Pivoting Variable Cam Follower

一种凸轮随动件、可变的技术,应用在凸轮随动件、凸轮、发动机元件等方向,能够解决挺杆/凸轮接触系统没有经历实施方案或成功、缺乏成功等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

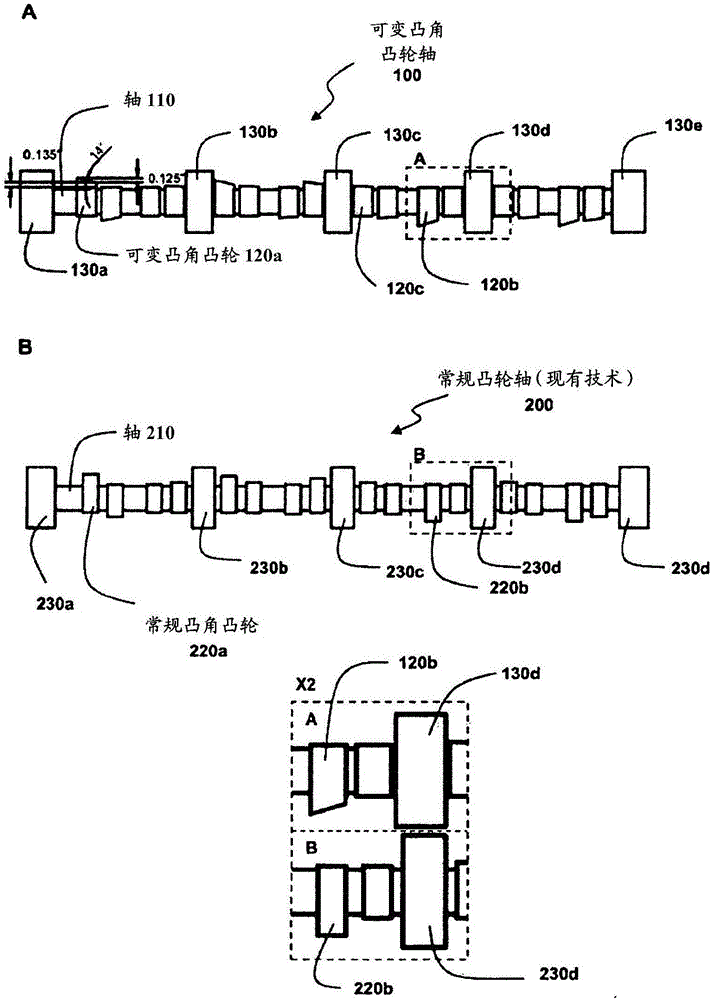

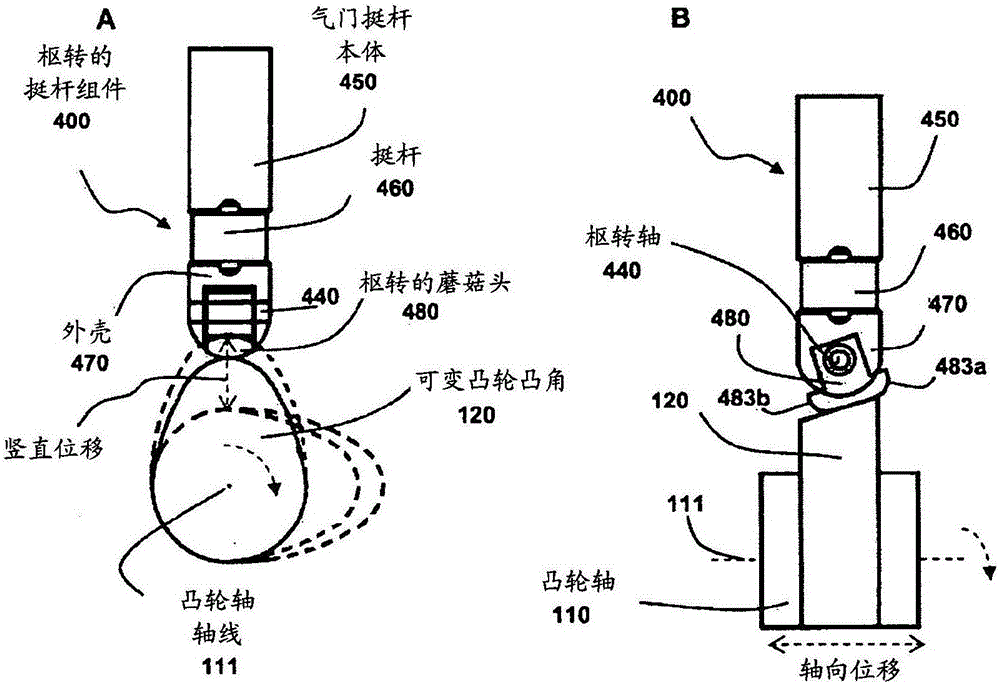

[0062] Fundamental

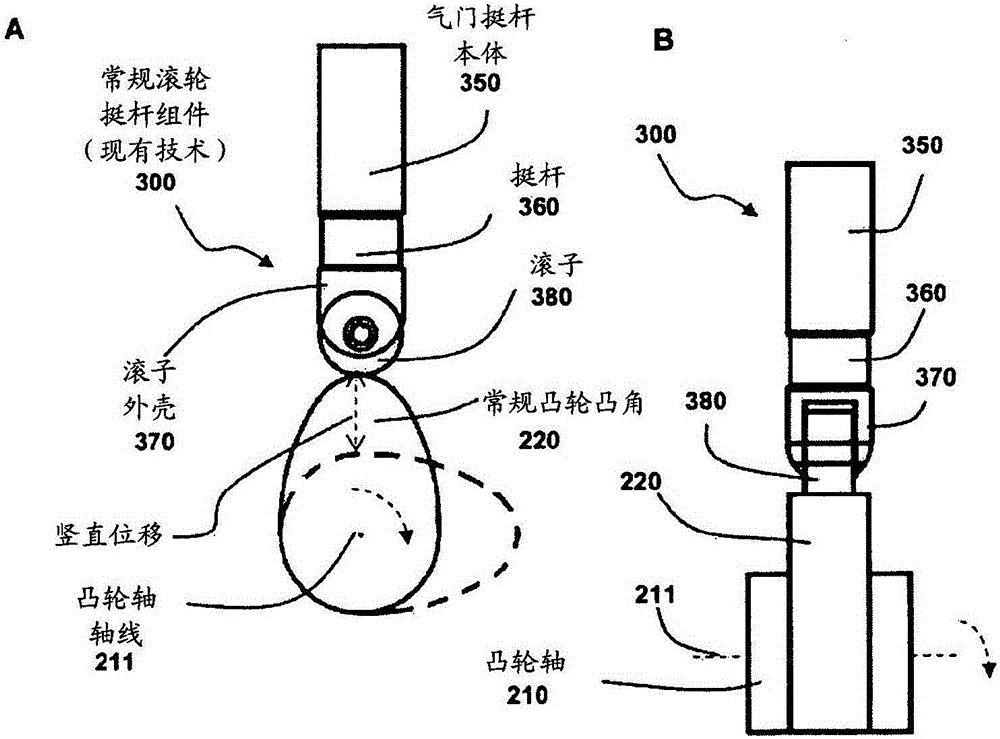

[0063] Axial displacement of the camshaft has been accomplished by pushing against a clutch-like bearing assembly using hydraulic pistons or mechanical actuators. The actuation may be provided automatically with respect to the change in rotational speed or linked to the throttle position. It will be appreciated that springs may be used to restore and resist valve movement. Airbags, hydraulic systems and track systems can replace springs for this type of variable valve technology. Variations in valve timing during engine operation allow engine performance to be modified to match operating conditions. Variations in the relative shape of a given cam within a variable cam system may enable independent phasing of the intake cams, independent phasing of the exhaust cams, equal phasing of the intake and exhaust, or phasing of the exhaust and exhaust cams. The intake cams are phased independently of each other.

[0064] In previous efforts to produce improved ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com