Patents

Literature

67results about How to "Reduce local wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

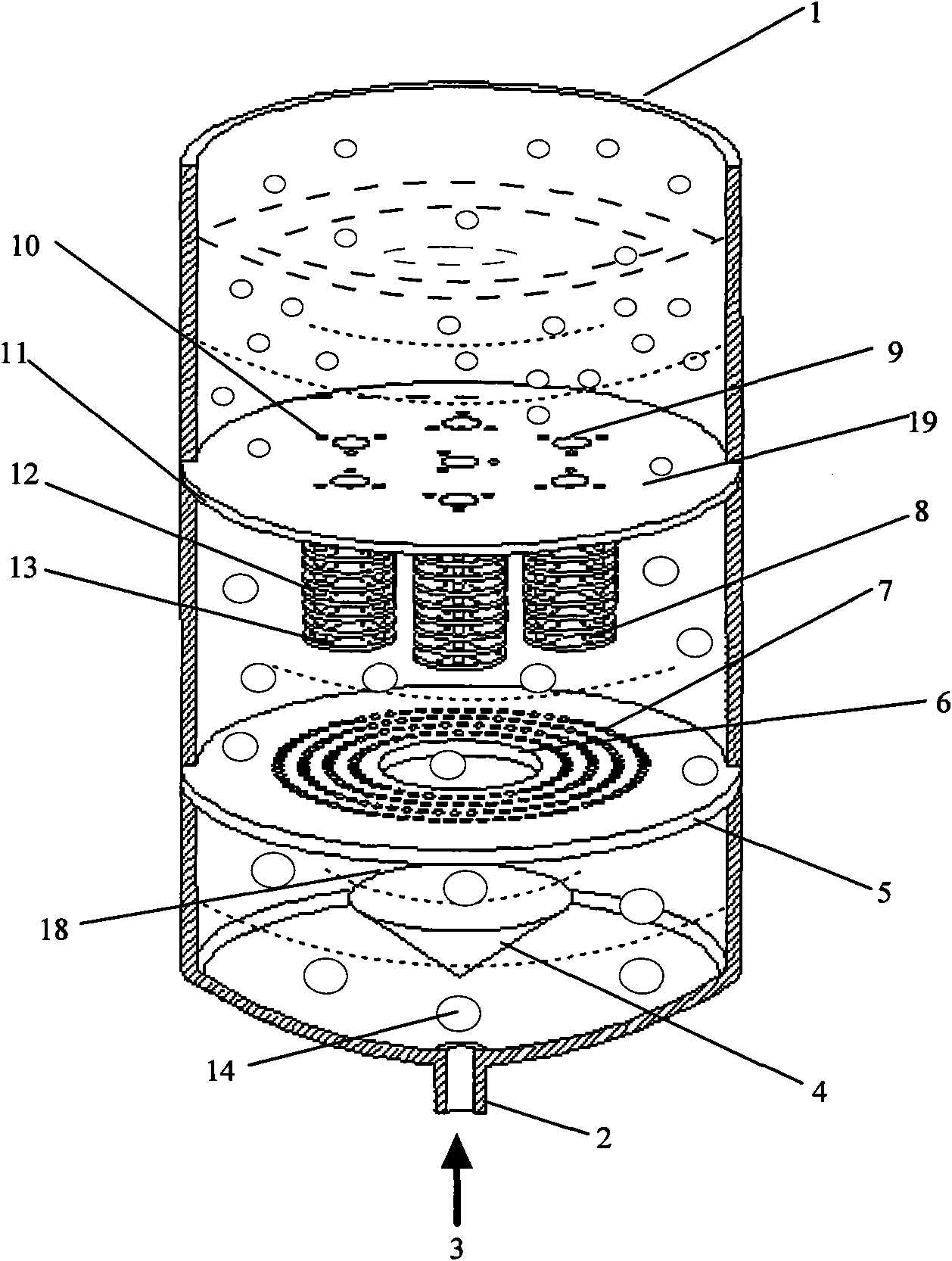

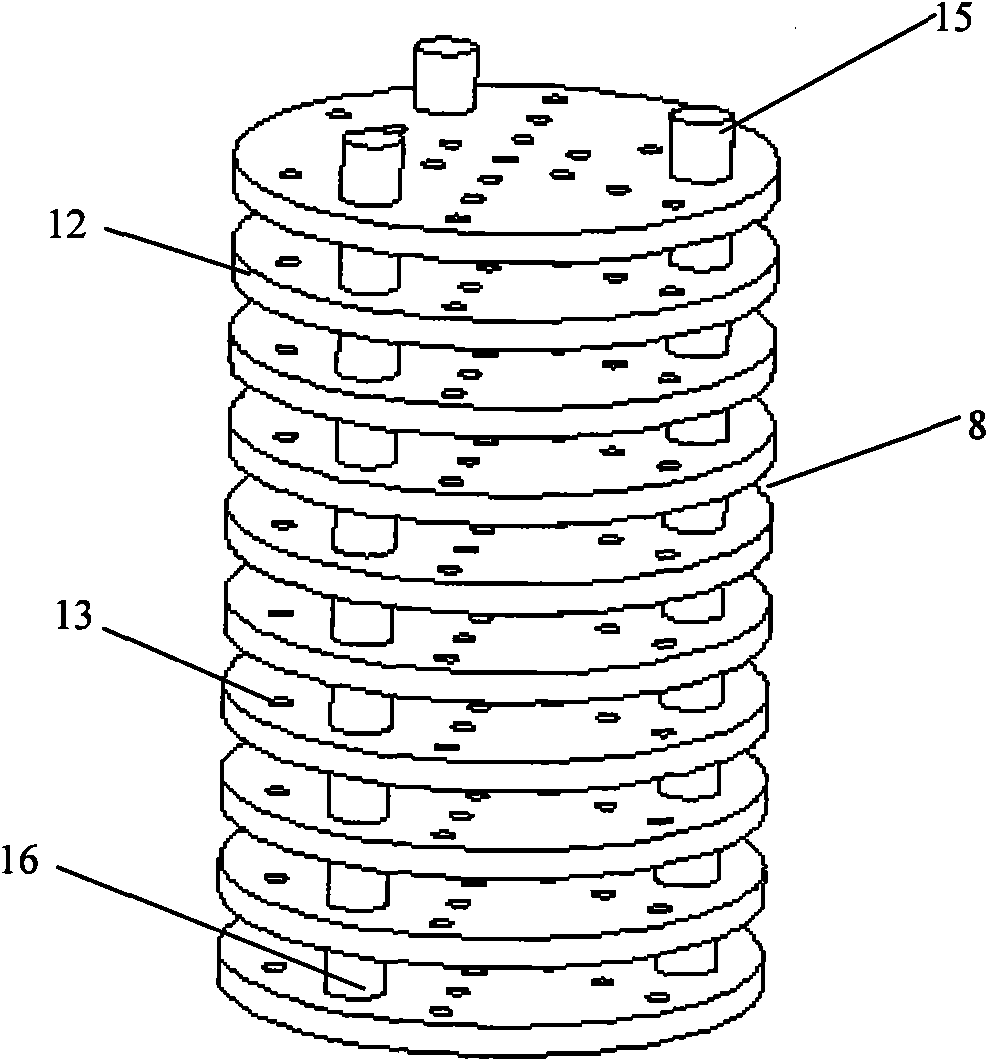

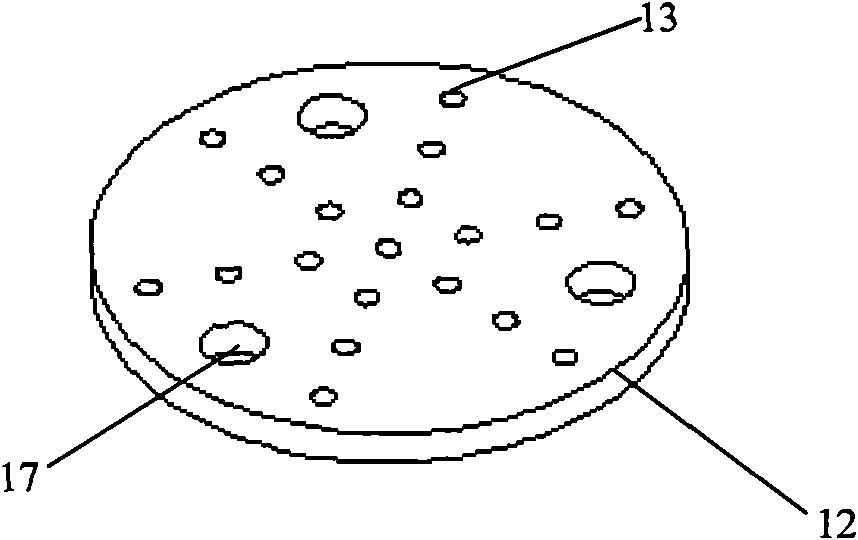

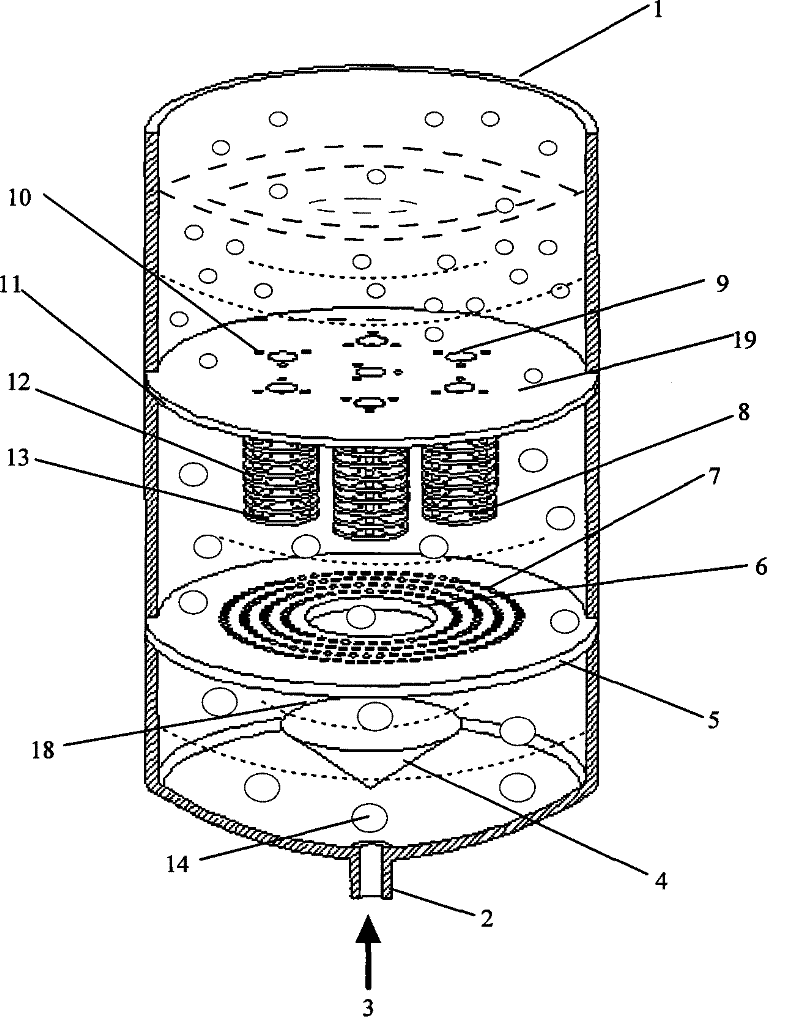

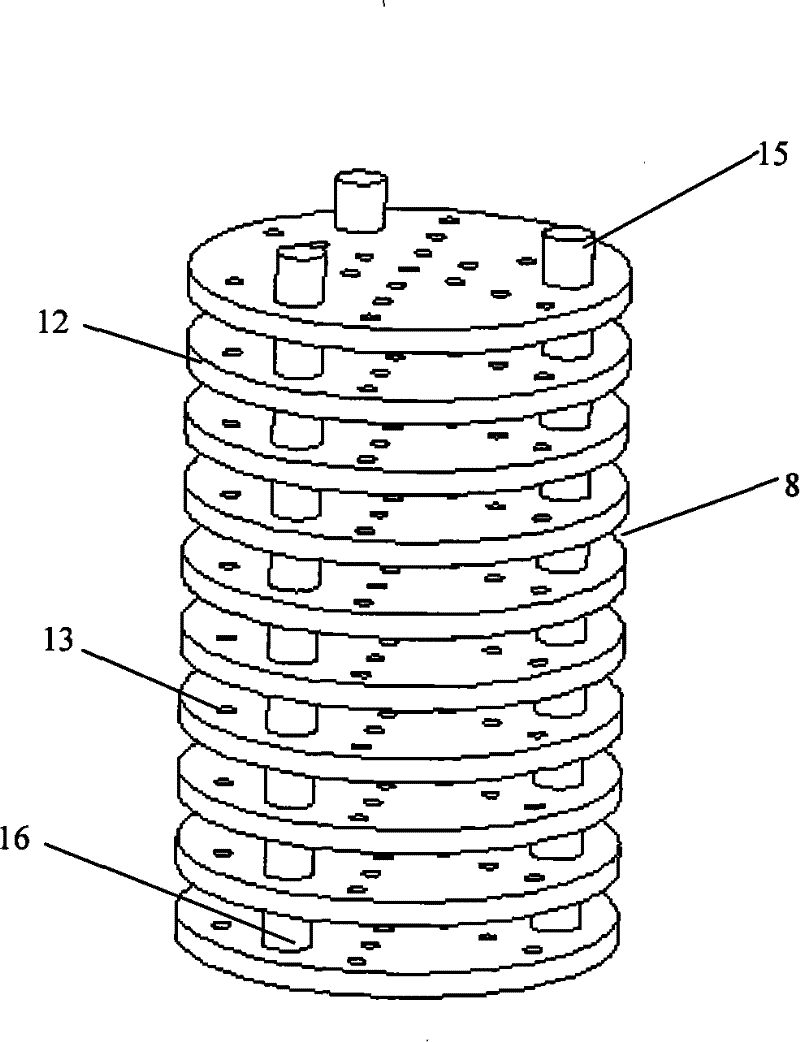

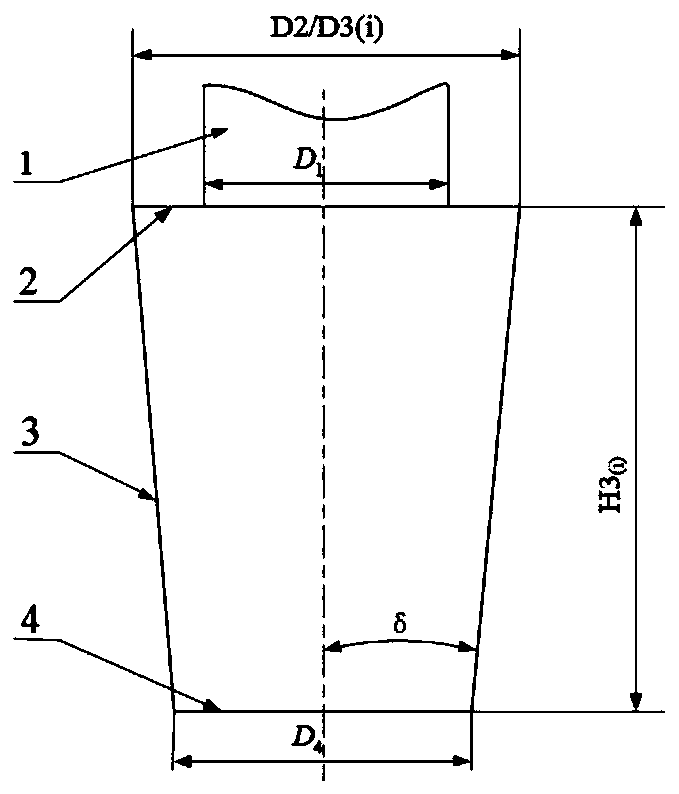

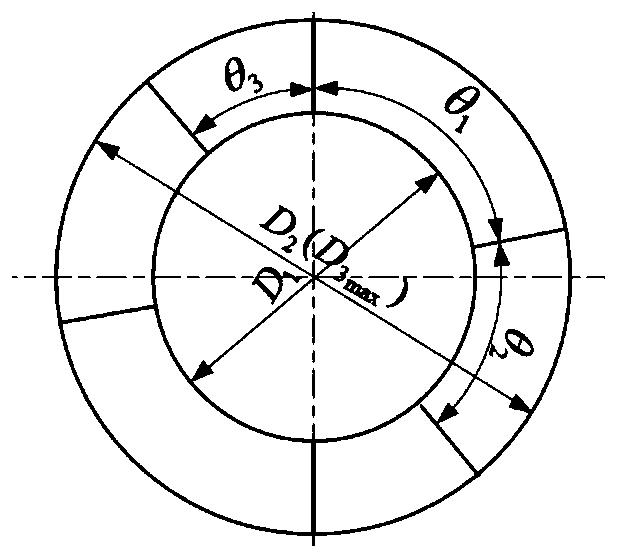

Up-flow reactor and application thereof

ActiveCN101632911AEvenly distributedSimple structureHydrocarbon oils refiningChemical/physical processesWaxShortest distance

The invention discloses an up-flow reactor, which comprises an initial distributor positioned at the bottom of the reactor and an intermediate distributor above the initial distributor. The initial distributor consists of a conical traverse baffle and a sieve plate positioned above the conical traverse baffle; and the intermediate distributor consists of an open pore sieve plate and a sieve plate string structure. The up-flow reactor provided by the invention can realize even distribution of gas in the reactor in short distance so as to improve the utilization rate of a catalyst and increase the space of a catalyst bed layer in the reactor. The up-flow reactor of the invention is particularly applied to a hydrogenation process of heavy oil (comprising wax oil, residual oil, coal liquefied oil and the like).

Owner:CHINA PETROLEUM & CHEM CORP +1

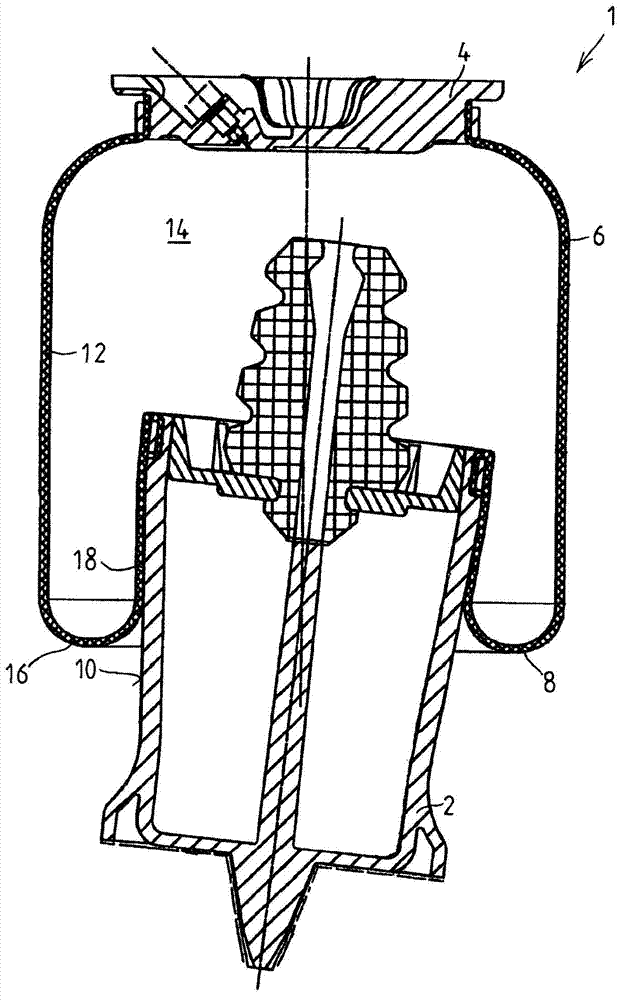

Piston for internal combustion engines

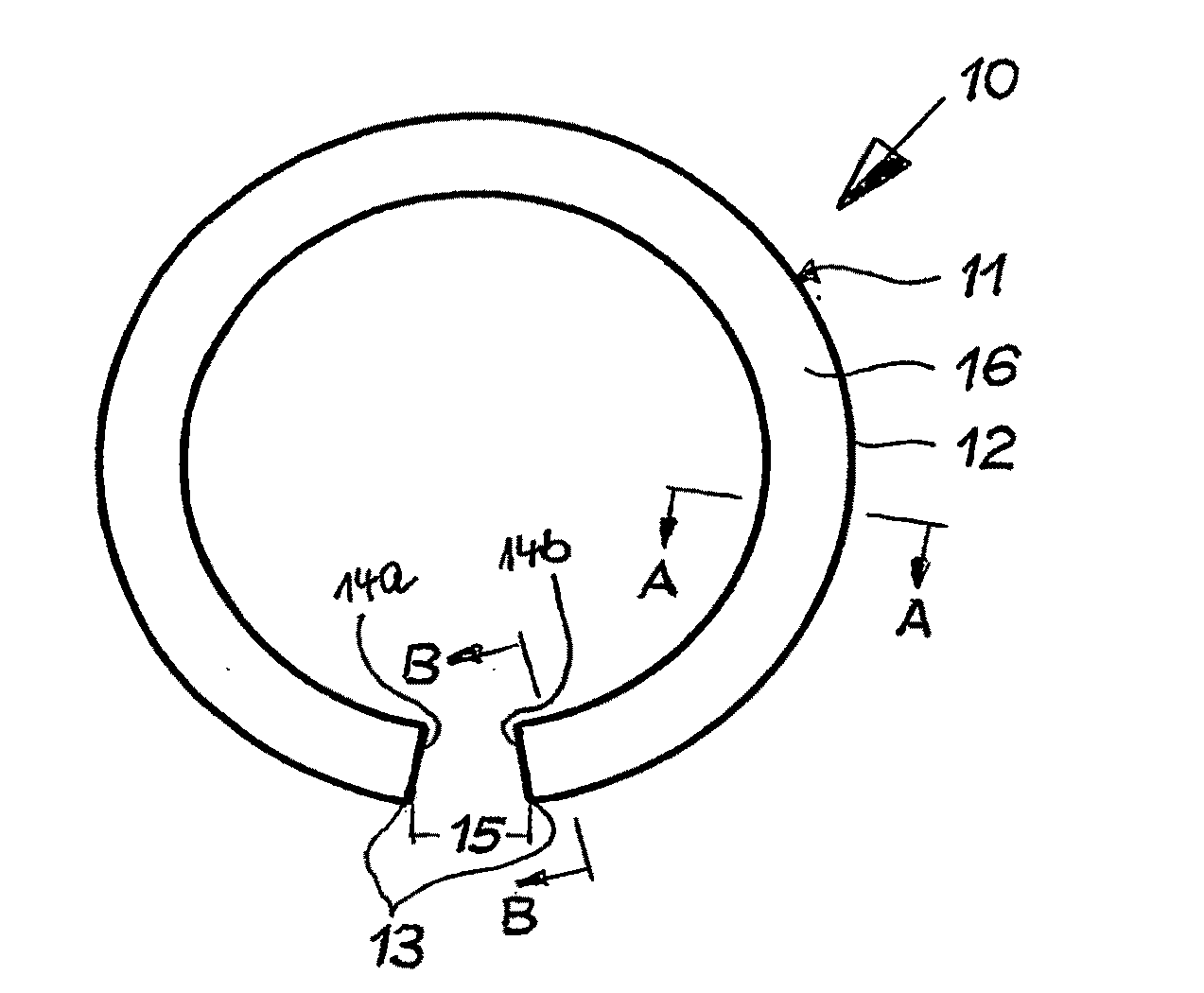

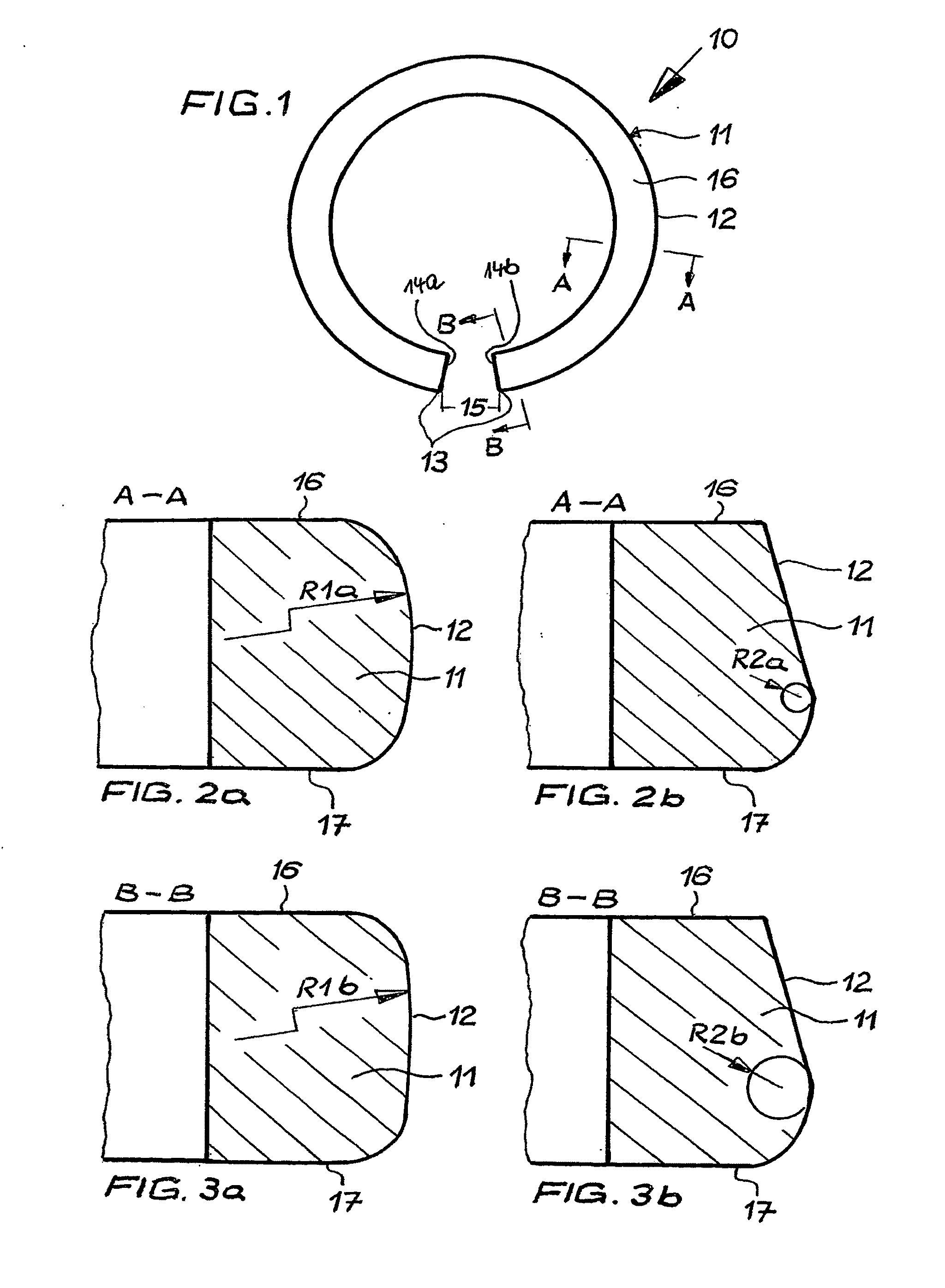

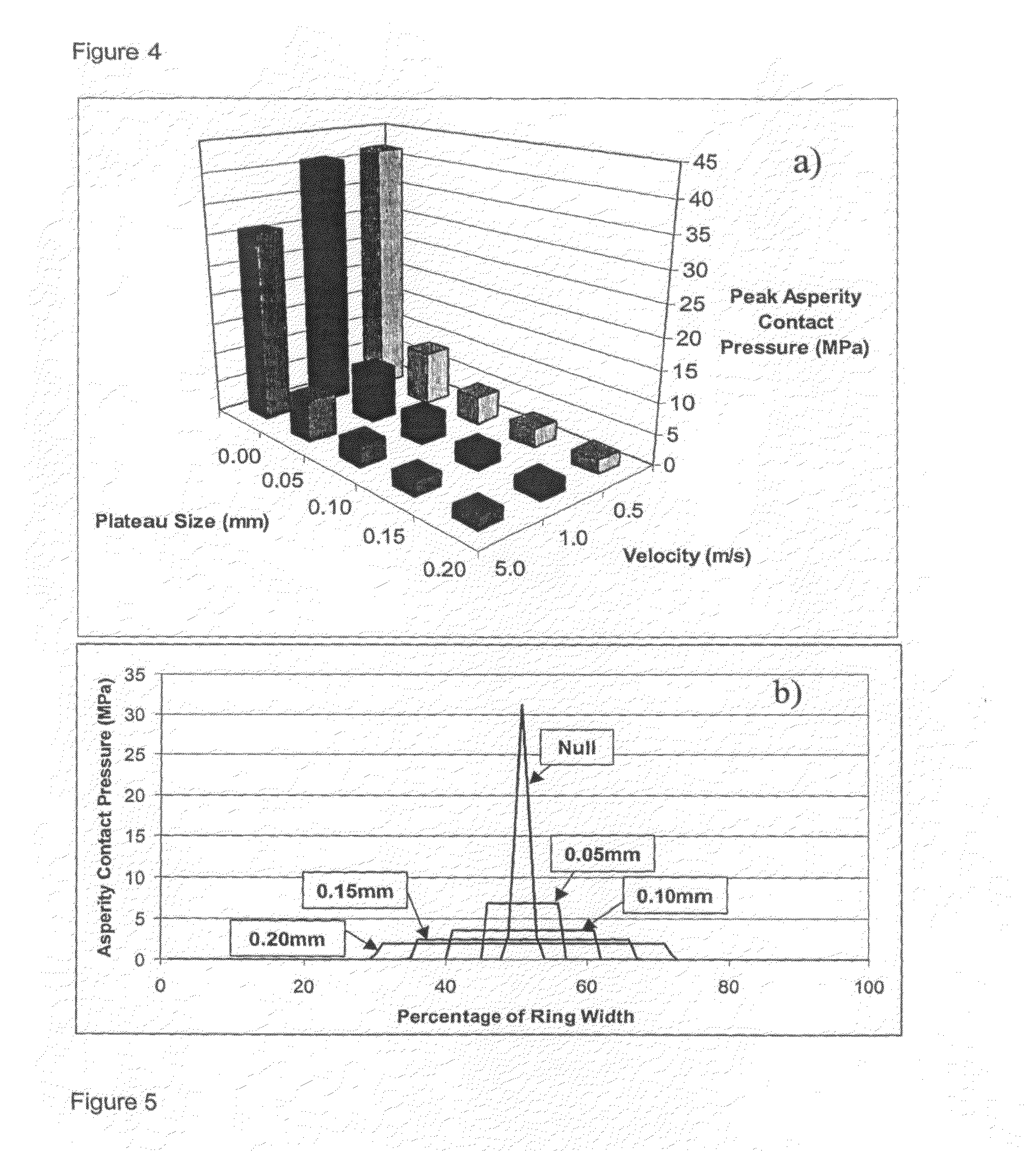

ActiveUS20100090416A1Reduce local wearMinimize risk of failurePiston ringsBraking action transmissionPiston ringInternal combustion engine

