Leaked oil ignition test system based on typical mechanical thermal surface of marine engine room

A test system, hot surface technology, applied in the direction of analyzing materials, material thermal analysis, measuring devices, etc., can solve problems such as inaccuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

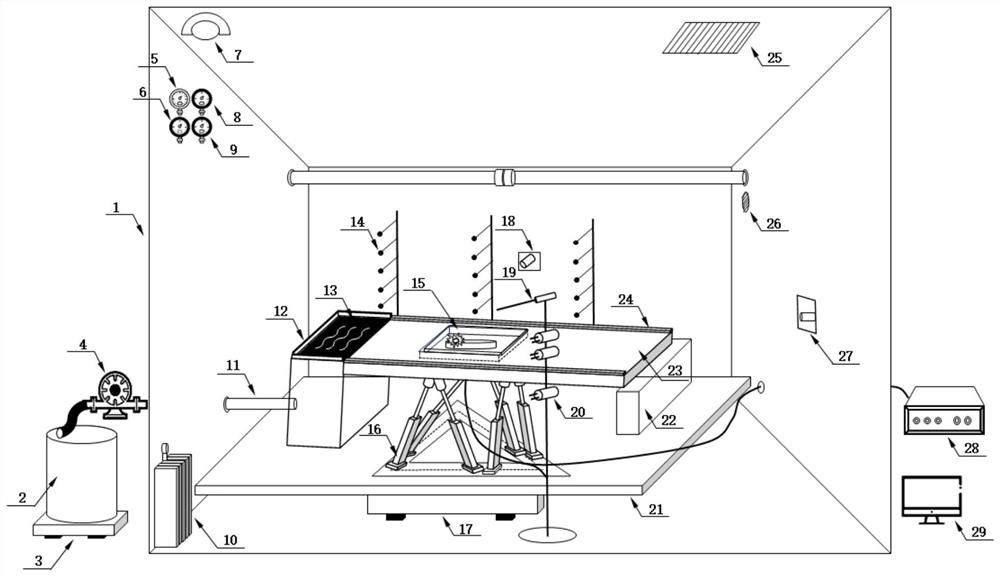

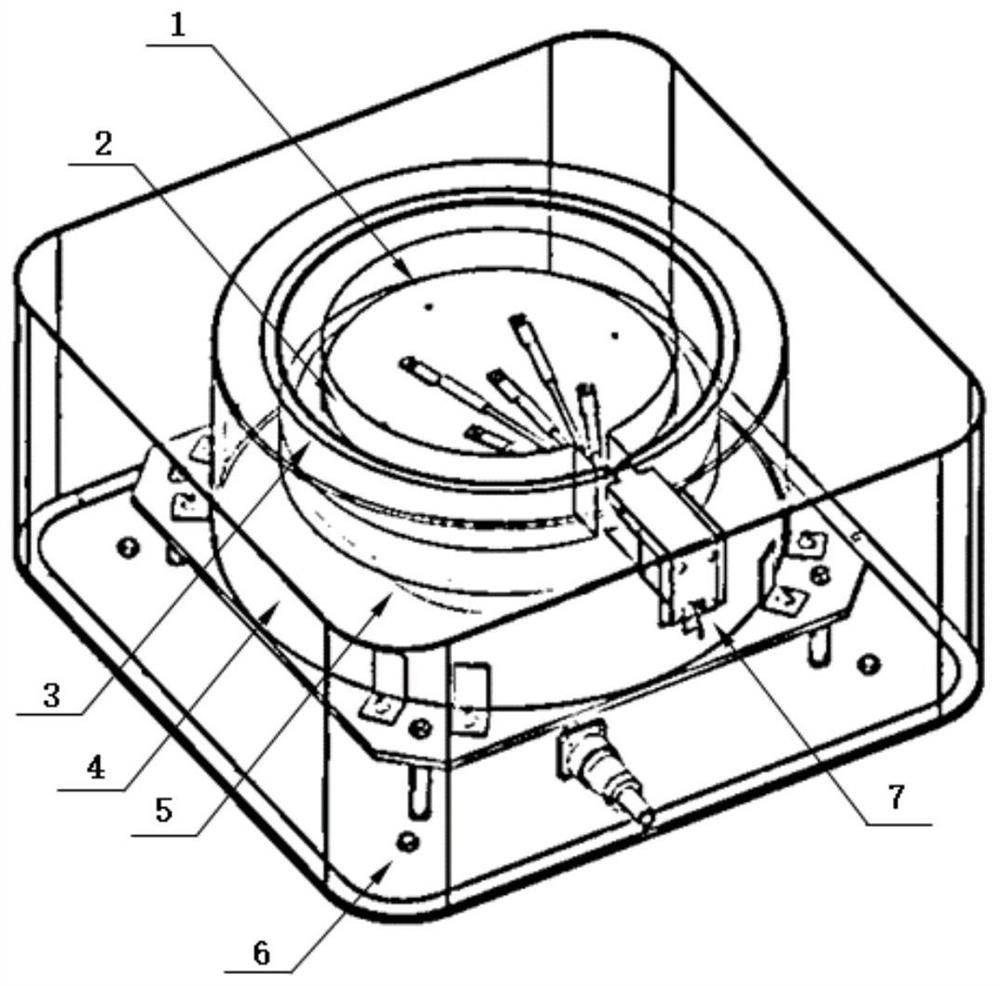

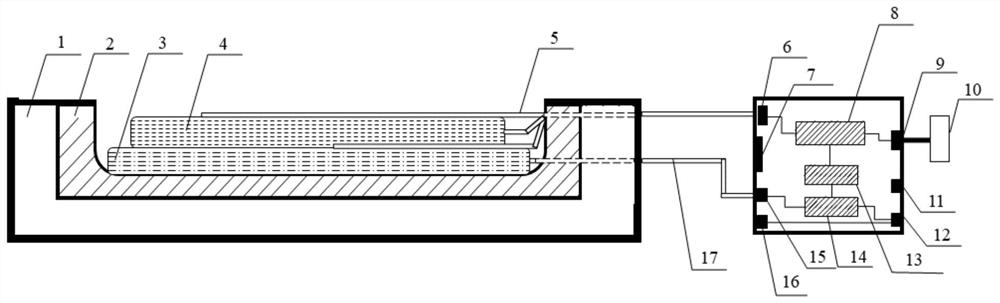

[0029] figure 1 A schematic diagram of a test platform for oil leakage and hot surface ignition testing in a ship's engine room designed for the present invention. At the beginning of the experiment, first turn on the main power switch of the measurement and control circuit box and the operating software of the upper computer, select the correct communication COM port on the software interface, and set basic information such as temperature control mode and safety parameters. figure 2 It is a mechanical thermal surface simulation device for ship engine room, and its structure includes components such as image 3 As shown, including the device support base, insulation cover, heating plate, simulated mechanical thermal surface, surface thermocouple, thermocouple connection wire interface, cooling fan, single-chip microcomputer, USB interface, upper machine position, heating status indicator light and power on, The main power switch of the device, the drive board, the relay, the...

Embodiment 2

[0031] The experimental testing system of the above-mentioned embodiment 1 can realize the simulation and collection of characterization parameters for the dynamic process of different leaked oils being ignited on the typical mechanical heat surface of the test ship engine room, as follows:

[0032] Since the high-temperature mechanical heating surface inside the ship’s engine room is usually in a closed or semi-closed cabin environment, when the combustible fuel used in the ship flows in liquid form and touches the high-temperature mechanical heating surface, whether the ignition phenomenon can occur is not related to the high-temperature mechanical heating In addition to the relationship between the surface temperature, it is also closely related to the air velocity inside the ship's engine room near the high-temperature mechanical heat surface, the liquid auto-ignition temperature of the marine oil, the physical parameters of the oil, and the movement of the ship. Therefore,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com