Patents

Literature

66results about How to "Stable clamping work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coloring and paint spraying device for woodcarving craft

ActiveCN111111990ASpray evenlyBlow dry in timePretreated surfacesLiquid spraying apparatusEngineeringMaterial resources

The invention relates to a coloring and paint spraying device for a woodcarving craft. The coloring and paint spraying device comprises a bottom plate, a rotary lifting device, a clamping device and apaint spraying and drying device, supporting plates are mounted at the lower end of the bottom plate in a left-right symmetrical manner, the rotary lifting device is mounted between the inner walls of the supporting plates, the clamping device is mounted at the upper end of the rotary lifting device, and the upper end of the bottom plate is provided with the paint spraying and drying device. Thecoloring and paint spraying device for the woodcarving craft can solve the following problems, existing when paint spraying on the existing woodcarving surface is carried out, that 1, when manual paint spraying is carried out, the operation procedure is complex and inconvenient, a large amount of manpower and material resources are consumed, the production efficiency is low, the pollution to the environment is serious, the manual paint spraying environment is poor, great harm is caused to the human body; a human body works in a place with high paint concentration for a long time, so that the body is easily suffered from diseases such as respiratory tract; and 2, the existing automatic paint spraying device for the craft is low in paint spraying efficiency and uneven in spraying, and the appearance of a product is influenced.

