Patents

Literature

394results about How to "Guaranteed to be heated" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

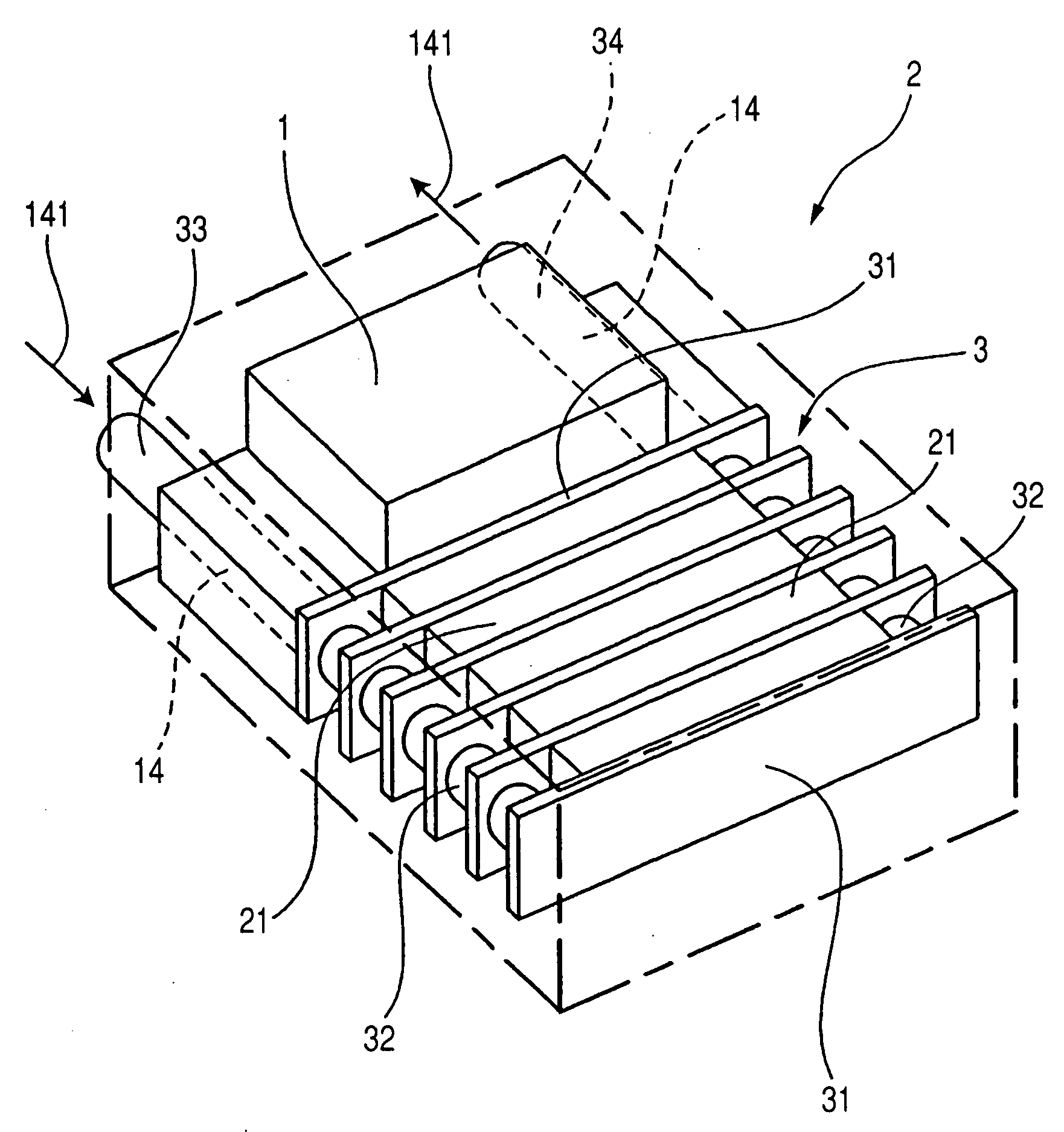

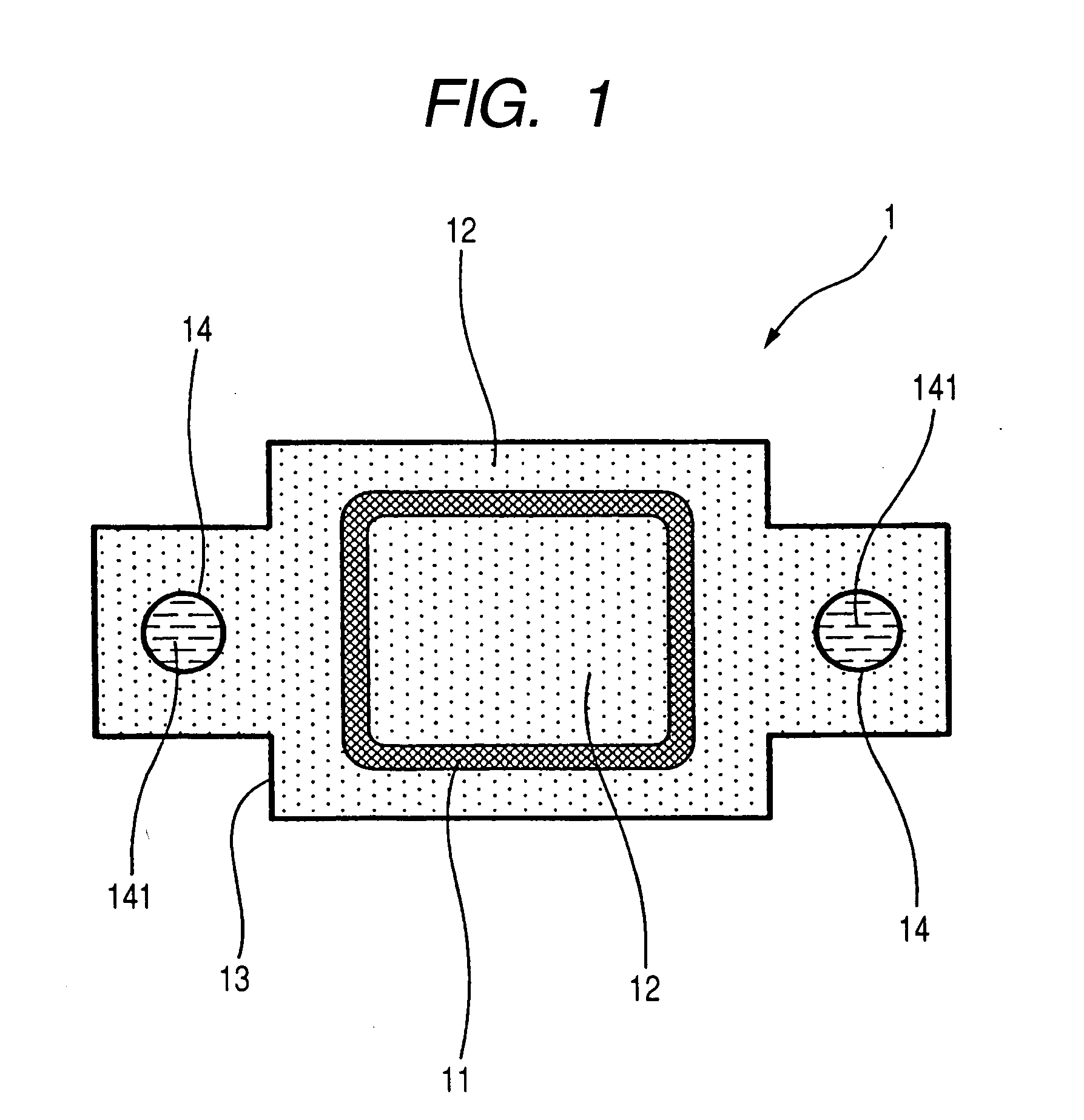

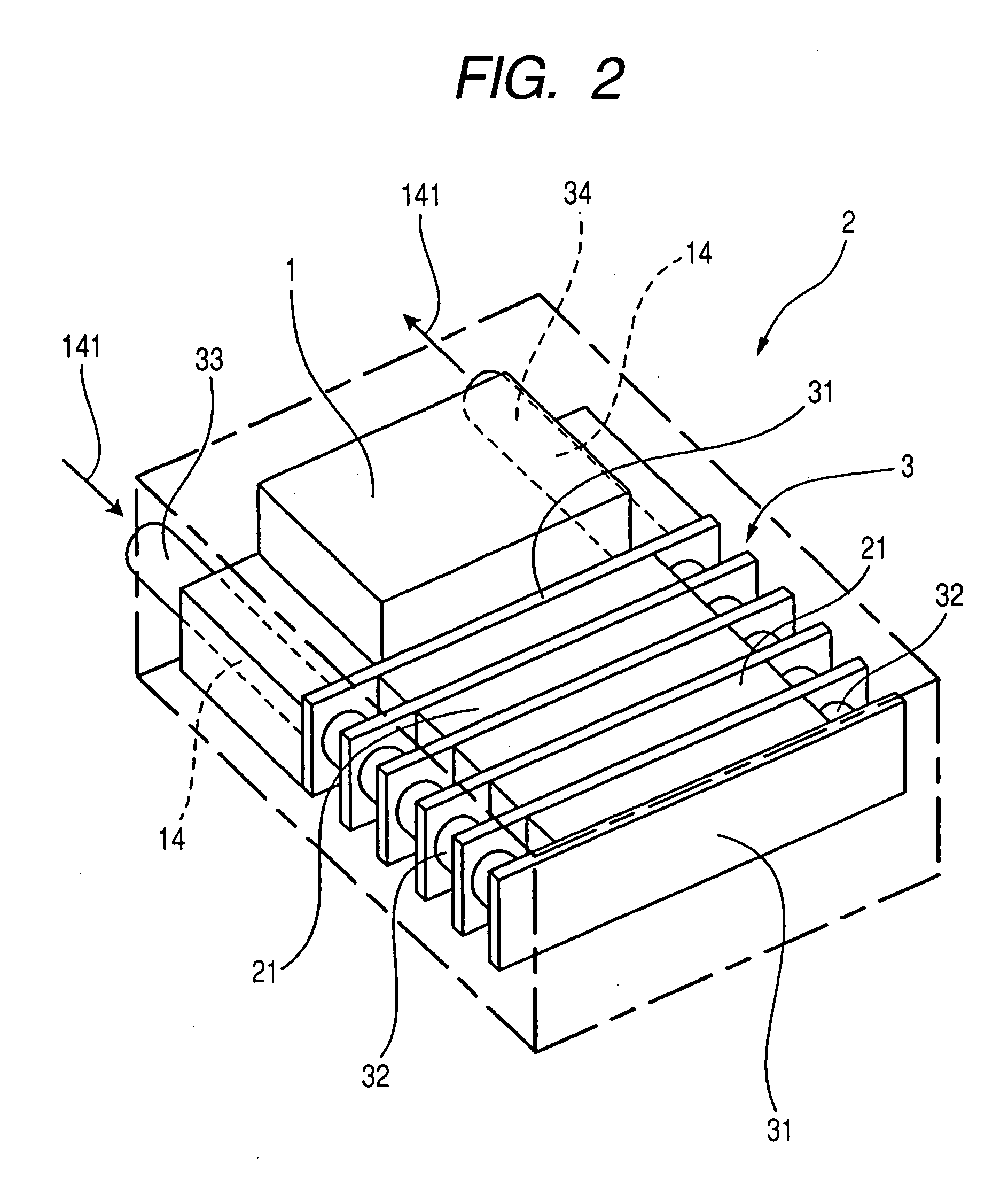

Reactor and power converter incorporating the reactor

ActiveUS20070295715A1Efficient heat radiationImprove cooling effectTransformers/inductances coolingInductances/transformers/magnets manufactureNuclear engineeringEngineering

A reactor is provided with a coil, a core, and a case. The coil generates magnetic flux in response to supply of current thereto. The core is made of magnetic powder-containing resin filled in spaces inside and outside of the core. The case accommodates therein the coil and the core. The reactor is also provided with a cooling pipe (cooling member), which is arranged to be in contact with the core. A power converter is provided with semiconductor modules, a cooler, and the reactor. In the power converter, the cooler is arranged partially being in contact with the core of the reactor.

