Patents

Literature

249results about "Cranks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

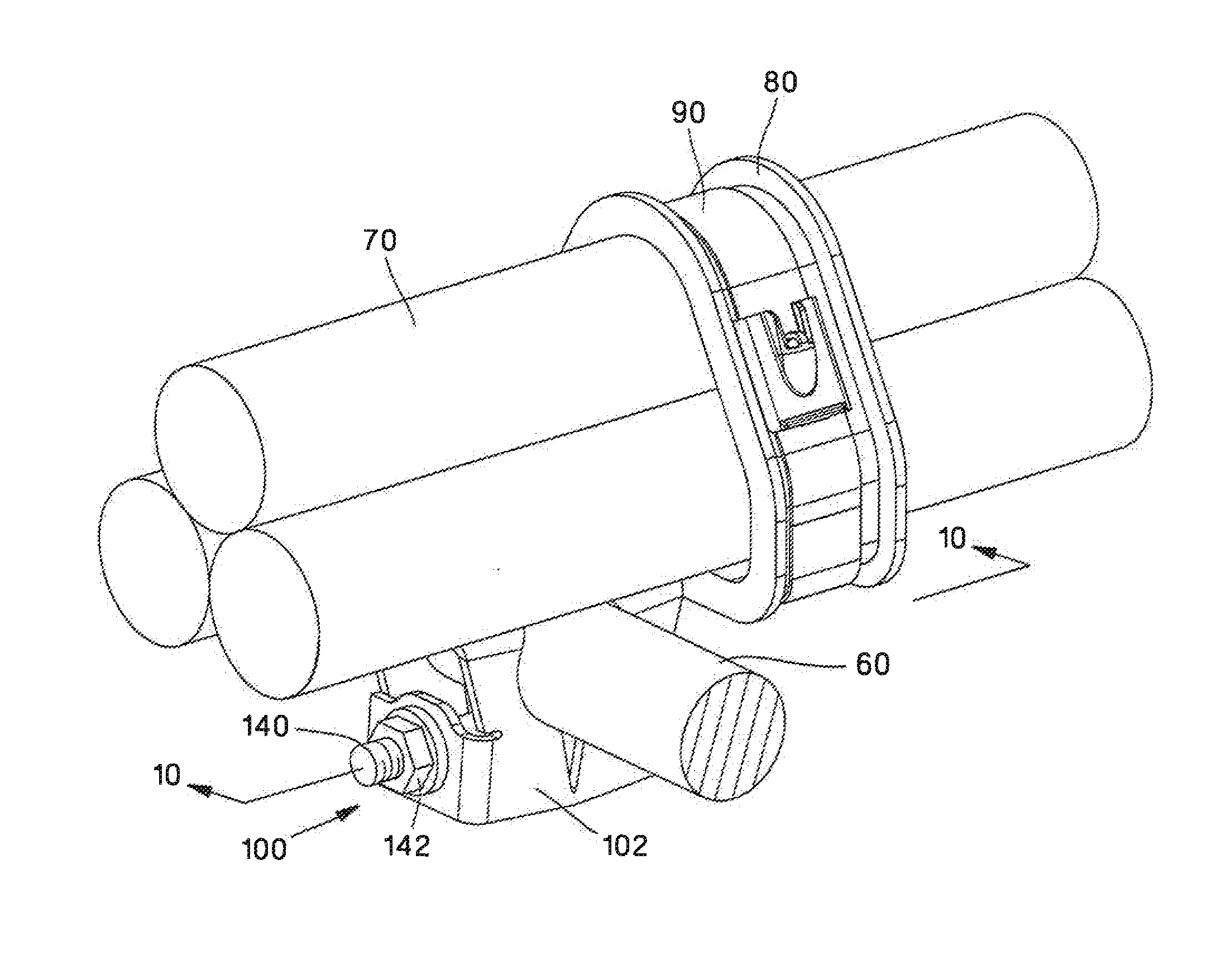

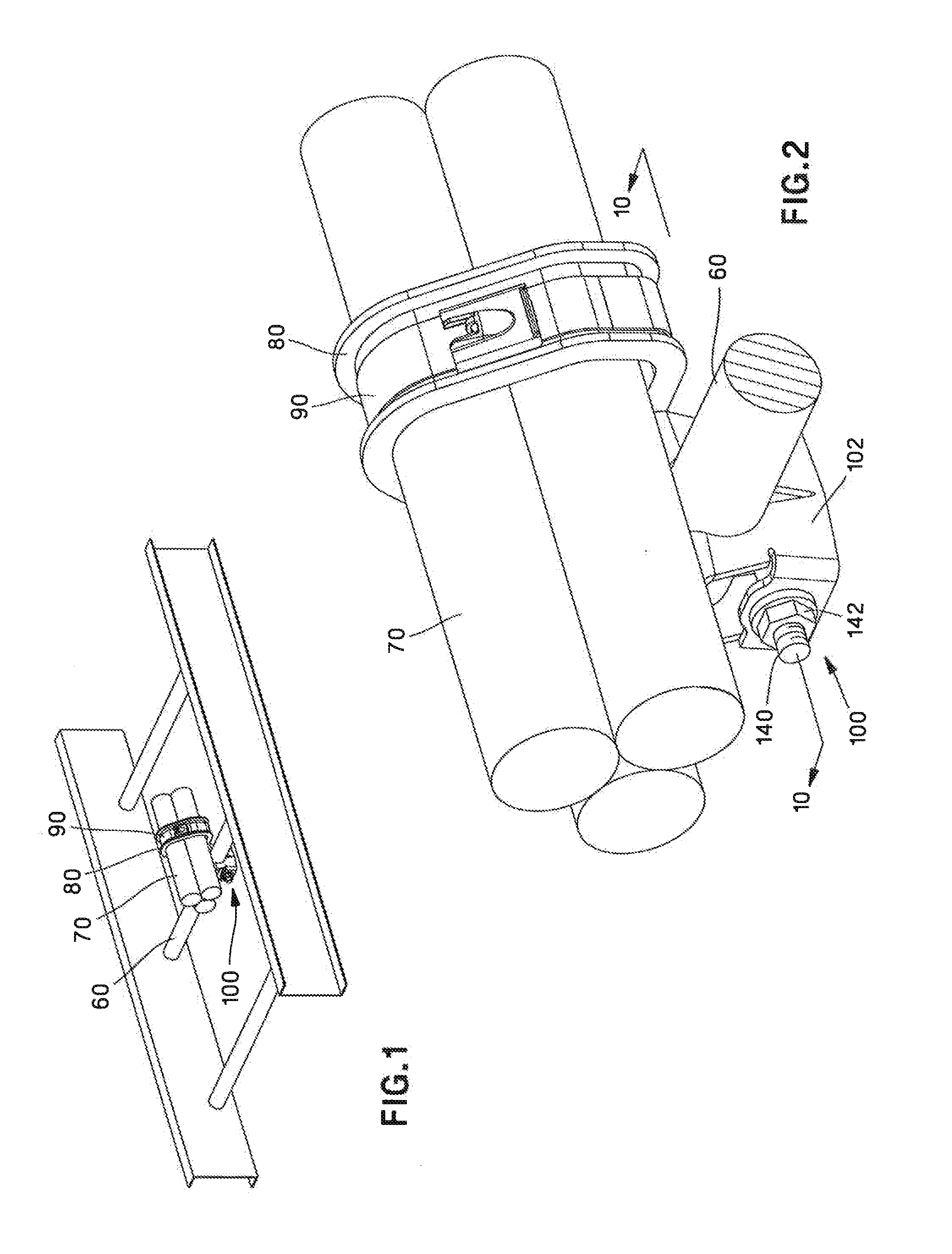

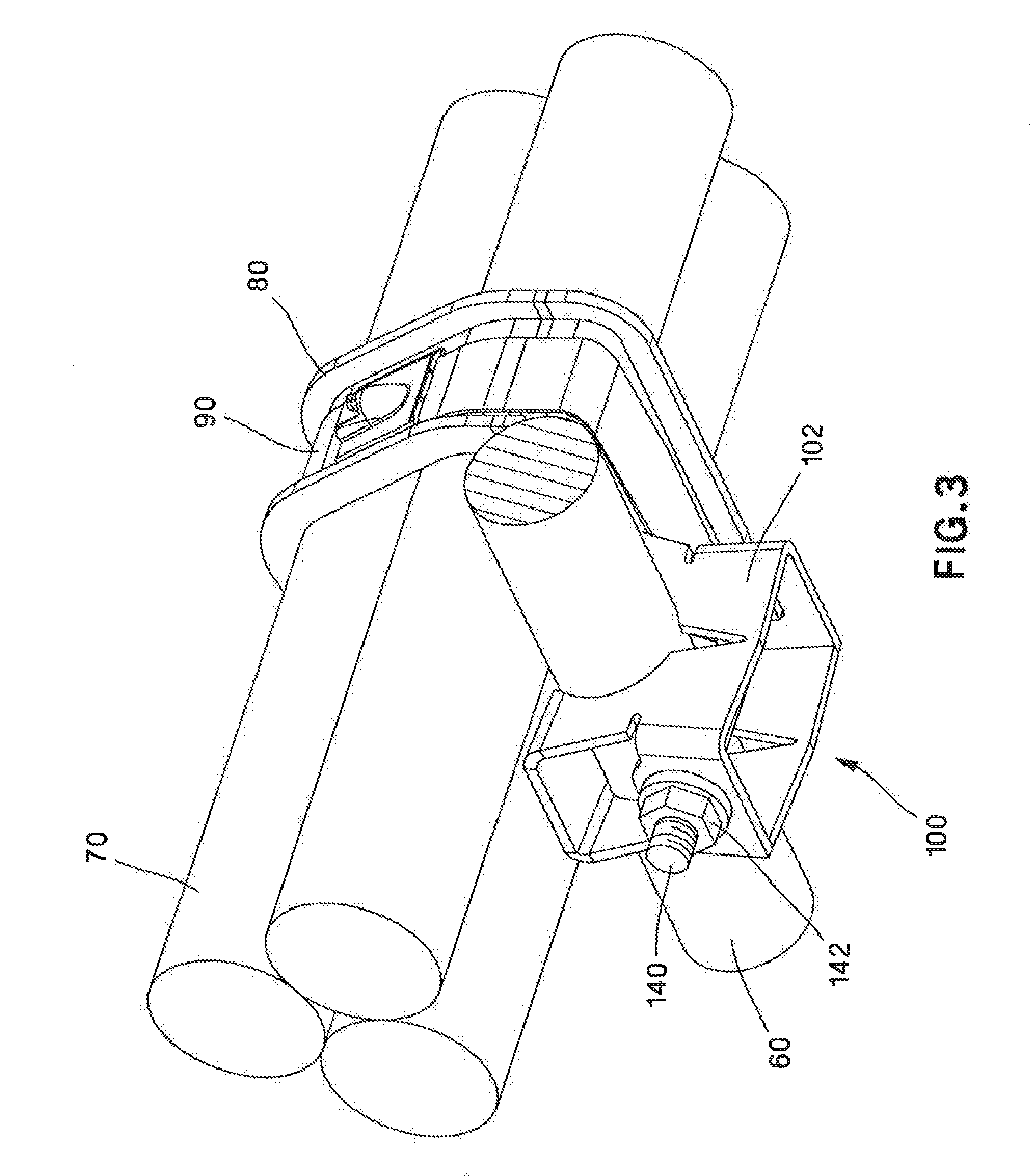

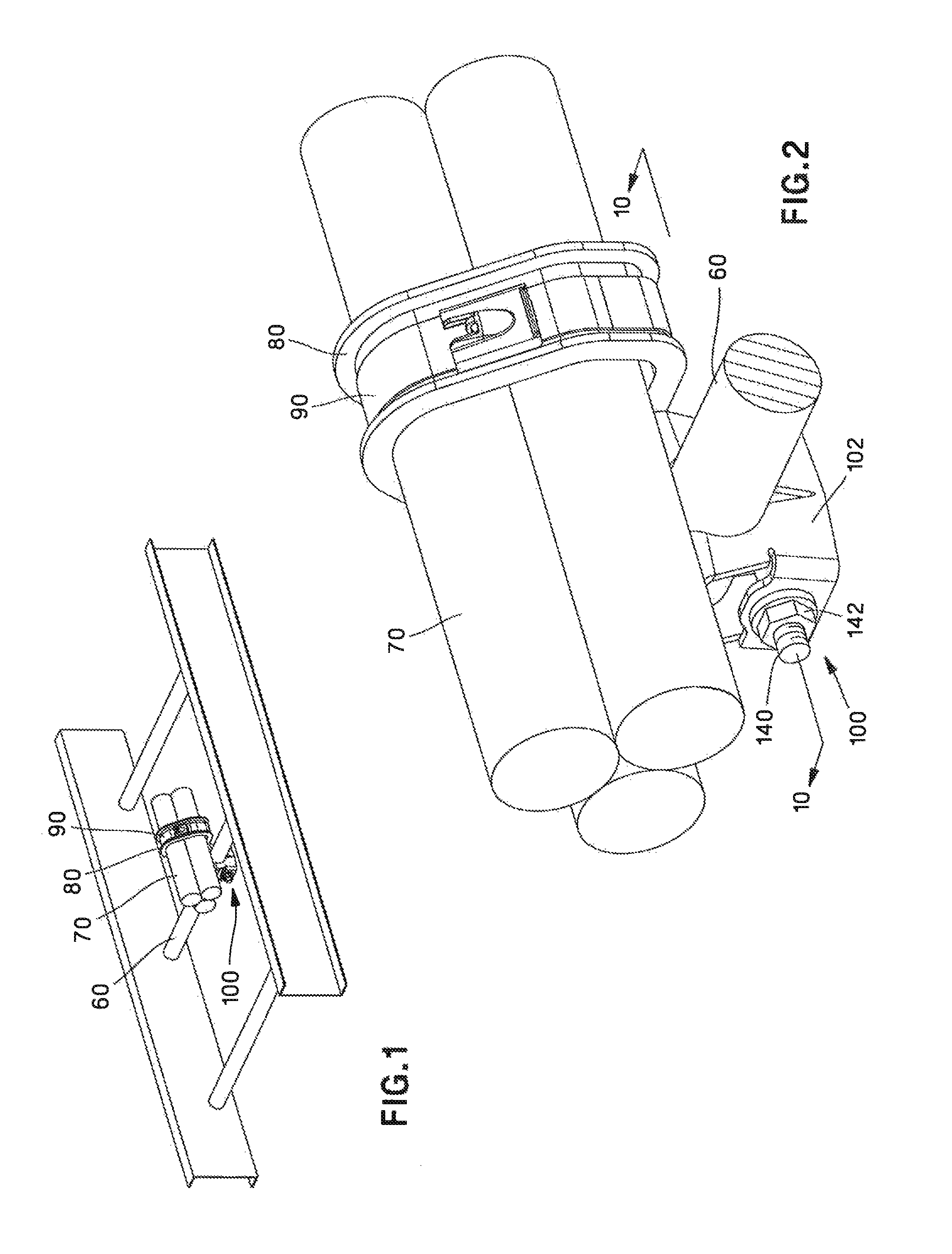

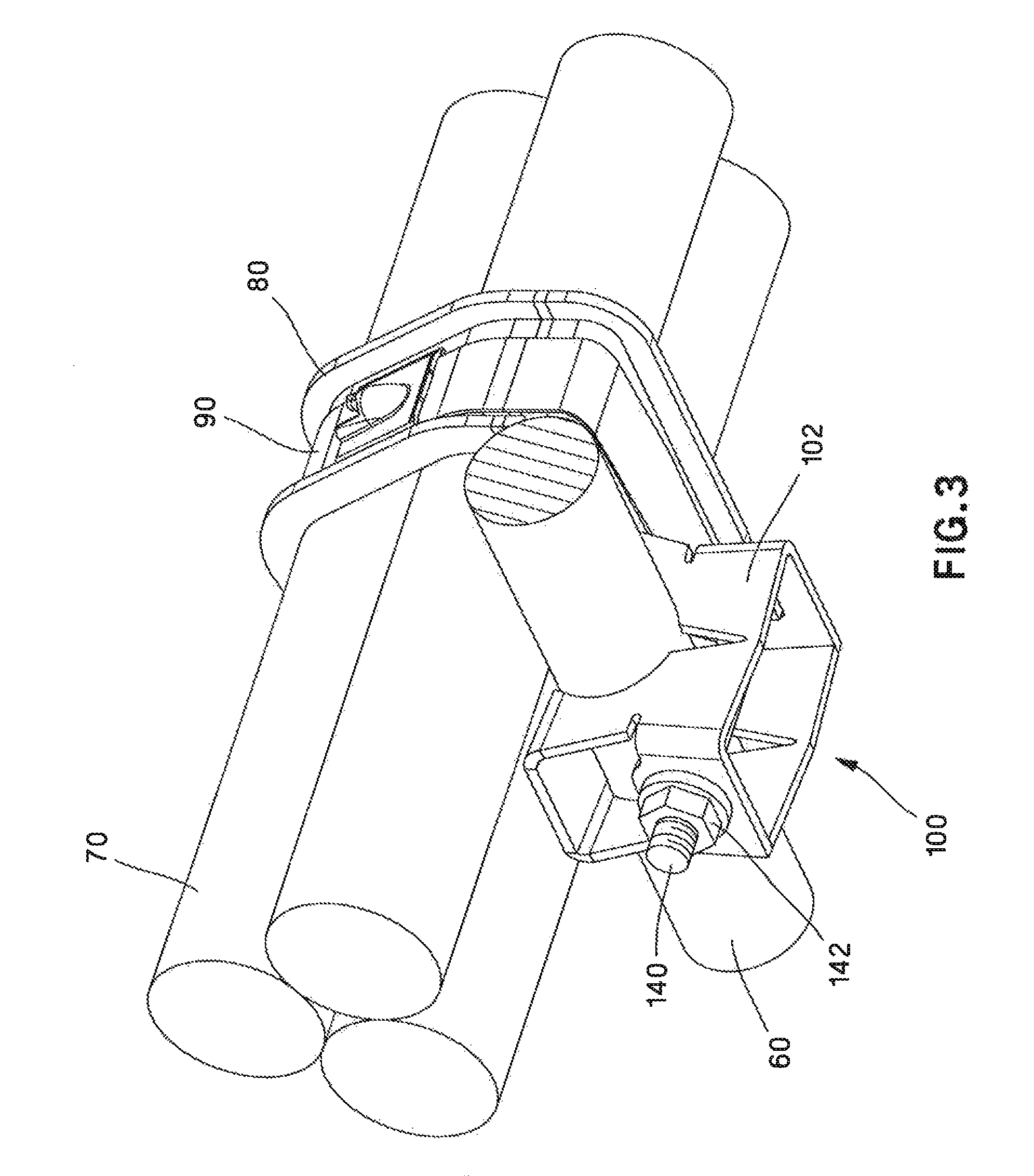

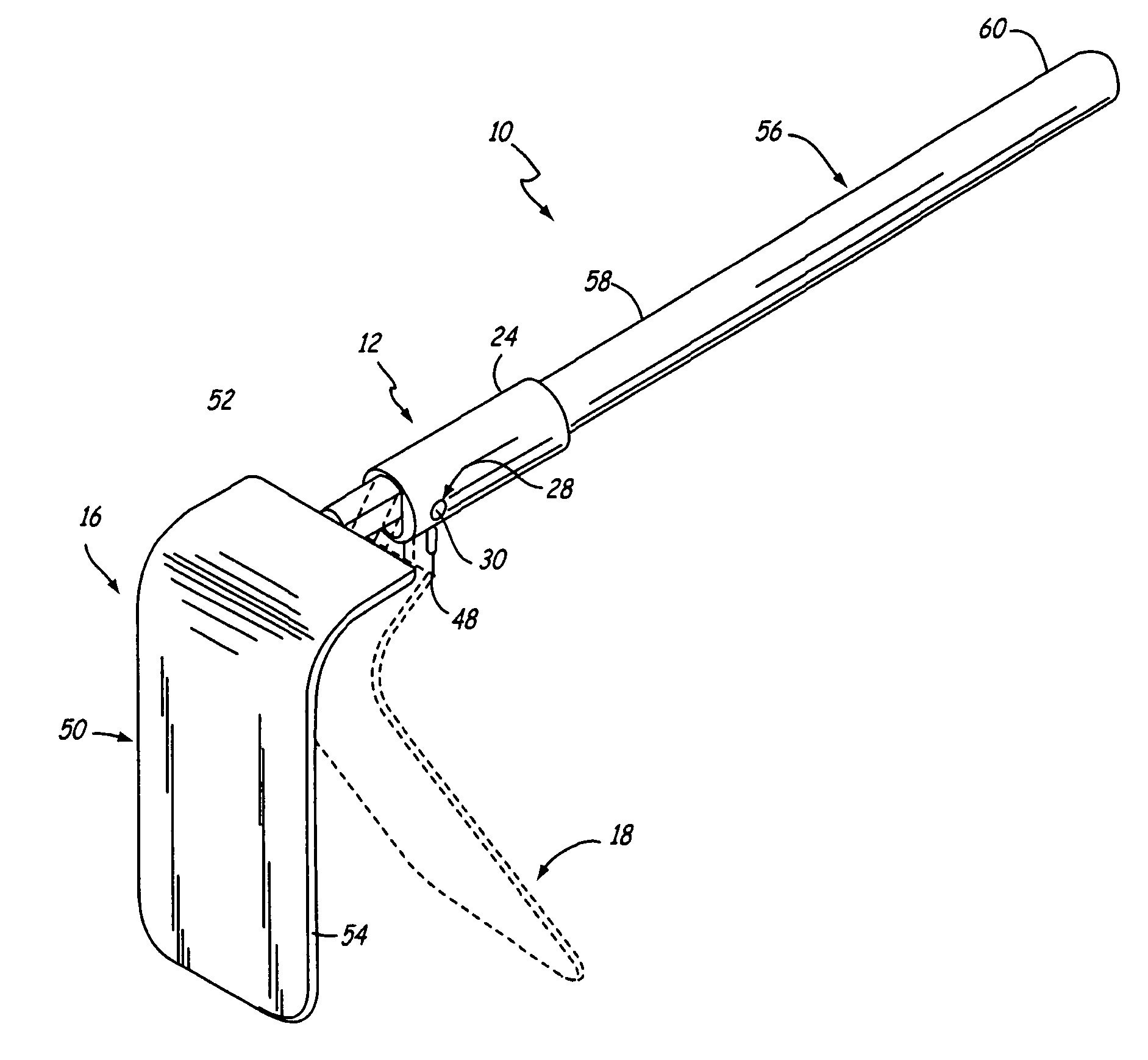

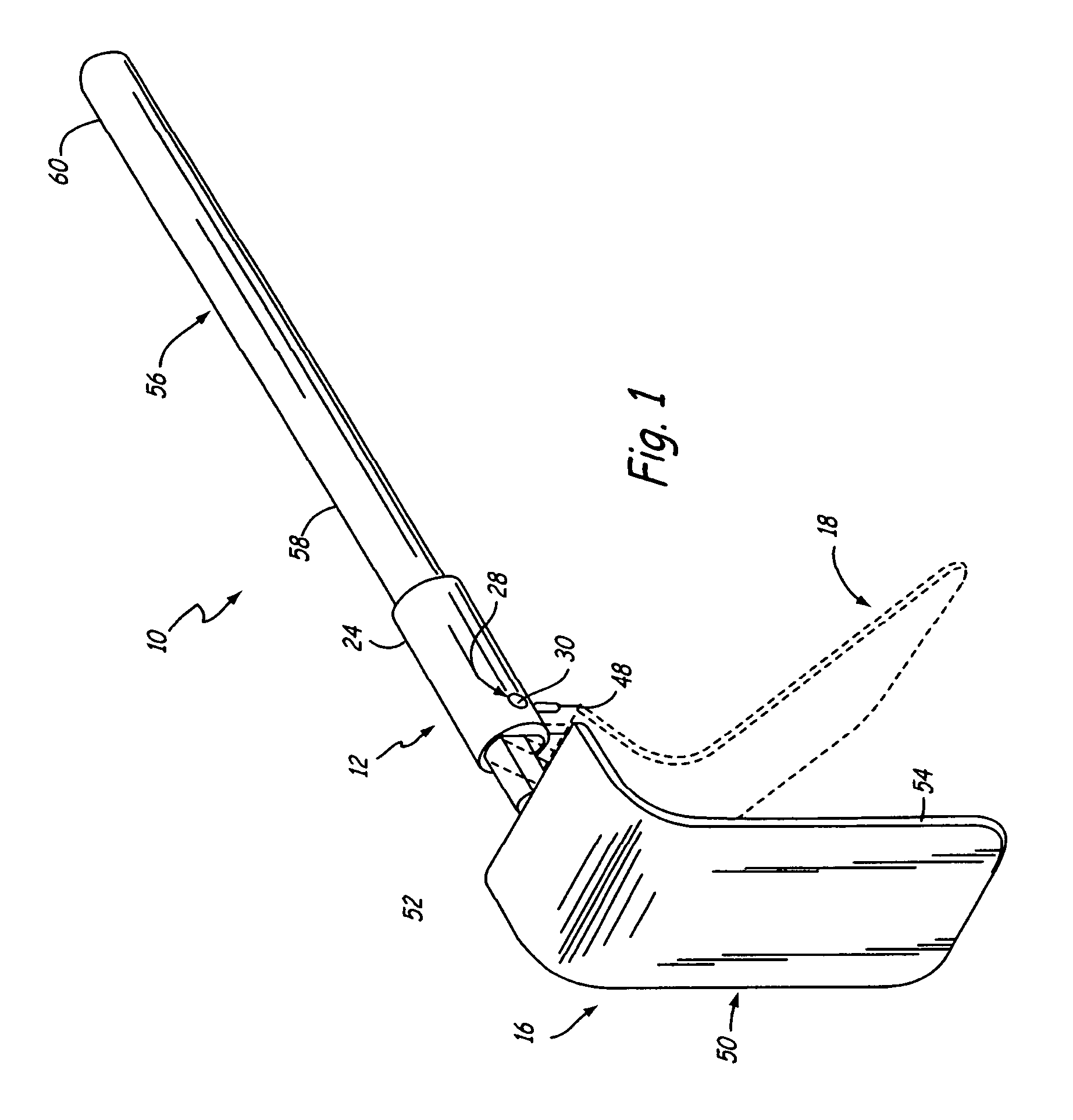

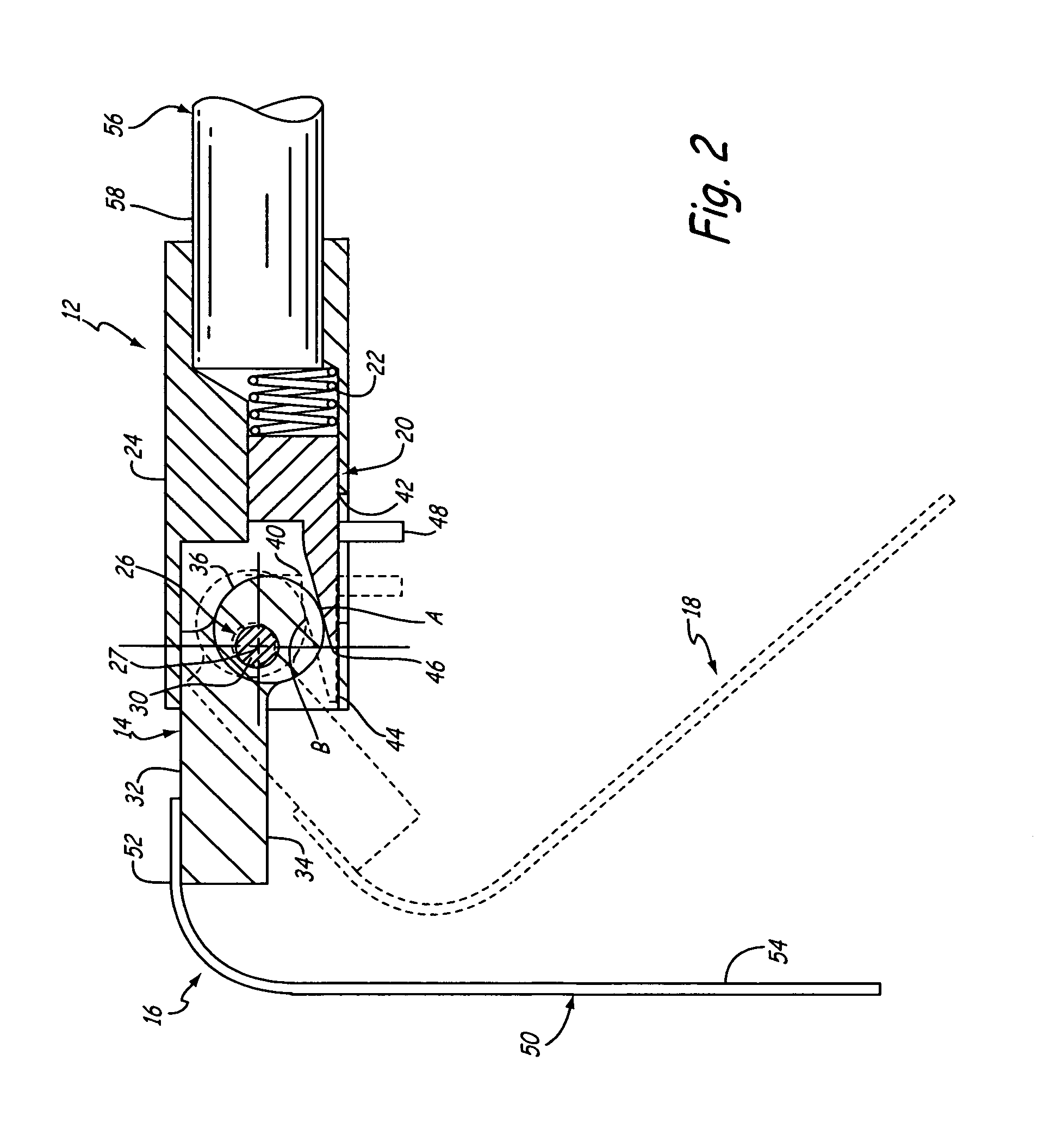

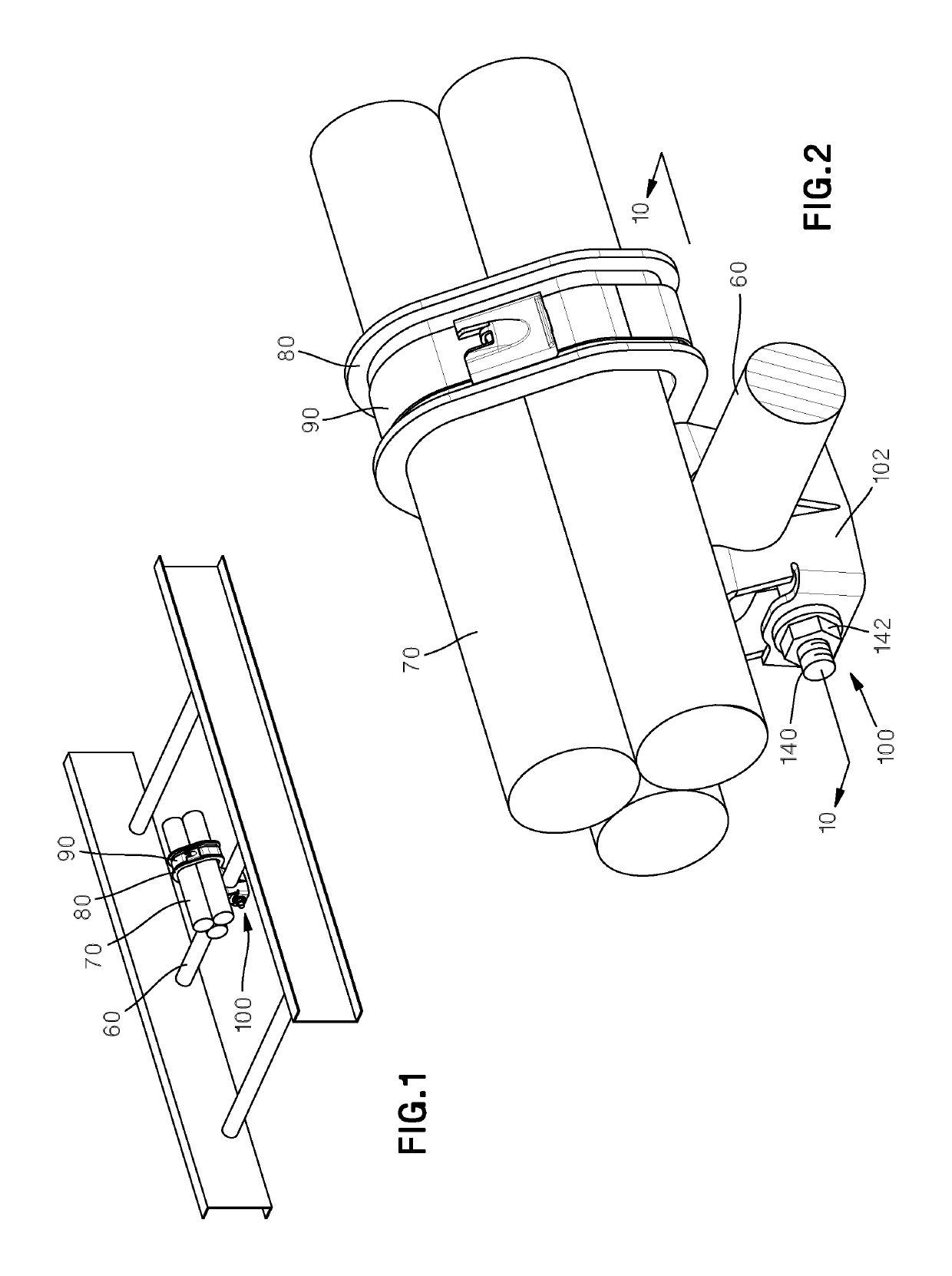

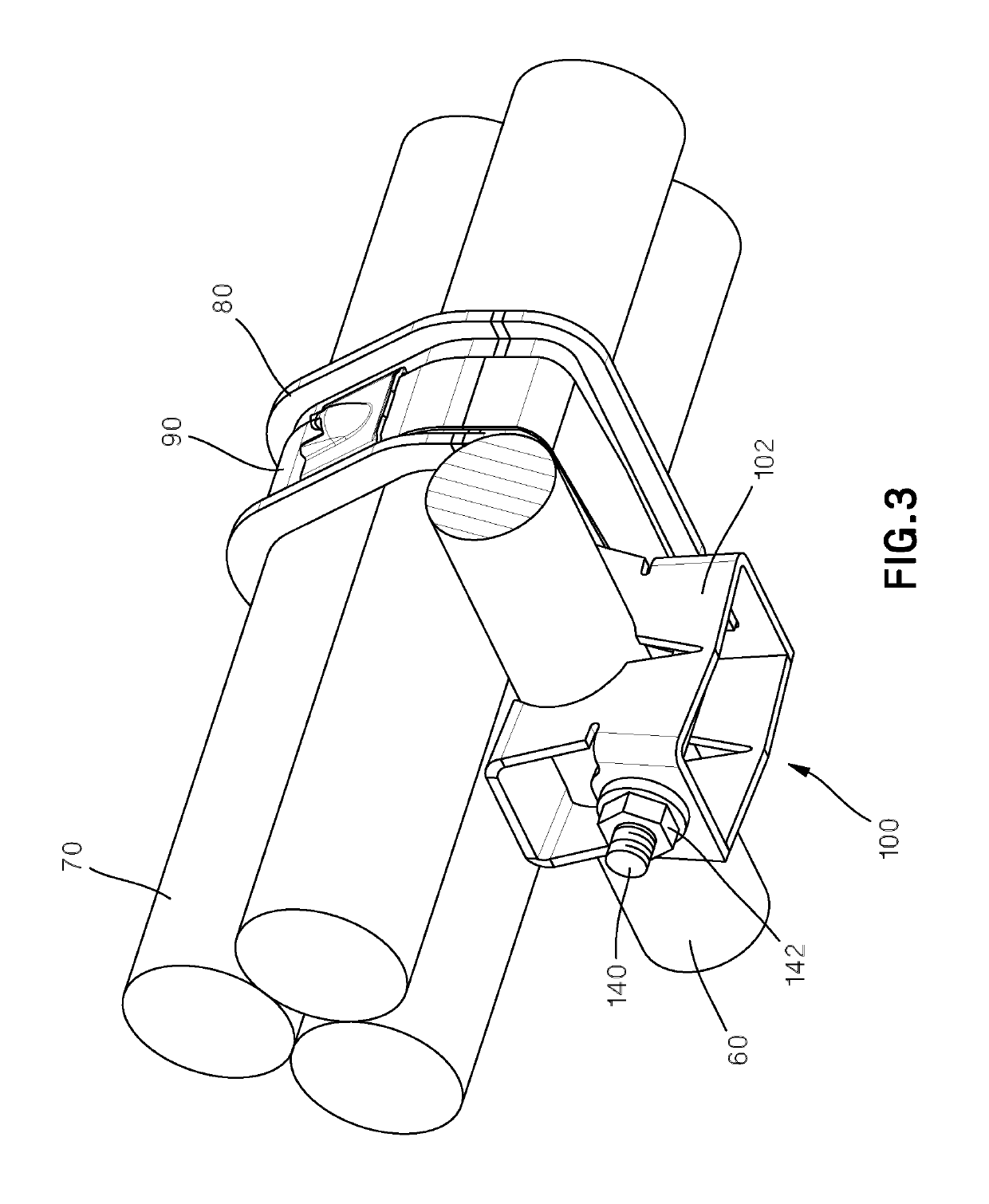

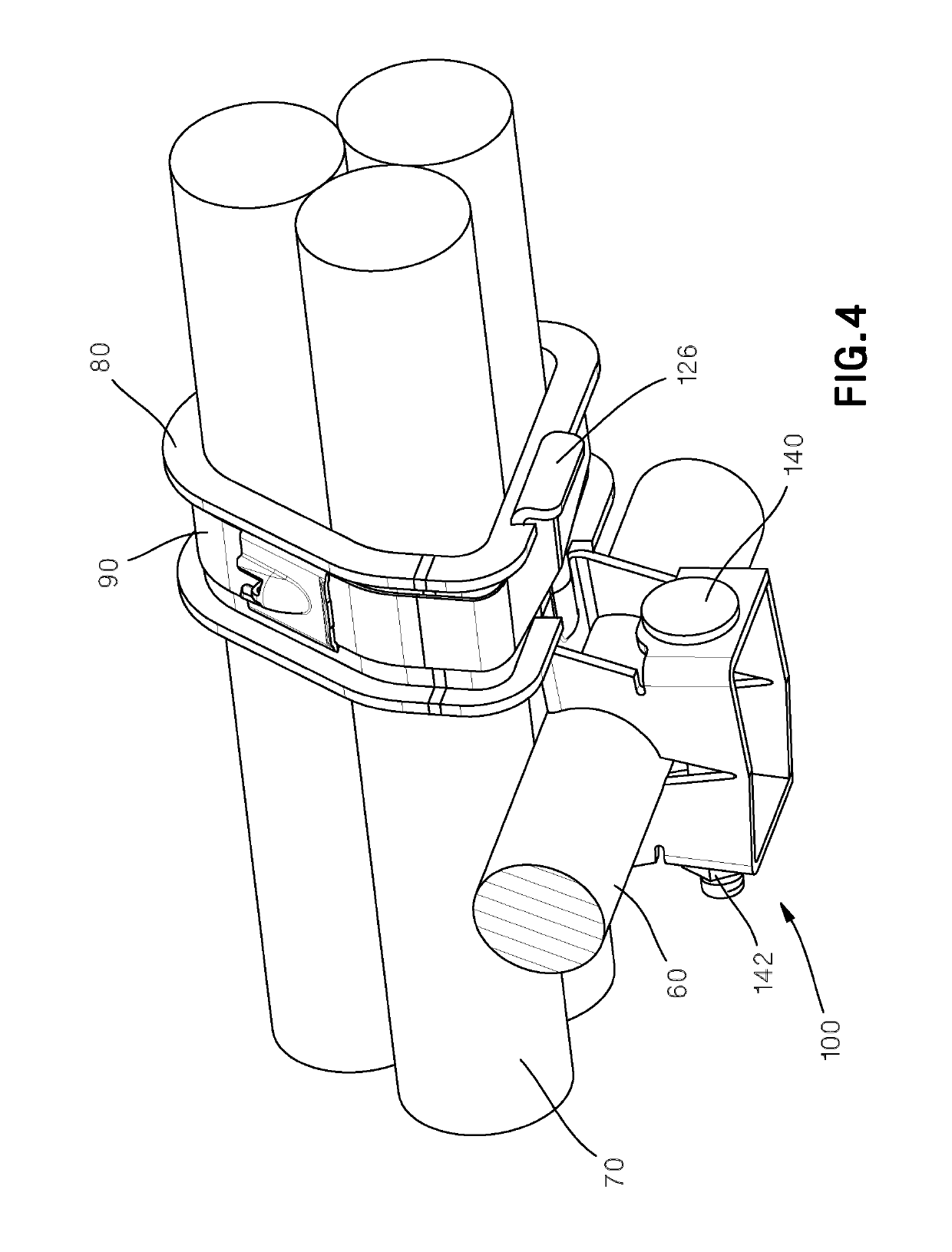

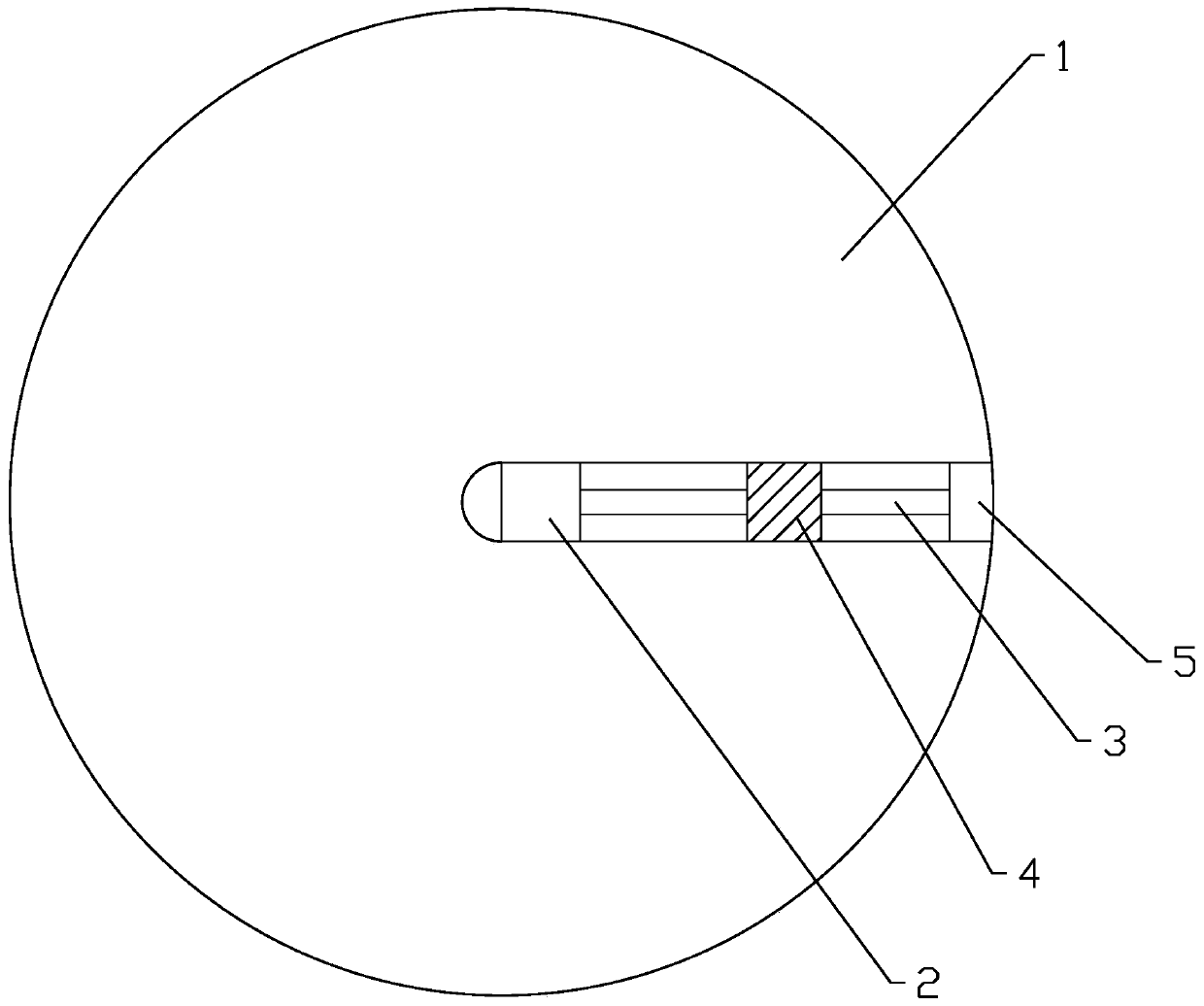

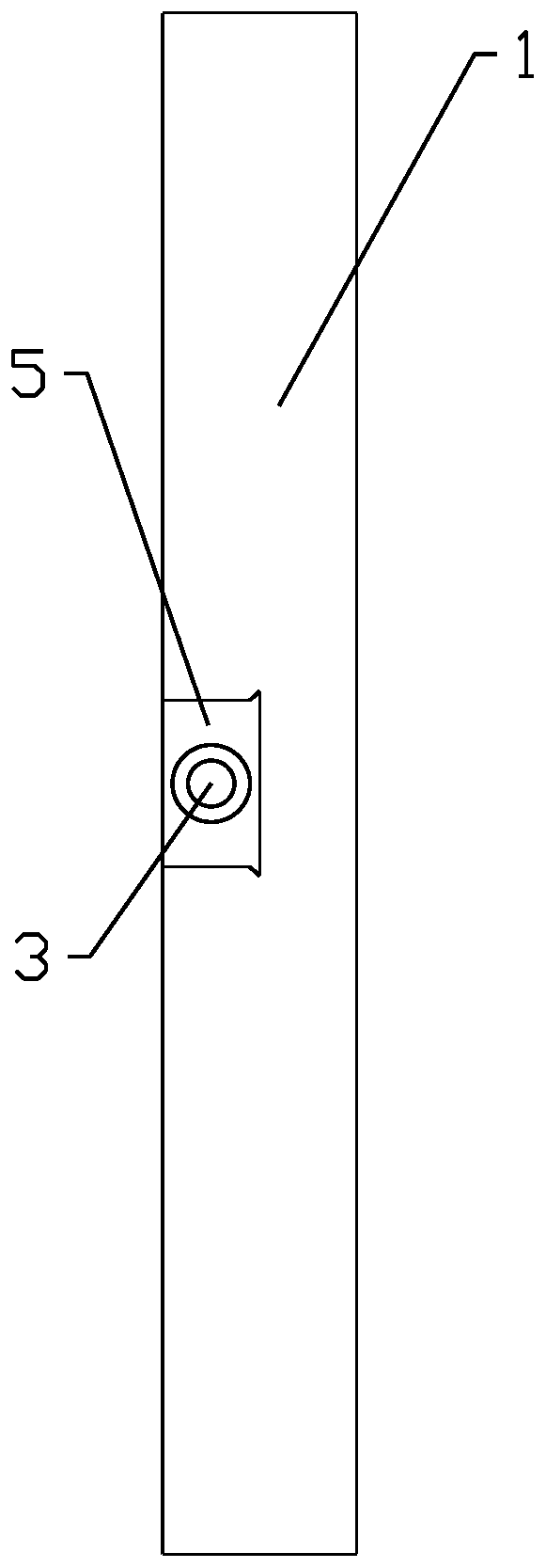

Cradle Clamp Bracket Assembly

A cradle clamp bracket assembly is disclosed. The cradle clamp bracket assembly secures cables to rungs of a ladder rack. The cradle clamp bracket assembly includes an elongated bracket having a first portion and a raised second portion. The first portion includes a slot located along the center of the first portion. The raised second portion includes a downwardly extending flange and at least one gusset to strengthen the bracket. The cradle clamp bracket assembly also includes a retainer that is received in the slot to engage the rung of the ladder rack.

Owner:PANDUIT

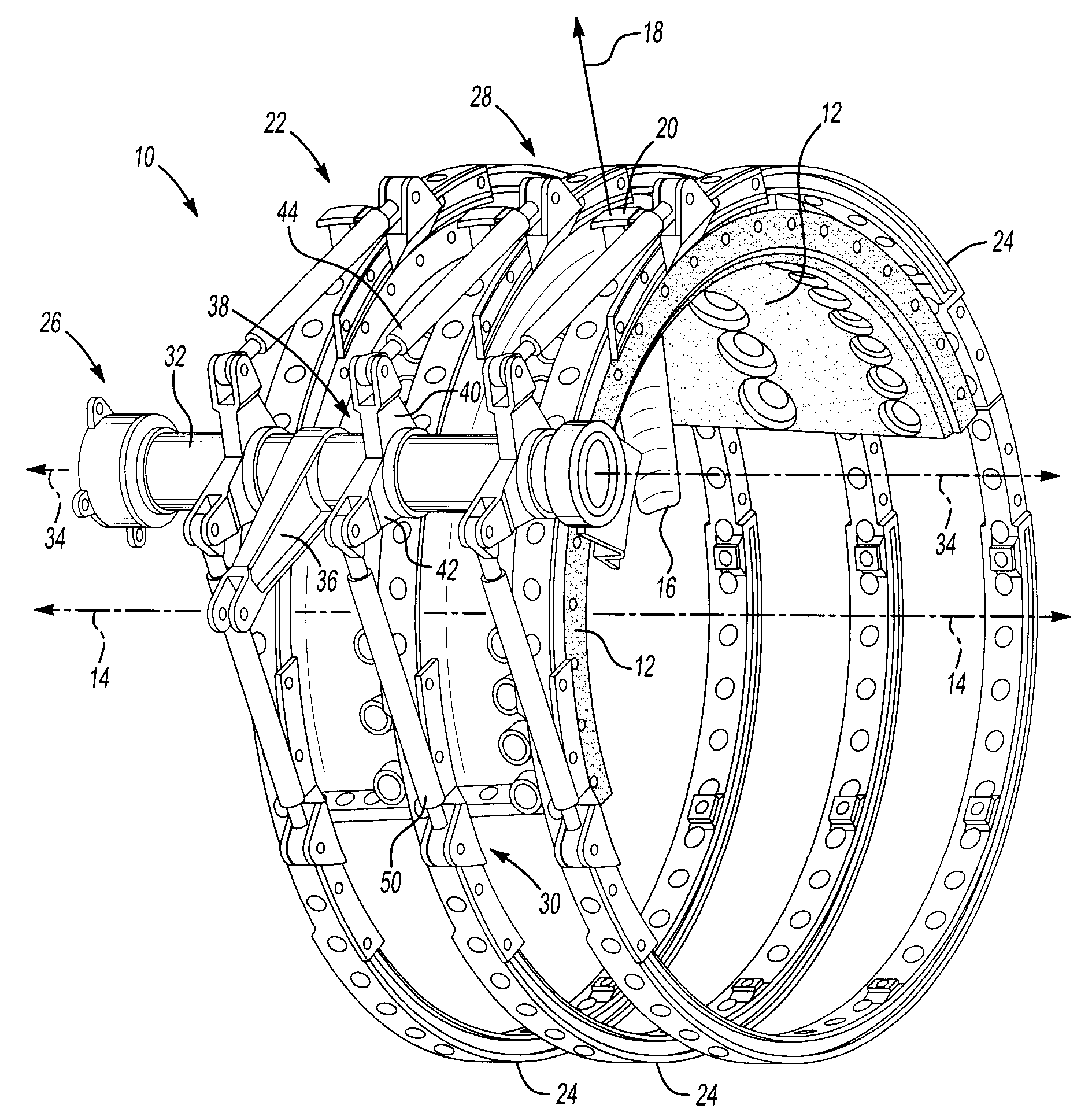

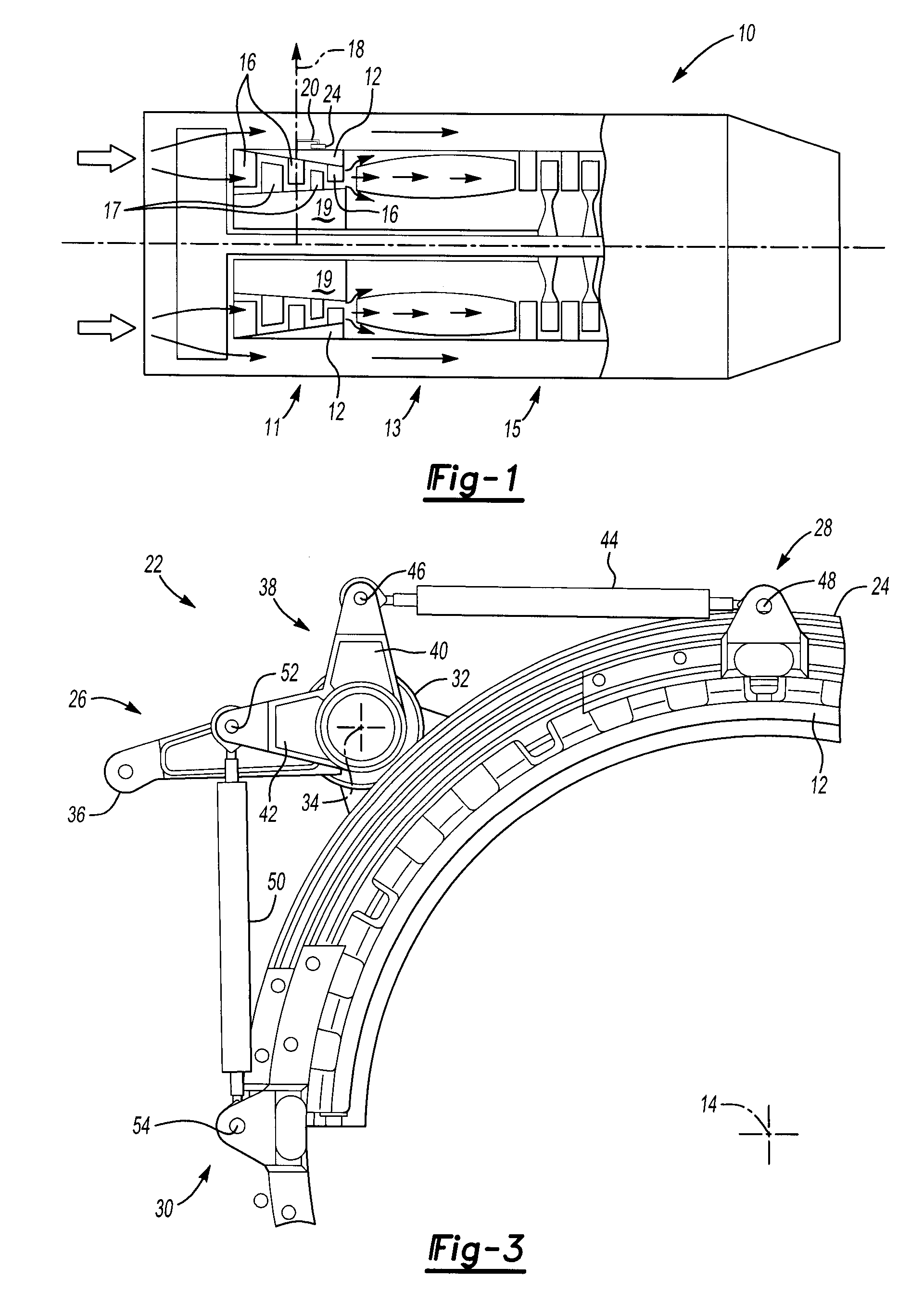

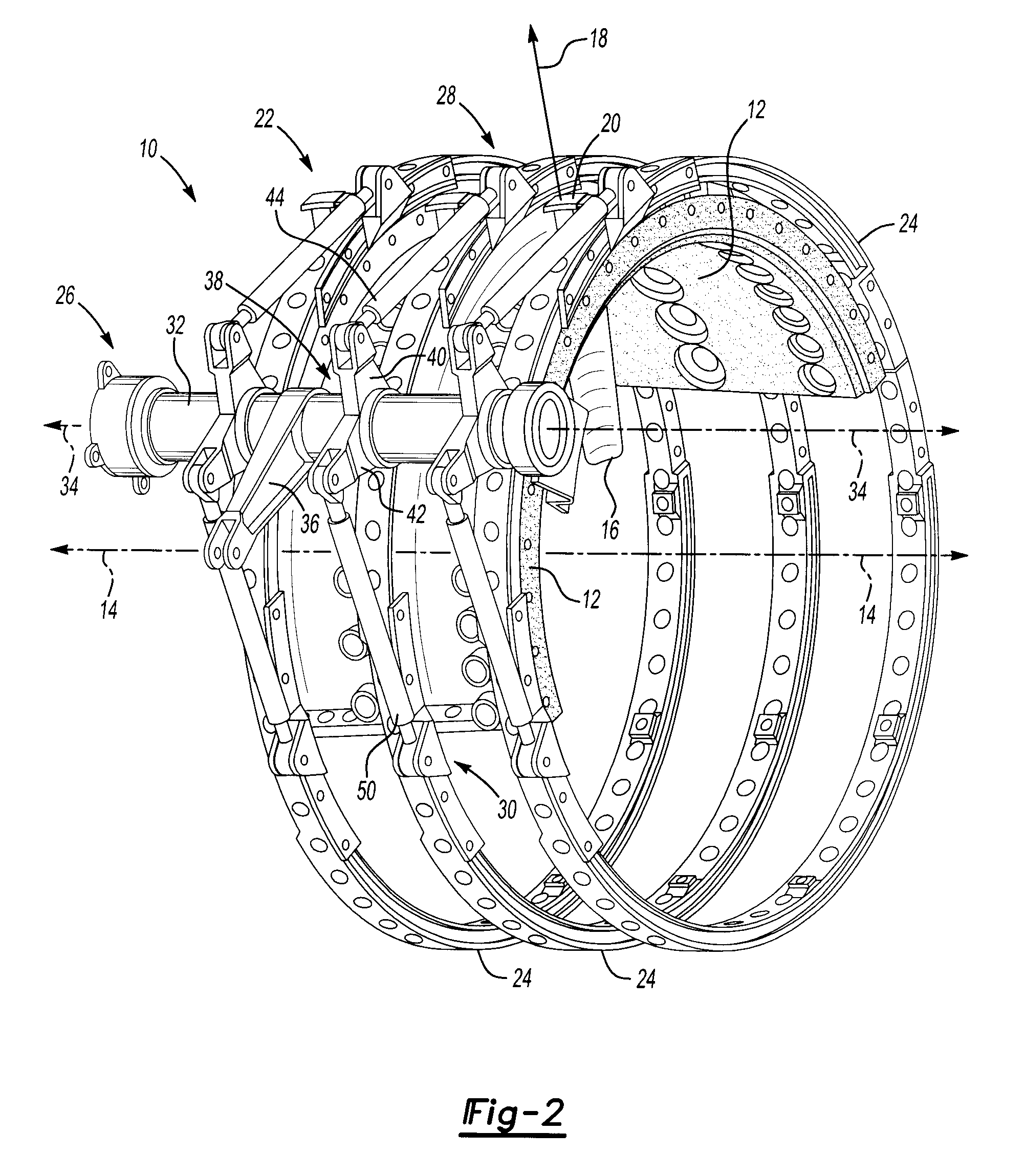

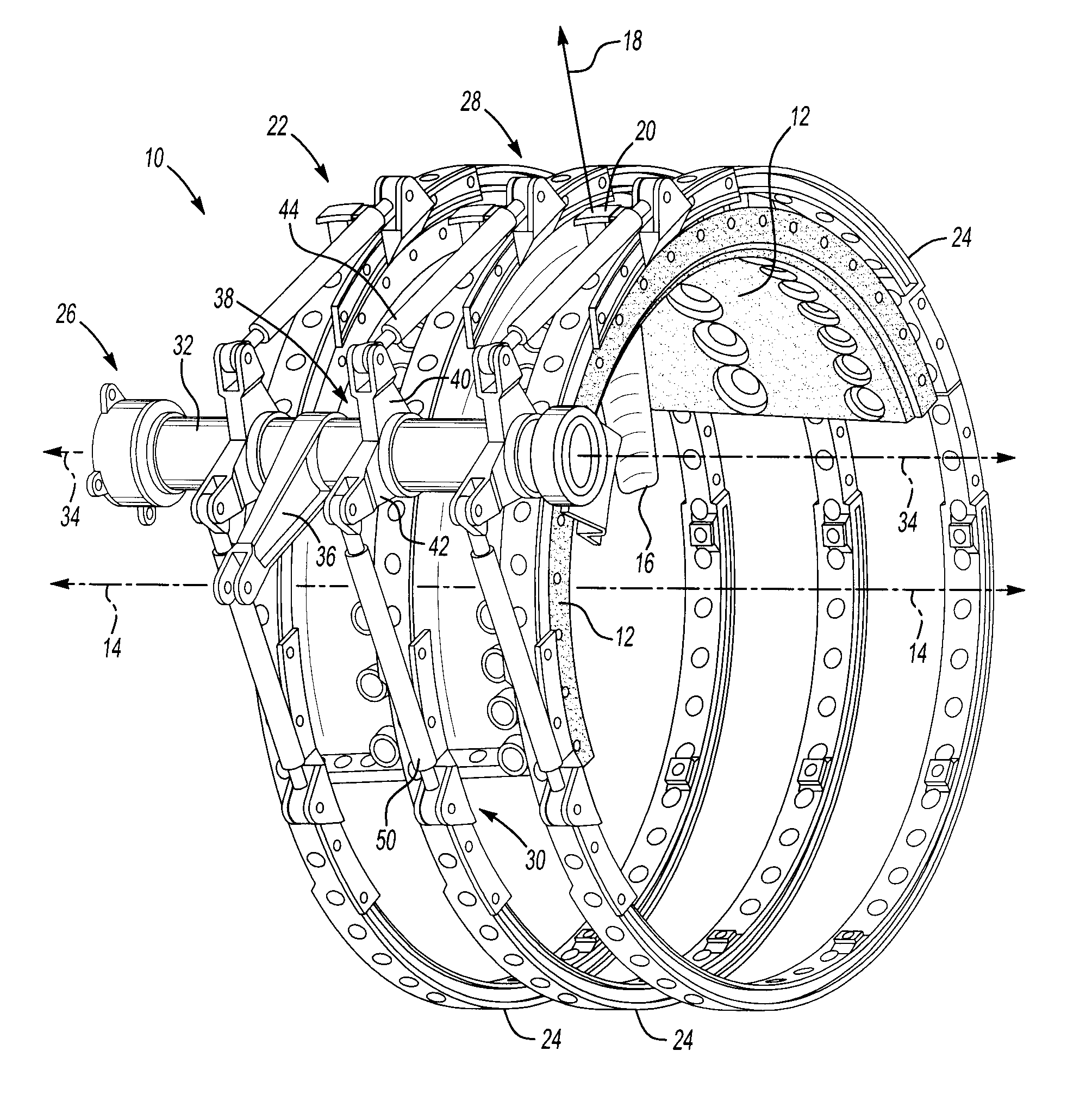

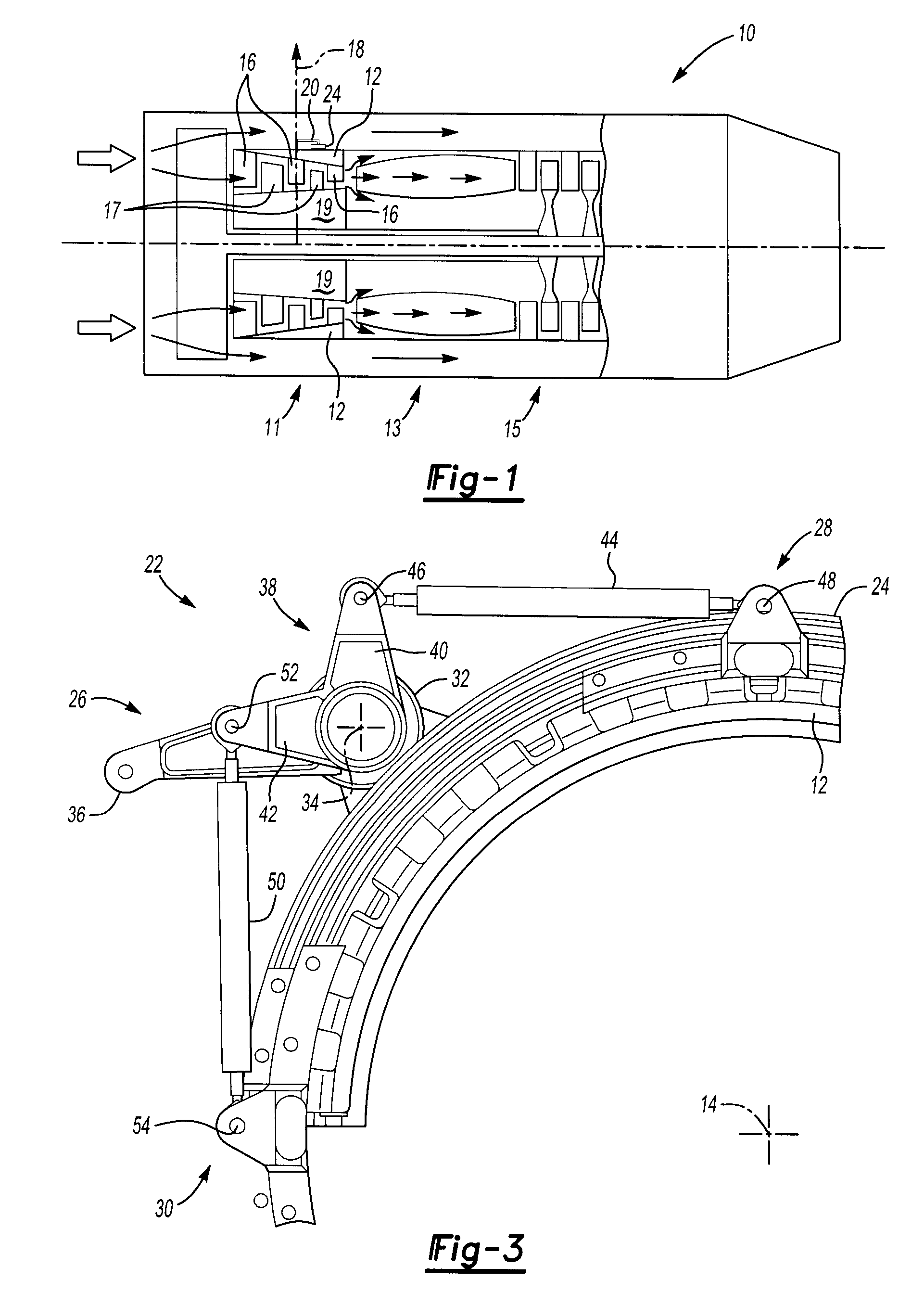

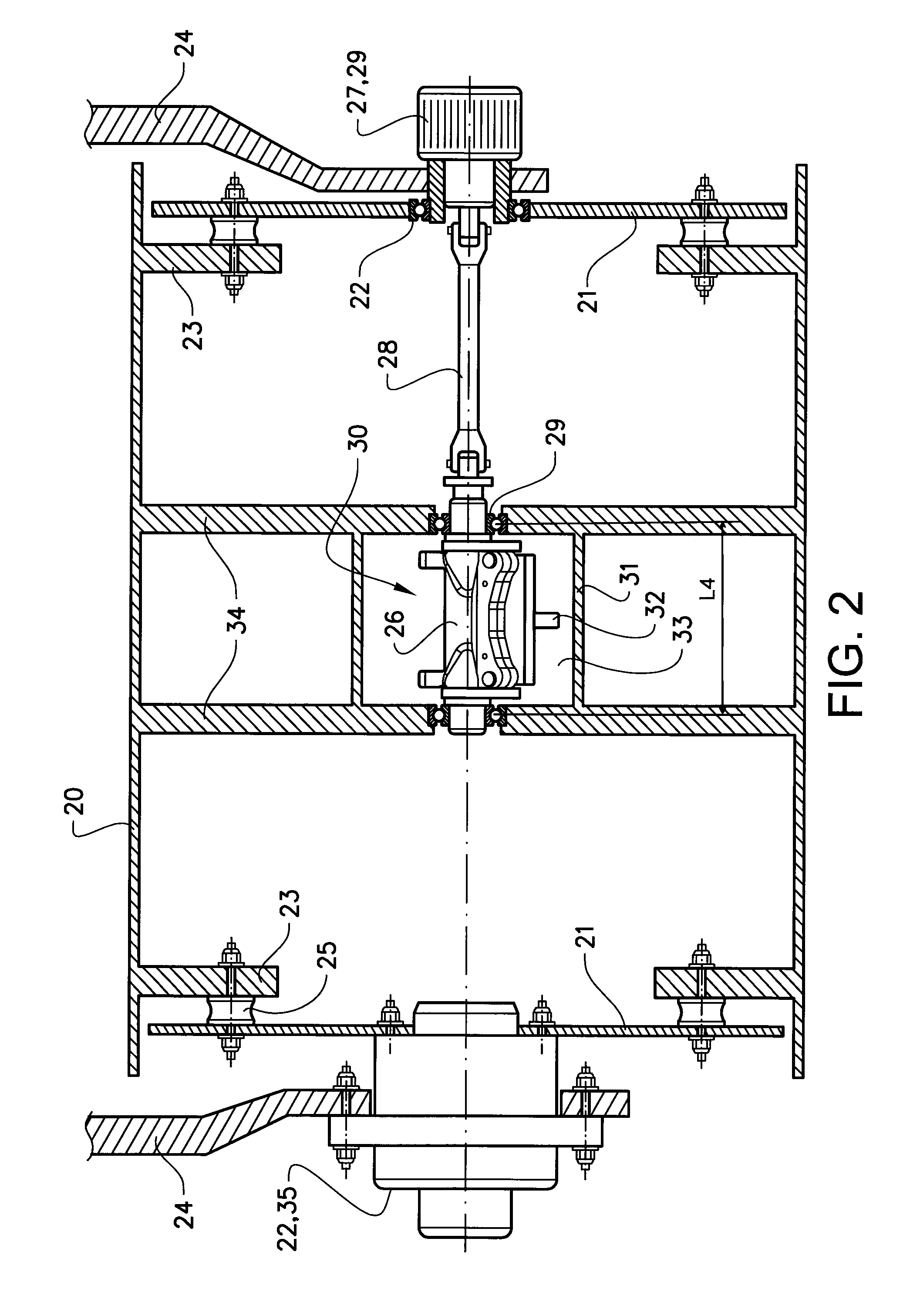

Variable vane actuation system

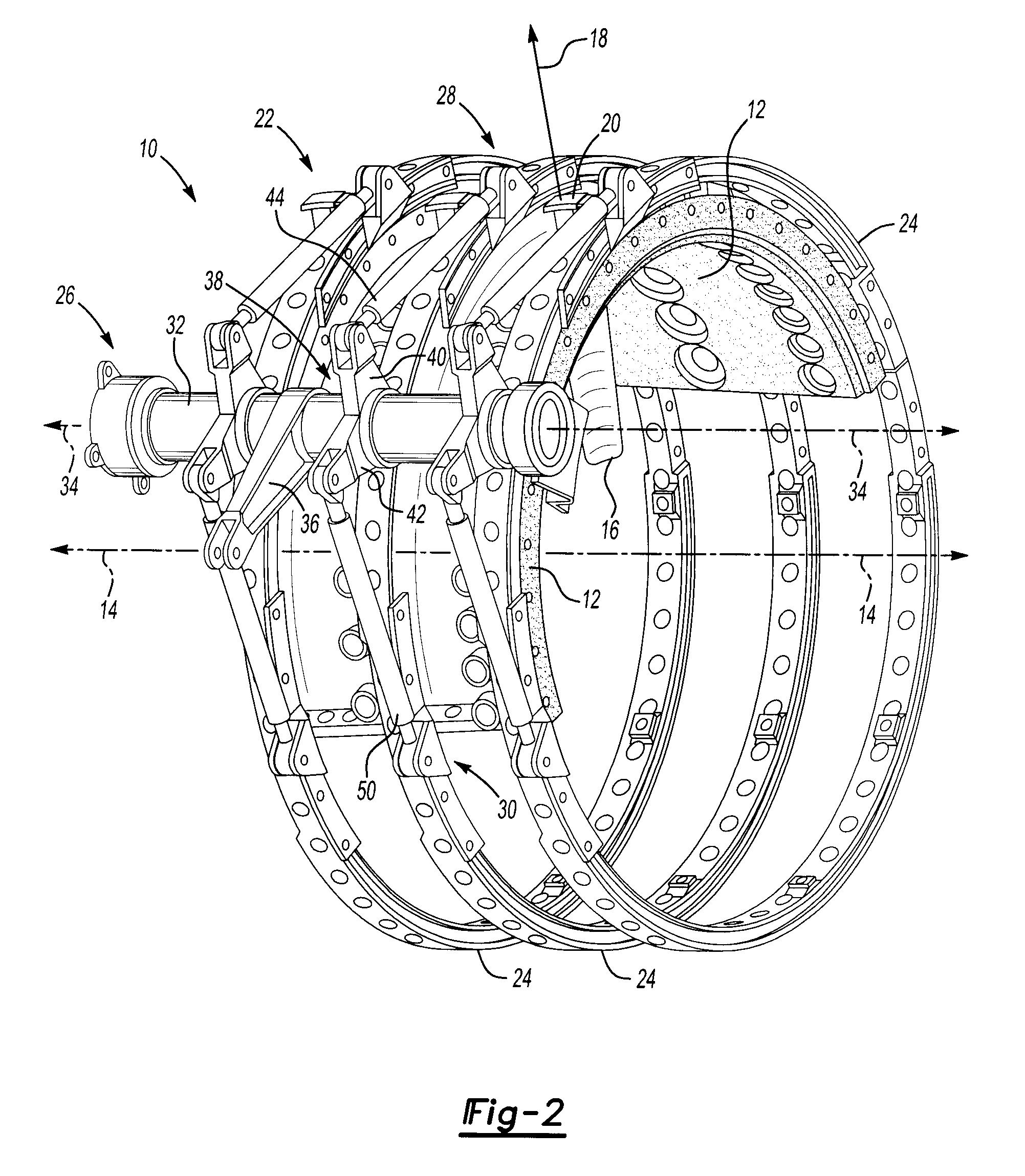

A variable vane actuation system is disclosed herein. The variable vane actuation system includes a ring member disposed for pivoting movement about a centerline axis. The ring member is engaged with a plurality of vanes in a turbine engine such that the plurality of vanes pivot in response to the pivoting movement of the ring member. The