Double-layer corrugated filter cloth and welding positioning device, welding device and welding method thereof

A welding positioning and corrugation technology, used in welding/welding/cutting items, welding equipment, non-electric welding equipment, etc., can solve the problems affecting the use effect of industrial dust collectors, the failure of filter element strength, and the weak structure, so as to improve the service life. , Improve production efficiency and improve the effect of docking firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

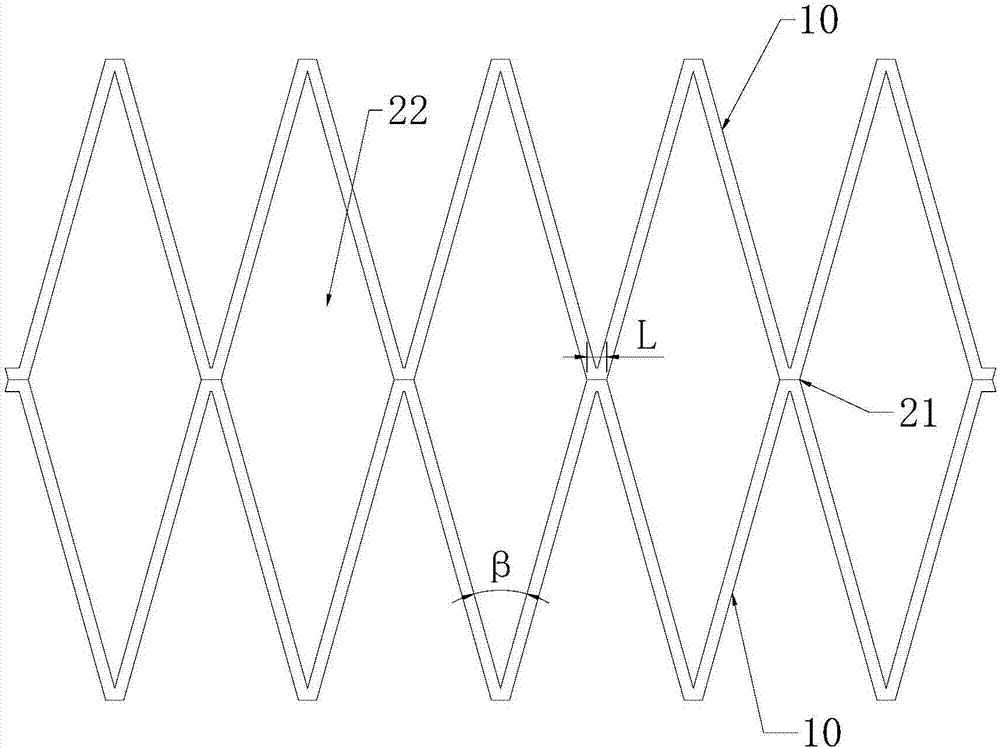

[0045] Such as figure 1 As shown, it is a double-layer corrugated filter cloth according to the present invention, including two layers of corrugated filter cloth 10 arranged oppositely. The cloth 10 is arranged symmetrically, so that the troughs of one layer of corrugated filter cloth 10 are in contact with the peaks of another layer of corrugated filter cloth 10, and then ultrasonic welding is performed on the conflicting positions. The width L of the welded seam 21 after welding is 1~ 1.5 mm, a channel 22 is formed between two adjacent welds 21 .

[0046] Using ultrasonic welding and setting the weld seam to a width L of 1 to 1.5mm can improve the strength of the weld seam 21 of the double-layer corrugated filter cloth and the overall structural strength of the double-layer corrugated filter cloth. The two-layer corrugated filter cloth 10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com