Patents

Literature

65results about How to "No falling off" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for target material component welding

InactiveCN103521916AEasy to spreadAvoid the disadvantage of not being able to realize large-size target weldingNon-electric welding apparatusWeld strengthUltimate tensile strength

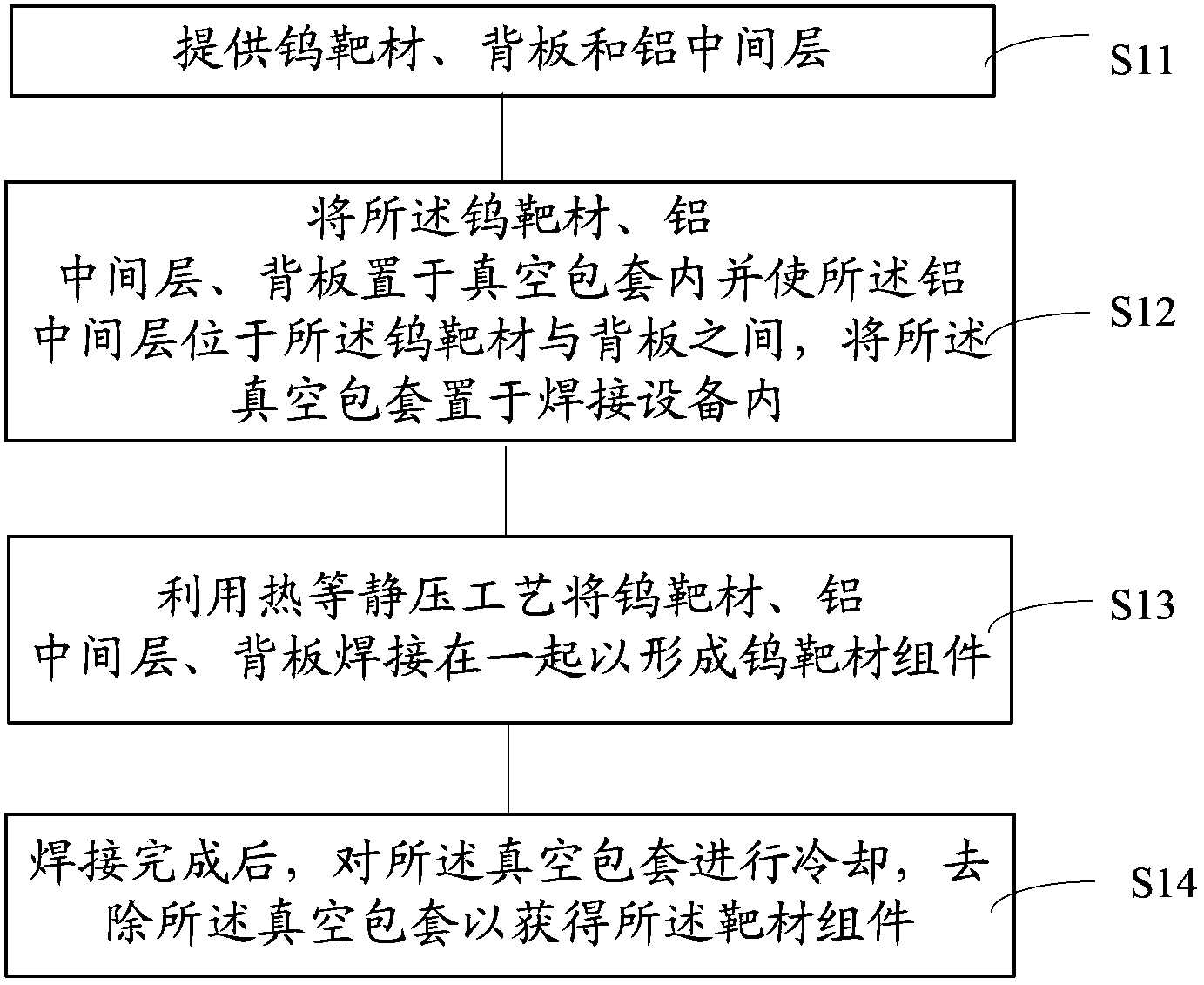

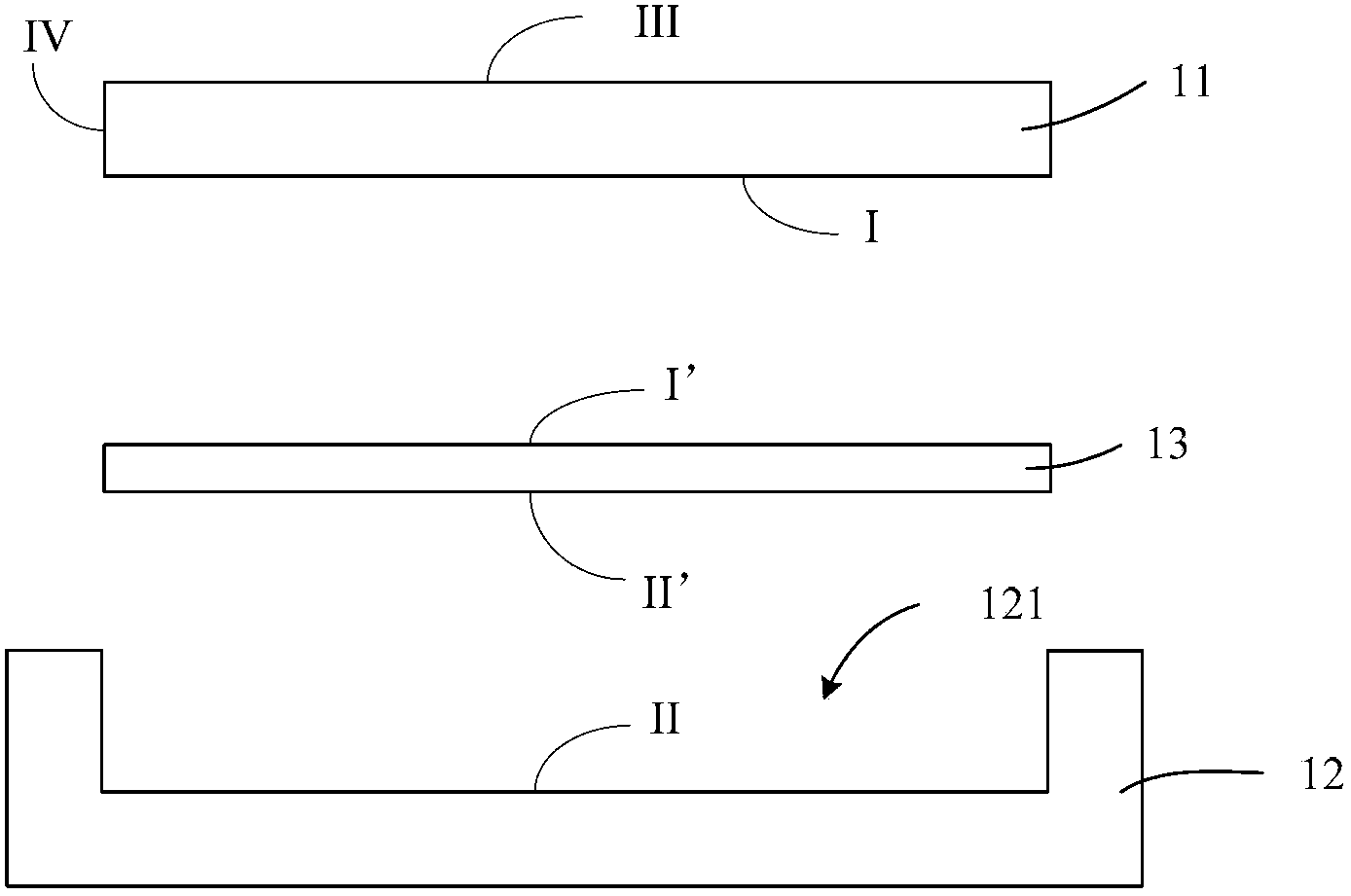

The invention provides a method for target material component welding. The method comprises the following steps that a tungsten target material, a back board and an aluminum middle layer are provided; the tungsten target material, the aluminum middle layer and the back board are placed in a vacuum bag, the aluminum middle layer is located between the tungsten target material and the back board, and the vacuum bag is arranged in a welding device; the hot isostatic pressure technology is used for welding the tungsten target material, the aluminum middle layer and the back board together to form a target material component; after welding is completed, the vacuum bag is cooled and removed, so that the target material component is obtained. Due to the fat that the aluminum middle layer is additionally arranged between the tungsten target material and the back board, and the hot isostatic pressure technology is used for welding the tungsten target material and the back board together, welding efficiency is improved, the formed target material component is good in welding binding rate, high in welding strength and small in deformation, large-area welding can be achieved, and therefore the requirements for long-term stable production and using of target materials can be met.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

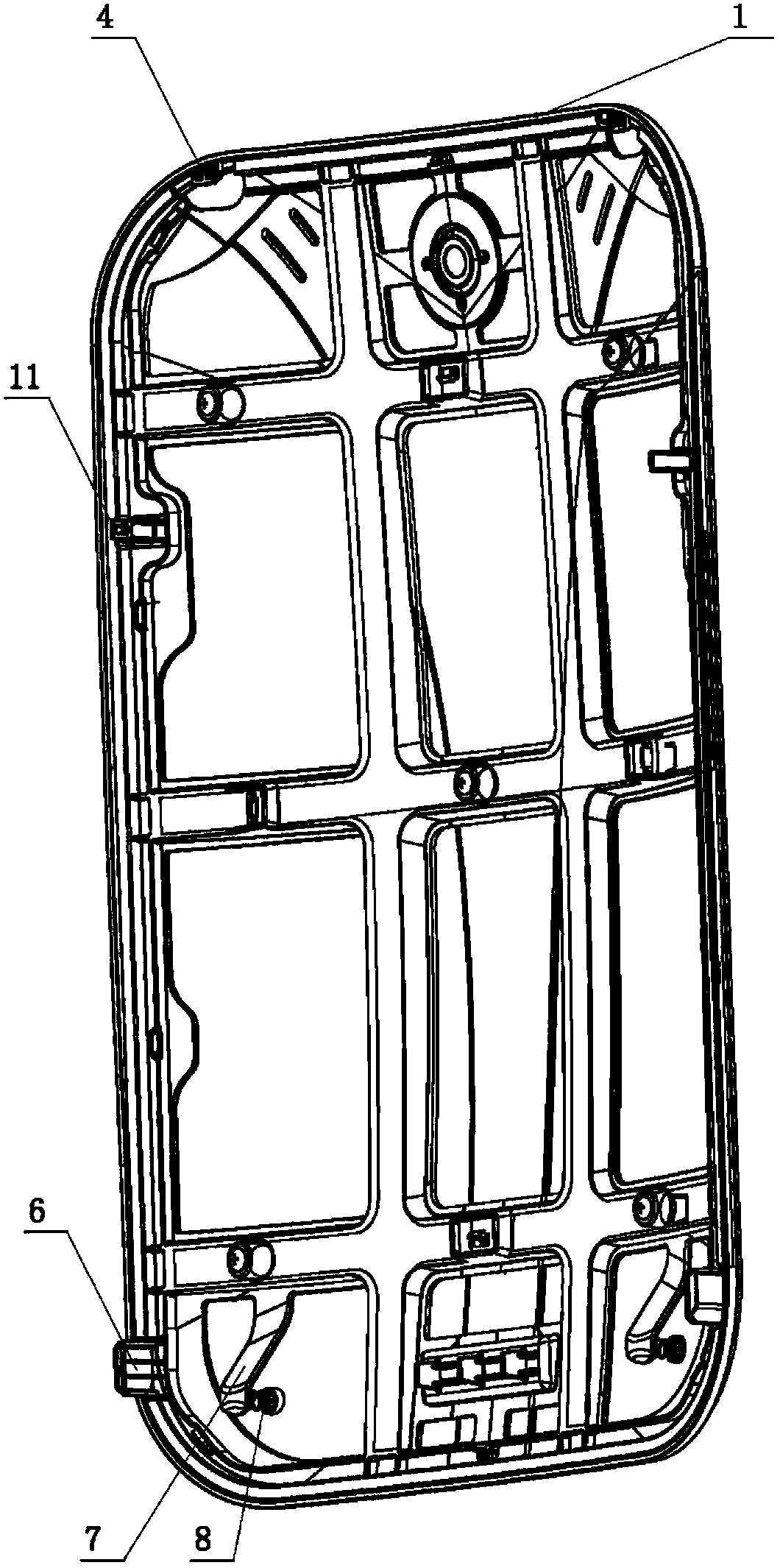

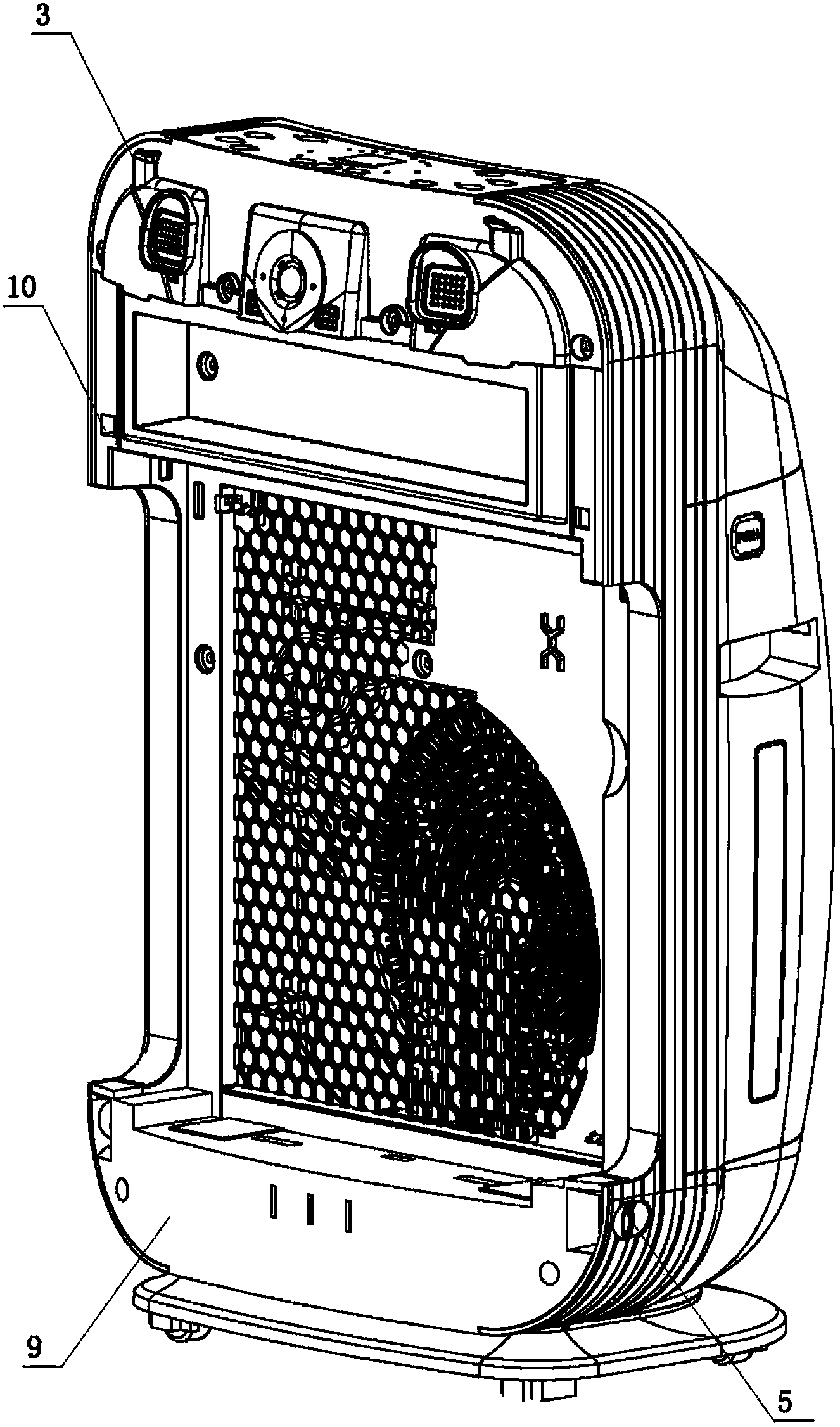

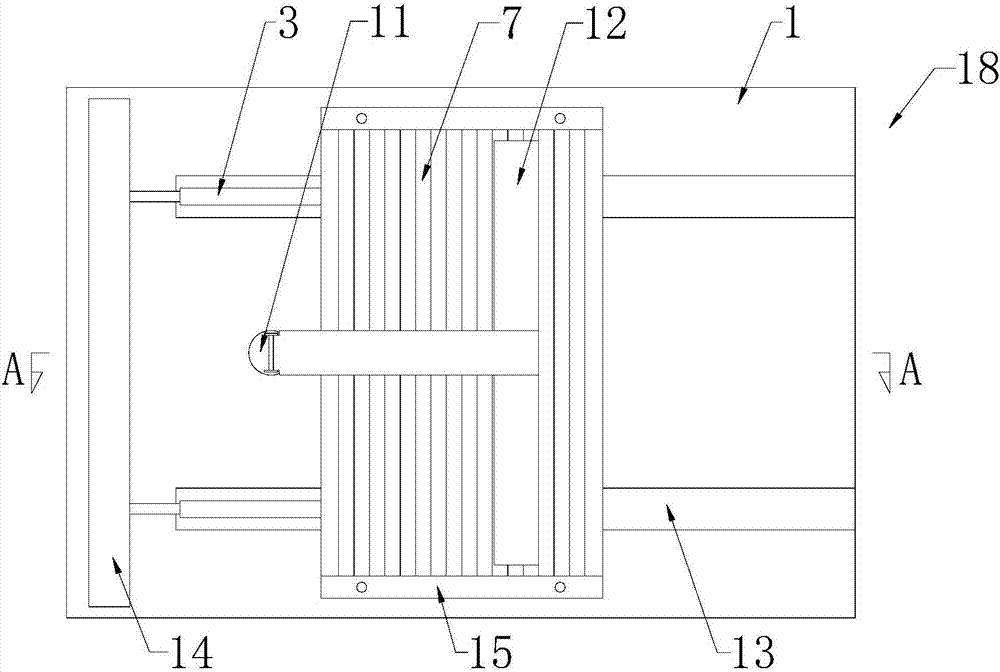

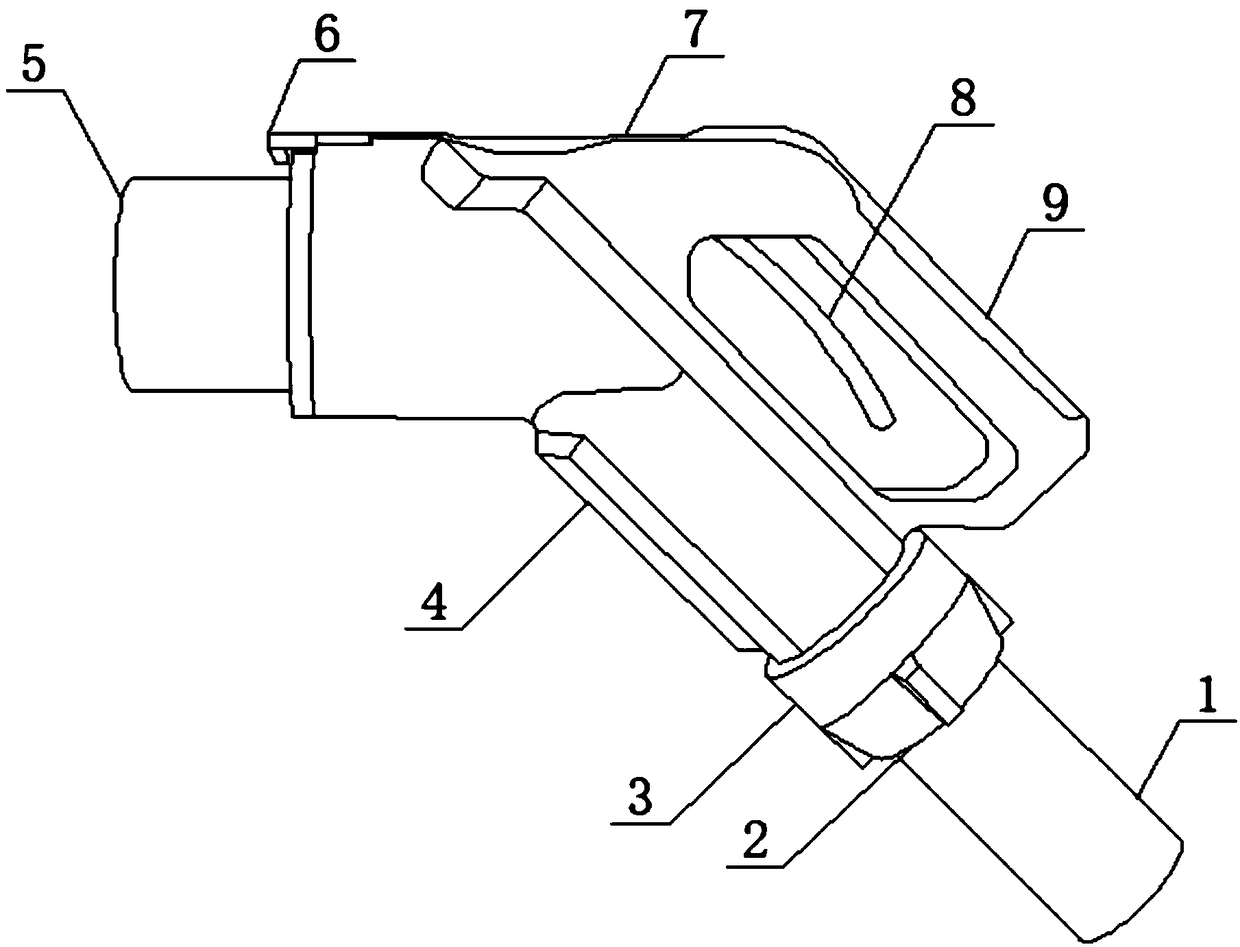

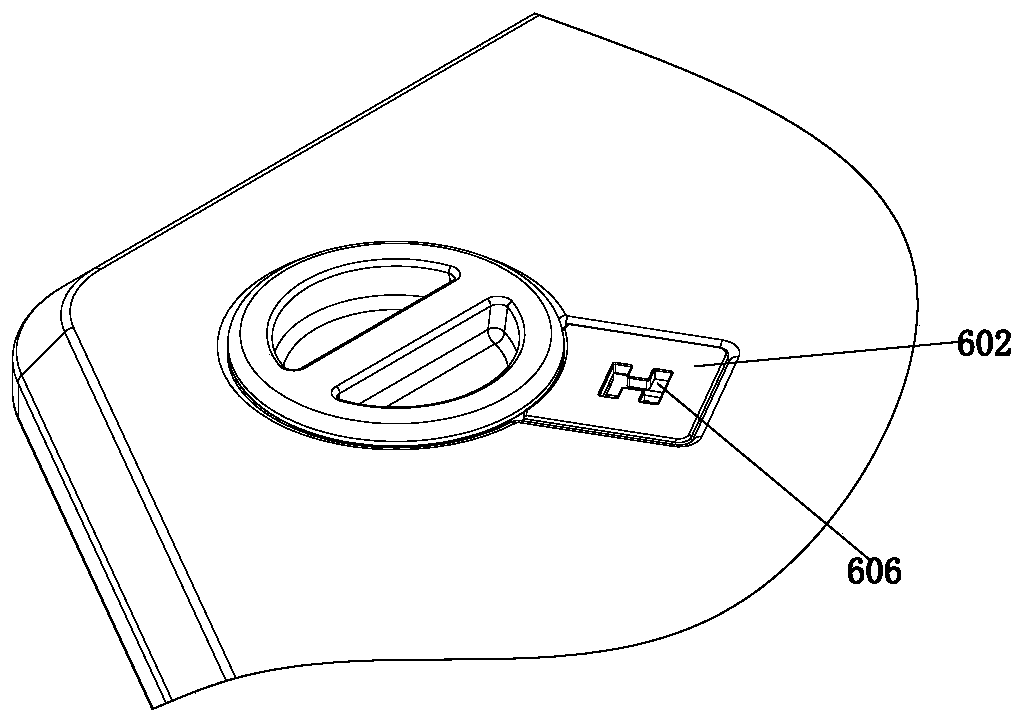

Body and panel connecting device and air purifier with same

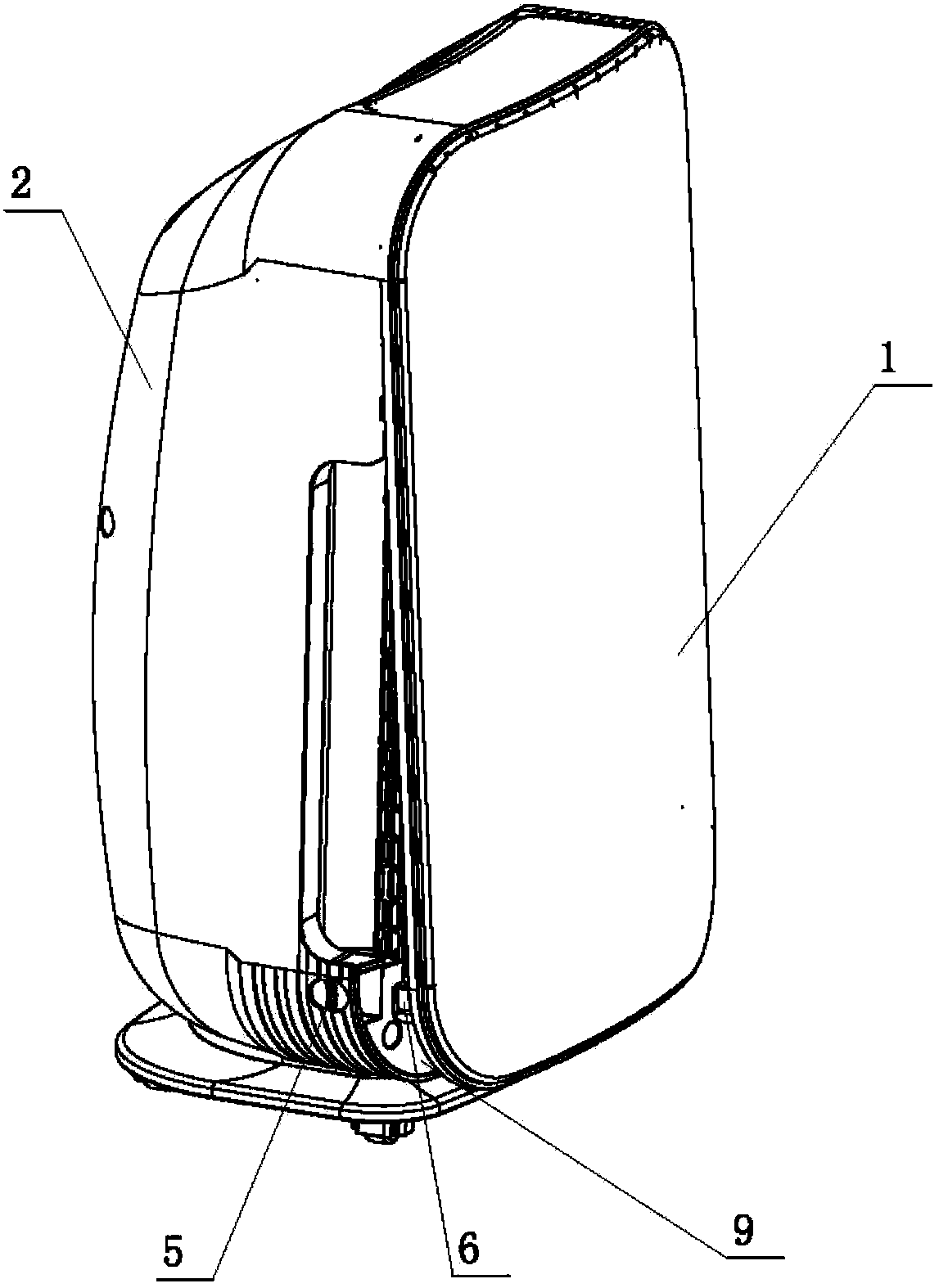

ActiveCN103423287ASimple structureEasy to useHooksAir purifierElectrical and Electronics engineering

The invention provides a body and panel connecting device and an air purifier with the same. The body and panel connecting device comprises hooks, hook seats, first fasteners, first fastener seats and elastic structures; the hooks are arranged on a panel, and the hook seats are matched with the hooks and are arranged on a body; the first fasteners are arranged on the panel, and the first fastener seats are matched with the first fasteners and are arranged on the body; the elastic structures are arranged on the inner side of the panel. The body and panel connecting device and the air purifier have the advantages that the body and panel connecting device is simple in structure and convenient to use, and an operator only needs to easily push extending portions of the first fastener seats via the elastic structures, so that the panel can be conveniently and quickly detached.