variable vane actuation system also includes a ring moving device engaged with the ring member at first and second positions spaced from one another about the centerline axis. The ring moving device is operable to apply first and second forces, respectively, at the first and second positions to pivot the ring member.

Owner:ROLLS ROYCE CORP

Variable vane actuation system

A variable vane actuation system is disclosed herein. The variable vane actuation system includes a ring member disposed for pivoting movement about a centerline axis. The ring member is engaged with a plurality of vanes in a turbine engine such that the plurality of vanes pivot in response to the pivoting movement of the ring member. The variable vane actuation system also includes a ring moving device engaged with the ring member at first and second positions spaced from one another about the centerline axis. The ring moving device is operable to apply first and second forces, respectively, at the first and second positions to pivot the ring member.

Owner:ROLLS ROYCE CORP

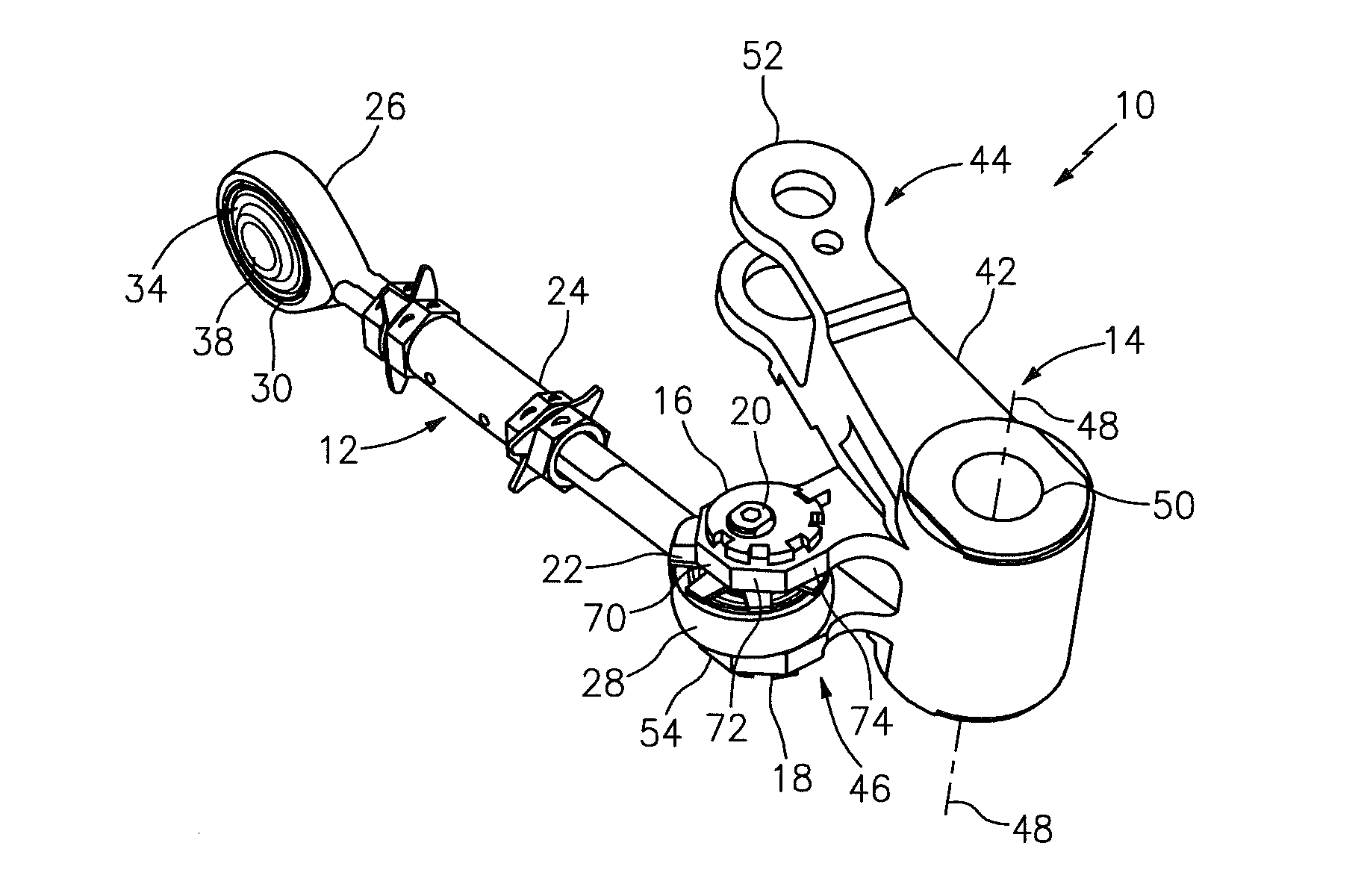

Adjustable clevis assembly

An adjustable clevis assembly includes a clevis, a first adjustment sleeve, a second adjustment sleeve, a tongue and a clevis pin. The clevis includes a first support flange with a first sleeve aperture and a second support flange with a second sleeve aperture. The first adjustment sleeve is seated in the first sleeve aperture, and includes a first pin aperture that is eccentric relative to the first sleeve aperture. The second adjustment sleeve is seated in the second sleeve aperture, and includes a second pin aperture that is eccentric relative to the second sleeve aperture. The tongue is arranged between the first support flange and the second support flange. The clevis pin extends through the first pin aperture, the second pin aperture and a third pin aperture in the tongue.

