Patents

Literature

202 results about "High-temperature electrolysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-temperature electrolysis (also HTE or steam electrolysis) is a technology for producing hydrogen from water at high temperatures.

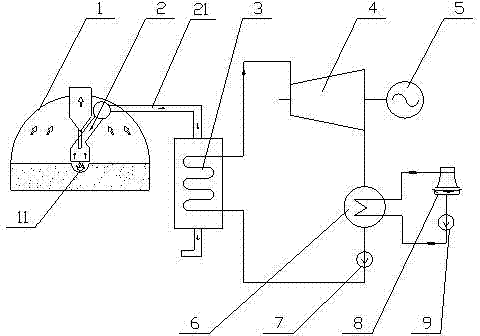

Recuperative combustion system

InactiveUS20110041740A1Reducing and eliminating amount of oxygenSolid fuel combustionIndirect carbon-dioxide mitigationOxygenDimethyl ether

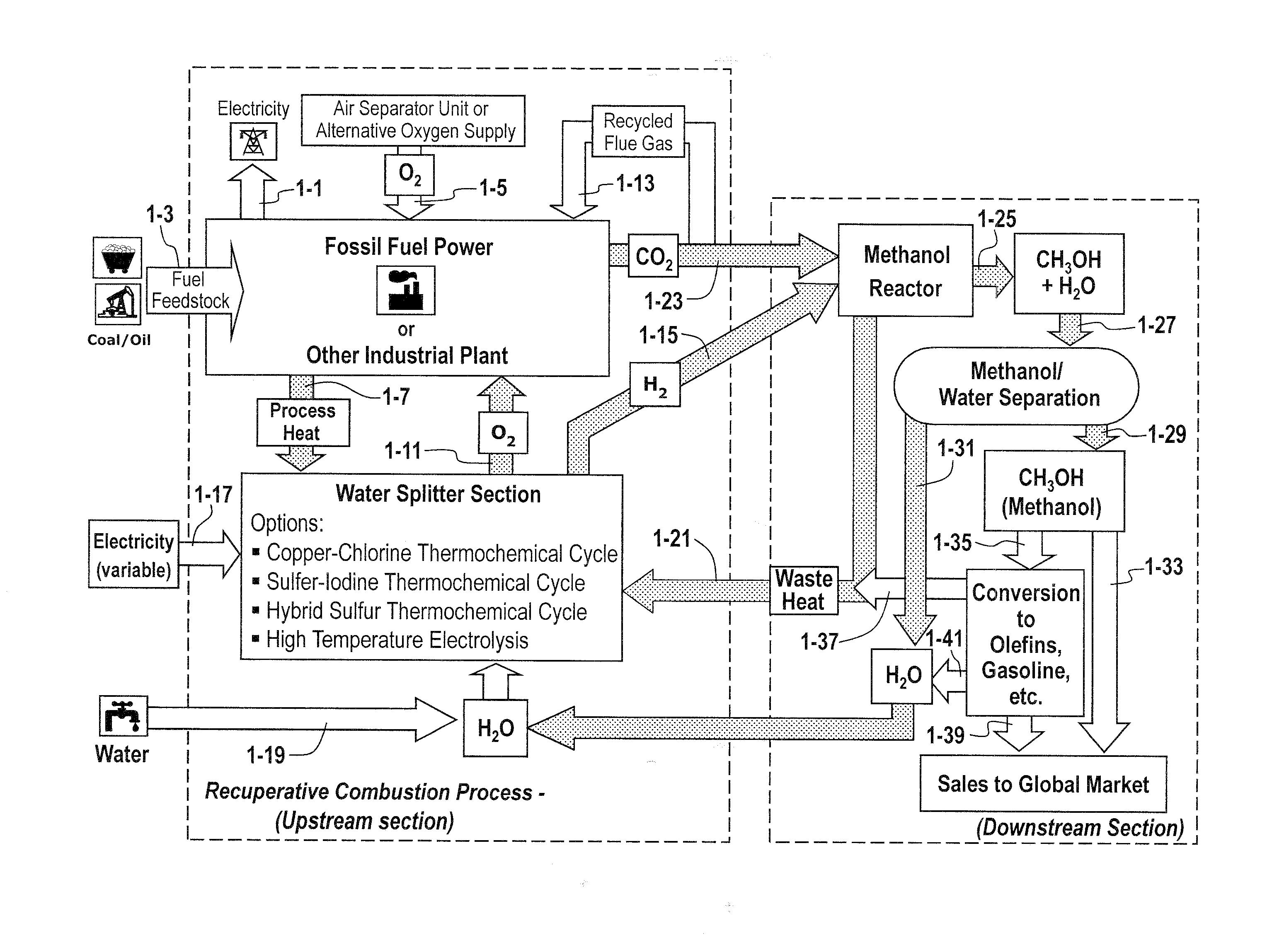

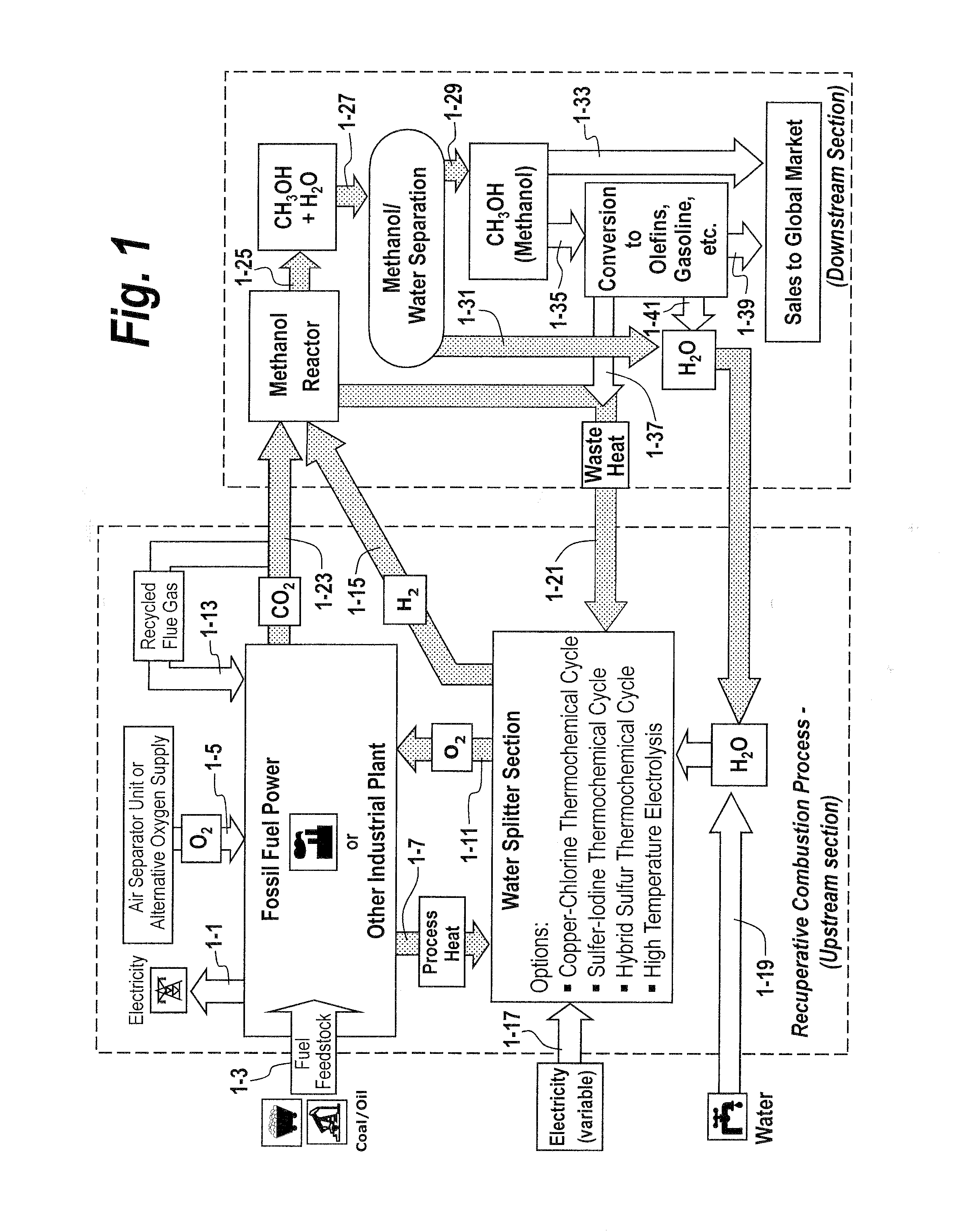

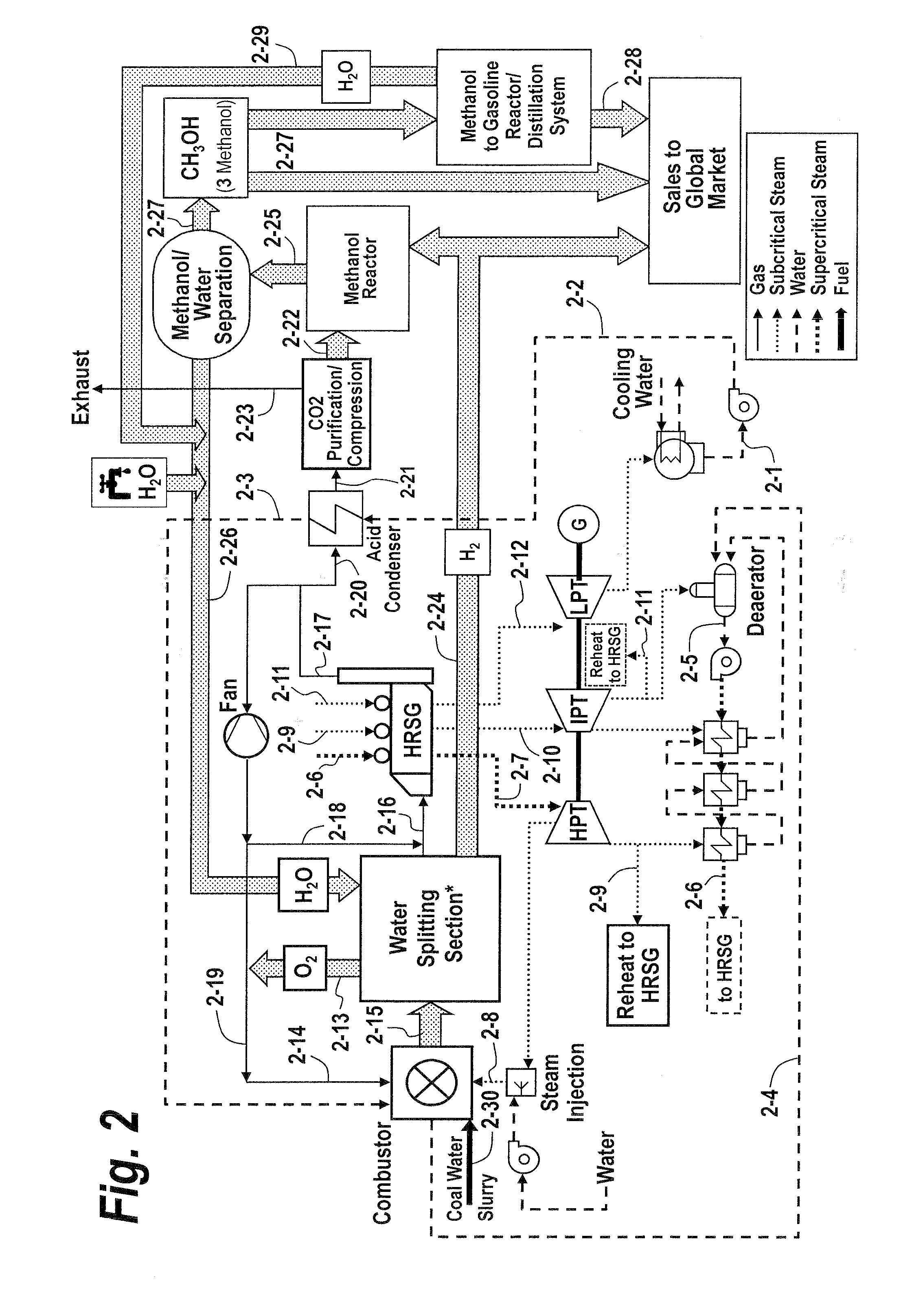

The methods and systems described herein relate to a recuperative combustion system that recuperates energy from fuel combustion that would otherwise be lost. The recuperative combustion system minimizes or eliminates the need for an air separator unit through the use of a clean water splitter section, consisting of a thermochemical cycle or high-temperature electrolysis. Water is split into its component hydrogen and oxygen, primarily with process heat from the combustion process. The oxygen produced by the water splitter provides oxygen necessary for oxy-fuel combustion, thereby reducing or eliminating the need for the power intensive air separator unit and / or external oxygen source, significantly increasing the efficiency of the oxy-fuel combustion cycle. Hydrogen produced by the water splitter may be used for a variety of industrial uses, or combined with carbon dioxide (captured from the flue gases produced by said combustion process) to produce methanol. Methanol can further be refined in a methanol to gasoline reactor to produce dimethyl ether, olefins or high grade gasoline. Described herein are methods and systems that 1) increase oxy-fuel combustion efficiency, 2) produce hydrogen for a suite of industrial / energy uses, and 3) capture carbon dioxide and convert it to high value hydrocarbons.