Owner:GREE ELECTRIC APPLIANCES INC

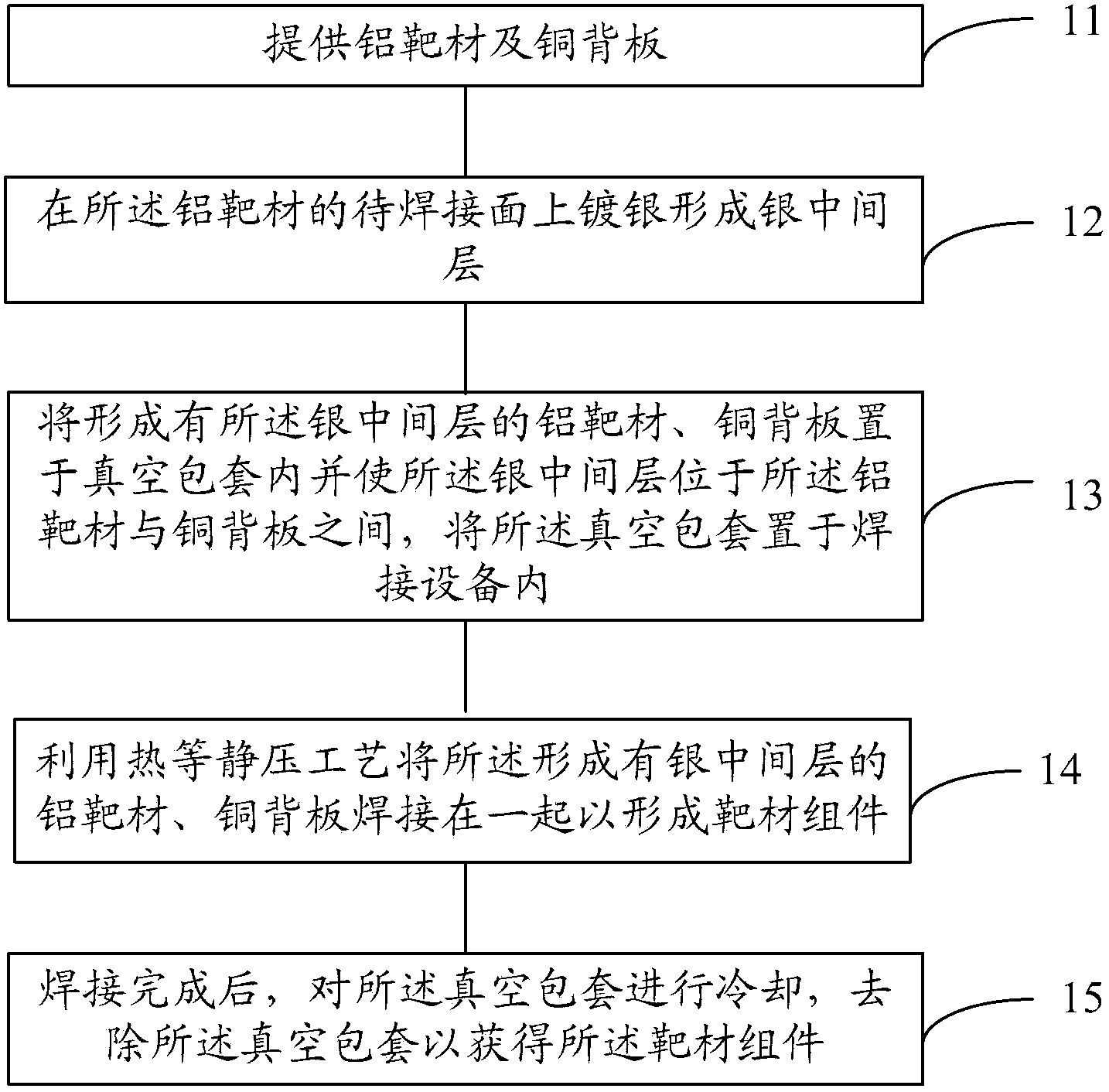

Method for target material component welding

InactiveCN103521910ANo falling offNot prone to recrystallizationVacuum evaporation coatingSputtering coatingSputteringWeld strength

The invention provides a method for target material component welding. The method comprises the following steps that an aluminum target material and a copper back board are provided; silver is plated on a face to be welded of the aluminum target material to form a silver middle layer; the aluminum target material with the silver middle layer and the copper back board are placed in a vacuum bag, the silver middle layer is located between the aluminum target material and the copper back board, and the vacuum bag is arranged in a welding device; the hot isostatic pressure technology is used for welding the aluminum target material with the silver middle layer and the copper back board together to form a target material component; after welding is completed, the vacuum bag is cooled and removed, so that the target material component is obtained. The method is high in welding efficiency, the formed target material component is good in welding binding rate, high in welding strength and small in deformation, the internal organization structure of the aluminum target material in the target material component meets the sputtering requirement, and therefore requirements for long-time stable production and using of target materials can be met.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Wood anti-corrosion mildew-proof treatment method

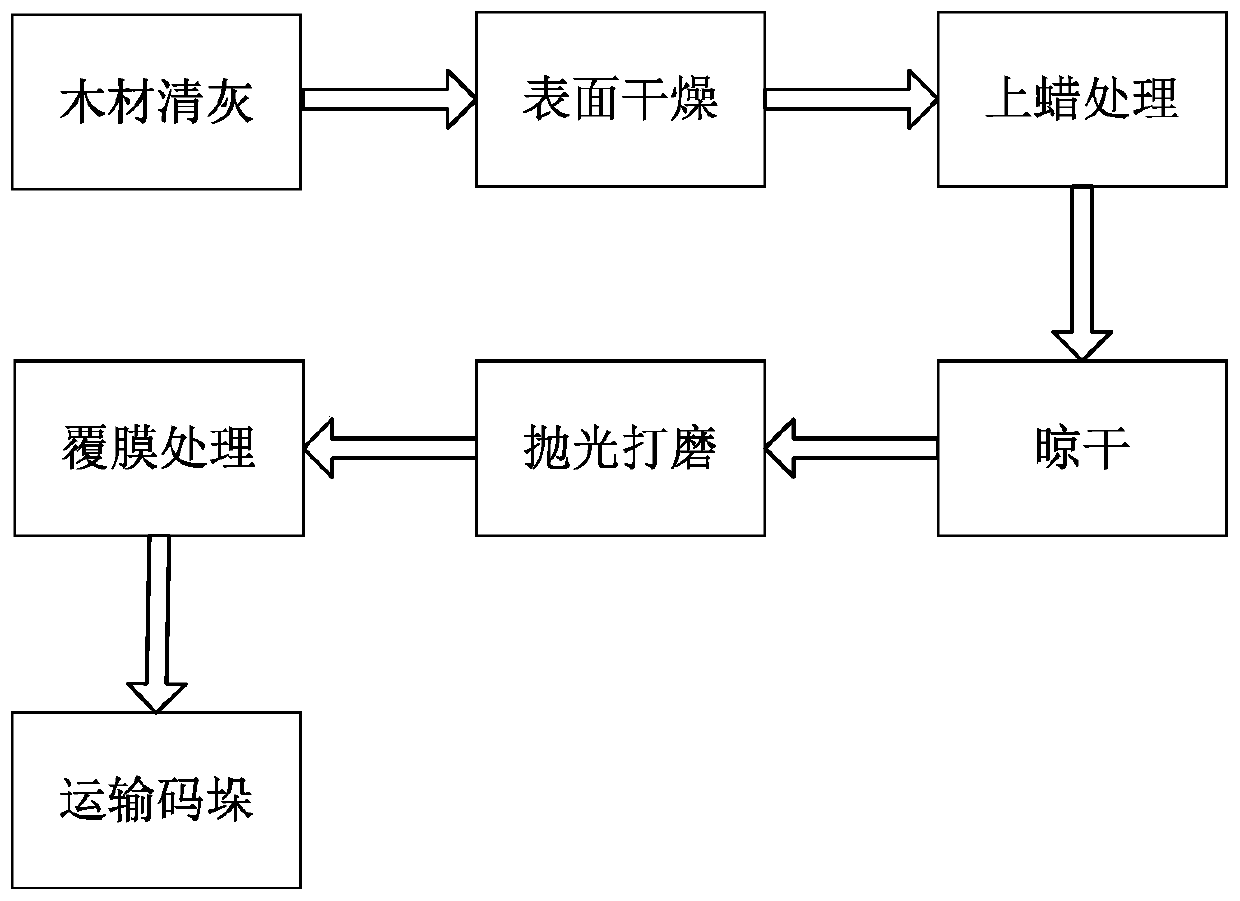

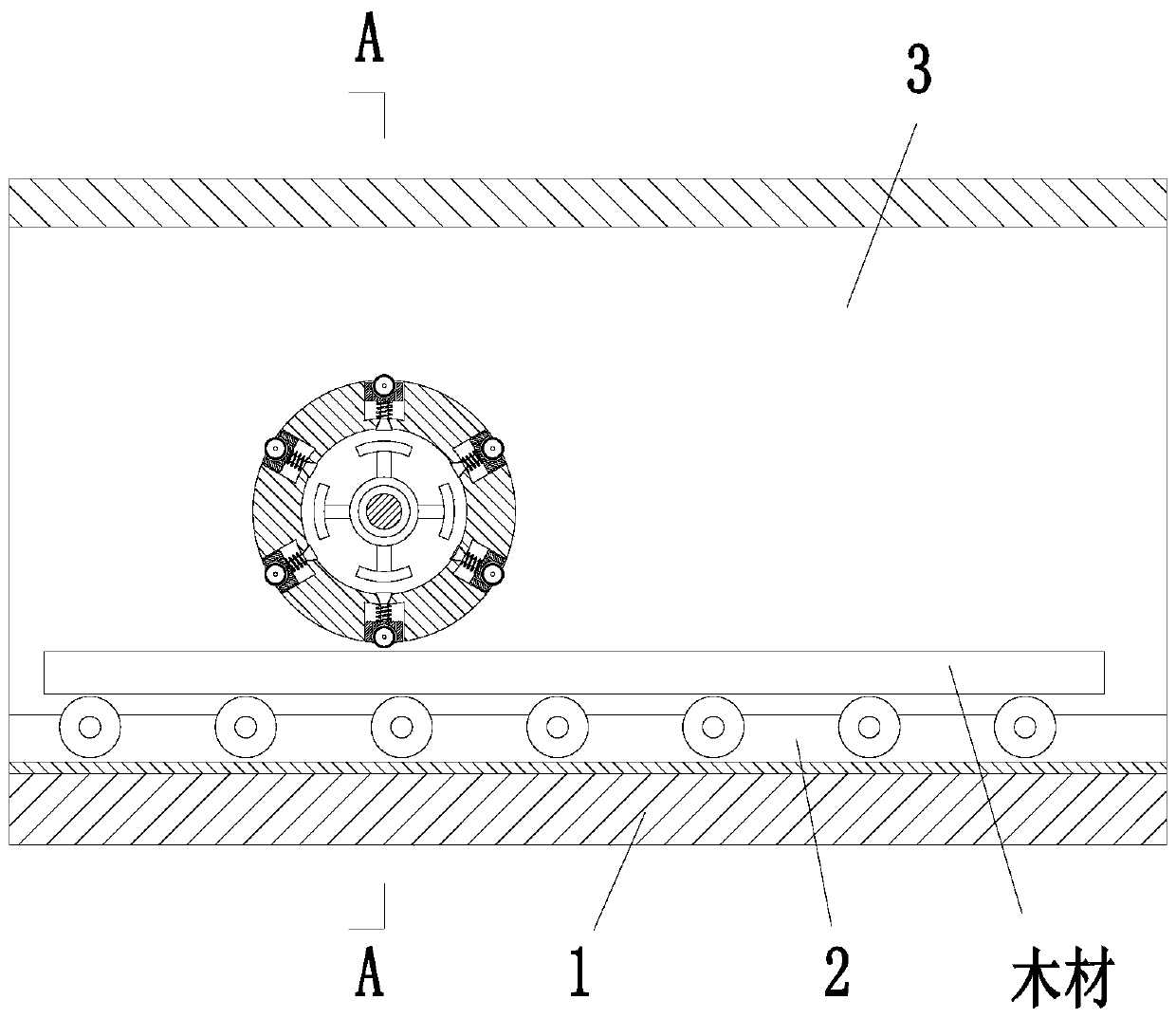

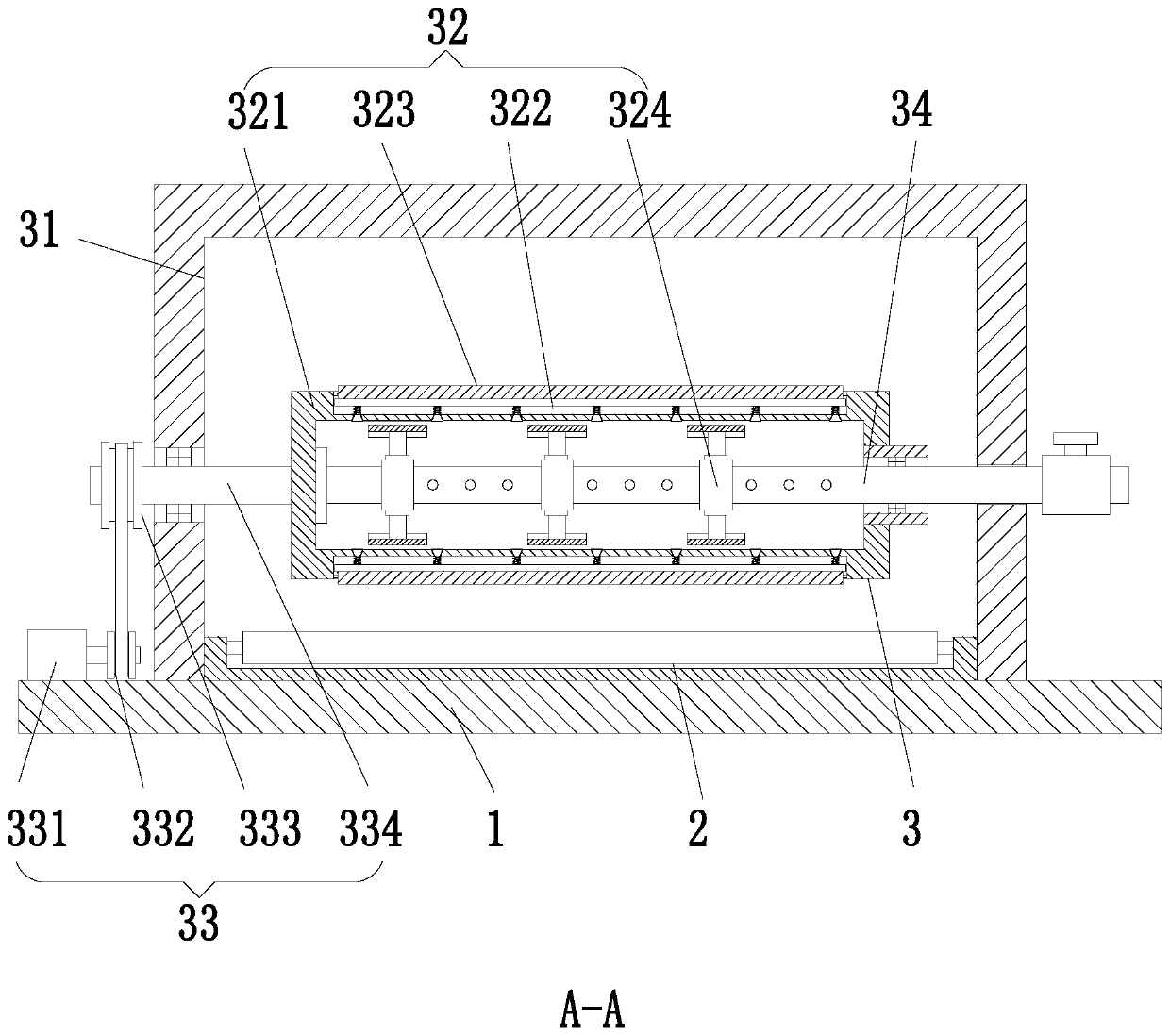

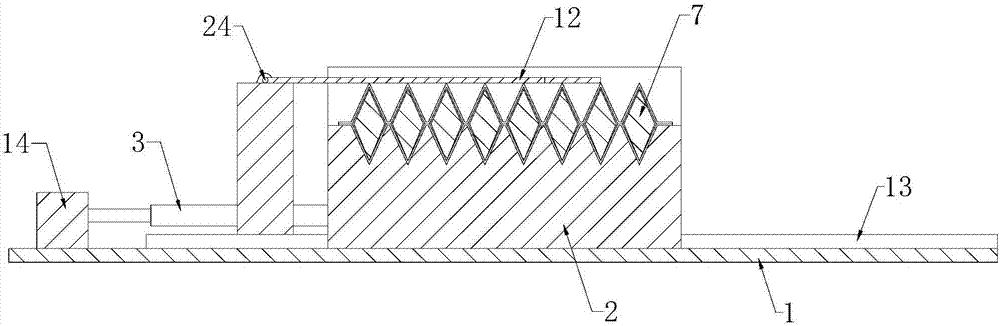

The invention relates to a wood anti-corrosion mildew-proof treatment method. According to the method, a bottom plate, a conveying belt and a waxing device are included; the conveying belt is arrangedin the middle of the upper end of the bottom plate; the waxing device is arranged above the conveying belt; and the lower end of the waxing device is arranged on the bottom plate. By means of the method, the following problems are solved: when conventional equipment is used for waxing for corrosion prevention and mildew prevention treatment on the wood, the wax liquid is usually not uniformly coated, and the surface of the wood is often not waxed fully, so that the wax layer on the surface of the wood is prone to falling off to enable the wood to deform and twist due to be susceptible to moisture, and subsequent processing and use of the wood is affected disadvantageously; poor coating effect and low coating efficiency of the conventional waxing equipment when being used for waxing the wood lead to increase in wood processing cost; and meanwhile, due to the fact that the wax liquid is prone to solidifying when being cooled, the circulation effect of the wax liquid is influenced, and the wax coating efficiency is reduced.

Owner:郭沙

Functional inorganic mineral wall material

InactiveCN106892636AGuaranteed normal generationKeep dry and cleanCovering/liningsSodium BentoniteMetakaolin

The invention belongs to the field of building coatings and particularly relates to a functional inorganic mineral wall material. The functional inorganic mineral wall material is prepared from, by mass, 20-40 parts of ground calcium carbonate, 10-20 parts of ash calcium powder, 0-10 parts of washed kaolin, 0-10 parts of metakaolin, 0-10 parts of calcined kaolin, 0-5 parts of calcium bentonite, 5-15 parts of diatomaceous earth, 0-10 parts of zeolites, 10-30 parts of modified gypsum, 0-20 parts of magnesium oxide, 0-10 parts of magnesium sulfate, 0-5 parts of titanium dioxide, 0-5 parts of white cement, 0-5 parts of sepiolite, 0-5 parts of attapulgite, 2-5 parts of talcum powder, 0-5 parts of wollastonite, 0.5-1 part of water-retaining agent and 0-2 parts of nano titanium dioxide photocatalyst.

Owner:陈锦

Surface nitriding treatment process of hard alloy cutter

InactiveCN106399917AExtend your lifeHigh hardnessSolid state diffusion coatingSurface layerRoom temperature

The invention discloses a surface nitriding treatment process of a hard alloy cutter. The process includes the steps that firstly, the hard alloy cutter is placed in a solution to be ultrasonically cleaned for 10-20 min, oil dirt, dust, sweat stains and the like are removed, and the cutter is blow-dried with hot air; then the cleaned tool and an energizer are placed in a vacuum furnace to be vacuumized, and then heating is started for temperature rise; and finally when the temperature in the furnace reaches the specified temperature, ammonia gas of certain pressure is introduced, the ammonia gas is replaced at set intervals, heating is stopped after heat preservation is carried out for a period of time, and the cutter is cooled to room temperature in the furnace. A nitrided case with certain thickness can be formed on the surface layer of the hard alloy cutter treated through the surface nitriding treatment process, the nitrided case is high in hardness and good in corrosion resistance and abrasion resistance, is generated in the surface layer of a base body, and cannot fall off, and the service life of the tool is greatly prolonged; and meanwhile, the process is easy to operate, and the preparation cost is low.

Owner:XINAN TOOLS GUIZHOU PROV

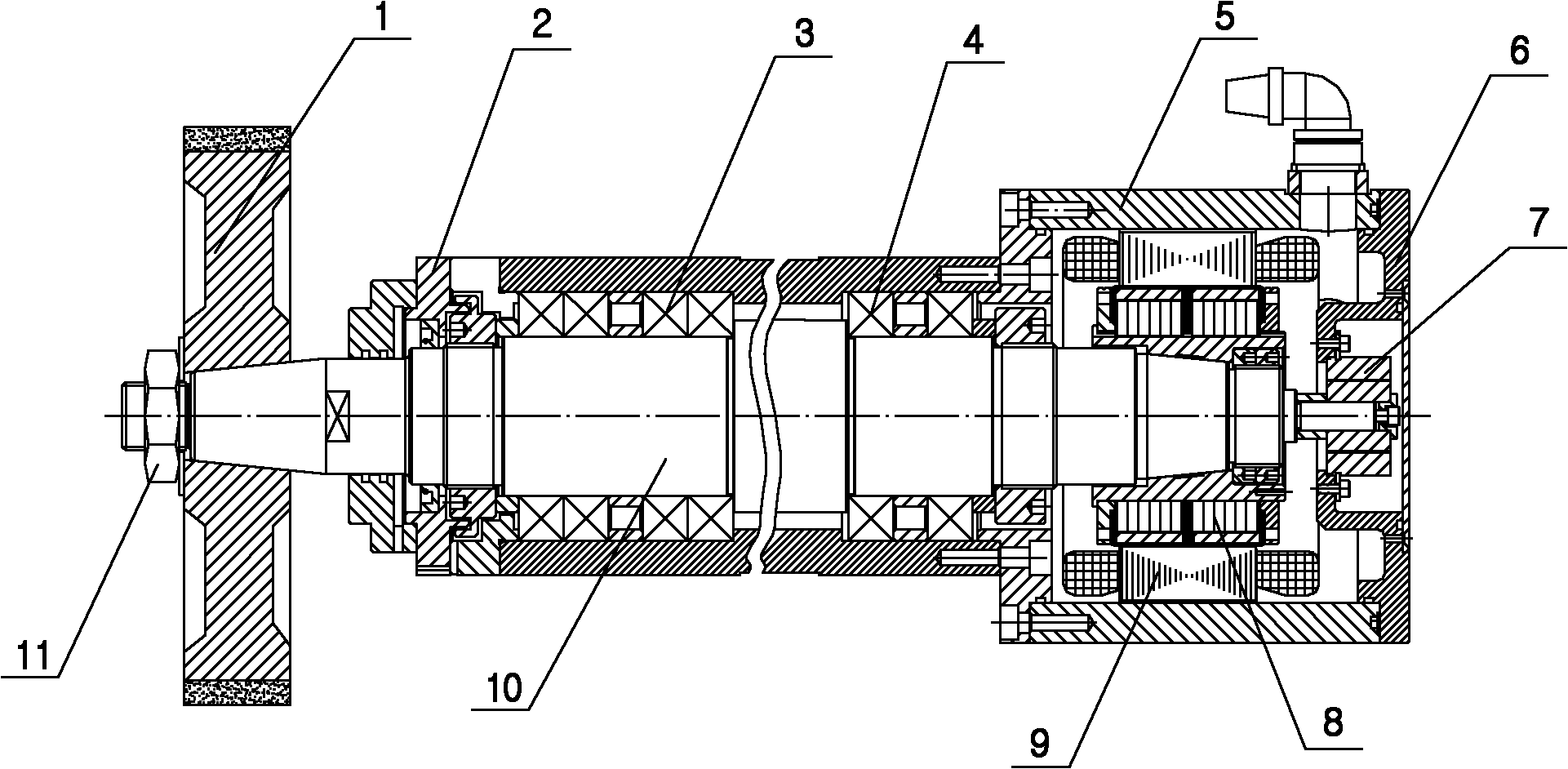

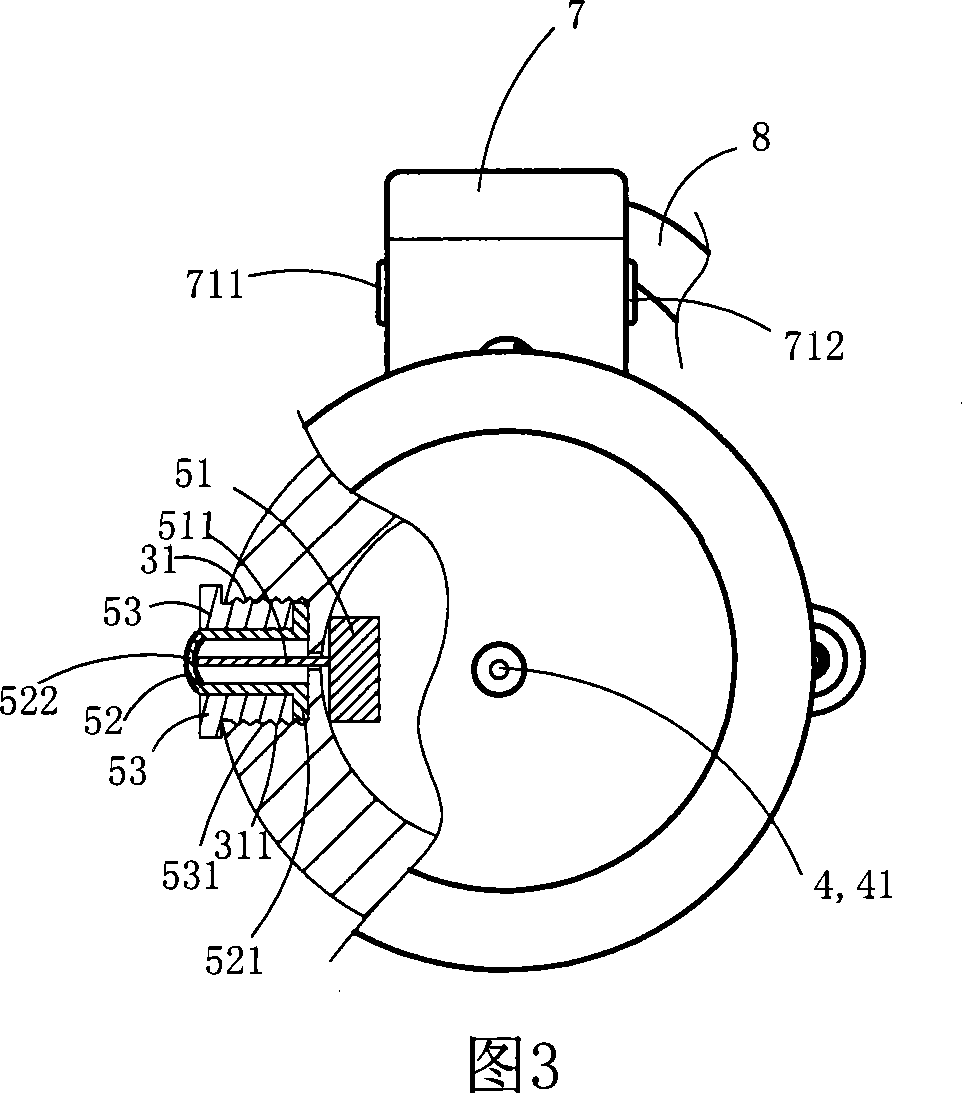

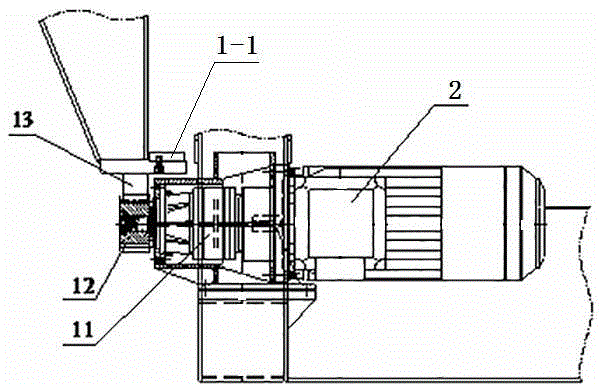

Rear-mounted grinding wheel main shaft motor of plane grinding machine

InactiveCN102390025ALarge corner rangeBroaden applicationMagnetic circuit rotating partsStructural associationPermanent magnet rotorEngineering