Owner:UNITED TECH CORP

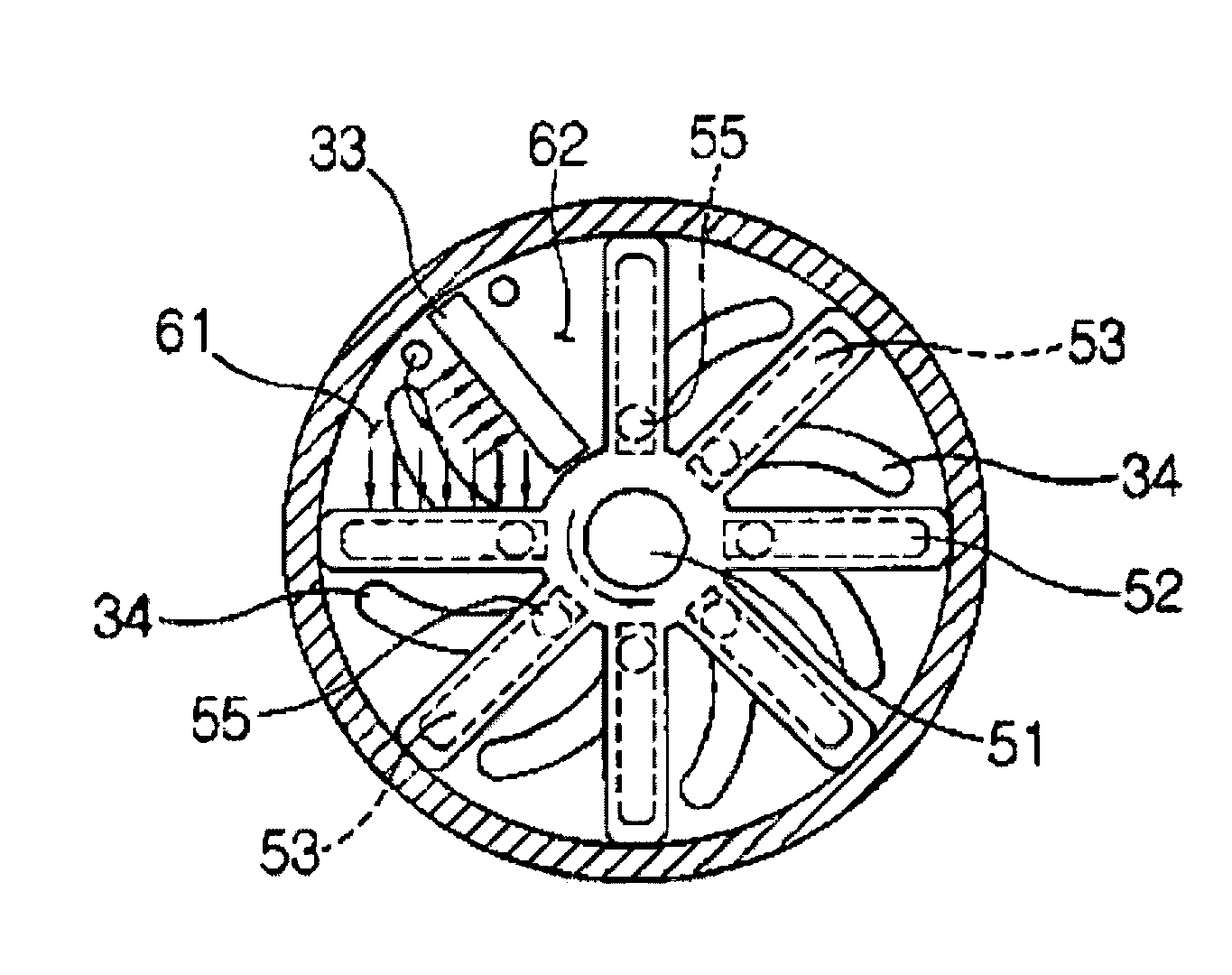

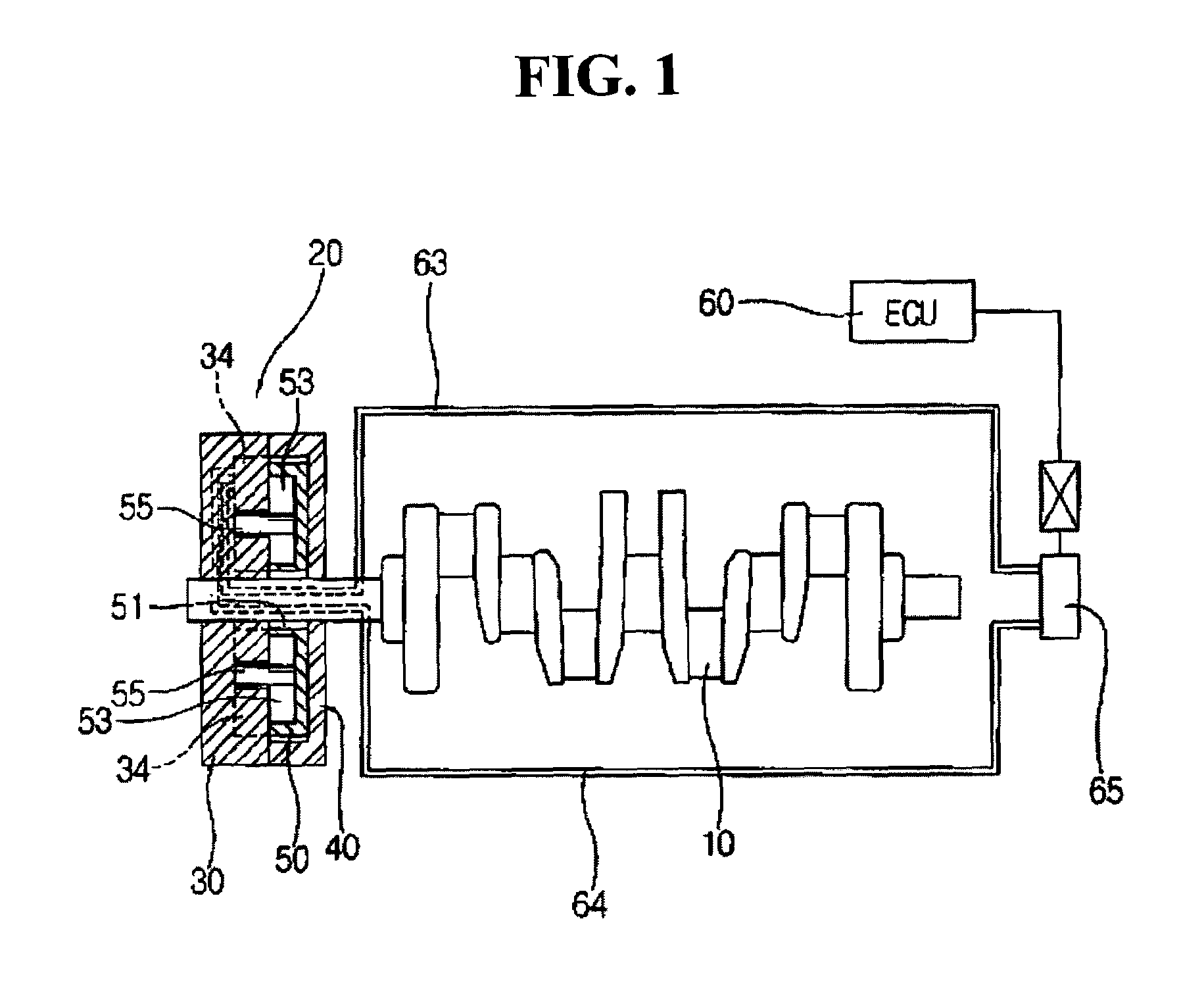

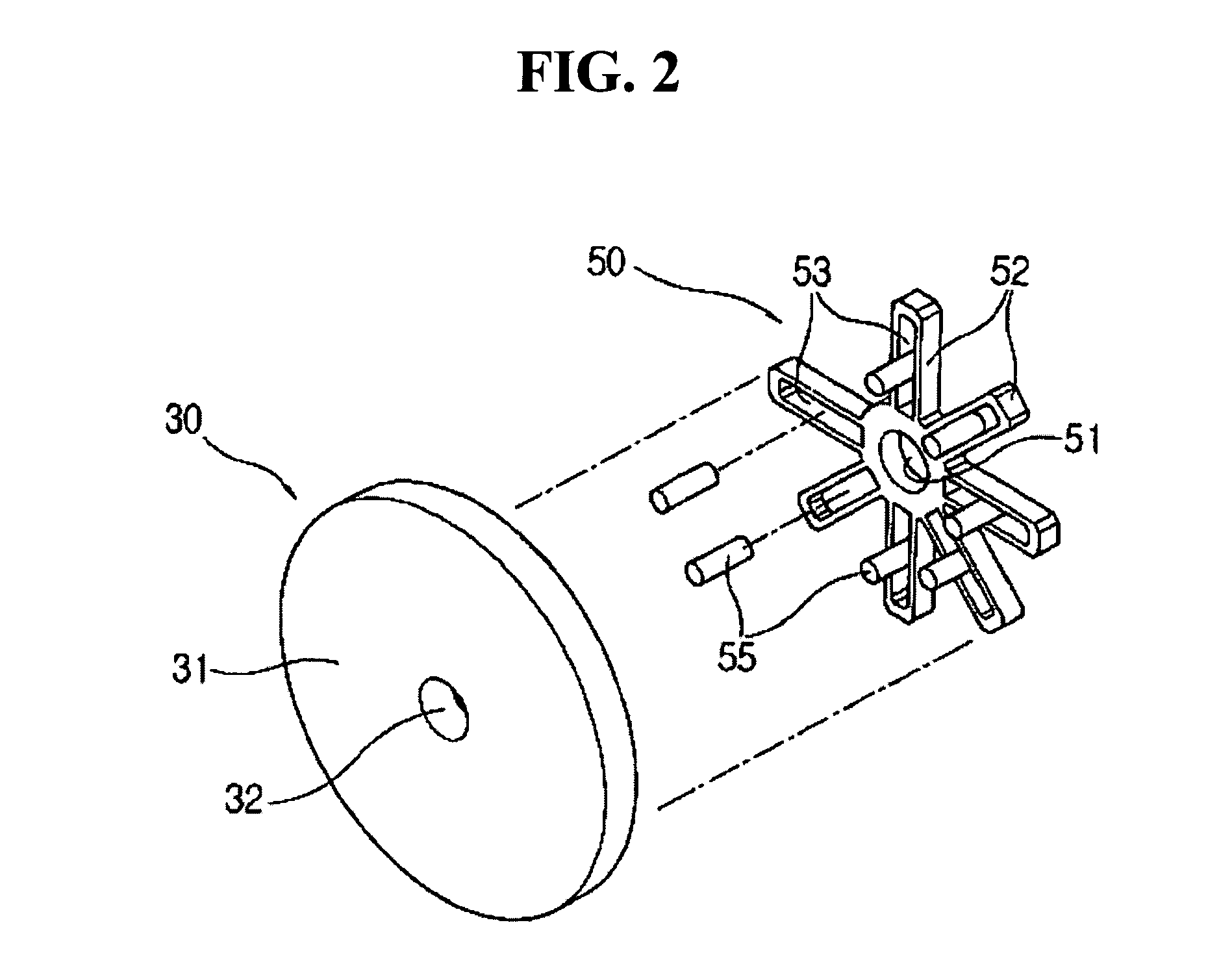

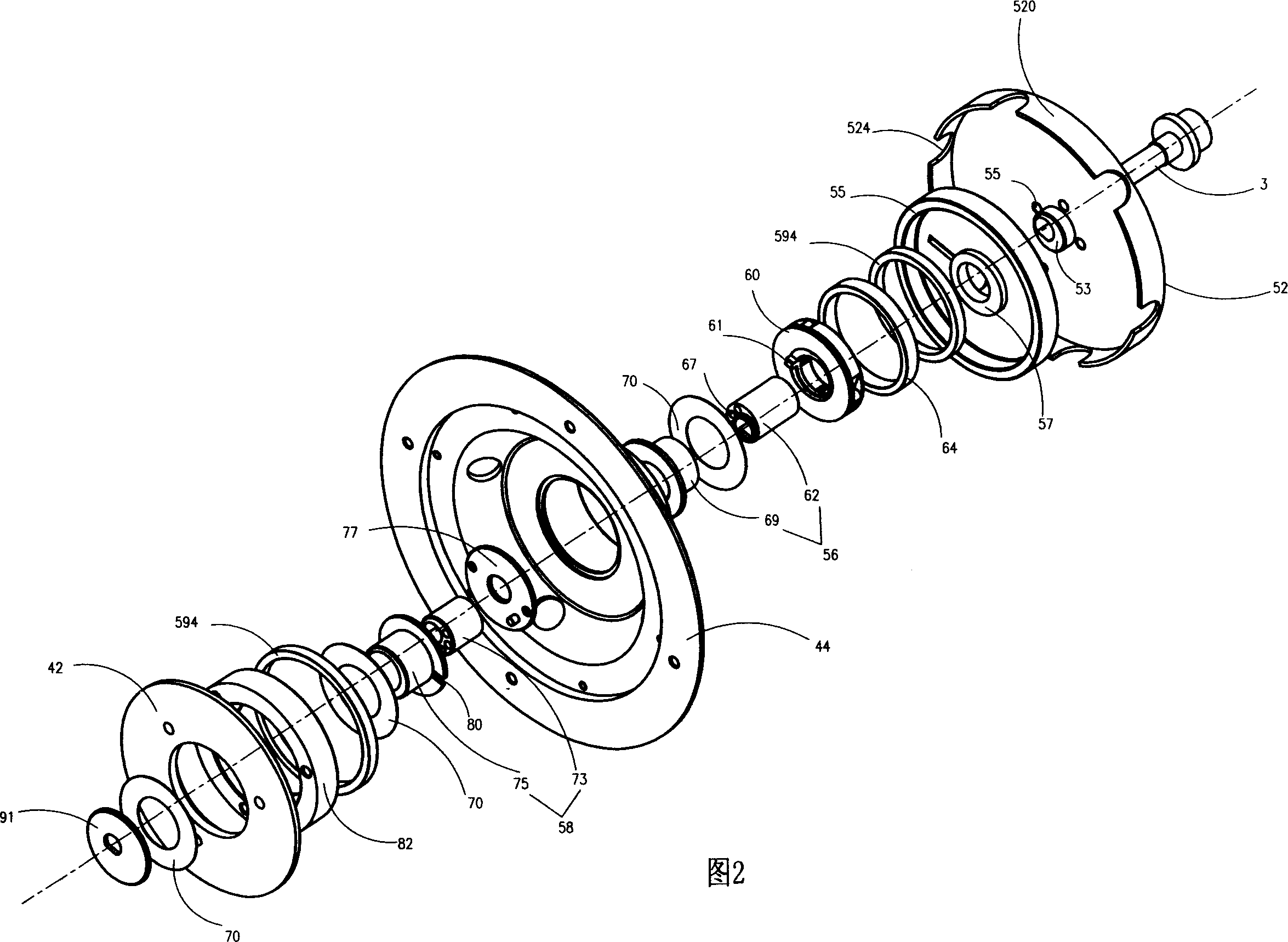

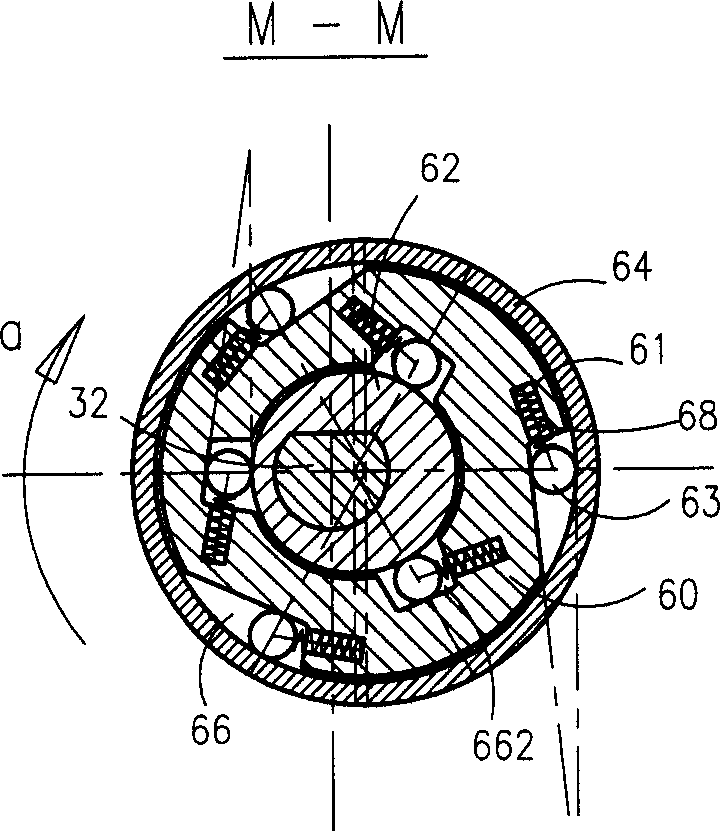

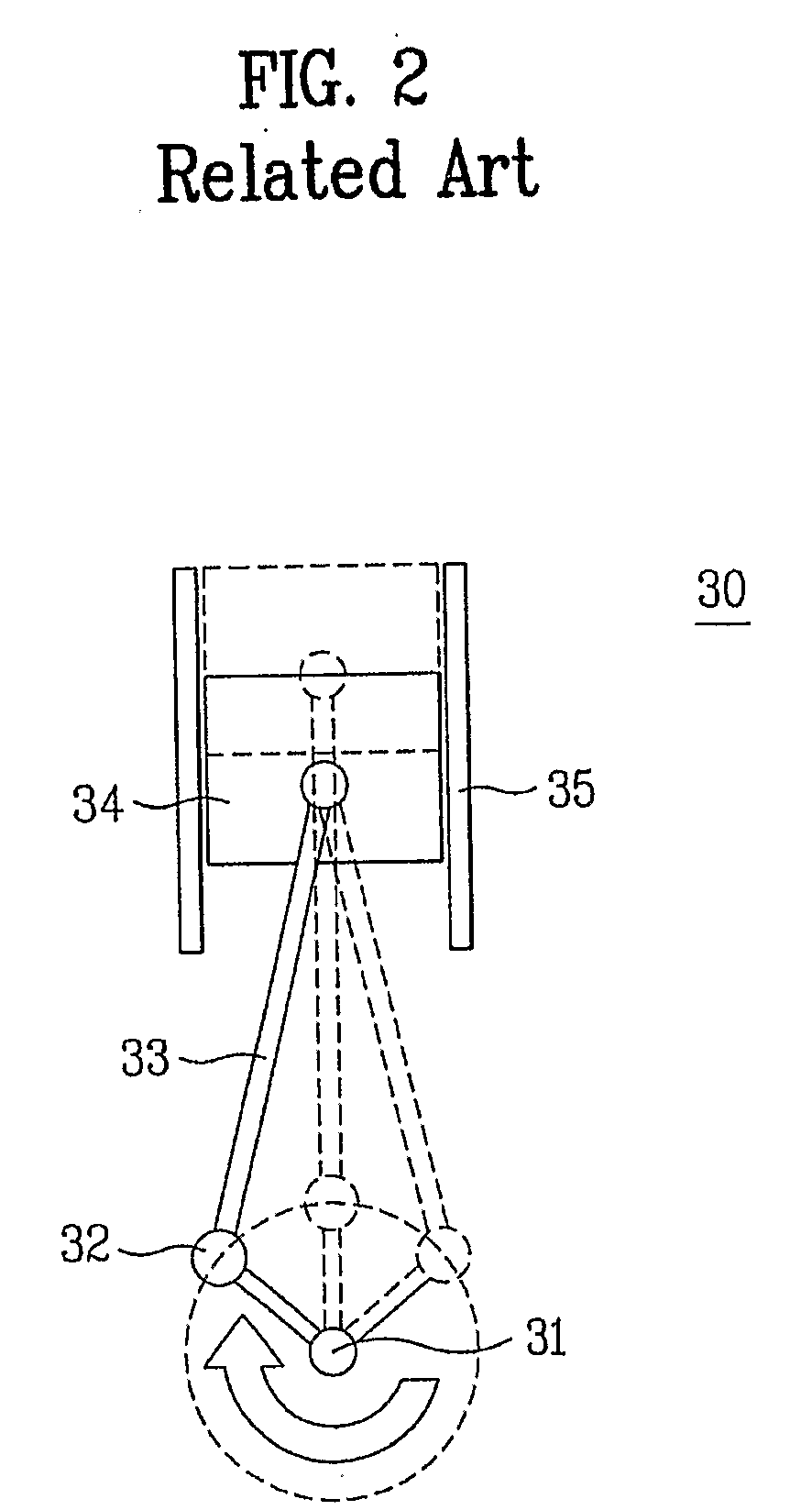

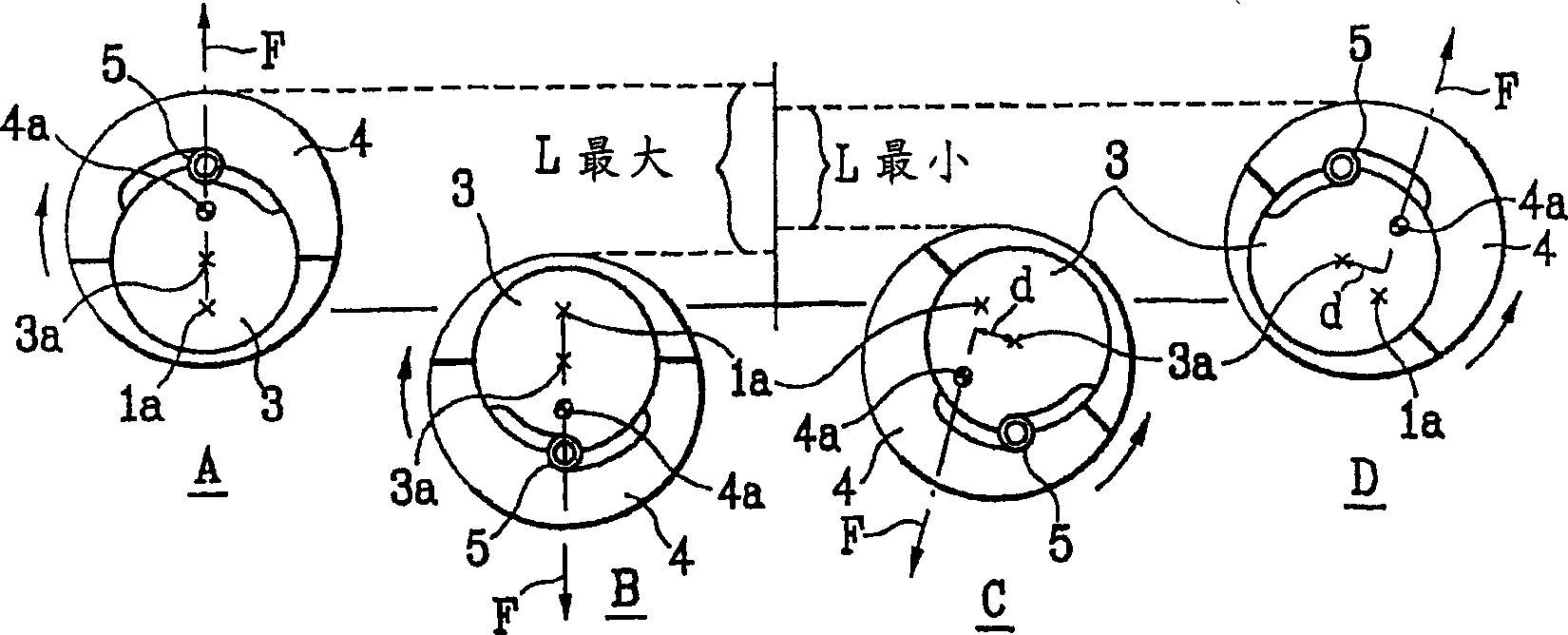

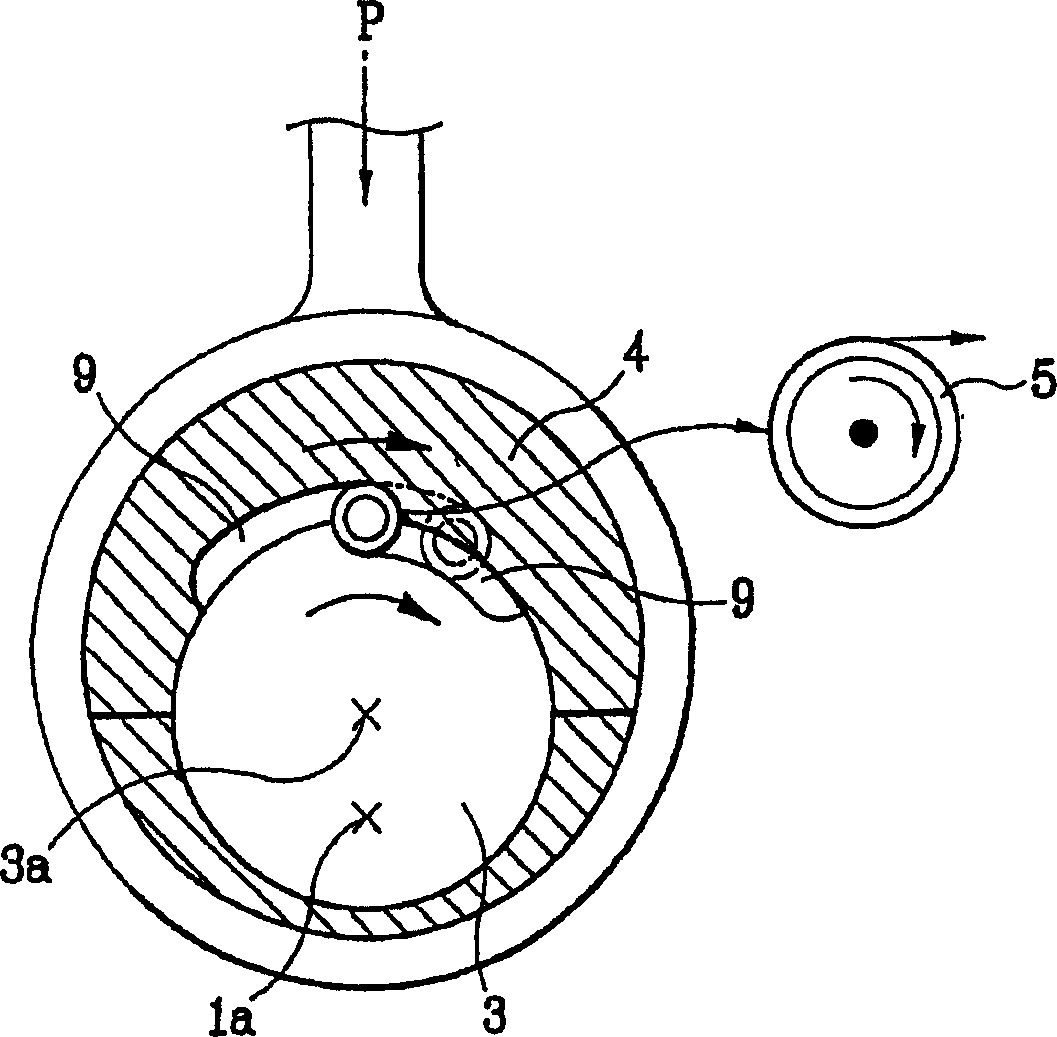

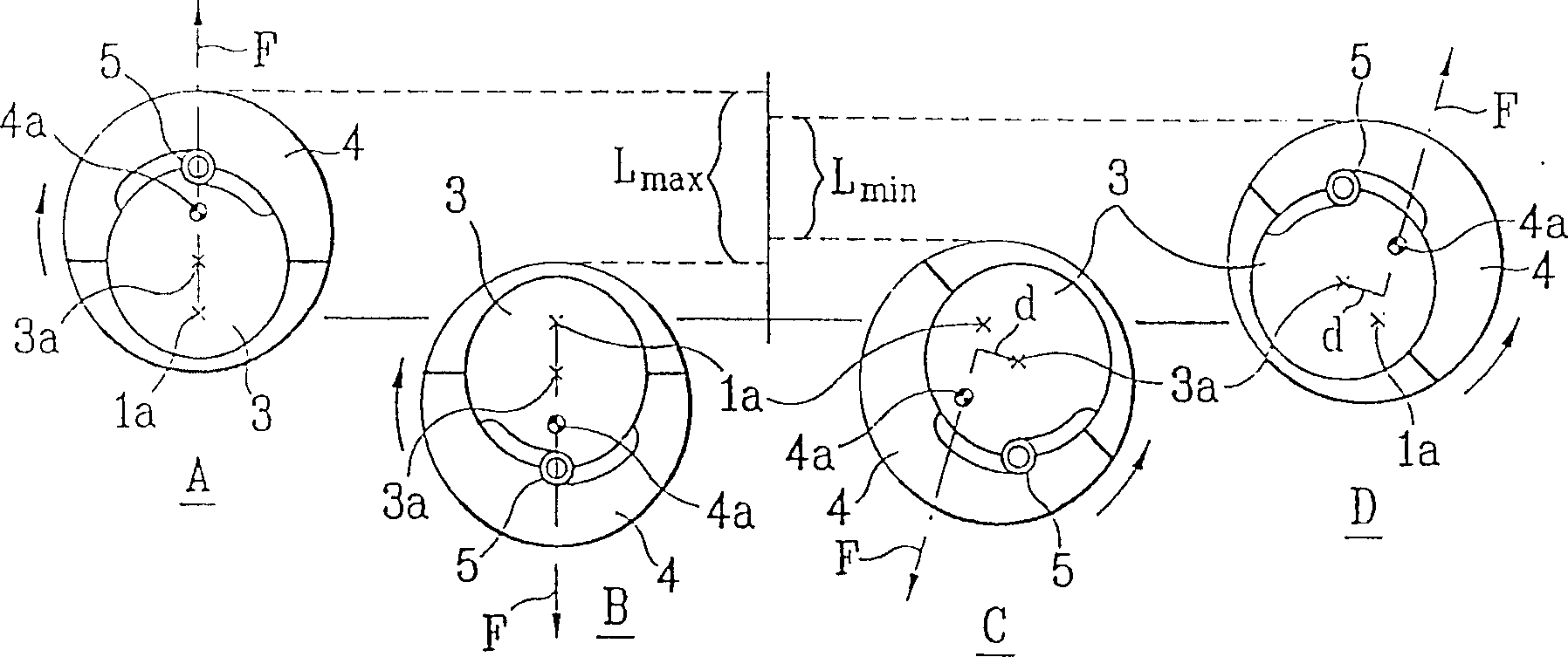

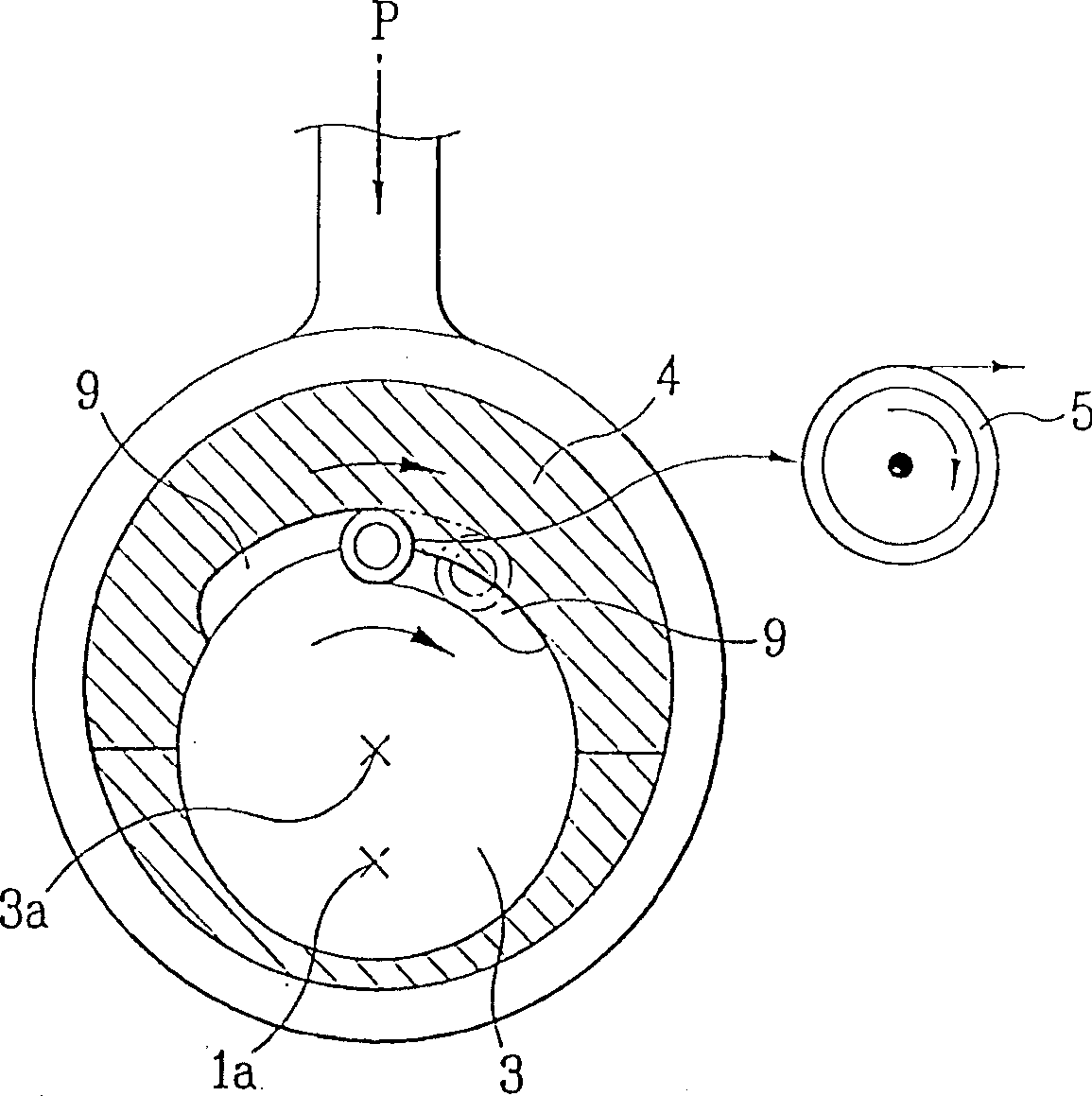

Variable inertia flywheel apparatus

InactiveUS7044022B2Efficiency sometimes variesControlling membersRotating vibration suppressionFlywheelHydraulic pressure

In a flywheel having variable inertia, first and second guide grooves are respectively formed at a body and a rotatable member such that an overlapping position thereof is varied according to a relative rotation thereof. A movable mass is disposed at the overlapping position, and the rotatable member rotates relatively to the body by hydraulic pressure.