Owner:TOKIN CORP

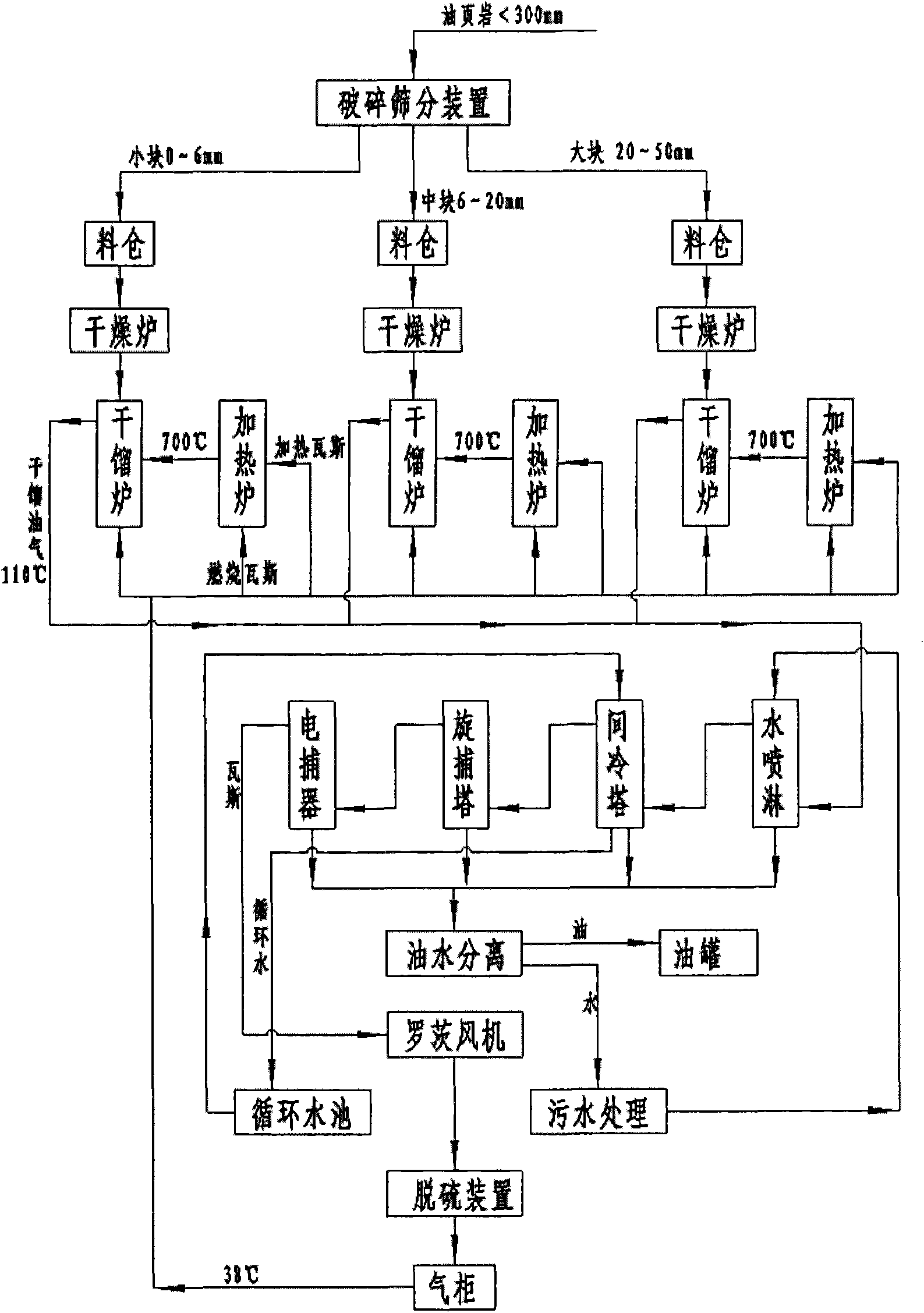

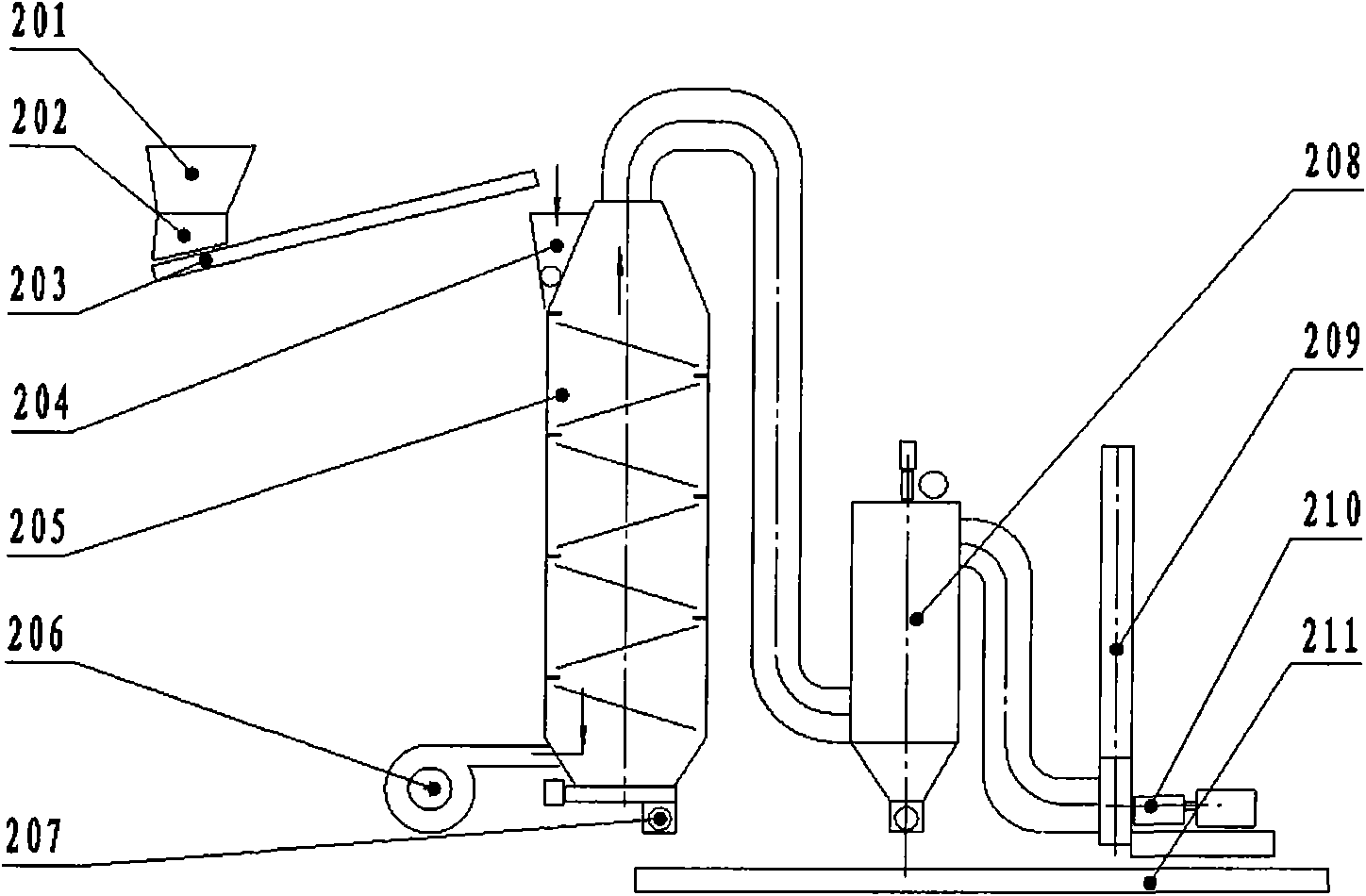

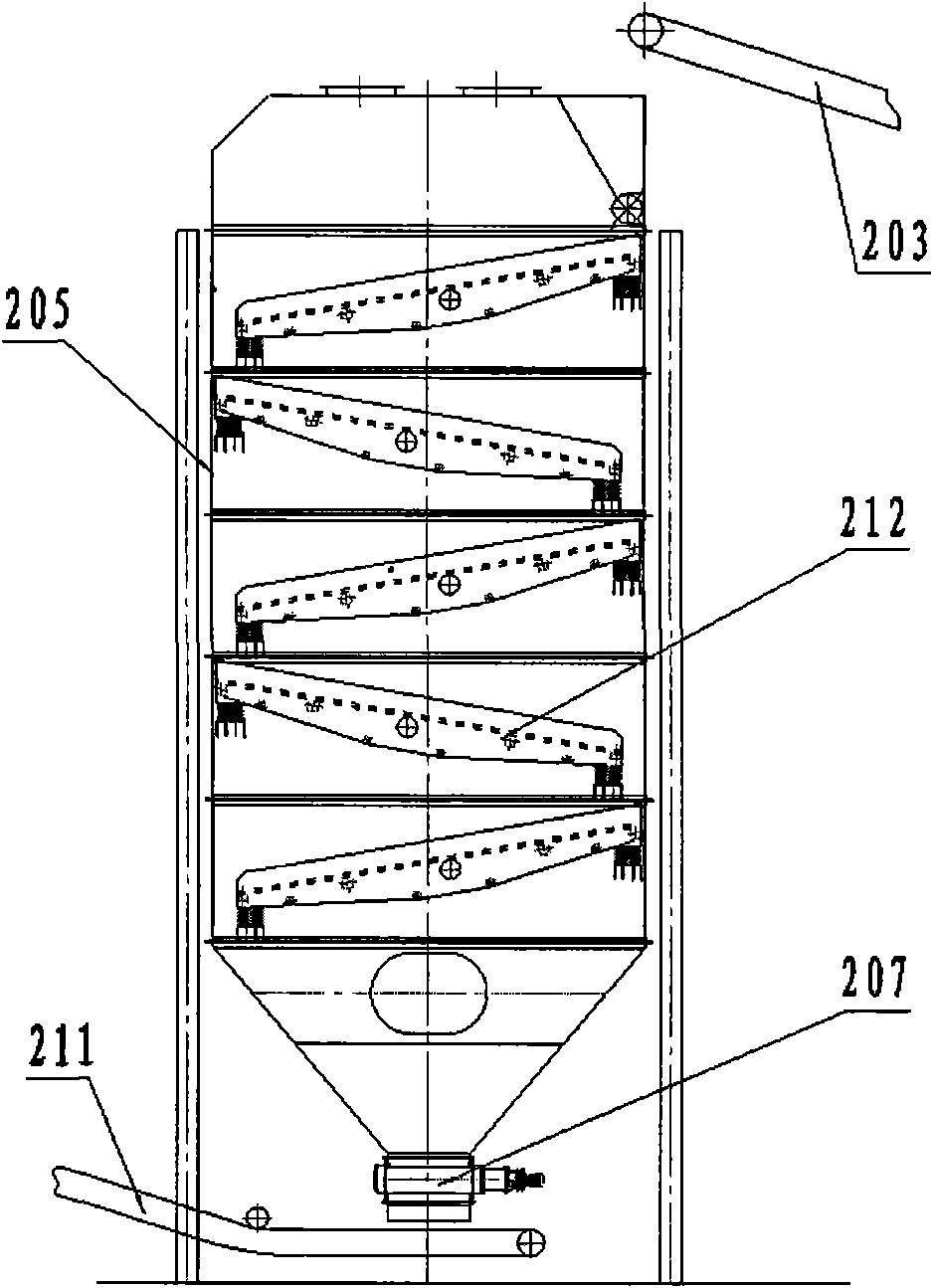

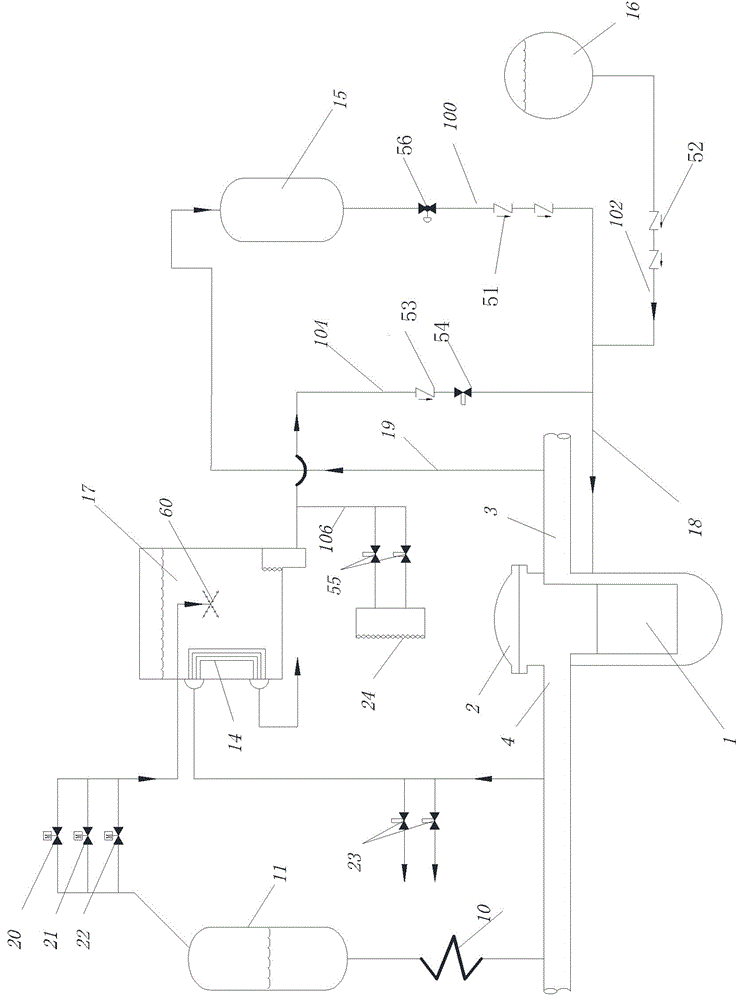

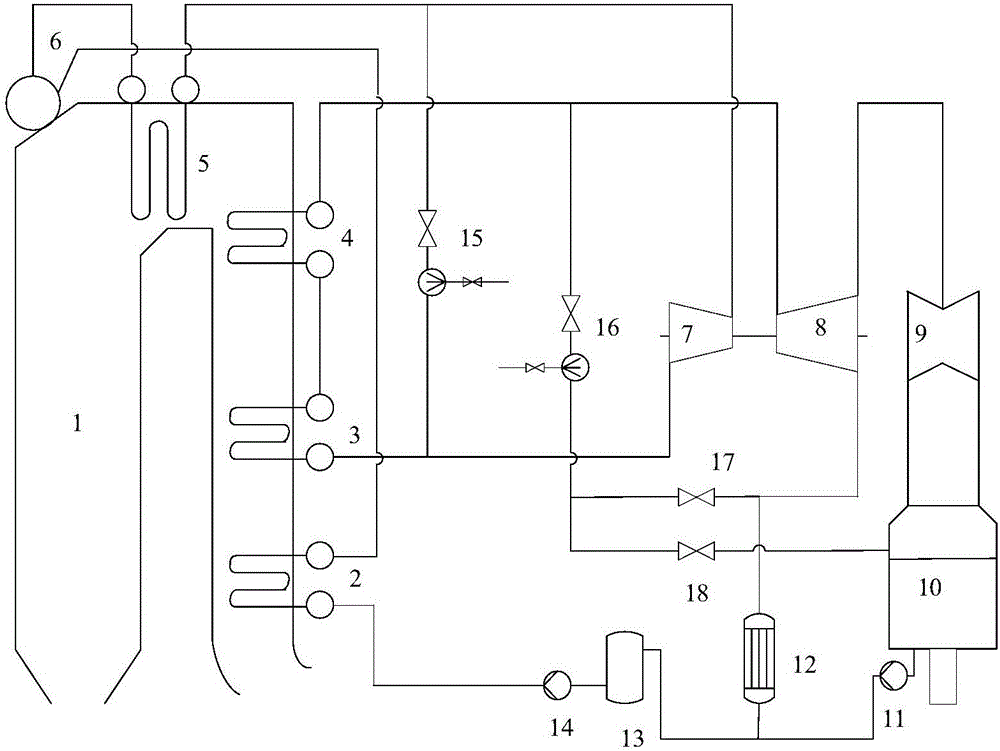

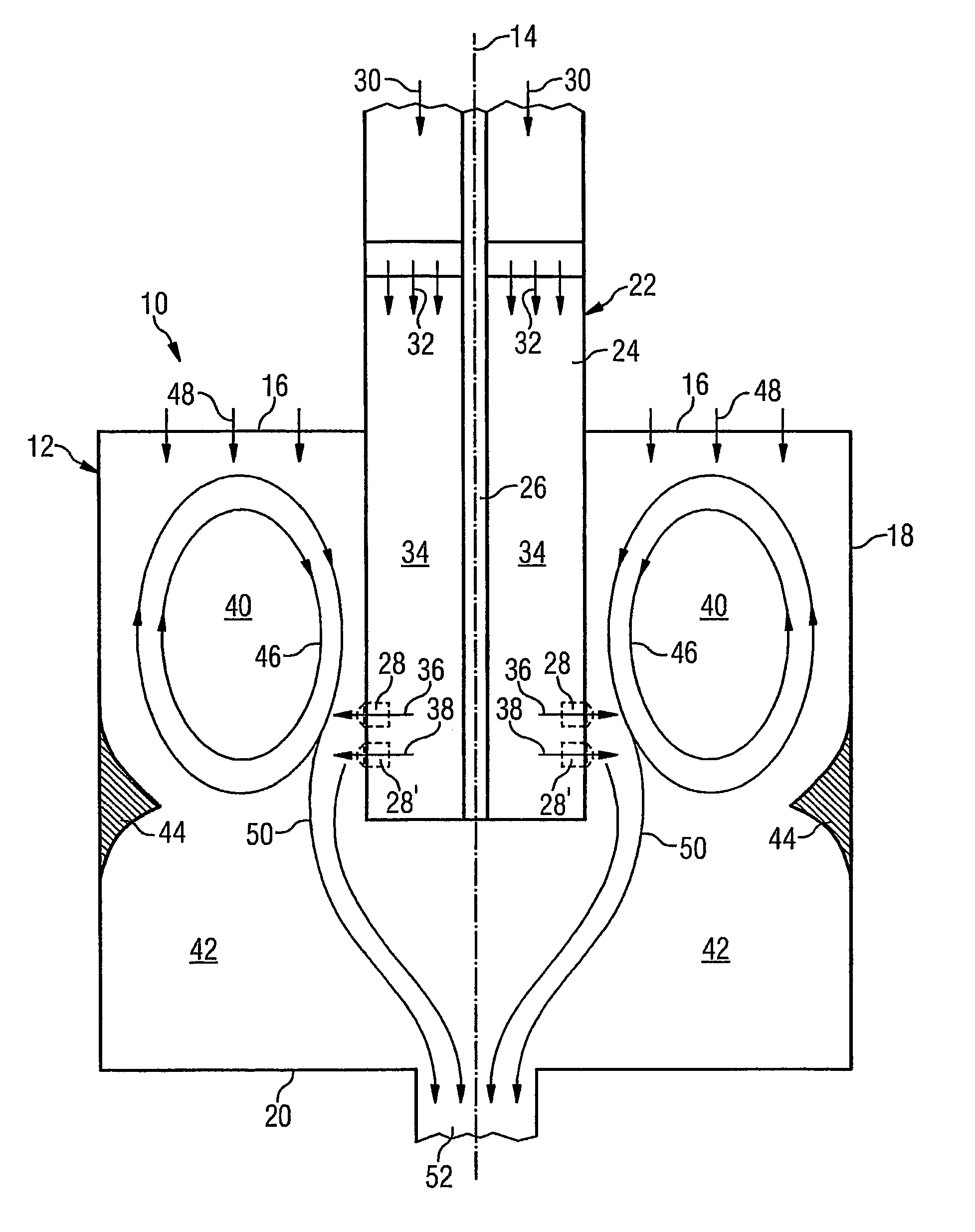

Huadian type process and device for dry distillation of oil shale

ActiveCN101942313AGuaranteed to be heatedGuaranteed temperature requirementsDirect heating destructive distillationCombustible gas purificationHeat carrierCooling tower

The invention provides a process and device for carrying out stage dry distillation on oil shale under the state of full recycle, with the gas as the heat carrier. The oil shale is divided into three different sizes (such as 0-6mm, 6-20mm and 20-50mm) through crushing and screening, and the oil shale is firstly dried and heated to the temperature between 50 DEG C and 150 DEG C by the waste smoke exhausted from gas heating furnaces and then enters into the different sizes of furnaces for dry distillation to undergo dry distillation. After being treated by water spraying and an indirect cooling tower, a rotary trapper and an electric trapper for oil collection, the dry distillation oil and gas undergo oil-gas-water separation, and after separation, the oil enters into a storage tank, the water enters into a circulating water tank and the first part of gases serves as the heat carrier and is recycled, the second part of gases is used as the fuels for the heating furnaces and the third part of gases is used as the fuel gases for power generation.

Owner:辽宁成大能源科技有限公司

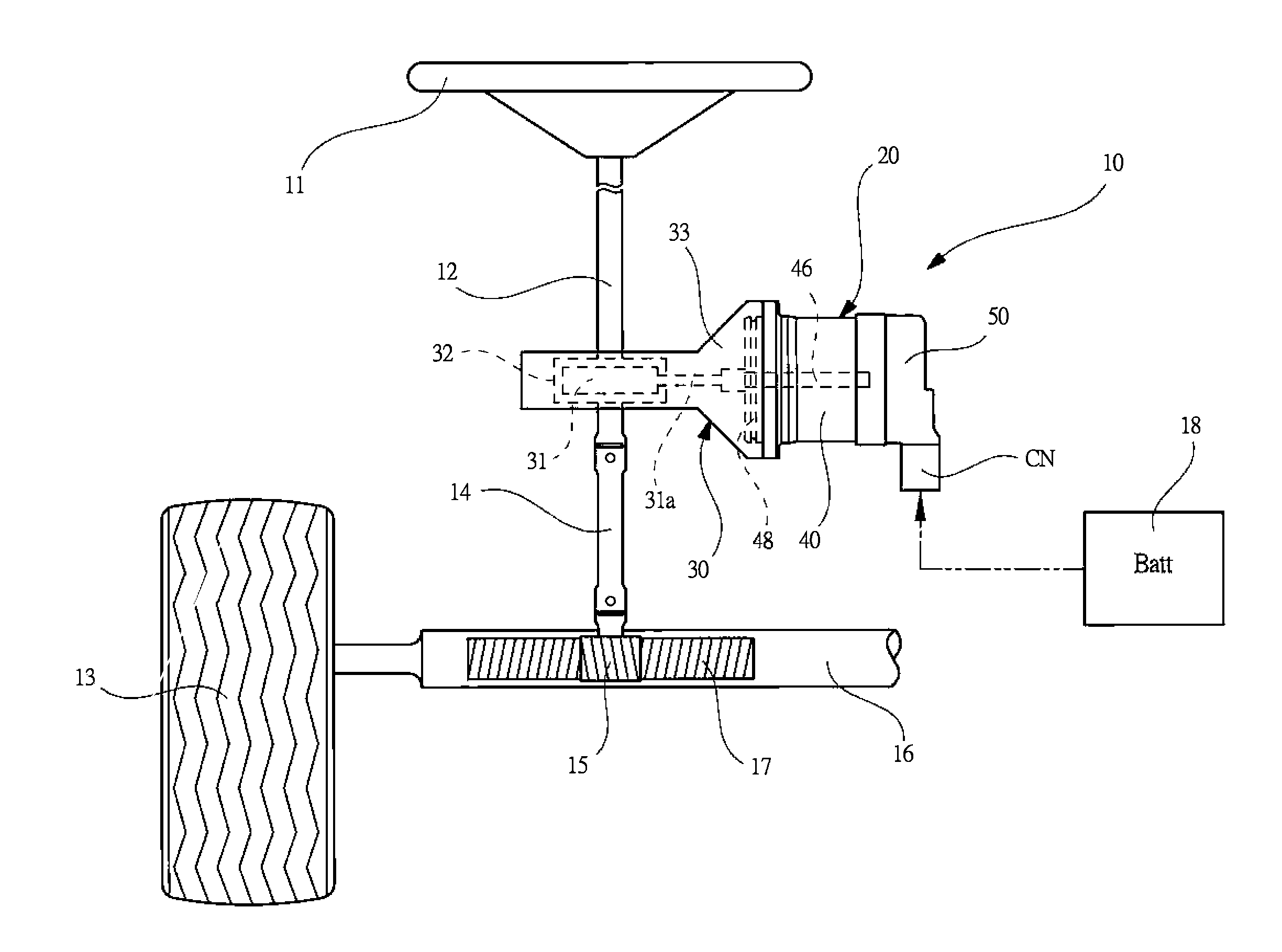

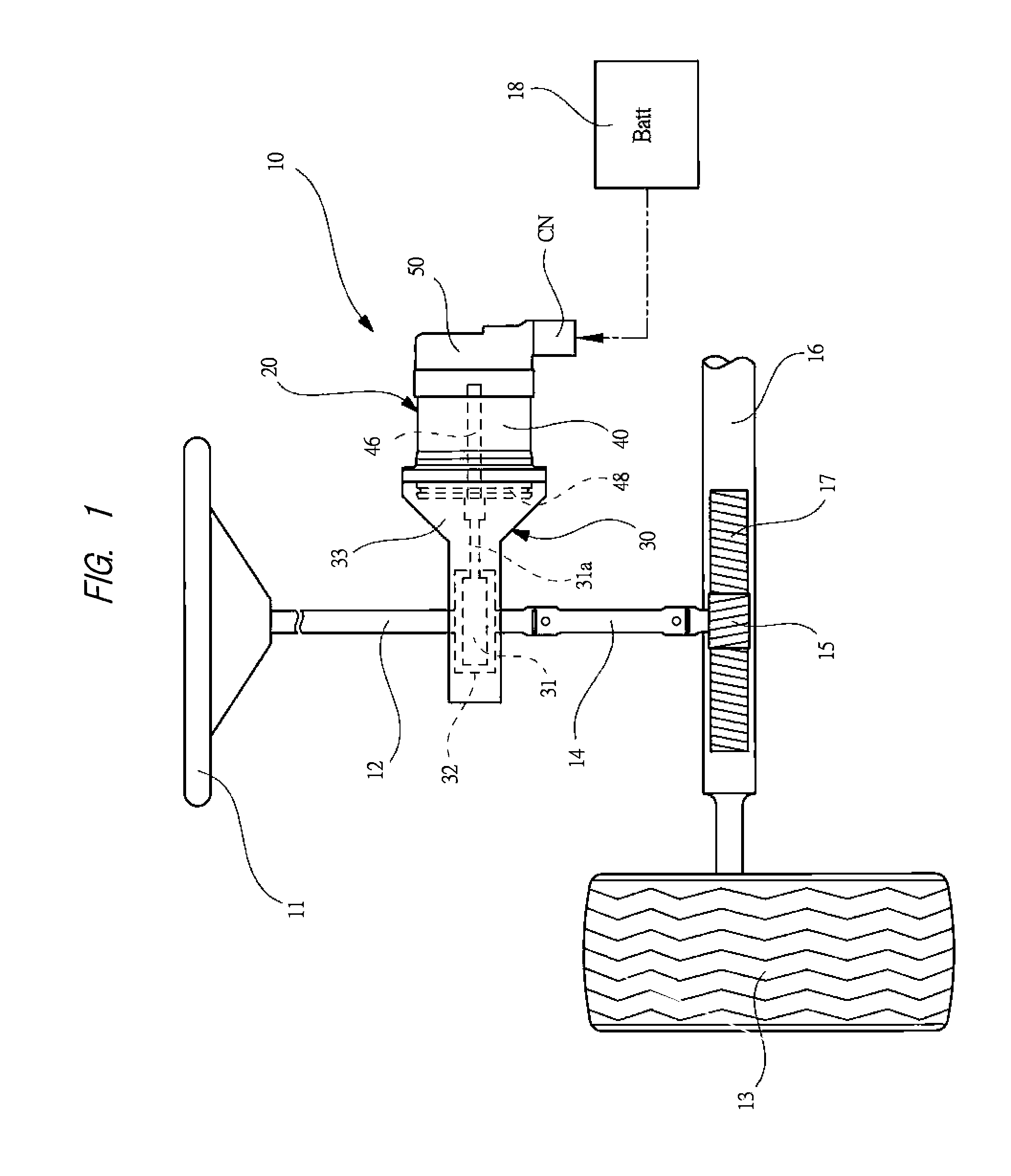

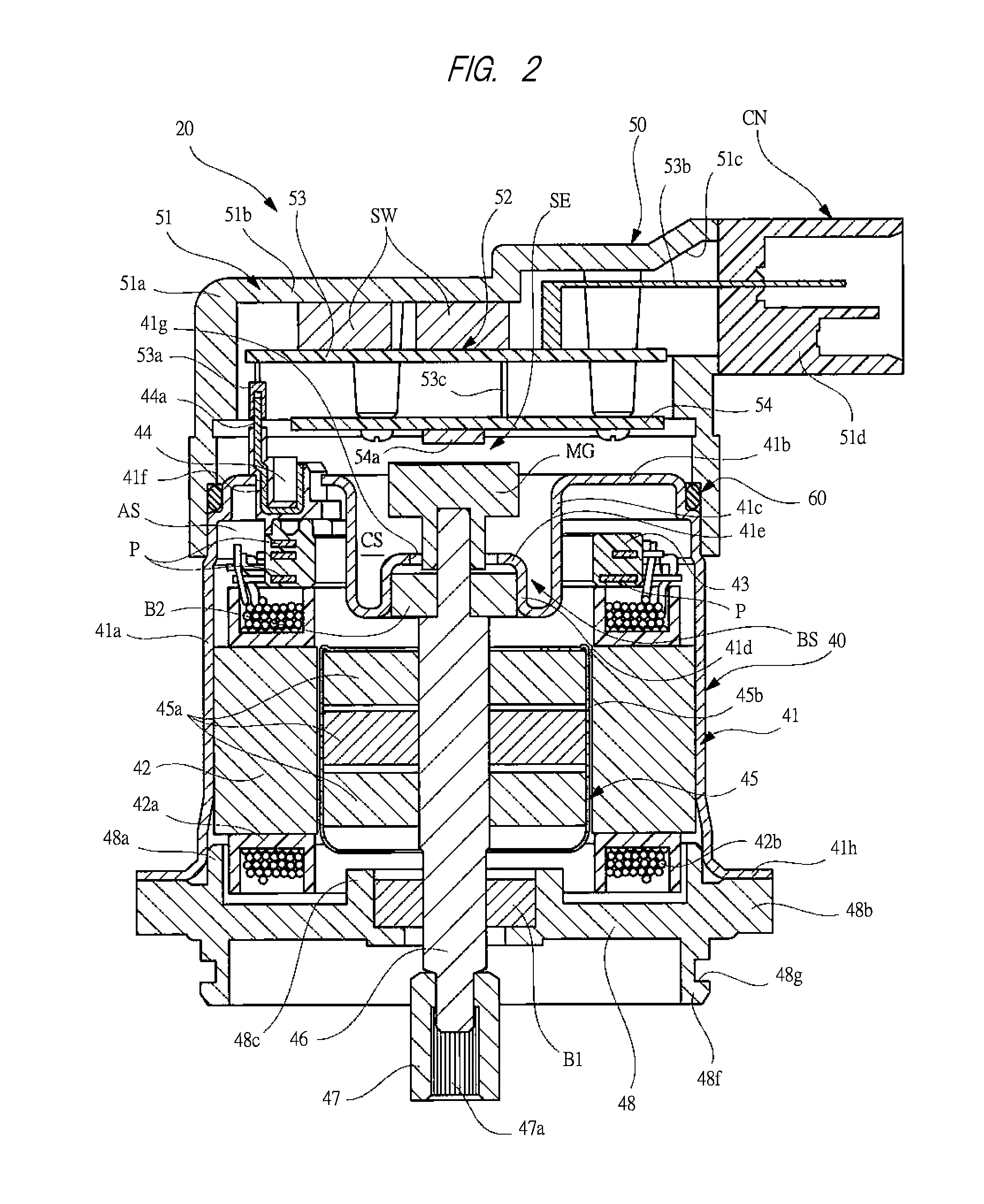

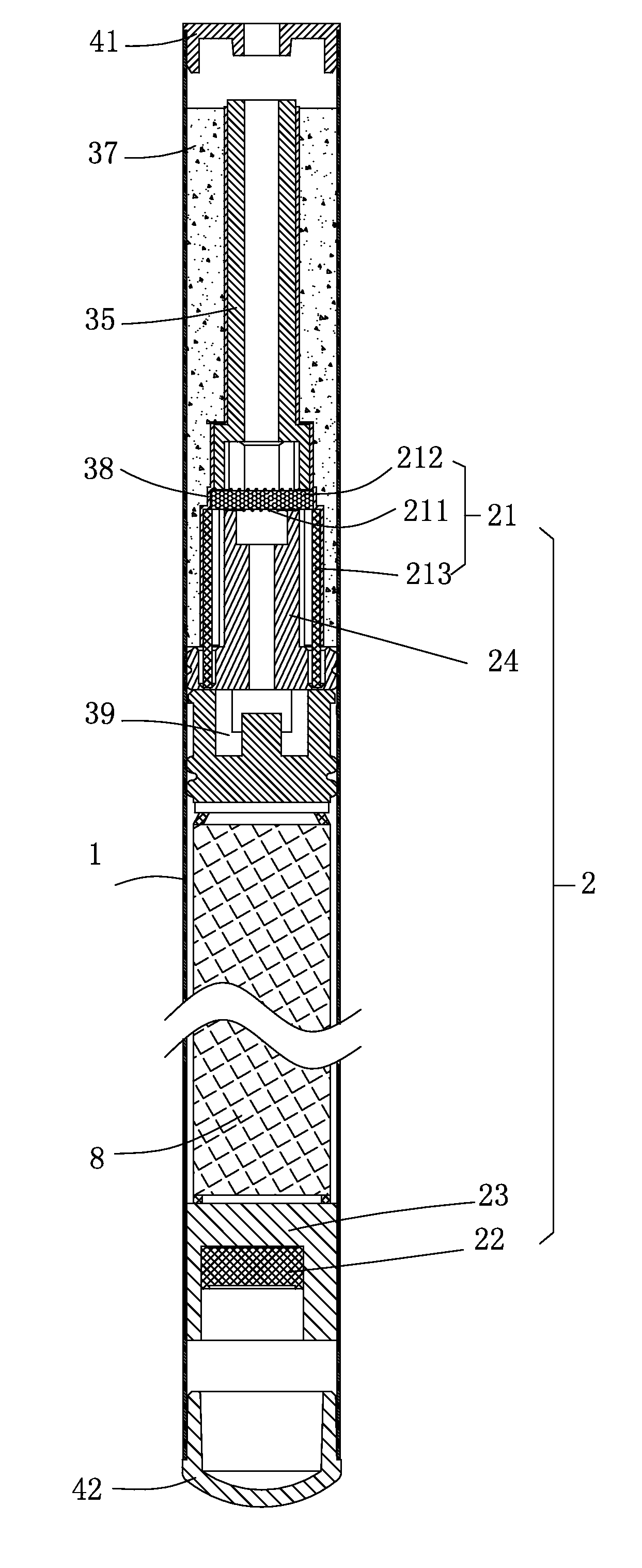

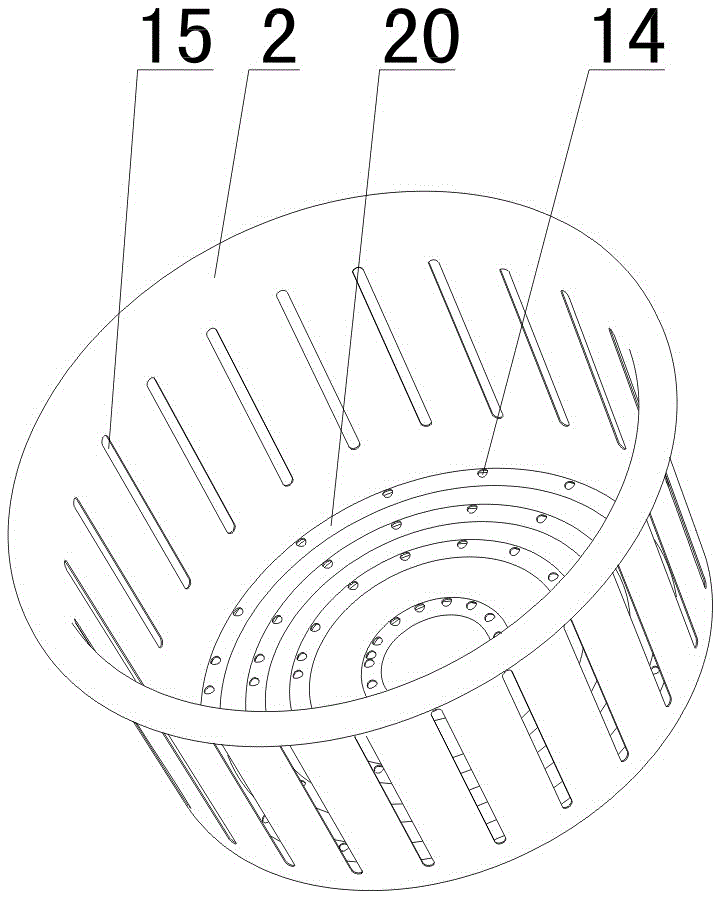

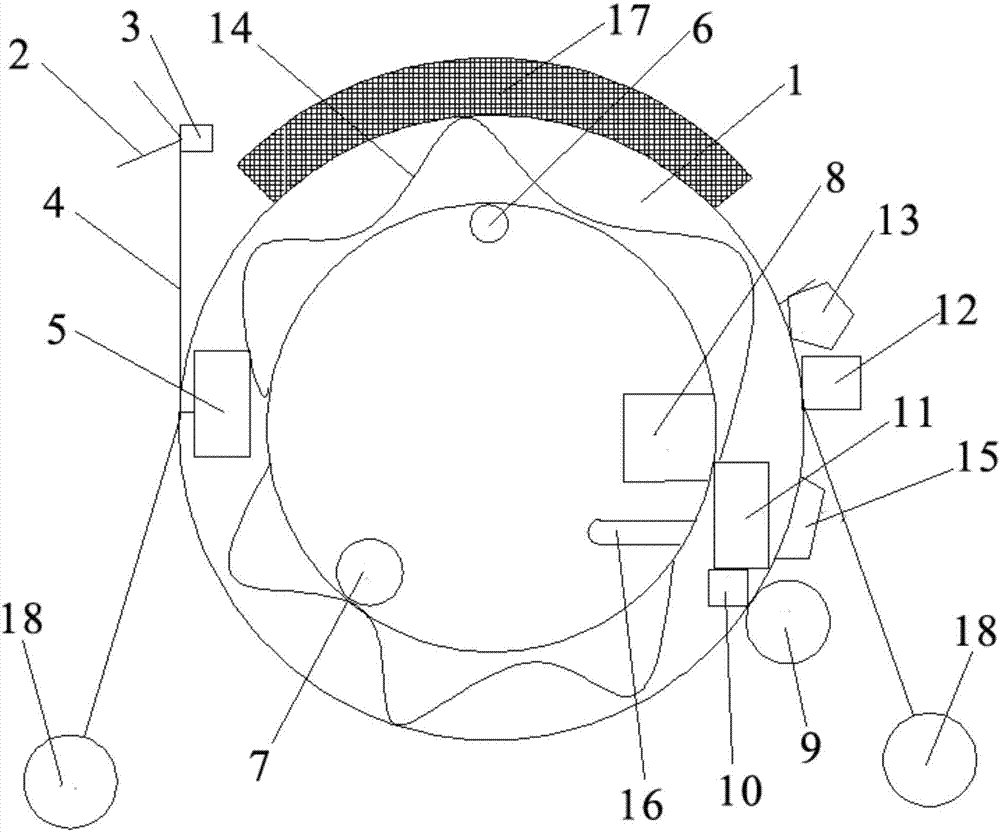

Brushless motor

InactiveUS20130099609A1Easy to produceLow production costAssociation with control/drive circuitsDC commutatorBrushless motorsEngineering

A brushless motor includes: a motor case 41 in which a cylindrical stator core 42 formed from steel plate by press molding is secured; a bracket 48 on one side in an axial direction of a motor case, a tip side of a rotary shaft 46 secured to a rotor 45 being rotatably supported by the bracket; and a housing member 51 on the other side in the axial direction of the motor case, a control device 52 for controlling the rotation of the rotor being accommodated in the housing member, the control device having a power-related circuit board 53 disposed on the side of a bottom 51b of the housing member and a control-related circuit board 54 disposed on the side of an opening of the housing member, semiconductor switching devices SW being disposed on the power-related circuit board in contact with the housing member.