The invention discloses a rear-mounted grinding wheel main shaft motor of a plane grinding machine, which is characterized by comprising a shell, a main shaft, a permanent magnet rotor assembly, a stator assembly, an encoder, a front end cover and a rear end cover, wherein the main shaft is arranged in the shell through a bearing I and a bearing II; the stator assembly is arranged in the shell and is located at the rear end of the shell; the permanent magnet rotor assembly is arranged on the main shaft; the front end cover is arranged at the front end of the shell; the rear end cover is arranged at the rear end of the shell; the encoder is arranged at the rear end of the main shaft and is connected with an external driver; the main shaft extends from the front end cover; the part of the main shaft is a conical surface, which extends from the front end cover; and the conical surface of the main shaft is provided with a grinding wheel grinding head. The rear-mounted grinding wheel main shaft motor of the plane grinding machine is capable of expanding the rotation angle of the grinding head and expanding the application range of the plane grinding machine.

Owner:XIAN HESHENG POWER TECH CO LTD

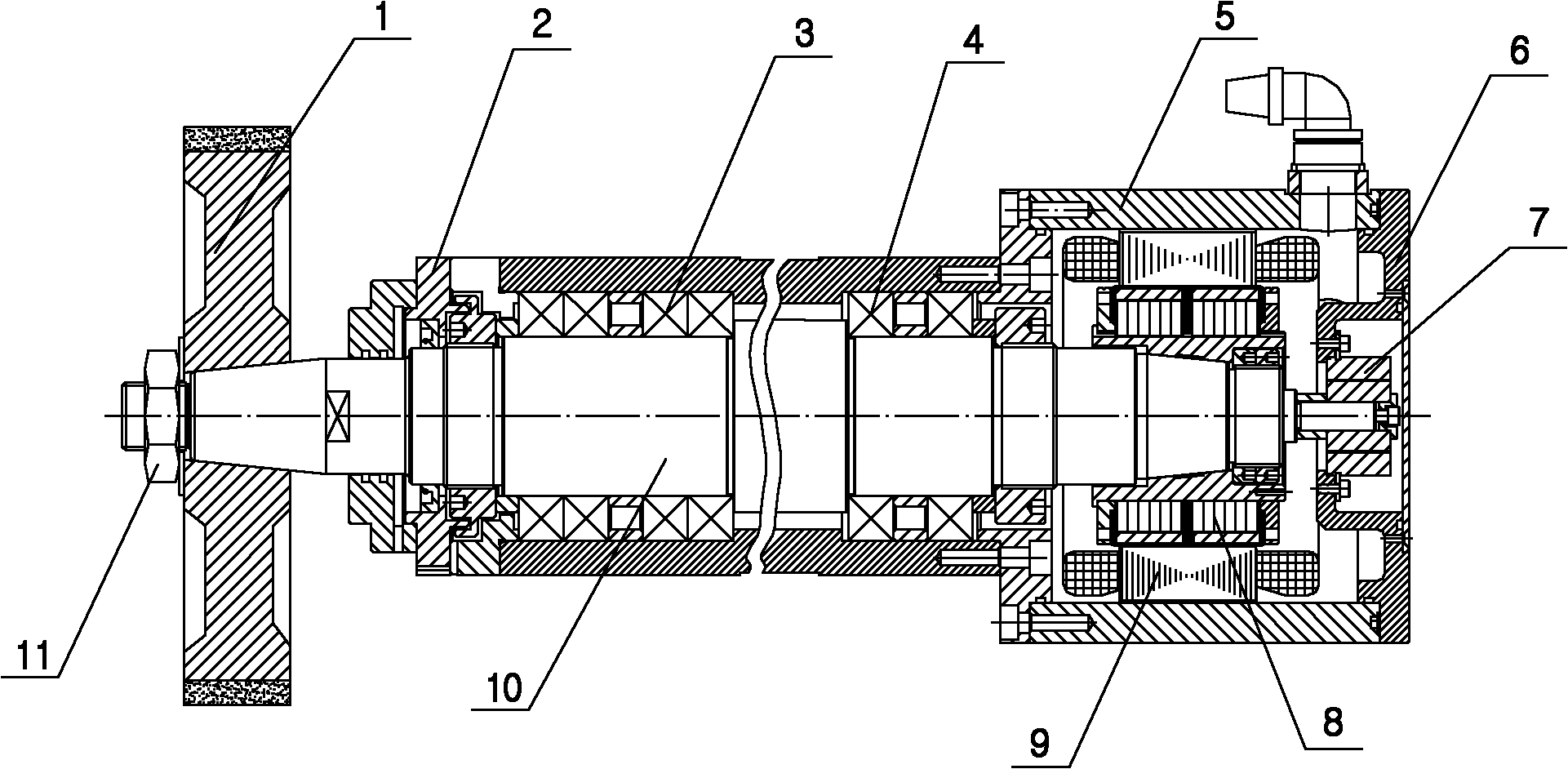

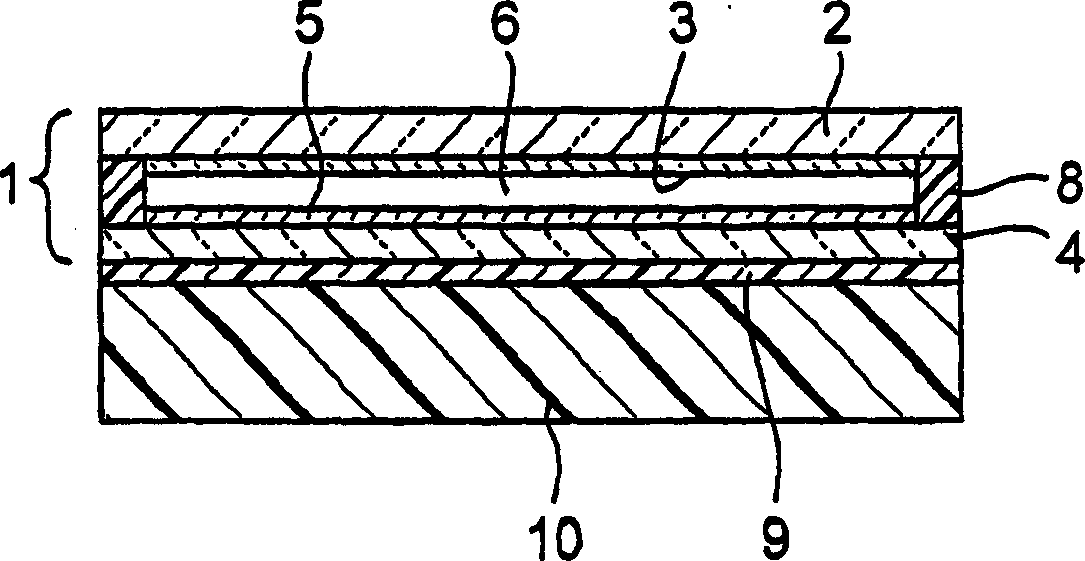

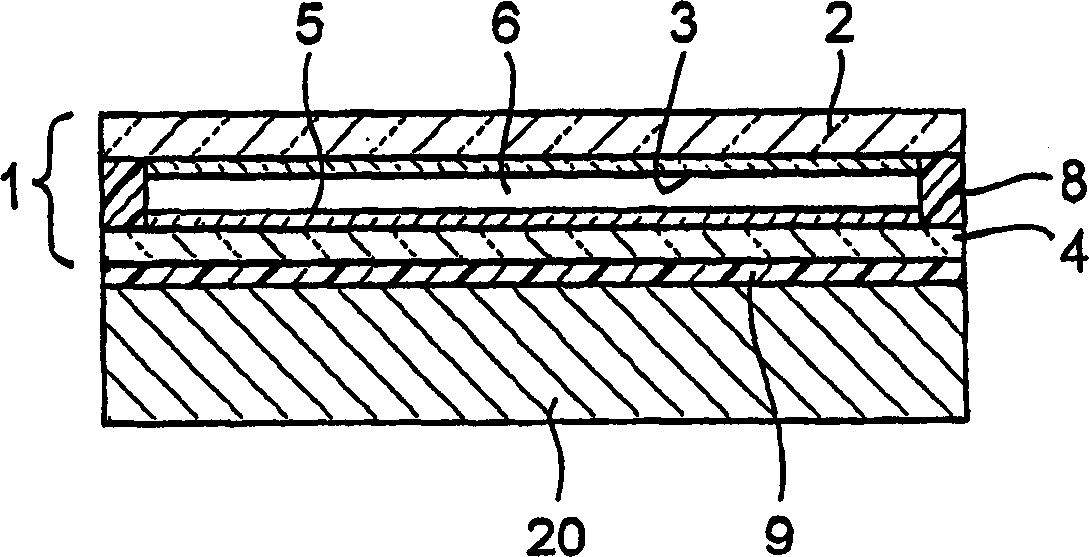

Touch panel with adhesive layer

InactiveCN1679129ANo falling offIncrease stiffnessElectric switchesInput/output processes for data processingDisplay deviceRoom temperature

A touch panel with an adhesive layer, comprising the adhesive layer (9) for sticking, on the entire surface of a display (20), a touch panel body (1) having an upper electrode plate having an upper electrode (3) formed of a transparent conductive film formed on the lower surface of an upper insulation substrate (2) formed of a transparent plastic film and a lower electrode plate having a lower electrode (5) formed of a transparent conductive film formed on the upper surface of a lower insulation substrate (4) formed of a transparent plastic film and opposed to the upper electrode plate through an air layer (6) between the upper electrode plate and the lower electrode plate and a separate support plate member (10) for the adhesive layer, wherein the bending rigidity of the transparent plastic film at a room temperature is 0.3 to 40 kgf.cm<2> when the width (b) of the separate support plate member (10) in cross section is 12 cm.

Owner:NISSHA PRINTING COMPANY

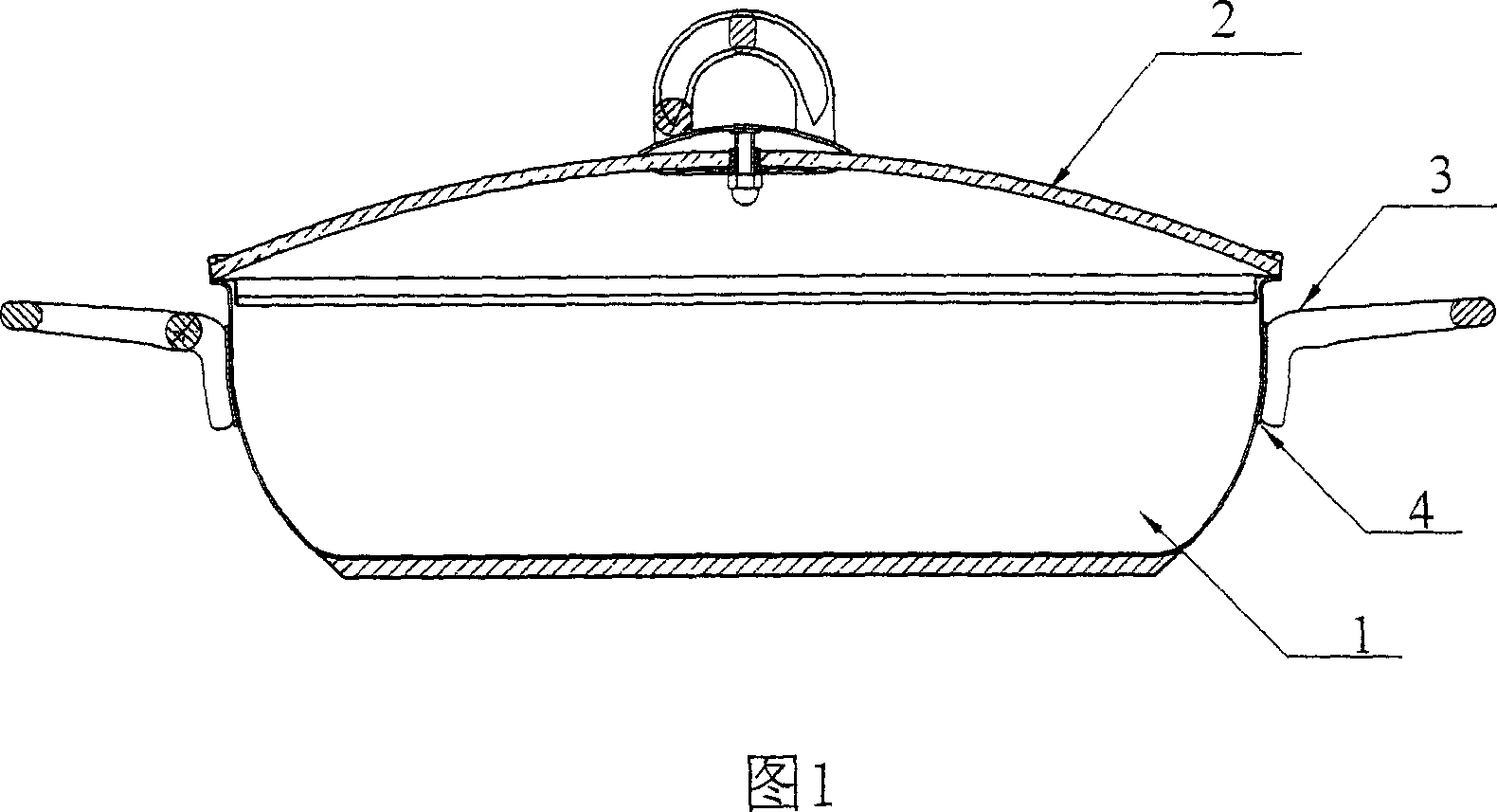

Metal pot and its handle connecting method

InactiveCN1986132ANo falling offDoes not affect appearanceSoldering apparatusKitchen equipmentEngineeringMetal

The present invention discloses a kind of metal pot and its handle connecting method. The metal pot includes one pot body, one pot cover and one handle, and features the increased welding connection block between the pot body and the handle. During connection, the welding connection block is first coated with metal welding powder to its two sides, then set between the handle and the pot body and the handle is heated for welding the handle, welding connection block and the pot body together. The pot thus produced has good look and firm connection of handle.

Owner:SHANGHAI GUANHUA STAINLESS STEEL PROD

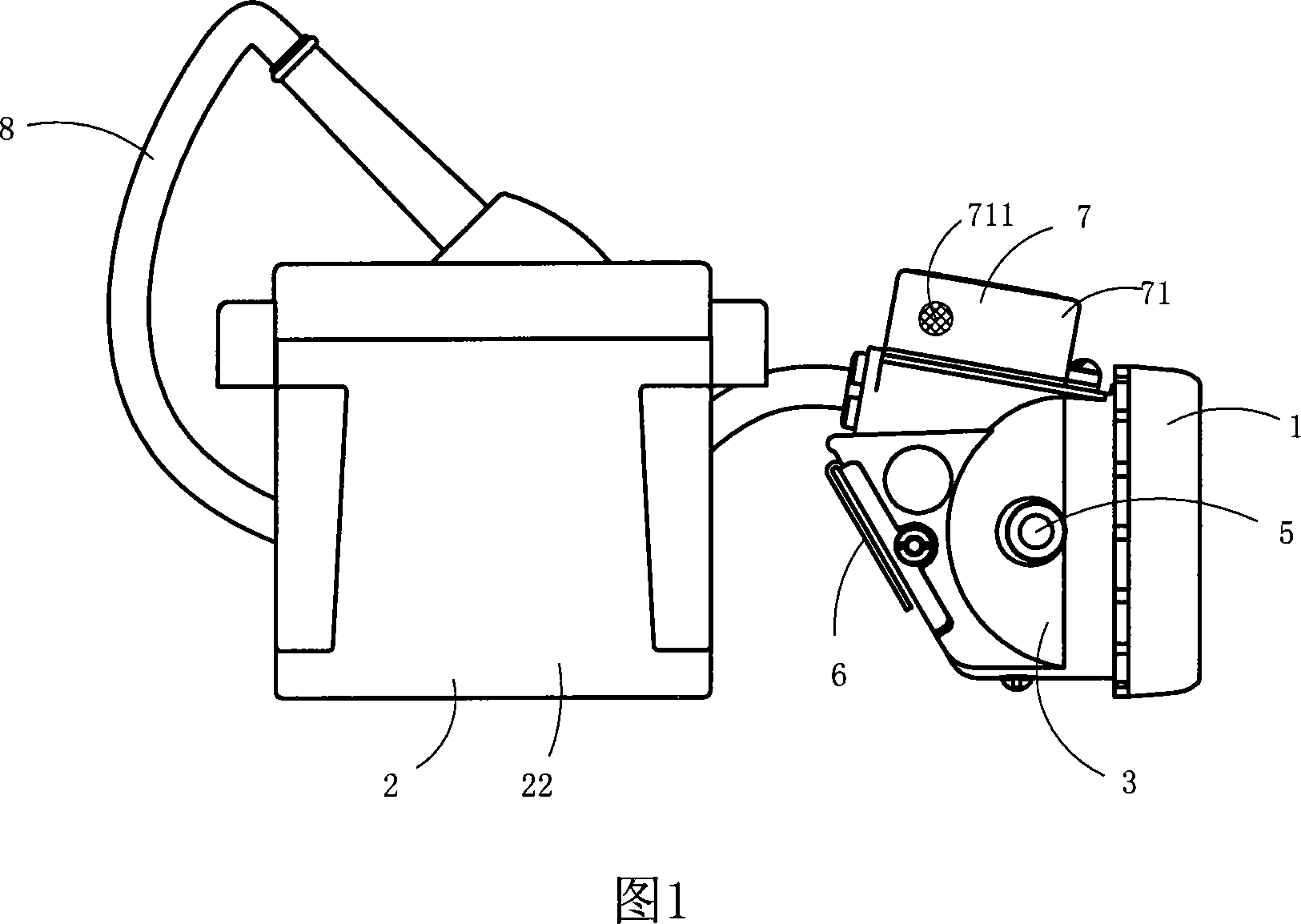

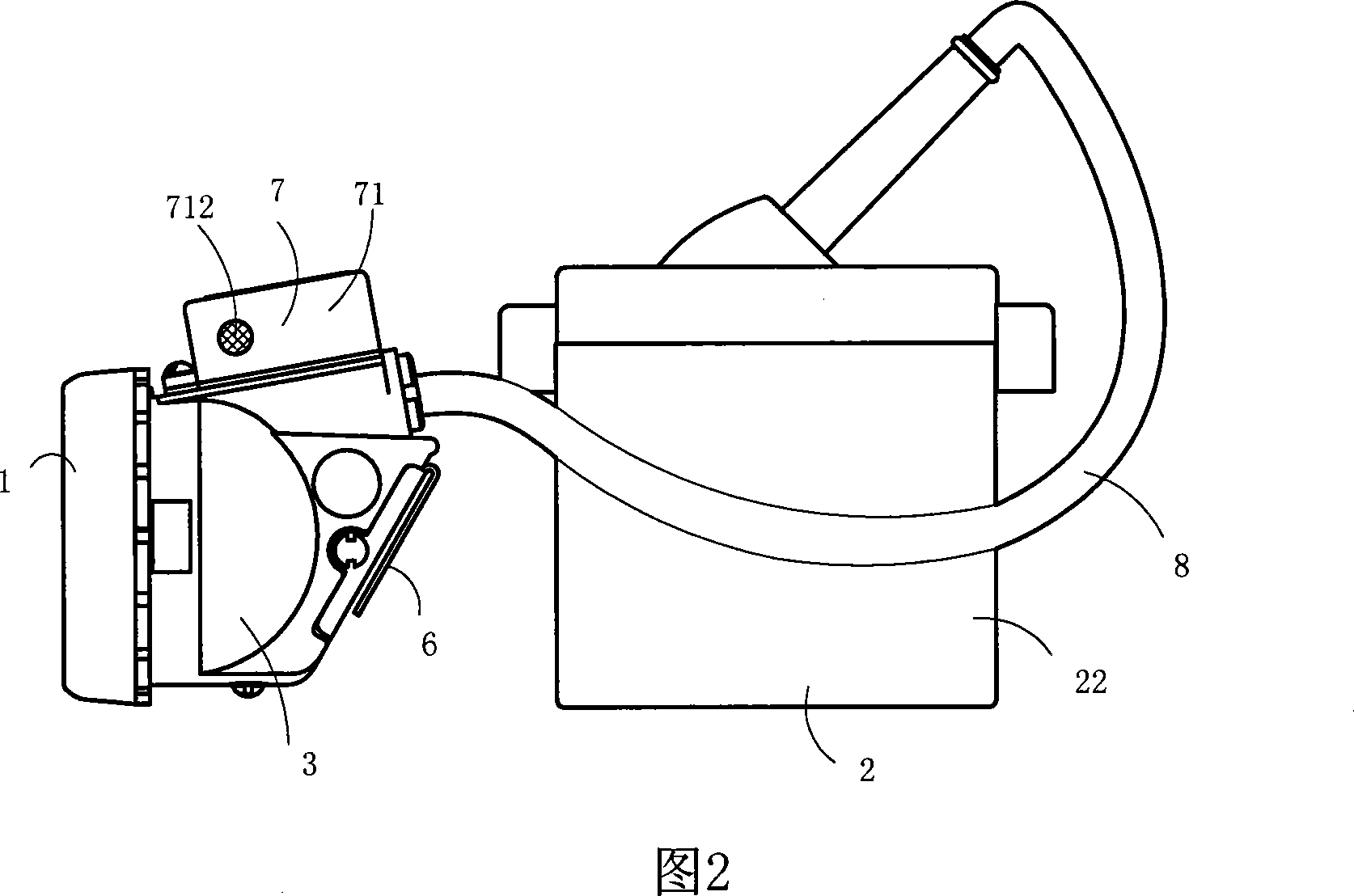

Miners' lamp

InactiveCN101055060AEasy to disassembleQuick and easy disassemblyLighting applicationsElectric circuit arrangementsElectricityElectric power

The present invention discloses a miner's lamp which includes a lamp head assembly, an electric power assembly and wires for electrically connecting the lamp head assembly and the electric power assembly; the lamp head assembly includes a housing, an illumination lamp and an illumination lamp switch assembly; the wall of the housing is disposed with a mounting hole, the illumination lamp switch assembly includes a microswitch disposed in the housing, an elastic sealing cover and a position bolt coupled with the mounting hole; the touch handle of the microswitch lies in the mounting hole, the sealing cover encloses the touch handle of the microswitch, the position bolt fixes the sealing cover in the mounting hole. The invention has the advantages of good safety, convenient maintenance and long use life.