Owner:HYUNDAI MOTOR CO LTD

Cradle clamp bracket assembly

Owner:PANDUIT

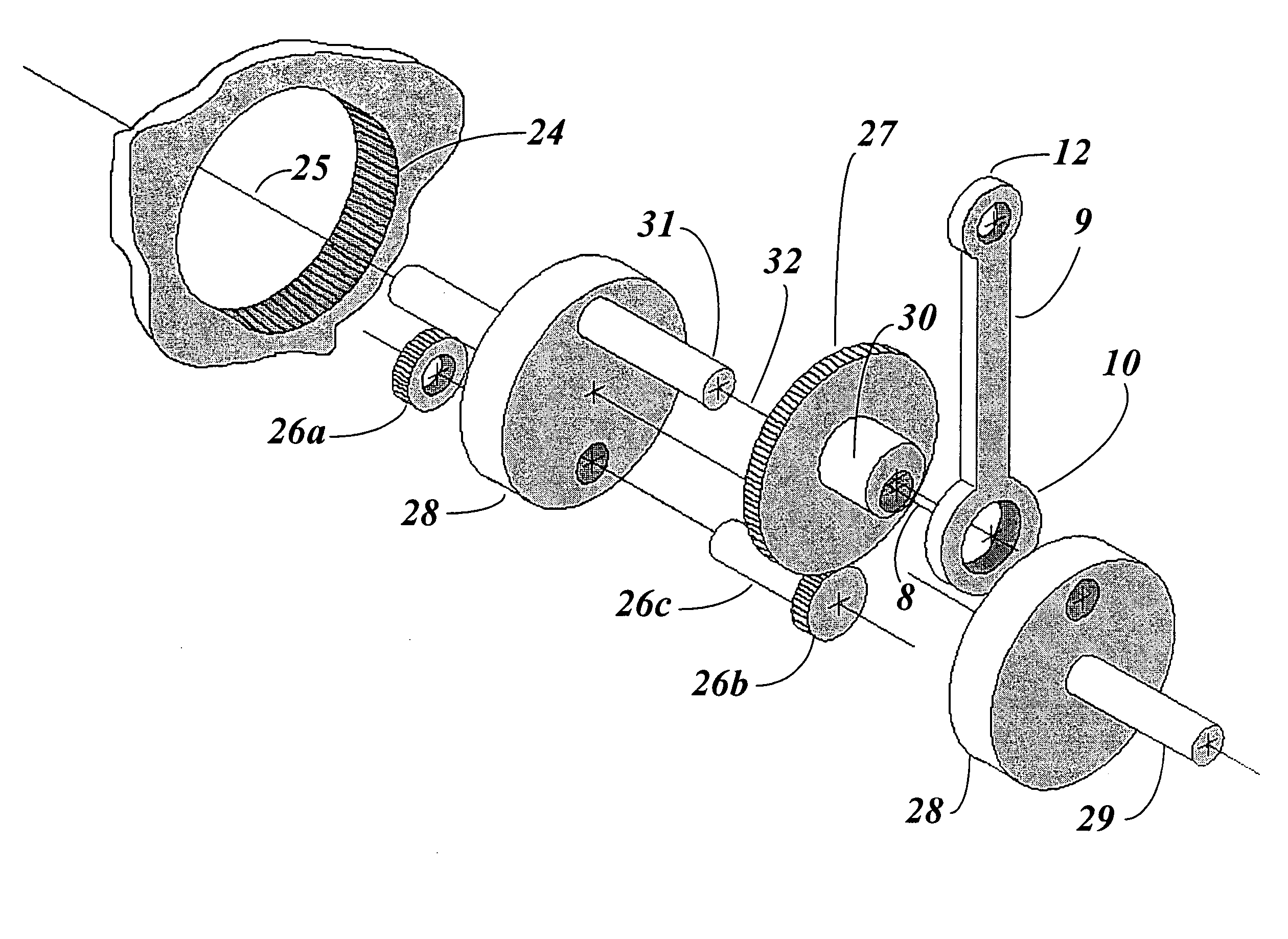

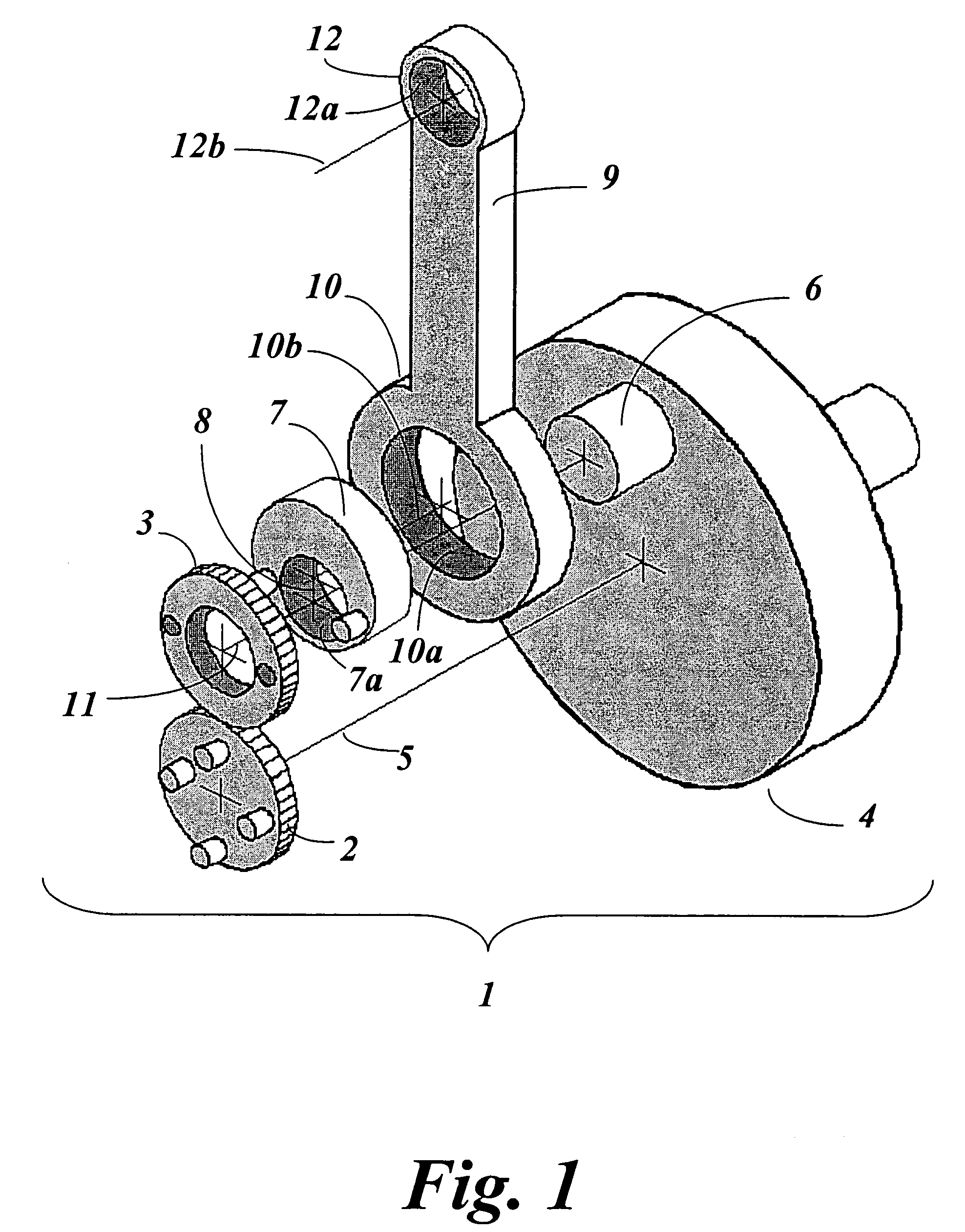

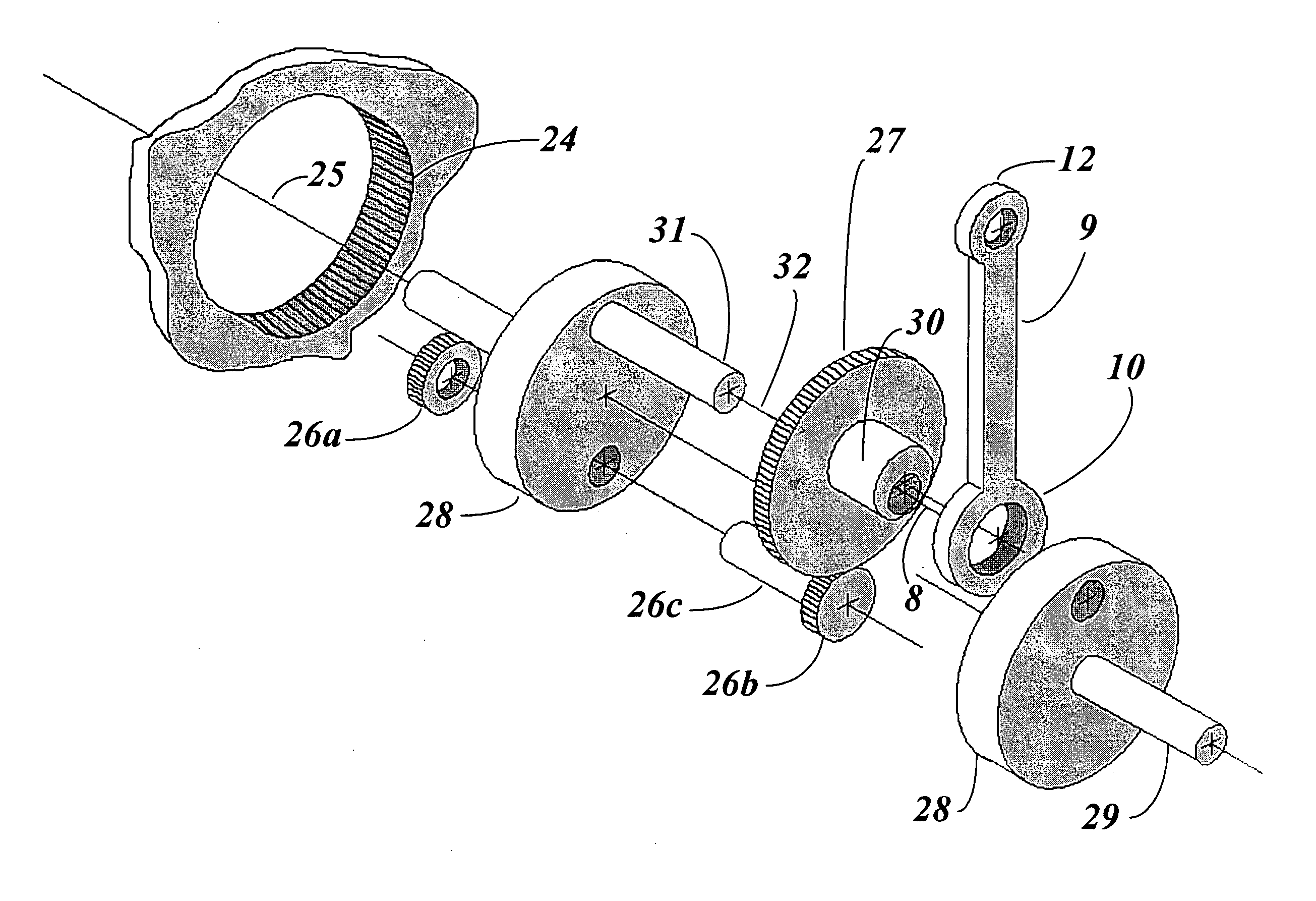

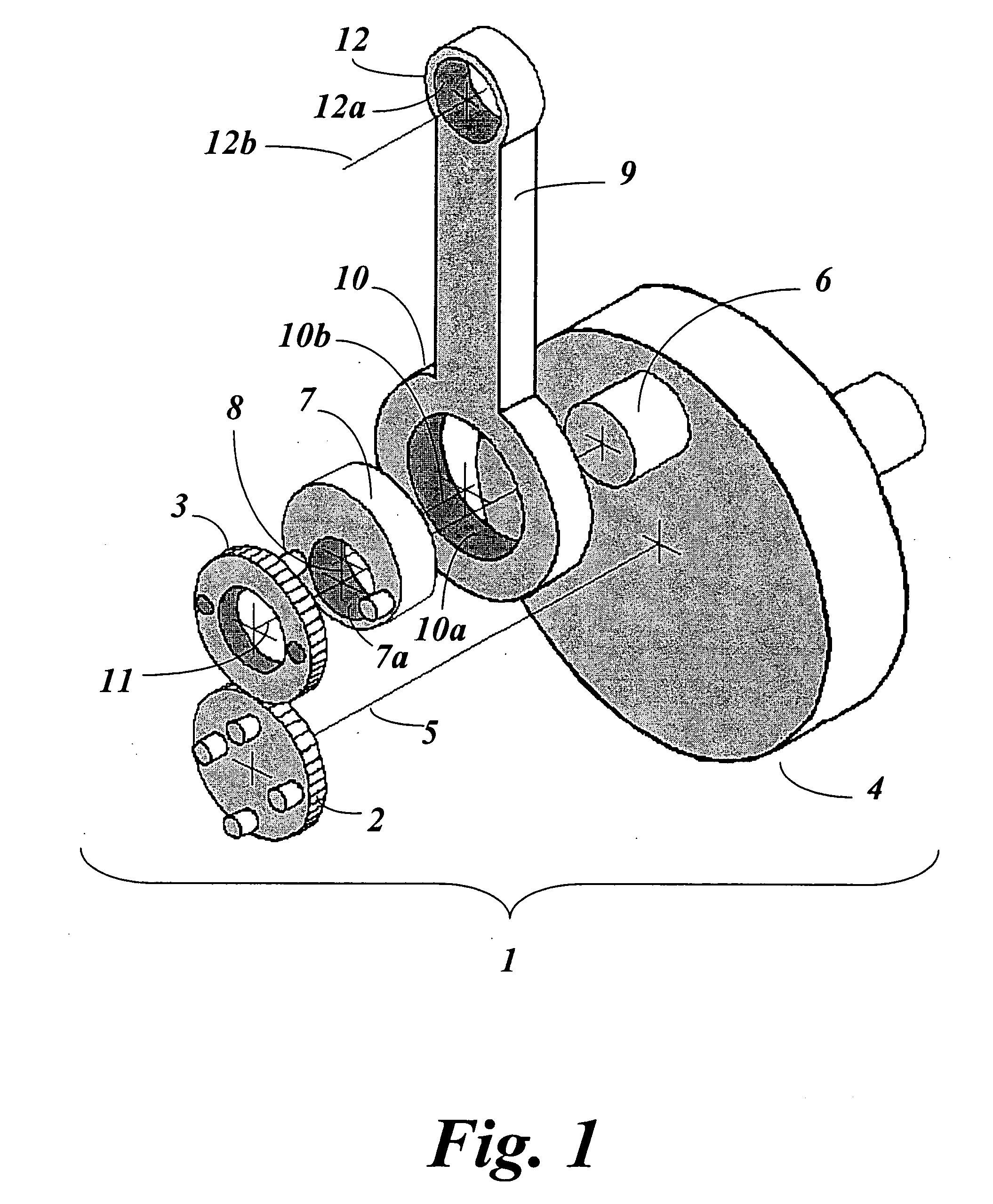

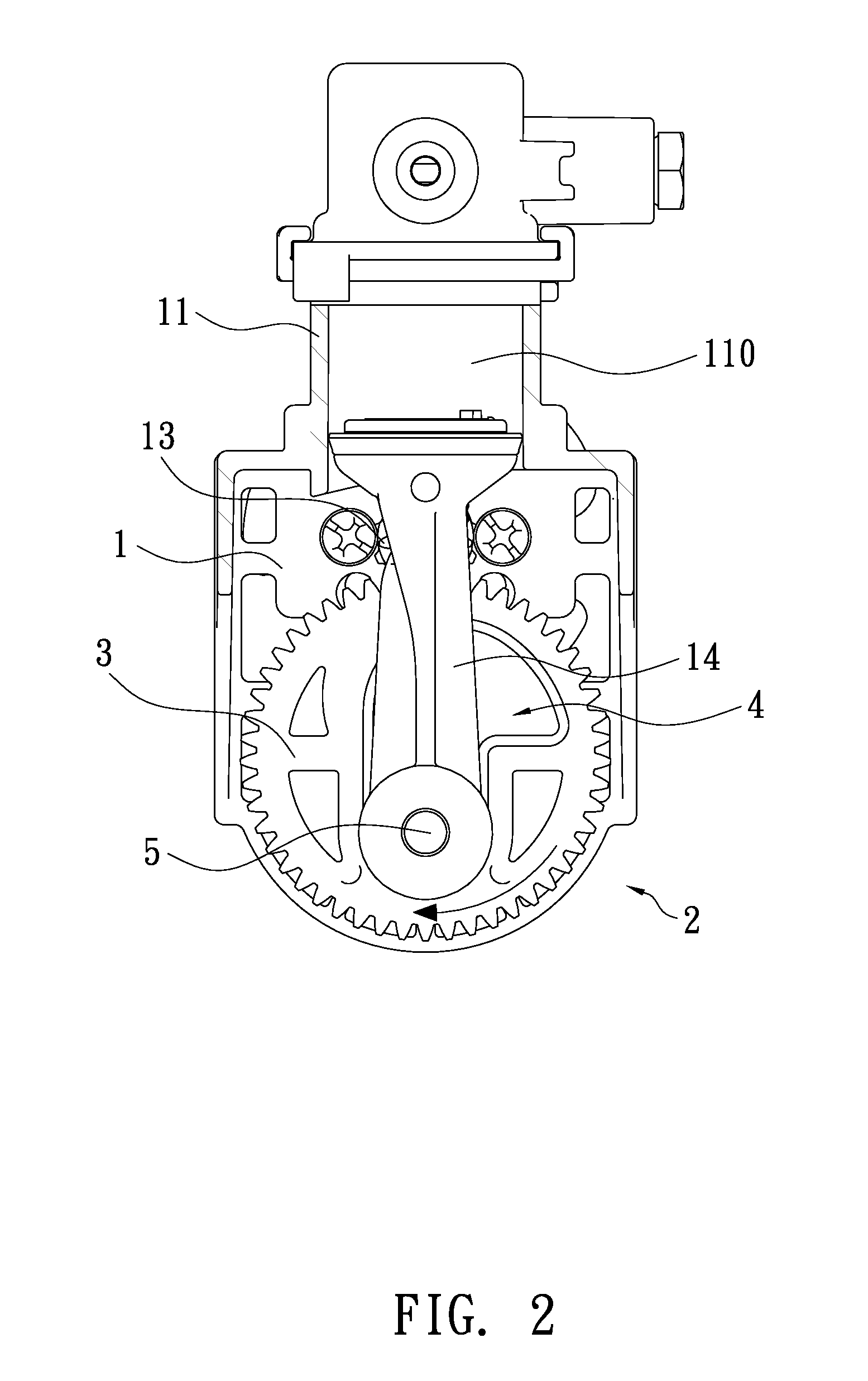

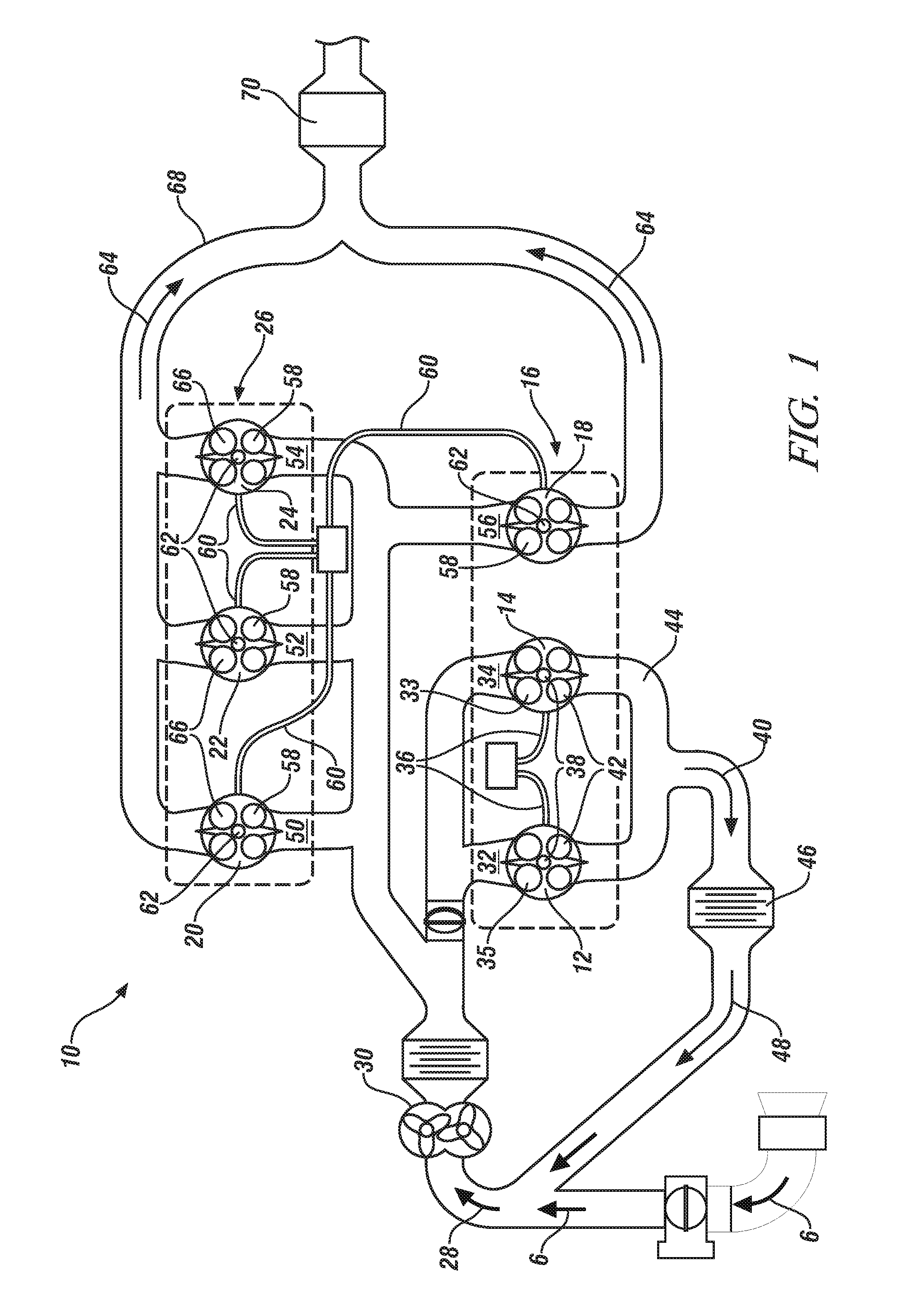

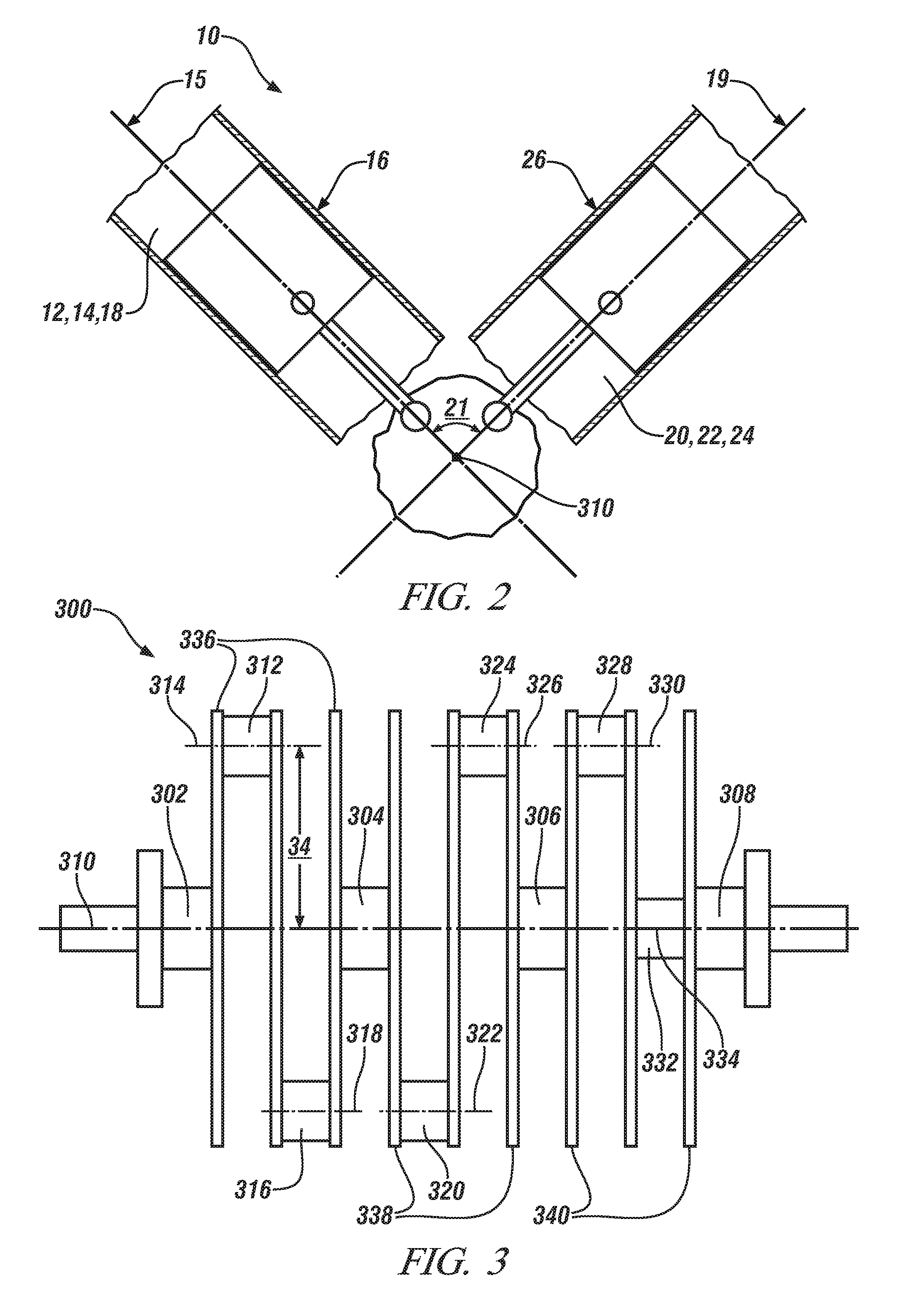

Epitrochoidal crankshaft mechanism and method

ActiveUS7185557B2High power outputImprove efficiencyRotary bearingsGearingFour-stroke engineInternal combustion engine

This invention relates to a mechanism and method for enhancing the performance of both two stroke and four stroke cycle reciprocating piston internal combustion engines, reciprocating piston pumps and compressors by generating an Epitrochoidal path of travel for the lower end of the connecting rod. The piston, attached to the upper end of the connecting rod, will be made to dwell at the lower part of its travel, enhancing the output of the engine, pump or compressor through better utilization of the available cylinder pressure.

Owner:MAROZZI

Epitrochoidal crankshaft mechanism and method

ActiveUS20060053964A1High outputIncrease distanceRotary bearingsGearingFour-stroke engineInternal combustion engine

This invention relates to a mechanism and method for enhancing the performance of both two stroke and four stroke cycle reciprocating piston internal combustion engines, reciprocating piston pumps and compressors by generating an Epitrochoidal path of travel for the lower end of the connecting rod. The piston, attached to the upper end of the connecting rod, will be made to dwell at the lower part of its travel, enhancing the output of the engine, pump or compressor through better utilization of the available cylinder pressure.

Owner:MAROZZI

Cam-wedge locking mechanism

Owner:MINNESOTA SCI

Eccentricity regulating mechanism

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

Crank machining technology

InactiveCN103481040AImprove productivityReasonable arrangement of processing proceduresCranksEccentricsProduction rateMachine parts

Owner:QINGDAO CONNECTINROD MACHINERY

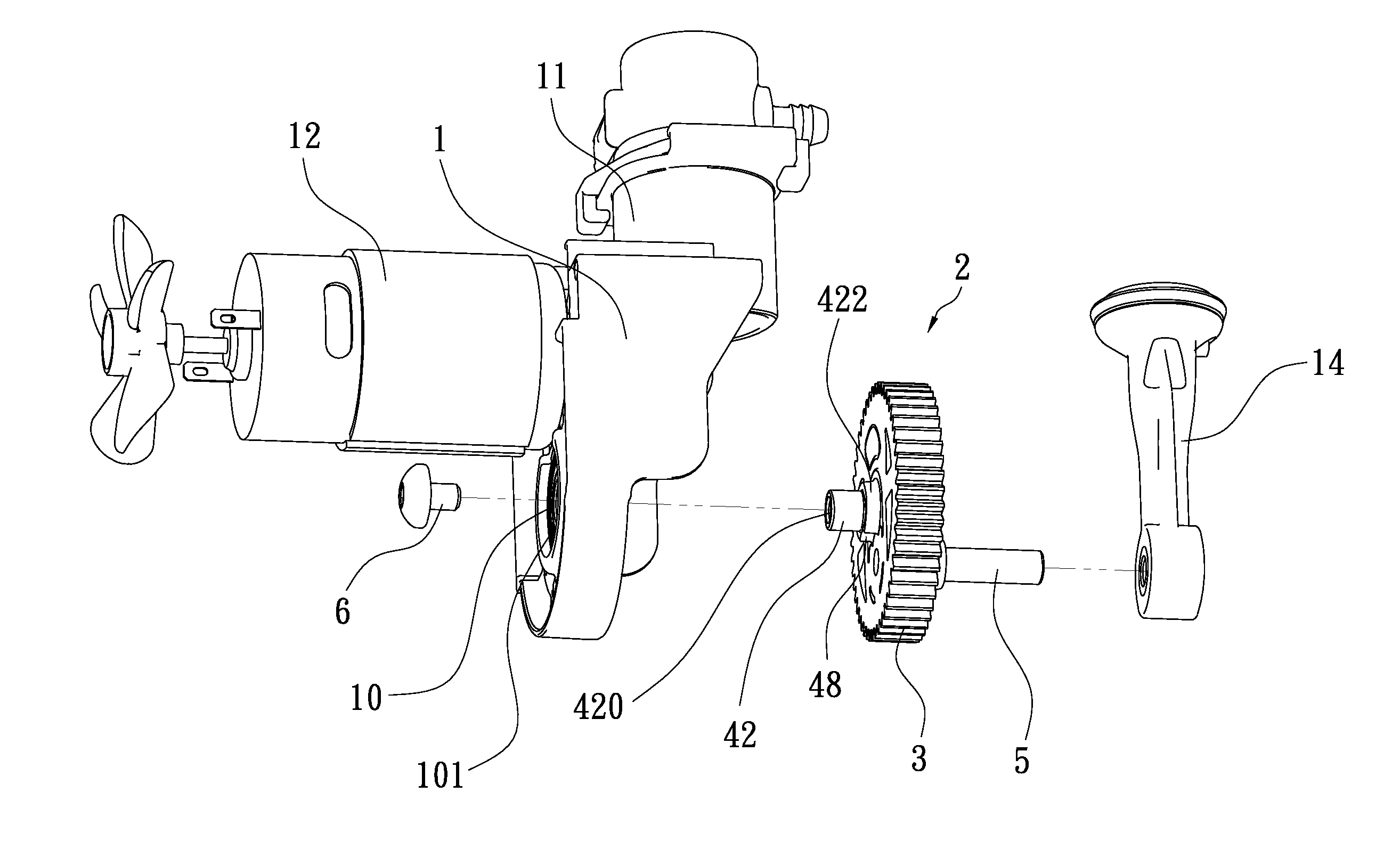

Air compressor with improved rotating device

ActiveUS20150330379A1Facilitate upstrokeMore momentumPositive displacement pump componentsCranksLeft halfLinear compressor

An air compressor includes a rotating device pivotally connected to a piston body. The rotating device includes a gear body and a counterweight. The gear body is formed together with a counterweight, wherein the counterweight is provided with a crankshaft corresponding to the center of the gear body and a crankpin placed at a distance from the crankshaft. The counterweight is horizontally divided into two integrally formed halves, including a left half and a right half, with a common line connected between the center of the crankshaft and the center of the crankpin, wherein the first half has a weight different from the second half, so that the piston body gathers more rotational momentum from the counterweight at BDC to facilitate upstrokes, so that the piston body can conduct reciprocating motion more smoothly, and thus the service life of the air compressor can be increased.

Owner:CHOU

Method for manufacturing eccentric wheel through powder metallurgy

ActiveCN103223489AEnhance the effect of mixing and pressingHigh bulk densityCranksEccentricsPolyethylene vinyl acetateMixed materials

The invention discloses a method for manufacturing an eccentric wheel through powder metallurgy. The method comprises the following step: the eccentric wheel is manufactured by the following raw materials in percentage by weight: 0.2-0.4 percent of nickel, 0.4-0.6 percent of molybdenum, 0.6-0.8 percent of tin, 0.3-0.5 percent of aluminium oxide powder, 0.8-1 percent of graphite powder, 0.4-0.6 percent of petroleum wax, 4-6 percent of copper, 1-2 percent of performance additive and the balance of iron. According to the invention, through the added performance additive, superfine powder is provided in the mixed material, and the superfine powder can be filled in the gaps of large particles, so that apparent density of the mixture is improved; the superfine powder is mainly formed by nano-zinc oxide powder and calcium stearate, and through additives including a silane coupling agent and the like, a novel performance additive is obtained, and various physical properties about wear resistance and the like of the product are further improved, and as polyethylene vinyl acetate and liquid petrolatum are taken as lubricants to be added into the performance additive, the effect of the performance additive during mixing and pressing is enhanced, the blank pressing strength of a powder metallurgy structural piece under equal pressing pressure is greatly improved, combination form and pore shape of raw material particles are changed, and the problem about crack generation is solved from the root cause.

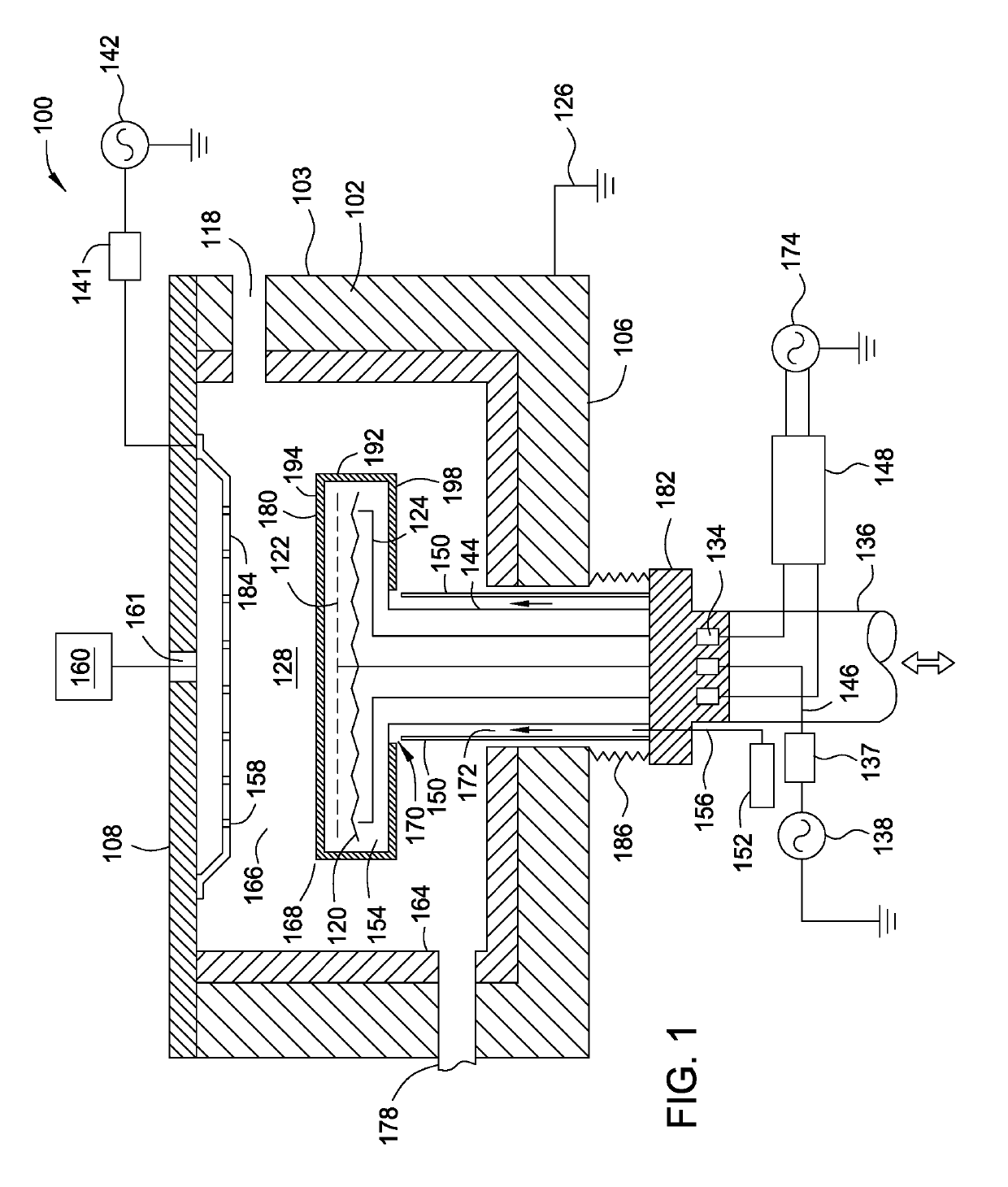

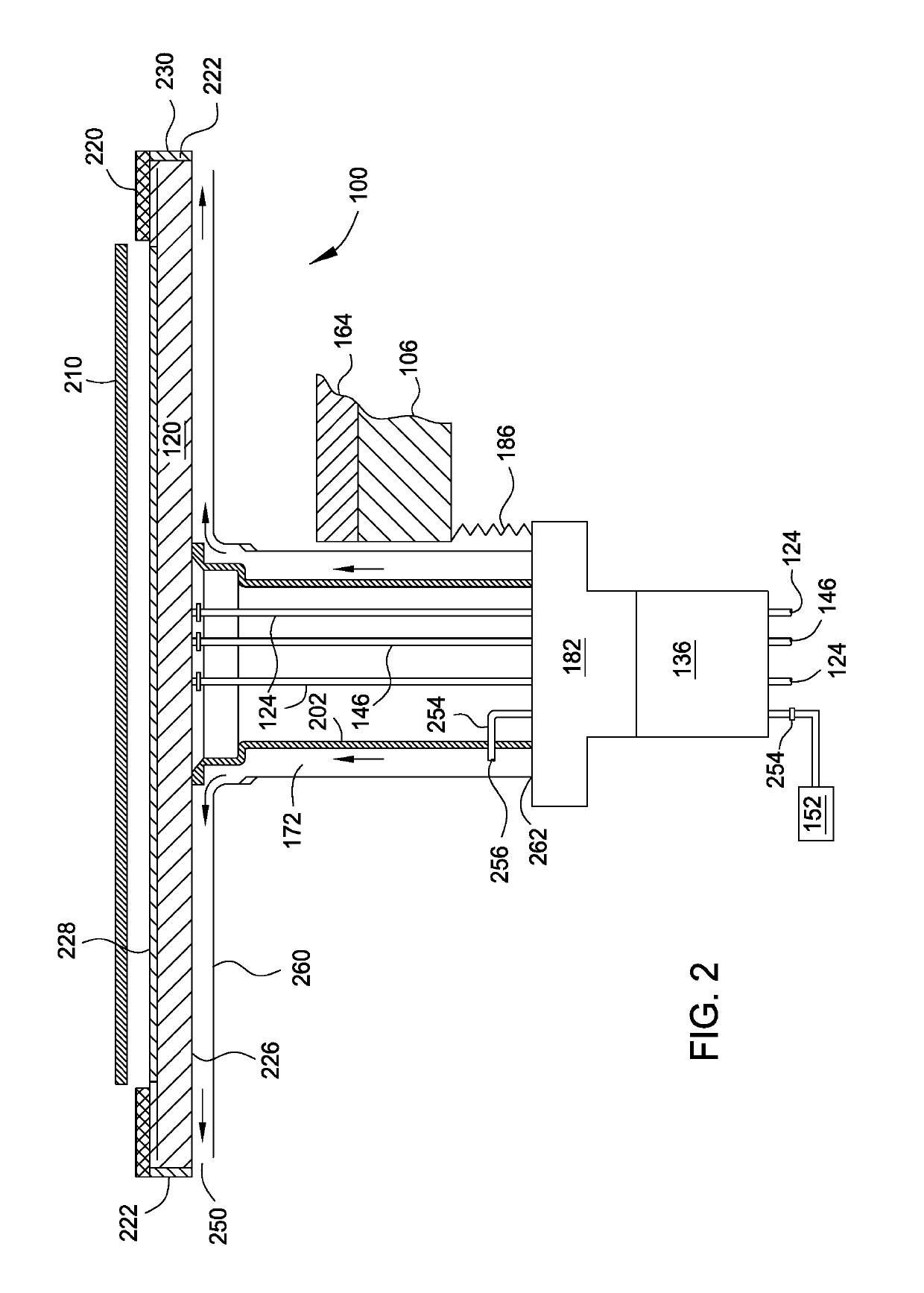

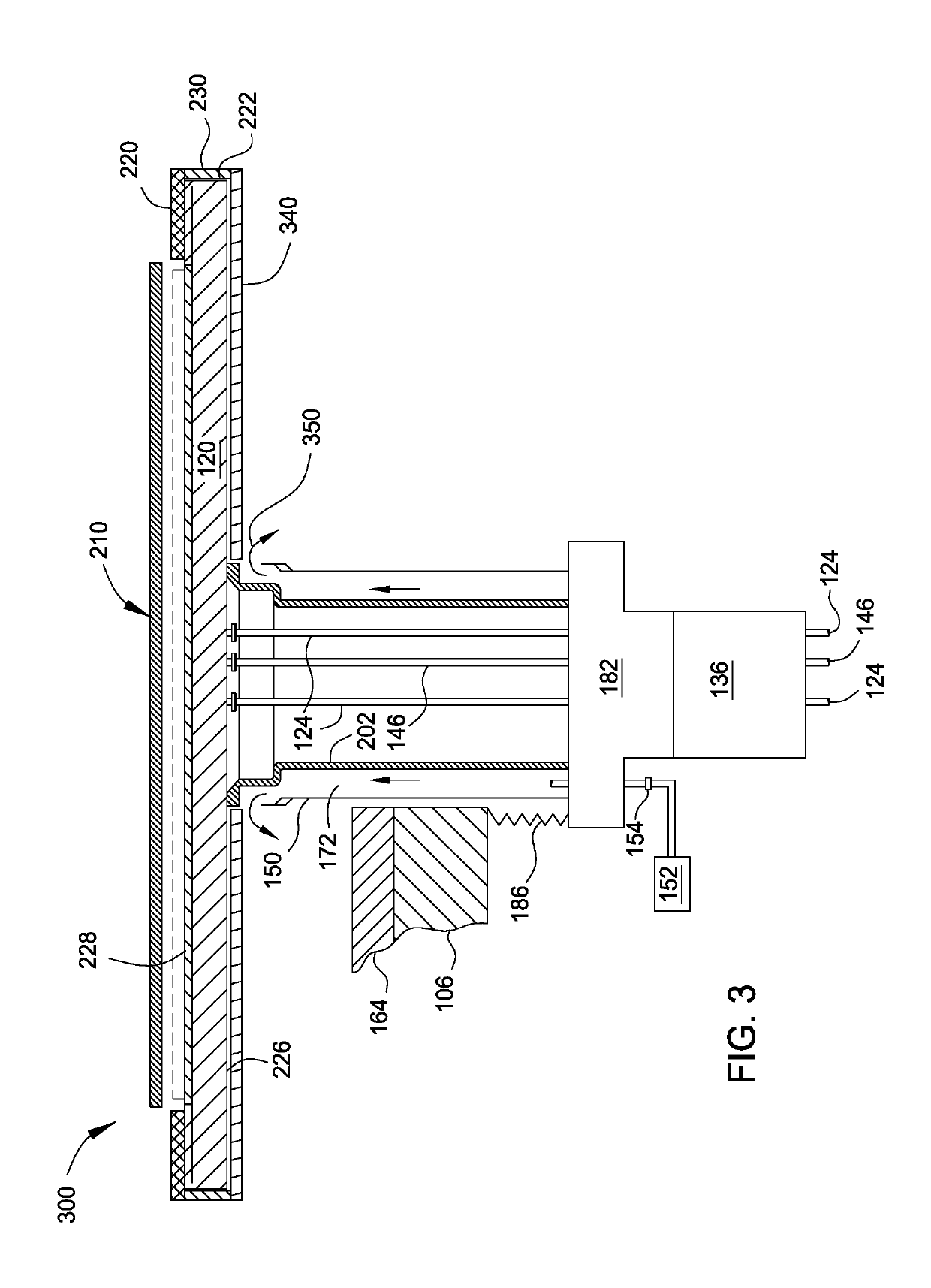

Plasma corrision resistive heater for high temperature processing

ActiveUS20190203350A1Corrosion resistanceConnecting rodsSemiconductor/solid-state device manufacturingCelsius DegreeEngineering

Implementations described herein protect a substrate support from corrosive cleaning gases used at high temperatures. In one embodiment, a substrate support has a shaft having an outer wall. The substrate support has a heater. The heater has a body having a top surface, a side surface and a bottom surface extending from the outer wall of the shaft. The top surface is configured to support a substrate during plasma processing of the substrate. A covering is provided for at least two of the top surface, side surface and bottom surface. The covering is selected to resist corrosion of the body at temperatures in excess of about 400 degrees Celsius. A sleeve circumscribing the shaft, the sleeve and the outer wall of the shaft forming a space therebetween, the space adapted to flow a purge gas therethrough in a direction toward the body.