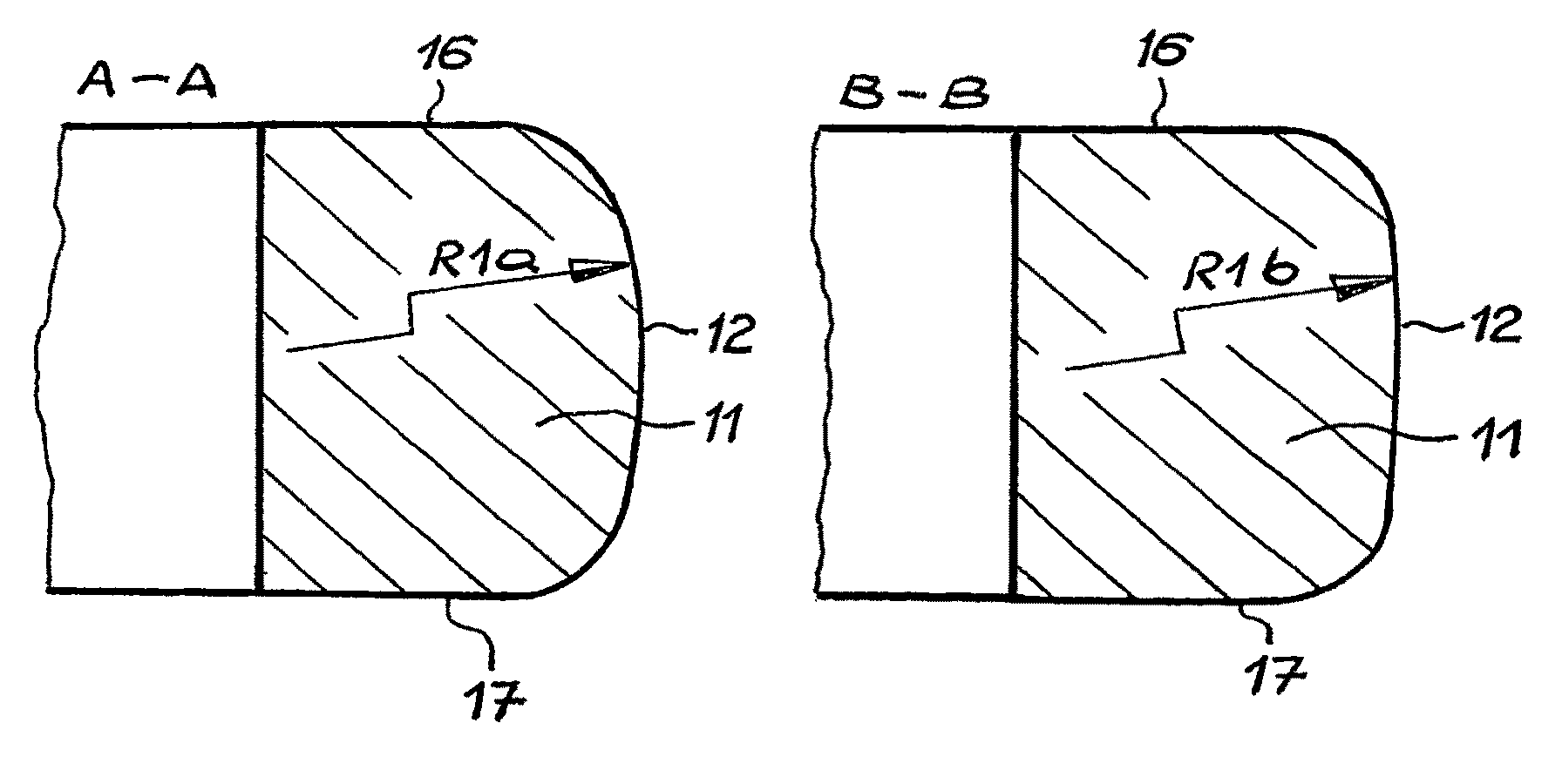

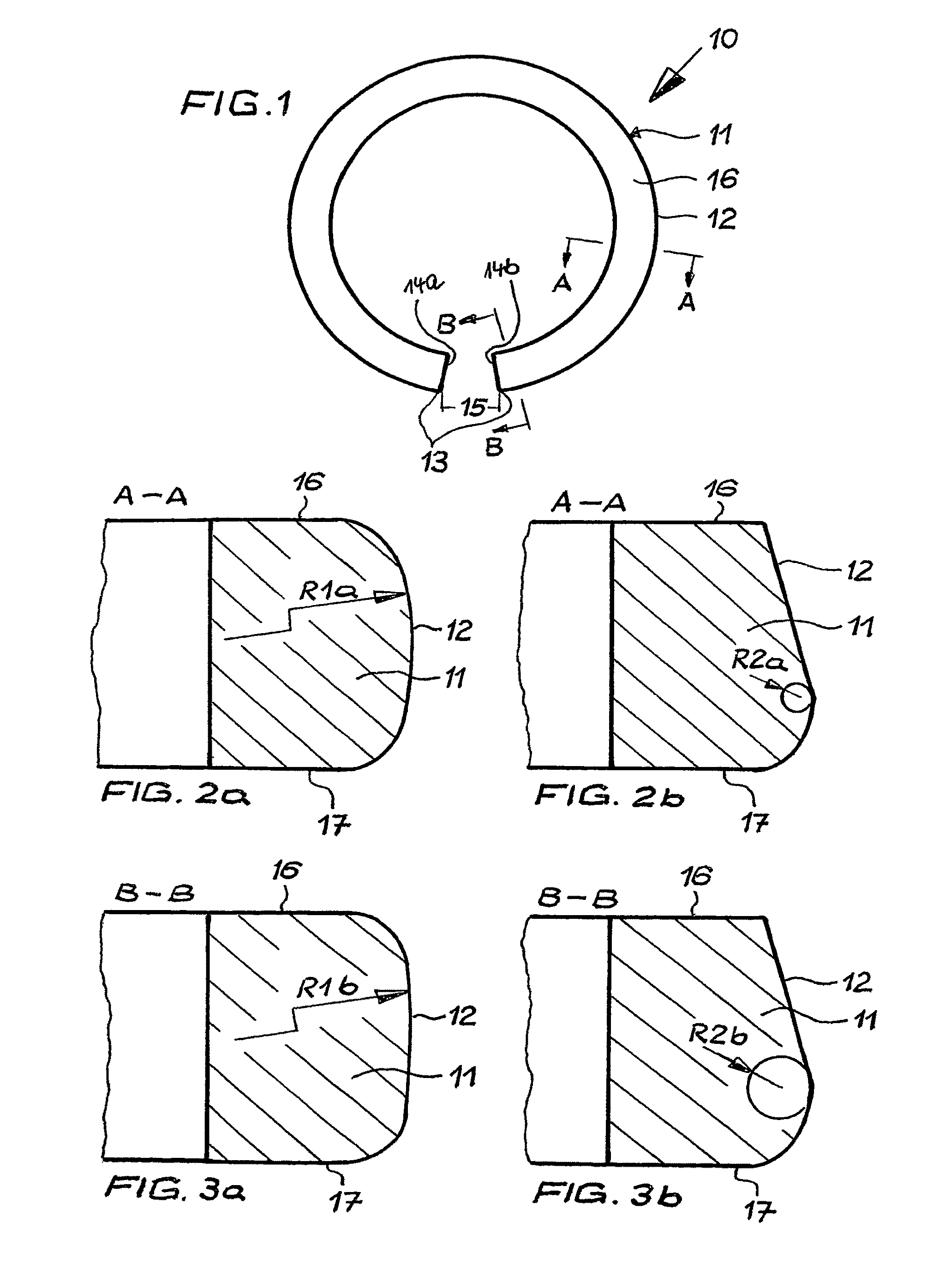

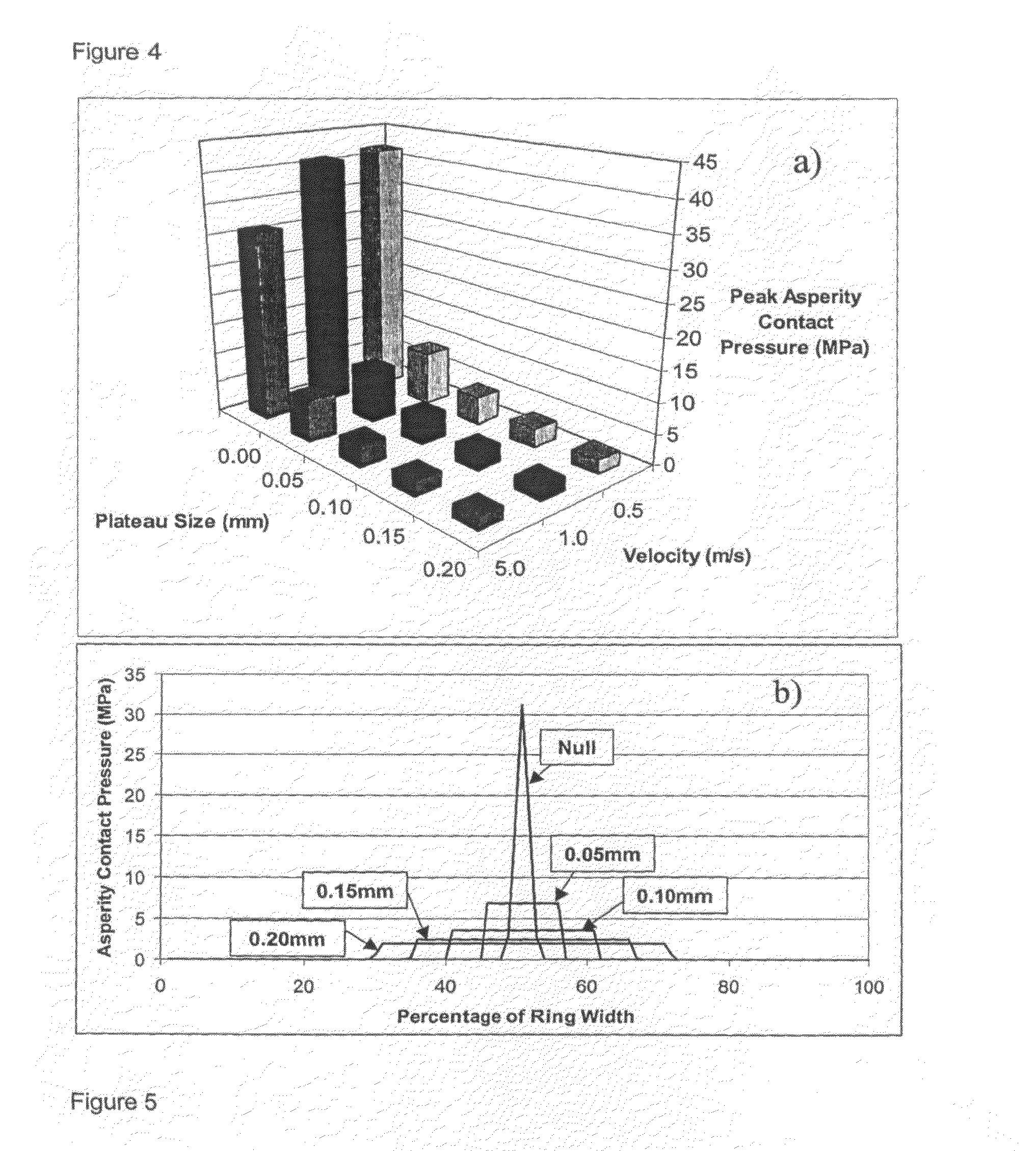

The present invention relates to a piston ring (10), particularly a compression ring, for an internal combustion engine, comprising a ring-shaped body (11) having a ring joint formed by butt ends (14a, 14b), the ring-shaped body (11) further having a ring contact face (12) along its perimeter, for contacting a cylinder wall in operation. According to the invention, the ring contact face (12) has a barrel-shaped profile, the barrel-shaped profile having in any of its cross-sections an area of maximum curvature, whose radius of curvature increases in the direction of the butt ends (14a, 14b).