Owner:周建清

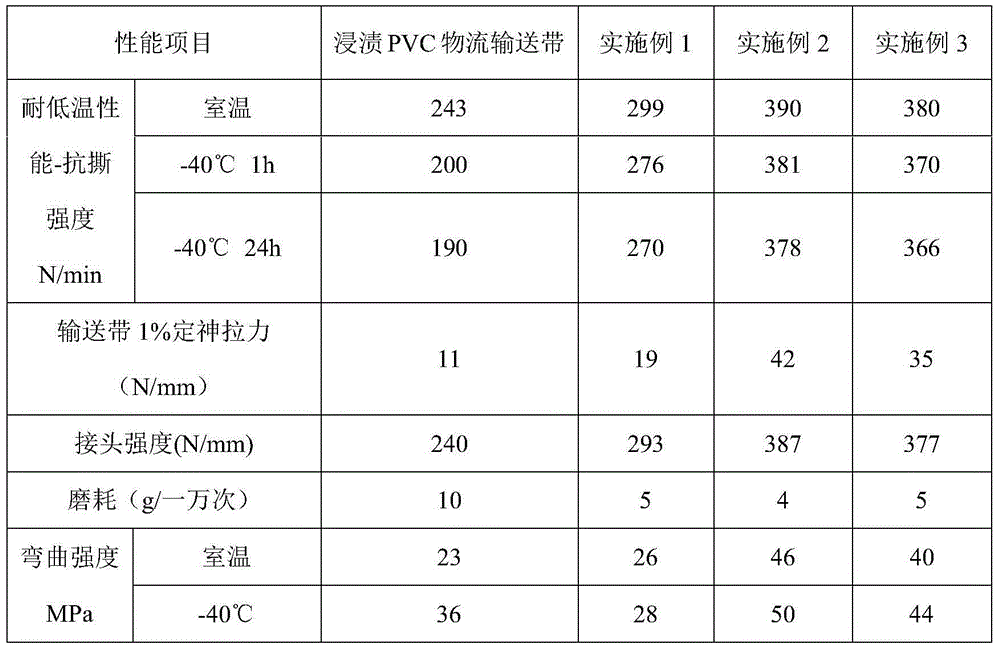

Wear-resisting low-temperature-resisting PUR logistics conveying belt and preparation method thereof

The invention relates to a wear-resisting low-temperature-resisting PUR logistics conveying belt and a preparation method thereof. The logistics conveying belt comprises a middle framework fabric layer and a PUR coating immersed at the upper and lower surfaces of the middle framework fabric layer; the thickness of the logistics conveying belt is 4-5 mm, and the surface shore hardness is 80-90 HA. When the logistics conveying belt is prepared, the PUR is immersion is performed on a polyester fiber base cloth after the pre-molding treatment by a dual-roller impregnator; then the polyester fiber base cloth is repeatedly extruded for 2-3 times at 110-120 DEG C; PUR solidification is carried out under the condition of constant temperature and humidity, the back face of the conveying belt is polished, and thus the PUR logistics conveying belt is prepared. Compared with prior art, the polyester fiber base cloth is prepared by PUR immersing technique; the low-temperature resistance thereof is better than that of the like product immersed by traditional PVC; the logistics conveying belt can be used for a long term under 40 DEG C low-temperature environment; the PUR logistics conveying belt effectively solves the technical problems that the logistics conveying belt is big in surface hardness, hardened and off-line ran, easy to break, short in service life, bad in wear resistance, and other technical problems of the logistics conveying belt under the low-temperature environment.

Owner:INO IND BELTING CO LTD

Ionic liquid modified bar code carbon strip back coating and preparation method thereof

InactiveCN108485358ASolve heat resistanceFix stability issuesFireproof paintsThermographyOrganic solventDouble bond

The invention relates to an ionic liquid modified bar code carbon strip back coating which is prepared from the following raw materials in parts by weight: 10-50 parts of an acrylic monomer, 0.5-2 parts of a silane coupling agent, 0.5-3 parts of an ionic liquid containing double bonds; 15-30 parts of organic silicon, 13-73.5 parts of an organic solvent and 0.5-2 parts of a catalyst. The inventionprovides the ionic liquid modified bar code carbon strip back coating and a preparation process. By means of block polymerization, the ionic liquid containing double bonds is introduced into a high molecular chain of the polyacrylate back coating, and the high molecular back coating with low resistivity is coated with a bar code carbon strip, so that static electricity generated and accumulated onthe carbon strip are reduced effectively, and therefore, the printing using quality of the back coating is guaranteed.

Owner:HENAN UNIV OF SCI & TECH

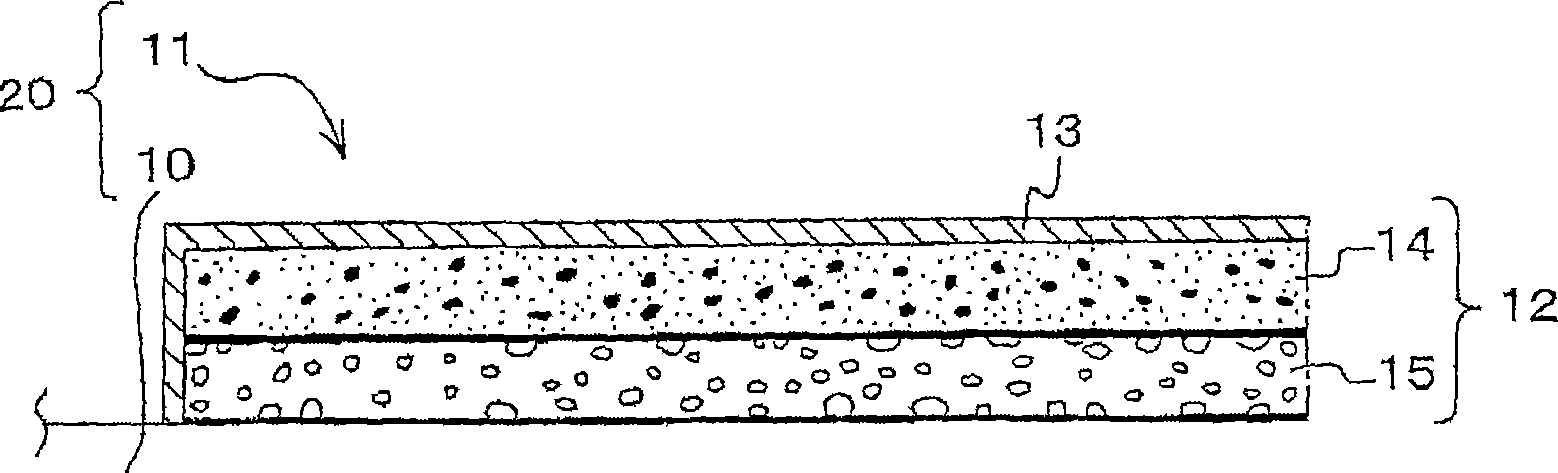

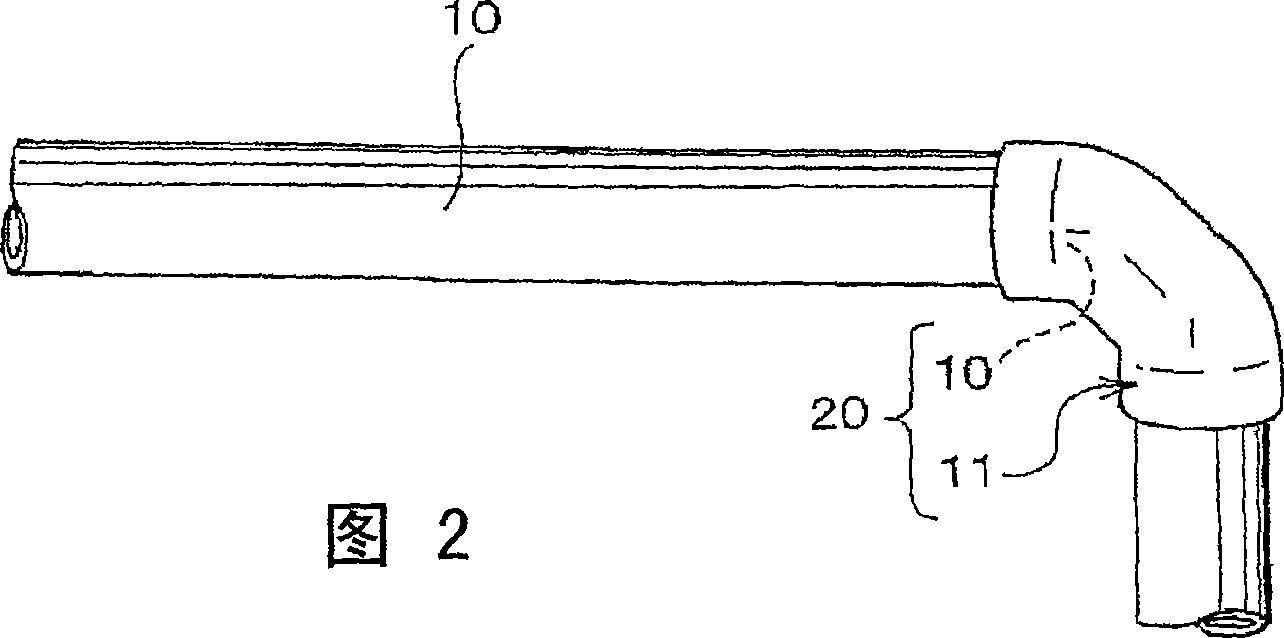

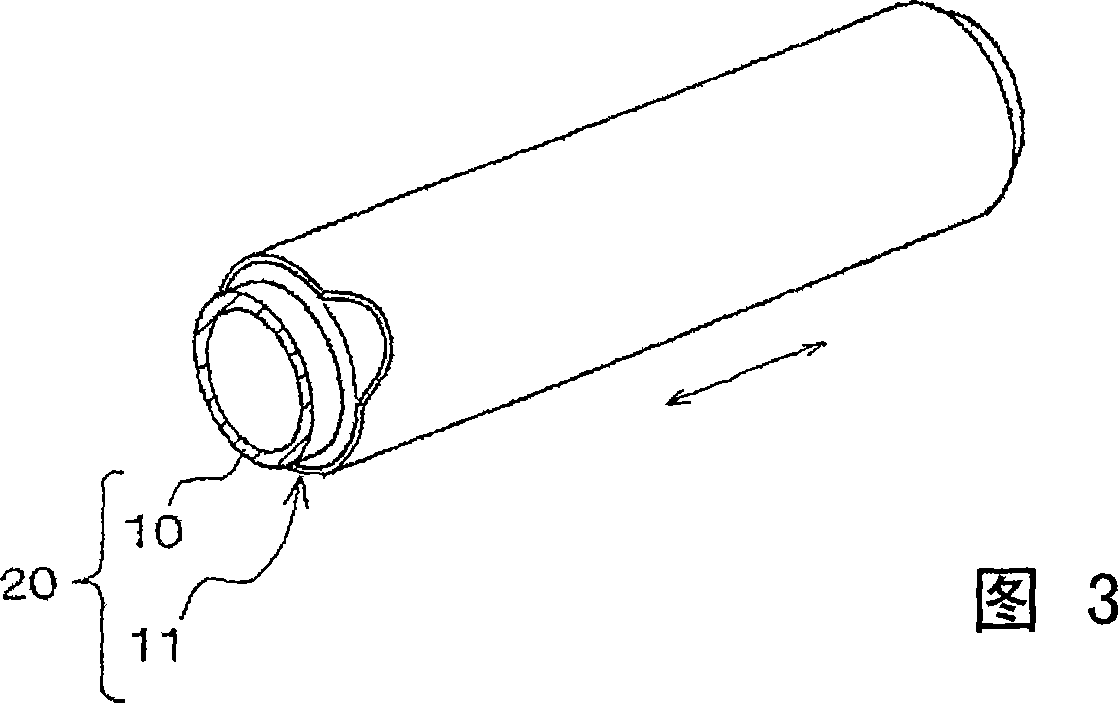

Soundproof coating material and soundproof drain pipe

It provides a soundproof coating material and a soundproof drain pipe. The soundproof coating material comprises a soundproof layer coated on the outer periphery of a pipe having a sound insulating outer layer with an elastic modulus of 1.0 10<6> to 3.0 10<6>Pa and a sound absorbing inner layer with an elastic modulus of 0.5 10<3> to 2.0 10<3>Pa so that the soundproof layer can be securely and smoothly mounted on the outer periphery of the pipe. Accordingly, in the soundproof drain pipe thus obtained, the soundproof layer is allowed to slide on the outer periphery of the pipe and the soundproof layer is prevented from being fallen off from the outer periphery of the pipe. As a result, the handling of the soundproof drain pipe can be improved and supply / drain noise therefrom can be effectively reduced.

Owner:SHISHIAI KK

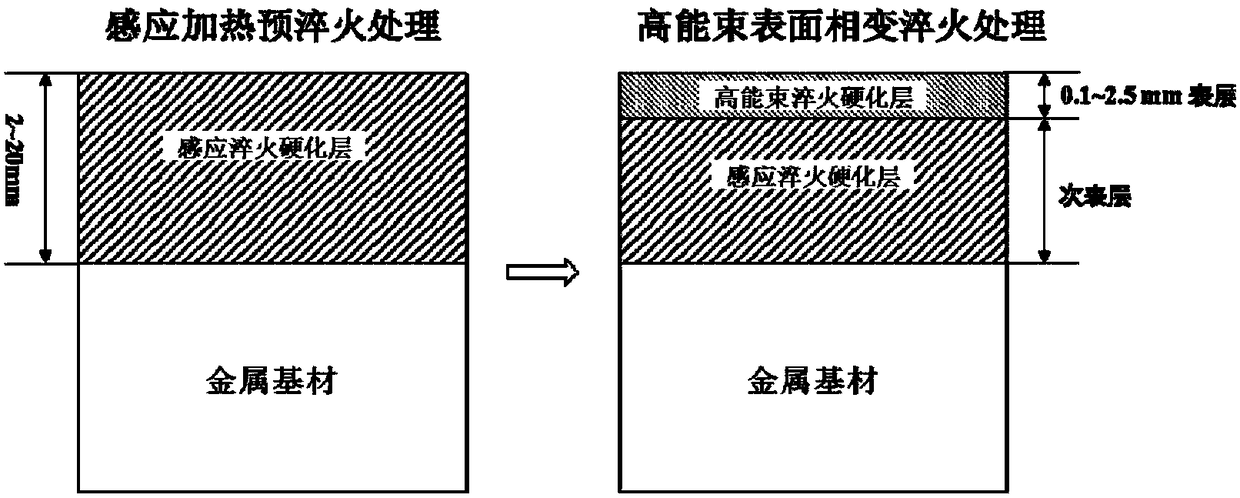

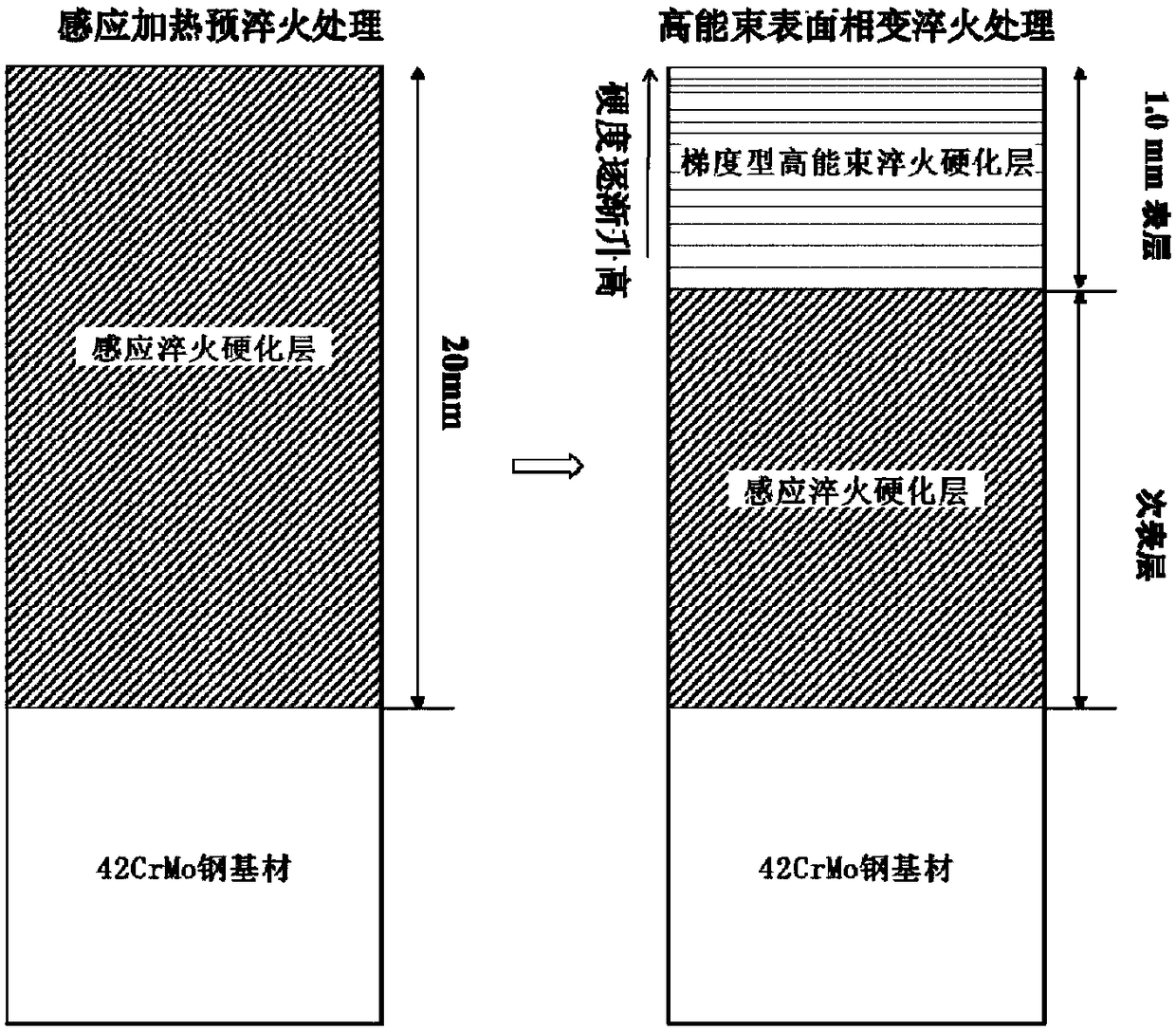

Deep-layer high-hardness composite surface quenching reinforcing method

InactiveCN108315531AAchieve continuous hardeningNo falling offIncreasing energy efficiencyAlloyInduction hardening

The invention discloses a deep-layer high-hardness composite surface quenching reinforcing method of metal and alloy members and belongs to the field of surface heat treatment. The method comprises the steps: firstly, obtaining an induction quenched hardened layer with a depth of 2 to 20mm, a grain size of 7 to 10 levels and a hardness value of 45 to 62HRC on the surface of a part through induction heating pre-quenching; then utilizing machining to make the part reach an assembling accuracy and a finish degree required by the surface; finally, utilizing high energy beam surface phase change quenching to obtain a high energy beam quenched hardened layer with a depth of 0.1 to 2.5mm, a grain size of 10 to 16 levels and a hardness value of 62HRC on the surface of the part. The obtained composite hardened layer disclosed by the invention is prepared from the induction quenched hardened layer on the secondary surface layer and the high energy beam quenched hardened layer on the surface layer; thus, surface wear resistance and fatigue life of the metal and alloy materials are improved, and a strict requirement of the modern industry on the metal and alloy materials is met.

Owner:HUAZHONG UNIV OF SCI & TECH

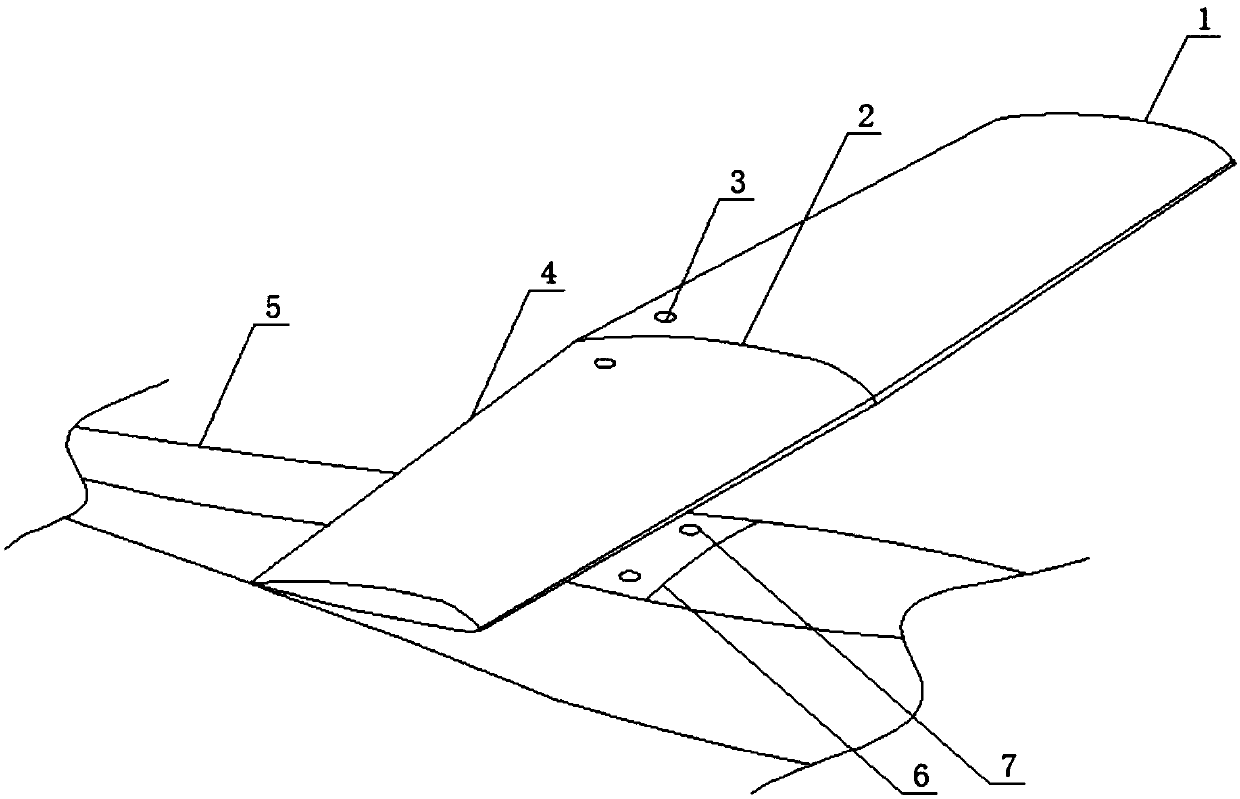

High-stability and firmly-mounted fixed wing aircraft wing

PendingCN109572992AExtended service lifeInhibit sheddingSpars/stringersAircraft assemblyUltimate tensile strengthFuselage

The invention discloses a high-stability and firmly-mounted fixed wing aircraft wing. The high-stability and firmly-mounted fixed wing aircraft wing comprises a first wing and a mounting groove; the mounting groove is formed in the lower end of the left side of the first wing; the first wing is connected with the mounting groove in a sleeving manner; a fixing clamping seat is arranged to penetratethrough the surface end of the lower end of the left side of the first wing; and the fixing clamping seat is connected with the first wing in a through manner. According to the high-stability and firmly-mounted fixed wing aircraft wing, by arranging a support reinforcing plate at the perpendicularly intersected part of the first wing and a second wing, the support reinforcing plate can enable a suffered impact force to be stable to prevent a phenomenon that the first wing and the second wing cannot fall off; and therefore,damages of the first wing and the second wing caused by fall-off are avoided so that the service life of the integral structure of the fixed wing aircraft wing can be prolonged; and moreover, influences caused by factors such as a clearance and a manufacturing error areeliminated while the connecting strength between the first wing and an aircraft body and the connecting strength between the second wing and the aircraft body are guaranteed.

