Device and method for measuring curvature, friction, evenness and hairiness of yarn in combined mode

A measuring device and yarn technology, which is applied in the fields of evenness and hairiness measuring devices, bending and friction, can solve the problems of yarn comprehensive performance error, increase of machine and cost, cumbersome testing process, etc., and achieve fast real-time measurement , saving land, excellent repeatability and reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 118

[0056] Measurement of hairiness, evenness, bending resistance and coefficient of friction of embodiment 118tex cotton yarn

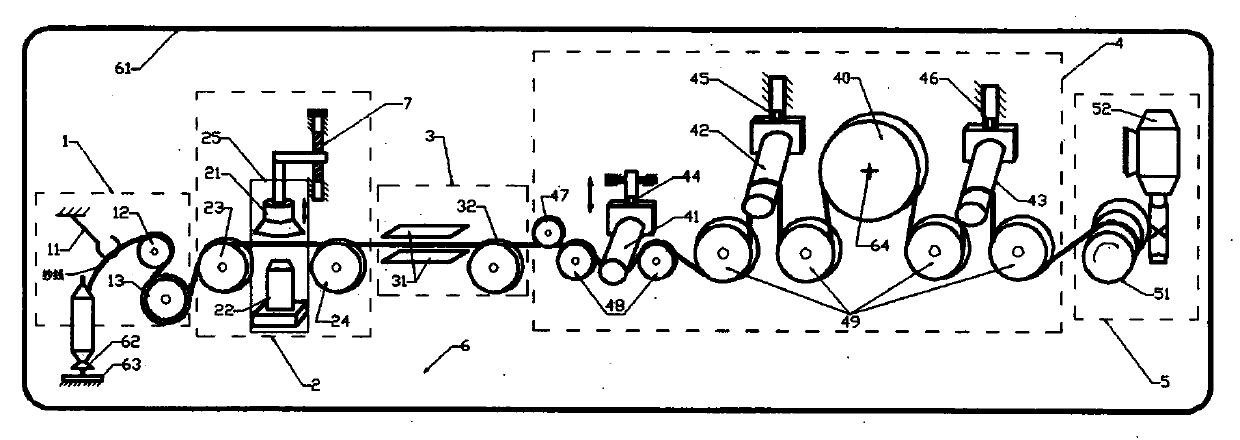

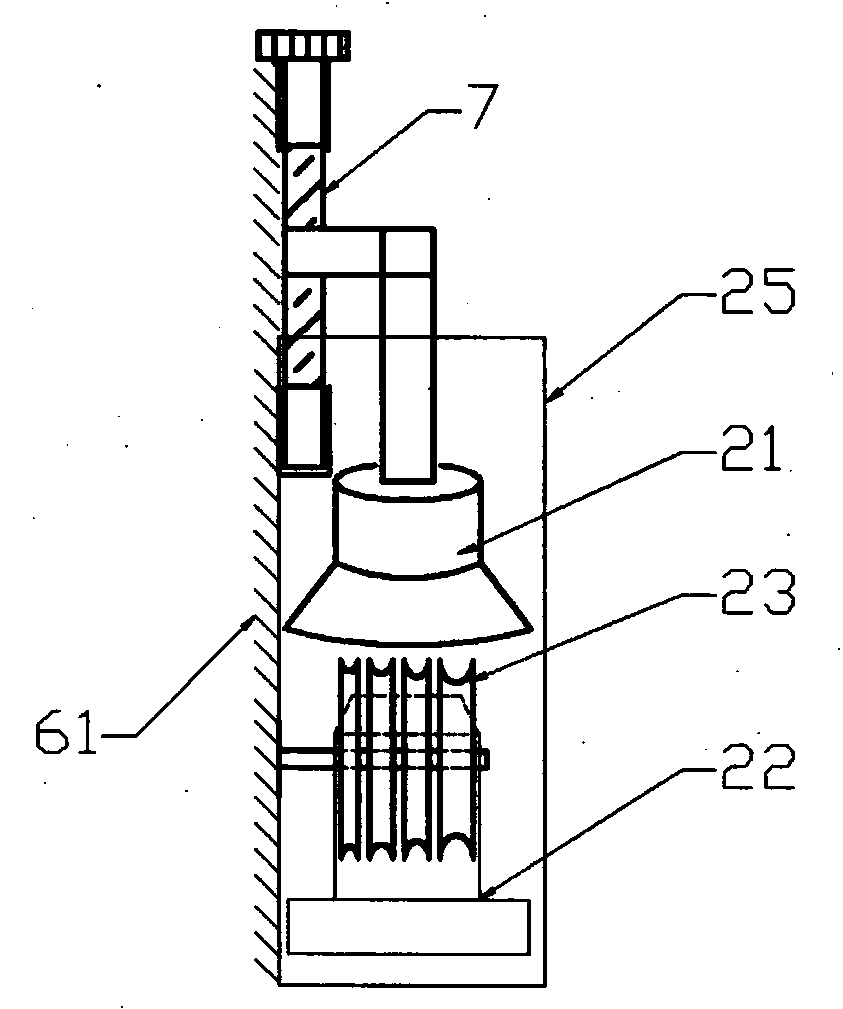

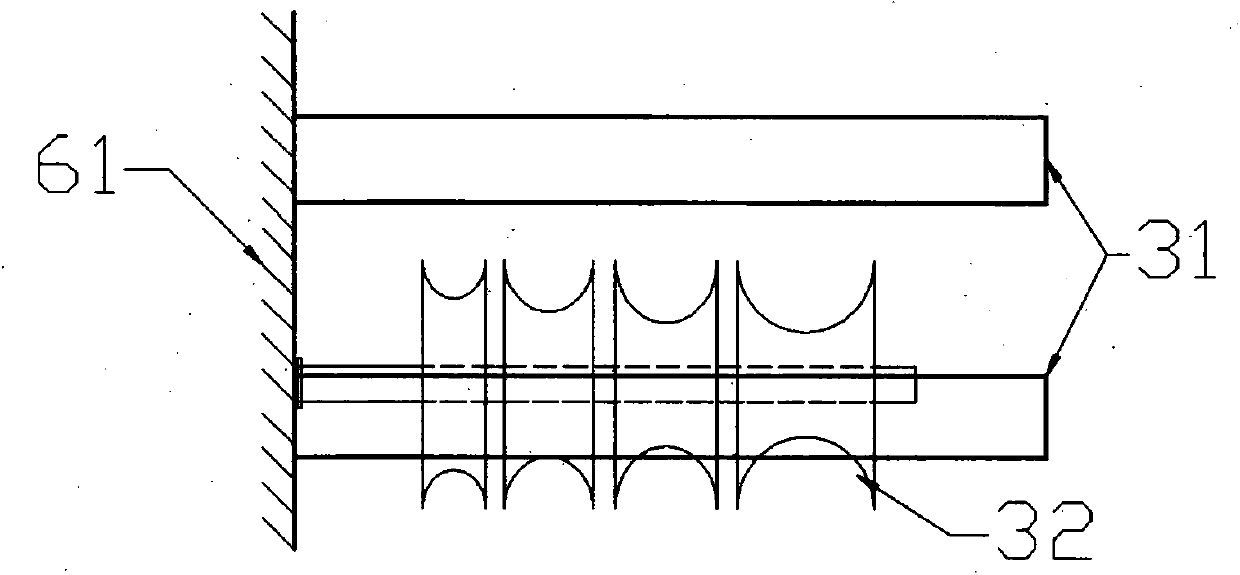

[0057] The schematic diagram of the device of the present invention is as figure 1 As shown, the leading yarn guide roller 12, the first yarn guide idler 23, the second yarn guide idler 24, the third yarn guide idler 32, the limit roller 47, the double idler roller 48, the pressing needle 41, The schematic diagram of the shaft section of the front support needle 42, the guide roller 49, the friction roller 40 and the rear support needle 43 is as Figure 6 As shown, the concave radius of the above-mentioned rollers and needles is selected as 3mm; the preload tension of the damping turntable 13 is set to be 0.05cN / tex; the range of the first force sensor 44 is selected to be 100cN, and the accuracy is 0.01 cN; the range of the selected second force sensor 45 and the third force sensor 46 is 300cN, and the precision is 0.01cN; the shooting times of setting h...

Embodiment 226

[0059] Measurement of hairiness, evenness, bending resistance and coefficient of friction of embodiment 226tex cotton yarn