Owner:NANJING FORESTRY UNIV

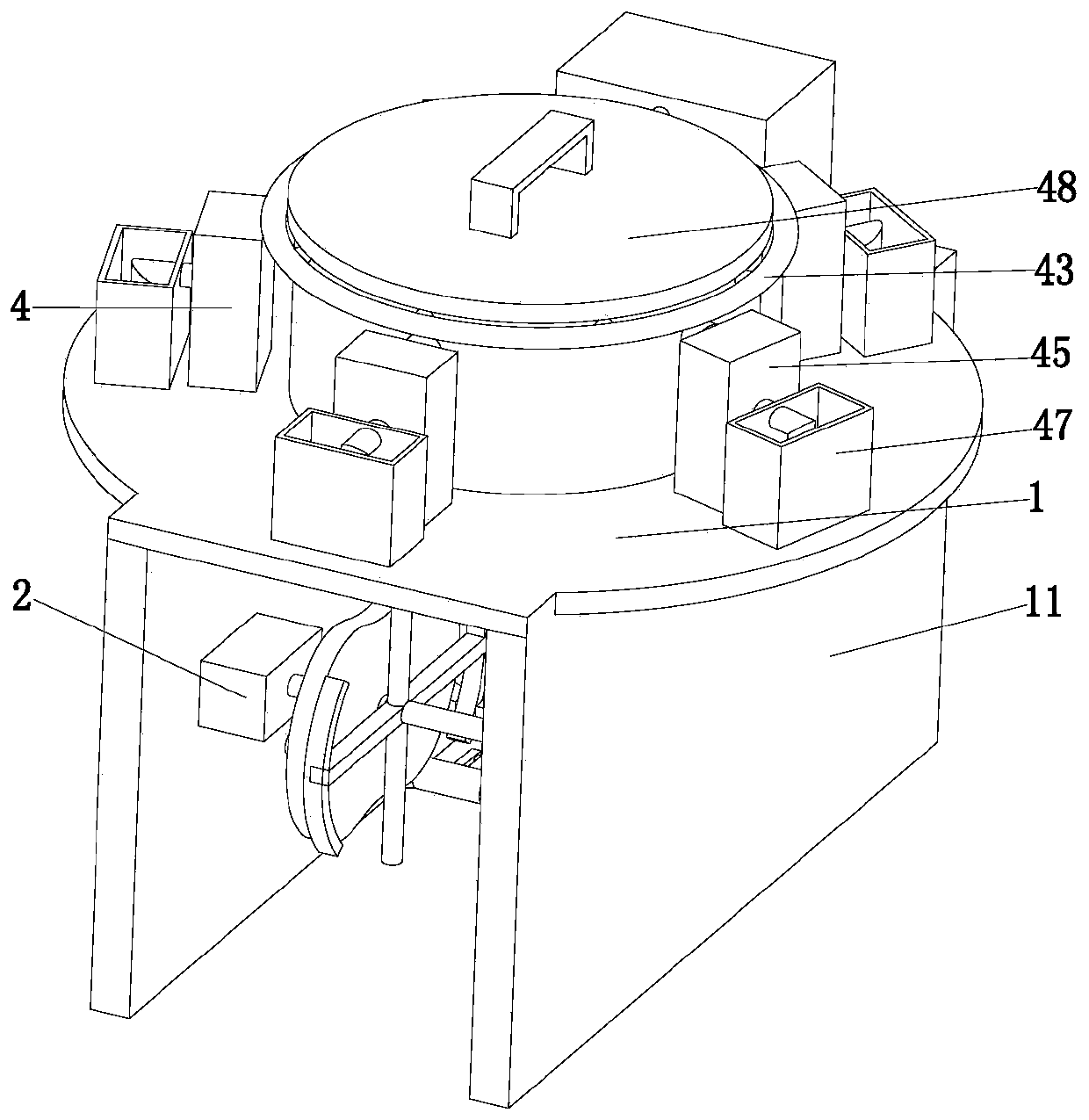

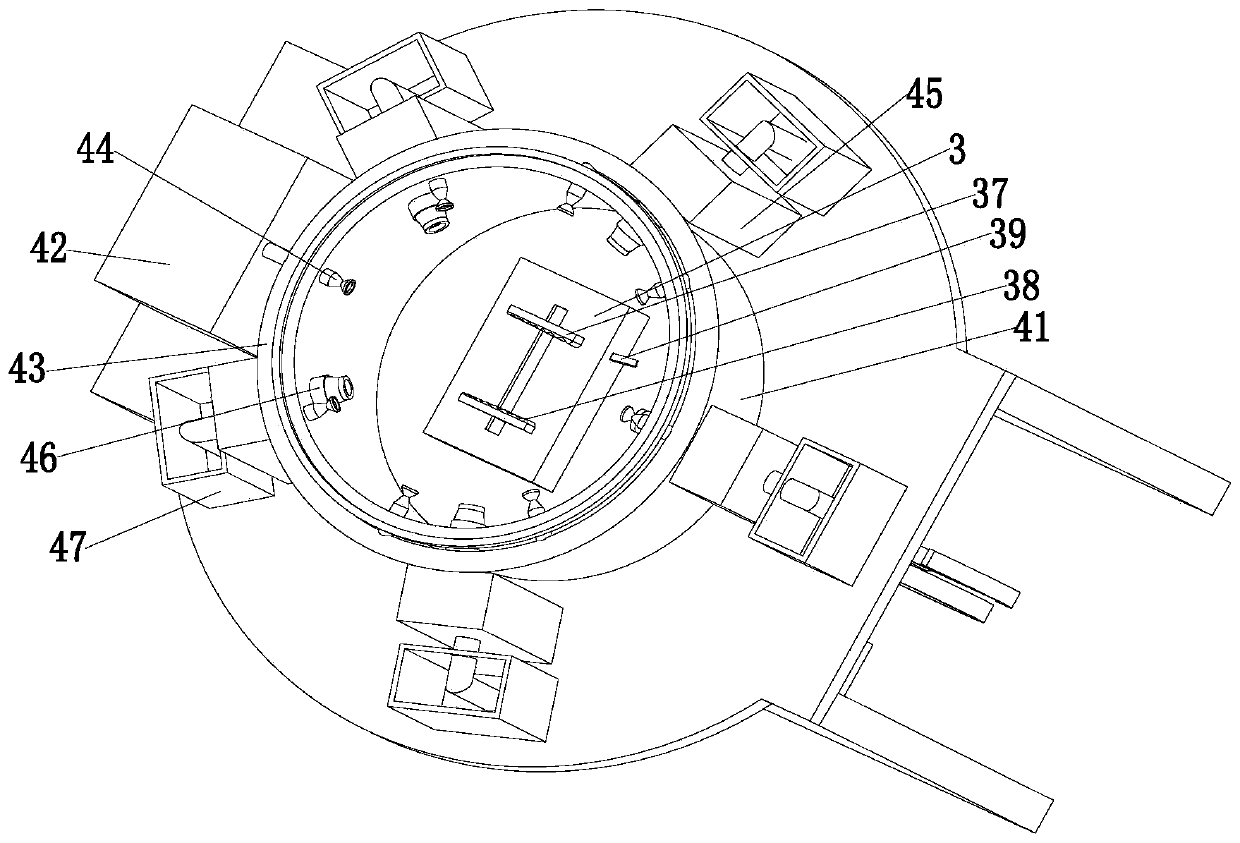

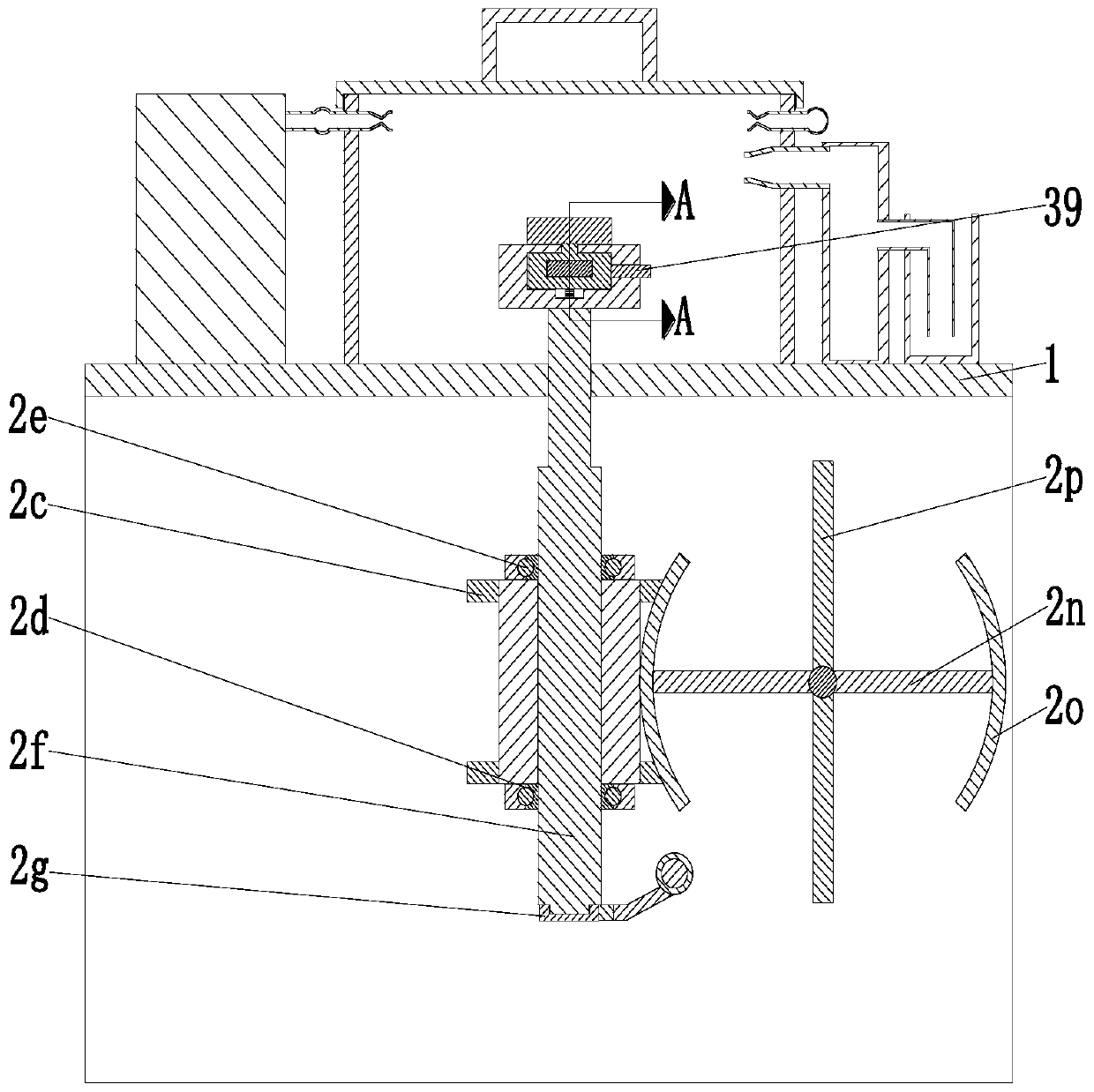

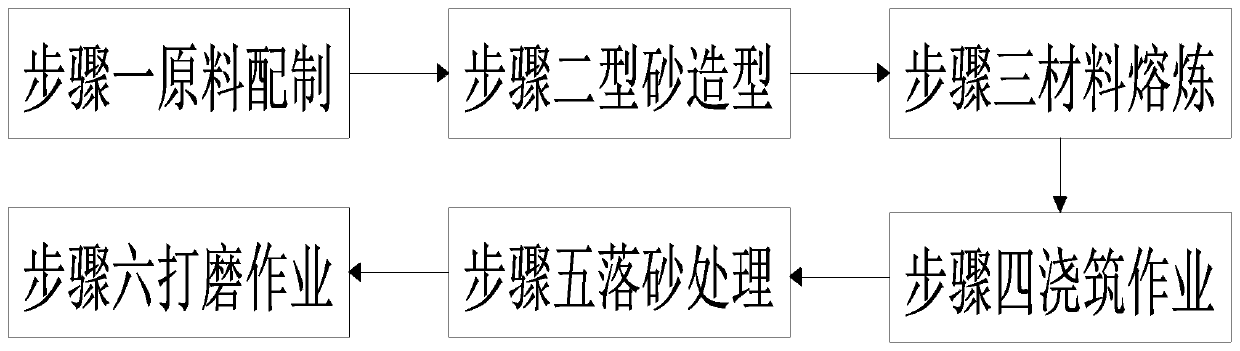

Metal casting machining and manufacturing process

ActiveCN111299556AImprove spraying efficiencyFull sanding jobGrinding drivesFoundry mouldsPolishingGrinding wheel

The invention relates to a metal casting machining and manufacturing process. The process mainly comprises the following steps of raw material preparation, molding sand molding, material smelting, pouring operation, shakeout treatment, polishing operation and the like; and used casting polishing equipment comprises a bottom plate, a rotating device, a clamping device and a polishing device. The process can solve the following problems existing in existing casting grinding that a, existing casting grinding is mainly operated manually, a casting is placed on a platform in the grinding process, then a riser is aligned with a grinding wheel to be ground, the grinding depth is judged manually in the grinding mode, the grinding feeding amount is difficult to control, and the grinding quality isdifficult to guarantee; and b, a traditional casting grinding device is large in noise, severe in vibration, unstable in operation, inconvenient to adjust and operate, low in grinding efficiency, poorin grinding quality and prone to the phenomenon of incomplete grinding in the operation process; and the spraying efficiency of casting grinding can be improved.

