Bearing arrangements in refrigeration reciprocating compressor

A refrigeration compressor and bearing arrangement technology, applied to bearings, crankshaft bearings, shafts and bearings, etc., can solve the problems of high cost and difficulty in use, reduce local wear, avoid the increase of starting torque, and improve bearing conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

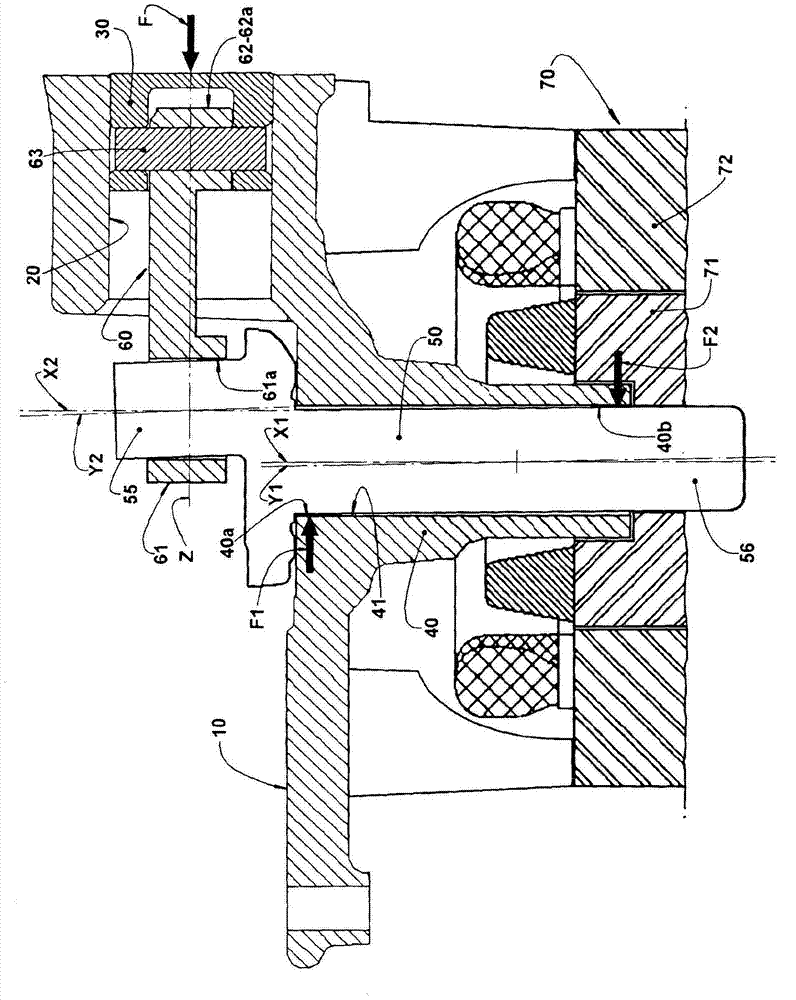

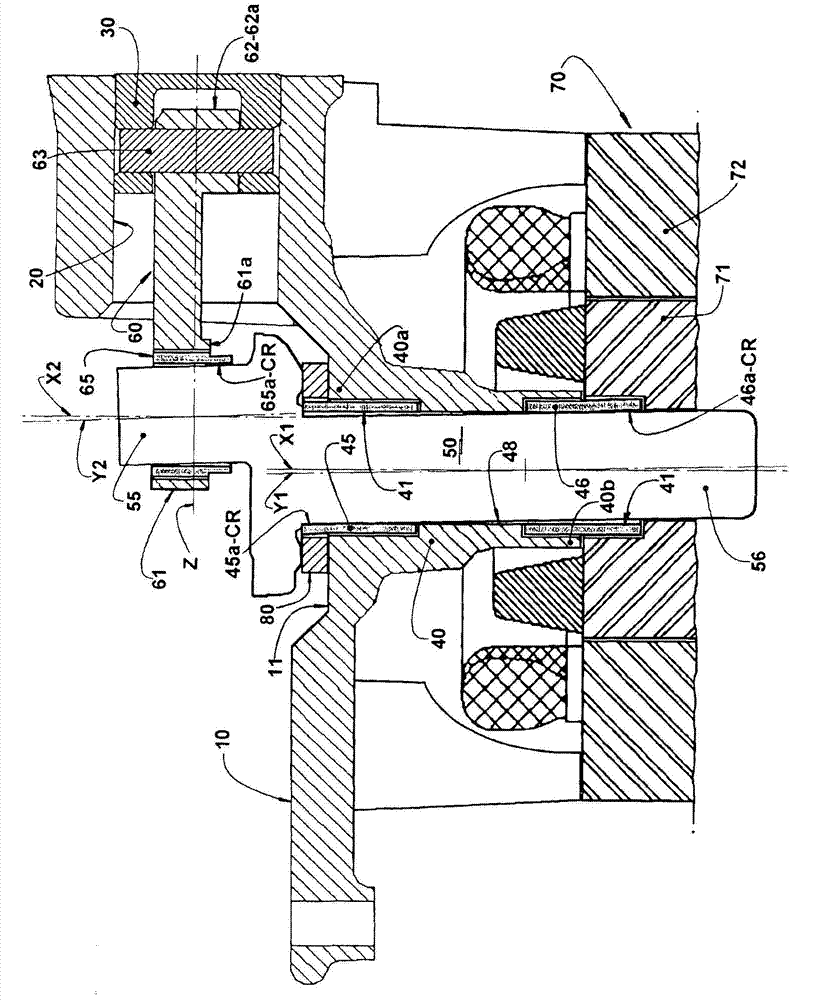

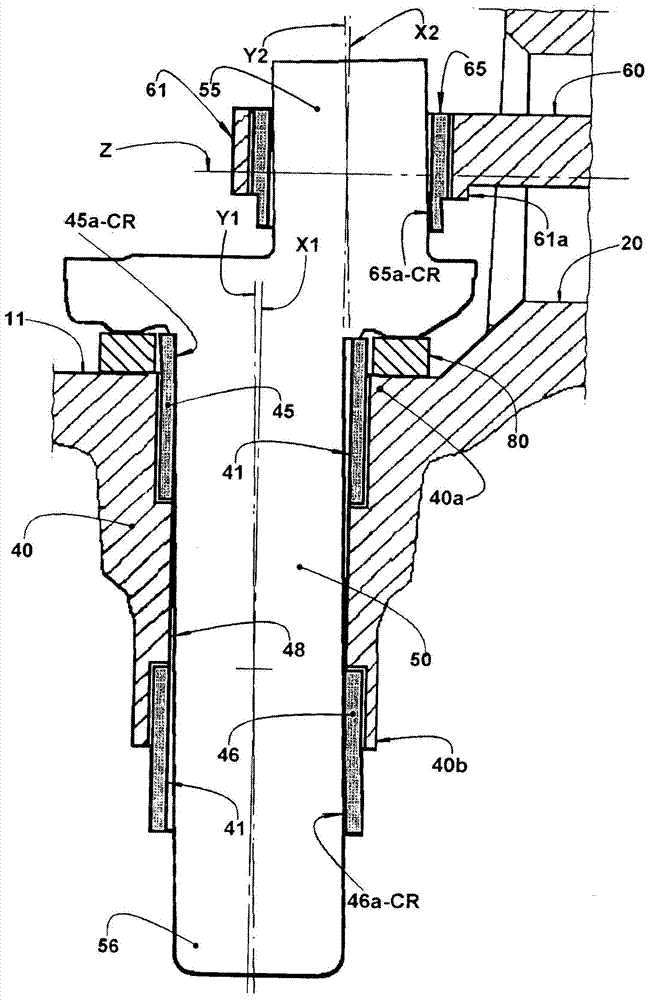

[0035] As already described and shown previously in Figures 1 and 2 of the accompanying drawings, the bearing arrangement of the invention is suitable for use in refrigeration compressors of the type comprising a crankshaft in the interior of a housing (not shown) The box 10 , the crankcase generally in a single casting, defines a cylinder 20 with axis Z and a bearing hub 40 internally defining a radial bearing 41 with axis X1 .

[0036] A crankshaft 50 having an axis Y1 is mounted inside the radial bearing 41 of the bearing hub 40 and has an eccentric end portion 55 having an axis Y2 outwardly from the first end portion 40a of the bearing hub 40 and a free end portion 56 protruding outward from the second end portion 40 b of the bearing hub 40 .

[0037] Piston 30 is housed in cylinder 20 for displacement therein by reciprocating motion via connecting rod 60 having: an end defining a larger bore 61 mounted about eccentric end portion 55 of crankshaft 50; and opposite end, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com