Patents

Literature

53results about How to "Optimizing Flow Paths" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

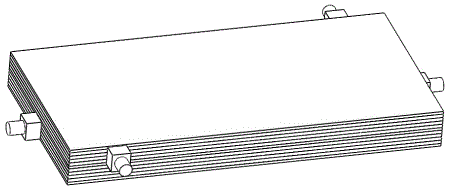

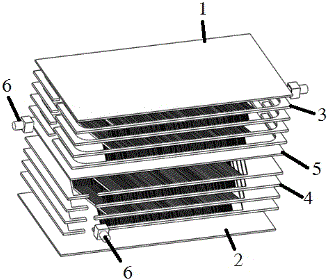

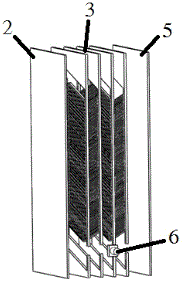

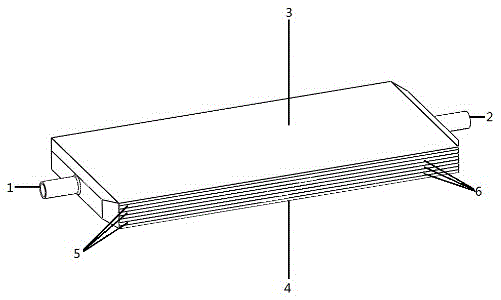

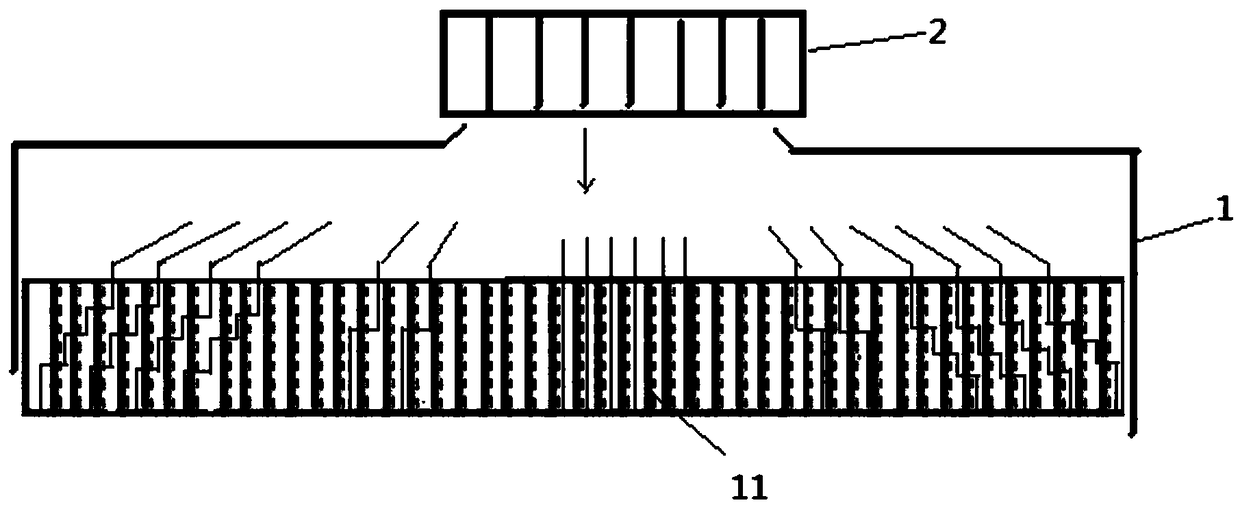

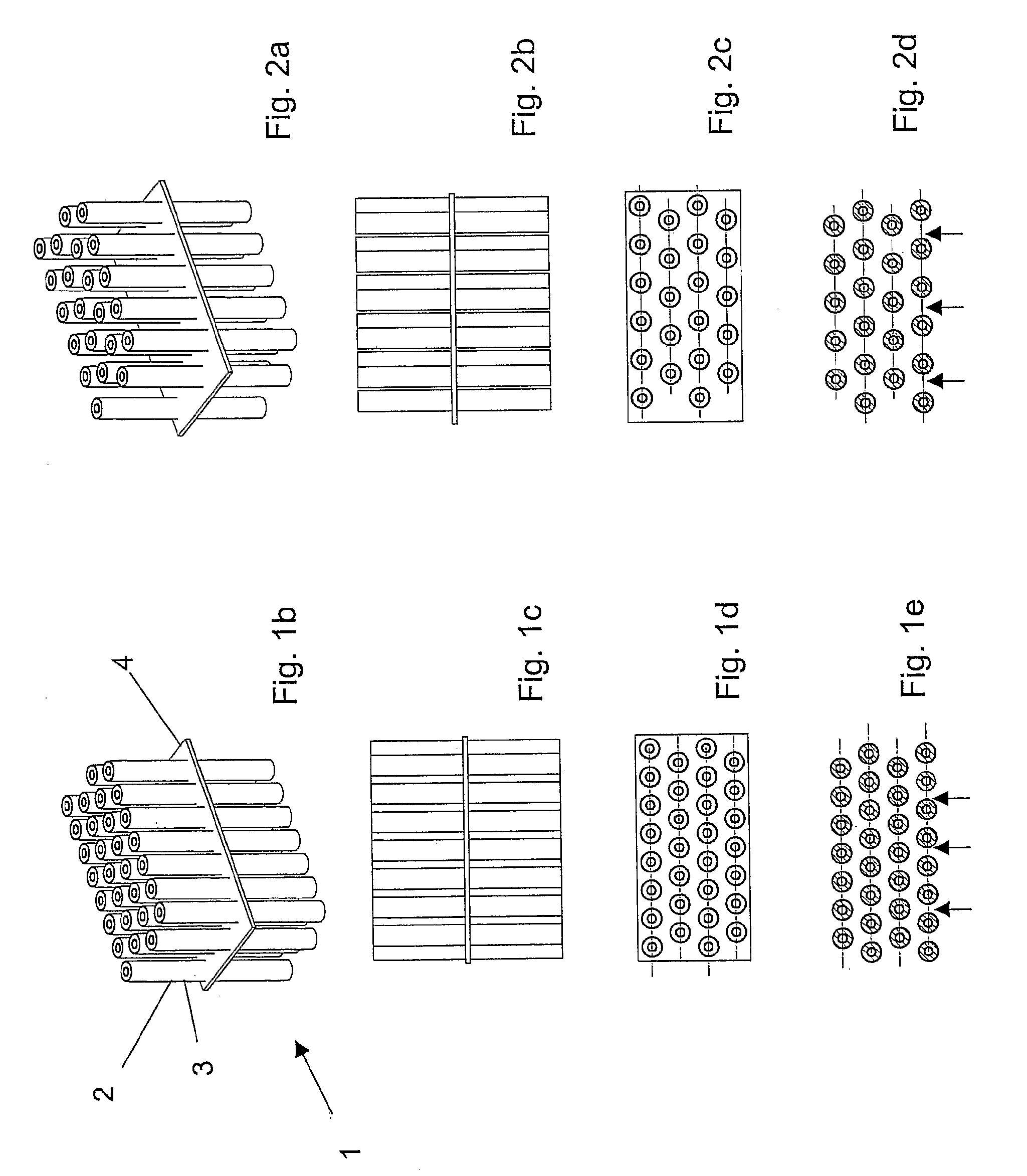

Micro-channel heat exchanger

InactiveCN105486129AIncrease processOptimizing Flow PathsHeat exchanger casingsStationary plate conduit assembliesFusion weldingEngineering

A micro-channel heat exchanger comprises an upper cover plate, a lower cover plate, a transverse heat exchange structure, a longitudinal heat exchange structure, a middle partition plate and working medium inlet / outlet units. The upper cover plate, the middle partition plate and the lower cover plate are sequentially arranged in parallel, and a transverse heat exchange piece unit is arranged between the upper cover plate and the middle partition plate; a longitudinal heat exchange piece unit is arranged between the middle partition plate and the lower cover plate; and the transverse heat exchange piece unit and the longitudinal heat exchange piece unit are each provided with one inlet / outlet working medium unit; the transverse heat exchange structure at least comprises a transverse heat exchange unit, and the longitudinal heat exchange structure at least comprises a longitudinal heat exchange unit. The flow process of each flow way can be designed to be the same, and a diffusion fusion welding structure can be adopted for connection of partition plates. According to the heat exchanger, multilayer cross flow, uniform heat exchange and flow disturbance can be achieved, the heat exchange efficiency of the heat exchanger can be further improved, and the running cost is reduced.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

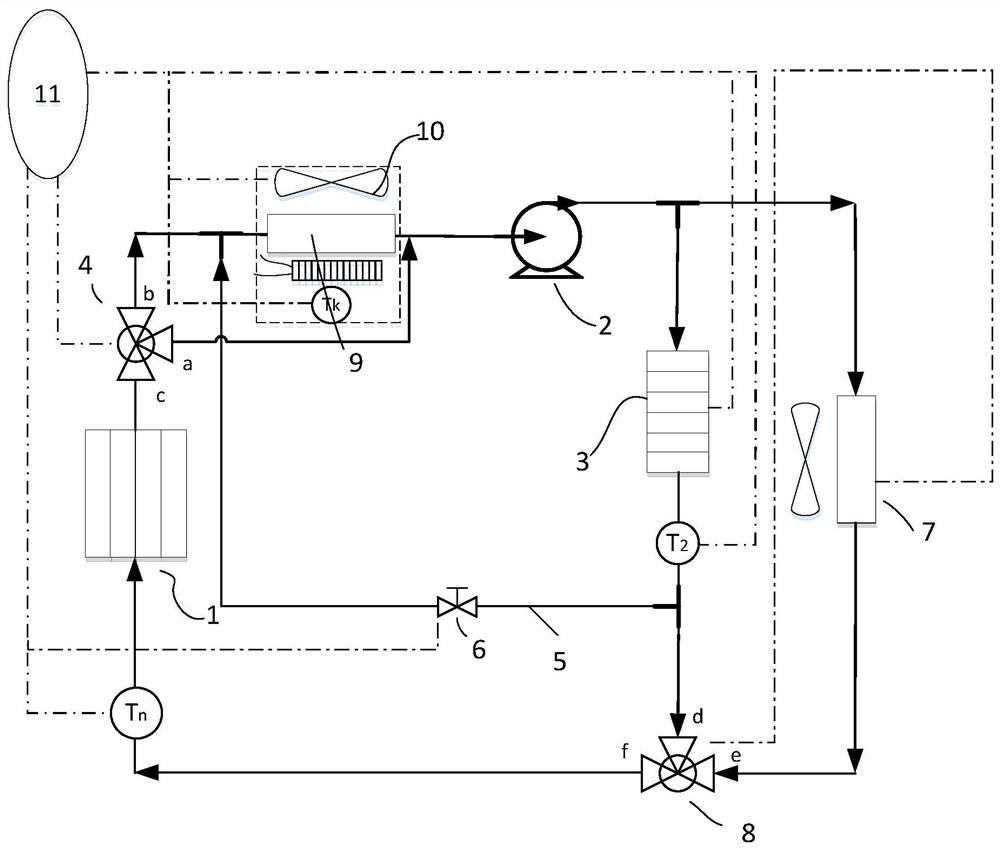

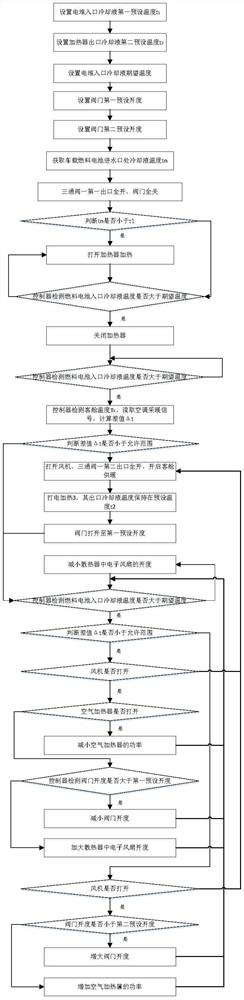

Hydrogen fuel cell automobile hydrothermal management system and control method thereof

ActiveCN112208392AImprove heating effectOptimizing Flow PathsAir-treating devicesVehicle heating/cooling devicesHydrogen fuel cellEngineering

The invention relates to a hydrogen fuel cell automobile hydrothermal management system which comprises a fuel cell, a main water pump and a heater which are sequentially communicated through a pipeline to form a circulation loop, and further comprises a first three-way valve, an inlet of the three-way valve I is communicated with an outlet of the fuel cell through a pipeline, and one outlet is communicated with the main water pump through a pipeline, the other outlet is communicated with an inlet of heating equipment in an automobile passenger cabin through a pipeline, and an outlet of the heating equipment is communicated with a pipeline between the three-way valve I and the main water pump through a pipeline; a pipeline between the fuel cell and the heater is communicated with a pipeline between the three-way valve I and the heating equipment through a heating loop, and a valve is mounted on the heating loop; the invention further provides a control method of the hydrogen fuel cellautomobile hydrothermal management system. The system has the beneficial effects that the flowing path of cooling liquid is optimized when the automobile passenger cabin does not need to be heated, the heating capacity in the automobile passenger cabin is improved while normal operation of the system is guaranteed, and energy consumption is reduced.