Owner:APPLIED MATERIALS INC

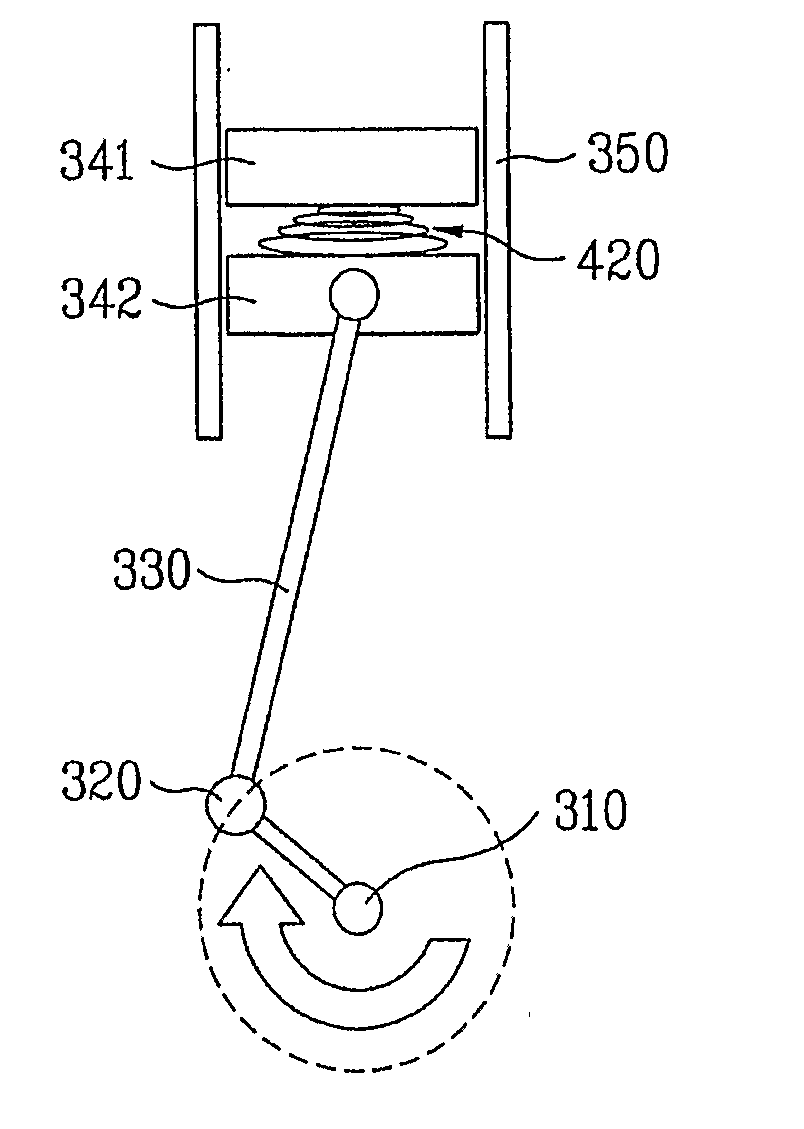

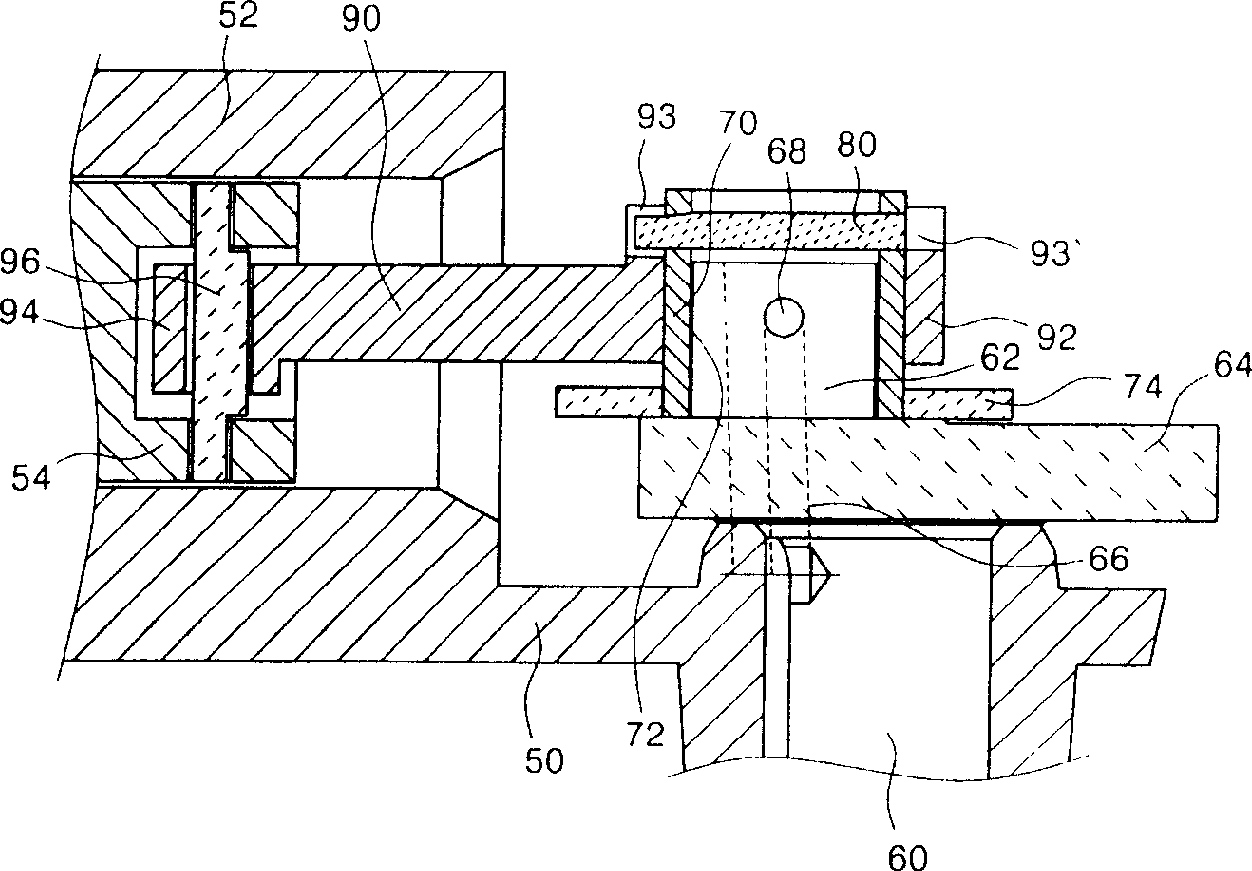

Compressor

InactiveUS20080022850A1Reduce torqueEasy to compressConnecting rodsPositive displacement pump componentsEngineeringRefrigerant

Compressor including a supplementary torque providing part for reducing a speed of a piston (340) in compression of refrigerant, and increasing the speed of the piston (340) in drawing of the refrigerant, thereby reducing a compression rate of the refrigerant in compression relatively, and increasing a re-expansion rate, to maximize a suction efficiency.

Owner:LG ELECTRONICS INC

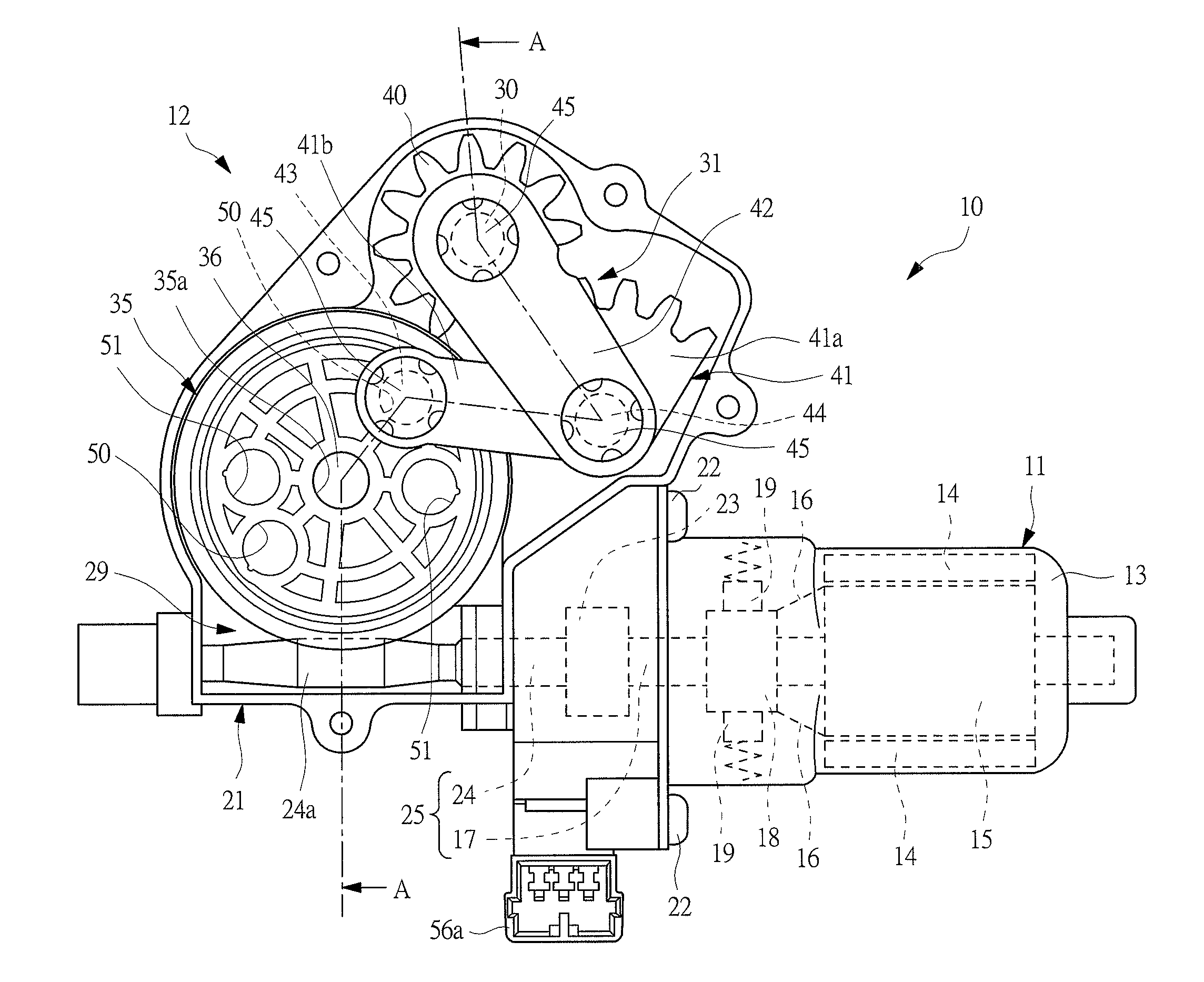

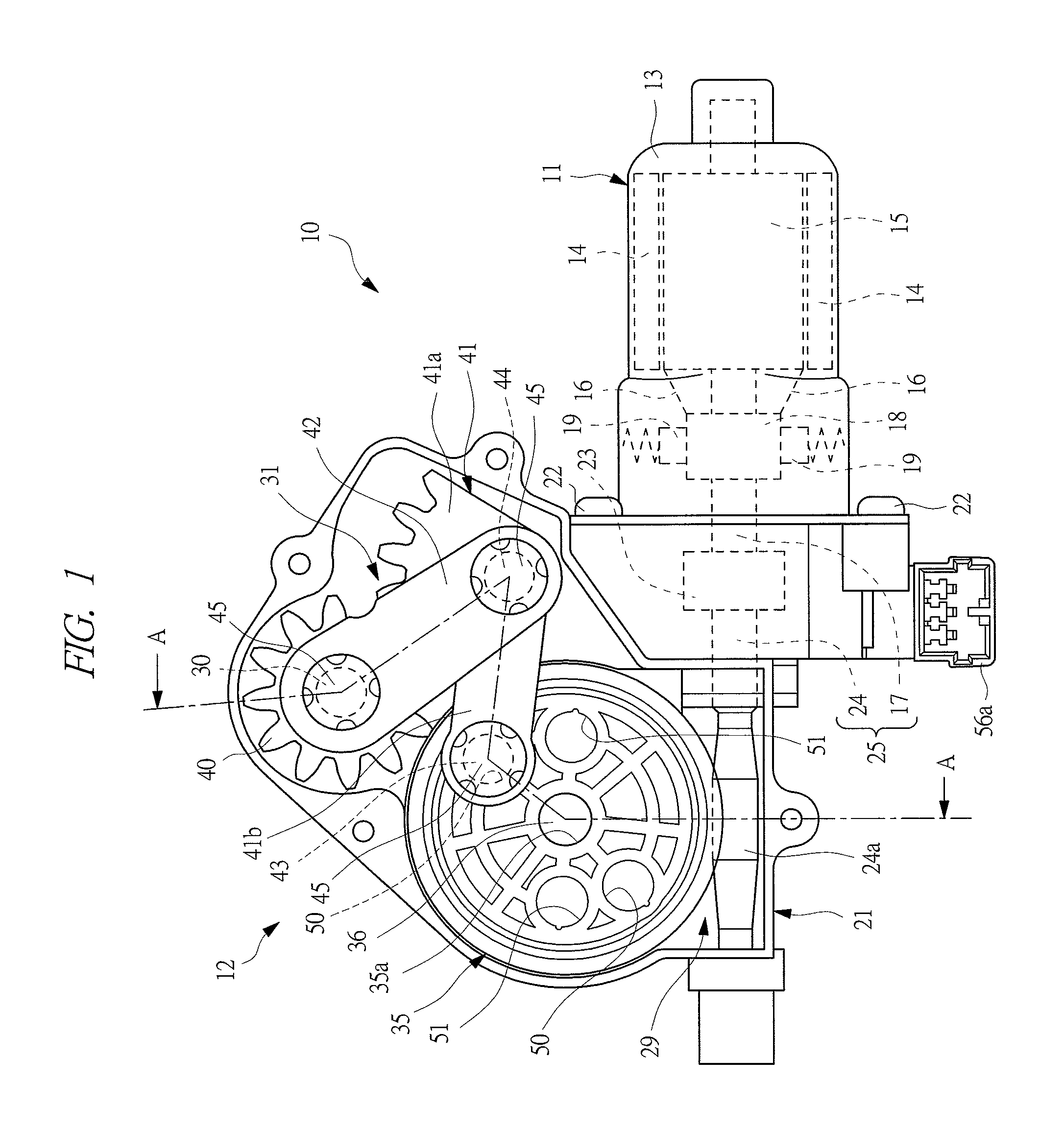

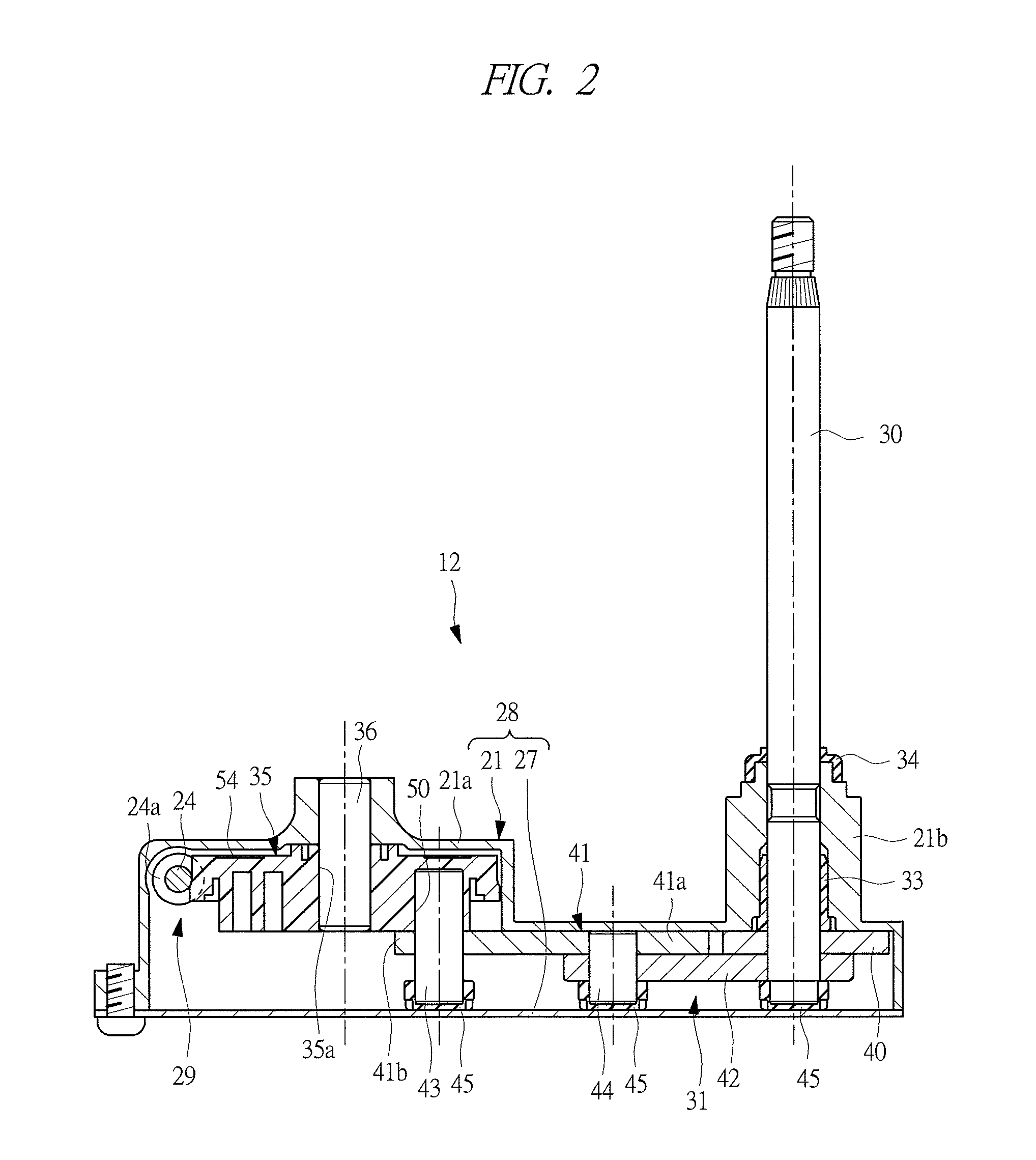

Wiper motor

A wiper motor 10 has a reduction mechanism 29 for reducing the rotational speed of a motor shaft 25 and transmitting the reduced speed, and a motion conversion mechanism 31 for converting the rotational motion of the reduction mechanism 29 into a rotational motion and transmitting the motion to the output shaft 30. A pair of first connection holes 50 and a pair of second connection holes 51 are formed on a worm wheel 35 at a position deviated in a radial direction from an axial center of the worm wheel so that each of the holes is opened at the side of one axial end side. The worm wheel 35 can be used for both cases in which the output shaft 30 is swung within a first swinging region and in which the output shaft 30 is swung within a second swinging region.

Owner:MITSUBA CORP

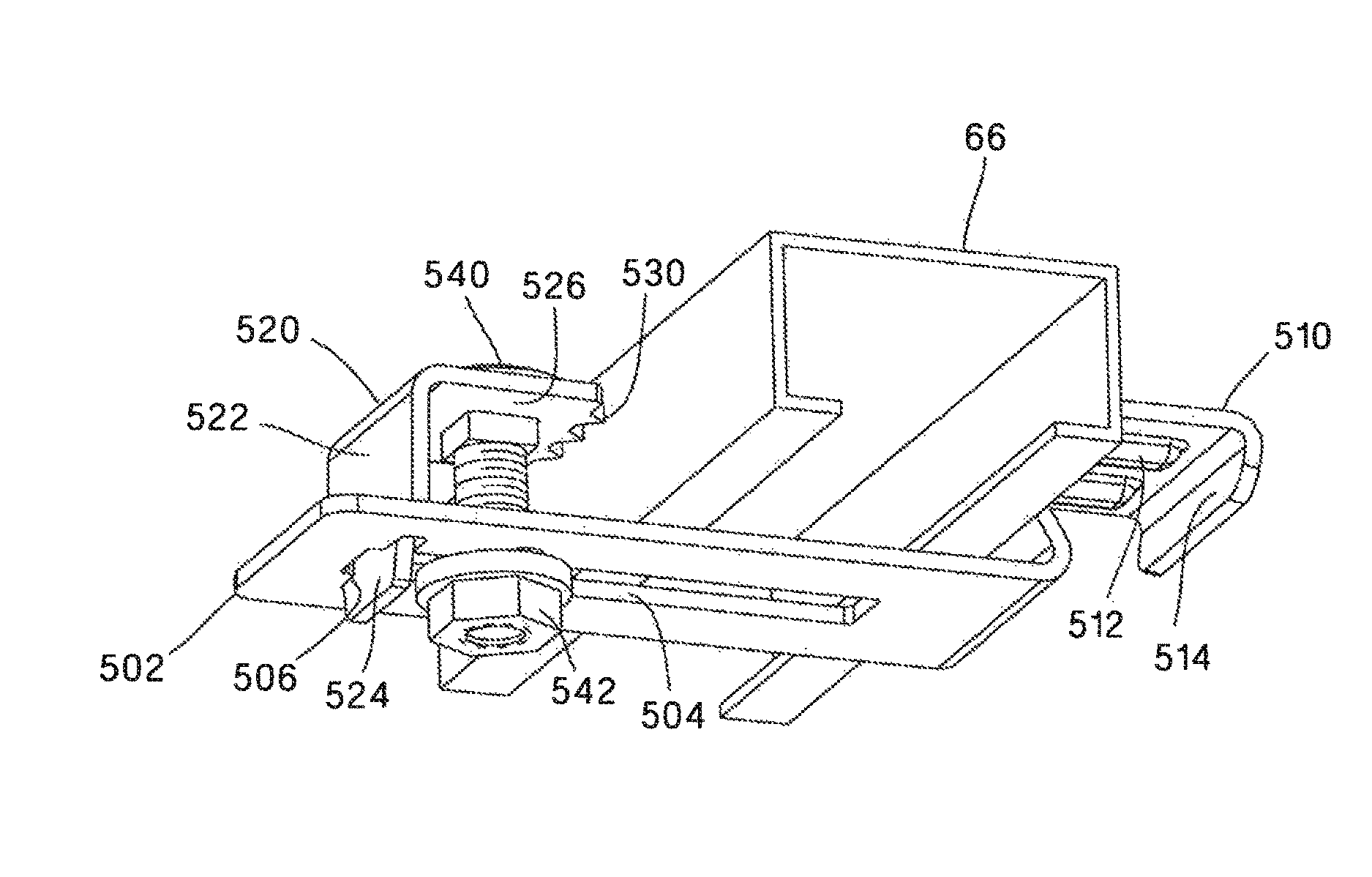

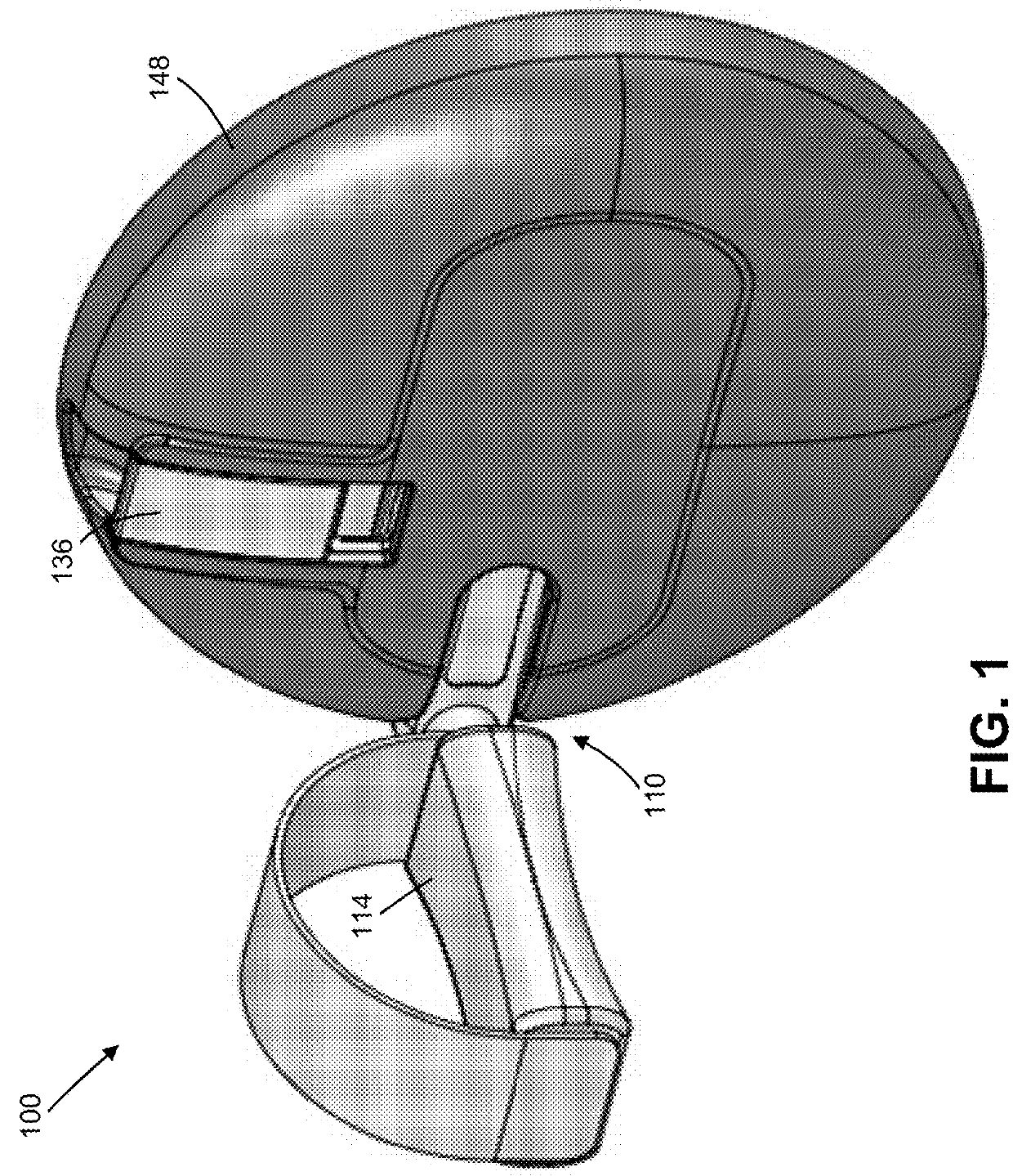

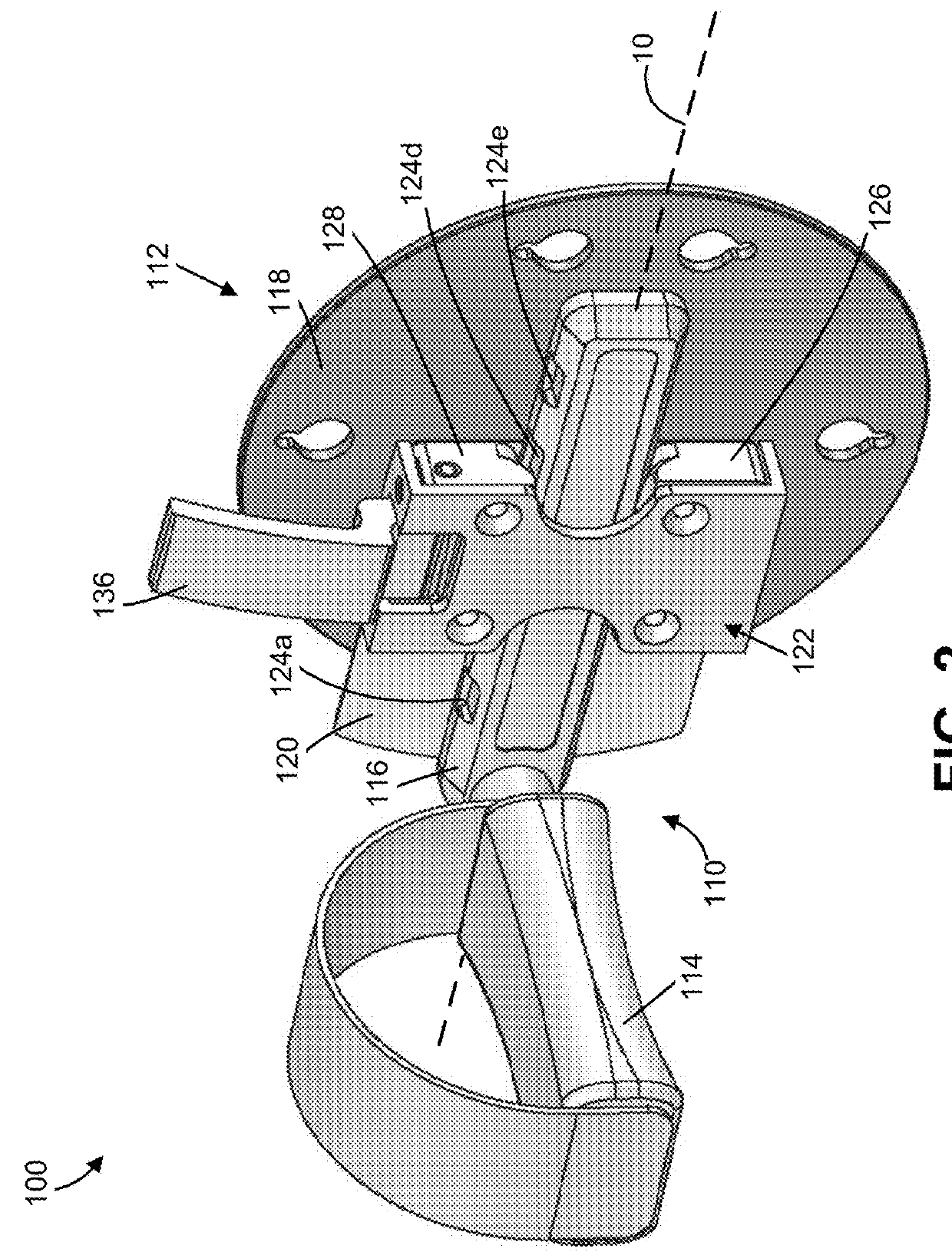

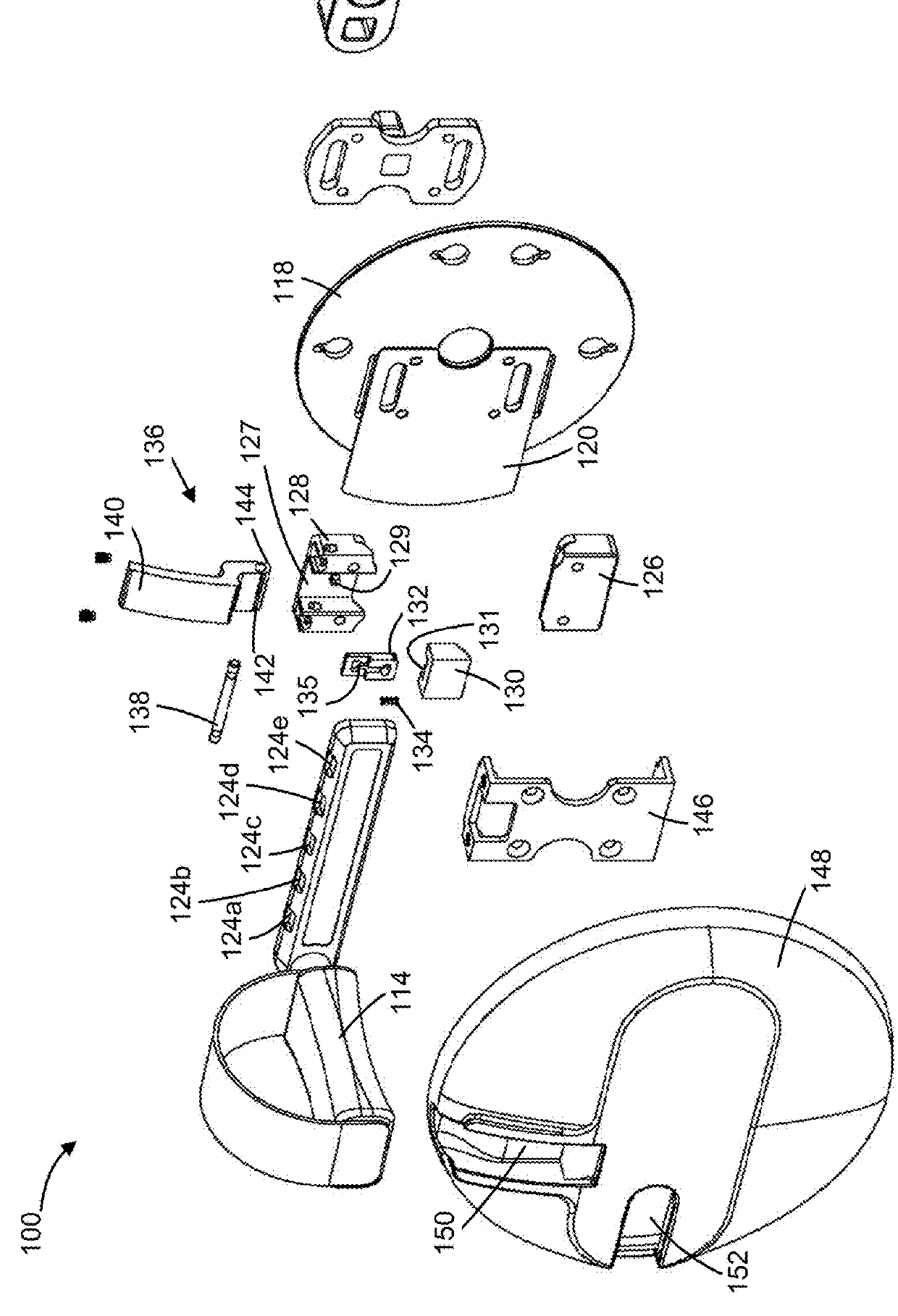

Stationary cycling pedal crank having an adjustable length

An adjustable crank assembly is provided. The adjustable crank assembly includes a crank arm having a surface with a plurality of notches, and a retention block that partially houses the crank arm and allows the crank arm to slide along an axis relative to the retention block. The retention block includes a clamping block and a locking pin, both of which being adapted to selectively engage the crank arm when the retention block is placed in a locked position, and a locking lever for transitioning between a locked position and an unlocked position. The locking lever provides a compressive force to the clamping block when placed in a locked position and a retracting force to the locking pin when placed in an unlocked position.

