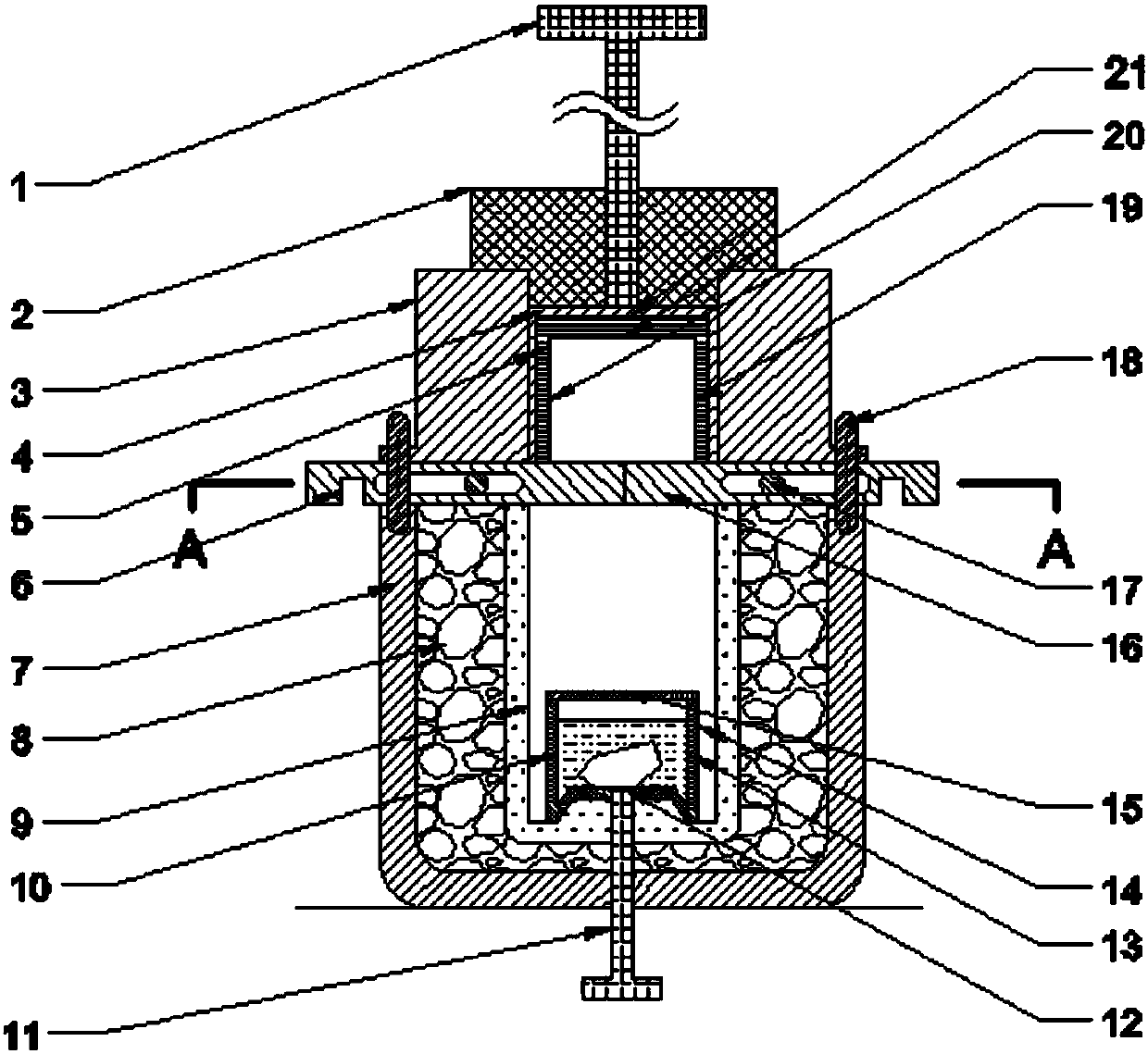

Rock specific heat capacity measuring device and measuring method

A measuring device and measuring method technology, which is applied in the field of specific heat capacity measurement, can solve the problems of increasing the contact area and shortening the time of thermal balance, and achieve the effect of improving the measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] dry measurement method

[0064] Firstly, the mass M of the rock sample is weighed 1 , sample cup mass M 2 , cooling cup mass M 3 , let the specific heat capacity C of the rock sample 1 , the materials of the sample cup and the inner layer of the cooling cup are known, and the specific volume of the sample cup is C 2 , The specific heat capacity of the cooling cup is C 3 .