Owner:山东天元重工有限公司

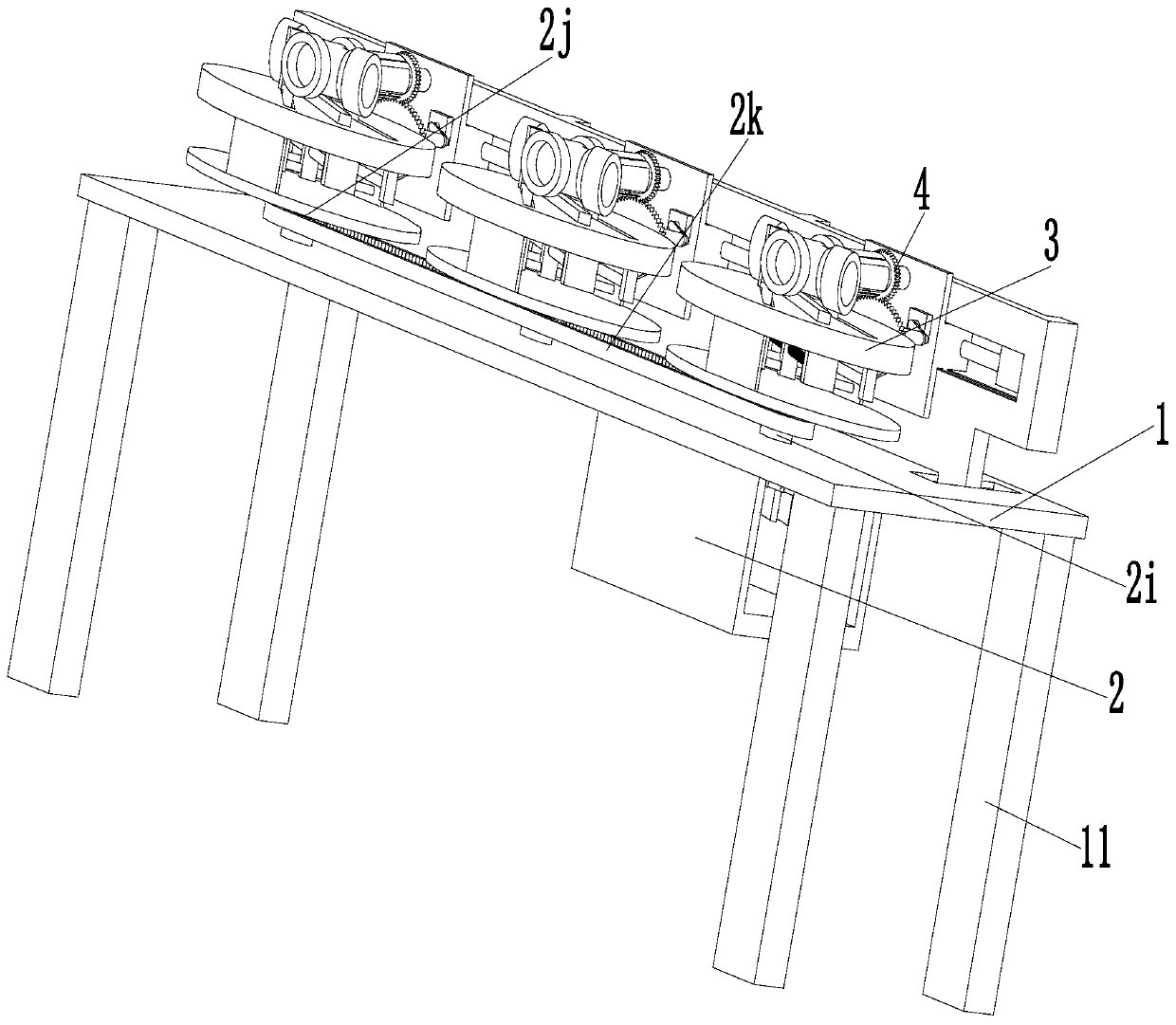

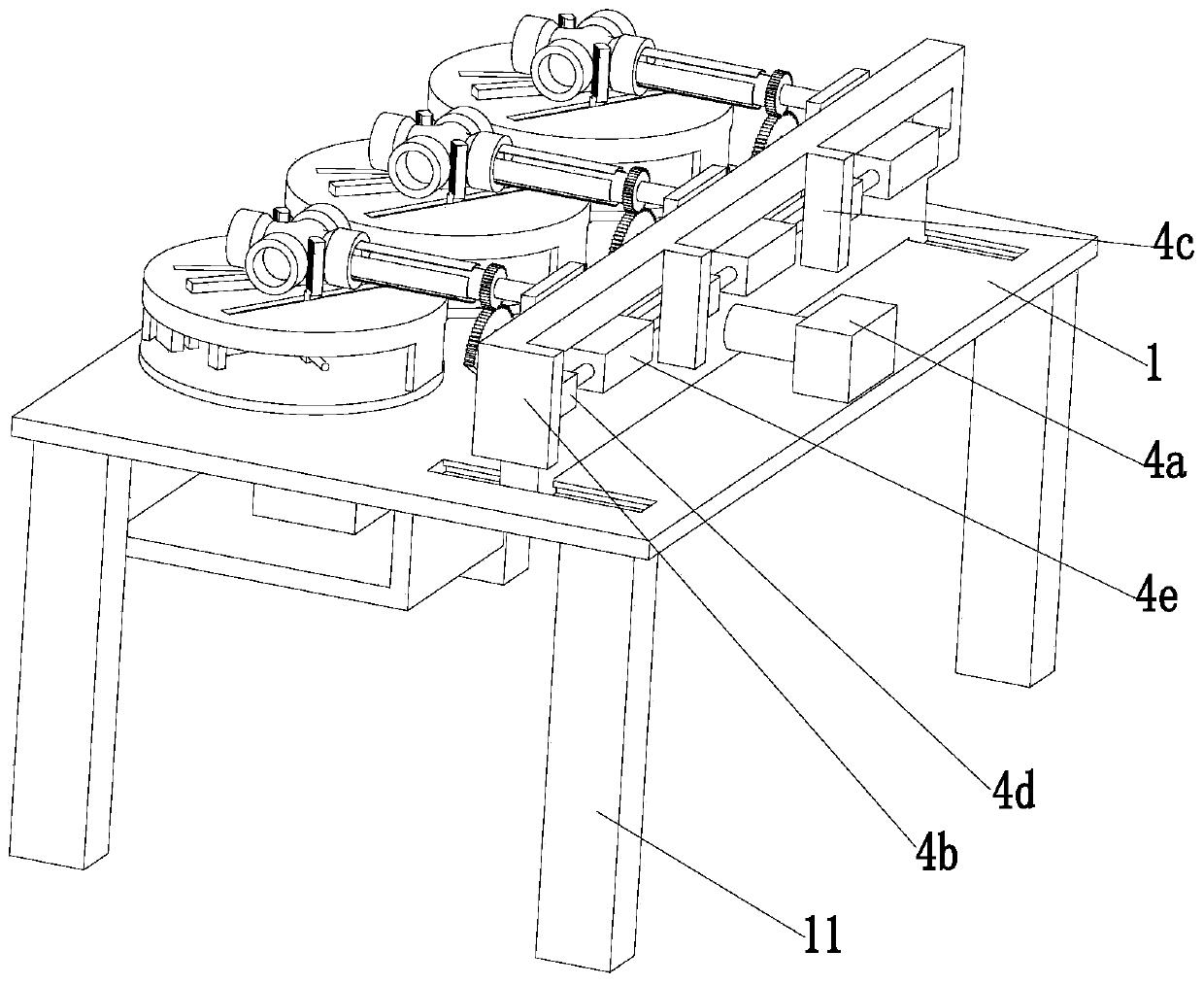

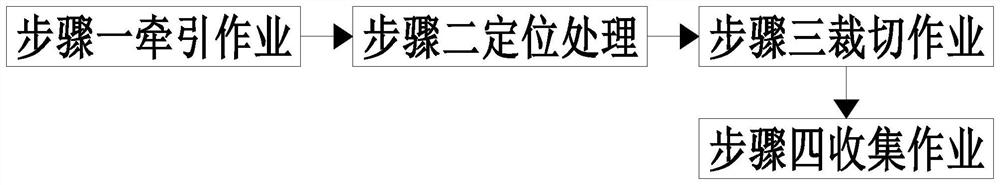

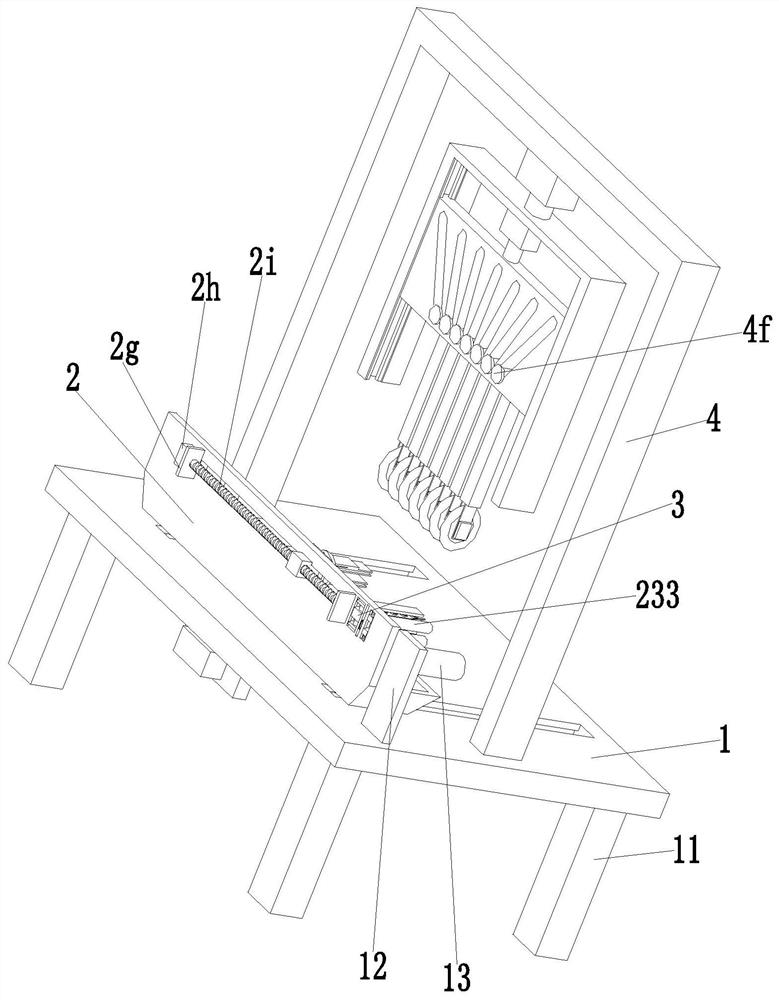

Rubber raw material pre-treatment method

InactiveCN111702833AImprove cutting efficiencyImprove cutting effectMetal working apparatusMechanical engineeringManual handling

The invention relates to a rubber raw material pre-treatment method. The method mainly comprises the following steps of traction work, positioning treatment, cutting work, collection work and other procedures. Used rubber raw material treatment equipment comprises a bottom plate, a traction device, a positioning device and a cutting device, and the problems existing in existing rubber strip cutting that cutting after manual measuring is adopted in traditional rubber strip cutting, when a worker uses a tool for cutting a rubber strip, due to manual operation errors, the worker is frequently hurt by the tool due to cutting, the efficiency of manual cutting of the rubber strip is low, the cutting quality cannot be ensured, the raw material is wasted, when existing rubber strip cutting equipment cuts the rubber strip, only one segment of rubber strip can be cut at one time, the cutting speed is low, the rubber strip cutting length is not even, a cut opening is not flat, and the rubber strip cutting efficiency and effect can be improved.