Owner:MINDBRIDGE INNOVATIONS

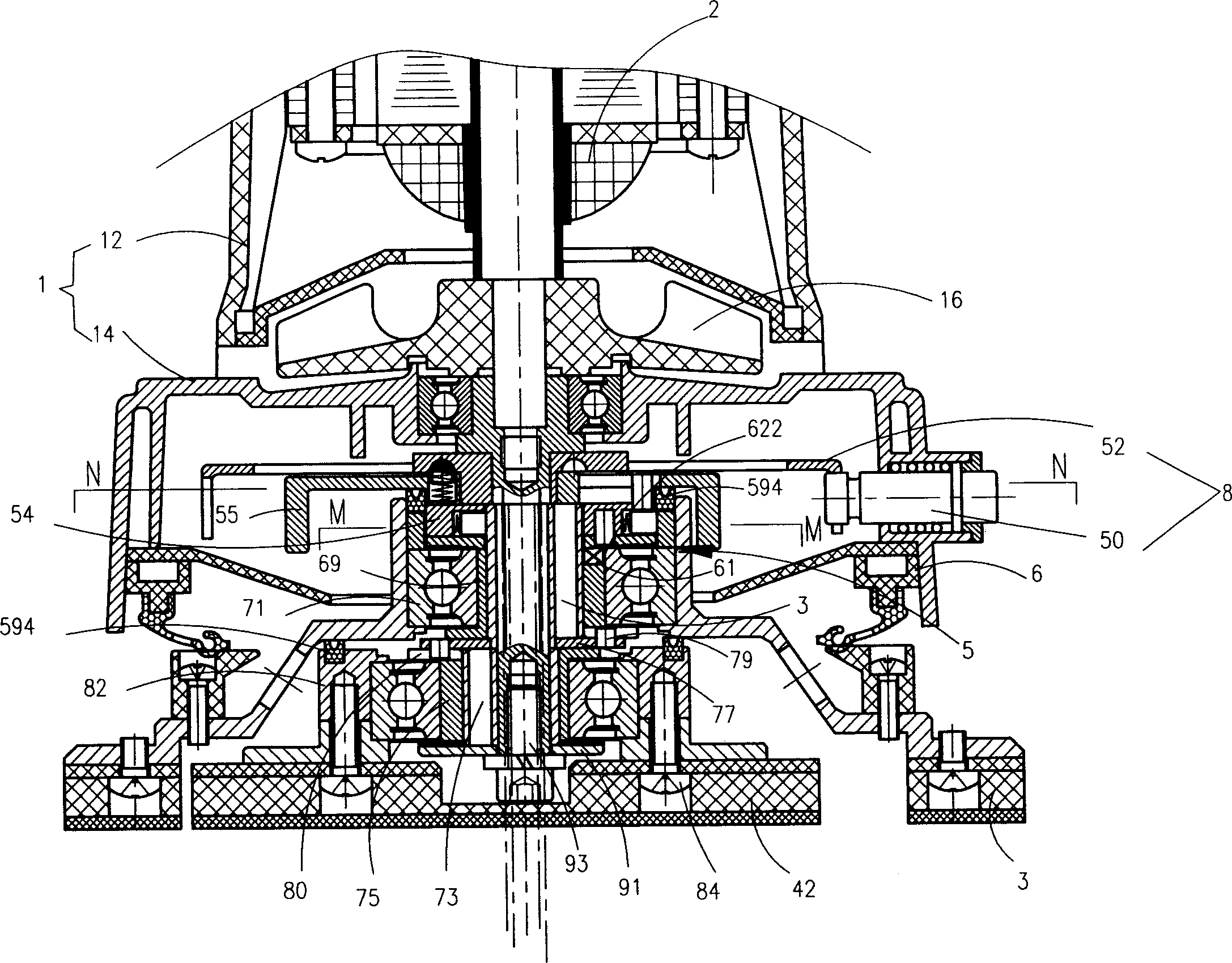

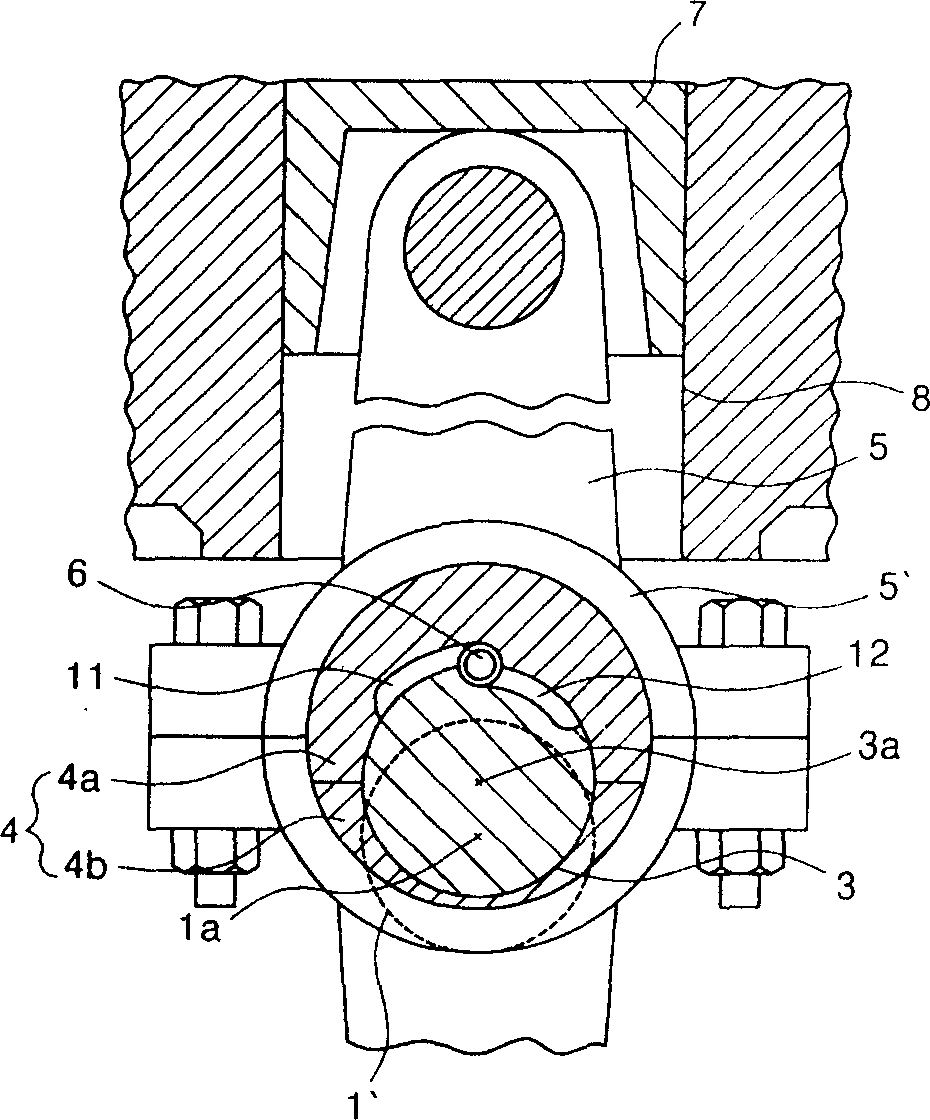

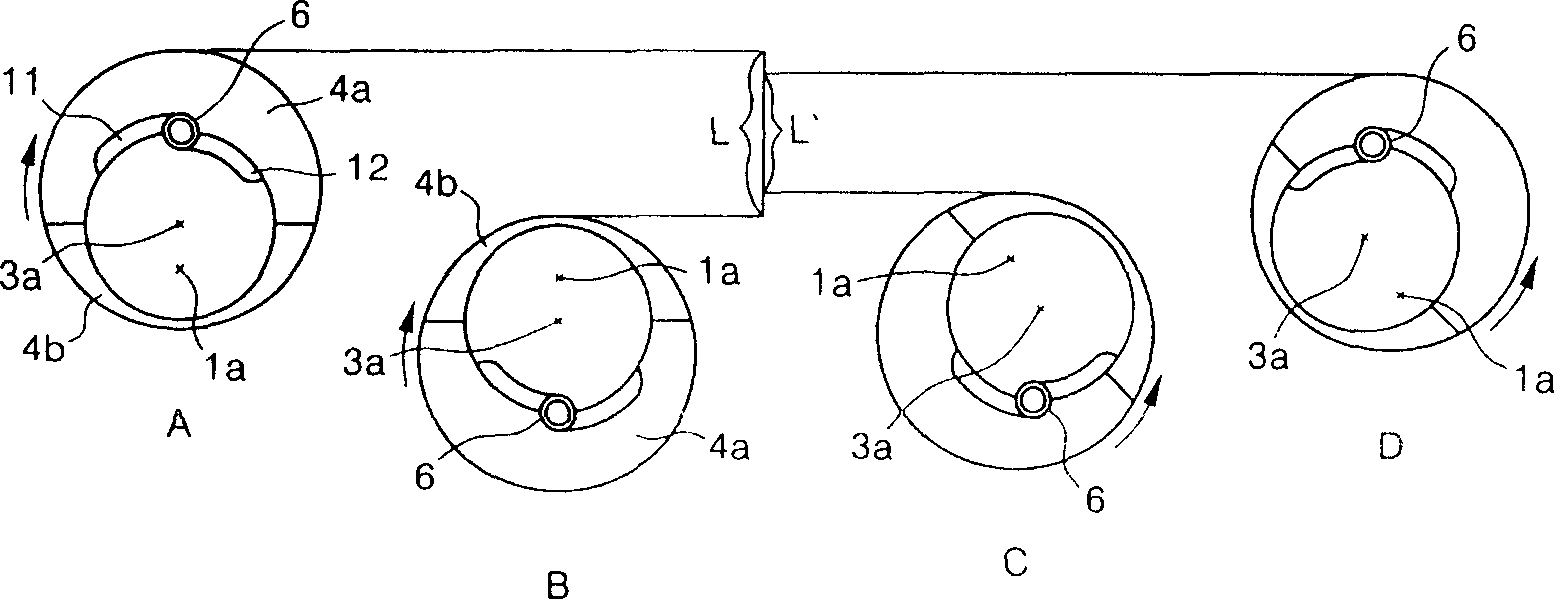

Dual capacity compressor

InactiveCN1527905AReally reliable fixedAvoid relative motionEngine of arcuate-engagement typeGearingClockwiseCrankshaft

A dual capacity compressor is provided to prevent relative movement between parts that maintain eccentricity. To this end, the dual capacity compressor comprises a power generating unit having reversible motor, and a crank shaft inserted into the motor; a compressing unit having a cylinder, a piston and a connecting rod connected with the piston; a crank pin eccentrically formed on an upper end portion of the crank shaft; a eccentric sleeve mounted between the crank pin and one end of the connecting rod; and a key member for completely restricting the eccentric sleeve to the crank pin.

Owner:LG ELECTRONICS INC

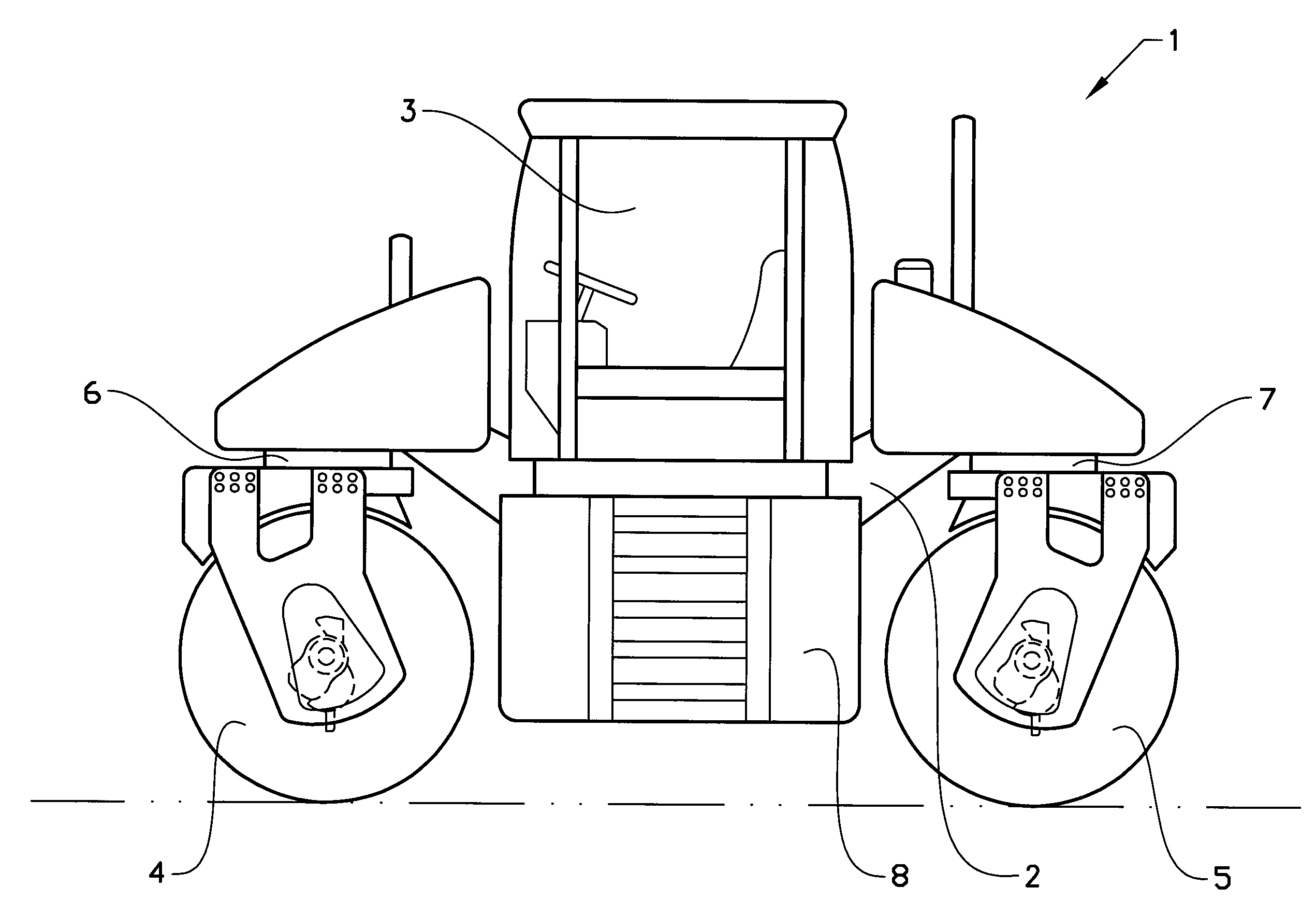

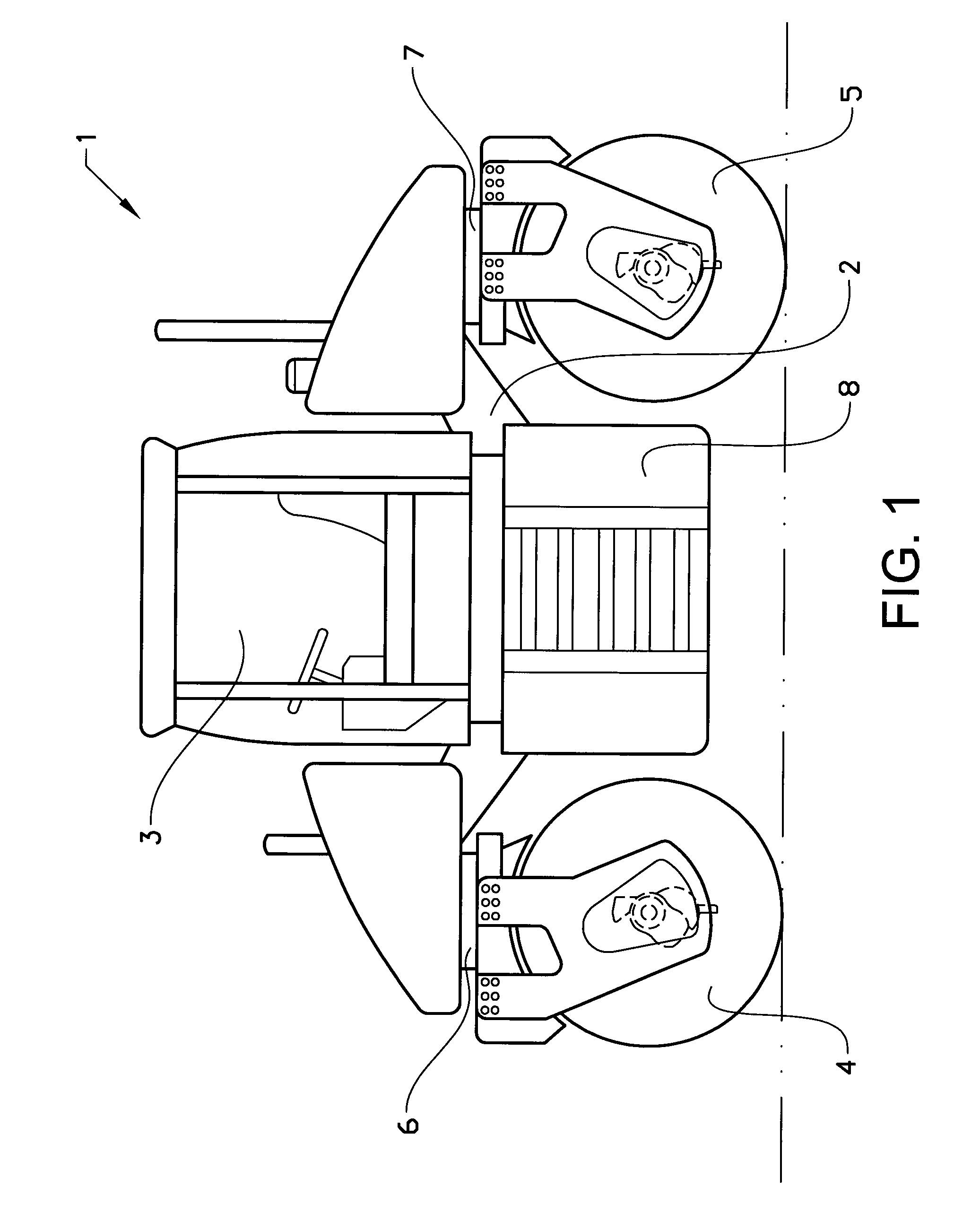

Assembly for vibrating a compacting drum of a compacting machine

ActiveUS20160102438A1Reduced moment of inertiaReduction in moment of inertiaControlling membersControlled membersEngineeringMechanical engineering

An assembly is provided for vibrating a compacting drum of a compacting machine. The assembly includes a shaft rotatably mountable to a compacting drum of the compacting machine. The centre of mass of the shaft is offset from the geometrical rotation axis of the shaft. An outer eccentric member is arranged outside of the shaft, wherein the centre of mass of the outer eccentric member is offset from the geometrical rotation axis of the shaft. The outer eccentric member is displaceably mounted relative to the shaft for adjustment of the eccentricity of the assembly. An extension of the outer eccentric member in a direction parallel with the geometrical rotation axis of the shaft is at least two times an average extension of the outer eccentric member in a radial direction perpendicular to the geometrical rotation axis of shaft such that a mass of the outer eccentric member forms a distributed load along the geometrical rotation axis of the shaft.

Owner:VOLVO CONSTR EQUIP

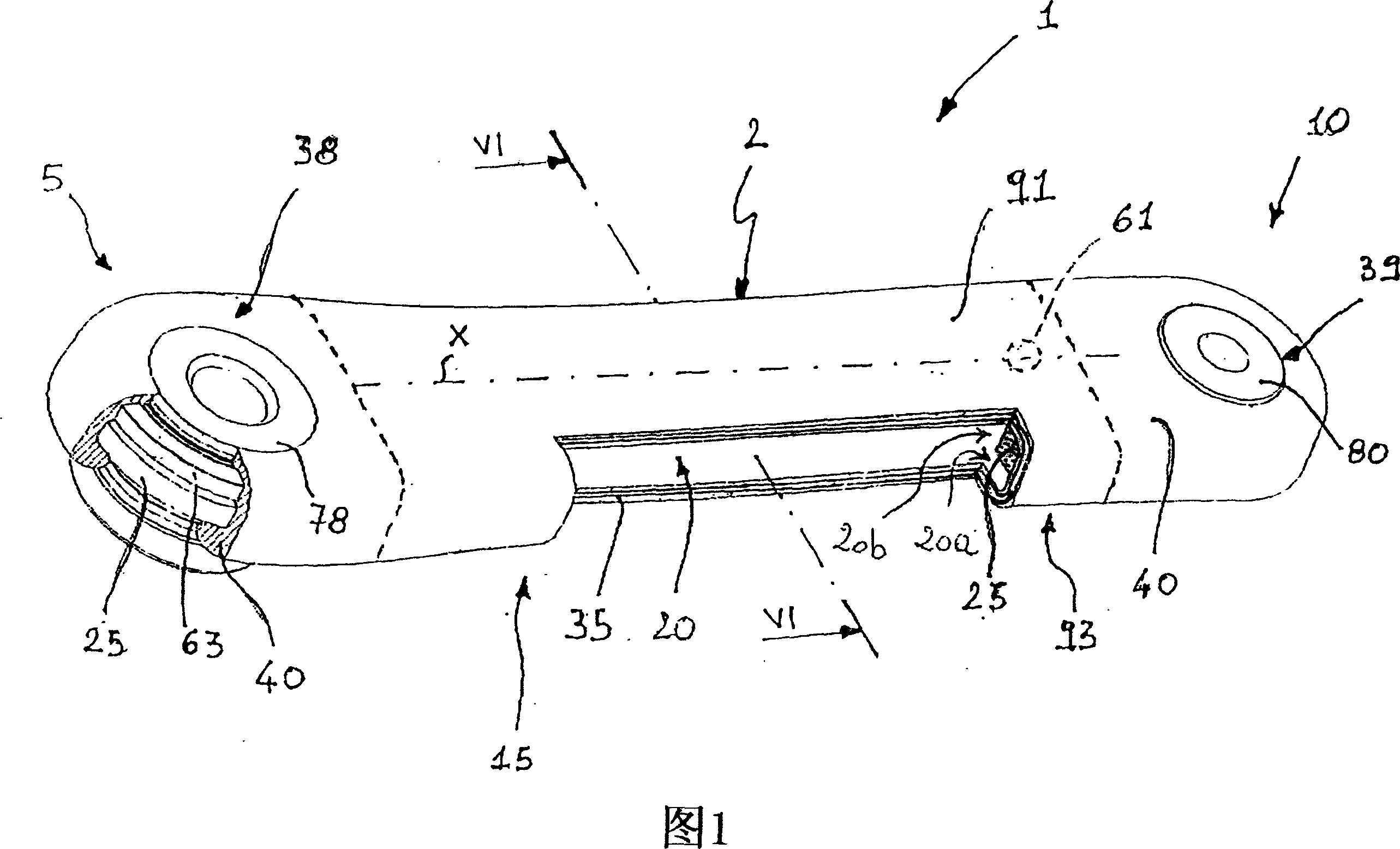

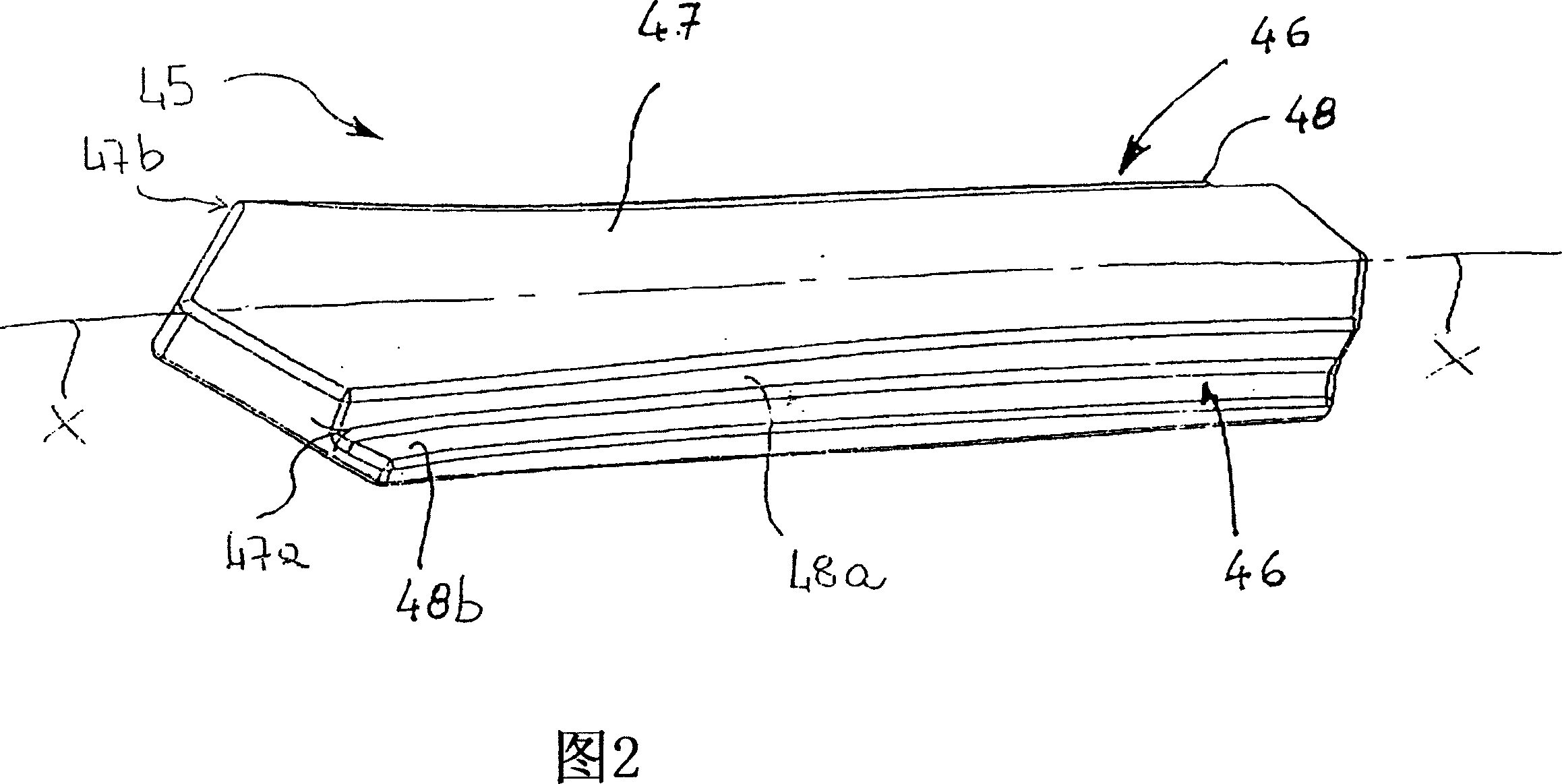

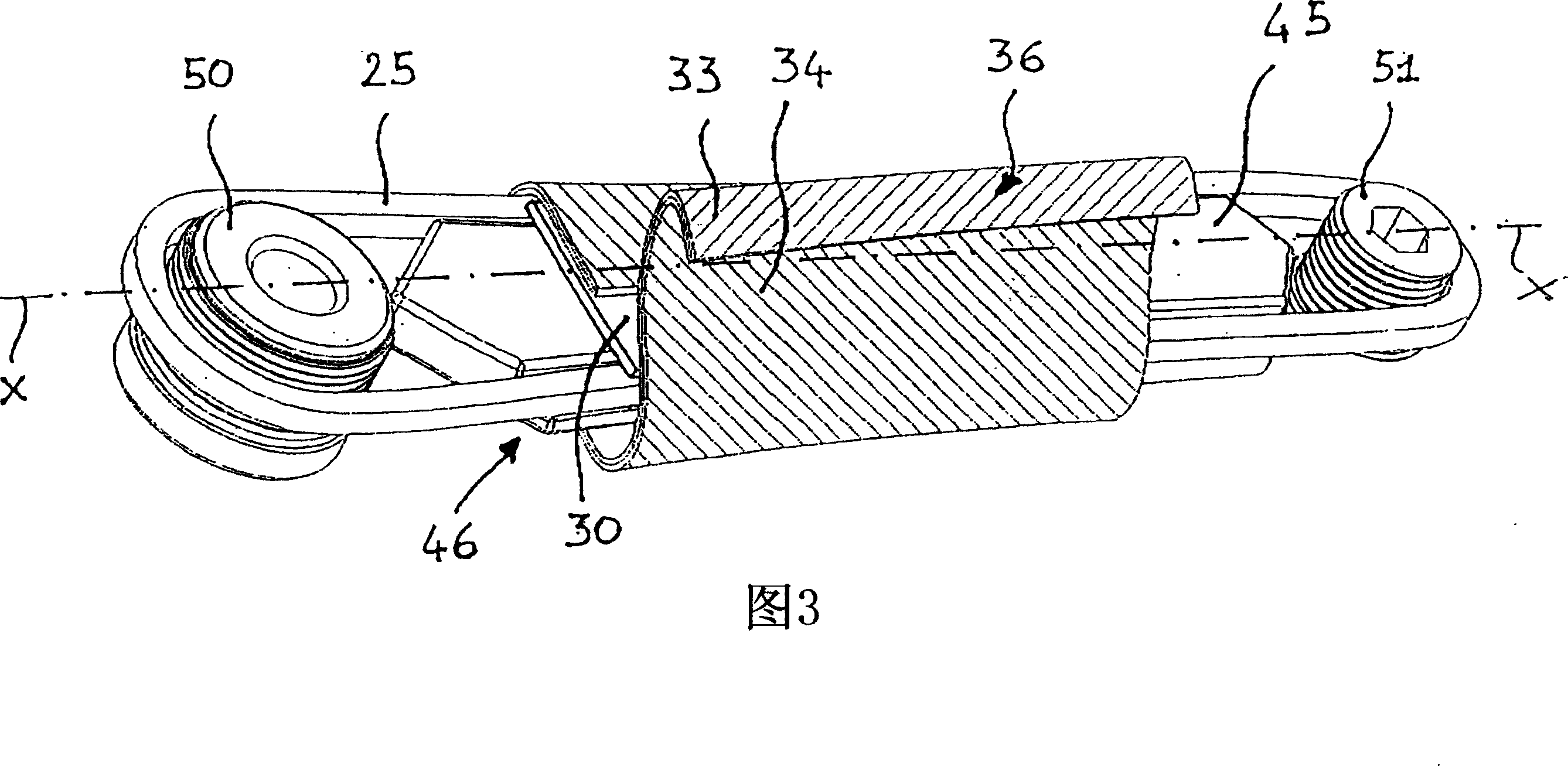

Bicycle pedal crank, intermediate product and method for manufactoring such a pedal crank

A bicycle pedal crank is described, comprising an elongated body extending along a longitudinal axis X-X and having a first end portion comprising a first seat for coupling with a bottom bracket of the bicycle, a second end portion comprising a second seat for coupling with a pedal and an intermediate portion extending between said first end portion and said second end portion and comprising an inner portion substantially without structural strength and a first reinforcement structure. In accordance with the invention, the first reinforcement structure comprises a tubular structure arranged around said inner portion and extending longitudinally for a part not longer than the longitudinal extension of said intermediate portion. Such a tubular structure, advantageously, ensures uniform structural capabilities around the portion substantially without structural capability. The extension of the tubular element is limited to just the intermediate portion of the pedal crank, that is without involving the end portions and the respective coupling seats, allows the pedal crank to be manufactured in a simple and quick way in a completely automated manner.

Owner:CAMPAGNOLO SRL

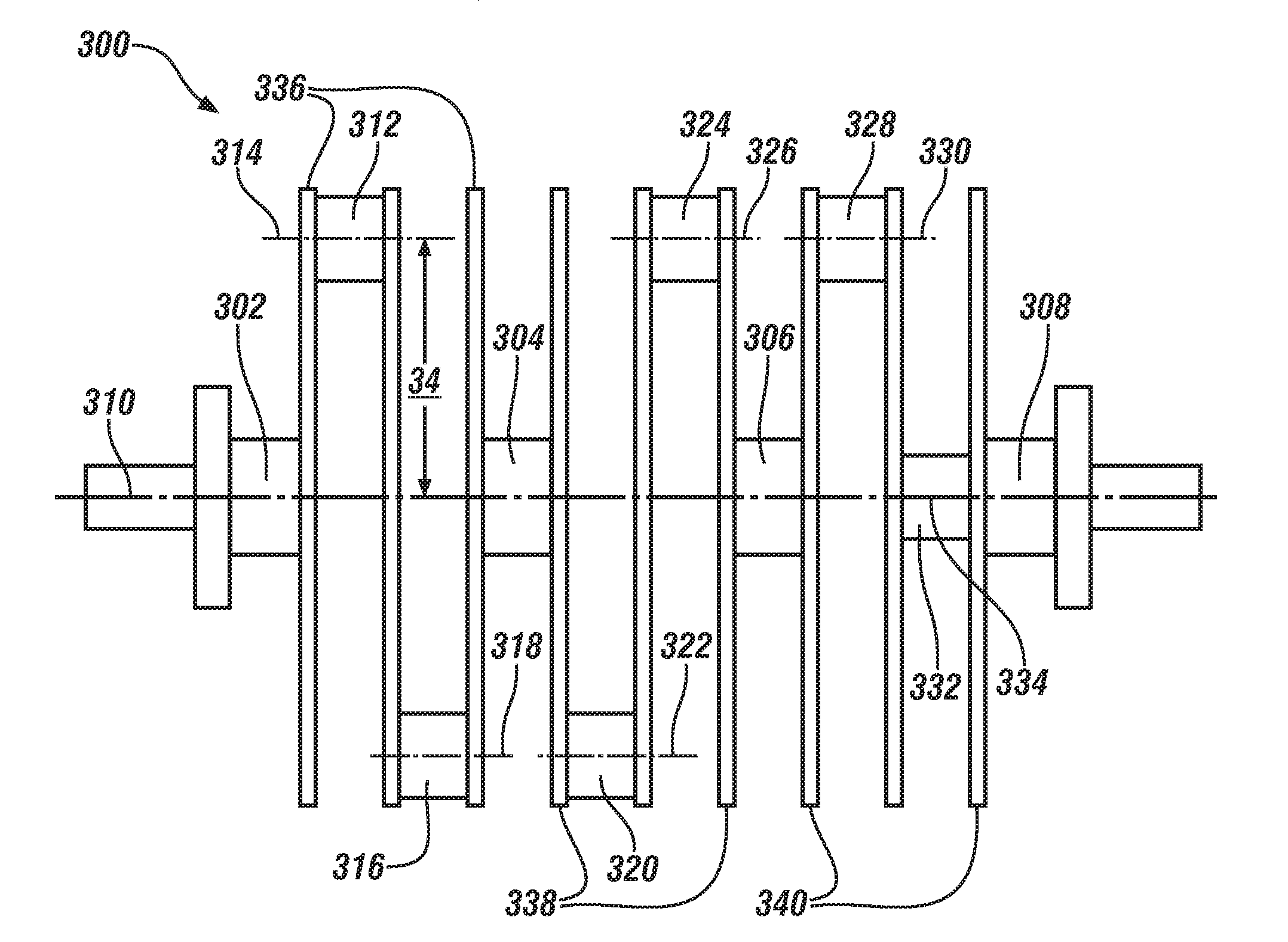

Crankshaft for an internal combustion engine

InactiveUS20130247715A1CrankshaftsNon-fuel substance addition to fuelEngineeringInternal combustion engine

A crankshaft for an internal combustion engine comprises at least four main journals aligned on a crankshaft axis of rotation and at least six crankpins, each being disposed about a respective crankpin axis and positioned between the at least four main journals. Each of the respective crankpin axes is oriented parallel to, and spaced radially from, the crankshaft axis of rotation. Each of the at least six crankpins is joined to a pair of crank arms for force transmission between each of the at least six crankpins and the respective pair of crank arms. Each crank arm is joined to a respective main journal for transmitting torque between the crank arm and the main journal. The at least six crankpins are disposed asymmetrically about the crankshaft axis of rotation.