Owner:武汉海亿新能源科技有限公司

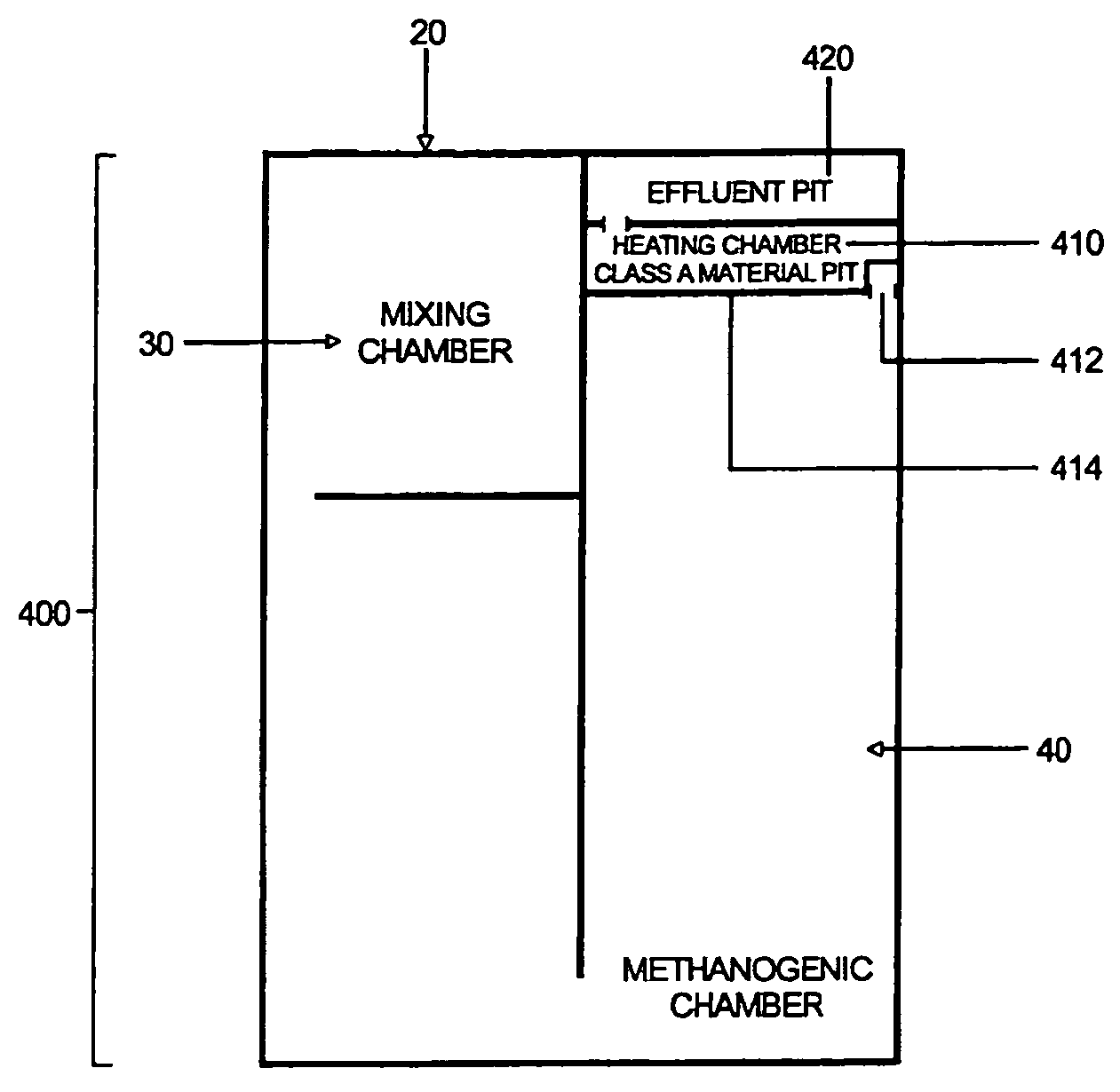

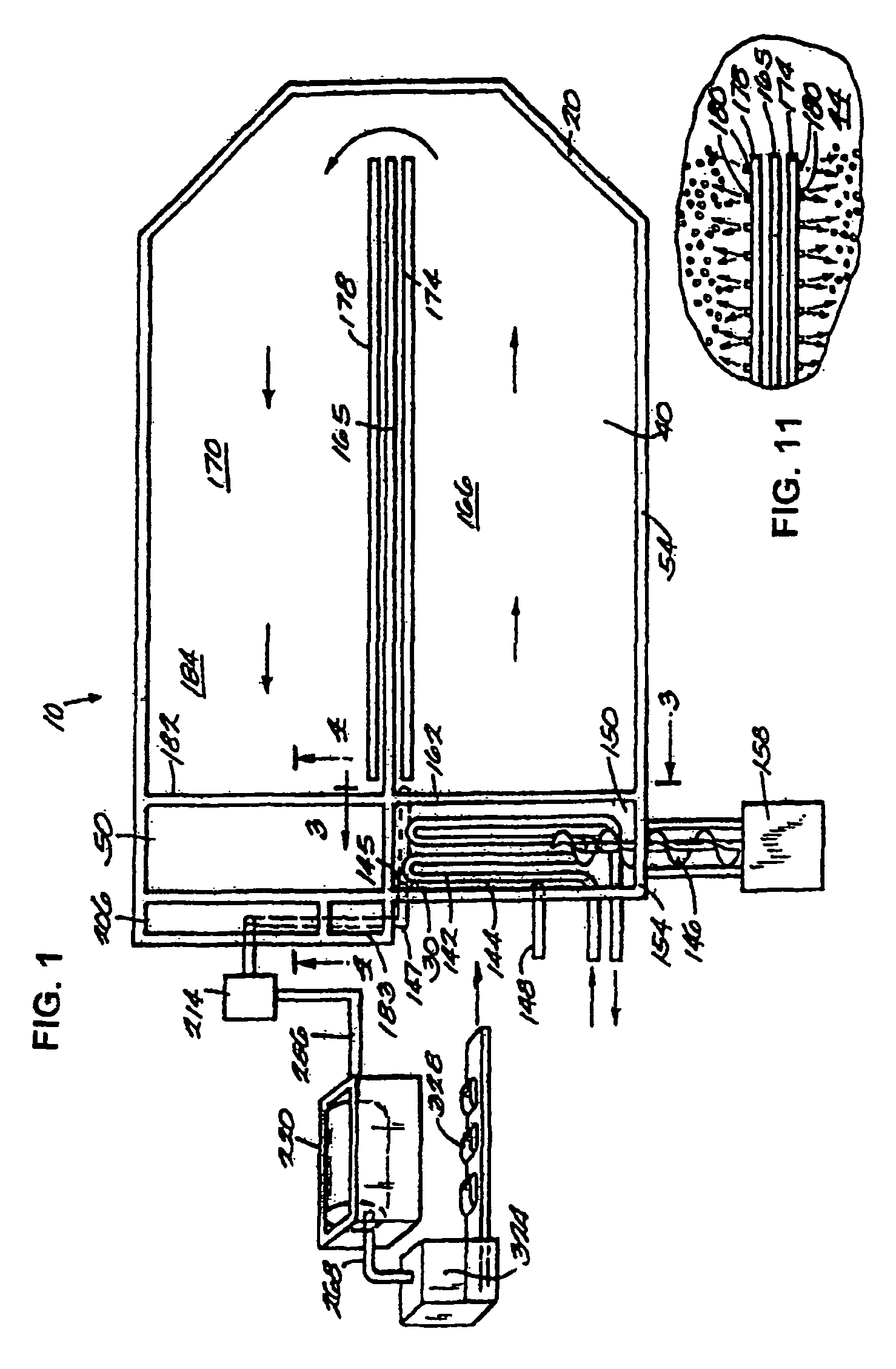

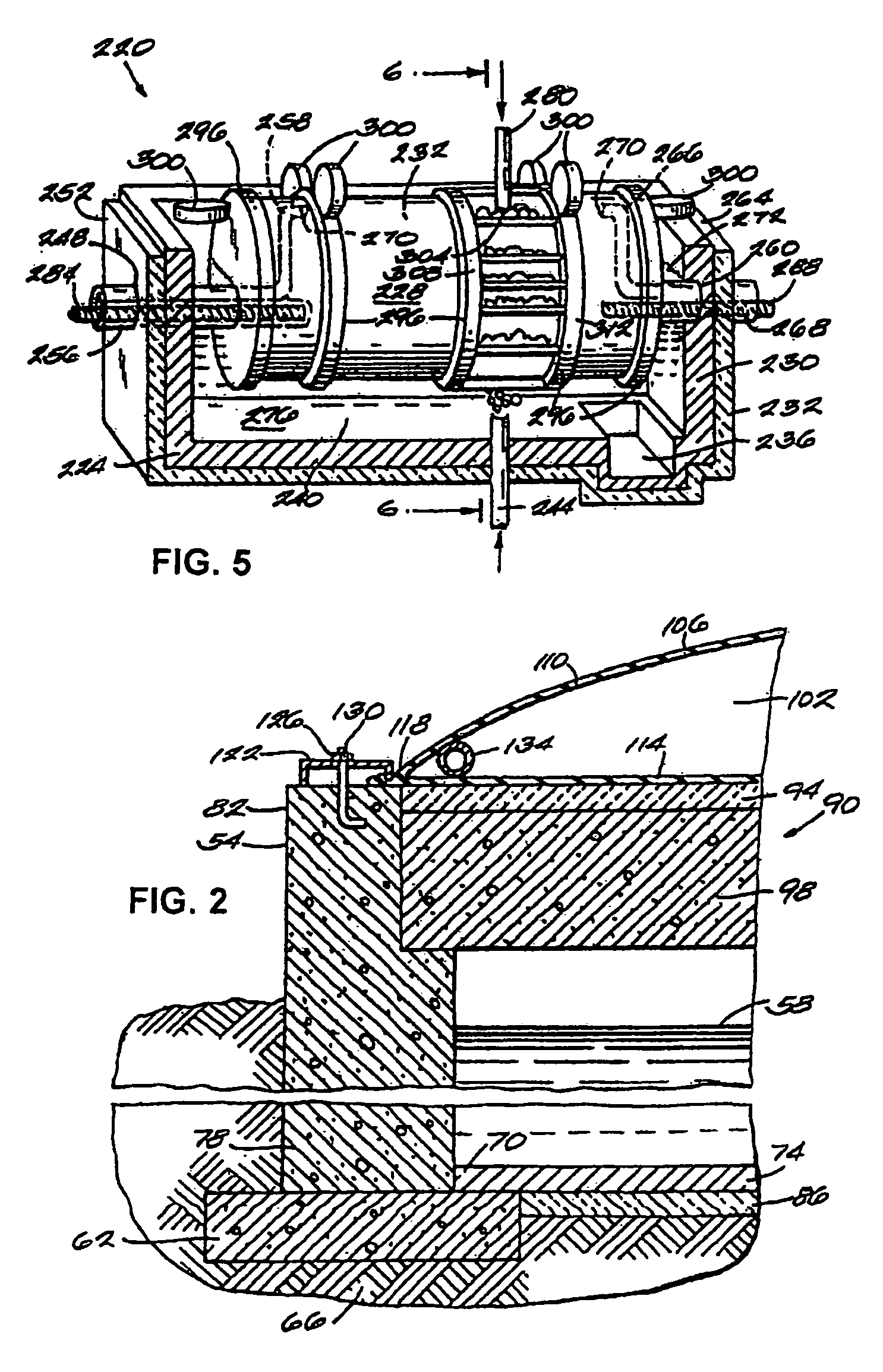

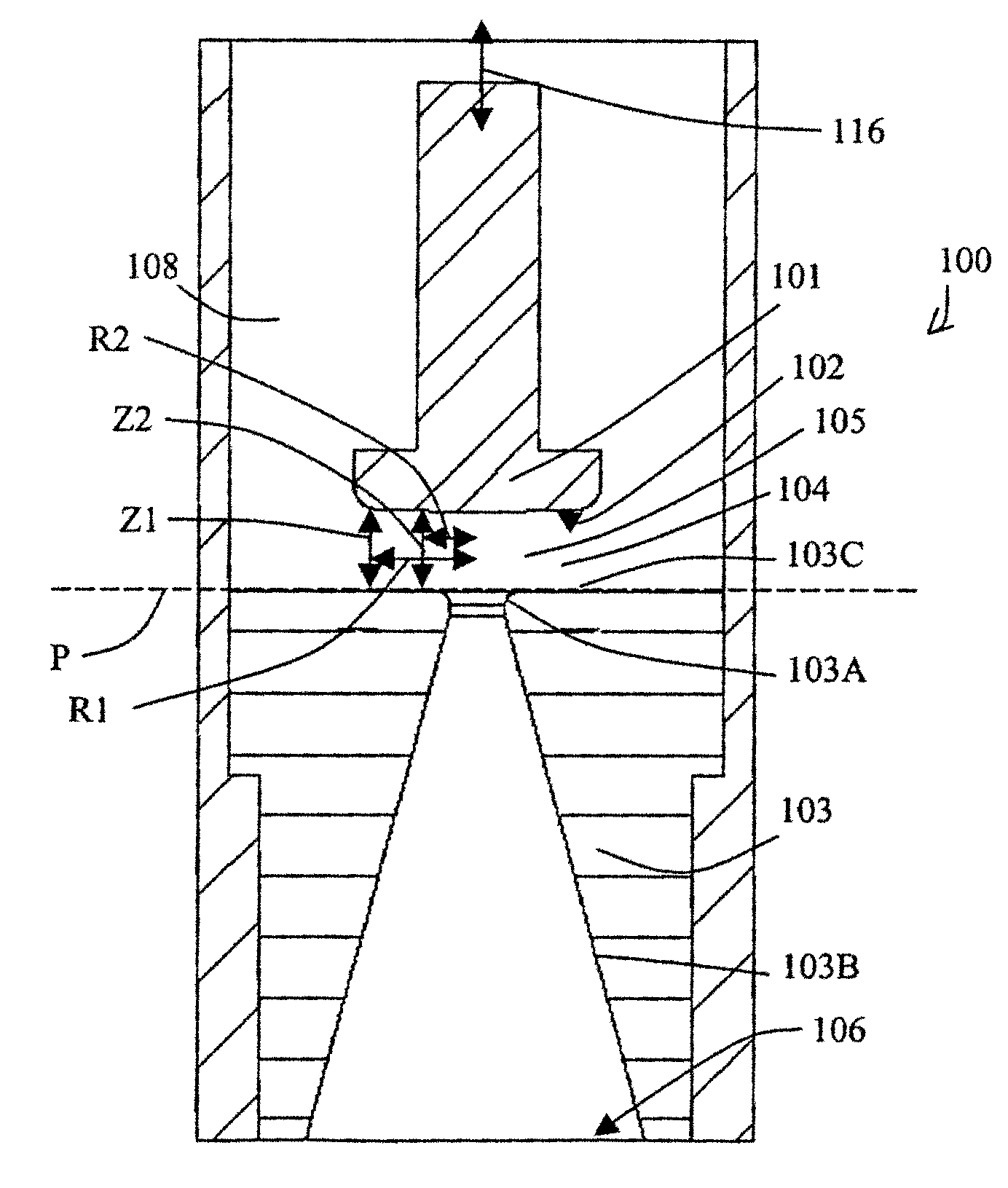

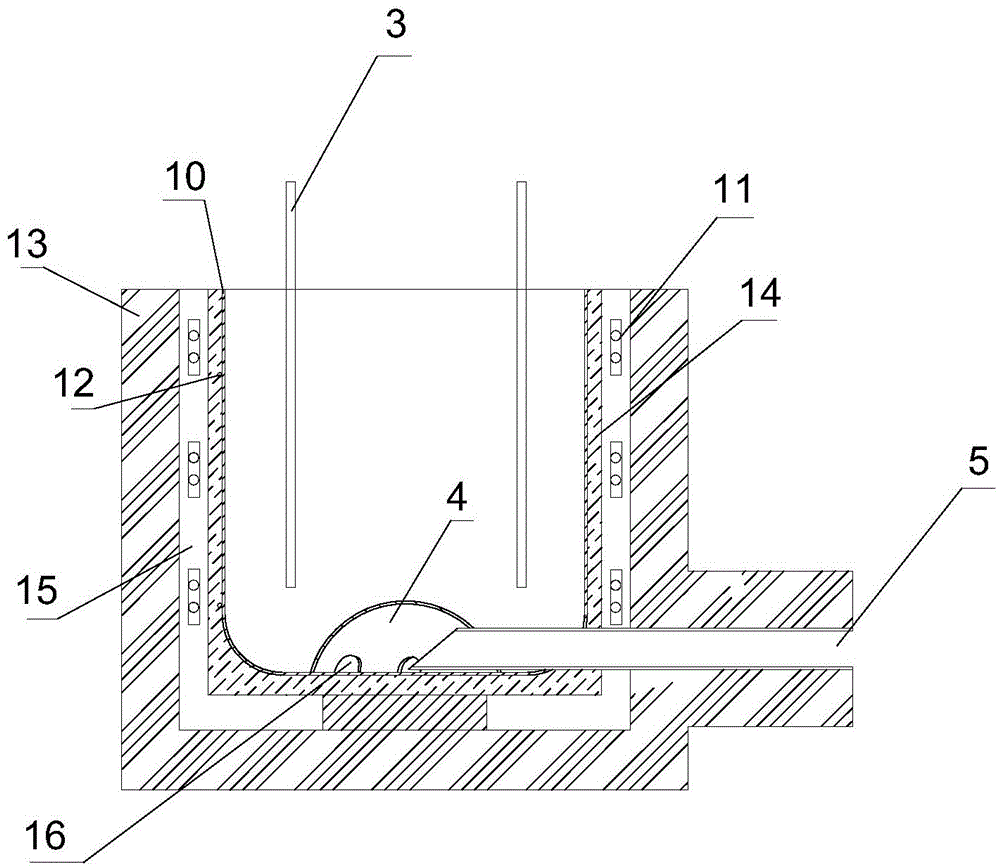

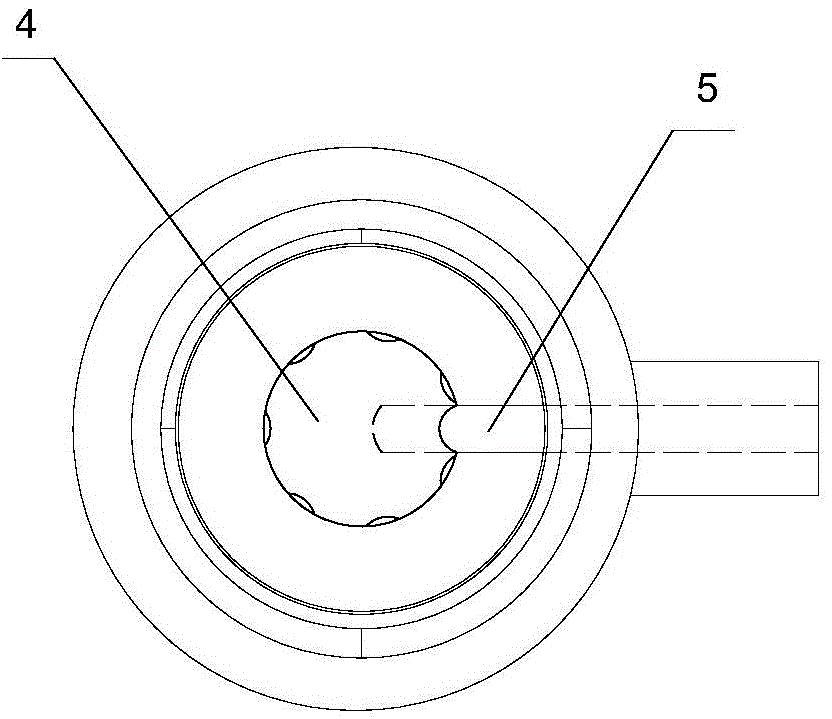

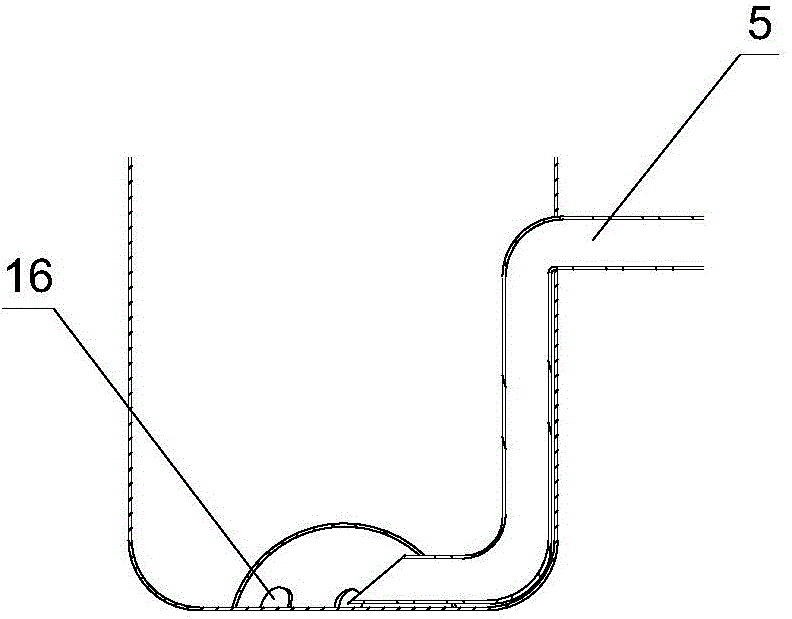

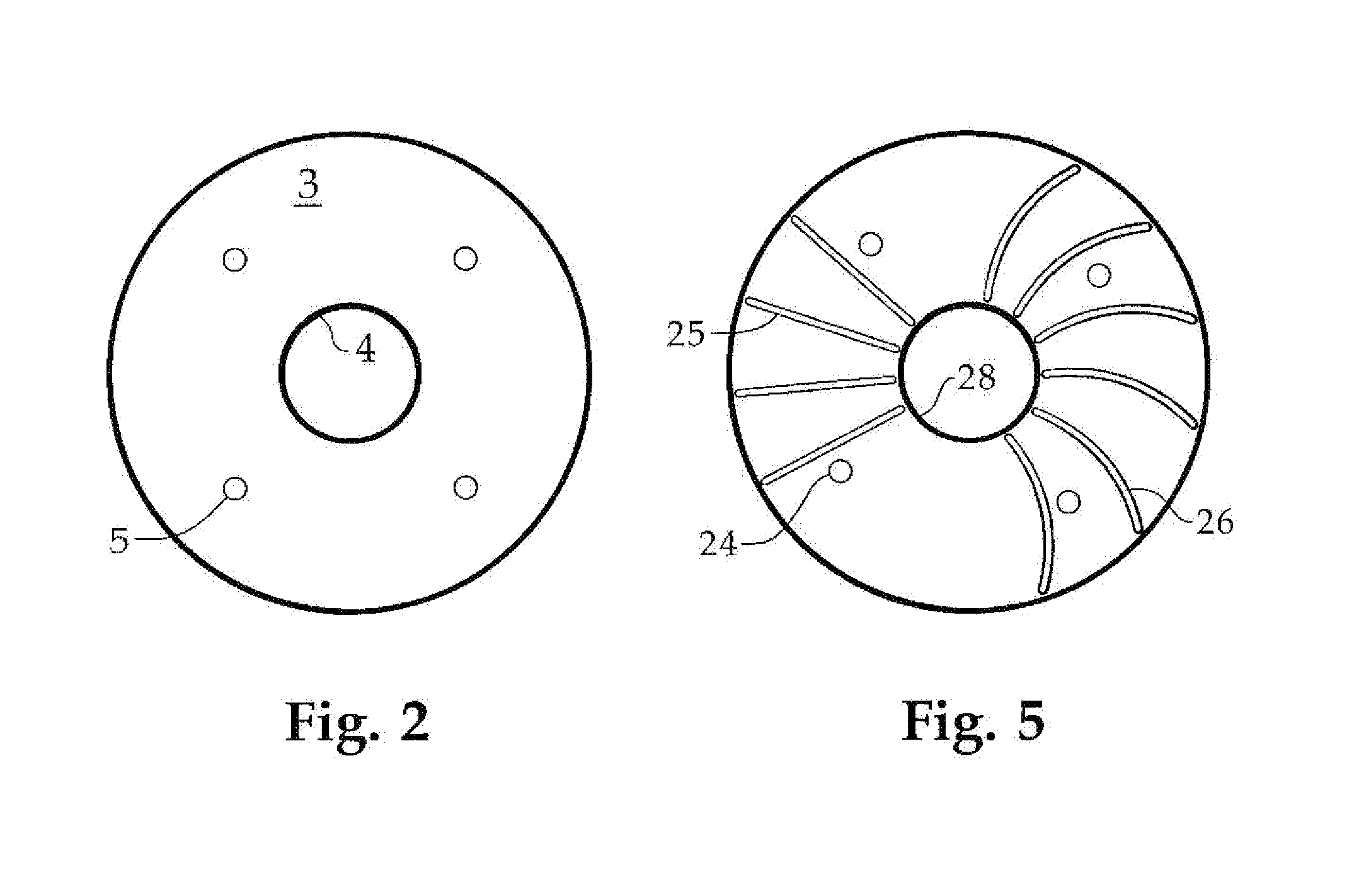

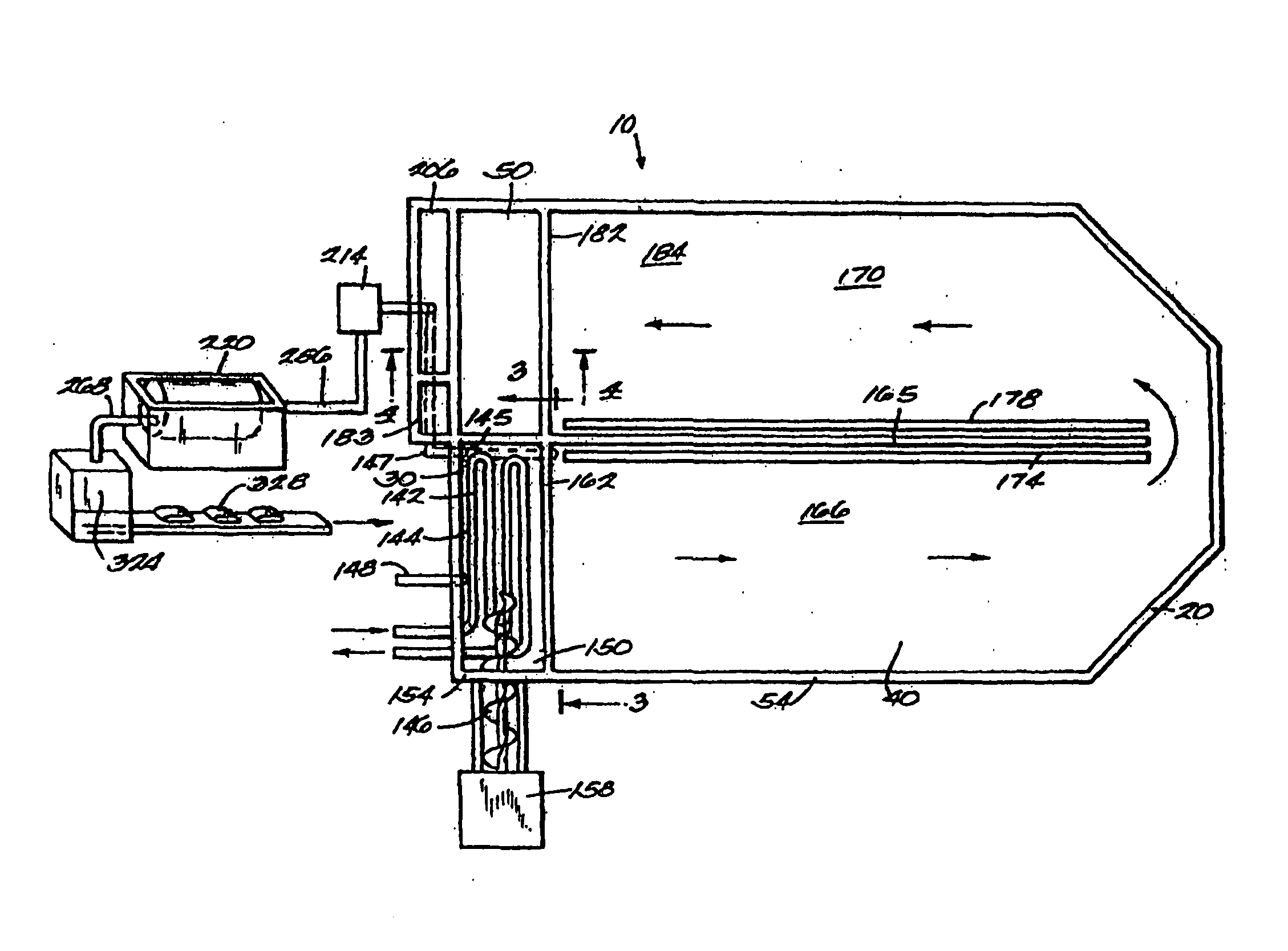

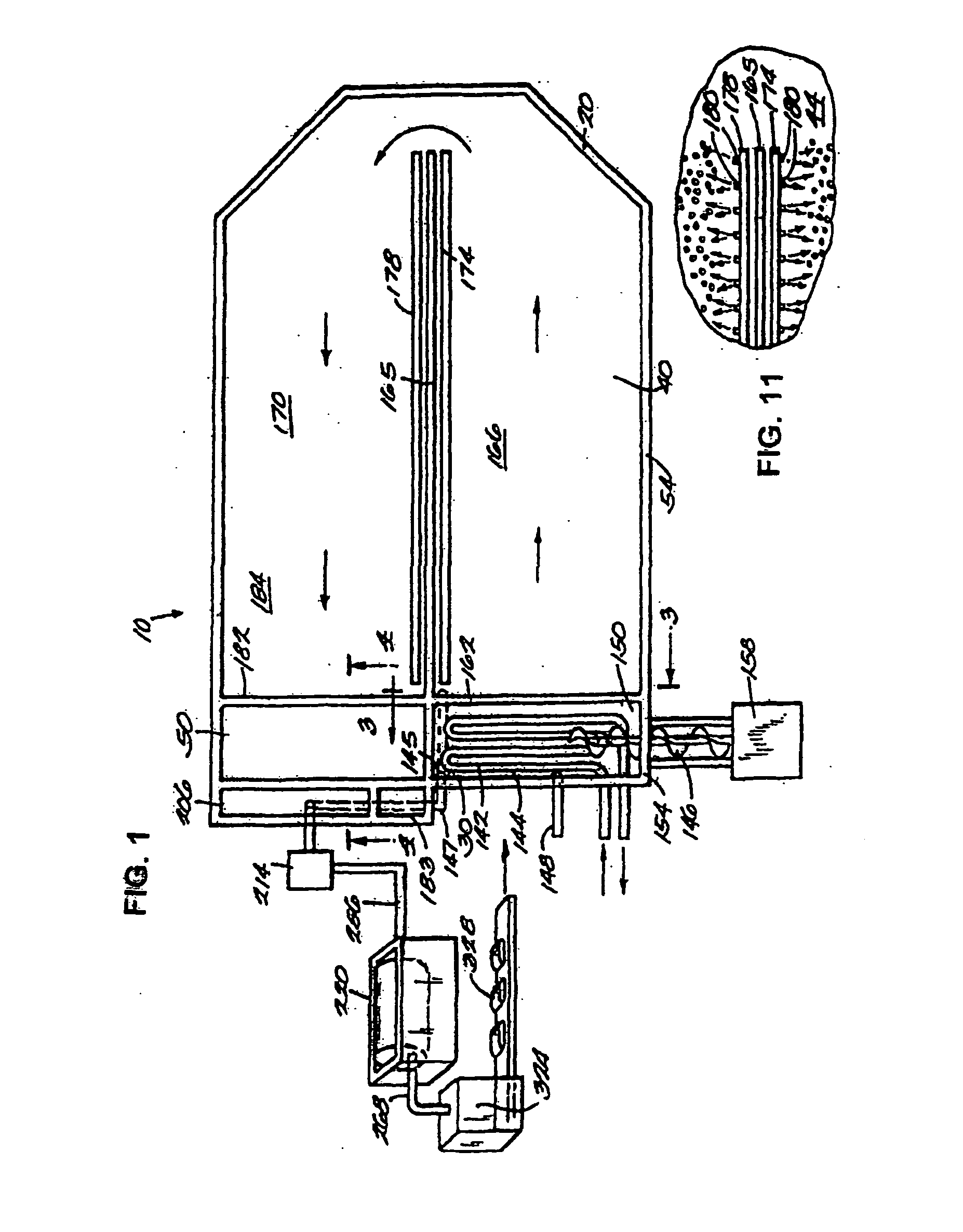

Biosolids digester and process for biosolids production

ActiveUS8835155B2Enhanced convectionOptimizing Flow PathsBio-organic fraction processingGas production bioreactorsPulp and paper industryBiosolids

The invention relates to methods and apparatuses for producing Class A biosolids. In yet another embodiment, the invention relates to a method comprising digesting waste material by anaerobic digestion, and yielding Class A biosolids. In still yet another embodiment, the invention relates to a system for anaerobic digestion of waste material to produce Class A biosolids. In still yet another embodiment, the invention relates to a system for anaerobic digestion of waste material comprising a mixing chamber, a digester, a heating pit, and an effluent pit.

Owner:DVO LICENSING

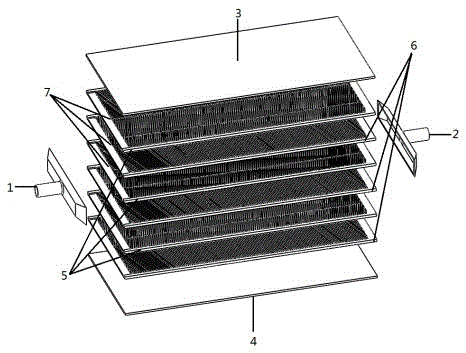

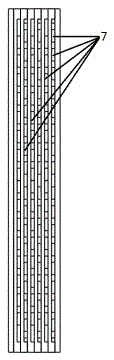

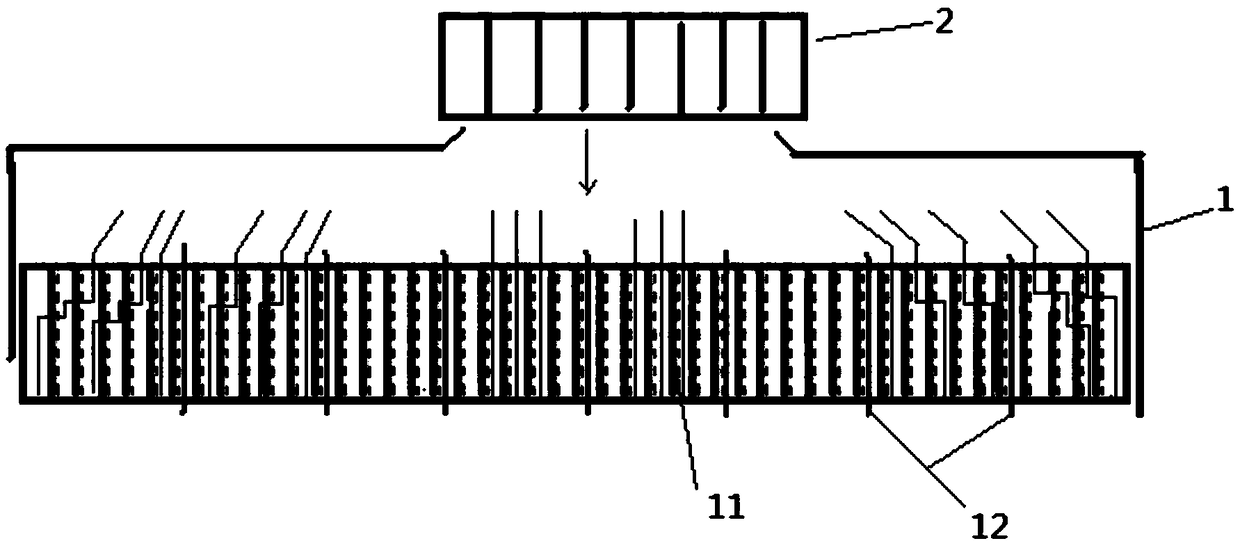

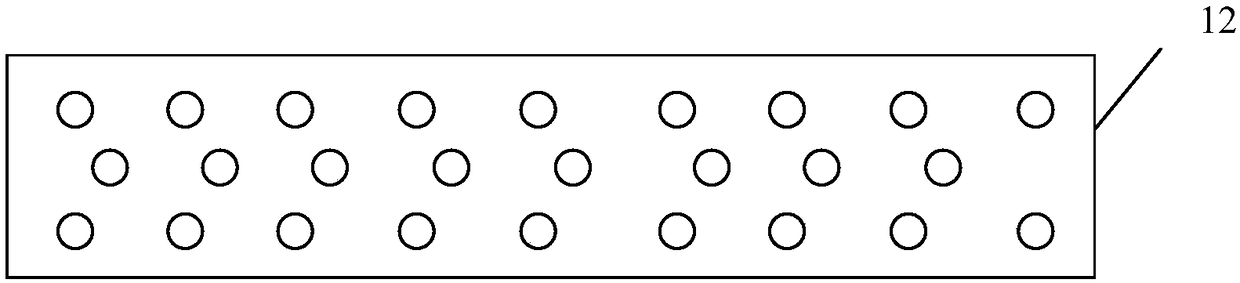

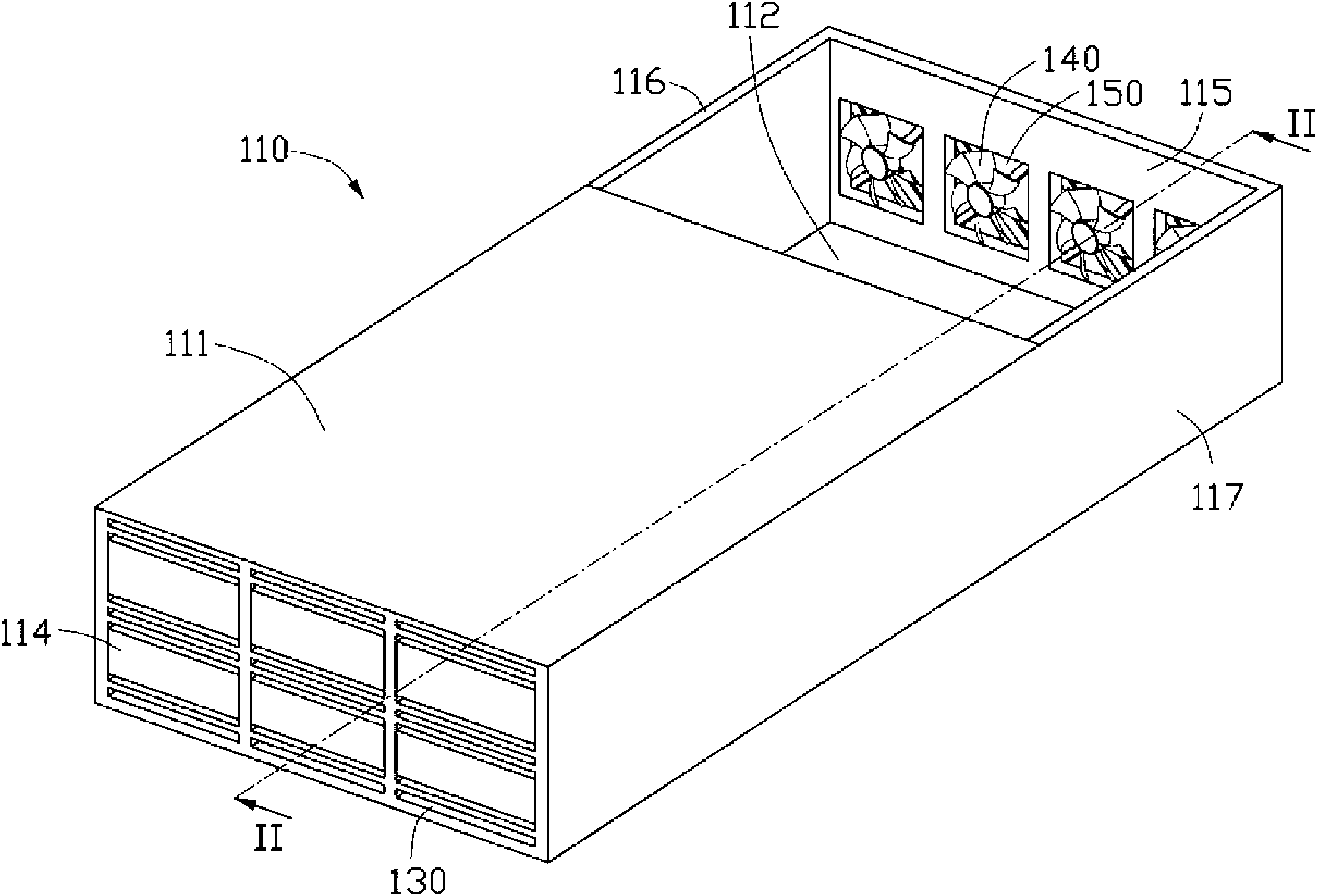

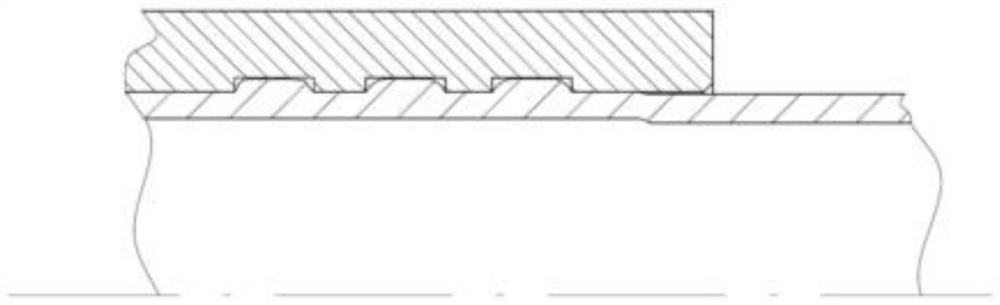

Microchannel heat radiator

InactiveCN105526813ASimple processEnhanced interactionHeat exchanger casingsStationary plate conduit assembliesEngineeringElectron

The invention relates to the technical field of heat radiation, particularly relates to a microchannel heat radiator and aims at further increasing the efficiency of the existing heat radiating device of an electronic device. The microchannel heat radiator comprises an upper cover plate, a lower cover plate, a fluid feeding unit, a fluid discharging unit and a plurality of heat exchange units, wherein each heat exchange unit is formed by reversely overlapping two heat exchange plates; each heat exchange plate is internally provided with a plurality of partition plates among which runners for allowing fluids to flow are formed; and the adjacent partition plates are intercrossed to form cavities. The partition plates of the adjacent heat exchange plates are crossed to form crossed and interconnected runners, so that the fluids can pass through different heat exchange plates; and due to the adoption of the flowing way, the flow paths of the fluids in the heat radiator are increased, flow routes are optimized, and heat exchange is more sufficient. In addition, due to the adoption of the design, the fluids in different runners can be mutually converged, hedged and dragged, the interaction between every two fluids can be enhanced, and the heat exchange effect can be improved.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

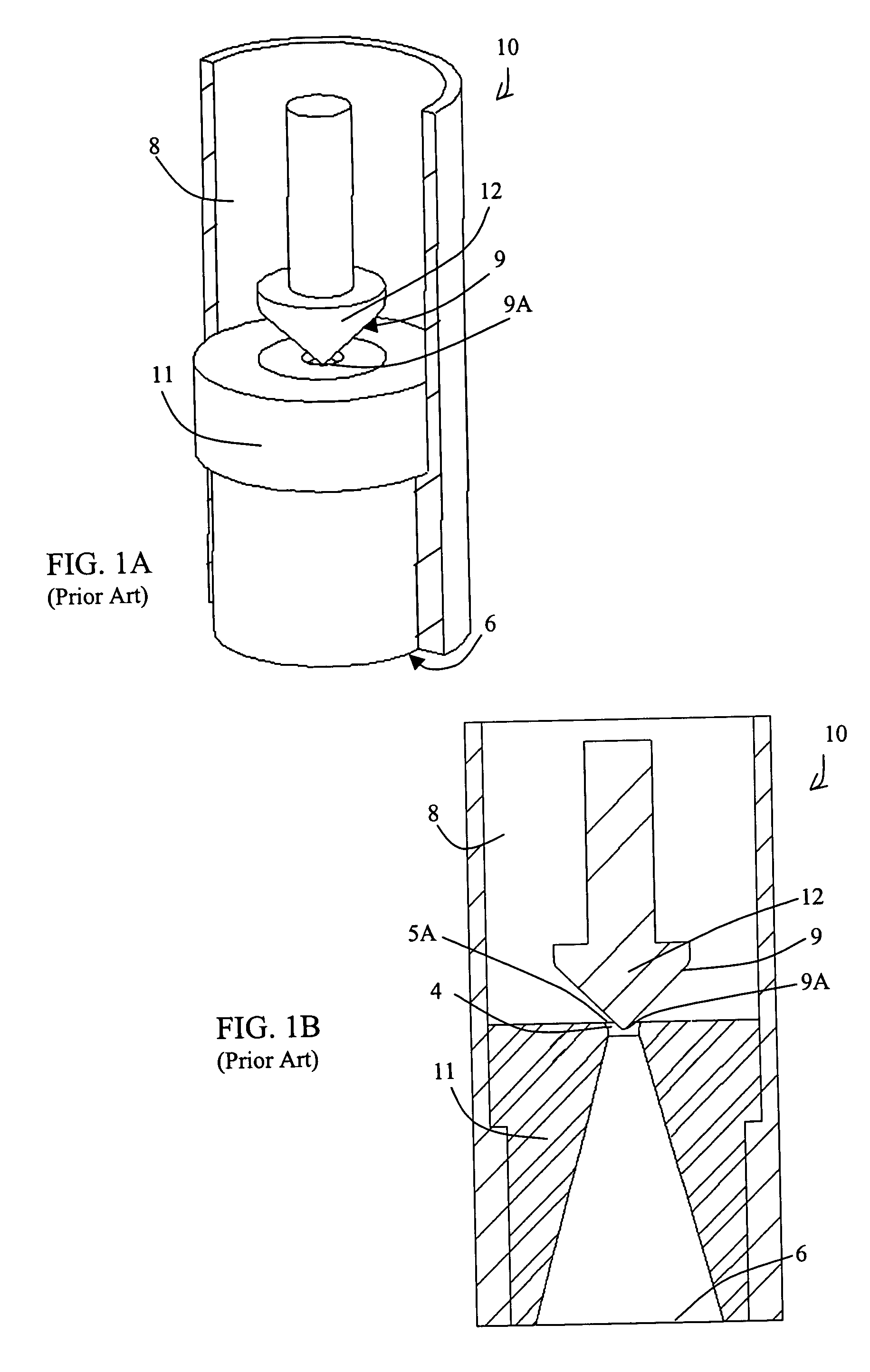

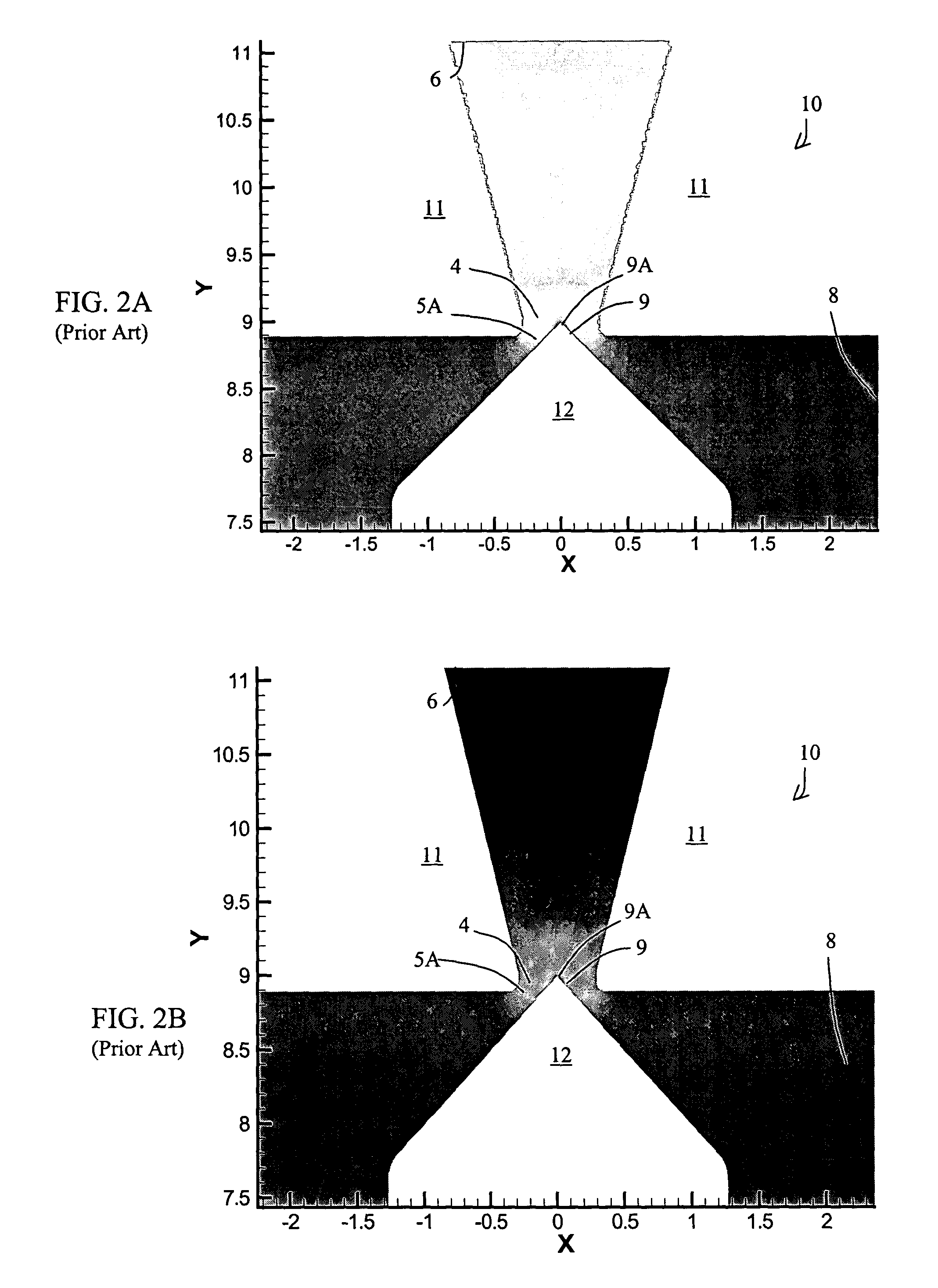

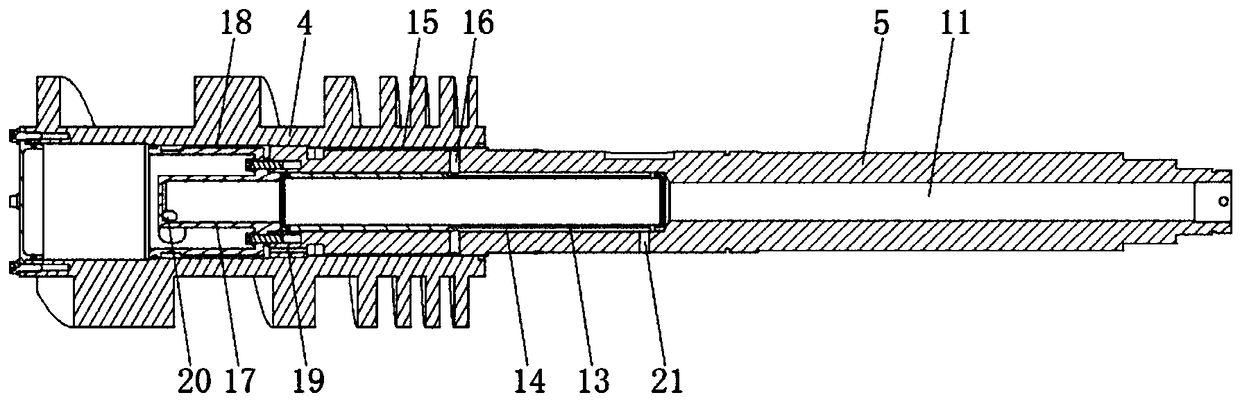

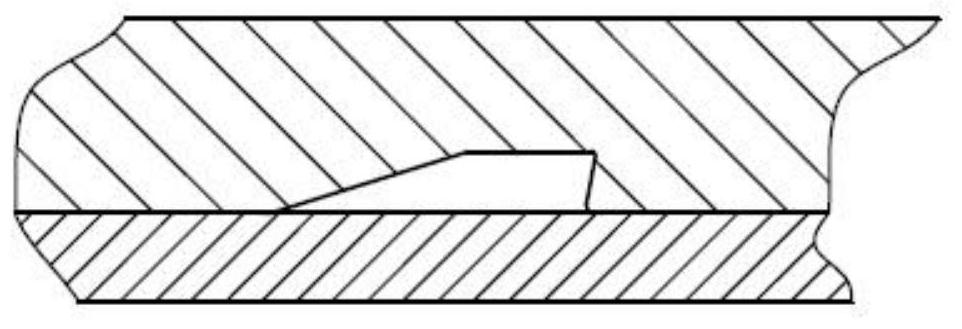

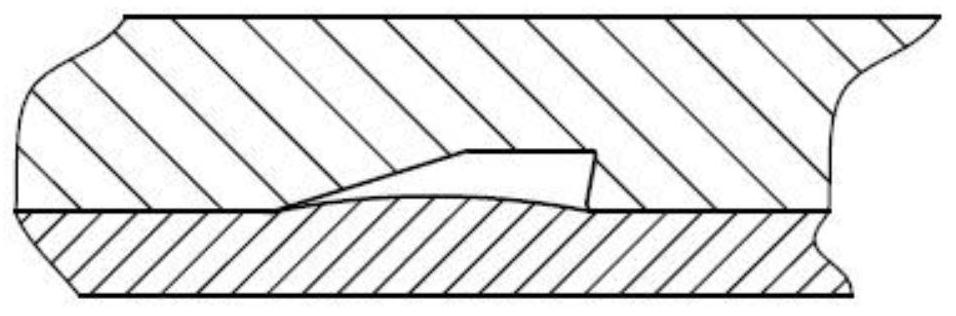

Fluent control valve

InactiveUS6988705B1Eliminates thrust variationLow costValve members for absorbing fluid energyPipe elementsFluid controlEngineering

A continuously variable fluent control valve for controlling supersonic flow of gas. The valve has an upper plate with a very slightly angled physical control surface and a lower plate with a physical nozzle inlet. As the valve opens and closes during supersonic flow, a hydrodynamic pintle forms in the nozzle inlet just below the physical control surface. The hydrodynamic pintle provides a fluid control surface for redirecting flow from horizontal fllow to vertical flow through the nozzle and, depending on the expansion needs of the supersonic flow, the hydrodynamic pintle changes shape, expanding or shrinking in the axial direction of the valve. Because of the nearly flat physical control surface of the upper plate, matieral ablation is significantly reduced. The fluid-fluid boundary between the hydrodynamic pintle and the supersonic flow produces a flow through the nozzle with little or no recirculation.

