Recuperative combustion system

a combustion system and recuperative technology, applied in the direction of solid fuel combustion, combustion types, lighting and heating apparatus, etc., can solve the problems of unproven long-term subterranean cosub>2 /sub>storage on a scale of hundreds to thousands of years (required for carbon dioxide mineralization), and achieve the effect of reducing or eliminating the amount of oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

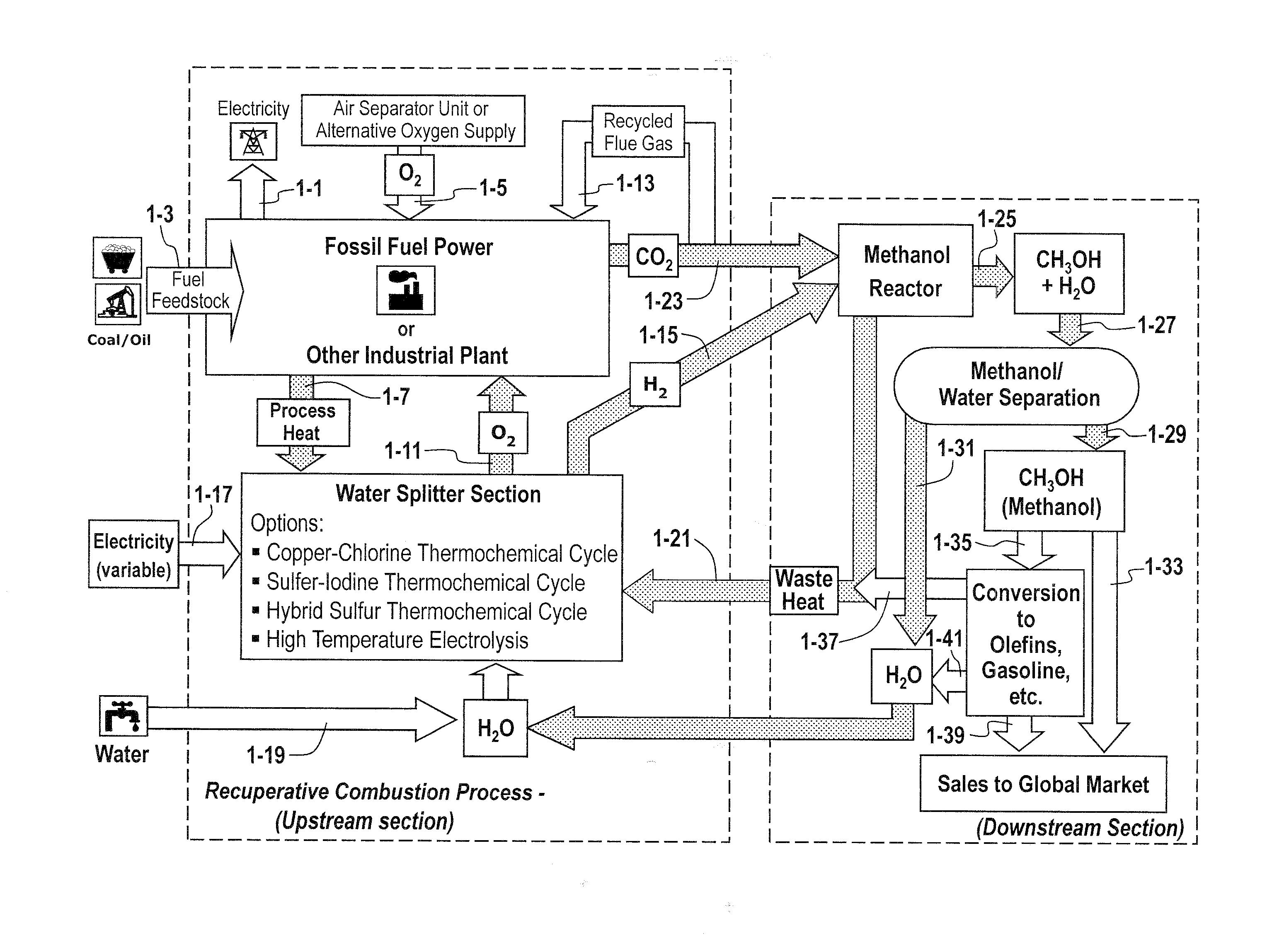

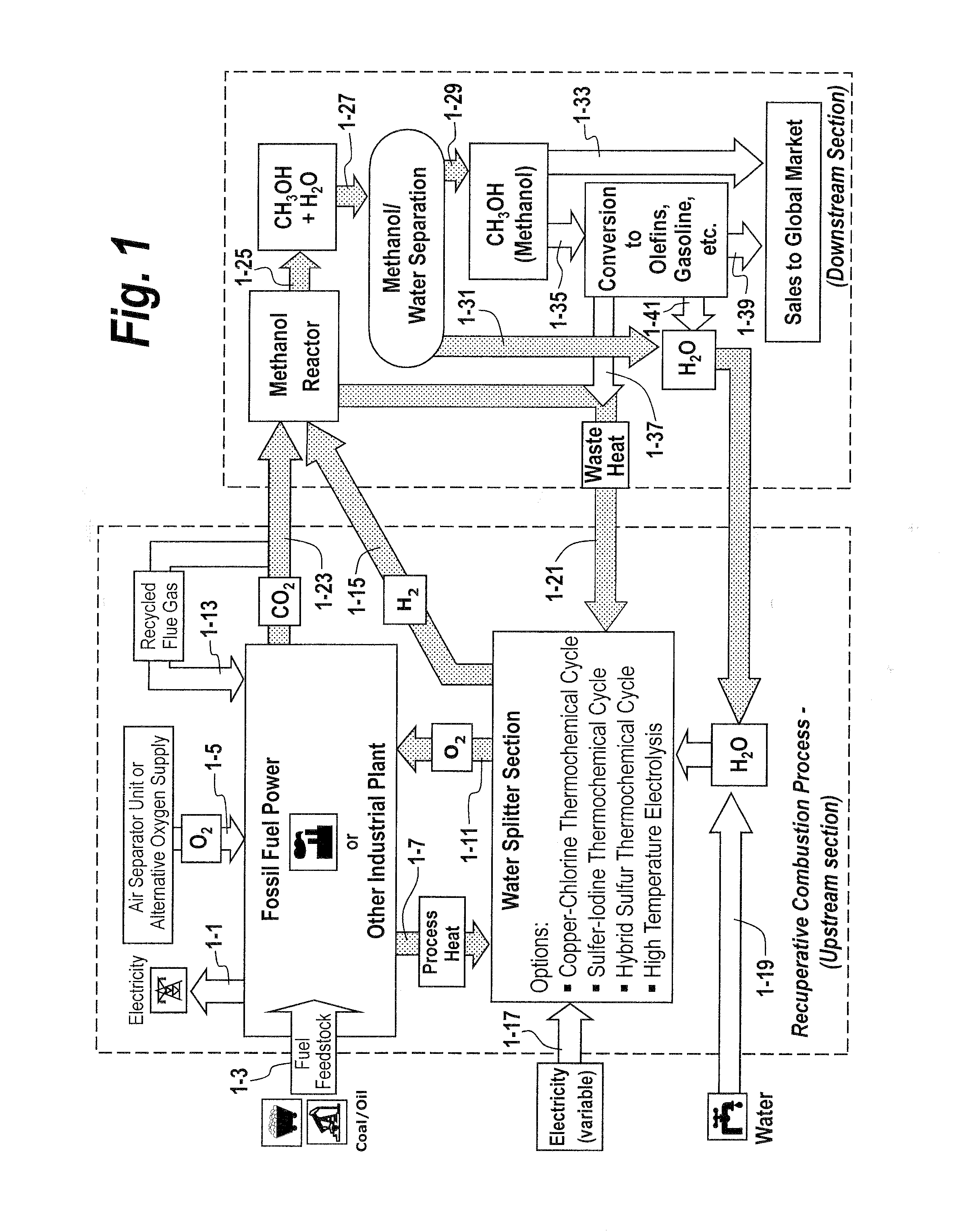