Owner:MITSUBA CORP

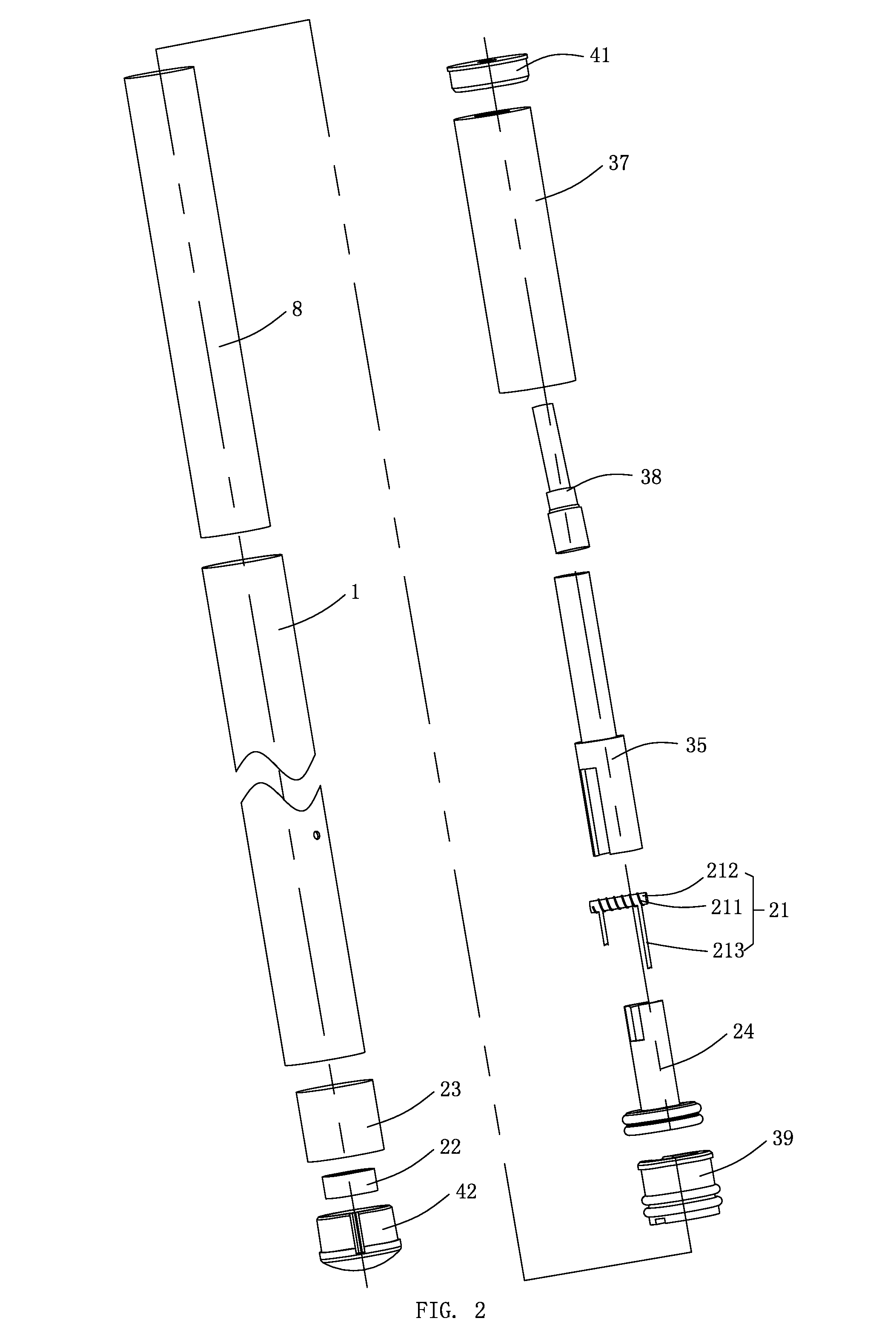

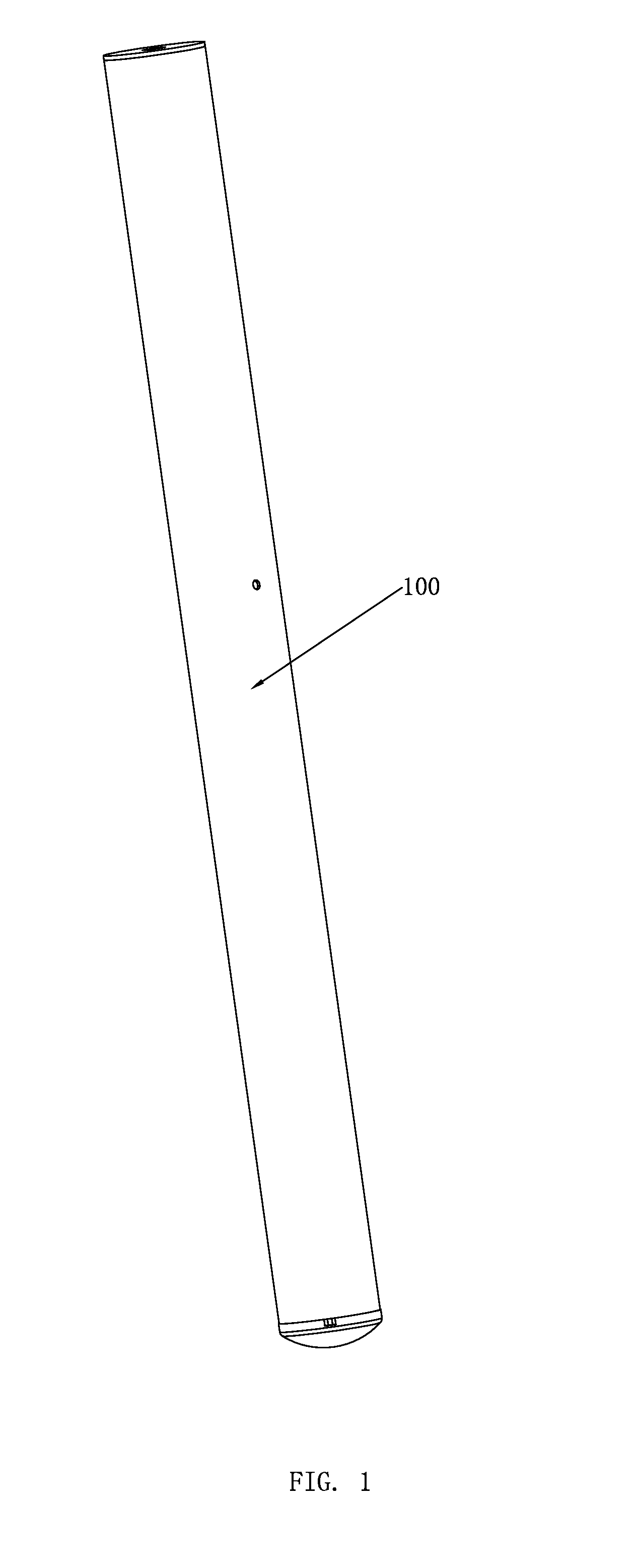

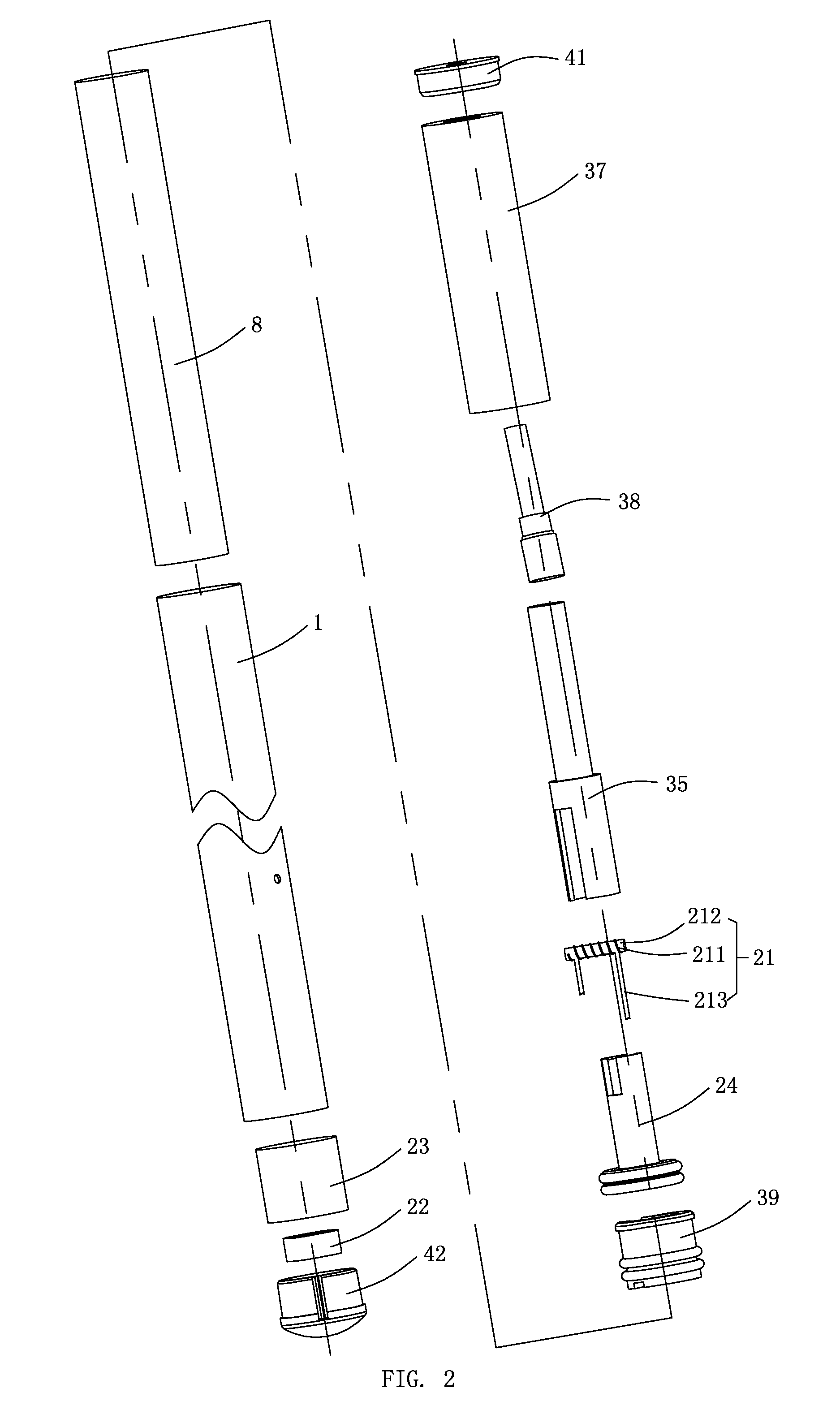

Electronic cigarette adopting organic cotton

InactiveUS9532601B2The internal structure is firm and reliableAvoid damageTobacco pipesTobacco devicesGlass fiberEngineering

An electronic cigarette adopting organic cotton includes a liquid storage component and an atomizing device, the atomizing device includes a hollow spiral heating wire, a liquid guiding member inserted in the heating wire, the liquid guiding member is made of non-fiberglass organic cotton materials; the atomizing device further includes a smog conduit inserted in the liquid storage component for supporting the liquid storage component and serving as a channel for the smog, the smog conduit comprises an outer sleeve and an inner sleeve, one inserted into another to position the liquid guiding member therebetween, and the liquid guiding member has its opposite ends respectively to be protruded out of an outer sidewall of the smog conduit and firmly abut against an inner sidewall of the liquid storage component. This kind of electronic cigarettes is harmless to the human body and has stable and reliable inner structure.

Owner:HUIZHOU KIMREE TECH

Glass composition, glass article, glass substrate for magnetic recording media, and method for producing the same

InactiveUS7309671B2High mechanical strengthGuaranteed to be heatedMagnetic materials for record carriersRecord information storageTO-18Metallurgy

A glass substrate of the present invention for magnetic recording media having high heat resistance and easy chemical strengthening ability at once has not been obtained, which is a glass composition essentially comprising 60 to 70 wt % SiO2, 5 to 20 wt % Al2O3, 0 to 1 wt % Li2O, 3 to 18 wt % Na2O, 0 to 9 wt % K2O, 0 to 10 wt % MgO, 1 to 15 wt % CaO, 0 to 4.5 wt % SrO, 0 to 1 wt % BaO, 0 to 1 wt % TiO2 and 0 to 1 wt % ZrO2, wherein the sum of Li2O, Na2O and K2O is from 5 to 25 wt %, and the sum of MgO, CaO, SrO and BaO is from 5 to 20 wt %.

