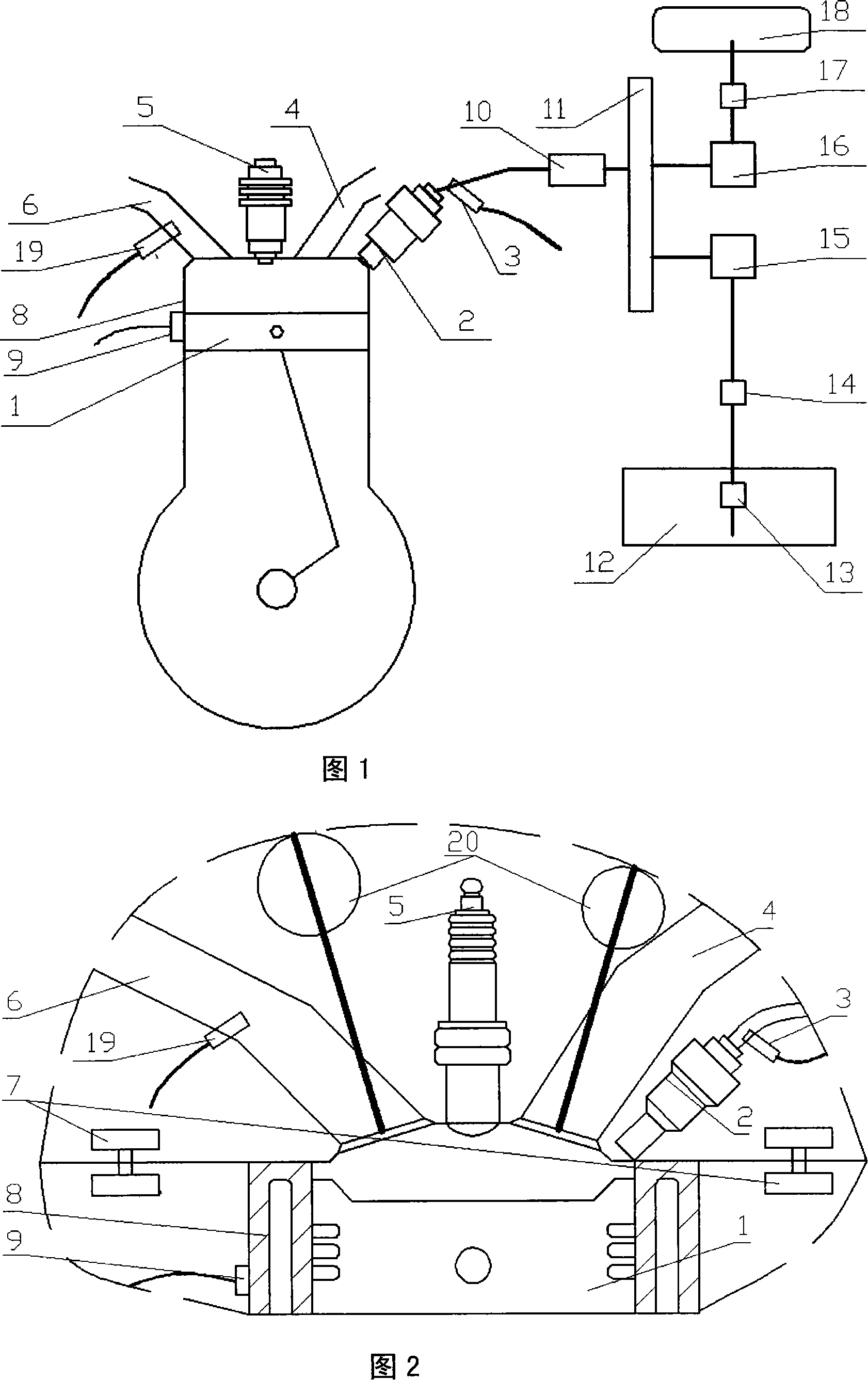

Flexible fuel engine with alterable compression ratio and control method thereof

A technology of flexible fuel and control method, applied in the direction of engine control, combustion engine, internal combustion piston engine, etc., which can solve the problems of prone to knocking, low thermal efficiency, and inability to adapt to the combustion characteristics of different fuels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

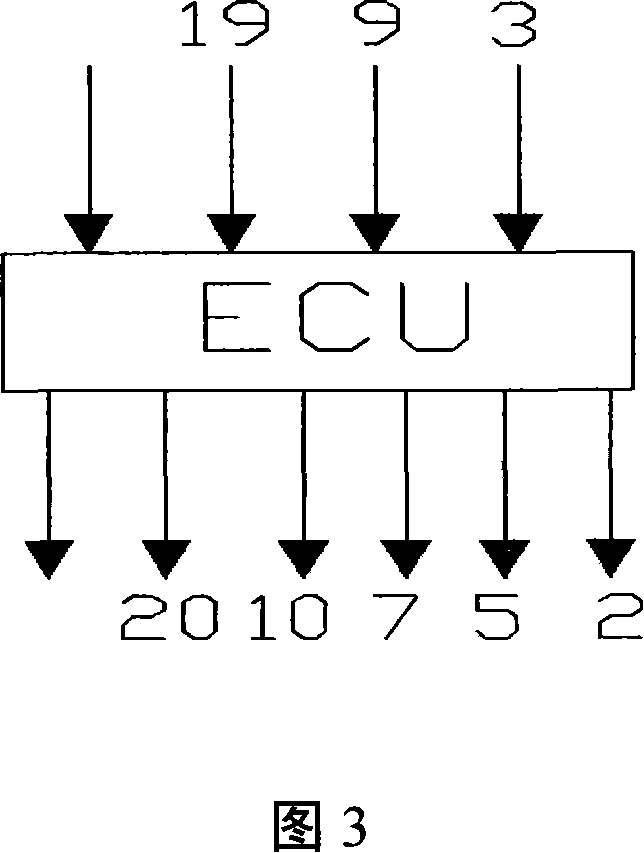

[0018] Embodiment 1: When gasoline fuel is used, the engine ECU receives the signal returned by the fuel sensor, adjusts the engine compression ratio to 8-10 through adjustment method 1 or adjustment method 2, and adjusts the combustion control strategy at the same time, and through VVT The mechanism adjusts the valve timing of the engine. At the same time, adjust the injection pressure of the fuel injector at 5-6MPa to adapt to the combustion characteristics of gasoline fuel.

Embodiment approach 2

[0019] Embodiment 2: When diesel or biodiesel fuel is used, the engine ECU receives the signal returned by the fuel sensor, adjusts the engine compression ratio to 14-18 by adjusting mode 1 or mode 2, and adjusts the combustion control strategy at the same time, And adjust the engine valve timing through the VVT mechanism. At the same time, adjust the injection pressure of the fuel injector at 100-200MPa to adapt to the combustion characteristics of diesel or biodiesel fuel.

Embodiment approach 3

[0020] Embodiment 3: When methanol fuel is used, the engine ECU receives the signal returned by the fuel sensor, adjusts the engine compression ratio to 10-12 through adjustment method 1 or adjustment method 2, and adjusts the combustion control strategy at the same time, and through VVT The mechanism adjusts the valve timing of the engine. At the same time, adjust the injection pressure of the fuel injector at 5-6MPa to adapt to the combustion characteristics of methanol fuel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com