Electro-thermal chemical cycle coupled solar fuel preparation system and method

A thermochemical cycle and fuel preparation technology, applied in solar heating systems, solar collectors for specific environments, chemical instruments and methods, etc. The effect of separating energy consumption and water-gas shift energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

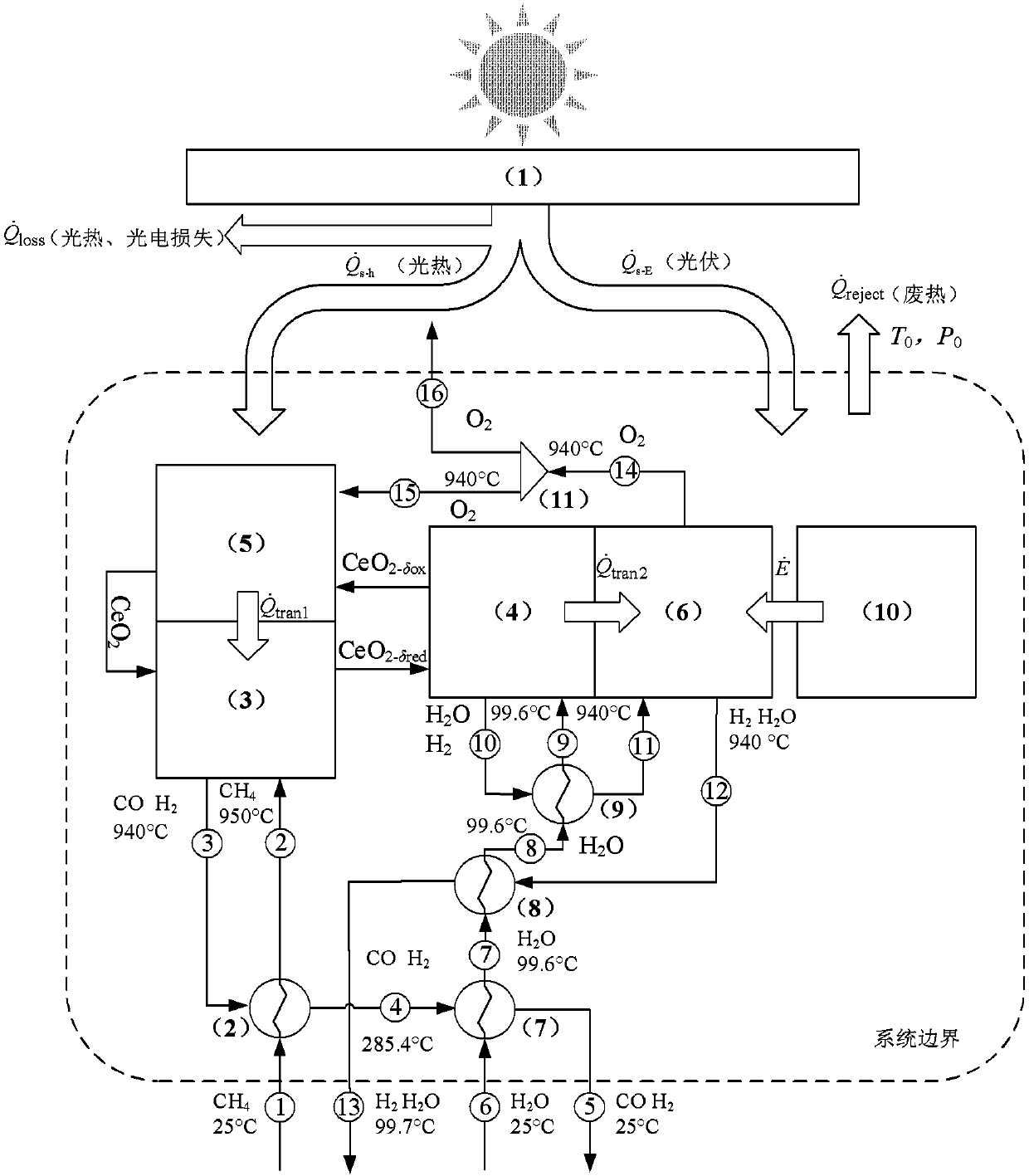

[0054] 1. System process description and effect analysis

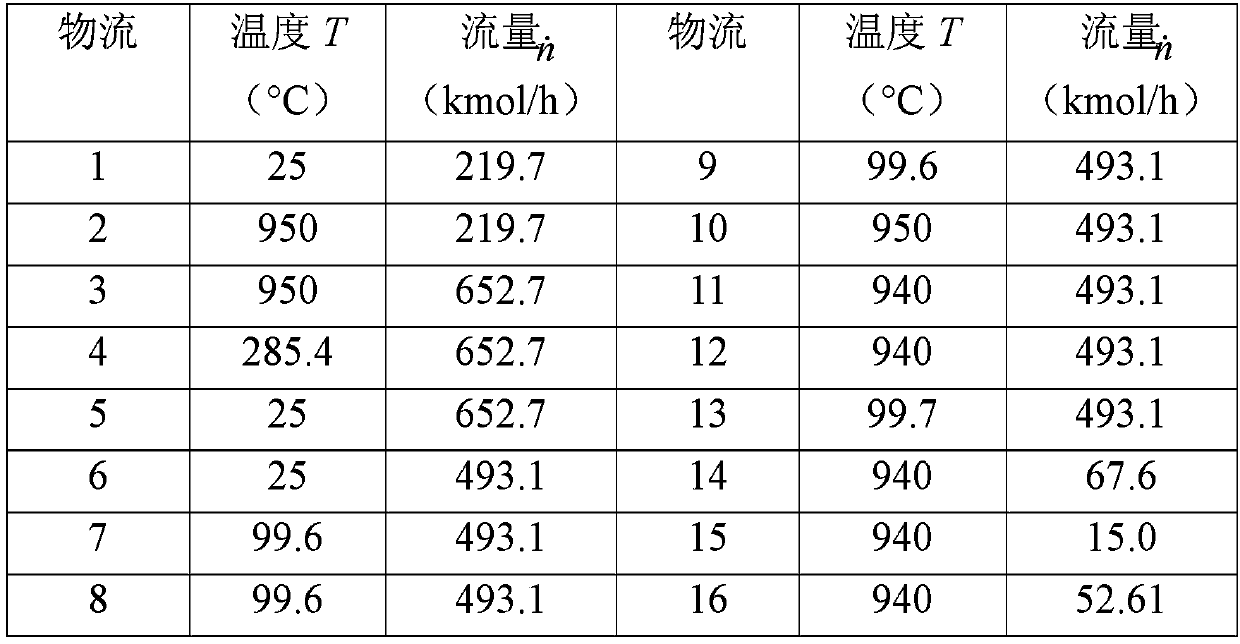

[0055] In this example, normal temperature CH 4 at 82.0m 3 / min flow rate in the heat exchanger 2 and reduction reactor 3 product flow heat exchange to complete the preheating, after preheating CH 4 Enter the reduction reactor 3 and the oxygen carrier CeO in the reactor 2 react to produce CO, H 2 , CO 2 、H 2 O, CeO 1.8 and other products. Room temperature H 2 Before O enters the oxidation reactor 3 at a rate of 147.9 L / min, it exchanges heat with the product stream of the reduction reactor 3 passing through the heat exchanger 2 in the heat exchanger 7 to complete the preheating, and then in the heat exchanger 8 and solid oxidation The heat exchange of the product flow in the electrolytic cell 6 completes the secondary preheating, and then the heat exchange of the product flow in the heat exchanger 9 and the oxidation reactor 4 completes the third-level preheating and enters the oxidation reactor 4, and enters t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com