Method for operating a leveling device of a vehicle

A technology of level adjustment and operation method, which is applied in vehicle springs, vehicle parts, transportation and packaging, etc., and can solve problems such as air spring bellows wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

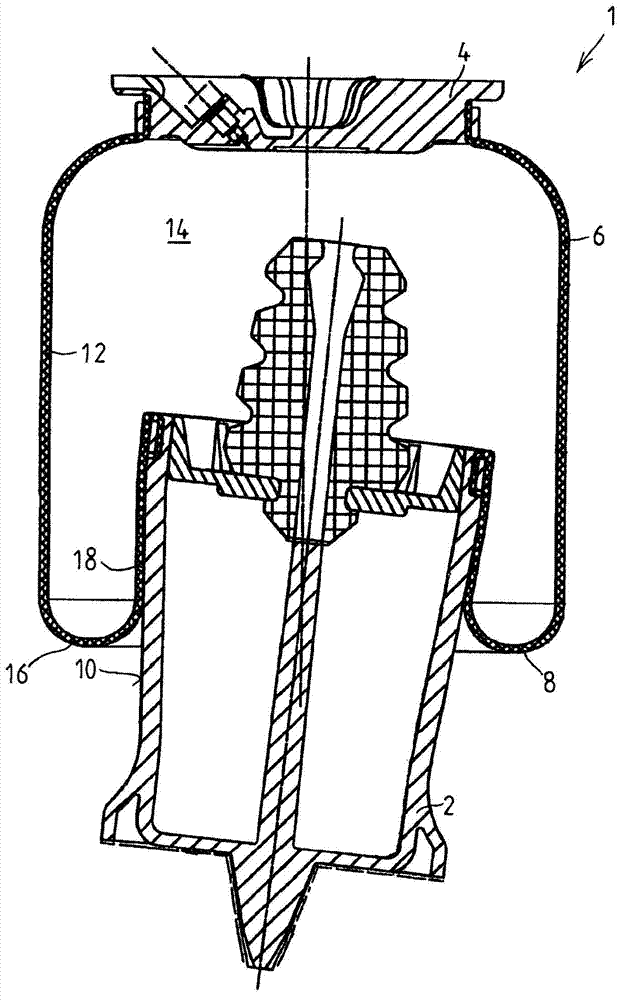

[0021] The figure shows a known air spring 1 . It has rolling pistons 2, bellows caps 4 arranged at vertical intervals, and rolling bellows 6 made of elastic material. The rolling bellows rolls with rolling folds 8 on the radially outer peripheral surface 10 of the rolling piston. As is clearly shown in the figure, the roll fold 8 is here part of the bellows wall 12 (Abschnitt). This is the part where the greatest amount of deflection and bending occurs, here about 180 degrees.

[0022] Here, the rolling bellows 6 together with the bellows cover 4 and the rolling piston 2 enclose an air chamber 14 . This air chamber is ventable and deflated to adjust the body level relative to the vehicle chassis.

[0023] The air spring 1 comprises a hollow air spring arrangement with level adjustment. With the aid of the leveling adjustment, the leveling setpoint can be adjusted and adjusted manually, for example during trailer loading on a slope, and / or automatically within the framewor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com