Owner:HOOSE KARL V

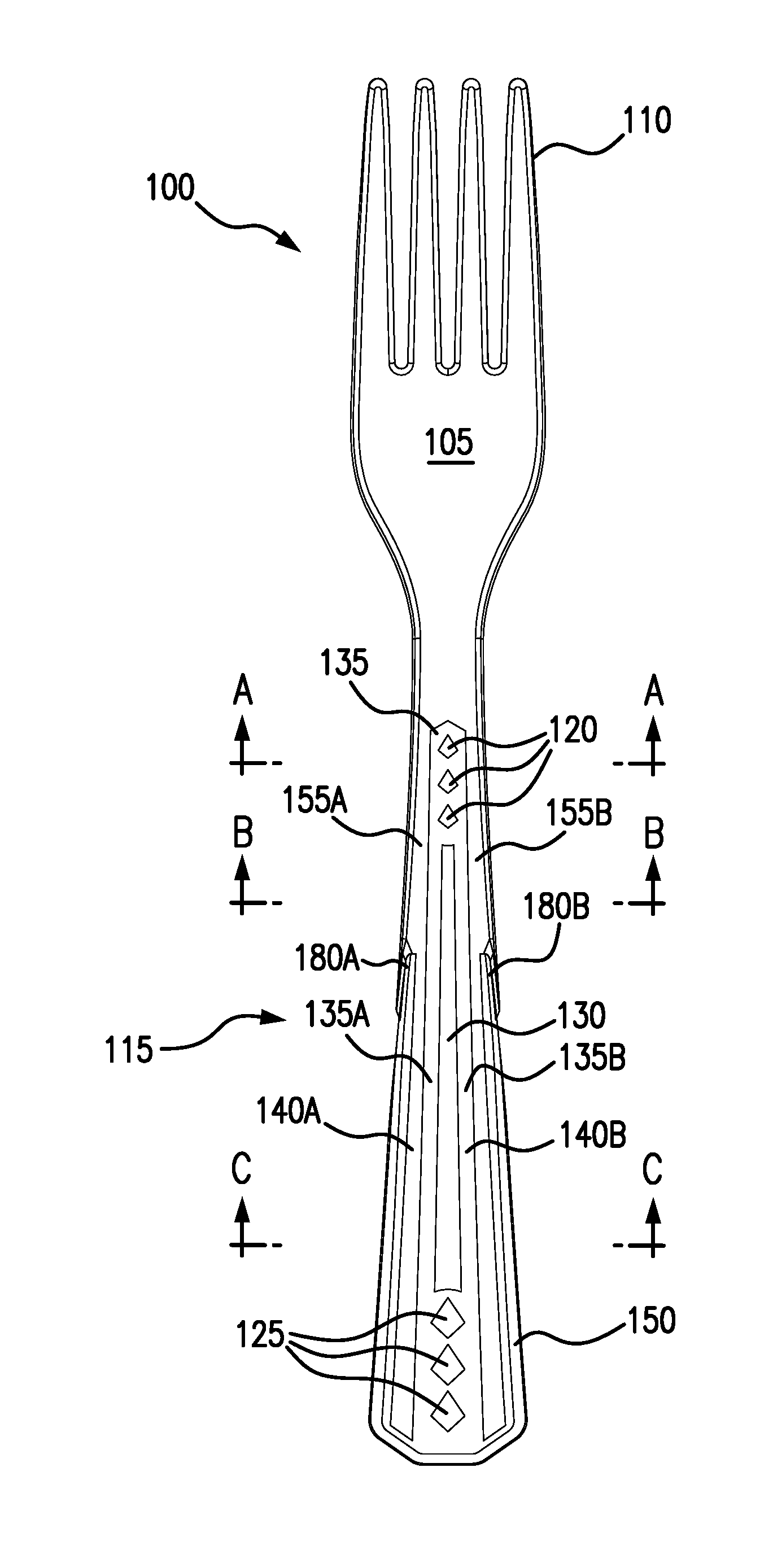

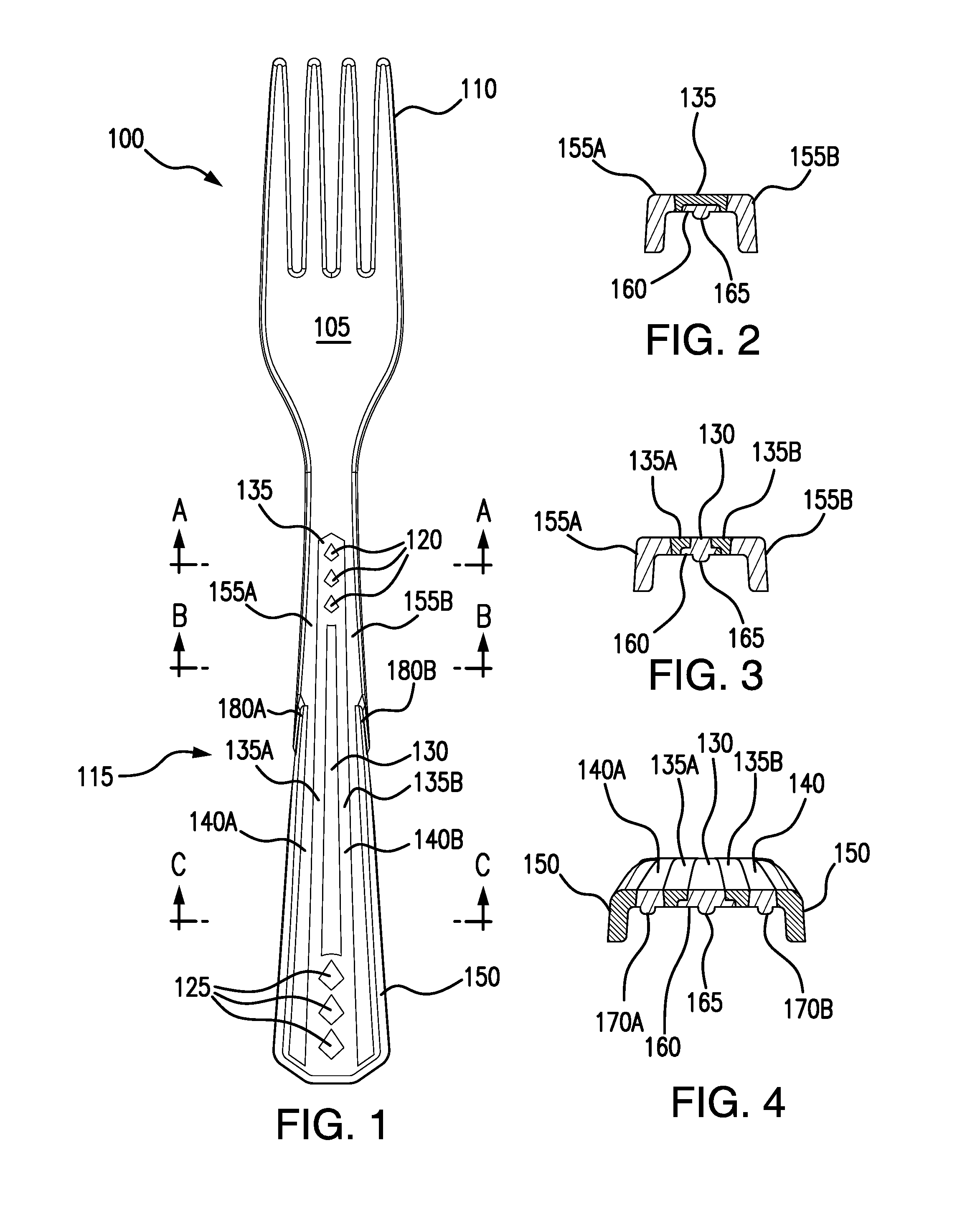

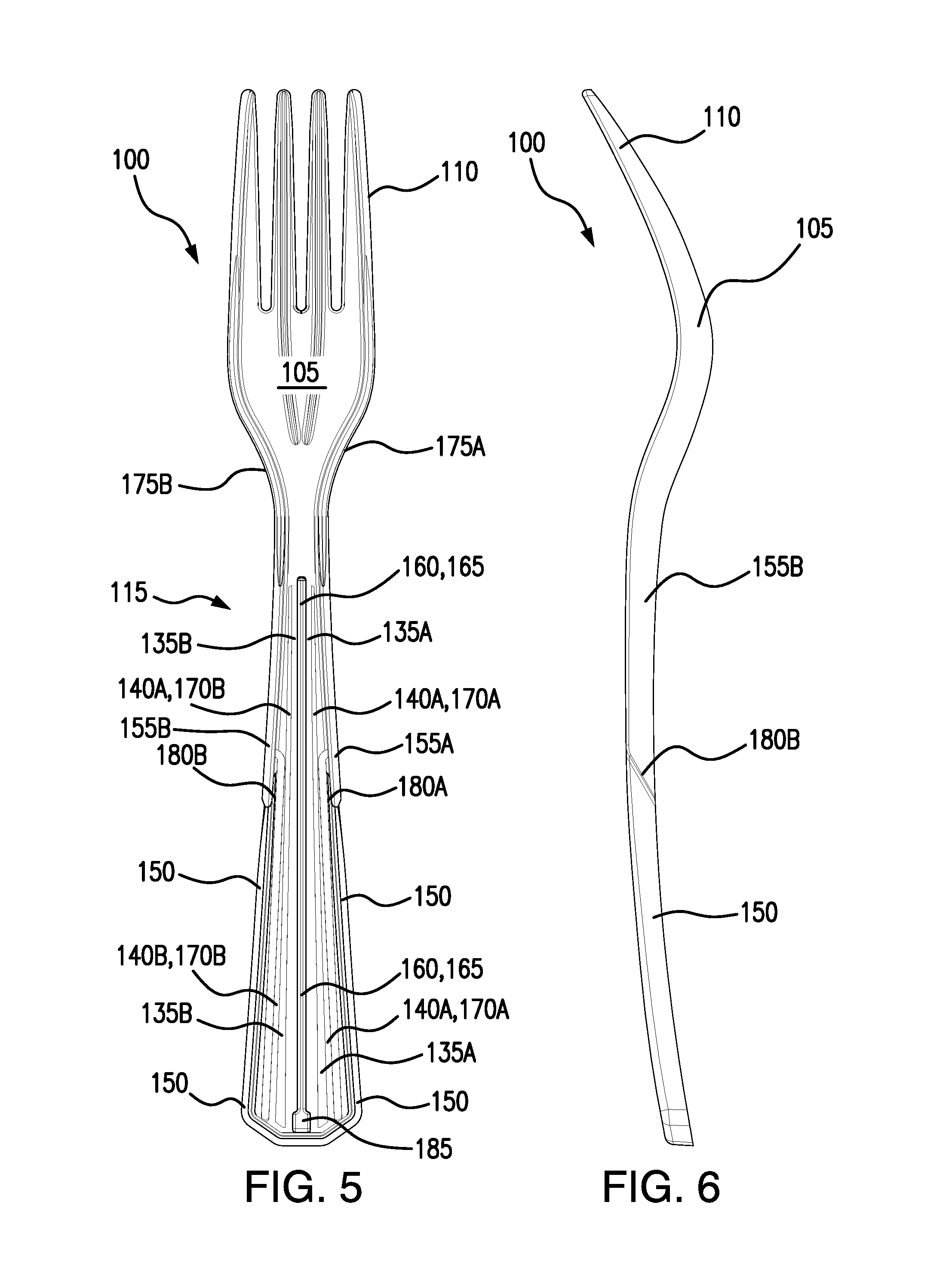

Overmolded low cost cutlery

InactiveUS20160374488A1Optimizing Flow PathsDomestic articlesMetal working apparatusCutleryEngineering

The invention relates to a molded article that includes a first molded structure that includes a working end, a bottom end, at least one wall member extending from the working end to the bottom end of the structure and at least partially or fully outlining a handle for the article, at least one decorative feature that resides on the handle surface of the article, and a connecting element that provides a flow path for first material to fill the decorative feature(s). The first molded structure is configured and dimensioned to receive a second material that also resides on the handle surface surrounding the decorative feature(s). The second shot molded structure is molded from the second material and includes surface portions that form top and bottom surfaces of the handle and that surround or encompass but do not cover the decorative feature(s) of the first molded structure.

Owner:MODERN PACKAGING LLC

Glass melting device and melting method therefor

ActiveCN104926081AAffects fluctuations in melting qualityExtended service lifePot furnacesGlass furnace apparatusCrucibleRefractive index

The present invention provides a melting device for melting glass complex powder into high-quality molten glass and a melting method therefor. The glass melting device comprises an outer crucible, a bubbler tube, an discharge tube and a heating device, and further comprises an inner crucible with a convex curved surface body structure, wherein the bubbler tube is inserted into the outer crucible; the inner crucible is arranged on the bottom in the outer crucible and a plurality of through holes are formed inthe convex curved surface of the inner crucible. By changing the structures of devices such as the outer crucible, the inner crucible, the bubbler tube, the discharge tube and the like, the glass melting device can improve a flow path of the molten glass, optimizes the whole flow and residence time, effectively reduces an area in which the molten glass flows slowly around the inner crucible, improves the residence time concentration degree of the molten glass in the melting device and improves the uniformity of the glass components, thereby ensuring physical and chemical performances such as the refractive index, the the Abbe number and the like of a glass product to be more uniform and stable.

Owner:CDGM OPTICAL GLASS

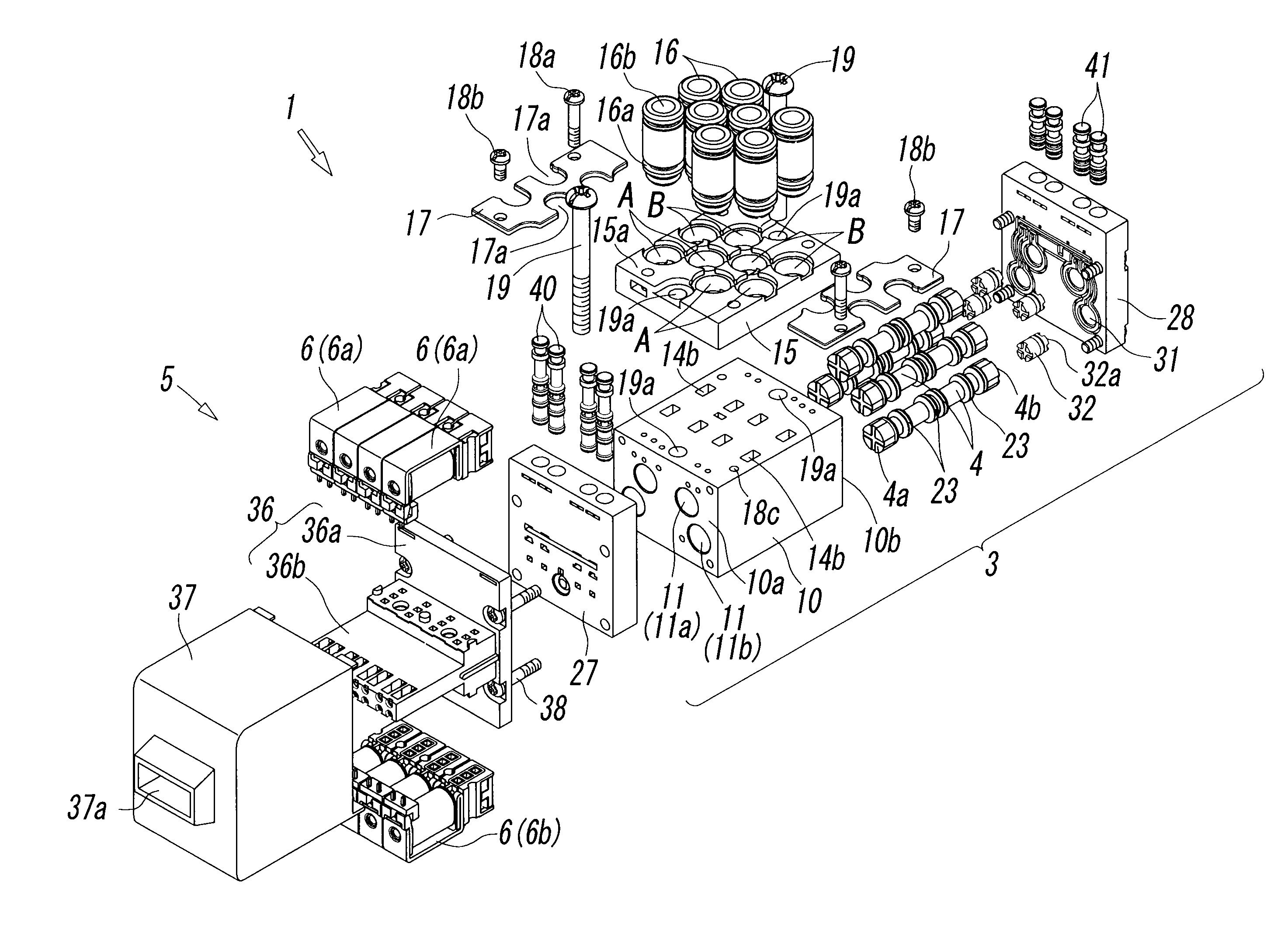

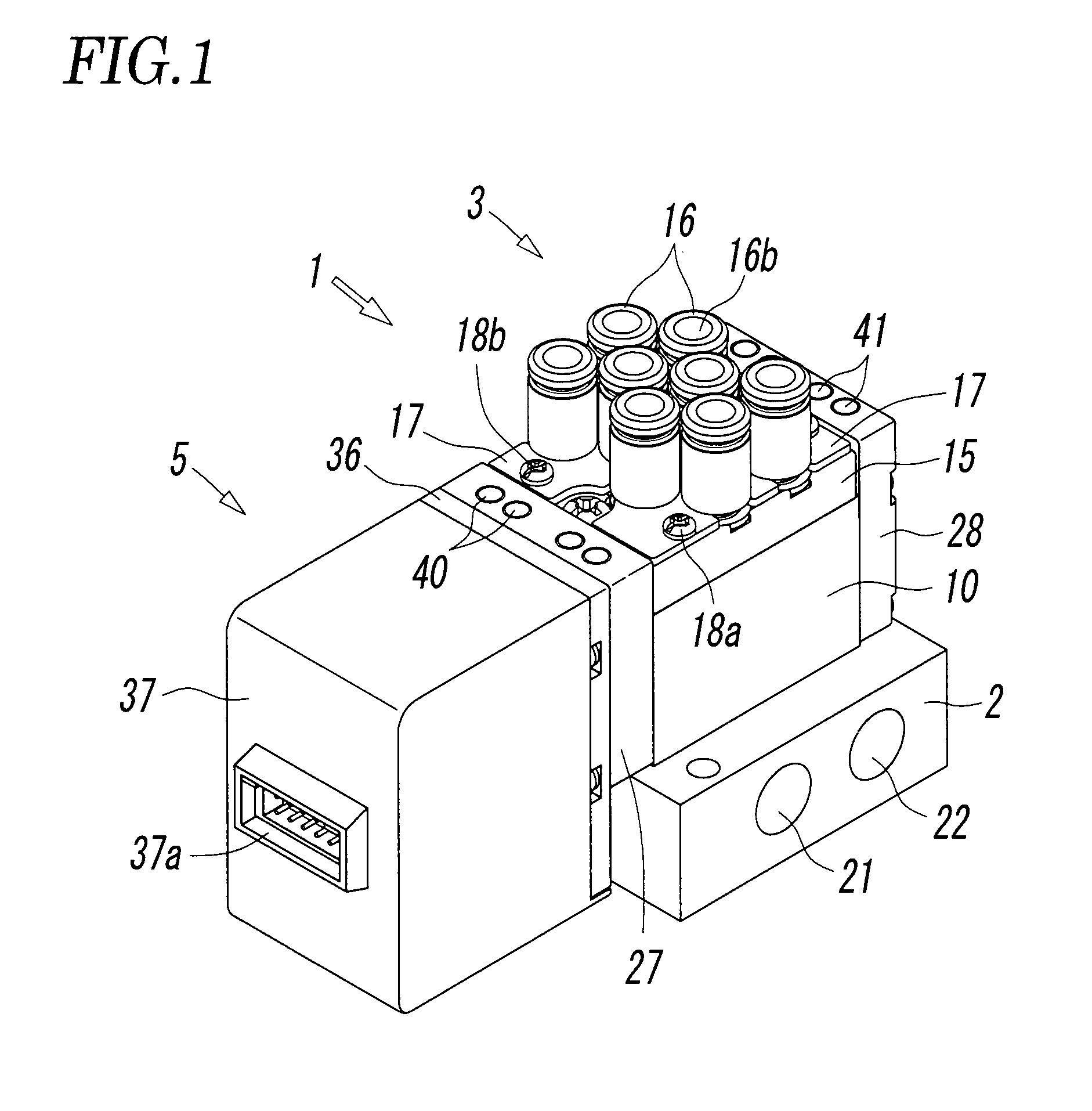

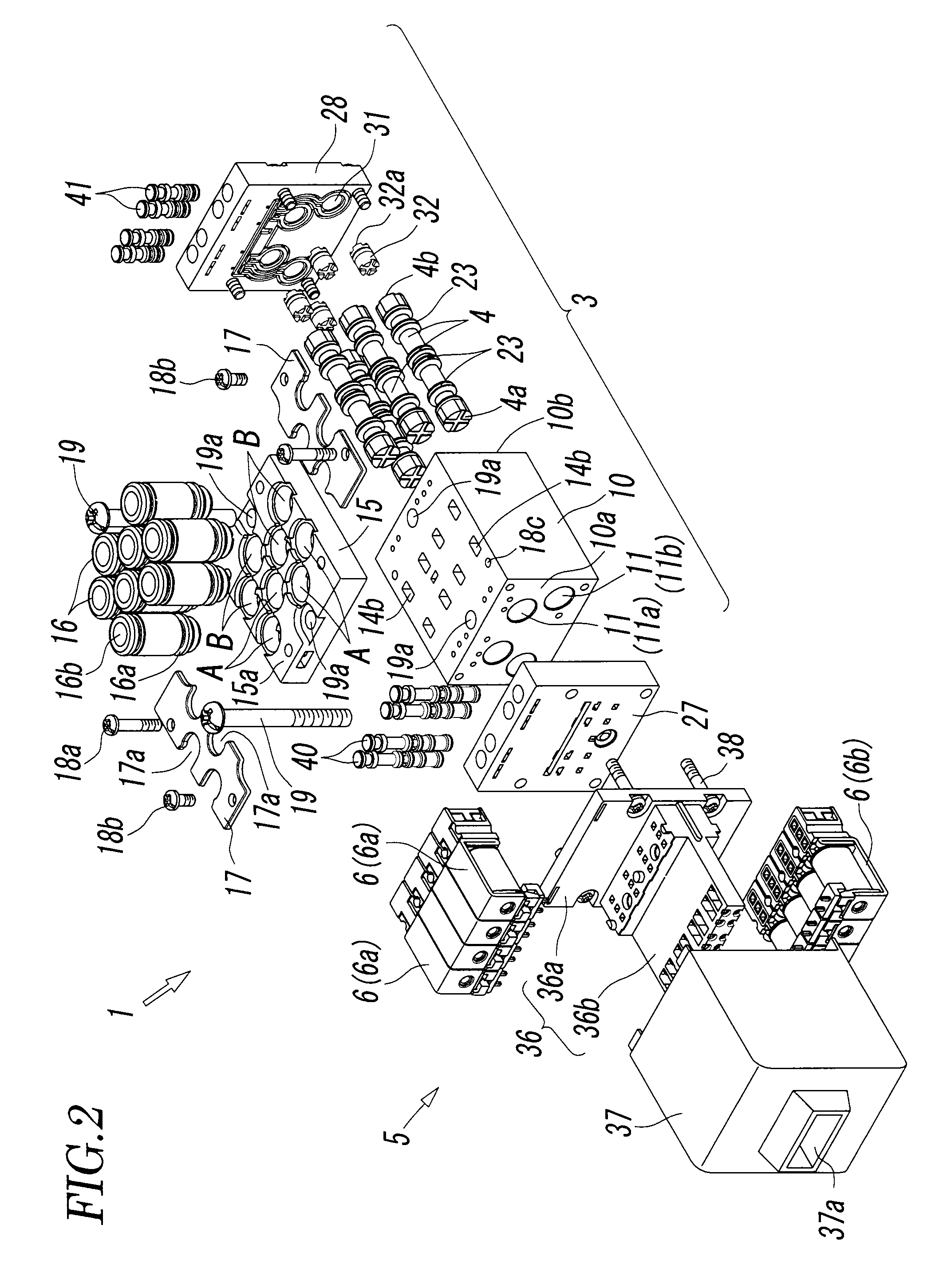

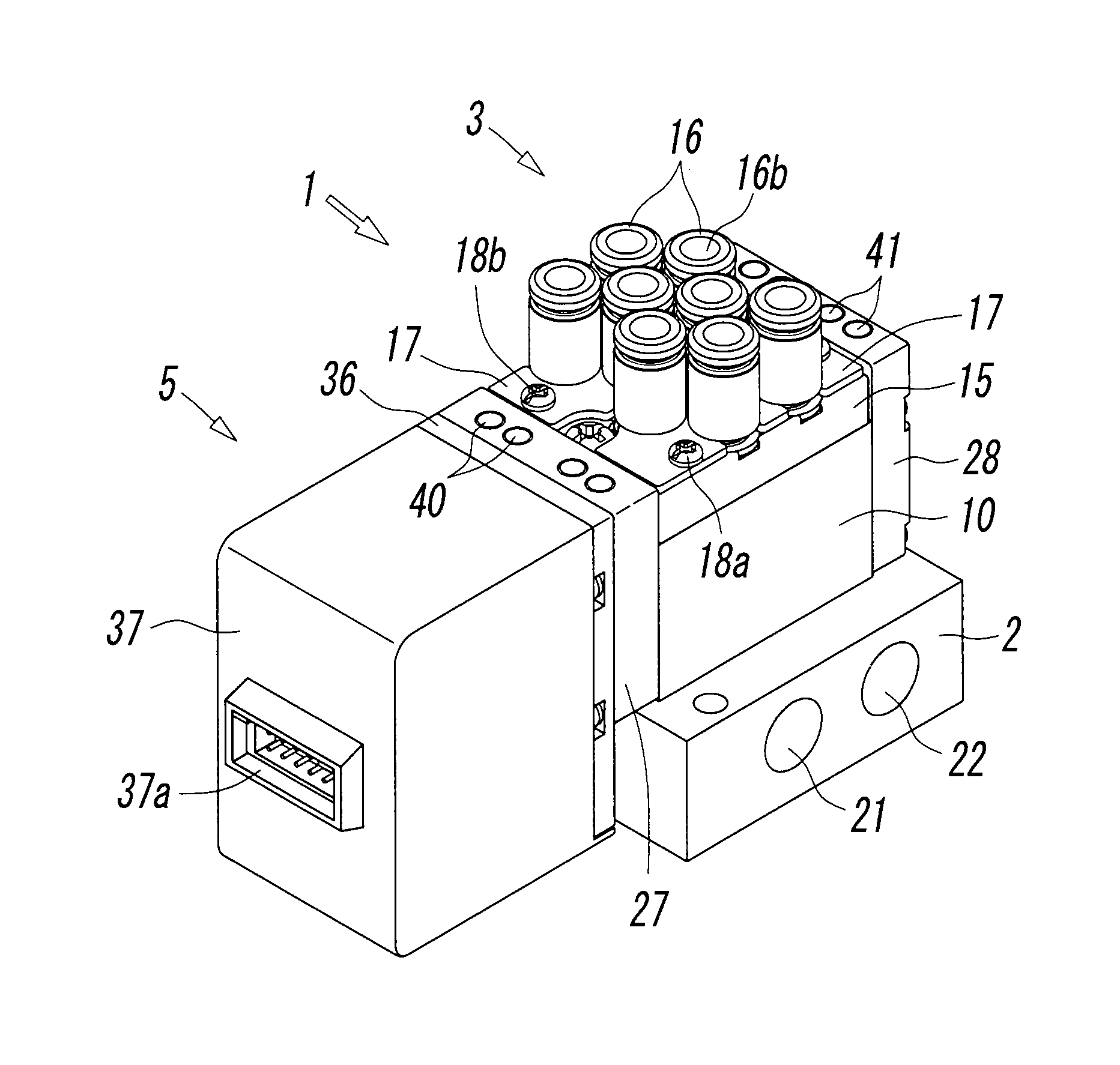

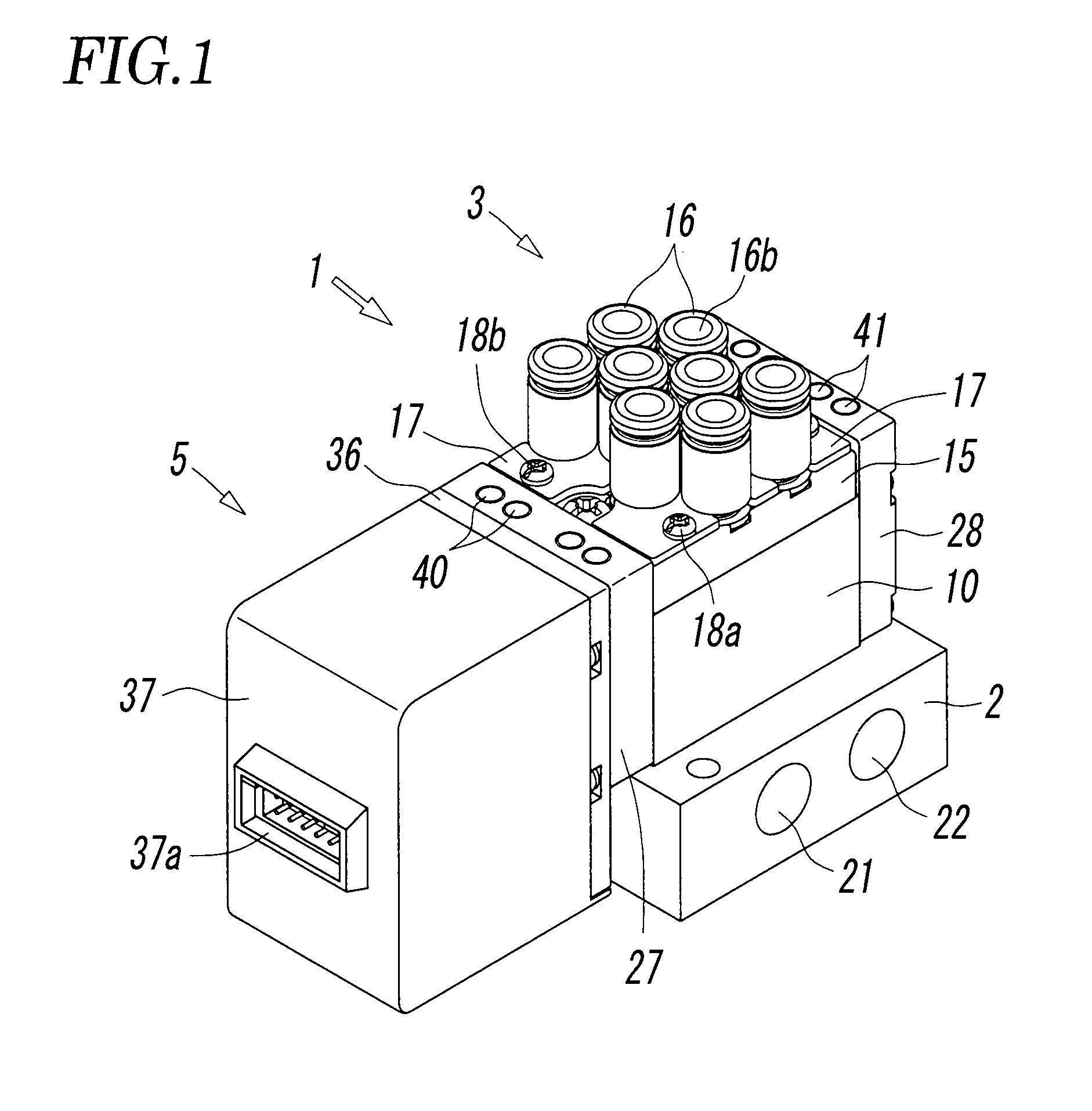

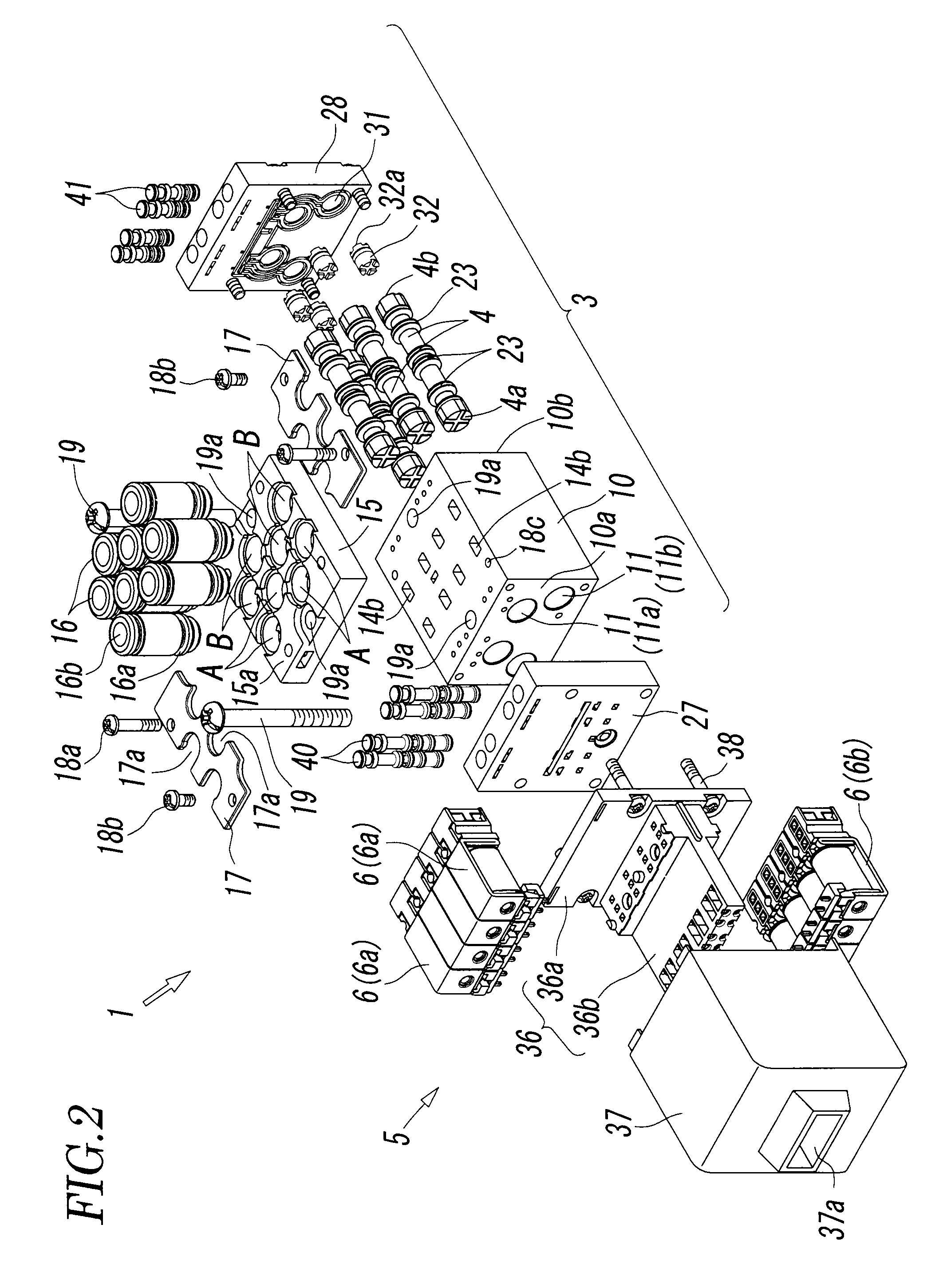

Multiple electromagnetic valve

ActiveUS20120085953A1Small sizeOptimizing Flow PathsOperating means/releasing devices for valvesServomotor componentsEngineeringElectromagnetic valve

A multiple electromagnetic valve includes a main valve portion in which four or more valve holes are formed parallel to each other inside a valve body, and a spool for switching flow paths is placed in each valve hole, and a pilot operating portion having solenoid-operated pilot valves that drive the spools with pilot fluid. The valve holes are disposed inside the valve body in two upper and lower tiers. A plurality of valve holes belongs in each of the upper tier and lower tier. The valve holes in the upper tier and the valve holes in the lower tier occupy different positions in the width direction of the valve body. The valve holes in the upper tier and the valve holes in the lower tier partially overlap each other in the plan view of the valve body.