Owner:REILLY TIMOTHY J

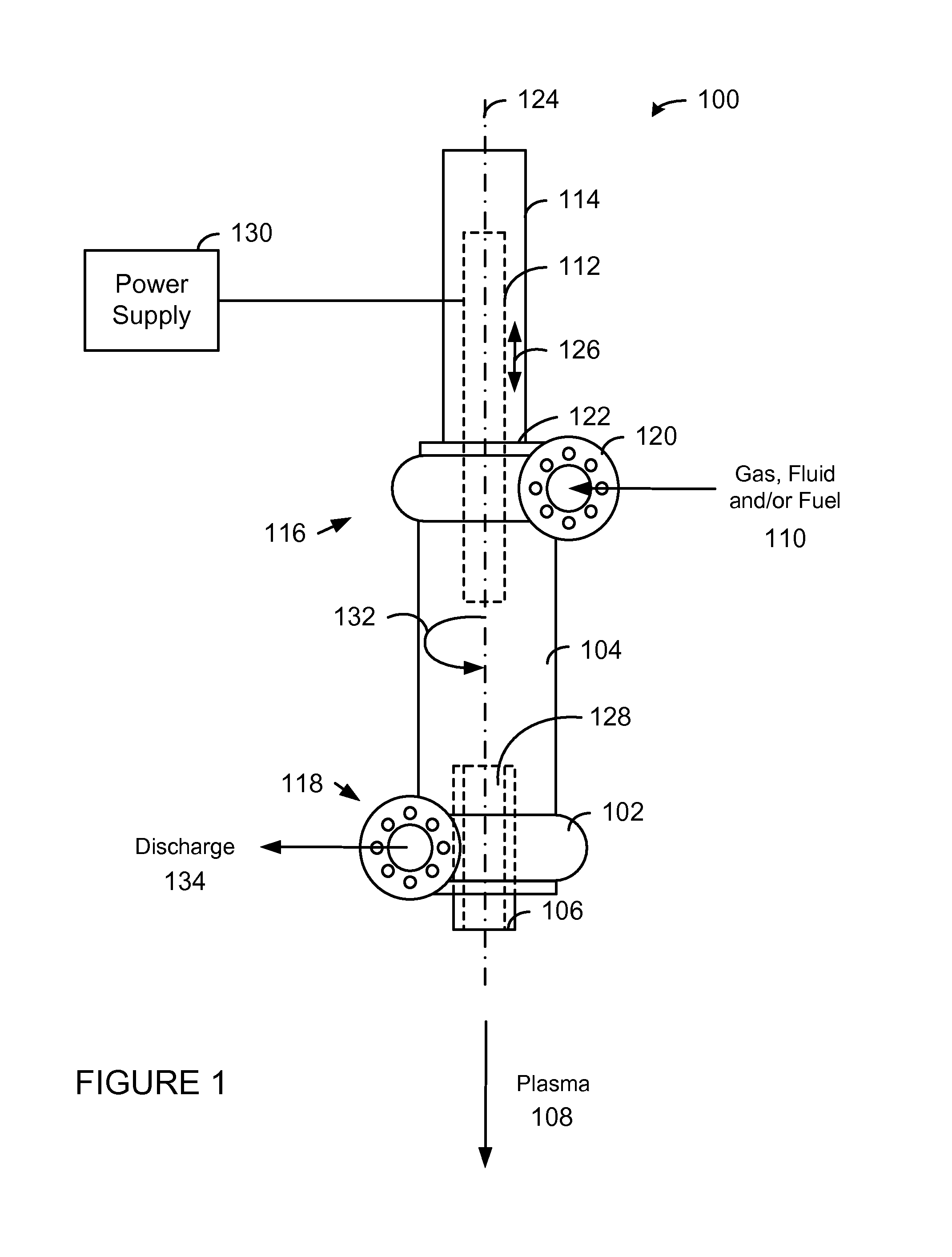

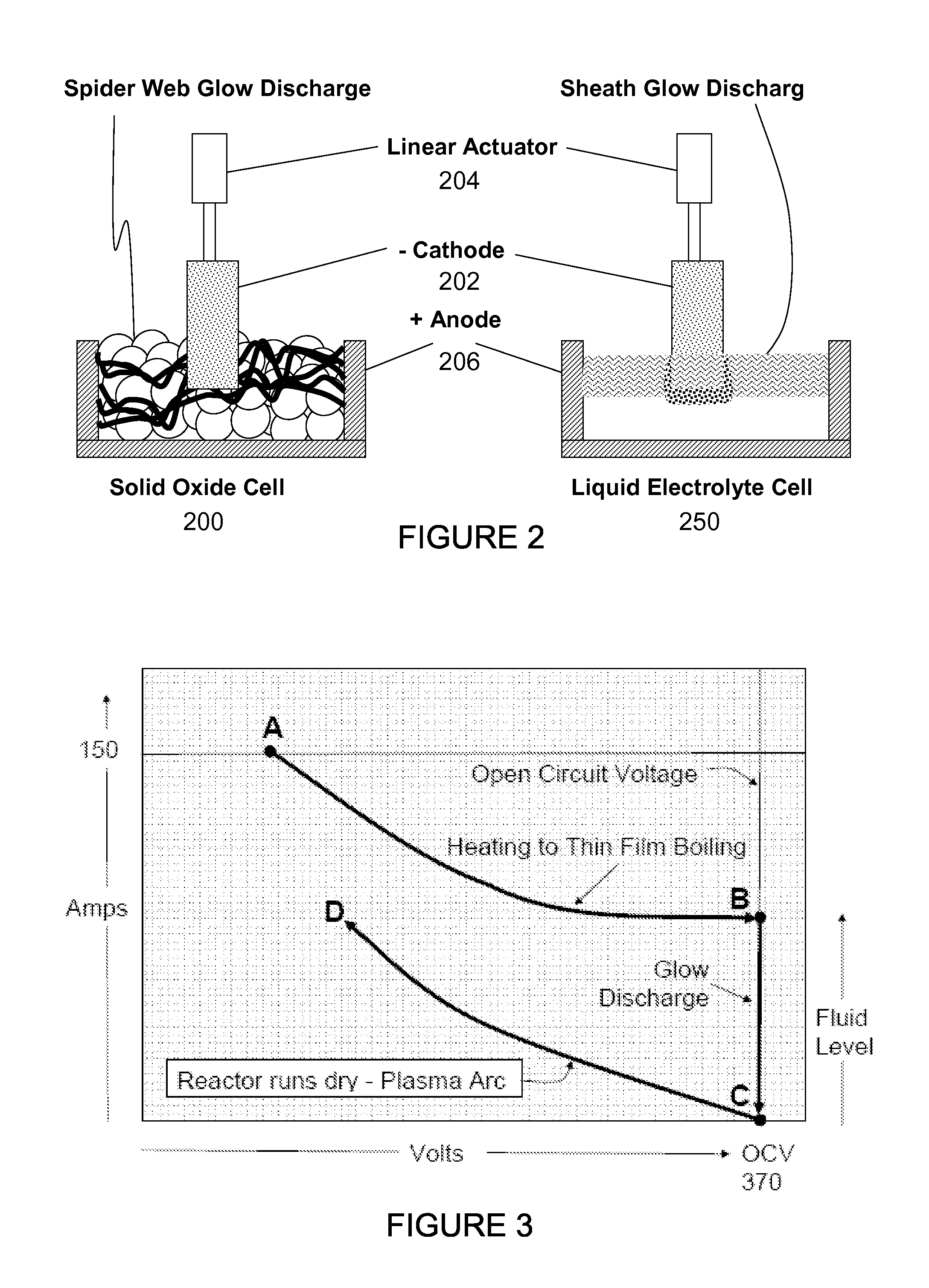

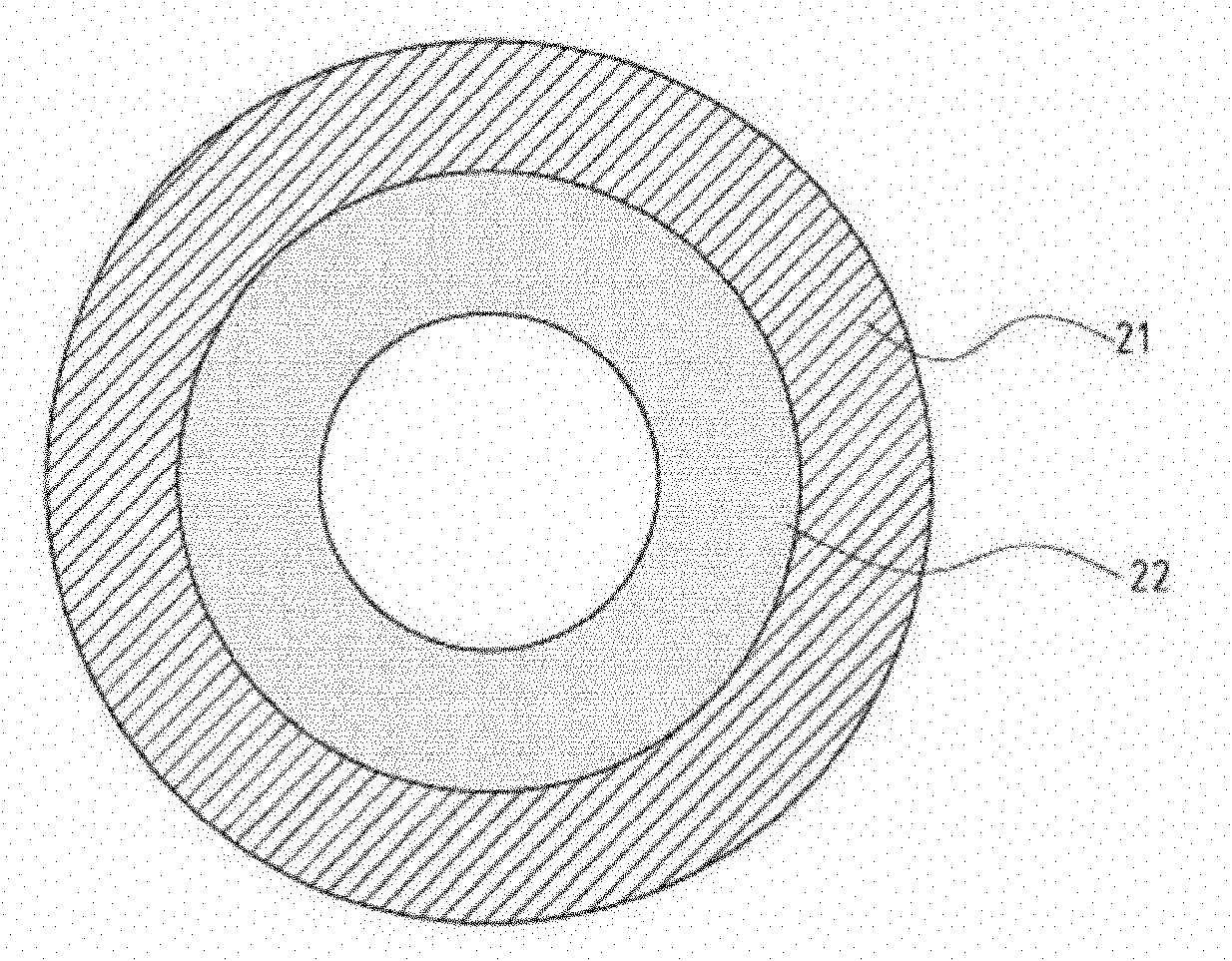

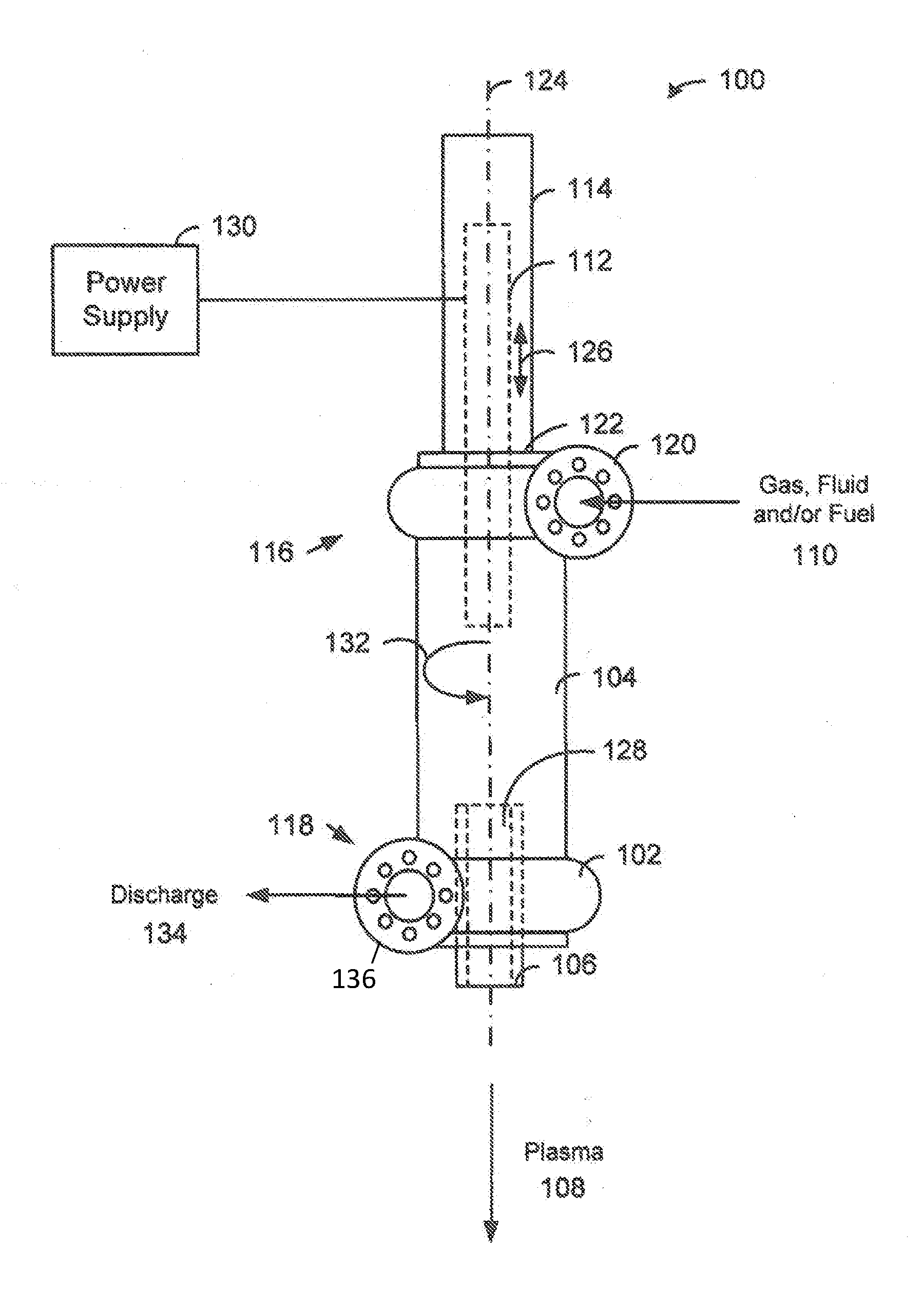

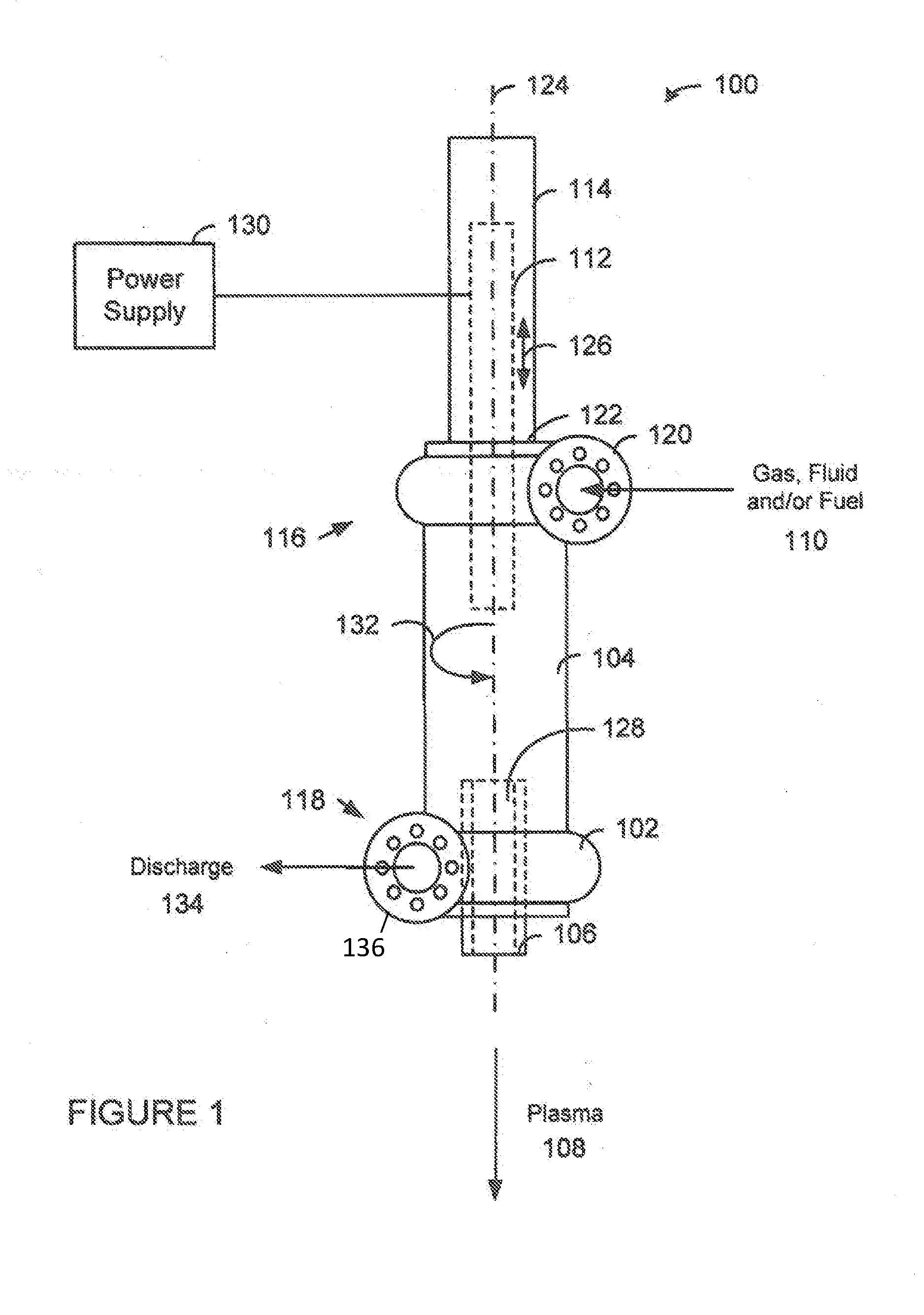

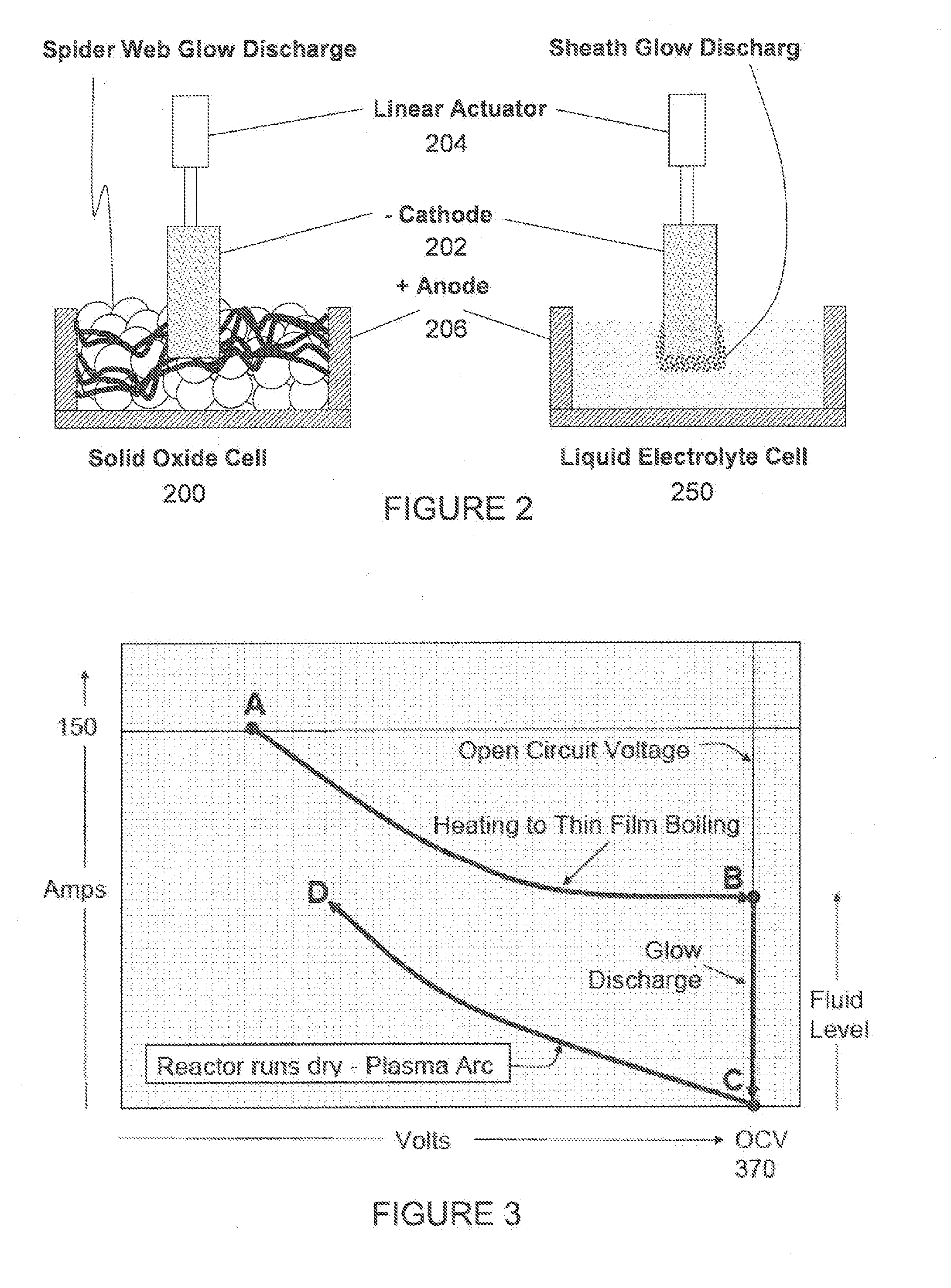

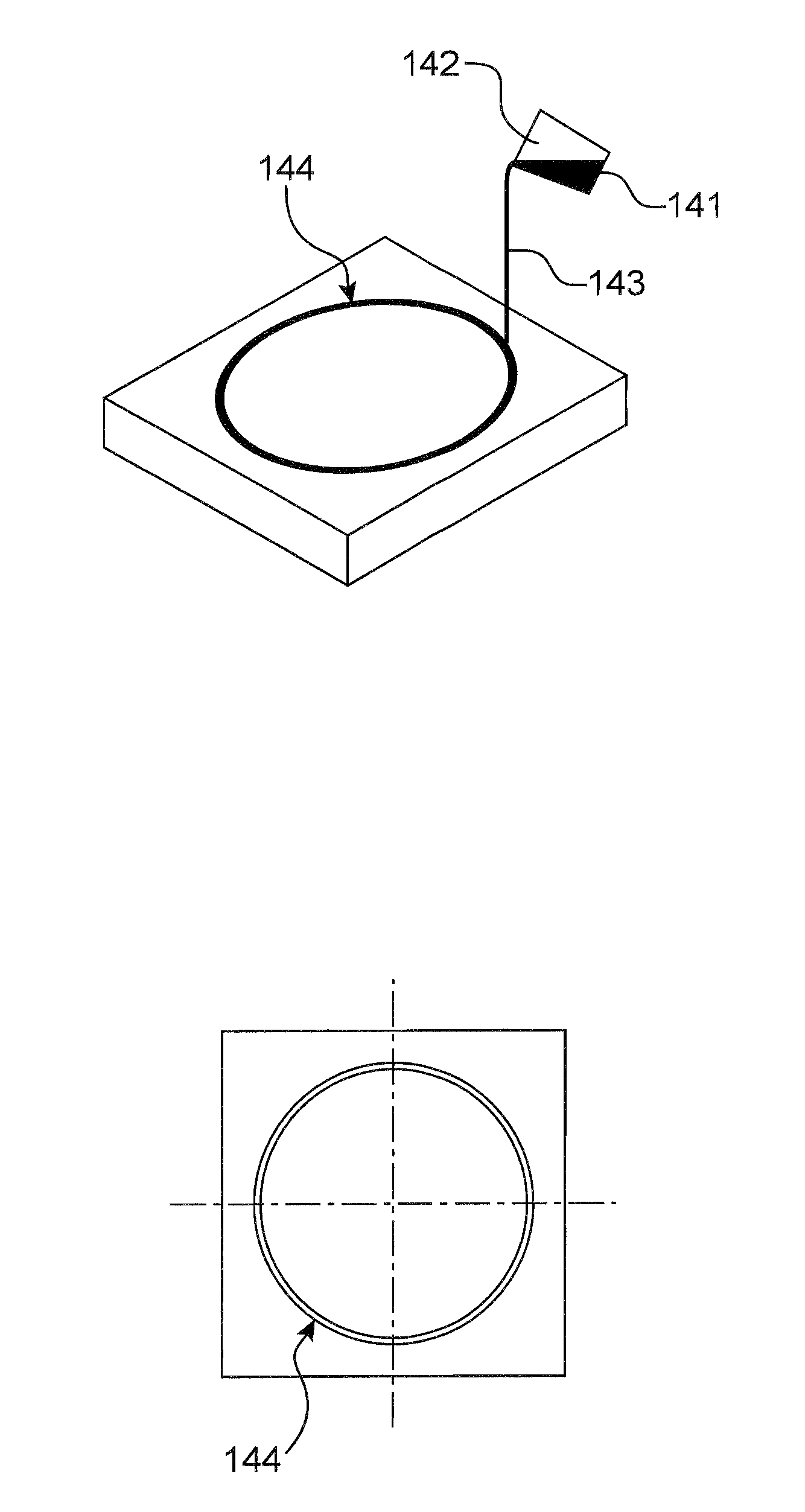

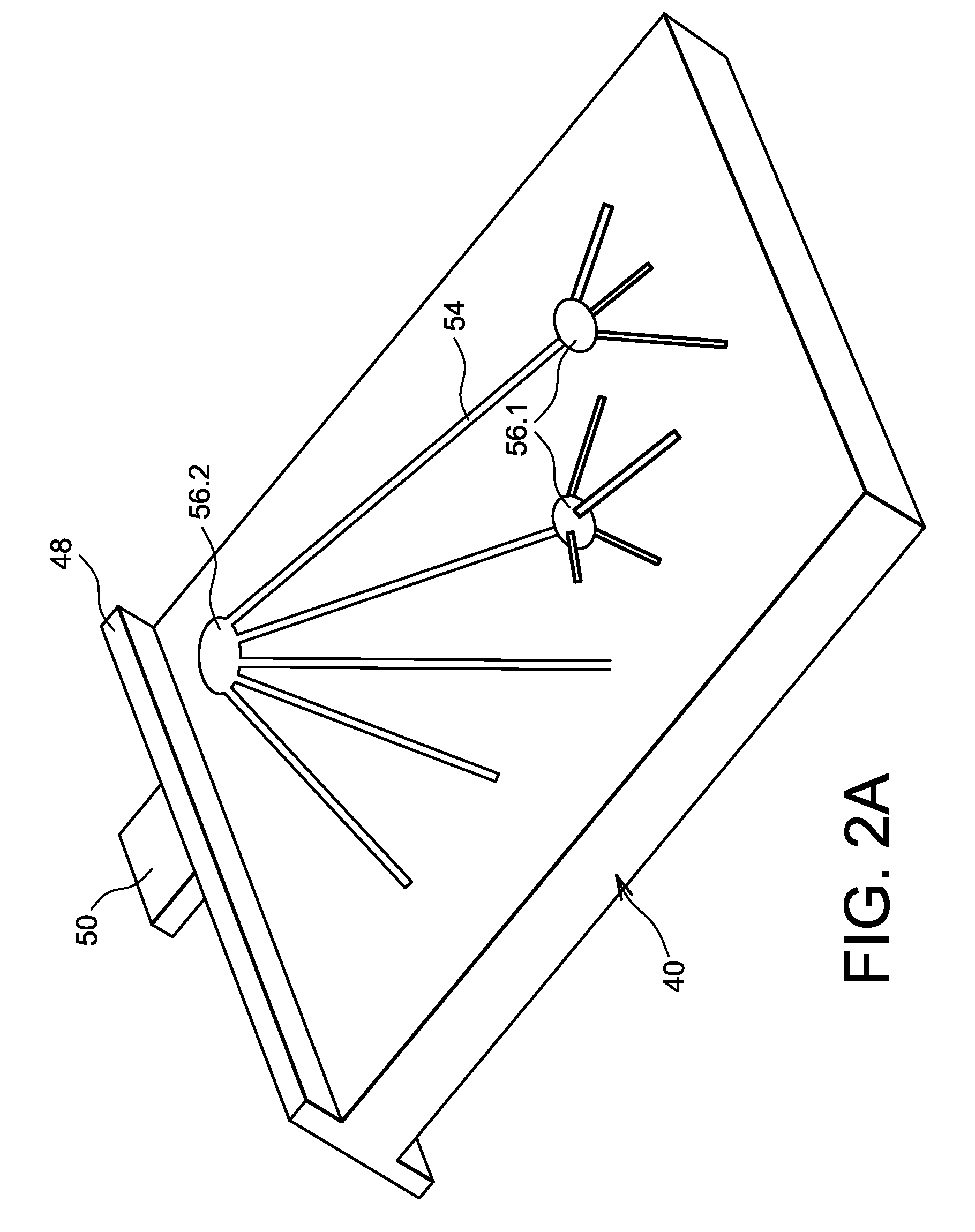

Solid oxide high temperature electrolysis glow discharge cell

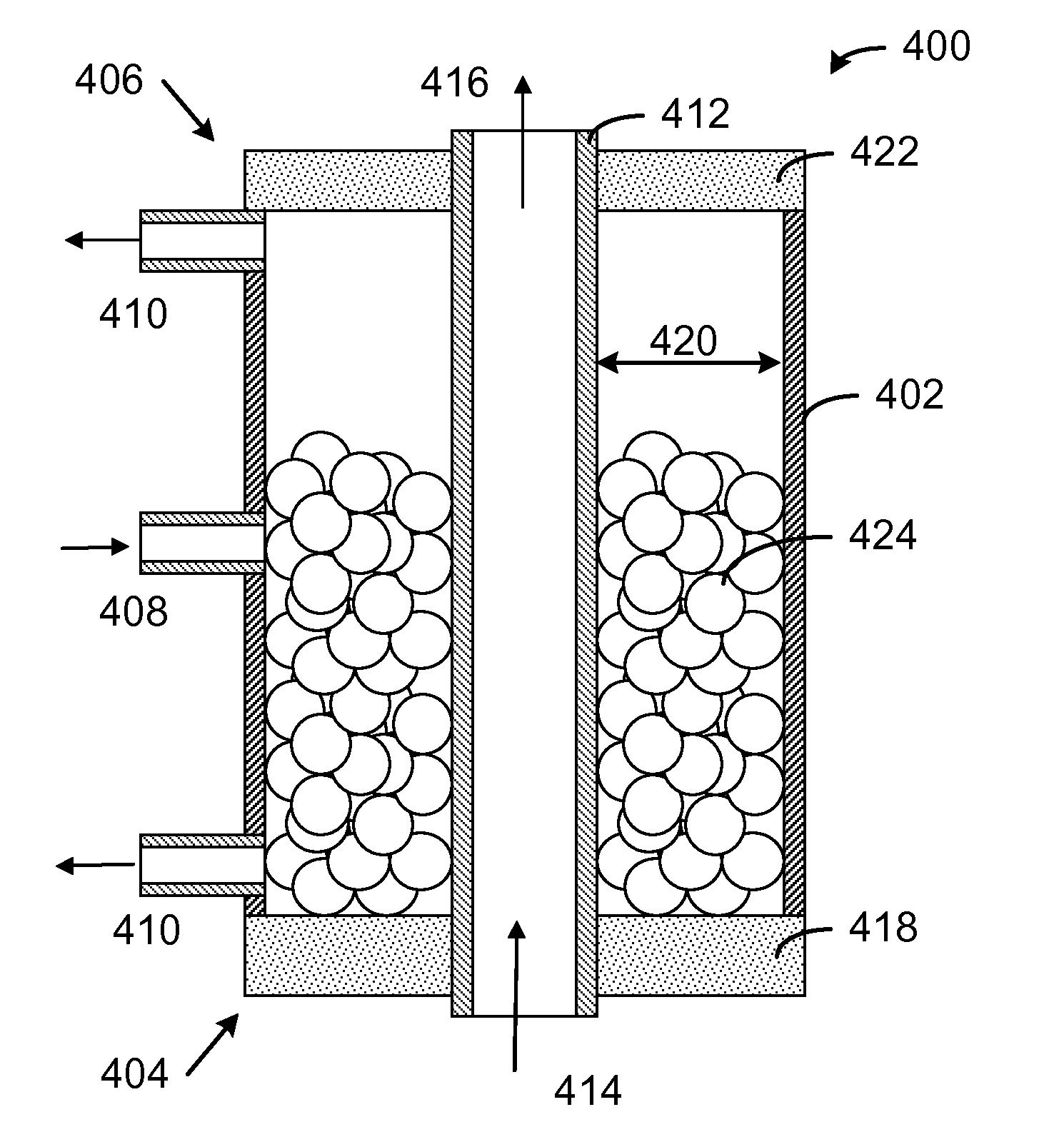

The present invention provides a glow discharge cell comprising an electrically conductive cylindrical vessel having a first end and a second end, and at least one inlet and one outlet; a hollow electrode aligned with a longitudinal axis of the cylindrical vessel and extending at least from the first end to the second end of the cylindrical vessel, wherein the hollow electrode has an inlet and an outlet; a first insulator that seals the first end of the cylindrical vessel around the hollow electrode and maintains a substantially equidistant gap between the cylindrical vessel and the hollow electrode; a second insulator that seals the second end of the cylindrical vessel around the hollow electrode and maintains the substantially equidistant gap between the cylindrical vessel and the hollow electrode; a non-conductive granular material disposed within the gap, wherein the non-conductive granular material (a) allows an electrically conductive fluid to flow between the cylindrical vessel and the hollow electrode, and (b) prevents electrical arcing between the cylindrical vessel and the hollow electrode during a electric glow discharge; and wherein the electric glow discharge is created whenever: (a) the glow discharge cell is connected to an electrical power source such that the cylindrical vessel is an anode and the hollow electrode is a cathode, and (b) the electrically conductive fluid is introduced into the gap.

Owner:FORET PLASMA LABS

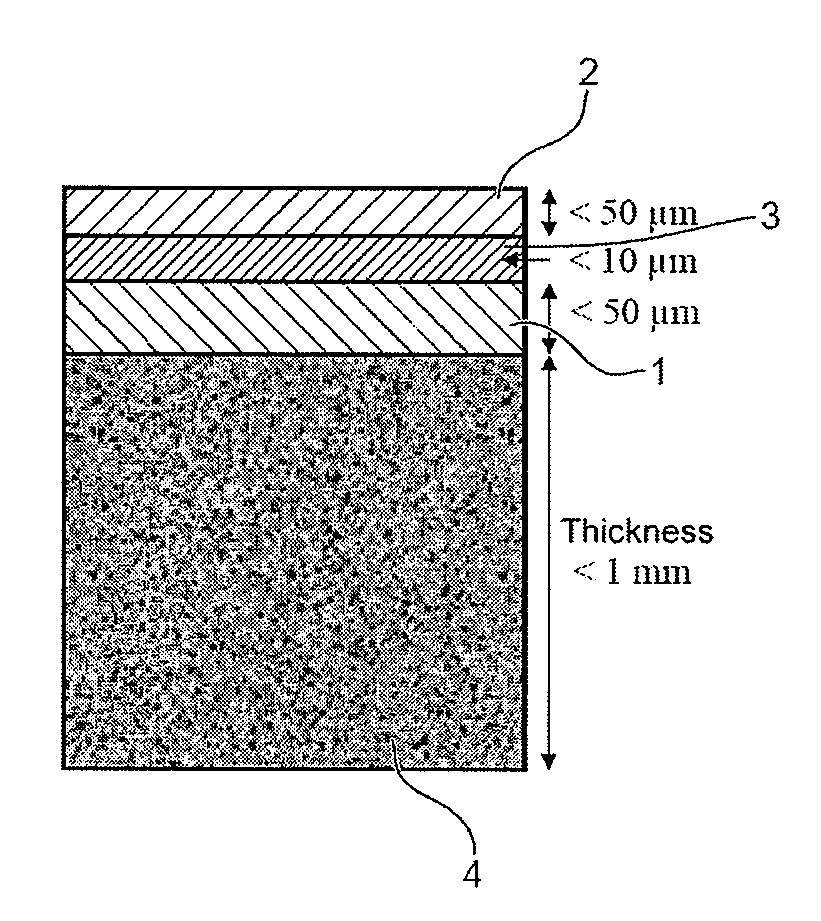

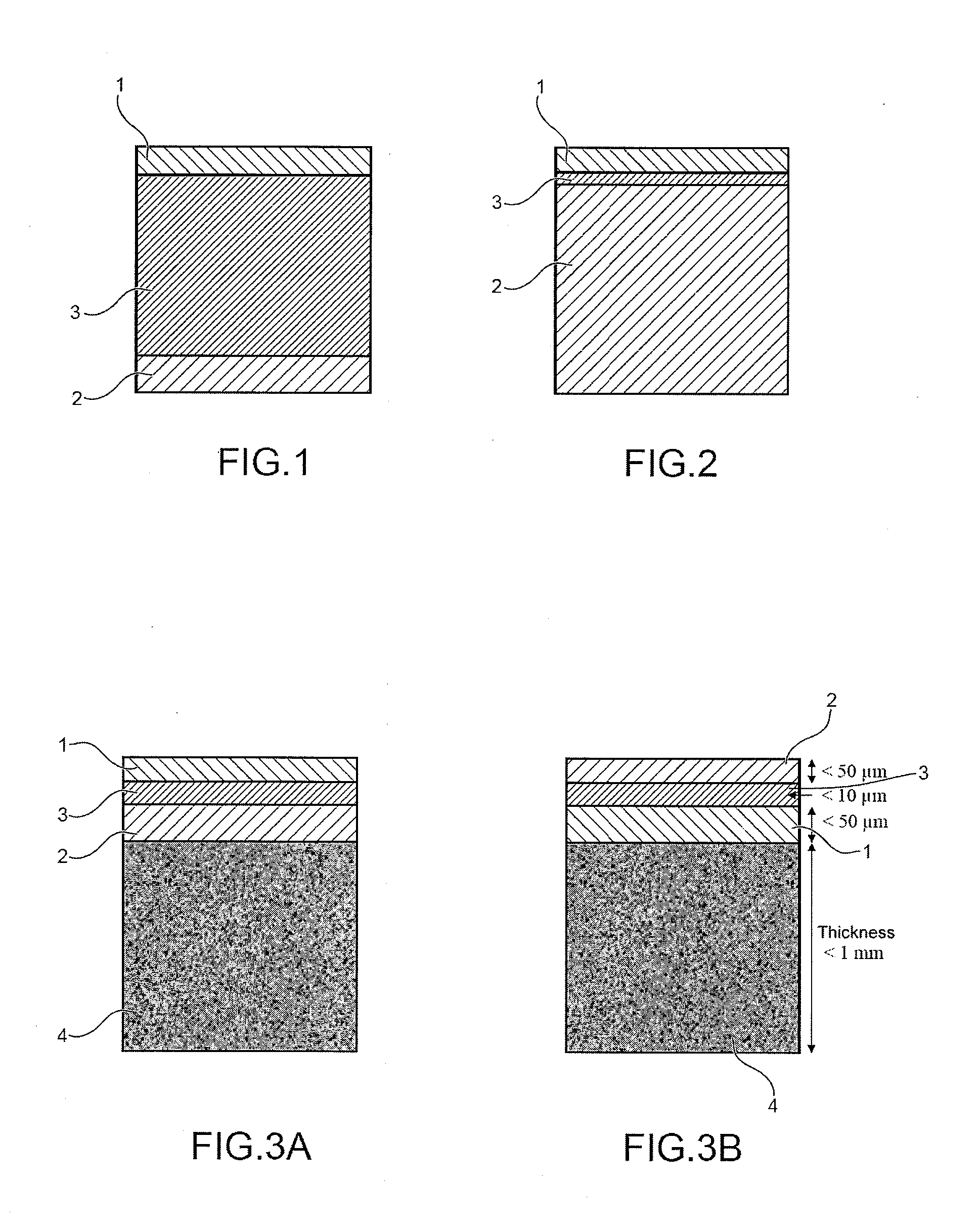

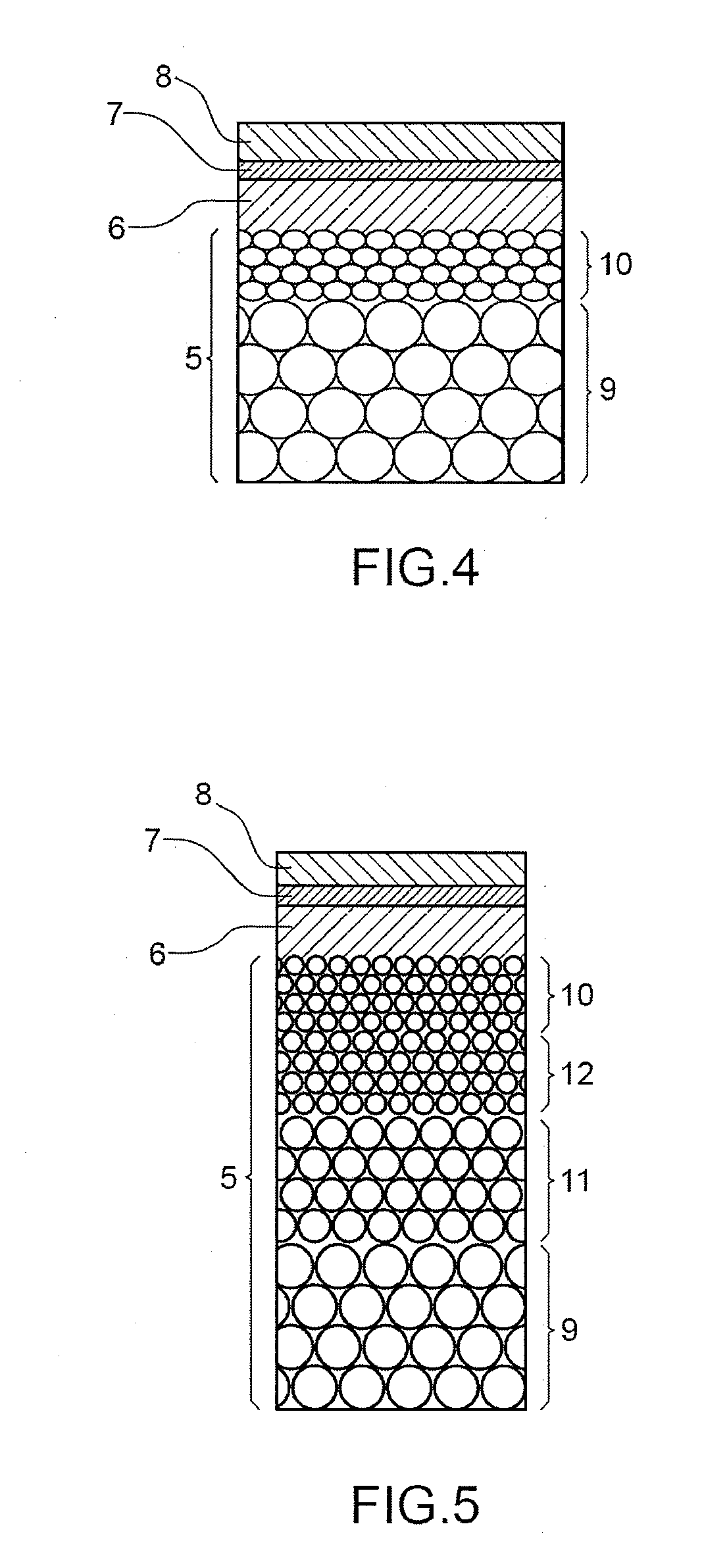

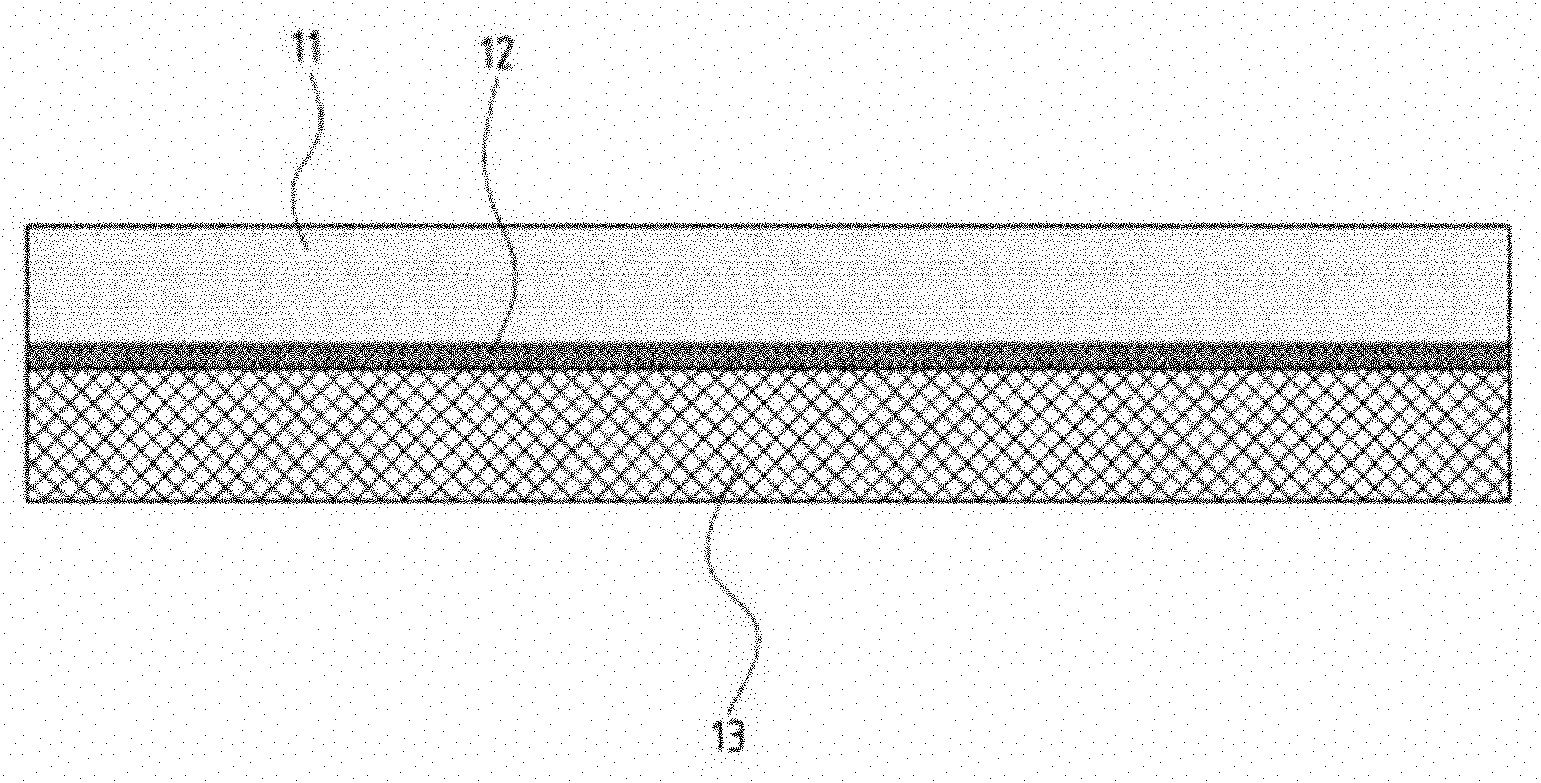

Substrate made of porous metal or metal alloy, preparation method thereof, and hte or sofc cells with a metal support comprising this substrate

A partly oxidized substrate, obtained by subjecting a substrate made of a porous metal or metal alloy comprising particles of at least one metal or metal alloy bound by sintering, said substrate comprising a first main surface and a second main surface, and said substrate having a porosity gradient from the first main surface to as far as the second main surface; to partial oxidation by an oxidizing gas such as oxygen and / or air.Method for preparing said substrate and high temperature electrolyzer cell (<<HTE>>) comprising said substrate.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

