Production line for cloth cutting

A production line and fabric technology, applied in the cutting of textile materials, thin material processing, textiles and papermaking, etc., can solve problems affecting production efficiency and processing quality, and achieve the effects of saving labor, improving service life and avoiding slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

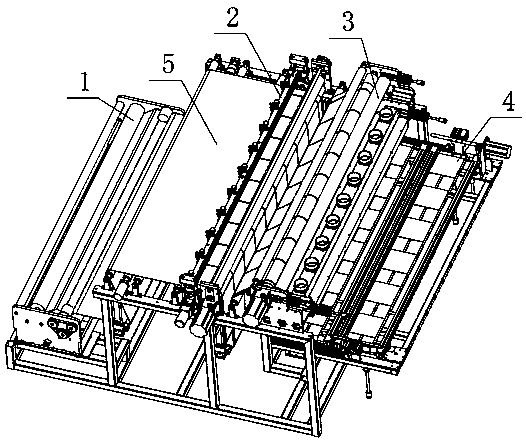

[0044] As shown in the accompanying drawings, a production line for cloth cutting in this embodiment includes a cloth unwinding machine 1, a cloth strip cutting machine 2, a cloth block cutting machine 3 and a cloth rotating machine arranged in sequence along the moving direction of the cloth 5. Receiver 4. The preferred cloth 5 in this embodiment is a dust-free cloth.

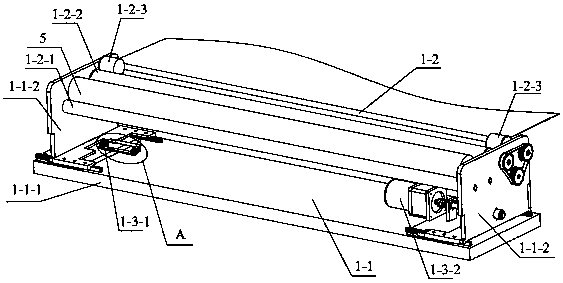

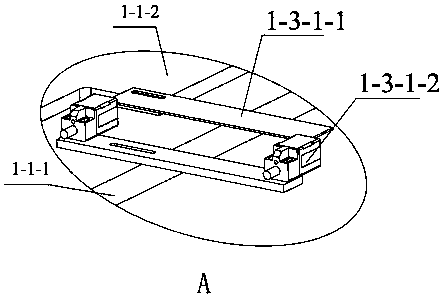

[0045] The cloth feeding machine 1 includes: a feeding machine frame 1-1 and a feeding transmission mechanism 1-2. The unwinding machine frame 1-1 includes: a base 1-1-1 and supports 1-1-2 installed at both ends of the base 1-1-1. The feeding transmission mechanism 1-2 includes: two supporting rollers 1-2-1, two active cloth guide rollers 1-2-2 and an intermediate friction conveying roller 1-2-3. The two support rollers 1-2-1 are non-contact settings. The two active cloth guide rollers 1-2-2 are arranged on the discharge ends of the two supporting cloth rollers 1-2-1. The two active cloth guide rollers 1-2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com