Owner:SMC CORP

Heat exchanger and air conditioner

ActiveCN108895861AOptimizing Flow PathsImprove heat transfer effectEvaporators/condensersHeat exhanger finsEngineeringPlate heat exchanger

The invention discloses a heat exchanger and an air conditioner, and belongs to the technical field of air conditioners. The heat exchanger comprises one or more crack fins and one or more flat platefins, wherein one or more through holes are formed in each crack fin and runs through heat exchange tubes, and the adjacent through holes are communicated through cracks so that air can circulate in the cracks of the adjacent crack fins; one or more through holes are formed in each flat plate fin and used for running through the heat exchange tubes, and each flat plate fin is arranged between theadjacent crack fins so that the crack fins between the adjacent flat plate fins can form an air circulation region. In the heat exchanger, the flat plate fins are inserted into the crack fins throughpenetrating, in this way, the flowing route of the air is optimized, the heat exchange effect of the heat exchanger is improved, and heat exchange efficiency is improved.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

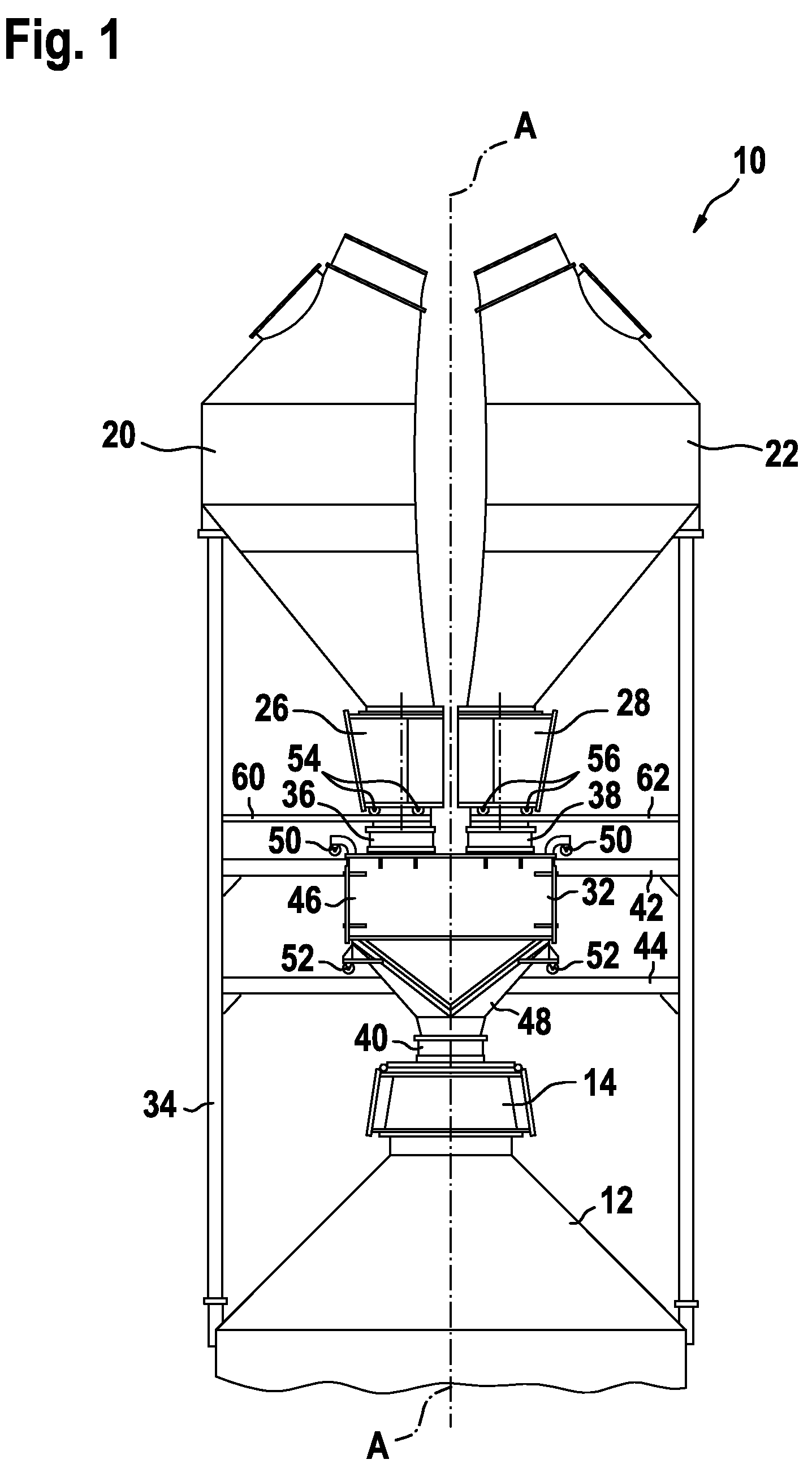

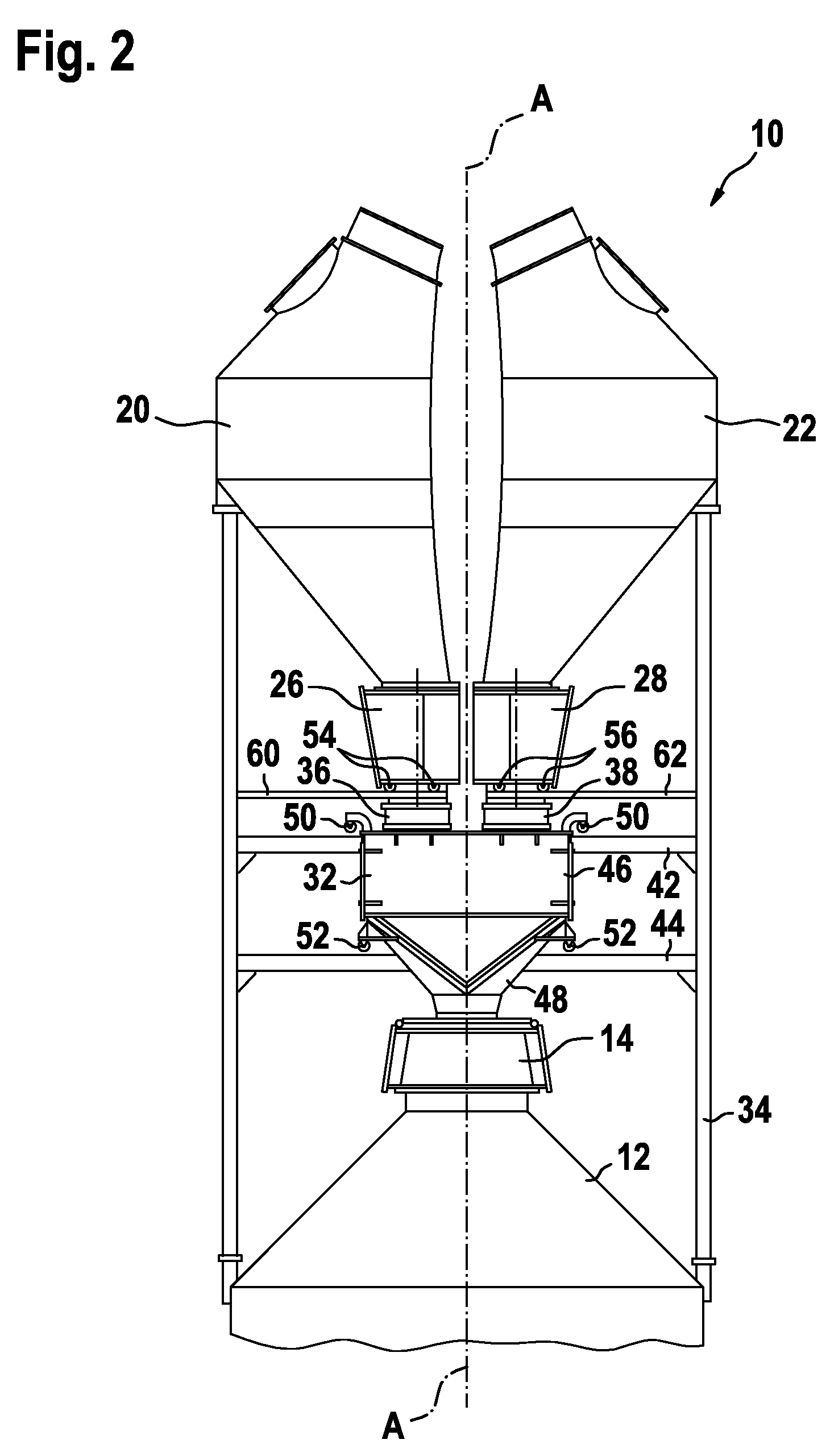

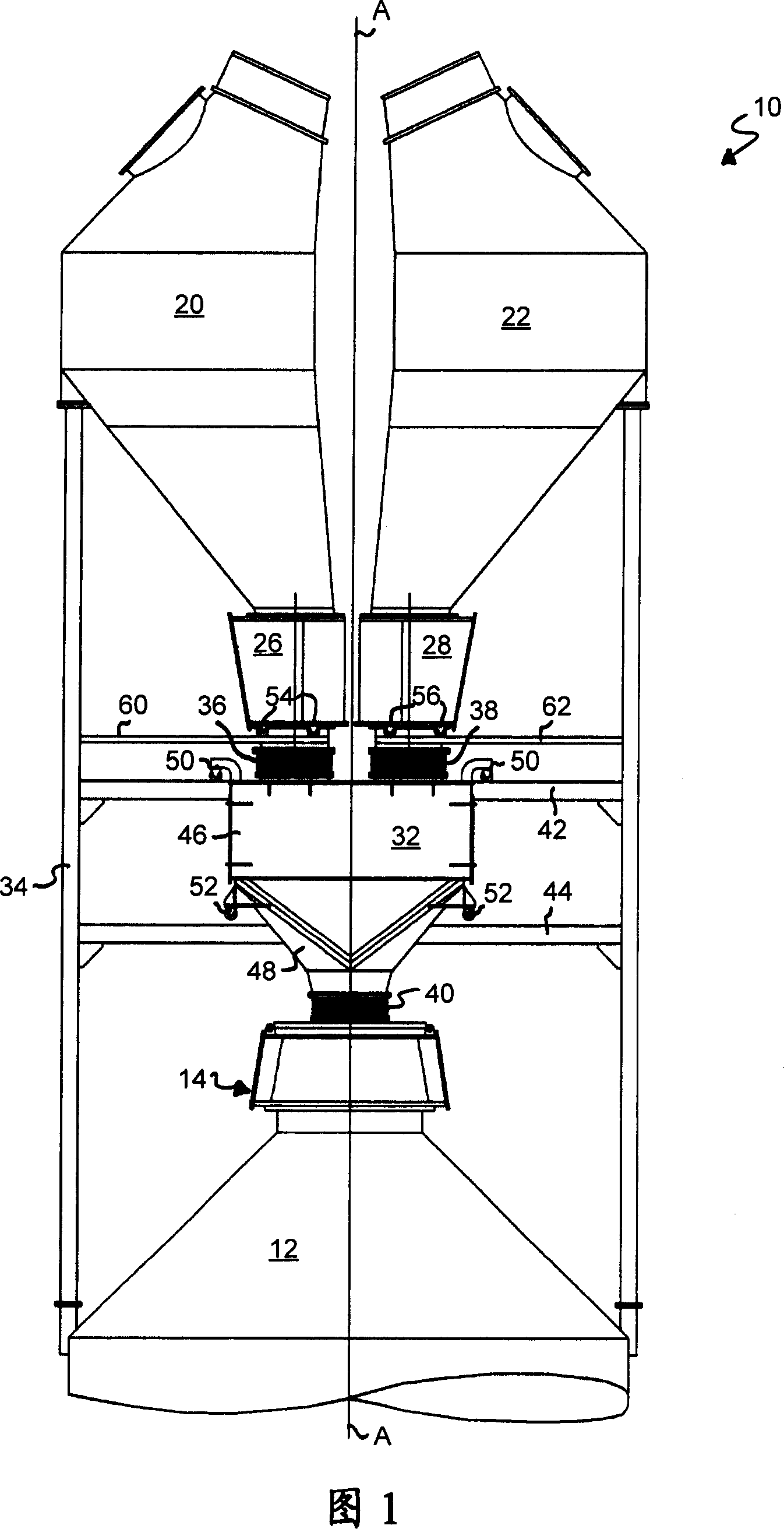

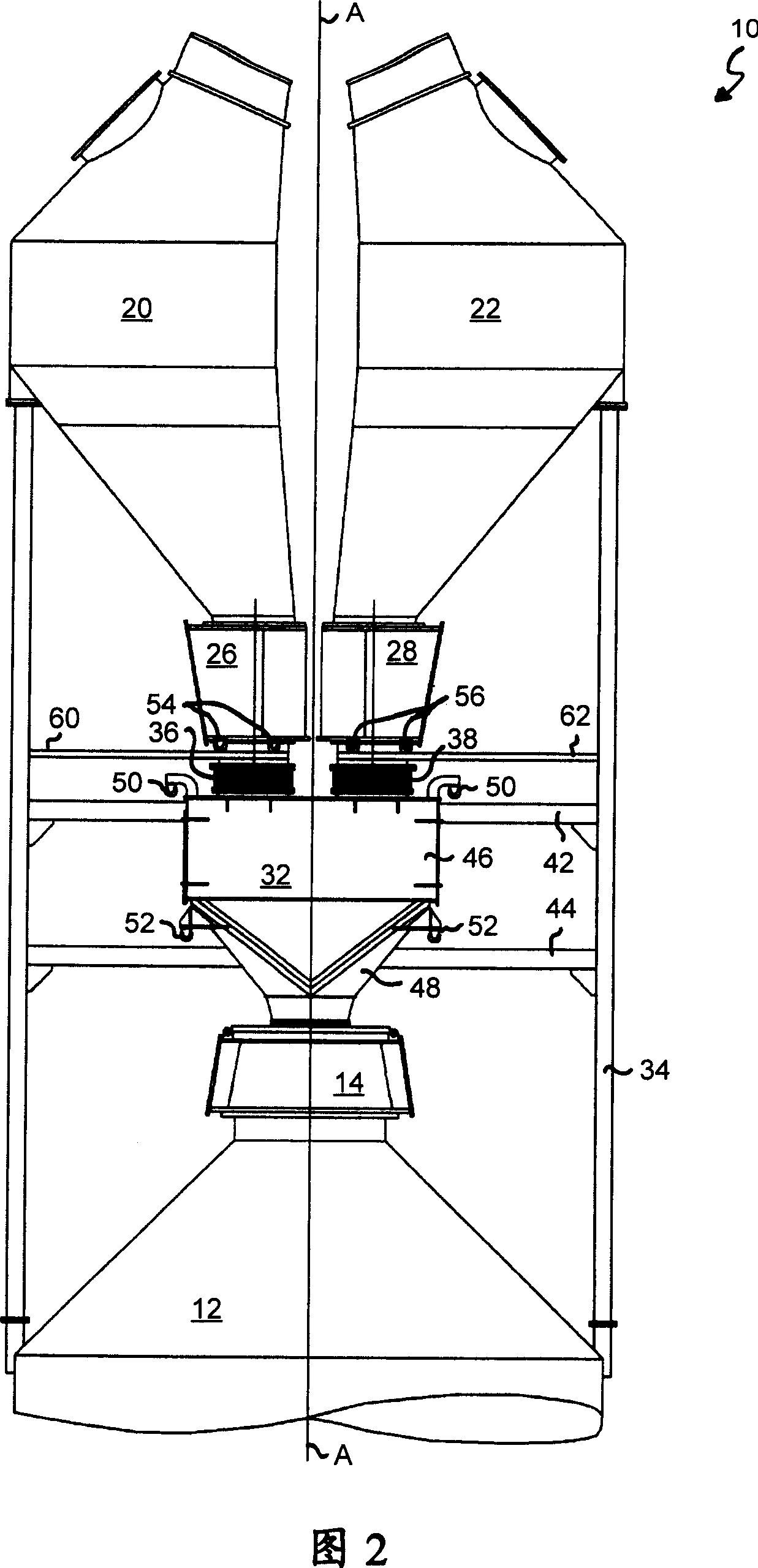

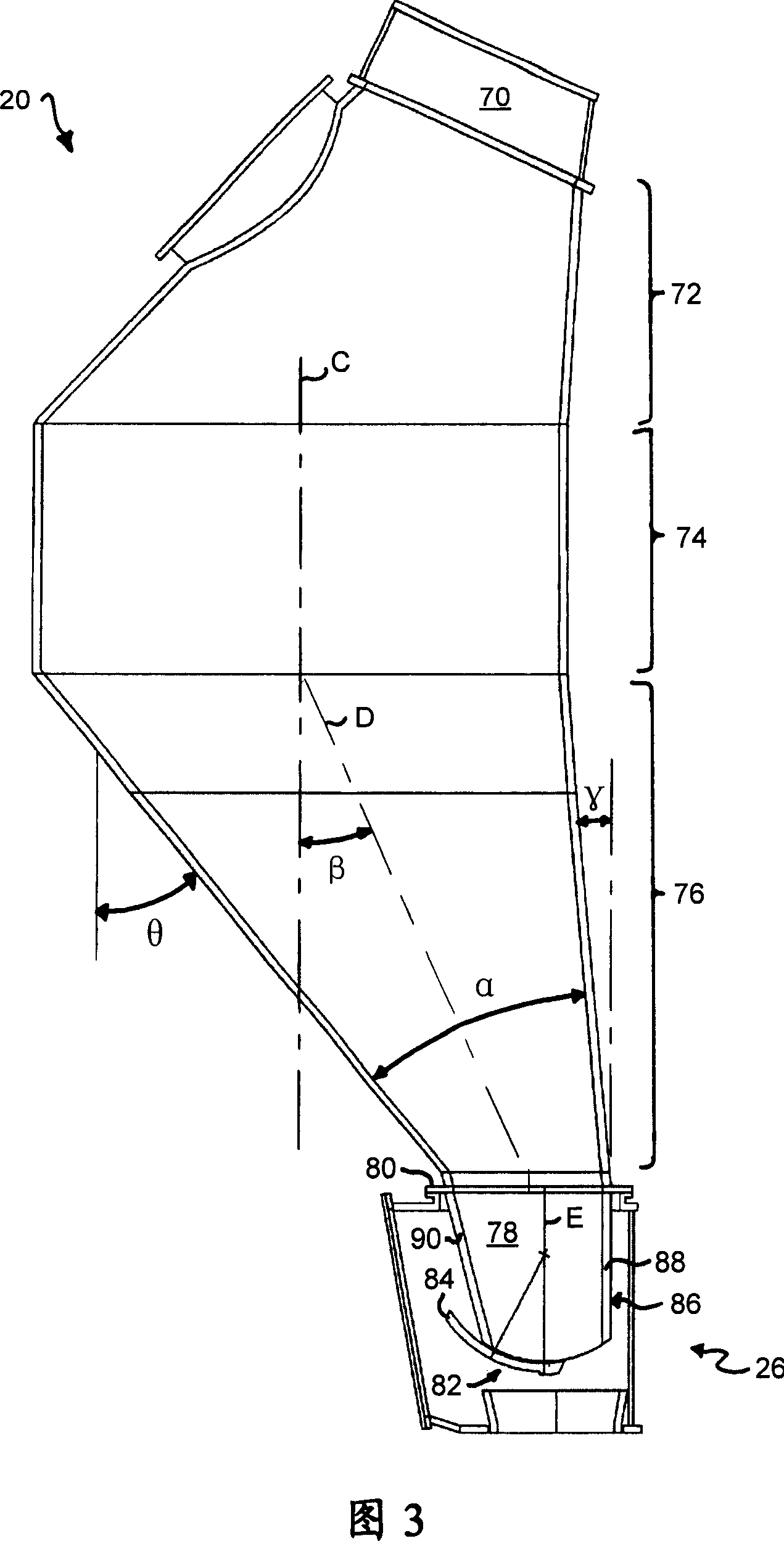

Multiple hopper charging installation for a shaft furnace

InactiveUS8092136B2Reduce asymmetryDrawback can be obviatedConveyorsLarge containersEngineeringShaft furnace

A multiple hopper charging installation for a shaft furnace includes a rotary distribution device for distributing bulk material in the shaft furnace by rotating a distribution member about a central axis of the shaft furnace and at least two hoppers arranged in parallel and offset from the central axis above the rotary distribution device. Each hopper has a lower funnel part ending in an outlet portion and each hopper has a material gate valve with a shutter member associated to its outlet portion. According to the invention, each funnel part is configured asymmetrically with its outlet portion being eccentric and arranged proximate to the central axis, each outlet portion is oriented vertically so as to produce a substantially vertical outflow of bulk material and each material gate valve has a one-piece shutter member and is configured with its respective shutter member opening in a direction pointing away from the central axis such that any partial valve opening area is located on the side of the associated outlet portion proximate to the central axis.

Owner:PAUL WURTH SA

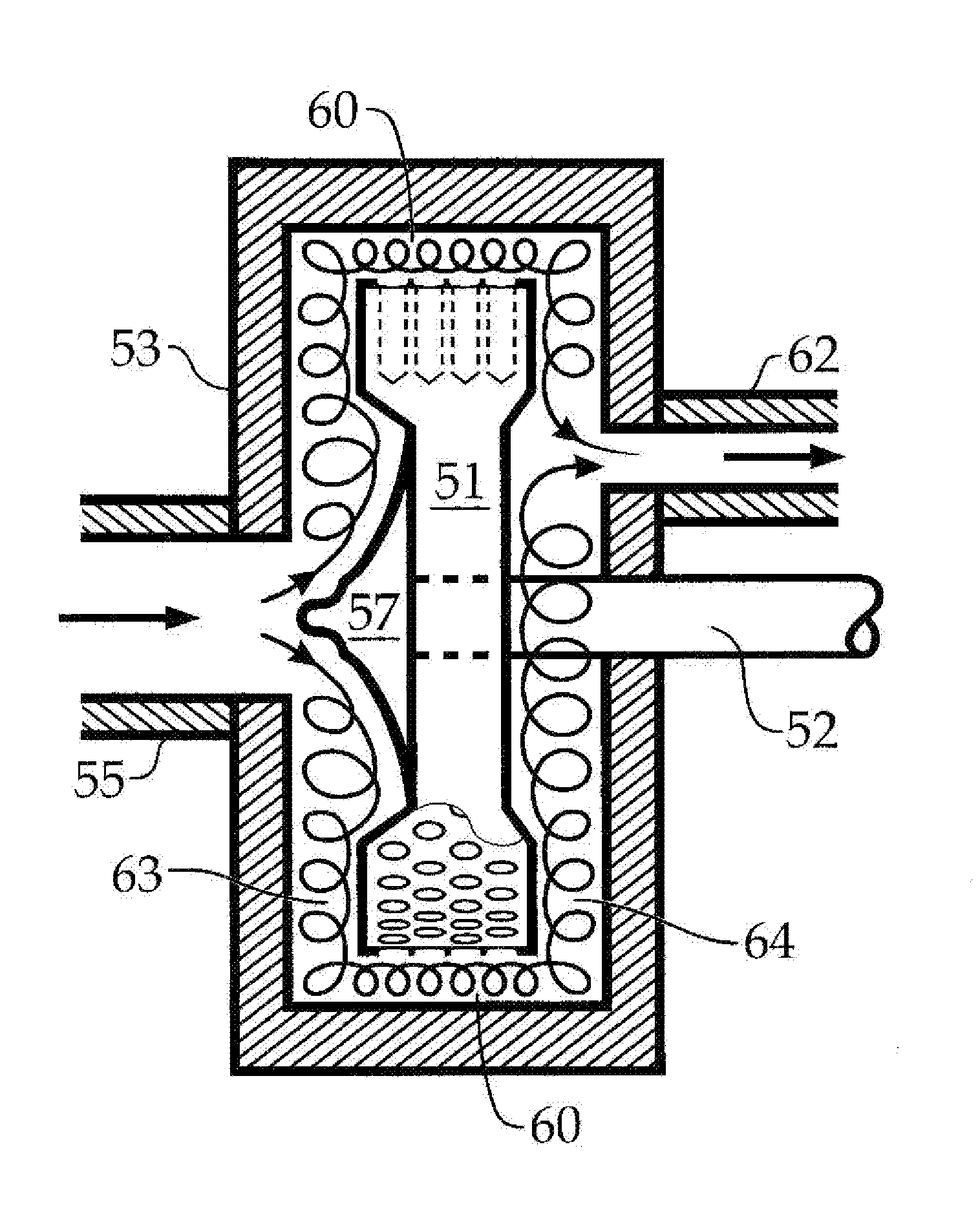

Cavitation Device

ActiveUS20160339400A1Good effectAmeliorates counterproductive dragFlow mixersPump componentsCavitationEngineering

An improved cavitation mixing and heating device employs an inlet directed toward the vertex of a conical or similar flow-directing element. The flow patterns of the fluid material to be mixed and heated are designed to preheat, spread, and create turbulent flow mixing of the fluid before it enters the cavitation zone, using heat generated in the cavitation zone that is conducted through the body of the cavitation rotor. The functions of the axially oriented inlet and flow directing element are assisted by a cantilever construction to alleviate stress on the bearings.

Owner:HIGHLAND FLUID TECH

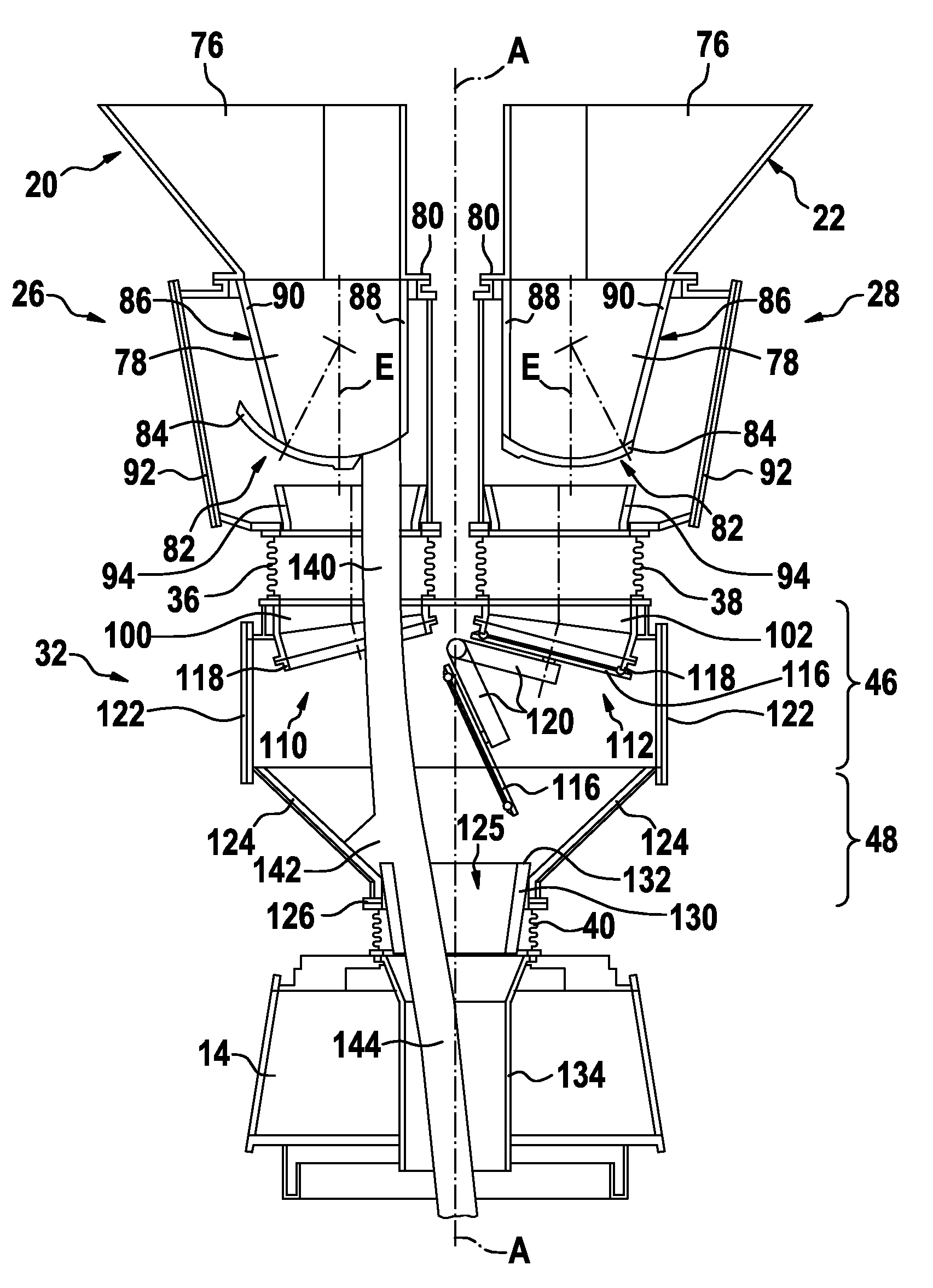

Three hopper charging installation for a shaft furnace

InactiveCN101004323AOptimizing Flow PathsEase of maintenance proceduresLarge containersBell-and-hopper arrangementShaft furnaceStellate Configuration

A three hopper charging installation (10') for a shaft furnace is disclosed. It comprises a rotary distribution device (14) for distributing bulk material in the furnace by rotating a distribution member about the furnace central axis (A) and a first, a second and a third hopper (20, 22, 24) arranged in parallel above the rotary distribution device and offset from the central axis. A sealing valve housing (32') is arranged between the hoppers and the distribution device. It has a top part (46') with a first, a second and a third inlet respectively communicating with the first, the second and the third hopper. A first, a second and a third sealing valve are provided in the top part. Each sealing valve comprises a flap which is pivotable between a closed sealing position and an open parking position. The sealing valve housing also has a funnel shaped bottom part (48') with an outlet communicating with the distribution device. According to the invention, the top part (46') of the sealing valve housing (32') has a tripartite stellate configuration in horizontal section with a central portion (156), in which the inlets are arranged adjacently in triangular relationship about the central axis (A), and with a first, a second and a third extension portion (160, 162, 164), each sealing valve being adapted such that its flap opens outwardly with respect to the central axis by pivoting into a parking position located in the first, second or third extension portion respectively.

Owner:PAUL WURTH SA

Multiple electromagnetic valve

ActiveUS8833396B2Small sizeOptimizing Flow PathsOperating means/releasing devices for valvesServomotor componentsEngineeringElectromagnetic valve

A multiple electromagnetic valve includes a main valve portion in which four or more valve holes are formed parallel to each other inside a valve body, and a spool for switching flow paths is placed in each valve hole, and a pilot operating portion having solenoid-operated pilot valves that drive the spools with pilot fluid. The valve holes are disposed inside the valve body in two upper and lower tiers. A plurality of valve holes belongs in each of the upper tier and lower tier. The valve holes in the upper tier and the valve holes in the lower tier occupy different positions in the width direction of the valve body. The valve holes in the upper tier and the valve holes in the lower tier partially overlap each other in the plan view of the valve body.