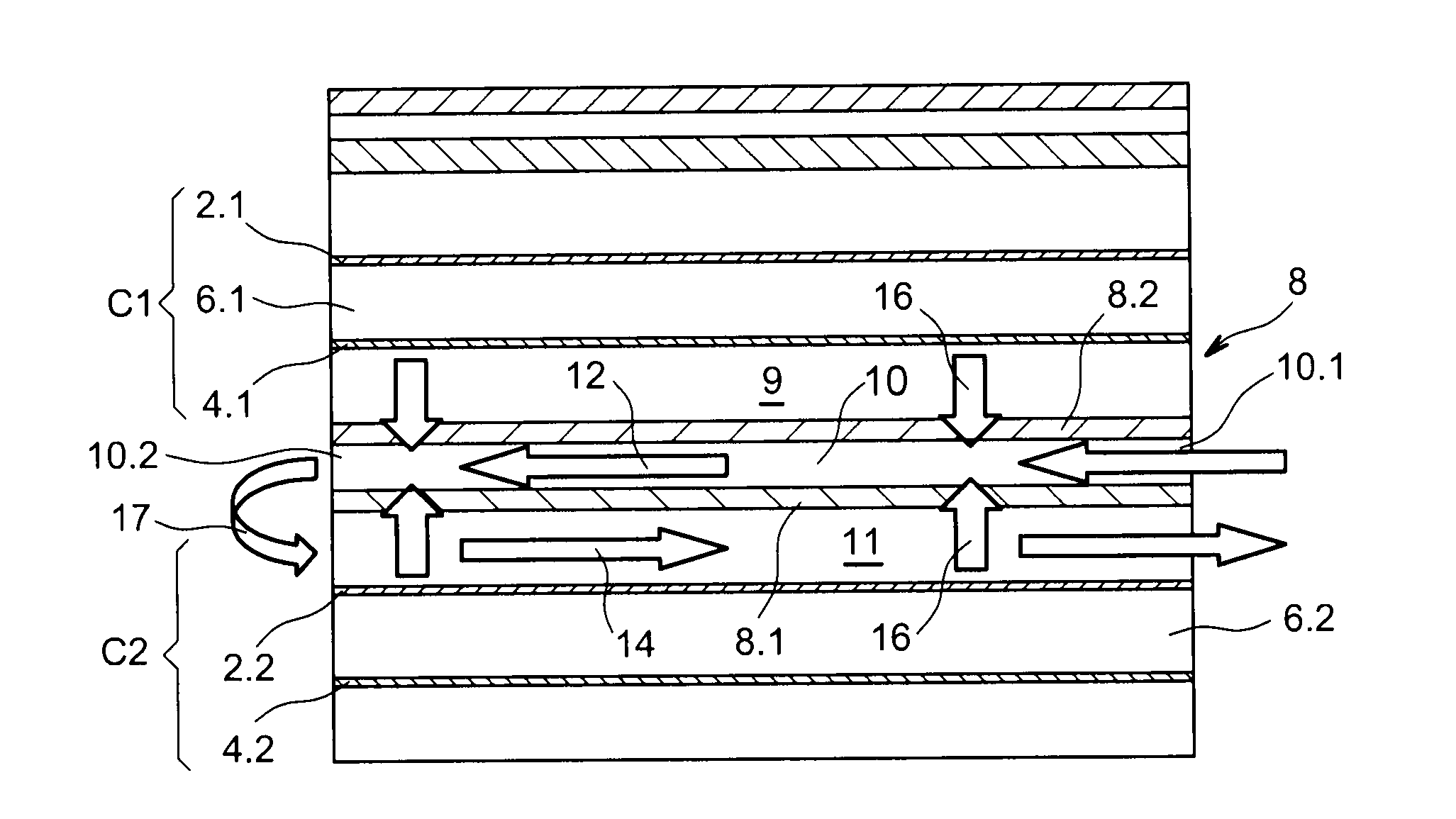

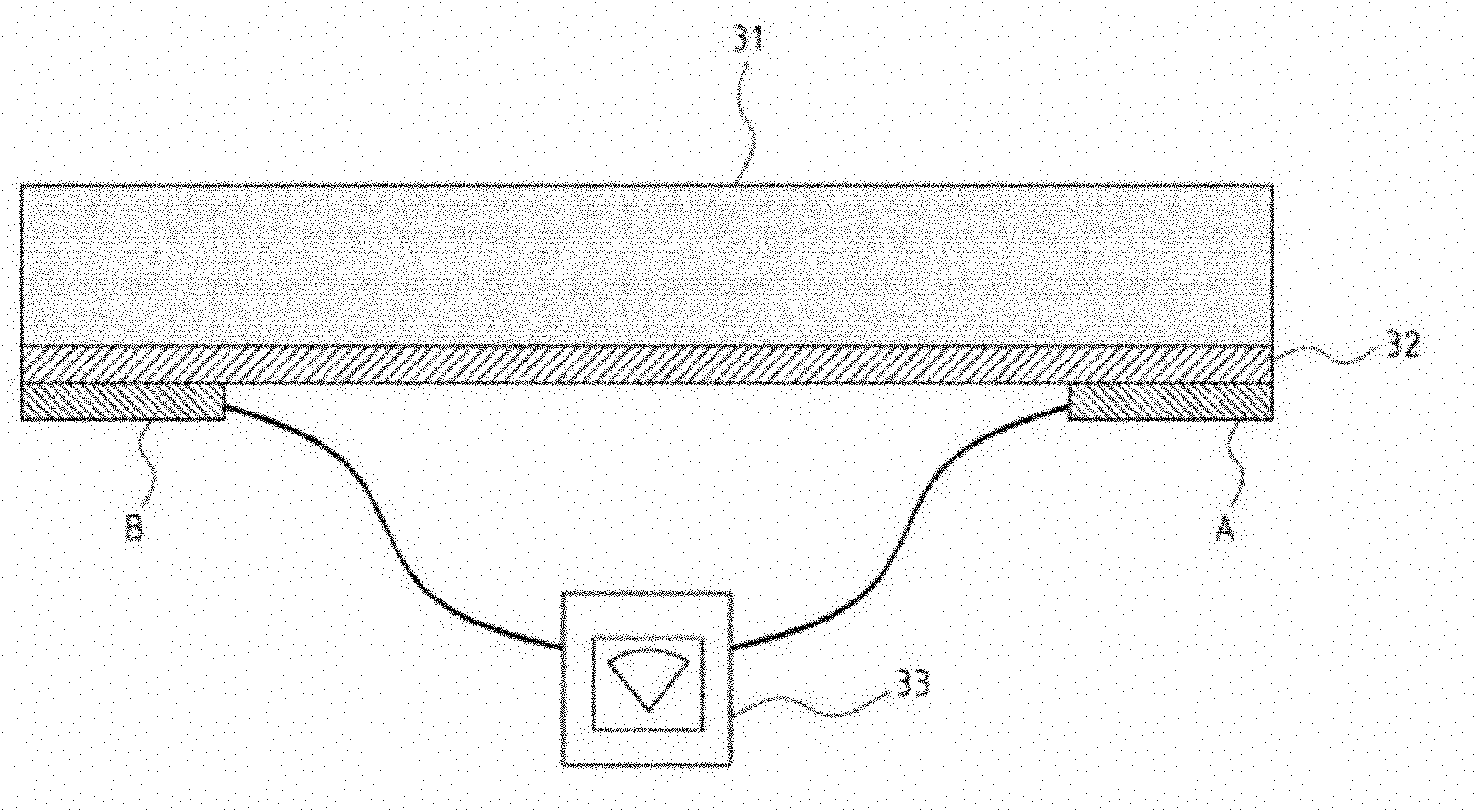

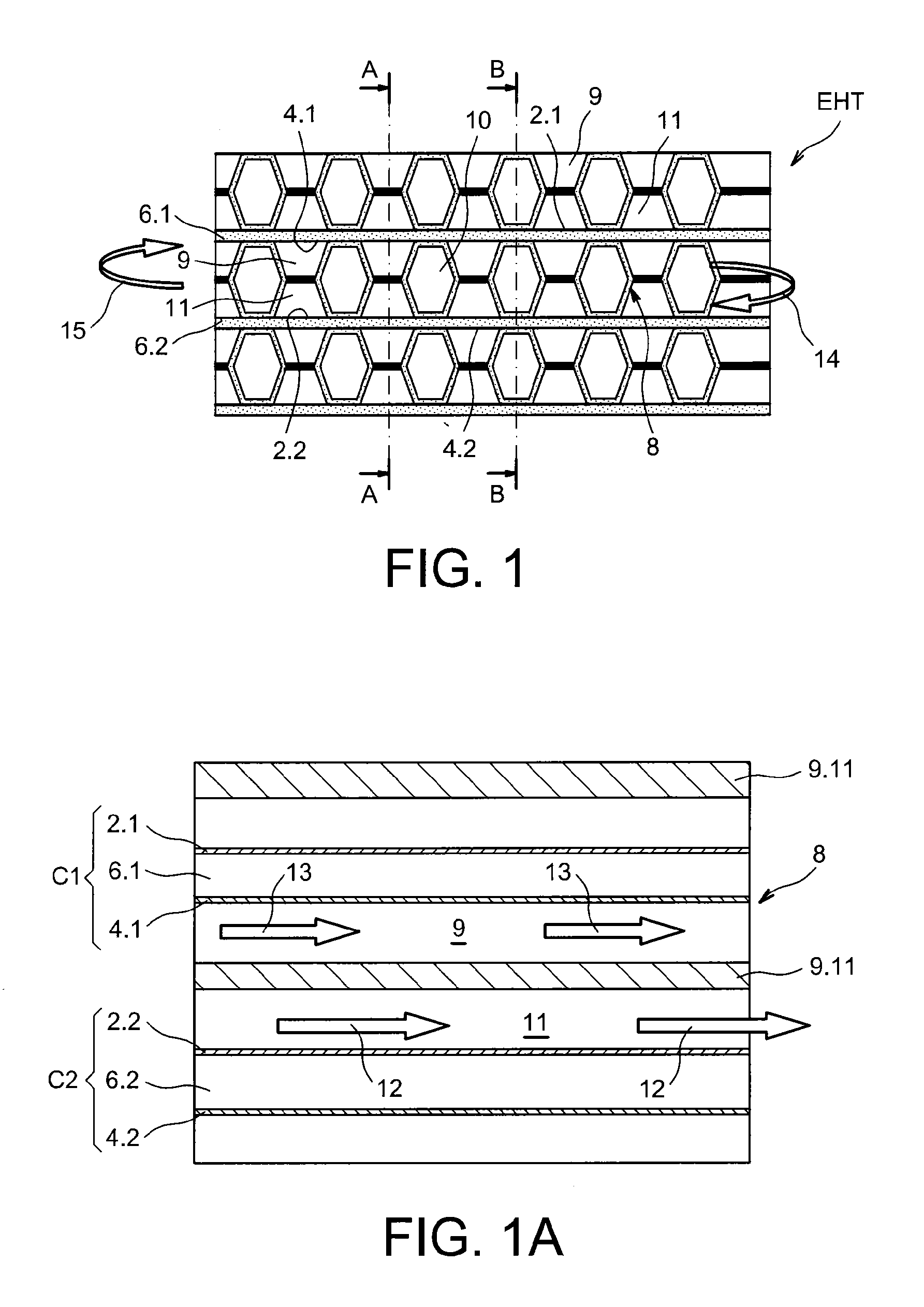

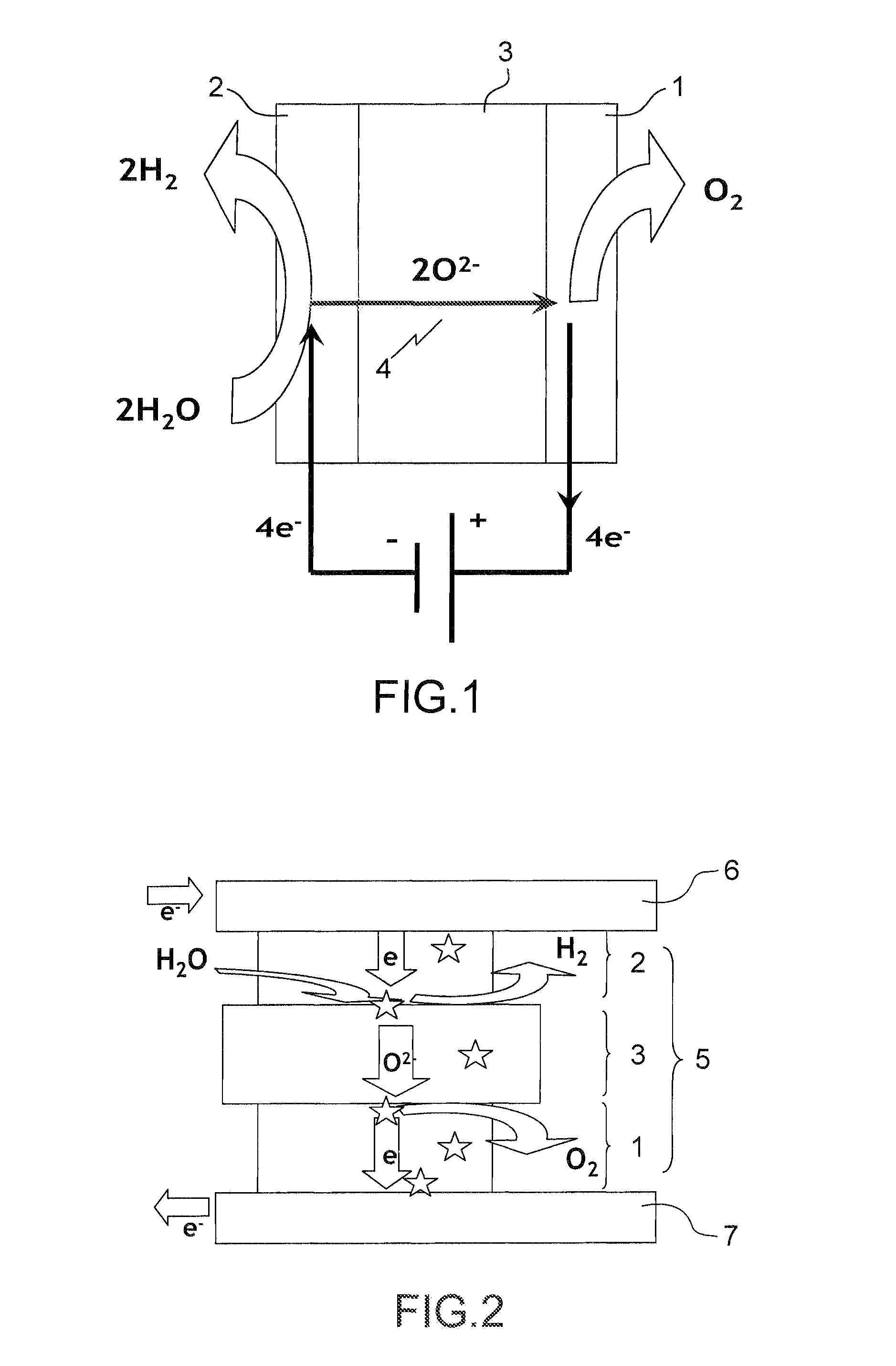

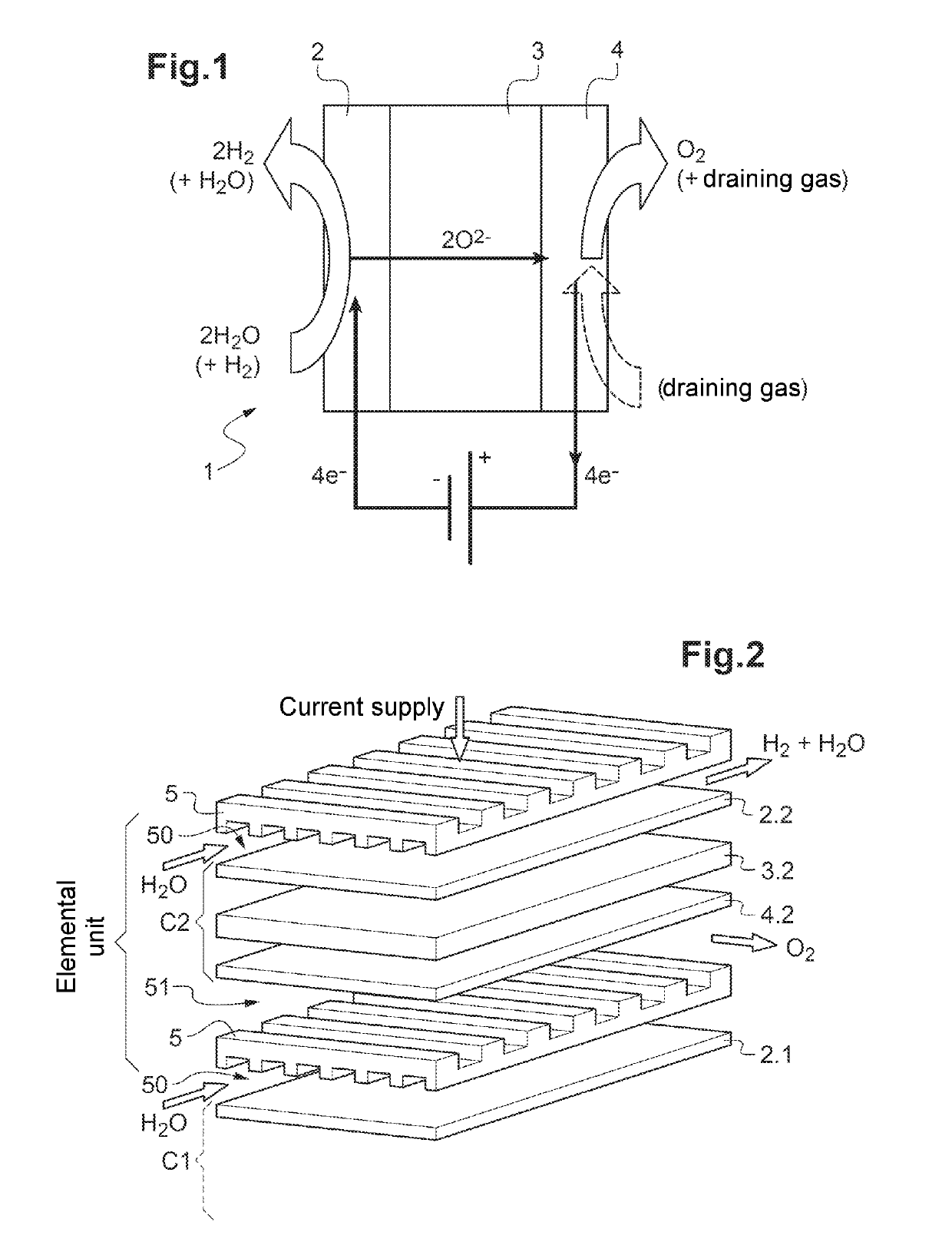

High temperature electrolyser with temperature homogenisation device

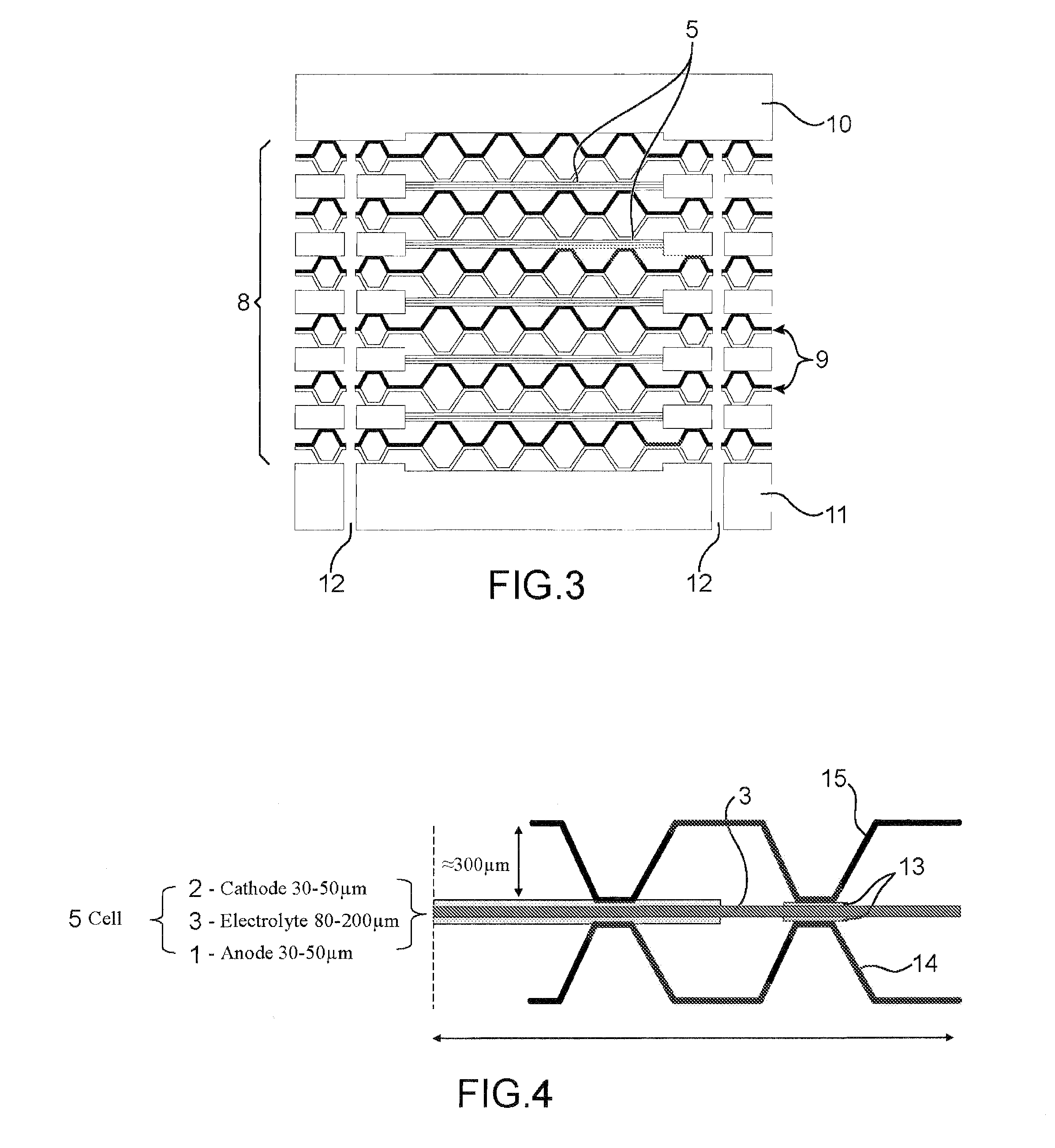

ActiveUS20100200422A1Easy to operateLow costCellsPhotography auxillary processesEngineeringElectrolyte

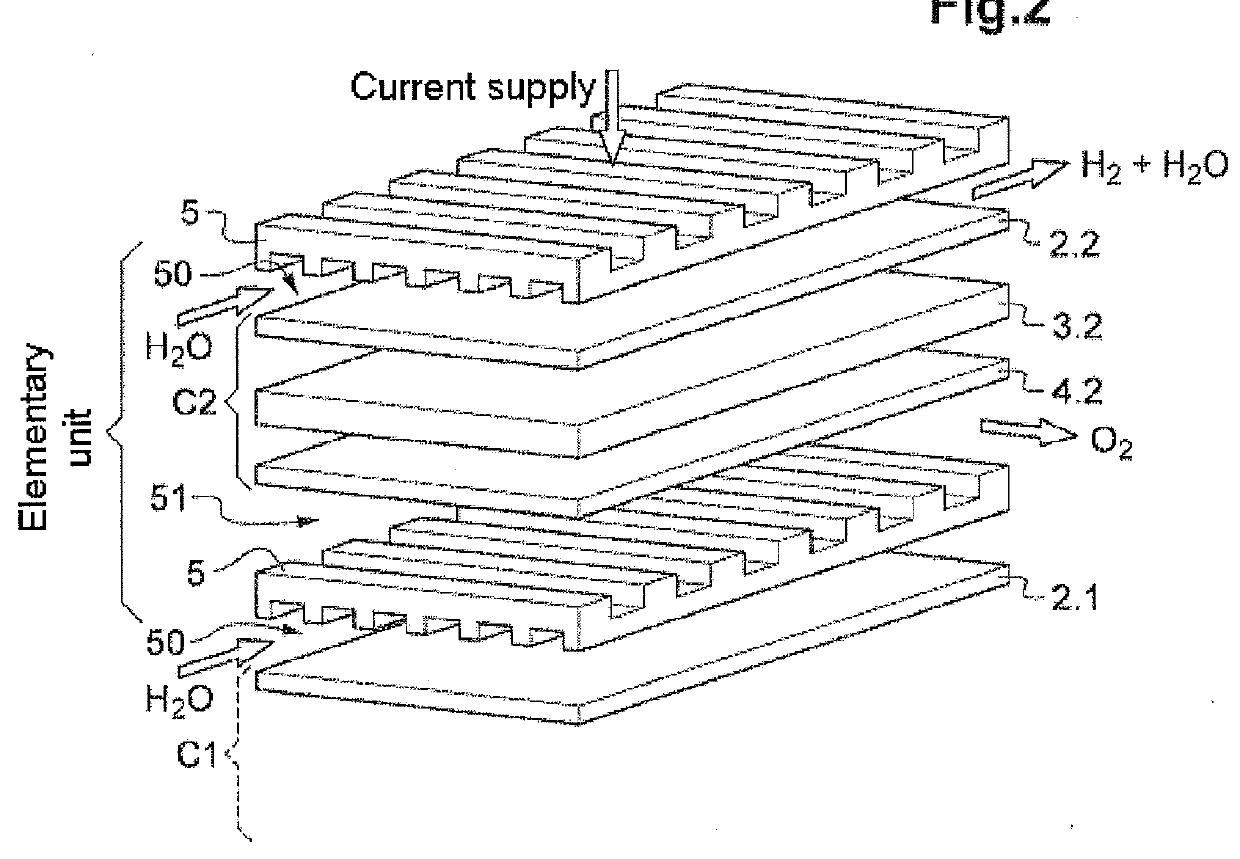

An electrolyser including a stack of a plurality of elementary electrolysis cells, each cell including a cathode, an anode, and an electrolyte provided between the cathode and the anode. An interconnection plate is interposed between each anode of an elementary cell and a cathode of a following elementary cell, the interconnection plate being in electric contact with the anode and the cathode. A pneumatic fluid is to be brought into contact with the cathodes, and the electrolyser further includes a mechanism ensuring circulation of the pneumatic fluid in the electrolyser for heating it up before contacting the same with the cathodes.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Porous ceramics composition, preparation method and application thereof

The invention provides a porous ceramics composition, a preparation method and application thereof, relating to a ceramic material. The porous ceramics composition comprises the following raw materials of 1 percent of powder particle body as a major material, 0.05-0.5 percent of binding agent, 0.01-0.4 percent of pore generating agent and 0.01-0.5 percent of dispersing agent. The preparation method comprises the steps of: adding the binding agent, the pore generating agent and the dispersing agent in the powder particle body used as the major raw material, mixing and stirring to obtain slurry; and carrying out a wet processing method or dry processing method on the slurry to obtain the finished product. The porous ceramics composition can be applied to the fields of a heat radiating assembly, a heating assembly, a heat exchange assembly, a heat conduction assembly, a heat insulation assembly, a catalytic catalyst carrier, a filtering assembly, a power generating assembly, a light-emitting assembly, a temperature-sensing assembly, a pressure-sensing assembly, a light-sensing assembly, a high temperature electrolysis isolation membrane assembly, a far infrared emitting assembly, an electromagnetic radiation reducing assembly, a battery assembly, a semiconductor module, a dehumidifying assembly, a water seepage brick, a drill cutting assembly, a die assembly and the like.