Owner:MAHLE INT GMBH +1

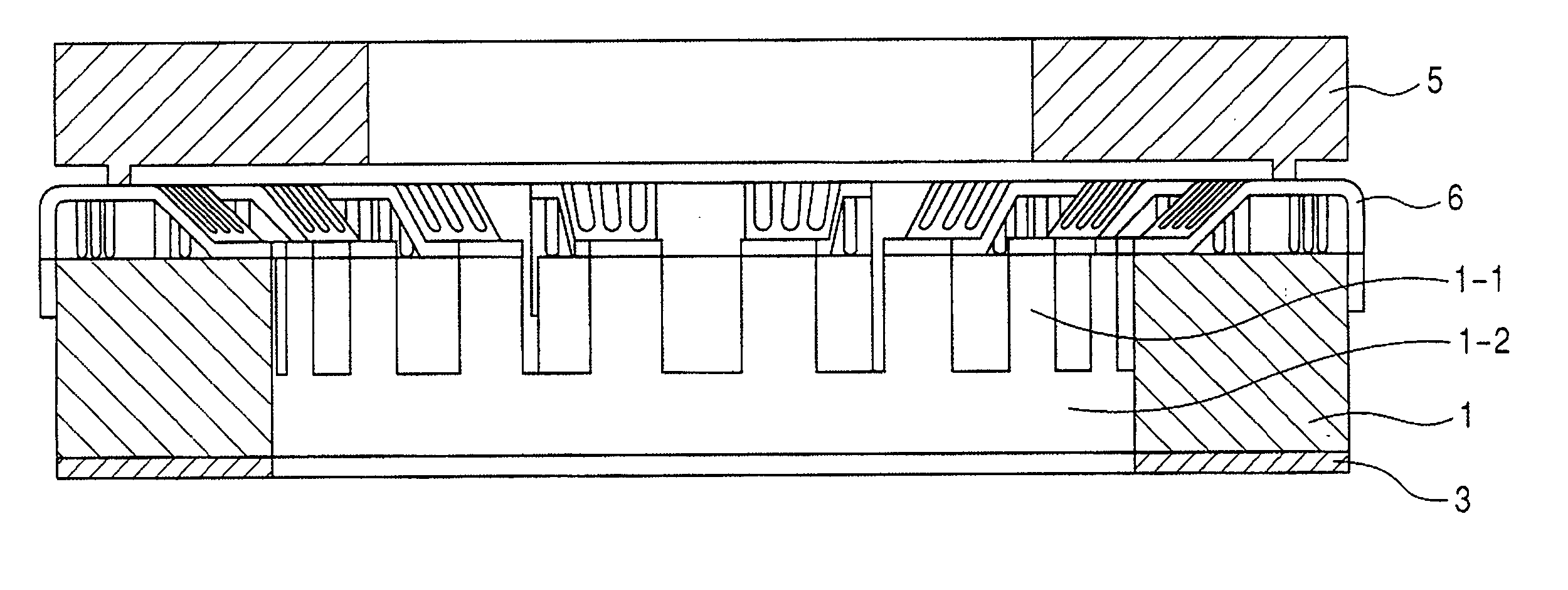

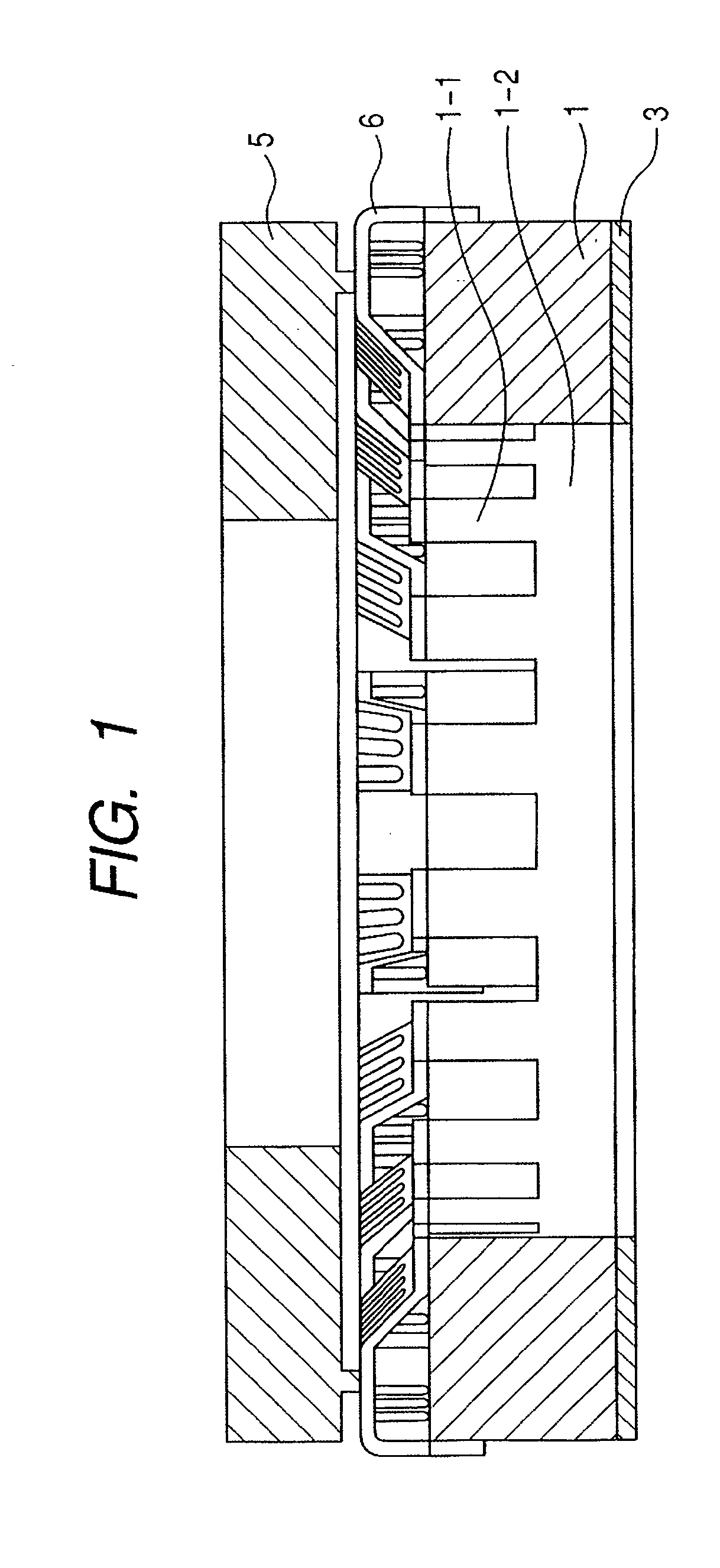

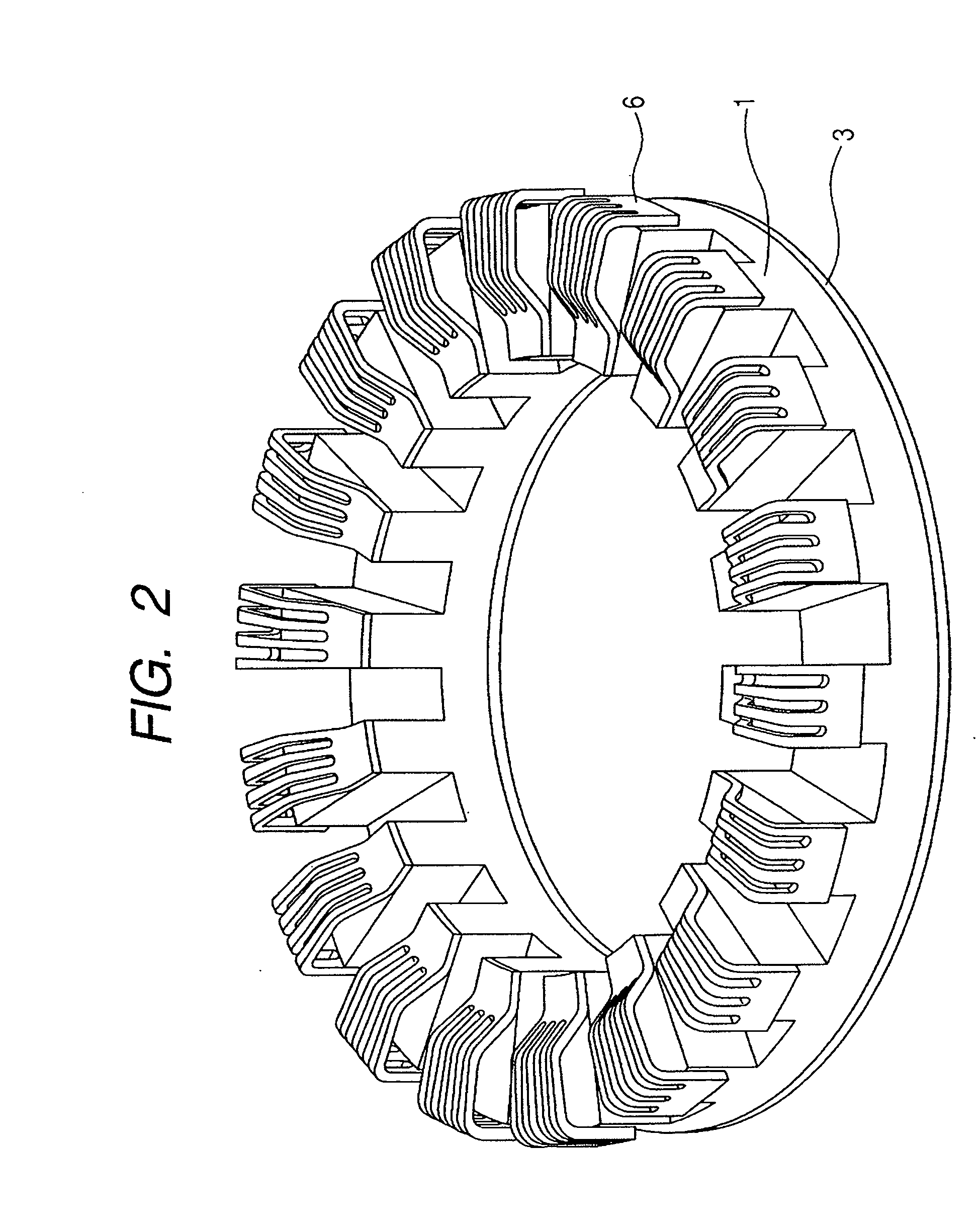

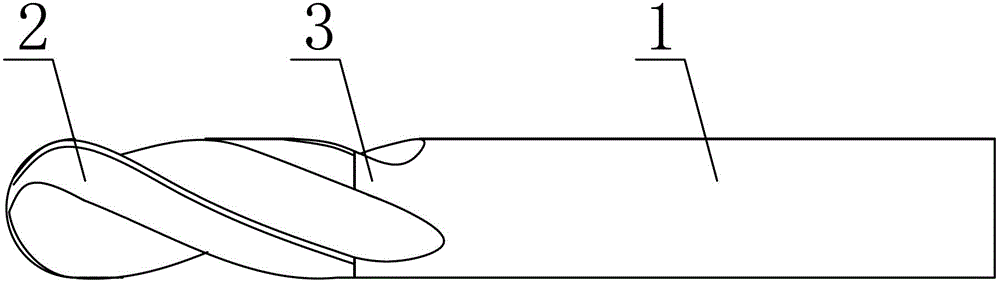

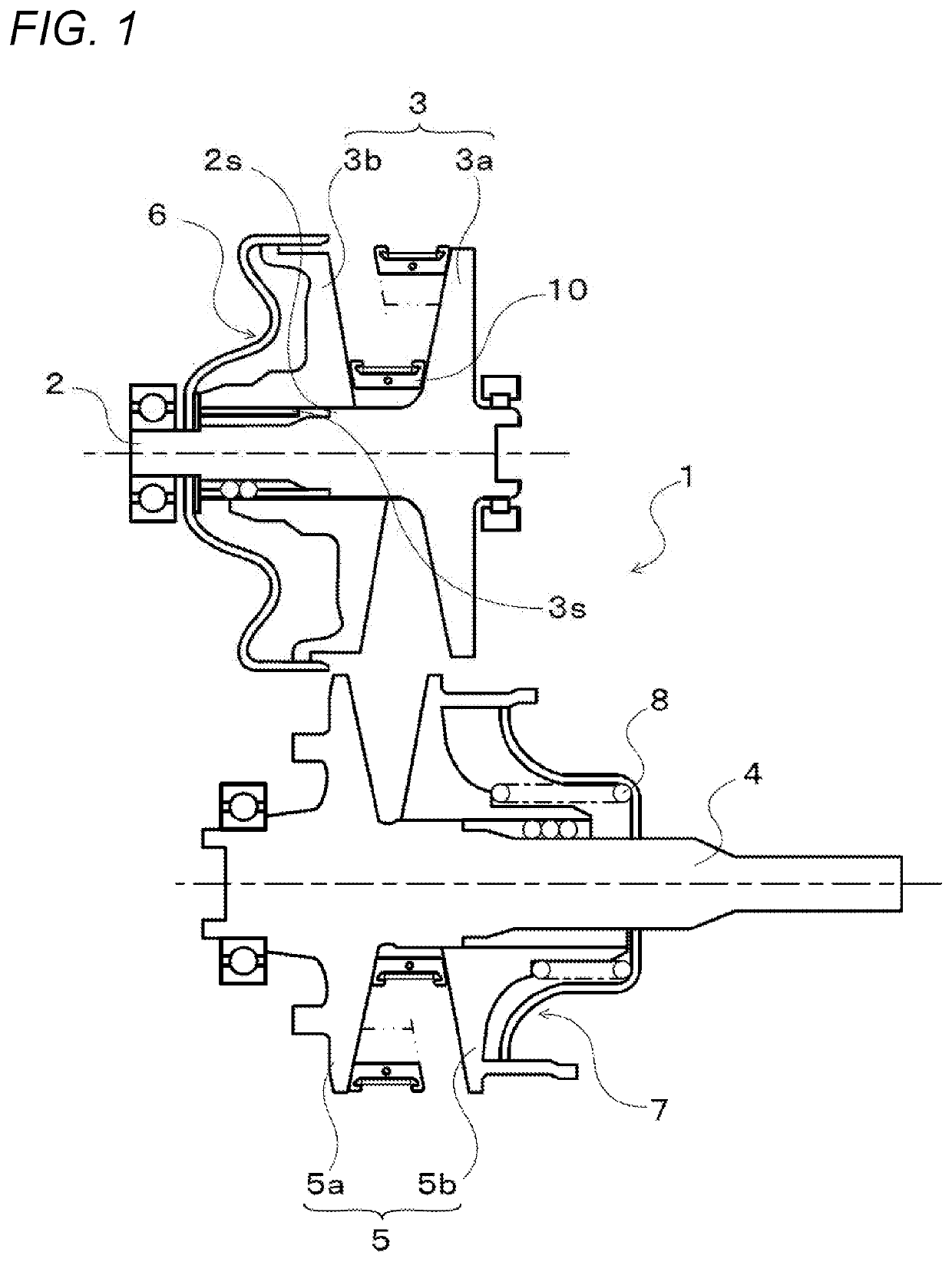

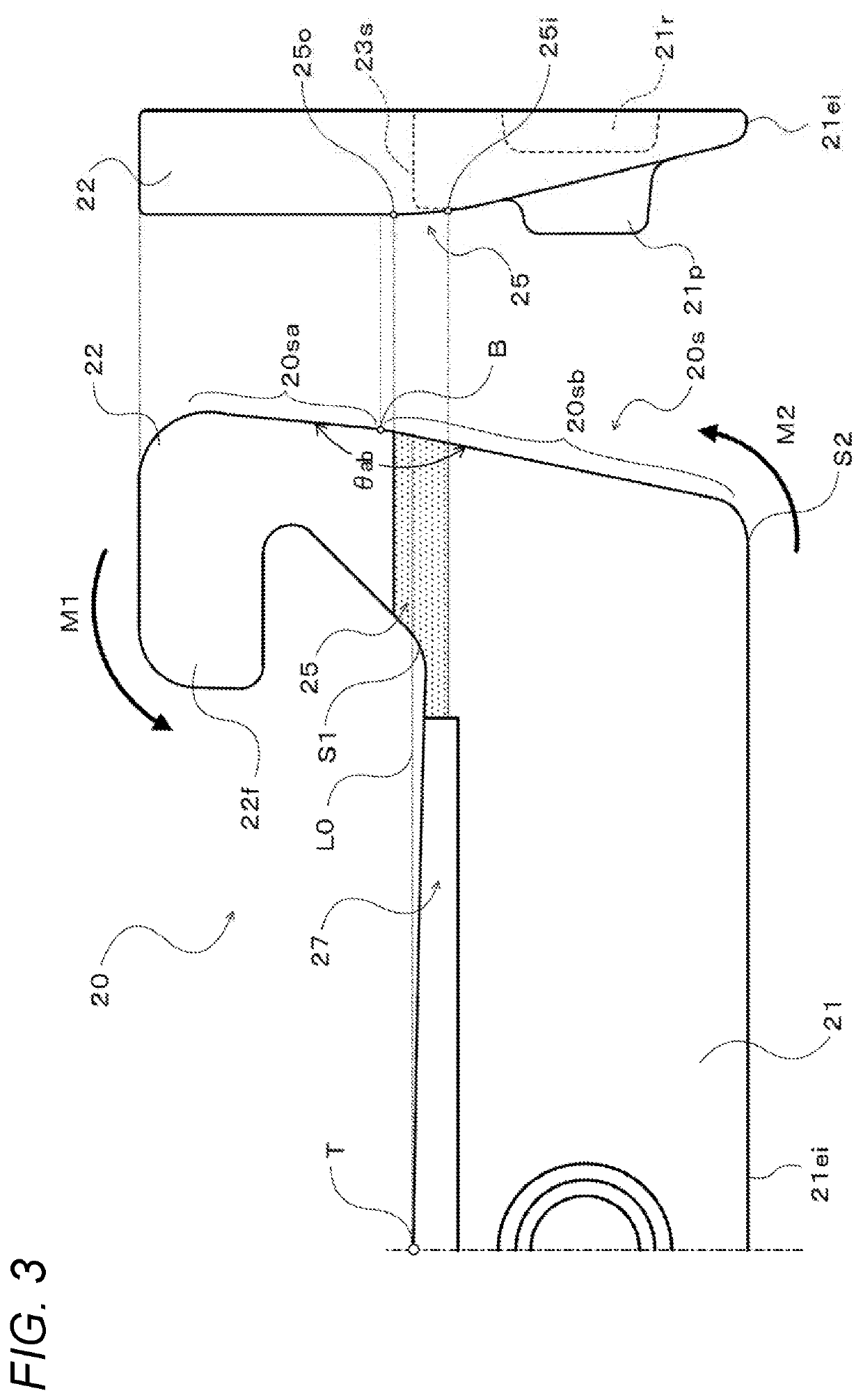

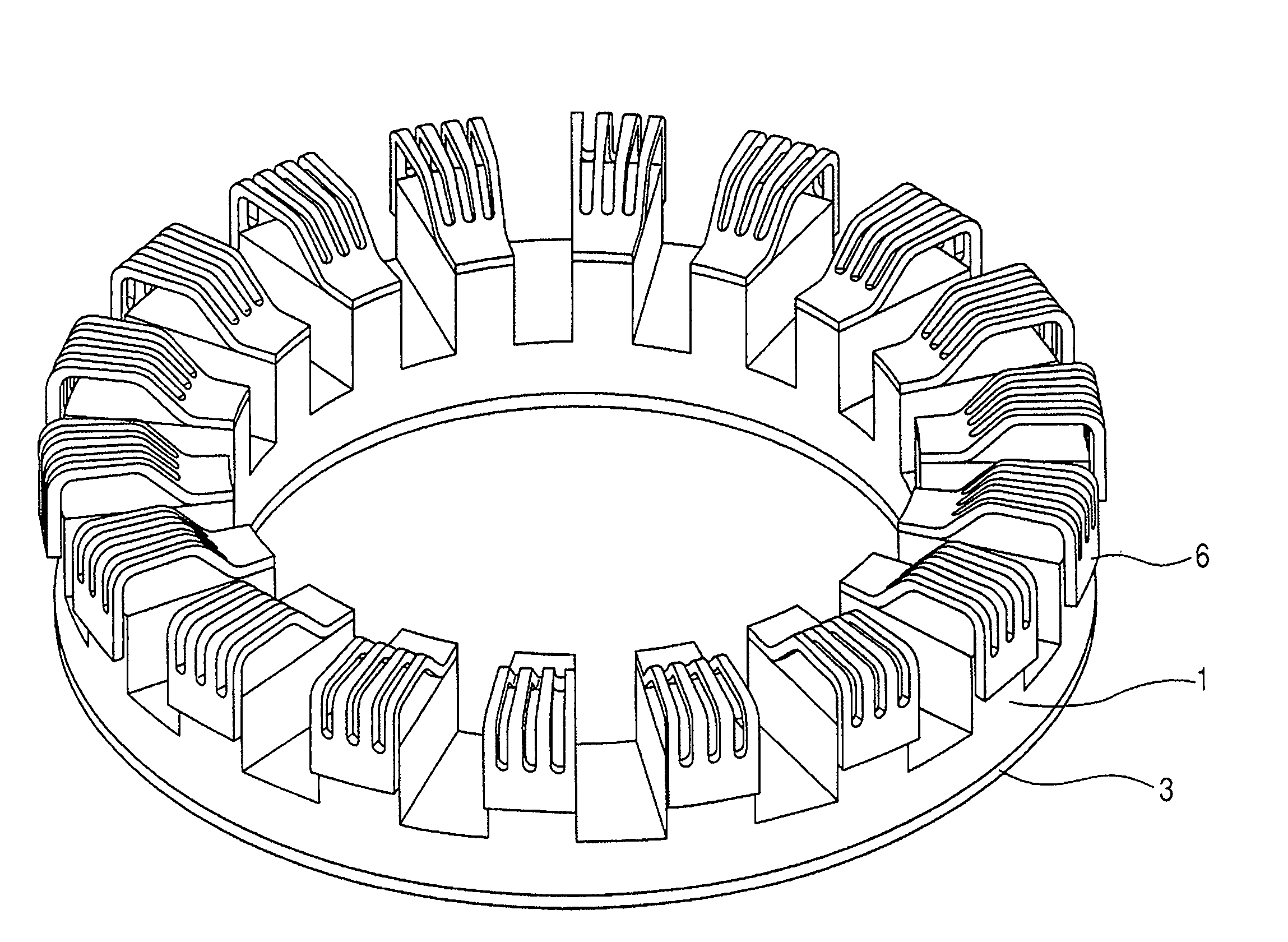

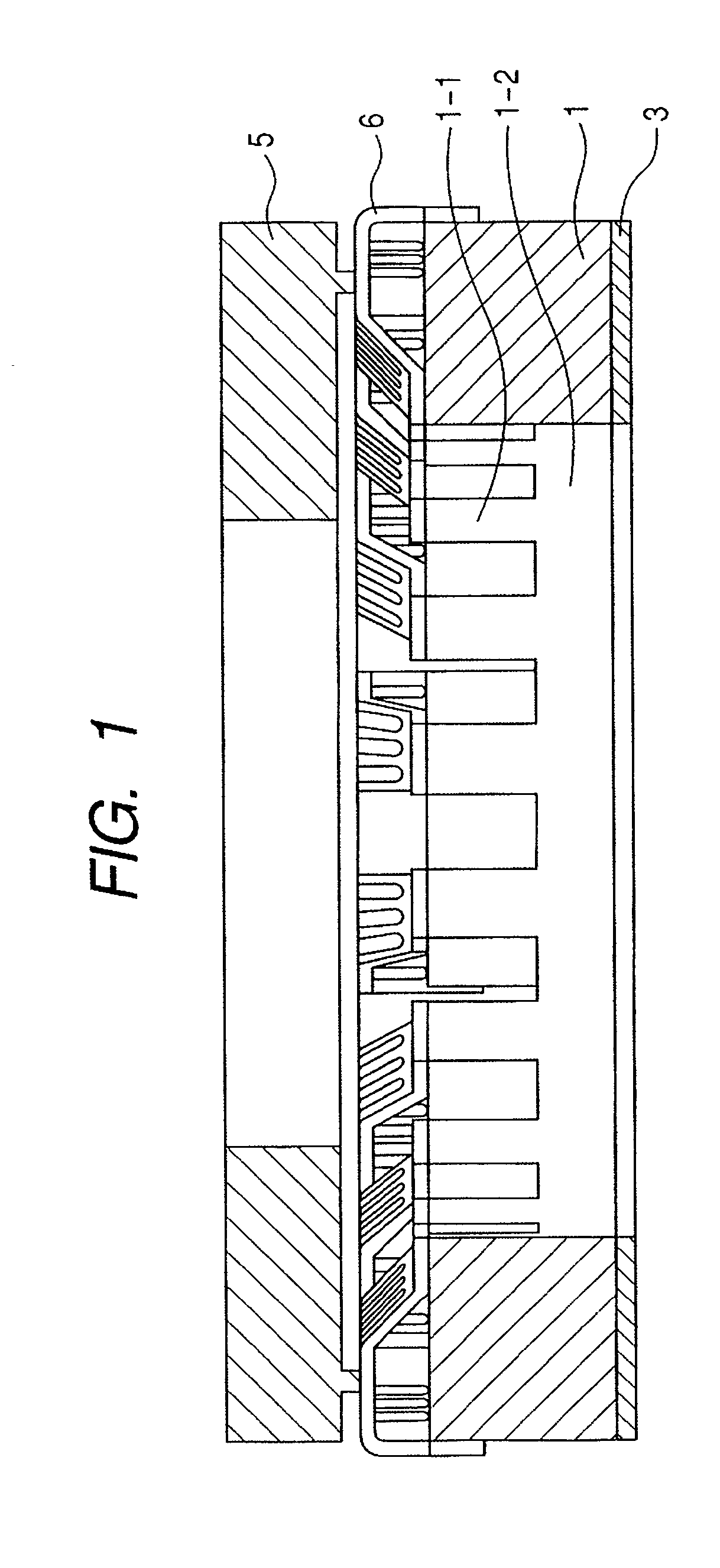

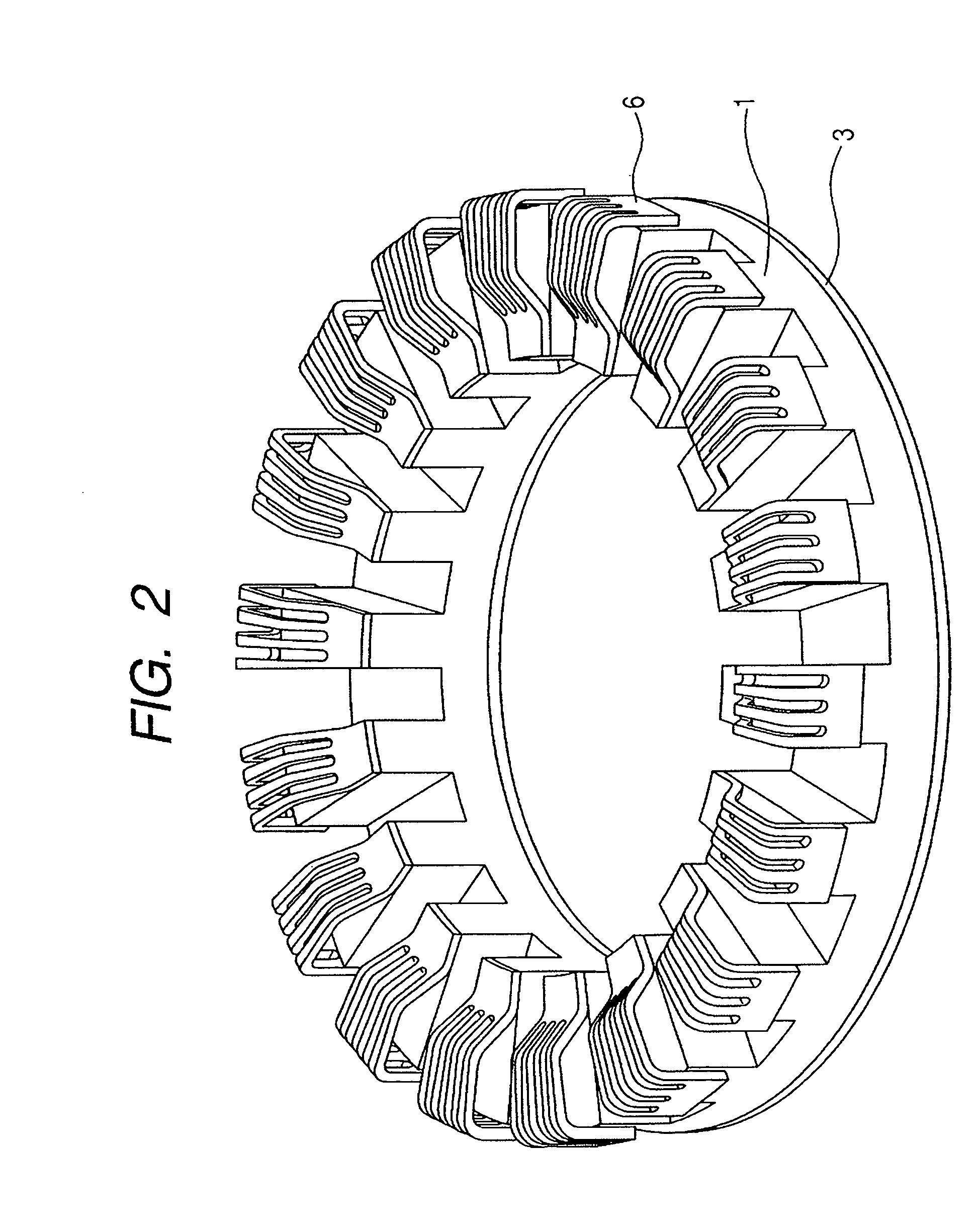

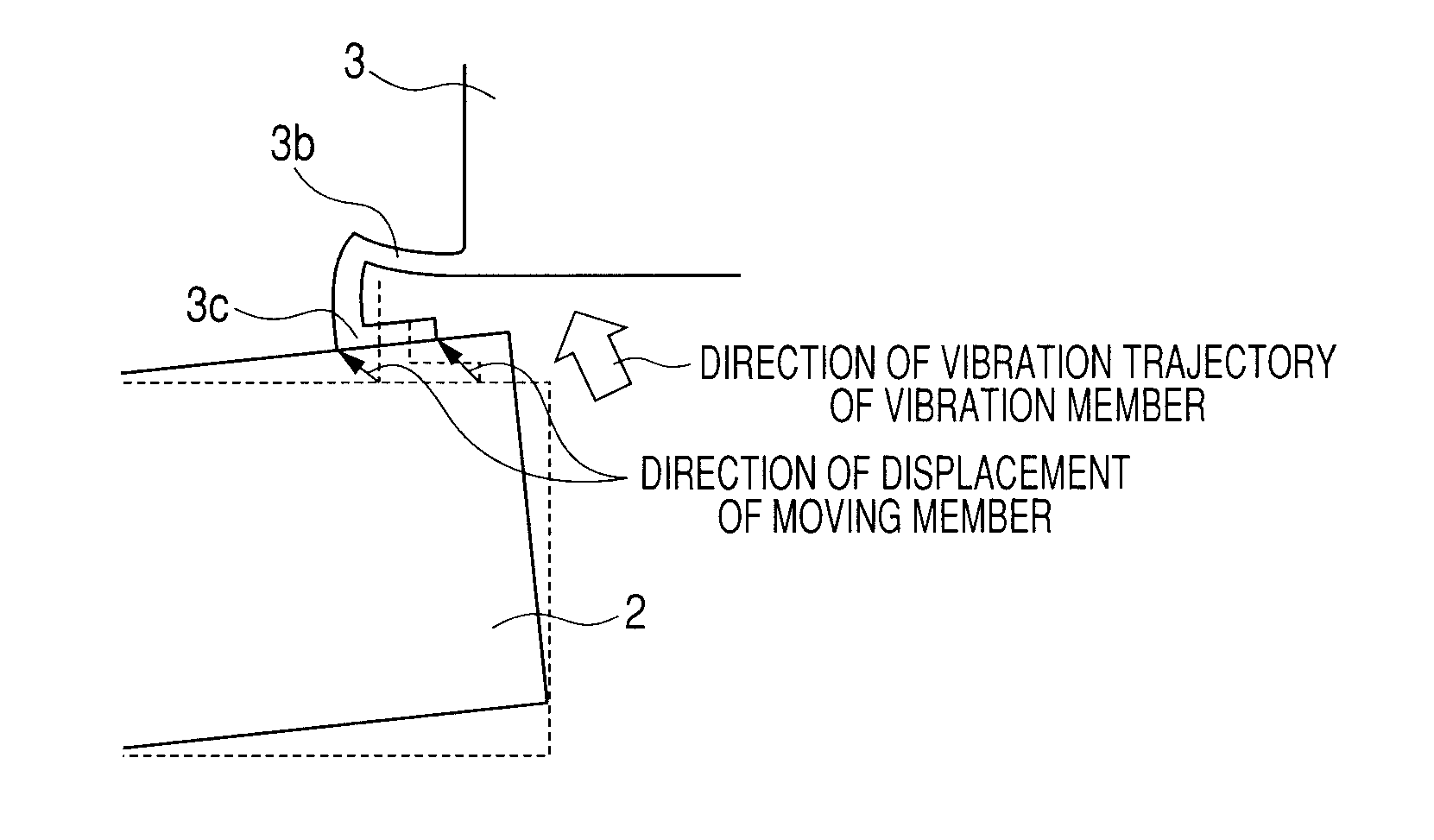

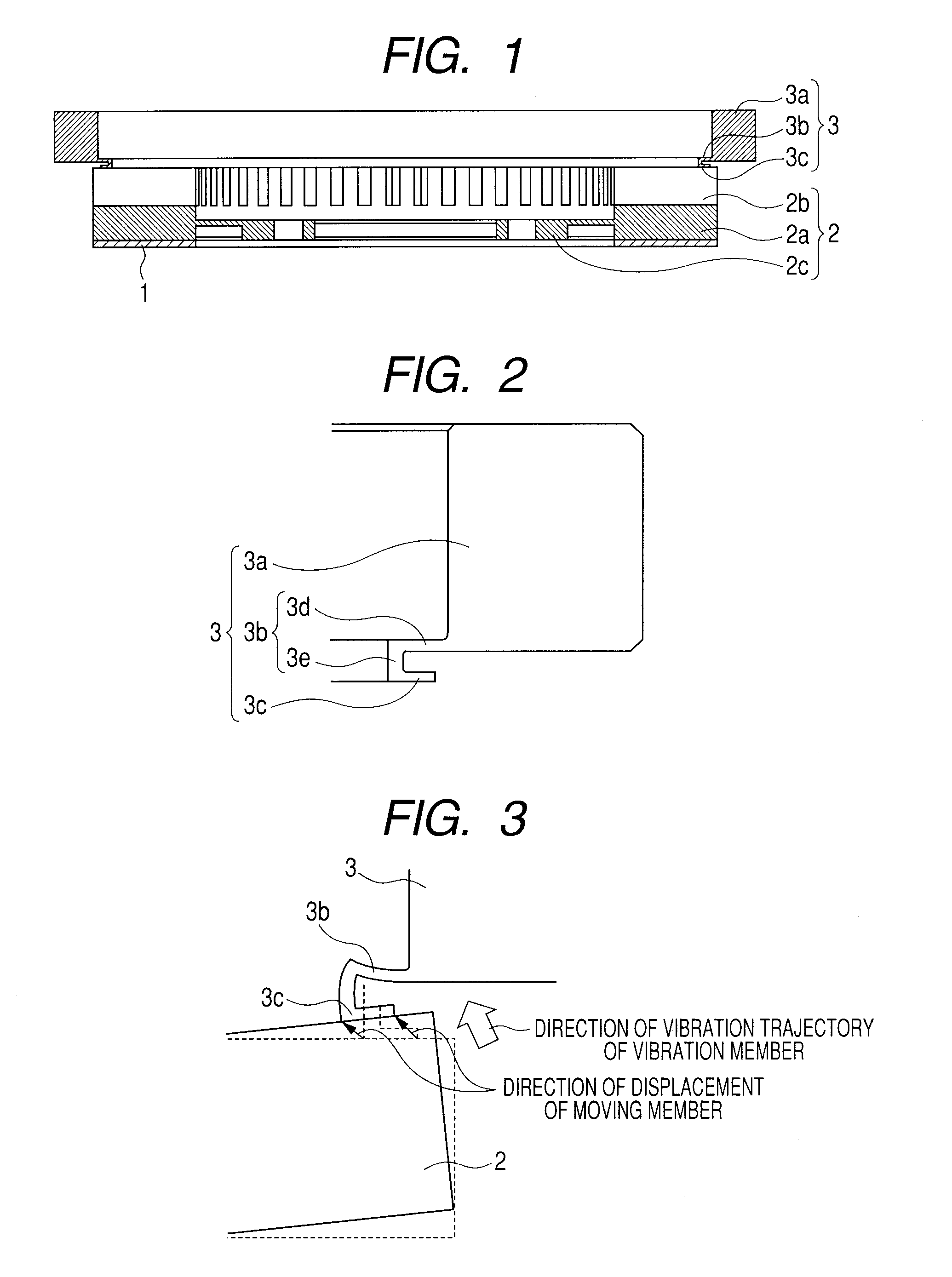

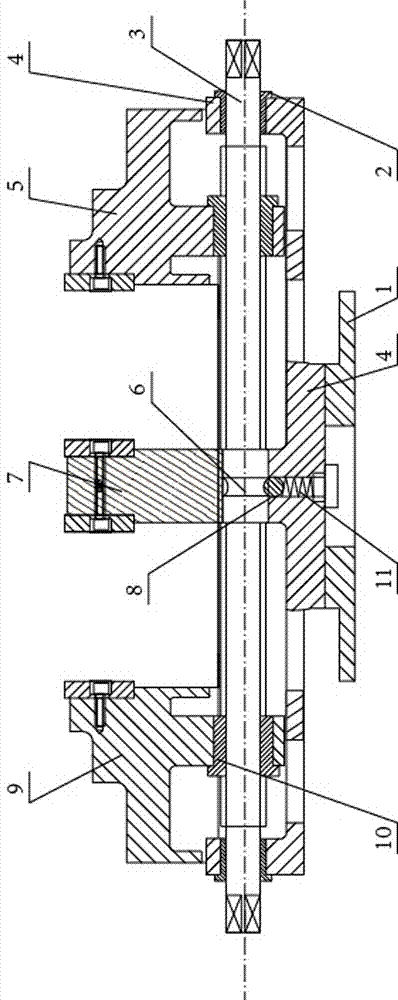

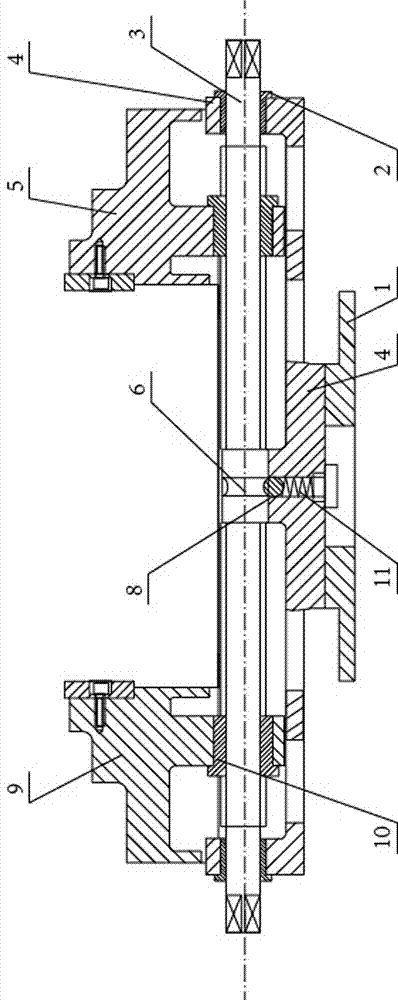

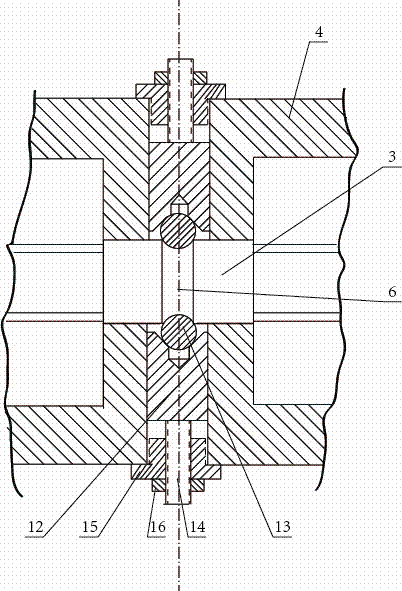

Vibration wave driving apparatus

InactiveUS20060220496A1Change inclinationReduce local wearPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesEngineeringFixed Beam

This invention provides a vibration wave driving apparatus which makes it possible to reduce the localized abrasion of a contact member, and reduce the deterioration of performance due to long-term driving. This vibration wave driving apparatus has a contact member which is provided with fixed portions fixed to the lengthwise opposite end portions of the vibration expanding portion of the vibration member, and a connecting portion integrally connecting the two fixed portions together and having opposite ends fixed beam structure divided into a plurality.