Owner:胡帆

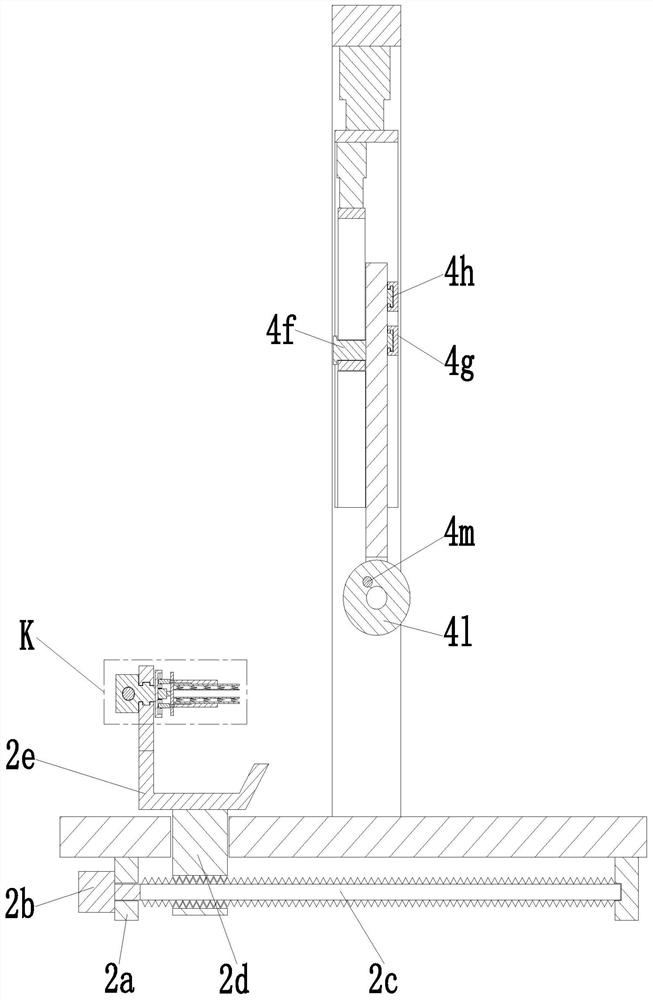

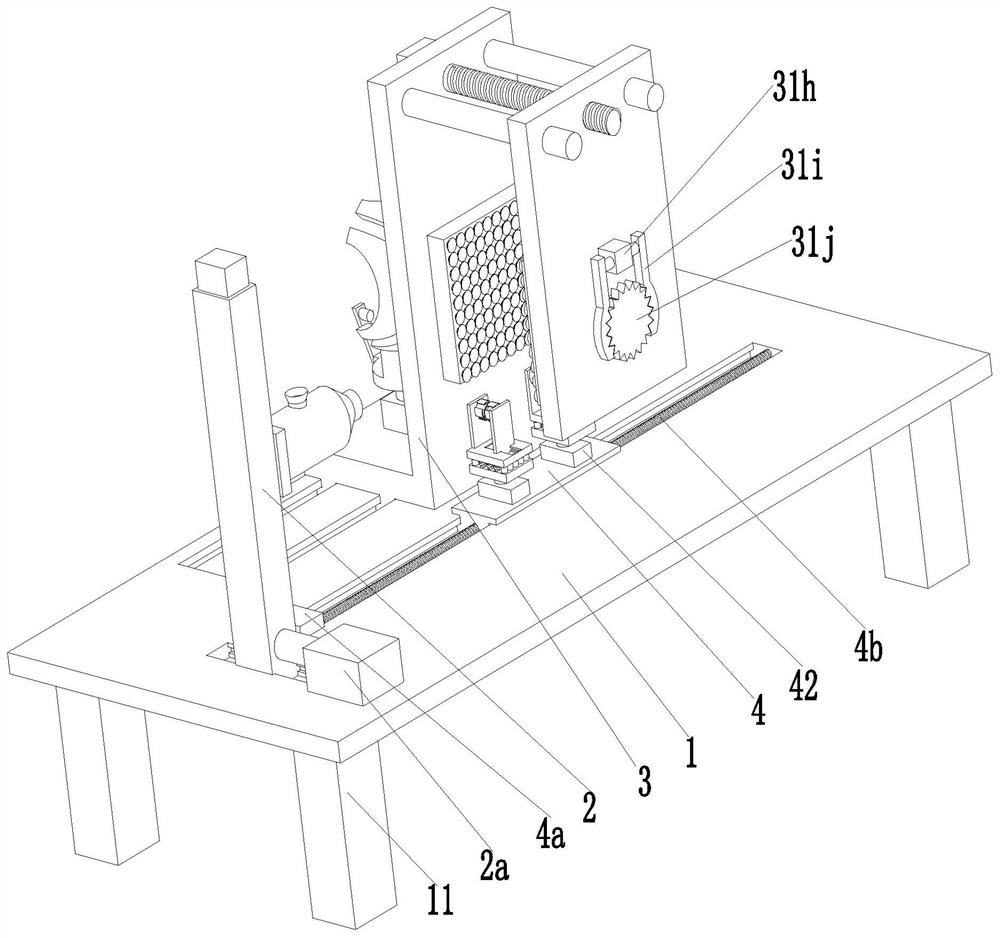

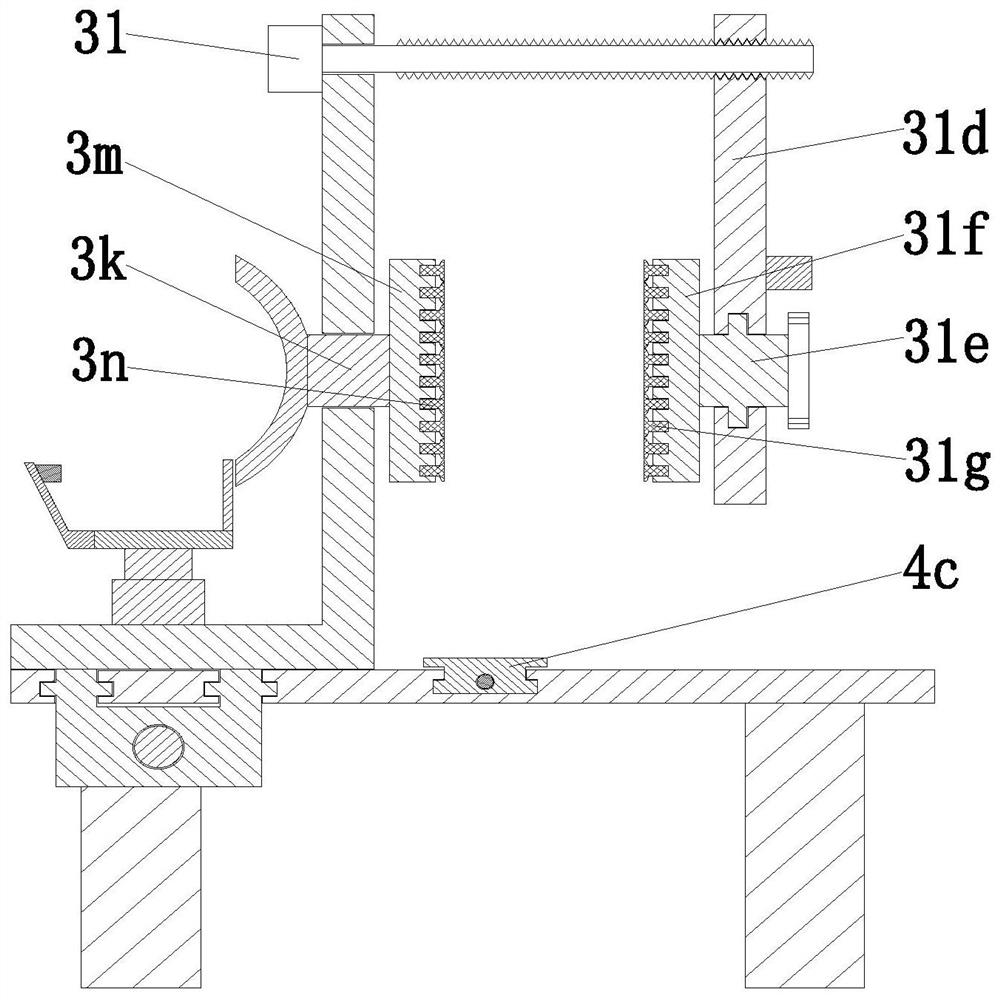

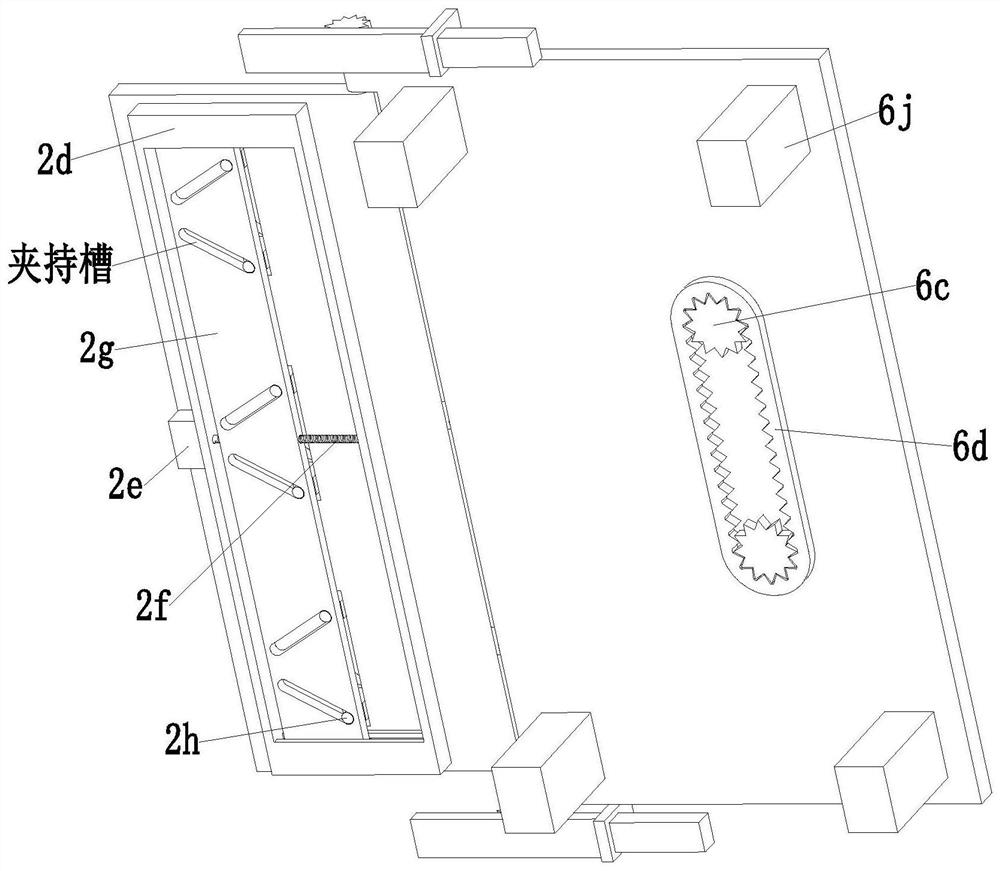

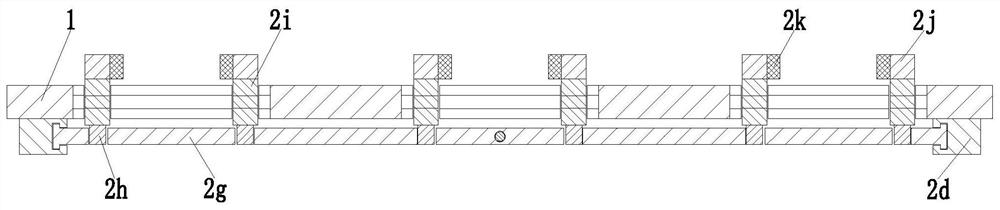

Edge sealing treatment method for artificial boards

ActiveCN111645165AImprove efficiencyGood effectGlue gunsDomestic articlesMaterials preparationAdhesive glue

