Quasi-distributed fiber sensor capable of measuring temperature and vibration simultaneously and manufacturing method

A fiber optic sensor, quasi-distributed technology, applied in thermometers, measuring heat, measuring devices, etc., can solve the problems of increased device size, fewer optical fiber sensors, and increased sensor size, so as to reduce device size, improve adaptability, Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

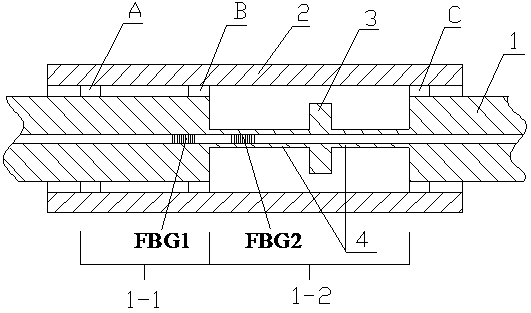

[0014] A quasi-distributed optical fiber sensor capable of simultaneously measuring temperature and vibration, the optical fiber sensor is composed of a common single-mode optical fiber 1 and a protective sheath 2;

[0015] The protective sleeve 2 is socketed outside the ordinary single-mode optical fiber 1, and the inner wall of the protective sleeve 2 is welded to the outer wall of the ordinary single-mode optical fiber 1;

[0016] There are 3 welding positions, the first welding position A, the second welding position B and the third welding position C are arranged in sequence along the axial direction of the protective sleeve 2;

[0017] The ordinary single-mode optical fiber 1 between the first welding position A and the second welding position B forms a temperature correction section 1-1, and the core of the ordinary single-mode optical fiber 1 within the scope of the temperature correction section 1-1 is provided with a first Bragg grating FBG1;

[0018] The ordinary s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com