Equipment and process for synthesizing methanol through solar energy hydrogen production

A technology for synthesizing methanol and solar energy, which is applied in the field of equipment and technology for synthesizing methanol from hydrogen production by solar energy, can solve the problem that water, a by-product of methanol production, is not well utilized, solar energy is not well utilized, and hydrogen raw material preparation efficiency is low. and other issues to achieve the effect of improving solar energy utilization efficiency, reducing heat demand and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

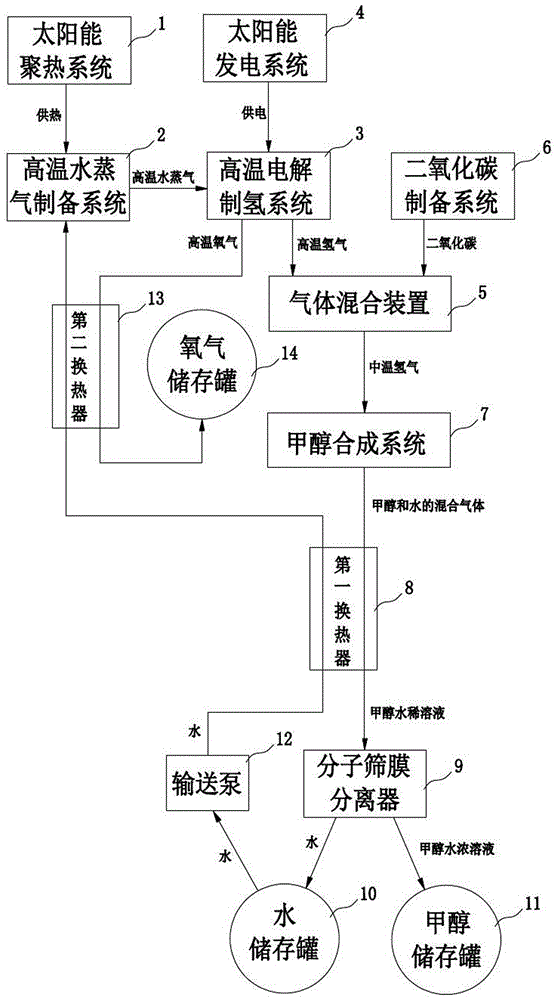

[0053] Such as figure 1 Shown, a kind of equipment of solar hydrogen production synthetic methanol, comprises:

[0054] The solar heat concentrating system 1 is used for concentrating and collecting heat, and provides thermal energy for the high-temperature water vapor preparation system 2; the solar heat concentrating system includes a solar concentrating heat collector, which is a trough-type solar concentrating Any one of dish solar concentrators, tower solar concentrators, and compound parabolic concentrators;

[0055] High-temperature water vapor production system 2 is used to prepare high-temperature water vapor at 800°C to 900°C by using the heat energy provided by solar heat collection system 1, and the high-temperature water vapor is supplied to high-temperature electrolysis hydrogen production system 3;

[0056] The solar power generation system 4 is used to use solar energy to generate direct current and supply it to the high-temperature electrolytic hydrogen produ...

Embodiment 2

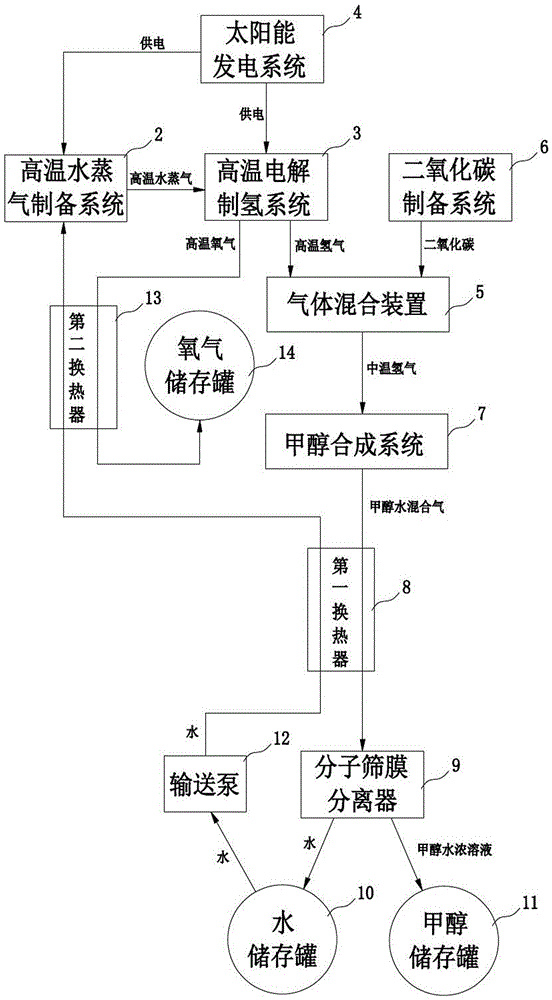

[0070] Such as figure 2 Shown, a kind of equipment of solar hydrogen production synthetic methanol, comprises:

[0071] The solar power generation system 4 is used for solar power generation, and is supplied to the high-temperature water vapor preparation system 2 and the high-temperature electrolytic hydrogen production system 3; the solar power generation system 4 includes solar cells, and the solar cells are monocrystalline silicon solar cells or polycrystalline silicon solar cells or non- Crystalline silicon solar cells;

[0072] The high-temperature steam production system 2 is equipped with an electric heater powered by solar energy (not shown in the figure). The high-temperature steam production system 2 uses the heat energy of the electric heater to produce high-temperature steam at 800°C to 900°C. Supply to the high temperature electrolysis hydrogen production system 3;

[0073] The high-temperature electrolytic hydrogen production system 3 uses the direct current ...

Embodiment 3

[0087] A process for synthesizing methanol from hydrogen produced by solar energy, comprising the following process steps:

[0088] a. Utilize solar heat collection or solar power generation to make the high-temperature water vapor preparation system work, prepare high-temperature water vapor at 800°C to 900°C, and supply it to the high-temperature electrolysis hydrogen production device;

[0089] b. Utilize the solar power generation system to supply direct current to the high-temperature electrolytic hydrogen production device, and the high-temperature electrolytic hydrogen production device electrolyzes high-temperature water vapor to produce hydrogen and oxygen, among which, the high-temperature hydrogen is transported to the gas mixing device; at the same time, the carbon dioxide production system is used to prepare carbon dioxide , sent to the gas mixing device;

[0090] c. In the gas mixing device, high-temperature hydrogen and carbon dioxide are mixed into a medium-tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com