Owner:HOYA CORP

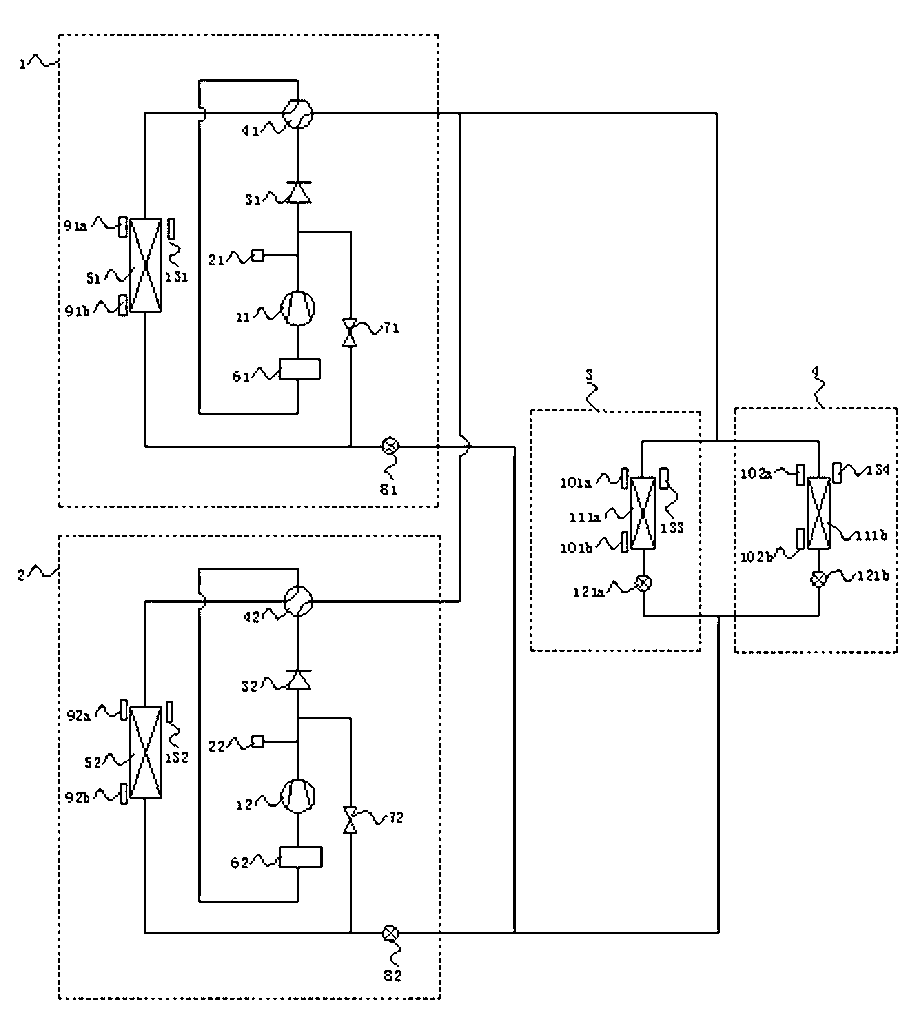

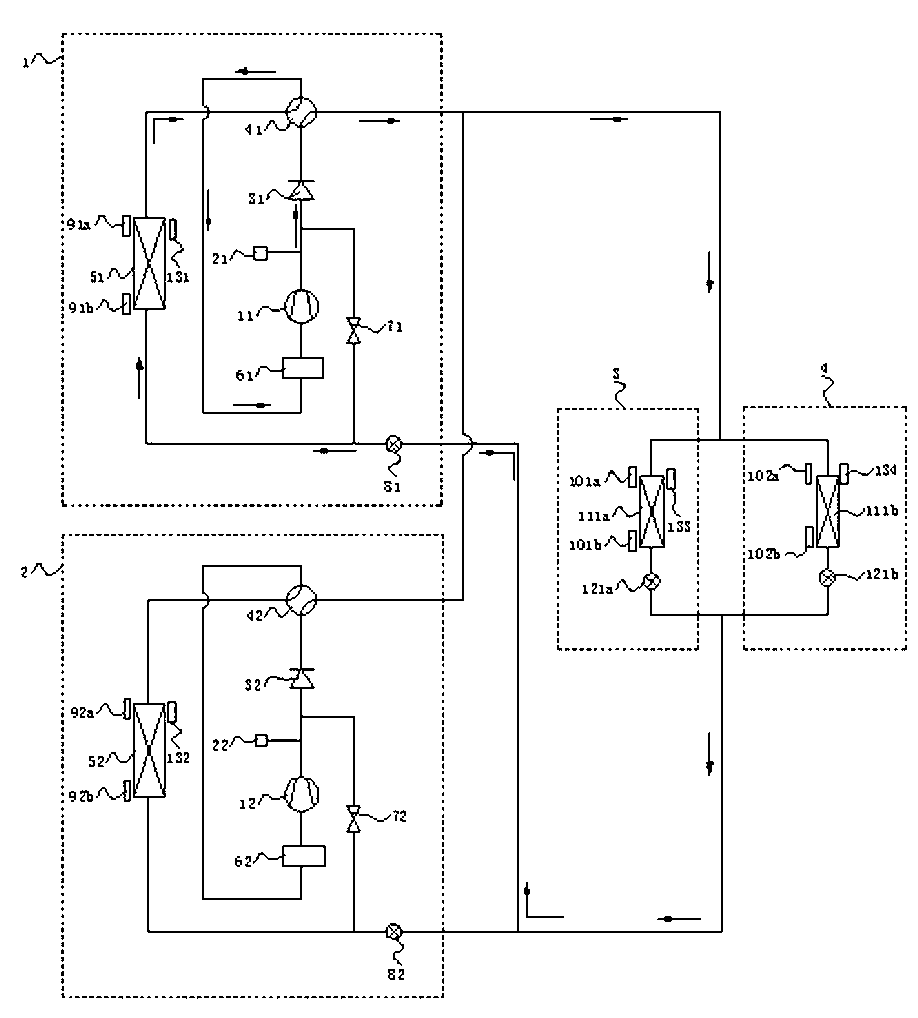

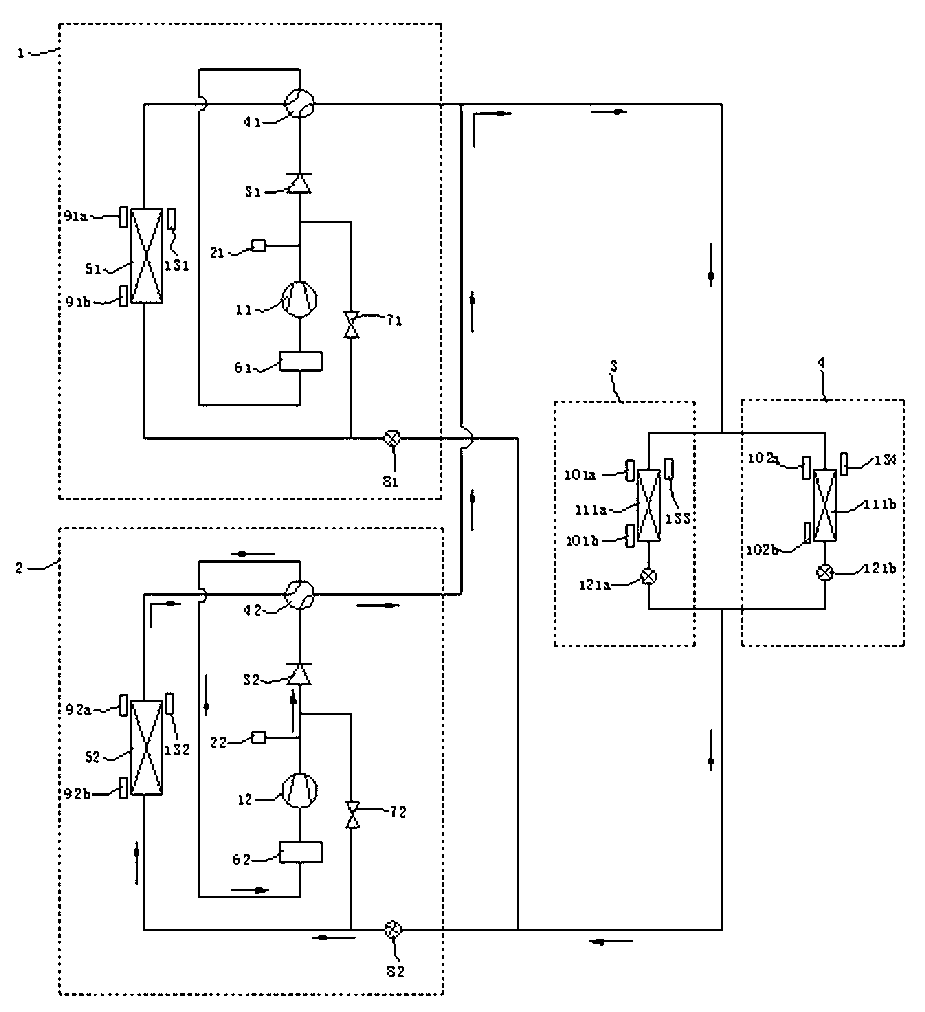

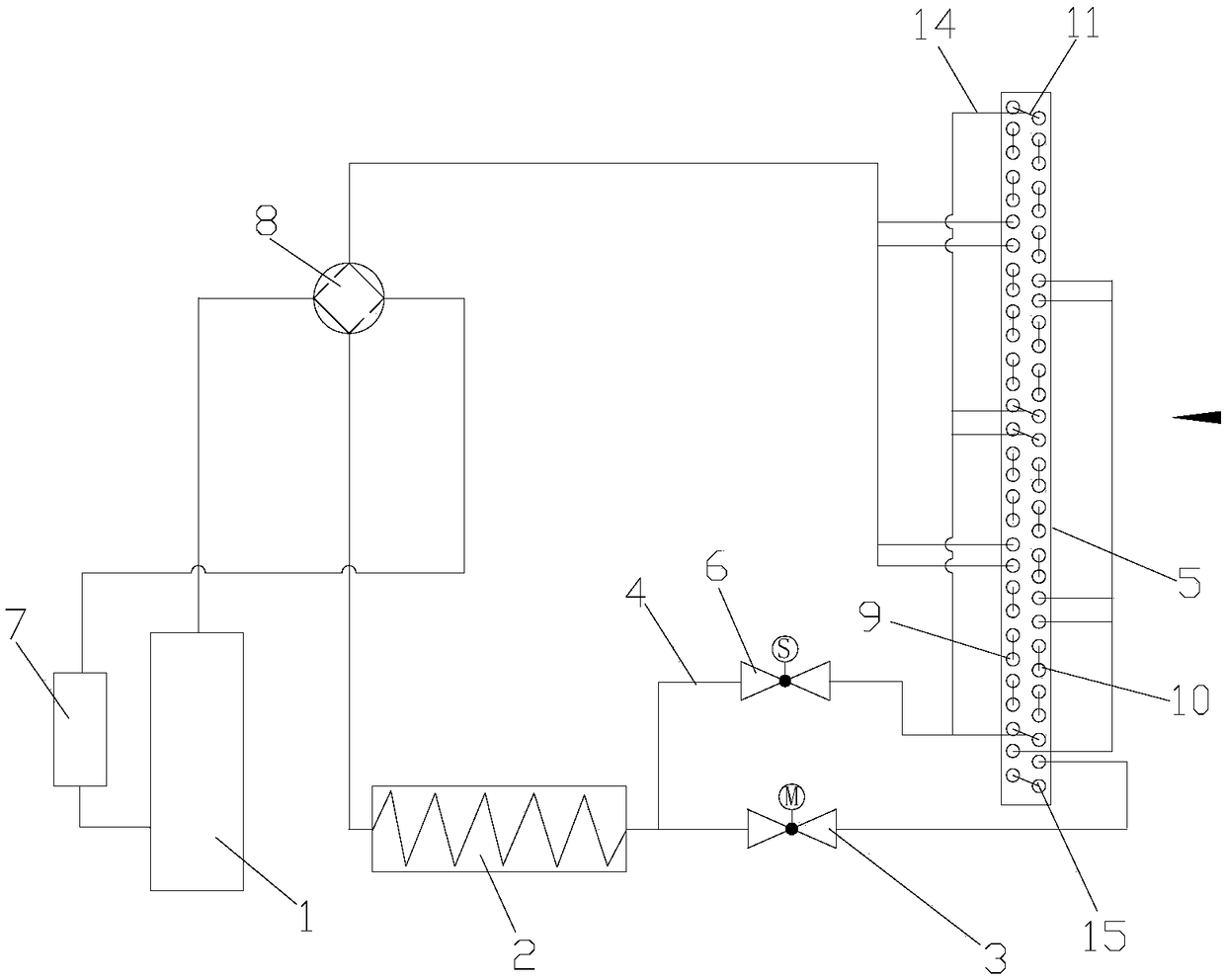

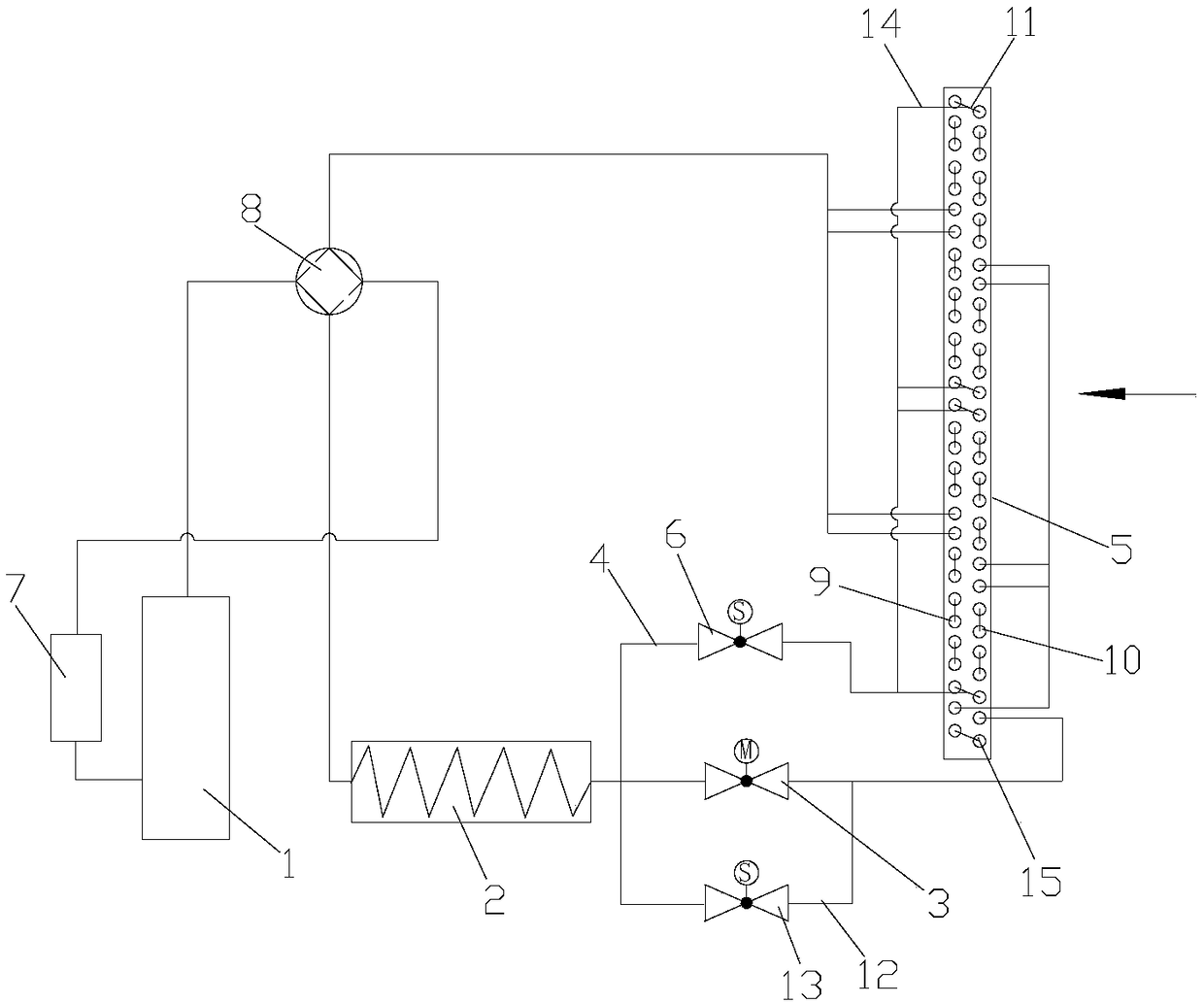

Variable refrigerant flow air conditioning system and control method thereof

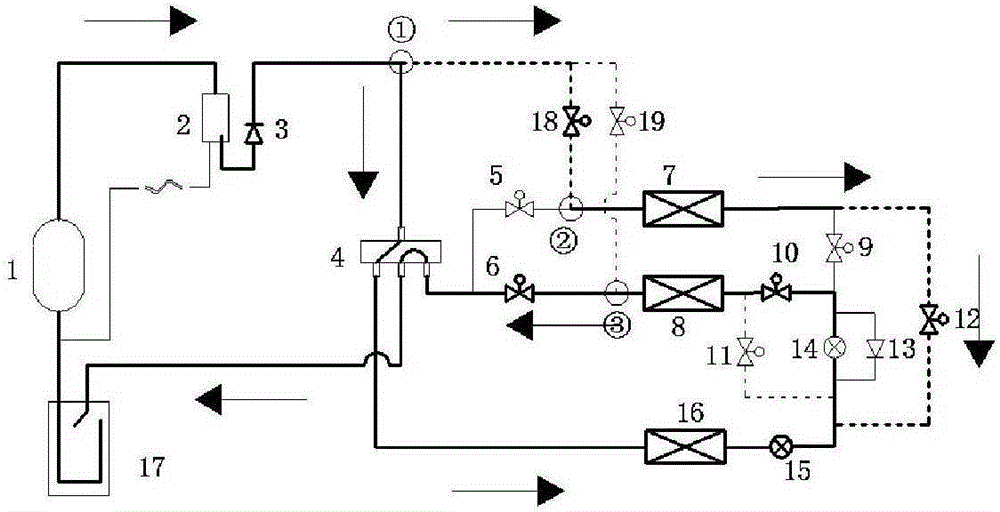

InactiveCN103123147AGuaranteed thermal comfortShorten the timeSpace heating and ventilation safety systemsLighting and heating apparatusEngineeringElectromagnetic valve

Disclosed is a variable refrigerant flow air conditioning system. The variable refrigerant flow air conditioning system is mainly composed of an outdoor unit, an indoor unit and a controller. The outdoor unit is formed by parallel connection of a first outdoor unit and a second outdoor unit. When one of the outdoor units needs defrosting operation, refrigerating fluid of a heating operating loop and refrigerating fluid of a defrosting operating loop are separated through opening and closing of an electromagnetic valve and an electronic expansion valve, and therefore heating and defrosting can not affect each other. Meanwhile, the refrigerating fluid circulation amounts in the heating loop and the defrosting loop are adjusted through control of the electromagnetic valve and the electronic expansion valve, the heating amount of the indoor unit is guaranteed through improvement of the frequency of a compressor corresponding to a heating operating system, and therefore the heat comfort degree of the indoor unit can be guaranteed. According to the variable refrigerant flow air conditioning system, normal heating of the indoor unit in the process of the defrosting operation can be guaranteed; and besides, in the process of entering and exiting from the defrosting process, the compressor does not need to be shut down, a four-way valve does not need to be reversed, and therefore defrosting operation time is greatly shortened, and comfortableness of an indoor environment is effectively improved.

Owner:NINGBO AOKESI ELECTRIC EQUIP FACTORY

Thermoplastic polymer composition, production method thereof, and shaped article and electric cable obtained therefrom

ActiveUS20080023215A1Raise the ratioReducing brittle temperatureInsulatorsPolymer scienceHeat resistance

Propylene-based resin compositions contain an inorganic filler in a high ratio and are excellent in flexibility, mechanical strength, elongation at break, heat resistance, scratch resistance, whitening resistance and flame retardancy. Shaped articles comprise the compositions. A first propylene-based resin composition of the present invention contains 5 to 64.9% by weight of a propylene-based polymer (A) having a melting point, as measured by differential scanning calorimetry (DSC), in the range of 120° C. to 170° C.; 0 to 59.9% by weight of a propylene-based polymer (B) having a melting point, as measured by differential scanning calorimetry (DSC), of less than 120° C. or having no observed melting point; 0.1 to 30% by weight of a graft-modified propylene-based polymer (C) obtained by graft modifying a propylene-based polymer having a melting point, as measured by differential scanning calorimetry (DSC), of less than 120° C. or having no observed melting point; and 35 to 75% by weight of an inorganic filler (D) (here, the total amount of (A), (B), (C) and (D) is 100% by weight).

Owner:MITSUI CHEM INC

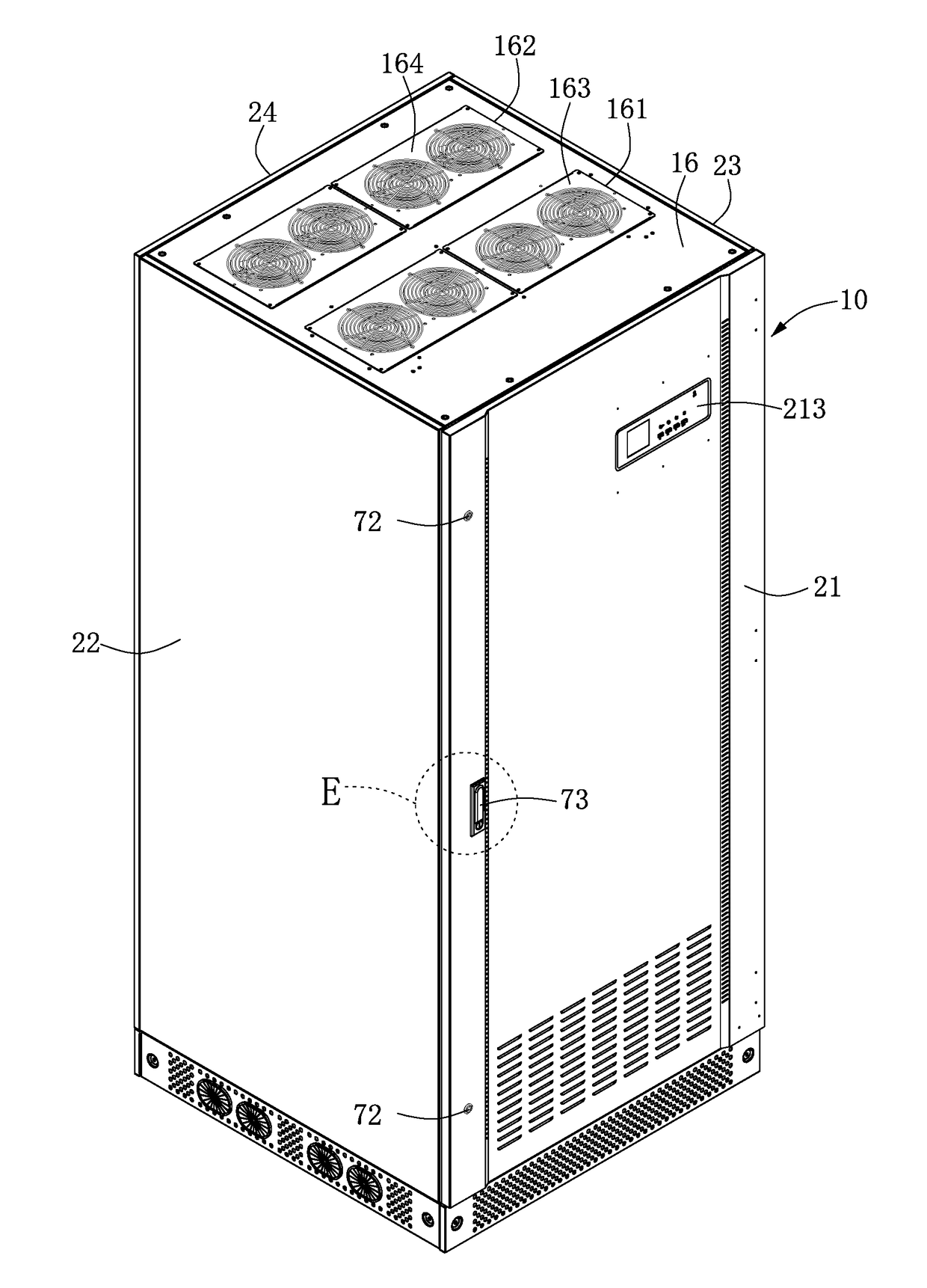

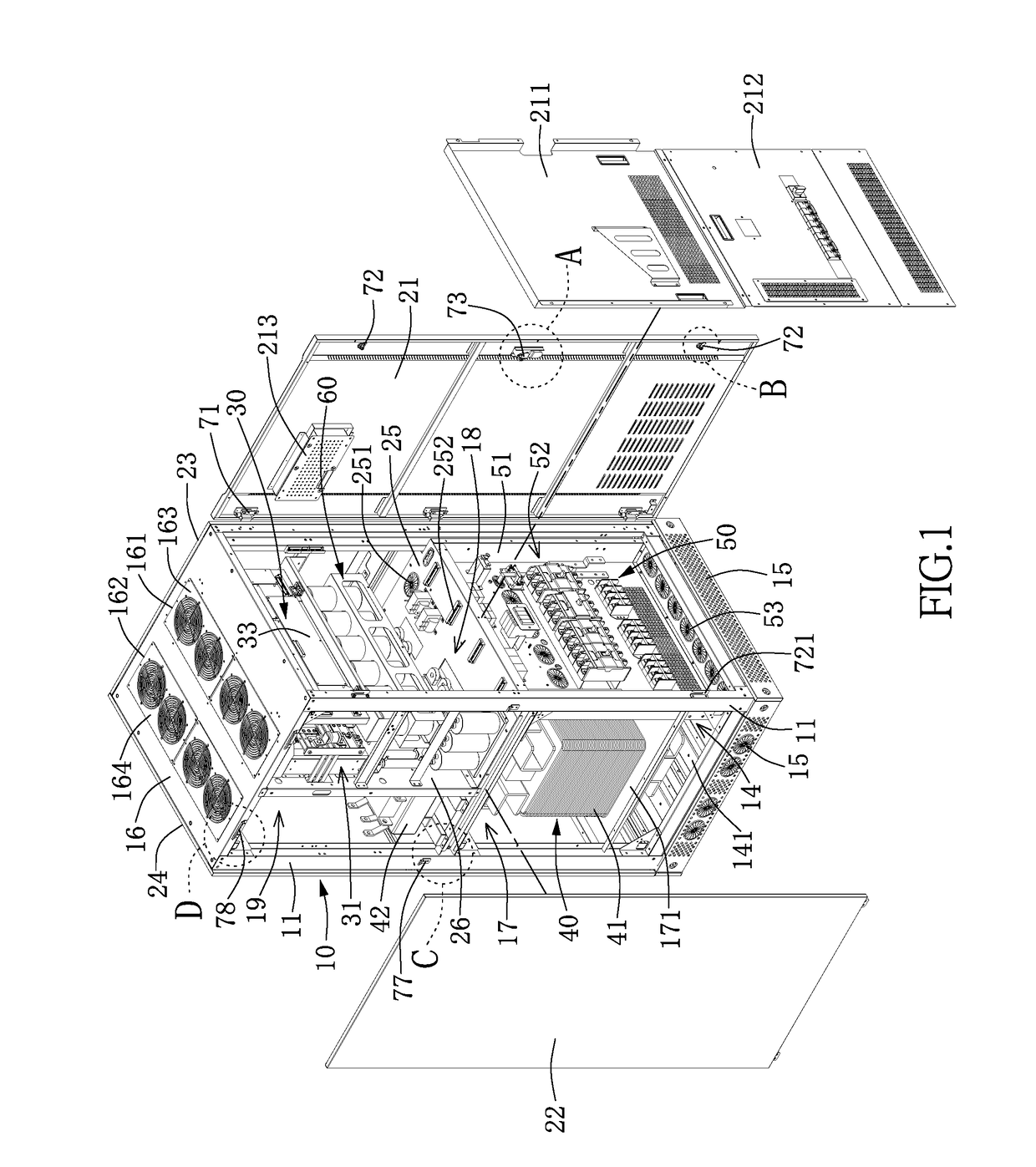

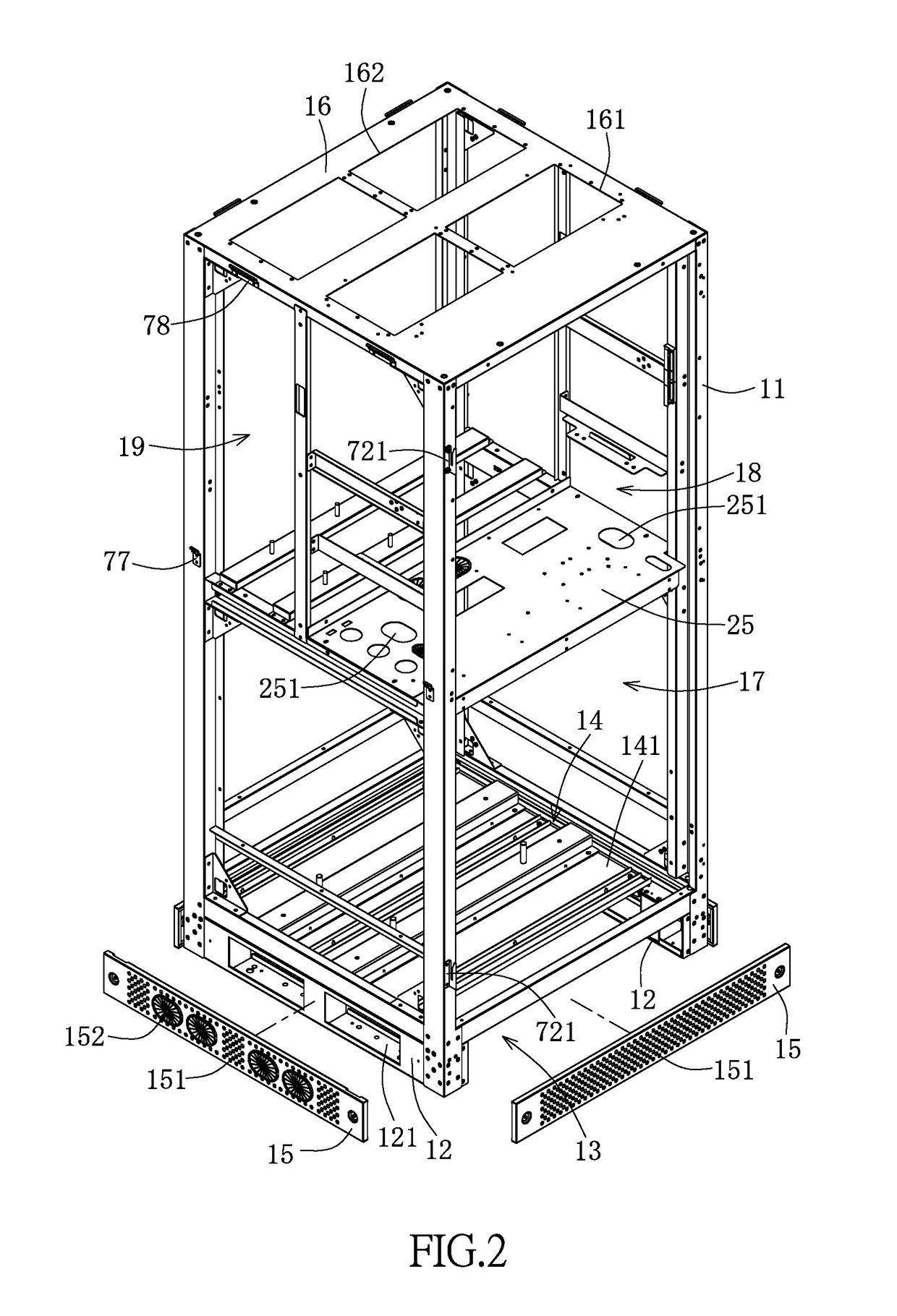

Chassis structure for industrial uninterruptible power supply system

ActiveUS20170172015A1Improve performanceImprove operation stability and reliability and safetyCasings/cabinets/drawers detailsPrinted circuit board receptaclesUninterruptible power supplyElectrical and Electronics engineering

The instant disclosure relates to a chassis structure for industrial uninterruptible power supply system including: a chassis having a frame and a front side panel, left side panel, right side panel, rear side panel and top panel installed on the frame; the chassis has a plurality of spacer on the bottom thereof for lifting the chassis from the ground for a distance to forming a gas-intake space; a plurality of protective plates disposed around the gas-intake space, each protective plate has a plurality of gas-intake hole; a bottom plate structure disposed between the bottom of the chassis and the gas-intake space and has at least a gas-intake gap; at least a venting hole disposed on the top panel of the chassis, each venting hole has at least an exhaust fan for outputting a gas from the chassis.

Owner:VOLTRONIC POWER TECH CORP

Electronic cigarette adopting organic cotton

InactiveUS20140196717A1The internal structure is firm and reliableAvoid damageTobacco devicesInhalatorsGlass fiberEngineering

An electronic cigarette adopting organic cotton includes a liquid storage component and an atomizing device, the atomizing device includes a hollow spiral heating wire, a liquid guiding member inserted in the heating wire, the liquid guiding member is made of non-fiberglass organic cotton materials; the atomizing device further includes a smog conduit inserted in the liquid storage component for supporting the liquid storage component and serving as a channel for the smog, the smog conduit comprises an outer sleeve and an inner sleeve, one inserted into another to position the liquid guiding member therebetween, and the liquid guiding member has its opposite ends respectively to be protruded out of an outer sidewall of the smog conduit and firmly abut against an inner sidewall of the liquid storage component. This kind of electronic cigarettes is harmless to the human body and has stable and reliable inner structure.

Owner:HUIZHOU KIMREE TECH

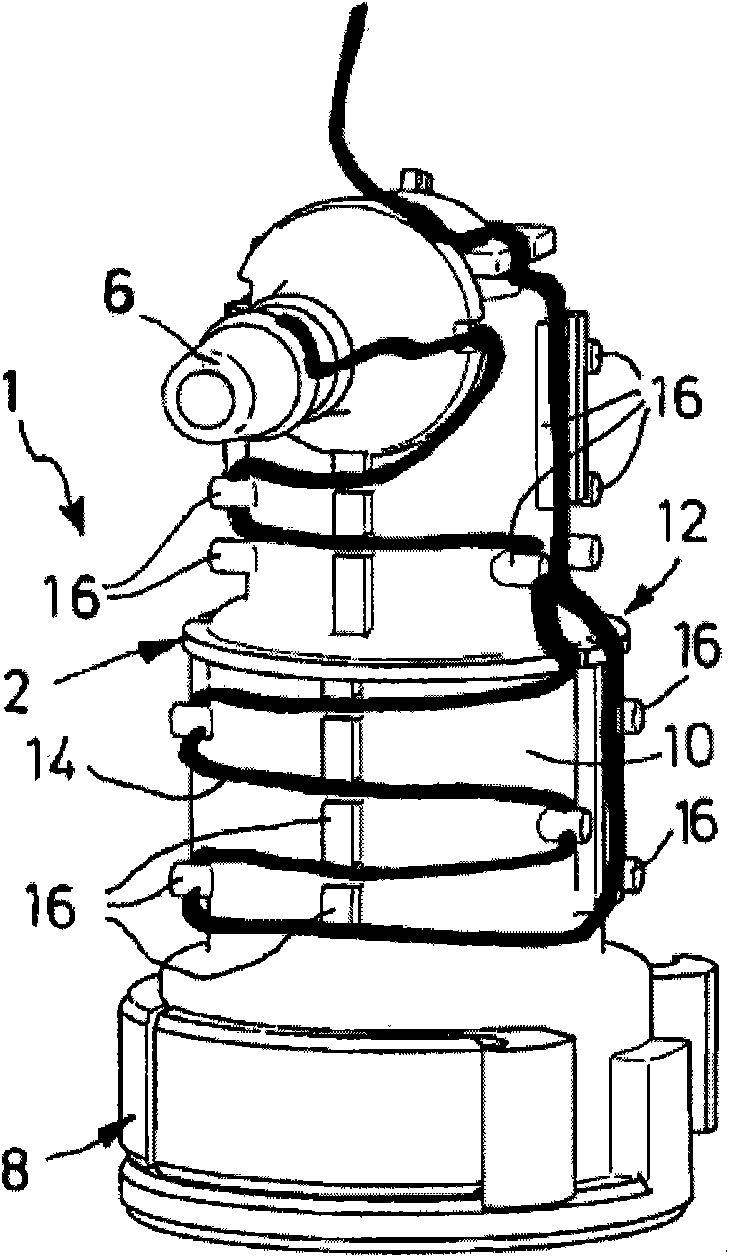

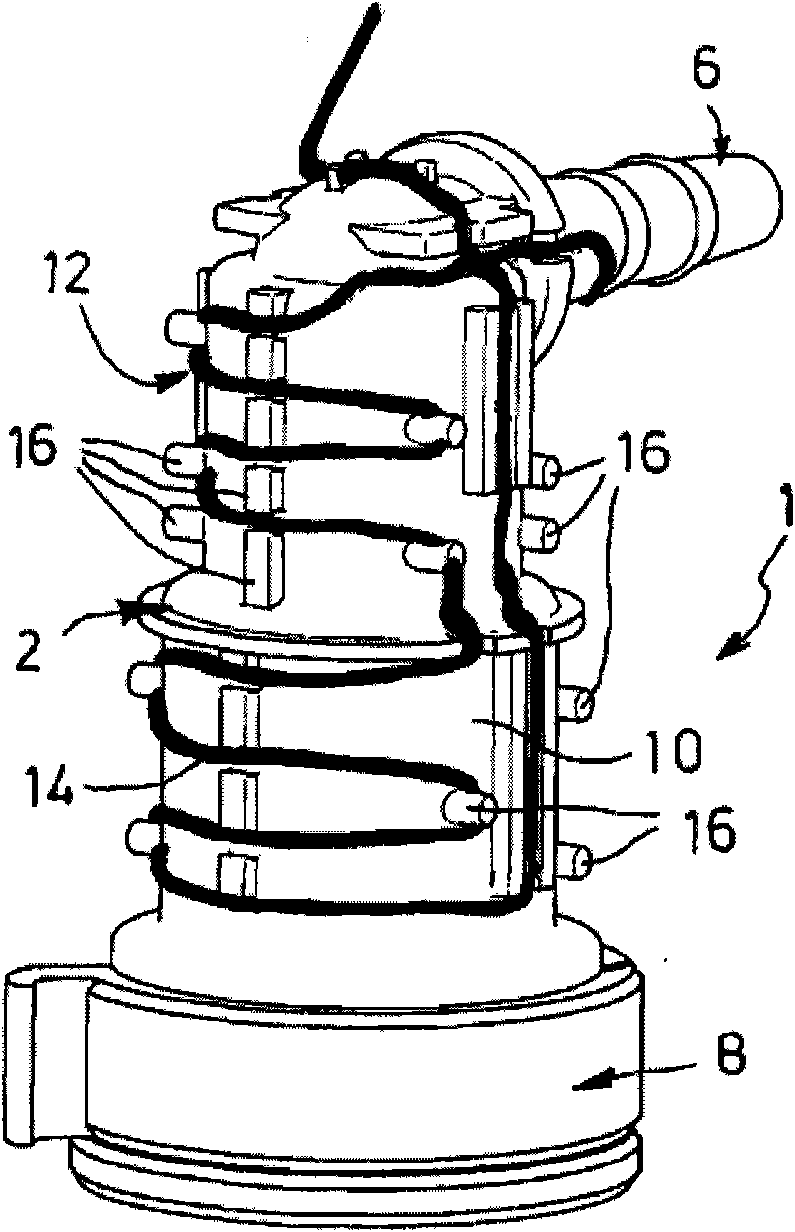

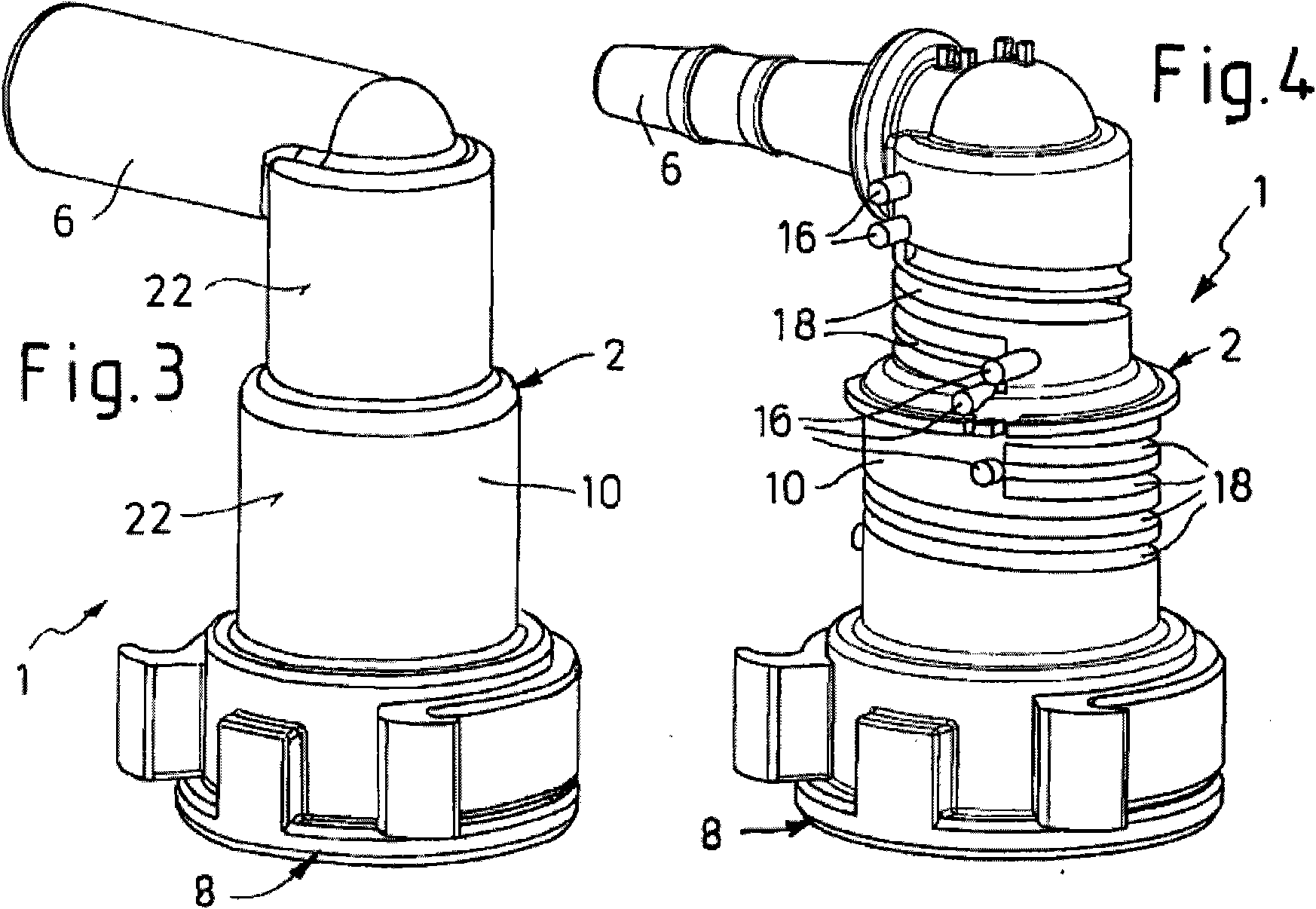

Line connector for media lines

ActiveCN101606014ACoagulation prevents or eliminatesCoagulation does not occurPipe heating/coolingMachines/enginesElectrical conductorGuide tube

The present invention relates to a line connector (1) for media lines, comprising a connecting piece (2) having at least one connection section (6, 8) for the connection to a media line (4) or to an assembly, and having a transitional section (10) comprising a flow channel (11), the section adjoining the connection section (6, 8). To this end, electrical heating means (12) are provided at least in the region of the transitional section (10) in an arrangement that at least partially surrounds the flow channel (11). The invention further relates to an assembled media line comprising a pipe line having a heating conductor (29) arranged on the circumference thereof, and a heatable line connector attached to at least one pipe line end of the media line.

