Drying method used for washing and drying all-in-one machine, and washing and drying all-in-one machine

An all-in-one machine, washing and drying technology, applied in the field of clothes drying, can solve the problems of poor drying uniformity, poor drying uniformity of drying objects, poor drying degree, etc., so as to improve the drying uniformity, set the end timing reasonably, The effect of drying process optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

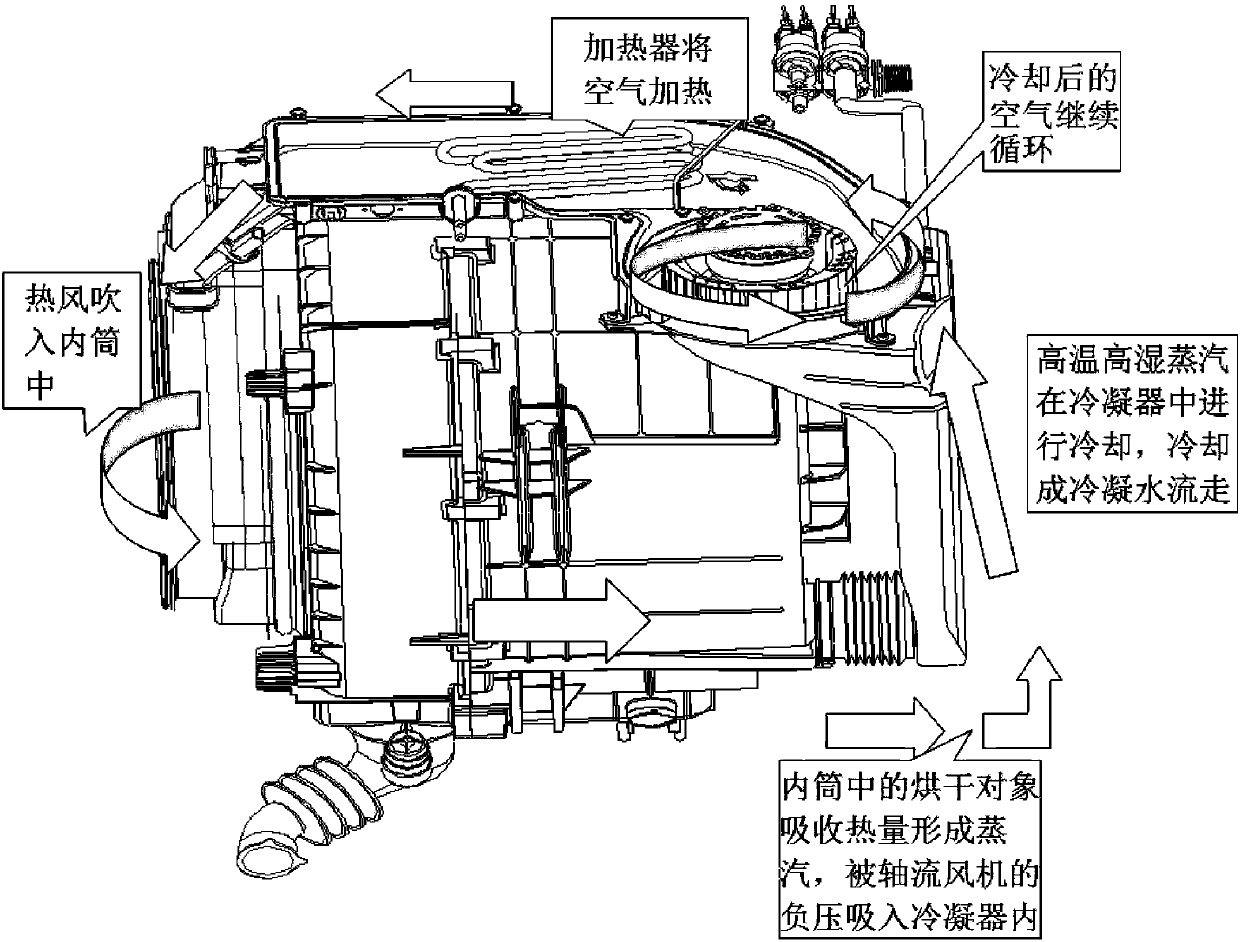

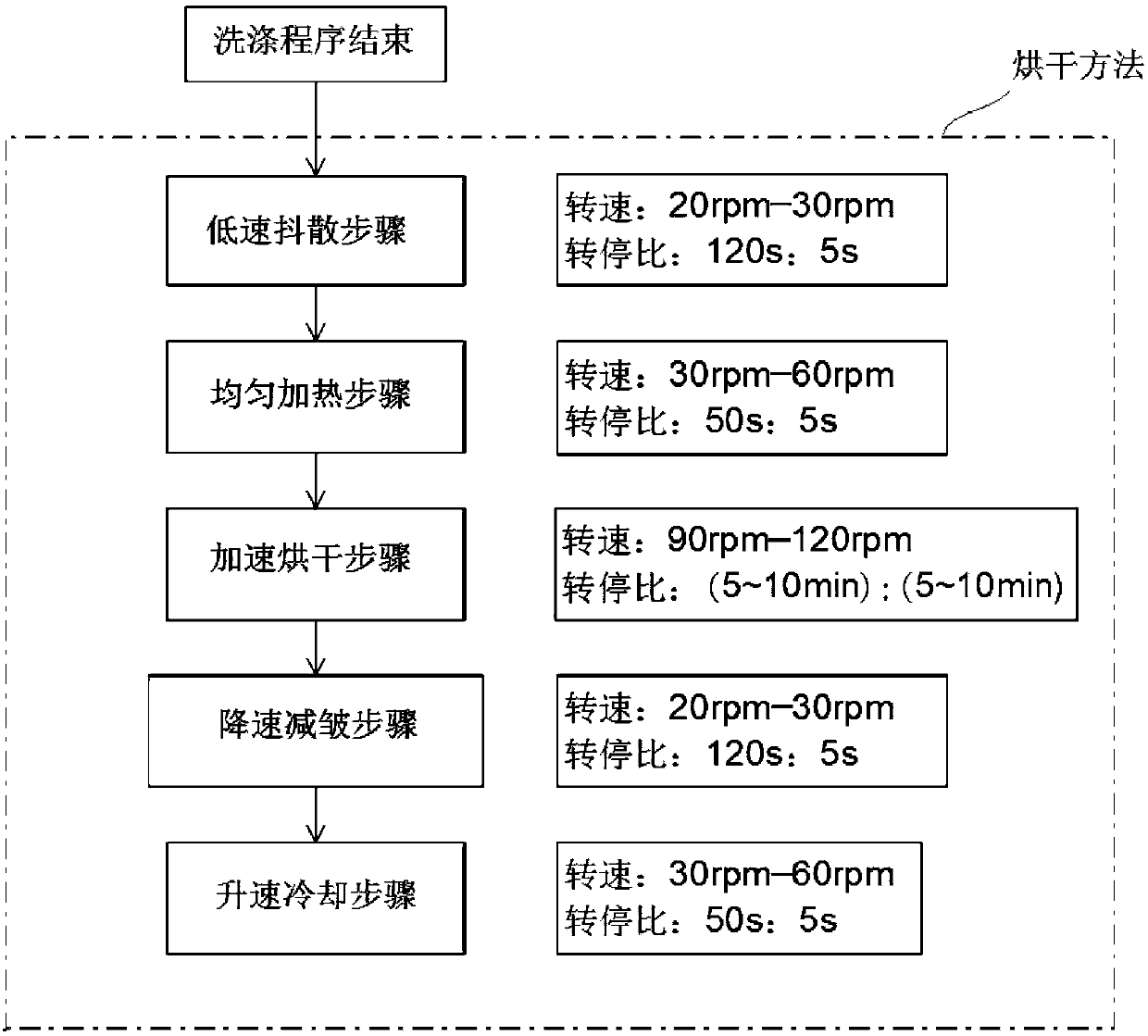

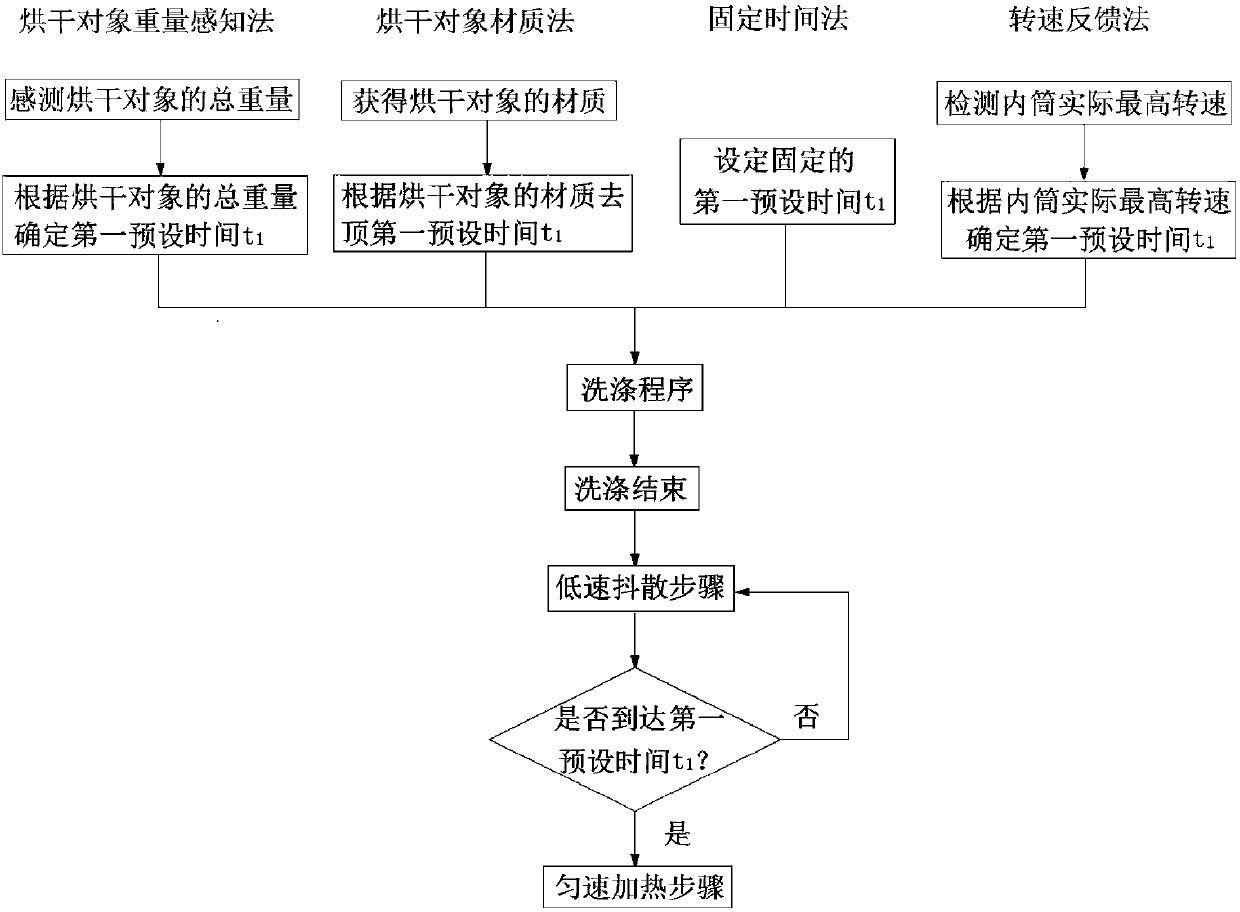

[0038] refer to figure 1 At present, the drying principle of the washing and drying all-in-one machine is: the air is heated by a heater (such as a set of heating wires), and the heated air (that is, hot air) is blown into the inner cylinder by a fan to form hot air, and the drying in the inner cylinder The object is heated to evaporate the water in it into high-temperature and high-humidity steam. The high-temperature and high-humidity steam is sucked into the condenser by the negative pressure formed by the axial flow fan. The high-temperature and high-humidity steam is condensed in the condenser to become condensed water, and the condensed water is exchanged The outer wall of the container flows down, and the cooled air continues to circulate. In the current drying process, the inner cylinder is set to rotate at a fixed speed and a fixed turn-to-stop ratio, so that the drying objects can be dried evenly. However, with the increase of the capacity of the drying object, espe...

Embodiment 2

[0071] In this embodiment, an integrated washer-dryer is provided, which adopts the drying method for the integrated washer-dryer in the first embodiment above. Therefore, the integrated washing and drying machine can make the hot air better contact the drying objects in the middle and rear of the inner cylinder, improve the overall drying uniformity of the drying objects, and improve the drying performance. In addition, because a time condition and two temperature conditions are designed to determine whether to end the accelerated drying step separately or in combination, the timing of the accelerated drying step is set more reasonably, and the entire drying process is also optimized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com