Owner:SMC CORP

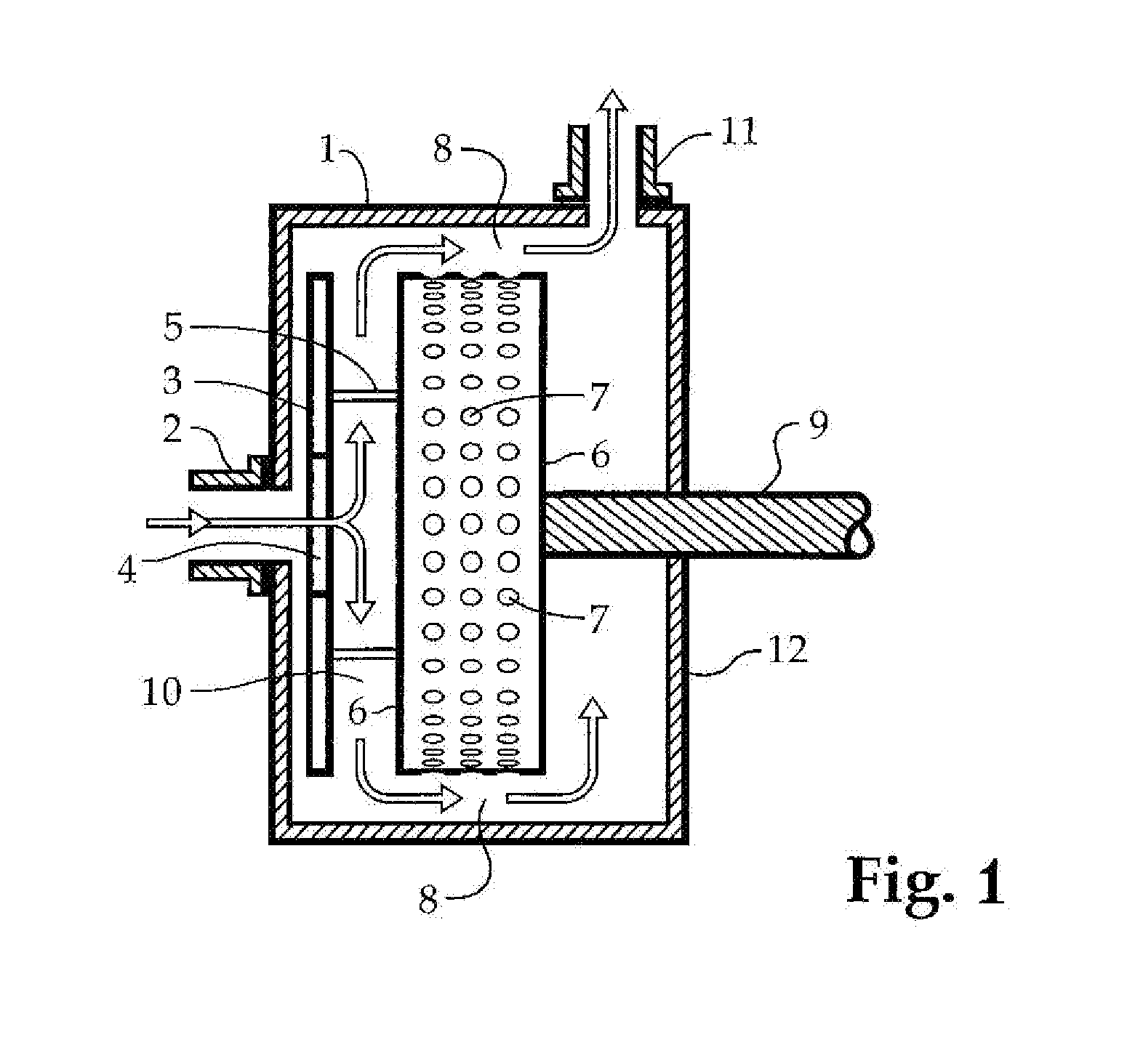

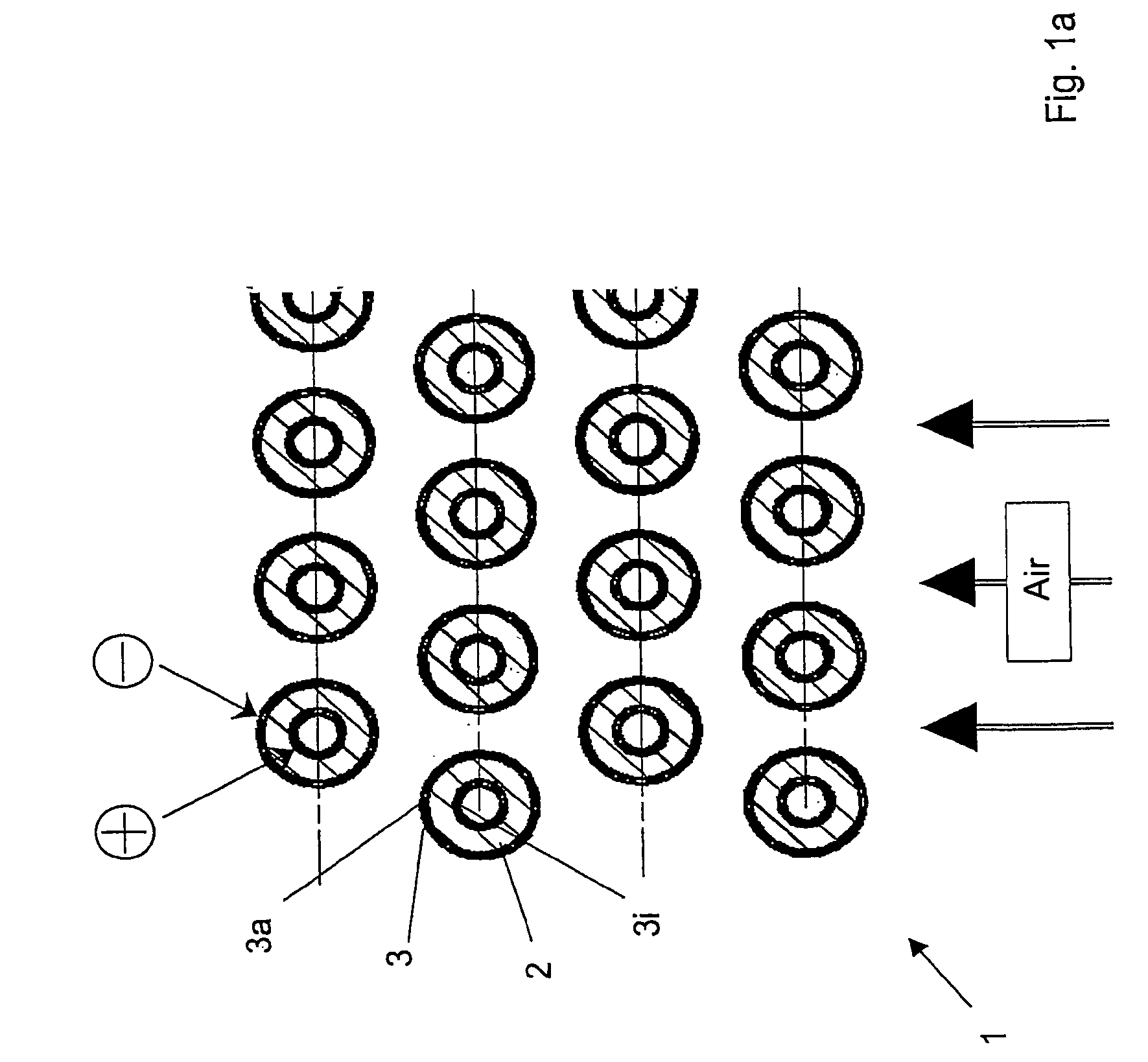

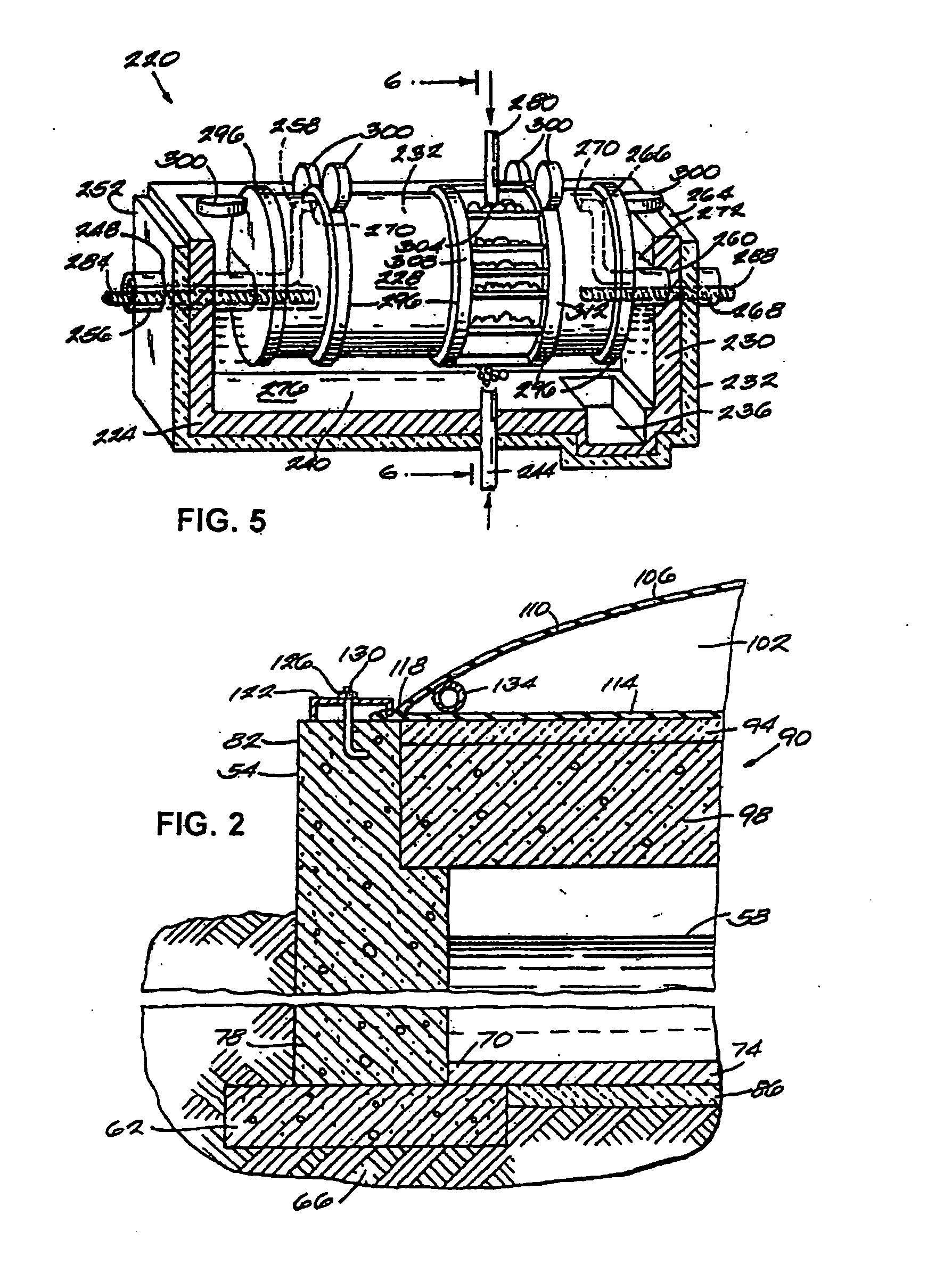

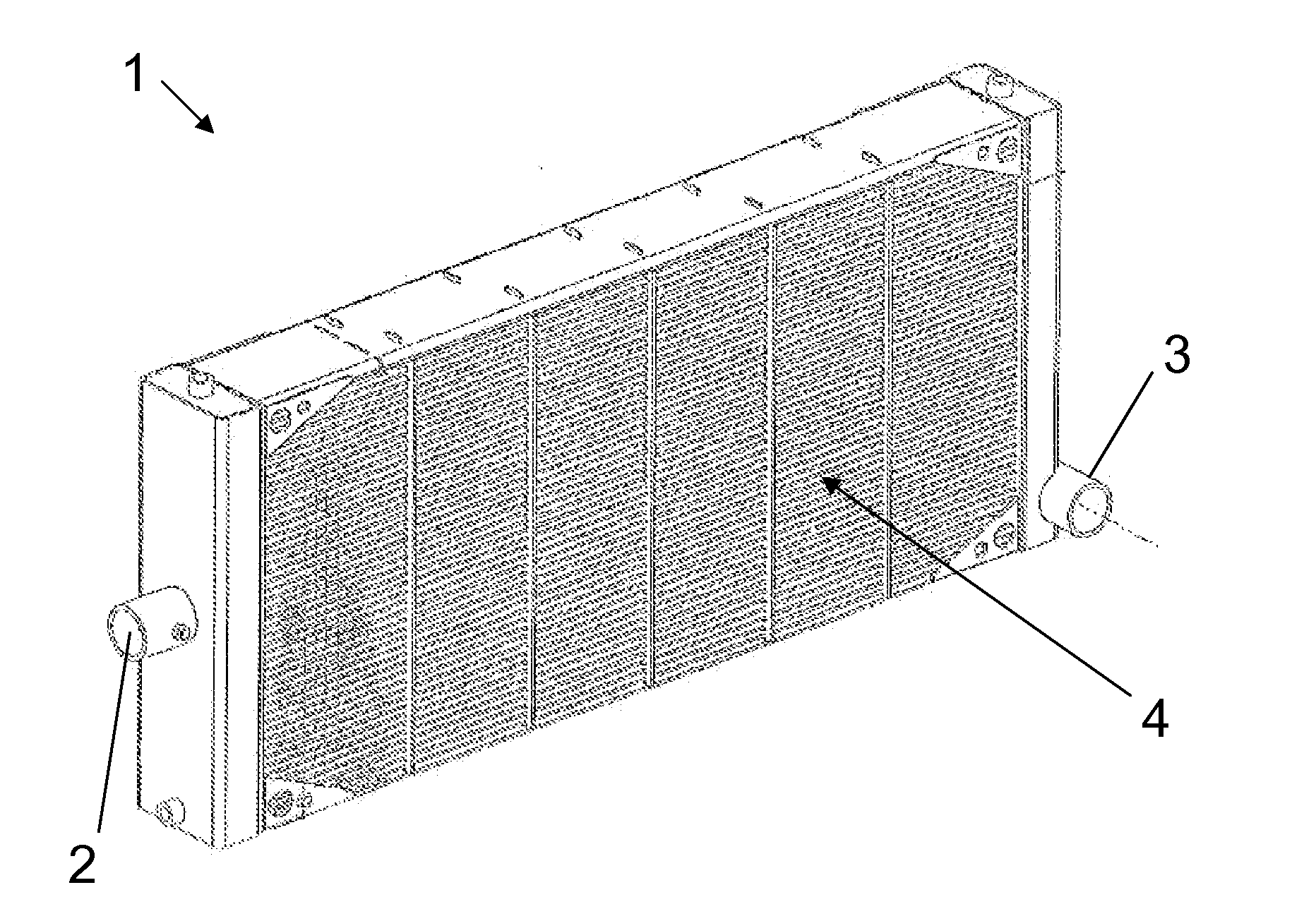

Added electrical heater for a heating system or air conditioner of a motor vehicle

ActiveUS8153938B2Reduce weight and manufacturing costSimplifies current currentHeater elementsVehicle heating/cooling devicesMobile vehicleConductive coating

The invention relates to an added electrical heater (1), especially for a heating system or air conditioner of a motor vehicle. A plurality of heating elements (2) are provided which are formed by PTC elements while being fitted with at least one electrically conducting coating (3).

Owner:BEHR GMBH & CO KG +1

Biosolids digester and process for biosolids production

ActiveUS20120329139A1Energy efficiencyEnhanced convectionBioreactor/fermenter combinationsBio-organic fraction processingPulp and paper industryBiosolids

The invention relates to methods and apparatuses for producing Class A biosolids. In yet another embodiment, the invention relates to a method comprising digesting waste material by anaerobic digestion, and yielding Class A biosolids. In still yet another embodiment, the invention relates to a system for anaerobic digestion of waste material to produce Class A biosolids. In still yet another embodiment, the invention relates to a system for anaerobic digestion of waste material comprising a mixing chamber, a digester, a heating pit, and an effluent pit.

Owner:DVO LICENSING

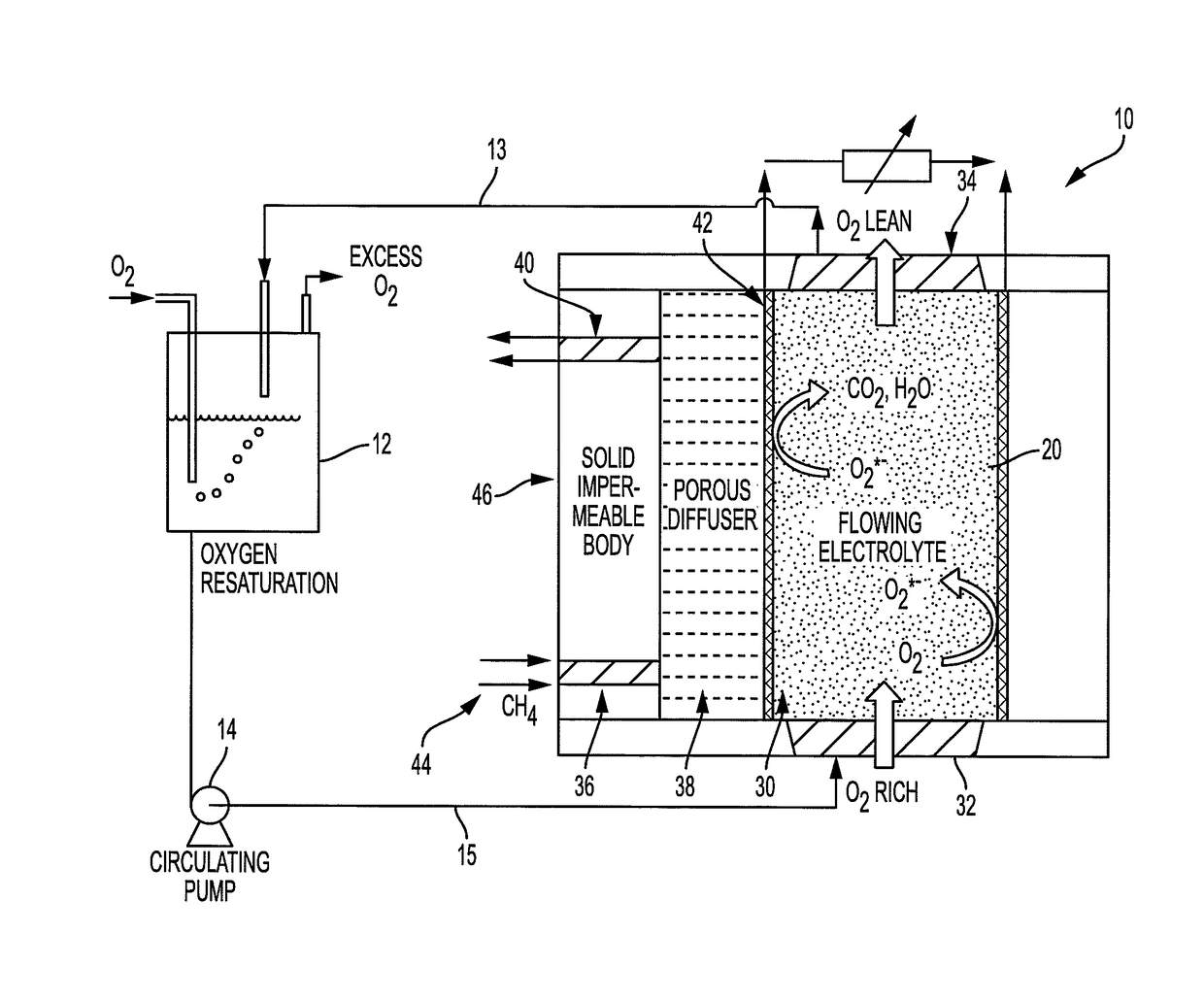

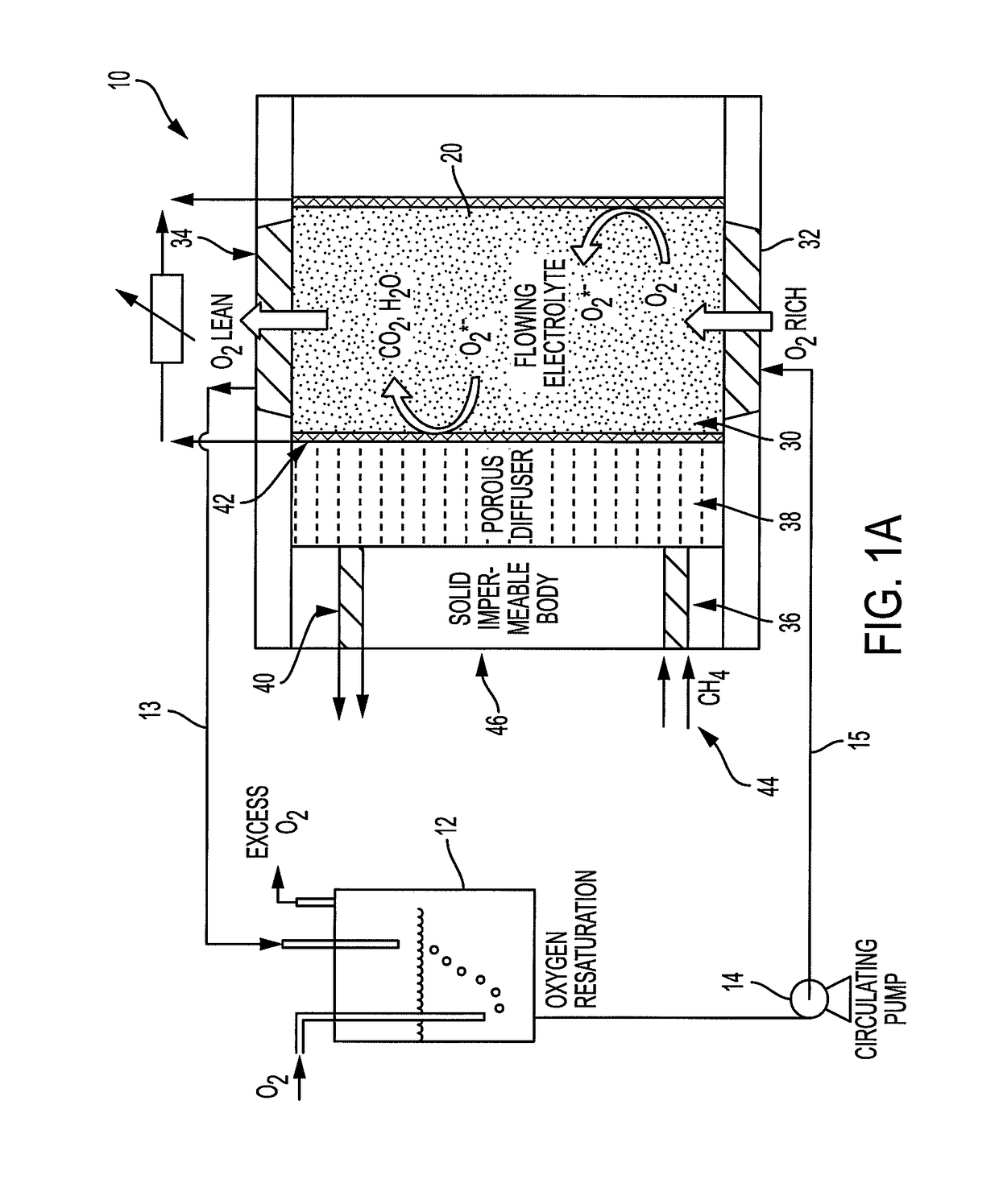

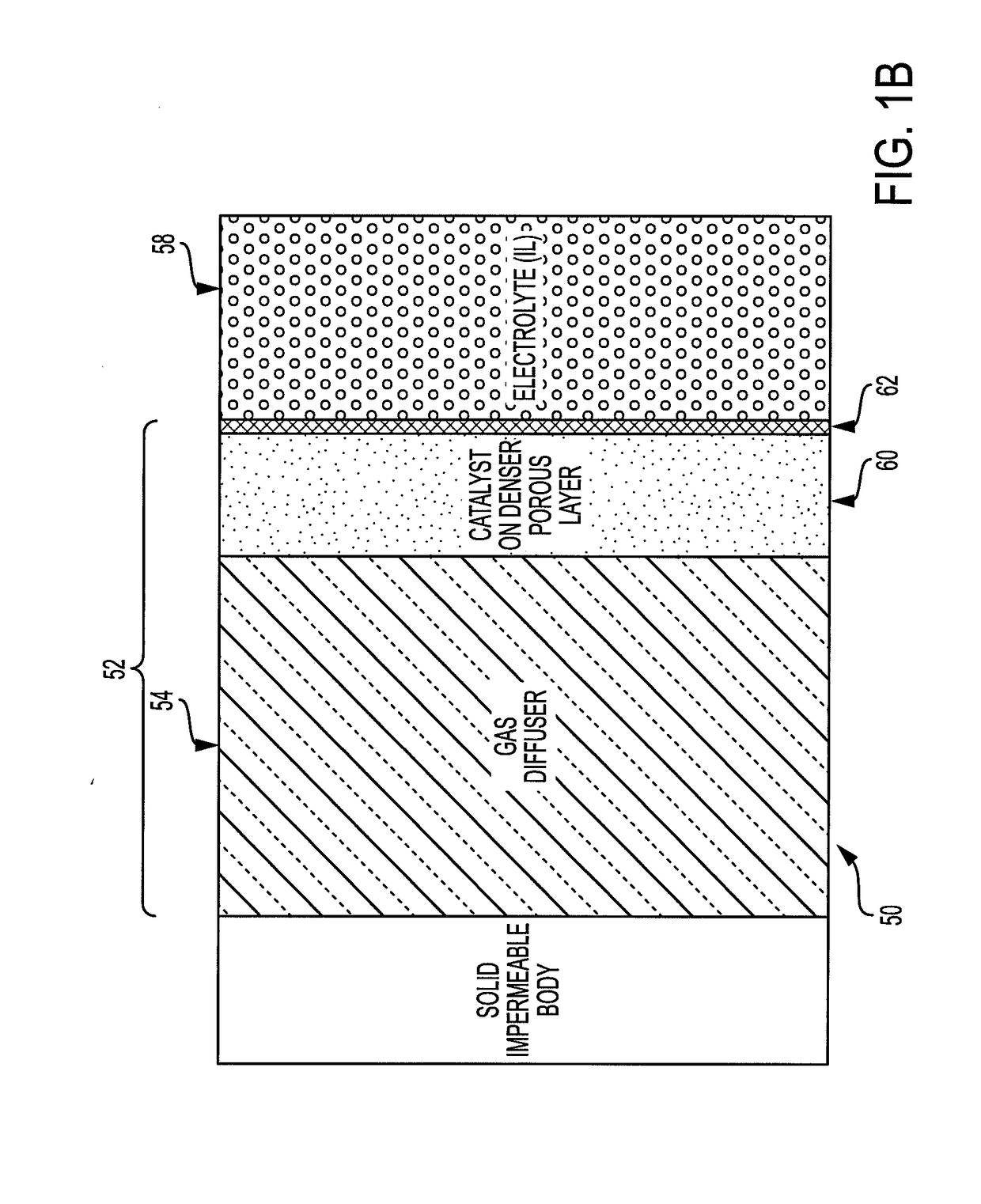

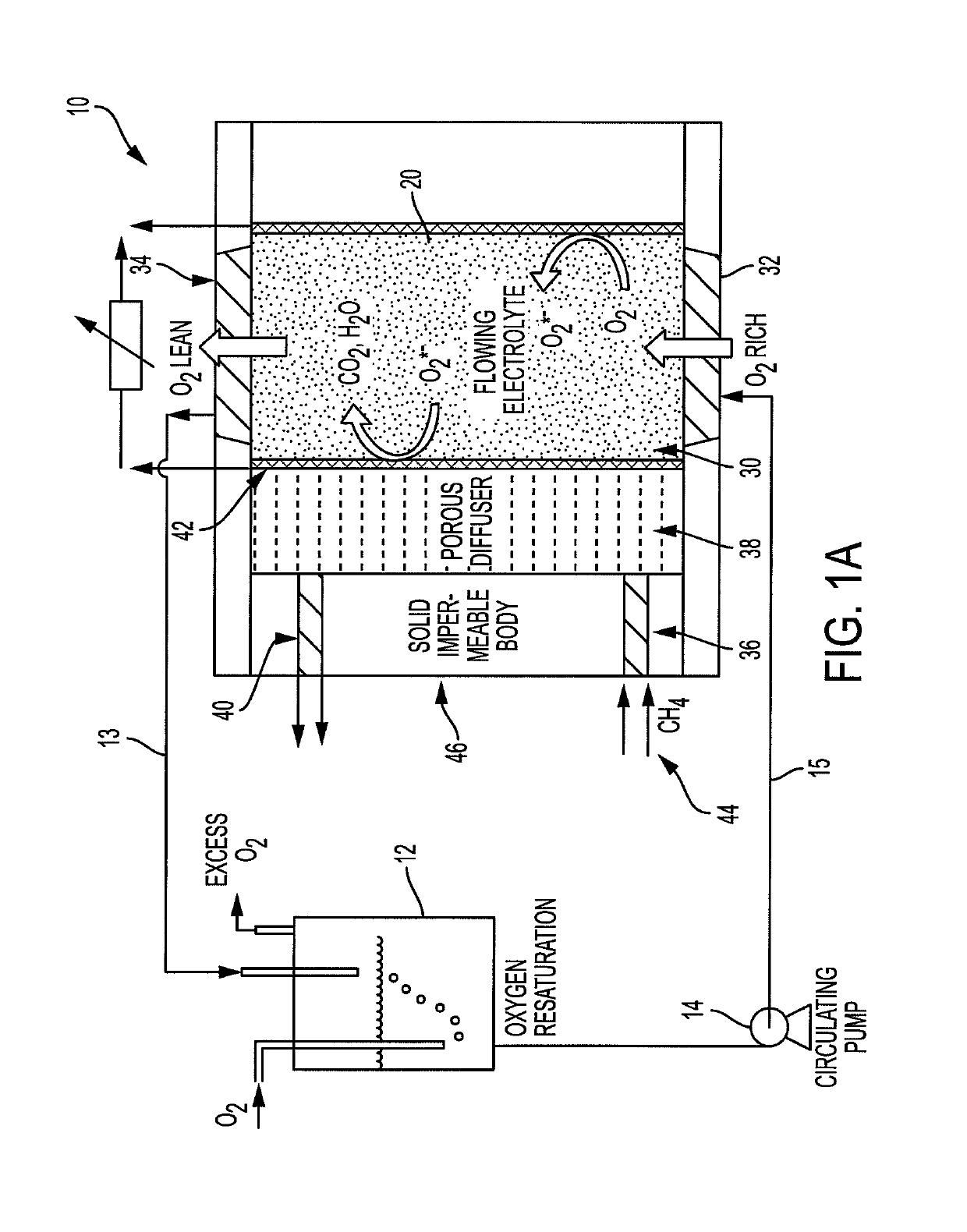

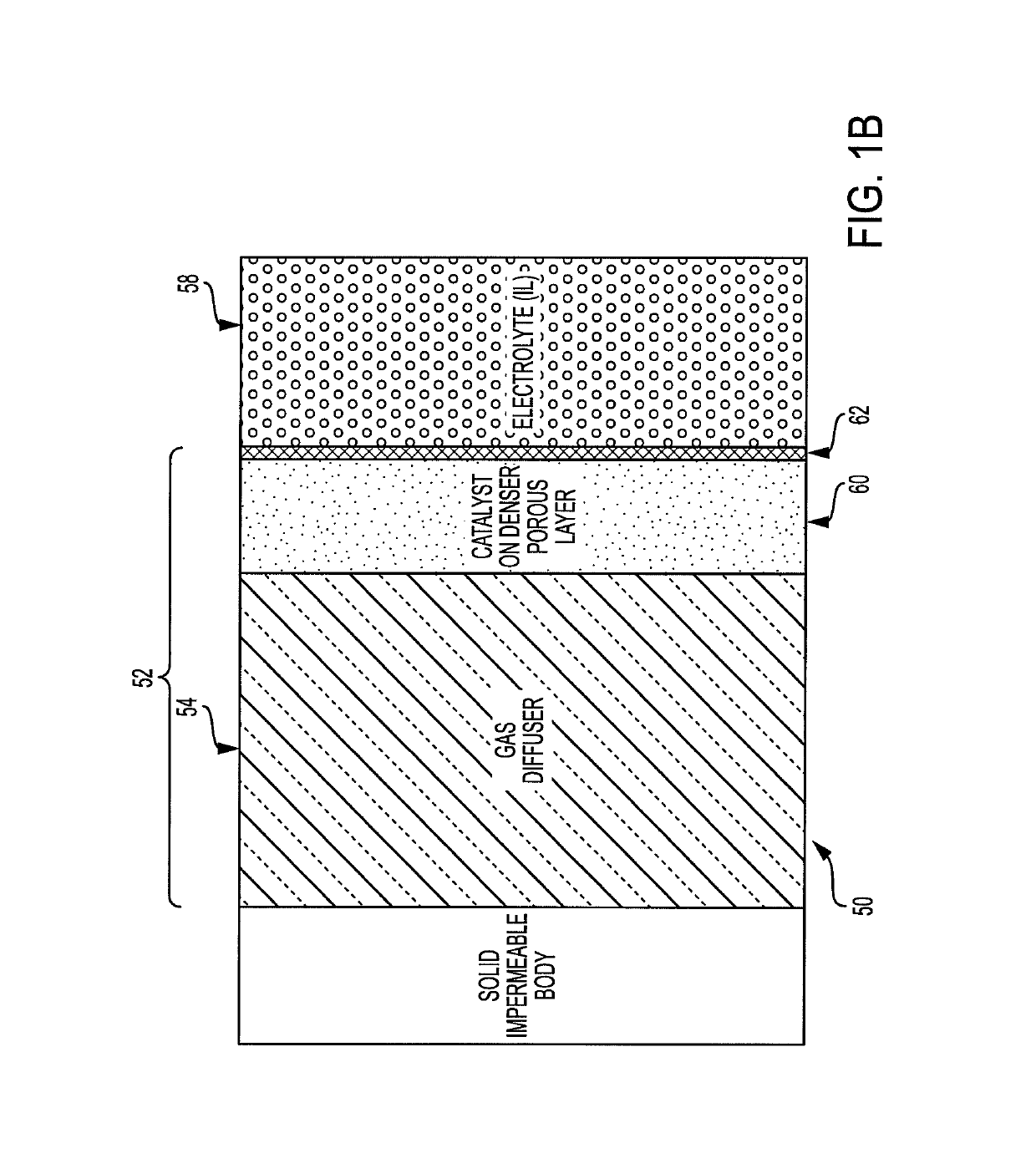

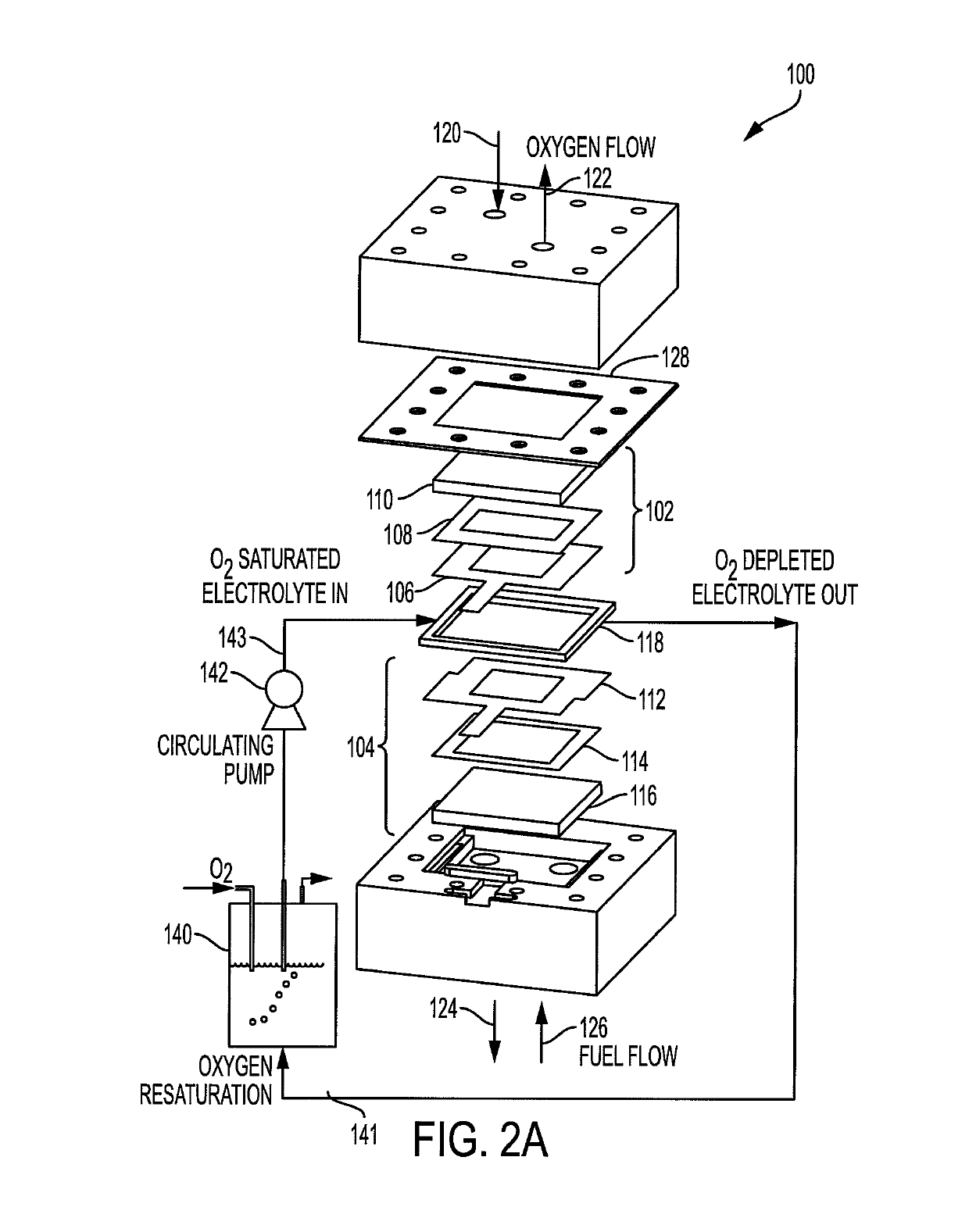

Flowing electrolyte fuel cell with improved performance and stability

ActiveUS20170187054A1Avoid mixingMaximize delivering capabilityElectrolyte stream managementCell electrodesPorositySystems design

A flowing electrolyte fuel cell system design (DHCFC-Flow) is provided. The use of a flowing oxygen-saturated electrolyte in a fuel cell offers a significant enhancement in the cell performance characteristics. The mass transfer and reaction kinetics of the superoxide / peroxide / oxide ion (mobile oxygen ion species) in the fuel cell are enhanced by recirculating an oxidizing gas-saturated electrolyte. Recirculating oxygen-saturated electrolyte through a liquid channel enhances the maximal current observed in a fuel cell. The use of a oxygen saturated electrolyte ensures that the reaction kinetics of the oxygen reduction reaction are fast and the use of convection ameliorates concentration gradients and the diffusion-limited maximum current density. The superoxide ion is generated in situ by the reduction of the oxygen dissolved in the gaseous electrolyte. Also, a dual porosity membrane allows the uniform flow of fuel (e.g., methane) on the fuel side, without allowing phase mixing. The capillary pressure for liquid intrusion into the gas phase and vice versa is quite large, estimated to be 1-10 psi. This makes it easier to control the fluctuations in gas / liquid velocity which might otherwise lead to phase mixing and the loss of fuel cell performance. In one variation, a dual-porosity membrane structure is incorporated in the system to allow uniform flow of fuel and prevent mixing of fuel with a liquid electrolyte.