Owner:CANON KK

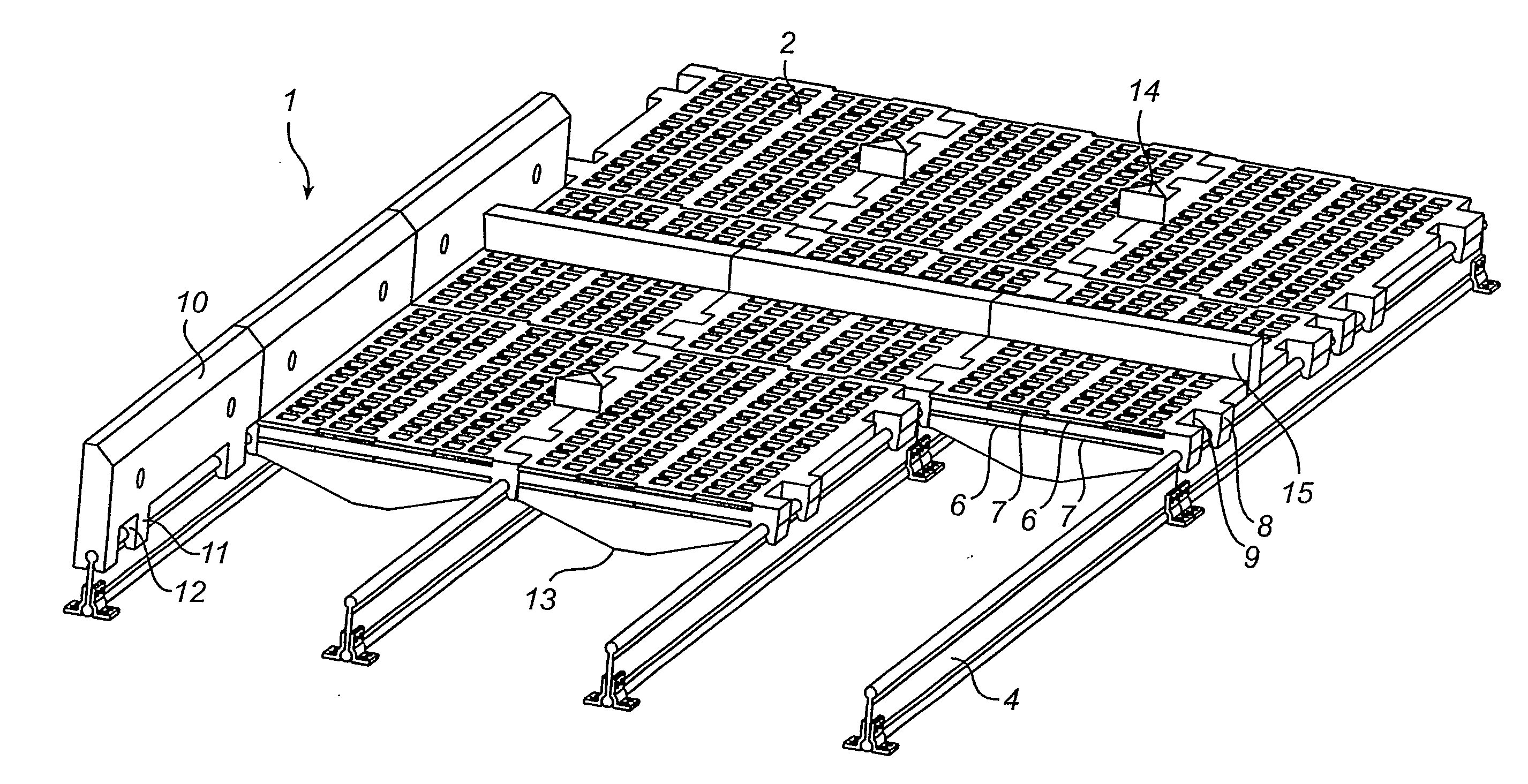

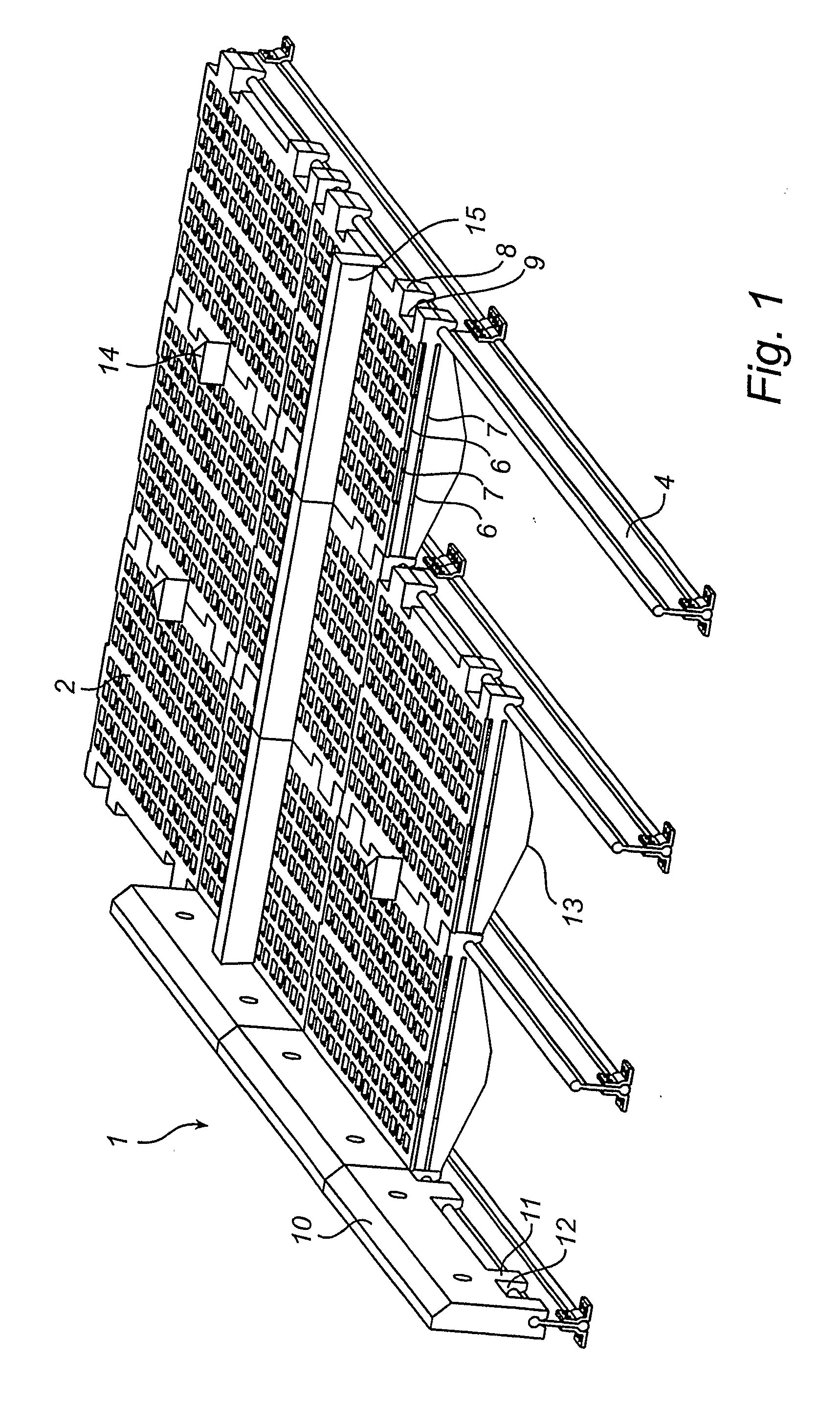

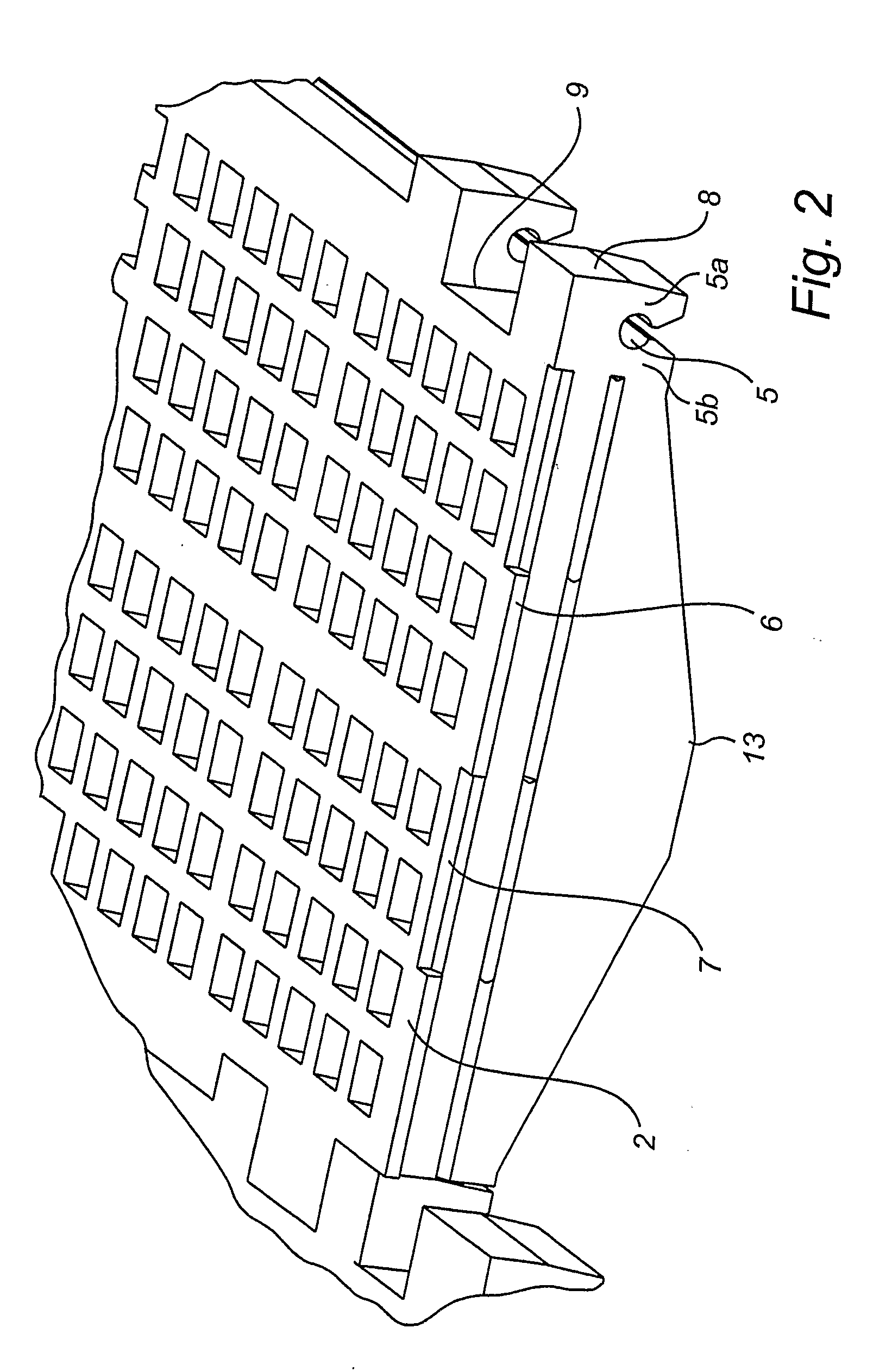

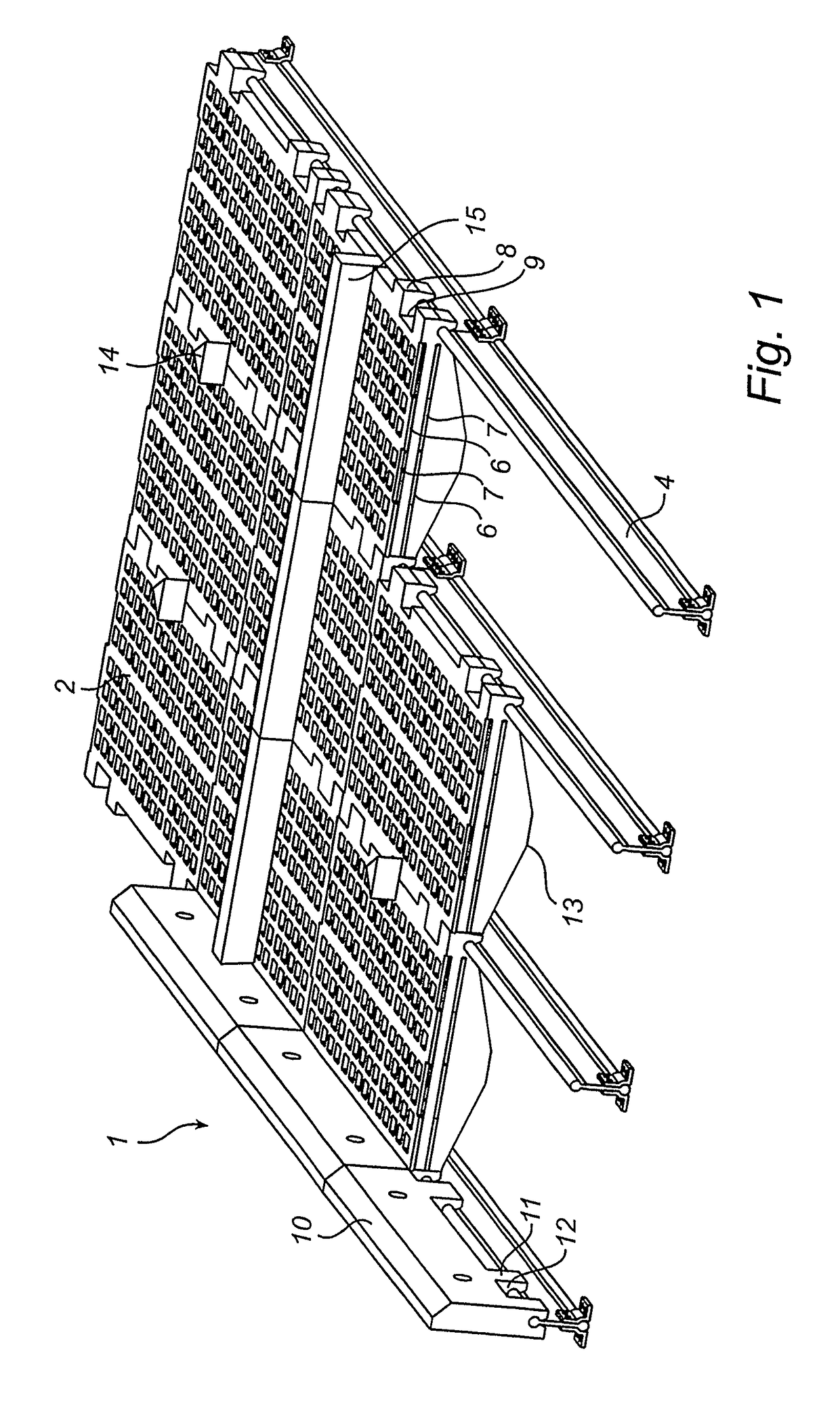

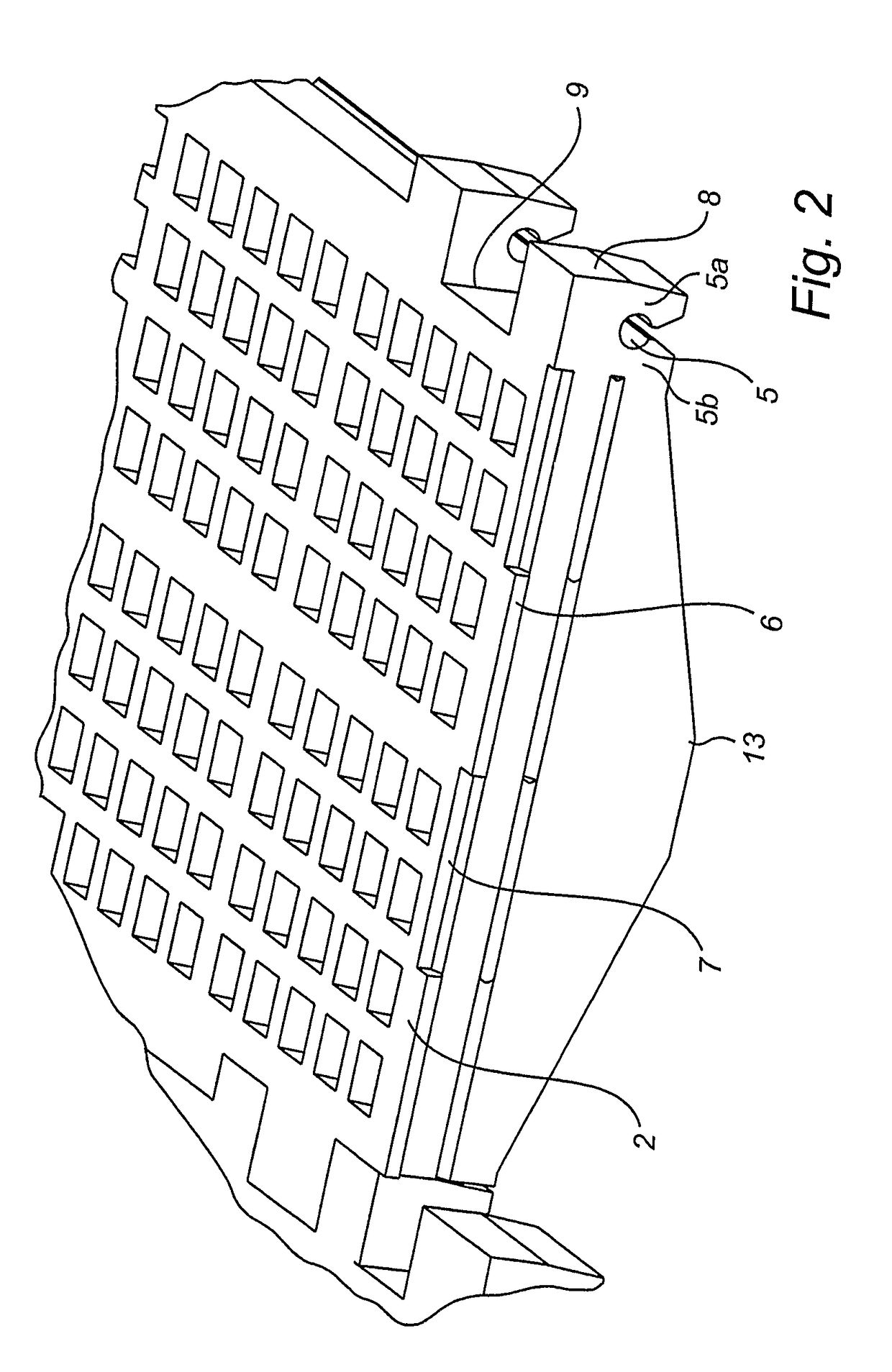

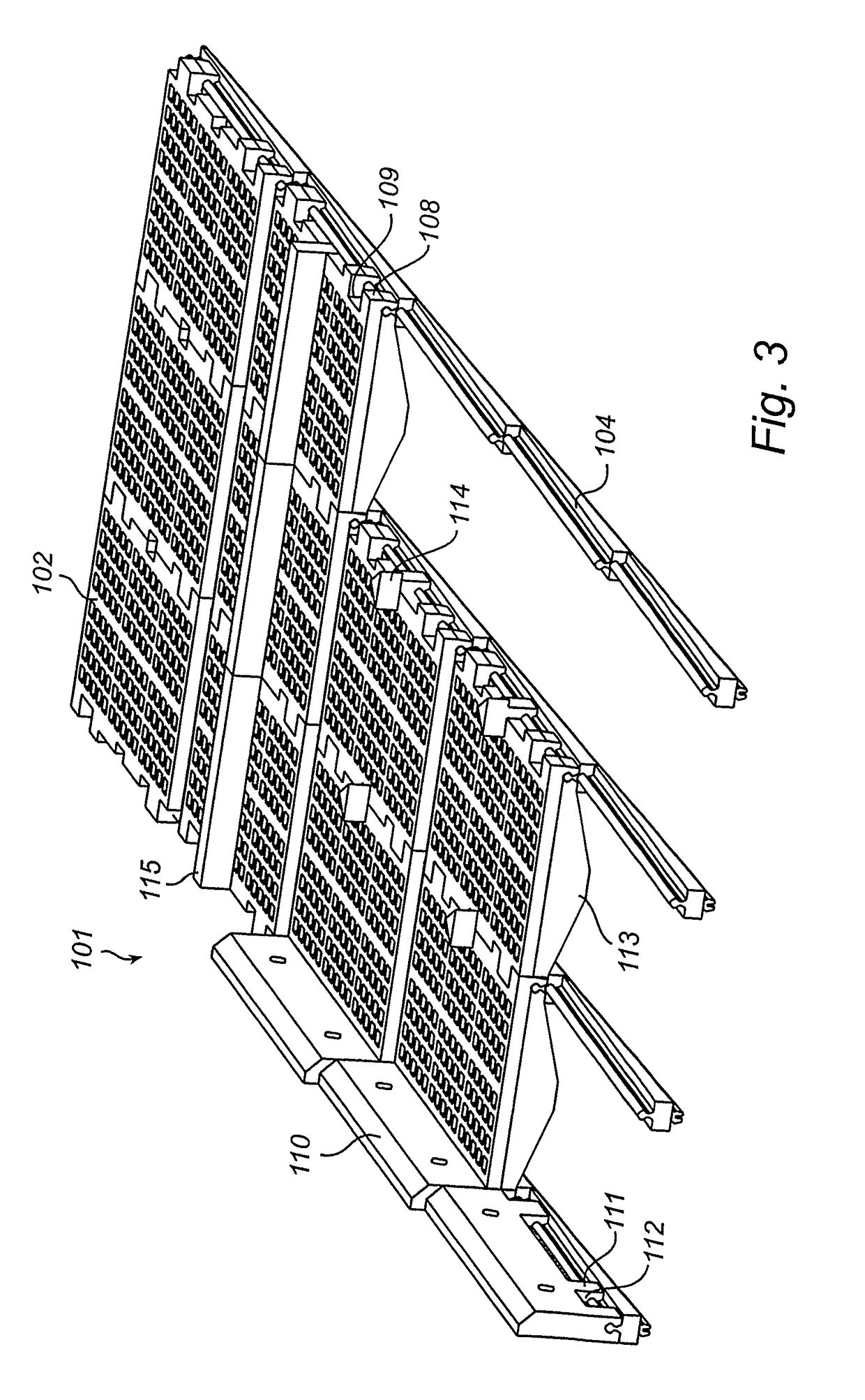

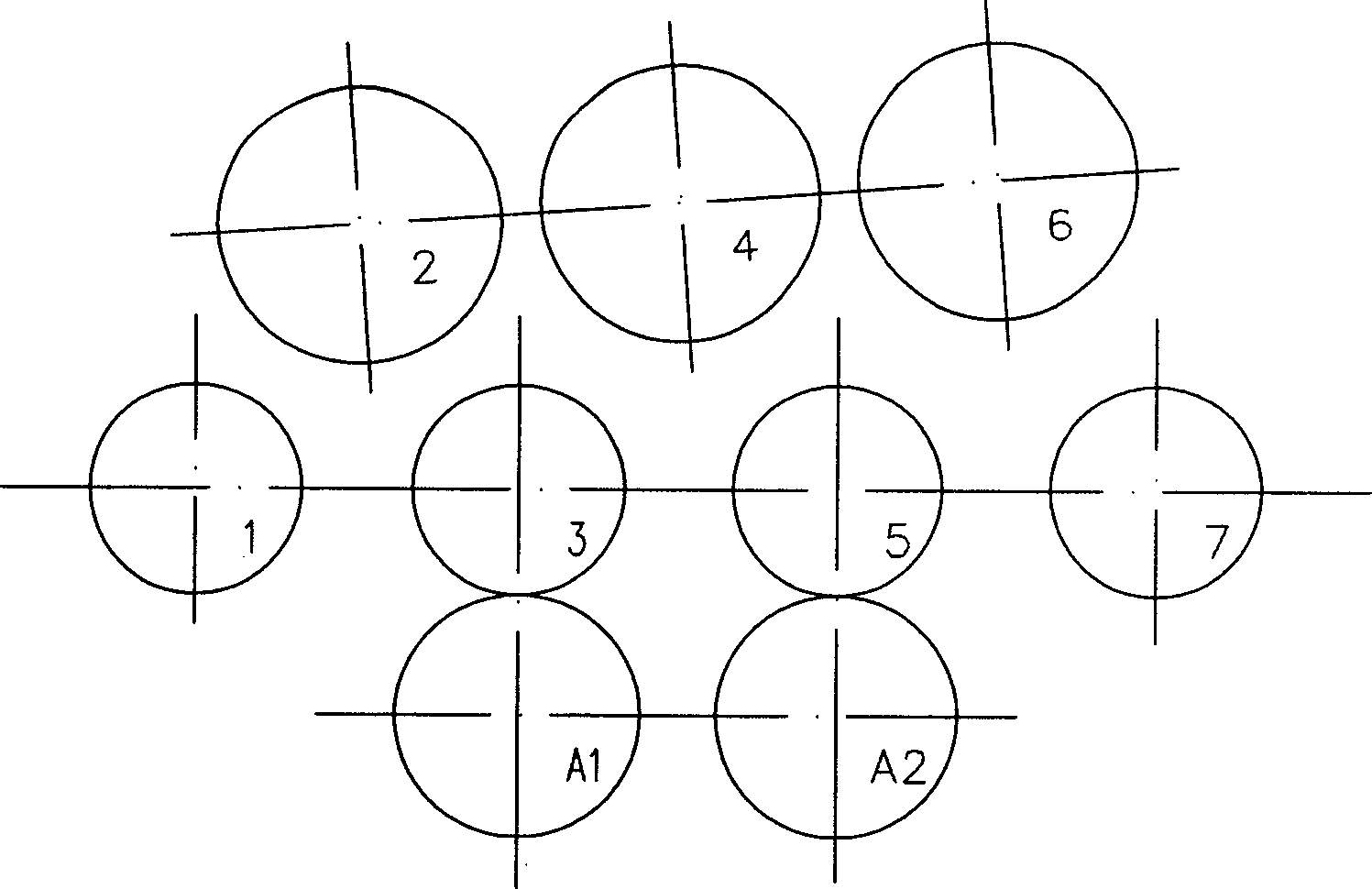

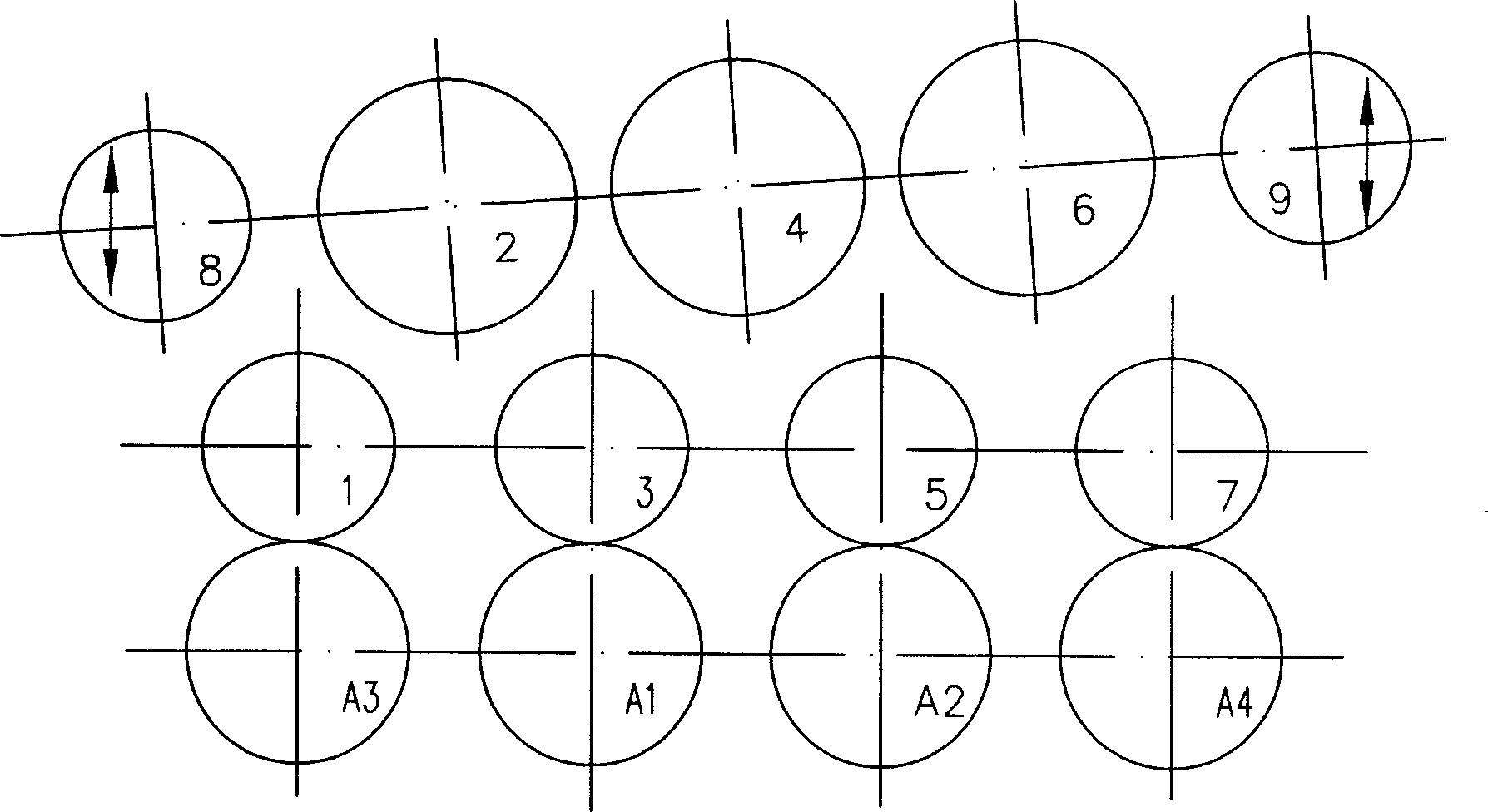

Screen and Screen Element

Owner:METSO OUTOTEC (FINLAND) OY

Thread turning process

The thread turning process includes the following steps: 1. rough machining of workpiece with rough turning tool; and 2. correcting thread form and eliminating the accumulated error of thread to obtain the required machining precision with finishing tool. The present invention has reduced wear of the finishing tool and raised thread machining precision.

