Bicycle pedal crank, intermediate product and method for manufactoring such a pedal crank

A bicycle and crank arm technology, applied in the field of bicycle crank arms, can solve problems such as wasting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

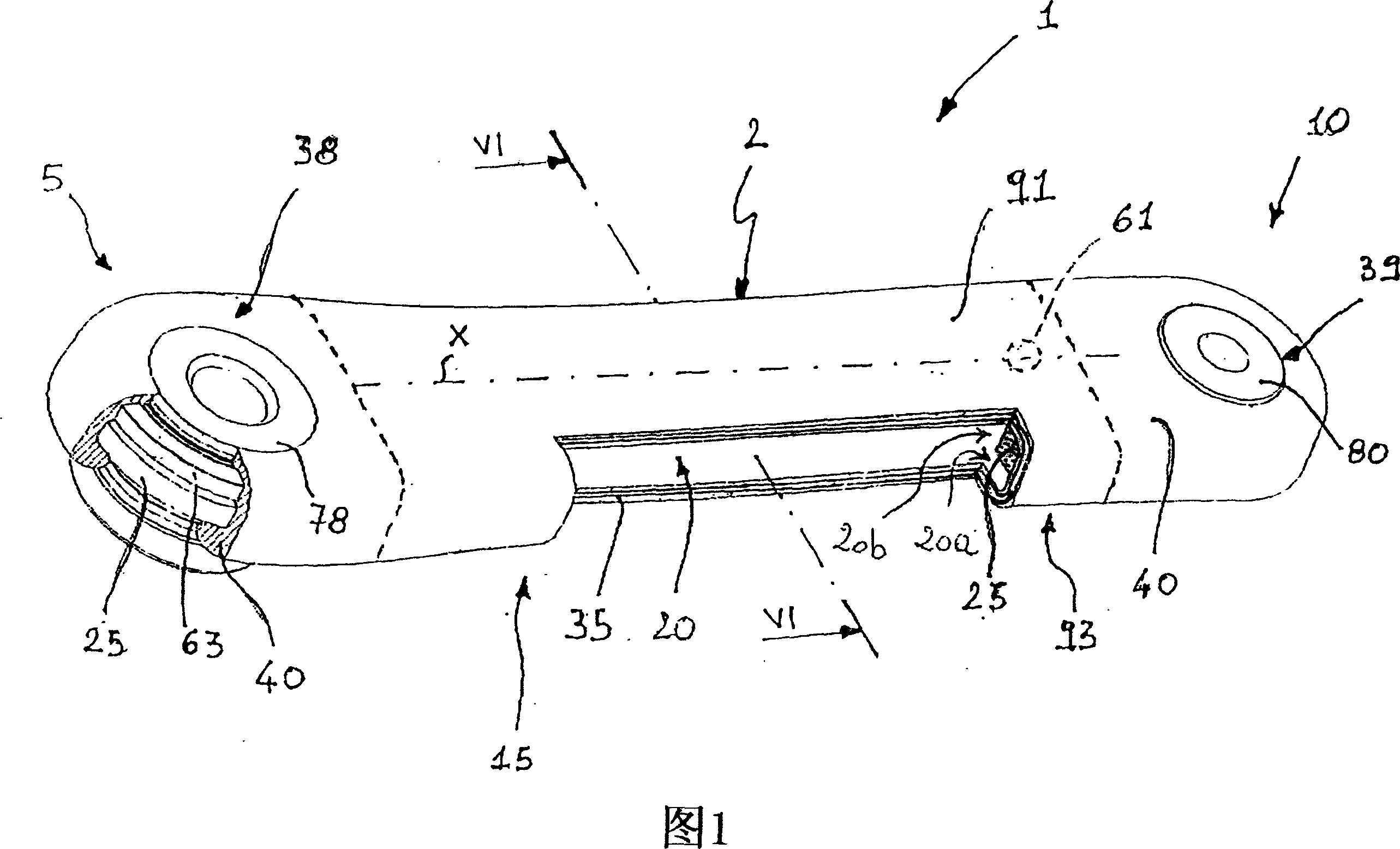

[0111] Referring to FIG. 1 , the bicycle crank arm according to the present invention, especially the left crank arm is indicated by 1 as a whole.

[0112] The crank arm 1 comprises an elongated body 2 extending along a longitudinal axis X-X and having a first end 5 comprising a first base 38 for coupling to a bicycle bottom bracket assembly (not shown), including a first base 38 for coupling to a pedal A second end 10 of a second base 39 (not shown), and an intermediate portion 15 extending between the ends 5 , 10 . On the crank arm 1 , a front surface 91 is defined which faces outwards when fitted to a bicycle, and a rear surface 93 which faces towards the bicycle frame when fitted to a bicycle.

[0113] The elongated body 2 is made in a single piece of composite material comprising structural fibers incorporated in a polymeric material. Typically, the structural fibers are selected from the group consisting of carbon fibers, glass fibers, aramid fibers, ceramic fibers, bor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com