The invention relates to an edge sealing treatment method for artificial boards. The method mainly includes the following steps of material preparation, clamping treatment, glue spraying operation, labeling operation and the like. Used edge sealing equipment for the artificial boards comprises a bottom plate, a glue spraying device, a clamping device and a labeling device. The following problems that a, during traditional artificial board edge sealing, glue needs to be manually sprayed to the edges of the artificial boards, then edge sealing strips are attached to the edges, to which the glueis sprayed, of the artificial boards for press fitting, the quality of manual edge sealing of the artificial boards is not consistent, the workload of workers is large, and the production efficiency of plywood is reduced; and b, when existing edge sealing equipment for the artificial boards is used for edge sealing of the artificial boards, the edge sealing strips cannot be stably attached to theedges of the artificial boards, the phenomenon that the edge sealing strips disengage frequently happens, the production efficiency of the artificial boards is affected, and raw materials are wasted existing in existing edge sealing of the artificial boards can be solved, and the efficiency and effect of edge sealing of the artificial boards can be improved.

Owner:东莞市中意厨房设备有限公司

Intelligent processing machine and processing method for backlight module production

InactiveCN113182977AReduce production efficiencyEasy to polishPolishing machinesGrinding drivesEngineeringMachine

The invention relates to an intelligent processing machine and processing method for backlight module production. The intelligent processing machine for backlight module production comprises a bottom plate, a rotating device, an adjusting device, a grinding device and a polishing device, wherein the rotating device is installed at the lower end of the bottom plate, the adjusting device is installed on the rotating device, the grinding device is installed at the right end of the bottom plate, and the polishing device is installed at the rear side of the right end of the bottom plate. By means of the intelligent processing machine and processing method for backlight module production, the problems which exist during welding splicing and grinding of front frames of existing backlight modules can be solved, and the problems are as followings: (1) the front frames of the traditional backlight modules need to be subjected to splicing positioning treatment before being welded, splicing positioning is mostly conducted through hand holding, and then welding treatment is conducted, so that splicing is unstable, and the welding quality of the front frames is affected; and (2) when the front frames of the existing backlight modules are welded and then ground, grinding treatment is mostly conducted manually, the manual grinding and polishing efficiency is low, and the grinding quality is not high, so that the production efficiency of the front frames is reduced.

