A flue gas waste heat power generation system for aluminum electrolytic cell with flue gas separation device

A power generation system, flue gas waste heat technology, applied in steam engine installations, machines/engines, mechanical equipment, etc., can solve the problem that the waste heat of electrolytic aluminum equipment cannot be effectively recycled.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

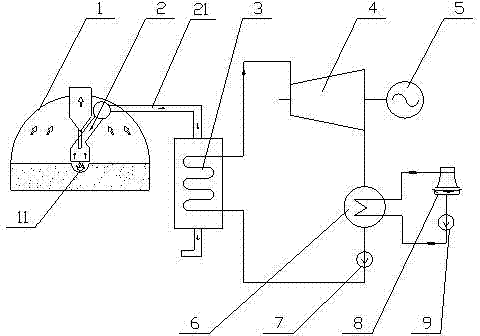

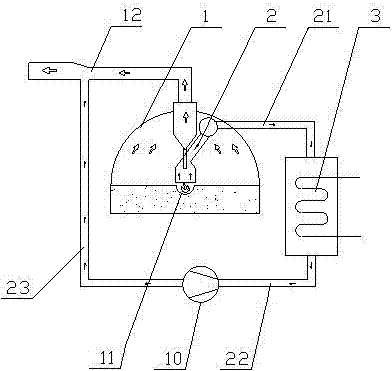

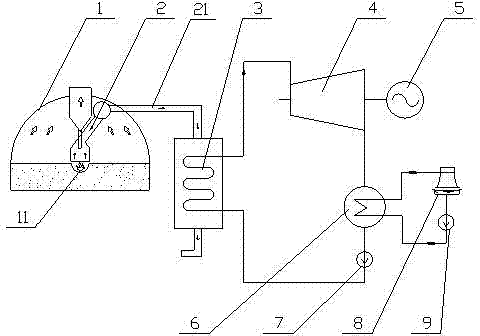

[0019] An embodiment of the present invention provides a flue gas waste heat power generation system of an aluminum electrolytic cell with a flue gas separation device, which is used to recover the waste heat of the flue gas of an aluminum electrolytic cell to generate electricity. This system is composed of flue gas system, waste heat boiler system, steam turbine generator set, condensing system and supporting electrical and control systems.

[0020] Such as figure 1 , 2 As shown, the flue gas system includes a flue gas separation device 2 arranged in the aluminum electrolytic cell 1, an induced draft fan 10, a first flue gas pipeline 21 for connecting the flue gas separation device and the waste heat boiler system, and a first flue gas pipeline 21 for connecting the waste heat boiler and the waste heat boiler system. The second flue gas duct 22 of the induced draft fan 10 and the third flue gas duct 23 for connecting the induced draft fan 10 and the original flue gas duct 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com