Method for target material component welding

A welding method and target technology, which are applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of poor welding bonding rate of target components, inability to achieve large-area welding, and low welding efficiency, and improve welding efficiency. Bonding rate and welding strength, satisfying long-term stable production and use of target materials, and high welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

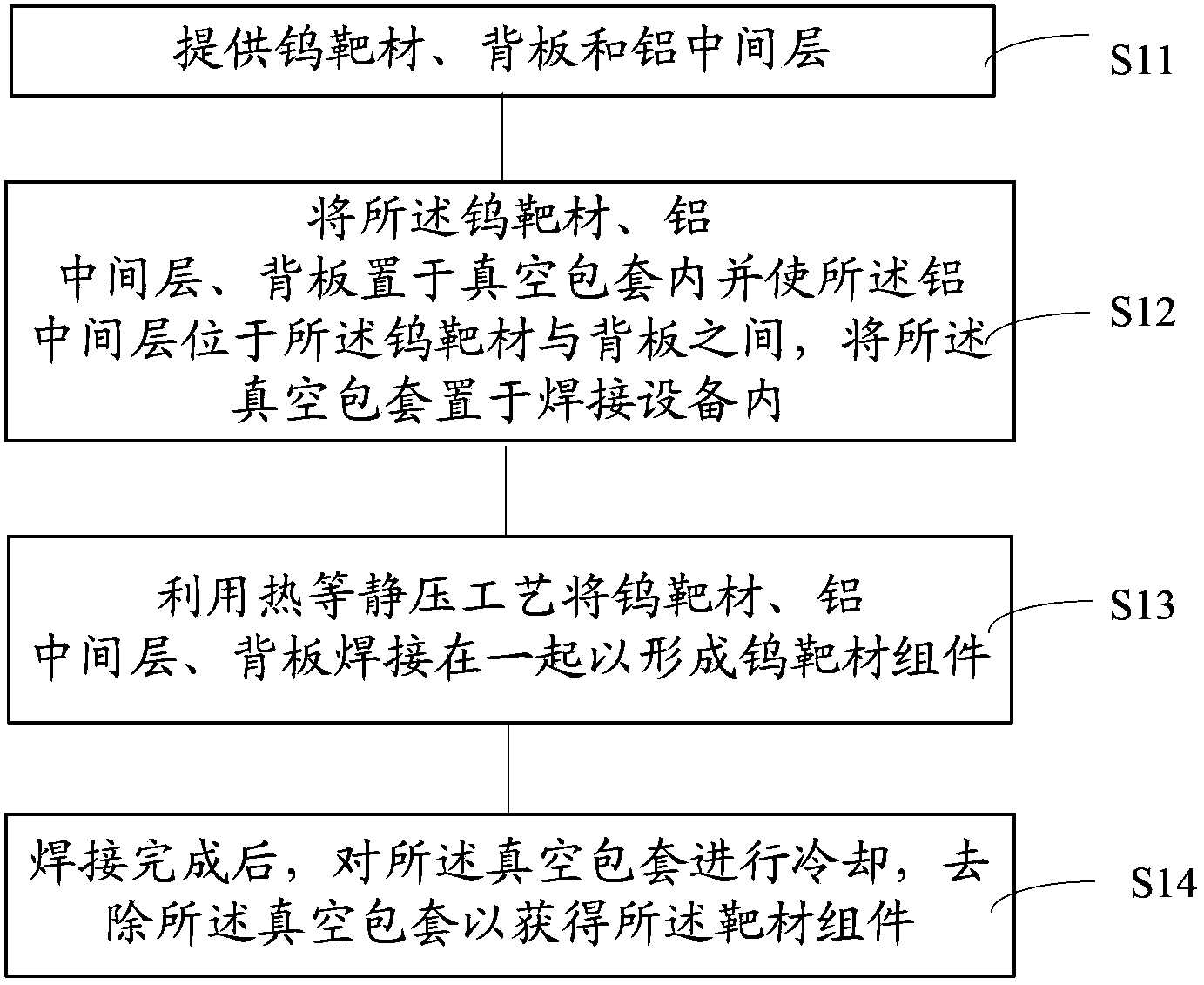

[0058] figure 1 It is the welding method flow chart of target assembly welding method embodiment 1 of the present invention. Include the following steps:

[0059] Execute step S11 to provide a tungsten target, a back plate and an aluminum intermediate layer;

[0060] Execute step S12, place the tungsten target material, the aluminum intermediate layer, and the back plate in the vacuum envelope and make the aluminum intermediate layer between the tungsten target material and the back plate, and place the vacuum envelope In welding equipment;

[0061] Execute step S13, using a hot isostatic pressing process to weld the tungsten target, the aluminum intermediate layer, and the back plate together to form a target assembly;

[0062] Step S14 is executed, after the welding is completed, the vacuum envelope is cooled, and the vacuum envelope is removed to obtain the target assembly.

