Temperature measuring device and maintenance device for concrete track slab and coupon

A temperature measuring device and concrete technology, which is applied in the field of concrete, can solve the problems of large temperature control error, inability to measure the temperature change of concrete, and difficulty in ensuring the high quality of concrete track slabs, so as to achieve the effect of improving production efficiency and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

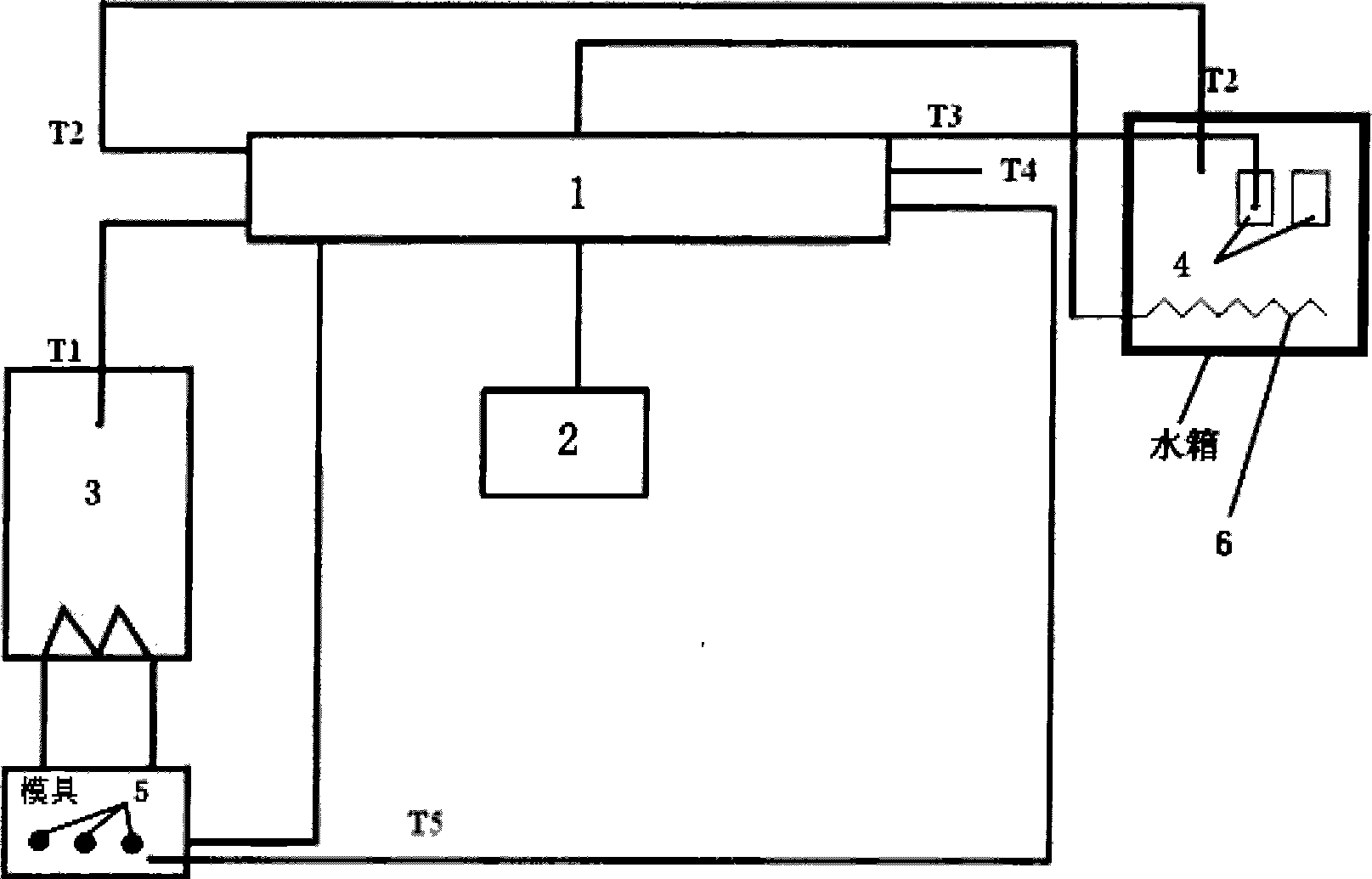