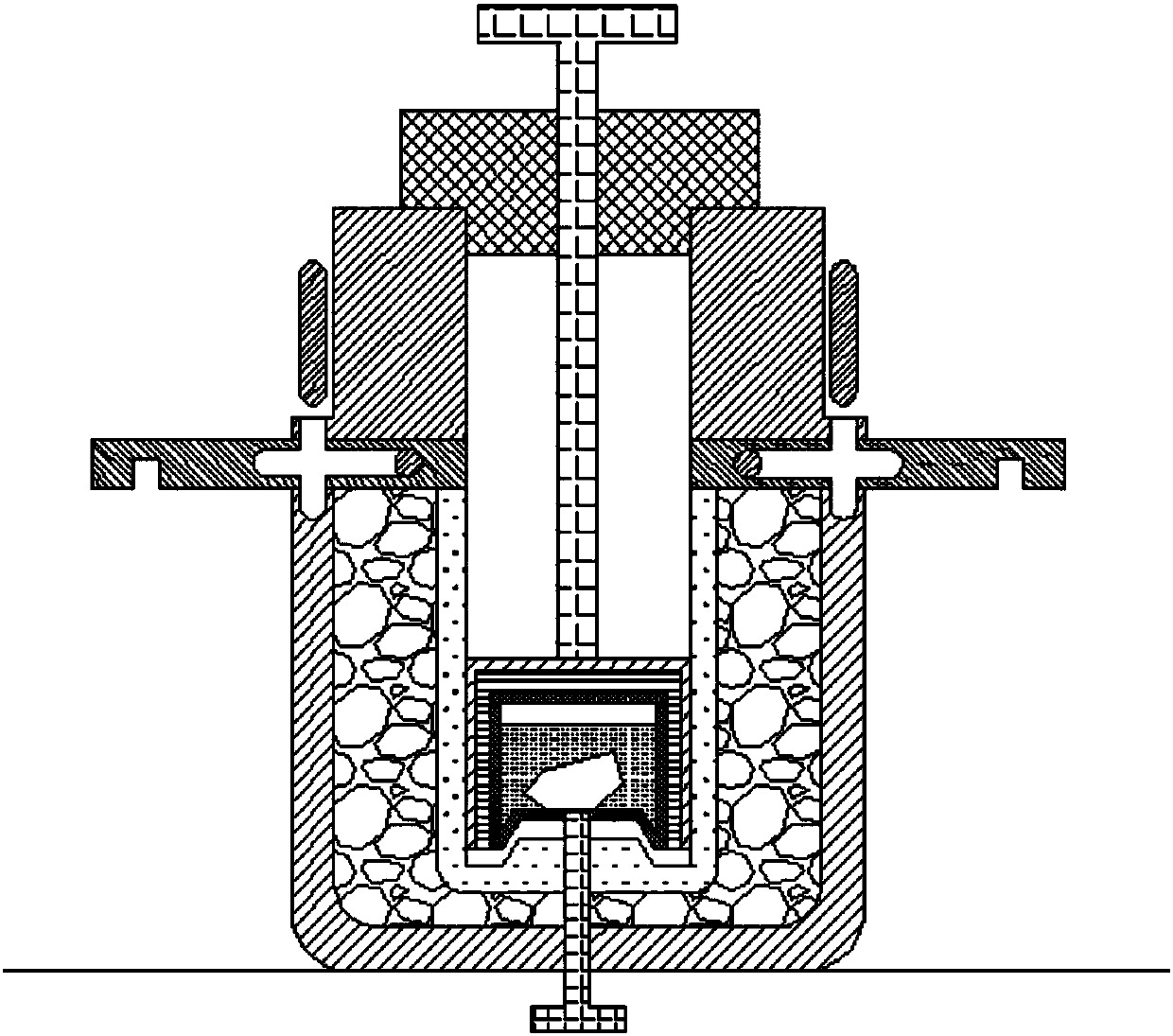

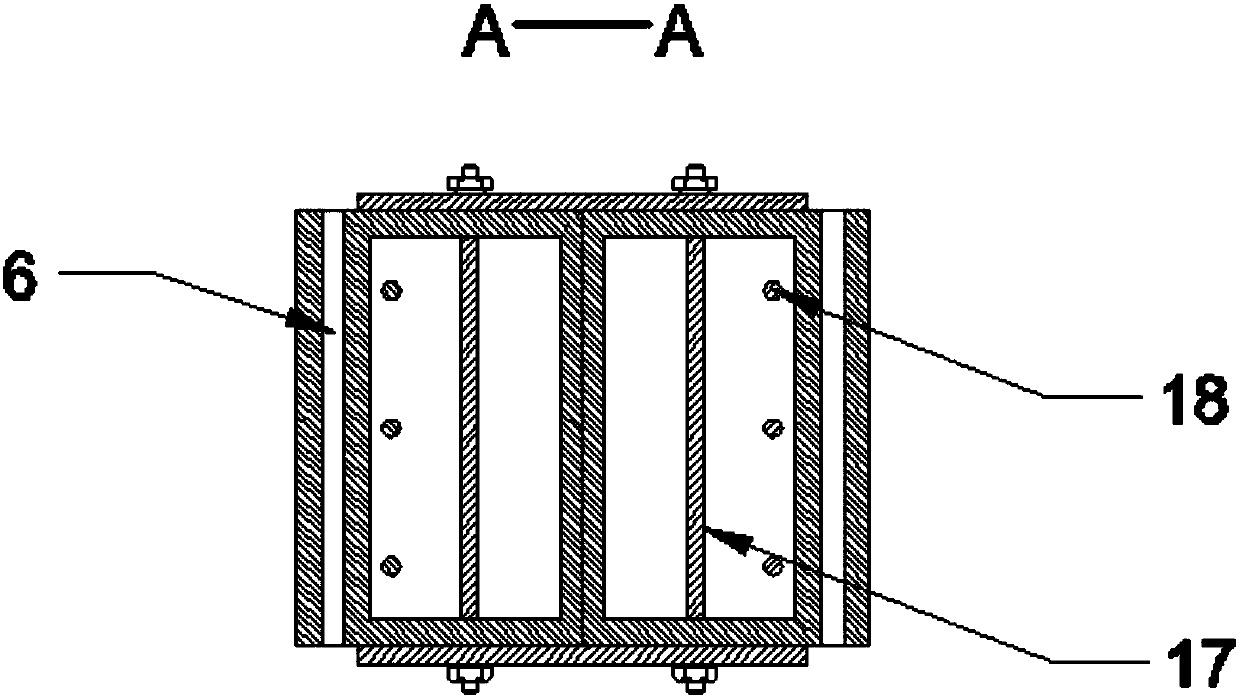

[0065] Remove the positioning pin 18 on the heat insulation board, pull a pair of heat insulation boards horizontally relative to each other, make the upper shell 2 communicate with the heating layer 9, then remove the upper end cover 2, and open the sample cup cover 15, and place the rock sample in the In the sample cup 14, ensure that the surface of the rock sample is in contact with the sample cup inwall, then cover the sample cup cover 15, close the heat shield 8, and install the upper end cover 2; through the fourth thermocouple 19, the fifth thermocouple 20 and the sixth thermocouple 21 m...

Embodiment 2

[0072] wet measurement method

[0073] When the measured rock sample is irregular and cannot be in good contact with the wall of the sample cup, add water to the sample cup, and the water acts as a medium for heat transfer to shorten the time required to reach thermal equilibrium. The specific measurement method is as follows:

[0074] Firstly, the mass M of the rock sample is weighed 1 , sample cup mass M 2 , cooling cup mass M 3 , the mass M of water added in the sample cup 4 , let the specific heat capacity C of the rock sample 1 , the materials of the sample cup and the cooling cup are known, and the specific volume of the sample cup is C 2 , the specific heat capacity of water C 3 , the specific heat capacity of the cooling cup is C 4 .

[0075] Put the rock sample in the sample cup 14, inject a certain amount of water and then cover the sample cup cover 15, the sample cup cover 15 seals the sample cup mouth to prevent the water from evaporating and dissipating hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com