[0060] The schematic diagram of the device of the present invention is as figure 1 As shown, the leading yarn guide roller 12, the first yarn guide idler 23, the second yarn guide idler 24, the third yarn guide idler 32, the limit roller 47, the double idler roller 48, the pressing needle 41, The schematic diagram of the shaft planing surface of the front support needle 42, the guide roller 49, the friction roller 40 and the rear support needle 43 is as follows Figure 6 As shown, and selected the concave radius of above-mentioned roller and needle is 8mm; The preloaded tension force of setting damping turntable 13 is 0.5cN / tex; The range of selecting the first force sensor 44 is 80cN, and the accuracy is 0.01cN; The range of the selected second force sensor 45 and the third force sensor 46 is 400cN, and the accuracy is 0.01cN; the number of shots of th...

Embodiment 318

[0062] Measurement of hairiness, evenness, bending resistance and coefficient of friction of embodiment 318.5tex viscose yarn

[0063] The schematic diagram of the device of the present invention is as figure 1 As shown, the leading yarn guide roller 12, the first yarn guide idler 23, the second yarn guide idler 24, the third yarn guide idler 32, the limit roller 47, the double idler roller 48, the pressing needle 41, The schematic diagram of the shaft planing surface of the front support needle 42, the guide roller 49, the friction roller 40 and the rear support needle 43 is as follows Figure 6 As shown, and selected the concave radius of above-mentioned roller and needle is 5mm; The preloading tension of setting damping turntable 13 is 0.2cN / tex; The range of selecting the first force sensor 44 is 50cN, and the accuracy is 0.01cN; the range of the selected second force sensor 45 and the third force sensor 46 is 400cN, and the accuracy is 0.01cN; the shooting times of the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com