Owner:江西冠一通用飞机有限公司 +1

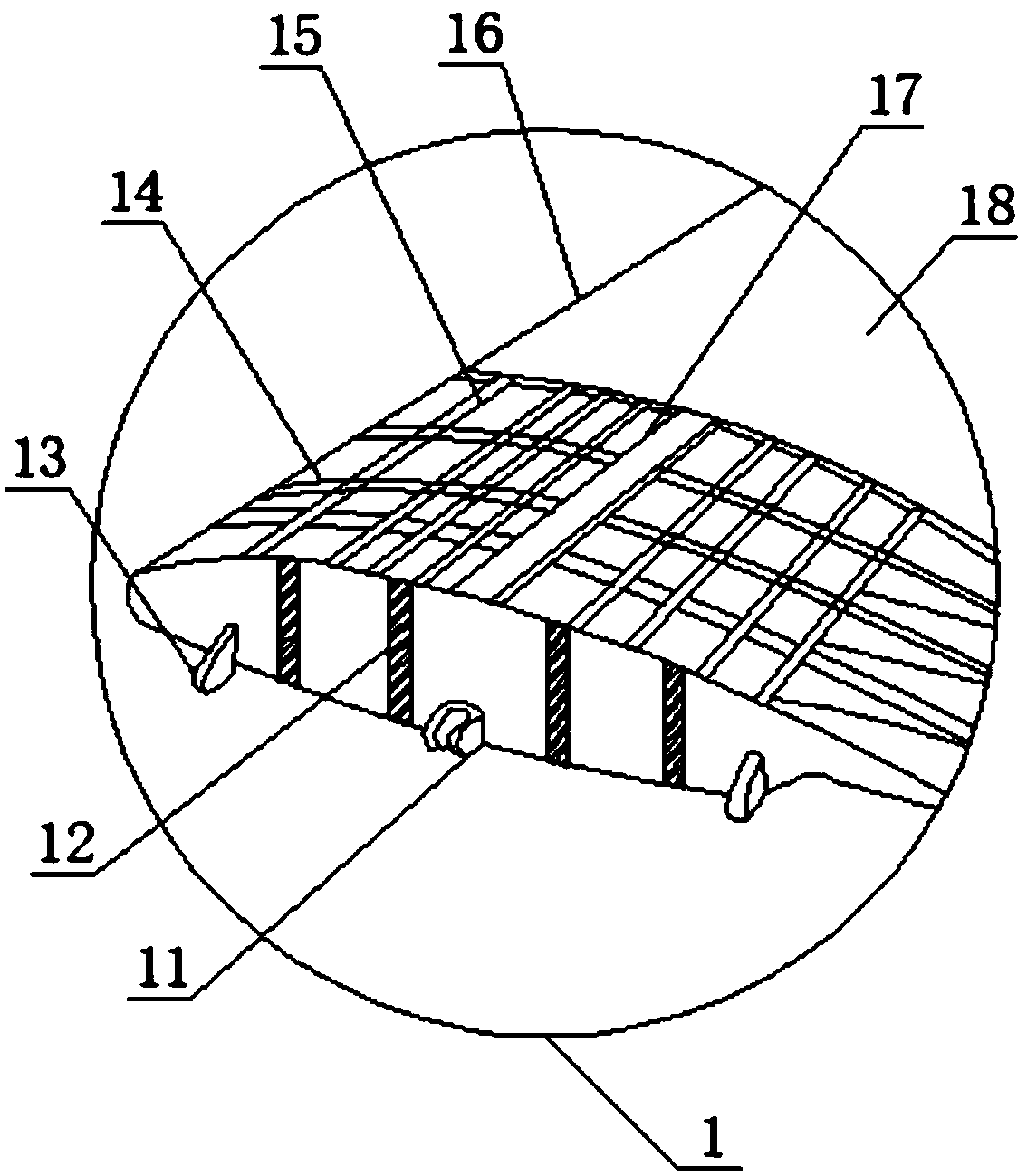

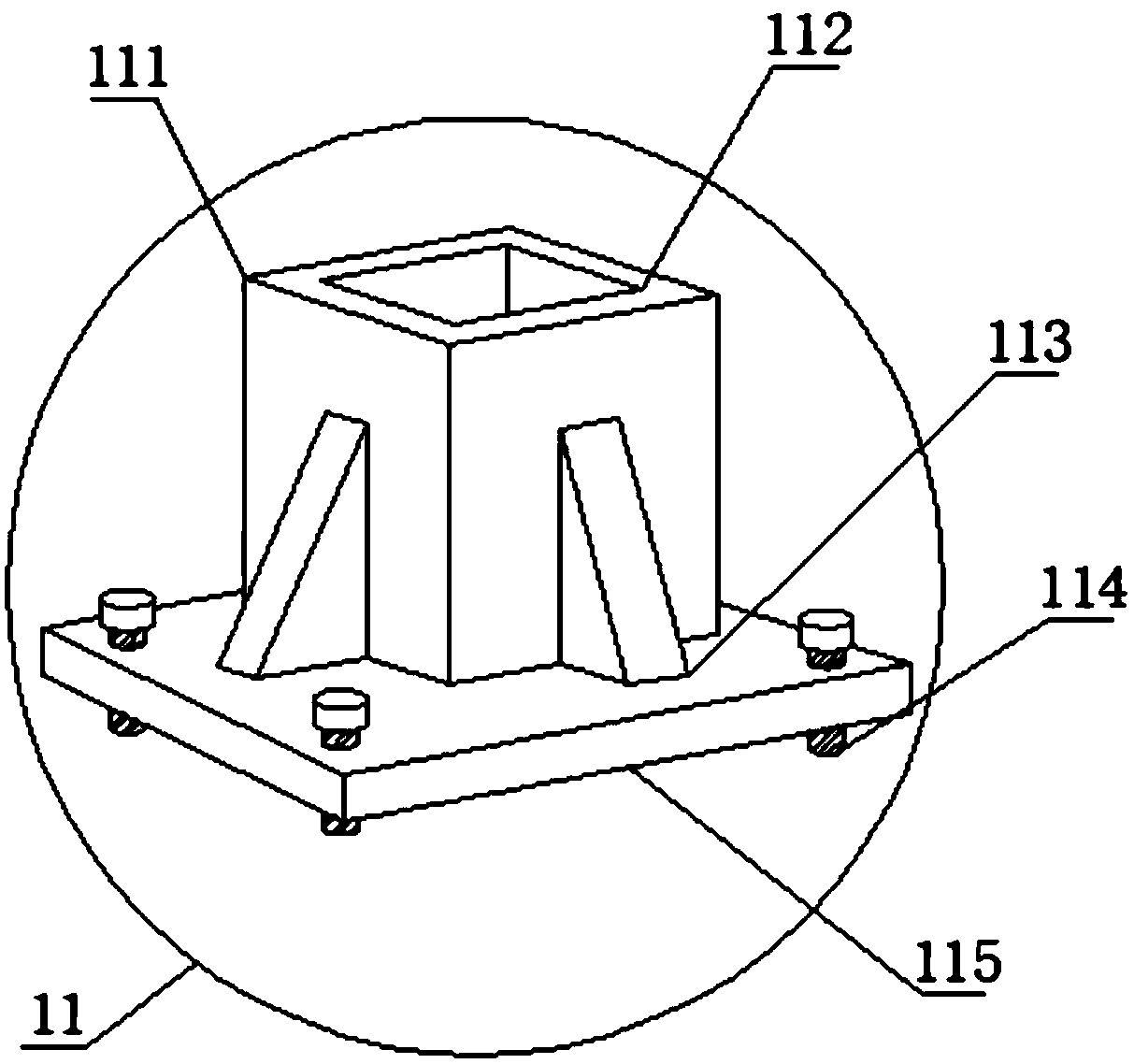

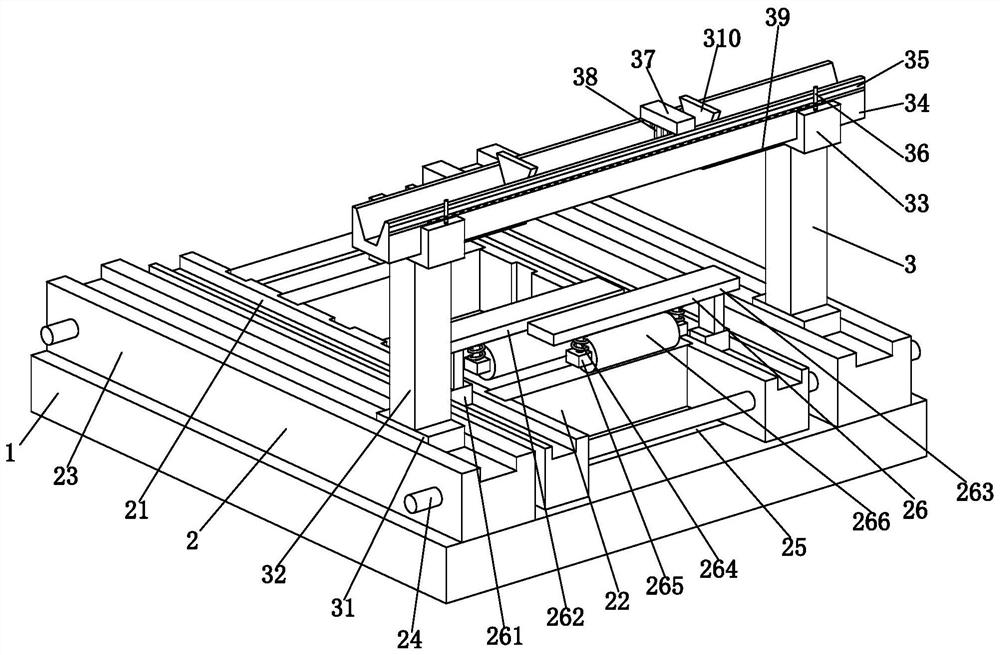

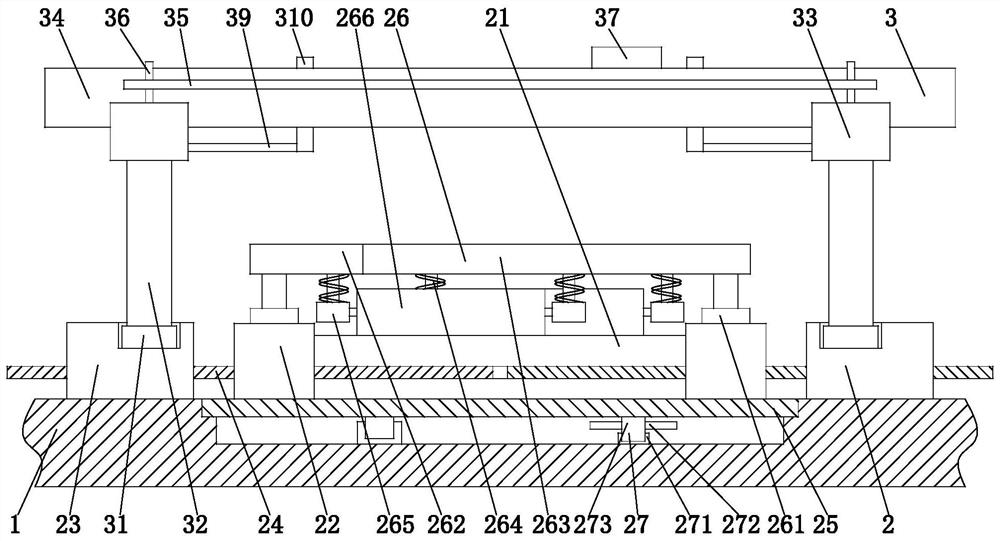

Construction method of cast-in-place concrete composite floor slab

The invention relates to a construction method of a cast-in-place concrete composite floor slab. A concrete composite floor slab forming device is adopted and comprises a bottom rack, a placing mechanism and a feeding mechanism. The construction method can solve the following problems that in the traditional cast-in-place concrete composite floor slab preparing and forming process, one cast-in-place concrete composite floor slab preparing and forming device can only produce cast-in-place concrete composite floor slabs of one specification, cast-in-place concrete composite floor slabs of different specifications are usually needed on a construction site, and therefore cast-in-place concrete composite floor slab preparing and forming devices of different models are needed, the production cost is high, the occupied area of the devices is large, and the construction progress is affected; and in the traditional cast-in-place concrete composite floor slab preparing and forming process, due to the fact that in the concrete pouring process, contact between concrete and aggregate is possibly incomplete, the concrete is not in complete contact with the aggregate after standing and solidifying, and the cast-in-place concrete composite floor slab is prone to being broken.

Owner:余姚市江林建筑工程有限公司

Watering flow well mouth oil extraction device for oil field ground exploitation technology

InactiveCN114086931AExtend the life cycleExtended service lifeFluid removalWell/borehole valve arrangementsOil fieldWater flow

The invention relates to the technical field of oil layer water injection equipment, and discloses a watering flow wellhead oil extraction device for an oil field ground exploitation technology, which comprises a water distributor main body, the middle part of the inner cavity of the water distributor main body is movably sleeved with an internal control valve core through a pressure spring positioned at the bottom of the water distributor main body, and the bottom of the inner cavity of the internal control valve core is provided with an elastic rubber block; and first through holes which extend to an inner cavity of the water distributor main body and are distributed in an annular array are formed in the middle of the outer surface of the water distributor main body. According to the watering flow well mouth oil extraction device for the oil field ground exploitation technology, a linkage structure is arranged between the water distributor body and the internal control valve element, so that an elastic rubber block on the linkage structure can be automatically shrunk to fall off the seat sealing ball body when bearing a large pressure; when separated layer water injection is carried out on an oil layer, extrusion abrasion caused by the setting ball to the elastic rubber block on the setting ball in the falling-off process can be effectively reduced, and the service cycle and the service life of the water distributor are effectively prolonged while the sealing performance of the water distributor component is guaranteed.

Owner:付洪亮

Solar device and manufacturing method thereof

InactiveCN101964369AImprove cooling effectLow costPhotovoltaic energy generationSemiconductor devicesFresnel lensEngineering physics

The invention relates to a solar device which comprises a ceramic base plate, a plurality of III-V group solar chips, and an encapsulation body, wherein the III-V group solar chips are arranged on the ceramic base plate and are used for converting solar energy into electric energy on the ceramic base plate; and the encapsulation body covers the ceramic base plate and the III-V group solar chips, at least one Fresnel lens is formed on the position of the encapsulation body corresponding to the III-V group solar chips, and sunlight passes through the Fresnel lens and is converged on the III-V group solar chips.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

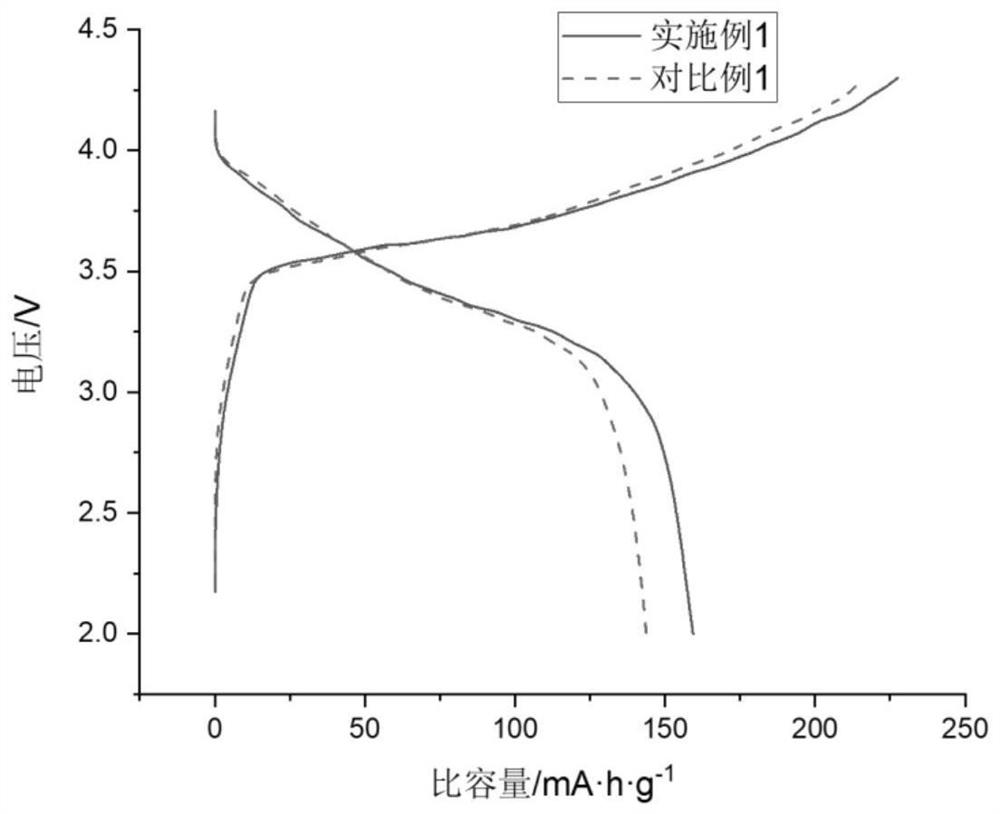

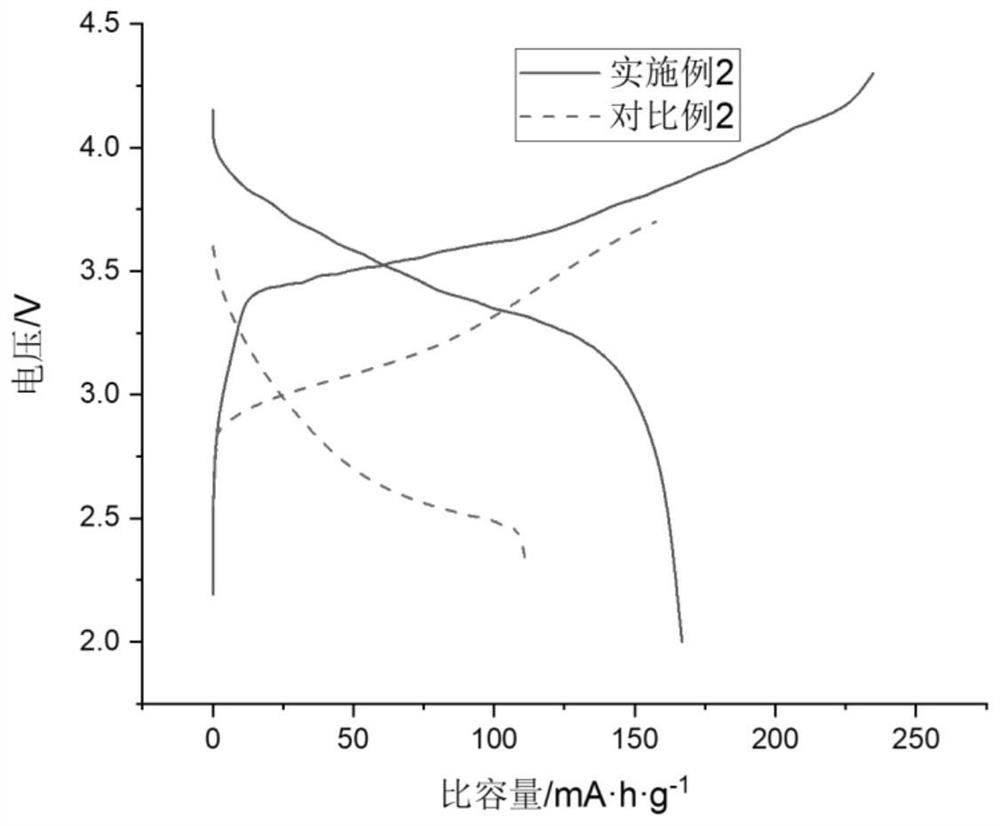

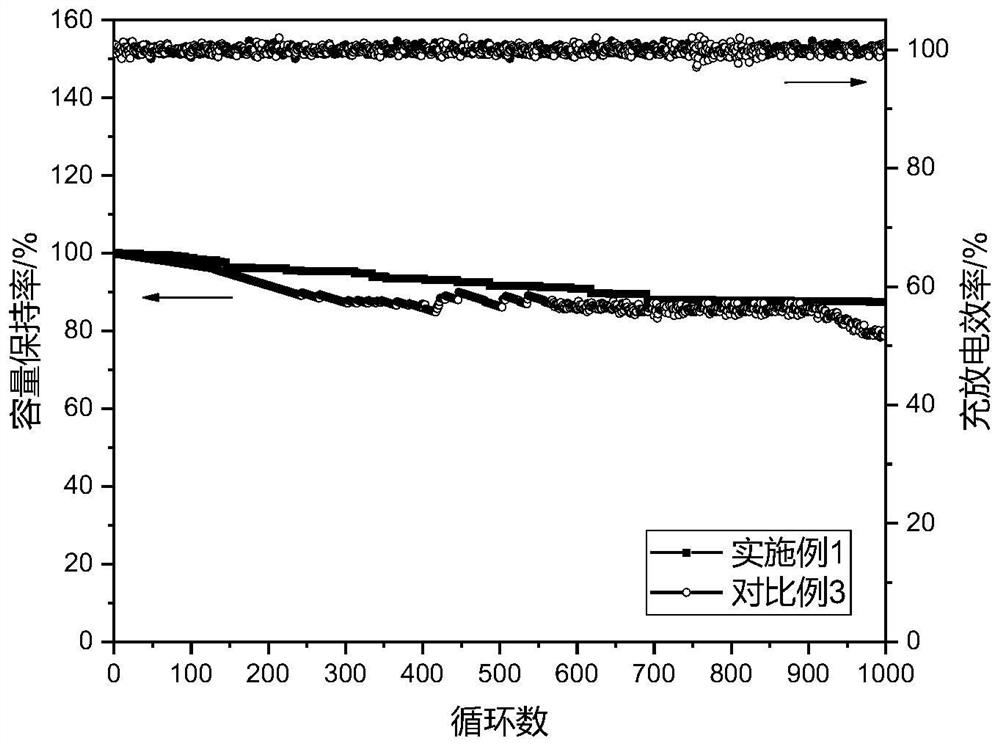

Lithium-silicon alloy negative electrode preparation method and sulfide all-solid-state battery

PendingCN114744161AIncrease cut-off voltageIncrease energy densityNegative electrodesSecondary cellsSolid state electrolyteDischarge efficiency

The invention provides a preparation method of a lithium-silicon alloy negative electrode and a sulfide all-solid-state battery. The preparation method comprises the steps of preparation of lithium-silicon alloy powder, preparation of a lithium-silicon alloy pole piece and preparation of the sulfide all-solid-state battery. The lithium silicon alloy negative electrode and the sulfide solid electrolyte can easily generate a LixSiSy layer with high ionic conductivity and low impedance to serve as an SEI film, so that an interface between the solid electrolyte and the negative electrode is stabilized, growth and formation of lithium dendrites are inhibited, expansion and shrinkage of the negative electrode in the charging and discharging process are avoided, and the service life of the solid electrolyte is prolonged. Therefore, the capacity, the cycling stability and the charge-discharge efficiency of the sulfide solid-state battery are improved, and the method has a wide application prospect.

Owner:SHANGHAI FIRM-LITHIUM NEW ENERGY TECH CO LTD

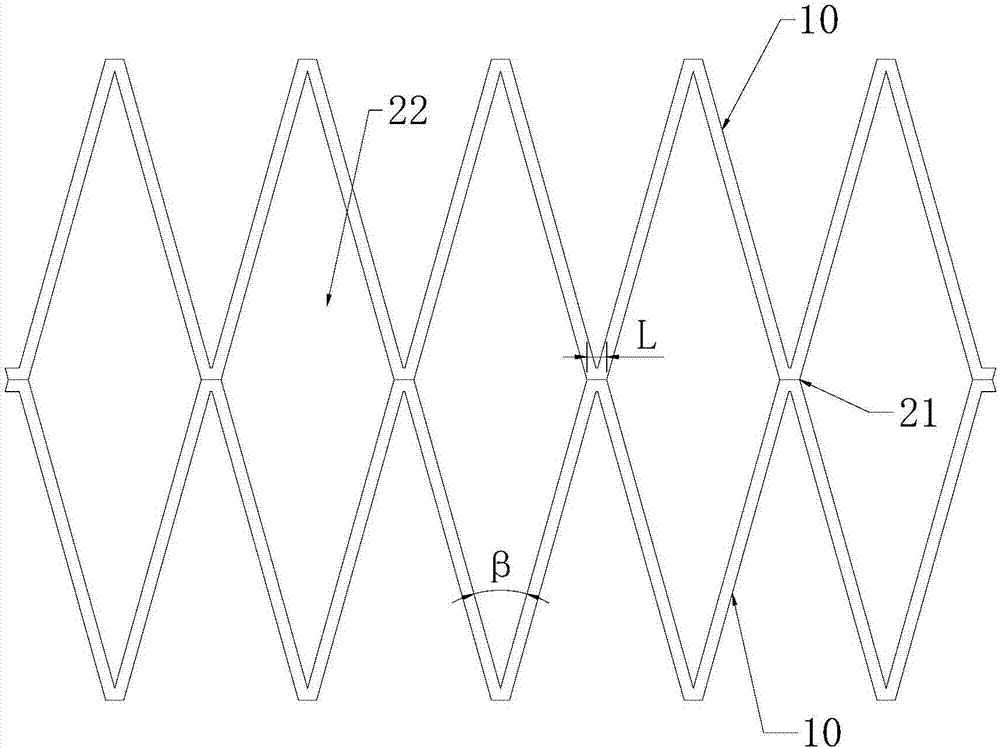

Double-layer corrugated filter cloth and welding positioning device, welding device and welding method thereof

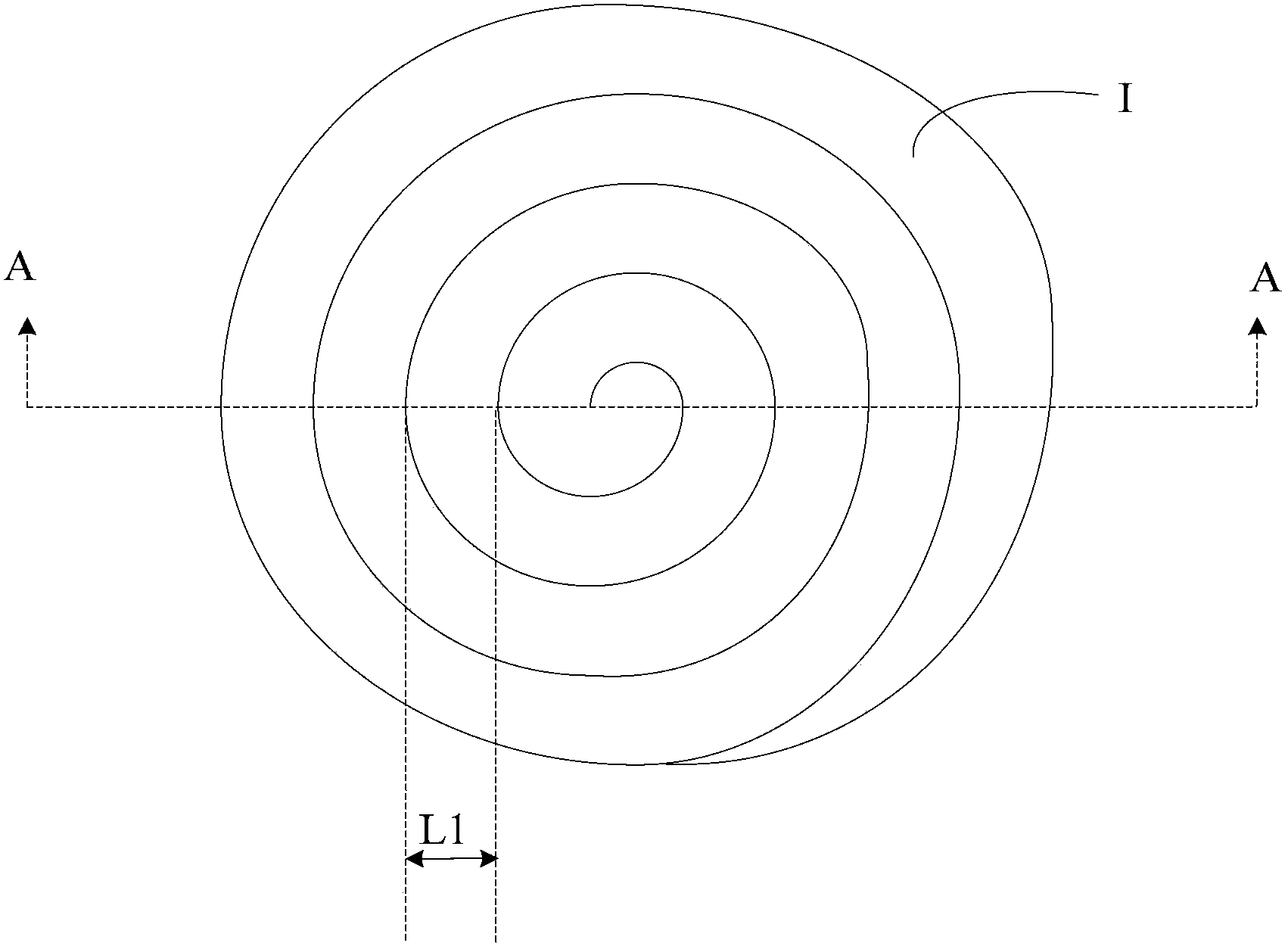

ActiveCN107052559AGuaranteed welding accuracyAchieve weldingHuman health protectionWelding/soldering/cutting articlesGreek letter betaUltrasonic welding

The invention discloses double-layer corrugated filter cloth. The double-layer corrugated filter cloth comprises two layers of corrugated filter cloth arranged oppositely. The folding angle beta of the two layers of corrugated filter cloth is not larger than 30 degrees, the two layers of corrugated filter cloth are symmetrically arranged, wave troughs of one layer of corrugated filter cloth abut against wave crests of the other layer of corrugated filter cloth one to one, then the abutting positions are subjected to ultrasonic welding, the width L of weld joints obtained after welding is completed ranges from 1 mm to 1.5 mm, and a channel is formed between every two adjacent weld joints. The weld joints of the double-layer corrugated filter cloth welded ultrasonically are firm and not likely to be separated, the service life of the double-layer corrugated filter cloth is greatly prolonged, no connecting medium exists, no medium disengaging phenomenon is generated, and it is completely eradicated that new contaminates are formed for an industrial dust remover by the double-layer corrugated filter cloth.