Owner:XEROX CORP

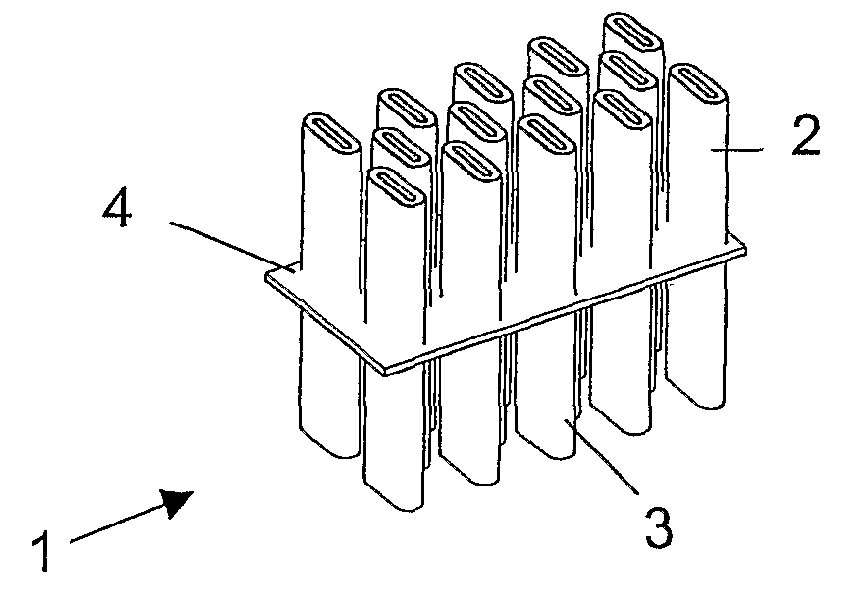

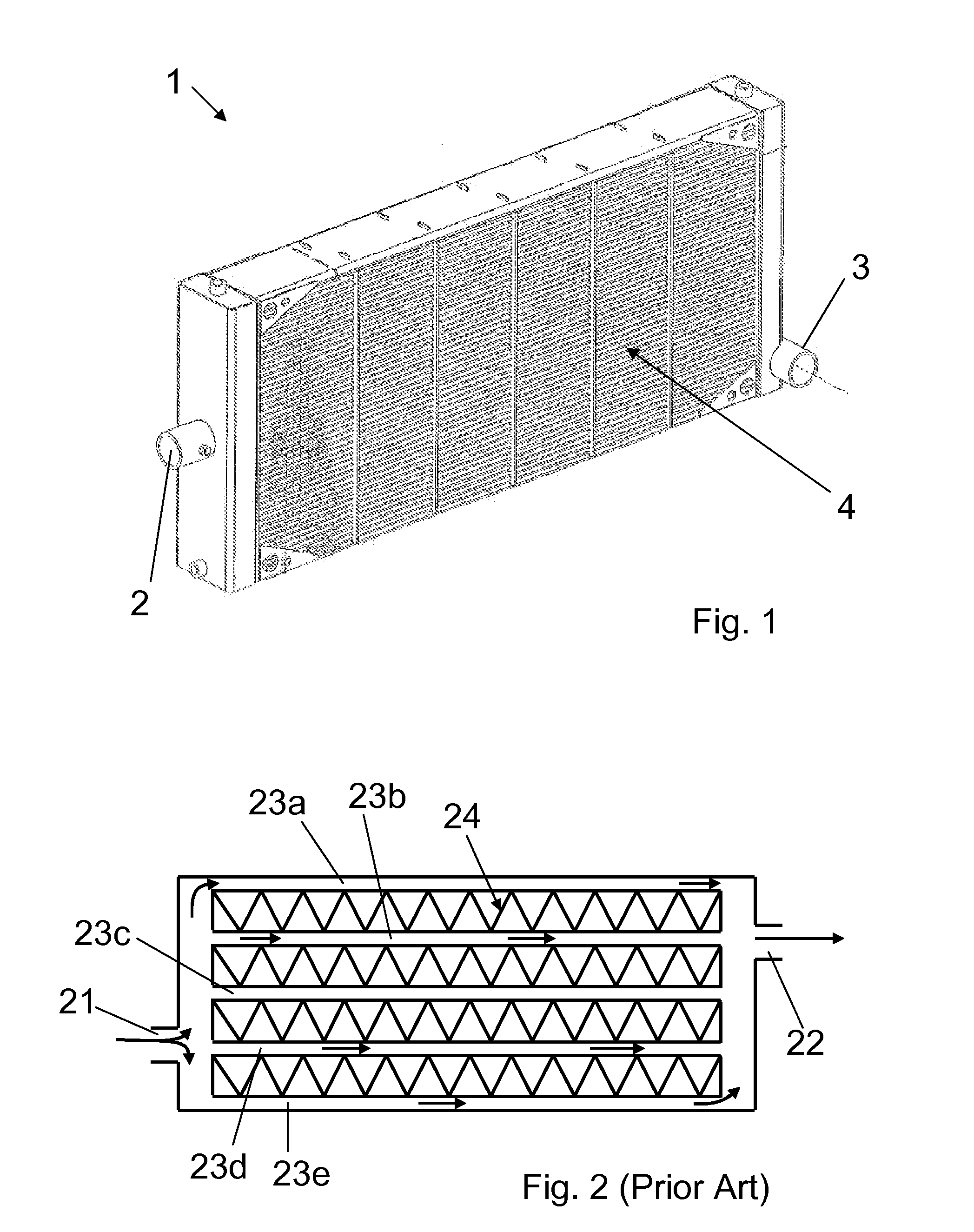

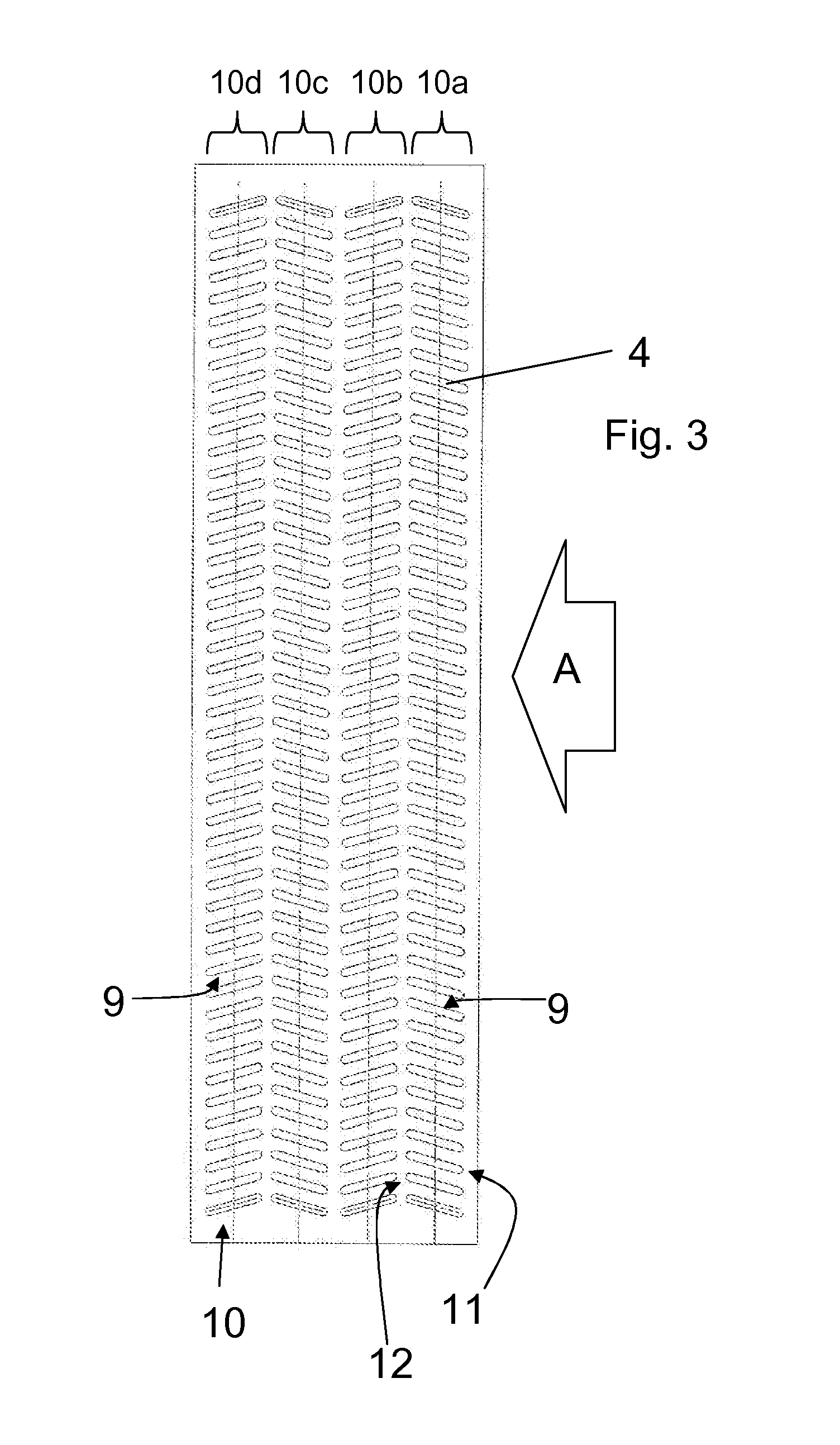

Heat exchanger

InactiveUS20110226452A1Optimizing Flow PathsImprove efficiencyHeat exhanger conduitsCorrosion preventionHeat flowPlate heat exchanger

A heat exchanger comprising a plurality of heat transfer tubes adapted to transport heat transfer fluid from an inlet to an outlet, the heat transfer tubes comprising elongate hollow members adapted to receive the heat transfer fluid therein, the heat exchanger adapted to receive a flow of heat removal fluid flow between the heat transfer tubes, wherein the heat transfer tubes are arranged such that the heat removal fluid is caused to follow a substantially undulating path through the heat exchanger.

Owner:ROCORE UK

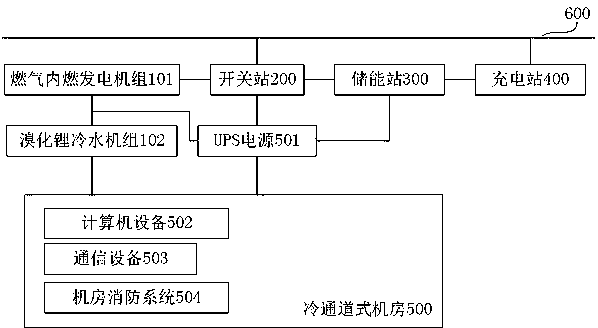

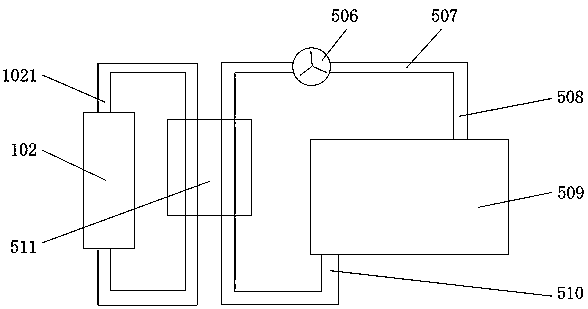

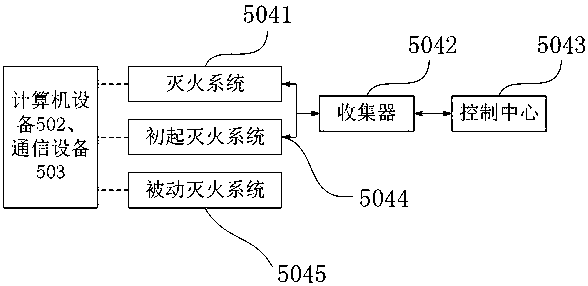

Intelligent energy system fusion station based on ubiquitous power Internet of Things

InactiveCN111093346AImprove power supply stabilityLow costData processing applicationsClimate change adaptationData centerLithium bromide

The invention relates to the technical field of intelligent power grids and particularly relates to an intelligent energy system fusion station based on the ubiquitous electric power Internet of Things. The system comprises an energy station, an energy storage station, a data center, a charging station and a switching station, wherein the data center comprises a cold channel type machine room, computer equipment, communication equipment, a machine room fire extinguishing system and a UPS power supply, wherein the computer equipment and the communication equipment are both deployed in the coldchannel type machine room and are powered by the UPS power supply, the UPS power supply is connected with the mains supply, the computer equipment is connected with the communication equipment, the machine room fire extinguishing system is arranged in the cold channel type machine room, a fire-fighting state of the computer equipment is monitored, and fire extinguishing is performed when a fire occurs, the energy station comprises a fuel gas internal combustion generator set and a lithium bromide water chilling unit, the energy storage station comprises a high-voltage cascade energy storage device, and the charging station comprises an intelligent power supply and a plurality of charging piles. The system is advantaged in that all the stations are coordinated and matched, so construction cost is saved, and the economic benefits are improved.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER CO LTD JIAXING POWER SUPPLY CO

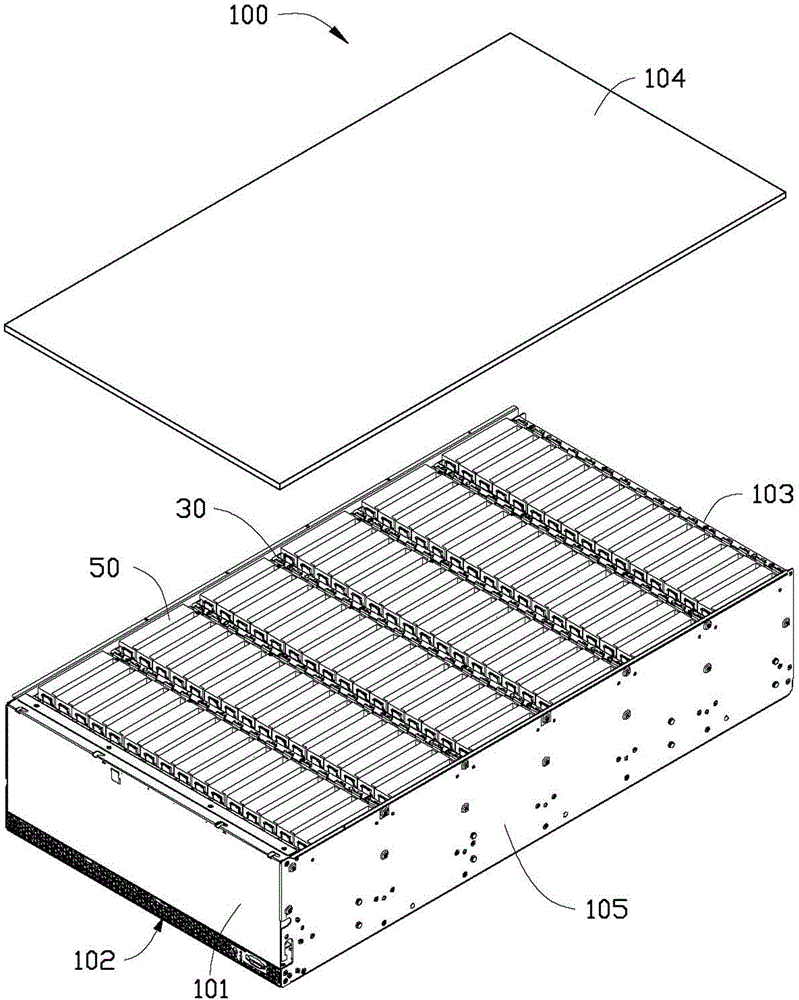

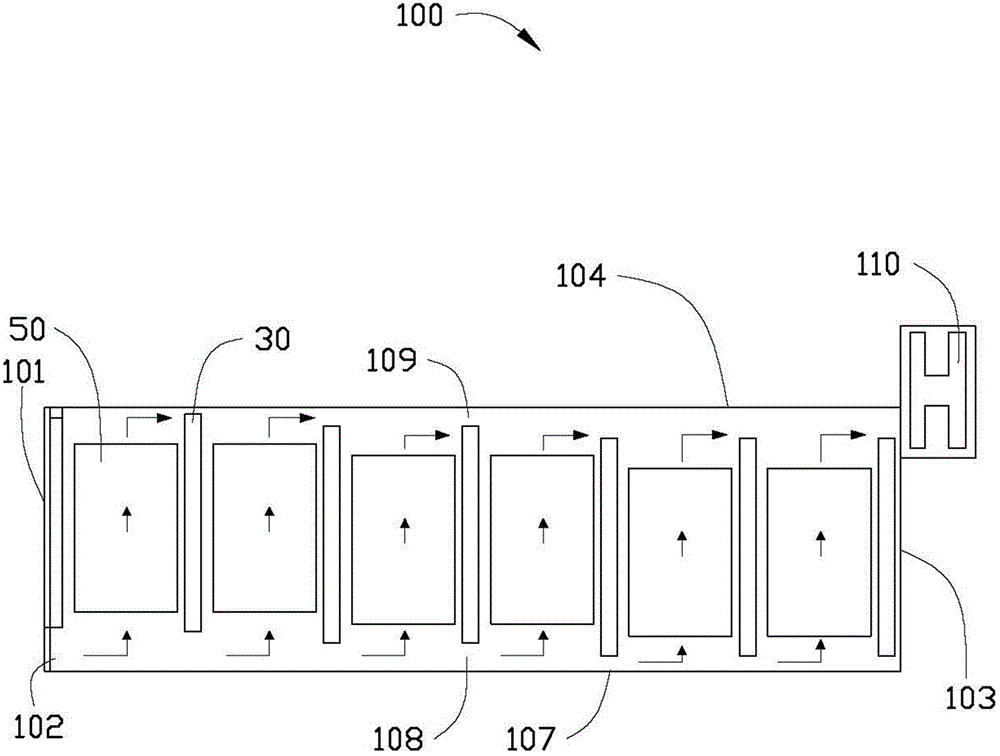

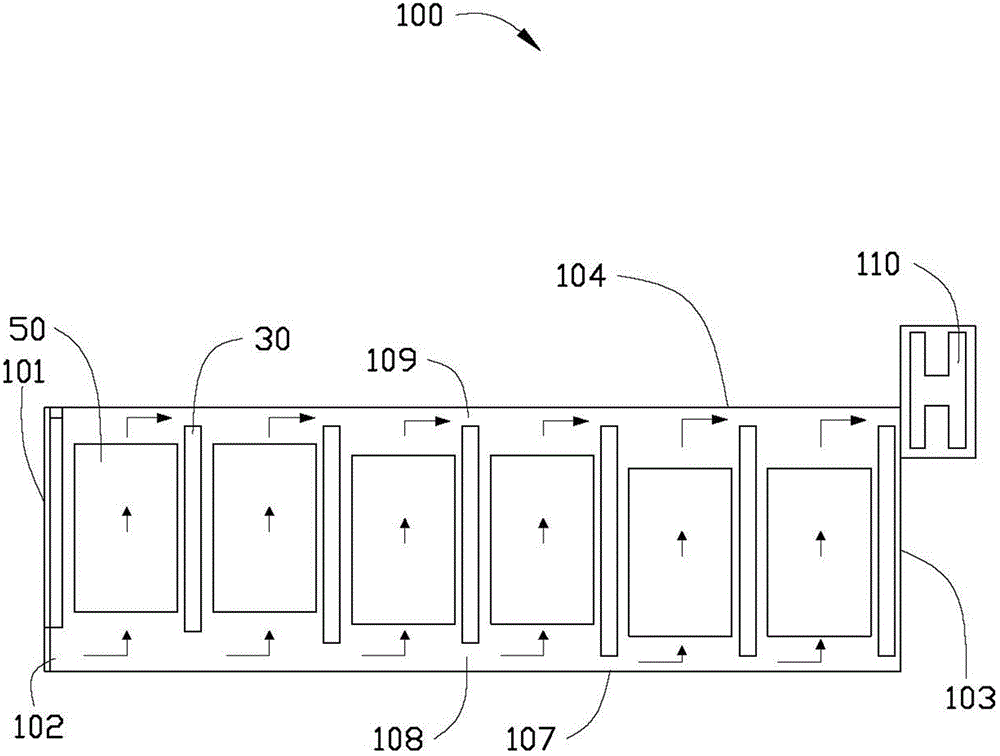

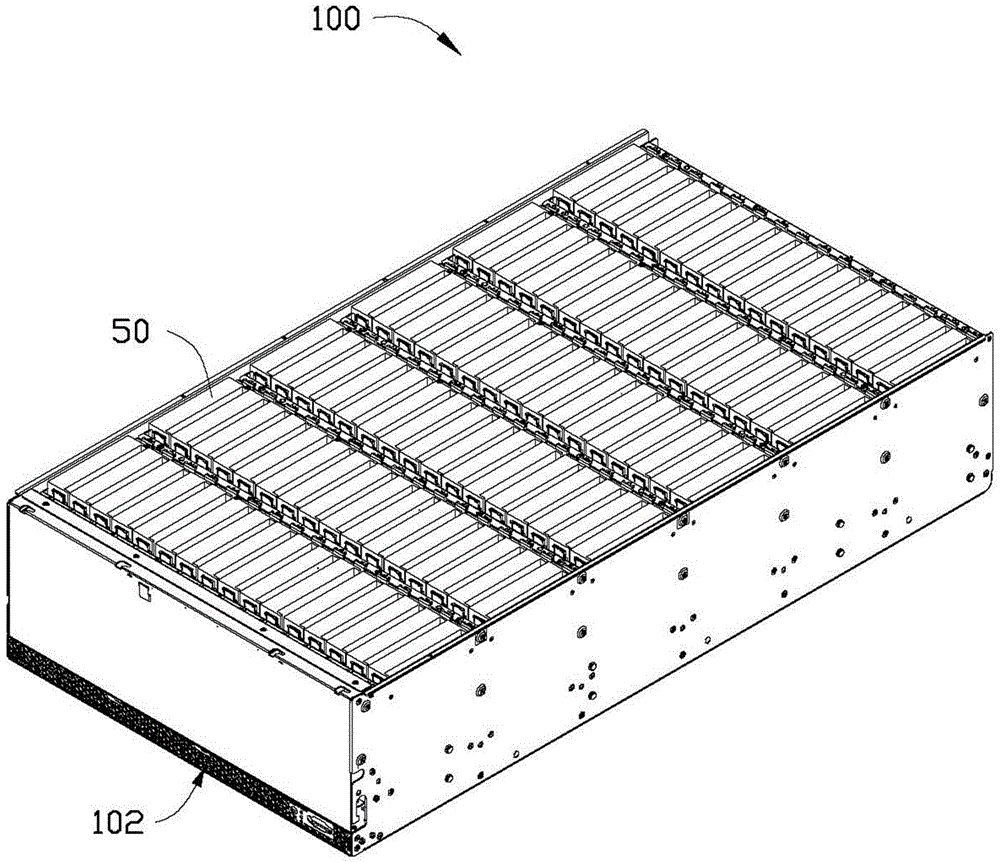

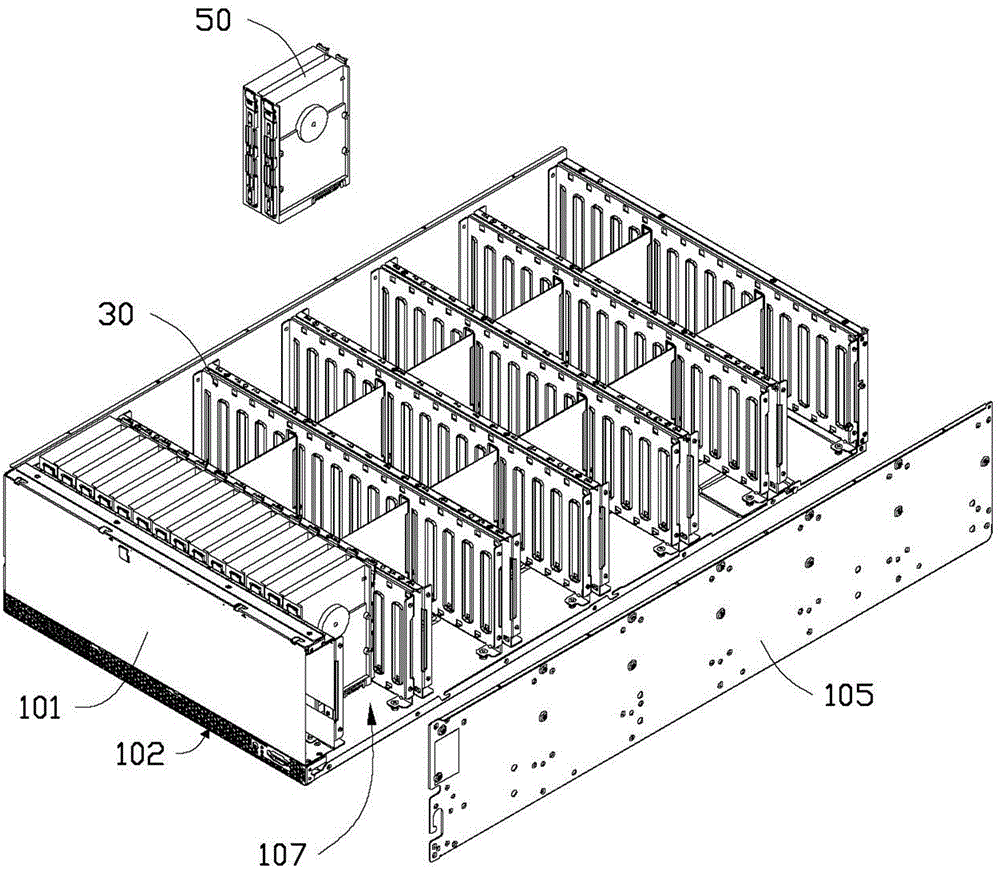

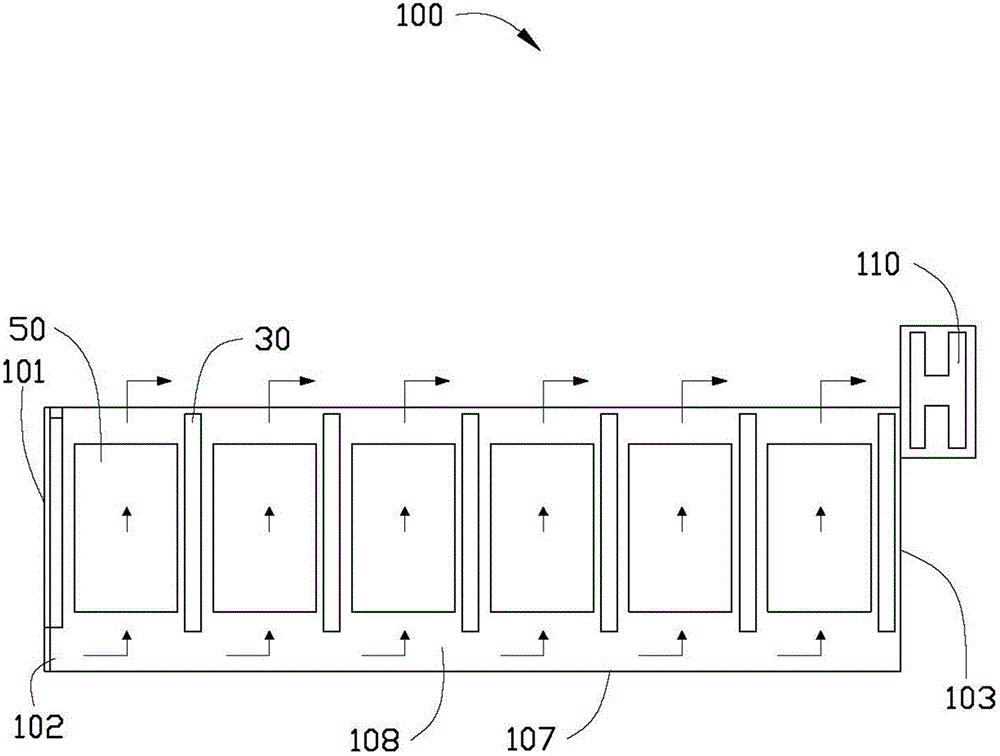

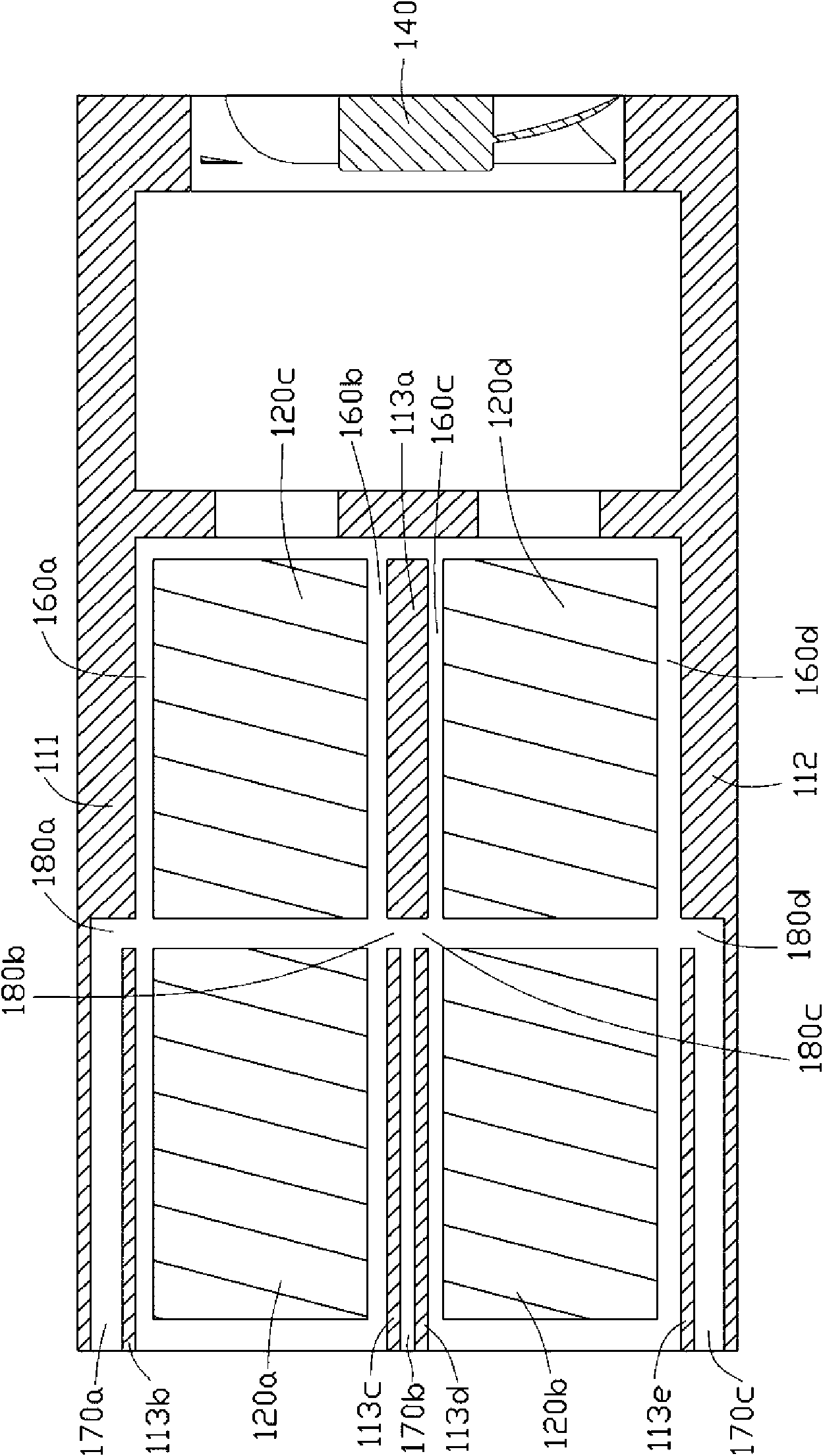

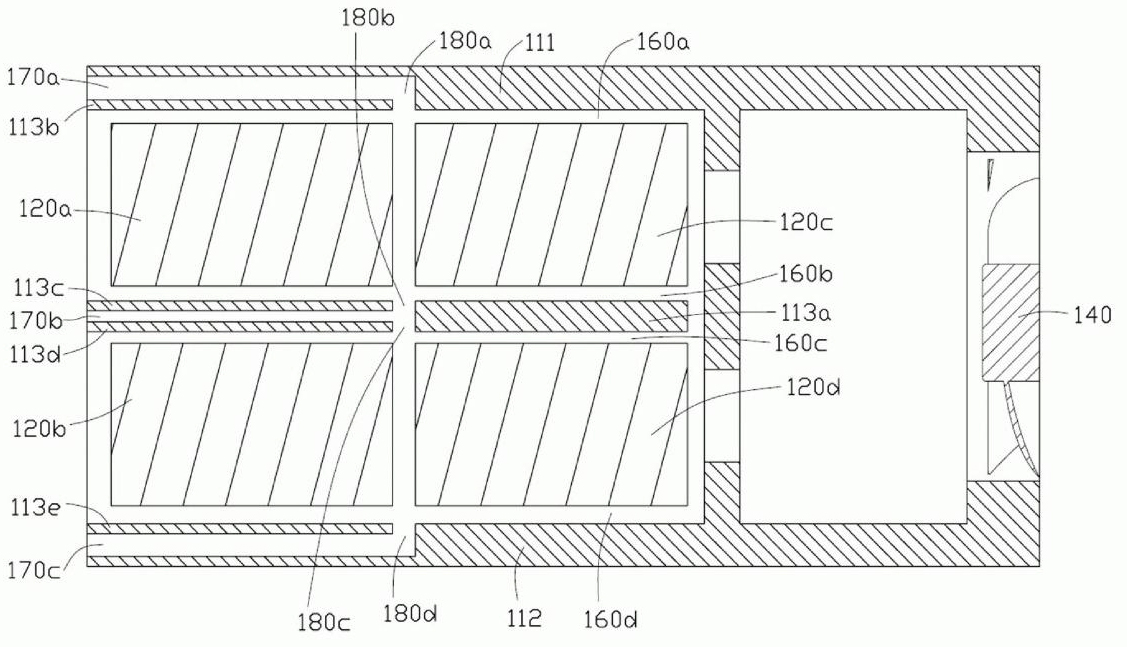

Electronic device

InactiveCN104423512AImprove cooling effectOptimizing Flow PathsDigital data processing detailsAirflowElectronic modules