Owner:麦乔智 +1

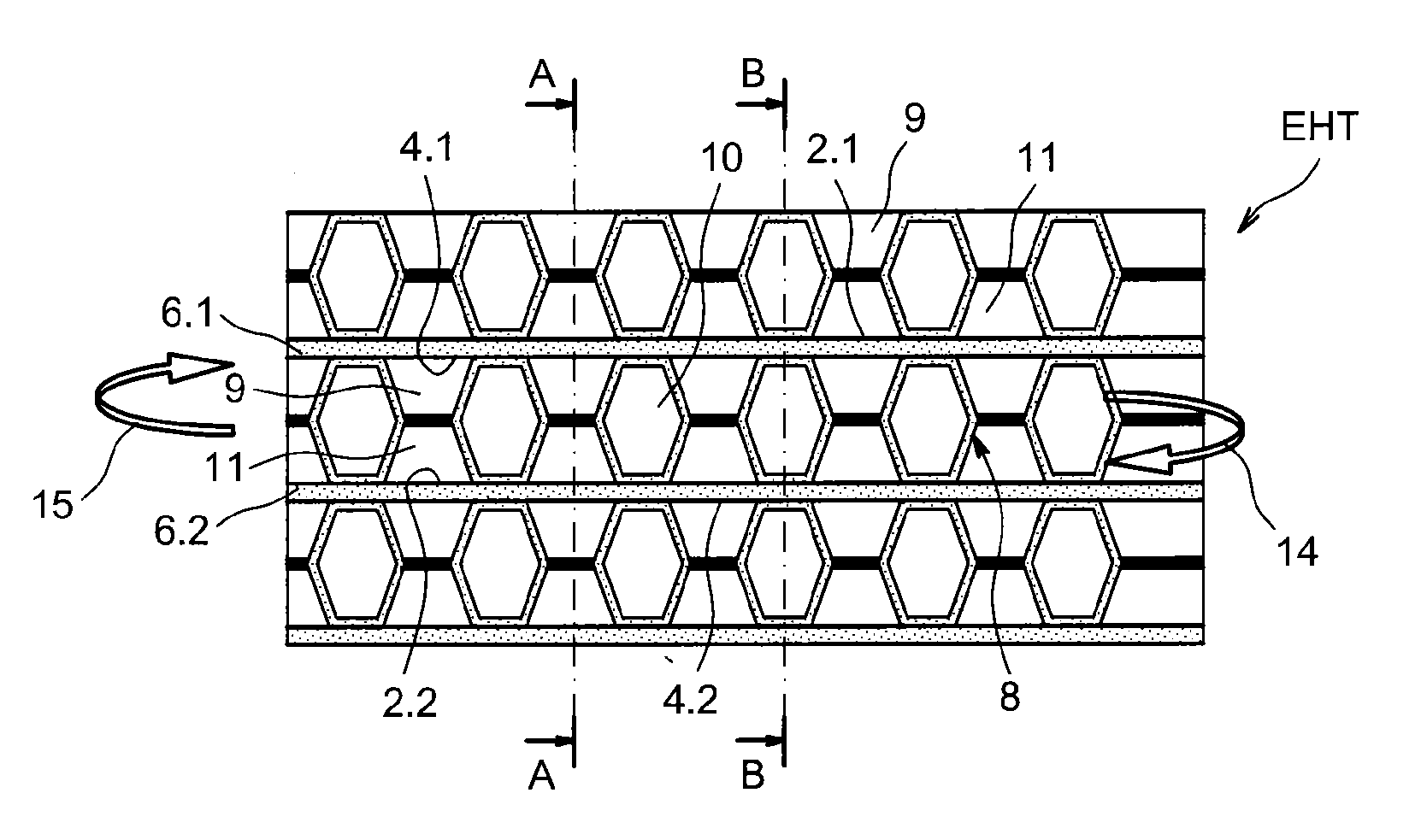

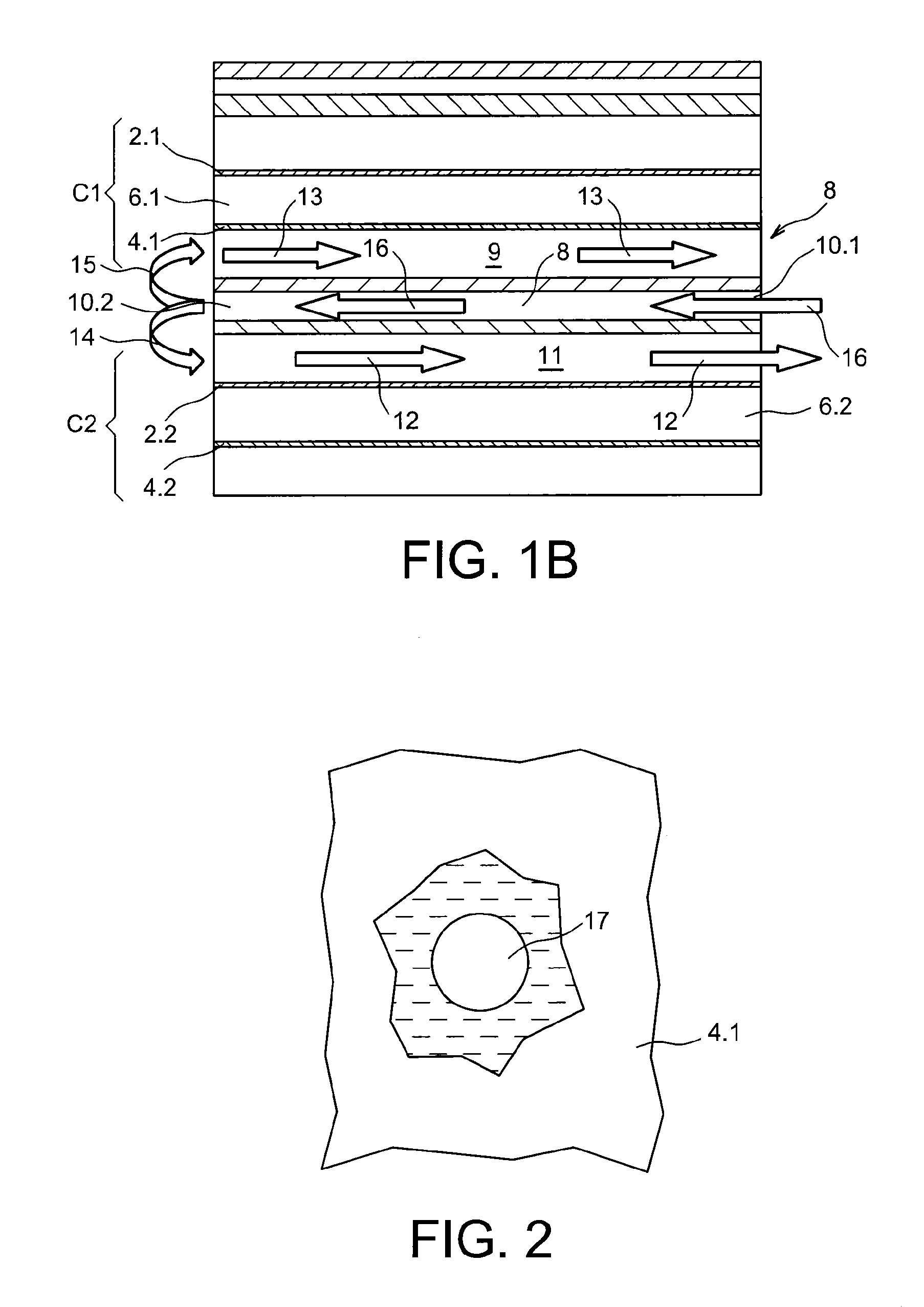

High temperature electrolyzer (HTE) having a stack of electrolysis cells and improved operating reliability and high efficiency

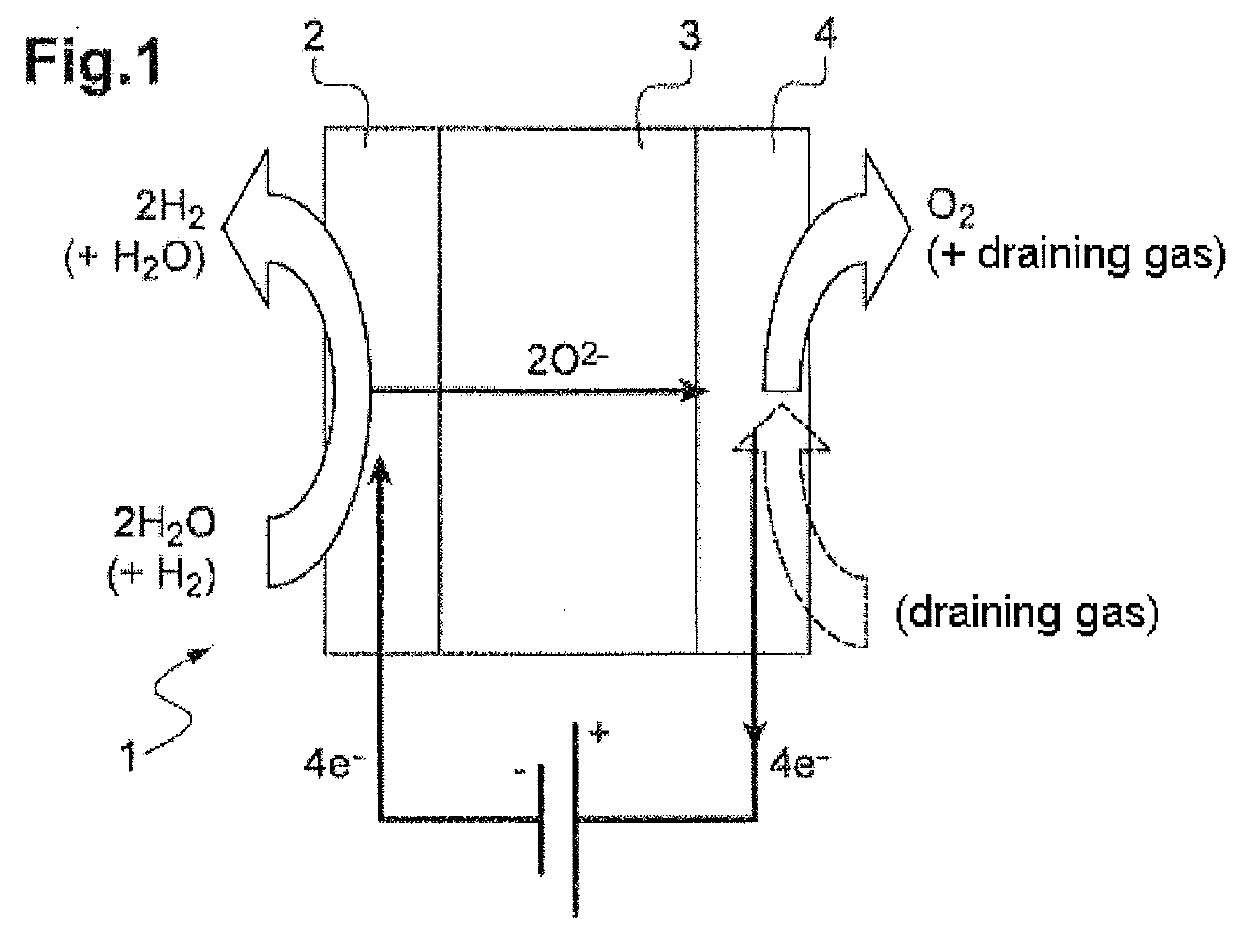

A high-temperature module for electrolysis of water with improved operational safety, in which steam containing at most 1% hydrogen can be made to flow simultaneously in each cathode and in each anode, as a draining gas, of a stack of cells. The stack of cells is housed in a sealed case and a mechanism for clamping by compression of the stack is included. The risks of leaks likely to cause impairments of efficiency and breakages of all or part of a stack EHT electrolyser are reduced, while a high level of efficiency is provided due to the fact that satisfactory electrical conduction is maintained by compression of the stack.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

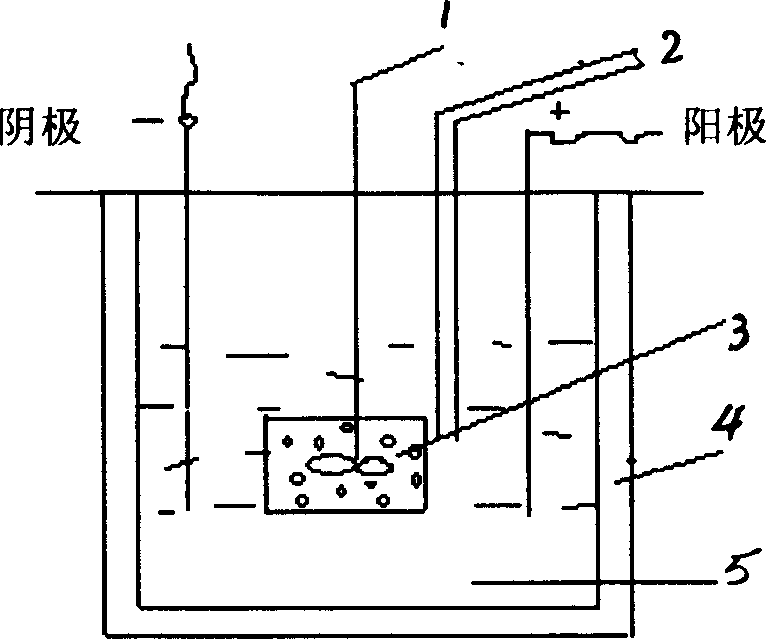

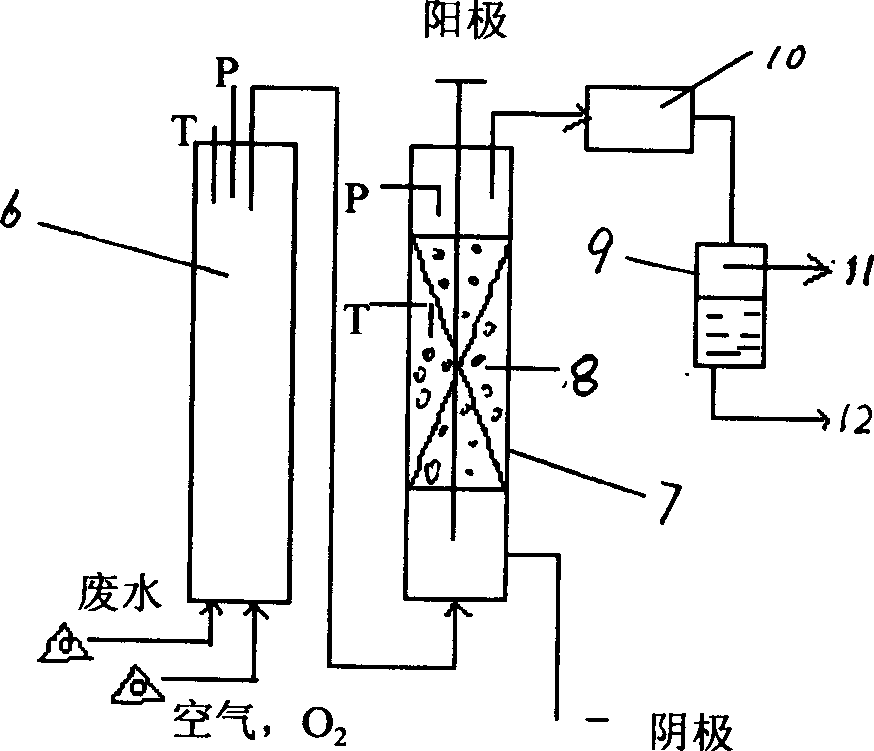

Method and apparatus for treating high concentrated organic wastewater by hydrothermal electrical catalytic oxidation

InactiveCN1654344ARelieve pressureLow costCatalyst carriersWater/sewage treatment by heatingHigh concentrationReaction temperature

The present invention is hydrothermal and electric catalytic oxidation process and apparatus for treating high concentration organic waste water. The present invention features that high concentration organic waste water is treated electrolytically at temperature from room temperature to 250 deg.c and pressure of 0.5-7 MPa while oxygen containing air is led in to eliminate organic compound and nitrous compound from waste water and to make them become CO2, N2, water or inorganic salt inside an intermittent or continuous electrolytic reactor. The present invention combines wet catalytic oxidation and high temperature electrolysis, and has relatively low reaction temperature and pressure, high organic waste water treating efficiency and low cost.

Owner:YUNNAN UNIV

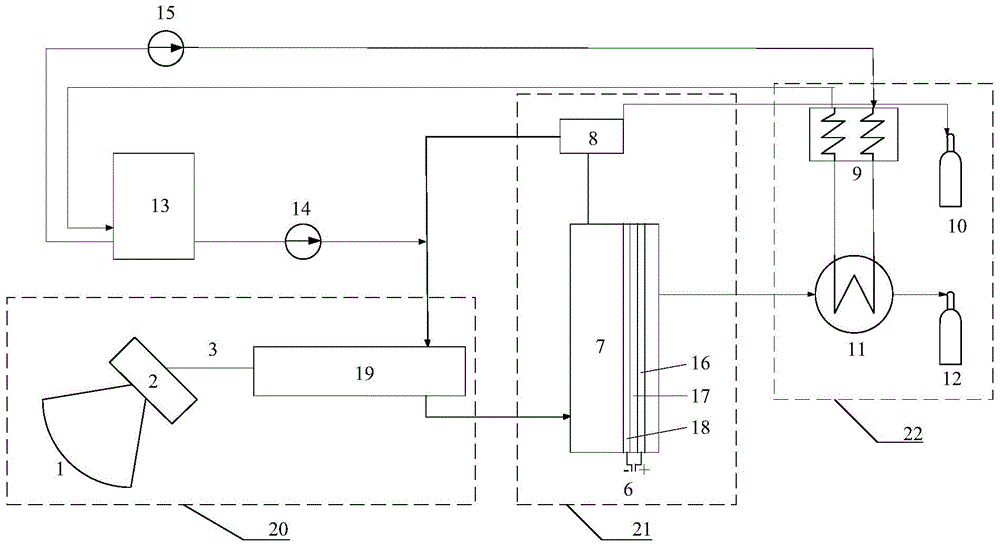

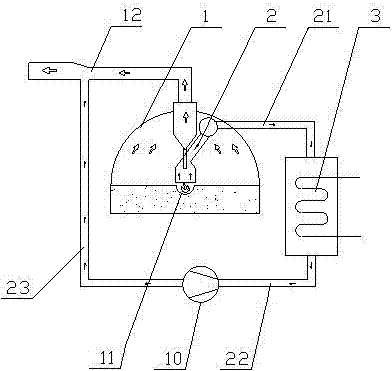

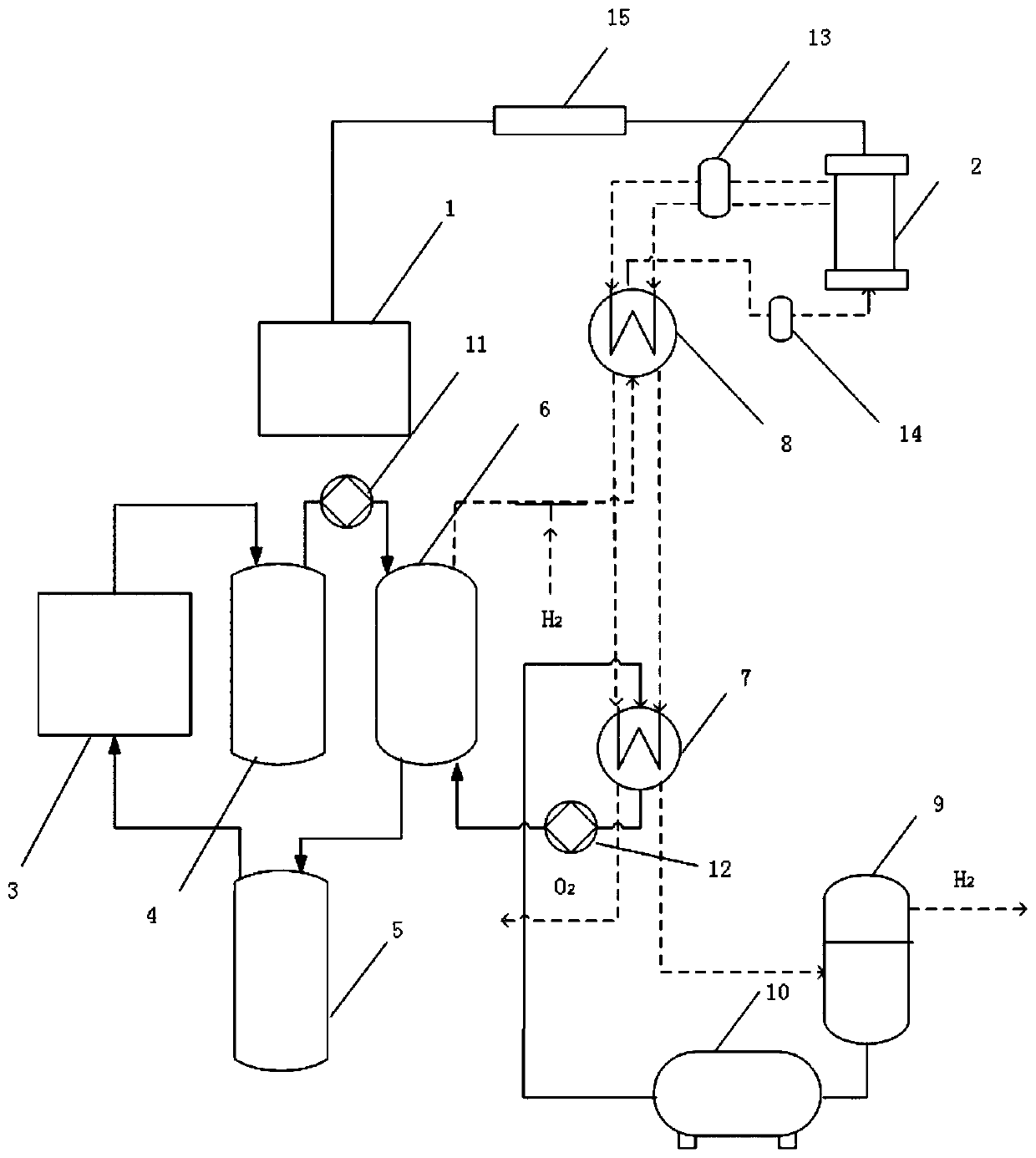

Solar optothermal coupled high-temperature water electrolysis hydrogen production system

ActiveCN104694950AResolve unstable situationsProduction environmental protectionCellsThermal energyProcess engineering

The invention provides a solar optothermal coupled high-temperature water electrolysis hydrogen production system. The system comprises a heat energy supply module, a hydrogen production and separation module and a storage module which are sequentially connected; the heat energy supply module comprises a condensation device, a heat collection device, a heat storage high-temperature heat pipe heat exchanger and a heat exchanger unit which are sequentially connected, and hydrogen and hydrogen are separated through electrolysis after a water and hydrogen mixture in the hydrogen production and separation module is heated into a steam and hydrogen mixture above 800 DEG C. Compared with the prior art, the hydrogen production system has the advantages that fossil energy does not need to be consumed, the productive process is more green and environmentally friendly, and the power consumption is greatly reduced; a stable heat source is provided through the system, the problem that a photo-thermal system is not stable due to changes in the weather is solved, the availability of the system is improved, and meanwhile the electrolytic efficiency of the system is improved.

Owner:STATE GRID CORP OF CHINA +1

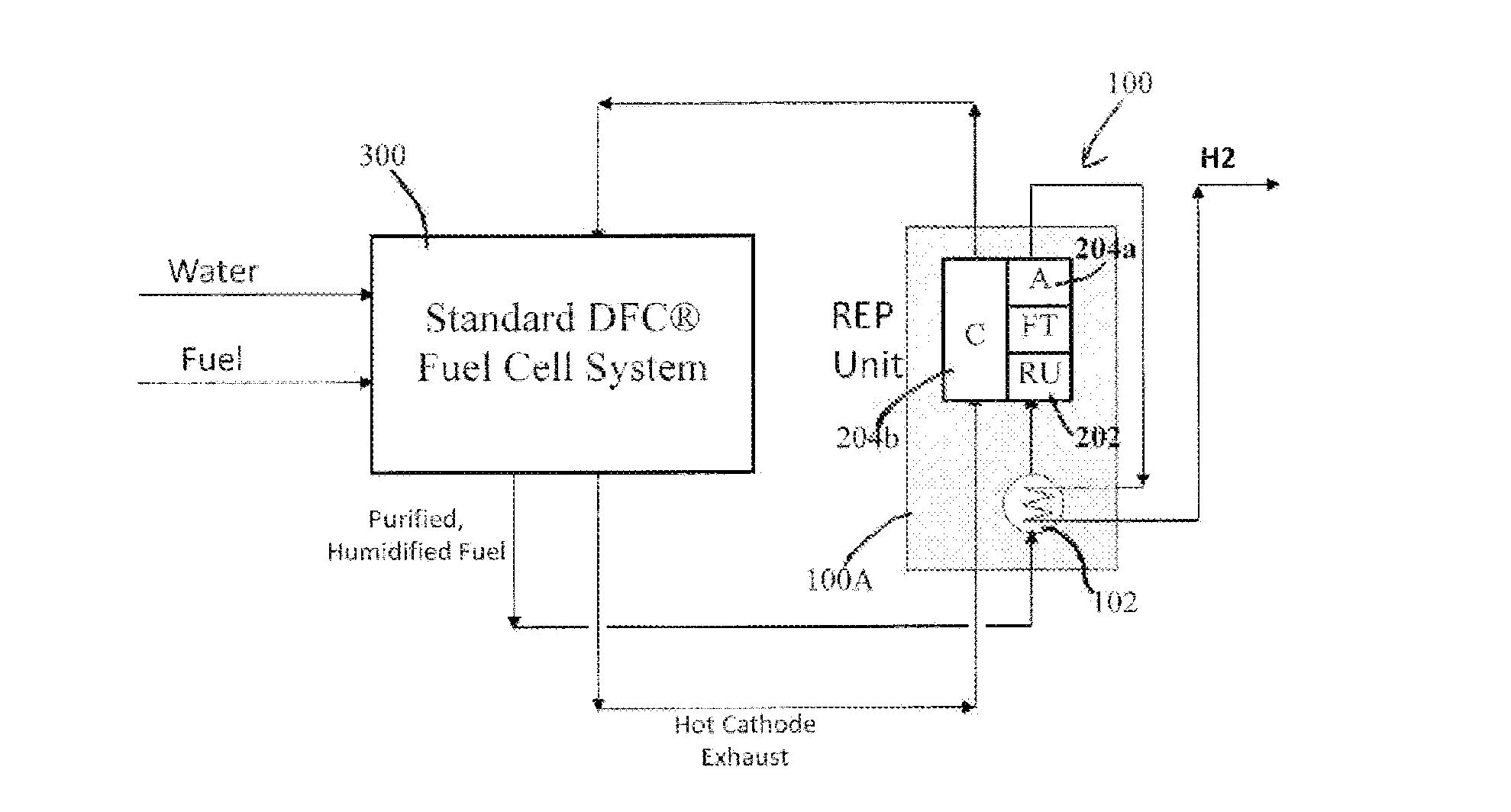

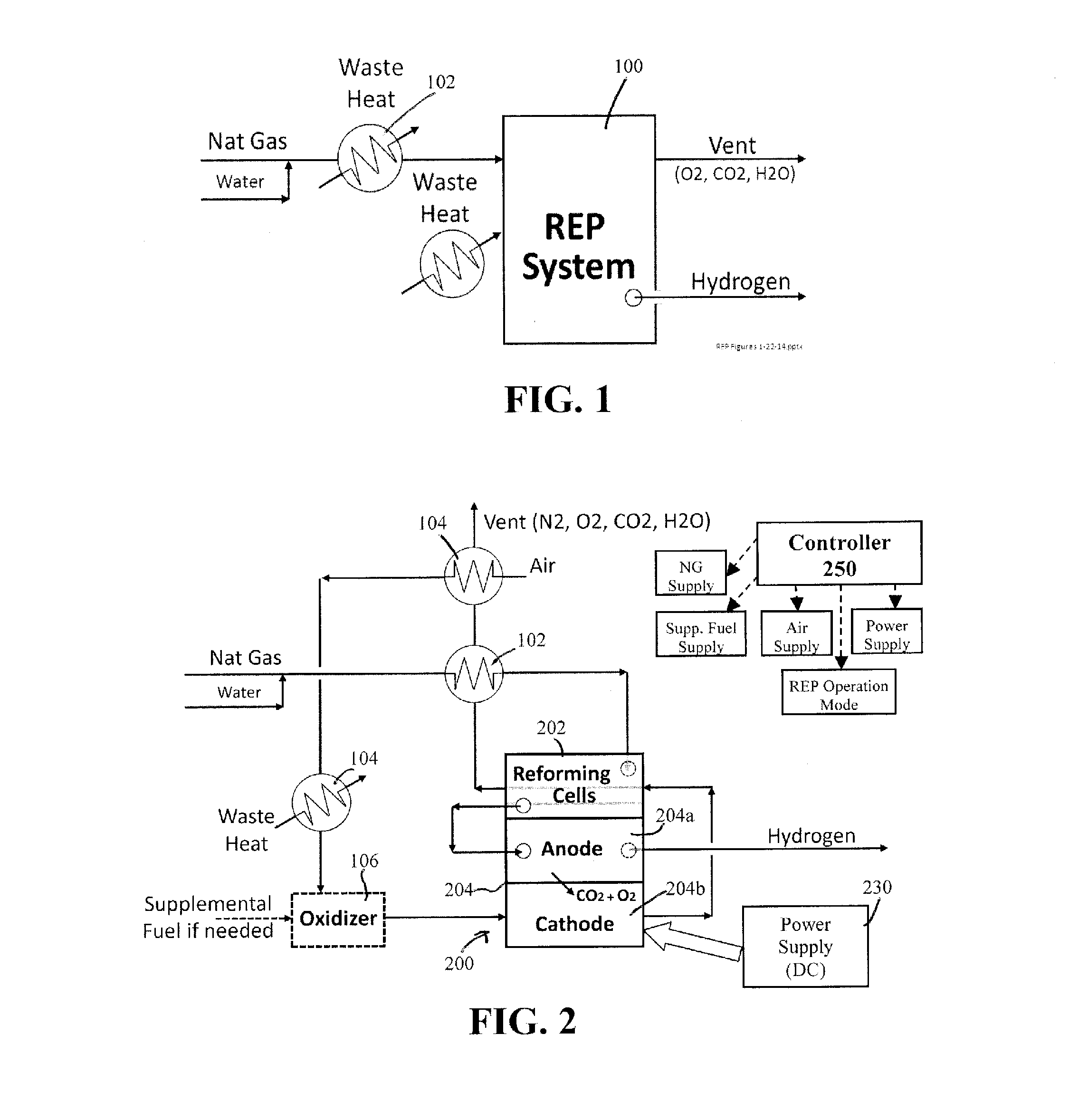

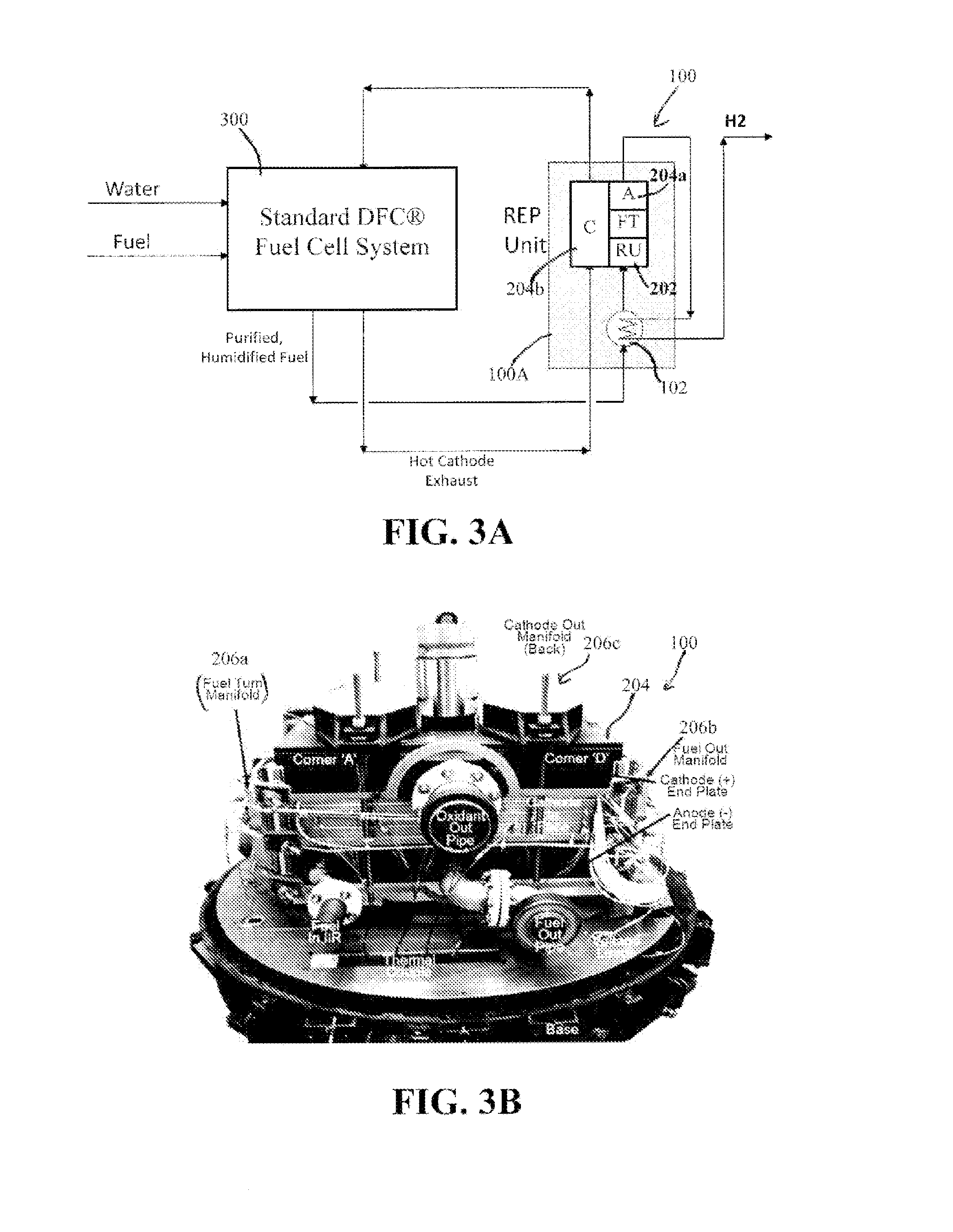

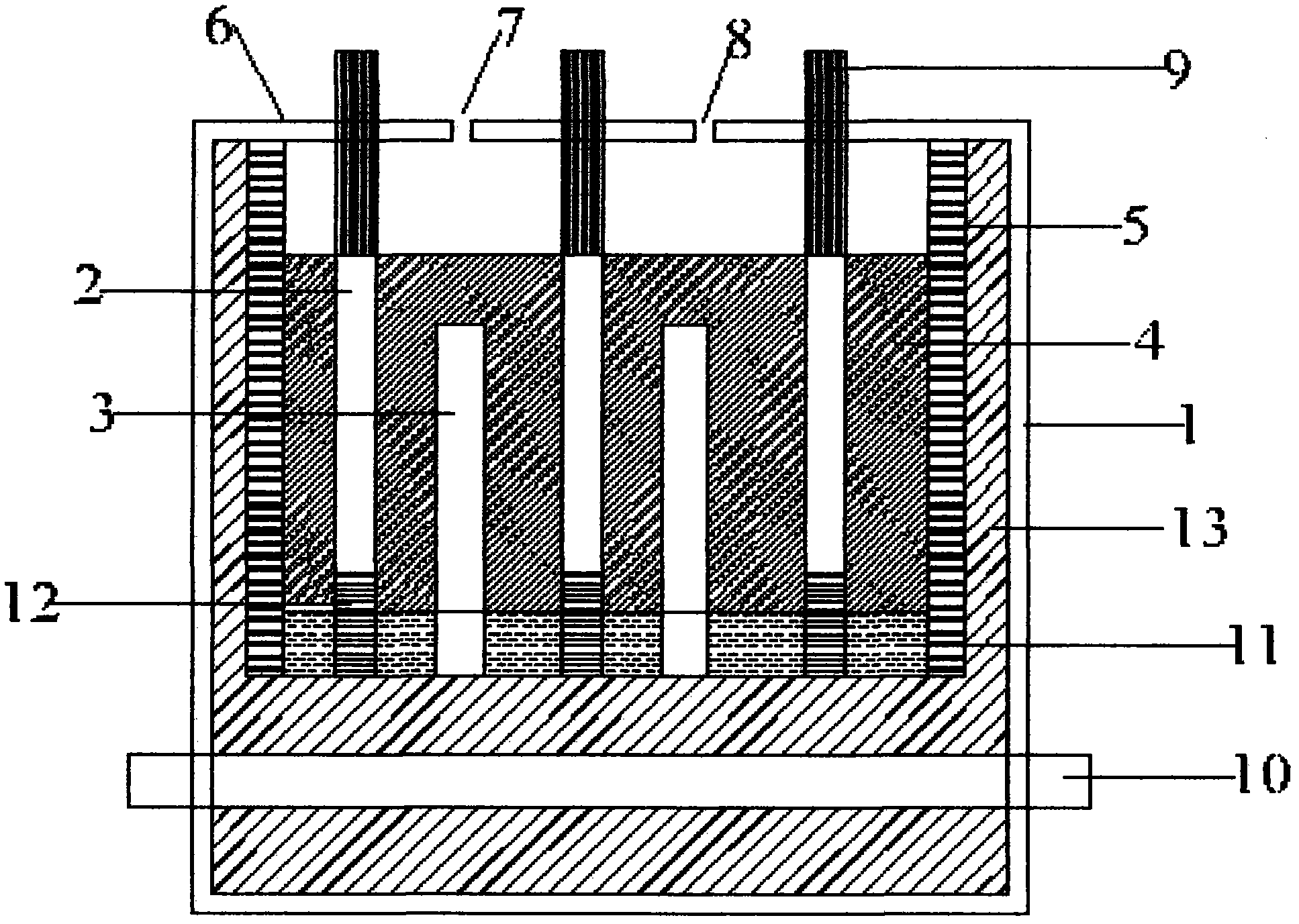

Reformer-electrolyzer-purifier (REP) assembly for hydrogen production, systems incorporating same and method of producing hydrogen

ActiveUS20160351930A1Low costEmission reductionElectrolysis componentsRegenerative fuel cellsFuel cellsProcess engineering

A high temperature electrolyzer assembly comprising at least one electrolyzer fuel cell including an anode and a cathode separated by an electrolyte matrix, and a power supply for applying a reverse voltage to the at least one electrolyzer fuel cell, wherein a gas feed comprising steam and one or more of CO2 and hydrocarbon fuel is fed to the anode of the at least one electrolyzer fuel cell, and wherein, when the power supply applies the reverse voltage to the at least one electrolyzer fuel cell, hydrogen-containing gas is generated by an electrolysis reaction in the anode of the at least one electrolyzer fuel cell and carbon dioxide is separated from the hydrogen-containing gas so that the at least one electrolyzer fuel cell outputs the hydrogen-containing gas and separately outputs an oxidant gas comprising carbon dioxide and oxygen.