Owner:VOSS AUTOMOTIVE

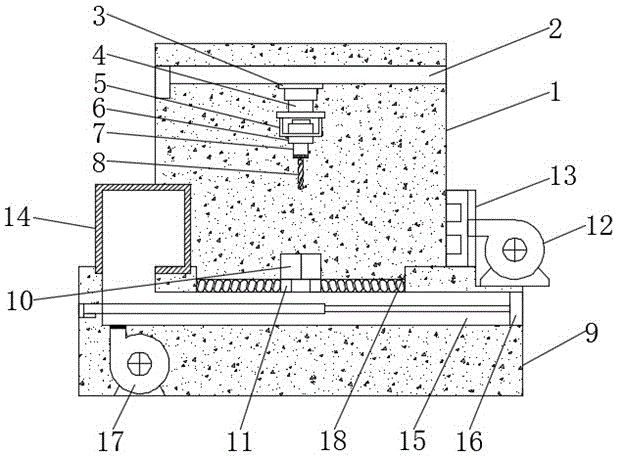

Drilling machine facilitating scrap collection

InactiveCN106514421AEasy to collectReduce precisionMaintainance and safety accessoriesBoring/drilling machinesFixed frameWorkload

The invention discloses a drilling machine facilitating scrap collection. The drilling machine comprises a support and a base. A linear motor is arranged on a top plate of the support. The bottom end of the linear motor is provided with a moving plate. The bottom end of the moving plate is provided with a telescopic rod. The bottom end of the telescopic rod is provided with a fixed frame. The middle portion of the bottom end of the fixed frame is connected with a pneumatic drilling machine in a sleeving mode. According to drilling machine facilitating scrap collection, wind generated by a draught fan is distributed through a flow distribution pipe to blow machined metal products; a suction fan operates to suck wind on a collection frame; wind flows to blow scraps generated after machining into the collection frame, and the scraps fall into a collection cavity; the electric telescopic rod operates to drive a cleaning plate to clean the scraps out of the collection cavity. Accordingly, scrap collection is facilitated, and the workload of workers is reduced. Heat generated during metal product machining is reduced. The cleanliness of the machine is guaranteed. The service life of the machine is prolonged. The machining precision of metal products is guaranteed.

Owner:WUXI CAIYUN MACHINERY & EQUIP

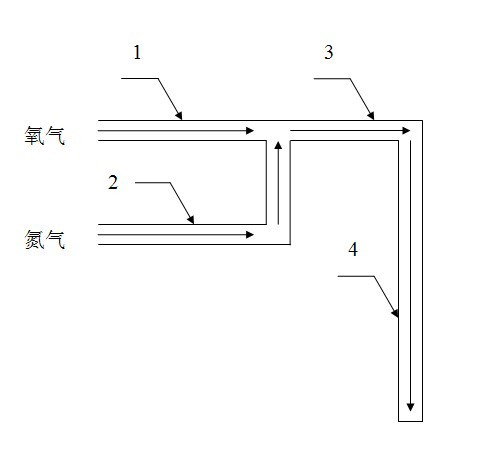

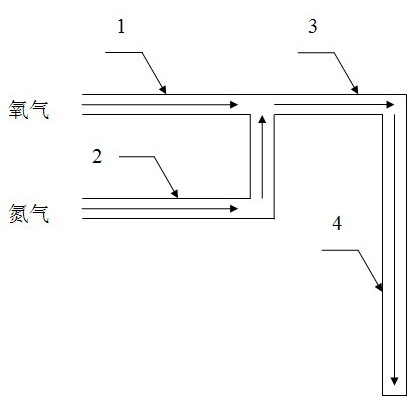

Method for extracting vanadium through composite blowing of converter

InactiveCN102127613ALow costNo need to increase investmentManufacturing convertersMelting tankOxygen

The invention relates to a method for extracting vanadium through composite blowing of a converter, and belongs to the technical field of vanadium extraction through converters in the metallurgy industry. Mixed gas of oxygen and nitrogen replaces pure oxygen to perform composite blowing on vanadium-containing molten iron; meanwhile, vanadium extraction is performed through bottom blowing of nitrogen or other inert gas of the converter; and by reducing the concentration of oxygen in a gas medium provided for a molten pool and ensuring the gas supply pressure required by stirring the molten pool, the temperature of the molten pool in the blowing process is raised stably and the requirement of vanadium extraction dynamics is met. By implementing the composite blowing in the vanadium extraction process, compared with a method of blowing with pure oxygen through an oxygen gun, the method has the advantages that: various economic and technical norms for vanadium extraction are improved obviously, considerable economic benefit is created, good conditions are created for the next procedure after the vanadium extraction, and the stable and smooth production of the previous and next procedures is ensured. The method is operated on the conventional converter gas supply system, investment is not needed to be increased, the ratio of both can be flexibly regulated, and the vanadium extraction requirements under different molten iron conditions are met.

Owner:HEBEI IRON AND STEEL

Tobacco mulching cultivation method

InactiveCN103168591AImprove permeabilityImprove biological activityFertilising methodsHorticultureAmmonium nitrateMoisture

The invention discloses a tobacco mulching cultivation method. The nitrogen application rate is 52.5 kg / hm<2>, the ratio of basal fertilizer and top-dressing is 7:3, N:P2O5:K2O is equal to 1:1:3, the basal application materials include 3000 kg / hm<2> of decomposed sesame cake fertilizer, 60 kg / hm<2> of ammonium nitrate, 80 kg / hm<2> of phosphatic fertilizer, 191.4 kg / hm<2> of potassium sulfate, 37.5 kg / hm<2> of zinc sulfate, and 22.5 kg / hm<2> of boric acid, the topdressing materials in the rosette stage include 37 kg / hm<2> of potassium sulfate and 84 kg / hm<2> of potassium nitrate. In the process of transplanting, 15 kg / hm<2> of potassium nitrate is applied in a nest mode, a plastic film is covered, the plastic film is uncovered in the former half period of June, and 7500 kg / hm<2> of wheat straws are covered after earth up until harvest is finished. The tobacco mulching cultivation method is capable of keeping appropriate soil moisture and heat conditions in the growth period of tobacco, enables the tobacco to form a layering and well-developed frame-shaped root system, and is favorable for coordination of water, fertilizer, air and heat of soil.

Owner:HENAN AGRICULTURAL UNIVERSITY

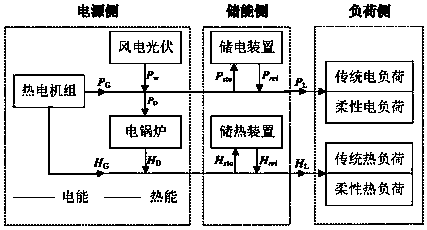

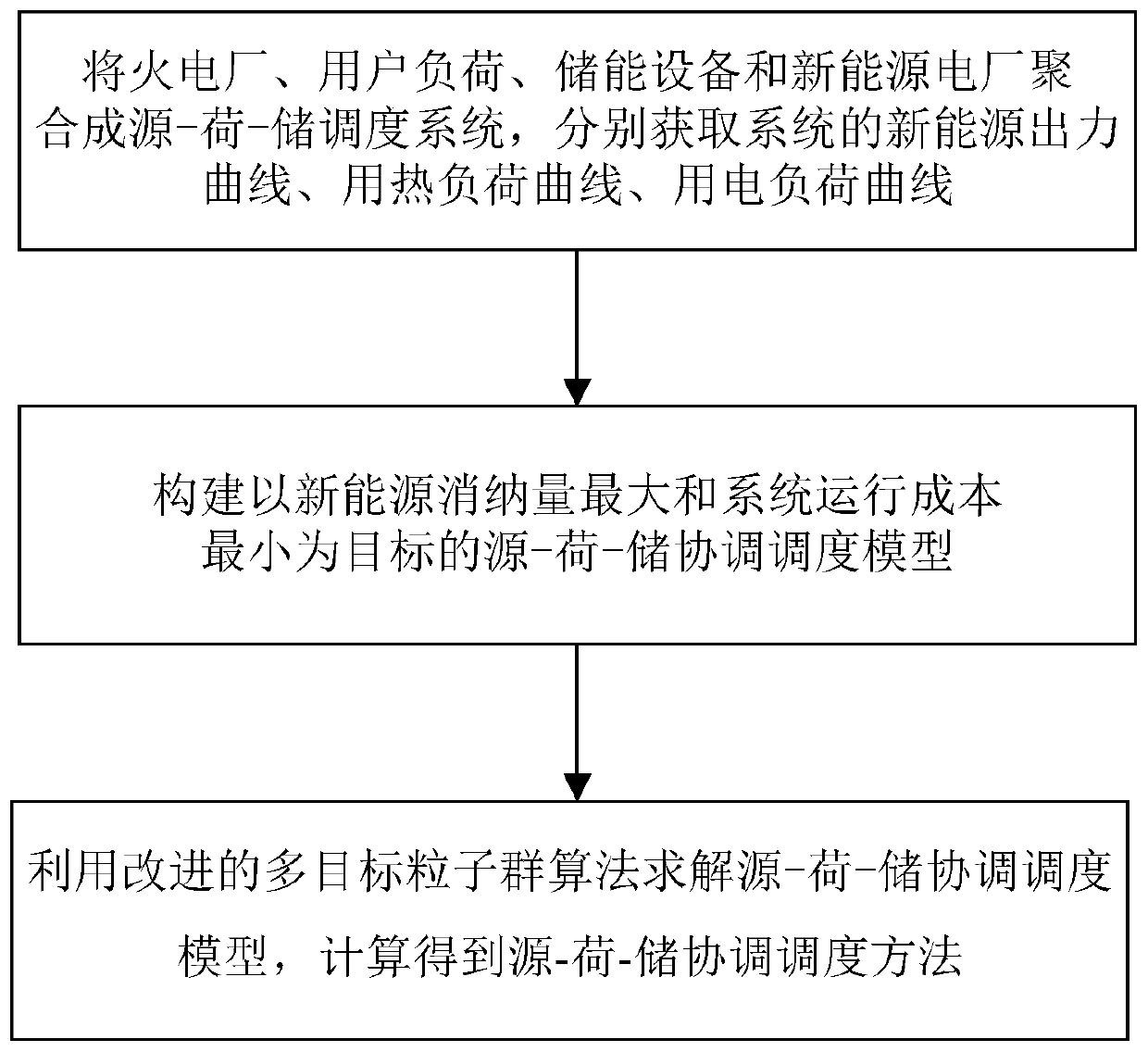

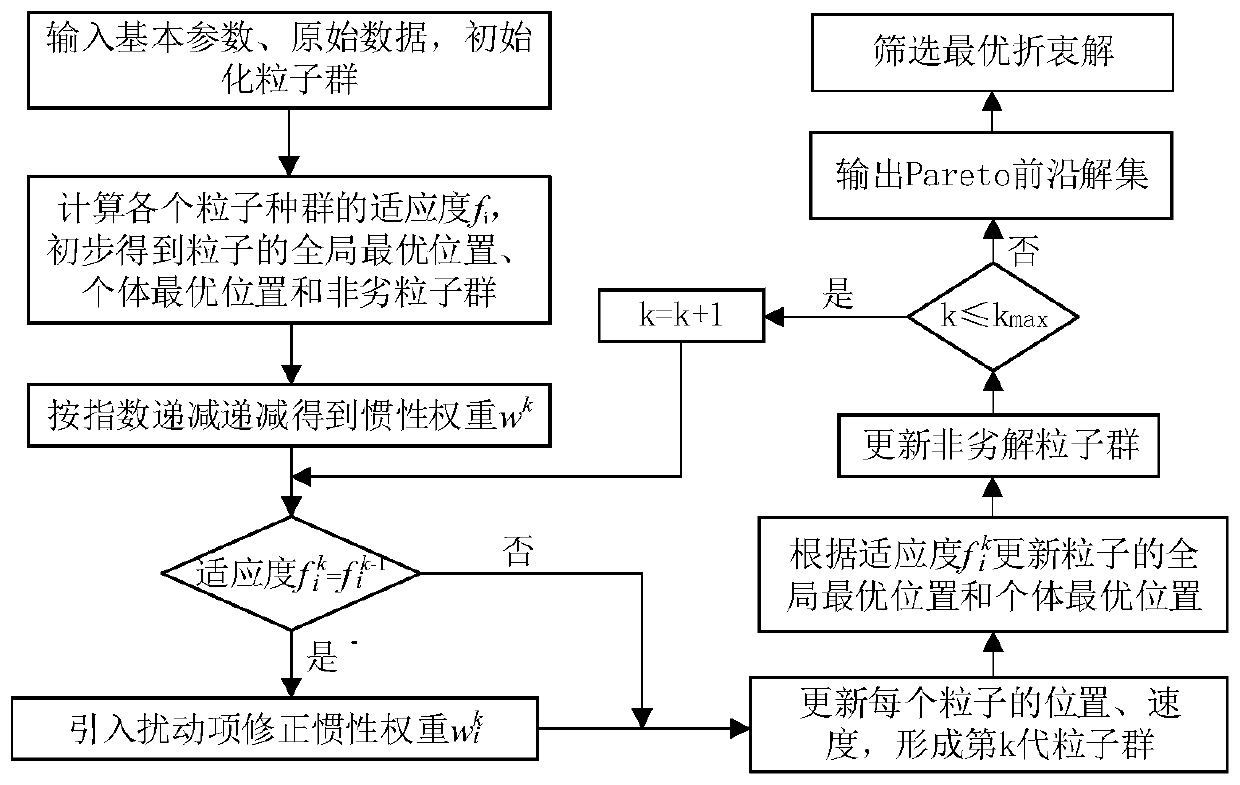

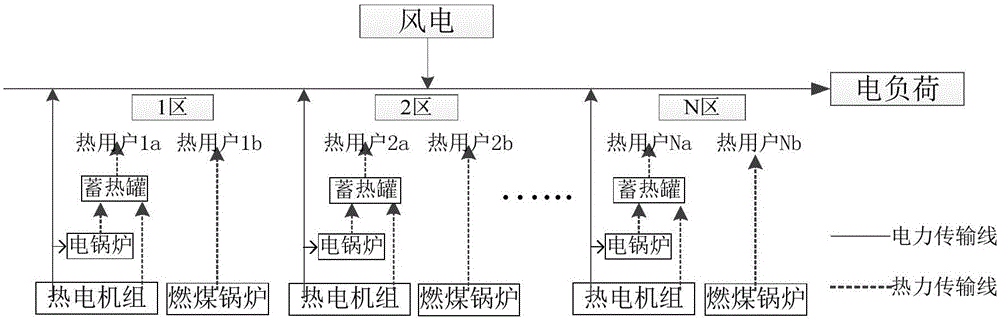

Source-load-storage coordinated scheduling method for improving new energy consumption

ActiveCN109742812AExpand the consumption spaceImprove consumption rateSingle network parallel feeding arrangementsAc network load balancingNew energyPower equipment

The invention discloses a source-load-storage coordinated scheduling method for improving new energy consumption. The method comprises the steps of S1, aggregating a thermal power plant, a new energypower plant, user loads and energy storage equipment into a source-load-storage scheduling system, and obtaining a new energy output curve, a heat utilization load curve and a power utilization load curve of the system; S2, establishing a source-load-storage coordinated scheduling model with the objective of maximizing new energy consumption quantity and minimizing the system operation cost; and S3, solving the source-load-storage coordinated scheduling model through utilization of improved multi-objective particle swarm optimization, and carrying out computing to obtain the source-load-storage coordinated scheduling method. The method has the advantages of simple realization method and flexible application. Schedulable resources such as power equipment, the user loads and the energy storage equipment in the system can be utilized rationally. The new energy consumption is facilitated, and moreover, operation cost of the system is reduced.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

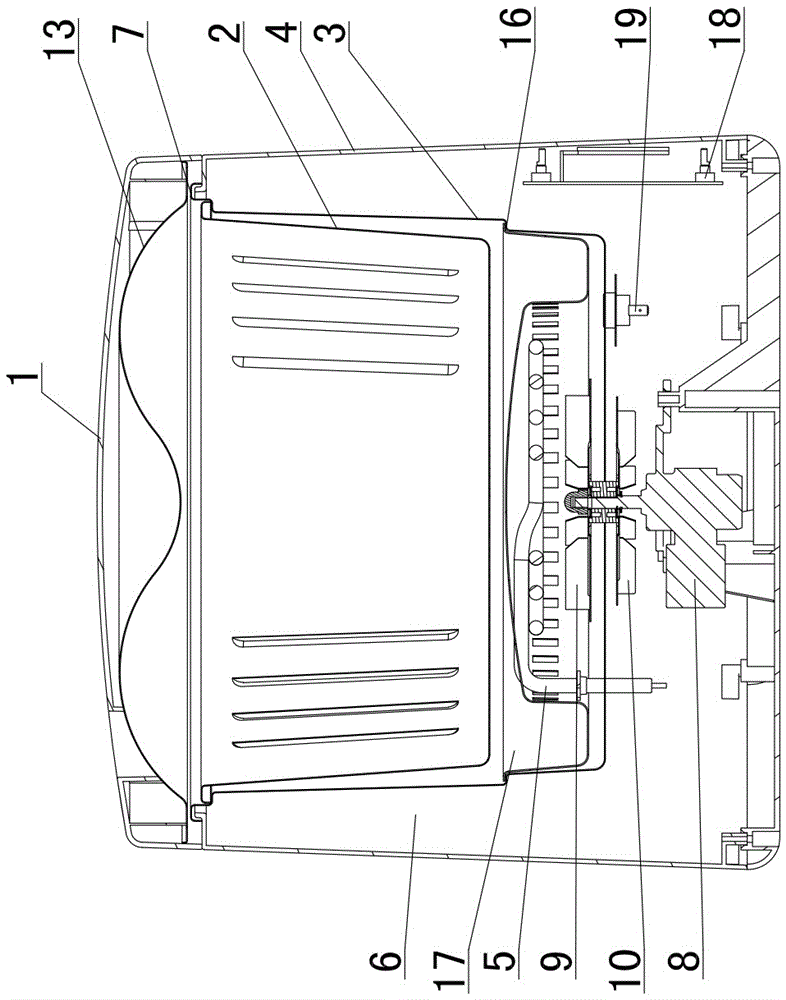

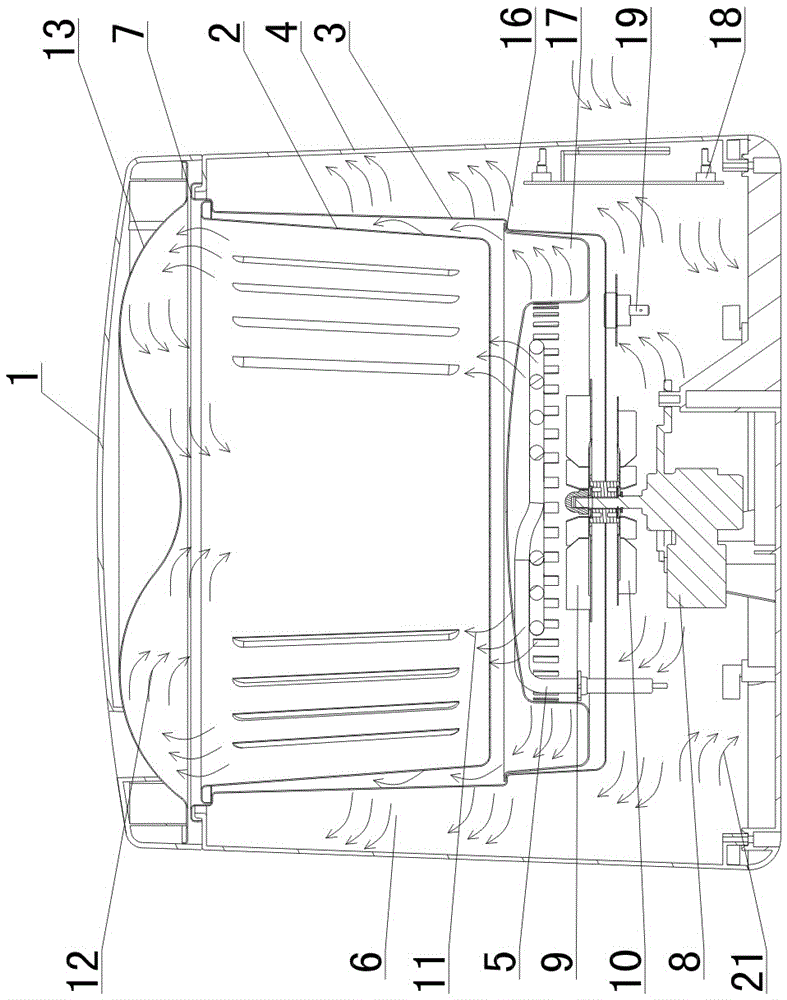

Multifunctional household air energy pot

InactiveCN105996809AHeating evenlyGuaranteed baking effectCooking utensils shields/jacketsRoasters/grillsCold airElectric machine

The invention provides a multifunctional household air energy pot which comprises an upper cover, an inner container, a heat insulating cover and a shell; a fan drive component and an electric heating pipe are arranged at the bottom of the heat insulating cover, the fan drive component comprises a drive motor, an upper fan blade and a lower fan blade, the upper fan blade and the lower fan blade are respectively adaptively mounted on a middle shaft of the drive motor, the drive motor drives the upper fan blade to rotate to form a hot air circulation path for heating the inner container, so that the air heat of a heat source is ensured, food is quickly and uniformly heated, and the food baking effect is ensured; meanwhile, the drive motor drives the lower fan blade to form a cold air circulation path for cooling the shell and drive motor, so that the use quality of products is ensured; as the heat insulation cover has an upper placing level convenient for installation of the inner container, the inner container can be replaced according to the type of the food to be processed, so that the food baking function and the food cooking function in the same equipment are achieved; the multifunctional household air energy pot is convenient to use and strong in adaptability.

Owner:FOSHAN SHUNDE HUIERJIA HOUSEHOLD ELECTRICAL

Method for producing polyaluminum chloride without heating

The invention discloses a method for producing polyaluminum chloride without heating. The method comprises the following concrete steps: (1) sequentially adding a waste aluminum chloride liquor generated in a Friedel-Craft reaction, an aluminiferous hydrochloric acid, an industrial hydrochloric acid and water into a heat insulating reaction kettle to prepare a mixed acid in which the percentage of Al2O3 is 1% to 4% and the percentage of HCl is 12% to 18%; (2) adding aluminum oxidized sludge into the mixed acid, stirring for 60-90 minutes until the aluminum oxidized sludge is completely dissolved, heating to the reaction temperature of 60 DEG C to 80 DEG C, controlling the percentage of the HCl in a semi-finished product to be 0.5% to 3.5% and the percentage of the Al2O3 in the semi-finished product to be not less than 5.0%; (3) adding calcium aluminate powder into a semi-finished product liquid, regulating the percentage of the Al2O3 in the reaction liquid to be 11% to 12% and the basicity of the reaction liquid to be 60% to 90%, maintaining the temperature required by the reaction by utilizing the heat generated in the reaction, timing when the temperature rises to 90 DEG C, reaction under preserved temperature for 60-90 minutes and performing a filter pressing treatment to obtain a finished polyaluminium chloride product. By adopting the method to prepare the polyaluminium chloride, the production process is simple, no steam does need to be heated, the emission of acid mist and waste slag is reduced, the production cost is lowered and the recycle of waste resources is realized; therefore, the method is an economical and practical production method which saves energy and reduces emissions.

