TFT glass BOD process rapid dynamic weighing system and weighing method

A dynamic weighing system and dynamic weighing technology, applied in glass manufacturing equipment, glass cutting devices, weighing, etc., can solve problems such as large data errors, failure to meet process requirements, and reduce the comprehensive yield of finished products, so as to reduce weighing The effect of reducing weight error, reducing weighing time, and improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

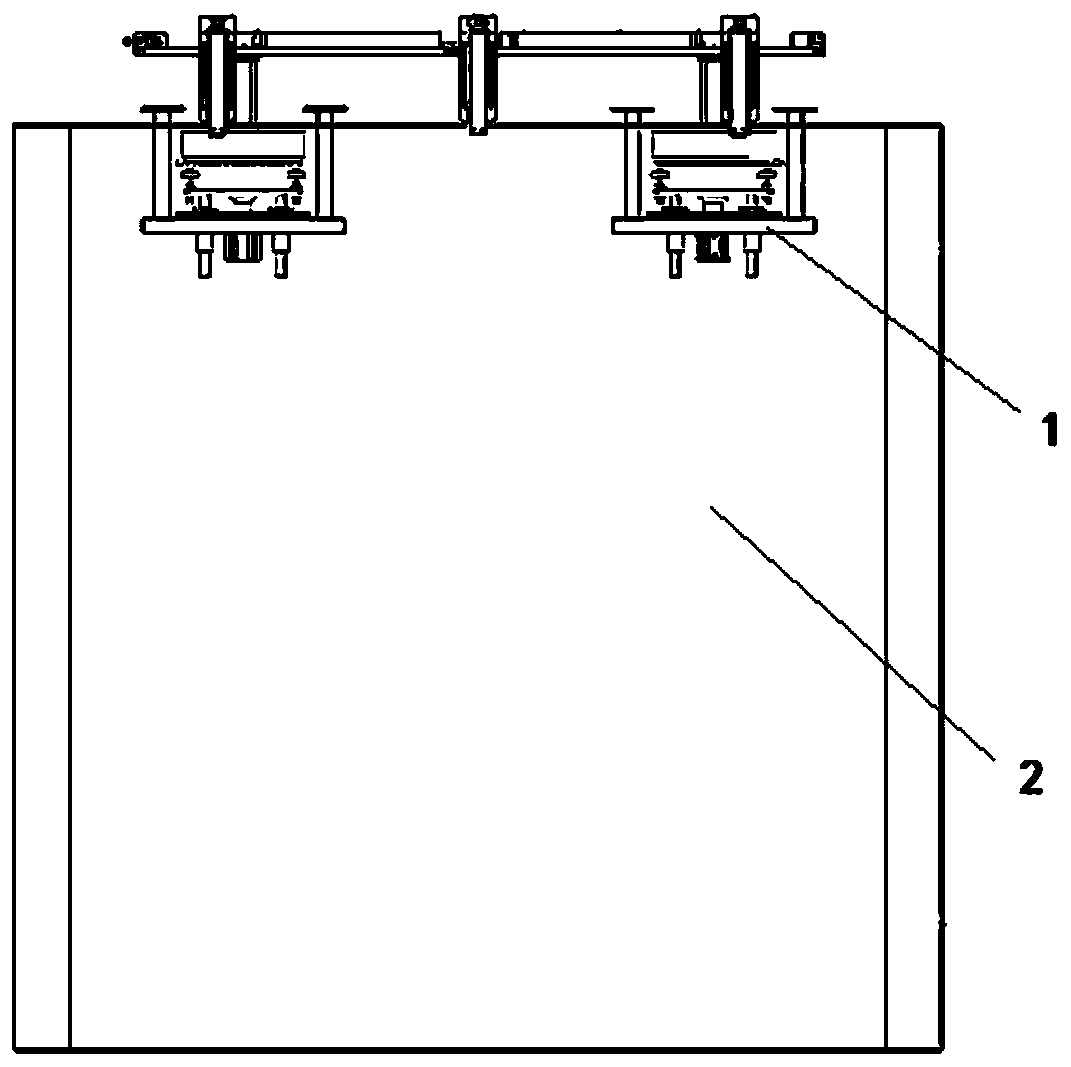

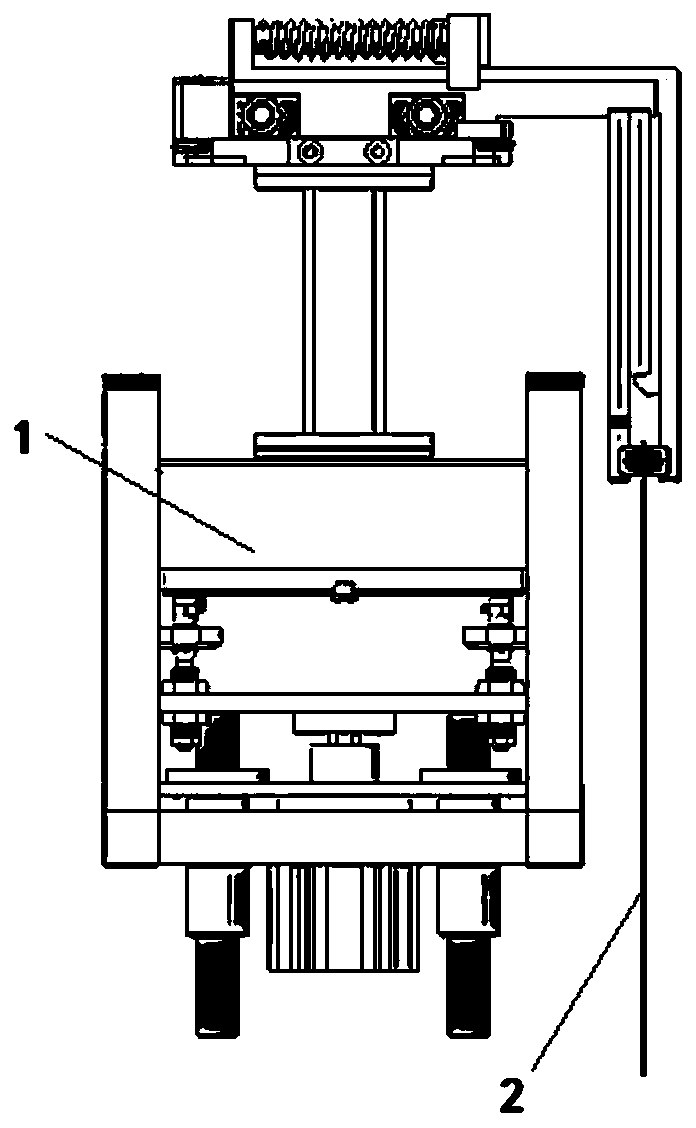

[0040] like Figure 1 to Figure 4 As shown, a fast dynamic weighing system for TFT glass BOD process, including two sets of weighing devices 1 and plc;