The invention discloses an electronic device. The electronic device comprises a case and a plurality of groups of electronic modules, wherein the case comprises a front plate, a rear plate, a top plate, two side plates, a bottom plate and a plurality of partitioning plates; the partitioning plates are arranged between the front plate and the rear plate in parallel and at intervals and are respectively and vertically connected with the two side plates; the electronic modules are respectively contained between two adjacent partitioning plates; an air inlet is arranged in the bottom part of the front plate; an interval is formed between the bottom end of each partitioning plate and the bottom plate; an interval is formed between the top end of each partitioning plate and the top plate; at least one of the top end of each partitioning plate or the bottom end of each partitioning plate is decreased in a stepped manner from front to rear; airflow flows upwards from the air inlet and the interval between the bottom end of each partitioning plate and the bottom plate, flows through the electronic module between two adjacent partitioning plates and then flows out from the rear plate. The electronic device disclosed by the invention has the advantages that an independent radiating channel is formed between every two adjacent partitioning plates, so that the flowing path of the airflow is improved; and the partitioning plates are arranged in a stepped manner, so that the radiating effect of the electronic device is improved.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

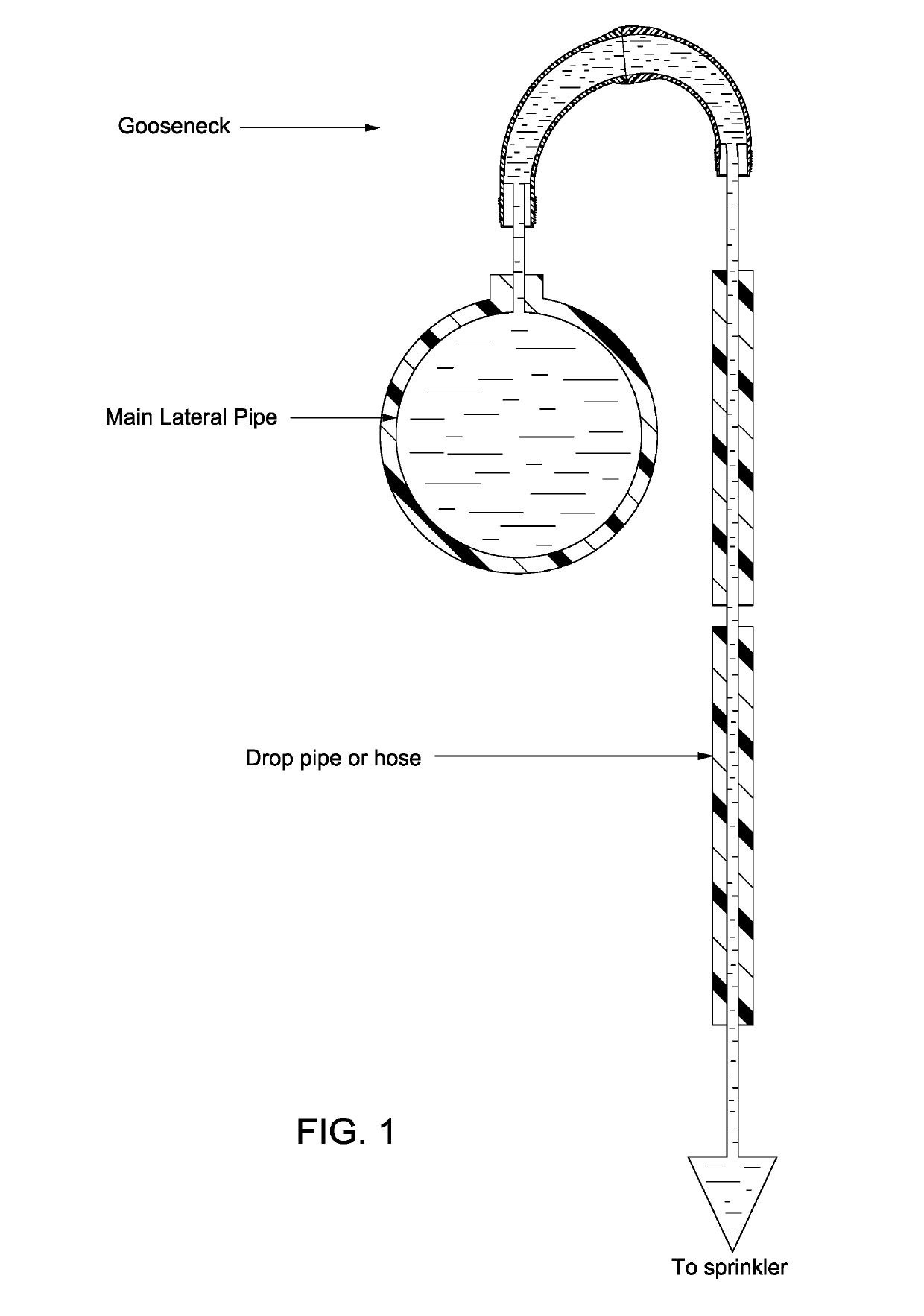

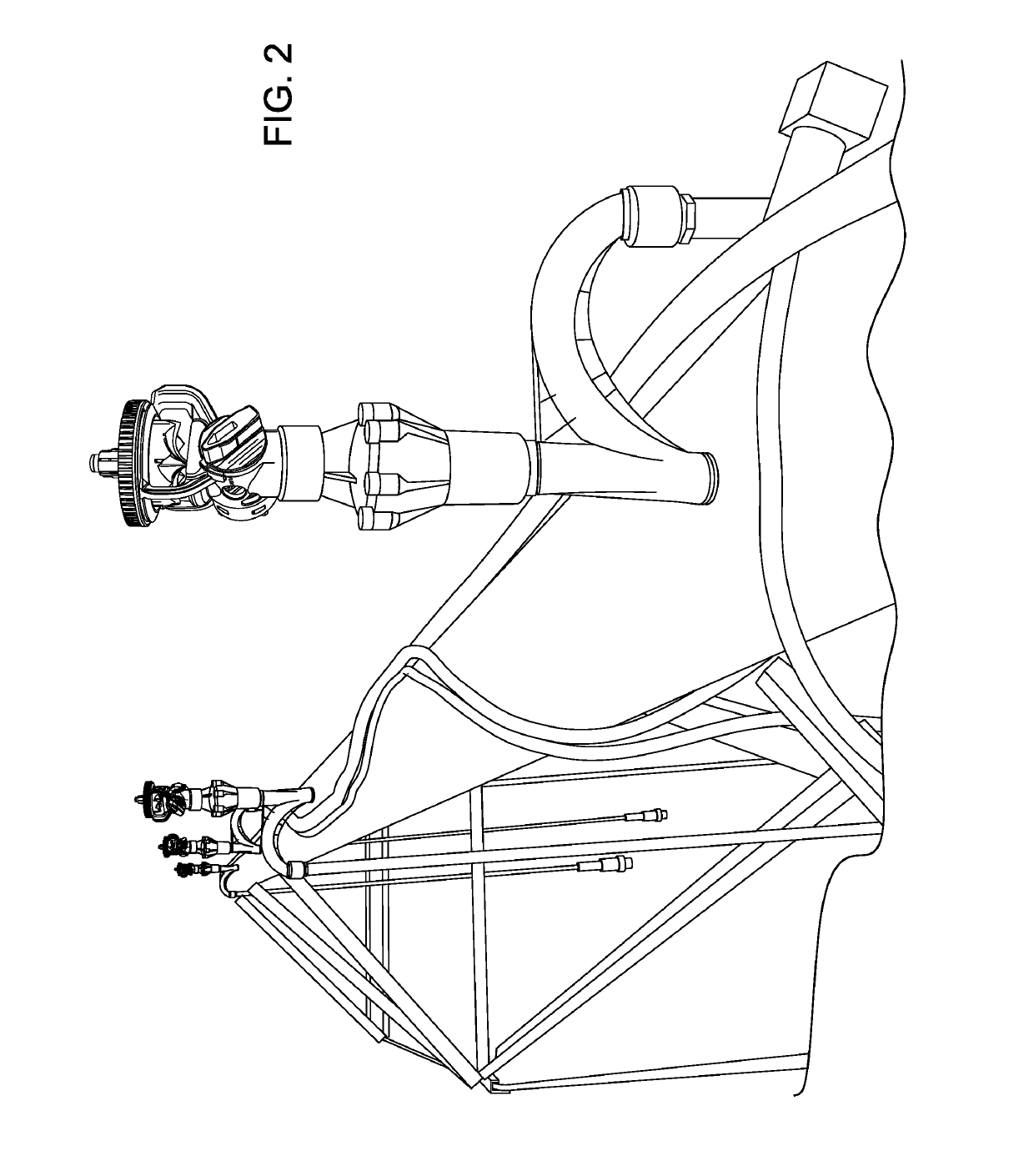

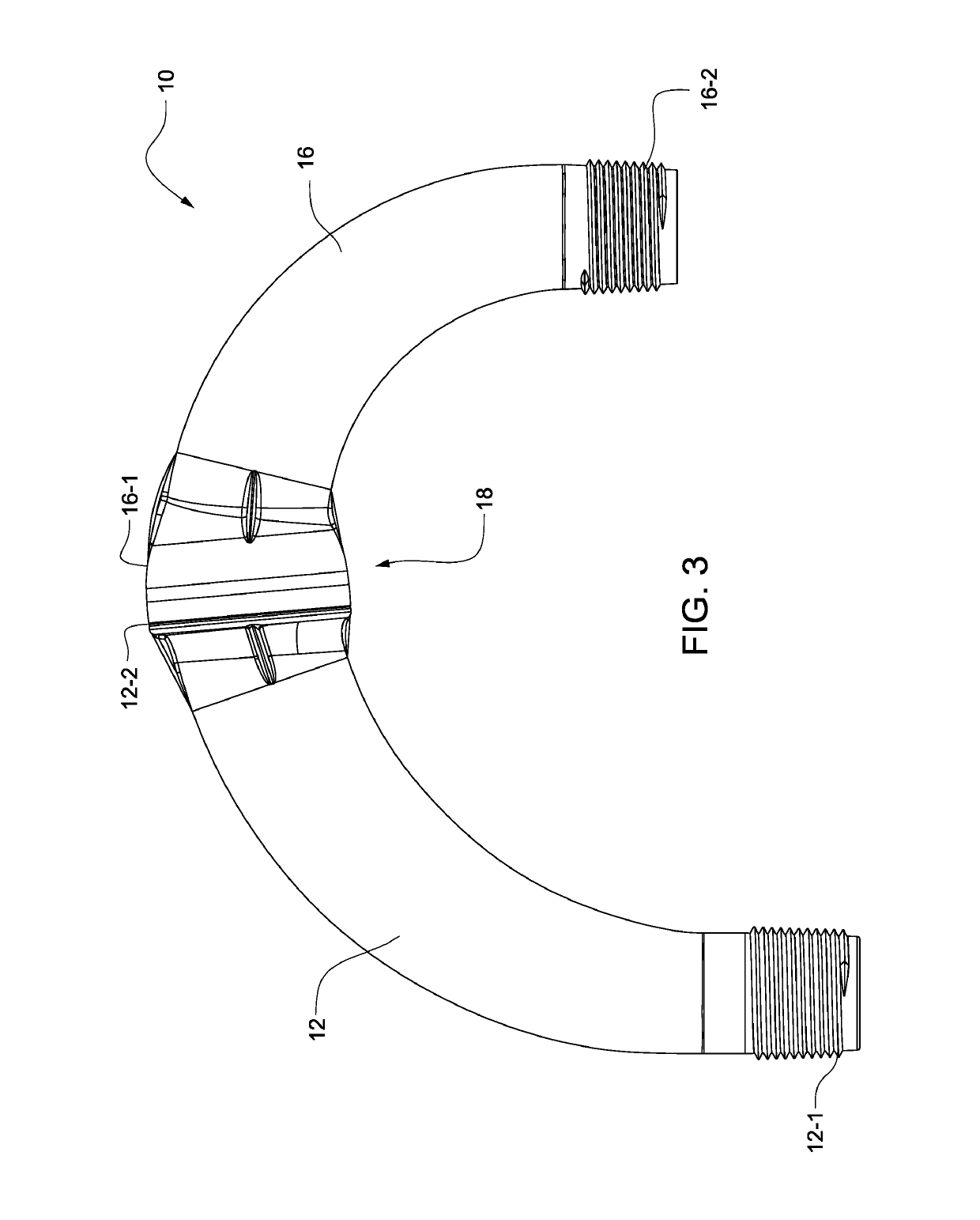

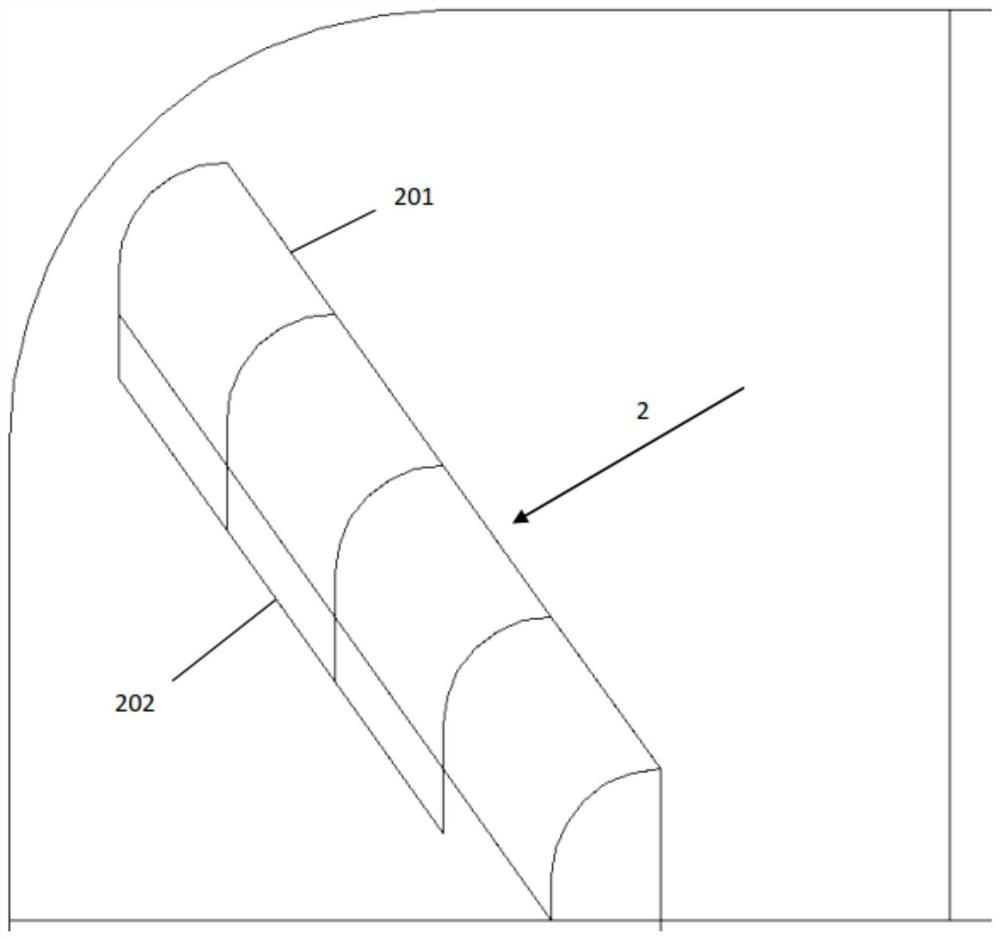

Center pivot irrigation gooseneck with varying cross-sectional diameters

ActiveUS20190154181A1Reduce pressure lossOptimize flow pathPipe supportsWatering devicesEngineeringCenter pivot irrigation

A gooseneck pipe includes a first pipe half having a first radiused centerline curve, and a second pipe half fixed to the first pipe half and having a second radiused centerline curve. The first and second pipe halves define a flow path. Cross-sectional diameters of the first and second pipe halves vary along the flow path. The varying diameters of the first and second pipe halves serve to mitigate pressure losses due in part to Dean vortices or secondary flow patterns in the flow path when a fluid is turned in the gooseneck pipe.

Owner:NELSON IRRIGATION

Electronic device

InactiveCN104423506AOptimizing Flow PathsImprove cooling effectDigital data processing detailsCooling/ventilation/heating modificationsEngineeringElectronic modules

An electronic device comprises a chassis, a plurality of separation plates and a plurality of electronic modules; the plurality of separation plates are separately arranged in the chassis in a straddled mode; every electronic module is arranged between the two corresponding adjacent separation plates; the chassis comprises a front plate, a rear plate, two lateral plates and a base plate; the separation plates are separately arranged between the front plate and the rear plate in a parallel mode and perpendicularly connected with the two lateral plates; the bottom of the front plate is provided with an air inlet; a gap is formed between the bottom of every separation plate and the base plate; the air flow enters the chassis from the air inlet and flows between every two adjacent separation plates through the gap formed at the bottom of every separation plate to perform heat dissipation on the electronic module which is arranged between the two adjacent separation plates and the air flow after heat dissipation passes above the electronic module to flow out of the rear plate. According to the electronic device, a heat dissipation channel is formed between every two adjacent separation plates and accordingly the flow path of the air flow is improved, the division on the air flow is implemented, and the heat dissipation effect of the electronic device is improved.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

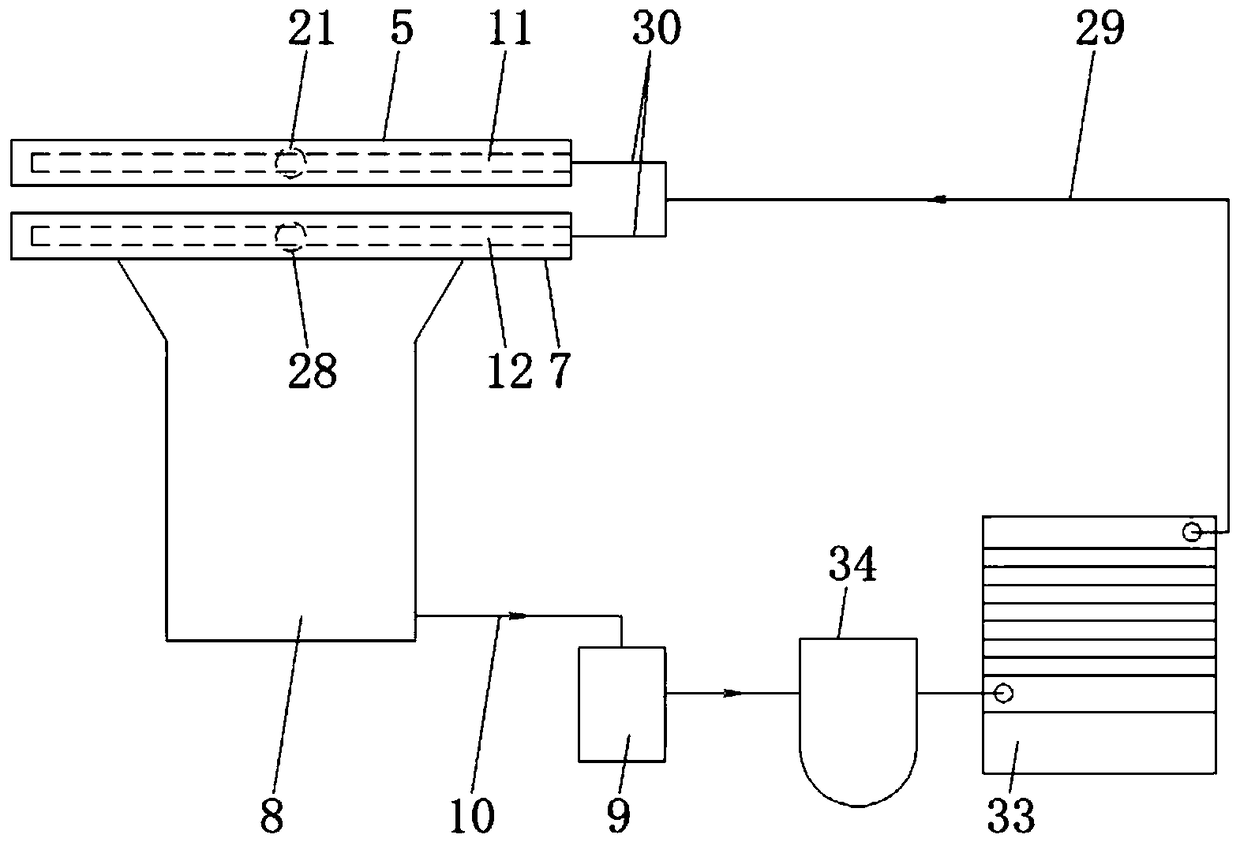

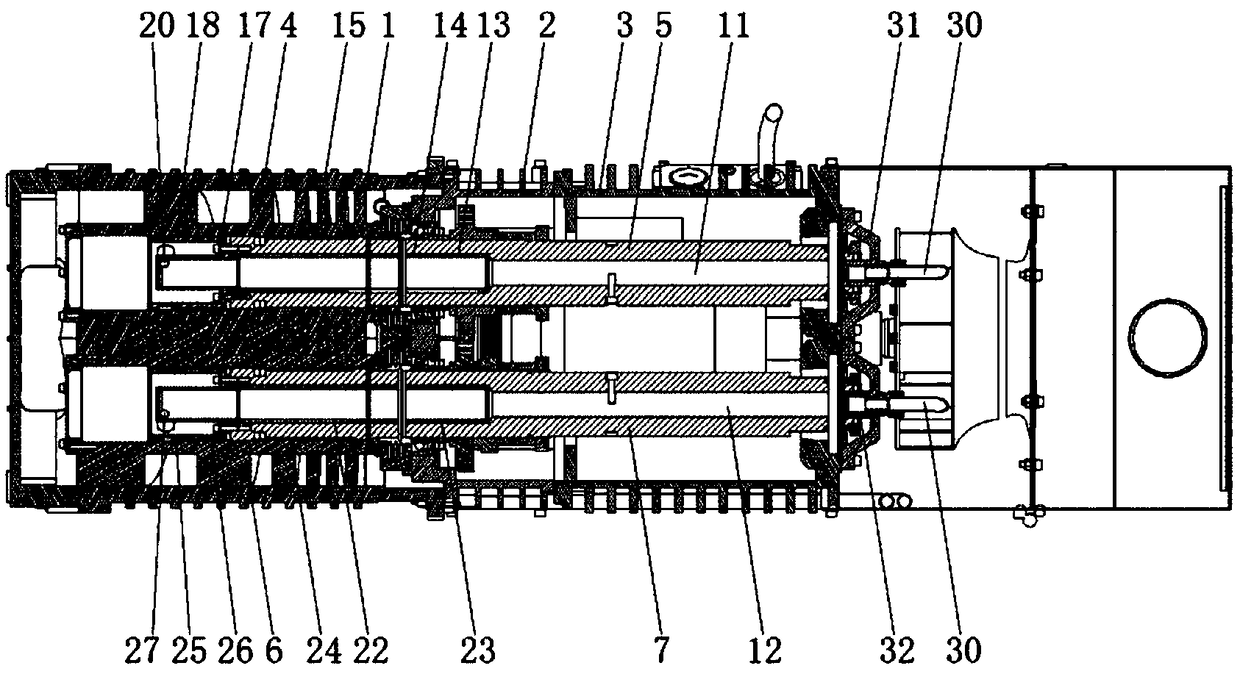

Heat dissipation system of dry screw vacuum pump

PendingCN108869295AExtended service lifeOptimizing Flow PathsRotary piston pumpsRotary piston liquid enginesPulp and paper industryVacuum pump

The invention provides a heat dissipation system of a dry screw vacuum pump, belongs to the technical field of vacuum pumps and solves the problems that the heat generated when screws in the existingdry screw vacuum pump rotate cannot be dissipated and the heat dissipation of the pump body is poor. The heat dissipation system of the dry screw vacuum pump comprises an oil tank, an oil pump and anoil pipe I used for connecting the oil tank with the oil pump, wherein a shaft hole I is formed in a screw I; a shaft hole II is formed in a screw II; an oil pipe component used for transporting oil liquid to the shaft hole I and the shaft II is arranged in the outlet of the oil pump; an oil returning component I is arranged on the screw I; an oil returning component II is arranged on the screw II. The heat dissipation system of the dry screw vacuum pump has the advantages of reasonable structure design and good heat dissipation effect.

Owner:CSIC CHONGQING INTELLIGENT EQUIP ENG DESIGN

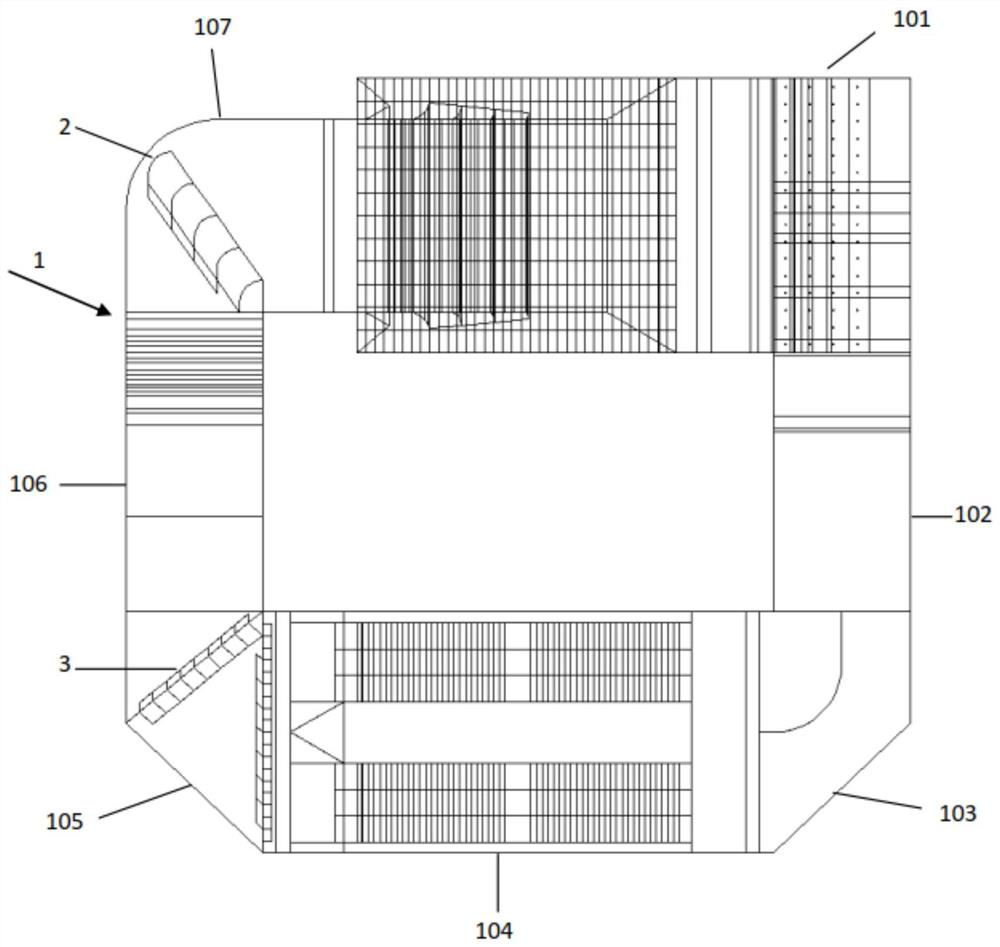

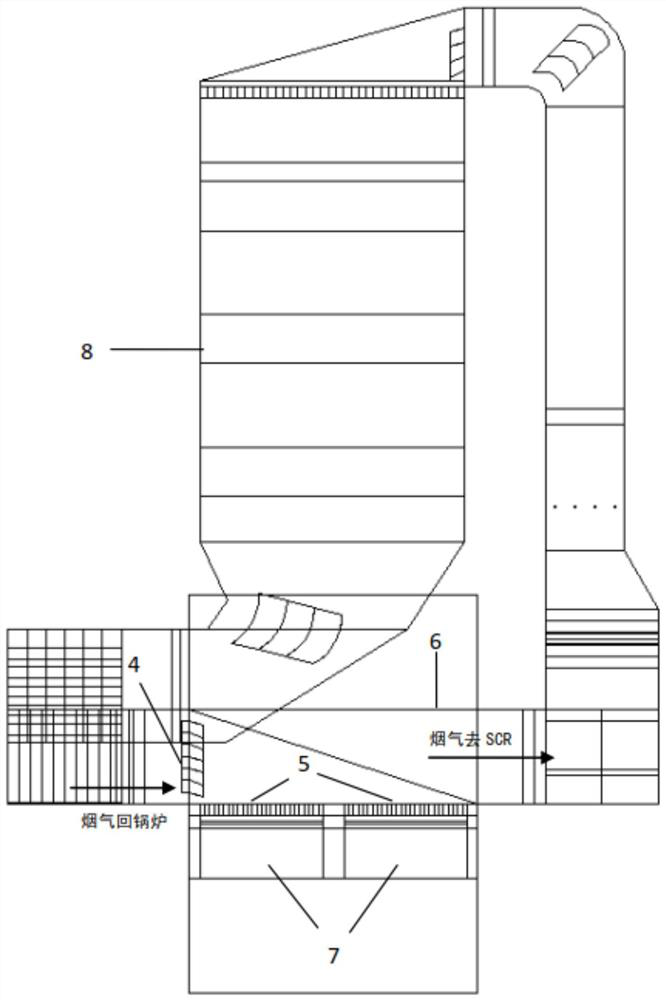

Flue gas flow velocity adjusting structure of SCR denitration device

PendingCN113566225ALow flow resistanceReduce flow lossGas treatmentDispersed particle separationFlueEngineering

The invention provides a flue gas flow velocity adjusting structure of an SCR denitration device, and aims to reduce the flue gas flow velocity deviation of a denitration outlet and uniformize the flue gas flow velocity of the outlet. The structure comprises a first group of flow guide plates, a second group of flow guide plates, a third group of flow guide plates and a group of flow equalizing plates; an SCR denitration flue comprises a first corner flue, a first straight pipe flue, a second corner flue, a third corner flue, a third straight pipe flue and a fourth corner flue; the first group of flow guide plates are arranged in the fourth corner flue; the second group of flow guide plates are arranged in the second corner flue; the third group of flow guide plates comprises a drainage part and a flow guide part which are uniformly arranged at intervals in the height direction of the fourth corner flue, the drainage part is parallel to the upper and lower surfaces of the fourth corner flue, and the flow guide part is parallel to the diagonal surface of a connecting flue; the group of flow equalizing plates comprises a plurality of flow equalizing plates which are arranged at intervals in the length direction of the gas inlet end of a low-temperature economizer, and the flow equalizing plates are vertically connected with the gas outlet end of the flue and are parallel to the cross section of the fourth corner flue.

Owner:XIAN THERMAL POWER RES INST CO LTD

Electronic device and heat radiating system thereof

ActiveCN101848625AOptimizing Flow PathsImprove cooling effectDigital data processing detailsCooling/ventilation/heating modificationsElectronic equipmentElectrical and Electronics engineering

Owner:HEBEI XINGLONG ELEVATORING EQUIP CO LTD

Flowing electrolyte fuel cell with improved performance and stability

InactiveUS10446861B2Avoid mixingMaximize delivering capabilityElectrolyte stream managementCell electrodesPorositySystems design

Owner:XEROX CORP

Automatic water adding humidification tank for respirator heating humidifier

PendingCN110496289AImprove the humidification effectConstant water volumeRespiratorsMedical devicesRespiratorWater level rise

The invention relates to an automatic water adding humidification tank for a respirator heating humidifier. The automatic water adding humidification tank comprises a tank body, and a gas inlet and agas outlet are formed in the top end of the tank body; a fixing mechanism is arranged in the tank body; a guide disc and a floating ball are sequentially hinged to the fixing mechanism; a sealing valve is arranged on the guide disc; a transmission rod is arranged between the floating ball and the guide disc; a water inlet is also formed in the position, over the sealing valve, on the tank body; and the water inlet is matched with the sealing valve. The automatic water adding humidification tank has the advantages that two-time sealing can be carried out, that is, when the water line reaches the floating ball, the guide disc and the floating ball act jointly for the first time to seal the water inlet, when the water level rises to the upper end of the floating ball due to other external reasons, the water inlet can further be sealed for the second time through the guide disc, and the double-sealing function is achieved; and in addition, the guide disc can provide an optimized gas flow direction for gas flowing through the humidification tank, and the function of enhancing the gas humidifying effect is achieved.