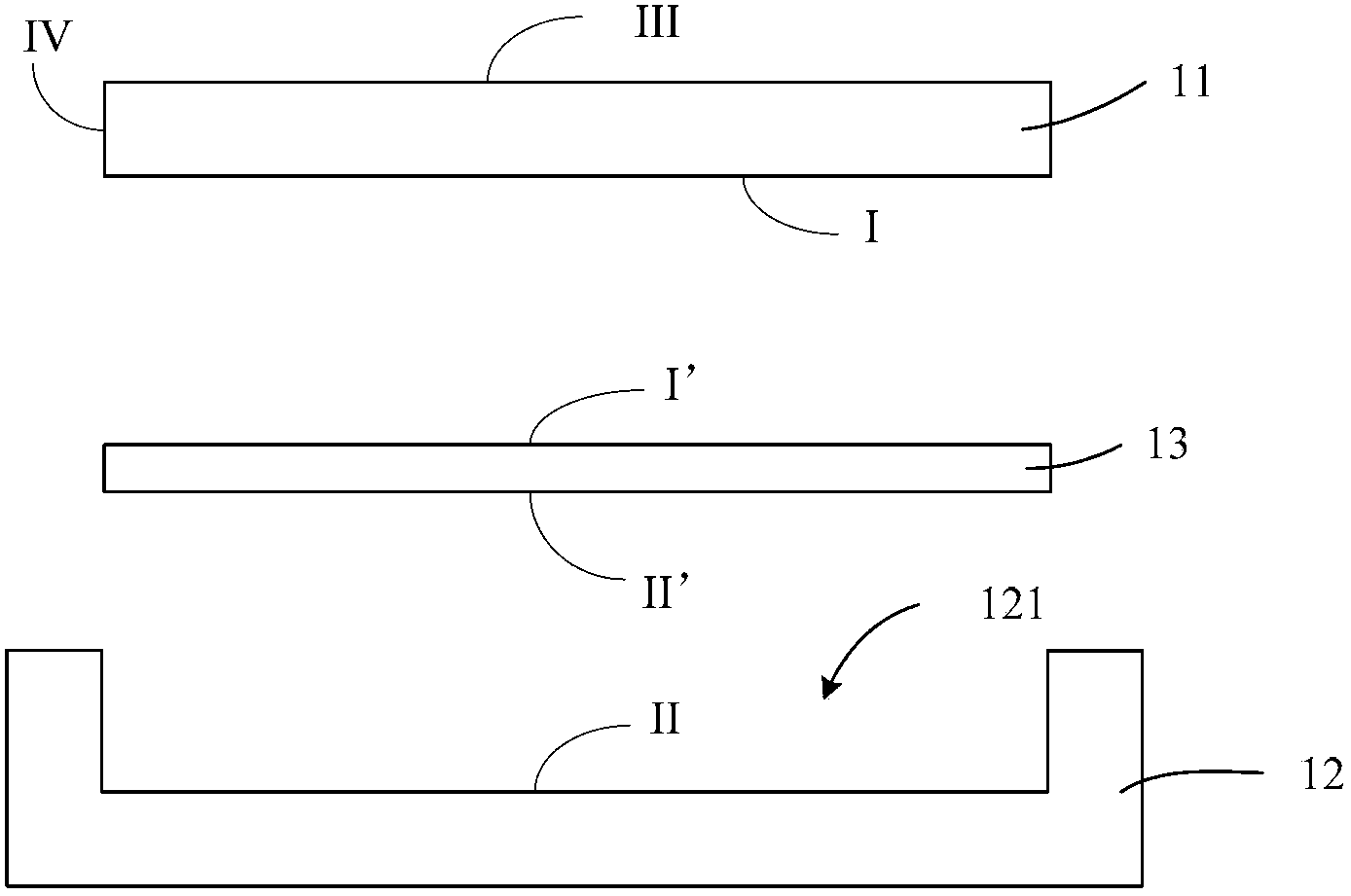

[0063] Please refer to figure 2 , firstly, step S11 is performed to provide a tungsten target...

Embodiment 2

[0101] Figure 11 It is a flow chart of the welding method of the target assembly in the second embodiment of the welding method of the target assembly of the present invention, which shows that when the intermediate layer between the tungsten target and the back plate is formed on the surface of the tungsten target to be welded, the Welding processes for target components such as Figure 11 As shown, it specifically includes the following steps:

[0102] Step S21 is executed to provide a tungsten target and a back plate.

[0103] Step S22 is executed to form an aluminum intermediate layer on the surface of the tungsten target to be welded so that the aluminum intermediate layer and the tungsten target form an integral body.

[0104] Execute step S23, place the tungsten target material and the back plate formed with the aluminum intermediate layer in the vacuum envelope and make the aluminum intermediate layer between the tungsten target material and the back plate, and plac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com