Owner:武汉敏之捷光电科技有限公司

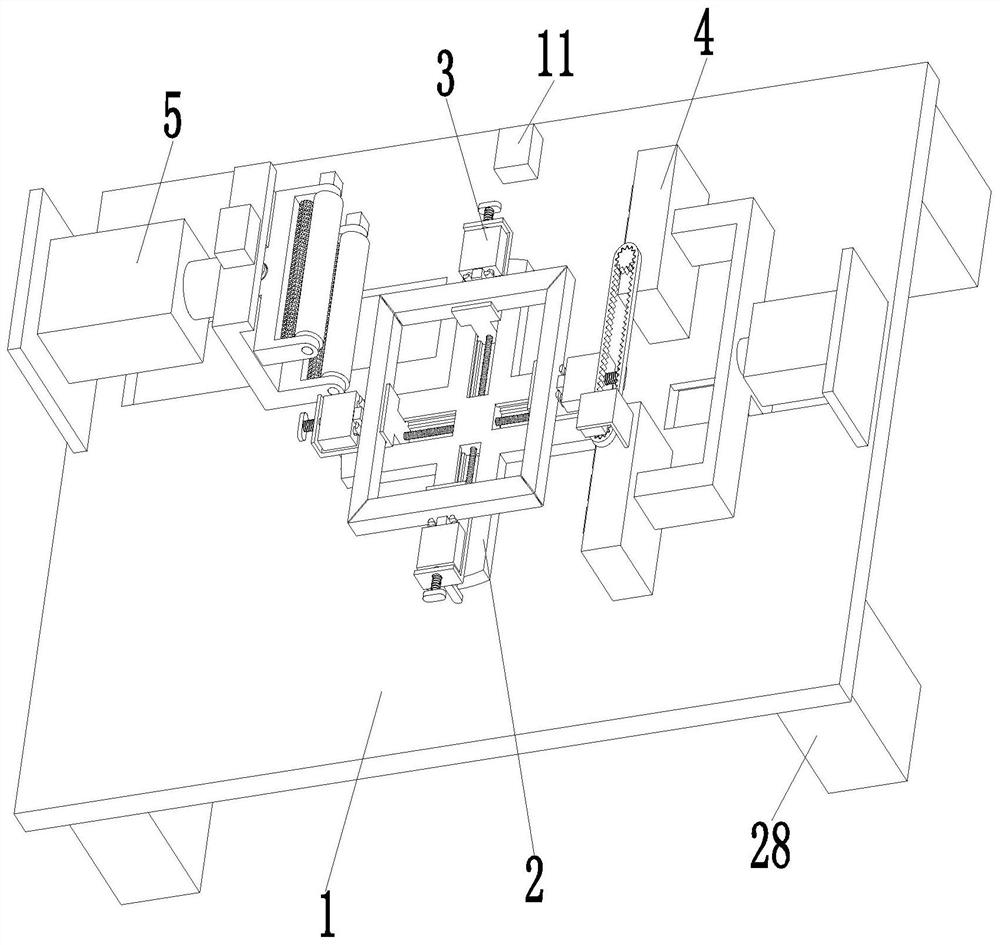

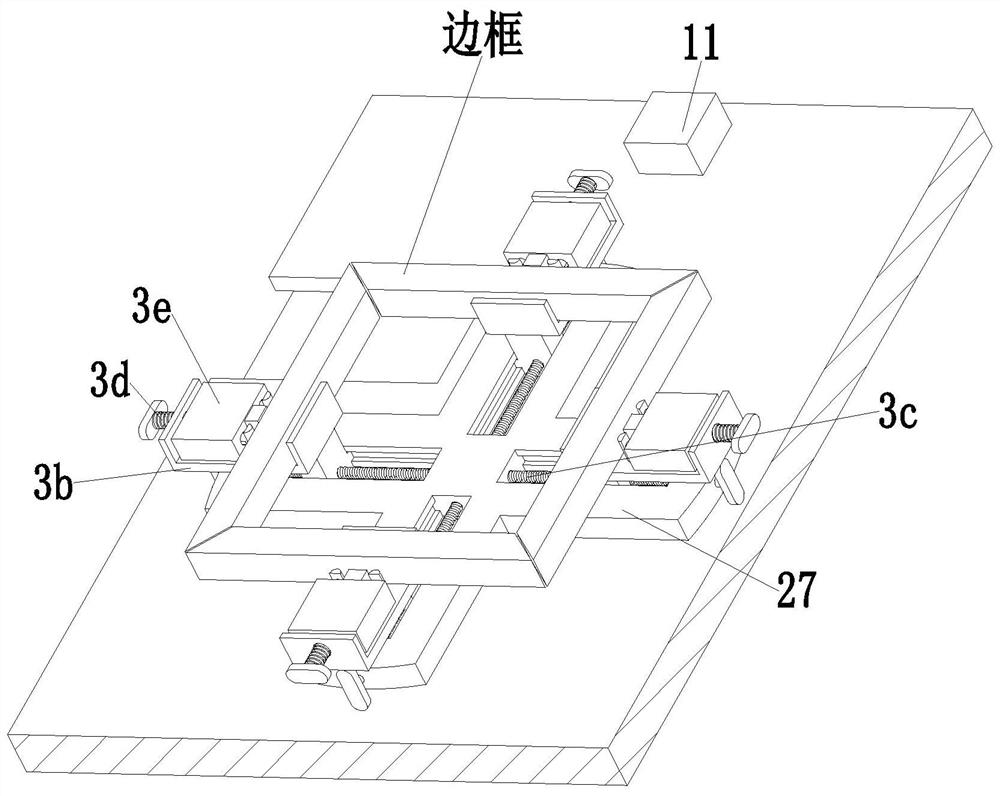

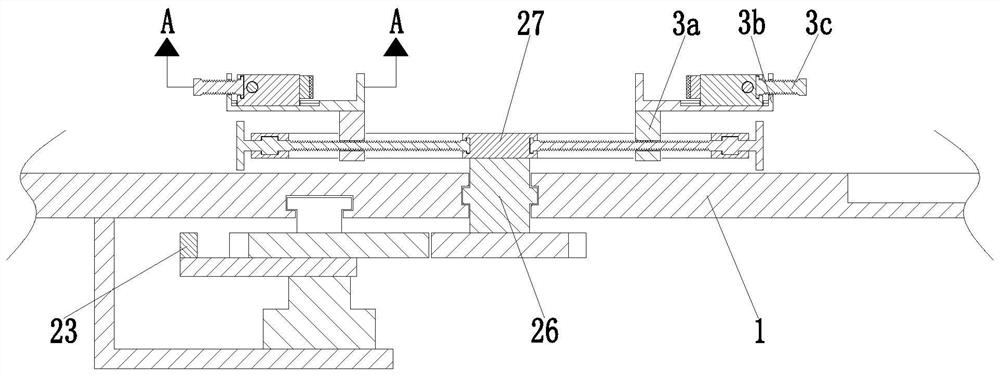

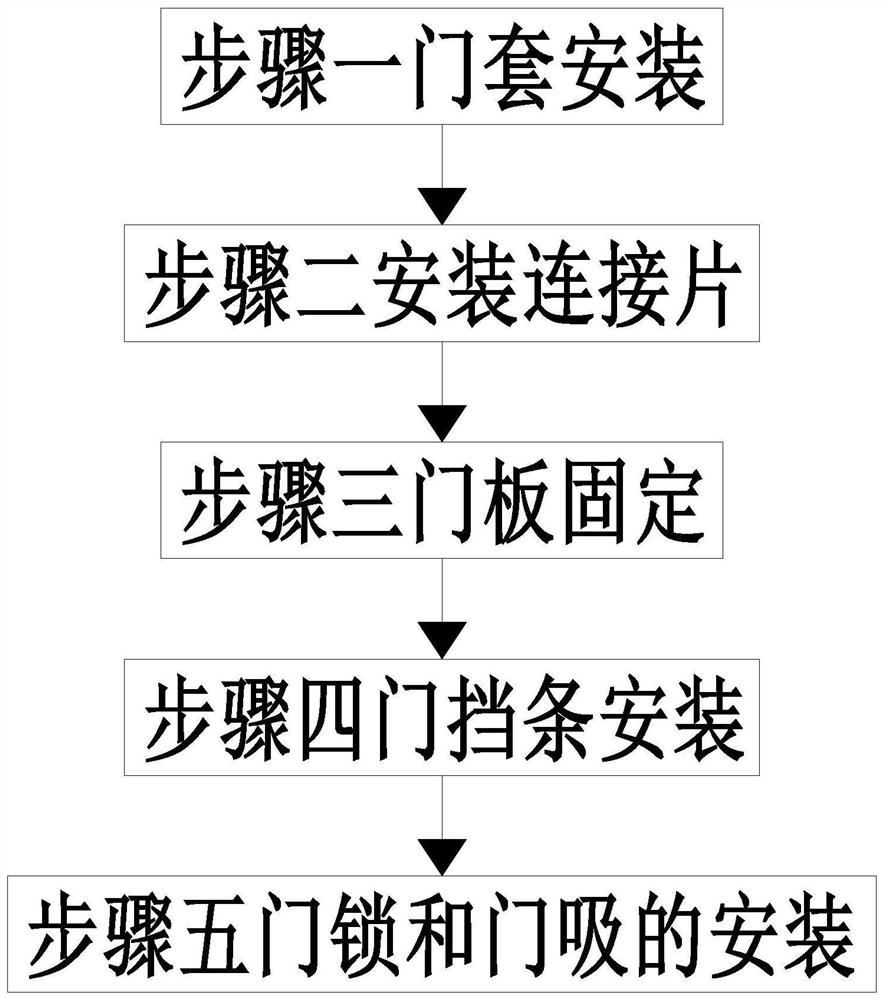

Wooden door mounting construction method

ActiveCN111764598AQuality improvementGuaranteed stabilityWindow/door framesSpecial door/window arrangementsEngineeringStructural engineering

Owner:莆田晟熙贸易有限公司

Chemical pressure vessel manufacturing and forming process

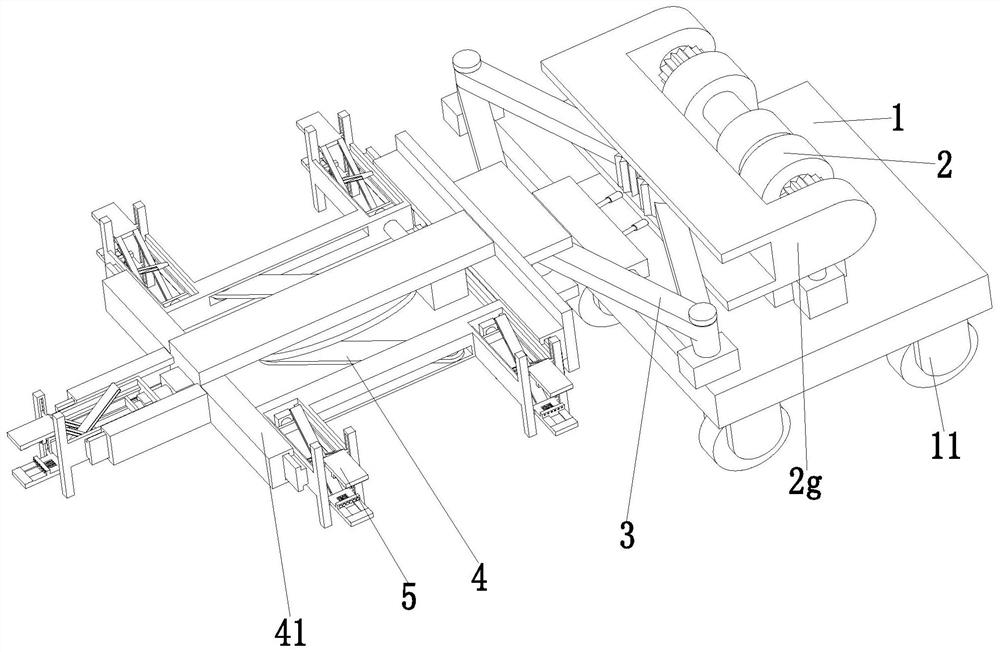

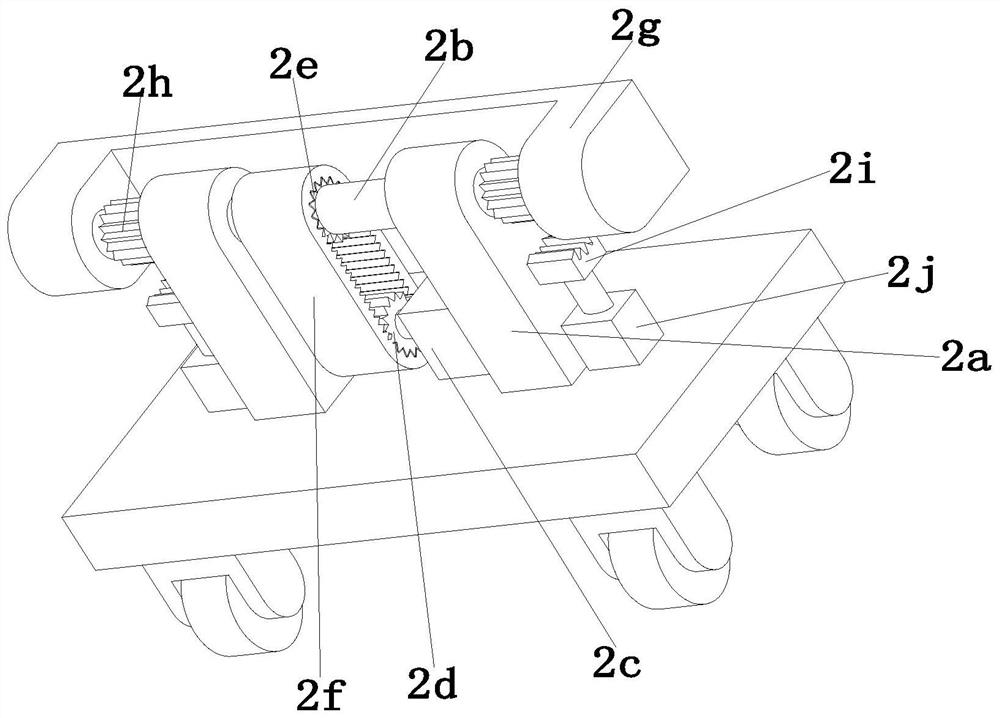

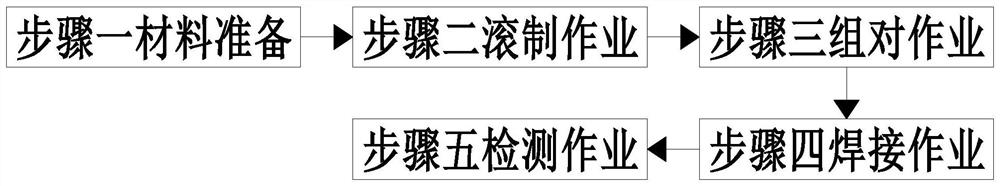

InactiveCN112676724ALow assembly efficiencyLight in massWelding/cutting auxillary devicesAuxillary welding devicesMaterials preparationStructural engineering

The invention relates to a chemical pressure vessel manufacturing and forming process. The chemical pressure vessel manufacturing and forming process mainly comprises the various procedures of material preparation, rolling operation, pairing operation, welding operation, detection operation and the like; and pressure vessel assembling equipment used in the chemical pressure vessel manufacturing and forming process comprises a bottom plate, a lifting device, a clamping device and an abutting device. The chemical pressure vessel manufacturing and forming process can solve the problems existing in butt joint assembly of an existing chemical pressure vessel that A, during the butt joint assembly of the traditional chemical pressure vessel, the stable butt joint operation cannot be performed on a pressure vessel barrel and a pressure vessel end socket, and the butt joint dislocation often occurs during the butt joint of the pressure vessel barrel and the pressure vessel end socket, so that the butt joint quality of the pressure vessel barrel and the pressure vessel end socket is reduced; and B, existing chemical pressure vessel butt joint assembling equipment cannot stably clamp and position the pressure vessel barrel, so that the pressure vessel assembling stability is affected, and the pressure vessel assembling efficiency is reduced.