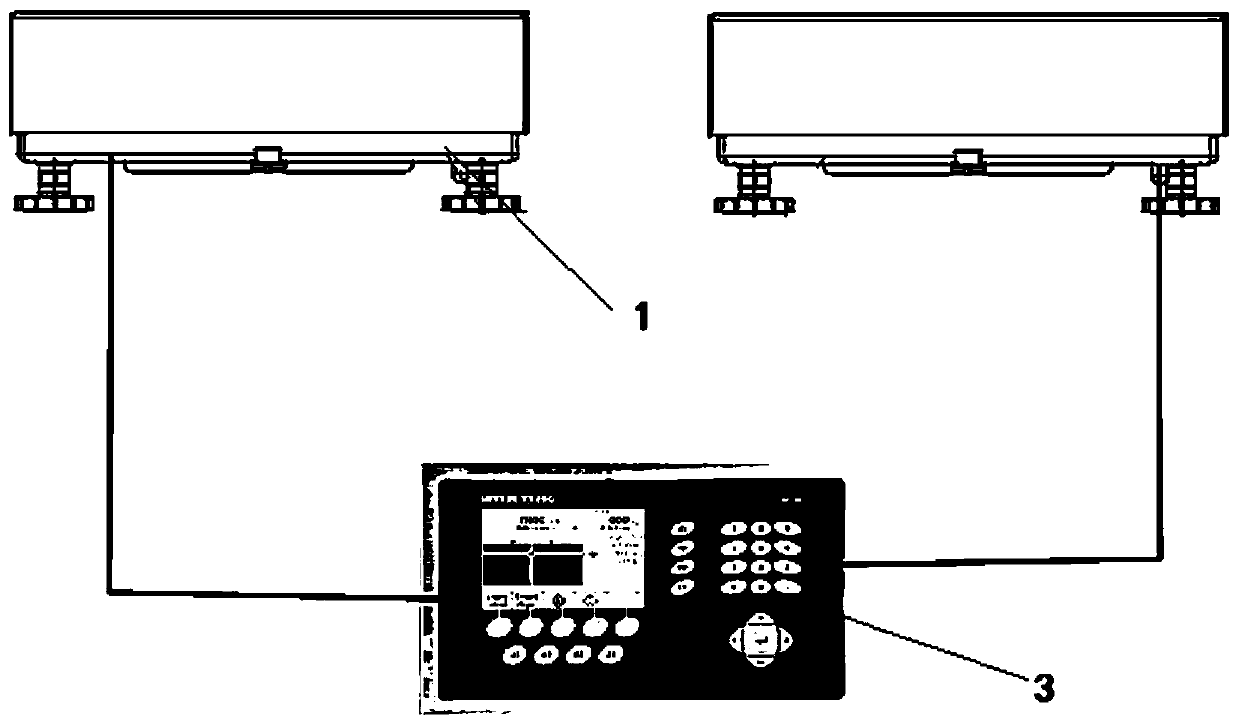

[0041] One group of weighing devices 1 is arranged at the no-load weighing station to measure the weight of the transport trolley; another group of weighing devices 1 is arranged at the load weighing station to measure the weight of the transport trolley and the weighing glass 2;

[0042] Each group of weighing devices 1 includes two high-precision measuring scales, the two high-precision measuring scales jointly complete the weight measurement, and the two high-precision measuring scales are connected to a high-precision scale instrument 3; the high-precision scale instrument 3 The output end is connected to the input end of the plc, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com