Owner:CHANGZHOU WUJIN YOUBANG WATER PURIFICATION MATERIALS

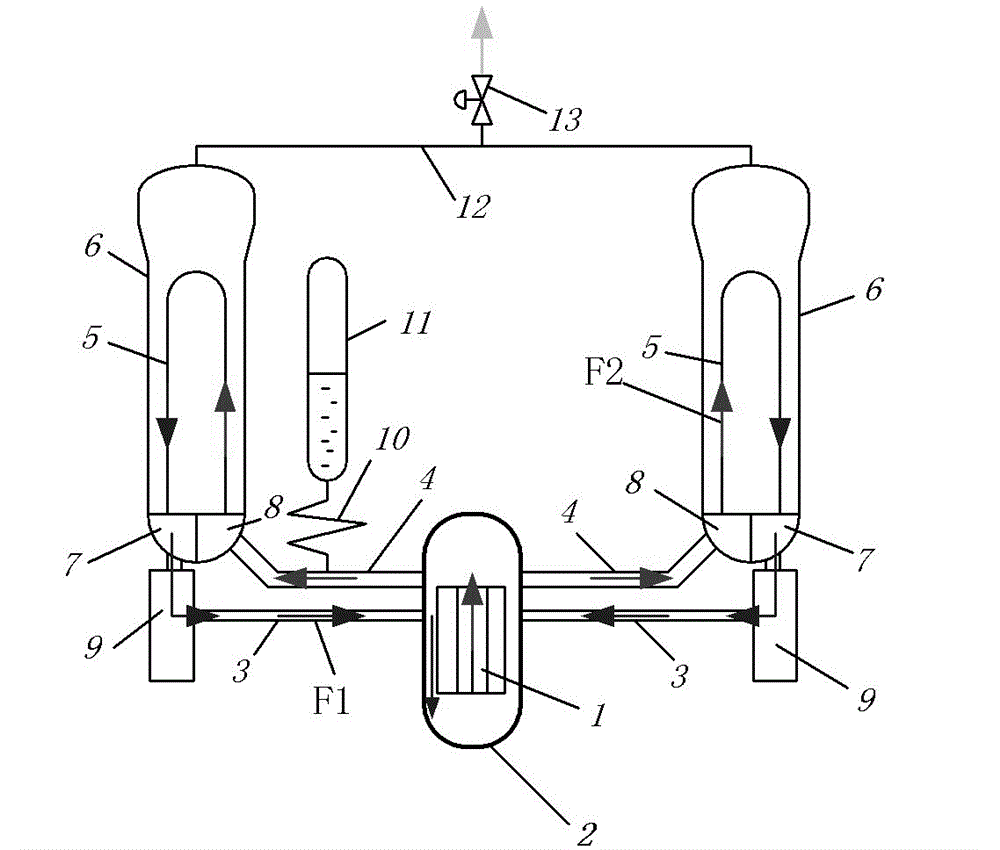

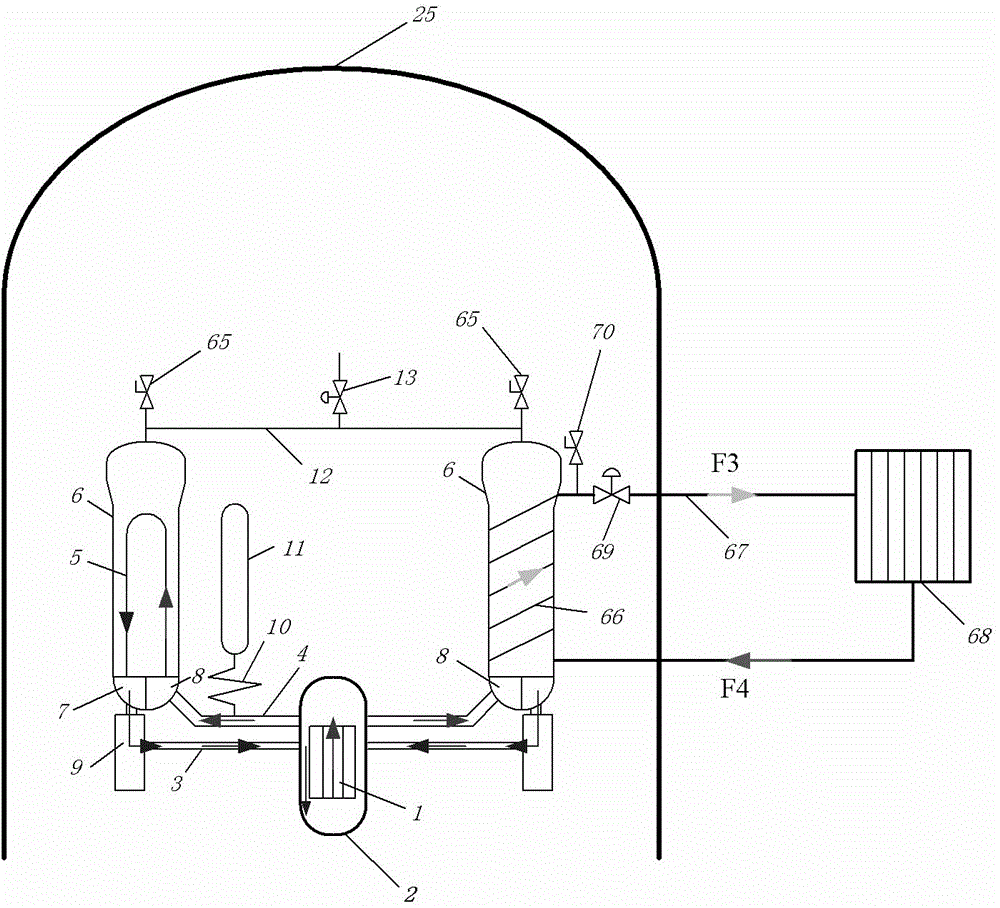

Passive residual heat removal system for nuclear power plant

ActiveCN105810256AConducive to production recoveryRelieve pressureNuclear energy generationCooling arrangementIsolation valveNuclear power

The invention relates to a passive residual heat removal system for a nuclear power plant. The passive residual heat removal system for the nuclear power plant comprises a steam generator shell heat exchanger, a heat exchange loop pipeline, a shell exterior heat exchanger, a pressure maintaining valve, an isolating valve and a heat transferring medium, wherein the heat exchange loop pipeline penetrates through a containment; the steam generator shell heat exchanger is distributed on a steam generator and is communicated with the heat exchange loop pipeline; the shell exterior heat exchanger is arranged outside the containment and is communicated with the heat exchange loop pipeline; the shell exterior heat exchanger is arranged at a high position relative to the position of the steam generator shell heat exchanger; the pressure maintaining valve and the isolating valve are arranged in the containment and are sequentially arranged between the steam generator shell heat exchanger and the shell exterior heat exchanger along a first flow direction of the heat transferring medium in the heat exchange loop pipeline; the passive residual heat removal system for the nuclear power plant is maintained in a relatively low pressure level by virtue of the pressure maintaining valve; and the isolating valve and a shutdown safety signal of a reactor are subjected to interlock opening to be used for continuously taking away heat in the steam generator during an accident.

Owner:STATE NUCLEAR HUAQING BEIJING NUCLEAR POWER TECH R & D CENT +1

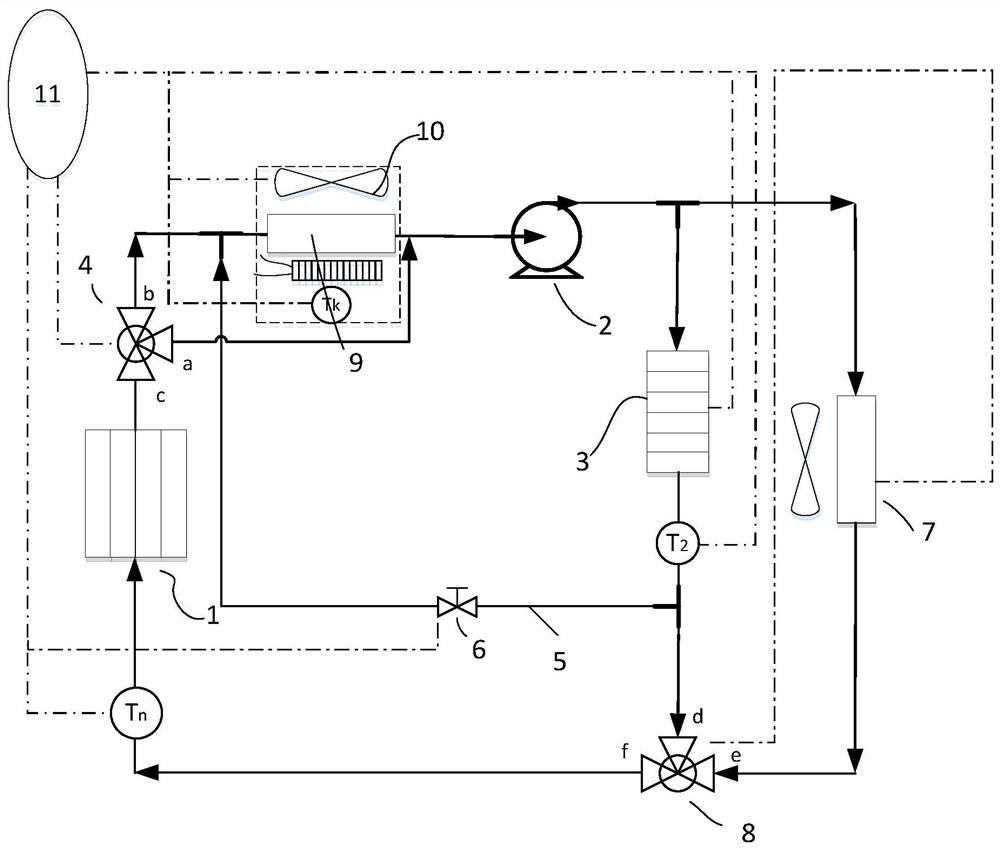

Hydrogen fuel cell automobile hydrothermal management system and control method thereof

ActiveCN112208392AImprove heating effectOptimizing Flow PathsAir-treating devicesVehicle heating/cooling devicesHydrogen fuel cellEngineering

The invention relates to a hydrogen fuel cell automobile hydrothermal management system which comprises a fuel cell, a main water pump and a heater which are sequentially communicated through a pipeline to form a circulation loop, and further comprises a first three-way valve, an inlet of the three-way valve I is communicated with an outlet of the fuel cell through a pipeline, and one outlet is communicated with the main water pump through a pipeline, the other outlet is communicated with an inlet of heating equipment in an automobile passenger cabin through a pipeline, and an outlet of the heating equipment is communicated with a pipeline between the three-way valve I and the main water pump through a pipeline; a pipeline between the fuel cell and the heater is communicated with a pipeline between the three-way valve I and the heating equipment through a heating loop, and a valve is mounted on the heating loop; the invention further provides a control method of the hydrogen fuel cellautomobile hydrothermal management system. The system has the beneficial effects that the flowing path of cooling liquid is optimized when the automobile passenger cabin does not need to be heated, the heating capacity in the automobile passenger cabin is improved while normal operation of the system is guaranteed, and energy consumption is reduced.

Owner:武汉海亿新能源科技有限公司

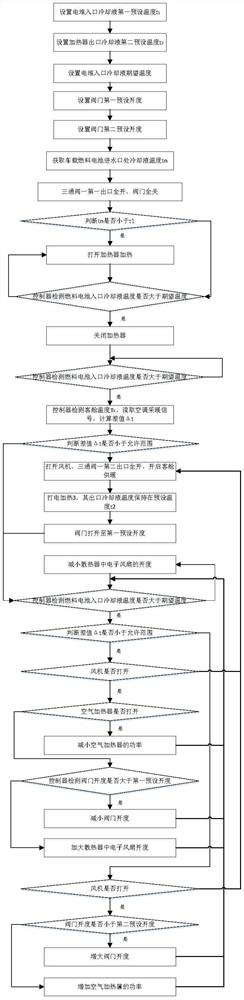

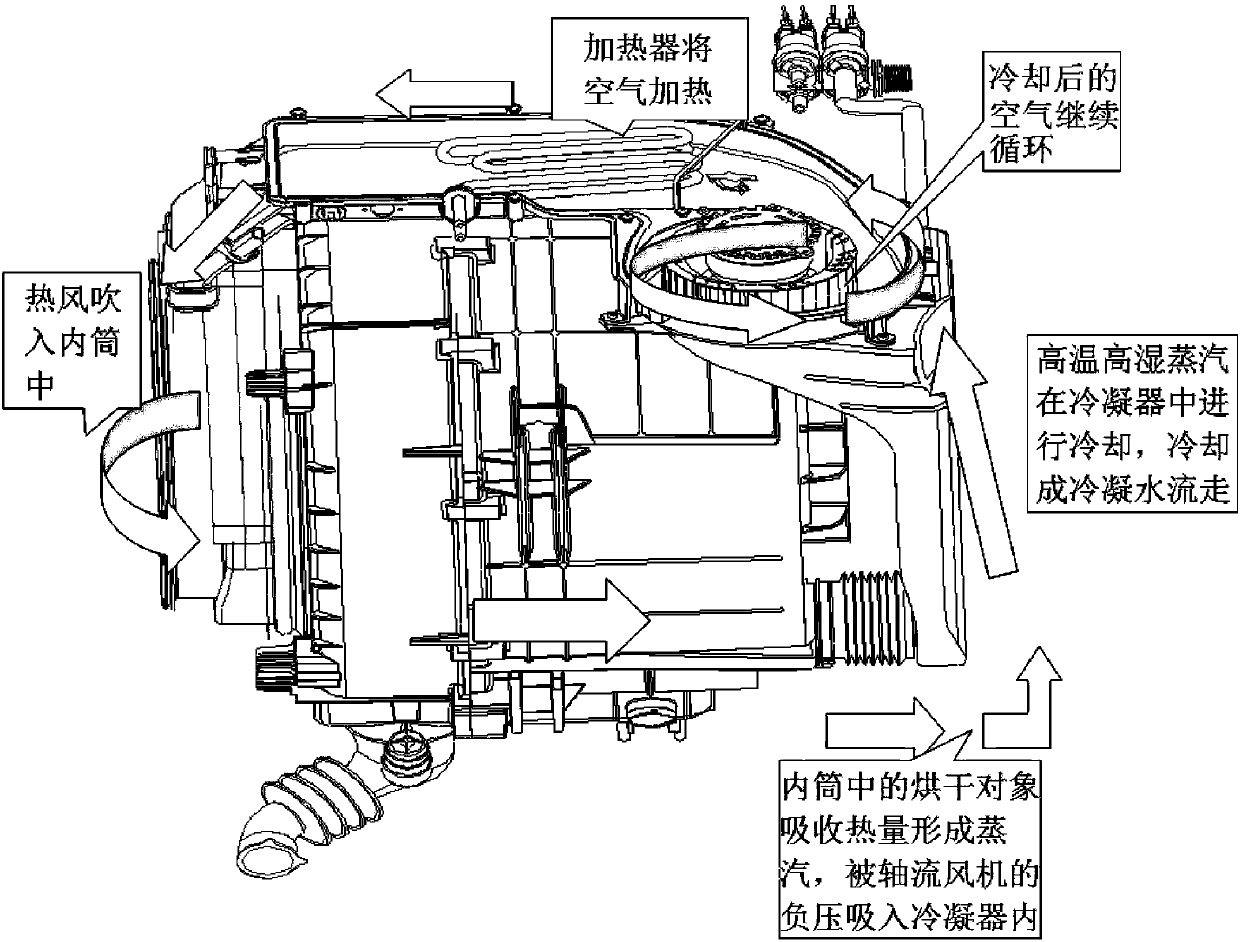

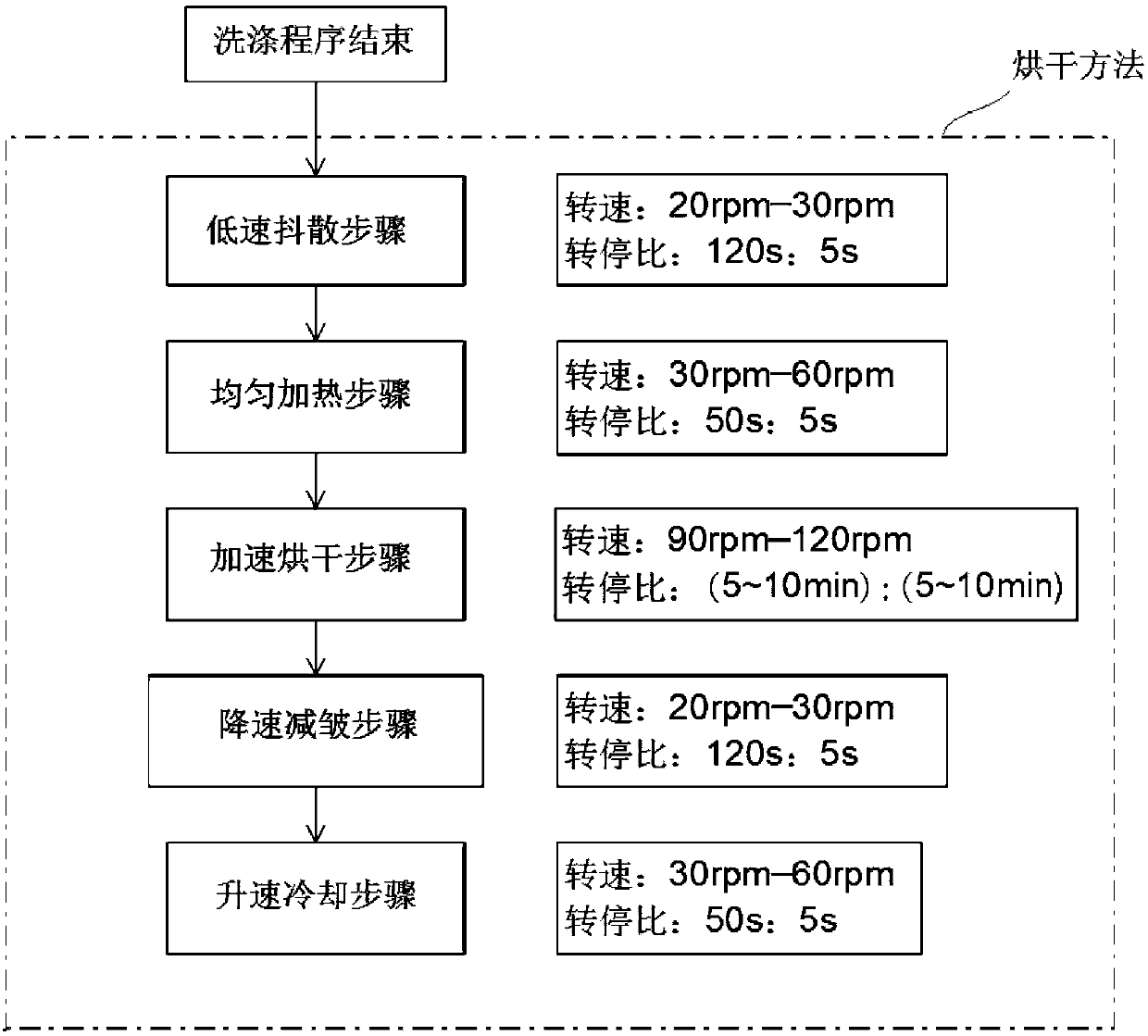

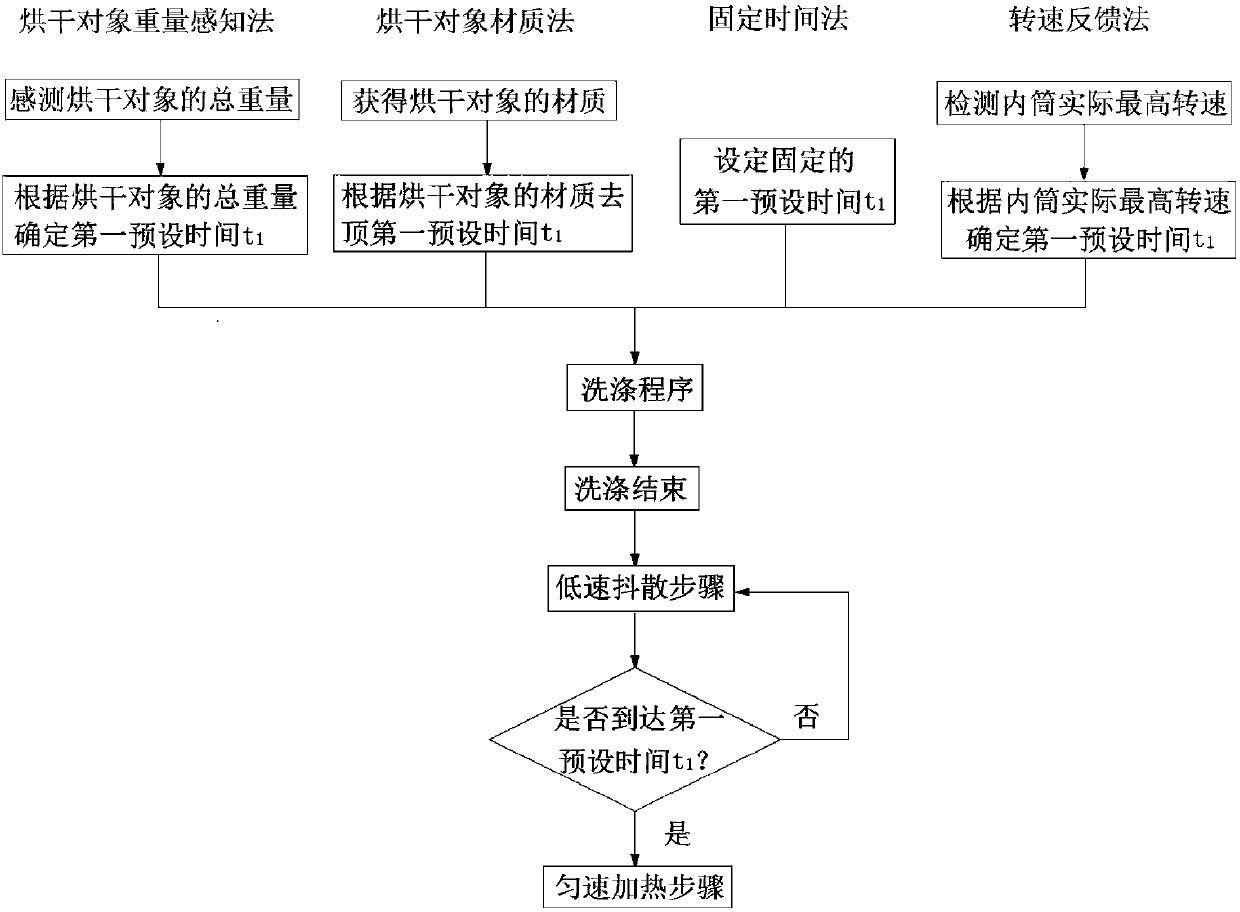

Drying method used for washing and drying all-in-one machine, and washing and drying all-in-one machine

ActiveCN107724028AIncrease contactImprove drying uniformityWashing machine with receptaclesTextiles and paperTime conditionStable state

The invention relates to the technical field of clothing drying, and especially relates to a drying method used for a washing and drying all-in-one machine, and a washing and drying all-in-one machine. The drying method comprises a low-speed shake-loose step, a constant speed heating step, and an accelerating drying step. After the accelerating drying step is executed for third preset time, and / orafter temperature in a barrel reaches a stable state, and / or after a difference value of temperature of an inner barrel and temperature of water in an outer barrel reaches a stable state, the accelerating drying step is ended. Therefore, different rotating speeds are used in the constant speed heating step and the accelerating drying step, so hot air preferably contacts with drying objects on themiddle and rear parts of the inner barrel, and integrated drying uniformity of the drying objects is improved and drying performance is improved. One time condition and two temperature conditions arerespectively or integrally used to determine whether to stop the accelerating drying step, and ending time is set to be more reasonable. The washing and drying all-in-one machine uses the above drying method, and drying performance is improved and the whole drying process is optimized.

Owner:CHONGQING HAIER ROLLER WASHING MASCH CO LTD +1

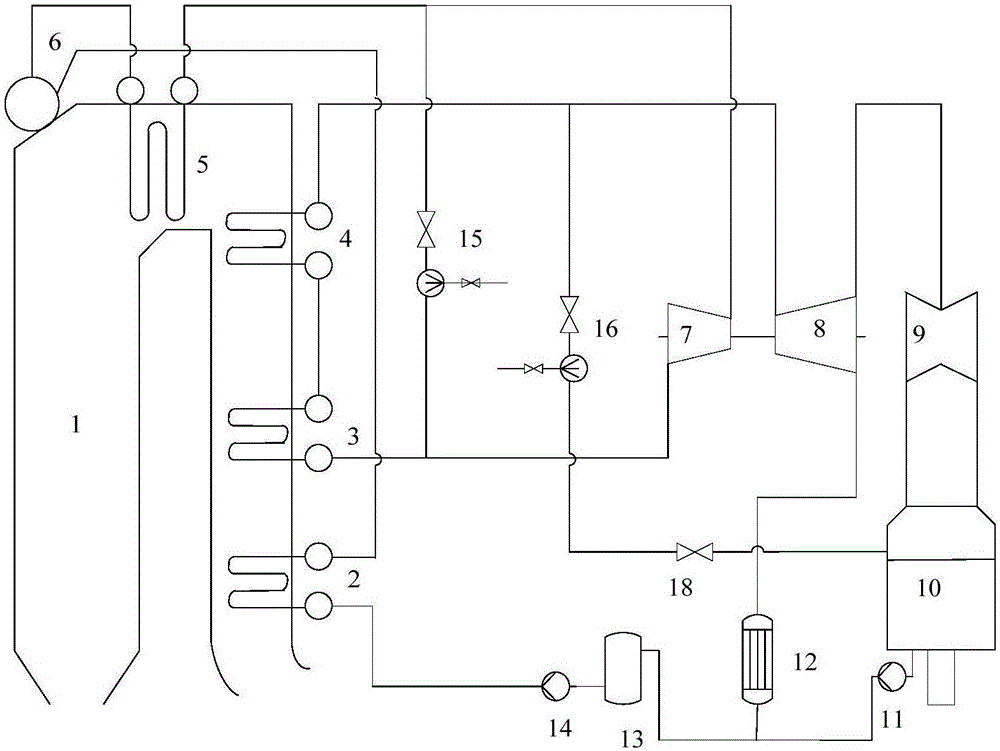

Steam-extracting and heat-supplying power station system with complete thermoelectric decoupling and working method

ActiveCN106838865AWith thermoelectric decoupling functionGuaranteed to be heatedSteam useSteam generation plantsElectricityPower station

The invention discloses a steam-extracting and heat-supplying power station system with complete thermoelectric decoupling and a working method. The steam-extracting and heat-supplying power station system is a power station system with steam extraction and heat supply and with in-series connection of two-stage bypasses. The steam-extracting and heat-supplying power station system and the working method disclosed by the invention have the advantages that by modification of the heat-supplying power station system of the original middle reheating unit, not only can the heat-supplying safety of regions at the heat-supplying peak period in winter be guaranteed, but also greatest reduction of the power-generation load of a steam turbine is allowed, so that the wind-electricity receiving capability can be greatly improved and the purpose of complete thermoelectric decoupling can be achieved. The scheme disclosed by the invention has the advantages of convenience in implementation, obvious effect, low investment cost and the like.