Owner:南京系原商贸有限公司

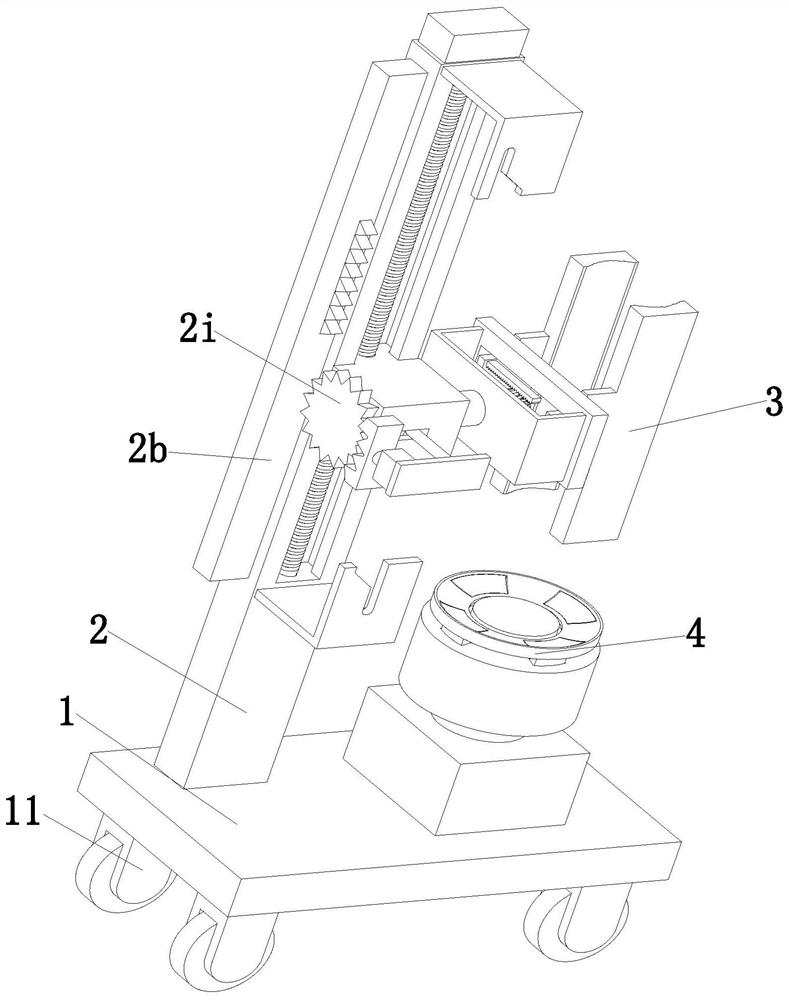

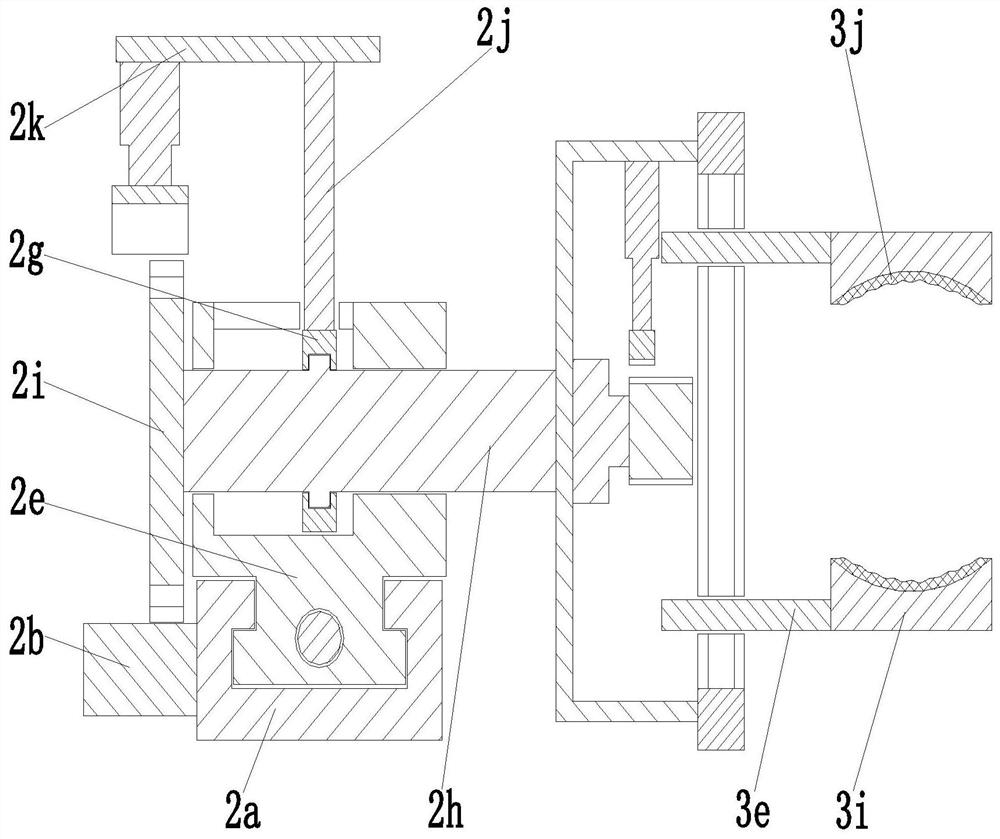

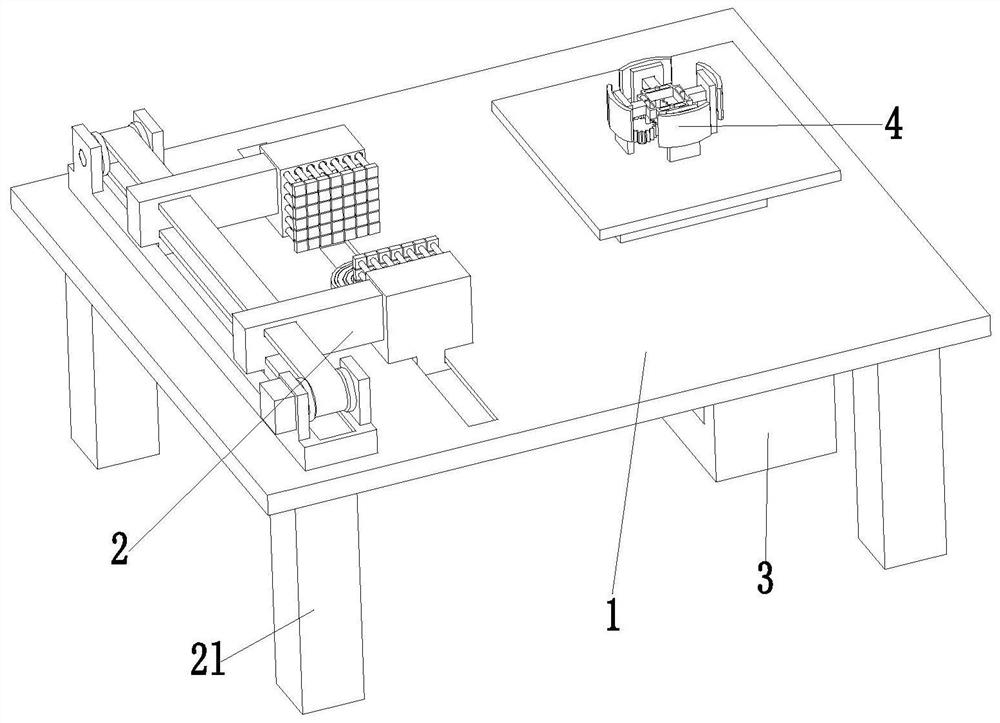

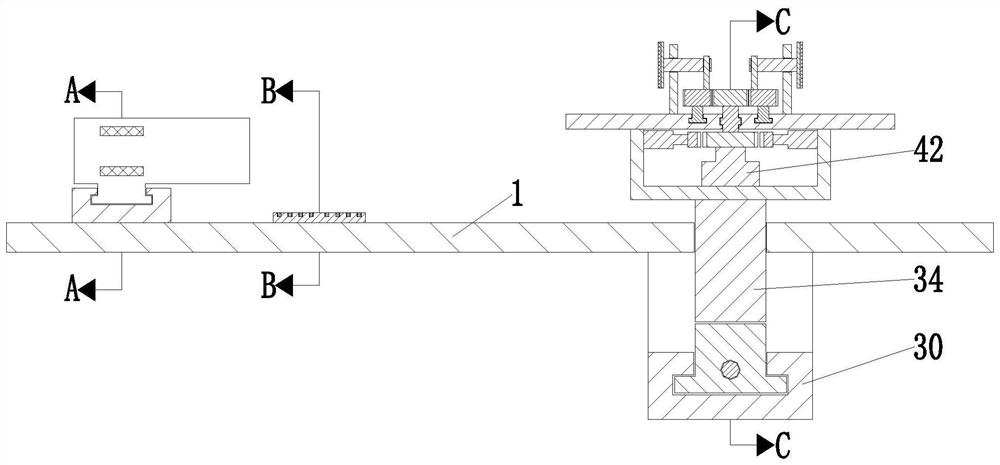