Owner:GM GLOBAL TECH OPERATIONS LLC

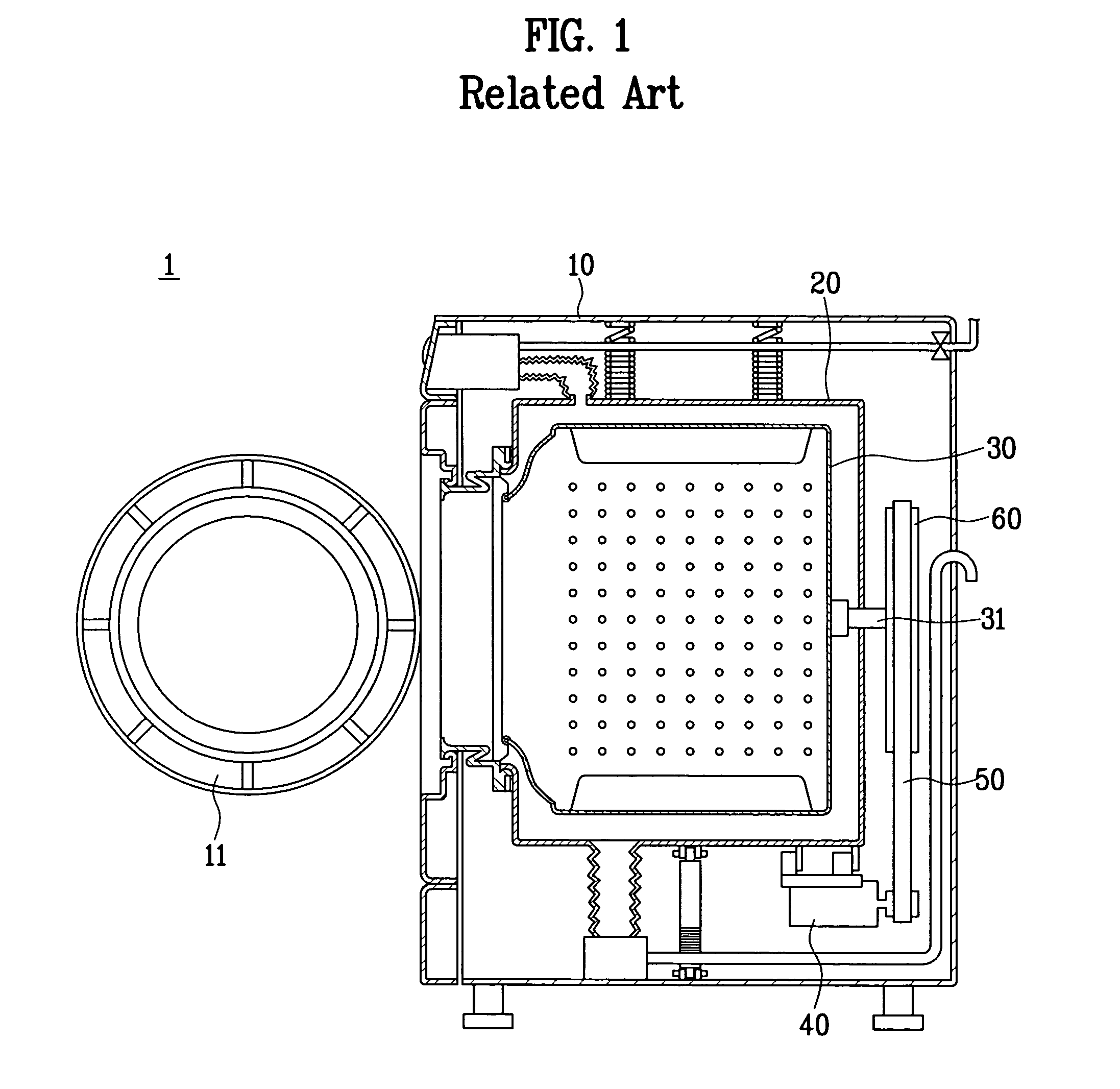

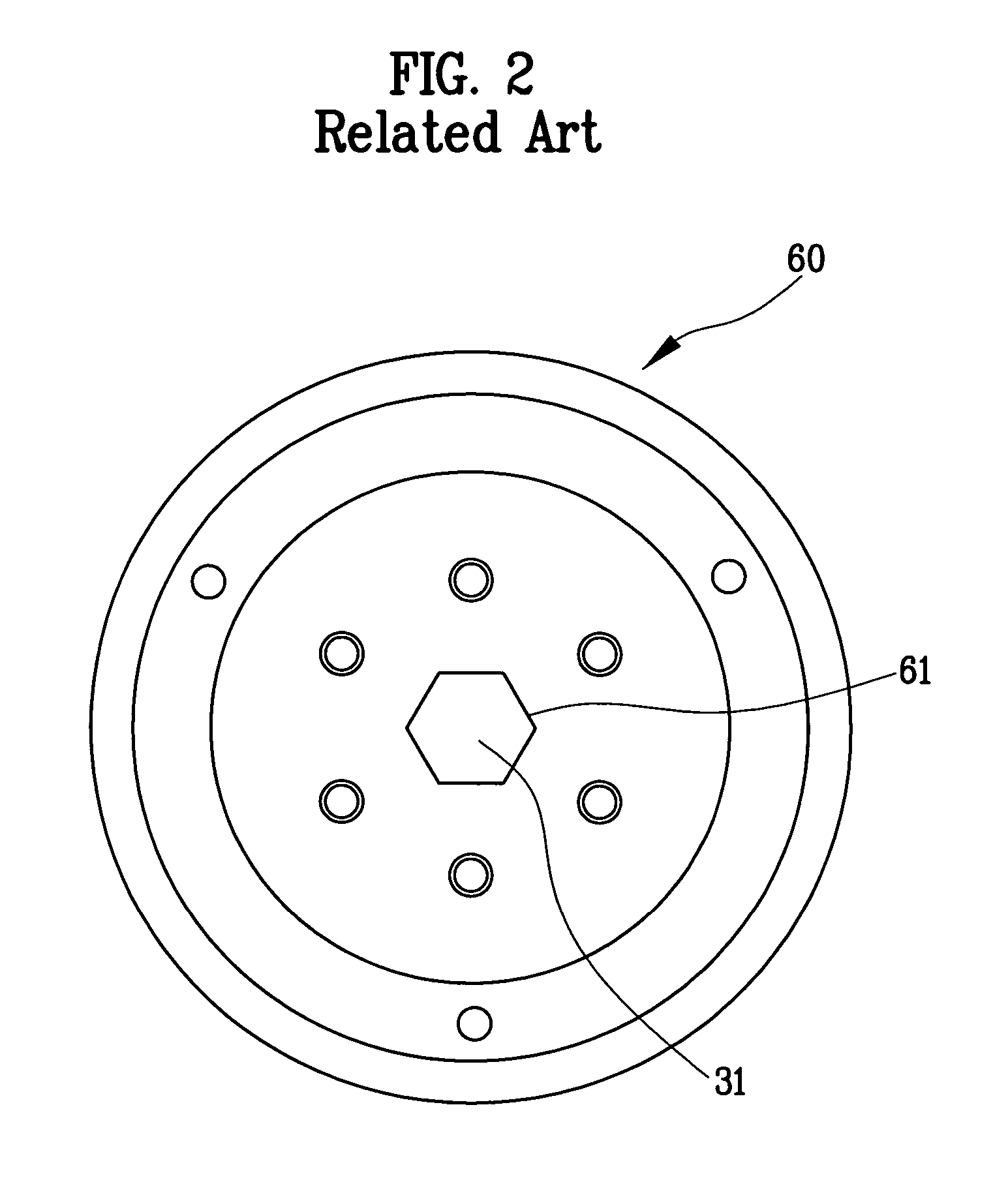

Pulley of washing machine

InactiveUS7415849B2Reduce weightHigh tensile strengthControlling membersControlled membersElectric machineryEngineering

A pulley of a washing machine, wherein the weight of the pulley is reduced by forming a strain-focused portion of the pulley with a high-rigidity material. The pulley of the washing machine having a motor for rotating a drum connected to one end of a shaft, includes a composite member, axially coupled to the other end of the shaft, for transferring a rotational force of the motor to the drum, the composite member being formed of at least two materials having dissimilar tensile strengths.

Owner:LG ELECTRONICS INC

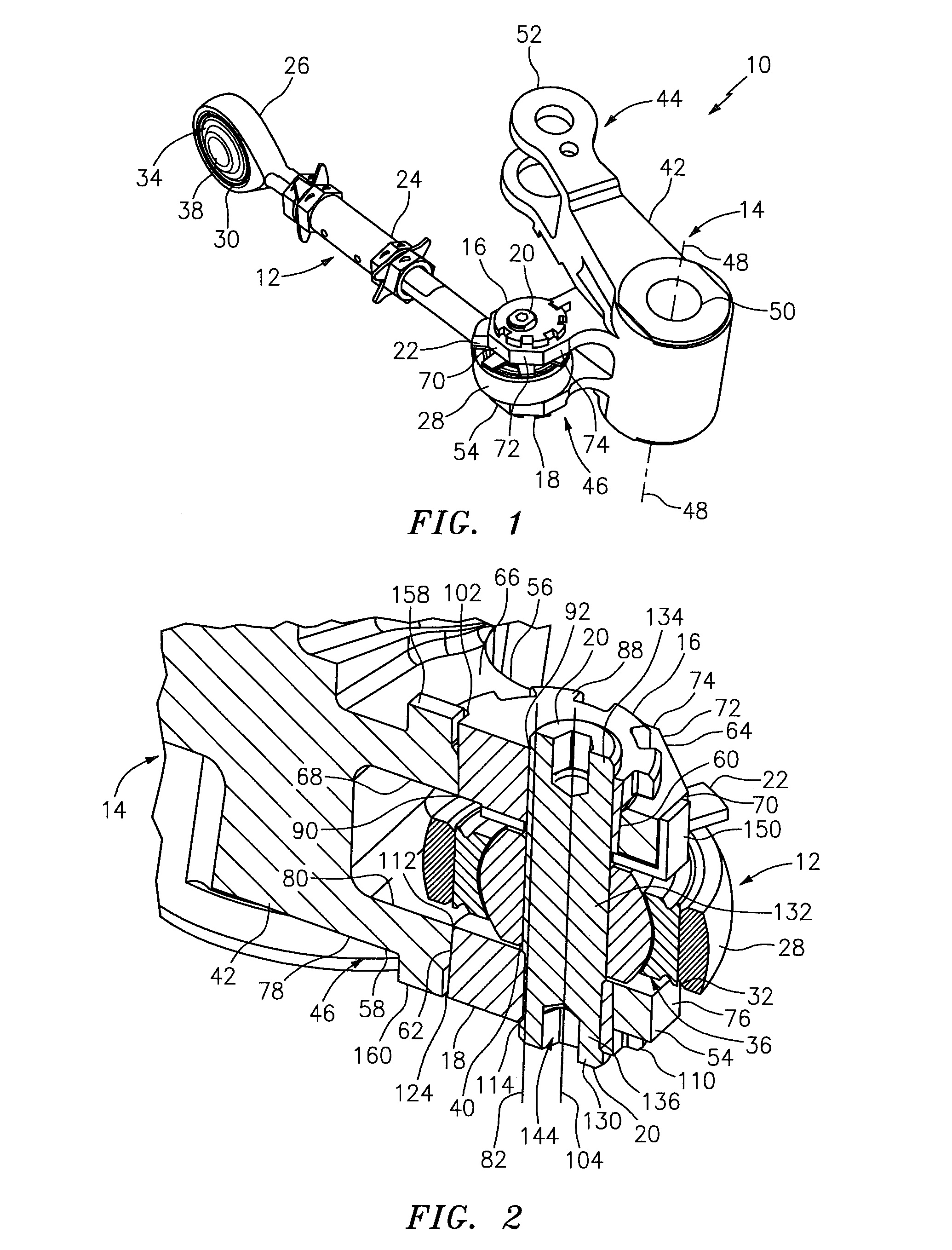

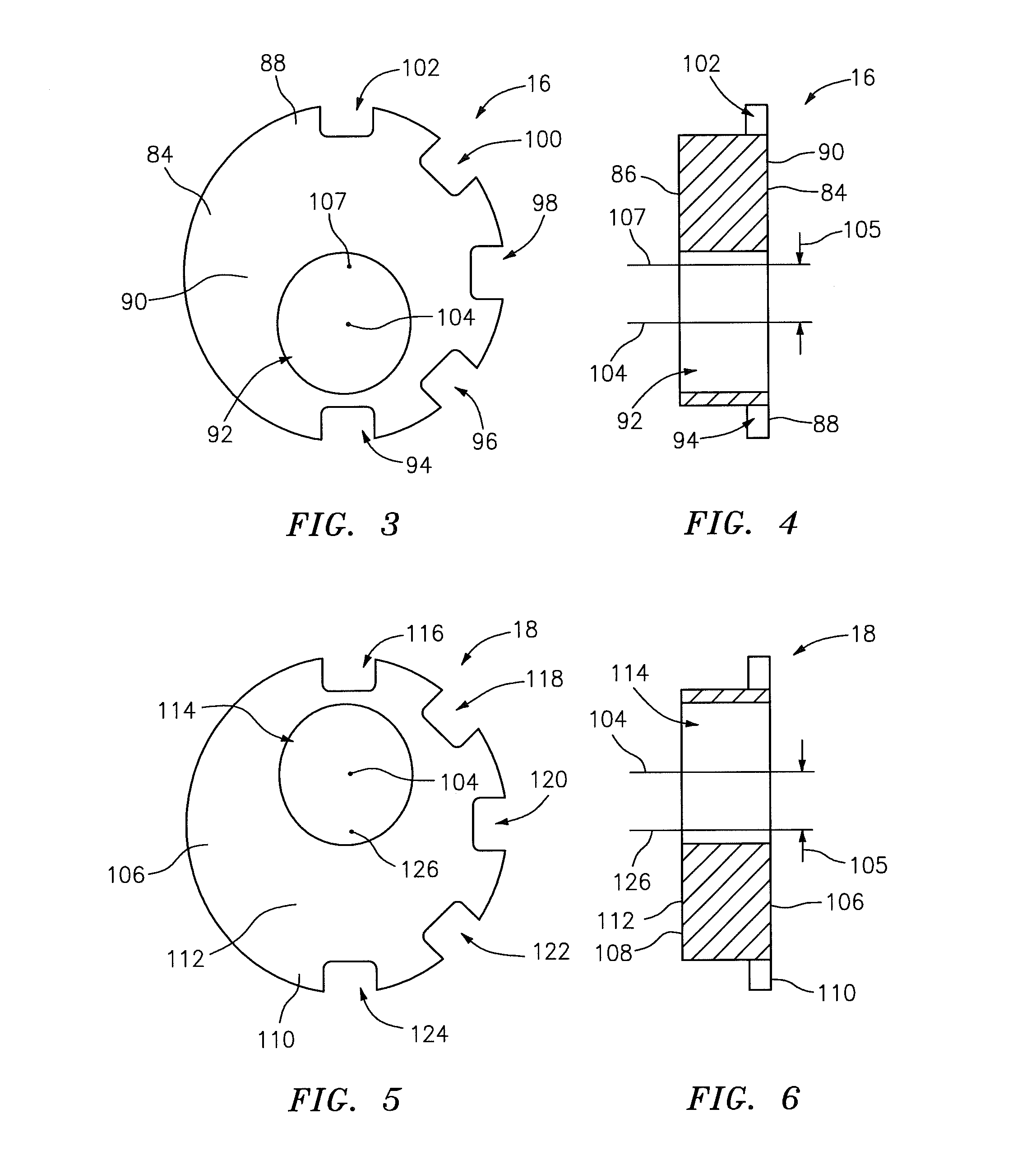

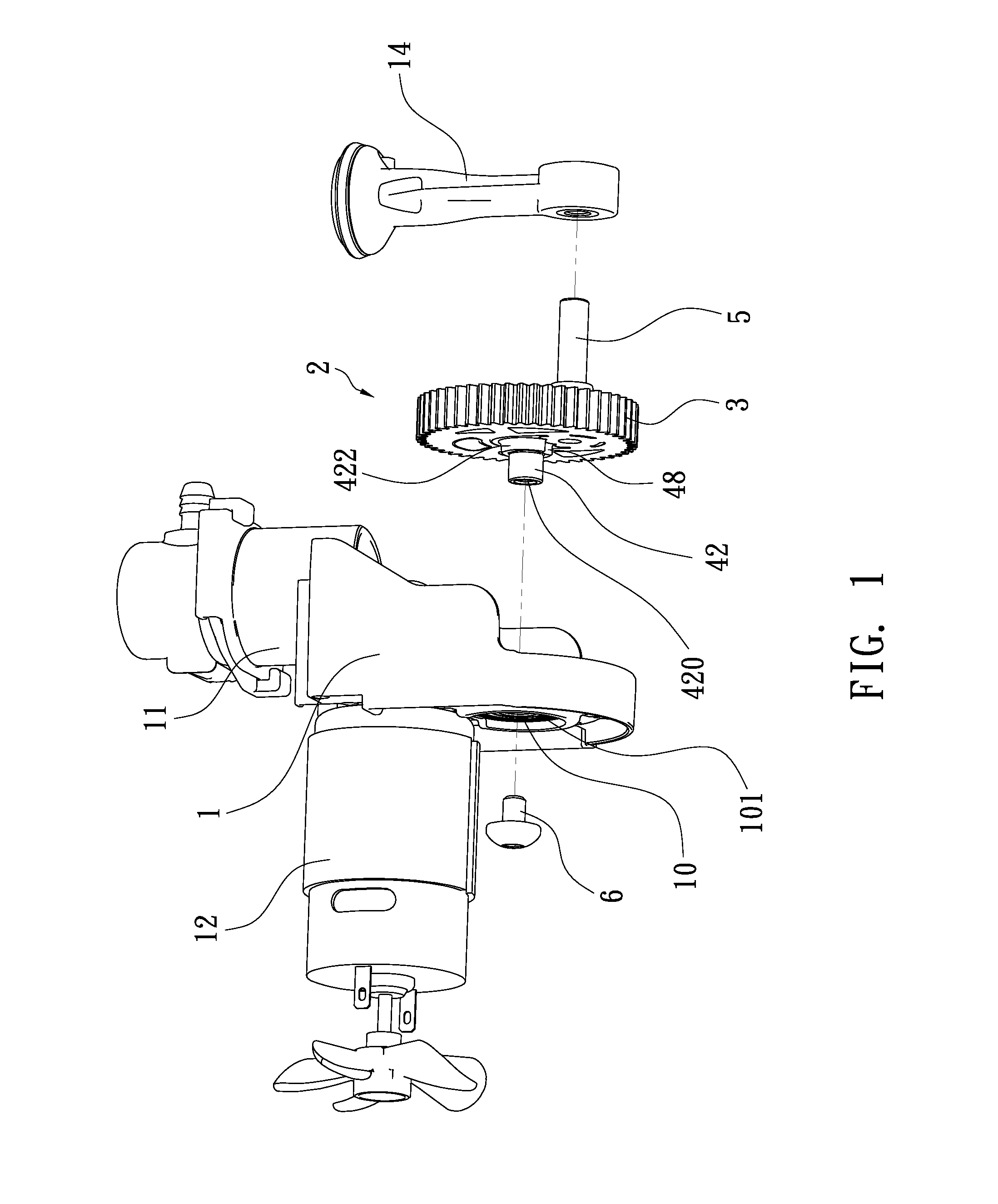

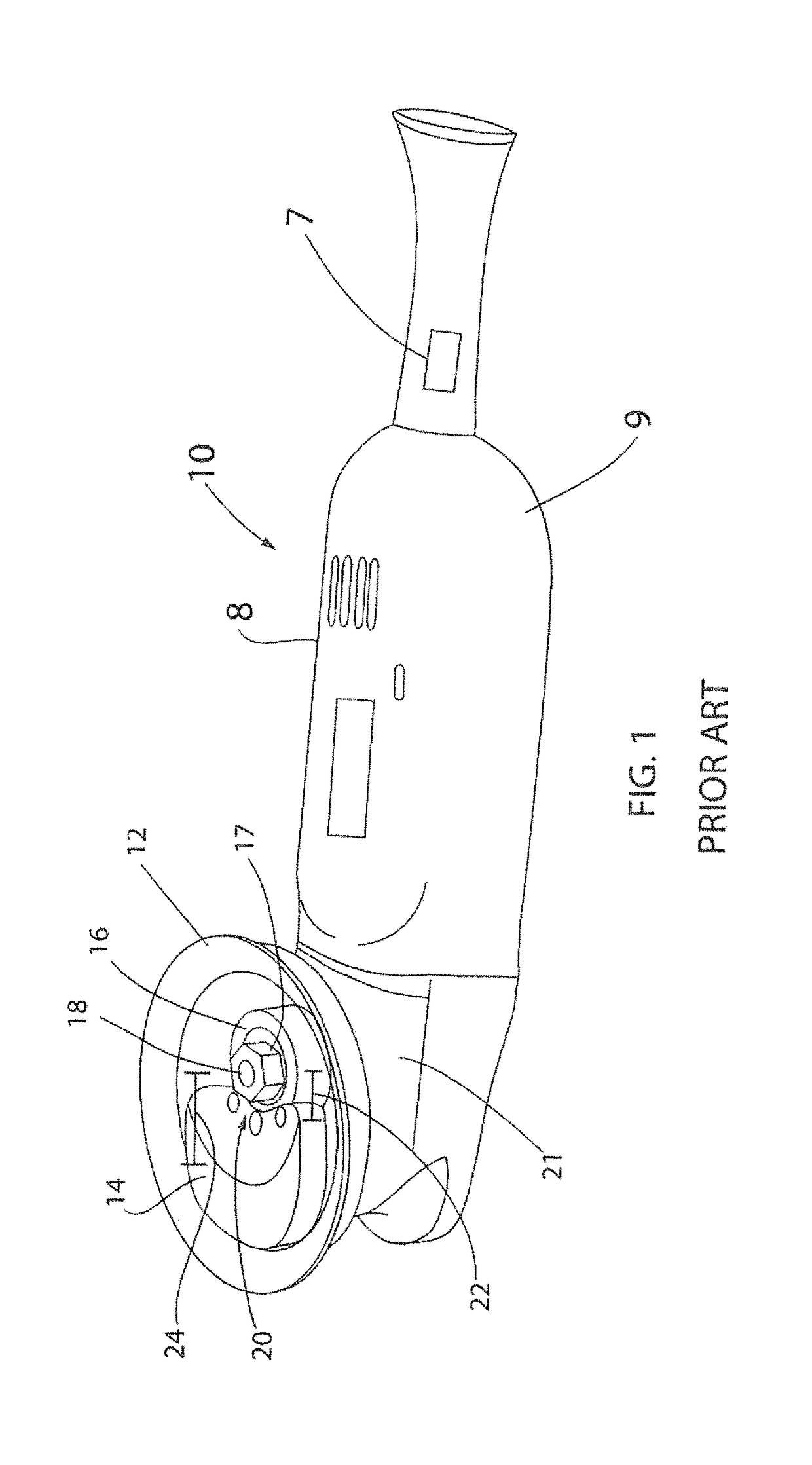

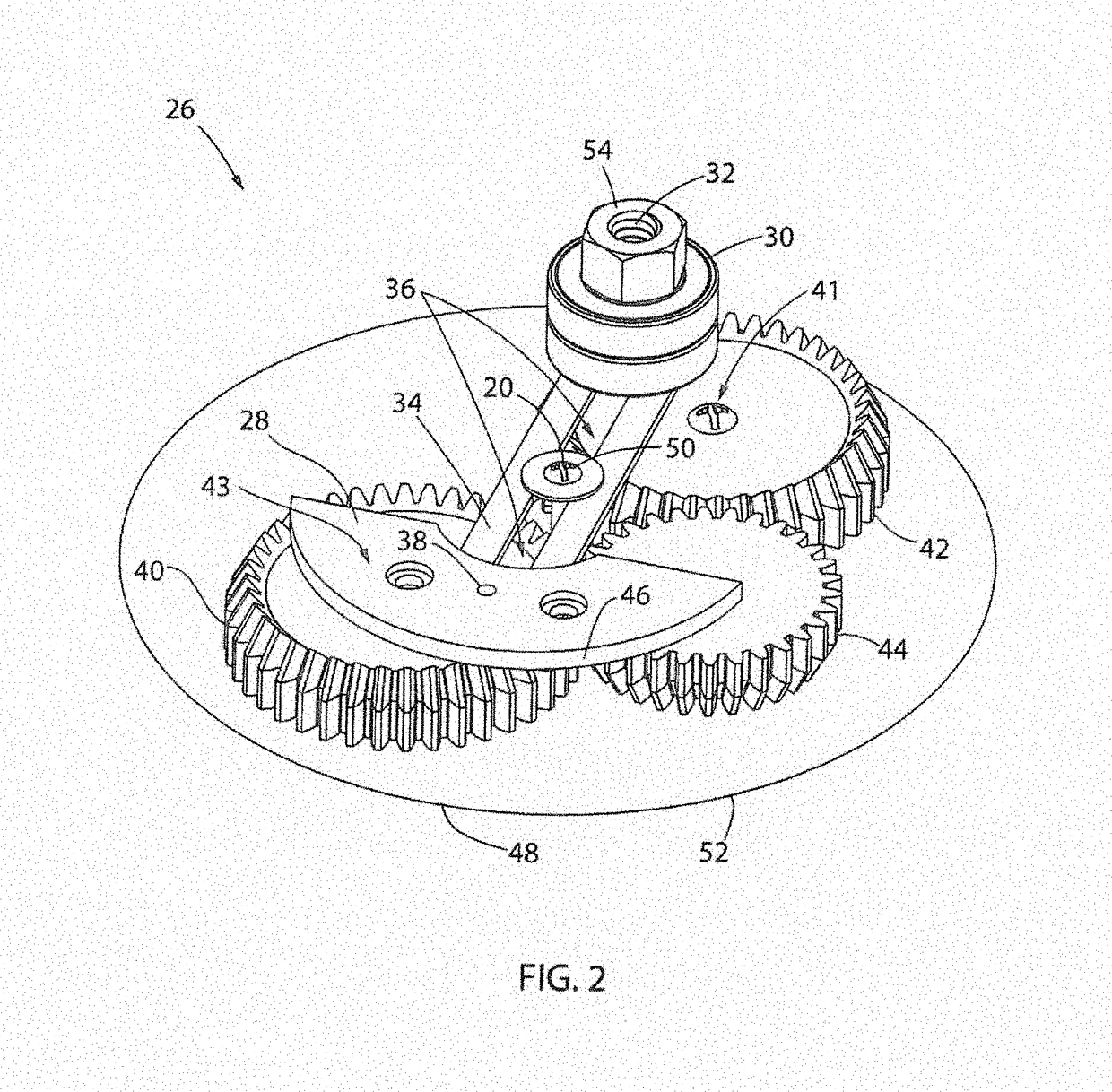

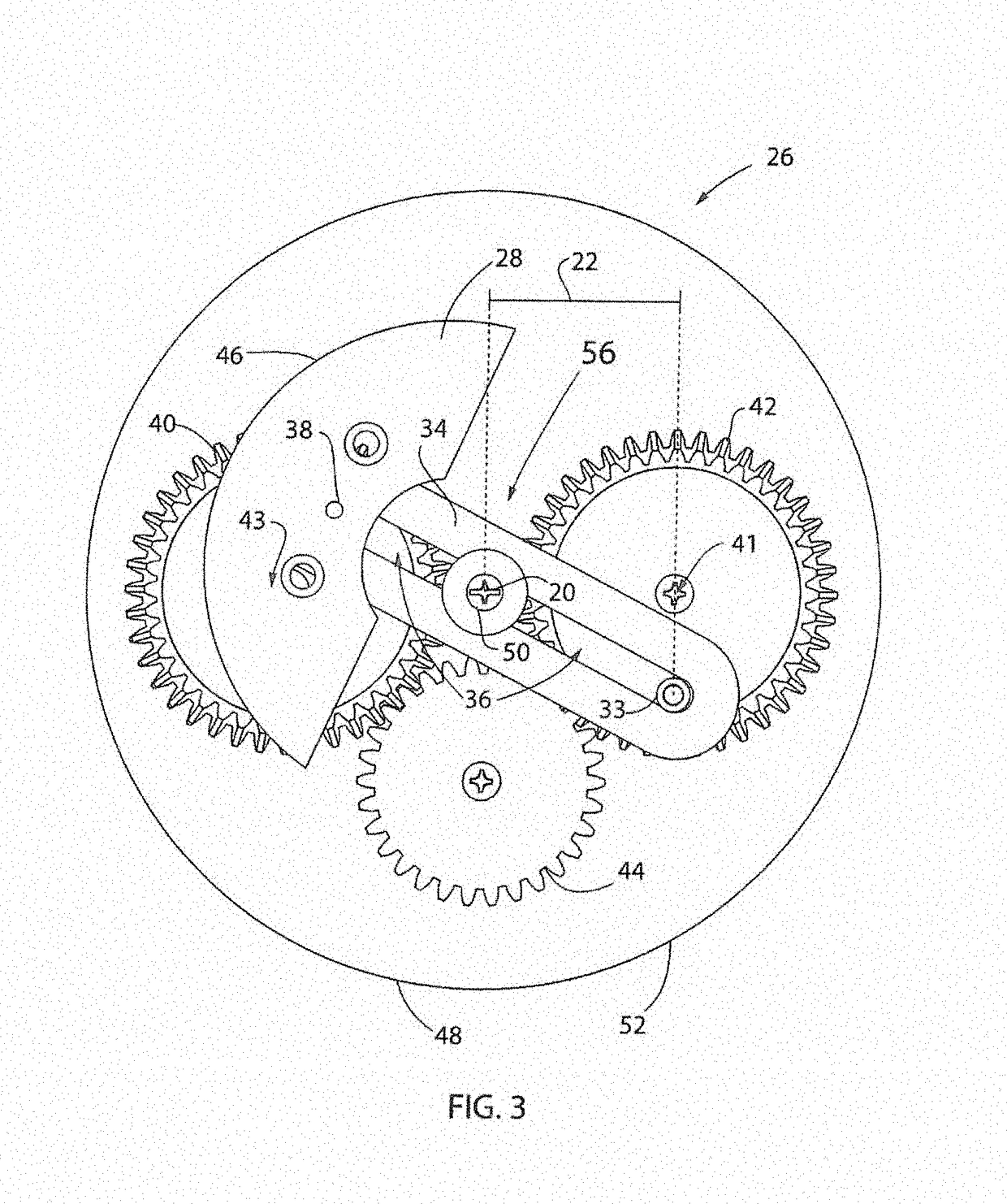

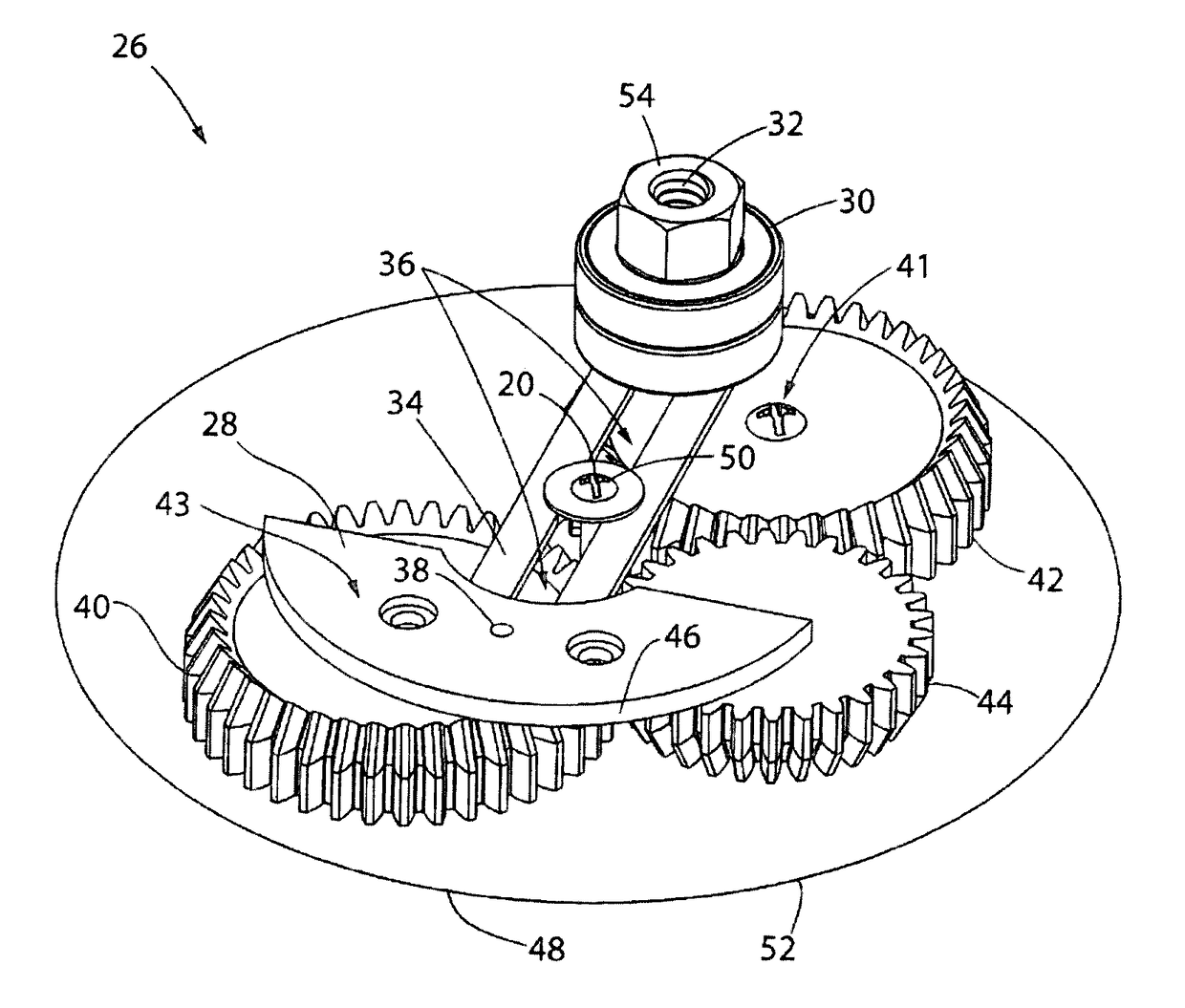

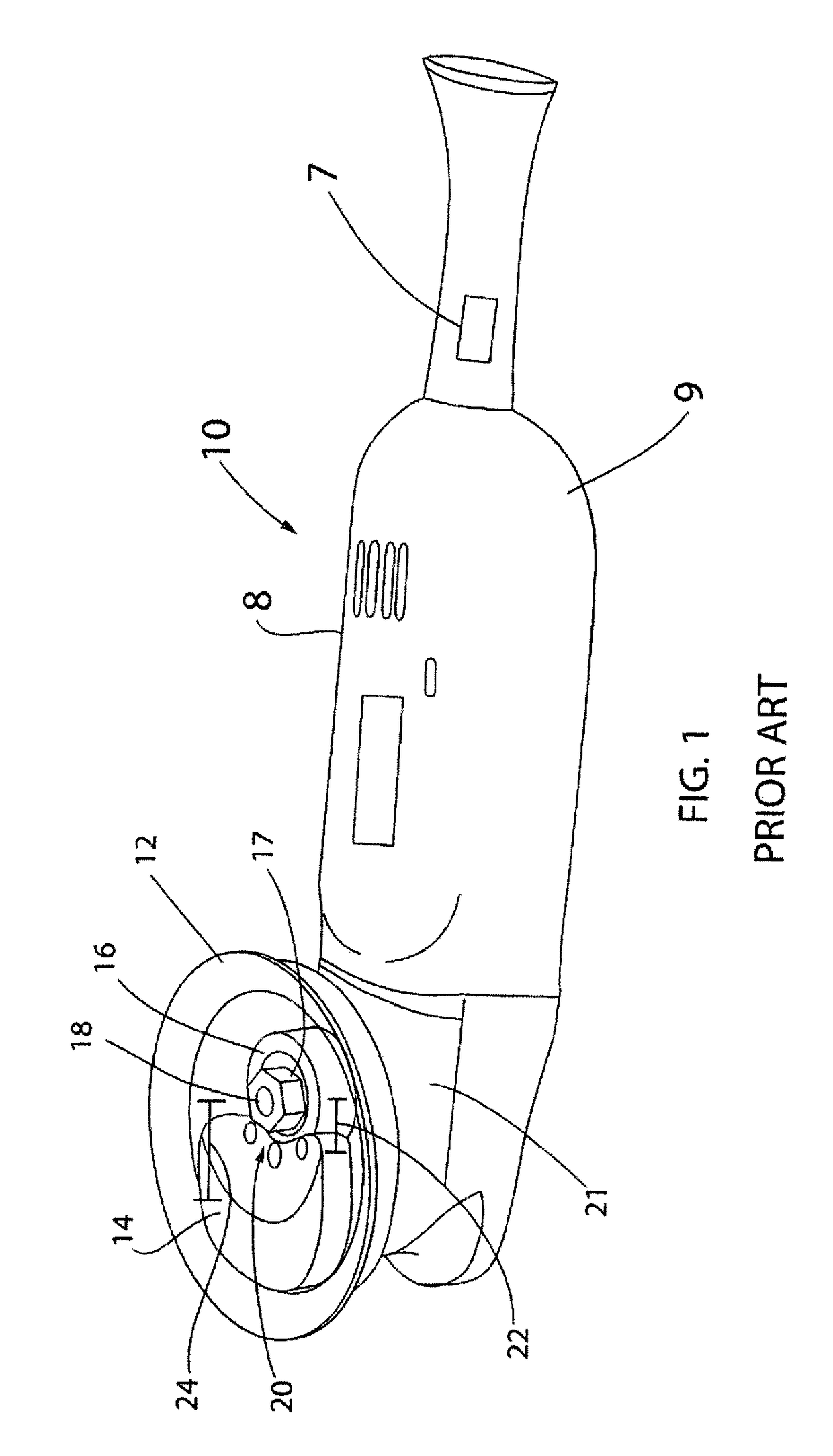

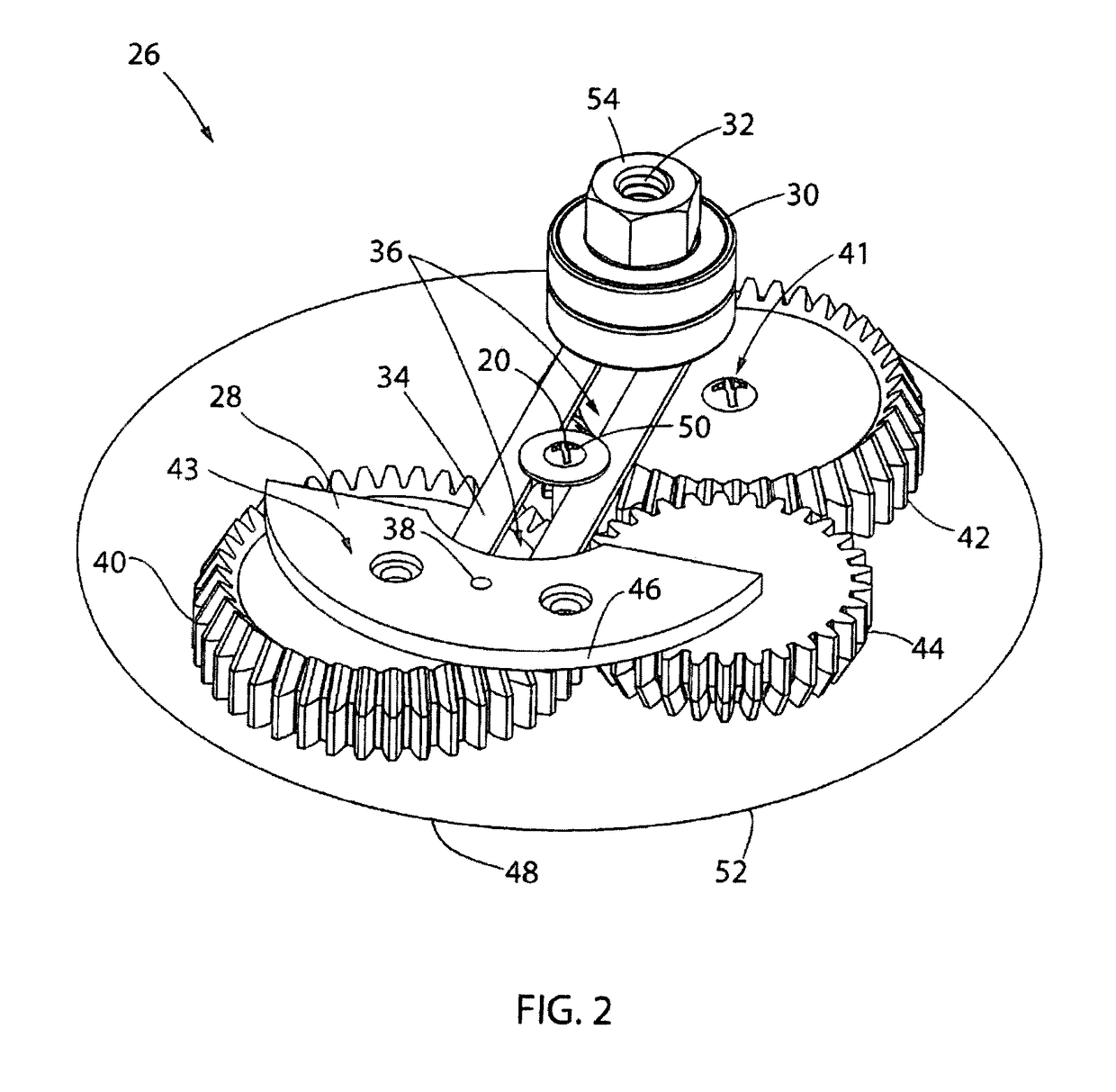

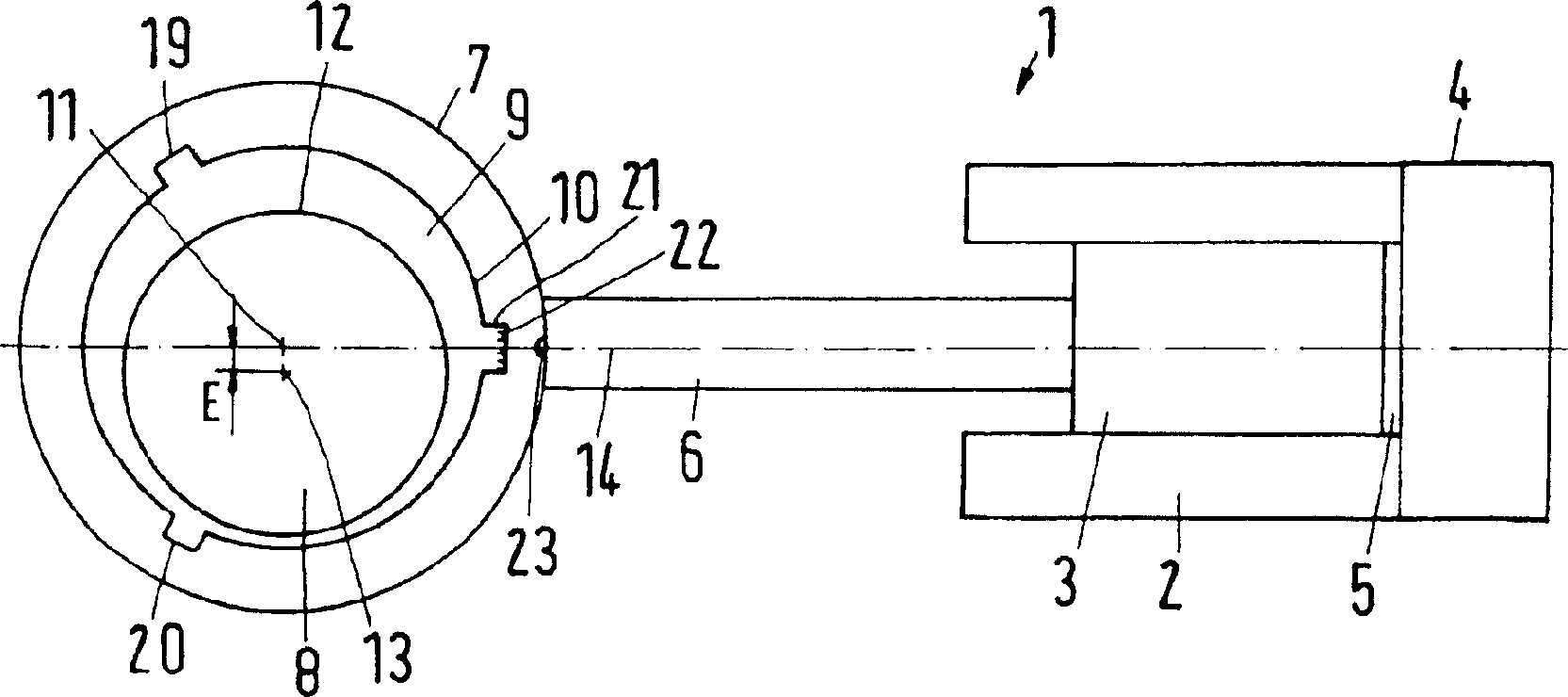

Adjustable stroke mechanism for random orbital machine

An adjustable stroke mechanism for a random orbital machine including a housing having a wall enclosing a cavity, an adjuster ring surrounding the housing and having a first set of gear teeth along a first portion of an inner surface, and a second set of gear teeth along a second portion of the inner surface, a counterweight having gear teeth on an exterior surface disposed within the housing, and a bearing carriage having gear teeth disposed within the housing. At least one counterweight gear that meshes with the gear teeth of the counterweight and the first set of gear teeth of the adjuster ring, and at least one bearing carriage gear that meshes with the gear teeth of the bearing carriage and the second set of gear teeth of the adjuster ring, so that movement of the adjuster ring causes movement of both the counterweight and the bearing carriage.

