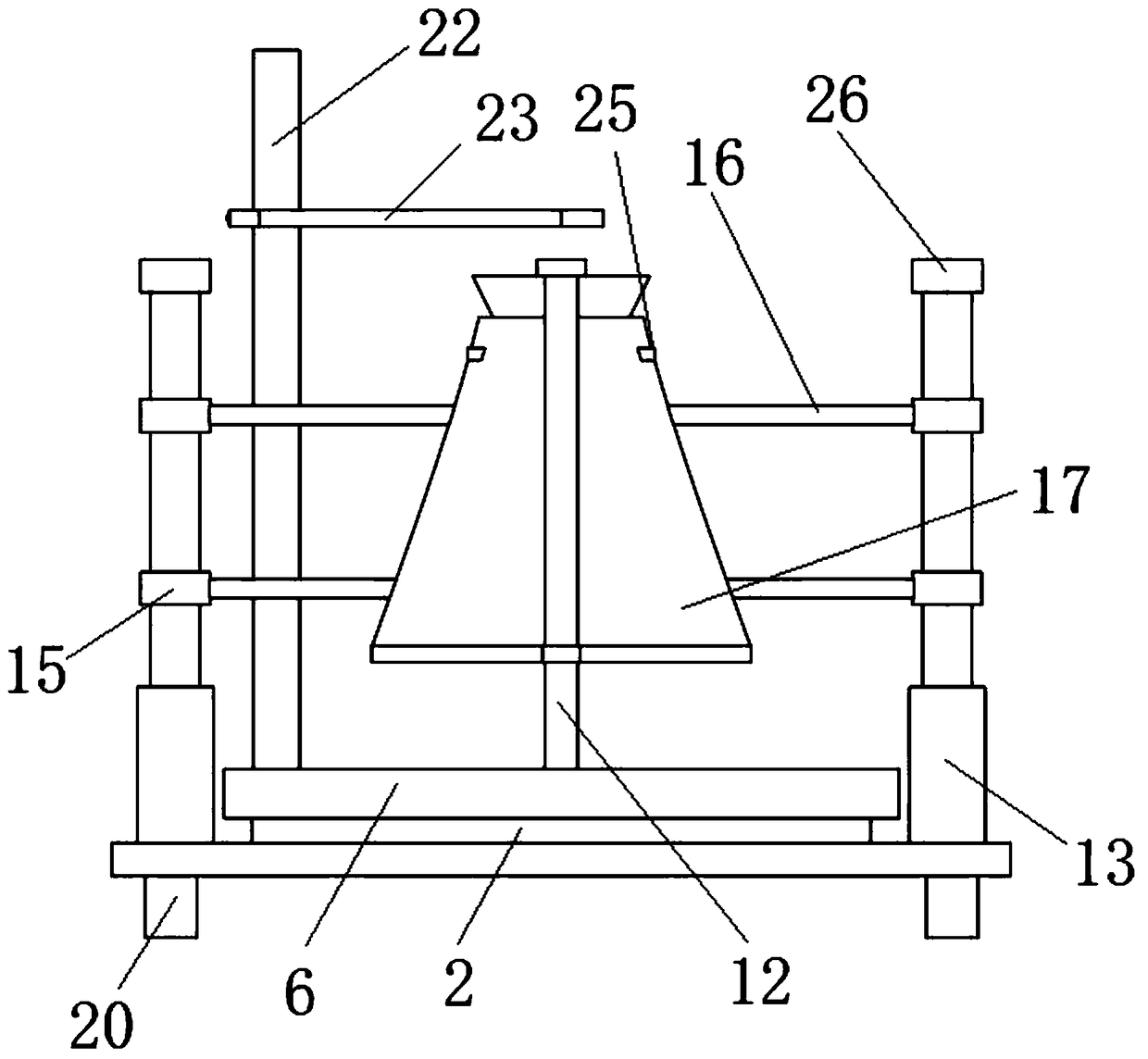

Instrument for measuring cement paste divergence

InactiveCN109061119APrevent outflowEliminate the effects of human errorMaterial testing goodsThird partyEngineering

The invention discloses an instrument for measuring cement paste divergence, related to the technical field of measuring equipment. The instrument for measuring the cement paste divergence comprises abase; a surface of the base is fixedly connected with a dial; a surface of the dial is provided with a location groove; the surface of the dial is fixedly connected with a number of arc-shaped calibrated scales; the side around the dial is fixedly connected with a number of fixture blocks; the side around the dial is connected with an operating panel through the fixture blocks in a stuck manner;a surface of the operating panel is fixedly connected with a baffle ring; a surface of the operating panel close to the dial is fixedly connected with a location block; a surface of the operating panel far from the dial is provided with a limit groove ; and a surface of the limit groove is movably connected with a rubber gasket. Through the designs of the dial, the arc-shaped calibrated scales, the rubber gasket and the limit groove disclosed by the invention, on the one hand, the outflow of the cement paste can effectively prevented; and on the other hand, after a slump bucket is lifted, third-party tools such as a flexible rule and the like are not required, and direct reading can be realized through the arc-shaped calibrated scales on the dial, which is quick and easy and can eliminatethe effects of personal error.

Owner:FOSHAN UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com