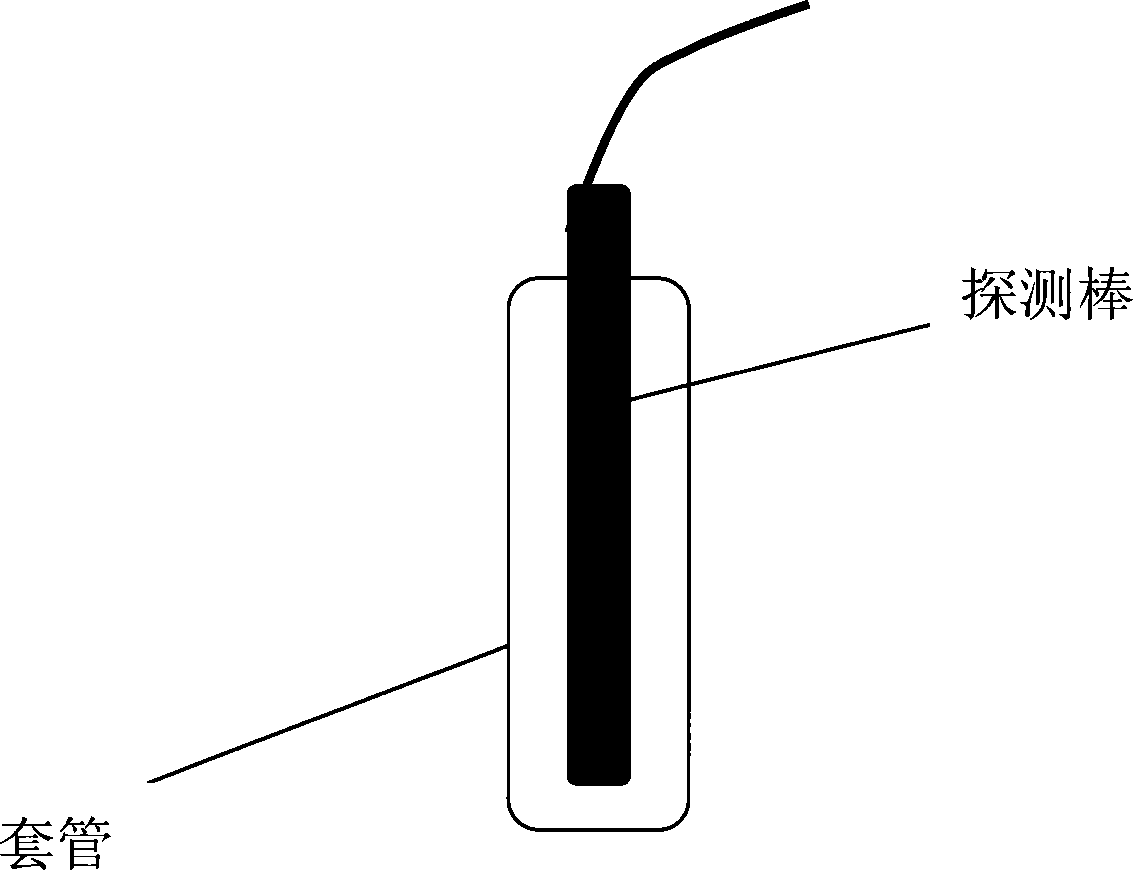

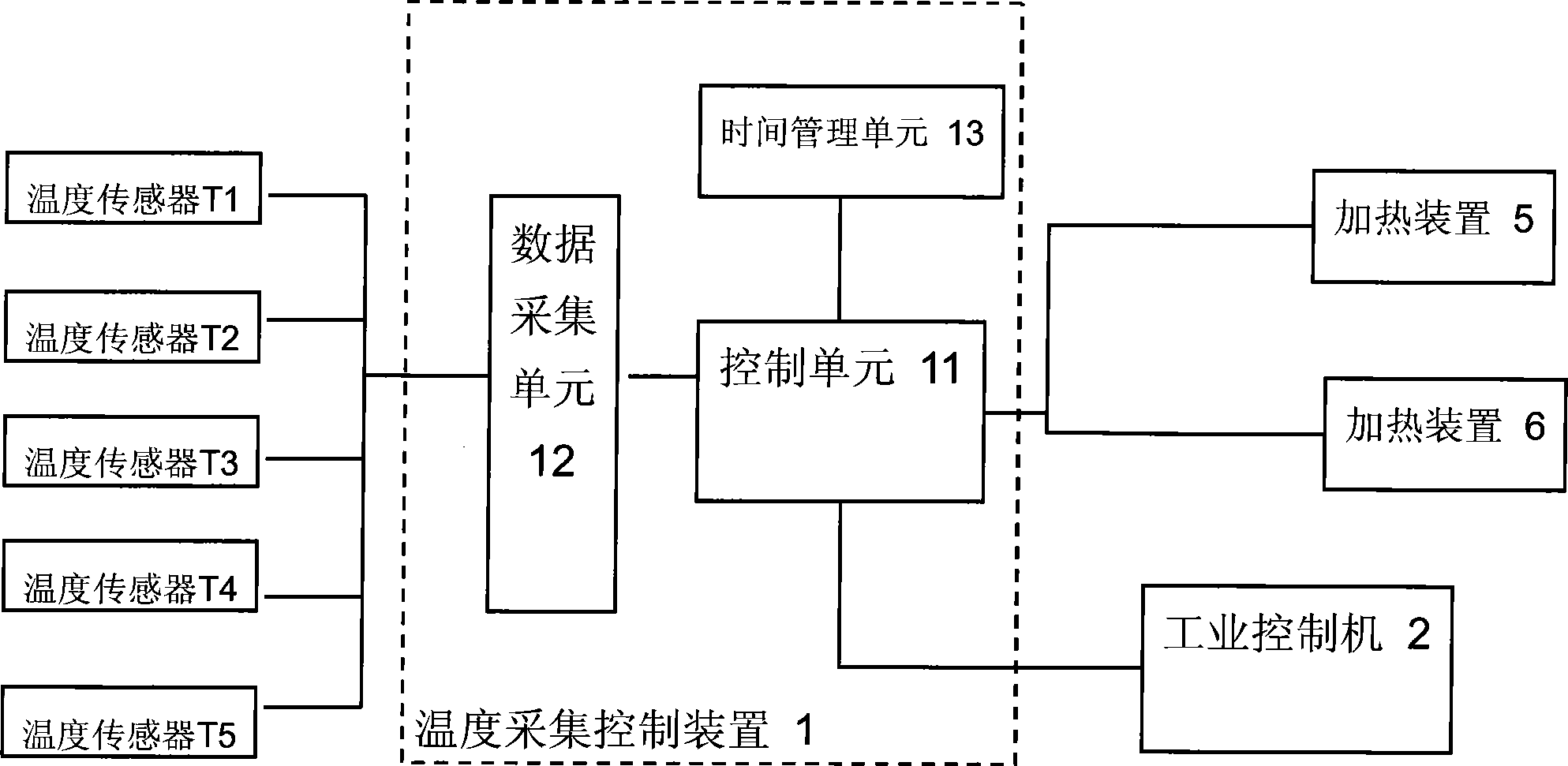

[0031] refer to figure 1 , figure 1 It is a structural schematic diagram of the maintenance equipment for the concrete track slab and the test block in the preferred embodiment of the present invention. As can be seen from the figure, the device includes temperature sensors T1 and T3. Wherein, the temperature sensor T1 is arranged at the core of the concrete track slab 3 (also called the simulation slab) for measuring the temperature of the core of the simulation slab. Such as figure 2 As shown, the temperature sensor T1 includes a detection rod and a detachable casing for enclosing the detection rod, wherein the detection rod is connected to the temperature acquisition and control device 1 through a cable. Before curing, the detection rod is inserted into the concrete together with the casing, preferably vertically, so the depth of insertion can be determined according to the height of the concrete track slab 3, generally set to 1 / 2 to 3 / 4 of the height Between, thereby ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com