Owner:FUELCELL ENERGY INC

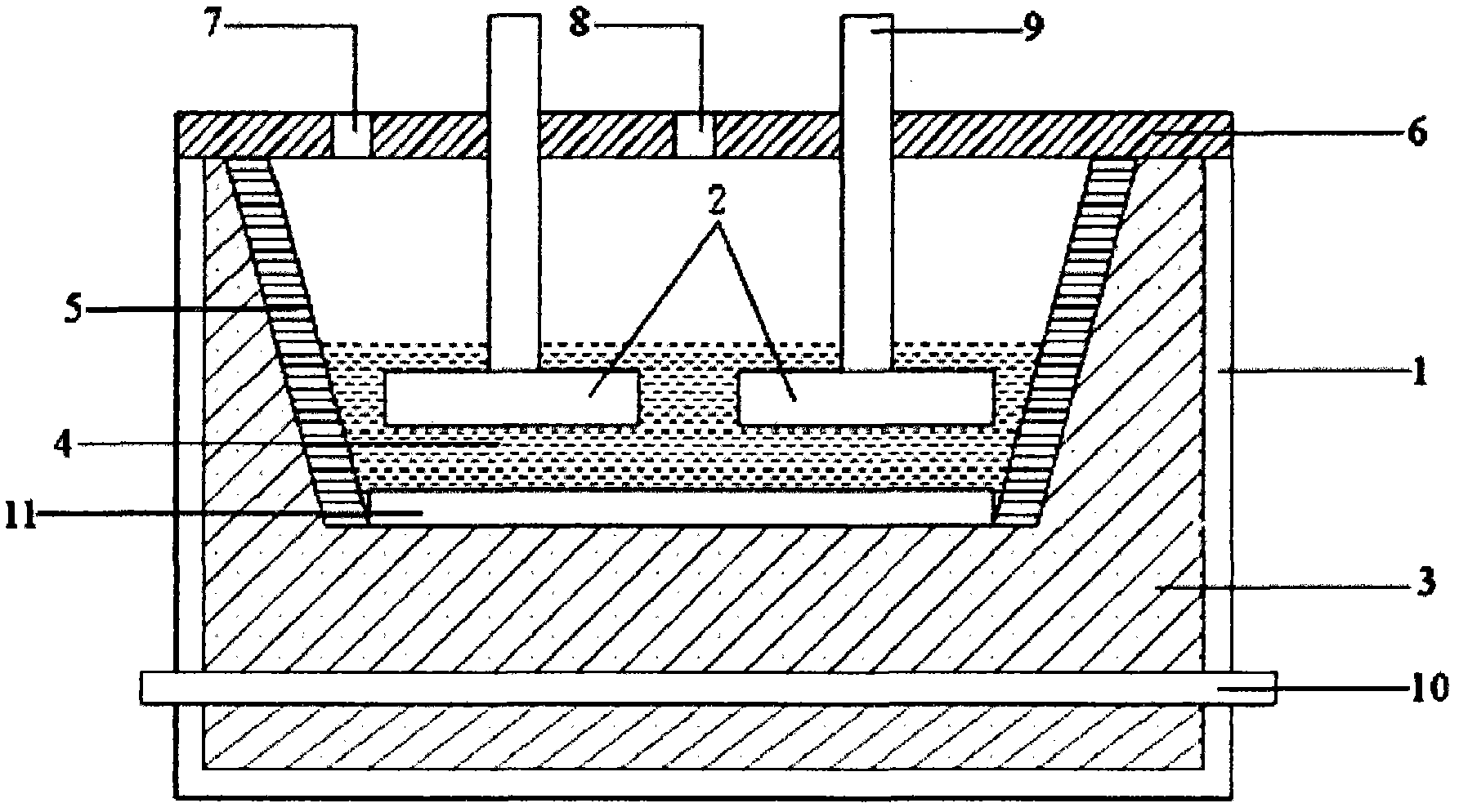

Novel electrolytic bath for aluminum electrolysis and electrolysis technology thereof

The invention discloses a novel electrolytic bath for aluminum electrolysis and an electrolysis technology thereof. A plurality of anodes and cathodes, which are perpendicular to the bottom of the bath, are parallelly arranged in the bath body, thus a multi-chamber electrolytic bath is formed, and the bath body contains some electrolyte. The electrolytic bath is characterized in that: the cathode is a composite of TiB2 and Al, and has the advantages of low cost, strong wet-ability to liquid aluminum, and no expanding and dropping off in a high-temperature electrolysis environment; the anode comprises following components: Fe, Cu, Ni, and Sn, wherein Fe and Cu is the main components, and the anode has the advantages of low overvoltage, high electric conductivity, low cost, strong oxidation resistant ability, and corrosion resistance; the low-temperature electrolyte is composed of following components in percentage by weight: 30 to 38 wt% of NaF, 49 to 60 wt% of AlF3, 1 to 5 wt% of LiF, 1 to 6 wt% of KF, and 3 to 6 wt% of Al2O3, wherein the mole ratio of NaF to AlF3 is 1.0 to 1.52. The multi-chamber electrolytic bath enlarges the area where electrodes carry out electrolysis reactions, so the yield can be increased by many times compared to that of an industrial single-chamber electrolytic bath if the two kinds of electrolytic baths have the same occupied area.

Owner:北京润括未来科技有限公司

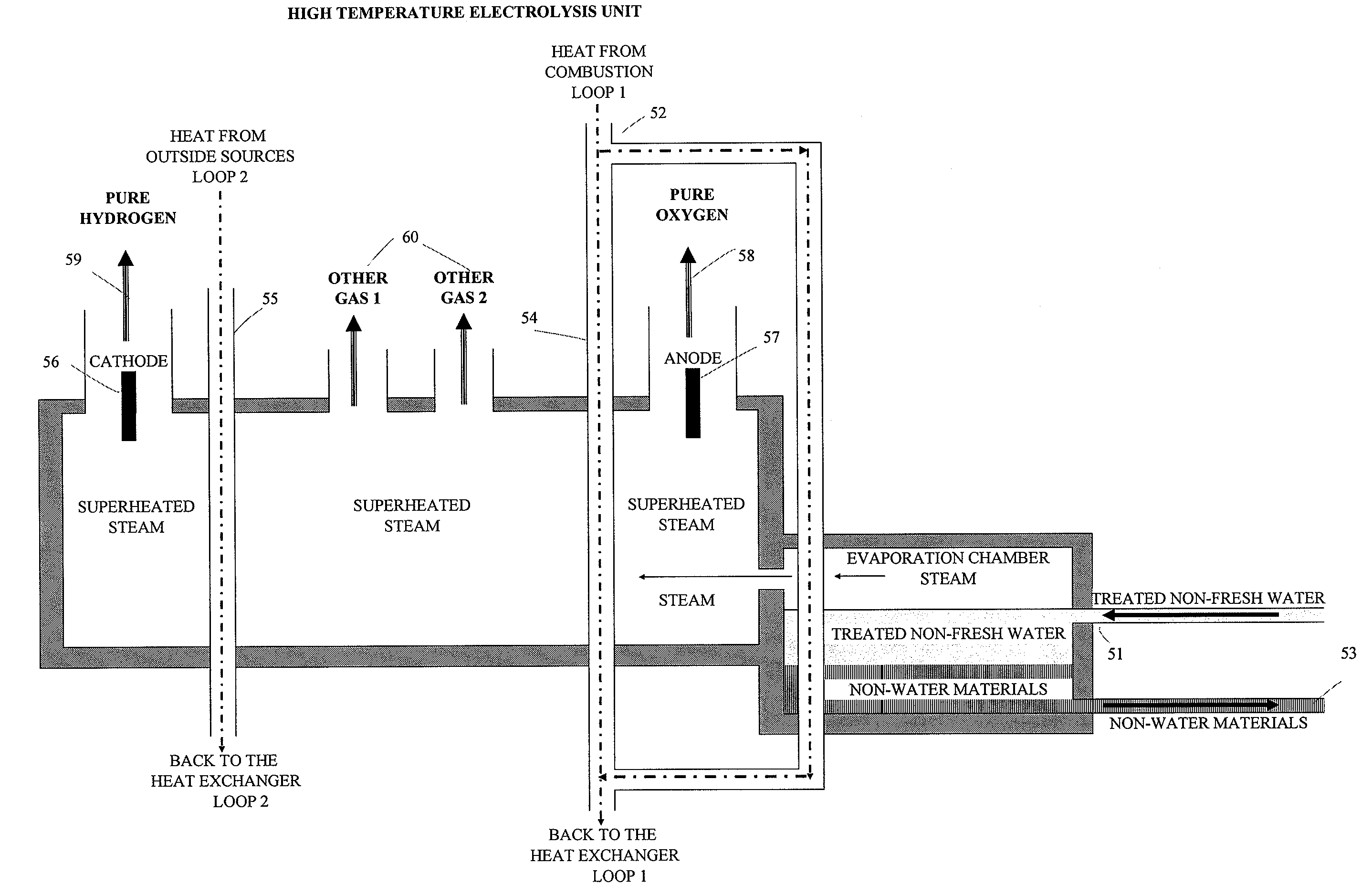

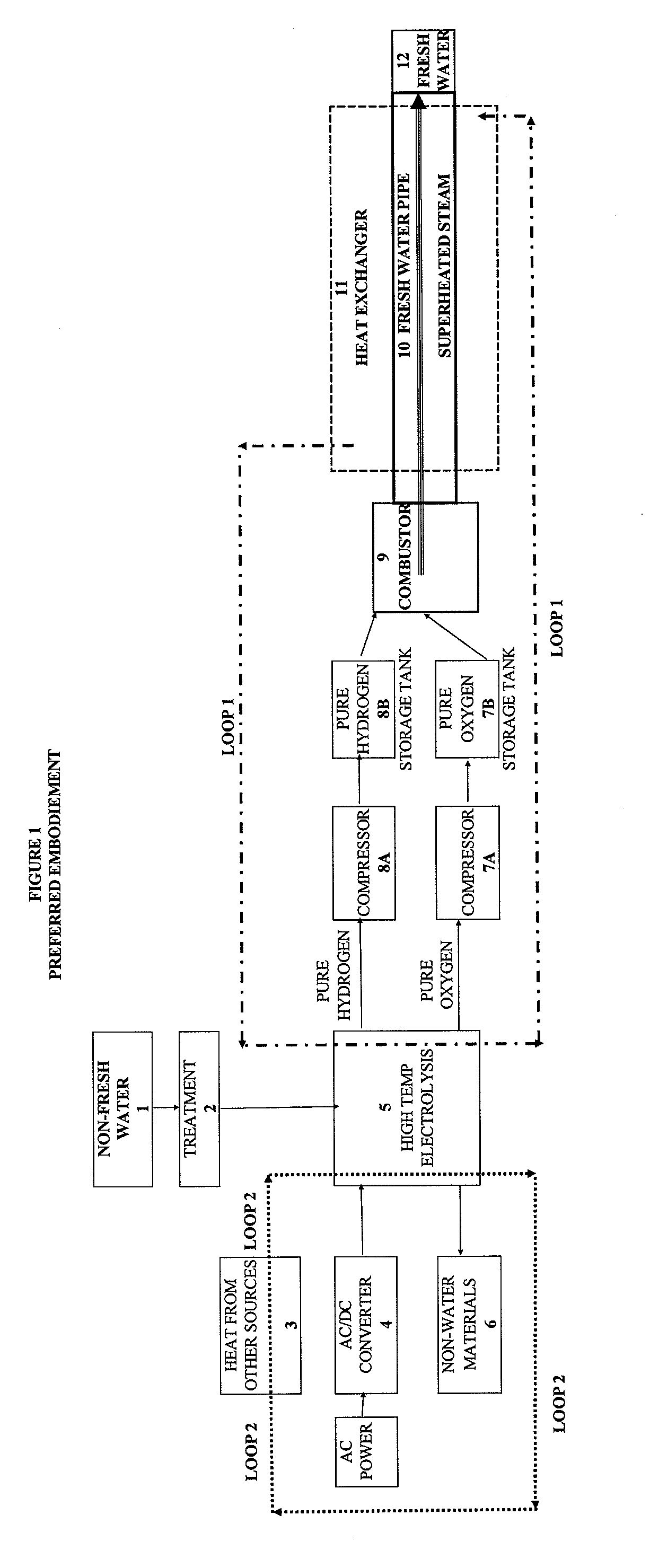

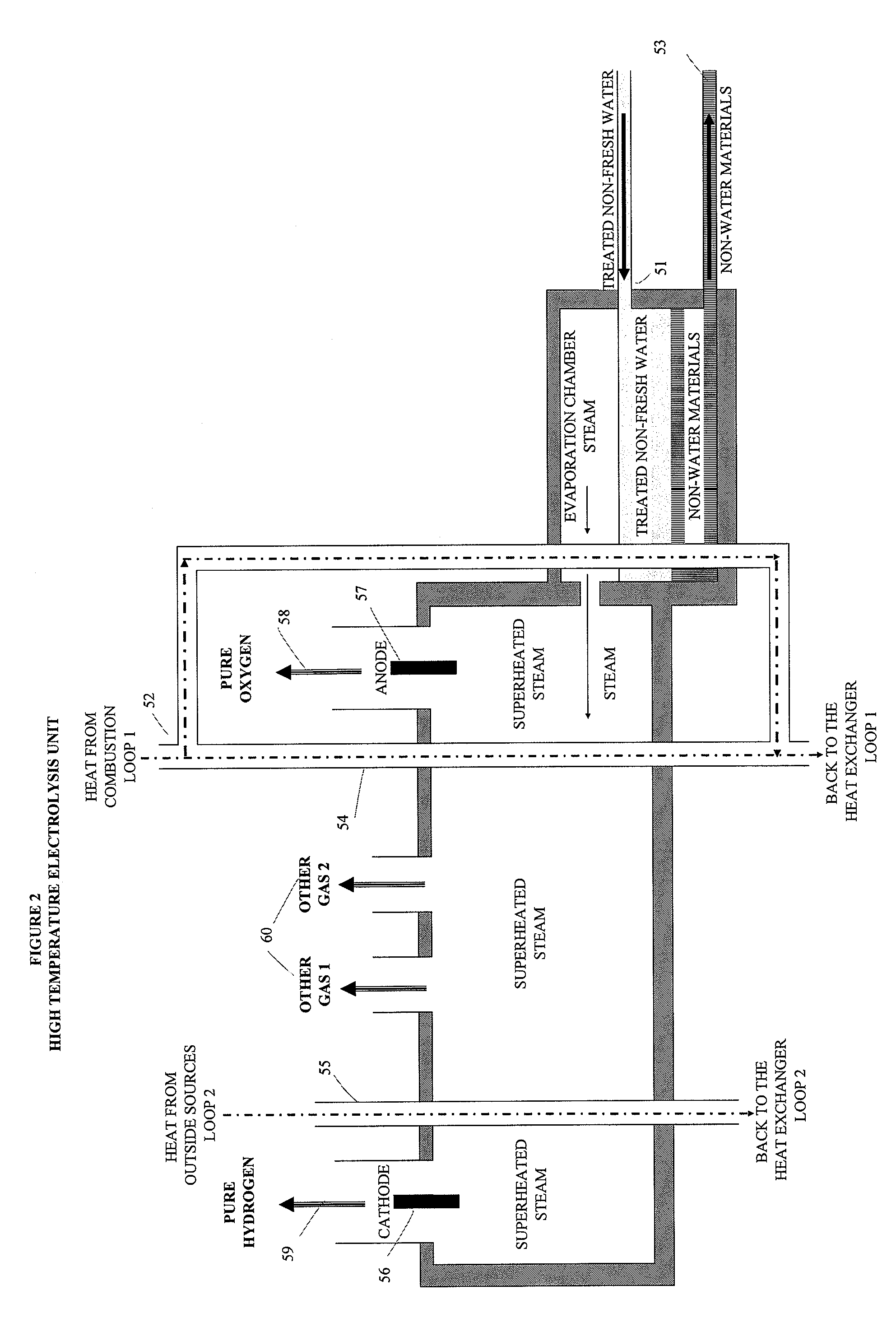

System and process for converting non-fresh water to fresh water

InactiveUS20100272630A1Reduce water supply costsReducing water cost water disposal costGeneral water supply conservationSeawater treatmentCombustorHydrogen

A method of converting non-fresh water to fresh water, referred to as the “Rosenbaum-Weisz Process”, is disclosed. The Process utilizes high temperature electrolysis to decompose the treated non-fresh water into hydrogen and oxygen. The generated hydrogen and oxygen are then combusted at elevated pressure in a high temperature combustor to generate high pressure high temperature superheated steam. The combustion of hydrogen and oxygen at elevated high pressure will prevent air from entering the combustor thereby preventing the creation of nitrous oxide (“NOX”) that might otherwise be created as a result of the high temperature created by the combustion. The heat from the high pressure high temperature superheated steam is then removed by a high temperature heat exchanger system and recycled back to the high temperature electrolysis unit. The superheated steam will condense, as a result of the heat extraction by the heat exchanger system, to produce fresh water.

Owner:HTE WATER CORP

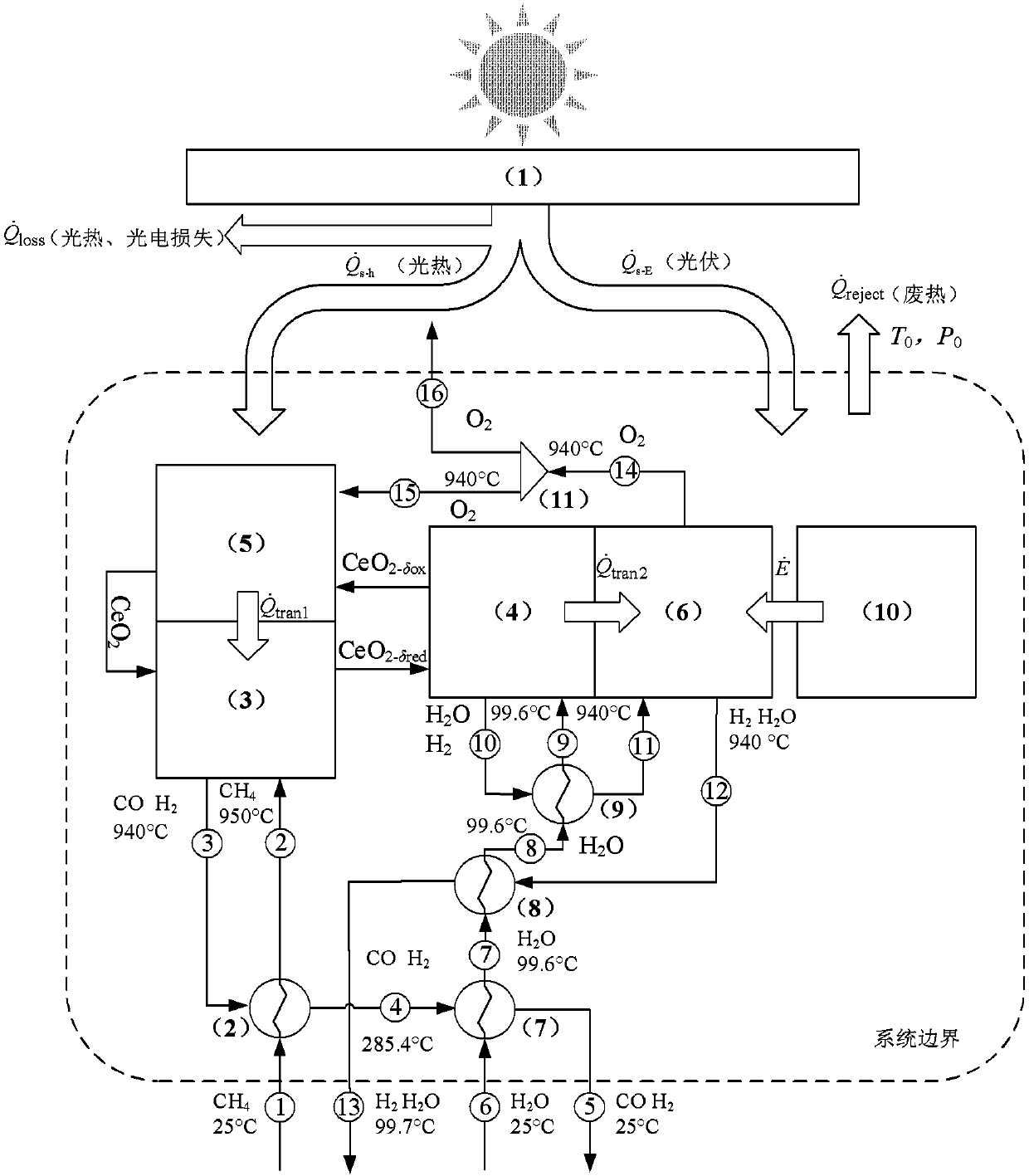

Electro-thermal chemical cycle coupled solar fuel preparation system and method

PendingCN108483396AImprove utilization efficiencyTake advantage ofSolar heating energyHydrogenThermal energySteam reforming

The invention discloses an electro-thermal chemical cycle coupled high-efficiency solar fuel preparation system and method. The system mainly comprises a light condensing and frequency dividing subsystem, a three-step methane steam reforming subsystem, and a high-temperature water electrolytic hydrogen producing subsystem, wherein a first solar spectrum obtained by the light condensing and frequency division subsystem drives the three-step methane steam reforming subsystem to perform a three-step methane water reforming reaction through heat collection; then a second spectrum drives the high-temperature water electrolytic hydrogen producing subsystem to perform reaction of producing H2 by electrolyzing water through a photovoltaic cell; the three-step methane steam reforming subsystem canprovide thermal energy, high-temperature steam source and reducing atmosphere to the high-temperature water electrolytic hydrogen producing subsystem, and pure O2 produced by the high-temperature water electrolytic hydrogen producing subsystem can be directly used in the three-step methane steam reforming subsystem. The high-efficiency solar fuel preparation system and method realize the synergistic coupling of solar thermochemical and electrochemical processes, and can efficiently produce pure hydrogen and high-quality syngas and efficiently convert solar energy into hydrocarbon and hydrogenfuel.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Methods for producing combustible gas from the electrolysis of water (HTE) or co-electrolysis with h2o/co2 in the same chamber, and associated catalytic reactor and system

The invention relates to a novel reactor design, wherein the pressurised chamber contains both a high-temperature electrolysis (HTE) reactor with elementary electrolysis cell stacking for producing either hydrogen or a synthesis gas (“syngas” for a H2+CO mixture) from water vapour H2O and carbon dioxide C02, and at least one catalyst arranged at a distance and downstream of the outlet of the electrolyser for converting the previously produced synthesis gas into the desired combustible gas, by means of heterogeneous catalysis, the synthesis gas having being produced either directly from the electrolysis reactor or indirectly by mixing the hydrogen produced with carbon dioxide C02 injected into the chamber.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

