Marine travelling crane

A marine and winch technology, applied in the field of special driving, can solve problems such as poor accuracy and reliability, and achieve the effects of improved accuracy and reliability, strong shaking ability and good walking stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing example the present invention is described in further detail:

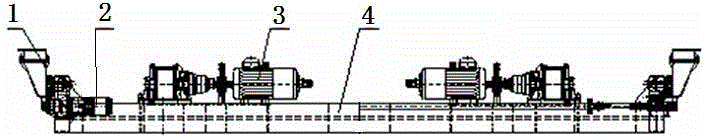

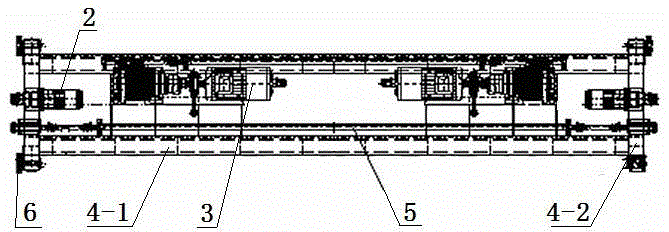

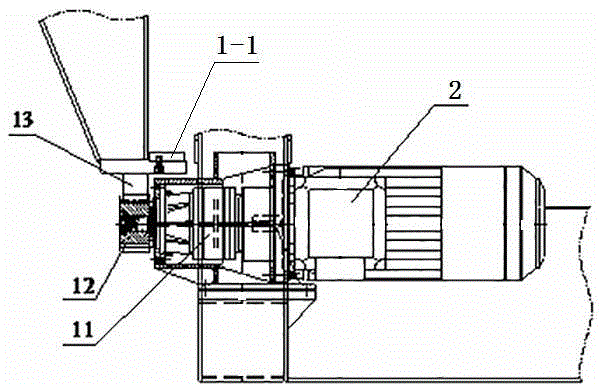

[0016] Such as figure 1 and figure 2 The shown marine crane includes two guide rail beams 1 equipped with longitudinal rails 1-1, racks 13 are installed at the bottom of the two guide rail beams 1; The running beam 4 that travels on the two longitudinal guide rails 1-1, the running beam 4 includes two parallel beams 4-1 and longitudinal beams 4-2 lapped on the two ends of the two beams 4-1. The root longitudinal beam 4-2 is respectively welded and connected with two beams 4-1; a connecting plate is welded between the beams 4-1; two wheel axles 6-2 are respectively installed on each longitudinal beam 4-2 through bearings. 1. Each wheel shaft 6-1 is equipped with a walking wheel 6 that is crimped with the longitudinal rail 1-1, and a guide wheel is installed between each longitudinal beam 4-2 and the guide rail beam 1 through the guide wheel shaft 14-1 14. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com