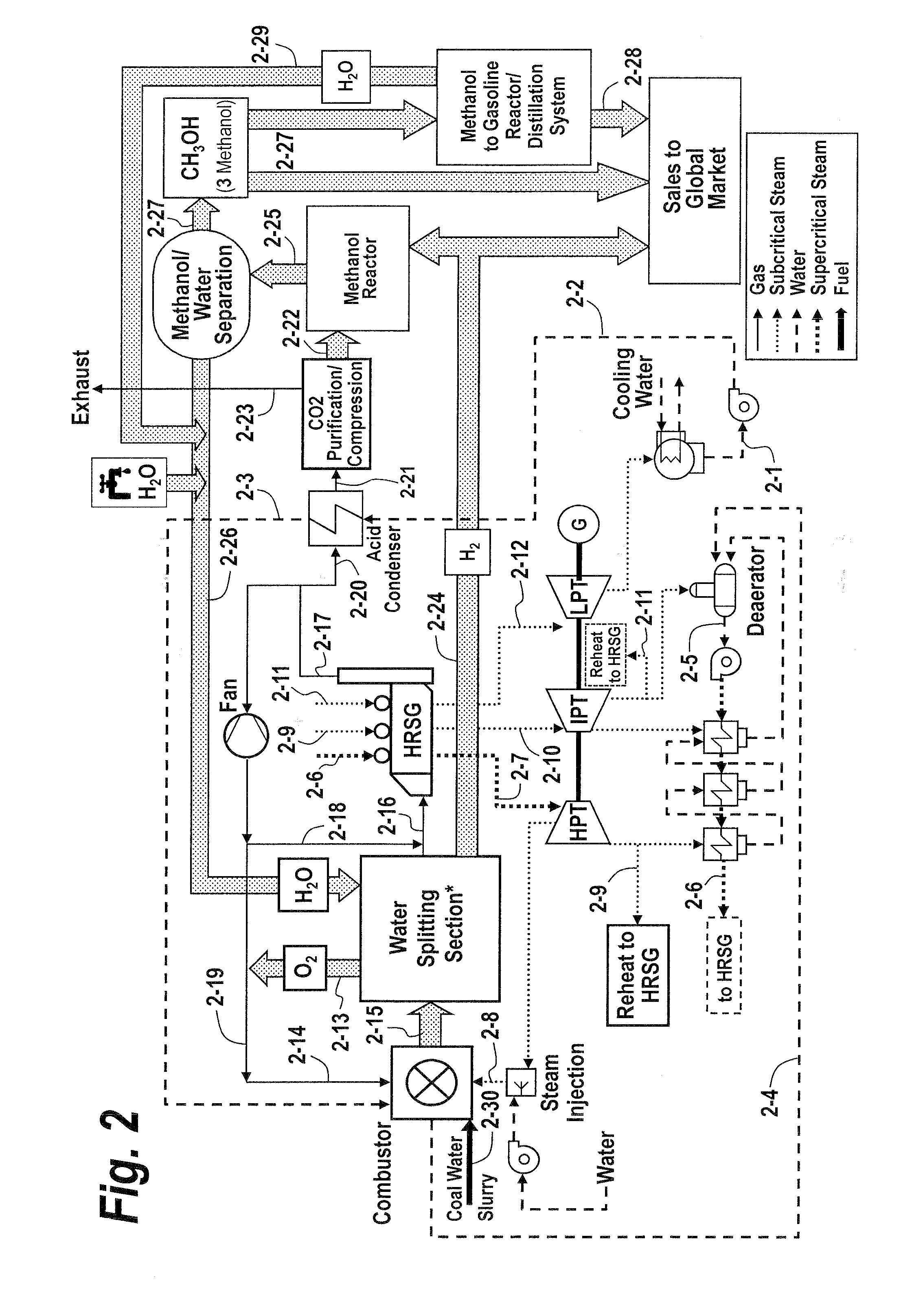

[0036]In one aspect, provided herein is a method for oxy-fuel combustion, comprising: providing a system comprising a combustion chamber arranged and disposed to receive fuel, oxygen and recycled flue gas and combust said fuel, oxygen and recycled flue gas to produce heat; capturing heat produced by the oxy-fuel combustion; using a portion of the heat to power a water splitter, thereby generating hydrogen gas and oxygen gas; and transferring the oxygen gas from the water splitter to the combustion chamber for use in said oxy-fuel combustion.

Combustion Chamber and Fuel

[0037]Oxy-fuel combustion for the production of electricity (FIG. 1-1) can occur in a variety of combustion systems. Non-limiting examples of combustion systems include: circulating fluidized bed boiler, pulverized coal boiler, and combustors. Combustible materials, including, but not limited to coal, coal / water slurry, petroleum products including oil, methane and natural gas, biomass, and plasma fuels (FIG. 1-3), may ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com