Owner:ZHANGJIAGANG ZEF IND FILTER

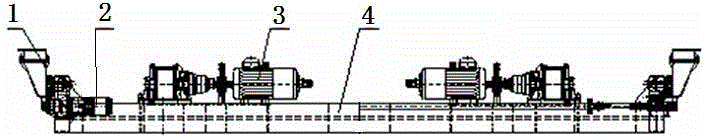

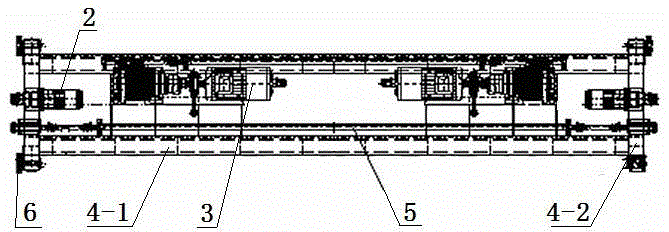

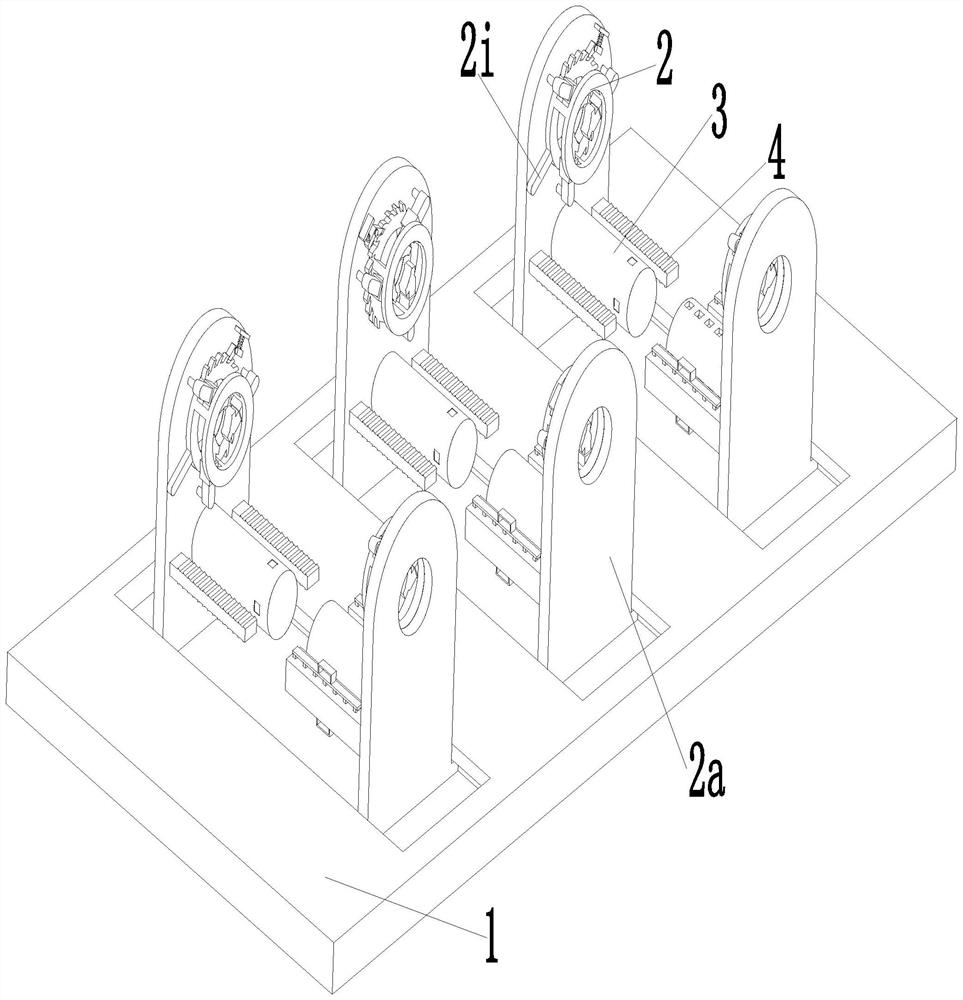

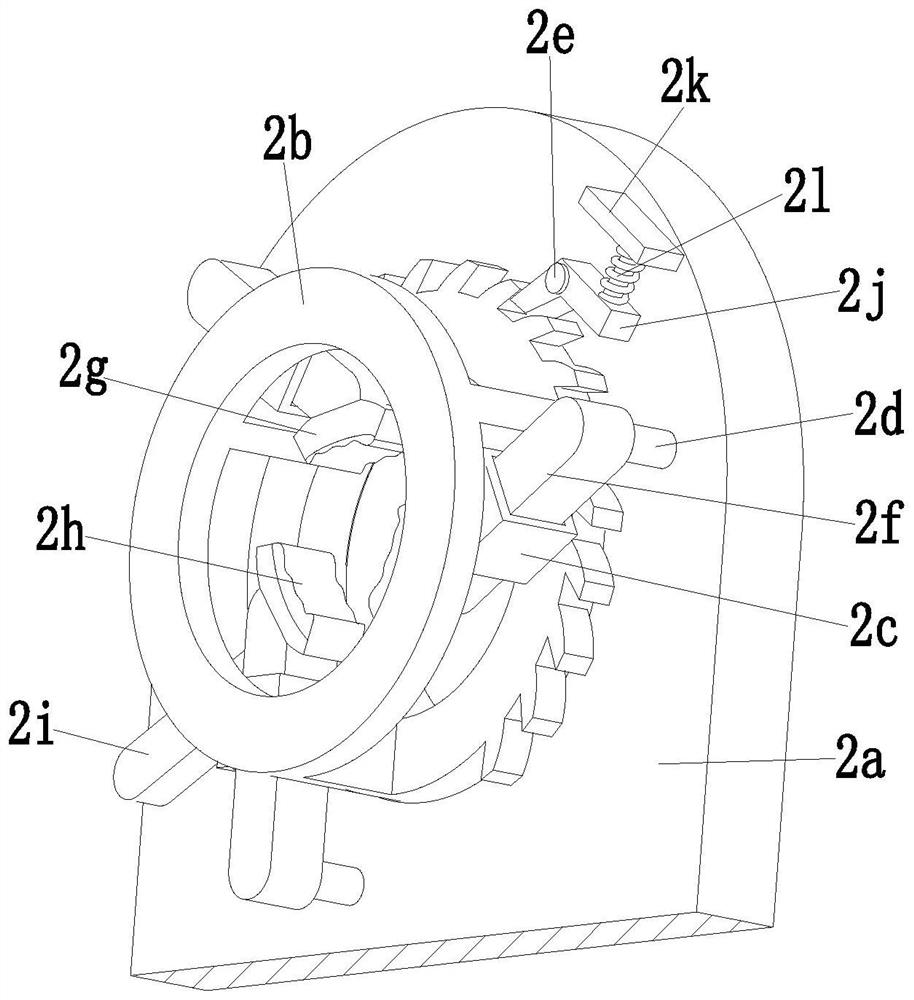

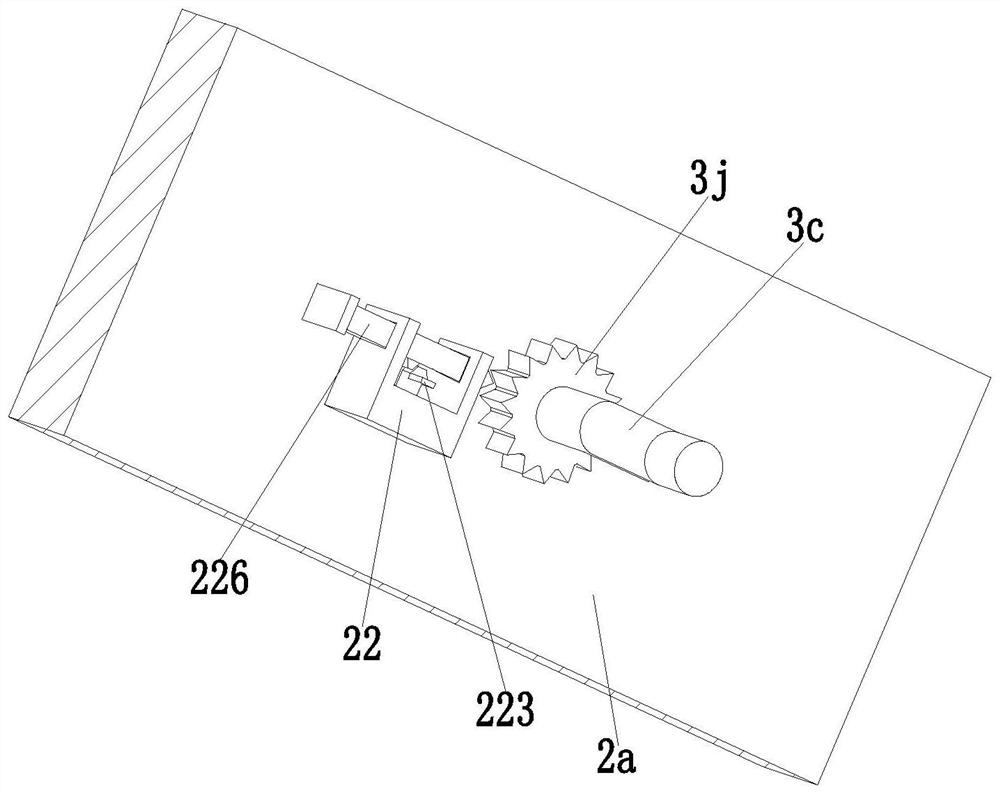

Marine travelling crane

ActiveCN104627823AStrong shaking abilityGood walking stabilityTravelling gearTrolleysGear driveWinch

The invention discloses a marine travelling crane relating to the technical field of manufacturing of the marine travelling cranes. The marine travelling crane comprises two guide rail beams provided with longitudinal guide rails, a travelling crane transverse beam which moves on the two longitudinal guide rails through walking wheels, and hoisting winch systems arranged on the travelling crane transverse beam, wherein racks are arranged at the bottoms of the guide rail beams; each of the two ends of the travelling crane transverse beam is at least provided with one walking small gear driven by a motor; the walking small gears are engaged with the racks; a synchronizer is arranged between the racks at the two ends of the travelling crane transverse beam; and the travelling crane transverse beam is provided with the two hoisting winch systems. Compared with the prior art, the marine travelling crane has the advantages that the problems that the hoisting accuracy and the hoisting reliability of an existing marine common travelling crane are poor can be solved.

