Flue gas flow velocity adjusting structure of SCR denitration device

A technology of flue gas flow rate and structure adjustment, which is applied to exhaust gas devices, gas treatment, separation methods, etc., can solve the problem of insignificant adjustment effect of flue gas flow rate, wear and leakage of low-temperature economizer tube bundles, and difficulty in flue gas velocity at the outlet, etc. To achieve the effect of optimizing flue gas flow resistance, reducing flow rate loss, and maintaining uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

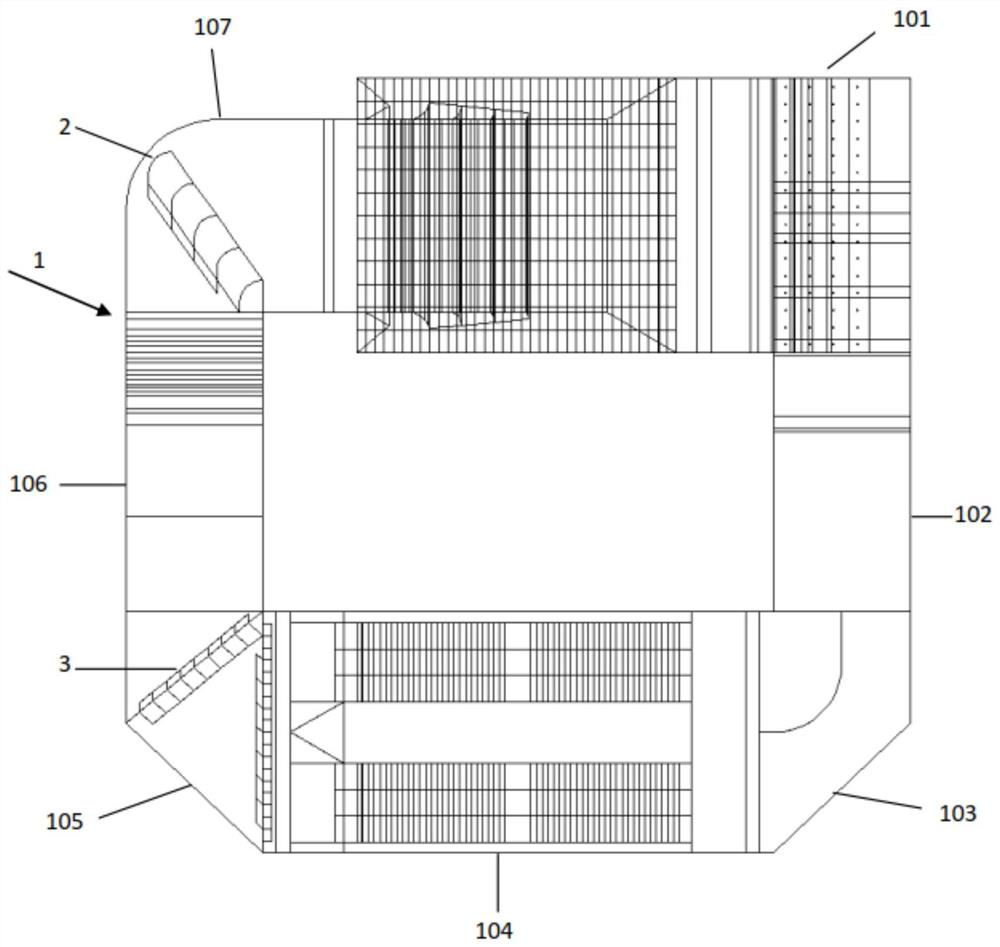

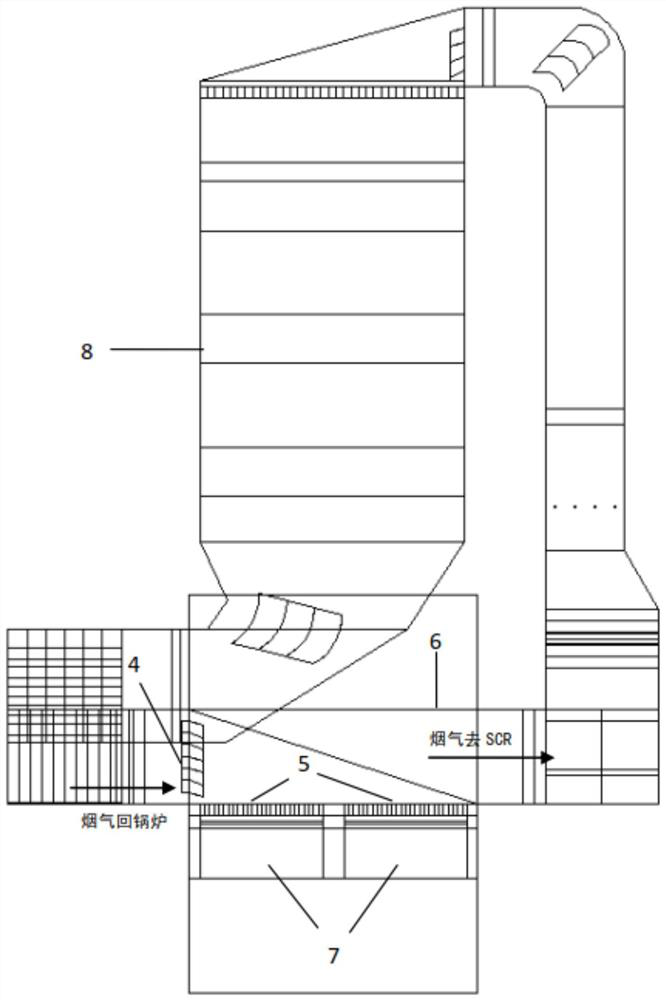

[0054] In this embodiment, a flue gas velocity adjustment structure of an SCR denitrification device is designed, and the specific design is as follows:

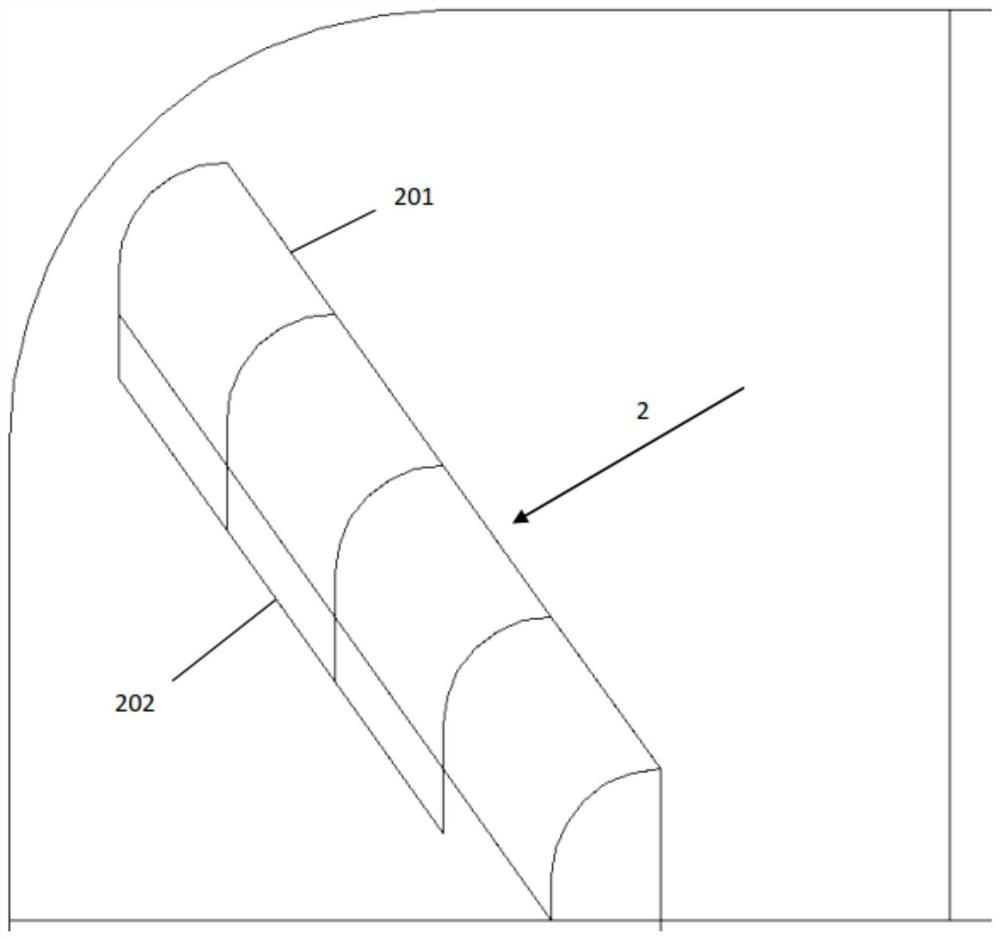

[0055] 1) At the fourth corner flue 107 of the SCR denitrification flue 1, five first deflectors are evenly arranged along the width direction. The arc-shaped diversion part 201 is a 90° arc, and the arc-shaped diversion part 201 is arranged parallel to the outer contour of the fourth corner flue 107, and the rectangular diversion part 202 is parallel to the side of the third straight pipe flue 106, and the arc The radius of the shaped drainage part 201 is 500mm, and the length of the rectangular drainage part 202 is 500mm;

[0056] 2) Arrange the second group of deflectors 3 at the third corner flue 105 of the SCR denitrification flue 1, including the first flue deflector 301, the second flue deflector 302, and the second flue deflector 303 and diagonal guide plate 304; the first flue guide plate 301 is arranged at interva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com