Owner:CHINA HUANENG GRP CO LTD +1

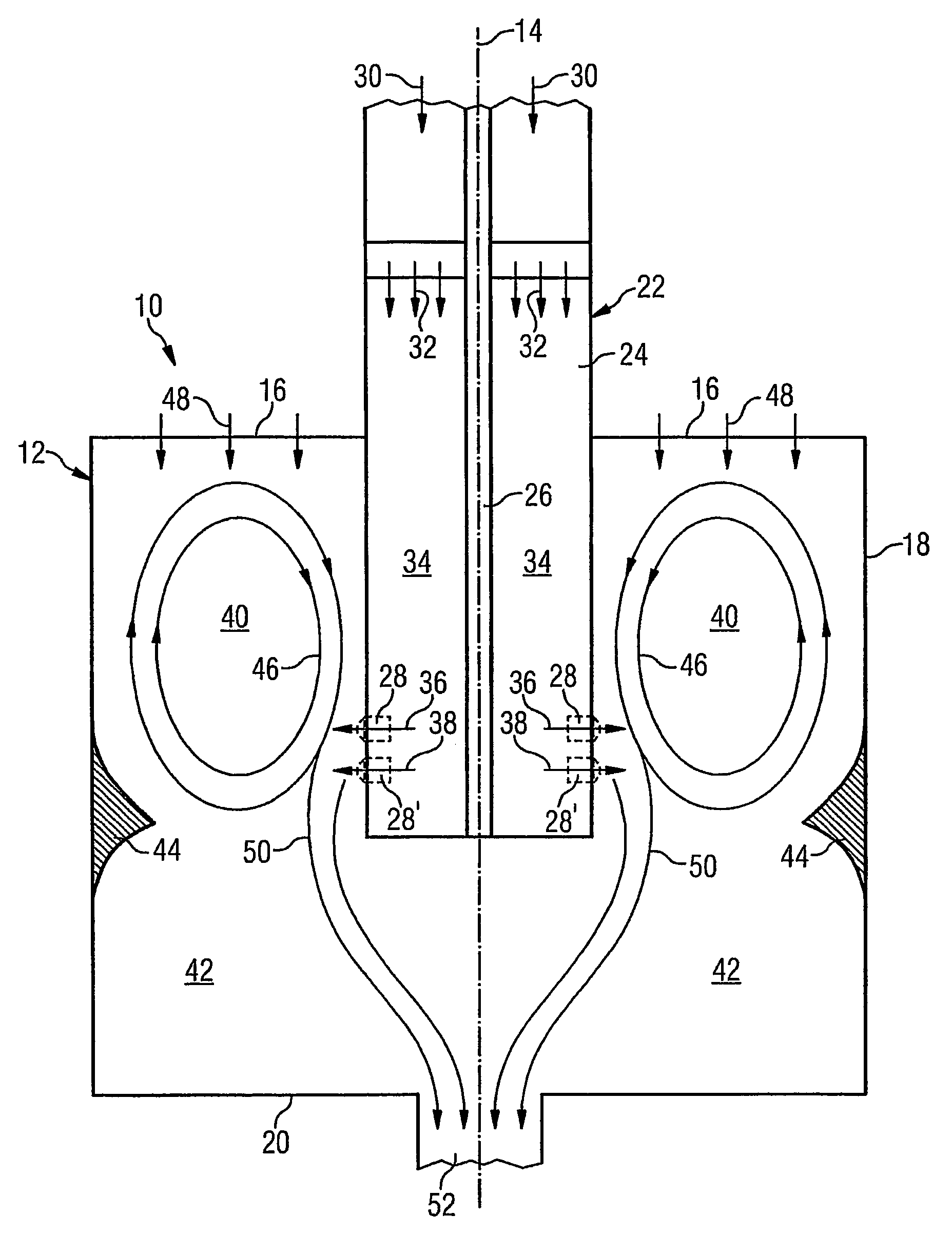

Method and device for the combustion of fuel

InactiveUS20070141519A1Promote combustionAvoid temperatureBurnersContinuous combustion chamberCombustion chamberNitrogen

A method and device for the combustion of fuel in a fuel chamber resulting in combustion which is particularly low in nitrogen, wherein fuel and combustion air are mixed before entering the combustion chamber avoiding self-ignition; a first part of the mixture is introduced into the combustion chamber such that it circulates inside the combustion chamber; other fuel is added to the circulatory flow of the first part of the mixture until it is heated up to ignition conditions; and at least one second part of the mixture is introduced into the combustion chamber in such a way that is mixed with hot combustion gas from the circulatory flow, heated up and combusted until it leaves the combustion chamber.

Owner:SIEMENS AG

Multifunctional marine lifesaving device

PendingCN107187564AExtend the waiting time for rescueImprove survival rateAuxillariesLighting and heating apparatusWave power generationMarine engineering

The invention discloses a multifunctional marine lifesaving device which comprises an inflation air bag for serving as a temporary shelter place, a wind power generation system, a wave power generation system, a positioning and navigation system, a solar cell panel and electric heating pipes. The inflation air bag is of a double-layer structure, and a switch valve, a manhole and a breather valve are respectively arranged on the inflation air bag. The wind power generation system is arranged outside the inflation air bag. The positioning and navigation system is arranged at the top of the inflation air bag. The solar cell panel is arranged outside the inflation air bag. The electric heating pipes are arranged in an inflation air bag interlayer. The multifunctional marine lifesaving device is simple in structure and convenient to operate, can rapidly provide a warm and food-supplying safe place where fresh air can be provided, positioning can be performed and the danger can be avoided for persons in distress after marine perils occurs, the time for waiting for rescue is prolonged, and the survival rate of the persons in distress is improved.

Owner:徐浩然

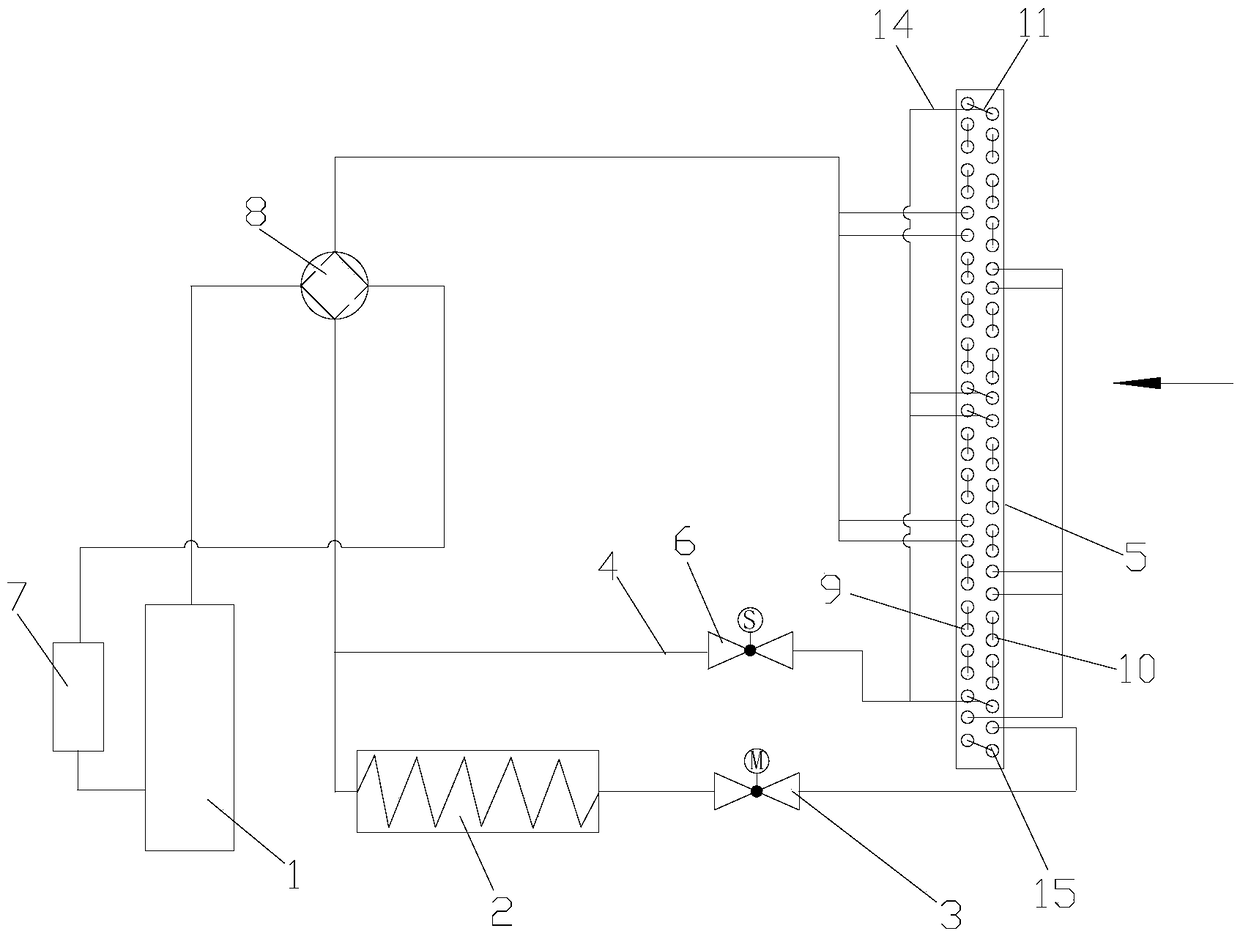

Air conditioner and control method thereof

ActiveCN109386982AImprove comfortGuaranteed to be heatedMechanical apparatusSpace heating and ventilation safety systemsEngineeringControl valves

The invention provides an air conditioner and a control method thereof. The air conditioner comprises a compressor (1), an indoor heat exchanger (2), a throttling device (3), a first by-pass line (4)and an outdoor heat exchanger (5), wherein the throttling device (3) is arranged on a pipeline between the indoor heat exchanger (2) and the outdoor heat exchanger (5), a first end of the first by-pass line (4) is connected to the outdoor heat exchanger (5), the first by-pass line (4) is used for conveying a high-temperature refrigerant to the outdoor heat exchanger (5), and a first control valve(6) used for controlling the on-off state of the first by-pass line (4) is arranged on the first by-pass line (4). According to the air conditioner, the defrosting cycle of the air conditioner can beprolonged, the defrosting time of the air conditioner can be shortened, and the indoor comfort can be improved.

Owner:GREE ELECTRIC APPLIANCES INC +1

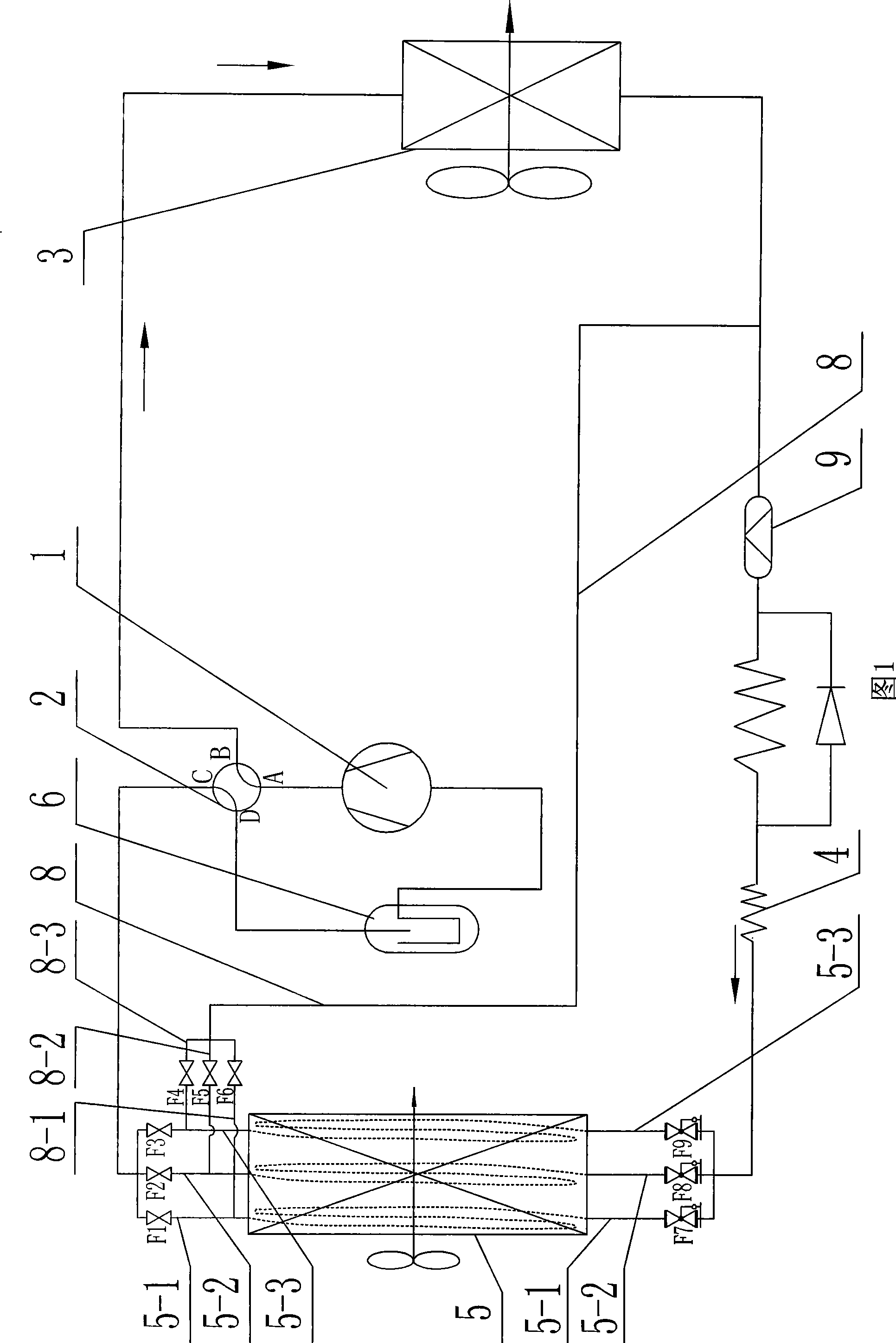

Air source heat pump system capable of continuously supplying heat by refrigerant super cooling defrost

InactiveCN101435638AReduce drastic changesEliminate the effects ofHeat pumpsCorrosion preventionIntermittent heatingEngineering

The invention discloses an air source heat pump system for continuous heat supply through utilizing the undercooling and defrosting of a cryogen and relates to an air source heat pump system. The system effectively solves the problems that the prior defrosting mode has drastic change of air suction pressure, reduces the heating load indoors, stops heat supply indoors and blows cold wind indoors in the defrosting process. The outlet end of a compressor is communicated with a first port of a four-way reversing valve; a second port of the four-way reversing valve is communicated with the inlet end of an indoor machine; the outlet end of the indoor machine is respectively communicated with one end of a first bypass shunt circuit, one end of a second bypass shunt circuit and one end of a third bypass shunt circuit; one end of the first bypass shunt circuit is provided with a seventh decompression valve; one end of the second bypass shunt circuit is provided with an eighth decompression valve; and one end of the third bypass shunt circuit is provided with a ninth decompression valve. The system realizes unintermittent heat supply in the defrosting process, reduces drastic change of air suction pressure of the compressor, is more stable in the conversion process of heat supply and defrosting and well removes the influence on the heating load indoors in the prior hot air bypass defrosting.

Owner:HARBIN INST OF TECH

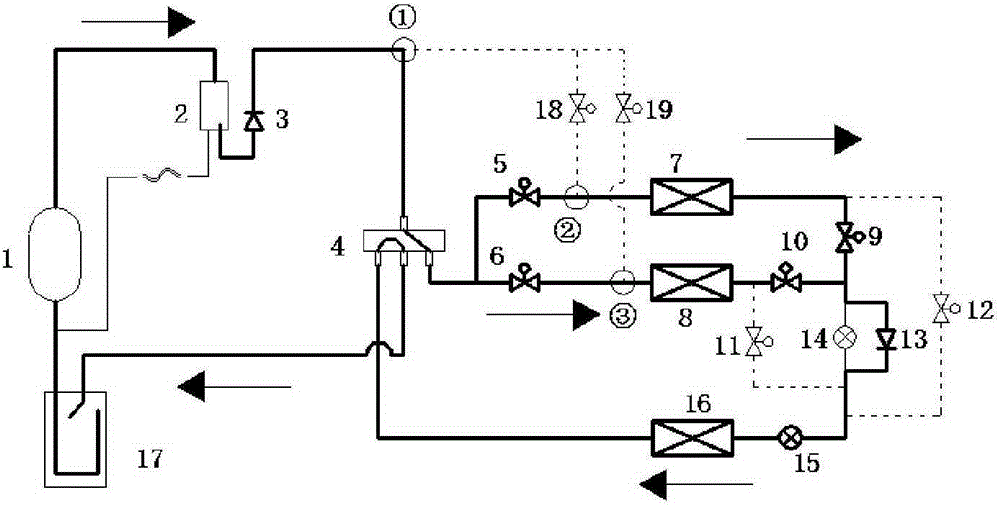

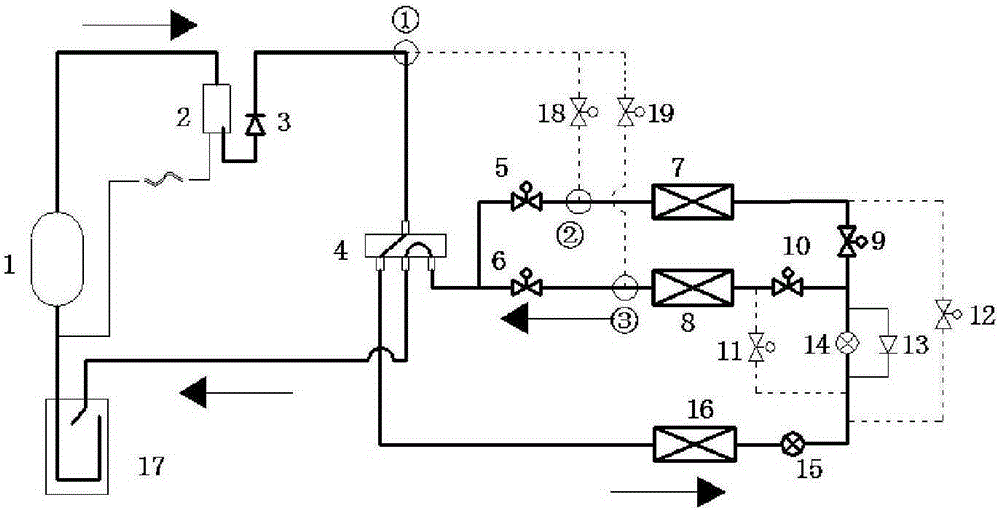

Air conditioning system and air conditioning system control method

InactiveCN105222436AGuaranteed to be heatedSpace heating and ventilation safety systemsSpace heating and ventilation control systemsFour-way valvePlate heat exchanger

The invention provides an air conditioning system and an air conditioning system control method. The air conditioning system comprises a compressor, a four-way valve, an indoor heat exchanger and outer heat exchangers. The outdoor heat exchangers comprise the first outdoor heat exchanger and the second outdoor heat exchanger which are independently arranged. Moreover, when the air conditioning system conducts refrigeration operation, the first outdoor heat exchanger and the second outdoor heat exchanger are used as condensers, and the indoor heat exchanger is used as an evaporator. When the air conditioning system conducts heating operation, the first outdoor heat exchanger and the second outdoor heat exchanger are used as evaporators, and the indoor heat exchanger is used as a condenser. When the air conditioning system conducts defrosting operation, one outdoor heat exchanger is used as a condenser, the other outdoor heat exchanger is used as an evaporator, and the indoor heat exchanger is used as a condenser. The outdoor heat exchangers are divided into two parts, and normal heating of an inner machine during defrosting is guaranteed.

Owner:GREE ELECTRIC APPLIANCES INC

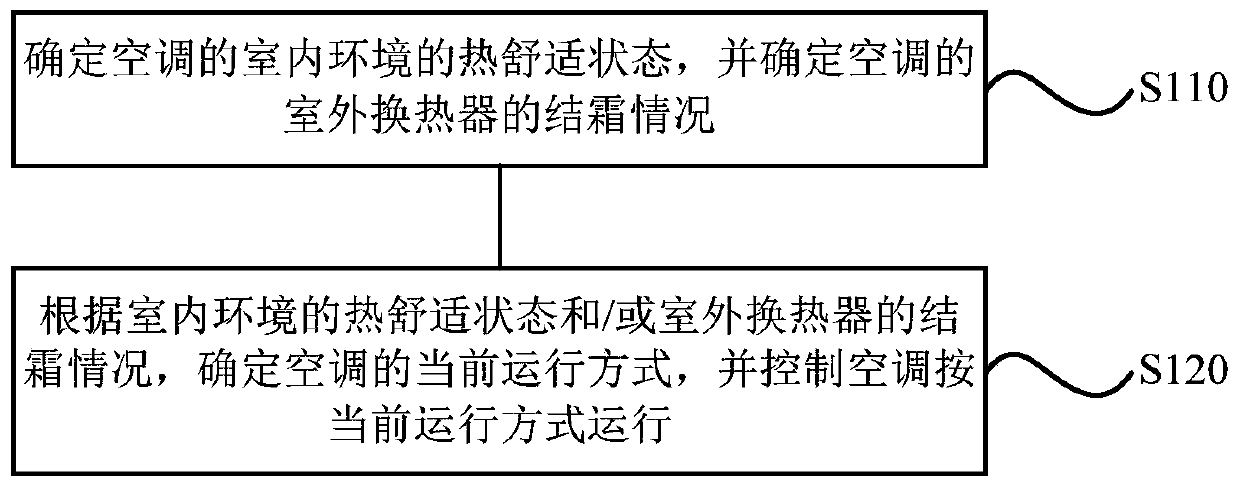

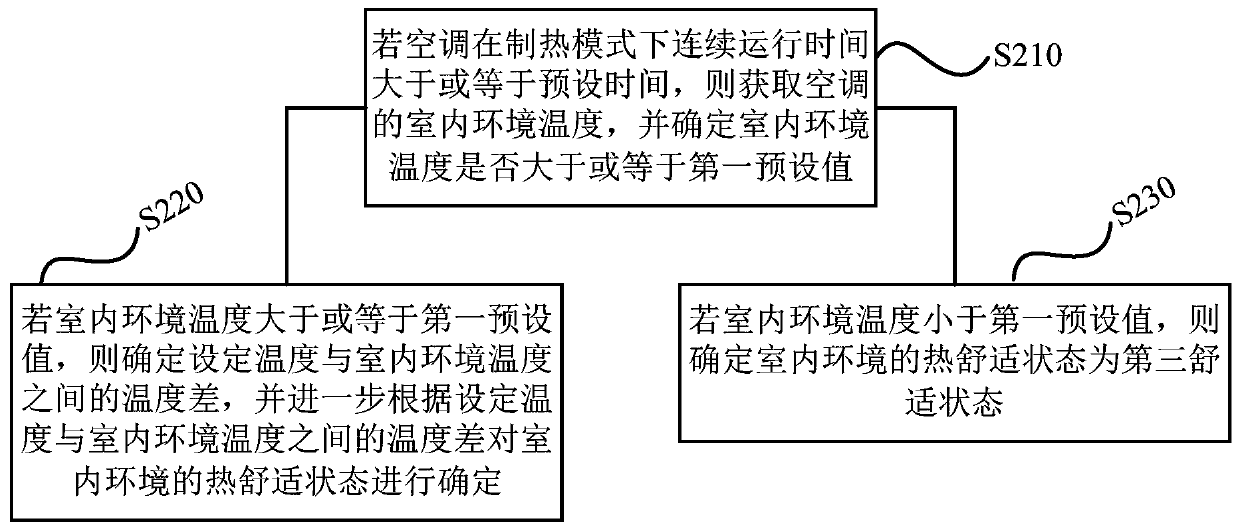

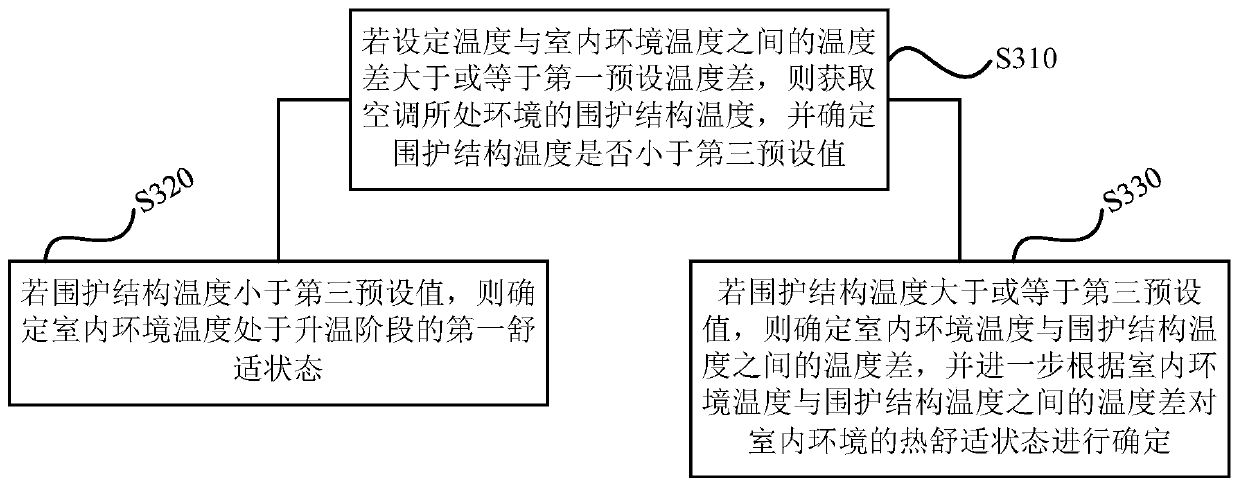

Air conditioner control method and device, storage medium and air conditioner

ActiveCN111174372AEnhance thermal comfort experienceSolve the uncomfortable problem when the indoor temperature drops greatlyMechanical apparatusRefrigeration safety arrangementThermal comfortEngineering

The invention discloses an air conditioner control method and device, a storage medium and an air conditioner. The method comprises the steps of determining a heat comfort state of an indoor environment of an air conditioner, and determining a frosting situation of an outdoor heat exchanger of the air conditioner; and according to the heat comfort state of the indoor environment and / or the frosting situation of the outdoor heat exchanger, determining a current operation mode of the air conditioner, and controlling the air conditioner to operate according to the current operation mode, whereinthe step of controlling the air conditioner to operate according to the current operation mode comprises: controlling the air conditioner to continuous operate at a heating mode, and controlling the air conditioner to reduce the output heat so as to operate, or controlling the air conditioner to operate at a defrosting mode, or controlling the air conditioner to stop or reduce frequency so as to operate. According to the scheme provided by the invention, the problem that since whether the air conditioner enters the defrosting mode or not is judged according to the temperature of the outdoor heat exchanger or a difference value between the temperature of the outdoor heat exchanger and the outdoor environment temperature, the heat comfort experience of a user is affected due to big indoor temperature drop during defrosting can be solved, and an effect on improving the heat comfort experience of the user during defrosting is achieved.

