Method for installing distributed sensing optical fibers used for monitoring strain of steel structure

A technology of sensing optical fiber and installation method, which is applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of inconvenient disassembly, uncertain location of steel structure damage and strain, inaccurate strain measurement results, etc., and achieve convenient disassembly process Fast, convenient and fast installation process, accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

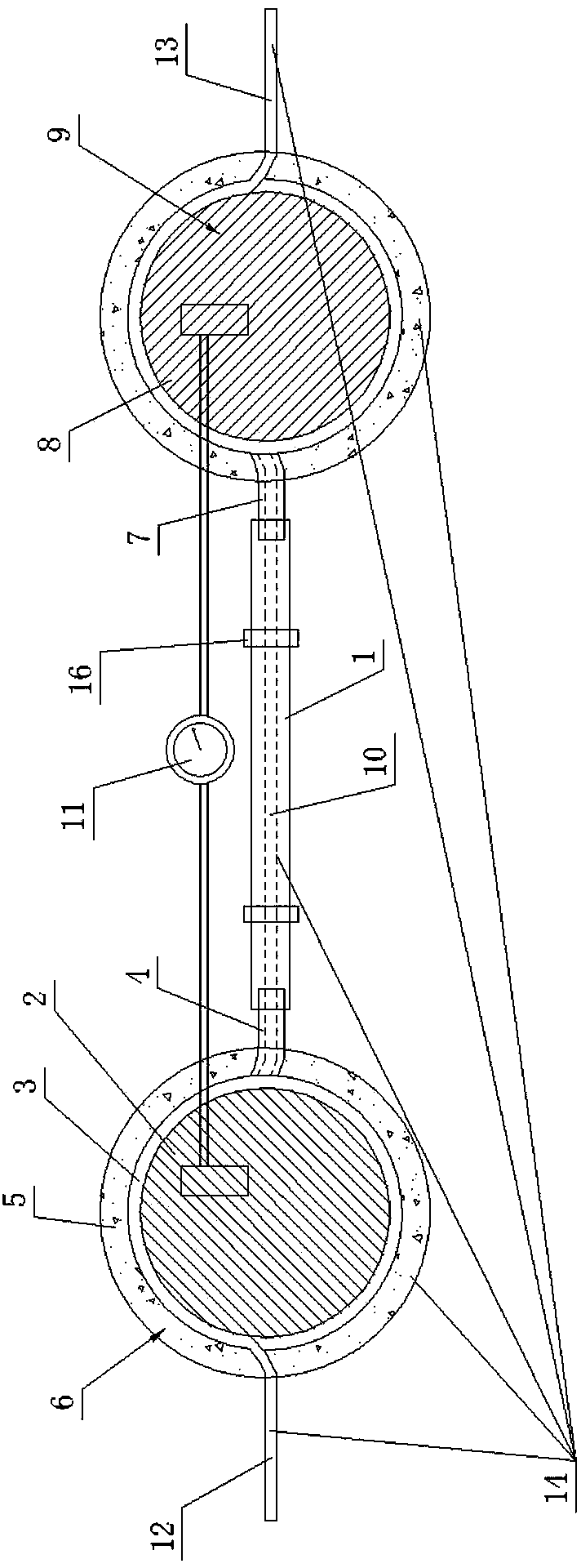

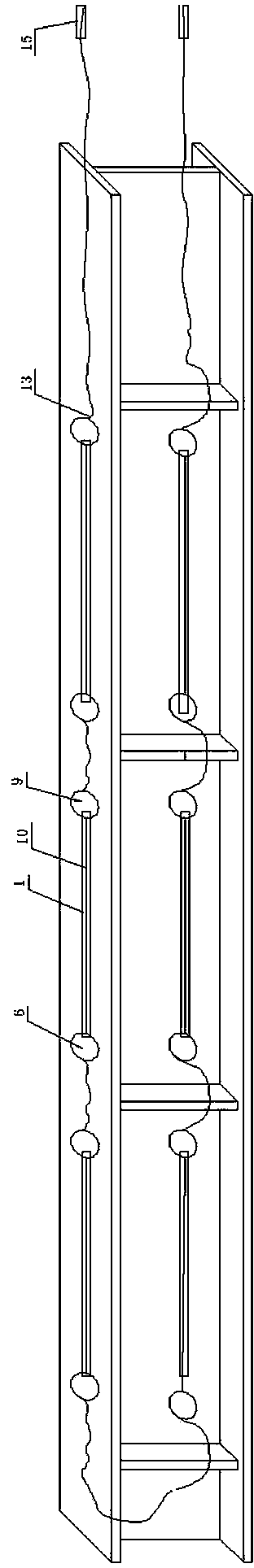

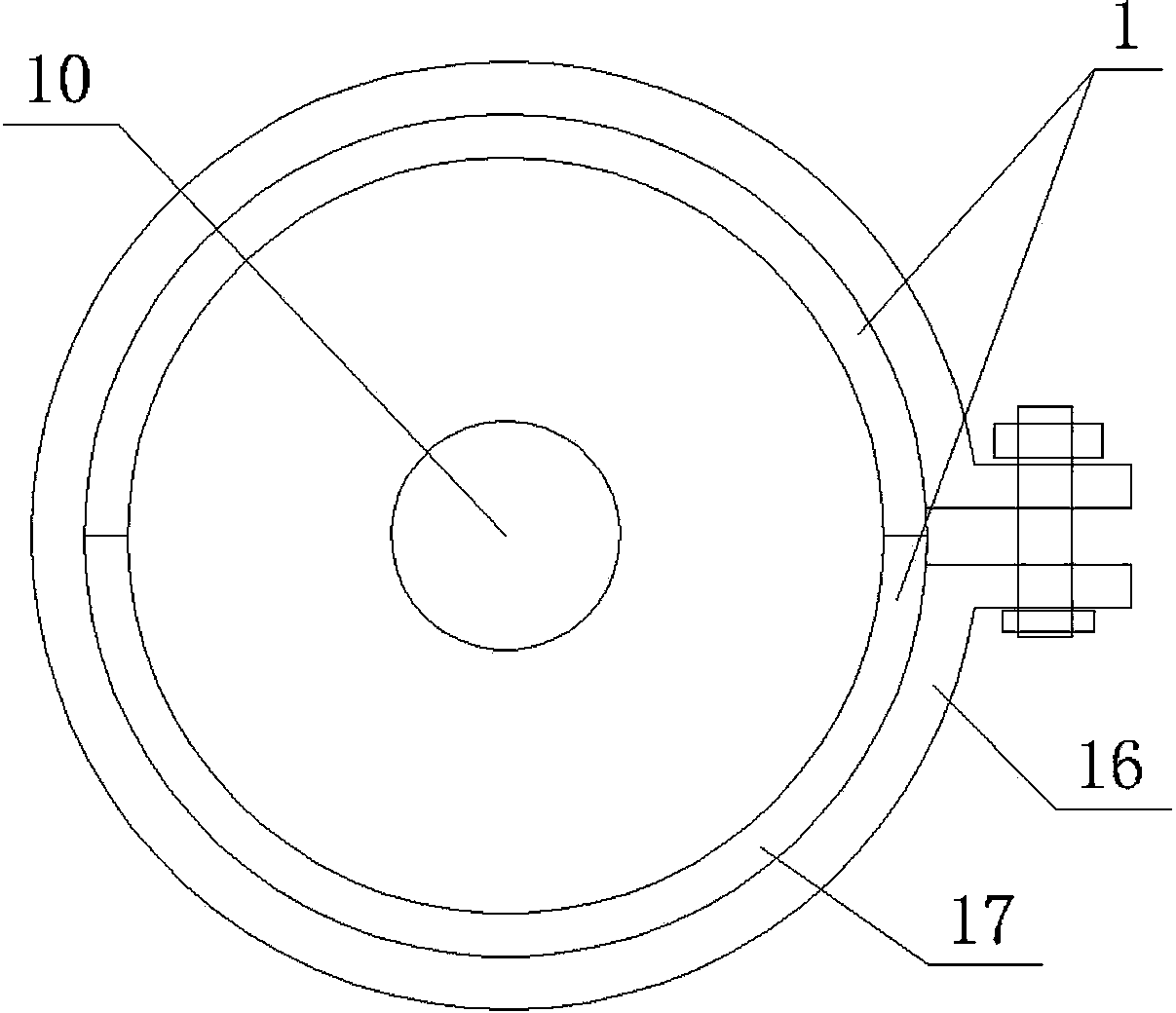

[0027] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention is used to install the distributed sensing optical fiber for monitoring the steel structure strain, and its steps are as follows.

[0028] a. Use a sensing fiber to wind multiple turns on the circumferential surface of the first round handle magnet 2 to form a temperature compensation coil 3, and pass the lead-out end of the temperature compensation coil 3 of the sensing fiber through the first correction sleeve 4; wherein, The first round magnet 2 and the second round magnet 8 of subsequent steps are all high-strength magnets with knobs, and the north and south poles of the magnetic block inside the high-strength magnets are rotated by turning the knobs to realize the magnetization process or demagnetization process.

[0029] b. Pouring an epoxy resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com