VVT (Variable Valve Timing) control method capable of combining self-learning feed-forward and active anti-interference feedback

A technology of feed-forward control and feedback control, applied in engine control, combustion engine, machine/engine, etc., can solve problems such as poor stability, repeated oscillation of the system, and inability to effectively compensate, and achieve avoidance of adjustment, low energy consumption, and improved control The Effect of Accuracy and Response Speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

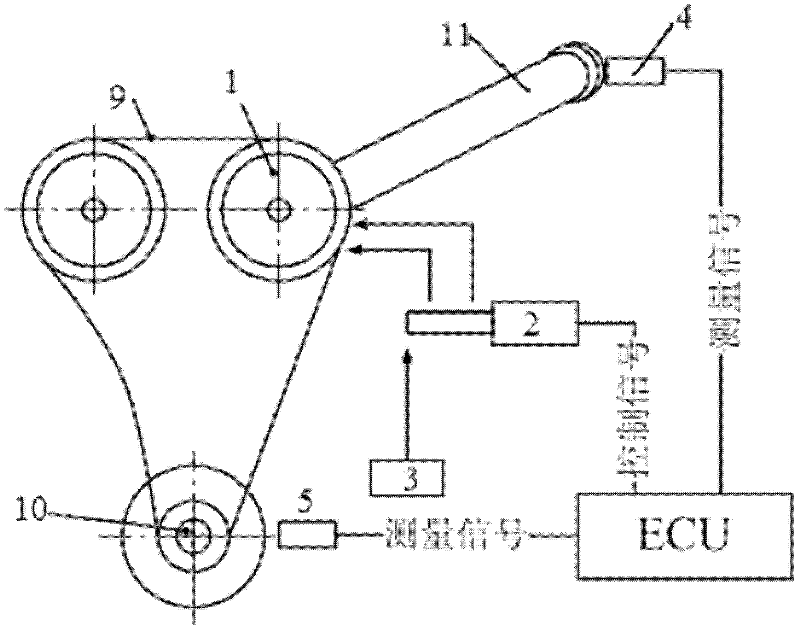

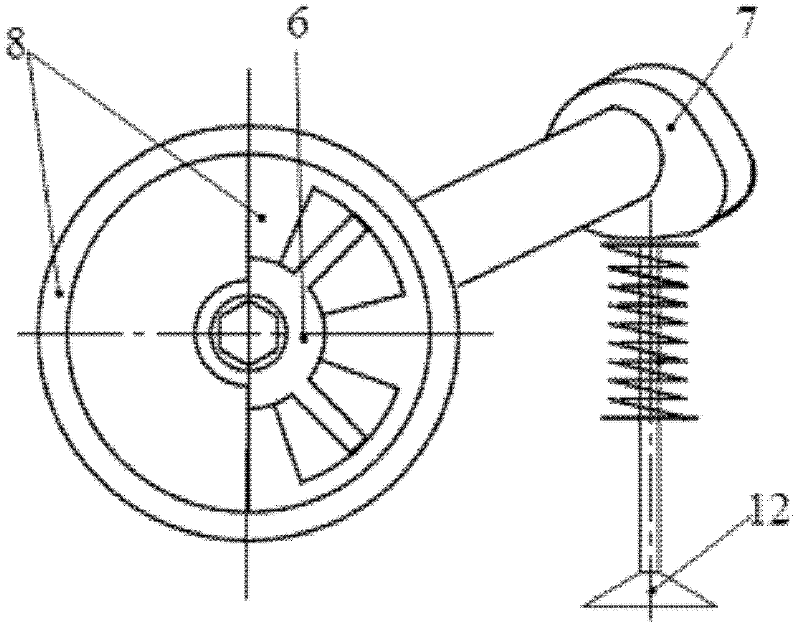

Method used

Image

Examples

Embodiment

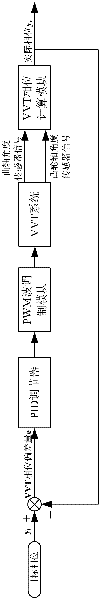

[0086] First, the target phase y of the current VVT system is calculated by the external module t ;

[0087] (1) Feedforward control

[0088] The transition process design module designs the transition process curve θ=f(t) of the VVT system according to the target phase;

[0089] The drive torque calculation module calculates the angular velocity ω and the angular acceleration α of the VVT system at the current moment according to the transition process curve θ=f(t) of the VVT system, so as to calculate the drive torque T required by the VVT system at this time;

[0090] The hydraulic oil flow calculation module calculates the hydraulic oil flow Q required by the VVT system at this time according to the drive torque T required by the VVT system calculated by the drive torque calculation module;

[0091] The solenoid valve current calculation module can calculate the current I of the solenoid valve of the VVT system according to the hydraulic oil flow Q required...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com