Owner:GREE ELECTRIC APPLIANCES WUHAN +2

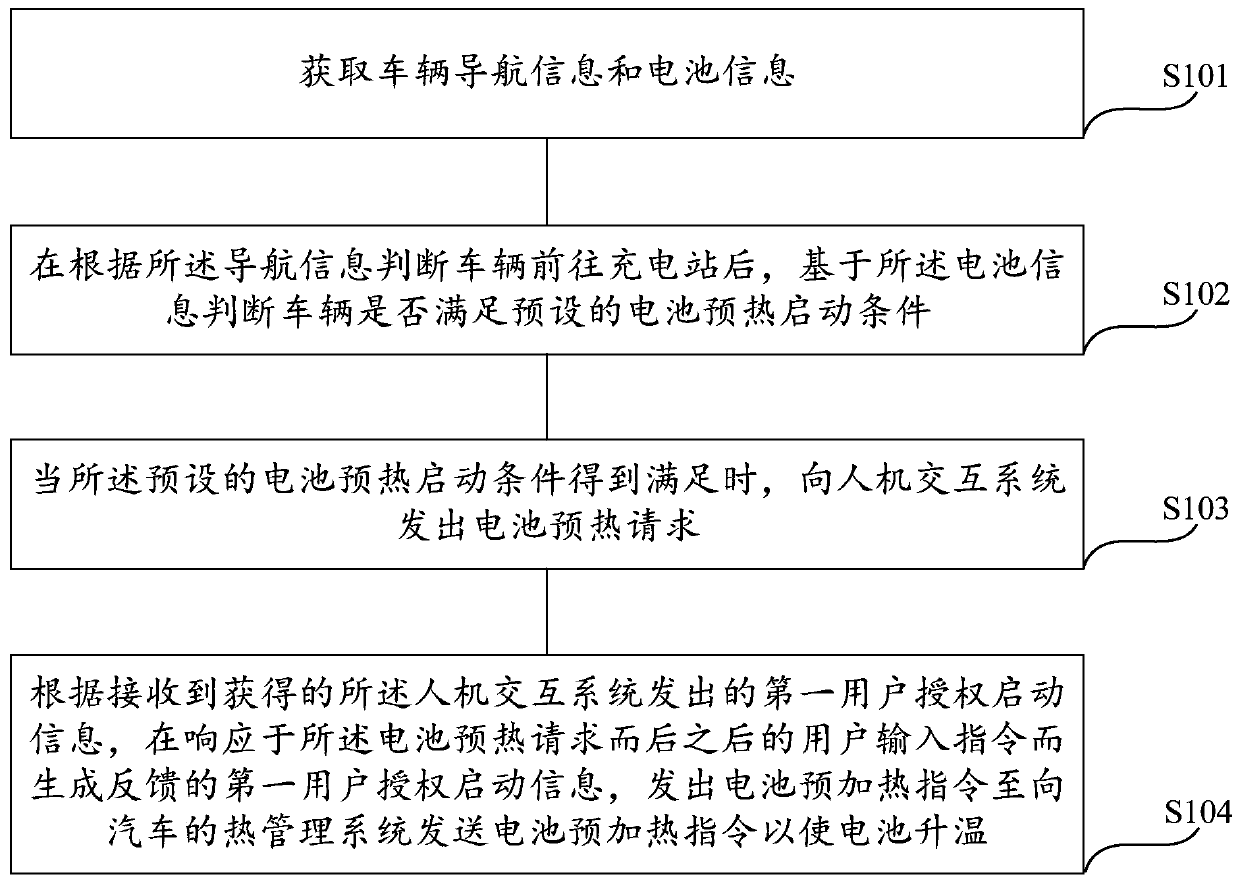

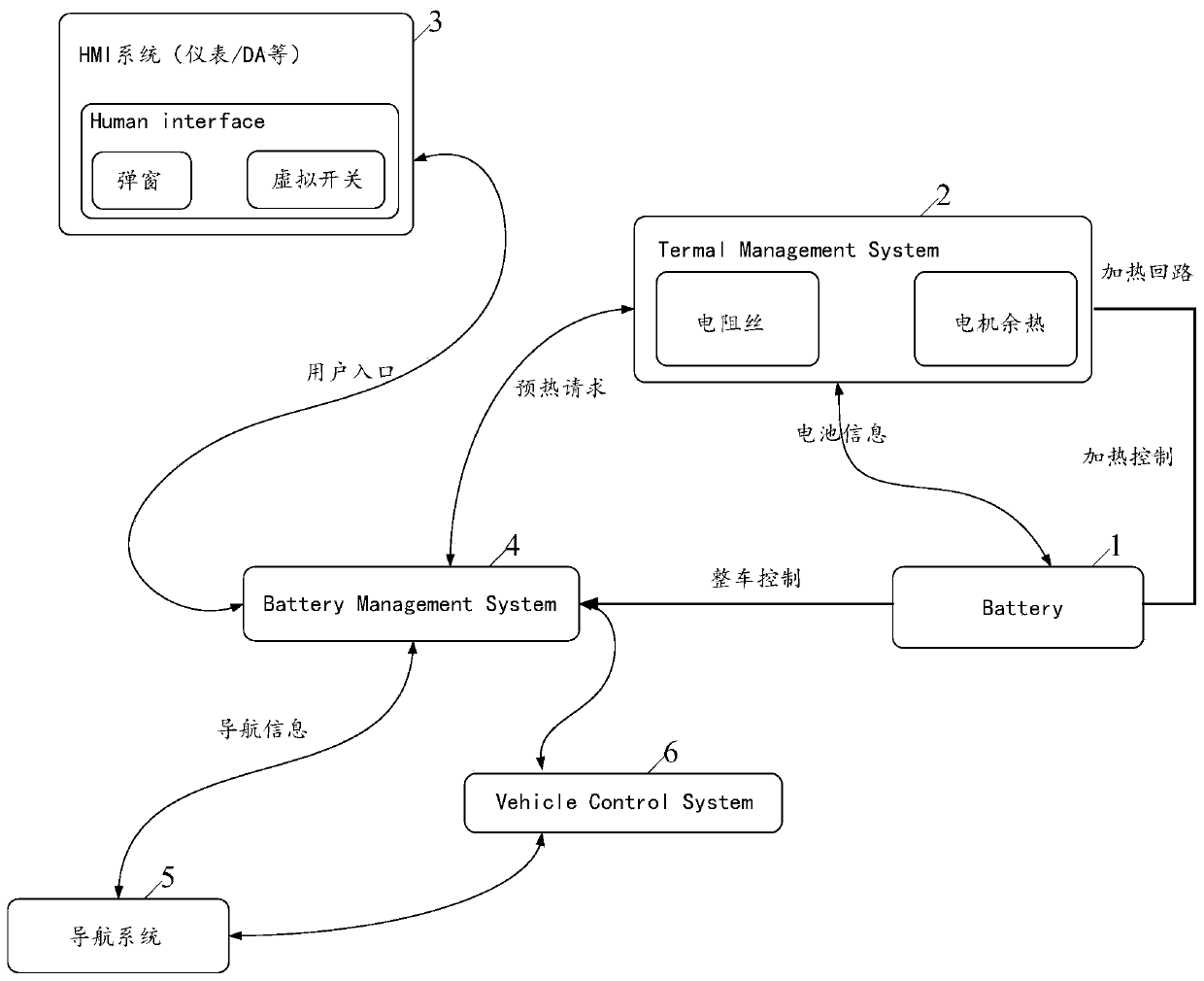

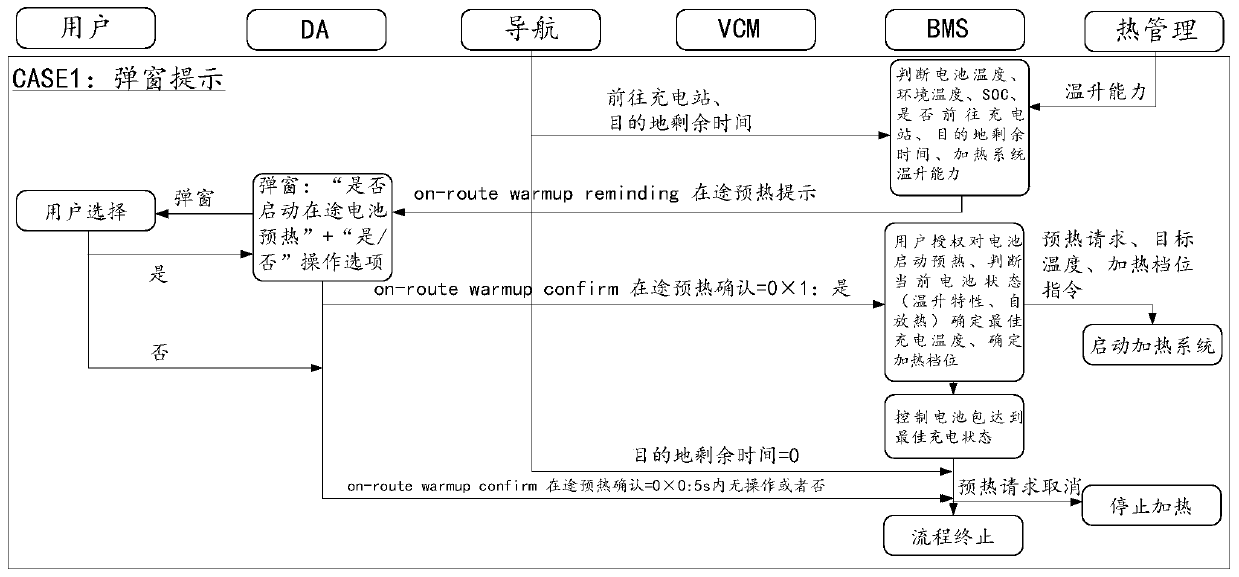

Vehicle in-transit battery preheating method and system and vehicle

InactiveCN111016738AIncrease the rate of chargingImprove experienceVehicular energy storageBattery/fuel cell control arrangementCharge rateProcess engineering

The invention discloses a vehicle in-transit battery preheating method and system and a vehicle. The method comprises the steps: acquiring vehicle navigation information and battery information; afterit is determined that the vehicle goes to a charging station according to the navigation information, determining whether the vehicle meets a preset battery preheating starting condition or not based on the battery information; when the preset battery preheating starting condition is met, sending a battery preheating request to a human-machine interaction system of the vehicle; and sending a battery preheating instruction to a thermal management system according to the obtained first user authorization starting information generated by the human-machine interaction system in response to thebattery preheating request so as to heat the battery. The charging rate of the battery in a low-temperature environment can be effectively improved, and the low-temperature vehicle use experience of auser is enhanced.

Owner:DONGFENG MOTOR CO LTD

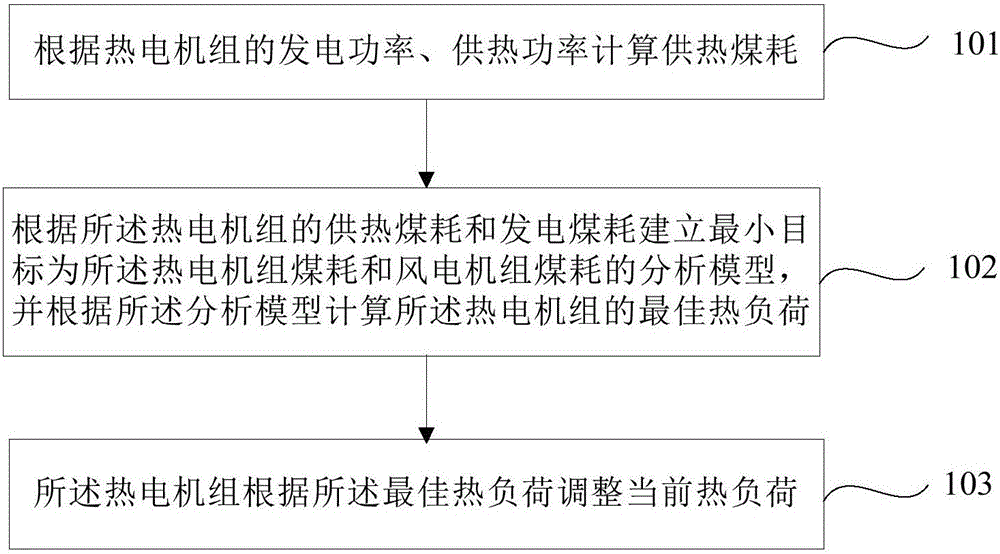

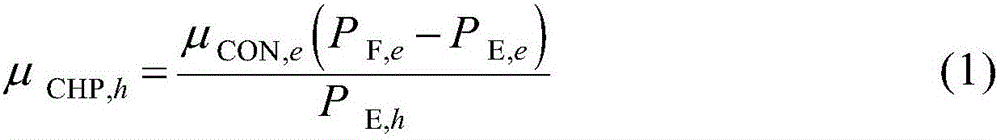

Wind curtailment absorption method in thermal power plant

ActiveCN106712033AGuaranteed to be heatedReduce consumptionAc networks with different sources same frequencyElectricityEngineering

The invention provides a wind curtailment absorption method in a thermal power plant. The method disclosed by the invention comprises the following steps: calculating heating coal consumption according to the generated power and heating power of a thermoelectric unit; establishing a minimum object to be an analytical model of coal consumption of the thermoelectric unit and coal consumption of a wind turbine generator according to the heating coal consumption and power generation coal consumption of the thermoelectric unit, and calculating the optimal thermal load of the thermoelectric unit according to the analytical model; and adjusting the current thermal load of the thermoelectric unit according to the optimal thermal load. The method disclosed by the invention solves the wind curtailment problem existing in the prior art. The wind curtailment reduction is realized, and the heat supply requirement of the thermal power plant is met.

Owner:DALIAN UNIV OF TECH

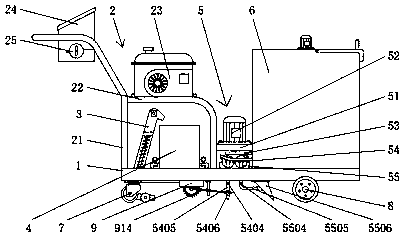

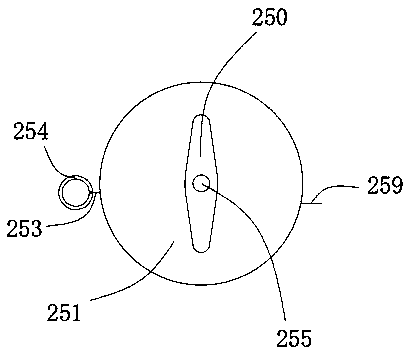

Road bridge asphalt pavement crack detection restoration device

The invention discloses a road bridge asphalt pavement crack detection restoration device comprises a vehicle body. The top surface of the vehicle body is, from left to right, sequentially provided with a control device, a correction device, a collection device, a driving device, and a fusion device. The left end of the bottom surface of the vehicle body is provided with a universal wheel, and theright end of the bottom surface of the vehicle body is provided with a walking wheel, and the bottom surface of the vehicle body is provided with a transmission device between the universal wheel andthe walking wheel. By adopting the cooperation among the control device, the correction device, the driving device, and the fusion device, the device can be used for blowing and sweeping sundries, pouring the asphalt, and correcting the asphalt at the same time, and then the restoration speed is additionally provided, and then the amount of used machine equipment and the amount of workers can bereduced, the asphalt recycling of the workers can be facilitated, the consumption amount of the asphalt can be reduced, the restoration costs can be reduced, and the practicability of the road bridgeasphalt pavement crack detection restoration device can be improved.

Owner:大冶市德晟公路工程有限公司

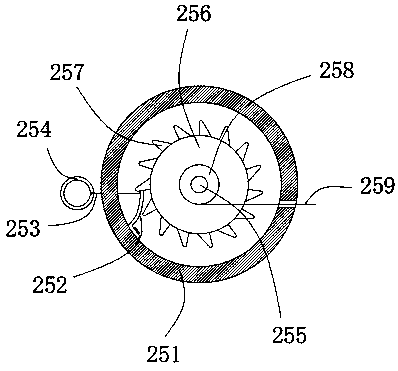

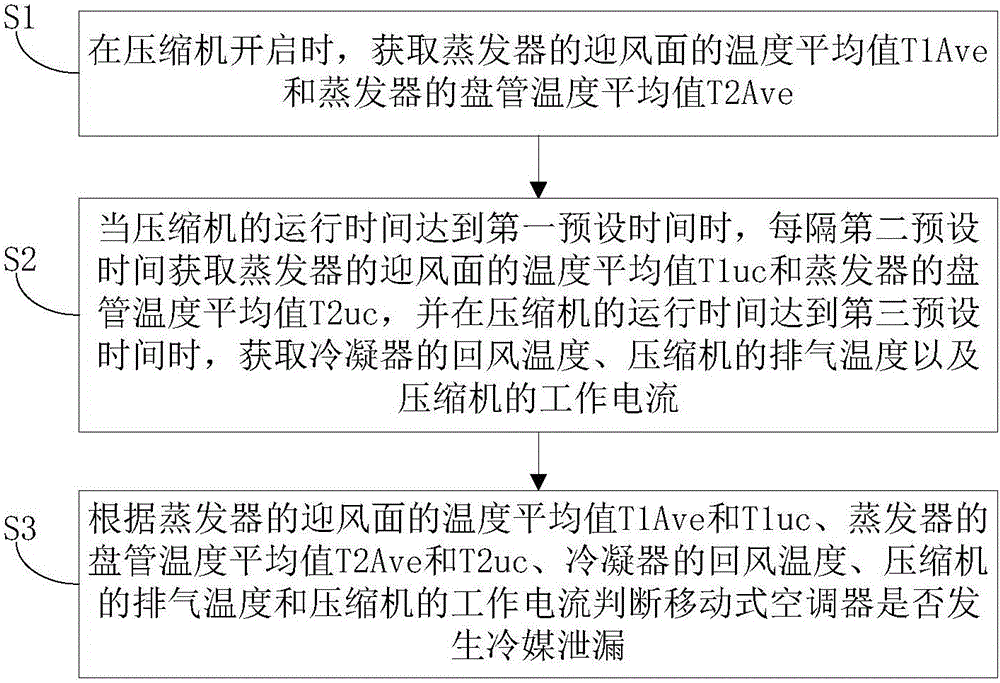

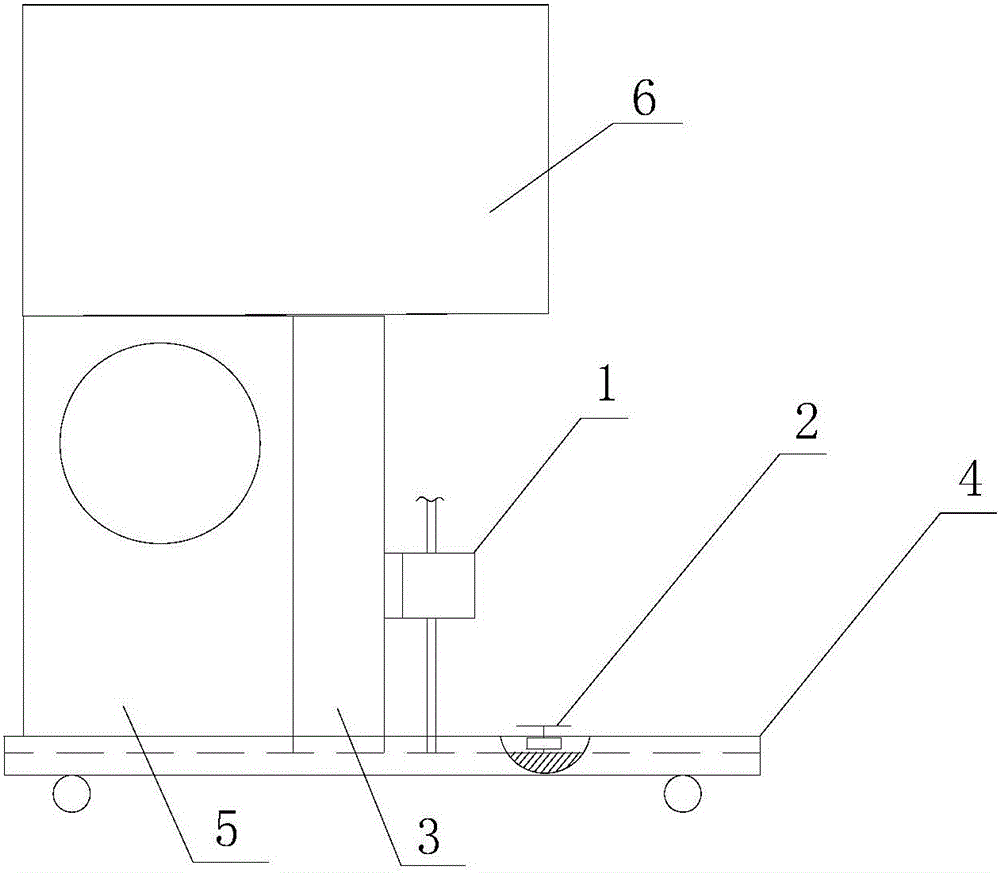

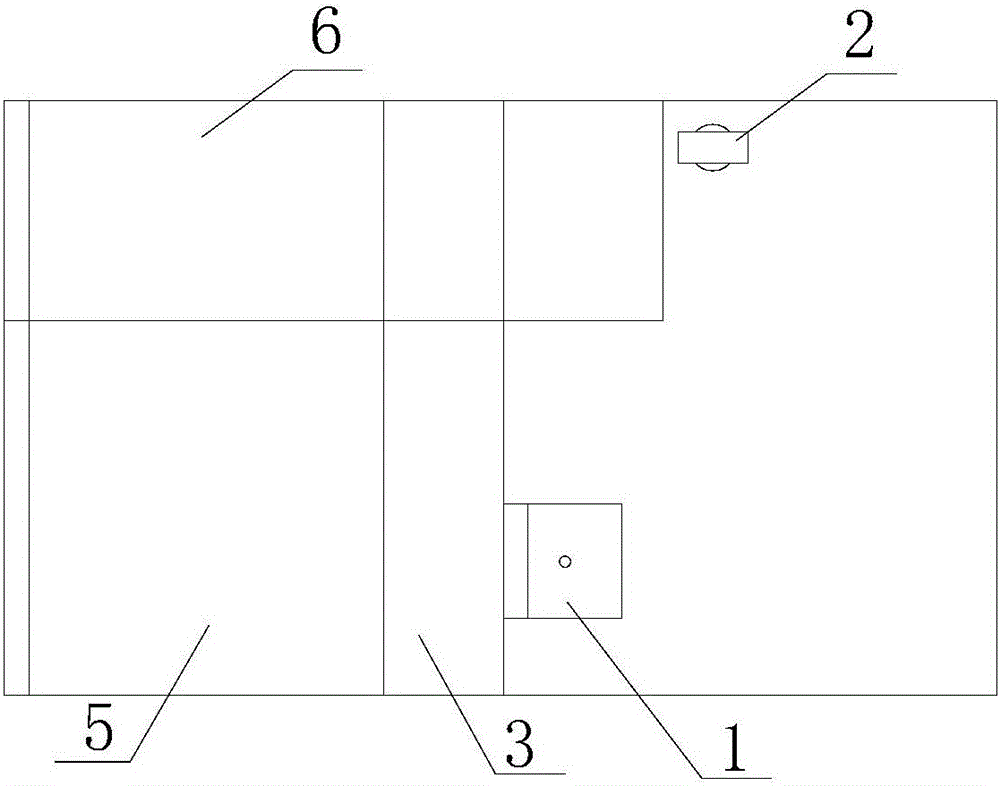

Mobile air conditioner and refrigerant leakage detection method thereof

ActiveCN106123205AEffective judgmentGuaranteed to be heatedDetection of fluid at leakage pointMechanical apparatusPower flowEngineering

The invention discloses a mobile air conditioner and a refrigerant leakage detection method thereof. The method comprises the following steps that when a compressor is started, the temperature average value T1Ave of the windward side of an evaporator and the temperature average value T2Ave of a coil pipe of the evaporator are obtained; when the operation time of the compressor reaches the first preset time, the temperature average value T1uc of the windward side of the evaporator and the temperature average value T2uc of the coil pipe of the evaporator are obtained every other second preset time, and when the operation time of the compressor reaches the third preset time, the return air temperature of a condenser, the exhaust temperature of the compressor and the working current of the compressor are obtained; and according to the T1Ave, the T1uc, the T2Ave, the T2uc, the return air temperature of the condenser, the exhaust temperature of the compressor and the working current of the compressor, whether the mobile air conditioner has a refrigerant leakage fault or not is judged. The method can effectively judge whether the mobile air conditioner has a refrigerant leakage fault or not.

Owner:WUHAN REFRIGERATION EQUIP OF MIDEA GROUP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com