Method and apparatus for treating high concentrated organic wastewater by hydrothermal electrical catalytic oxidation

A technology of organic wastewater and catalytic oxidation, applied in the direction of oxidized water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc., can solve problems such as high operating costs, long time, salt blockage, etc., to reduce costs and operating costs , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

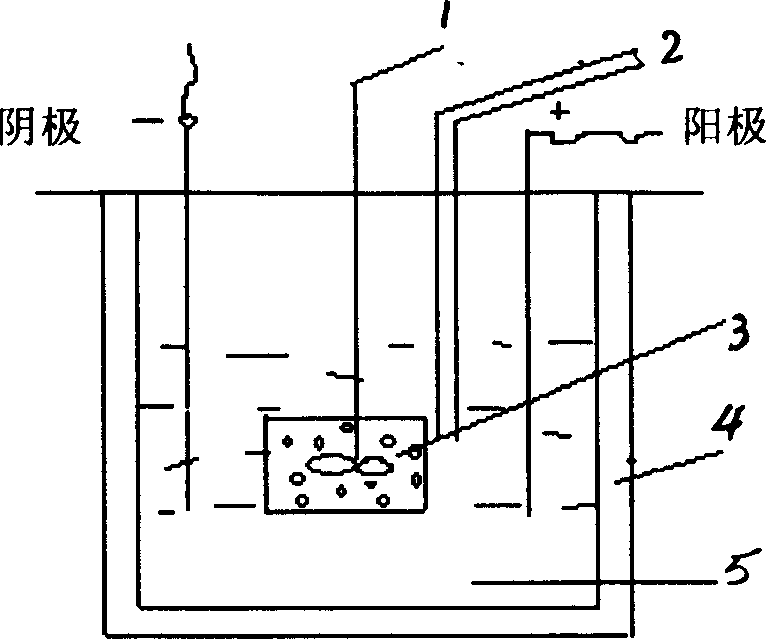

[0021] Embodiment 1: Implementation on the intermittent device:

[0022] 1. Using a batch reactor:

[0023] Reactor 316L stainless steel body 500ml (equipment of prior art);

[0024] Anode: Titanium mesh plated PbO 2 , 2×7mm (or plated with lead dioxide, or antimony trioxide, or tin oxide, or ruthenium oxide or their mixture);

[0025] Catalyst: a catalyst composed of 75% titanium oxide, 20% cerium oxide, 0.5% ruthenium, and 4.5% bismuth oxide (or other existing catalysts);

[0026] Cathode: the reactor itself;

[0027] Voltage: 6V; Current: 5A;

[0028] Electrolyte Na 2 SO 4 5% (accounting for 5% of the wastewater volume);

[0029] COD concentration (initial) 18000ppm 150ml waste water (phenol);

[0030] NH 3 -N concentration (initial) 3000ppm

[0031] o 2 Partial pressure 1MPa (initial) PH adjustment to 10

[0032] Temperature 200°C Reaction time 1 hour

[0033] COD removal rate 90% NH 3 -N 99%

Embodiment 2

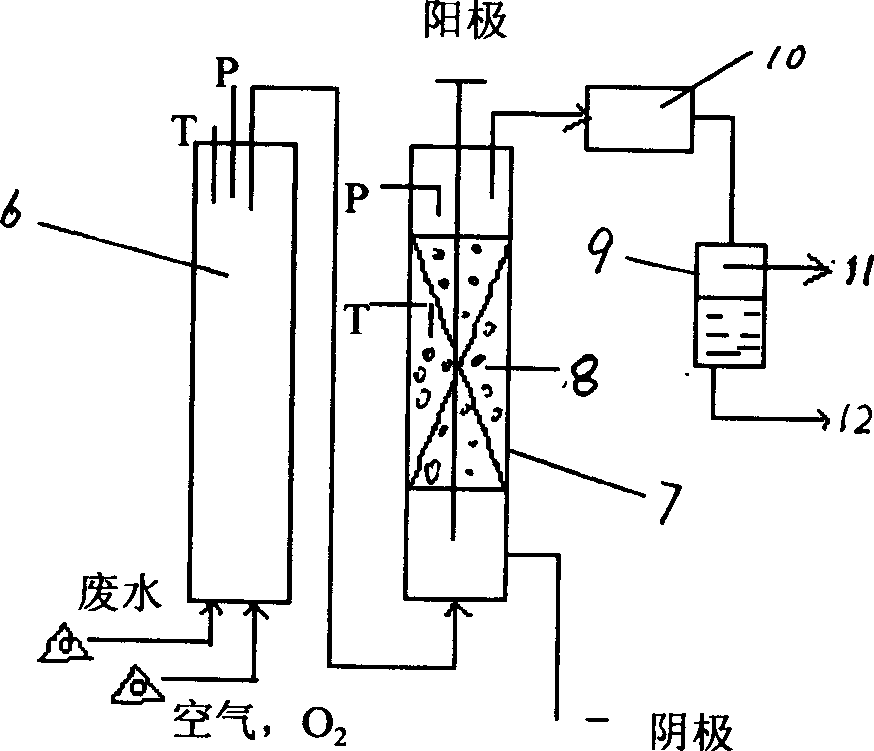

[0034] Example 2: Implementation on a continuous device

[0035] The electrolytic reactor is a cylindrical flow device, that is, sewage and oxygen-containing gas enter from the bottom of the reactor, and the treated sewage is continuously discharged after heat exchange and gas-liquid separation, so that sewage treatment can be carried out automatically and continuously.

[0036] in:

[0037] Anode: conductive carbon coated with a layer of tin oxide;

[0038] Catalyst: Ru / Ce-ZrO 2 ;

[0039] Voltage: 6V; Current: 5A;

[0040] Reactor volume 2L, NH 3 N concentration (initial) 3000ppm COD initial concentration 18000ppm (phenol and ammonium sulfate);

[0041] Cathode: the reactor itself;

[0042] The processing results are shown in the table below:

[0043] T 100°C 150°C 180°C 200°C 250°C

[0044] T 100°C 150°C 180°C 200°C

Embodiment 3

[0045] Example 3: Implementation on a continuous device:

[0046]The electrolytic reactor is a cylindrical flow device, that is, sewage and oxygen-containing gas enter from the bottom of the reactor, and the treated sewage is continuously discharged after heat exchange and gas-liquid separation, so that sewage treatment can be carried out automatically and continuously.

[0047] in:

[0048] Anode: Ruthenium oxide is first coated on the titanium rod, and then a layer of lead oxide is coated;

[0049] Cathode: titanium mesh;

[0050] Solid filling material: granular activated carbon (or granular diatomite, or shaped molecular sieve, or titanium oxide, or aluminum oxide, or zirconium oxide, or cordierite, or water-insoluble inorganic materials such as magnesium oxide);

[0051] Voltage: 6V, PO 2 Divided pressure is 2MPa; Current: 10A;

[0052] Wastewater is coking wastewater, COD is 19950PPm, NH 3 -N is 1300PPm;

[0053] Adjust pH ≈ 11, add 5% Na of wastewater 2 SO 4 as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com