Owner:祁宝栋

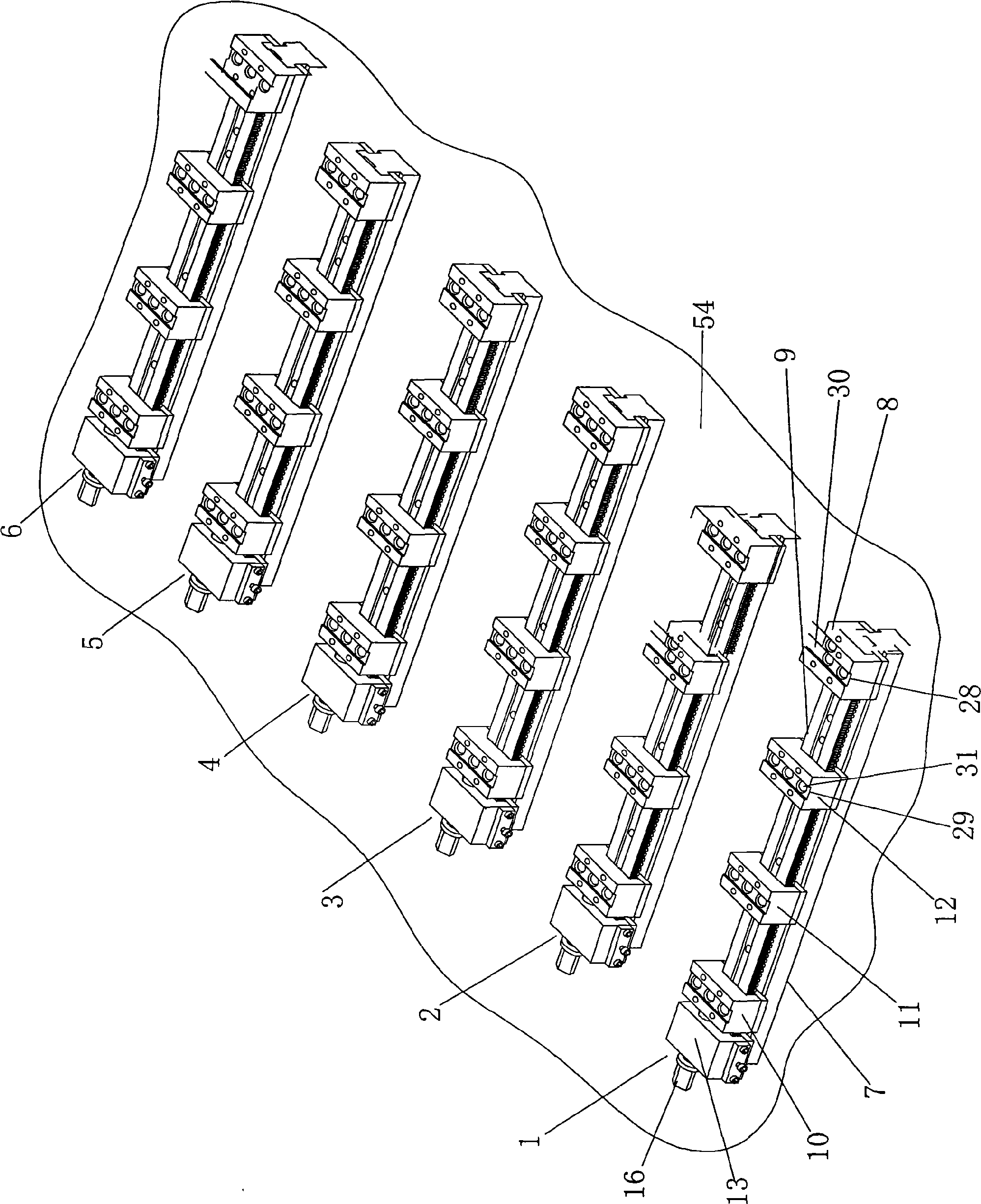

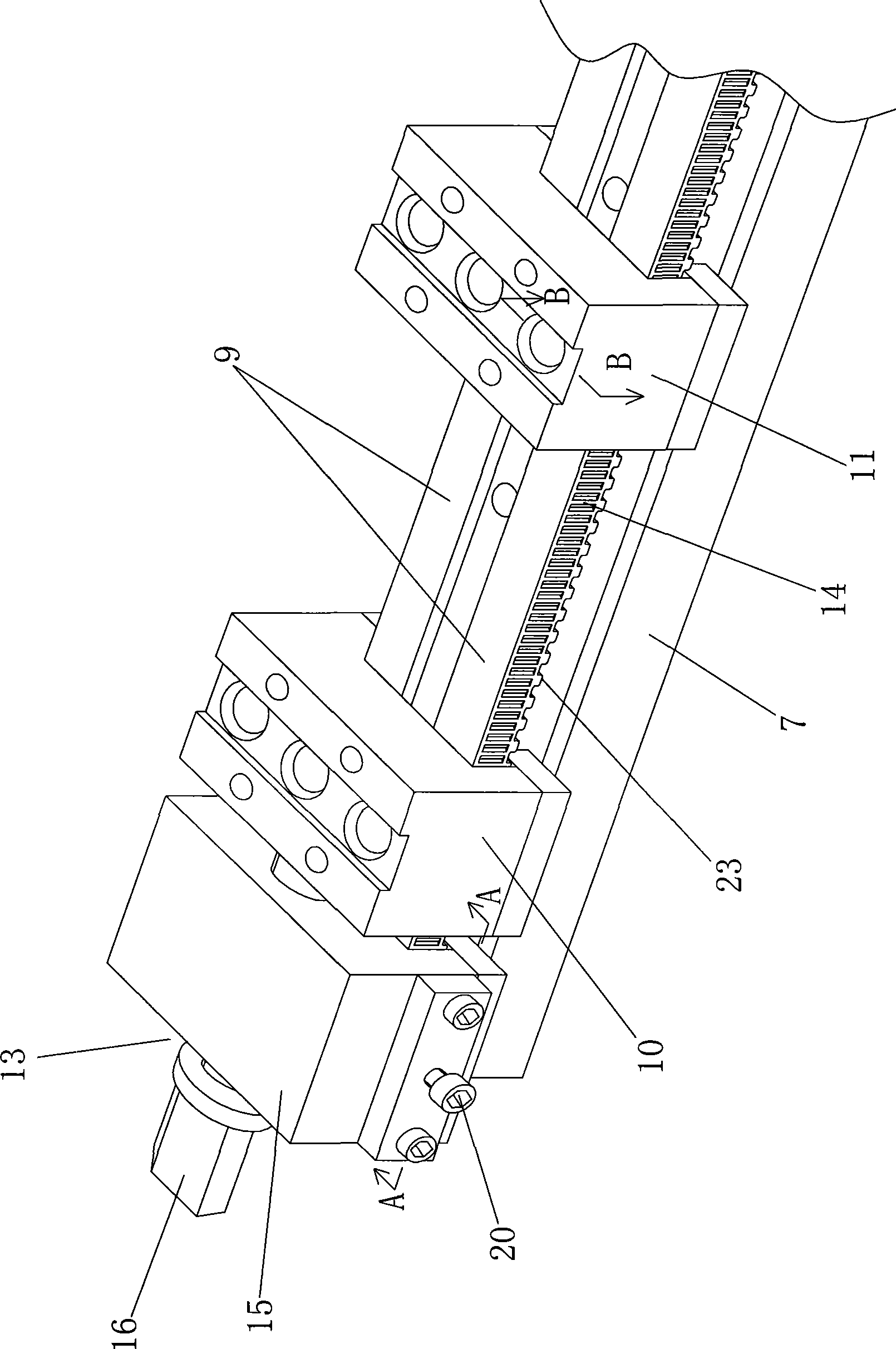

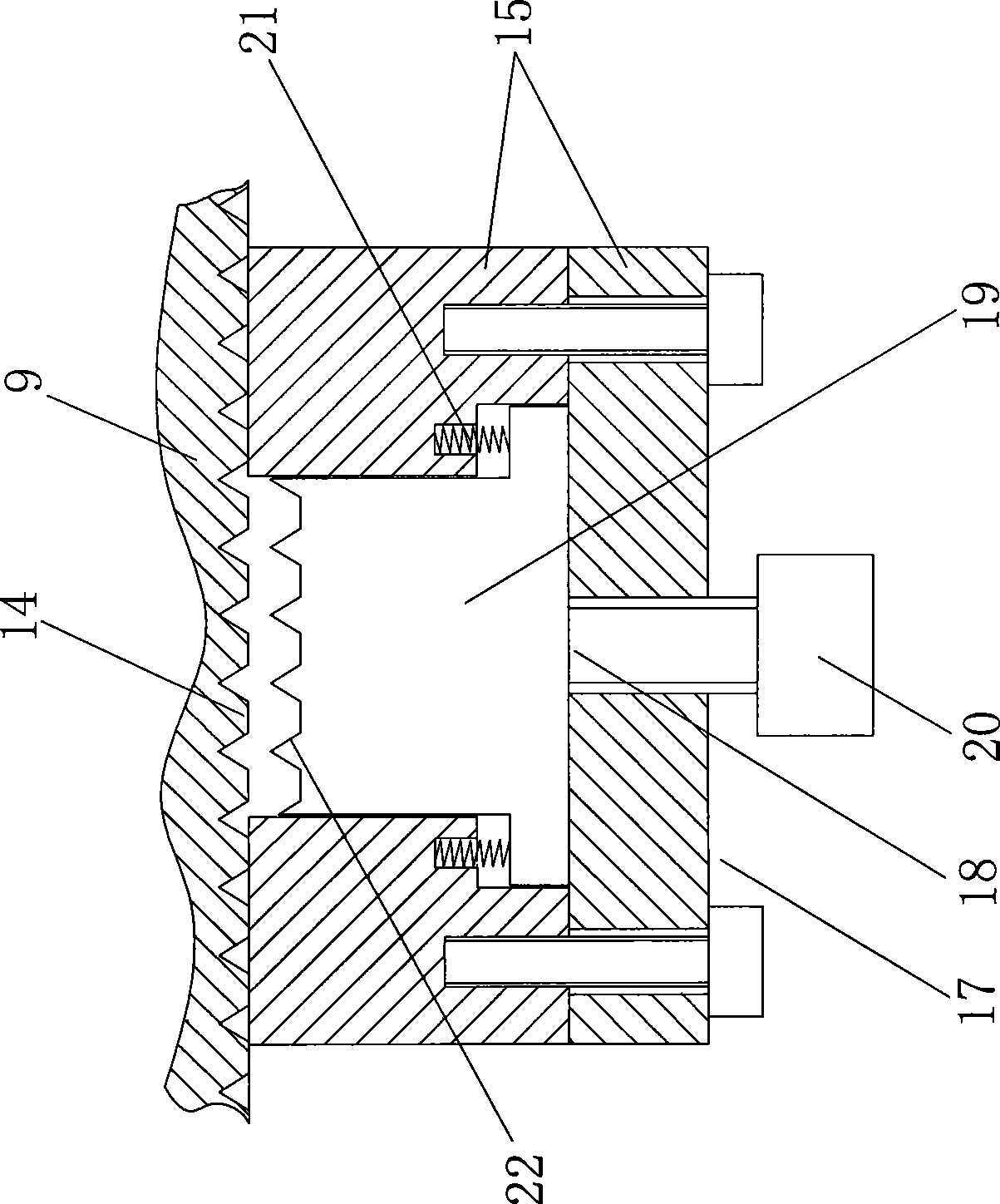

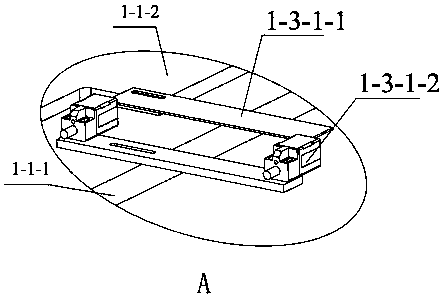

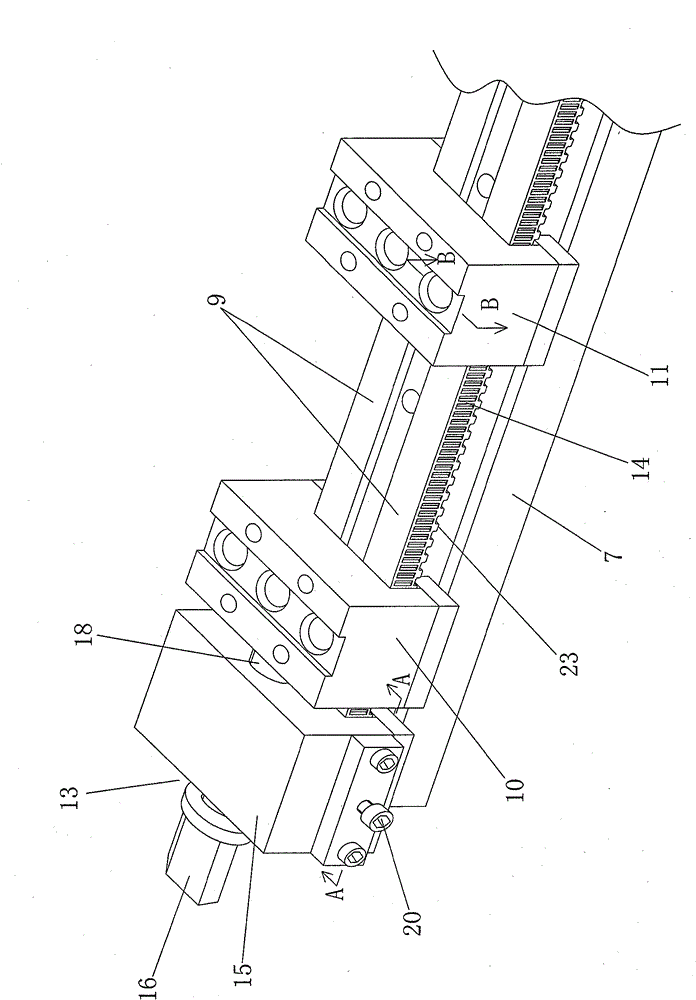

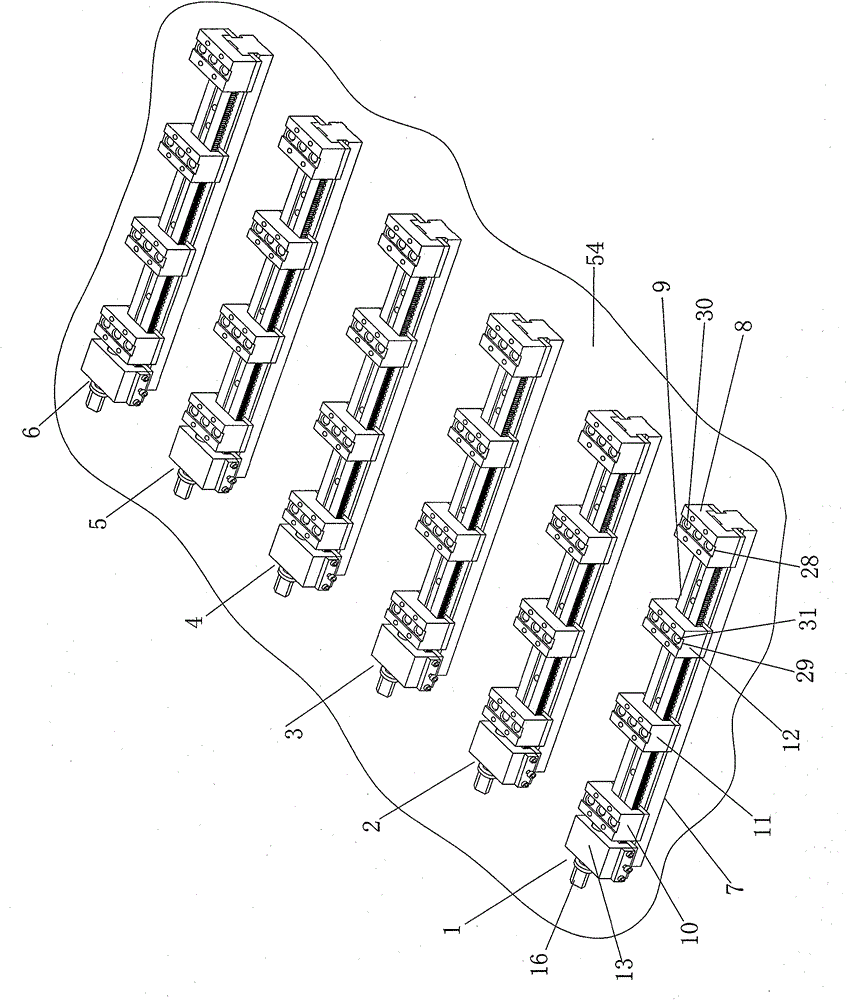

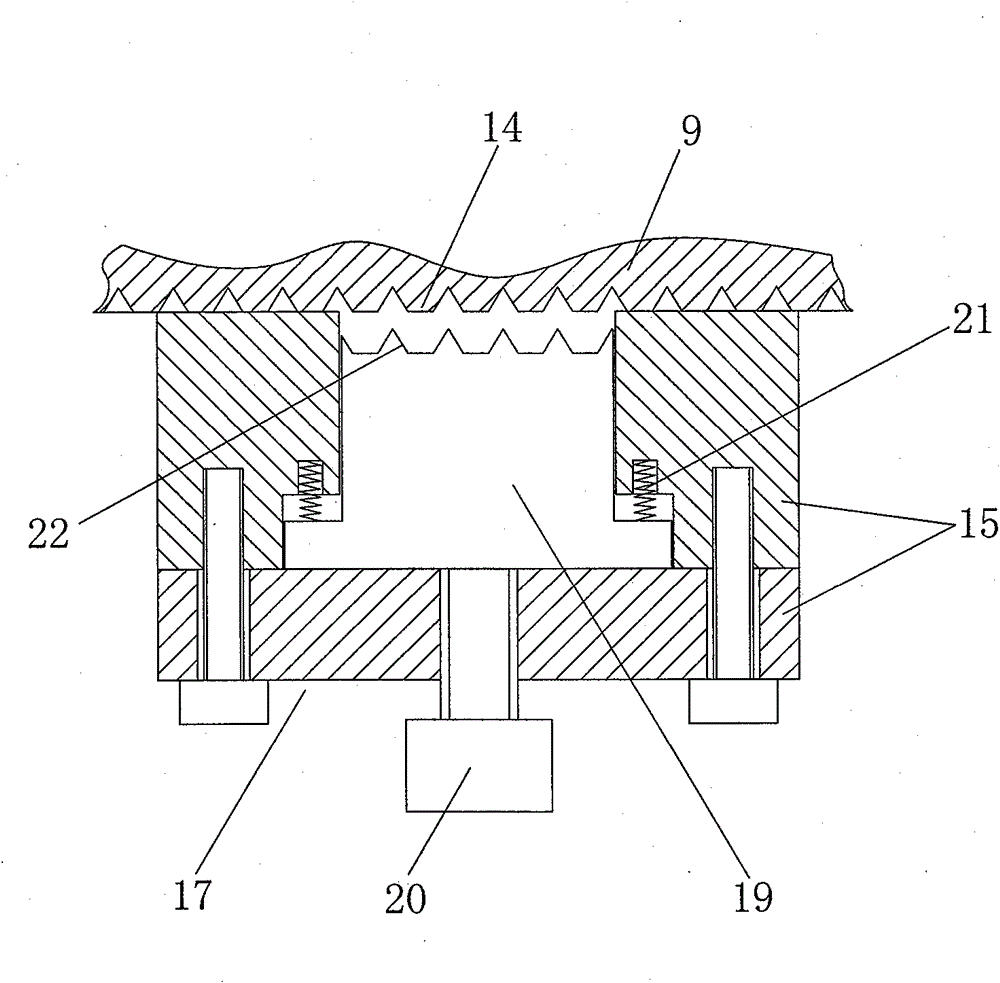

Juggle type precise flat tong for machine tool with large processing table

InactiveCN101502936AImprove work efficiencyReduce local wearPositioning apparatusMetal-working holdersMachine toolWear and tear

The invention relates to building block system precision flat-nose pliers for large processing table facet machine. The building block system precision flat-nose pliers is essentially to solve the problems of low machine work efficiency of the machine, noticeable partial wear and tear on operation parts of the machine, and poor processing precision of the work pieces with poor rigidity existed in the prior art. The technical proposal is as follows: a group of flat-nose pliers are installed on the work table facet of a machine, which is characterized in that a group of flat-nose pliers comprise three or more independent flat-nose pliers arranged in parallel; each independent flat-nose plier comprises a block, a fixed jaw fixed on the block, two or more movable jaws matched on the block guide rail in a sliding way, and a quick travel mechanism installed on the block; both outer side faces of the block guide rail are equipped with teeth rows; the quick travel mechanism comprises a nut seat matched with the block guide rail in a sliding way, a thrust screw thread matched with the nut seat by screw, and an expansion device arranged on both sides of the nut seat and matched with the teeth rows on both outer side faces of the block guide rail; and a thrust end of the thrust screw is matched with one movable jaw.

Owner:张应祥

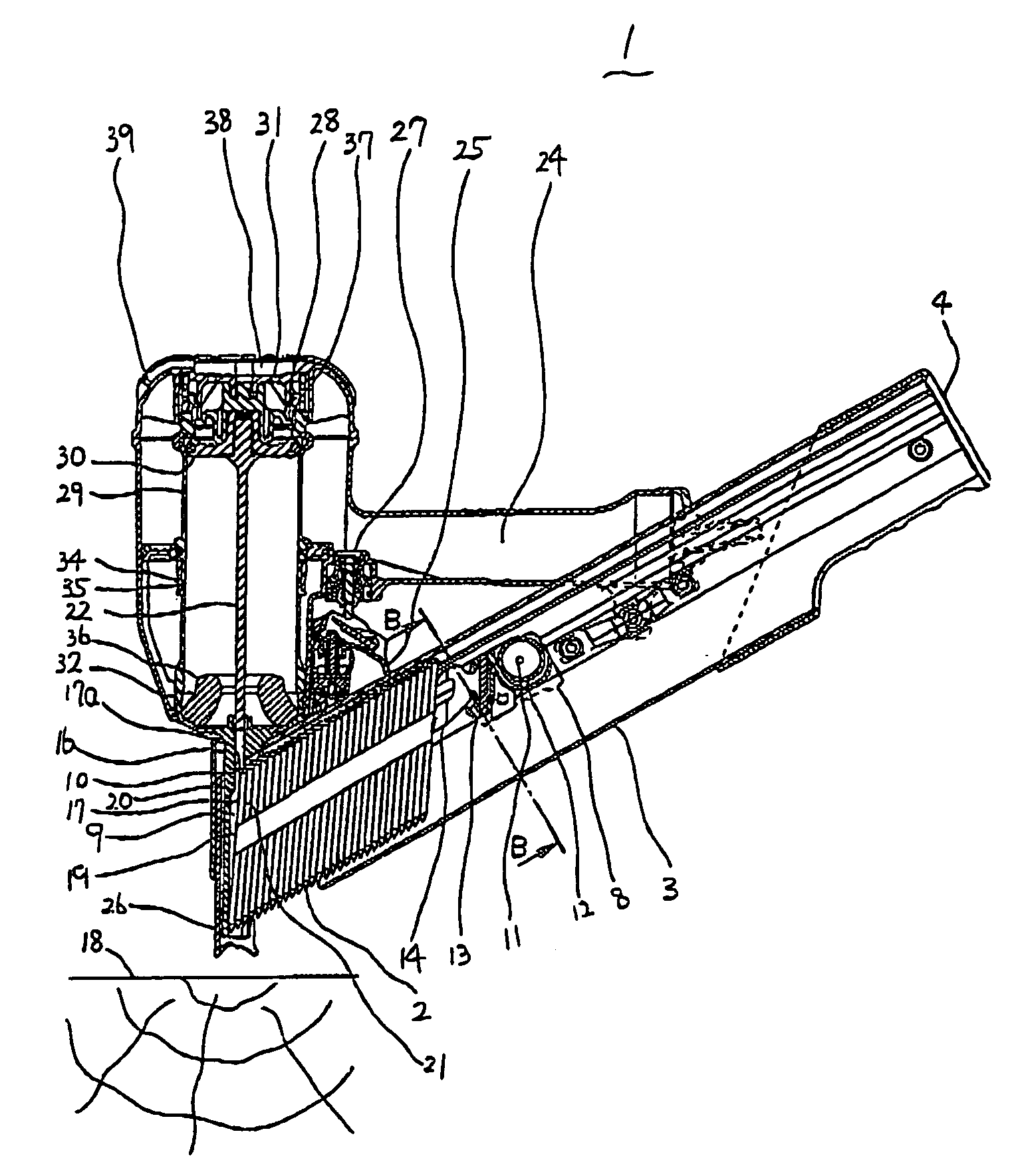

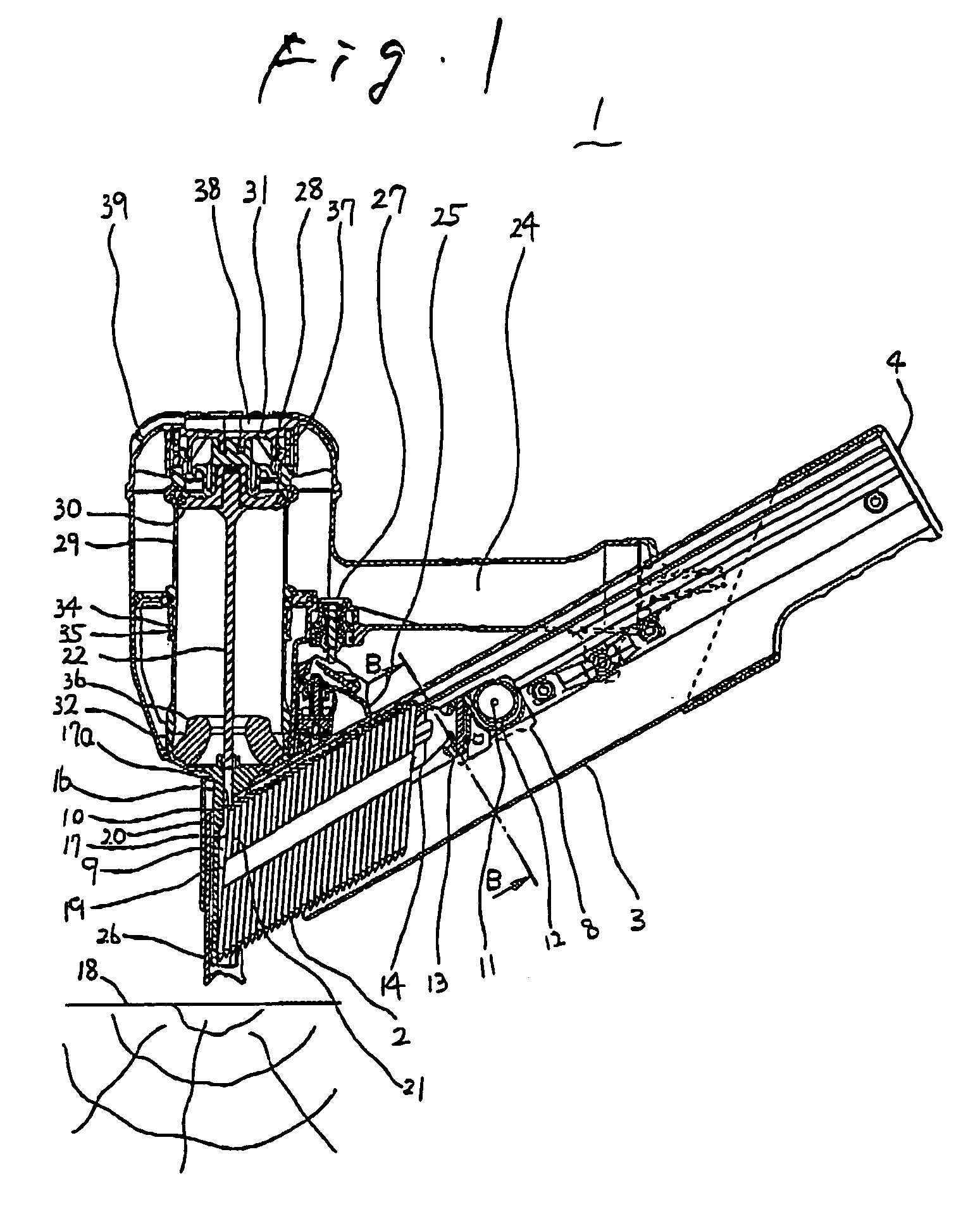

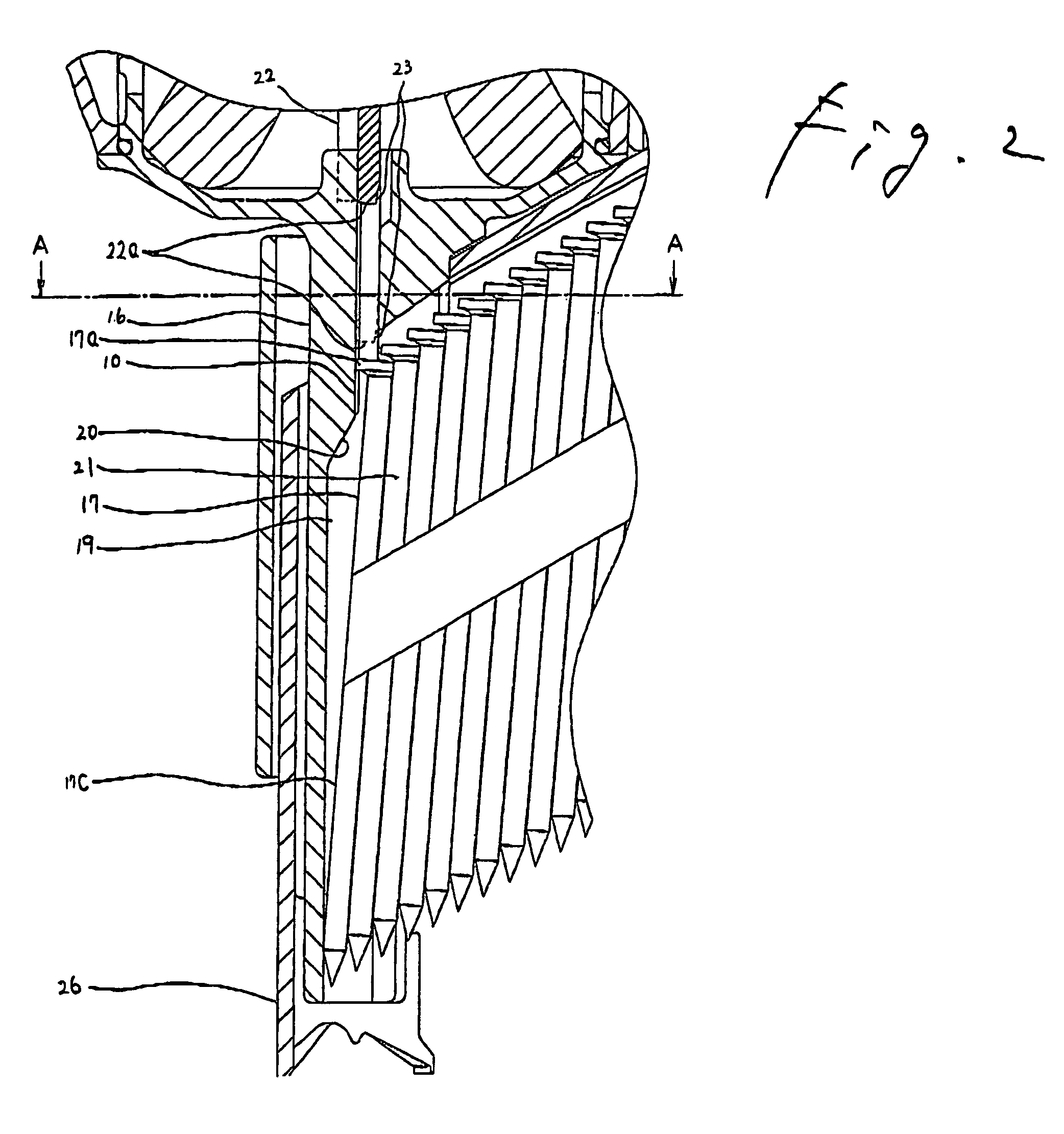

Fastener driving tool

A fastener driving tool includes: a driver blade adapted to drive nails joined to one another into an object in order; a nose adapted to guide the driver blade and nails; and a guide surface of a projection adapted to guide a head portion of a first nail struck out into an exit hole of the nose so that the second nail is not exposed to the exit hole. The guide surface of the projection is formed to a shape identical with that of the head portions of the nails.

Owner:KOKI HLDG CO LTD

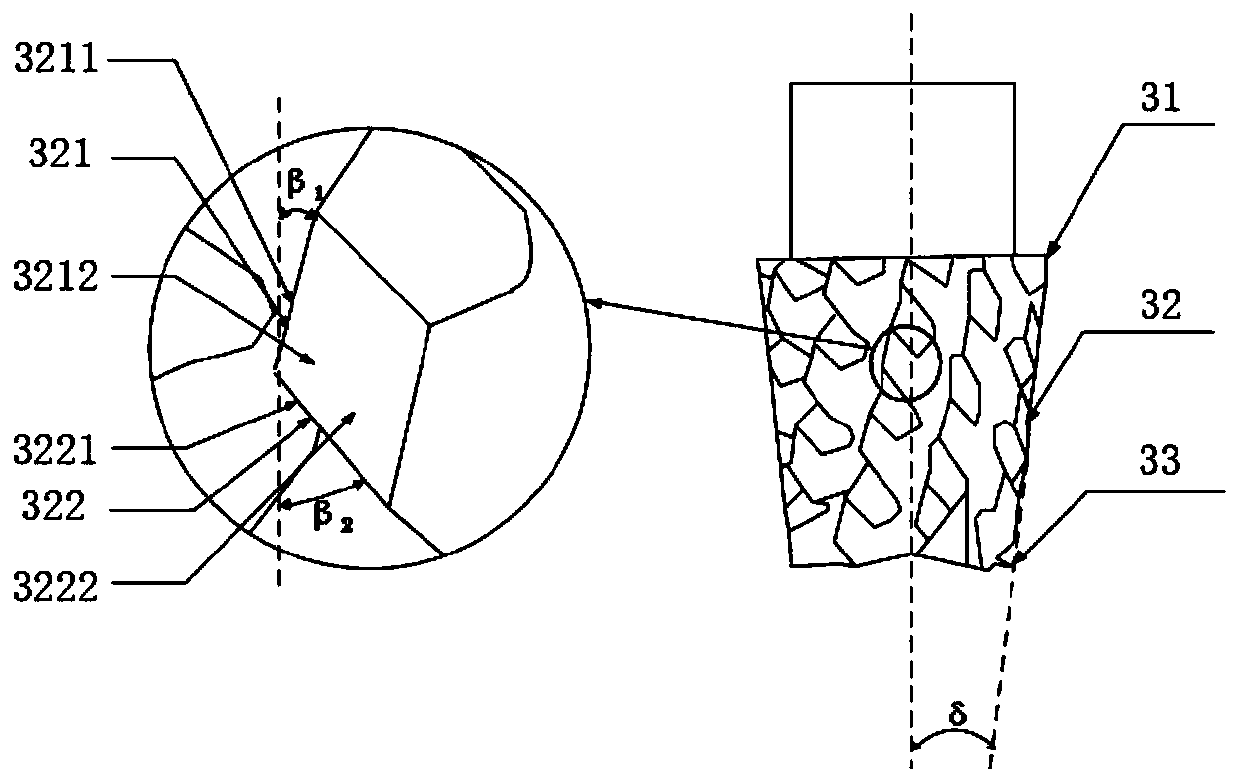

Anti-slag-bonding whirling pulverized coal combustor with low NOx

ActiveCN102878553AReduce local wearReduce washoutPulverulent fuel combustion burnersPower stationCombustor

The invention relates to an anti-slag-bonding whirling pulverized coal combustor with low NOx, which belongs to the technical field of power station boilers; the anti-slag-bonding whirled pulverized coal combustor comprises a central direct current air pipe, a primary air pipe, an inner secondary whirling air pipe, a middle secondary whirling air pipe, an adherence outer secondary direct current air pipe, a bow-shaped pulverized coal concentration separator and an air pipe expansion opening, wherein the central direct current air pipe is arranged on a center position in the primary air pipe; the inner secondary whirling air pipe is arranged outside the primary air pipe; the middle secondary whirling air pipe is arranged outside the inner secondary whirling air pipe; and the adherence outer secondary direct current air pipe is arranged outside the secondary whirling air pipe. According to the invention, the strong / thin separation of the pulverized coal in the primary air pipe is realized and is reasonably matched with air distribution so as to realize stable combustion with low air staging NOx; simultaneously, slag bonding because high-temperature melted ash content is contacted with a boiler wall is prevented effectively; and the anti-slag-bonding whirling pulverized coal combustor is characterized by simple structure, low resistance, abrasion prevention, convenient application and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

Piston for internal combustion engines

ActiveUS8157268B2Reduce local wearMinimize risk of failurePiston ringsBraking action transmissionCombustionPiston ring

The present invention relates to a piston ring (10), particularly a compression ring, for an internal combustion engine, comprising a ring-shaped body (11) having a ring joint (13) formed by butt ends (14a, 14b), the ring-shaped body (11) further having a ring contact face (12) along its perimeter, for contacting a cylinder wall in operation. According to the invention, the ring contact face (12) has a barrel-shaped profile, the barrel-shaped profile having in any of its cross-sections an area of maximum curvature, whose radius of curvature increases in the direction of the butt ends (14a, 14b).