Owner:SOUTH CHINA MARINE MACHINERY

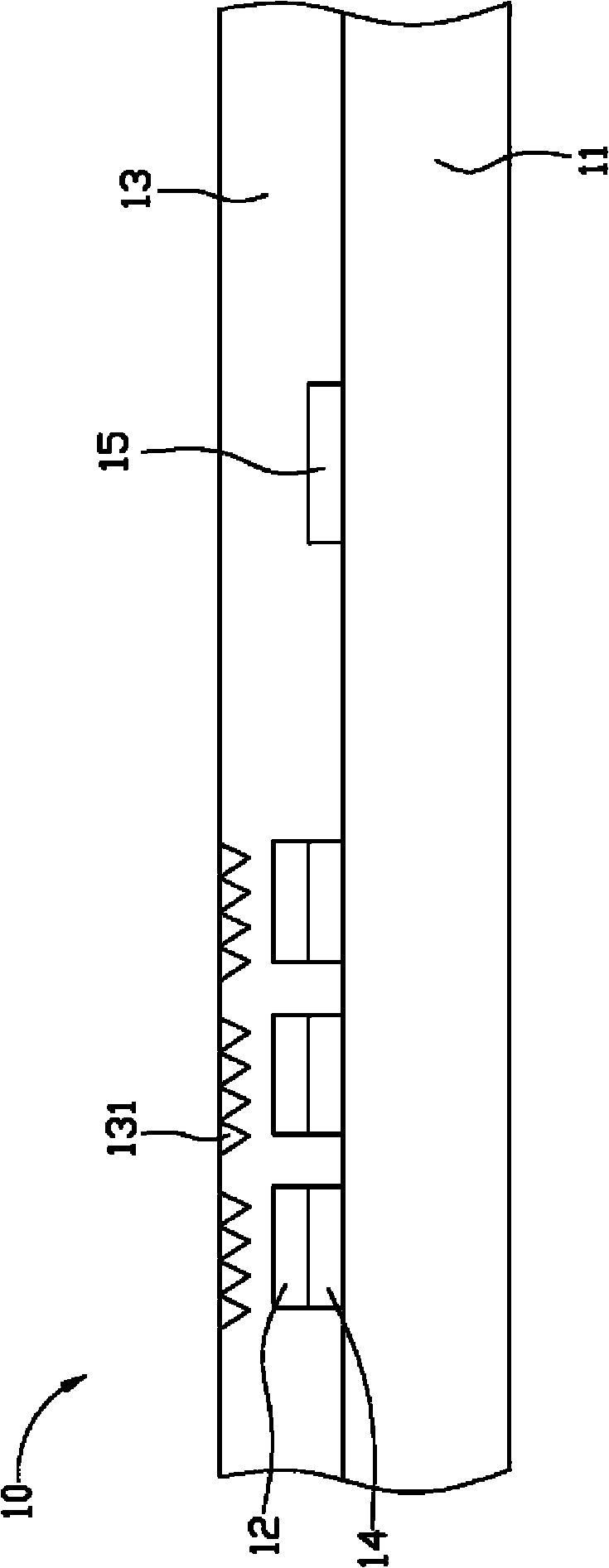

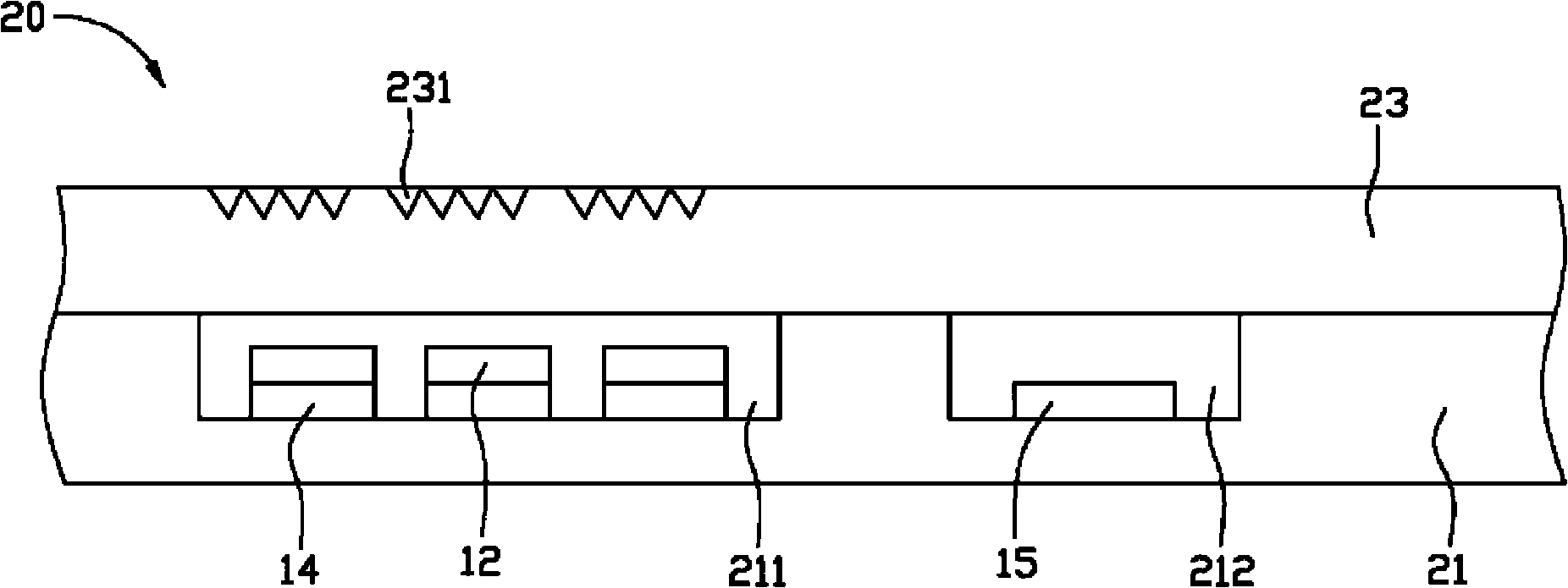

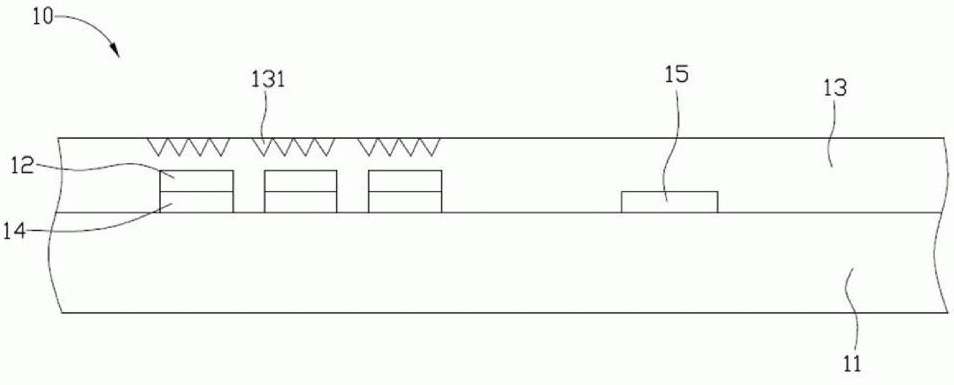

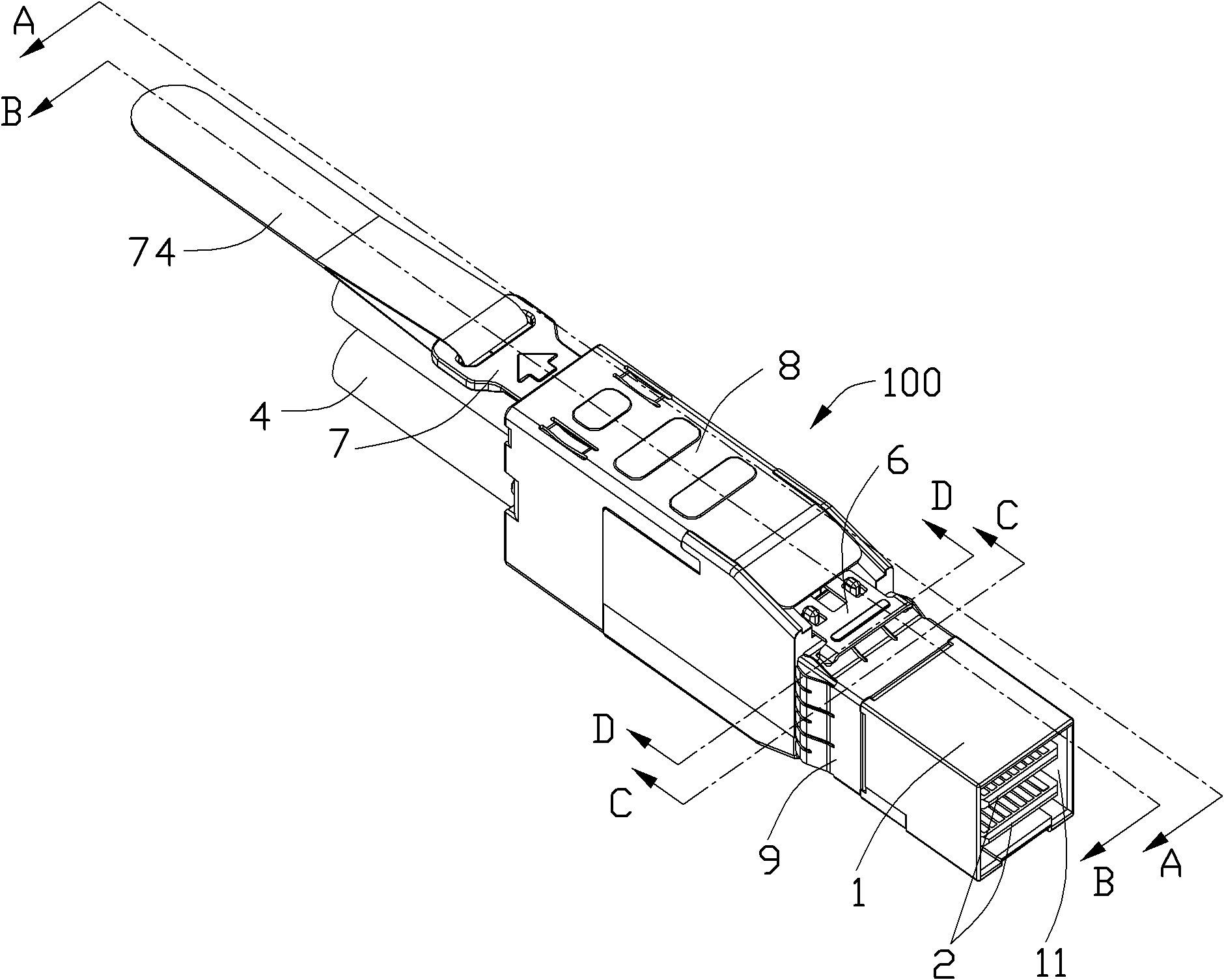

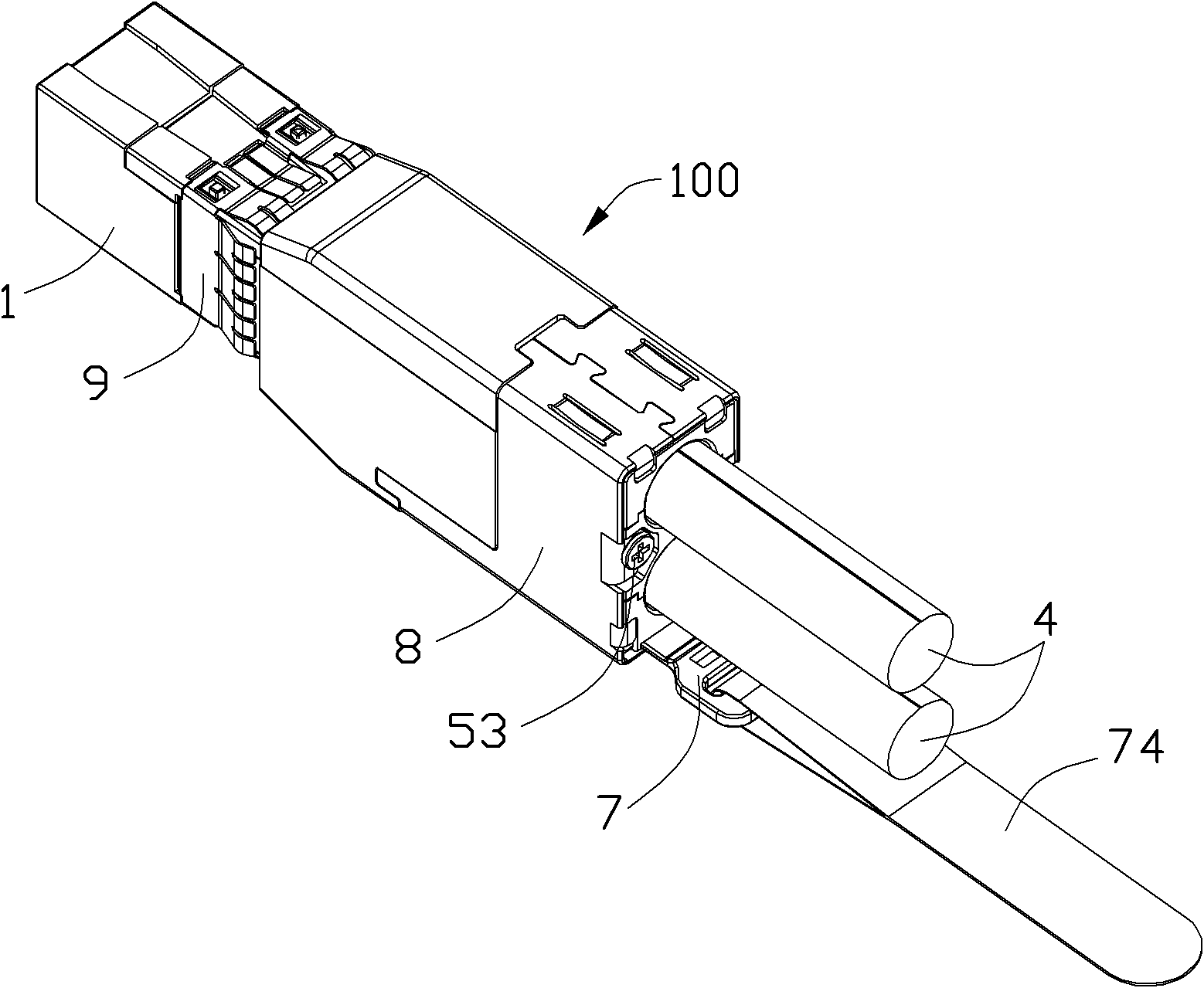

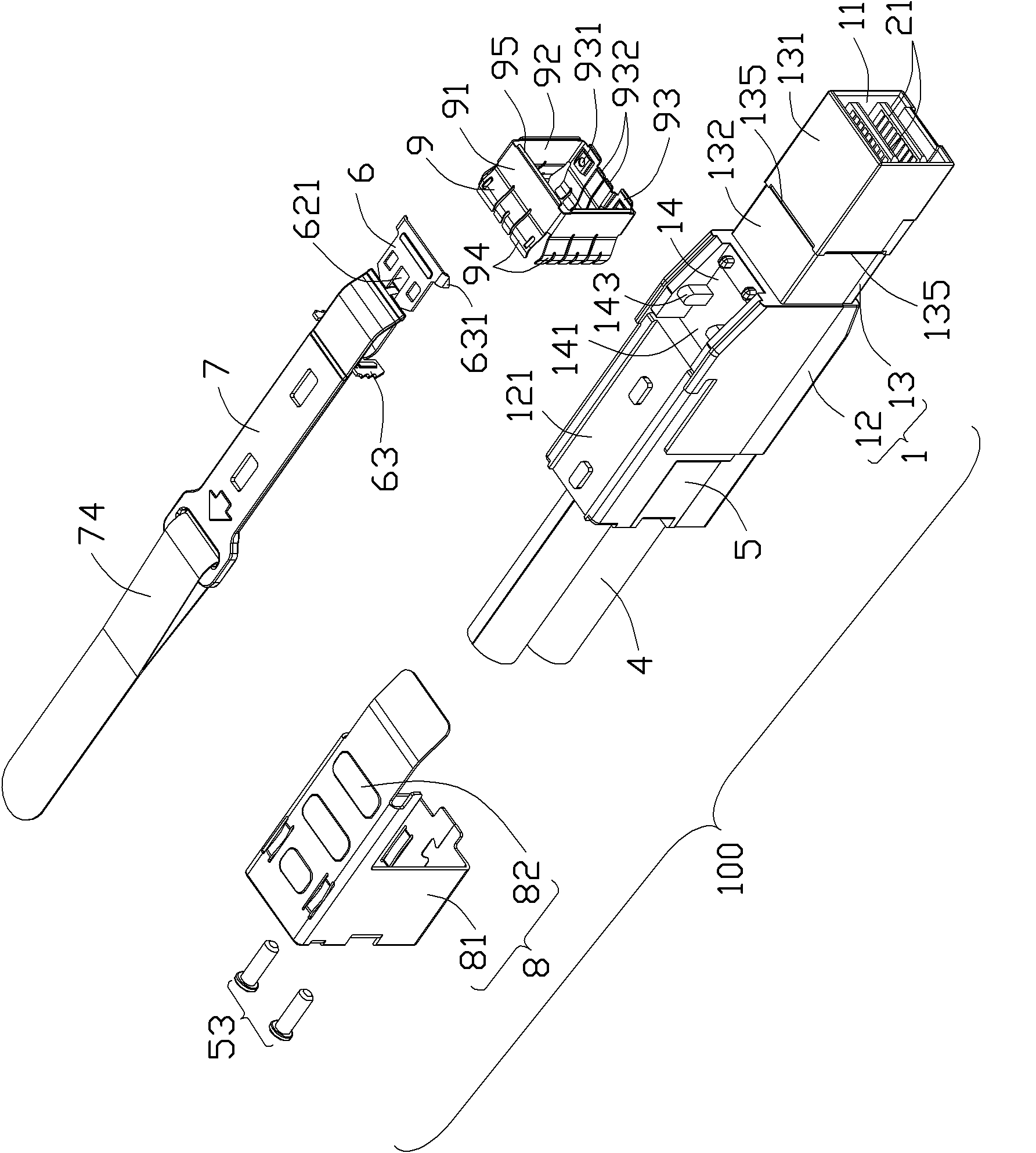

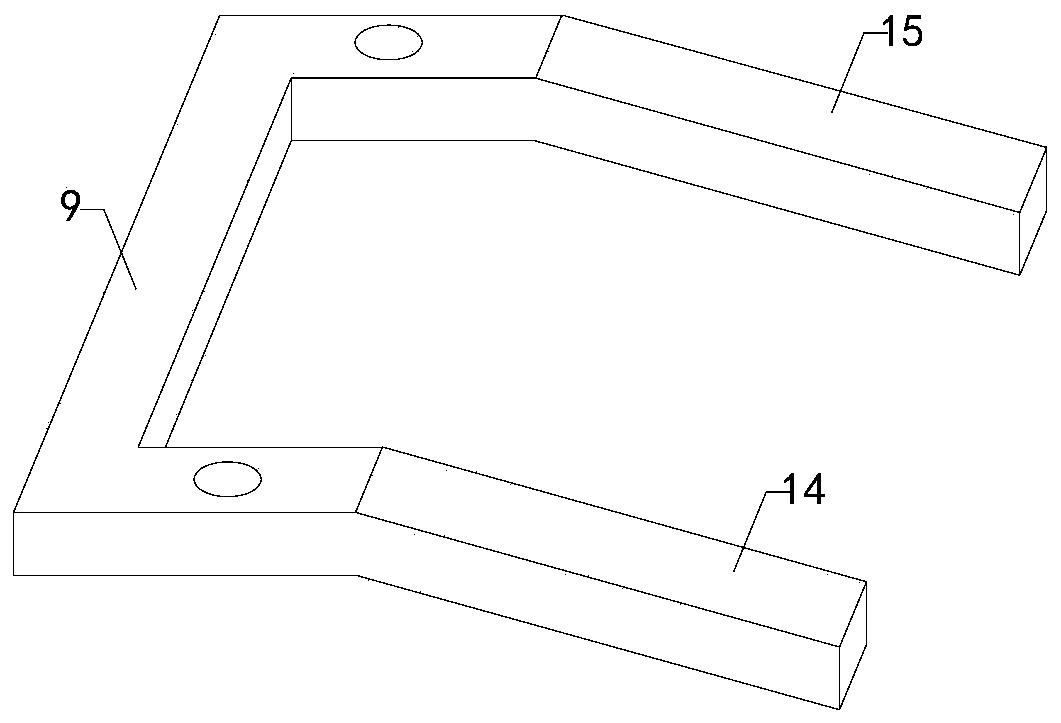

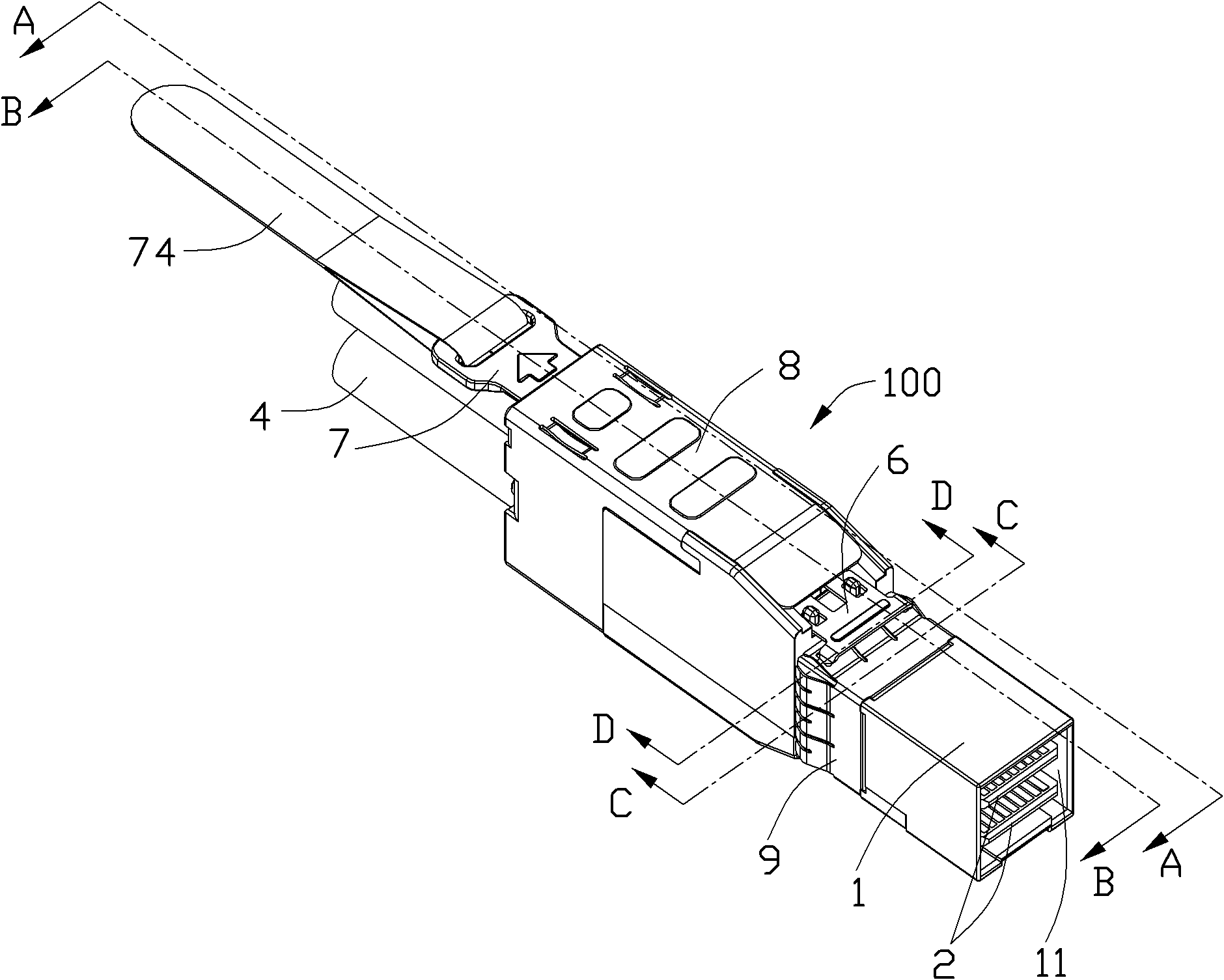

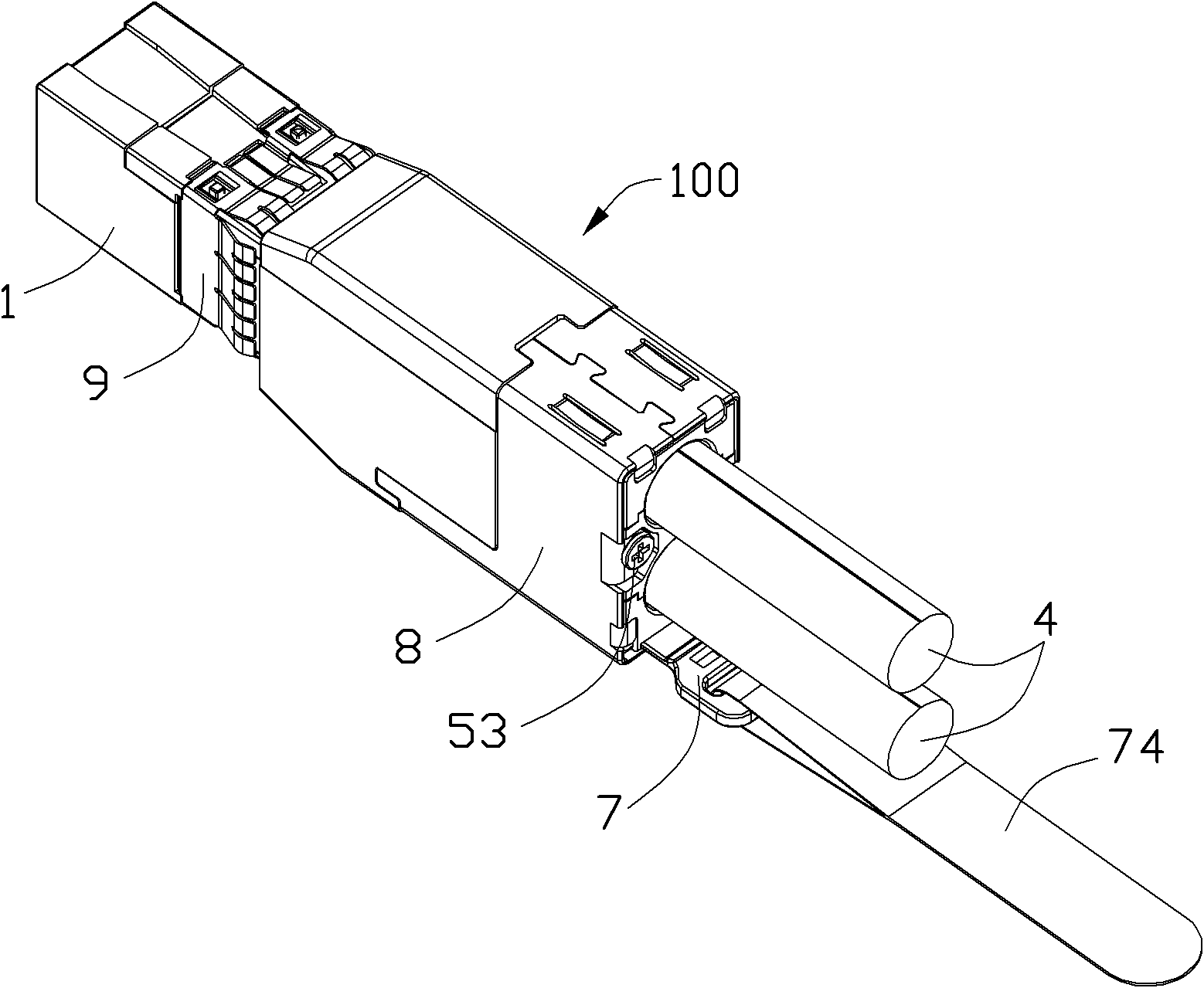

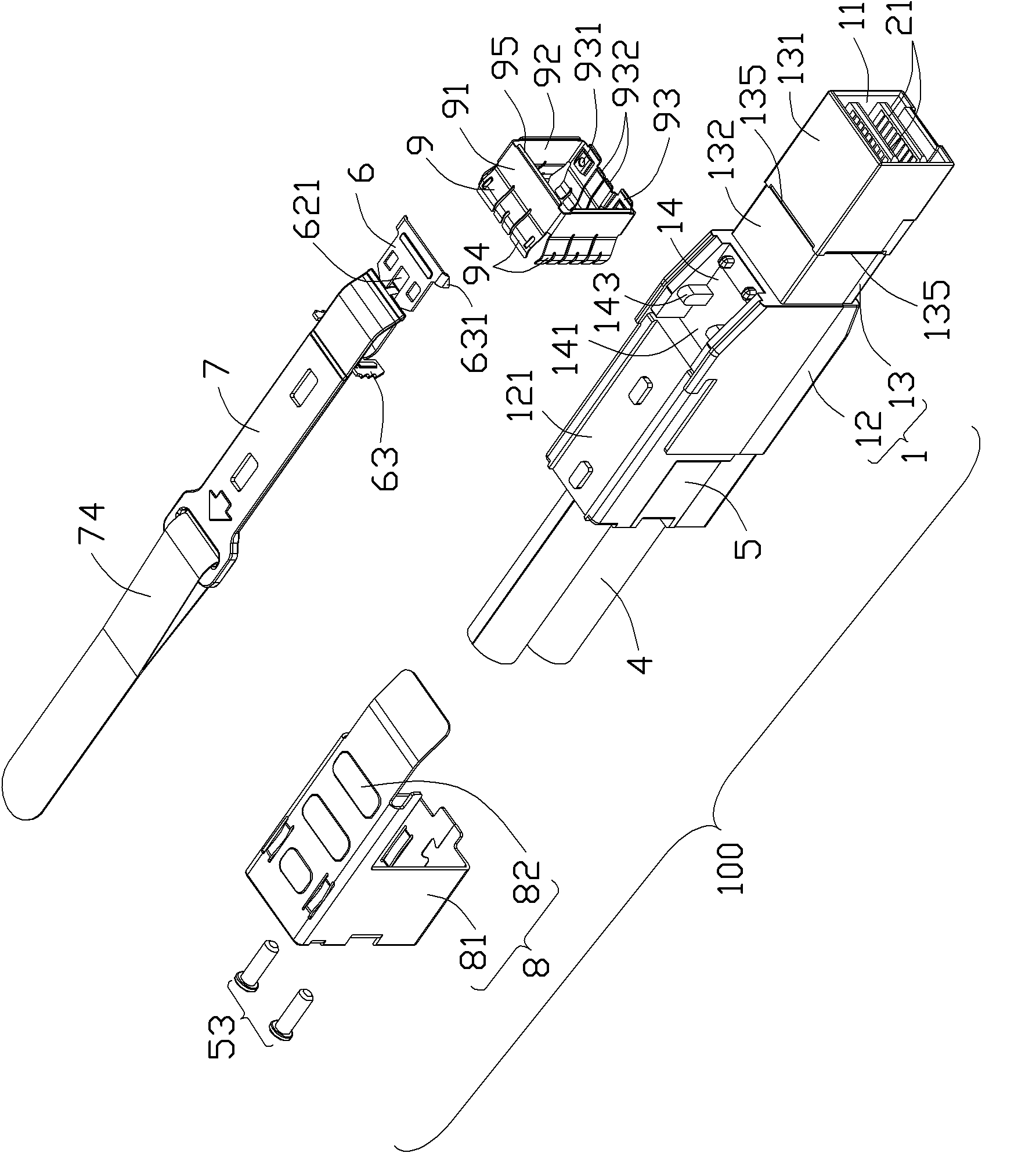

Electrical connector assembly

ActiveCN102646898ANo falling offGood anti-electromagnetic interferenceNetwork connectorsFixed connectionsButt jointEngineering

The invention provides an electrical connector assembly (100), which comprises a body (1) providing with an accommodating space (11), two printed circuit boards (2) and a locking device; the printed circuit boards (2) are arranged in parallel, are accommodated in the accommodating space (11) of the body (1) and are positioned with the body (1) mutually; the locking device is assembled on the body; the body comprises a body part (12) located at the rear end of the body and a butt joint part (13) which extends forwards from the front end surface of the body part; the electrical connector assembly further comprises a metal washer (9) which is assembled at the rear end of the periphery of the butt joint part of the body; a sunken area (132) is further arranged on the butt joint part of the body; the metal washer is accommodated and positioned in the sunken area; a groove (133) is arranged in the sunken area; an indent part (932) accommodated in the groove is formed on the metal washer. In such way, the metal washer can be firmly positioned on the body.

Owner:FOXCONN (KUNSHAN) COMPUTER CONNECTOR CO LTD +1

Thermal protection method for outer surface of electro-thermal boiler

ActiveCN107965754AImprove heat resistanceExtended service lifeFireproof paintsSteam boilersHeat resistanceEngineering

The invention discloses a thermal protection method for an outer surface of an electro-thermal boiler. The thermal protection method comprises the following steps of: (1) clearing the outer surface ofthe electro-thermal boiler, and adopting 800# abrasive paper to perform grinding treatment; (2) spraying a modifying solution to the grinded surface of the electro-thermal boiler; (3) uniformly coating heat-resistant paint on the surface of the electro-thermal boiler 100-120 minutes later, and completing treatment after paint is dried. The thermal protection method for the outer surface of the electro-thermal boiler provided by the invention is simple to operate, and is low in cost; and the treated electro-thermal boiler has excellent heat resistance, does not have a coating dropping phenomenon after being heated for a long time, and greatly prolongs the service life of the electro-thermal boiler.

Owner:ANHUI GUODIAN ENERGY EQUIP ENG

New structural DC charging gun

PendingCN109390776AExtended service lifeImprove stabilityVehicle connectorsRelieving strain on wire connectionEngineeringElectrical and Electronics engineering