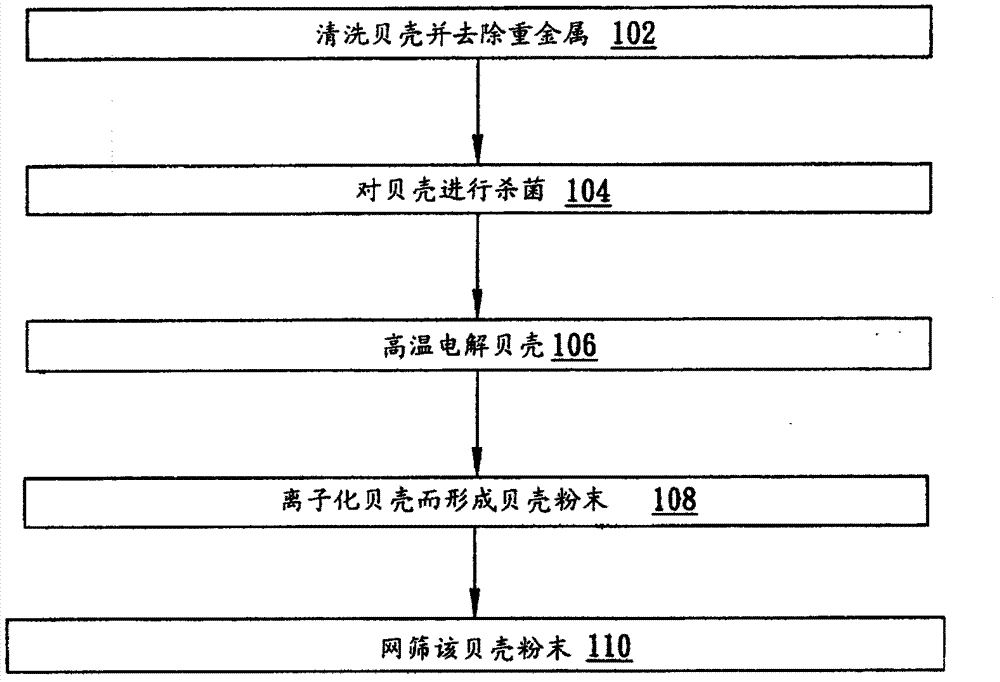

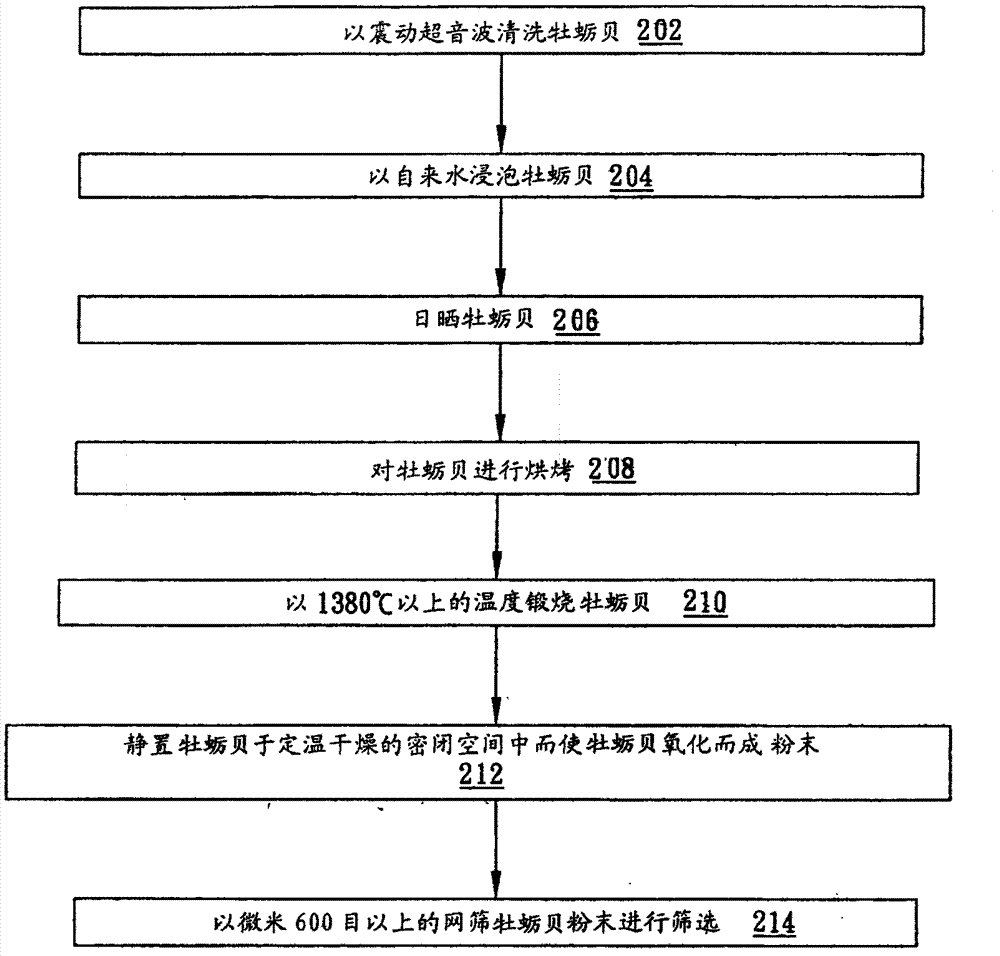

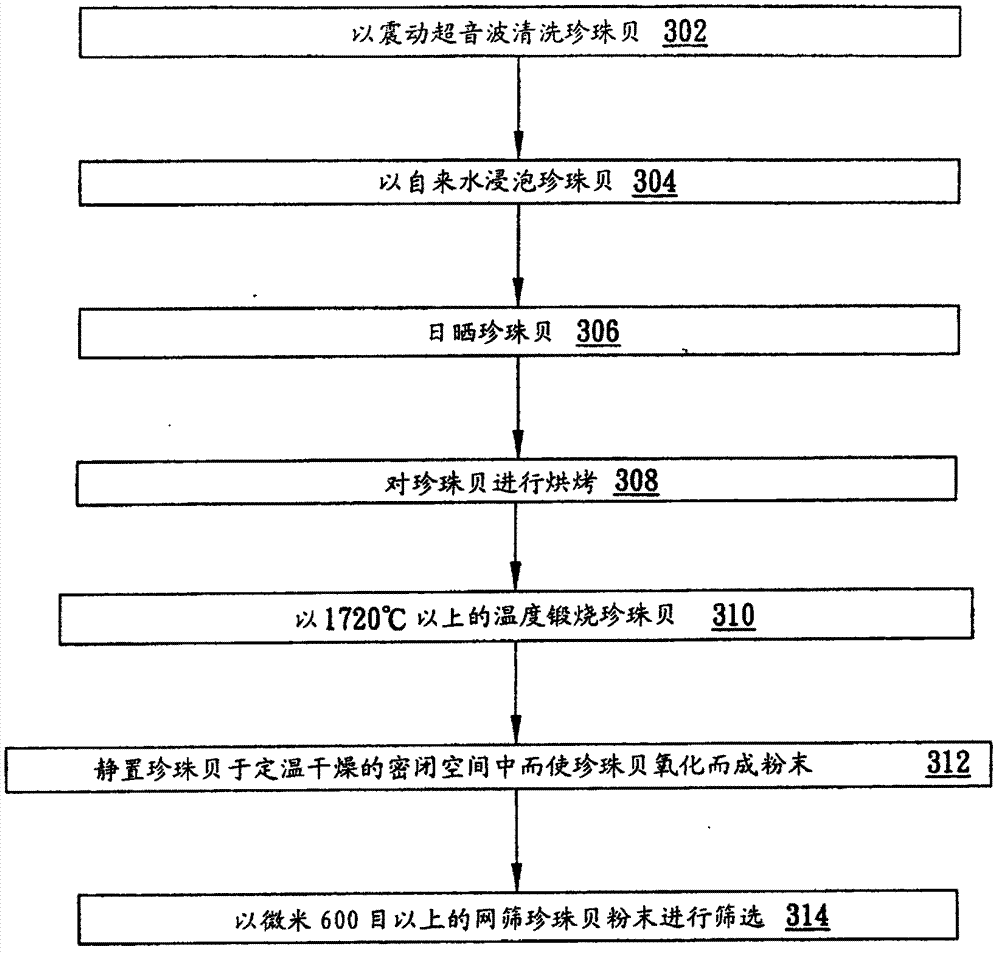

Natural cleaning agent for removing residual pesticide on fruit and vegetable surfaces and preparation method

InactiveCN103087846AHealth hazardNon-irritatingNon-surface-active detergent compositionsDetergent mixture composition preparationEcological environmentIrritation

The invention relates to a natural cleaning agent for removing residual pesticides on fruit and vegetable surfaces and a preparation method; the preparation method of the cleaning agent comprises the following steps: cleaning shells, removing heavy metal, sterilizing the shells, performing high temperature electrolysis and ionization of the sterilized shells to form solid powder, and refining with a mesh sieve to prepare nanometer powder; the cleaning agent comprises one or more than one natural shells according to certain weight ratios. The cleaning agent of the invention not only can remove residual toxic materials on fruit and vegetable surfaces, such as pesticides, sulfur dioxide and aflatoxin, prevent toxic materials from entering human body by eating of the fruit and vegetable, thus prevent continuous accumulation of the toxic materials in the body to damage human body health, but also has no toxicity or irritation to human skin, causes no secondary pollution of ecological environment, meets the development trend of green cleaning agents, and has good application prospects.

Owner:曾皇铭

Electrolyte for solid oxide fuel cell and preparation method thereof

InactiveCN103746134AImprove conductivityIncrease the open circuit voltageFinal product manufactureSolid electrolyte fuel cellsFuel cellsElectrical battery

The invention relates to an electrolyte for a solid oxide fuel cell and a preparation method thereof. In order to improve the performance of the electrolyte of the solid oxide fuel cell, the invention adopts a nitrate gel combustion method to prepare 30%BaCe0.8Y0.2O2.9-70%Ce0.8Gd0.2O1.9 electrolyte. When the electrolyte is used for the solid oxide fuel cell, the operating temperature of the cell is intermediate temperate 600-800 DEG C, but the operating temperature of the traditional solid oxide fuel cell is high temperate 900-1000 DEG C. The relative density of the electrolyte achieves 100 percent. Under the humid air atmosphere (3%H2O) and the temperature 700 DEG C, the conductivity is 0.01S / cm and is higher than the conductivity of the commonly-used electrolytes Ce0.8-Gd0.2O1.9 and BaCe0.8Y0.2O2.9 prepared by the same method.

Owner:FUZHOU UNIV

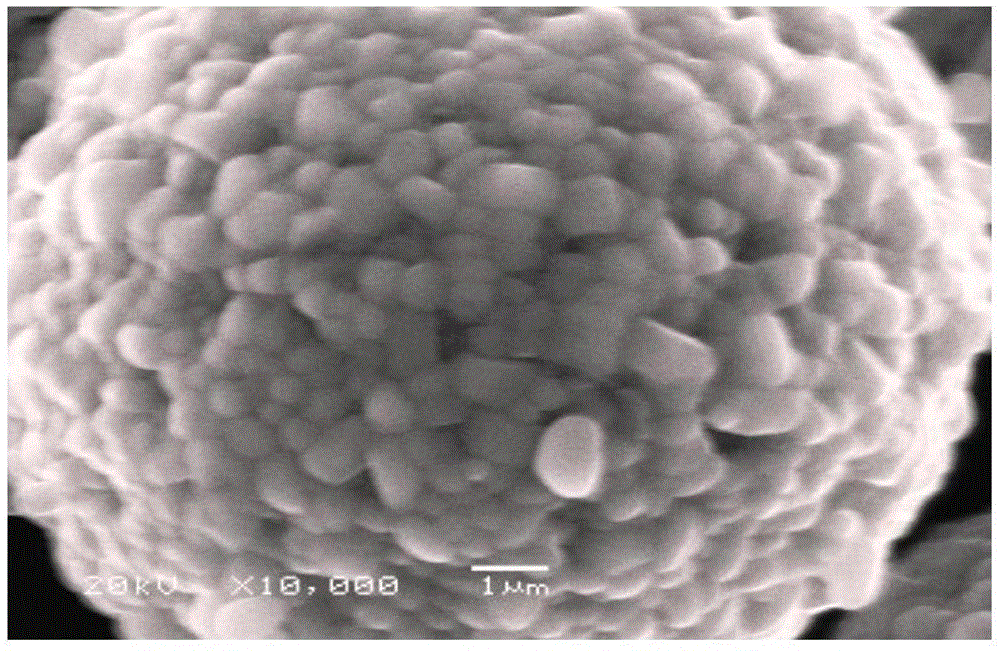

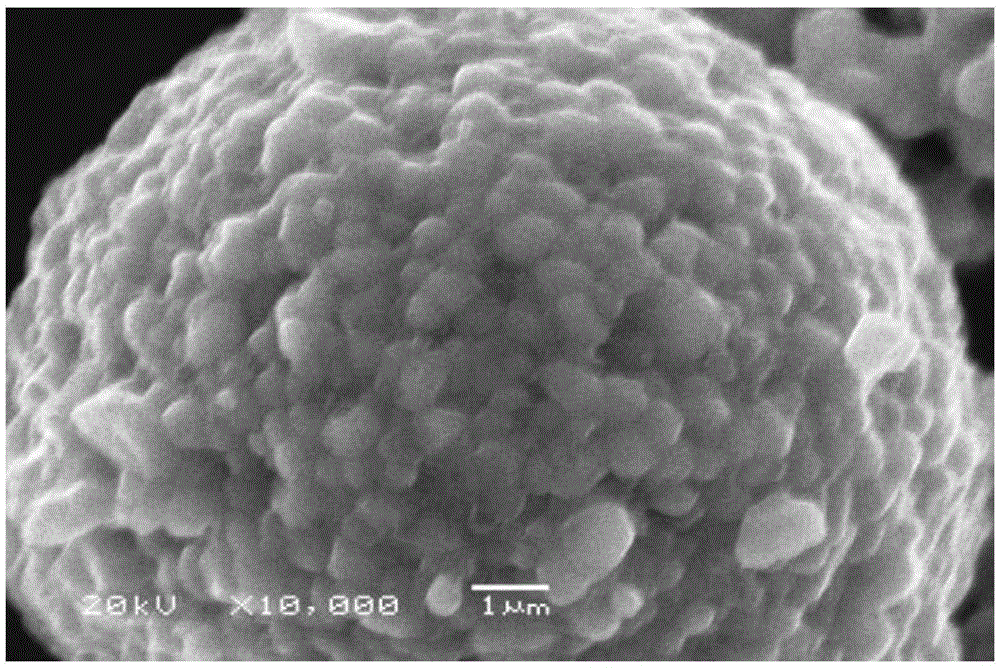

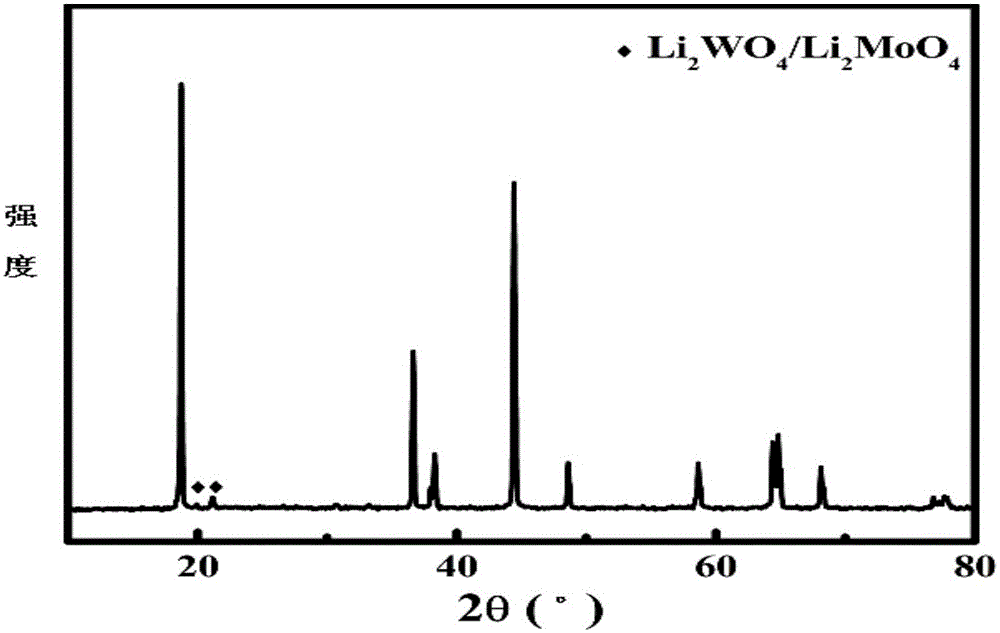

Modified lithium-ion battery cathode material and preparation method thereof

ActiveCN105140482AImprove air storage performanceImprove high temperature electrolyte storage performanceCell electrodesSecondary cellsMass ratioPhysical chemistry

The invention discloses a modified lithium-ion battery cathode material, which comprises a cathode material body and a lithium tungstomolybdic acid layer, wherein the lithium tungstomolybdic acid layer coats the surface of the cathode material body; and the mass ratio of the lithium tungstomolybdic acid layer to the cathode material body is (0.5-5) to 100. A preparation method comprises the following steps: (1) adding a lithium salt and a tungsten-molybdenum source to a solvent, and dissolving the lithium salt and the tungsten-molybdenum source to form a solution; (2) adding the cathode material body to the solution obtained from the step (1), stirring the cathode material evenly at constant temperature and drying the cathode material to obtain a precursor; and (3) heating the precursor to 250-550 DEG C, and roasting and cooling the precursor, so as to obtain the modified lithium-ion battery cathode material. According to the modified lithium-ion battery cathode material disclosed by the invention, the lithium tungstomolybdic acid layer coats the surface of the battery cathode material; CO2, H2O and electrolyte in air can be relatively well isolated; and the air storage performance of the material, the high-temperature electrolyte storage performance and the electrochemical cycling stability of the material are greatly improved.

Owner:CENT SOUTH UNIV

High temperature electrolysis glow discharge method

ActiveUS20160307733A1Steam generation heating methodsElectric discharge tubesElectrical connectionCondensed matter physics

The present invention provides a glow discharge assembly that includes an electrically conductive cylindrical screen, a flange assembly, an electrode, an insulator and a non-conductive granular material. The electrically conductive cylindrical screen has an open end and a closed end. The flange assembly is attached to and electrically connected to the open end of the electrically conductive cylindrical screen. The flange assembly has a hole with a first diameter aligned with a longitudinal axis of the electrically conductive cylindrical screen. The electrode is aligned with the longitudinal axis of the electrically conductive cylindrical screen and extends through the hole of the flange assembly into the electrically conductive cylindrical screen. The insulator seals the hole of the flange assembly around the electrode and maintains a substantially equidistant gap between the electrically conductive cylindrical screen and the electrode. The non-conductive granular material is disposed within the substantially equidistant gap.

Owner:FORET PLASMA LABS

Glass compositions for gaskets of apparatuses operating at high temperatures and assembling method using them

ActiveUS20120318022A1Meet rigid requirementsImprove balanceCellsFinal product manufactureFuel cellsPhotochemistry

A glass composition, characterized in that it is selected from the group consisting of: a glass composition (A) with the following molar percentages: 70 to 76% of SiO2, 7 to 8% of B2O3, 5 to 6% of Al2O3, and 10 to 17% of Na2O; and a glass composition (B) with the following molar percentages: 63 to 76% of SiO2, 5 to 12% of ZrO2, 0 to 12% of B2O3, 0 to 2% of La2O3, 11 to 14% of Na2O, and 3 to 5% of K2O. The glass composition can be used in a method for assembling parts, in particular for a method of manufacturing high-temperature electrolyzers (HTEs) or high-temperature fuel cells (SOFCs).

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

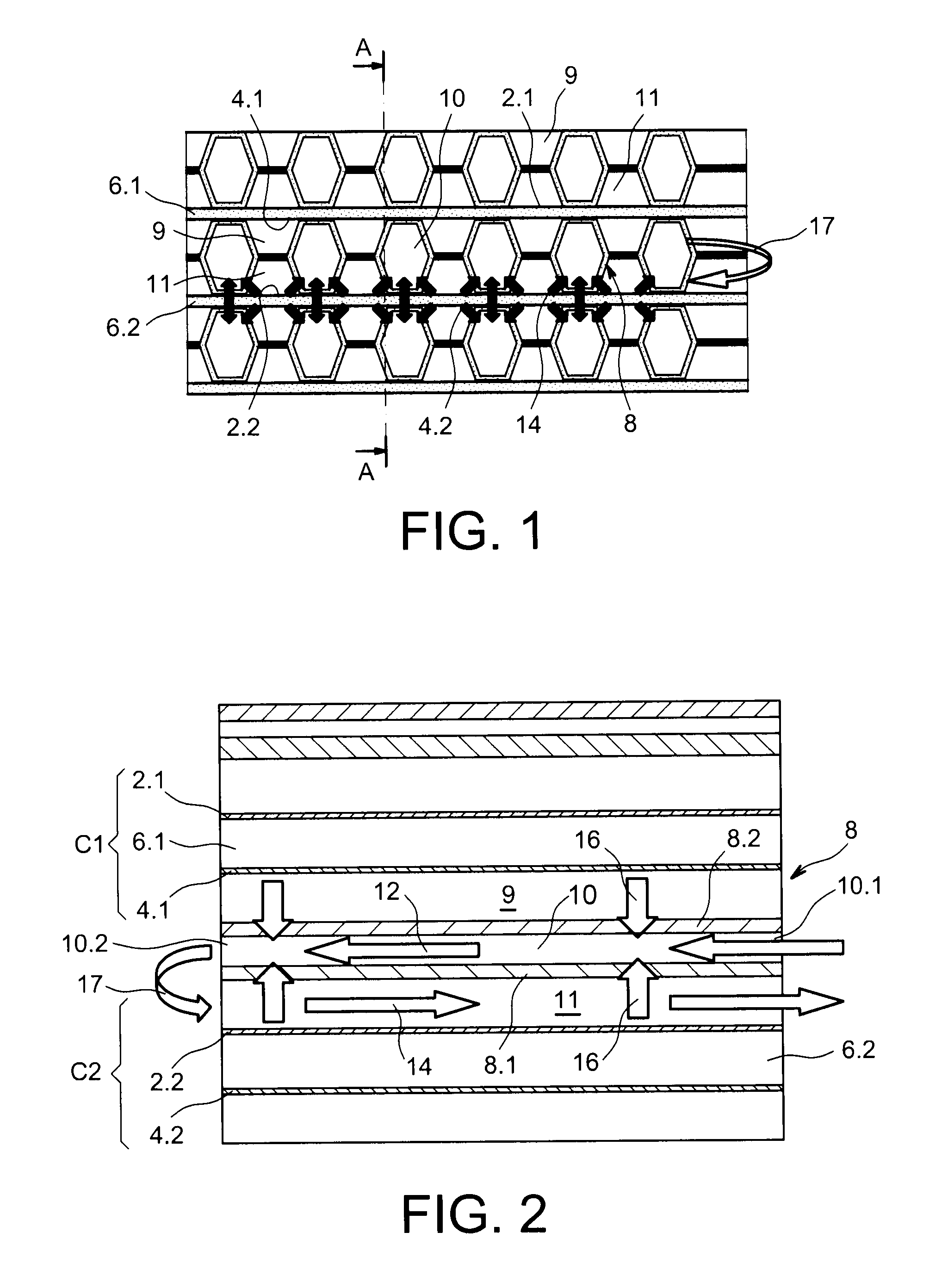

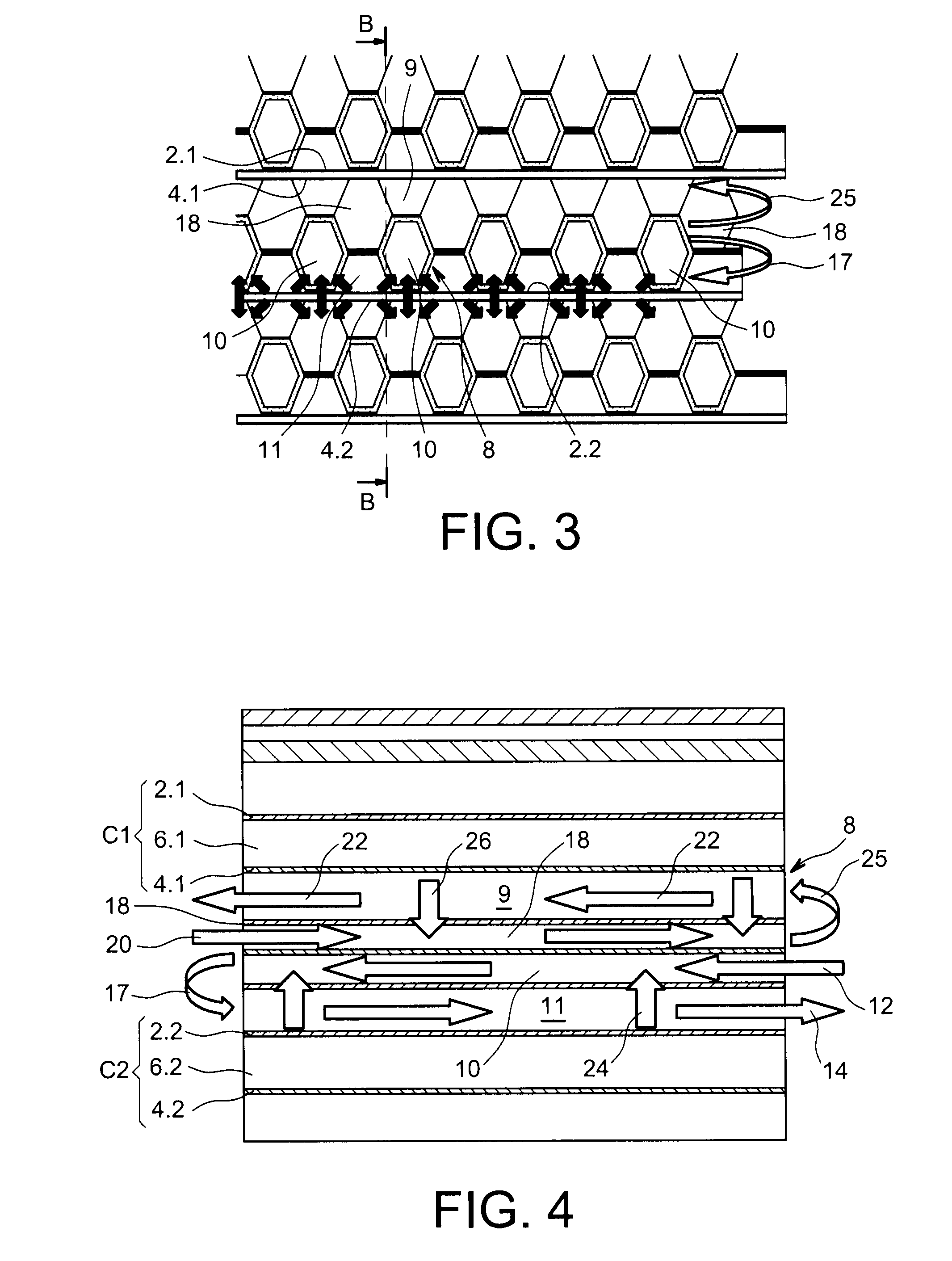

Method for high-temperature electrolysis of steam and another gas, related interconnector, electrolysis reactor and operating methods

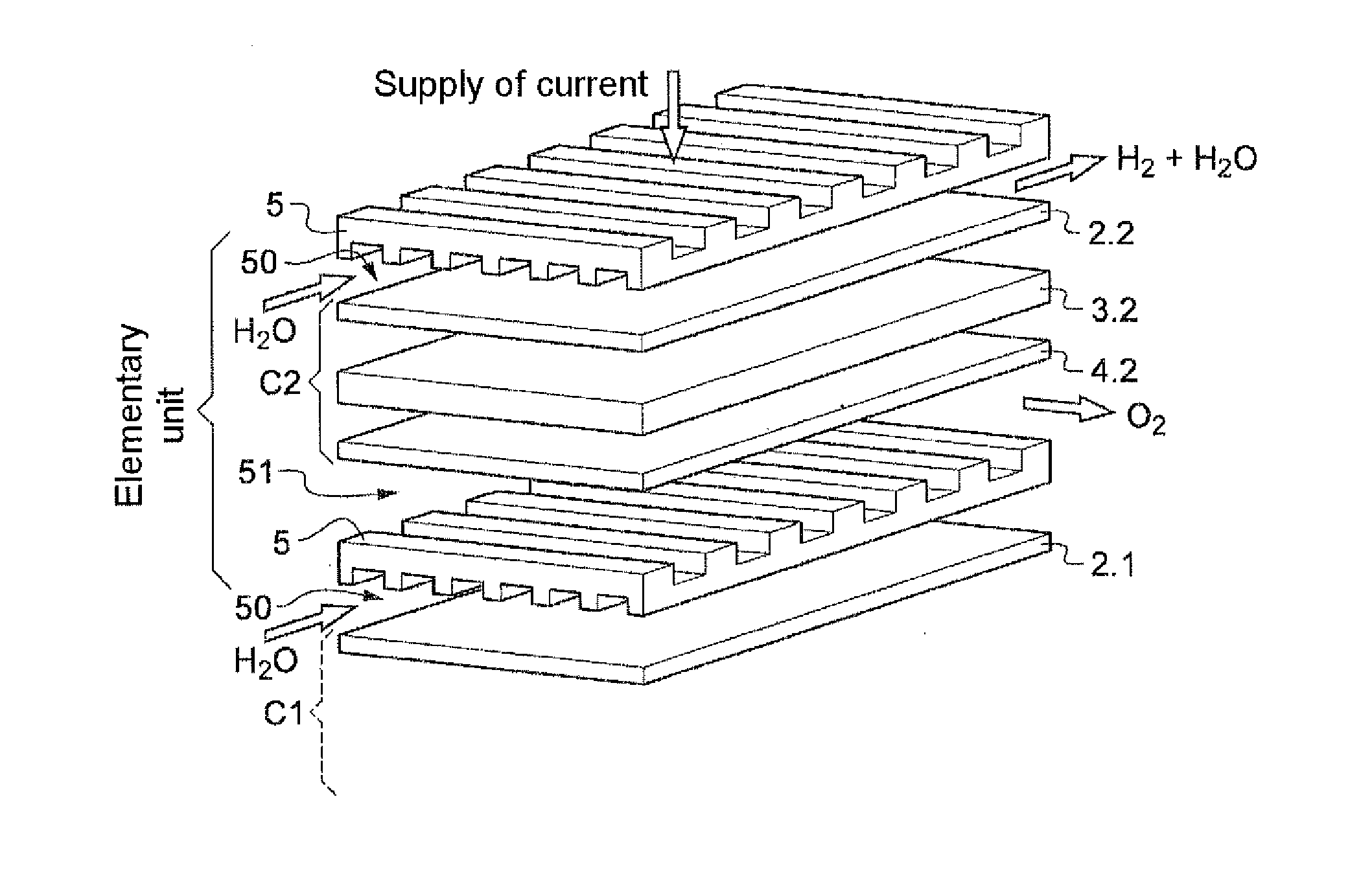

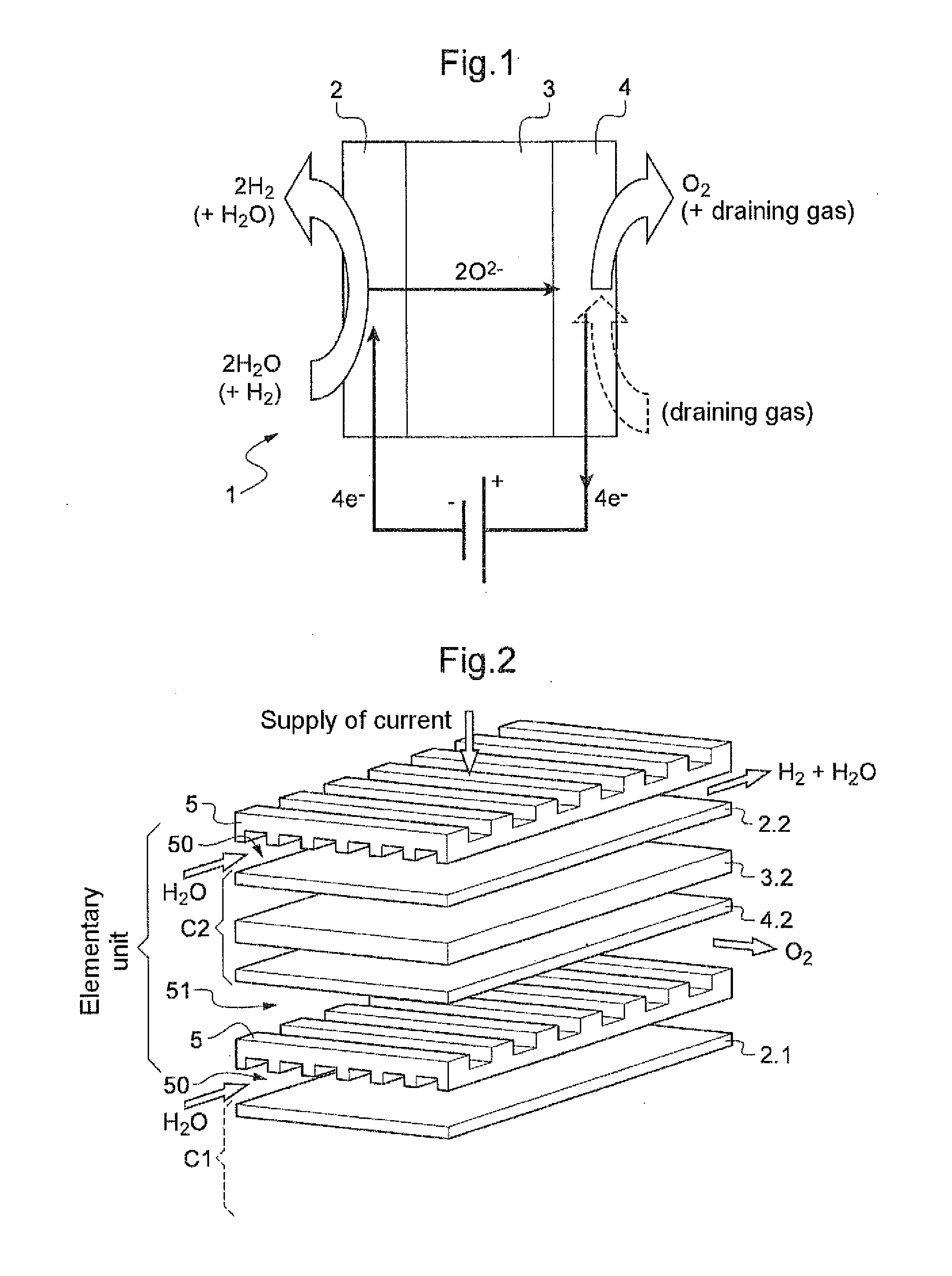

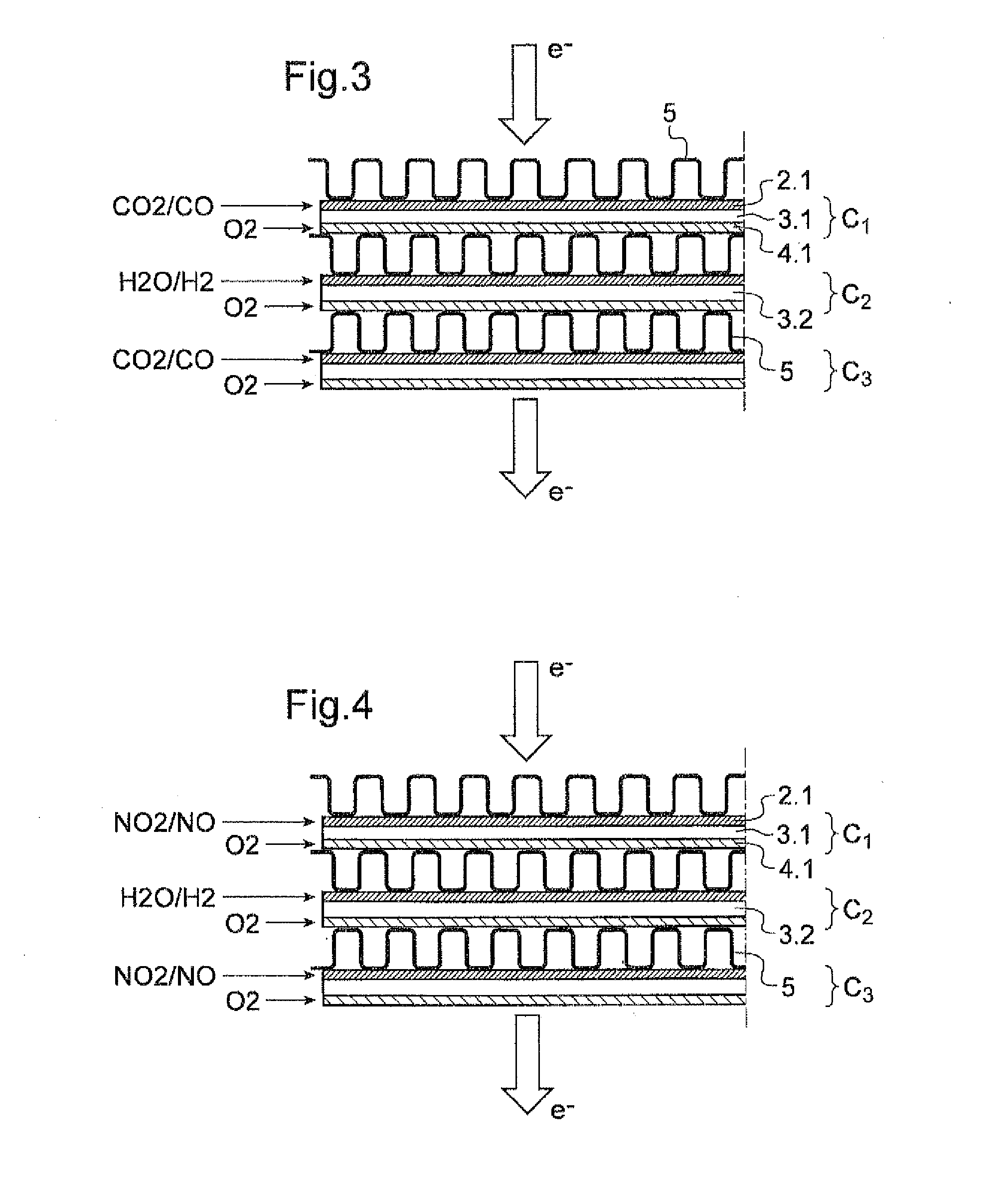

ActiveUS20150329979A1Drawback can be obviatedSuppression of shortcomingsCellsElectrolytic organic productionElectricityInterconnector