Owner:MAHLE INT GMBH +1

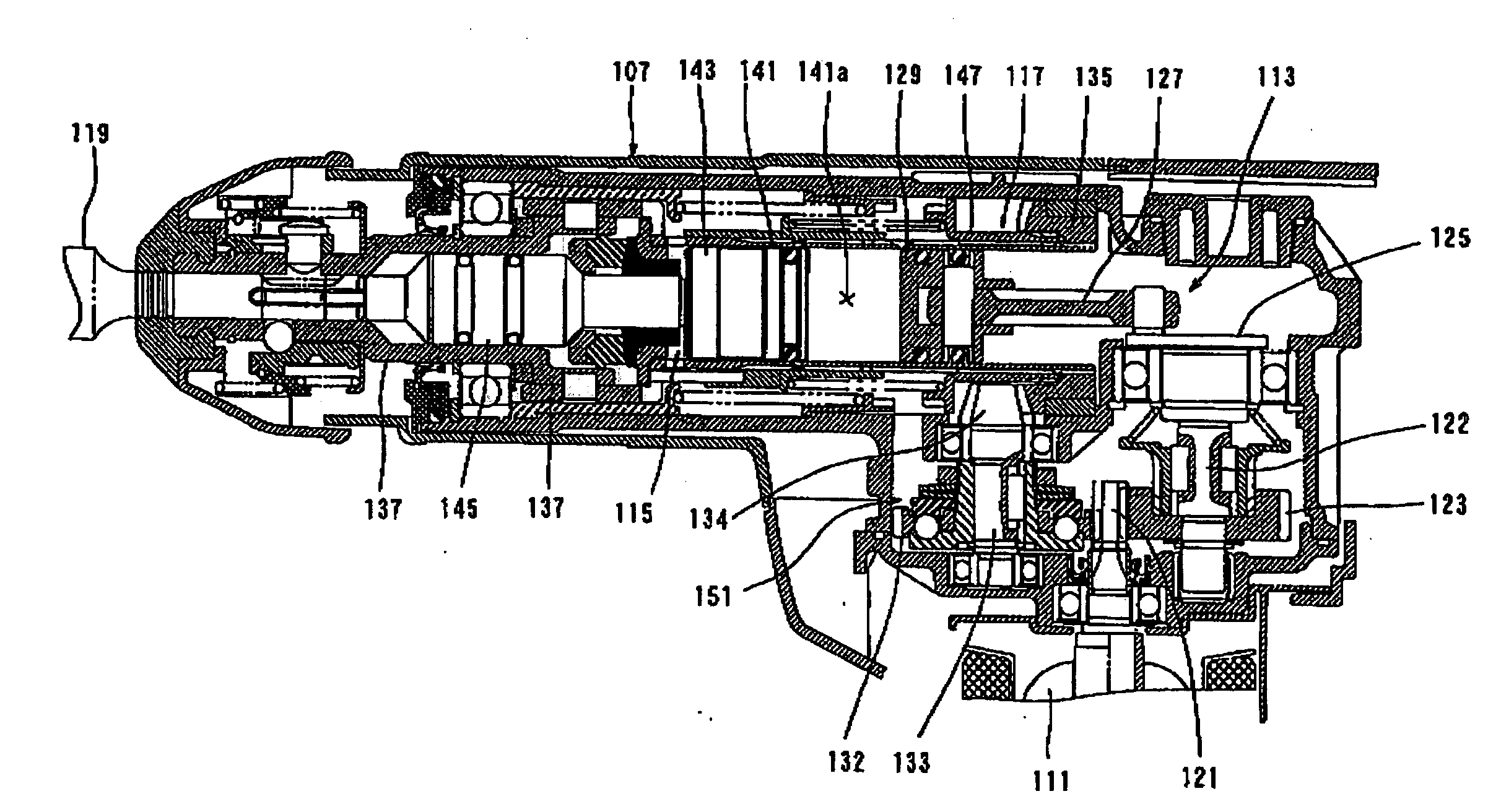

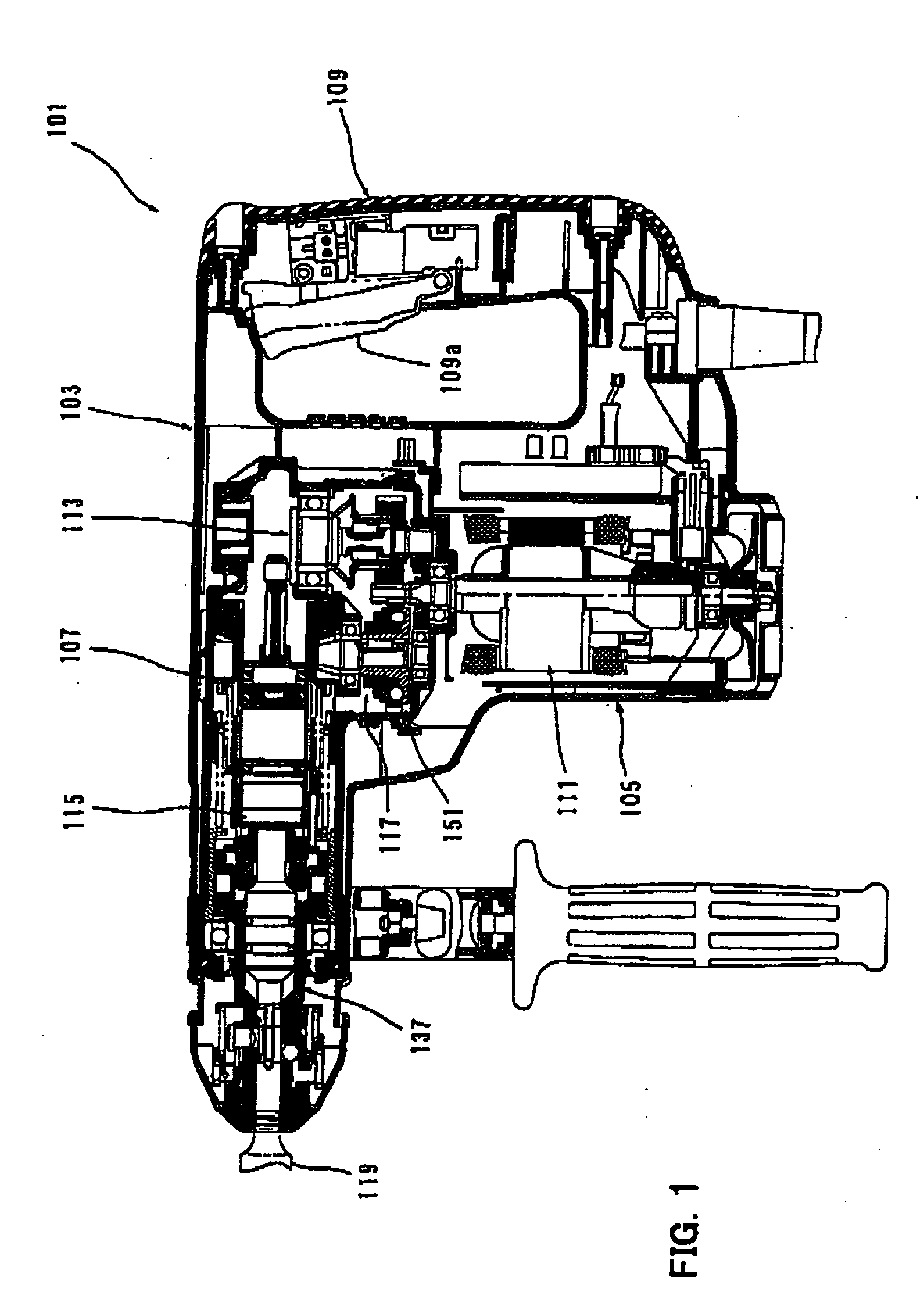

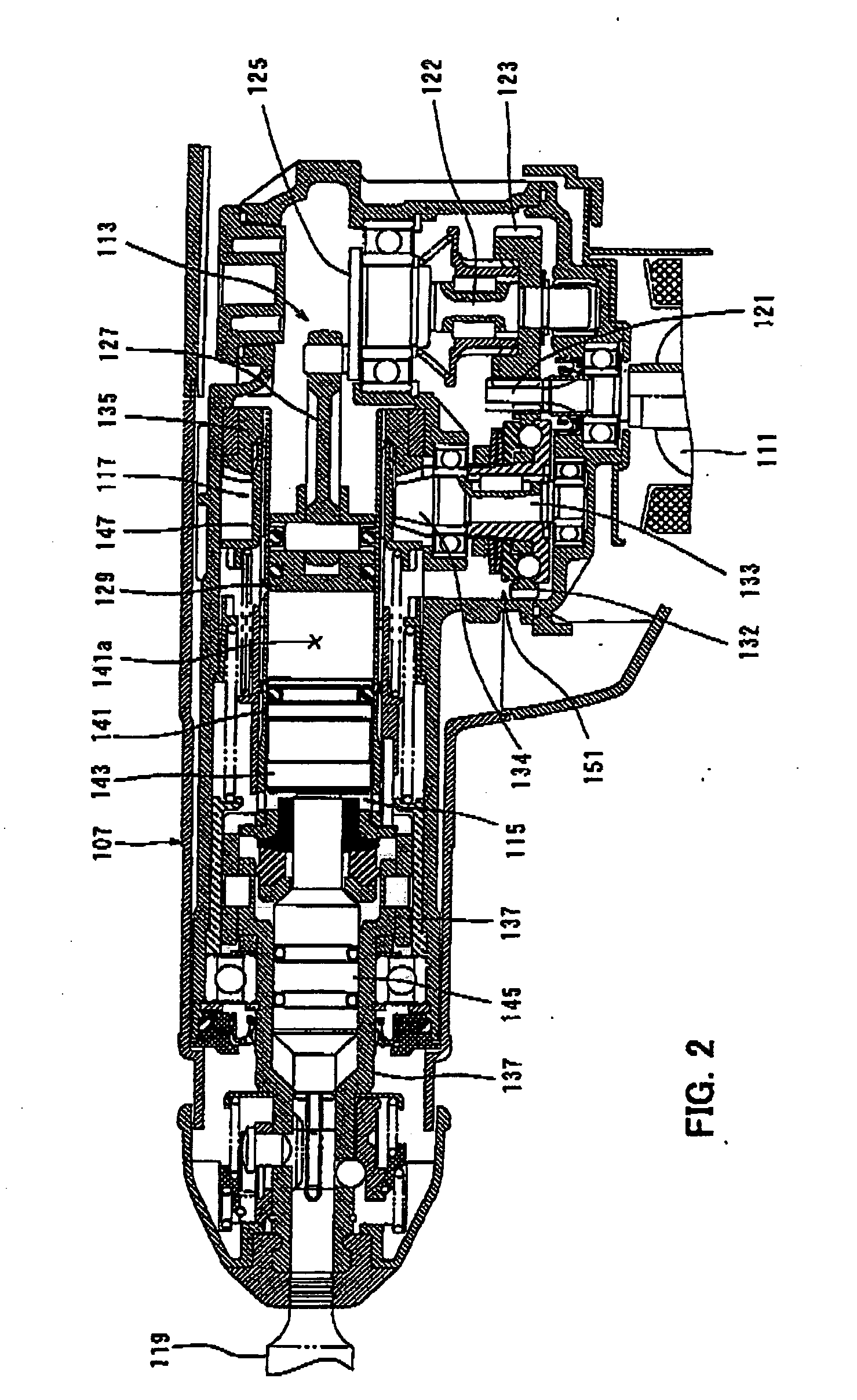

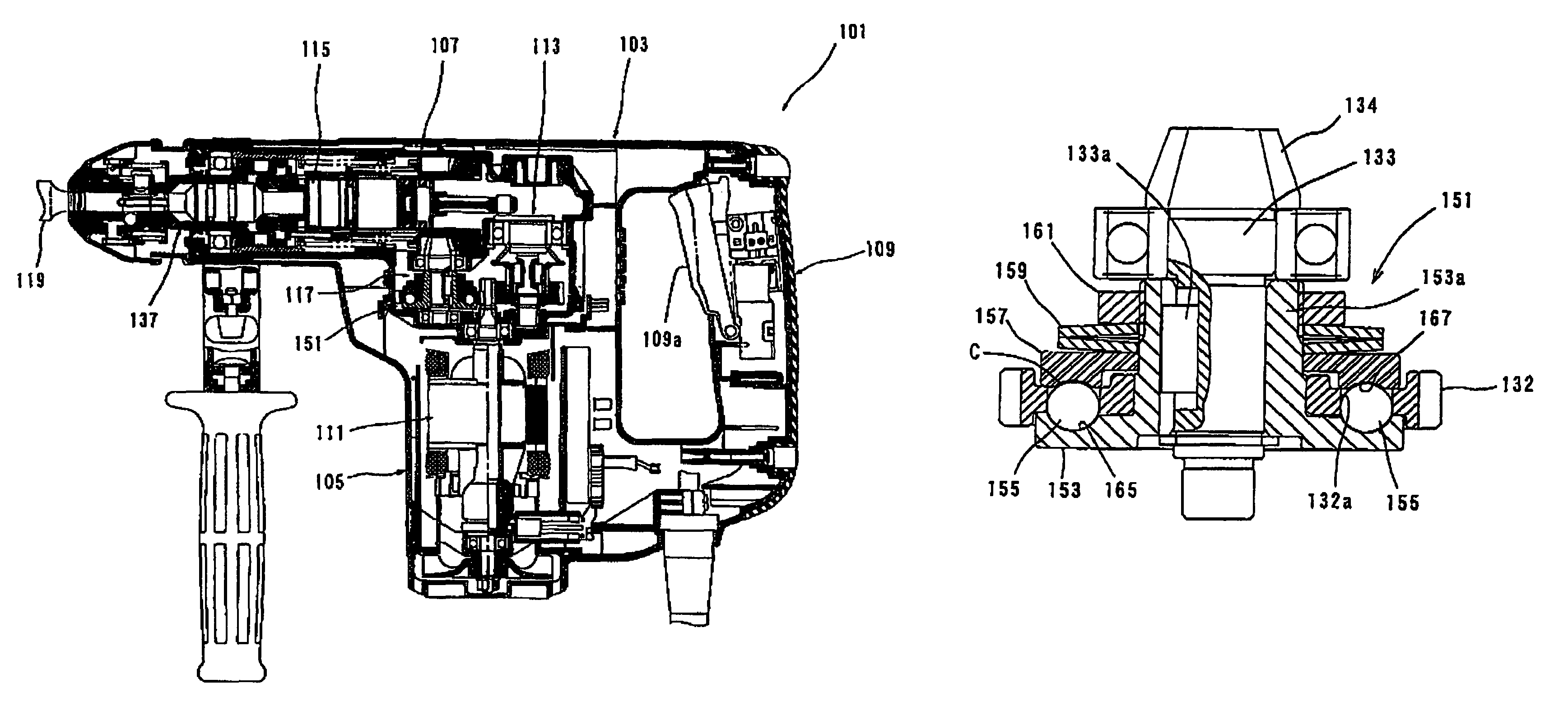

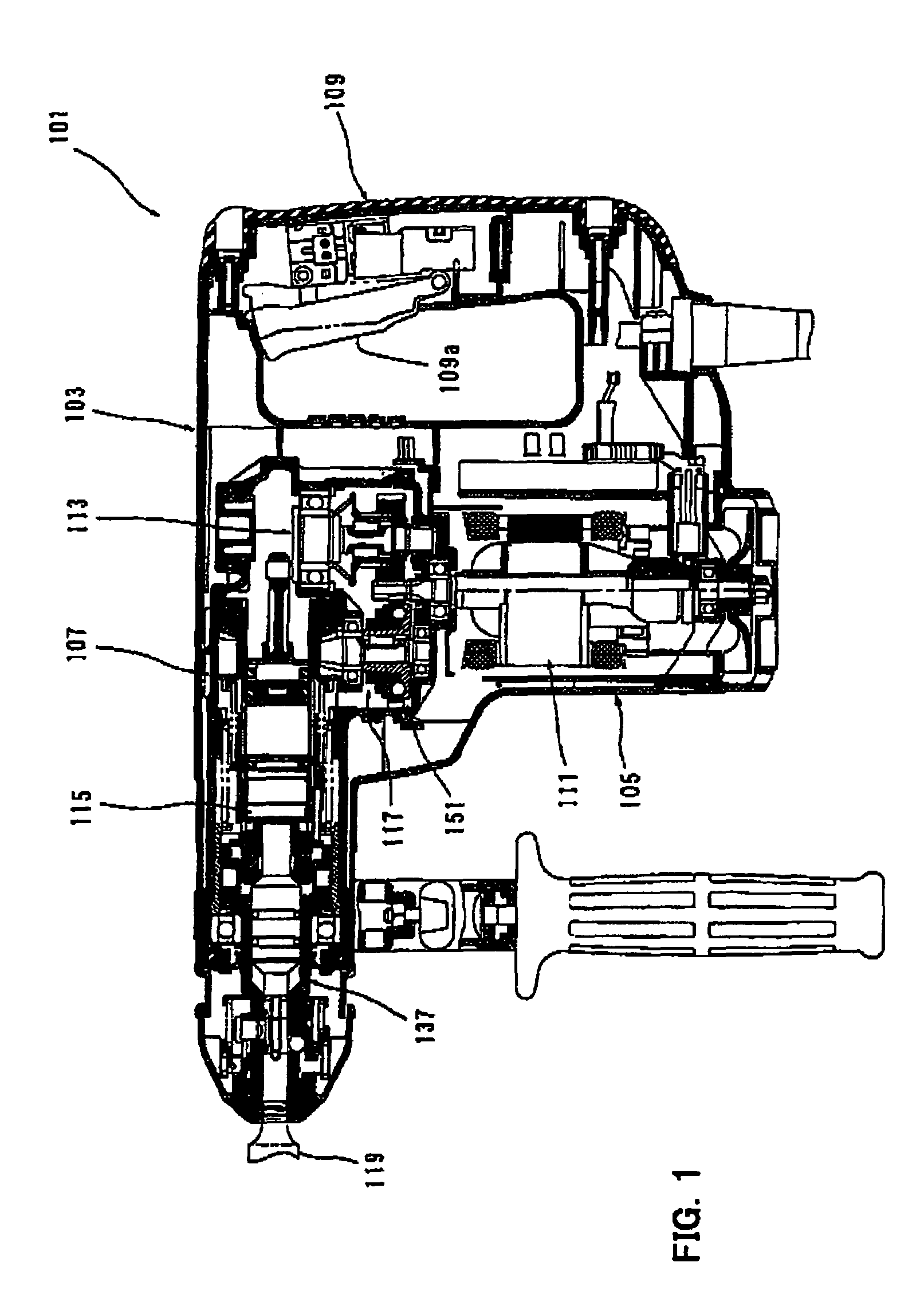

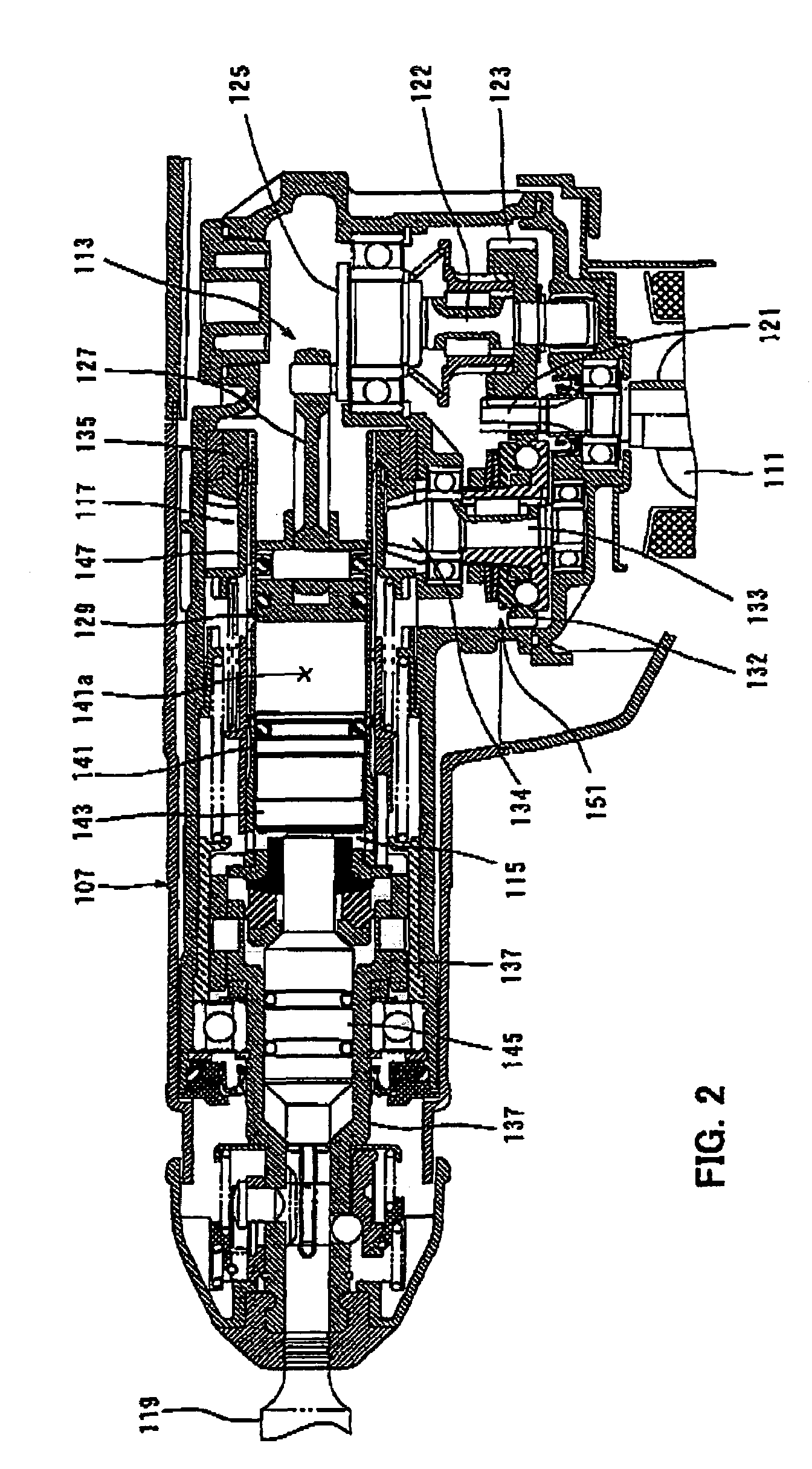

Power tool

ActiveUS20070158088A1Increased durabilityReduce wearDrilling rodsMechanical actuated clutchesTorque transmissionEngineering

It is an object of the invention to provide an effective technique for improving the durability of a torque limiter utilized in a power tool. The object is achieved by a representative power tool comprising a tool bit, a driving mechanism and a torque limiter. The torque limiter includes first and second rotating members, a ball, a pressing member and an elastic member. The second rotating member includes a power transmitting region with a groove continuously formed from a deepest groove part to a shallowest groove part to allow torque transmission and a power transmission interrupted region with a groove shallower than the shallowest groove part of the power transmitting region to interrupts the torque transmission. According to this construction, when the ball is in the power transmitting region, the pressing member contacts the first rotating member and is held in a position in which the biasing force of the elastic member is prevented from acting upon the ball.

Owner:MAKITA CORP

Power tool

ActiveUS7591326B2Increased durabilityReduce wearDrilling rodsMechanical actuated clutchesTorque transmissionEngineering

It is an object of the invention to provide an effective technique for improving the durability of a torque limiter utilized in a power tool. The object is achieved by a representative power tool comprising a tool bit, a driving mechanism and a torque limiter. The torque limiter includes first and second rotating members, a ball, a pressing member and an elastic member. The second rotating member includes a power transmitting region with a groove continuously formed from a deepest groove part to a shallowest groove part to allow torque transmission and a power transmission interrupted region with a groove shallower than the shallowest groove part of the power transmitting region to interrupts the torque transmission. According to this construction, when the ball is in the power transmitting region, the pressing member contacts the first rotating member and is held in a position in which the biasing force of the elastic member is prevented from acting upon the ball.

Owner:MAKITA CORP

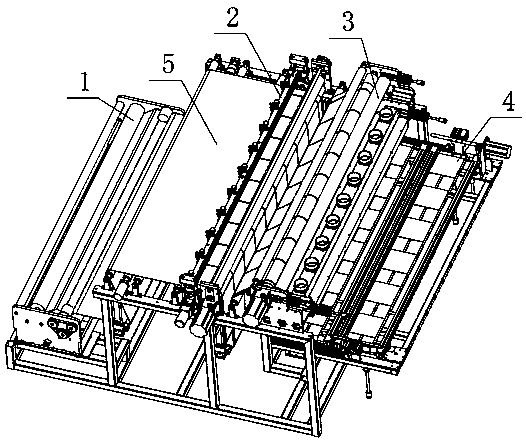

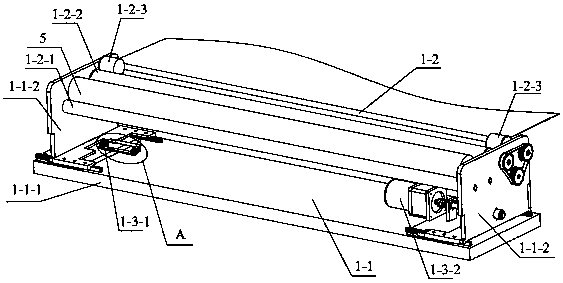

Production line for cloth cutting

ActiveCN109626048APrevent slippingUniform feedingSevering textilesTextile disintegration and recoveryProduction lineMechanical equipment

The invention discloses a production line for cloth cutting, aims at solving disadvantage that when cutting processing is performed on cloth, mechanical equipment have various problems in actual production to influence the processing quality, and the production efficiency is influenced by material receiving in a manual manner in the prior art and provides the production line for cloth cutting. Theproduction line for cloth cutting sequentially comprises a cloth releasing machine, a cloth strip cutting machine, a cloth block cutting machine and a cloth transferring machine in a cloth moving direction. The production line avoids the cloth from skidding, is beneficial to stably releasing the cloth at a constant speed, prolongs the service life of a hot knife, is beneficial to cutting the cloth, saves the manpower and improves the production efficiency by adopting automatic material receiving and is suitable for being used when the cloth is cut.

Owner:福建山普新材料有限公司

Ball-end milling cutter applicable to machining high-temperature alloy materials

The invention relates to a ball-end milling cutter applicable to machining high-temperature alloy materials. The ball-end milling cutter comprises a cutter clamping handle, a cutting portion and a transitional portion which are made of hard alloy materials, the transitional portion is positioned between the cutter clamping handle and the cutting portion, the cutting portion is provided with four spherical spiral cutting edges which are intersected at a ball end on the top of the milling cutter, a cutting edge passivation value of the ball end ranges from 0.3 micrometer to 0.5 micrometer, a spiral angle between two spherical spiral cutting edges which are symmetrically distributed is 40+ / -0.5 degrees, and a spiral angle between the other two spiral cutting edges which are symmetrically distributed is 42+ / -0.5 degrees. Cutting edge passivation treatment is performed for the R-angle position of the ball end, accordingly, connecting arc cutting points of the cutter are increased, the lengths of the cutting edges are increased, local abrasion is reduced, a resonance state is eliminated by the design of the different spiral angles of the cutter, and tipping is reduced.