Owner:CHONGQING MEDICAL UNIVERSITY

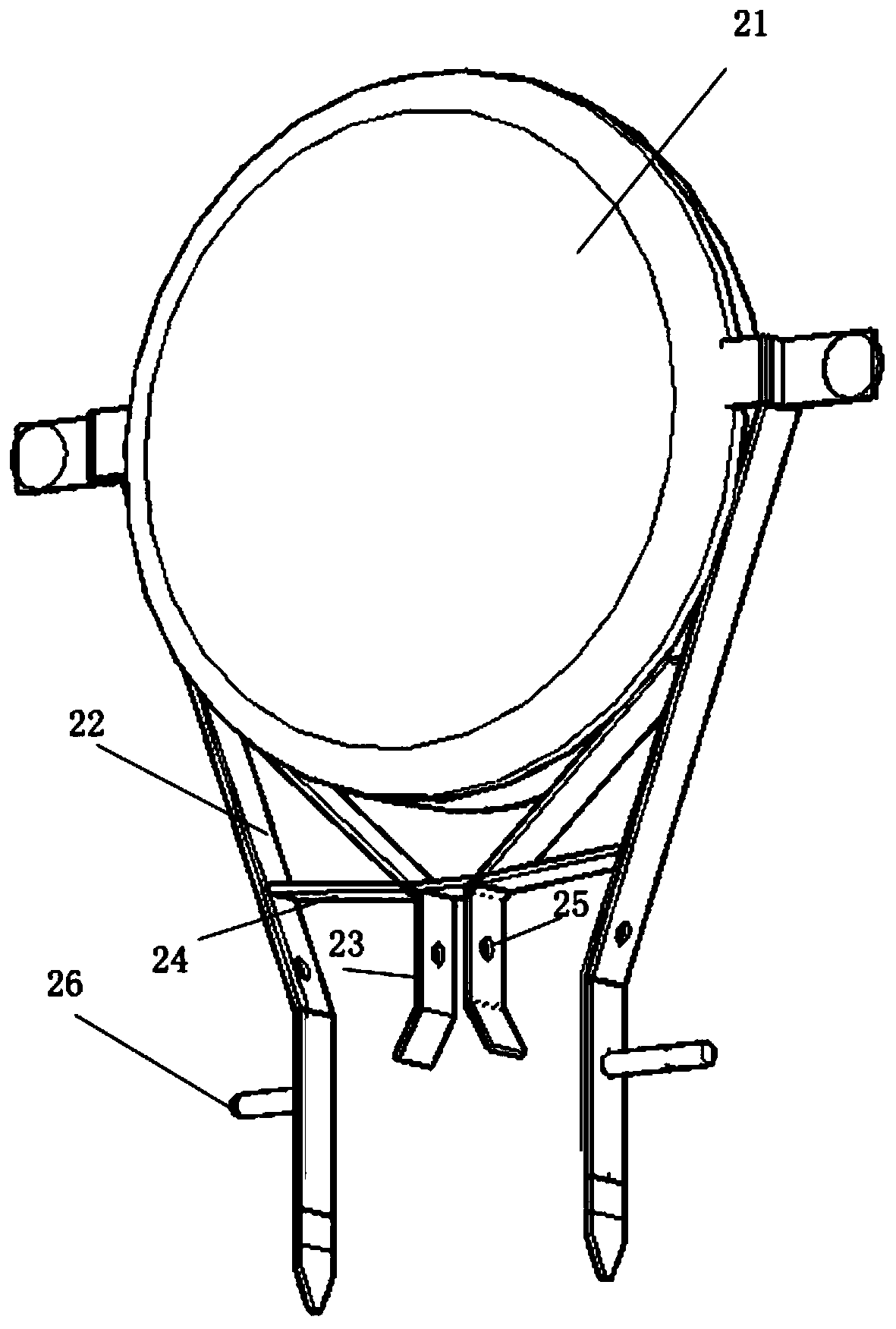

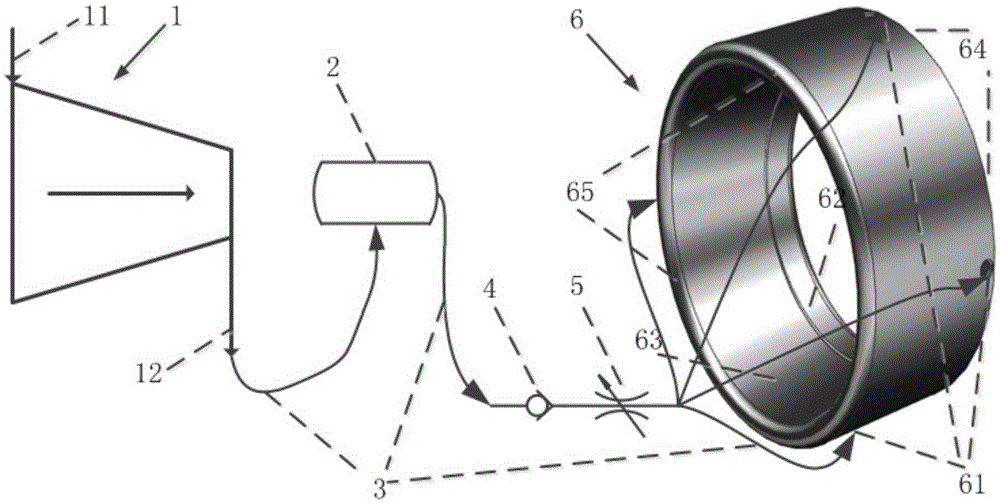

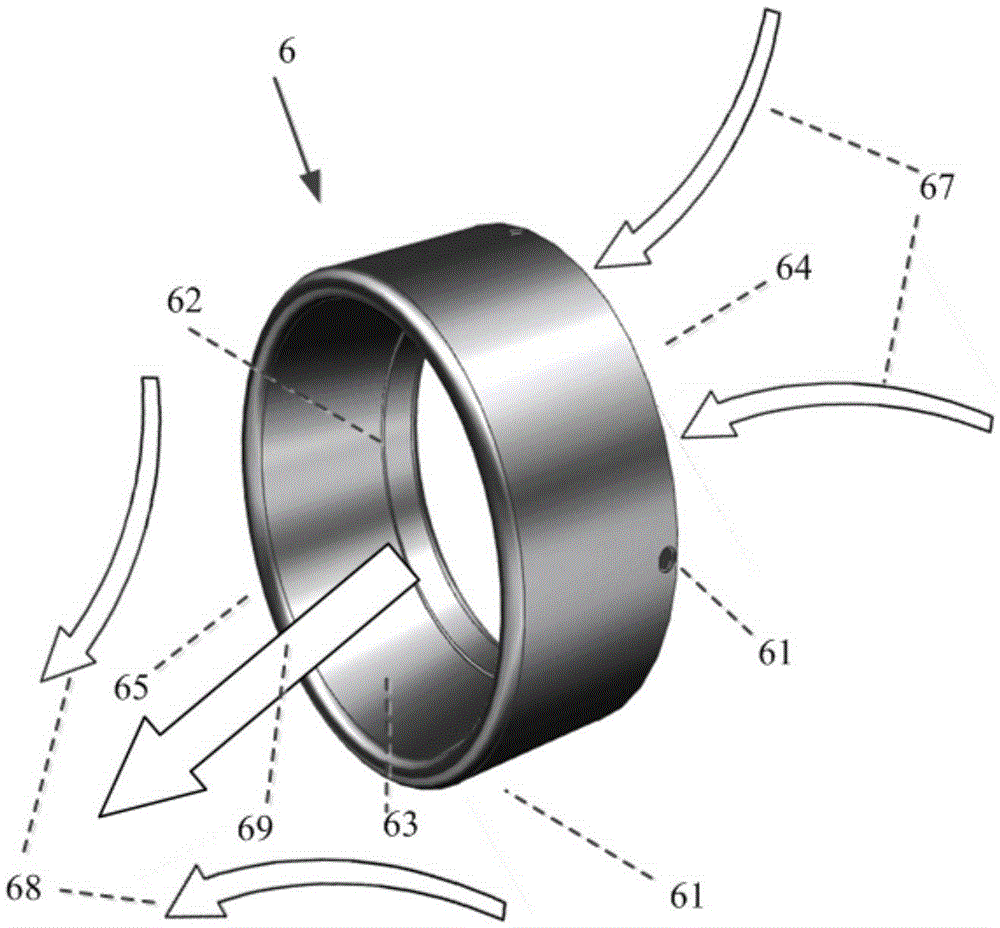

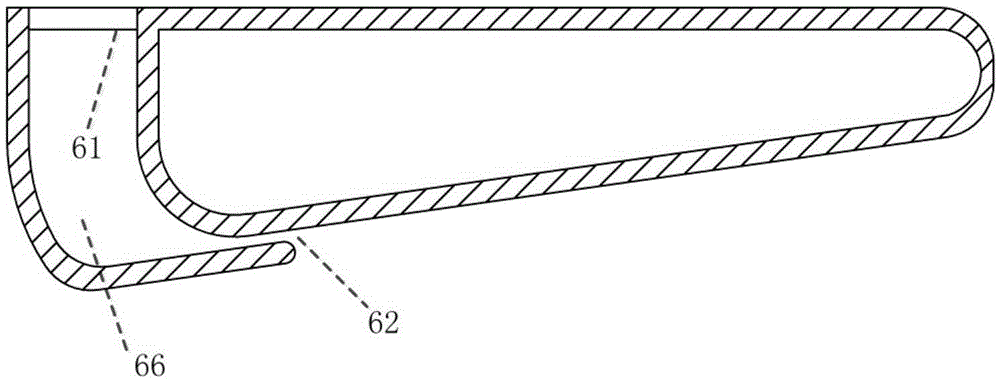

Remote-delivery bladeless ventilating system used in gunpowder and explosive field

InactiveCN105275892AGood for frequent cleaningAvoid Explosion HazardsJet pumpsPump installationsImpellerEngineering

The invention discloses a remote-delivery bladeless ventilating system used in the gunpowder and explosive field. By the adoption of the remote-delivery bladeless ventilating system used in the gunpowder and explosive field, the problem that explosion risks are caused easily in an existing ventilating system due to friction and collision between gunpowder and explosive dust or gunpowder and explosive particles at a rotary bearing and an impeller in the gunpowder and explosive field is solved. The remote-delivery bladeless ventilating system comprises an air source (1), an air storage tank (2), an air pipe (3), a one-way valve (4), a throttling valve (5) and a ventilating frame (6). The air source (1), the air storage tank (2), the one-way valve (4), the throttling valve (5) and the ventilating frame (6) are connected in sequence through the air pipe (3). The air source (1) and the air storage tank (2) are installed in safe places in a gunpowder-free and explosive-free environment. The ventilating frame (6) is installed in a dangerous place in a gunpowder and explosive environment. The remote-delivery bladeless ventilating system is simple in structure and low in energy consumption, and friction and collision between the gunpowder and explosive powder or particles and movement components in the ventilating system in the dangerous place in the gunpowder and explosive field can be avoided.

Owner:XIAN MODERN CHEM RES INST

Pipe joint and connecting method for inducing cold flow through axial resultant force of asymmetric annular grooves

ActiveCN113669520AOptimized sectionReduce stress concentrationNon-disconnectible pipe-jointsEngineeringPipe

The invention discloses a pipe joint and method for inducing cold flow through axial resultant force of asymmetric annular grooves, and relates to the technical field of pipe joints. The pipe joint comprises a pipe joint body, an inner hole is formed in the pipe joint body, the end of a guide pipe can enter the inner hole, and a plurality of annular grooves are formed in the inner hole; the annular grooves comprise the asymmetric annular grooves, the asymmetric annular grooves comprise groove bottoms, one sides of the groove bottoms are connected with first groove tops through first groove walls, the other sides of the groove bottoms are connected with second groove tops through second groove walls, included angles between the first groove walls and the axial direction of the inner hole and between the second groove walls and the axial direction of the inner hole are different, asymmetric arrangement is formed, axial pushing resultant force is formed for plastic deformation cold flow, cold flow is induced to generate directional flow, so that the radial extrusion load peak value is reduced, the geometric necessary dislocation density in the cold flow can be fully improved, a gradient high-strength nano microstructure is formed, and the connection reliability can be greatly improved. The connecting manufacturability of the pipe joint and the metal guide pipe can be improved, the connecting strength of the pipe joint is greatly improved, and the fatigue life of the pipe joint is greatly prolonged.

Owner:西安卓锐航空科技有限公司 +1

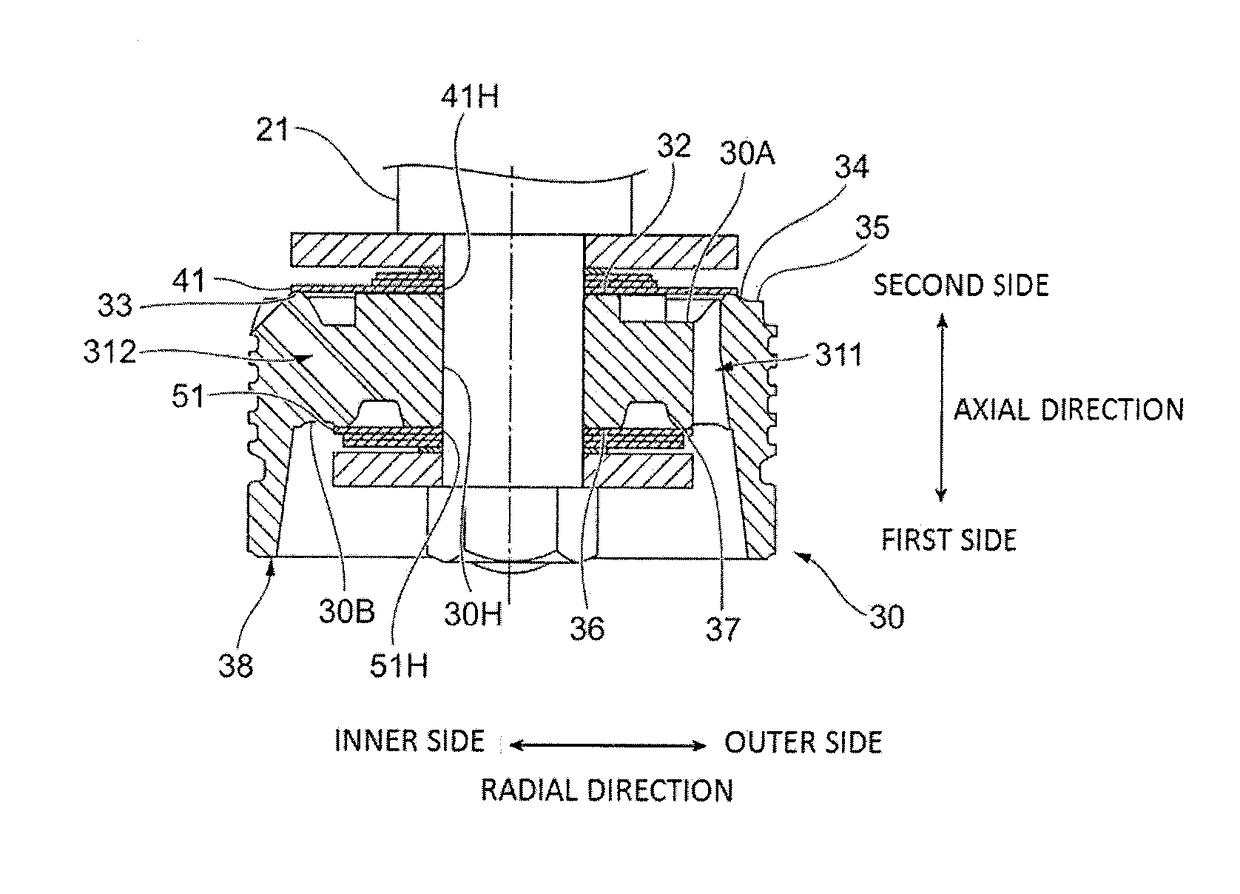

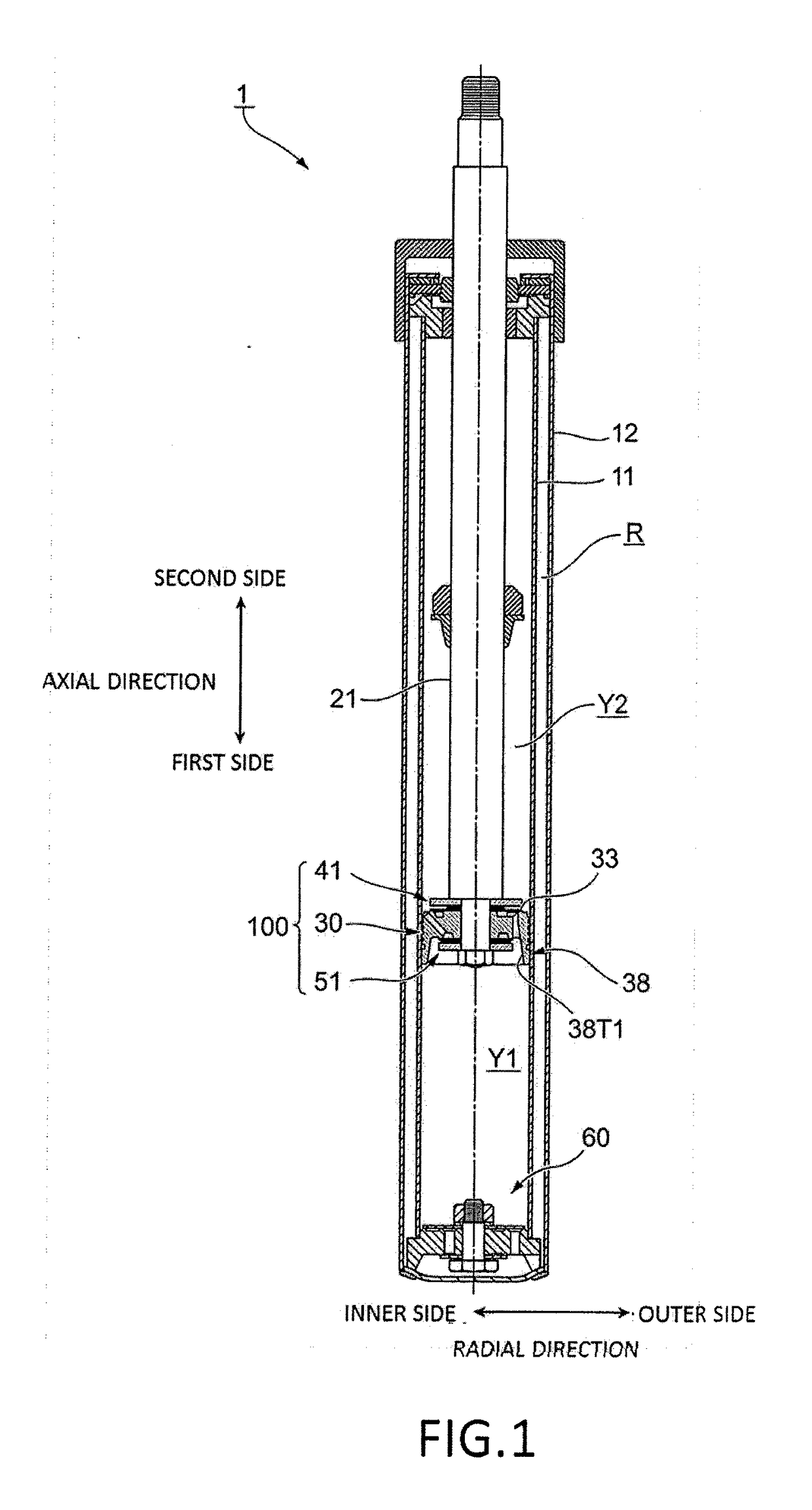

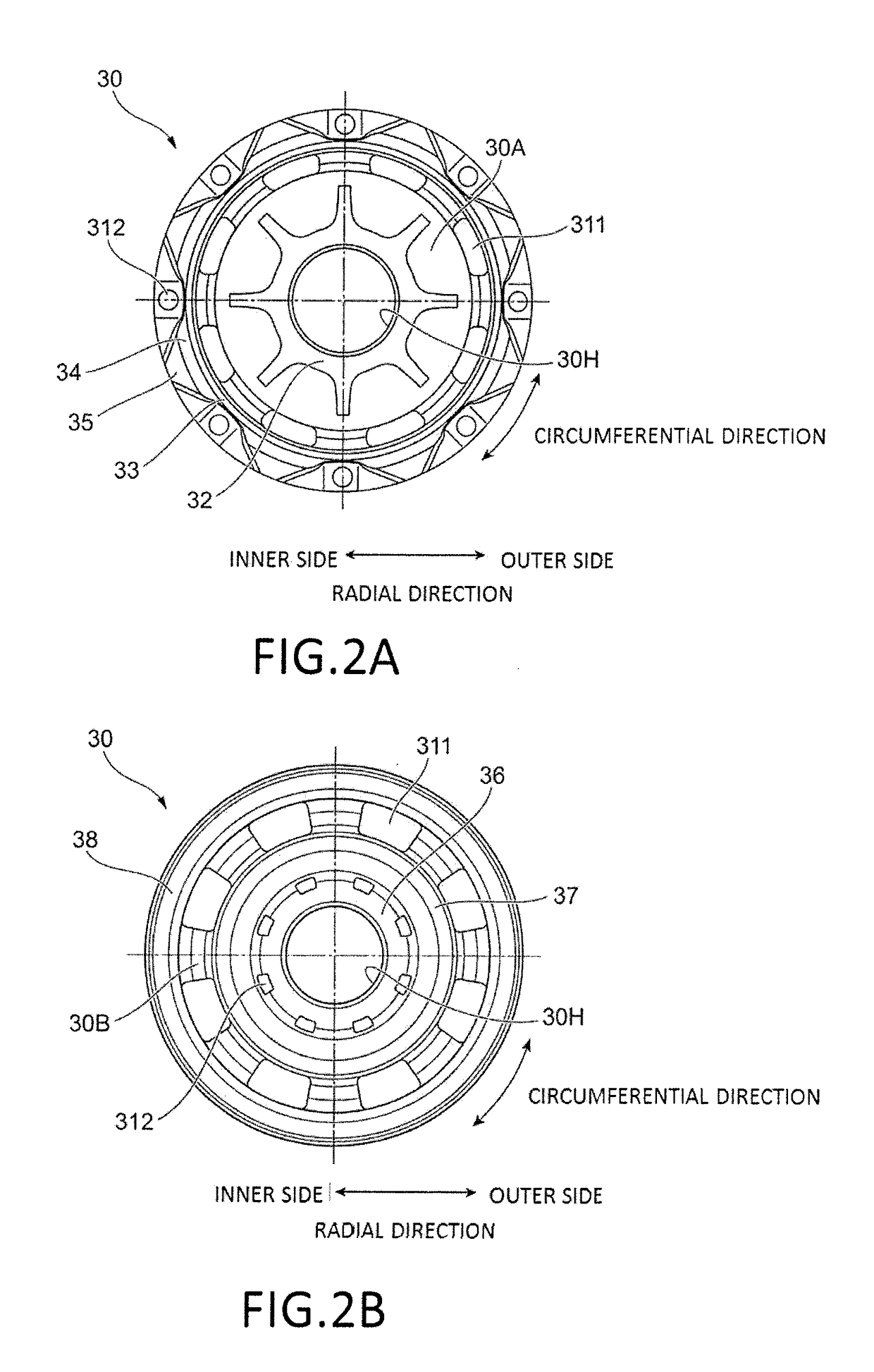

Pressure buffer device and flow path forming member

ActiveUS20170248188A1Optimizing Flow PathsEasy to manufactureSpringsShock absorbersEngineeringMechanical engineering

Owner:HITACHI ASTEMO LTD

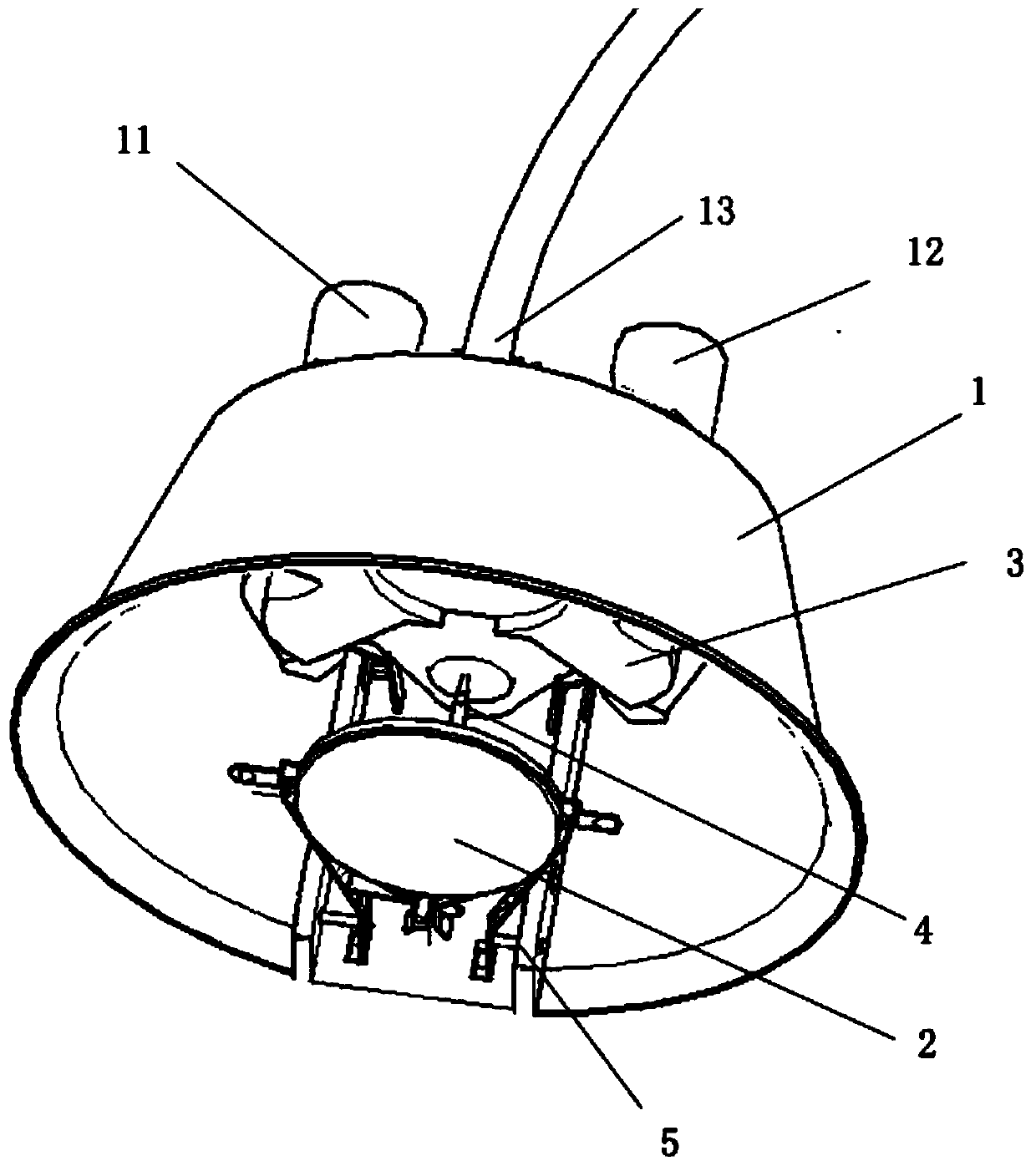

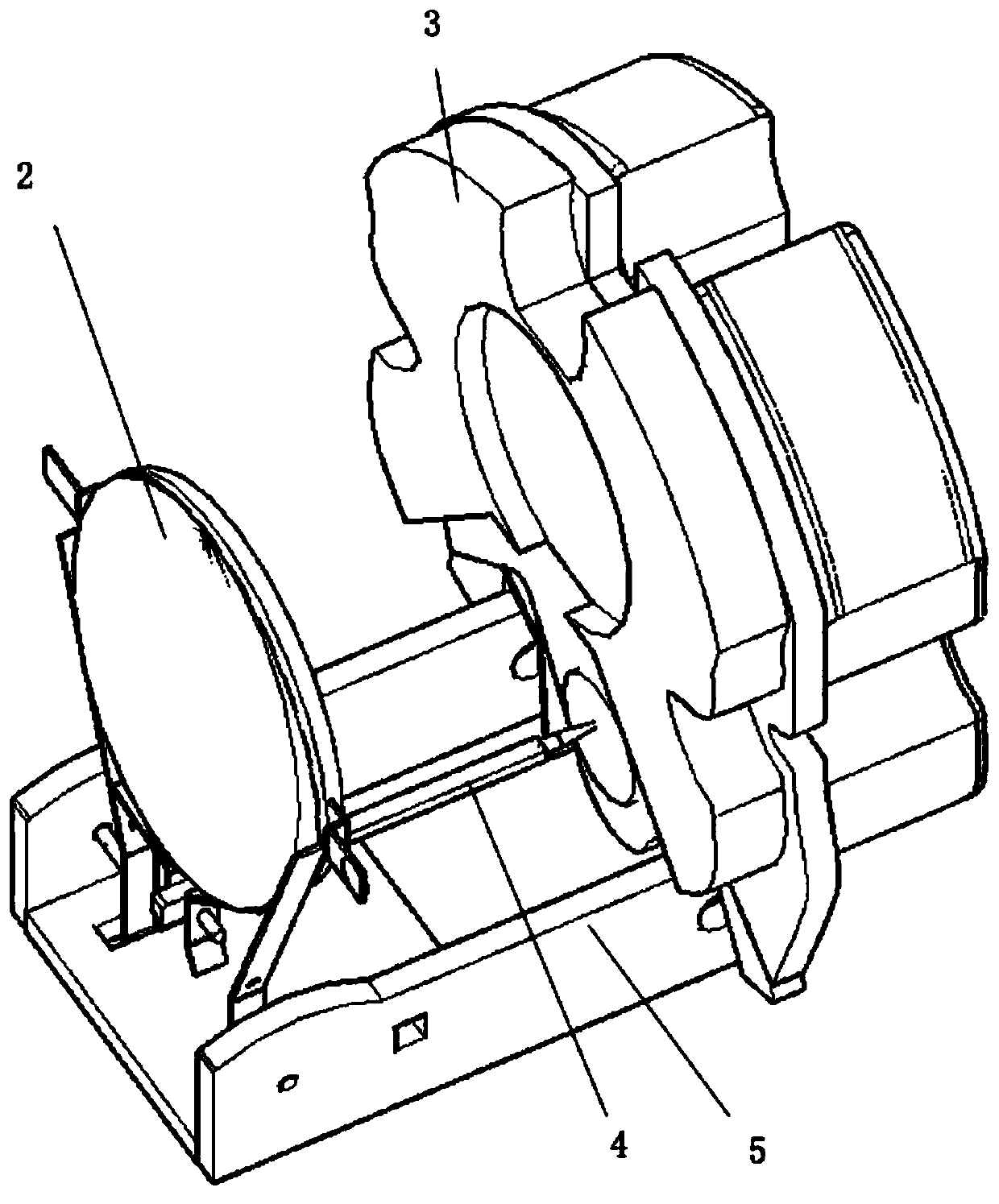

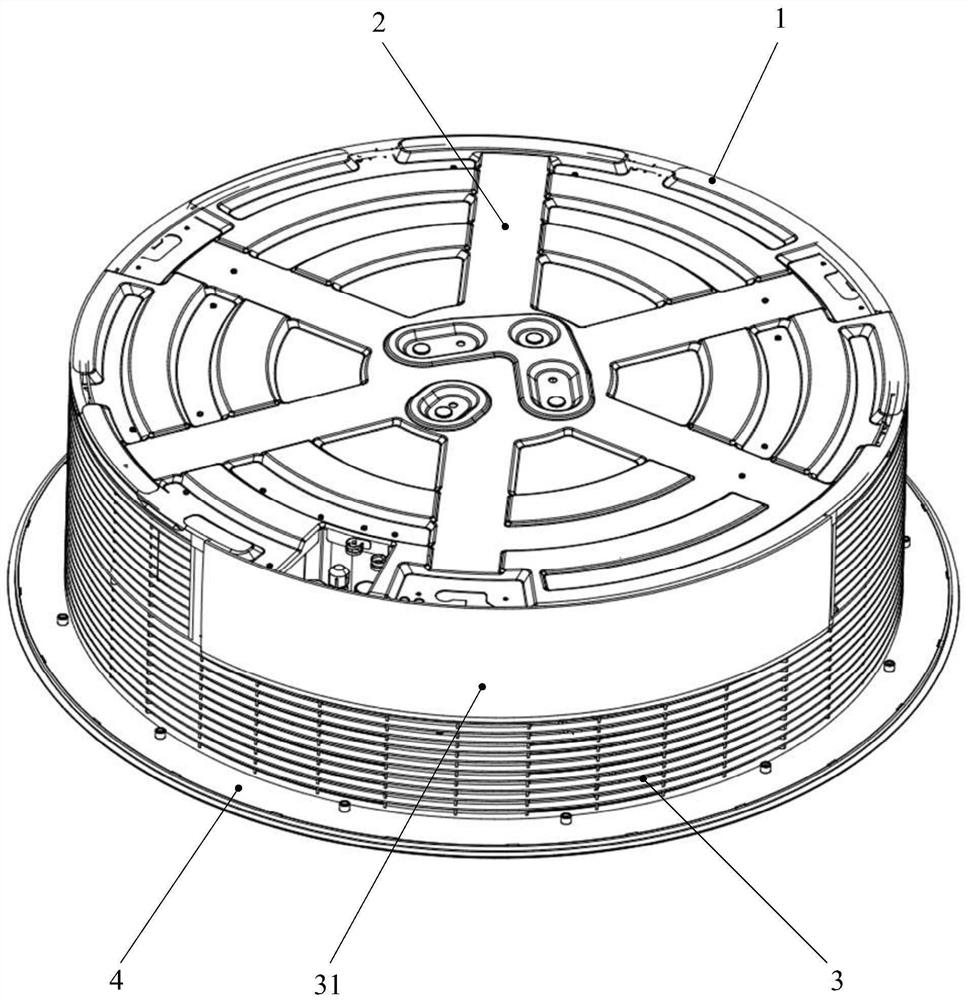

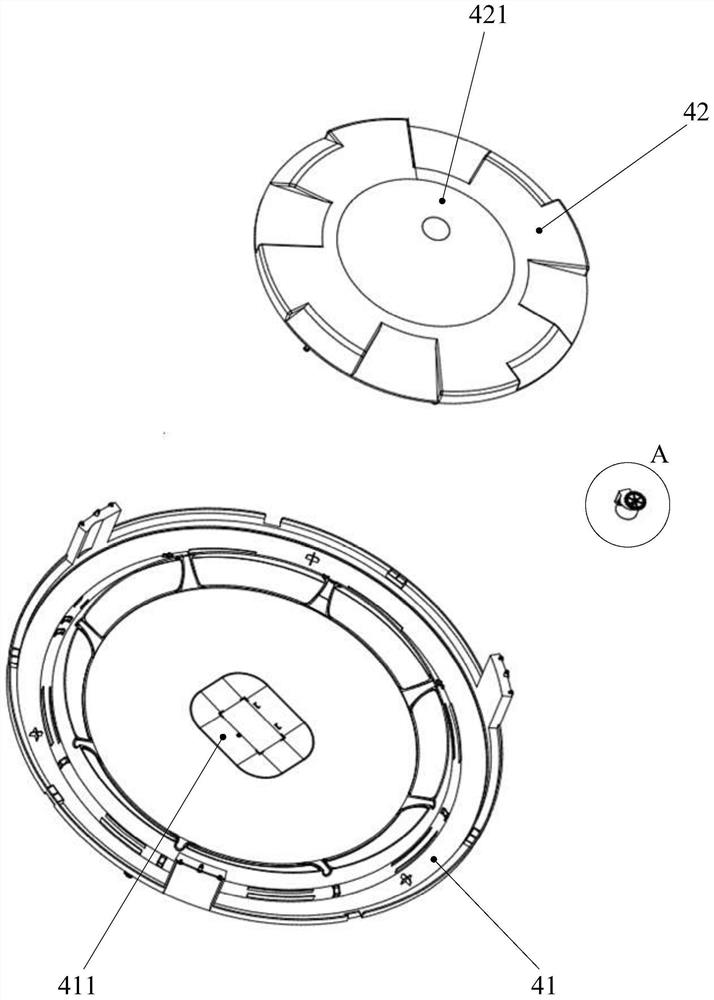

air conditioner indoor unit

ActiveCN109386883BLight weightReduce loadDucting arrangementsLighting and heating apparatusEngineeringAir conditioning

The invention relates to the field of air conditioning, in particular to an air conditioner indoor unit. In order to solve the problem that the local air supply volume and direction of the air supply cannot be adjusted in the existing air conditioner indoor unit because the air outlet is relatively fixed, the invention provides an air conditioner indoor unit , the air conditioner indoor unit includes a body, the side of the body is provided with an air intake grill along the circumference, the bottom of the body is provided with a panel frame, and the panel frame is provided with a first air outlet structure and a second air outlet structure , the first air outlet structure and the second air outlet structure form the air outlet of the air conditioner indoor unit, wherein the first air outlet structure and the second air outlet structure make out The local shape of the tuyeres changes. The air conditioner indoor unit of the present invention realizes the rotation adjustment of local air supply, and improves the air supply performance of the air conditioner indoor unit.

Owner:合肥海尔空调电子有限公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com