A method for high-temperature electrolysis of steam and another gas to be electrolysed, chosen from carbon dioxide and nitrogen dioxide, implemented in an electrolysis reactor includes a stack of elementary electrolysis cells each made of a cathode, an anode and an electrolyte inserted between the cathode and the anode, and a plurality of electric and fluid interconnectors each arranged between two adjacent elementary cells with one of the surfaces thereof in electric contact with the anode of one of the two elementary cells and the other one of the surfaces thereof in electric contact with the cathode of the other one of the two elementary cells. The steam is supplied and distributed to the cathode of one of the two adjacent elementary cells and either carbon dioxide or nitrogen dioxide is supplied and distributed to the cathode of the other one of the two elementary cells.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

A flue gas waste heat power generation system for aluminum electrolytic cell with flue gas separation device

InactiveCN102287245AImprove operational efficiencyIncrease power generationSteam engine plantsCogenerationHigh-temperature electrolysis

An aluminum electrolytic cell flue gas waste heat power generation system with a flue gas separation device includes a flue gas system, a waste heat boiler system, a steam turbine generator set, an electrical and a control system; the flue gas system is used to collect the high temperature generated by the anode of the aluminum electrolytic cell Flue gas, and send the high-temperature flue gas into the waste heat boiler system. The high-temperature flue gas performs heat exchange in the waste heat boiler system to generate steam, and the steam enters the turbogenerator unit for power generation; the electrical and control systems are used for the flue gas system. , waste heat boiler system, and steam turbine generator set provide power and coordinated control. The invention separates the high-temperature electrolysis flue gas through the flue gas separation device of the aluminum electrolytic cell, and inputs the flue gas into the waste heat boiler to generate steam, and then drives the steam turbine to rotate to drive the generator to generate electricity. The high-temperature flue gas can improve the steam parameters of the waste heat boiler and the waste heat recovery efficiency, and the improvement of the steam parameters can increase the operating efficiency of the steam turbine. The combined effect of the two improves the recovery rate of waste heat from the flue gas and the power generation of the waste heat power station.

Owner:BEIJING CENTURY BENEFITS

Device and method for high temperature electrolysis of seawater to prepare hydrogen

ActiveCN110923738AImprove securityImplement conversion storageCellsGeneral water supply conservationWater vaporThermal energy storage system

The invention relates to a device for high temperature electrolysis of seawater to prepare hydrogen. A high temperature water electrolysis hydrogen producing system and a seawater desalination systemare connected so that steam from the seawater desalination system is electrolyzed in a solid oxide electrolysis tank to obtain mixed gas composed of hydrogen and unreacted steam; the seawater desalination system is connected to a molten salt heat storage system so that the crystallized salts obtained by heating and evaporating seawater are taken as the raw materials for preparing chlorine salts for the molten salt heat storage system; the molten salt heat storage system is connected to the seawater desalination system so that the molten salt heat storage system provides heat for the heating ofseawater; and the molten salt heat storage system is connected to the high temperature water electrolysis hydrogen producing system so as to provide heat for the steam that enters the solid oxide electrolysis tank. The invention also provides a method for preparing hydrogen through high temperature seawater electrolysis by using the device mentioned above. The provided device and method can realize seawater high temperature electrolysis to produce hydrogen and seawater desalination at the same time, and have a wide application range.

Owner:上海氢程科技有限公司

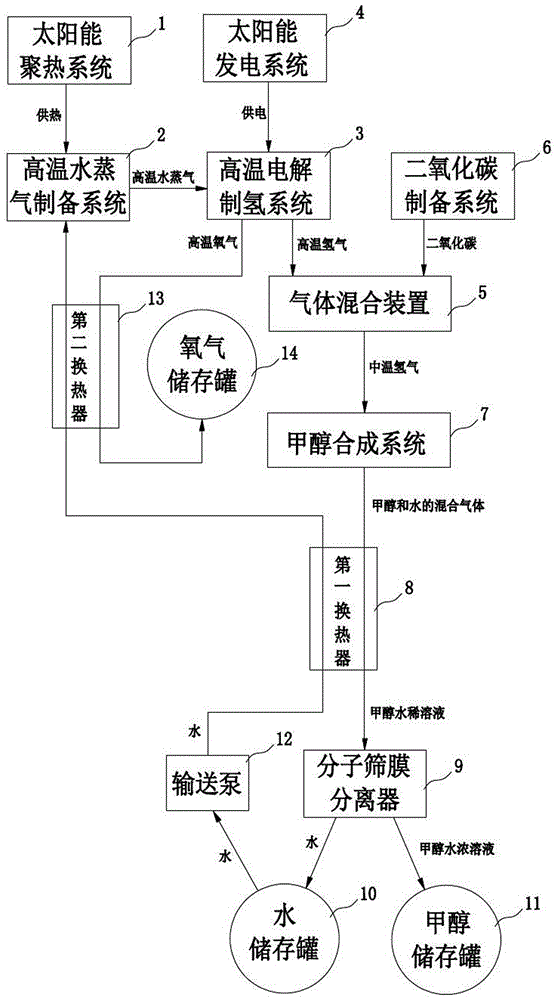

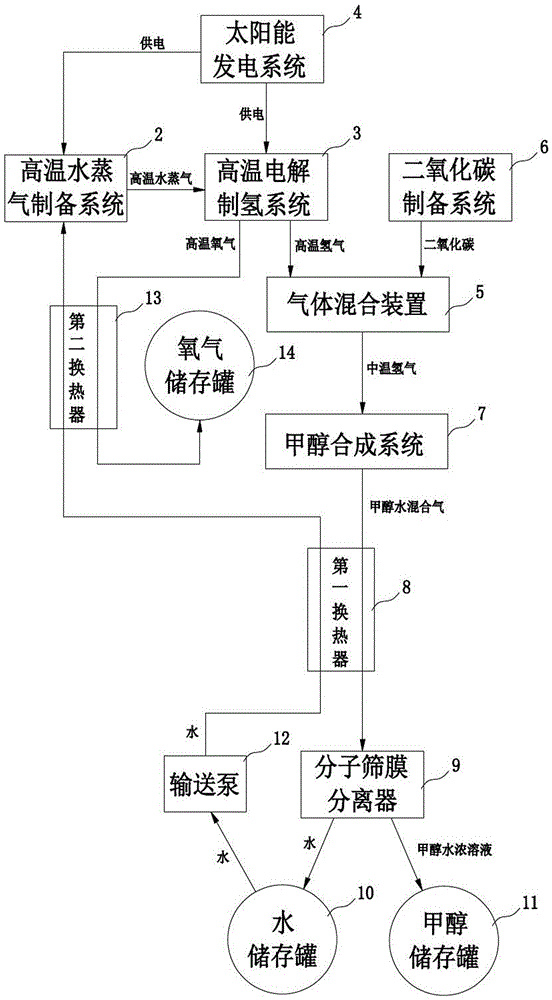

Equipment and process for synthesizing methanol through solar energy hydrogen production

ActiveCN106242946ATake advantage ofReduce wasteCellsOrganic compound preparationThermal energyWater storage tank

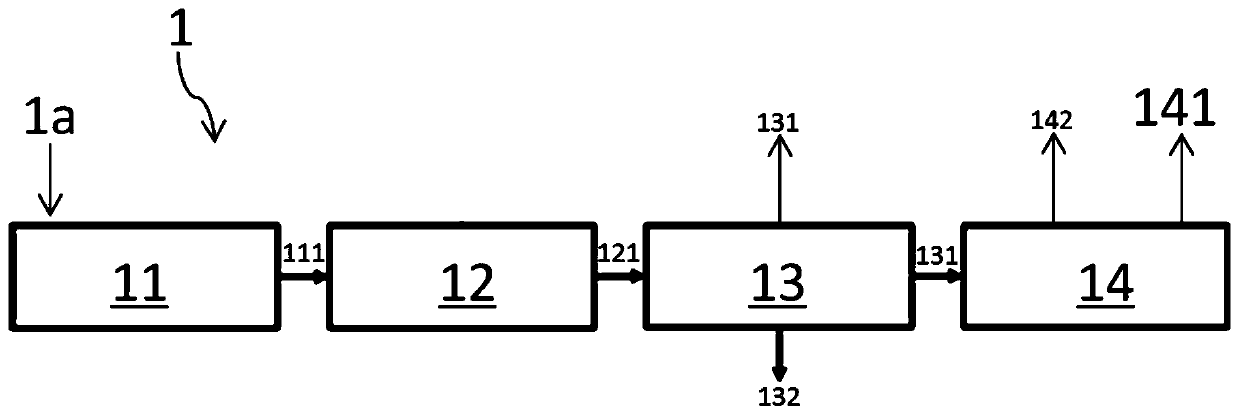

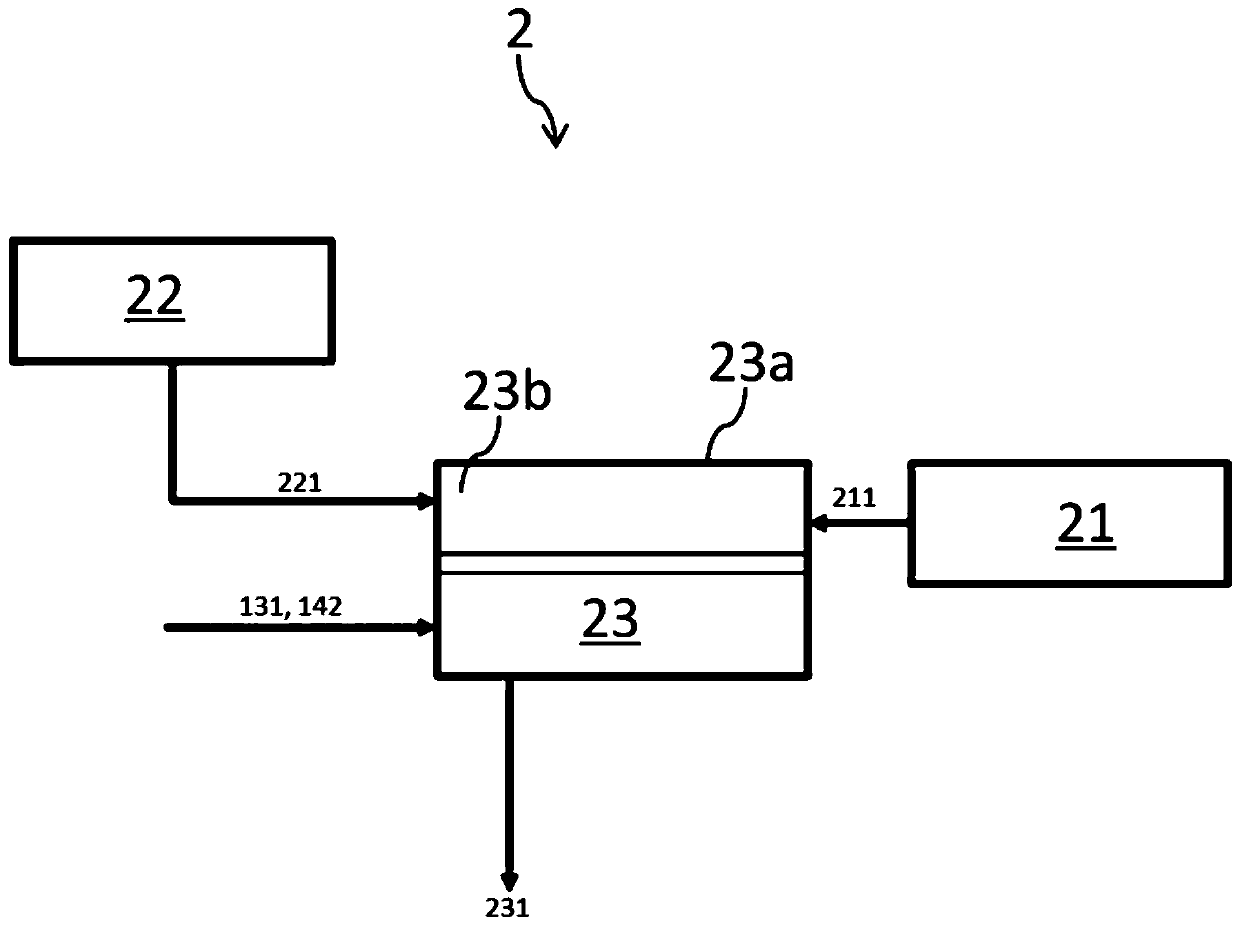

The invention discloses equipment and a process for synthesizing methanol through solar energy hydrogen production. The equipment comprises a solar energy heat accumulation system, a high-temperature water vapor preparation system, a solar power generation system, a high-temperature electrolysis hydrogen production system, a carbon dioxide preparation system, a gas mixing device, a methanol synthesis system, a first heat exchanger, a molecular sieve membrane separator, a methanol storage tank, a water storage tank and a conveying pump, wherein the high-temperature water vapor preparation system is used for preparing high-temperature water vapor at 800-900 DEG C by using heat energy provided by the solar energy heat accumulation system and supplying the high-temperature water vapor to the high-temperature electrolysis hydrogen production system; the first heat exchanger is mounted on a conveying pipe between the methanol synthesis system and the molecular sieve membrane separator; the molecular sieve membrane separator is used for separating water in methanol water-diluted solution, conveying the separated water to the water storage tank, and pumping the water to the high-temperature water vapor preparation system through the conveying pump. The equipment and the process provided by the invention are high in preparation efficiency of hydrogen raw materials and high in utilization rate of solar energy, and can fully utilize by-product water produced during the production of methanol.

Owner:GUANGDONG HYDROGEN ENERGY SCI & TECH

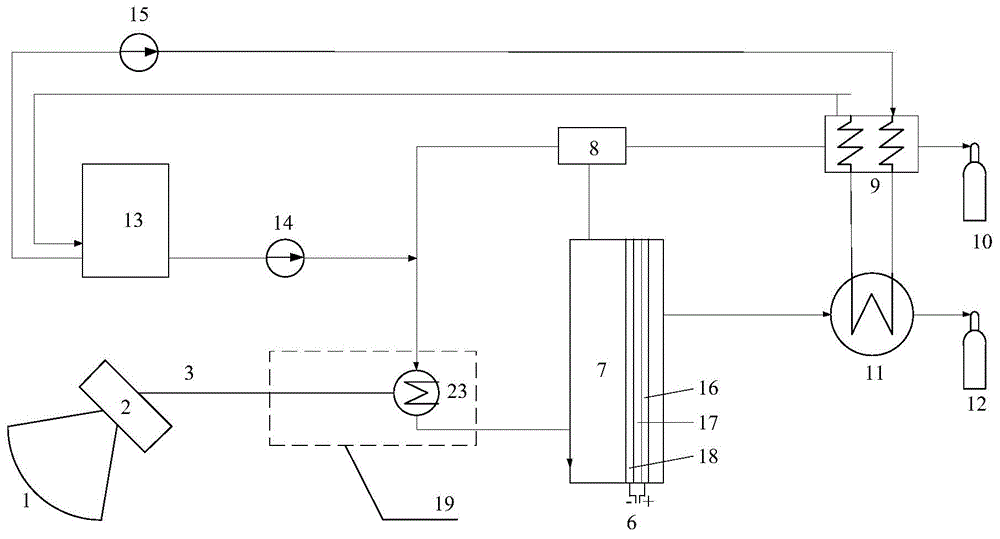

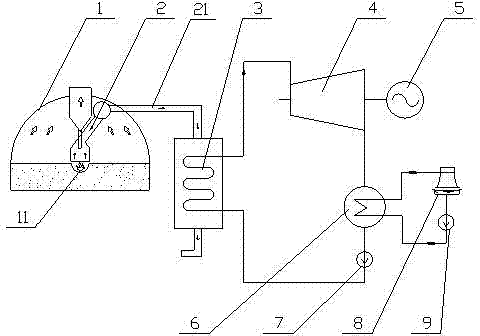

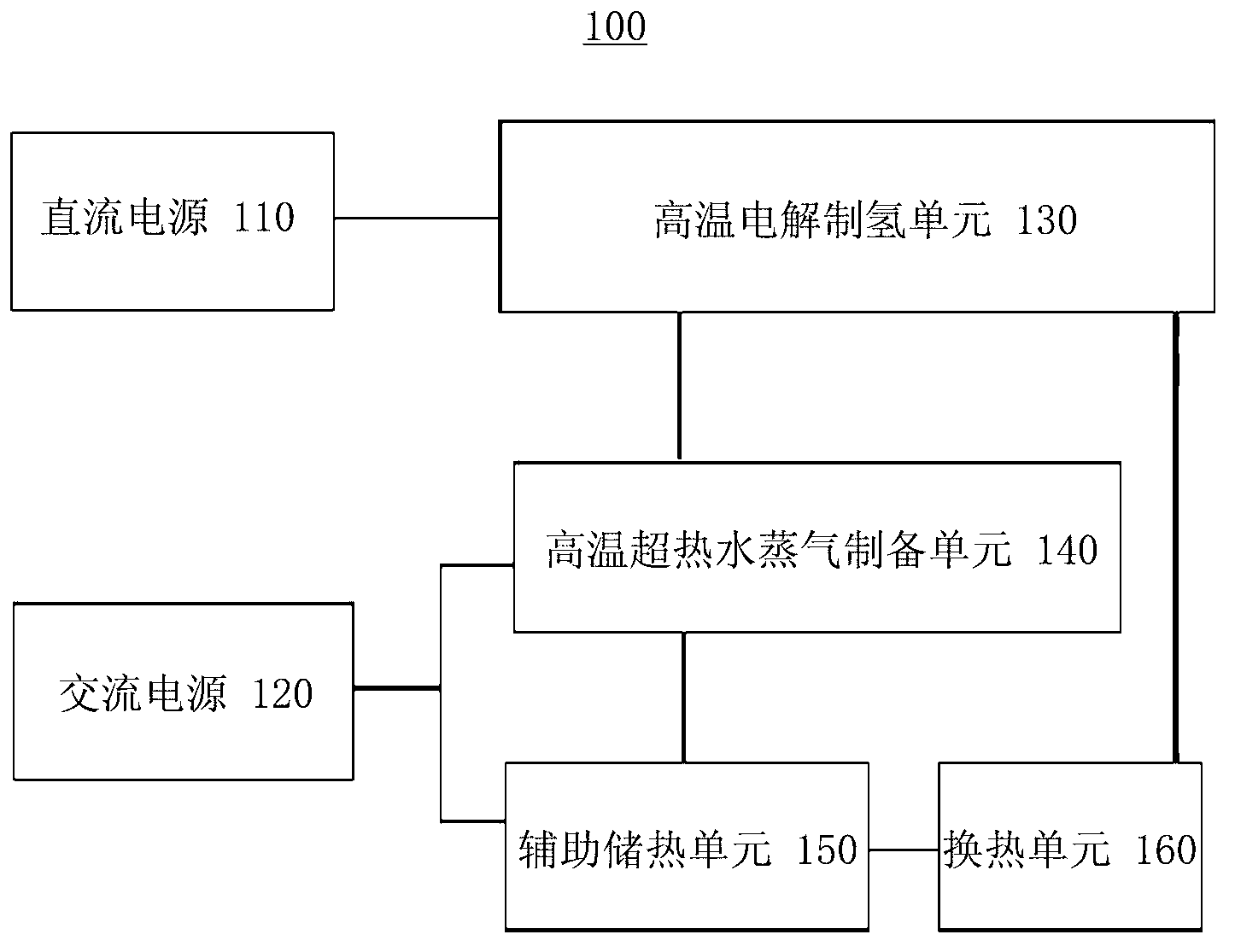

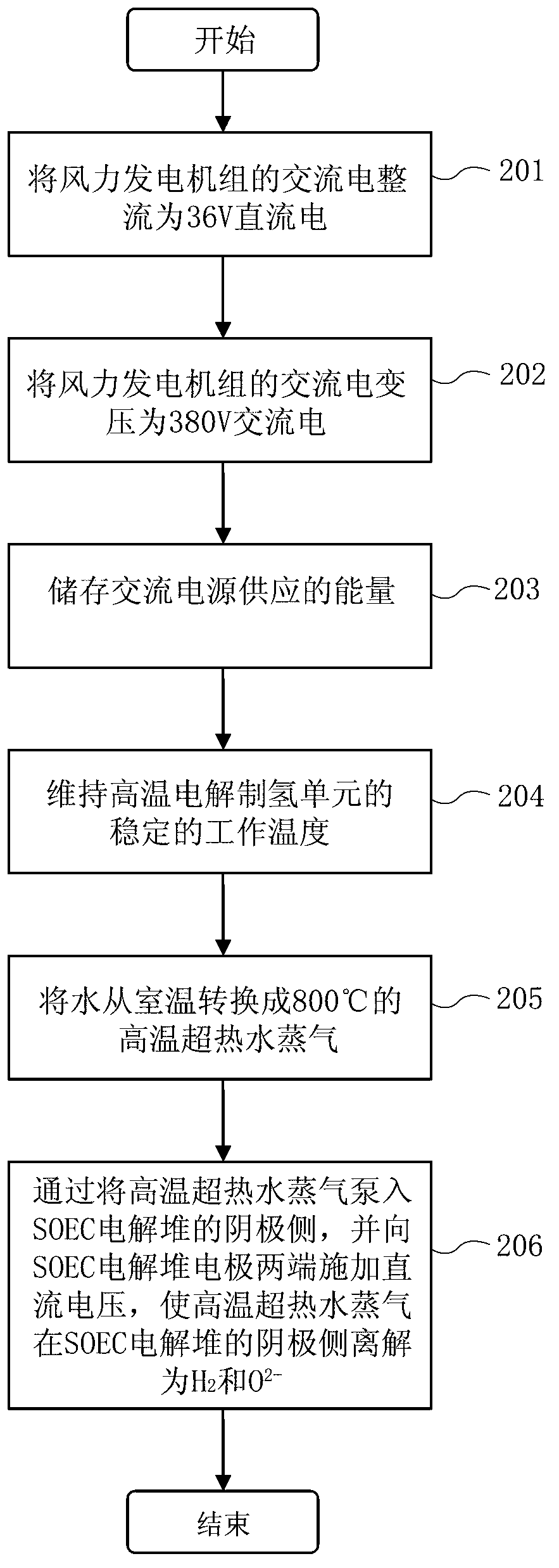

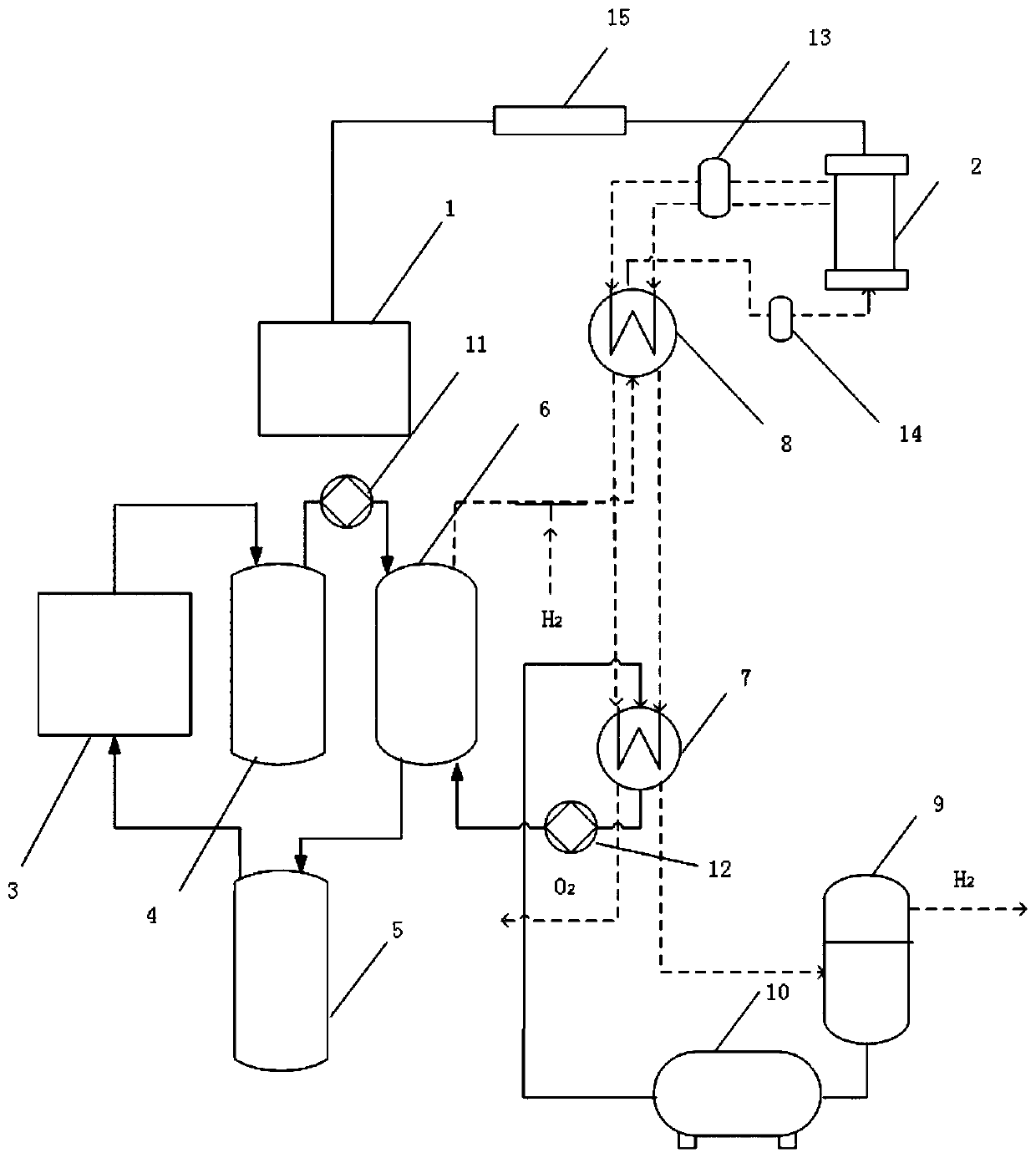

Wind power high temperature electrolytic hydrogen preparation system and method

The invention provides a wind power high temperature electrolytic hydrogen preparation system and a method. The system comprises a direct current power source, an alternating current power source, a high temperature super hot water vapor preparation unit, an auxiliary heat storage unit, a high temperature electrolytic hydrogen preparation unit and a heat exchange unit. The direct current power source rectifies alternating currents of a wind turbine generator system (WTGS) into direct currents of first voltage; the alternating current power source rectifies alternating currents of the WTGS into alternating currents of a second voltage; the high temperature super hot water vapor preparation unit prepares super hot water vapor based on the alternating currents of the alternating current power source; the auxiliary heat storage unit receives the alternating currents of the alternating current power source to store energy; the high temperature electrolytic hydrogen preparation unit utilizes direct current of the direct current power source to electrolyze the super hot water vapor prepared by the high temperature super hot water vapor preparation unit to prepare hydrogen; and the heat exchange unit exchanges heat in the high temperature electrolytic hydrogen preparation unit and the auxiliary heat storage unit so that the high temperature electrolytic hydrogen preparation unit is maintained at a stable temperature. When the alternating current voltage output by the alternating current power source is reduced apparently, the auxiliary heat storage unit supplies stored energy to the high temperature super hot water vapor preparation unit, so that the high temperature super hot water vapor preparation unit outputs super hot water vapor stably.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

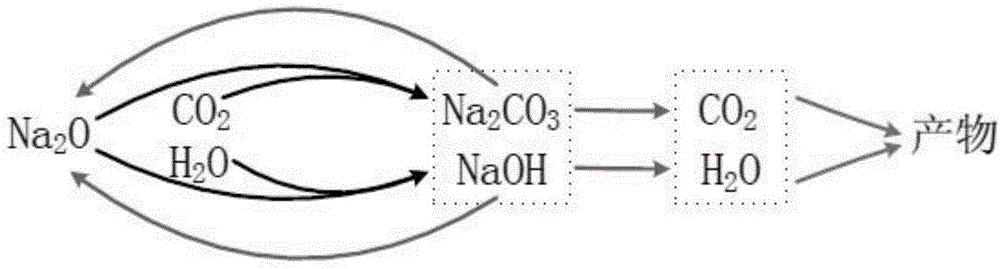

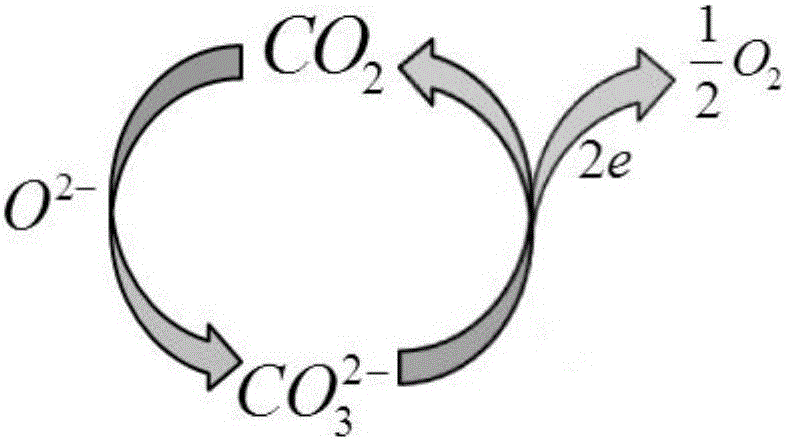

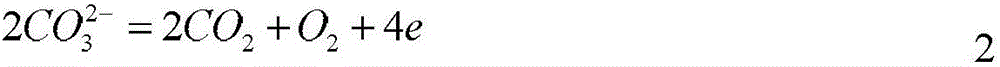

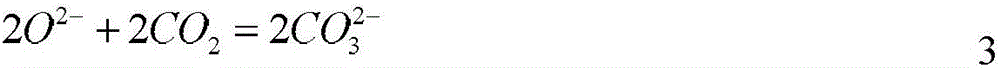

System for preparing synthetic gas by virtue of high-temperature electrolysis of CO2/H2O and application of system

ActiveCN104593804AAchieve conversionAchieve storageCellsChemical industryResource utilizationCarbonate

The invention relates to a system for preparing synthetic gas by virtue of high-temperature electrolysis of CO2 / H2O and an application of the system. The system comprises an electrolytic unit and an electric heating unit, wherein the electric heating unit is used for heating the electrolytic unit, the electrolytic unit comprises a direct current power source, a cathode, an anode, an electrolytic cell and an electrolyte, the electrolyte is a mixture of molten carbonate and molten hydroxide, or a mixture of molten carbonate and molten oxide or a mixture of molten carbonate, molten hydroxide and molten oxide; and in electrolysis, the current of the direct current power source is within (0A-3A) range, the temperature of the electrolytic cell is above 600 DEG C and the electrolyte is regenerated by virtue of absorbing CO2 / H2O in air. By virtue of the system, under low electrolysis voltage and a relatively low temperature, the preparation of synthetic gas by virtue of co-electrolysis of CO2 / H2O is achieved. The electrolysis reaction is relatively simple, the reaction selectivity is good and the resource utilization of CO2 can be simply and efficiently achieved in energy-saving and low cost manners.