Owner:CHANGZHOU HYDRAULIC COMPLETE EQUIP

Screen and screen element

Owner:METSO OUTOTEC (FINLAND) OY

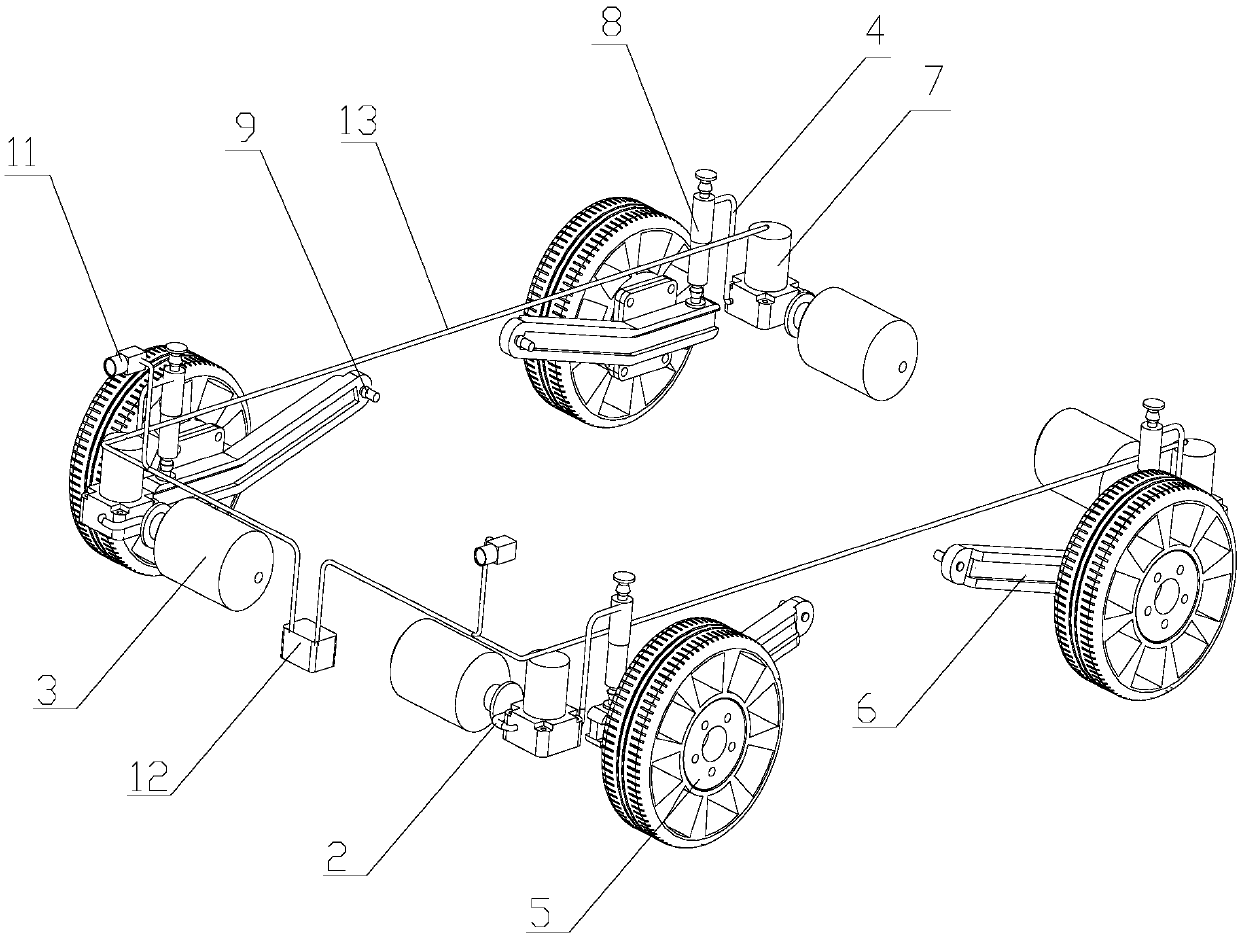

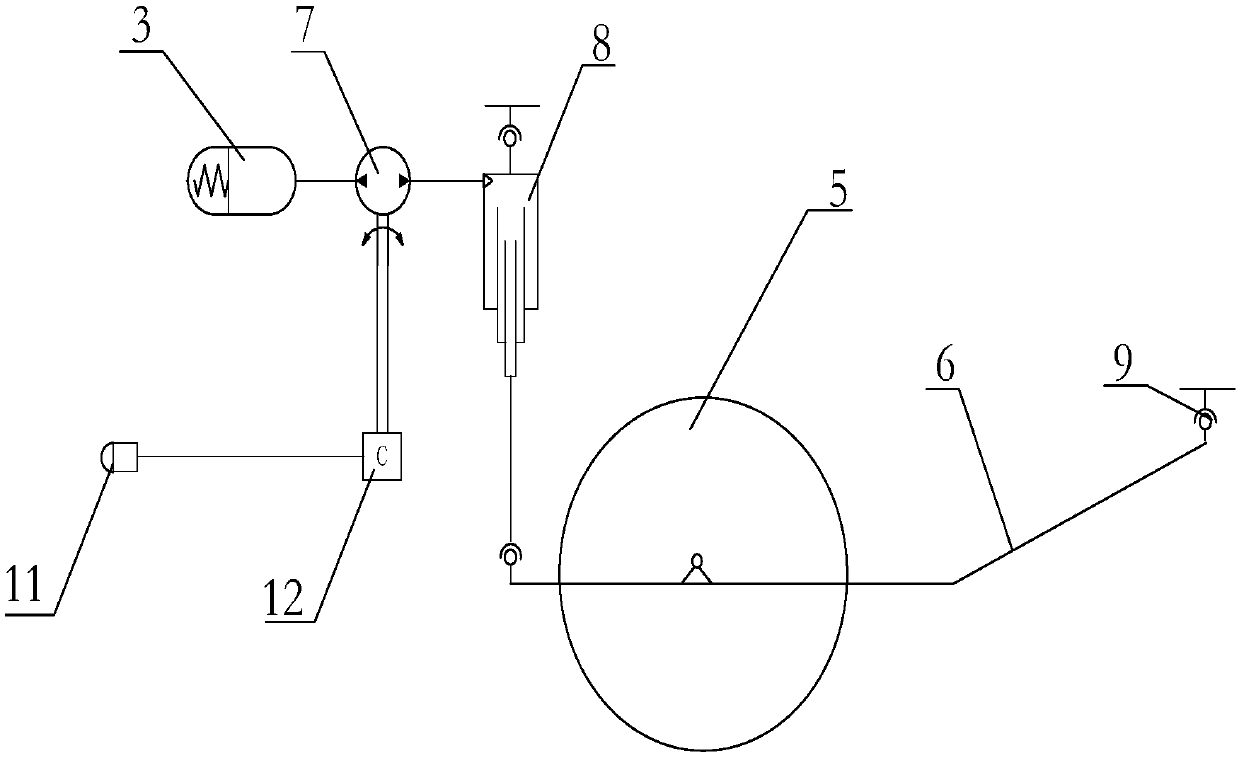

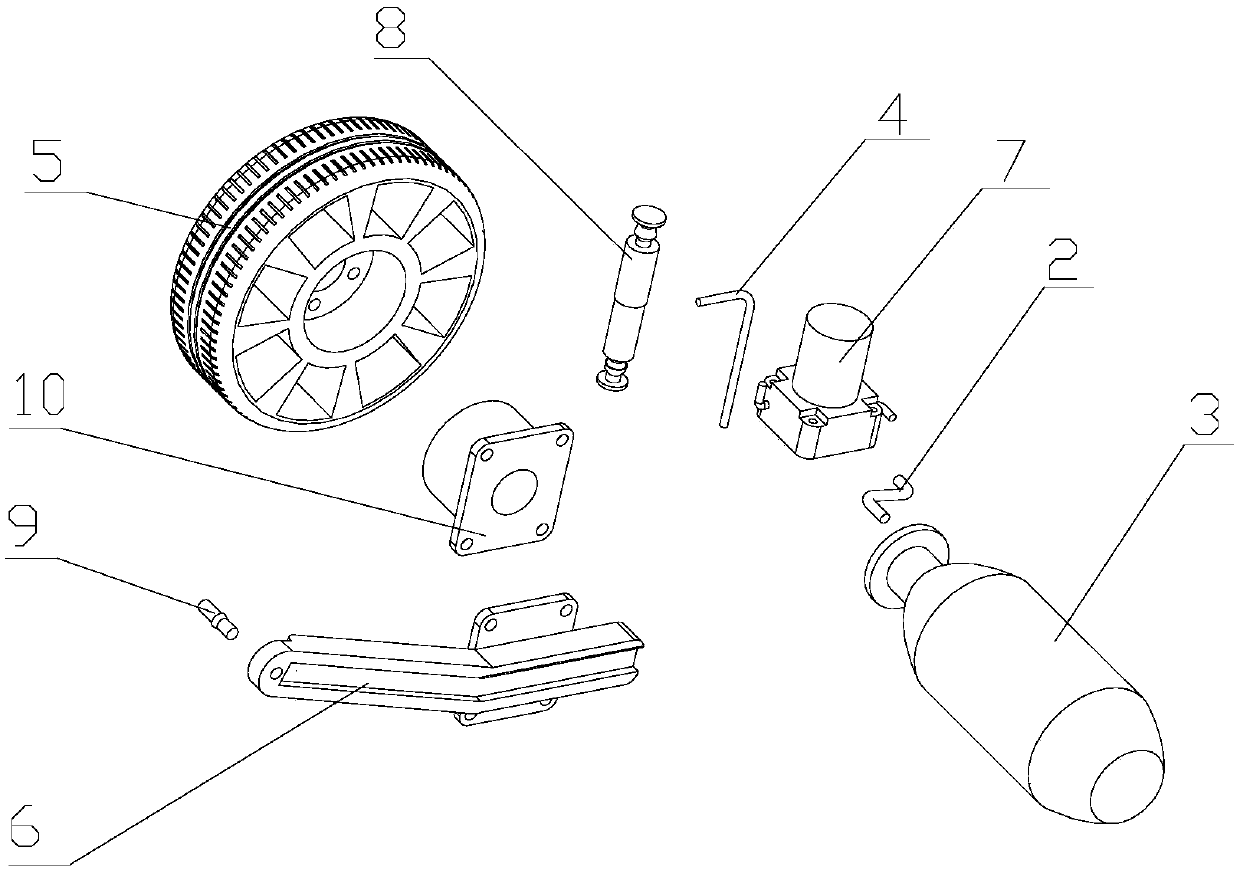

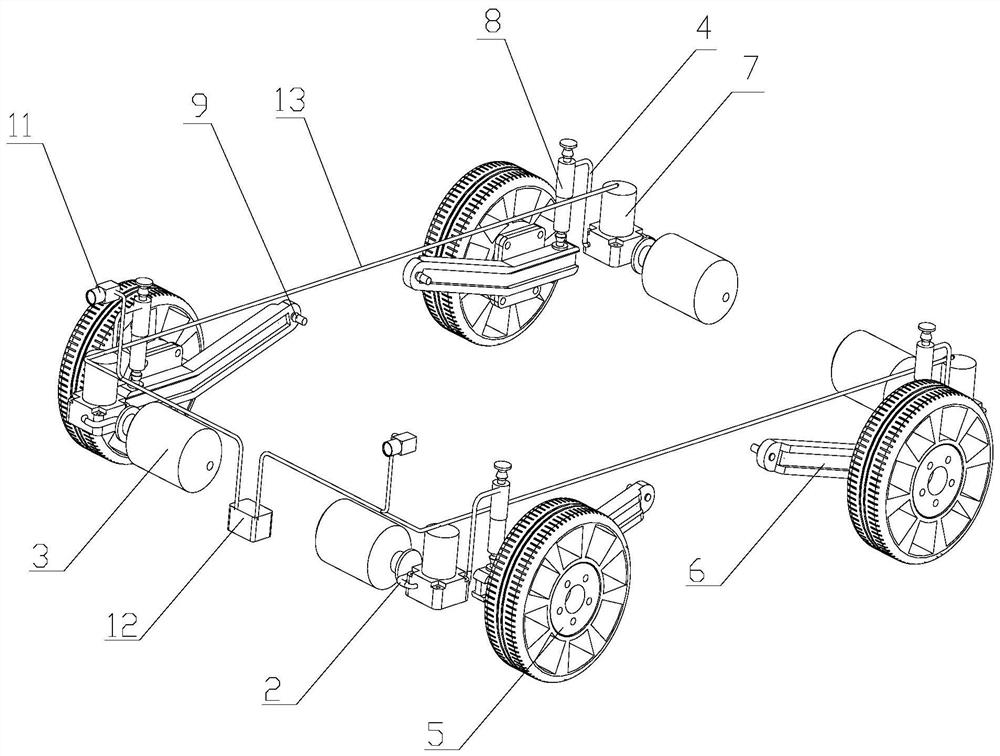

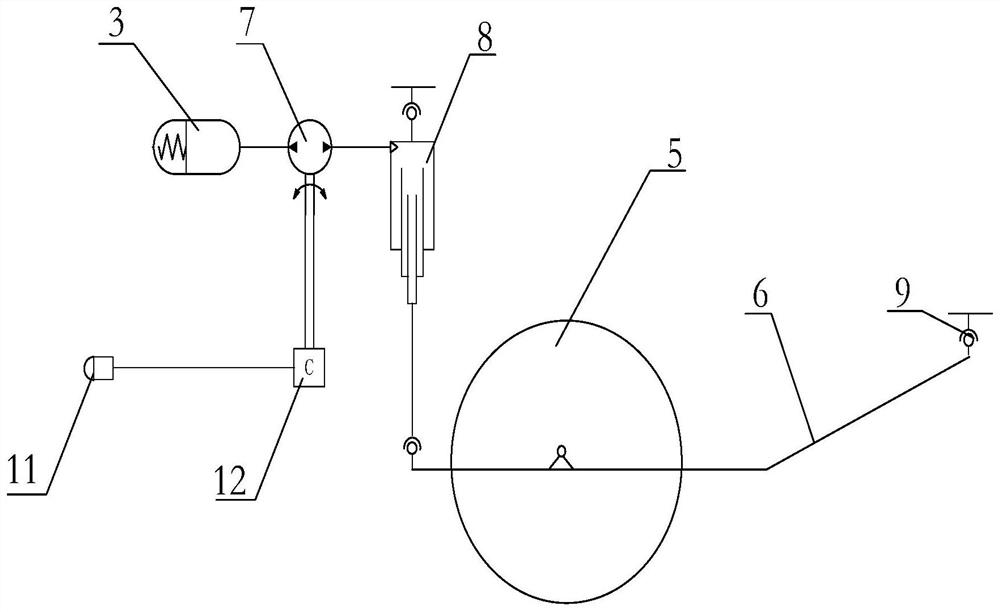

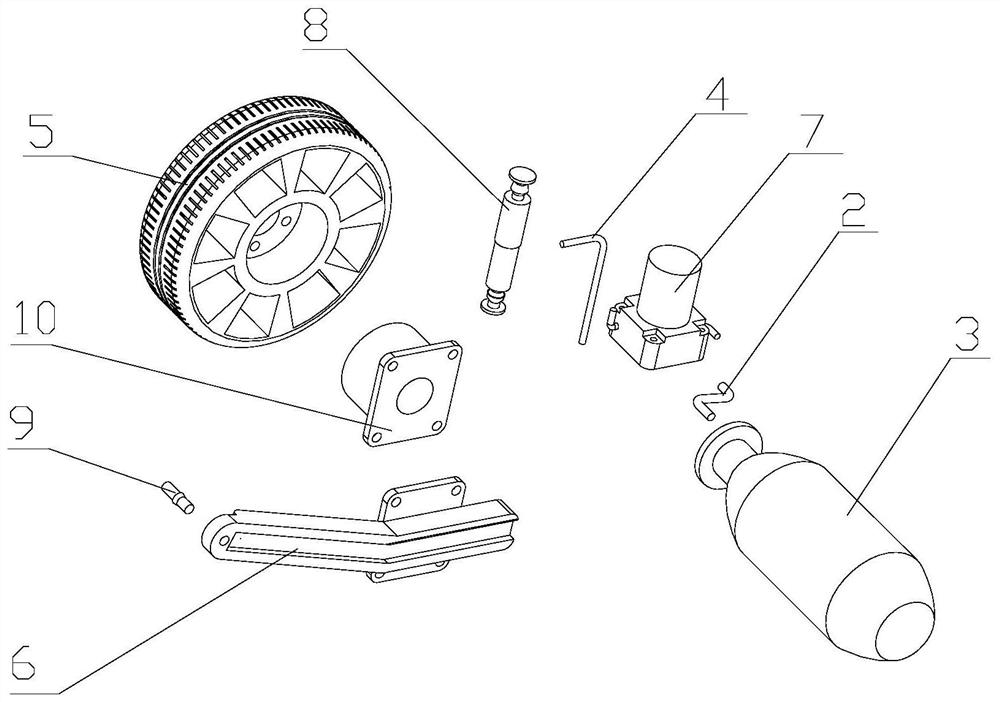

Fully-active suspension system and logistics vehicle applying same

InactiveCN109606053ABest damping stateWith adjustable functionResilient suspensionsTerrainControl line

The invention relates to a fully-active suspension system which comprises energy accumulators, electronic gear pumps, power cylinders, swing arms, a control system and steering knuckles, wherein the front end of each steering knuckle is cylindrical and the rear end of each steering knuckle is of a plate-like structure; a hub motor stator of each wheel is fixedly connected with the cylinder of eachsteering knuckle; the plate-like structure of each steering knuckle is fixedly connected with the side of one end of each swing arm; the upper surface of one end, connected with a hub, of each swingarm is connected with each power cylinder through a ball joint; the other end of each swing arm is connected with a vehicle body through a ball joint; each power cylinder communicates with a high-pressure oil outlet of each electronic gear pump through a second oil pipe; a low-pressure oil inlet of each electronic gear pump communicates with each corresponding energy accumulator through a first oil pipe; and the control system is connected with the electronic gear pumps through control lines. All-terrain road driving of small-sized vehicles such as logistics vehicles and the like is realized,and efficient vibration suppression and vibration absorption can be achieved.

Owner:JILIN UNIV

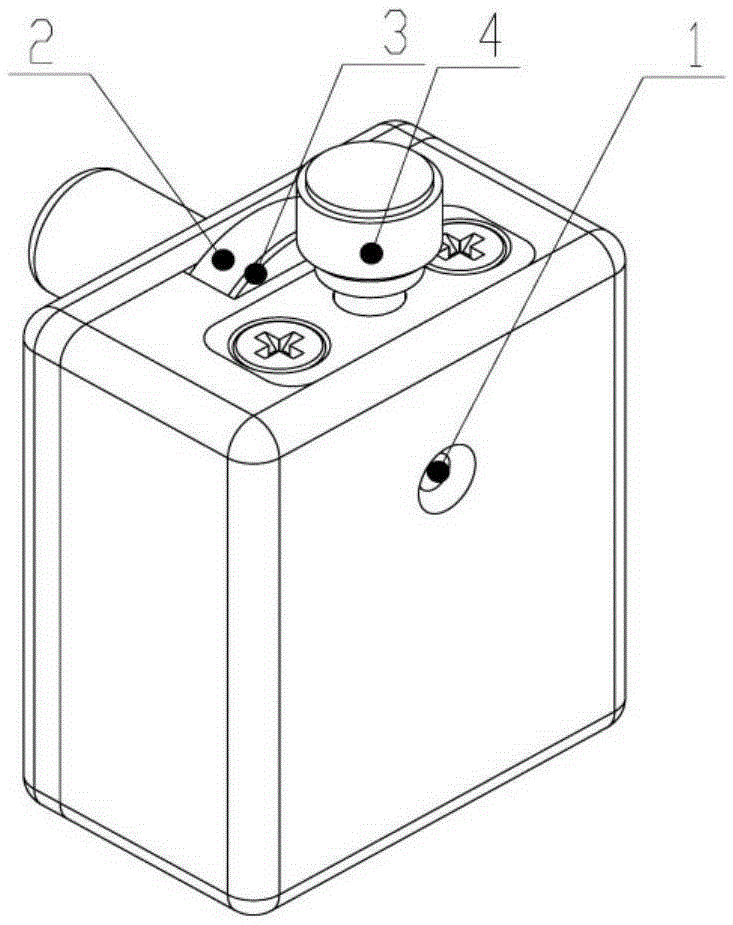

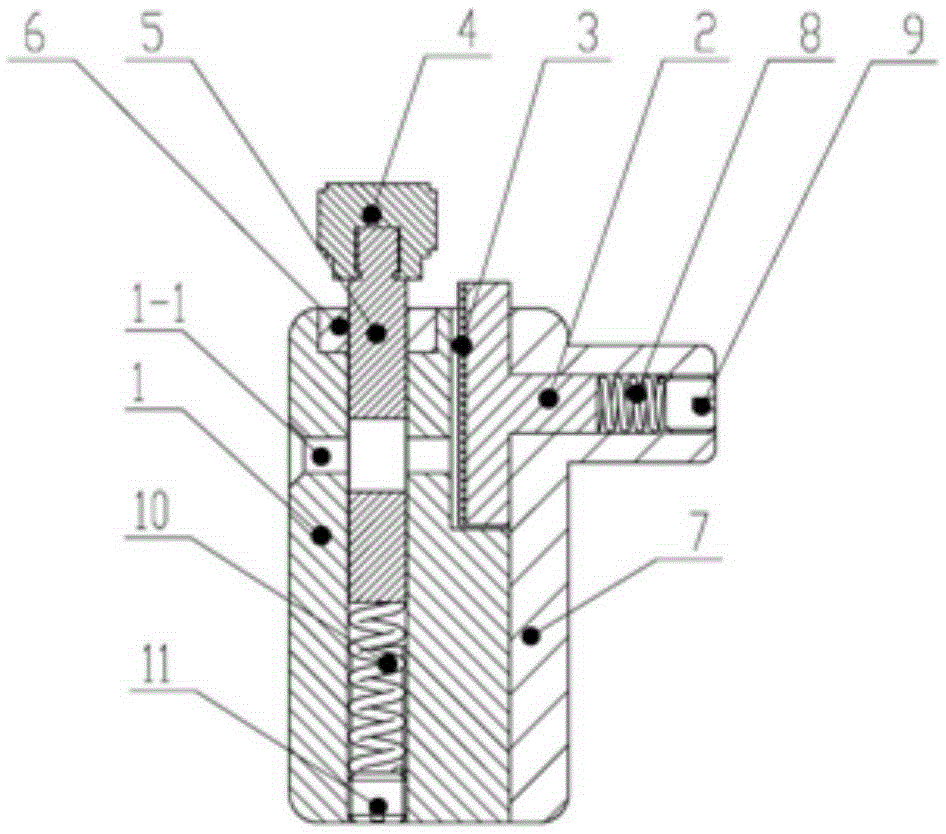

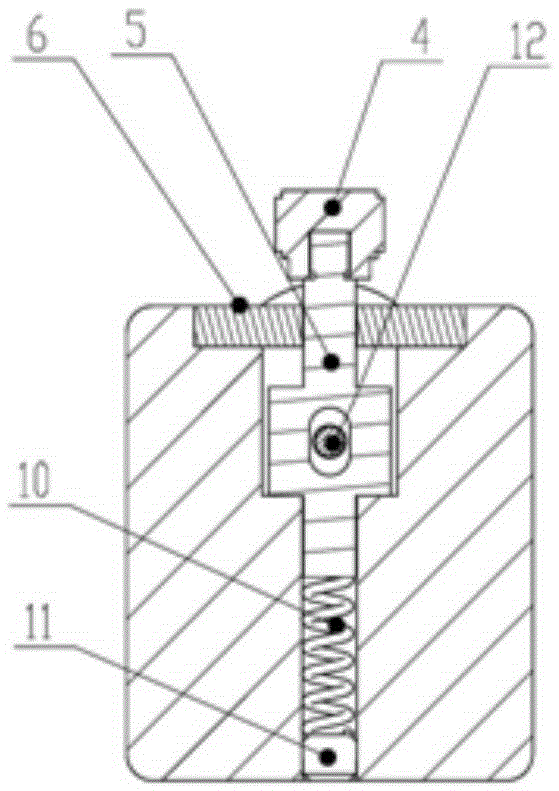

Coaxial probe short-circuit mechanism and operation method thereof

InactiveCN105375155AIncrease contactLow costLine/current collector detailsCoupling contact membersCoaxial probeEngineering

The invention discloses a coaxial probe short-circuit mechanism and an operation method thereof. The coaxial probe short-circuit mechanism structurally comprises a coaxial probe, a short-circuit plate, a base, a cover board and a cushion block, wherein the short-circuit plate is made of a flexible conductive material, and is fixedly arranged on the cushion block; a probe limiting hole through which the coaxial probe passes is formed in the base; and a limiting sliding block for locking the coaxial probe is also arranged on the base. The limiting sliding block is pressed to slip downwards in an operation; an open end of the coaxial probe simultaneously passes through the probe limiting hole and a through hole in the limiting sliding block; the short-circuit plate is pressed by the open end of the coaxial probe; the limiting sliding block is loosened; a sliding block spring rebounds; and the limiting sliding block slips upwards, so that locking and limiting of the coaxial probe are achieved. According to the coaxial probe short-circuit mechanism, a good contact can be formed by the open end of the coaxial probe and the short-circuit plate; the service lifetime of the short-circuit plate is prolonged; the clamping operation is convenient, fast and reliable; and the consistency of multiple calibrations is good.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

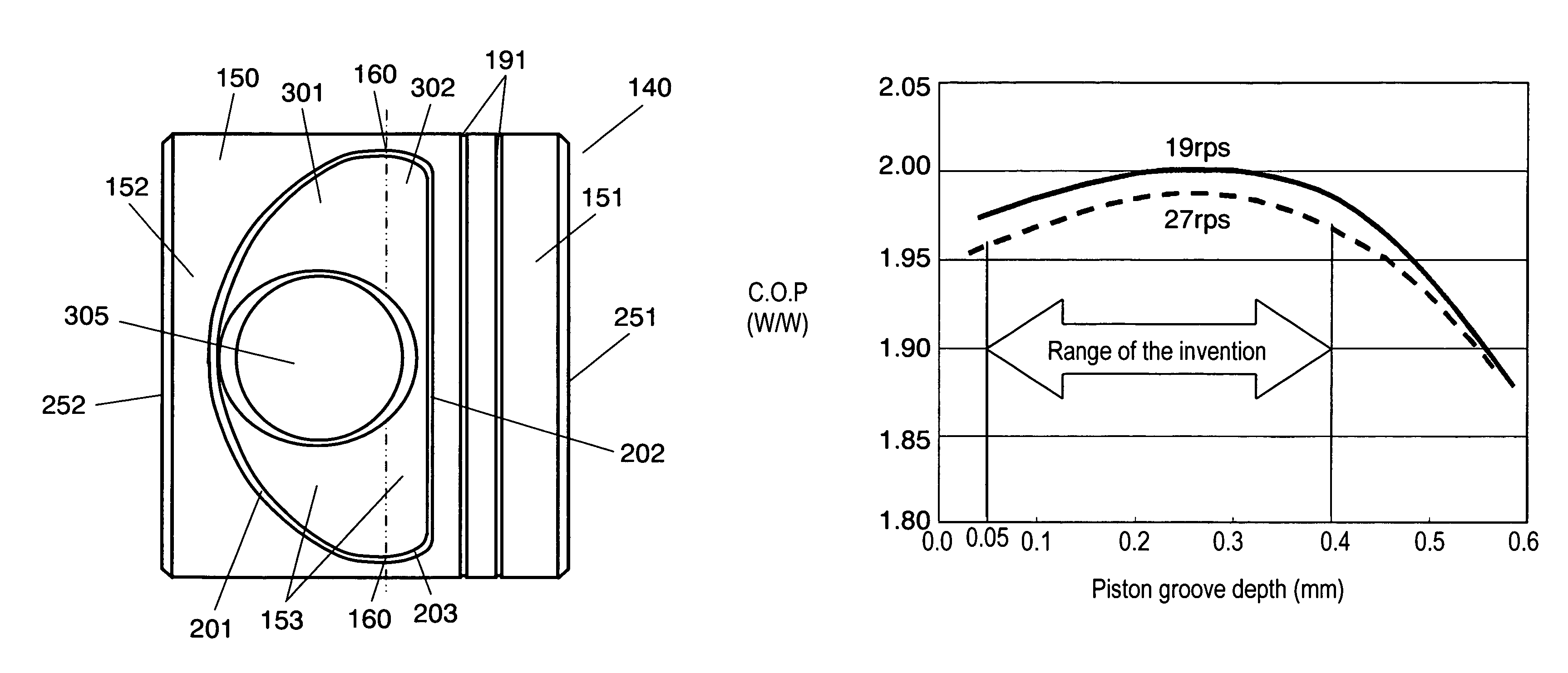

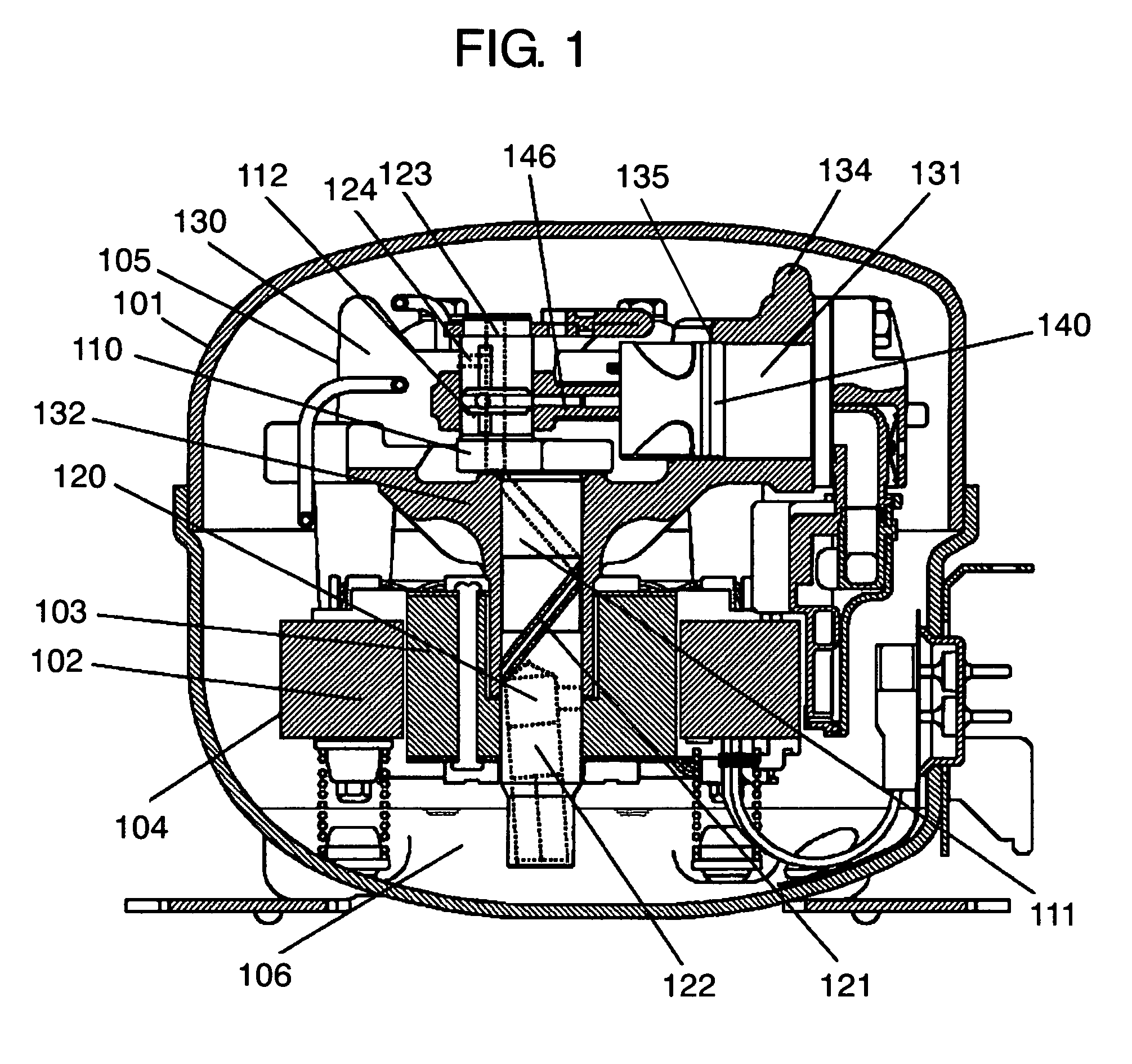

Hermetic compressor

ActiveUS8210832B2Low efficiencyImprove efficiencyPositive displacement pump componentsPiston pumpsMechanical engineeringPiston

The hermetic compressor has grooves provided at an upper side and a lower side of outer circumference of a piston. Of outer shape of the grooves, the outer shape of the grooves communicating with a space in the hermetic container at least when the piston is in a bottom dead center is a shape not forming parallel line to an axial center of the piston when the grooves are developed in a plane.

Owner:PANASONIC APPLIANCES REFRIGERATION DEVICES SINGAPORE

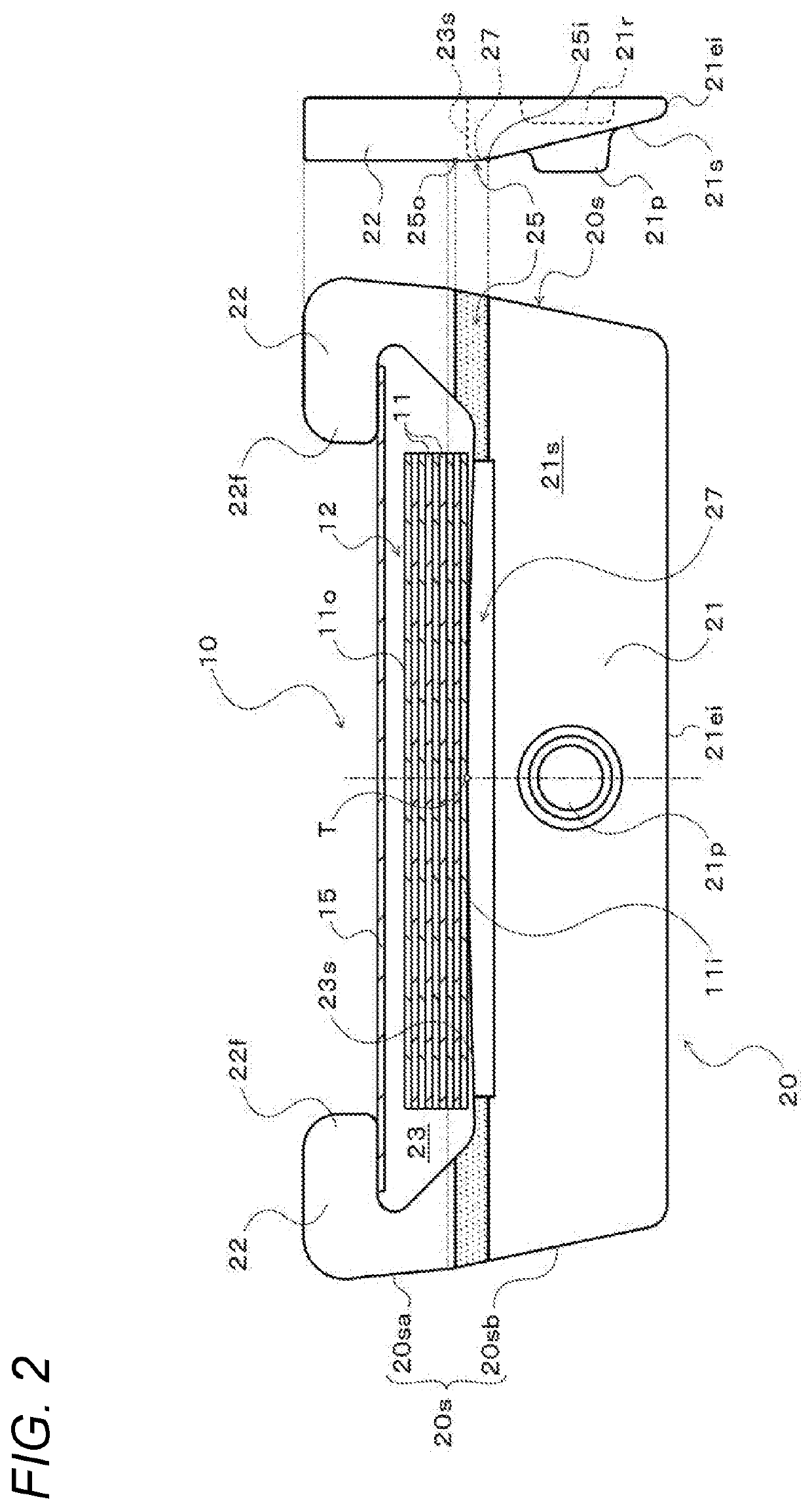

Transmission belt and continuously variable transmission, method for designing element, and method for producing element

Elements of a transmission belt wound around pulleys of a continuously variable transmission each include a body part, a pair of pillar parts, and a pair of side surfaces. The pair of side surfaces each include a first side surface formed on a corresponding one of the pillar parts; and a second side surface formed so as to continue from the first side surface, and located more on an inner circumference side than the first side surface. A pair of the first side surfaces each are formed so as to be inclined toward an inner side of a corresponding one of the pillar parts with respect to an extending direction, from an inner circumference side to an outer circumference side of a ring, of a corresponding one of the second side surfaces continuing from the first side surface, and a pair of the second side surfaces is formed such that the second side surfaces are spaced farther apart from each other as the second side surfaces extend from the inner circumference side to the outer circumference side, and that an angle formed between the pair of the second side surfaces is larger by 0.2 to 0.8 degrees than an opening angle of V-shaped grooves of the pulleys.