Owner:WEIHAI HONGLIN ELECTRIC POWER TECH CO LTD

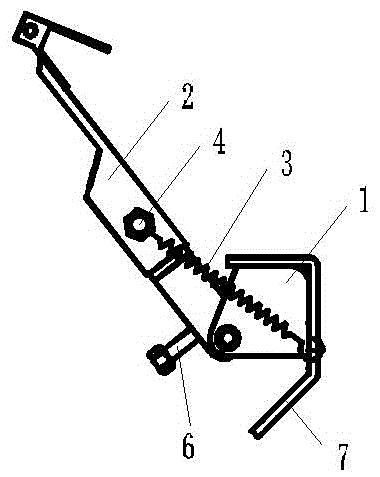

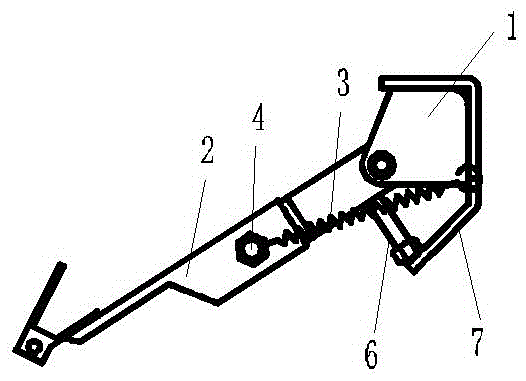

Anti-falling drop-out fuse

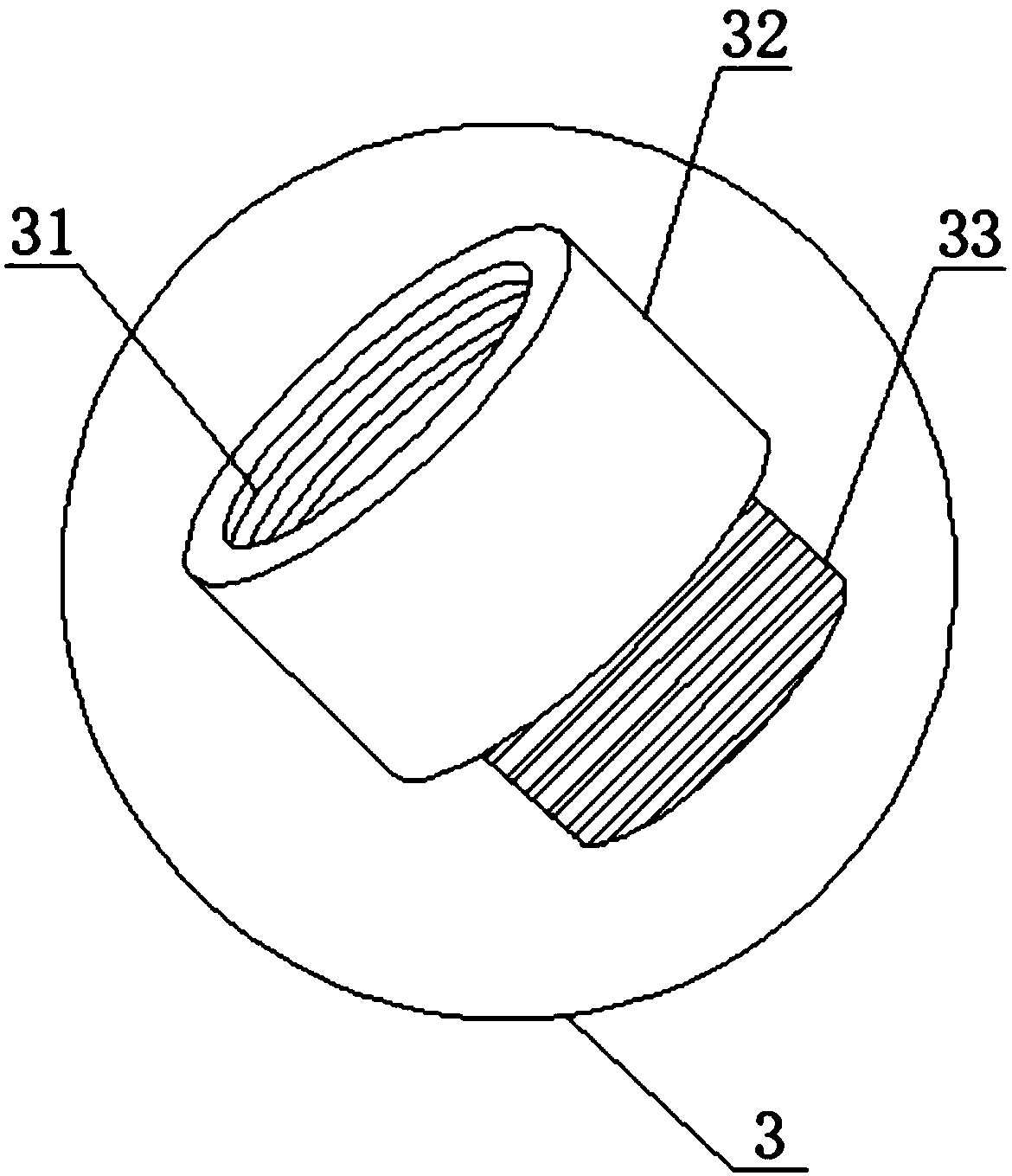

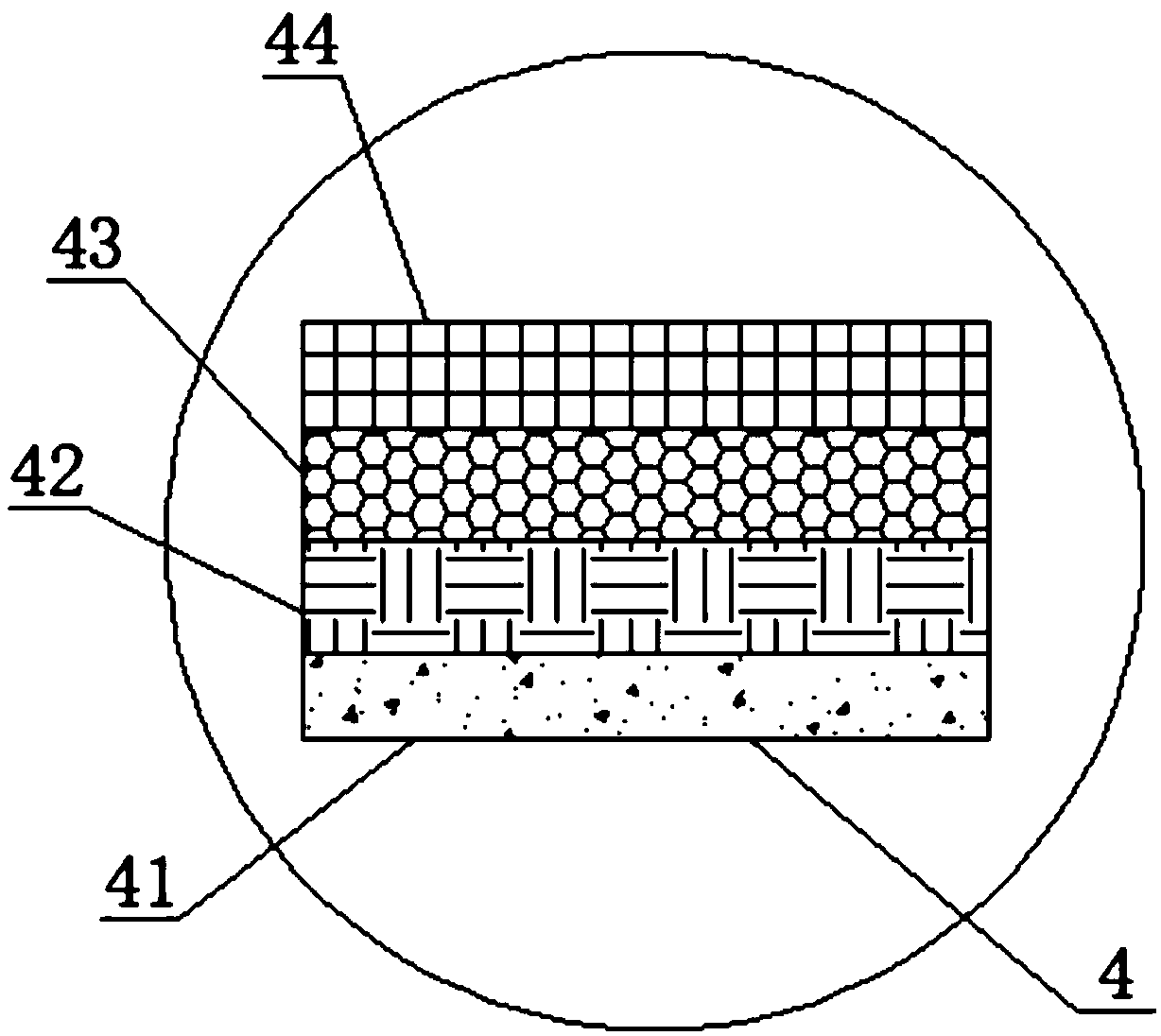

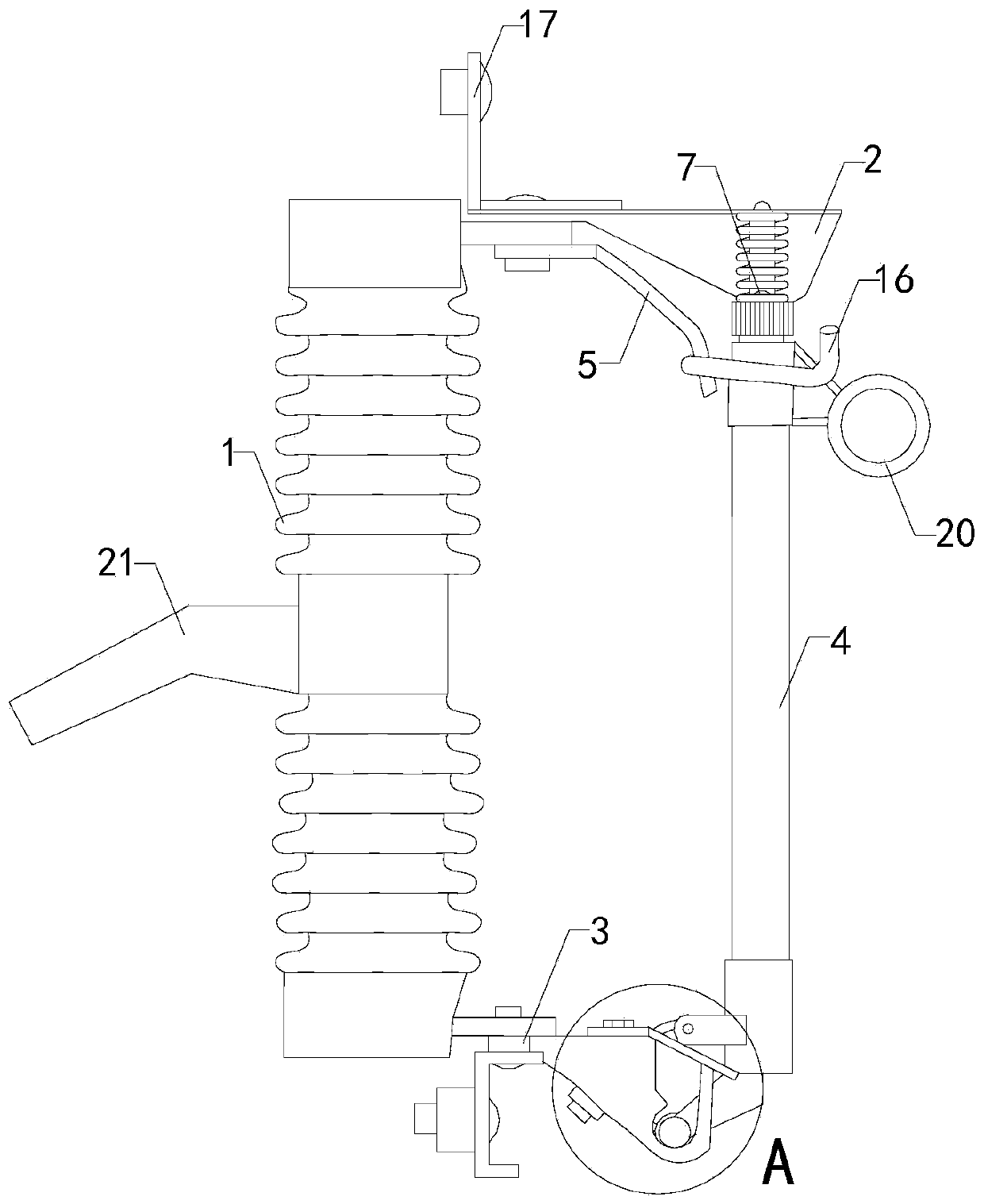

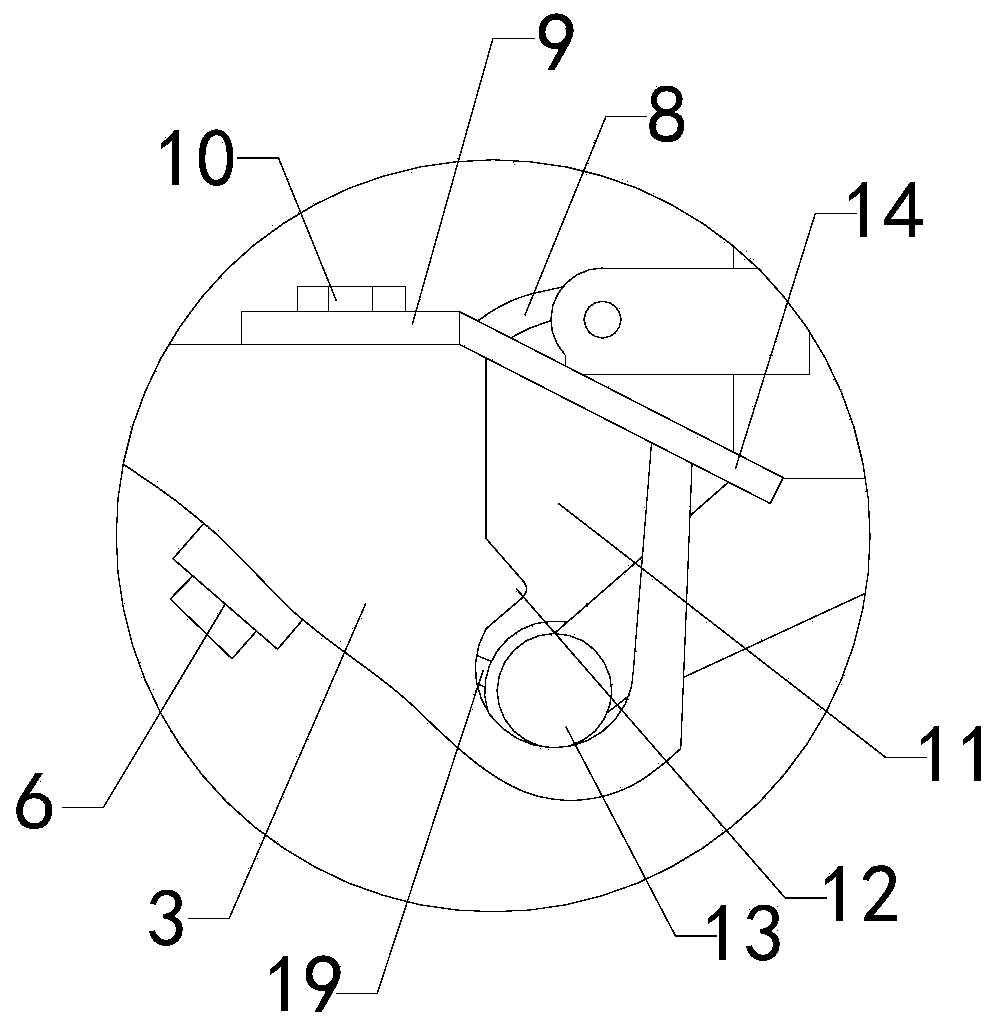

ActiveCN110706988AAvoid sheddingNo falling offEmergency protective devicesStructural engineeringMechanical engineering

The invention relates to the technical field of power distribution protection accessory devices, in particular to an anti-falling drop-out fuse, which ensures that a fuse tube reliably falls off afterbeing fused and does not fall off to the ground, so that the situation that equipment or electric power cannot be recovered in time due to the damage of the fuse tube is prevented, and the practicability is improved. The fuse comprises an insulator, an upper mounting rack, a lower mounting rack and the fuse tube. The upper mounting rack and the lower mounting rack are respectively mounted at thetop and the bottom of the insulator; an upper static contact and a lower static contact are respectively arranged on the upper mounting rack and the lower mounting rack; the top and the bottom of thefuse tube are respectively provided with an upper moving contact and a lower moving contact. An elastic spring and a fixed bolt are further included. The lower mounting rack is provided with an arc-shaped guide groove, the bottom of the arc-shaped guide groove is provided with a limiting protrusion, the lower moving contact is provided with a rotating shaft, the rotating shaft is rotatably arranged in the arc-shaped guide groove, the elastic spring is of a U-shaped structure, and the front side and the rear side of the left end of the elastic spring are provided with a front pressing piece anda rear pressing piece respectively.

Owner:国网山东省电力公司利津县供电公司 +1

Wire and cable connecting frame for overhead line of electric power tower

ActiveCN112152177BIncrease security risksStable clamping workSuspension arrangements for electric cablesTowerControl theory

The invention relates to a wire and cable connecting frame for an overhead line of an electric power tower, which includes a base plate, a clamping device, a positioning device and a docking device. The clamping device is installed on the base plate, and a positioning device and a docking device are installed on the clamping device. The present invention can solve the following difficult problems existing in the connection of existing wires and cables. 1. When docking traditional wires and cables, it is necessary to manually pull the wires and cables that need to be docked, and use tools to connect the wires and cables, and then Use cable connectors to connect and fix the processing, so the connected wires and cables are not firm; 2. The existing wire and cable connectors cannot perform stable clamping operations on the cables, and the phenomenon of broken cables often occurs. The clamping force of the cable is not enough, and it is not enough to withstand the bad weather in the later stage, and it is easy to loosen in the case of strong wind, which makes the wire and cable fall from a high altitude, and there is a big safety hazard.

Owner:ECONOMIC TECH RES INST OF STATE GRID ANHUI ELECTRIC POWER +1

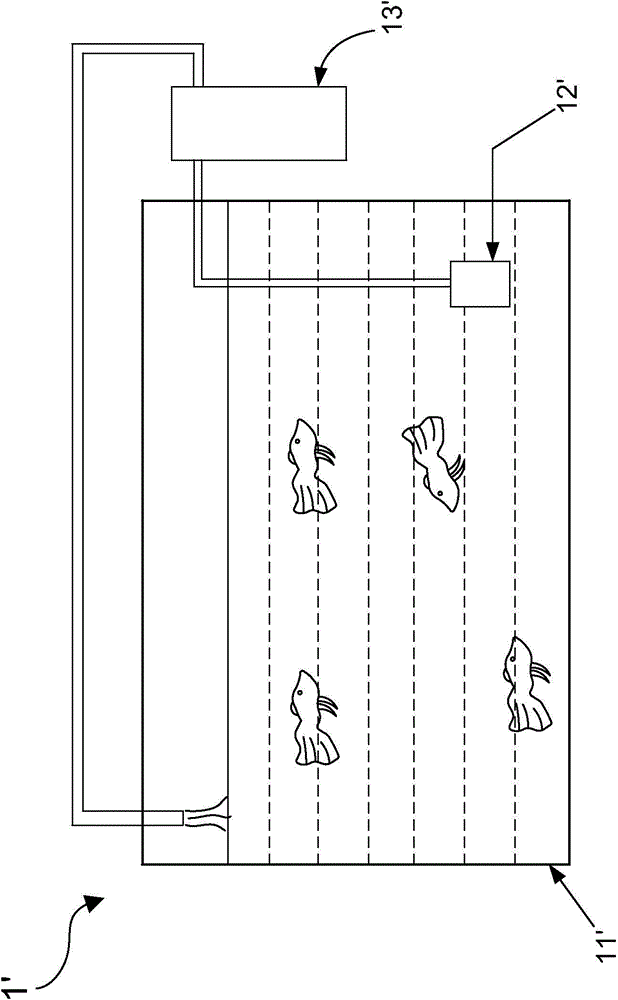

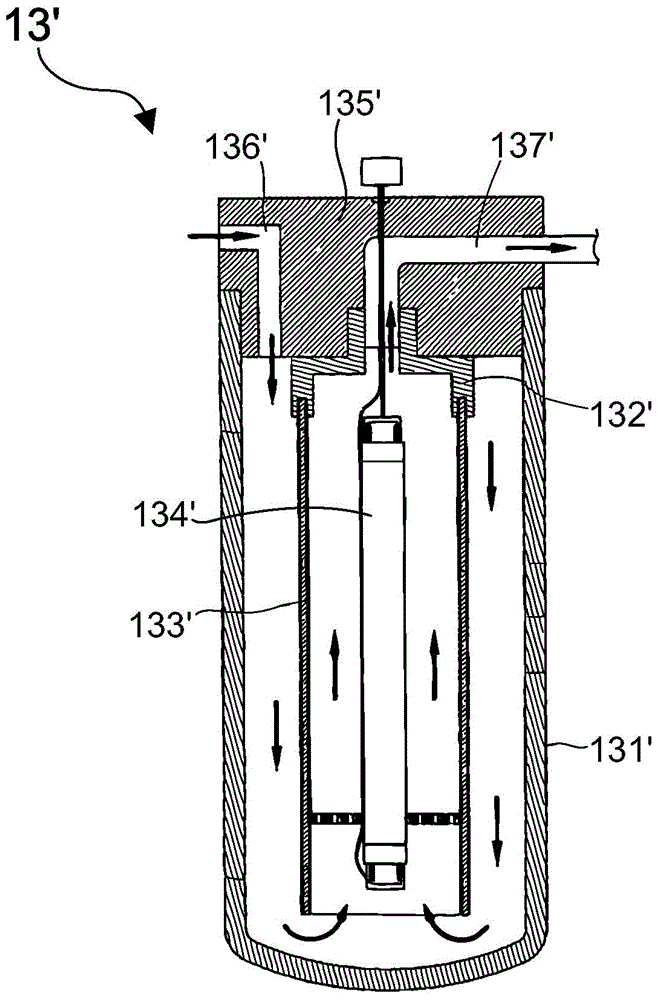

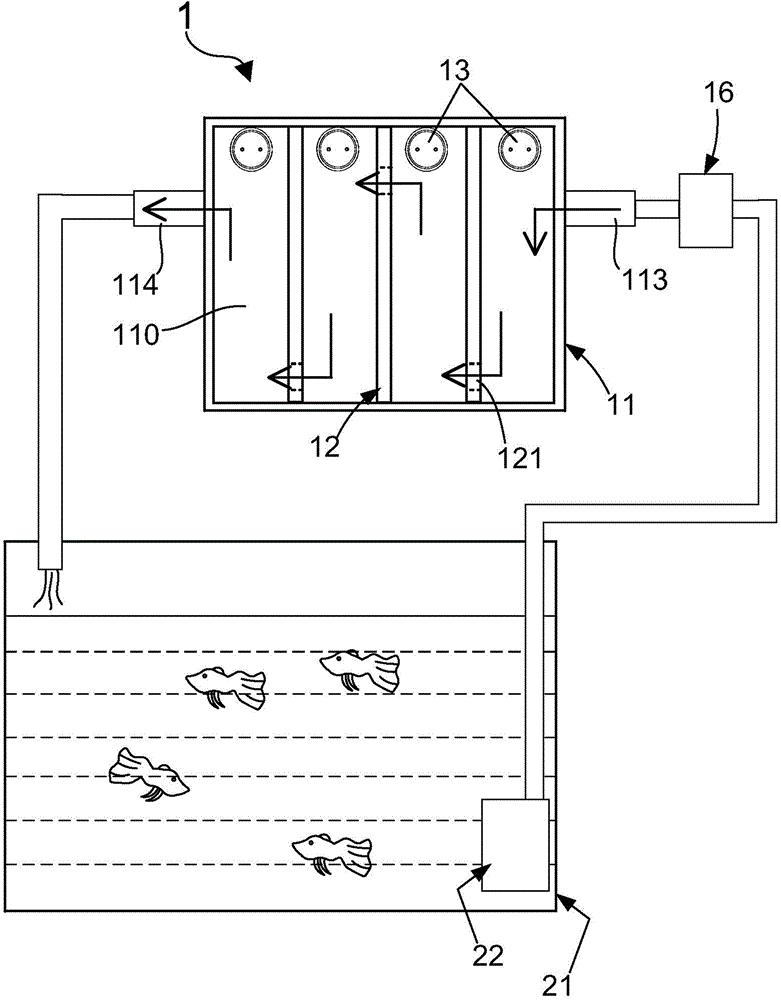

Water cleaning device

ActiveCN106135114AAdd a flow timeImprove a sterilization cleaning timePisciculture and aquariaWater flowEngineering

Disclosed is a water cleaning device. A containing space is arranged inside the water cleaning device. A plurality of transparent photocatalyst units with at least one opening are arranged in the containing space at equal intervals. Water to be cleaned can be guided and injected into the water cleaning device to flow along a zigzag water flow path inside the water cleaning device, accordingly, the flowing time of the water to be cleaned inside the water cleaning device is prolonged, and the sterilization clean time of the water to be cleaned inside the water cleaning device is prolonged. Different from existing photocatalyst glass plates, the photocatalyst glass plate is composed of a glass substrate, a photocatalyst coating film and a protective film, the protective film is made of a water corrosion resisting material, and the phenomenon that external water molecules invade through holes in the photocatalyst coating film to corrode the glass substrate can be avoided; the photocatalyst glass plate will not have the glass substrate acid regurgitation phenomenon; the photocatalyst coating film coating the glass substrate will not be disengaged from the glass substrate even when the glass substrate is in use for a long time.

Owner:CHIN WEI MIAO IND

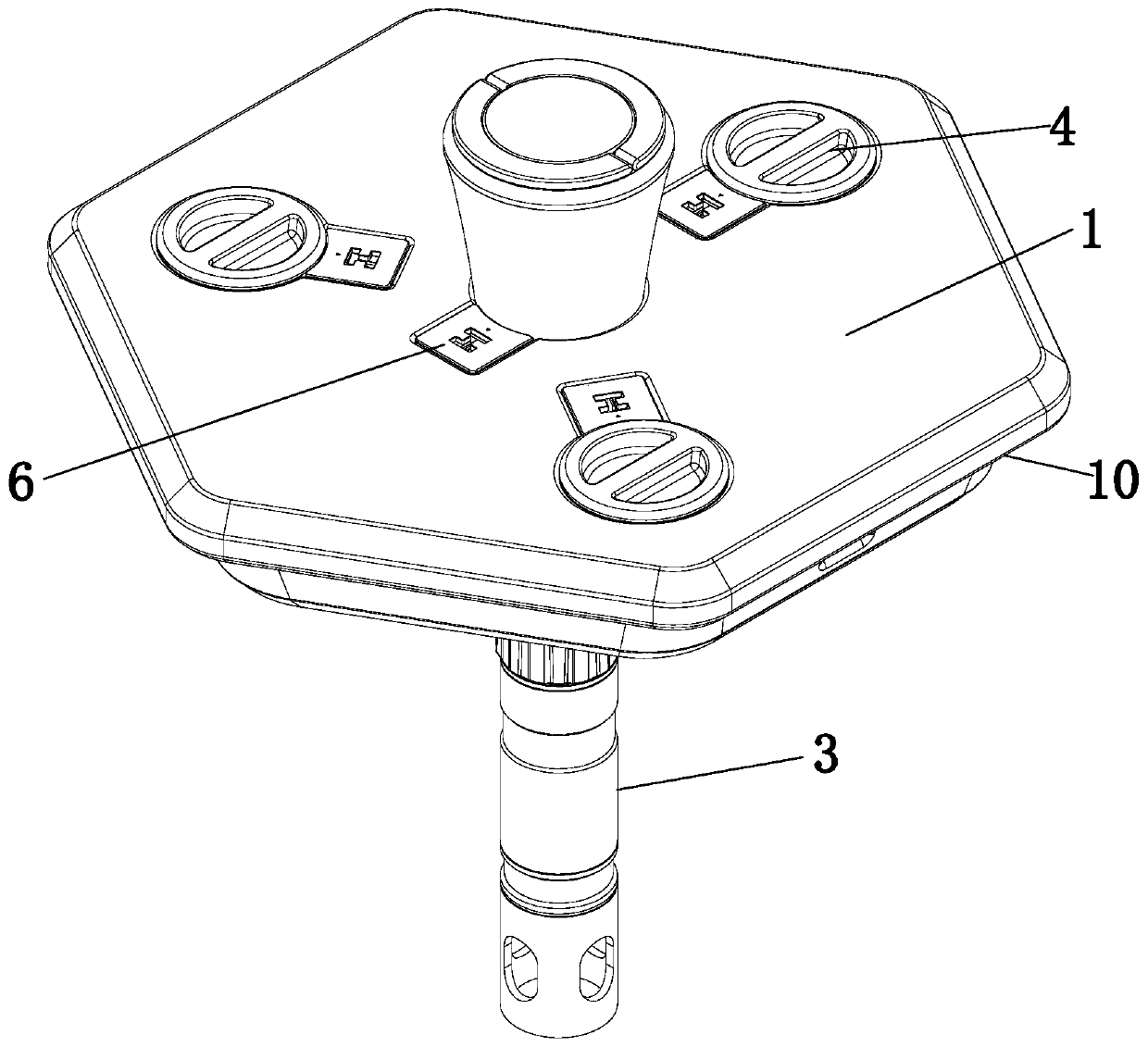

Spring assisted lifting device

Owner:WUHU AIRUITE ENVIRONMENTAL TECH

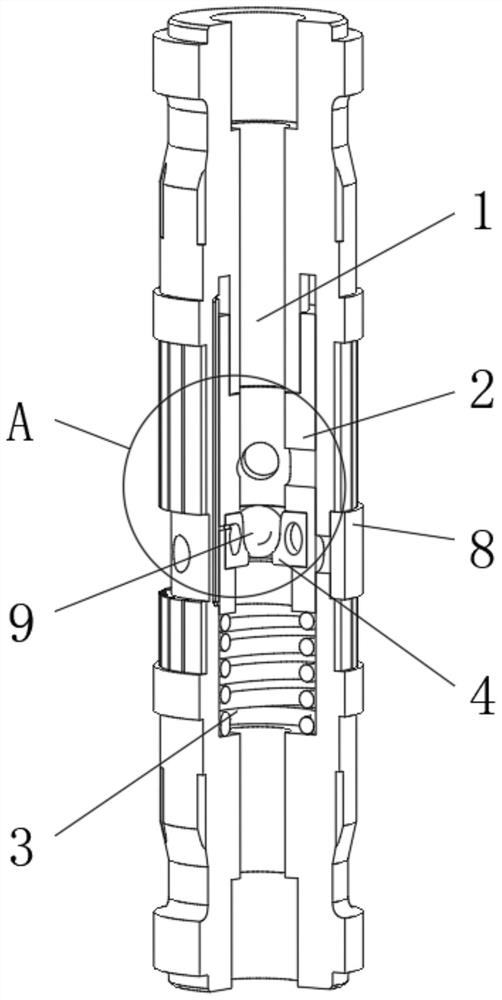

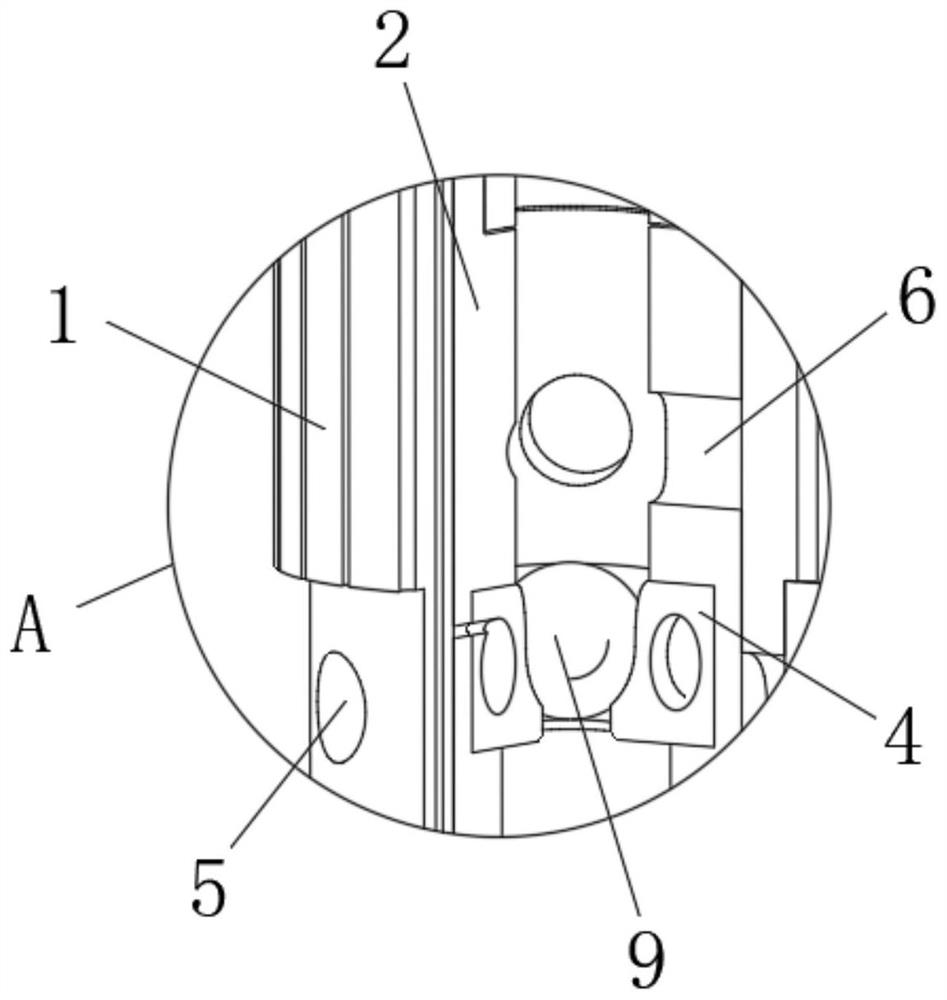

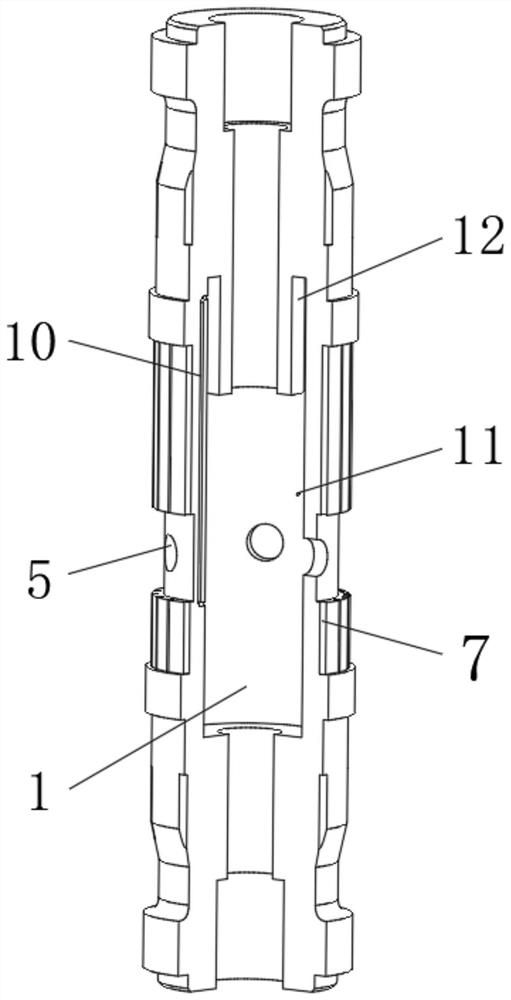

Water quality detector

The invention discloses a water quality detector which comprises a floating base (1). A plurality of fixing holes (2) are formed in the floating base (1), a detection device (3) is arranged in one fixing hole (2), and balance weight devices (4) are arranged in the remaining fixing holes (2). A groove (5) formed in the side face of each fixing hole (2) is further formed in the upper surface of thefloating base (1), a locking device (6) is arranged in each groove (5), a first clamping groove (7) matching each locking device (6) is formed in the side wall of the detection device (3), and a second clamping groove (8) matching each locking device (6) is formed in the side wall of each balance weight device (4). The water quality detector has the characteristic that the mounting firmness can beeffectively improved.

Owner:上一智慧环境(杭州)有限公司

Electrical Connector Assembly

ActiveCN102646898BNo falling offGood anti-electromagnetic interferenceNetwork connectorsFixed connectionsEngineeringElectrical and Electronics engineering

An electrical connector assembly (100) comprises: a housing (1) having a rear body portion (12) and a front mating portion (13), two paralleled printed circuit boards (2) disposed in the housing and positioned by the housing, two cables (4) respectively electrically connected to the two printed circuit boards, a spacer (3) sandwiched between the two printed circuit boards and positioned by the housing, a metallic holder (8) surrounding the body portion, and a metallic gasket (9) surrounding a rear section of the mating portion. The metallic gasket has a number of ribs (135) around a front end thereof and the housing has on an outer surface thereof a plurality of slits receiving the ribs (95).

Owner:FOXCONN (KUNSHAN) COMPUTER CONNECTOR CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com