Owner:NORTHEAST GASOLINEEUM UNIV

Preparing method for high-temperature melting carbonate air electrode of solid oxide electrolytic cell

The invention relates to a preparing method for an anode of an electrolytic cell, in particular to a preparing method for a high-temperature melting carbonate air electrode of a solid oxide electrolytic cell. The preparing method solves the problems that irreversible performance degradation exists in an existing high-temperature electrolytic cell electrode, and long-term stable running cannot be achieved. The method comprises the steps that firstly, an electrolyte is prepared; secondly, an electrolyte film is prepared; thirdly, a porous cathode is prepared; fourthly, a porous anode is prepared; and fifthly, carbonate is guided in the porous anode, and a confluence layer is prepared and sintered. The electrode disengaging phenomenon cannot happen to the electrolytic cell even under the large-current electrolysis, the service life of the electrolytic cell can be obviously prolonged, the electrode stability is improved, and the long-term stable running capability is achieved. The preparing method is suitable for the field of energy environment-friendly industries such as high-temperature water electrolysis, carbon dioxide electrolysis and water and carbon dioxide synchronous electrolysis.

Owner:山西晟菲科技有限公司

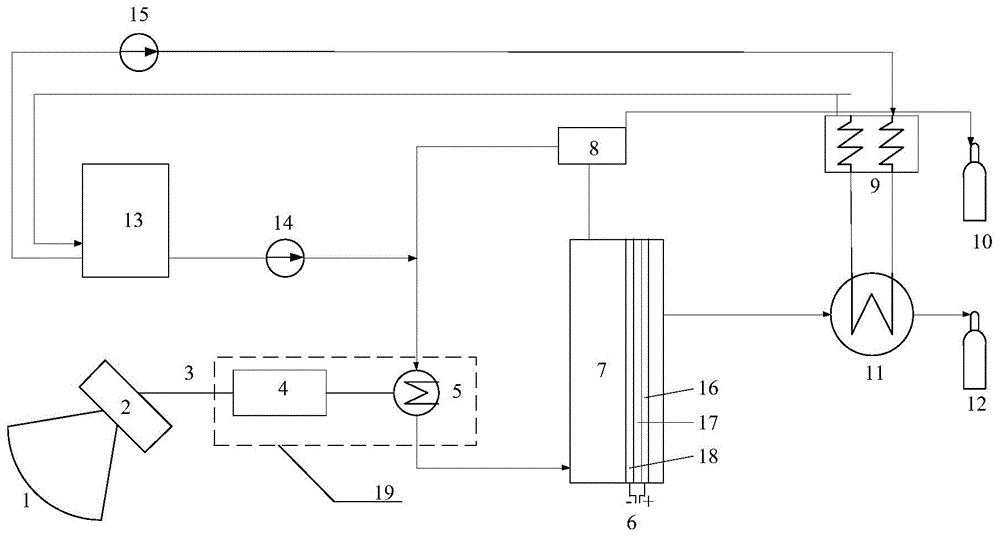

System and method for producing hydrogen through solar photovoltaic photo-thermal high-temperature water electrolysis

The invention discloses a system and a method for producing hydrogen through solar photovoltaic photo-thermal high-temperature water electrolysis, and belongs to the field of solar heat collection andphotovoltaic power generation water electrolysis hydrogen production. Two times of heat exchange are carried out on prepared high-temperature hydrogen and high-temperature oxygen, and the heat of high-temperature gas generated by electrolyzing water in a high-temperature electrolytic tank under a large current is fully utilized, so the efficiency of a solar water electrolysis system is optimizedand improved to a certain extent. The electrode poisoning caused by over-high temperature of the high-temperature solid oxide electrolytic tank is systematically optimized, so that the service life ofthe electrolytic tank is prolonged under the condition of ensuring the efficiency, and the economical efficiency of the solar water electrolysis system is improved. The system is coupled with photovoltaic photo-thermal and high-temperature electrolysis, solar energy is reasonably utilized for high-temperature hydrogen production, and instability caused by direct power generation of the solar energy is avoided. A current mature photothermal technology is reasonably utilized to solve the problems of low low-temperature hydrogen production efficiency, no environmental protection and the like.

Owner:XI AN JIAOTONG UNIV

Method for preparing high-temperature electrolytic capacitor anodized film

The invention discloses a preparation method for an anodic oxide film of a high-temperature electrolytic capacitor, which belongs to a capacitor manufacturing method. The invention aims at providing a manufacturing method for a capacitor capable of bearing a higher operating temperature. The method comprises the following steps of: dipping an anode into a phosphoric acid solution with a temperature of 70-90 DEG C and a volume percentage concentration of 0.1-1 percent, and applying a direct current with a voltage 1.5-2 times of the operating voltage of the capacitor and a boosting current density of 10-80mA / g for 60-240 minutes; taking the anode out, cleaning the anode in deionized water with a temperature of 60-70 DEG C, and drying the anode; dipping the anode into a phosphoric acid solution with a temperature of 140-170 DEG C and a volume percentage concentration of 2-10 percent for secondary high temperature oxidation treatment, and applying a direct current; and taking out the anode which undergoes the secondary high temperature oxidation treatment, and drying the anode. The electrolytic capacitor which can still work normally in a hot environment with a temperature of 200 DEG C is an indispensable electronic element in a power filter circuit.

Owner:CHINA ZHENHUA GRP XINYUN ELECTRONICS COMP ANDDEV CO LTD

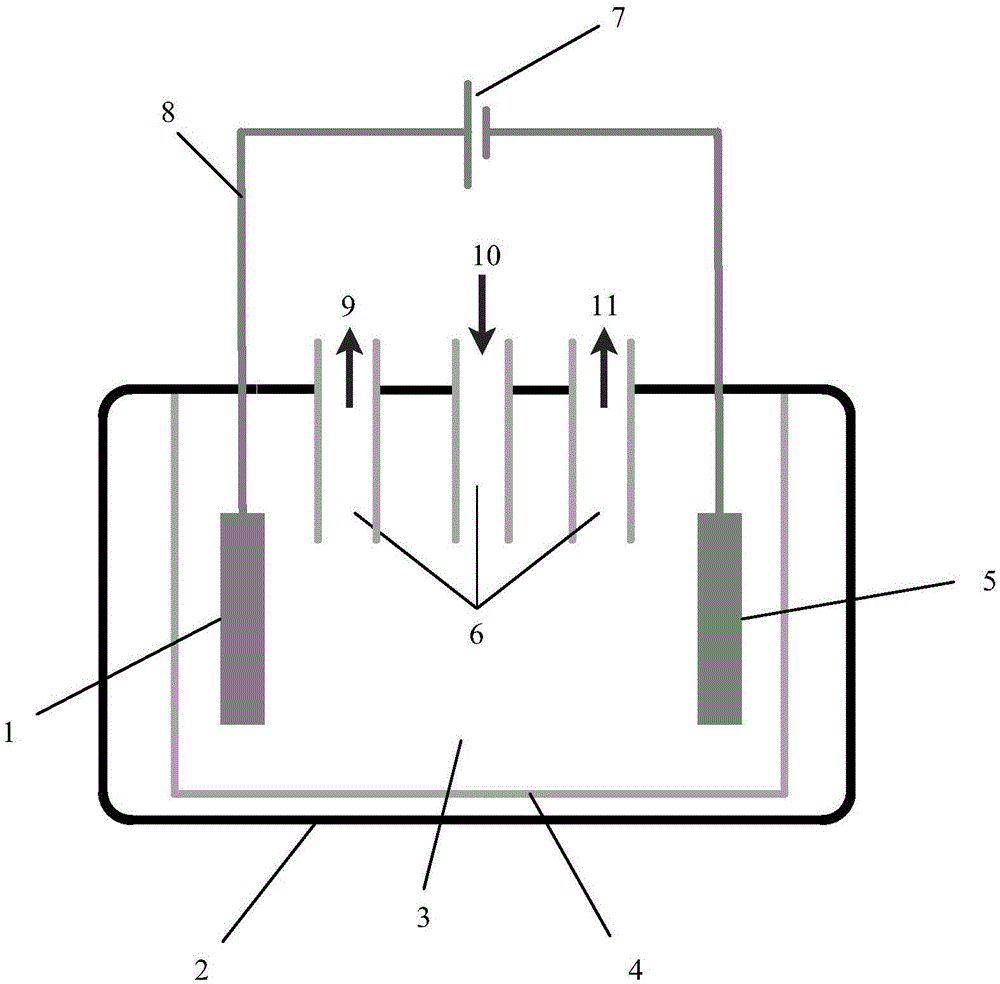

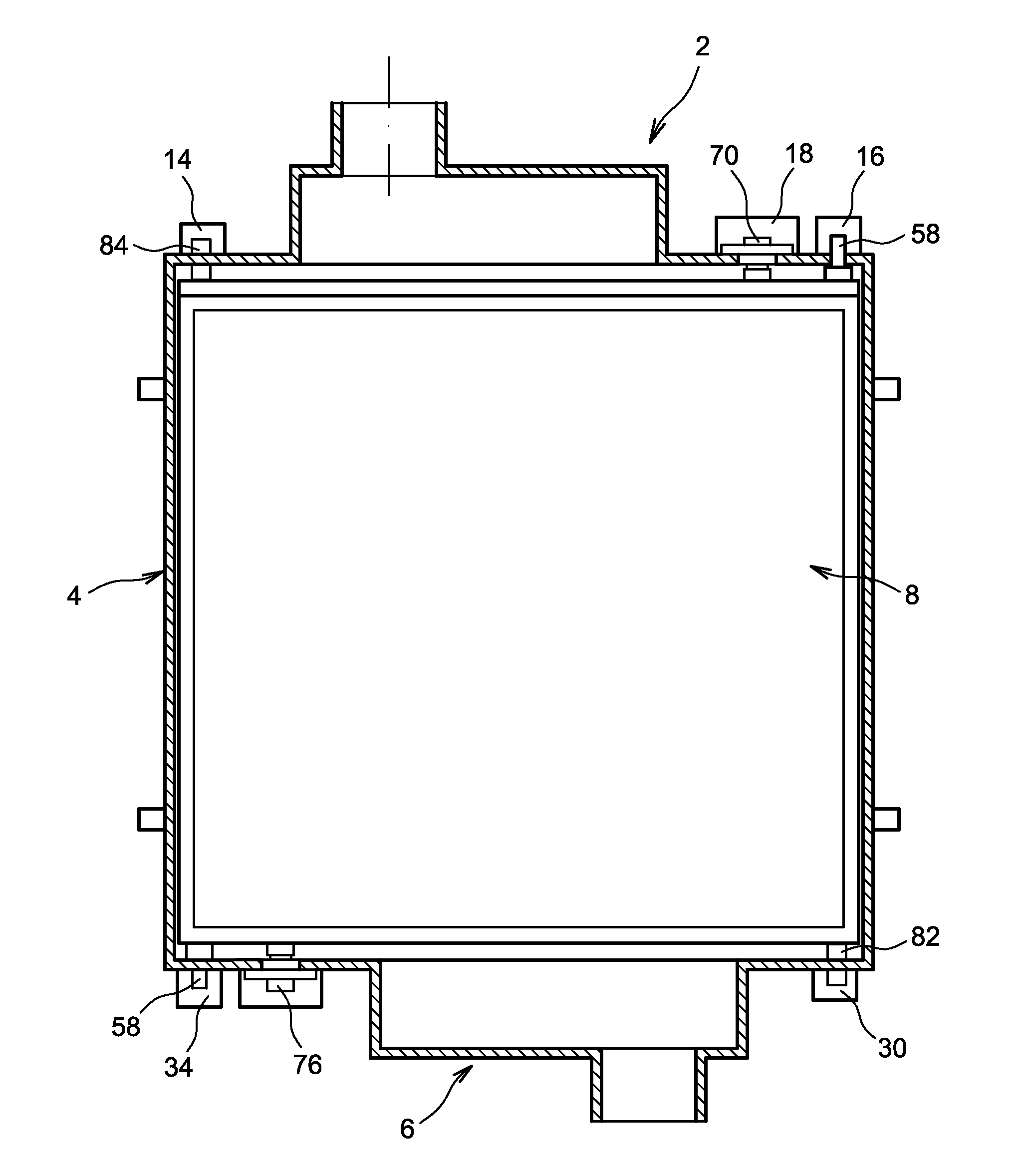

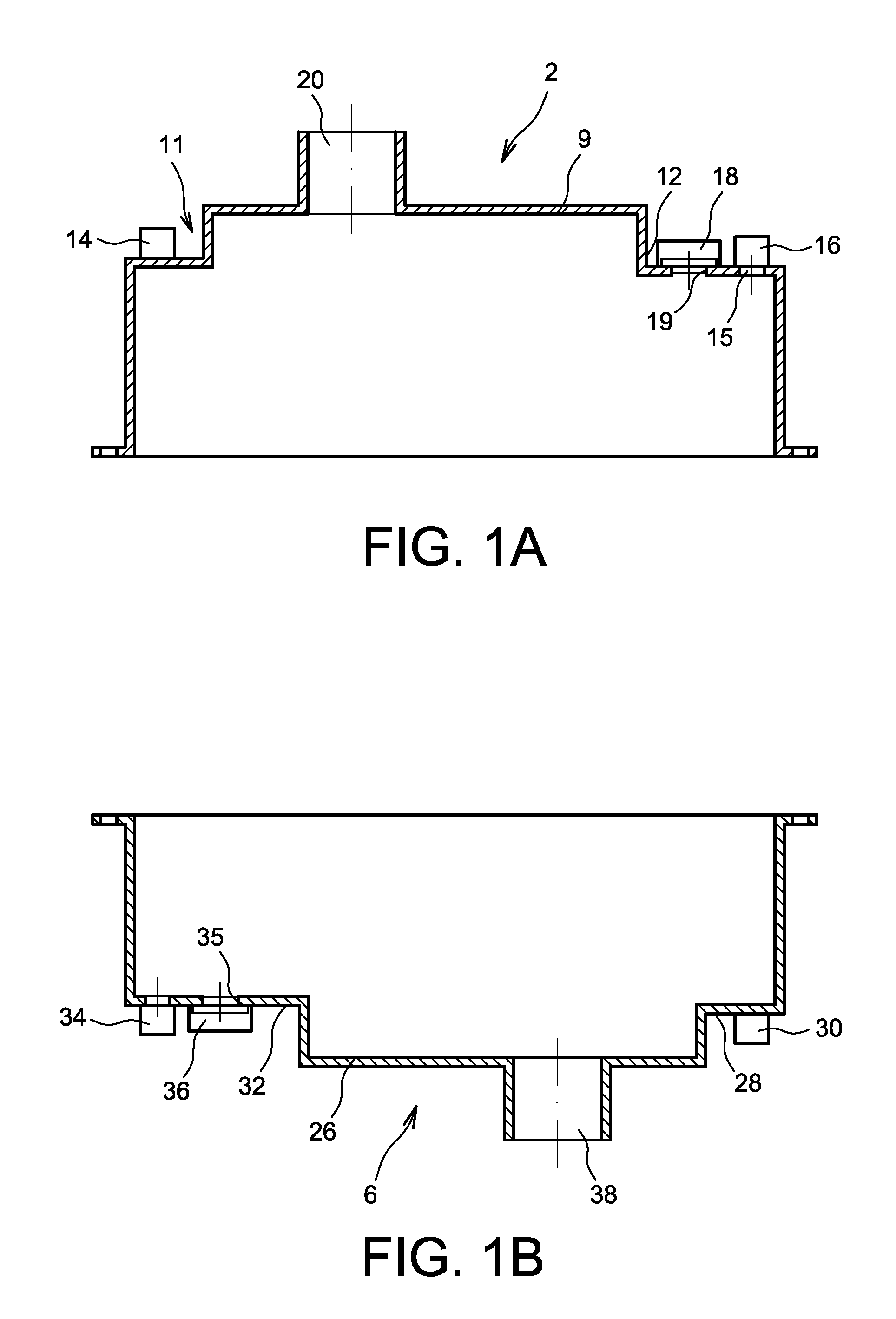

High-temperature and high-pressure electrolyser of allothermal operation

InactiveUS20100140102A1Stable temperatureSimple equipmentCellsPhotography auxillary processesEngineeringHigh pressure

An electrolyzer for high temperature electrolysis capable of operating in an allothermal mode including an enclosure, at least one electrolysis plate (8) including an anode and a cathode in combination and means for heating an active fluid intended to undergo a high temperature electrolysis, characterized in that the enclosure is capable of maintaining an electrolyte bath under high or very high pressure of several tens of bars, in that said heating means (10) are positioned in the enclosure and use a heat transfer fluid.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Aluminum plate production method with low energy consumption

InactiveCN106399729ASolve many oxidation impuritiesSolve the problem of high hydrogen contentHydrogen contentEconomic benefits

The invention discloses an aluminum plate production method with low energy consumption. High-temperature electrolytic aluminum melt is fed into a smelting furnace directly, the process of casting electrolytic primary aluminum melt into aluminum ingots for remelting and remelting heating are omitted, labor is saved, the energy consumption of aluminum plate production is reduced greatly, the production cost is reduced, and the production benefit is increased; meanwhile, aluminum burning loss during remelting is reduced, and the economic benefit is increased; and the aluminum melt is refined by adding carbon tetrachloride, grains are refined by adding an aluminum-titanium alloy, the problems of many oxidation impurities and high hydrogen content of the electrolytic aluminum melt are solved, and the product quality is improved and meets production standards.

Owner:ANHUI FENGHUI METAL

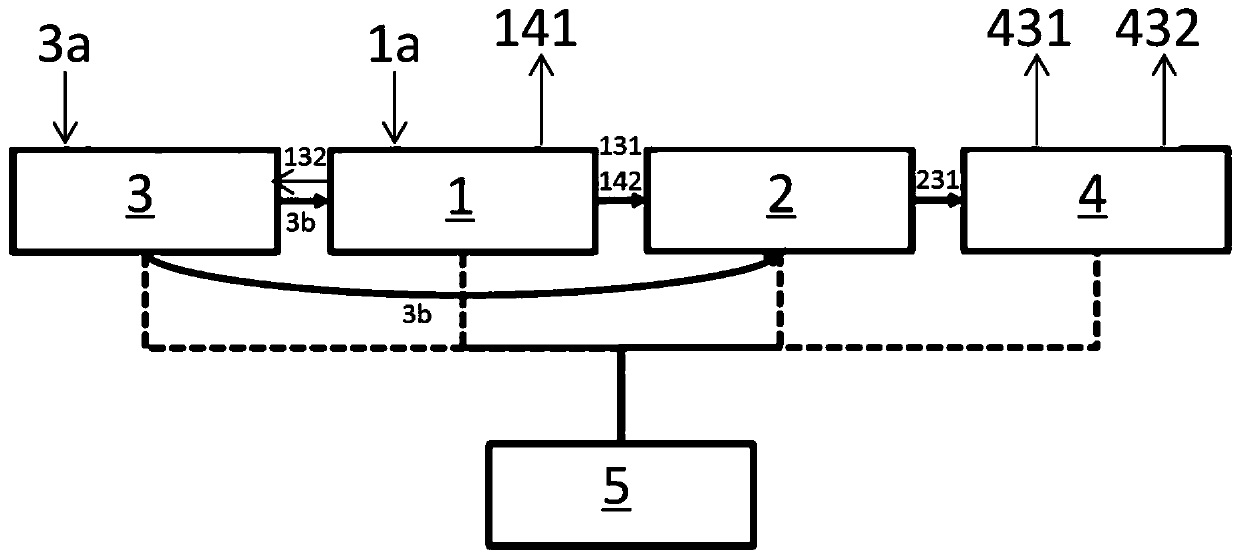

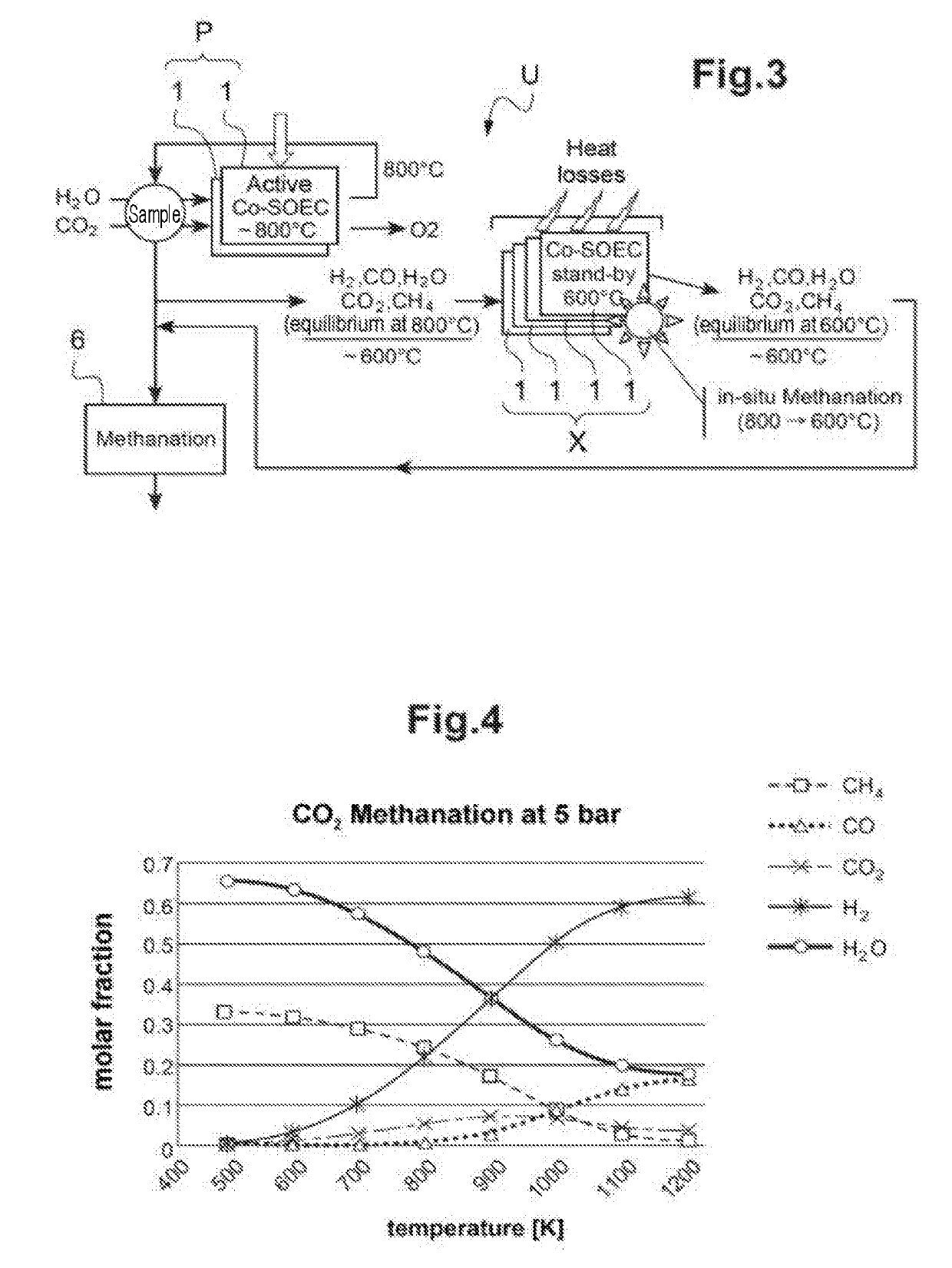

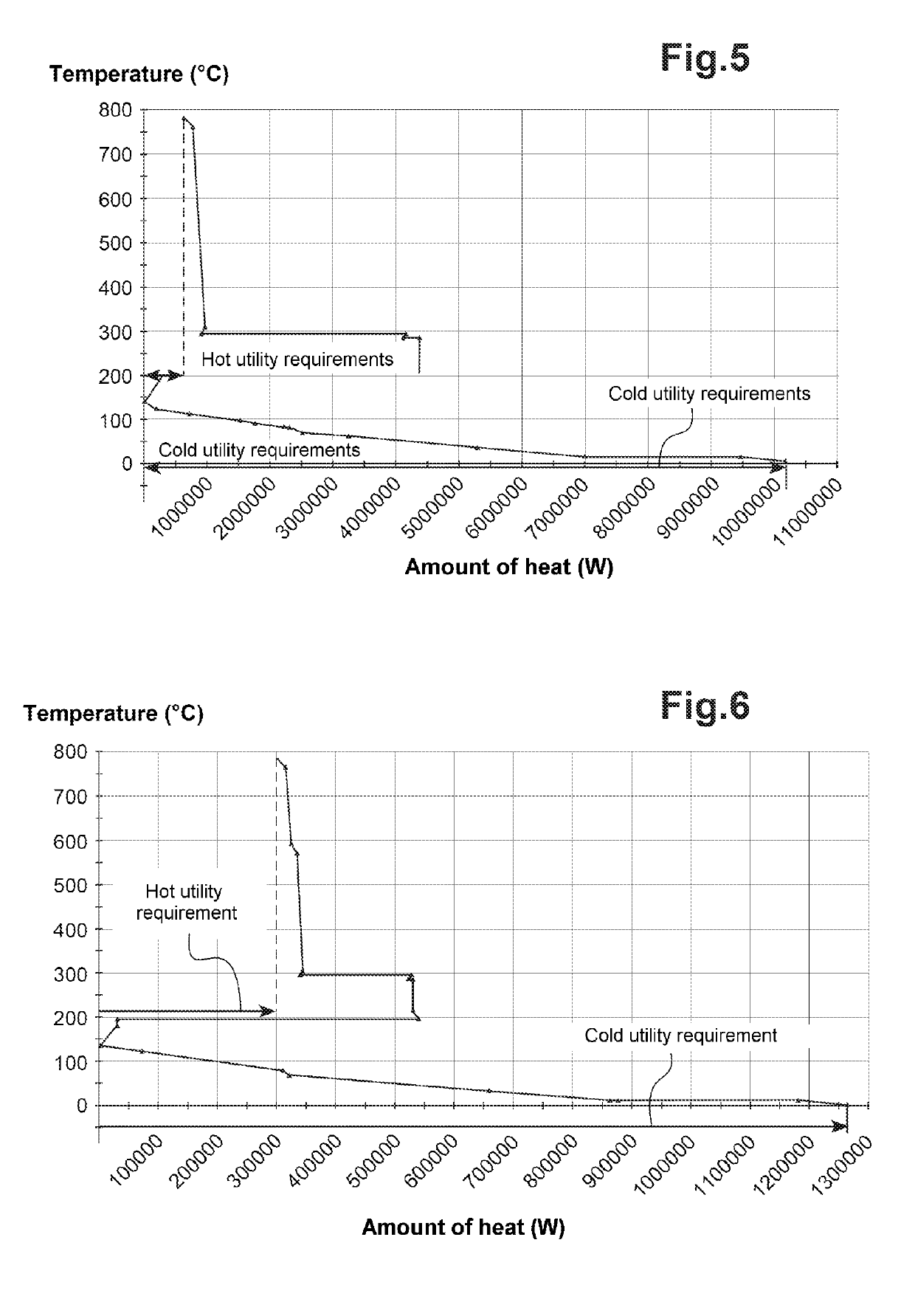

Process for starting mode or stand-by mode operation of a power-to-gas unit comprising a plurality of high-temperature electrolysis (SOEC) or co-electrolysis reactors

The application relates to a process for operating in starting mode or in stand-by mode a unit, termed power-to-gas unit, comprising a number N of reactors (1) with a stack of elemental electrolysis cells of solid oxide type (SOEC), the cathodes of which are made of methanation reaction catalyst material(s).

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com