Owner:AISIN CORP +1

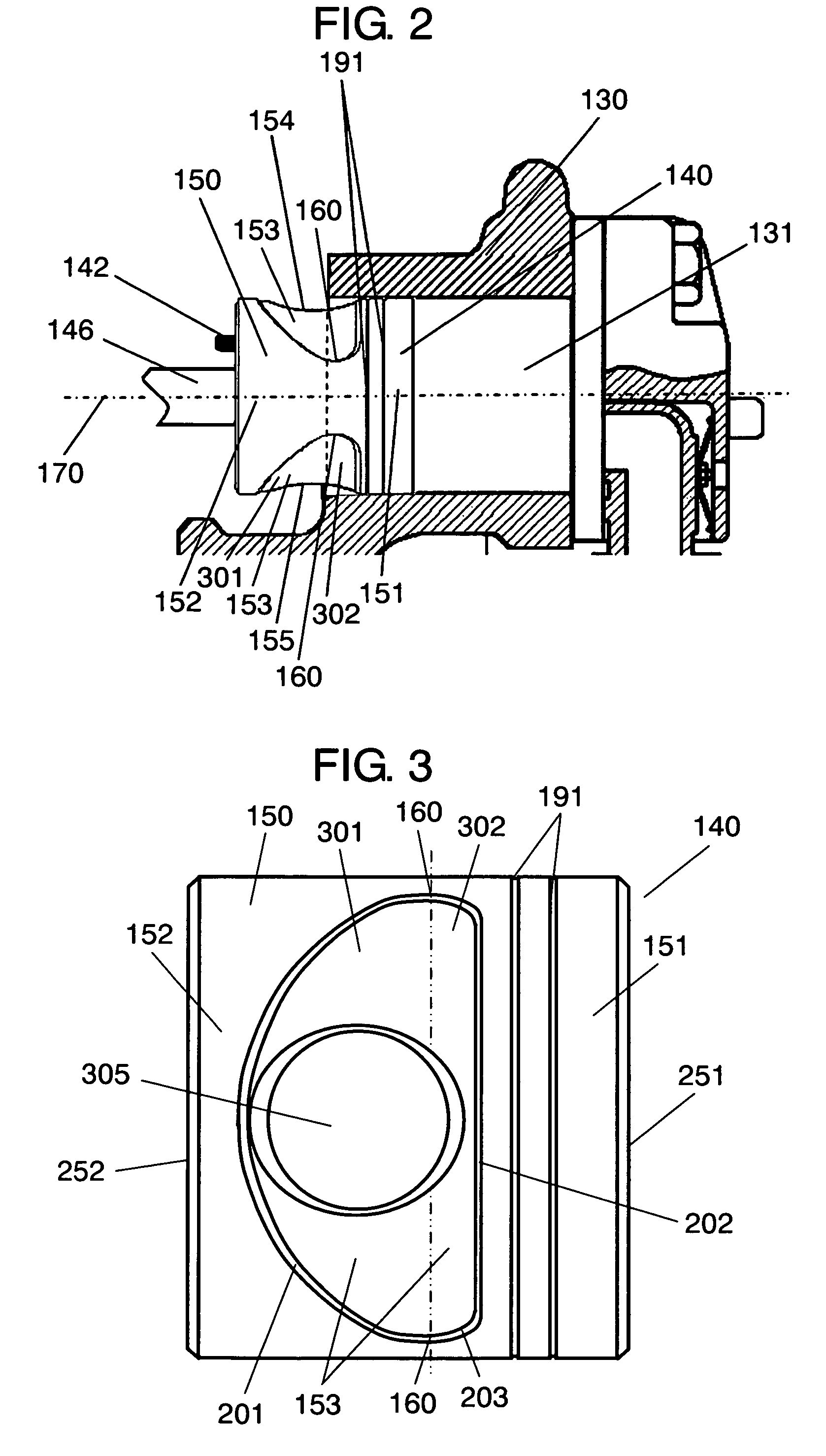

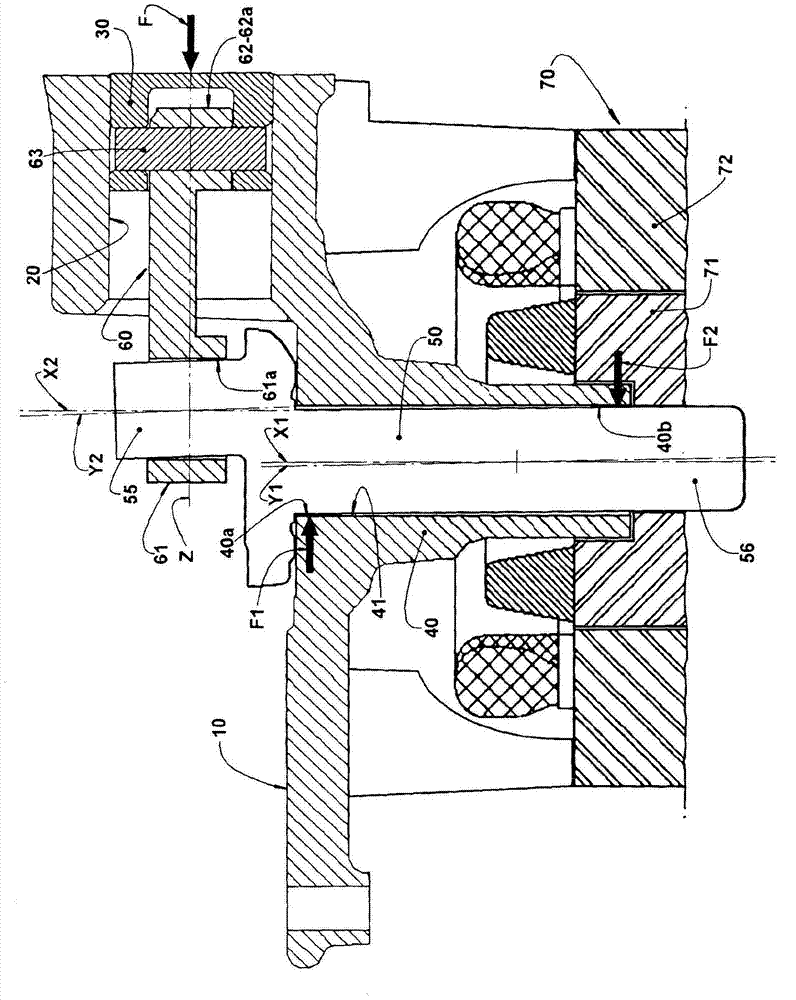

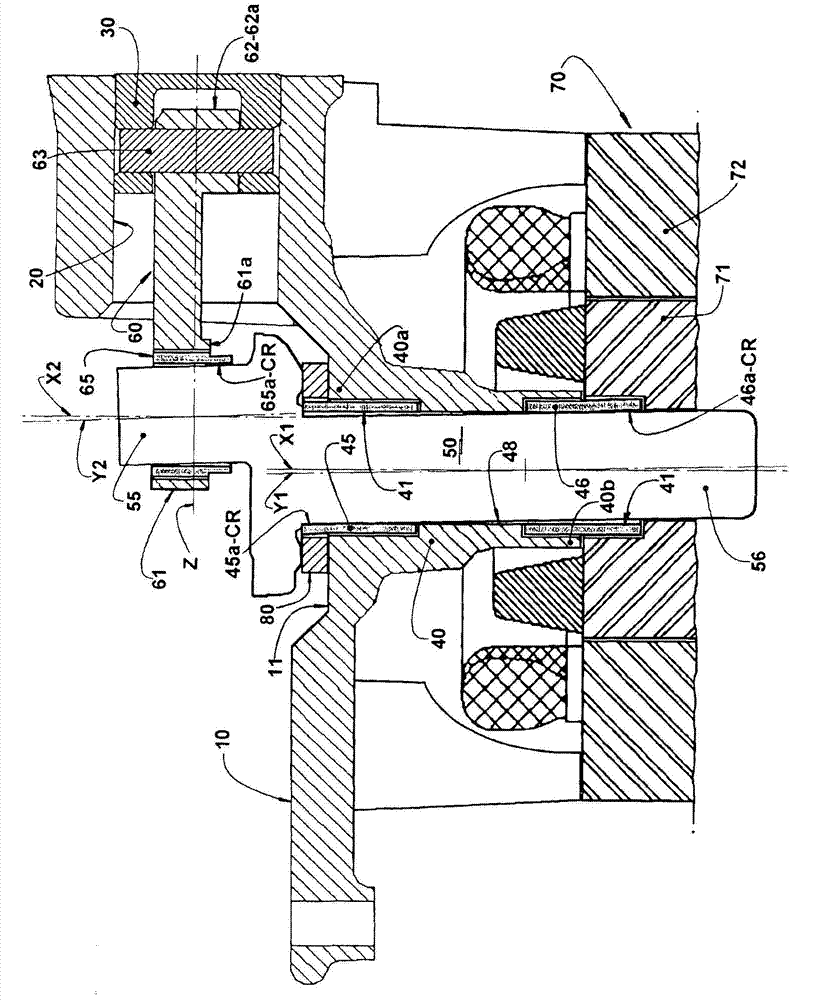

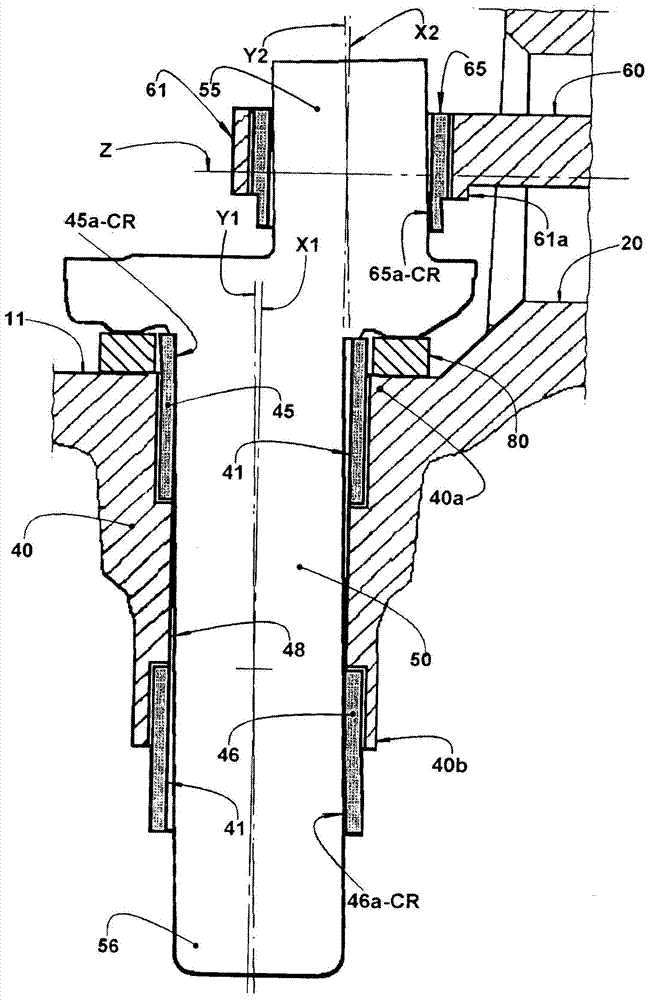

Bearing arrangements in refrigeration reciprocating compressor

ActiveCN104813040AWith concentricity deviationImprove bearing conditionsCrankshaftsPositive displacement pump componentsRefrigeration compressorLarge eyes

The compressor comprises: a crankcase (10) carrying a cylinder (20) and a bearing hub (40) having a first and a second end portions (40a, 40b) and defining a radial bearing (41), in which is housed a crankshaft (50); and a connecting rod (60) coupled to a piston (30) housed in the cylinder (20) and having a larger eye (61) mounted in an eccentric end portion (55) of the crankshaft (50). Each of said end portions (40a, 40b) is defined by a bushing extension (45, 46) affixed in the interior of the bearing hub (40) and having an end portion (45a, 46a) projecting outwards from the bearing hub (40), in order to be elastically and radially deformed when pressed by a confronting portion of the crankshaft (50), which presents coaxiality deviation in relation to the axis (X1) of the radial bearing (41).

Owner:EMPRESA BRASILEIRA DE COMPRESSORES SA (EMBRACO)

Roller type leveling machine

InactiveCN1733380AImproved positional accuracy for tiltHigh positioning accuracyMetallic materialsEngineering

The invention relates to roll-type plate flattening machine belonged to forging equipment for metals shaping, which comprises active row work roller that has larger roller diameter, no supporting roller and active beam and less roller number, fixed row work roller with supporting roller and a frame, lifting tilting equipment, balancing equipment, main gear, and electric controller; wherein, it is pin joint between bearing block and bottom end of lifting screw bar in active row work roller. This machine can reduce difference of deflections on upper and down directions and improve flattening precision.

Owner:张挺胜

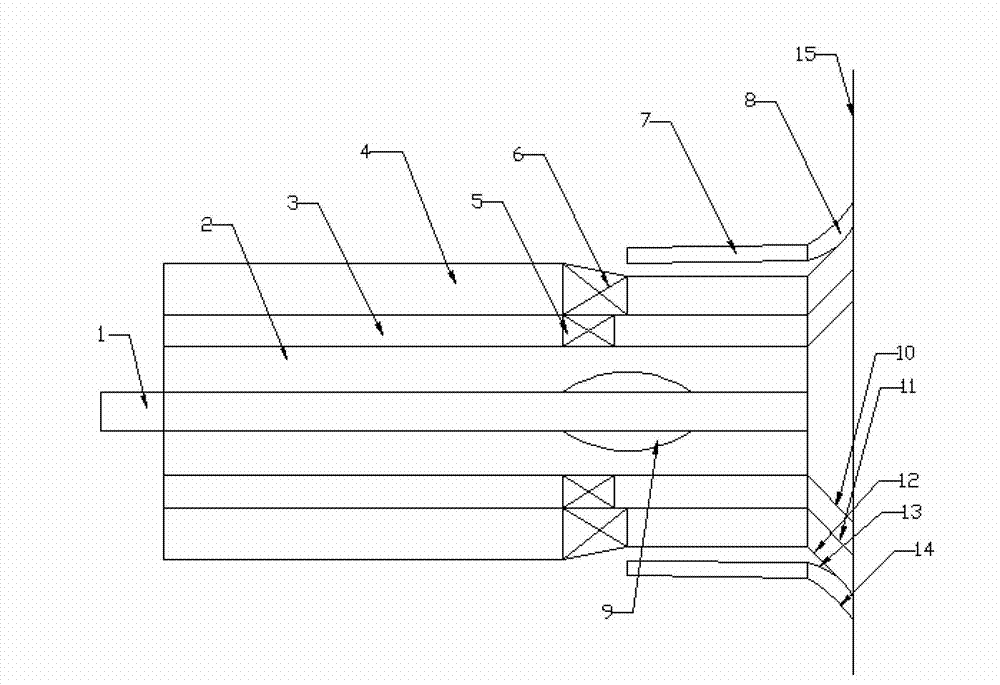

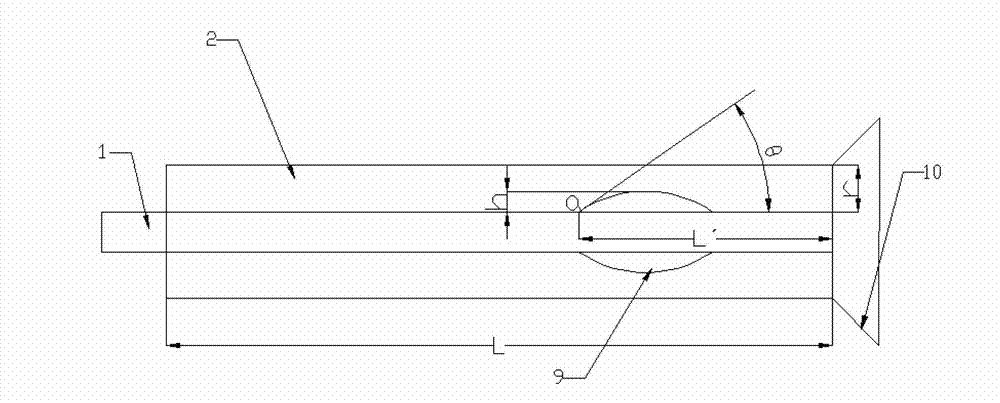

Up-flow reactor and application thereof

ActiveCN101632911BEvenly distributedSimple structureHydrocarbon oils refiningChemical/physical processesWaxShortest distance

The invention discloses an up-flow reactor, which comprises an initial distributor positioned at the bottom of the reactor and an intermediate distributor above the initial distributor. The initial distributor consists of a conical traverse baffle and a sieve plate positioned above the conical traverse baffle; and the intermediate distributor consists of an open pore sieve plate and a sieve platestring structure. The up-flow reactor provided by the invention can realize even distribution of gas in the reactor in short distance so as to improve the utilization rate of a catalyst and increase the space of a catalyst bed layer in the reactor. The up-flow reactor of the invention is particularly applied to a hydrogenation process of heavy oil (comprising wax oil, residual oil, coal liquefiedoil and the like).

Owner:CHINA PETROLEUM & CHEM CORP +1

Vibration wave driving apparatus

InactiveUS7439653B2Change inclinationReduce local wearPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesEngineeringFixed Beam

This invention provides a vibration wave driving apparatus which makes it possible to reduce the localized abrasion of a contact member, and reduce the deterioration of performance due to long-term driving. This vibration wave driving apparatus has a contact member which is provided with fixed portions fixed to the lengthwise opposite end portions of the vibration expanding portion of the vibration member, and a connecting portion integrally connecting the two fixed portions together and having opposite ends fixed beam structure divided into a plurality.

Owner:CANON KK

Efficient carbon fiber reinforced plastic hole making cutter and dip angle hole making method

ActiveCN110497005AReduce local wearMeet the requirements of hole making precisionMilling cuttersMilling equipment detailsFiberCarbon fibers

The invention discloses an efficient carbon fiber reinforced plastic hole making cutter and a dip angle hole making method, and belongs to the field of carbon fiber reinforced plastic machining. The cutter comprises a cutter bar, a milling supplementary cutting edge, a combined cutting part and a bottom cutting part which are connected in sequence. The dip angle hole making method mainly comprisesthe steps that parameters are calculated; the cutter is parallel to the axis of hole diameter and rotates downwards to carry out feeding in the axial direction, and layer-by-layer shunting machiningis carried out, so that the hole diameter error can finally keep at IT7 - IT8; if the hole diameter error does not meet IT8 - IT9, the dip angle between cutter and the axis of the hole diameter is adjusted, hole pre-milling is carried out, the hole is completed through zero empty trip milling supplementary, the axis of the cutter is adjusted to be parallel to the axis of the hole diameter and eccentric distance, and the allowance of the hole diameter is removed; and if the hole diameter error does not meet the IT7 - IT8, the dip angle between the cutter and the axis of the hole diameter is maintained, the hole pre-milling and the hole completing through milling supplementary are carried out, the cutter returns to an initial null point after the hole making is completed, and quality detection is carried out. According to the efficient carbon fiber reinforced plastic hole making cutter and the dip angle hole making method, the machining defects such as burrs, layering of the carbon fiberreinforced plastic can be avoided.

Owner:HARBIN UNIV OF SCI & TECH

Method for operating a leveling device of a vehicle

InactiveCN102905917AExtended service lifeUniform wearResilient suspensionsVehicle springsAir springEngineering

The invention relates to a method for operating a leveling device of a vehicle body of a vehicle, said device comprising at least one air spring (1). According to the invention, the level of the vehicle body is adjusted at the beginning, during or immediately prior to ending a trip at least once to a level that deviates from a target level predetermined for the trip. In this way, different regions of the jacket wall of an air bellows are subjected to a maximum load during the trip, thus no longer limiting the wear of the bellows wall exclusively to the region associated with the target level, but distributing it to larger regions of the bellows wall.

Owner:KNORR-BREMSE SYST FUER NUTZFAHRZEUGE GMBH

Connecting method with powder dust separating device, vertical type invert exhaust-heating boiler and exhaust pipeline

InactiveCN101275812AReduce local wearLong runIncreasing energy efficiencySteam generation using hot heat carriersExhaust fumesEngineering

A connecting method of a dust separation device, a vertical inverted waste-heat boiler and an exhaust piping, aids in dispensing with an independent settling chamber in the dust separation device and the vertical inverted waste-heat boiler(3) by virtue of integration of the dust device and the waste-heat boiler(3), so as to decrease area and obtain reduction of concentrated wear of the waste-heat boiler(3), effectively solving the wear problem of heating surface of the waste-heat boiler(3) which ensures a long term safety operation.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

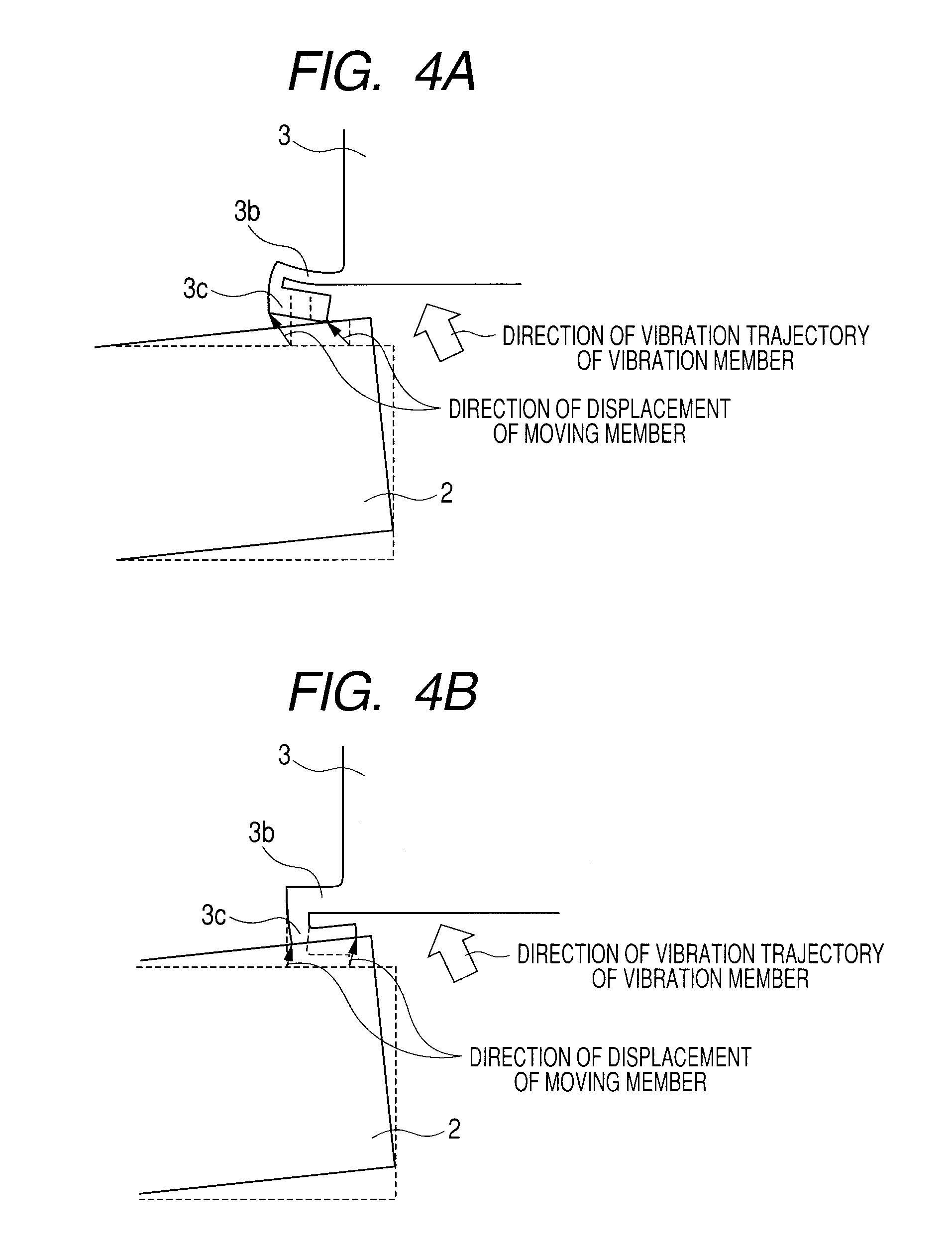

Rotary type vibration wave driving apparatus

InactiveUS9154056B2Reduce local wearPerformance deteriorationPiezoelectric/electrostriction/magnetostriction machinesMechanical energyEngineering

A rotary type vibration wave driving apparatus which is capable of reducing local wear of a contacting member and of reducing performance deterioration due to long term operation is provided. The apparatus includes a electro-mechanical energy conversion element, an vibration member fixed to the electro-mechanical energy conversion element and vibrated by a voltage being supplied to the electro-mechanical energy conversion element, and a moving member being brought into contact with the vibration member and frictionally driven by the vibration, and is configured such that the moving member includes a supporting portion extended from the main body portion of the moving member, and a contacting portion extended from the supporting portion and being brought into contact with the vibration member, and such that each of the supporting portion and the contacting portion is configured to be elastically deformable in the rotation axis direction of the moving member.

Owner:CANON KK

Bidirectional flat-nose pliers for machine

InactiveCN103659379ARest assured to playPlay a precise heartWork clamping meansPositioning apparatusAxial displacementEngineering

The invention relates to a pair of bidirectional flat-nose pliers for a machine. When the bidirectional flat-nose pliers serve as a pair of double-jaw flat-nose pliers for a machine, the bidirectional flat-nose pliers can clamp two workpieces one time instead of one, the number of shutdown times is reduced, production efficiency is improved by more than one time, and the method is suitable for an occasion with a low requirement for centering of the workpieces; when the bidirectional flat-nose pliers serve as a pair of centering flat-nose pliers for a machine, axial displacement of a lead screw is precisely limited under the abutting effect of a front centering steel ball and a rear centering steel ball and the force applied by the two centering steel balls of two locking mechanisms jointly, and therefore precise centering of the workpieces is achieved. In this way, the bidirectional flat-nose pliers can achieve dual purposes.

Owner:NORTHEAST GASOLINEEUM UNIV

Juggle type precise flat tong for machine tool with large processing table

InactiveCN101502936BExtended service lifeReduce local wearPositioning apparatusMetal-working holdersEngineeringScrew thread

The invention relates to building block system precision flat-nose pliers for large processing table facet machine. The building block system precision flat-nose pliers is essentially to solve the problems of low machine work efficiency of the machine, noticeable partial wear and tear on operation parts of the machine, and poor processing precision of the work pieces with poor rigidity existed in the prior art. The technical proposal is as follows: a group of flat-nose pliers are installed on the work table facet of a machine, which is characterized in that a group of flat-nose pliers comprise more than three independent flat-nose pliers arranged in parallel; each independent flat-nose plier comprises a block, a fixed jaw fixed on the block, two or more movable jaws matched on the block guide rail in a sliding way, and a quick travel mechanism installed on the block; both outer side faces of the block guide rail are equipped with teeth rows; the quick travel mechanism comprises a nut seat matched with the block guide rail in a sliding way, a thrust screw thread matched with the nut seat by screw, and an expansion device arranged on both sides of the nut seat and matched with the teeth rows on both outer side faces of the block guide rail; and a thrust end of the thrust screw is matched with one movable jaw.

Owner:张应祥

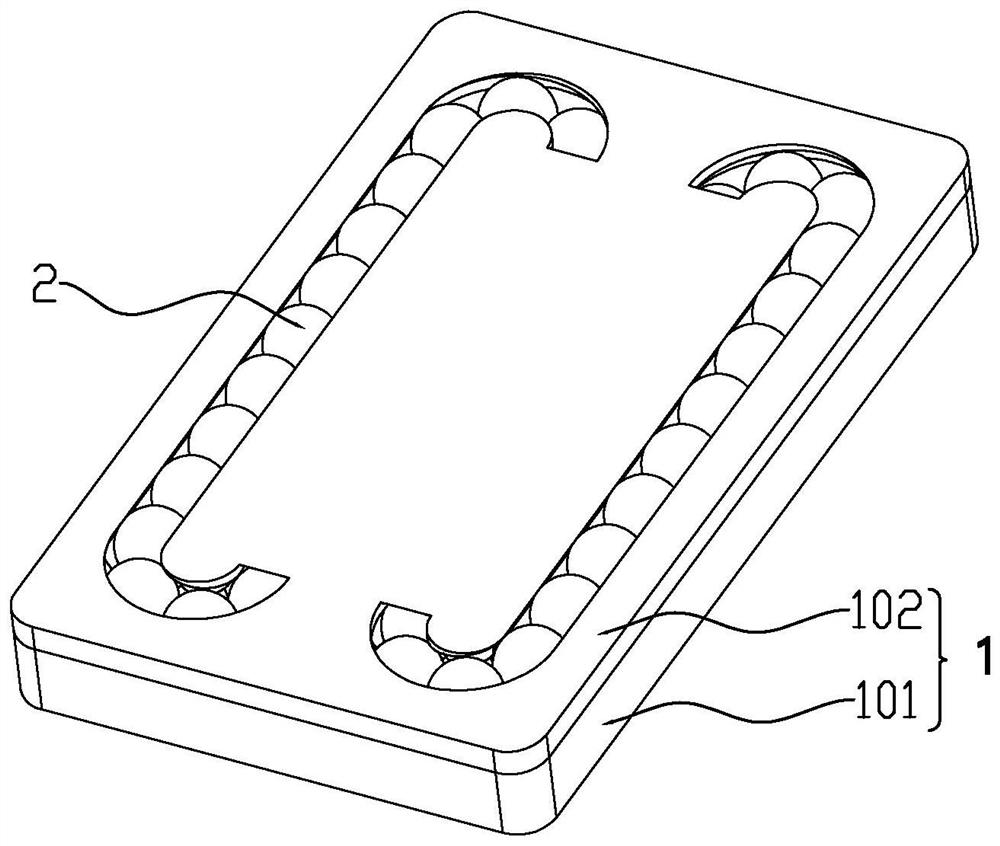

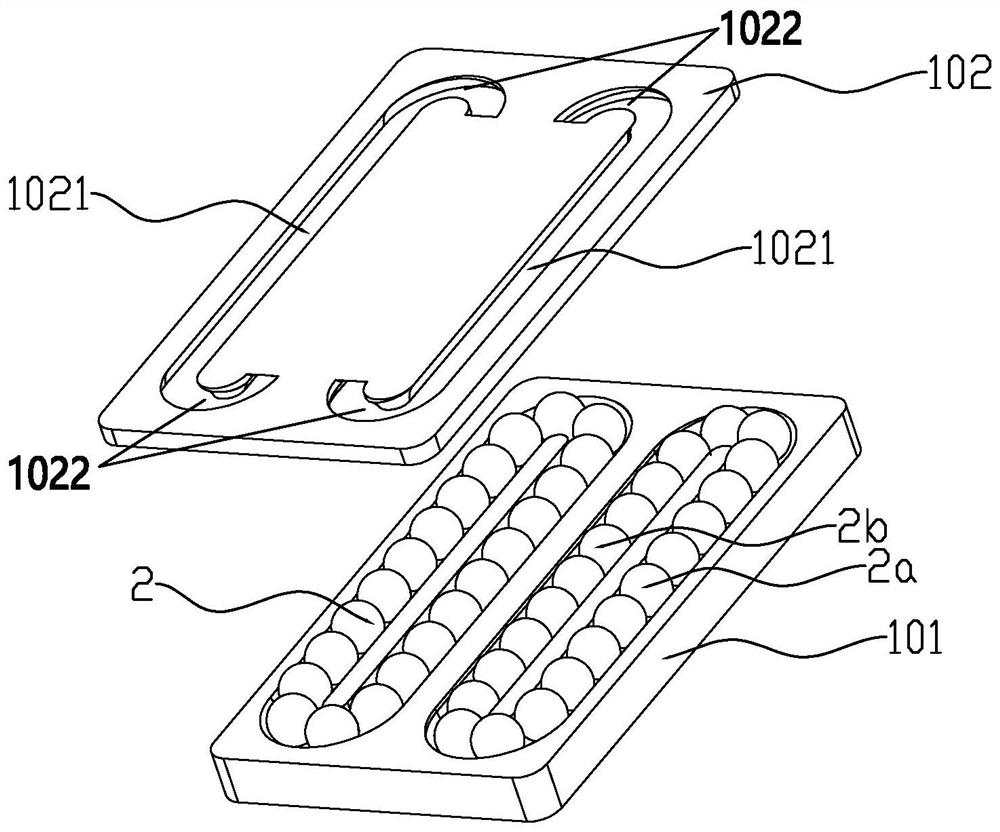

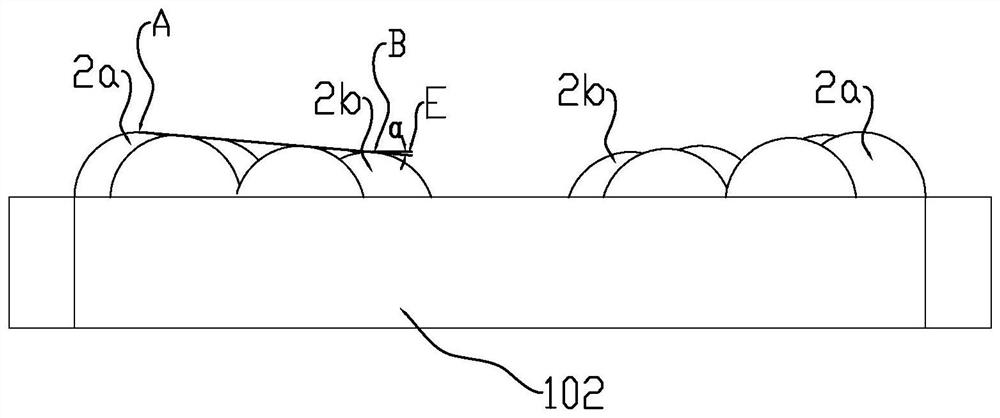

Sliding abrasion-resistant device with internal circulation rolling bodies

ActiveCN113023371AGuaranteed cycleSimple structureNon-mechanical conveyorsStructural engineeringControl theory

The invention discloses a sliding abrasion-resistant device with internal circulation rolling bodies, and belongs to the technical field of plane sliding. The sliding abrasion-resistant device comprises an outer frame and the multiple rolling bodies, wherein the outer frame is equipped with circulation tracks; the rolling bodies circulate in the circulation tracks; the circulation tracks comprise load sections, return sections and steering sections; the steering sections are used for the endless connections between the load sections and the return sections; the depths of the return sections are greater than those of the load sections; a sliding object is carried on the rolling bodies in the load sections and is in zero contact with the rolling bodies in the return sections; when the sliding object slides, the rolling bodies in the load sections roll under the action of friction force; and then, all the rolling bodies are driven to circulate in the circulation tracks. According to the sliding abrasion-resistant device, the sliding friction of the sliding object is converted into the rolling friction, so that the friction of the sliding object at the same pressure can be greatly reduced, the sliding process can be facilitated, both the time and the labor can be saved, and meanwhile, the abrasion can be reduced; furthermore, the depths of the return sections are greater than those of the load sections, the sliding object is arranged on the rolling bodies in the load sections, and the contact between the sliding object and the rolling bodies in the return sections is prevented, so that the normal circulation of the rolling bodies in the sliding process of the sliding object can be guaranteed.

Owner:ZHEJIANG JIECHANG LINEAR MOTION TECH

A logistics vehicle with a fully active suspension system and its application

InactiveCN109606053BReduce local wearRealize the steering functionResilient suspensionsGear pumpLogistics management

The invention relates to a fully-active suspension system which comprises energy accumulators, electronic gear pumps, power cylinders, swing arms, a control system and steering knuckles, wherein the front end of each steering knuckle is cylindrical and the rear end of each steering knuckle is of a plate-like structure; a hub motor stator of each wheel is fixedly connected with the cylinder of eachsteering knuckle; the plate-like structure of each steering knuckle is fixedly connected with the side of one end of each swing arm; the upper surface of one end, connected with a hub, of each swingarm is connected with each power cylinder through a ball joint; the other end of each swing arm is connected with a vehicle body through a ball joint; each power cylinder communicates with a high-pressure oil outlet of each electronic gear pump through a second oil pipe; a low-pressure oil inlet of each electronic gear pump communicates with each corresponding energy accumulator through a first oil pipe; and the control system is connected with the electronic gear pumps through control lines. All-terrain road driving of small-sized vehicles such as logistics vehicles and the like is realized,and efficient vibration suppression and vibration absorption can be achieved.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com