Microchannel heat radiator

A radiator and micro-channel technology, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., can solve the problems of insufficient heat exchange of working medium, short residence time of working medium, and low heat exchange efficiency. , to avoid the problem of uneven heat exchange, increase the interaction, and enhance the heat exchange effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

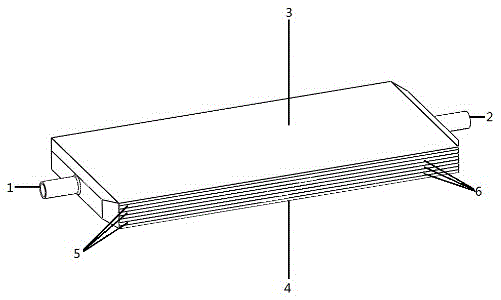

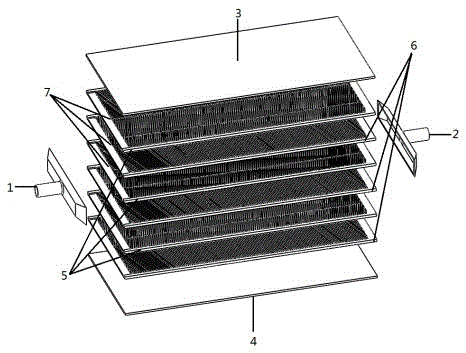

[0029] Depend on figure 1 , figure 2 It can be seen that the radiator in this example consists of a fluid inlet unit 1, a fluid outlet unit 2, an upper cover plate 3, a lower cover plate 4, and rectangular first heat exchange fins 5 and second heat exchange fins 6. composition. A heat dissipation unit is formed by stacking two heat exchange fins in opposite directions. It can be seen from the figure that more than one heat exchange unit is used in this example.

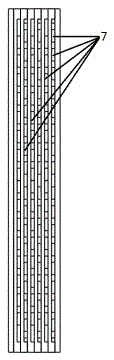

[0030] The fluid inlet and outlet 7 communicate with the fluid inlet unit 1 and the fluid outlet unit 2 respectively, and the fluid can flow from the fluid inlet unit 1 into the radiator, and then flow into the heat exchange fin from the fluid inlet and outlet 7, After heat exchange in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com