Owner:LAKE COUNTRY TOOL LLC

Adjustable Stroke Mechanism for Random Orbital Machine

An adjustable stroke mechanism for a random orbital machine including a housing having a wall enclosing a cavity, an adjuster ring surrounding the housing and having a first set of gear teeth along a first portion of an inner surface, and a second set of gear teeth along a second portion of the inner surface, a counterweight having gear teeth on an exterior surface disposed within the housing, and a bearing carriage having gear teeth disposed within the housing. At least one counterweight gear that meshes with the gear teeth of the counterweight and the first set of gear teeth of the adjuster ring, and at least one bearing carriage gear that meshes with the gear teeth of the bearing carriage and the second set of gear teeth of the adjuster ring, so that movement of the adjuster ring causes movement of both the counterweight and the bearing carriage.

Owner:LAKE COUNTRY TOOL LLC

Cradle clamp bracket assembly

A bracket assembly that secures cables to rungs of a ladder rack. The bracket has a bottom portion, sidewalls, and an upper portion. The bracket is positioned under the rectangular body of the ladder rung and secured thereto with an interference fit. At least one cable is positioned on the ladder rung and the upper portion of the bracket. A tie secures the cable to the upper portion of the bracket.

Owner:PANDUIT

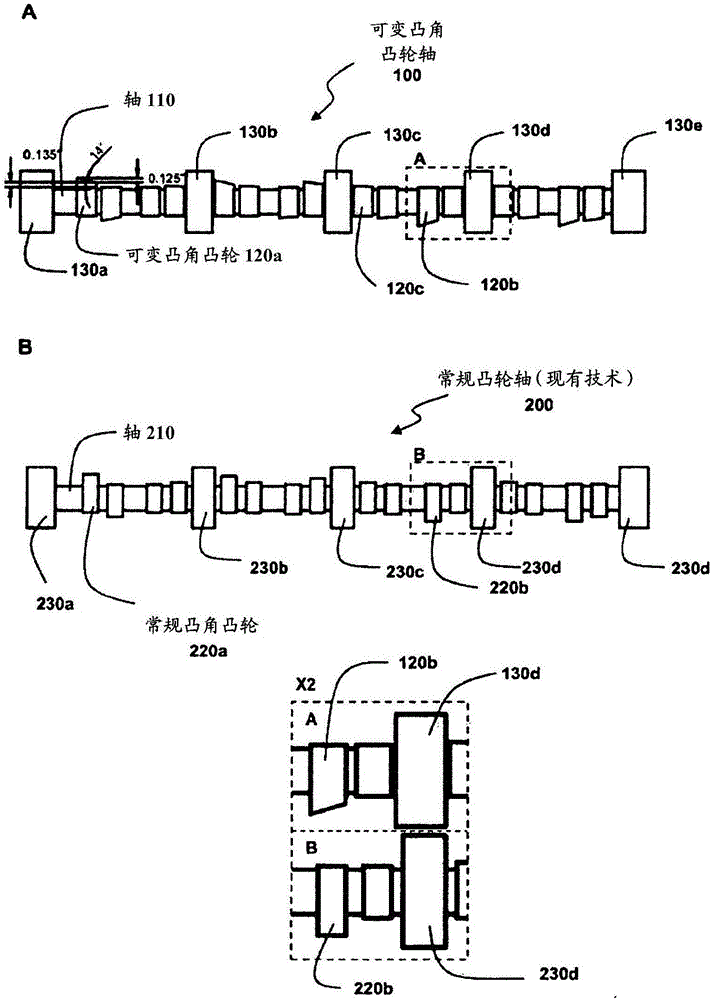

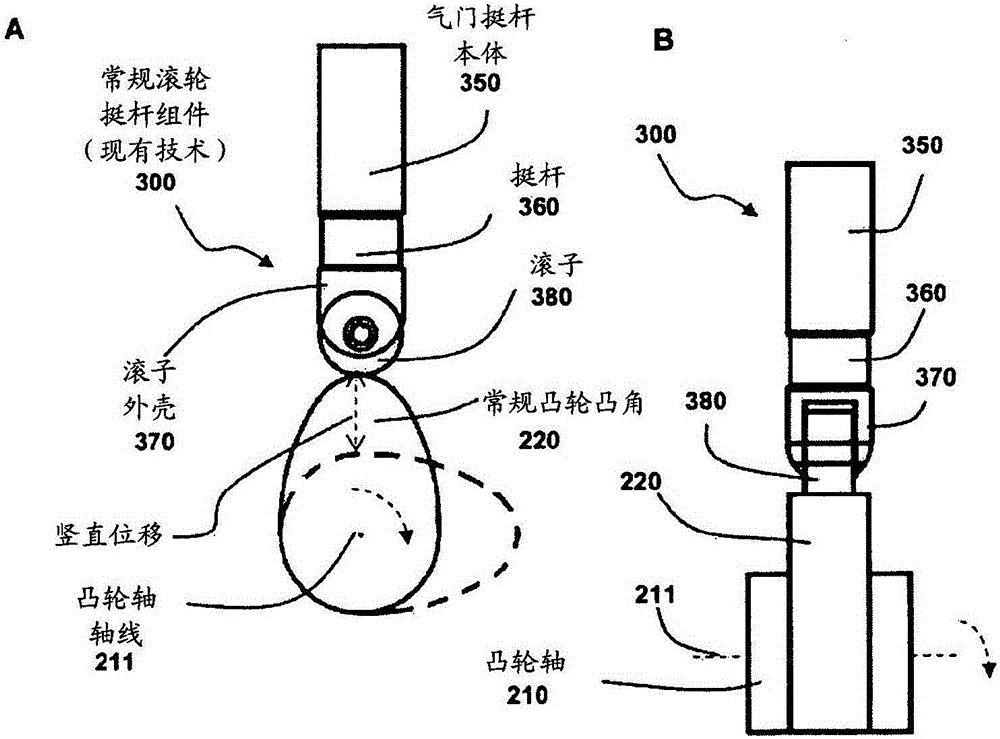

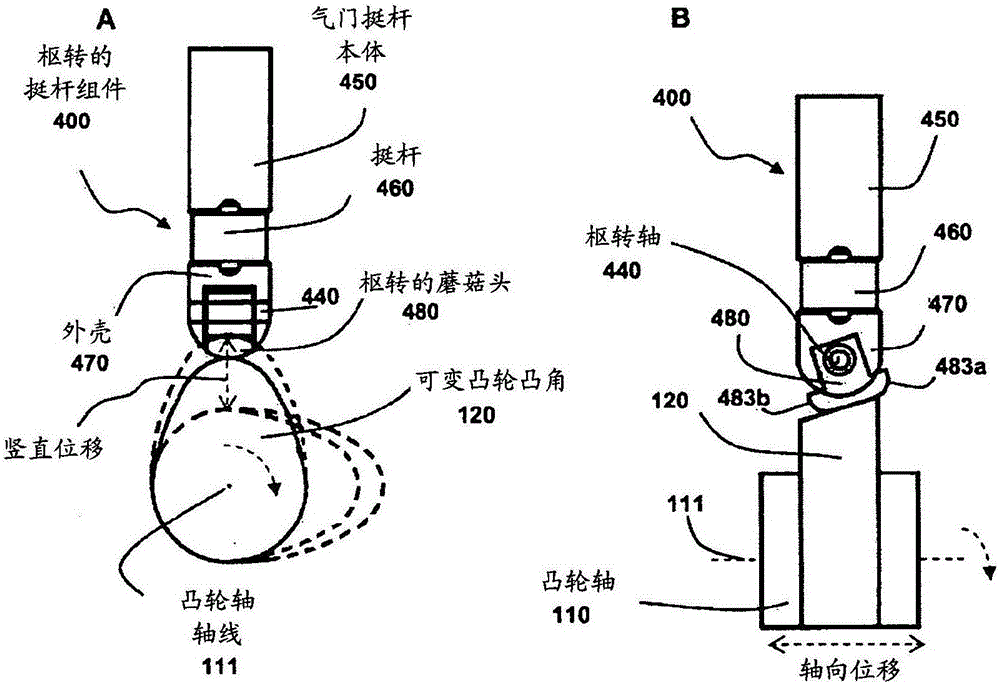

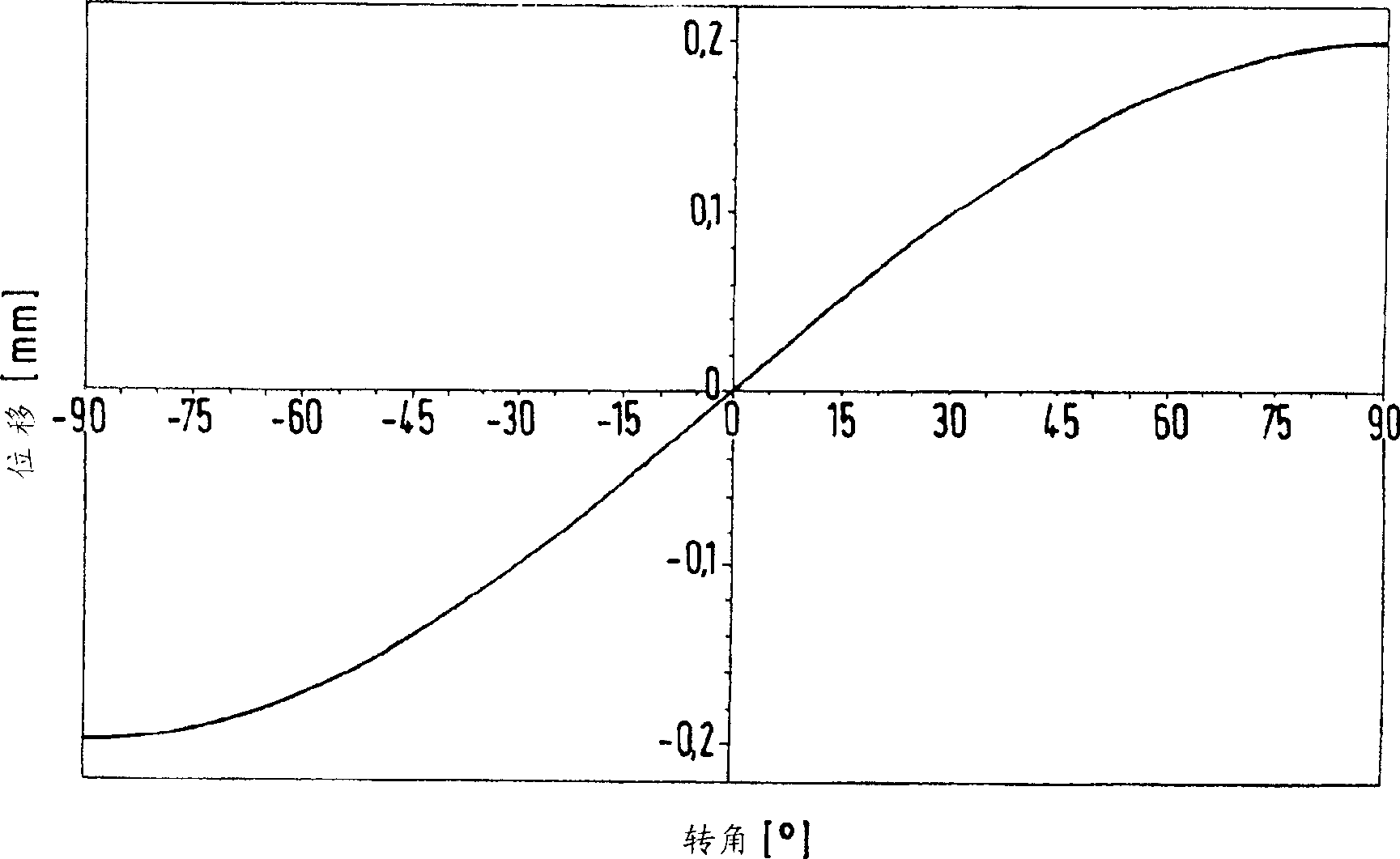

Pivoting Variable Cam Follower

Owner:丹尼尔·波默洛

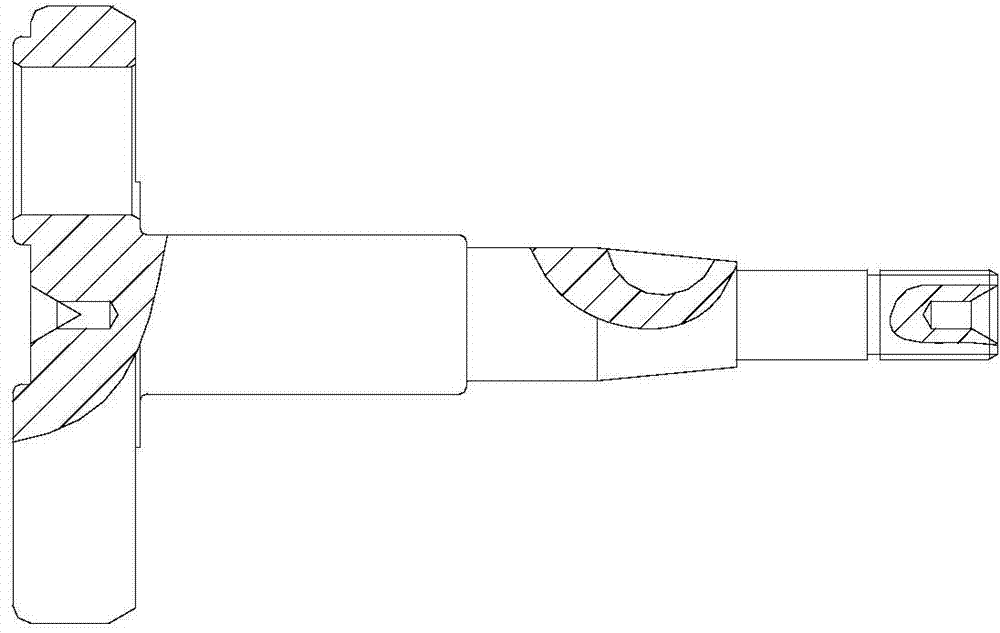

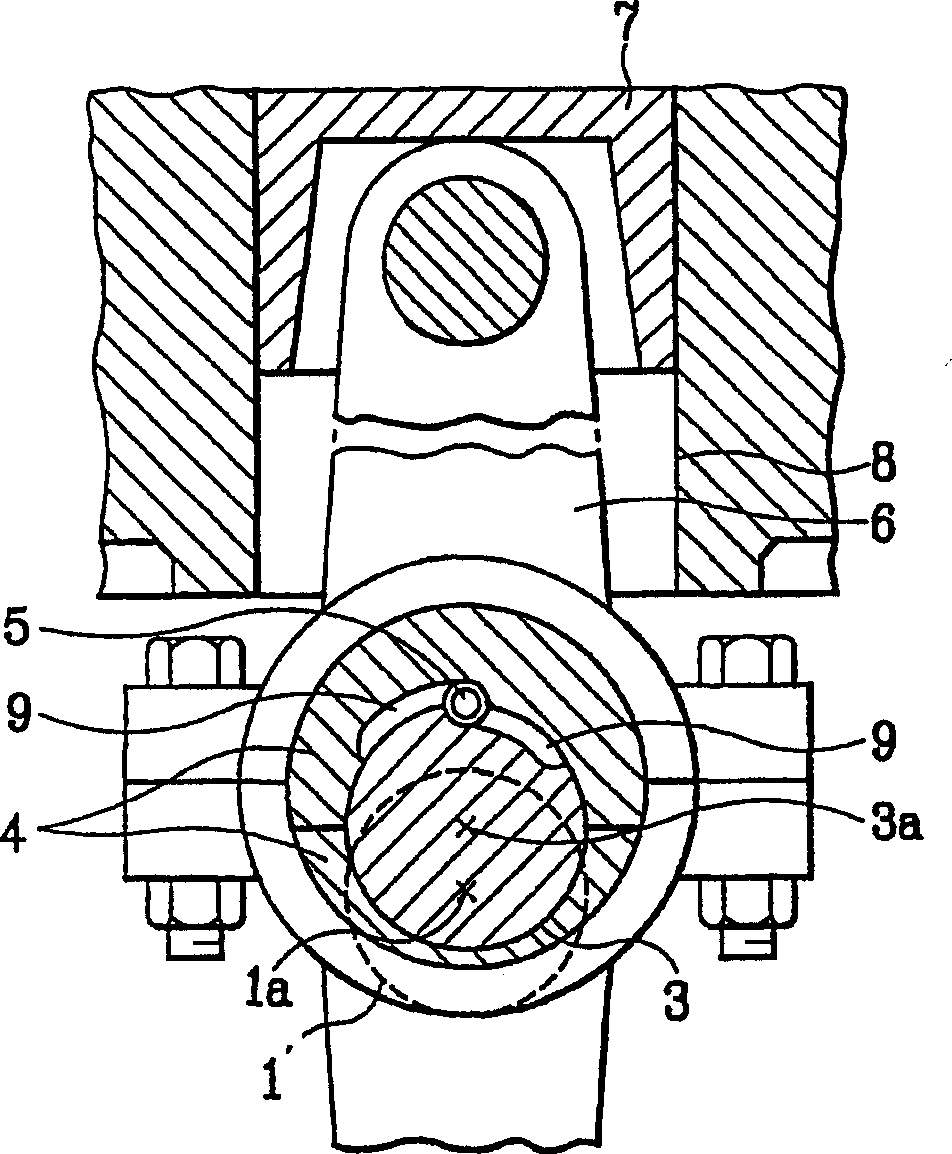

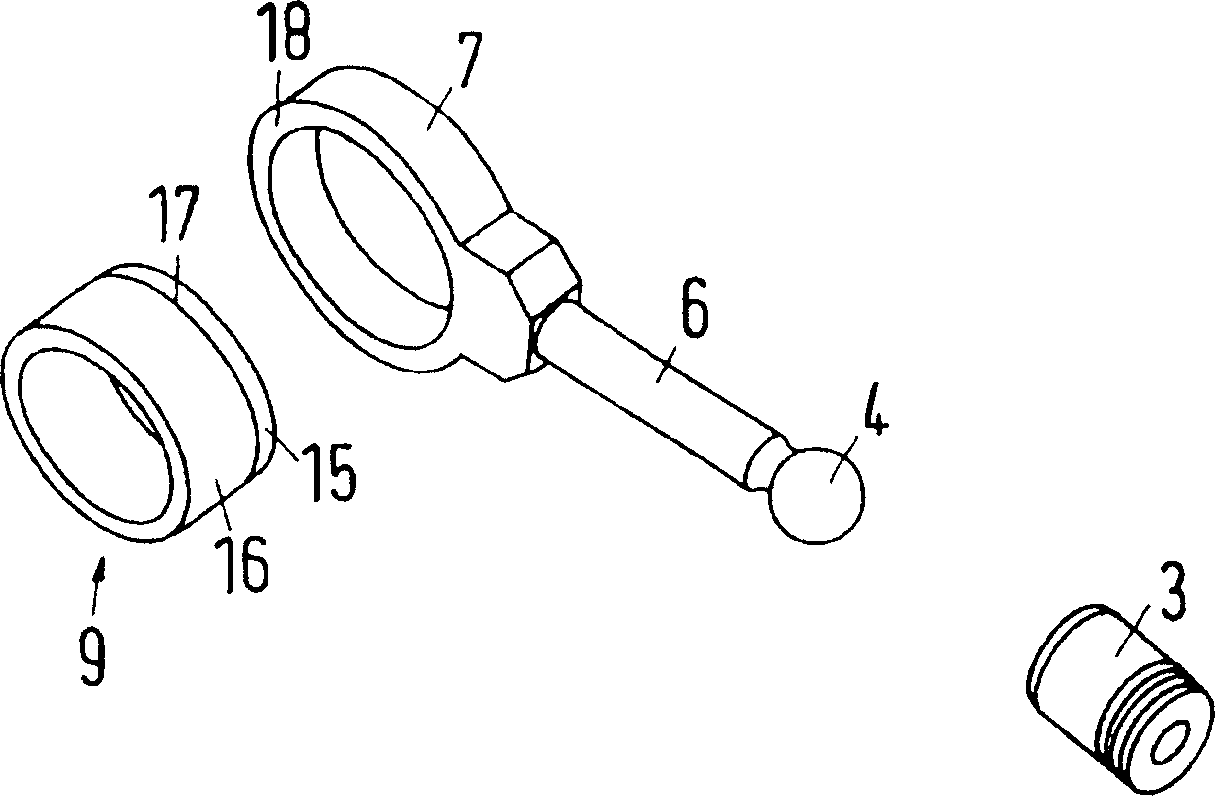

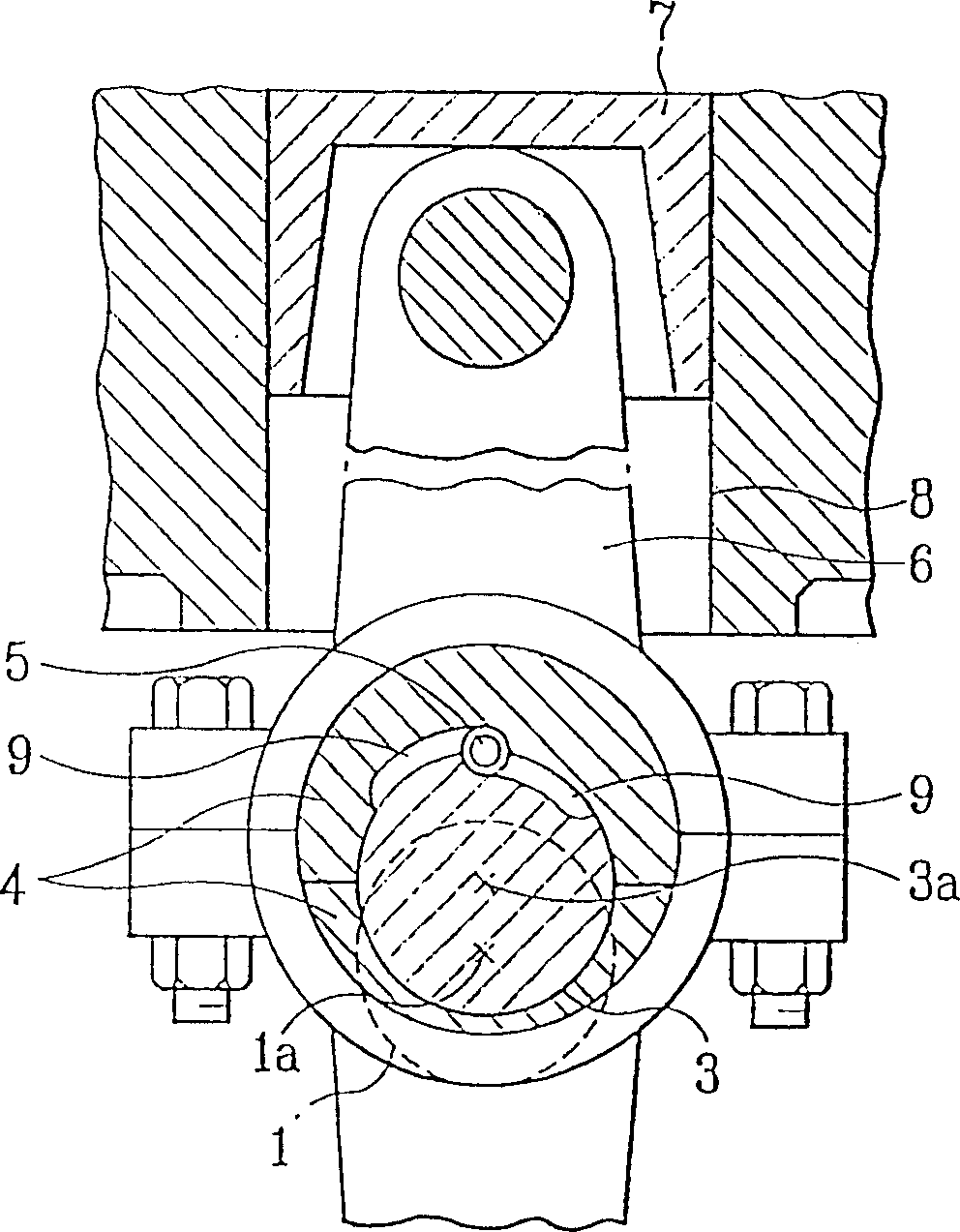

Piston type compressor and assembling method thereof

InactiveCN1740565APrecise positioningEasy to assembleConnecting rod bearingsRotary bearingsMechanical engineeringCrankshaft

The piston (3) is moved inside a cylinder of a refrigerant condensing device assembled of a crankshaft with a crank pin accommodated inside an eye (7) at the connecting rod (6) and a bearing bush (9) between the pin and the eye (7). The outer surface of the pin and the inner surface of the eye (7) are asymmetrically arranged. The outer surface of the bearing bush (9) is divided into a shallow sliding segment (15) and a higher main segment (16) facilitating a convenient positioning before the final pressing.

Owner:SECOP GMBH

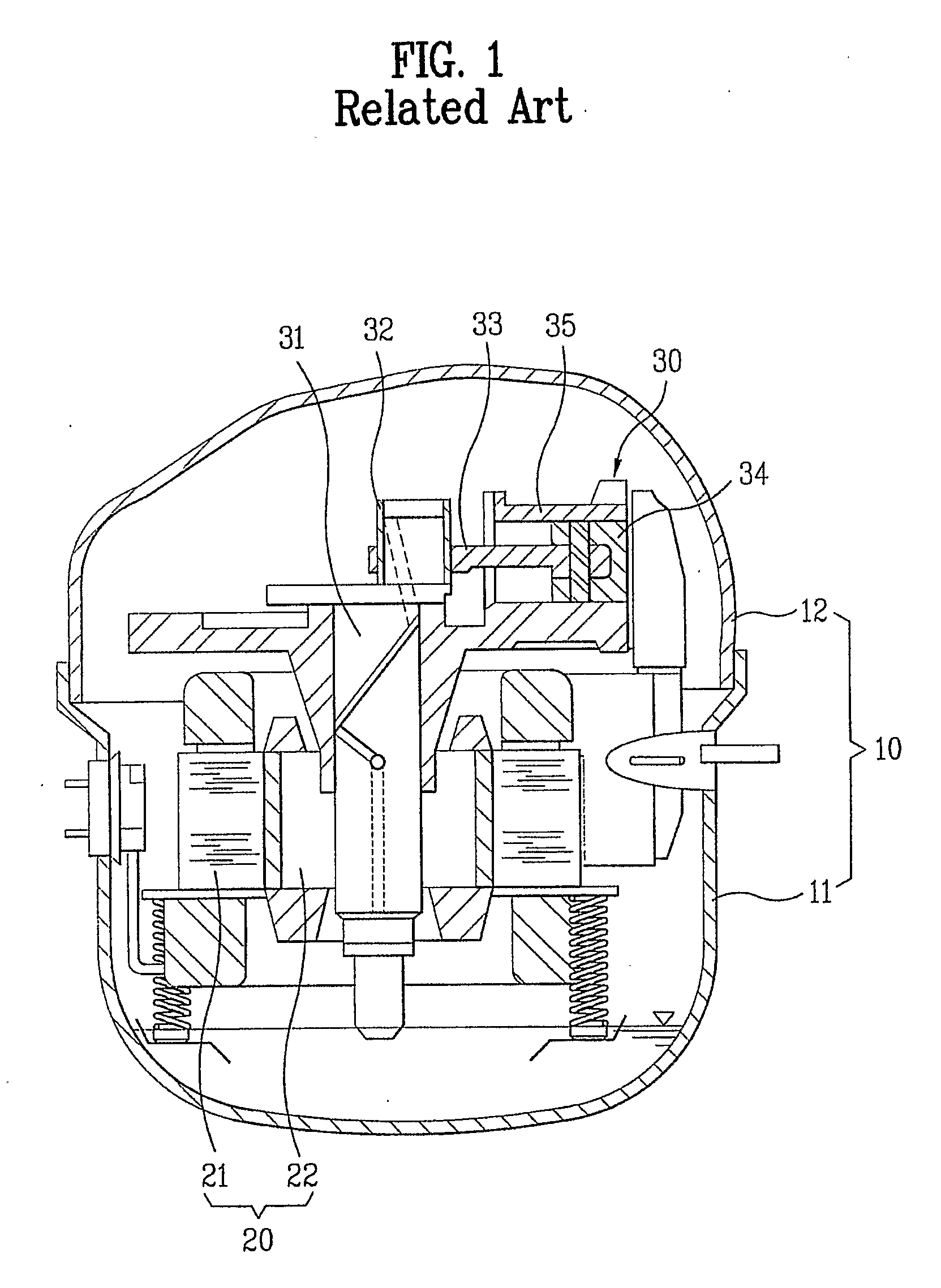

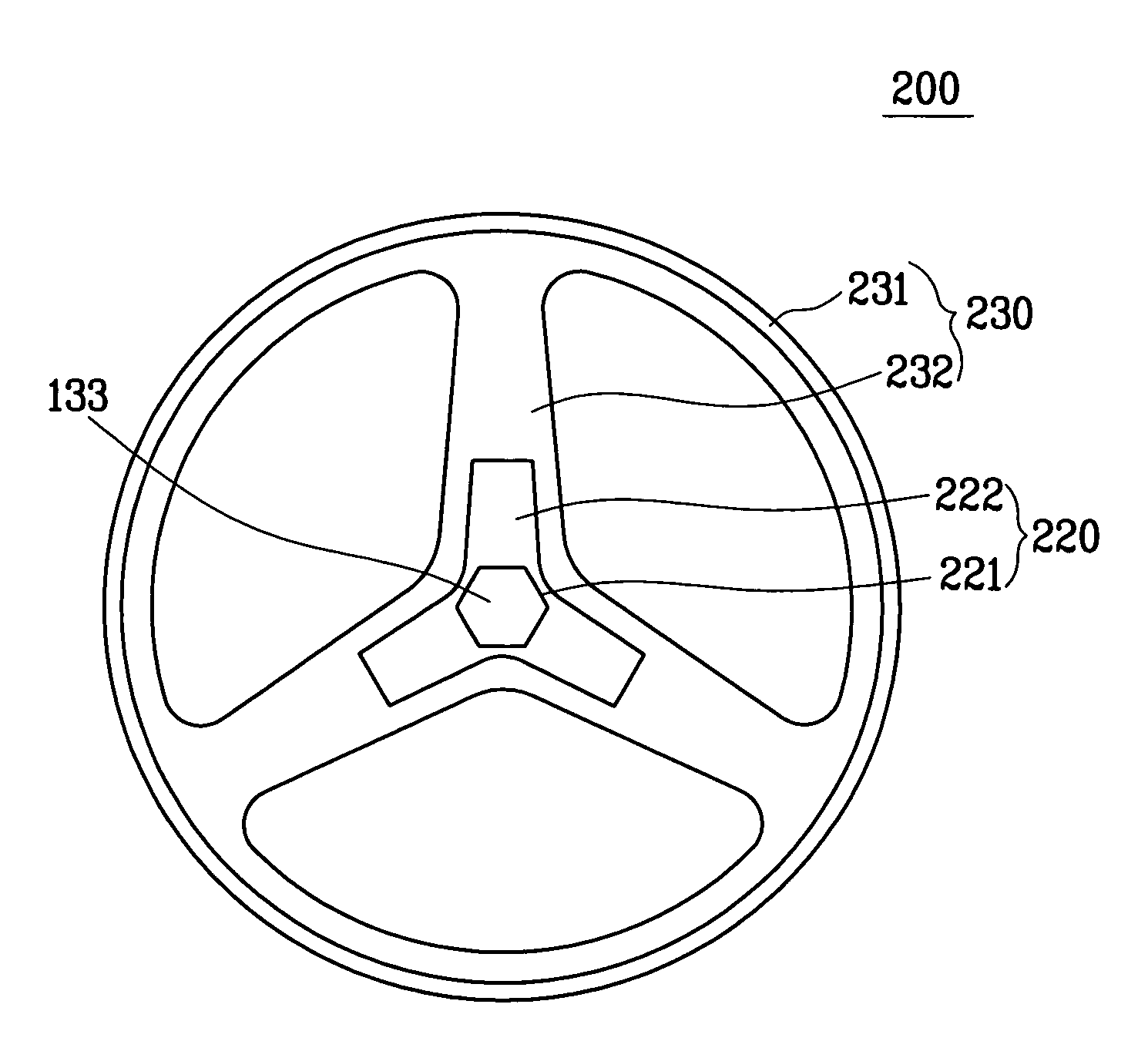

Dual capacity compressor

InactiveCN1708646AEasy to operateImprove operational efficiencyPositive displacement pump componentsEngine fuctionsEngineeringCrankshaft

The dual capacity compressor comprises a power generating section (20) having a reversible electric motor (21, 22) and a crankshaft (23) embedded in the electric motor (21, 23); a compression section (30), It has a cylinder (32), piston (31) and connecting rod (33); a crank pin (110) located on the upper part of the crankshaft (23), which is eccentric to the axis of the crankshaft; an eccentric sleeve (120), which The barrel is rotatably engaged with the crank pin (110) and the connecting rod (33) respectively; the key member (130) is used to rigidly fasten the eccentric sleeve (120) to the crank pin in all directions of rotation of the motor (110); and an eccentric block (200) arranged on the eccentric sleeve (120), the eccentric block is used to make the eccentric sleeve (120) rotate around the crank pin (110). Thereby preventing the relative movement between the components to maintain a constant eccentricity and allow the components to move smoothly.

Owner:LG ELECTRONICS INC

Eccentric wheel with adjustable eccentric distance

PendingCN110439916AEasy to adjustSave replacementCranksEccentricsAgricultural engineeringGravity center

The invention discloses an eccentric wheel with the adjustable eccentric distance. The eccentric wheel comprises a disc, a motor, a lead screw, a sliding block and a dovetail groove clamp. The motor,the lead screw, the sliding block and the dovetail groove clamp are arranged in the disc, the motor is fixed to the center position of the disc, the lead screw is connected to the motor, the sliding block is connected with the lead screw, and the dovetail groove clamp is arranged in the disc in order to prevent the sliding block from disengaging. When the eccentric distance of the eccentric wheelneeds to be adjusted, the eccentric distance is changed by controlling the motor, the gravity center of the eccentric wheel is conveniently adjusted, inconvenience caused during replacement and manualadjustment is omitted, and the working efficiency is improved.

Owner:SOUTHWEST JIAOTONG UNIV

Locking device for dual capacity compressor

InactiveCN1566650AIncreased durabilityFunction increasePositive displacement pump componentsCranksEngineeringMechanical engineering

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com