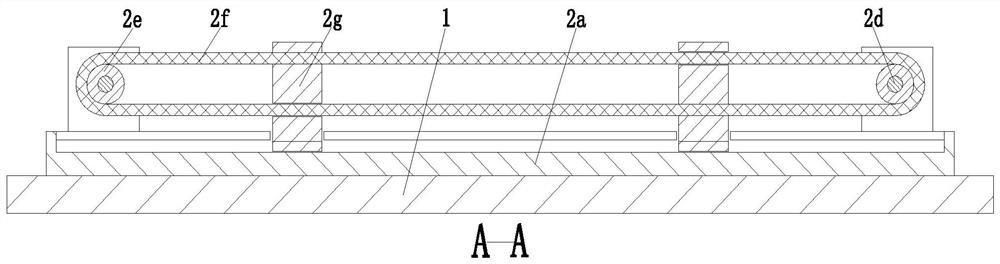

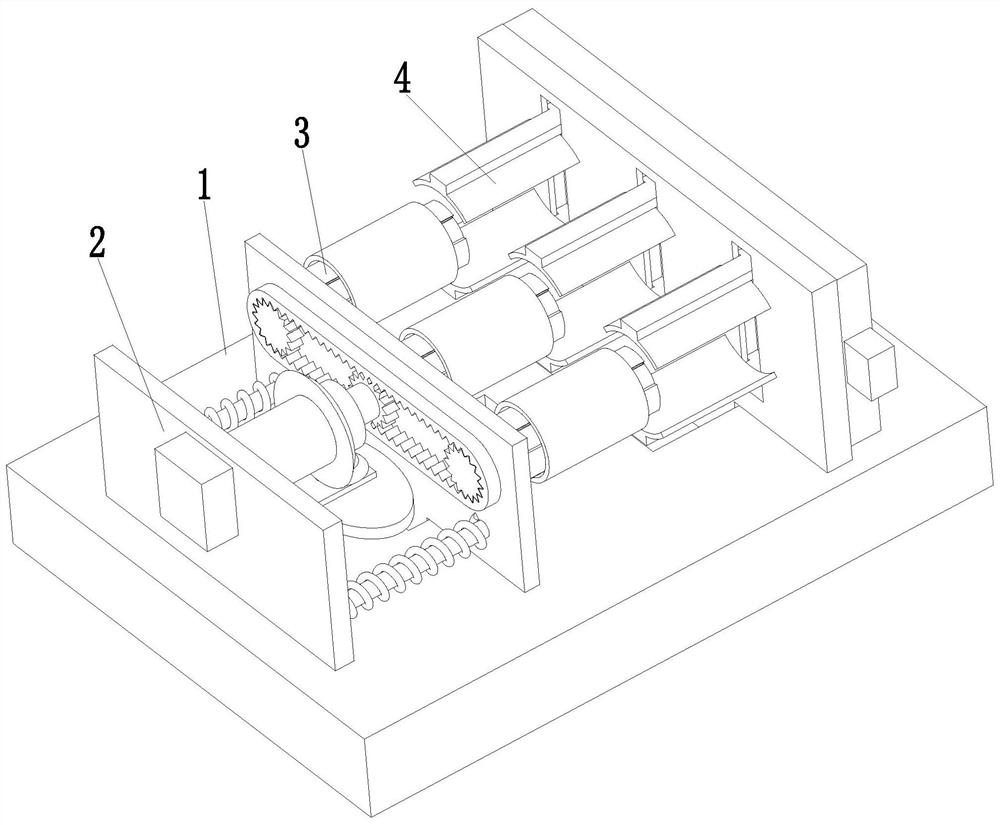

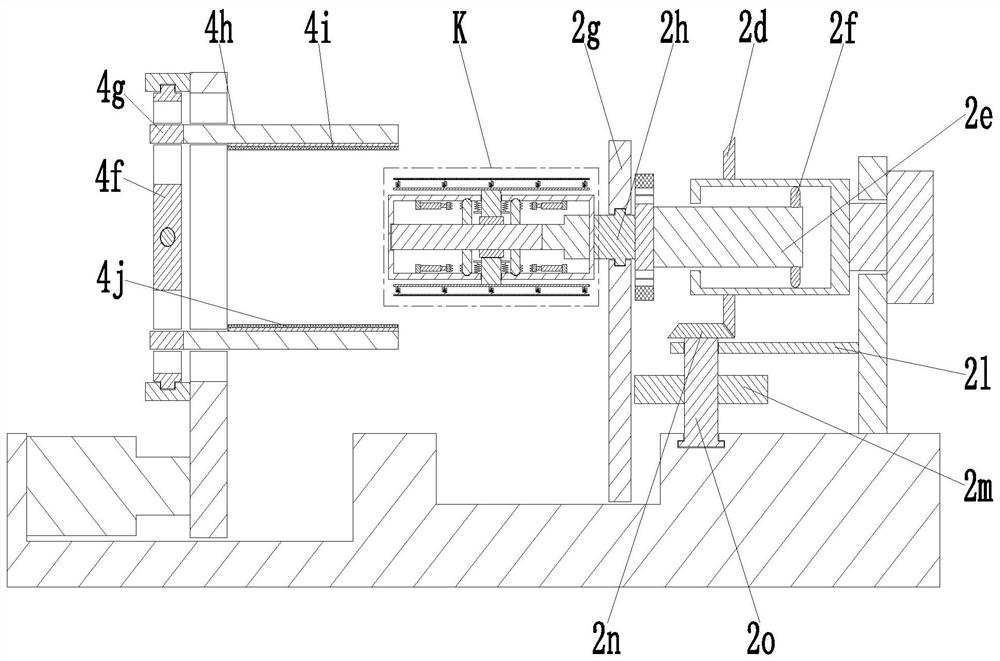

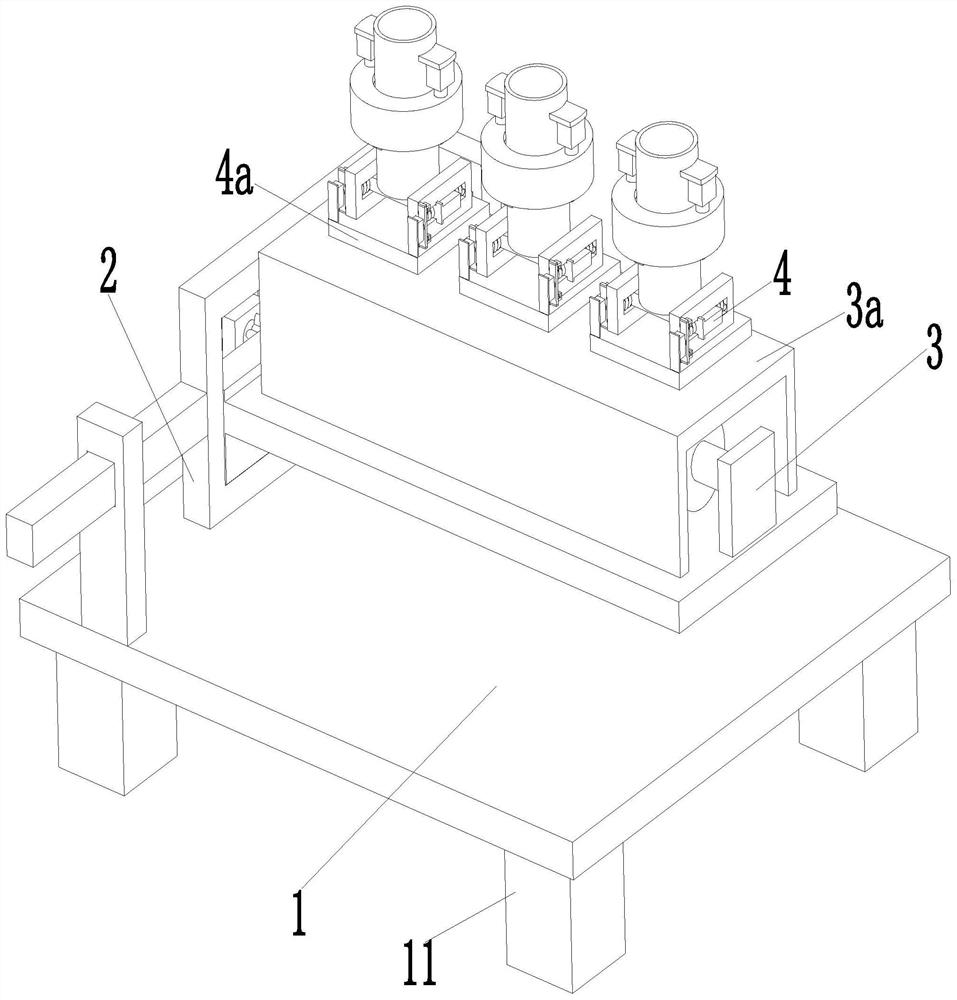

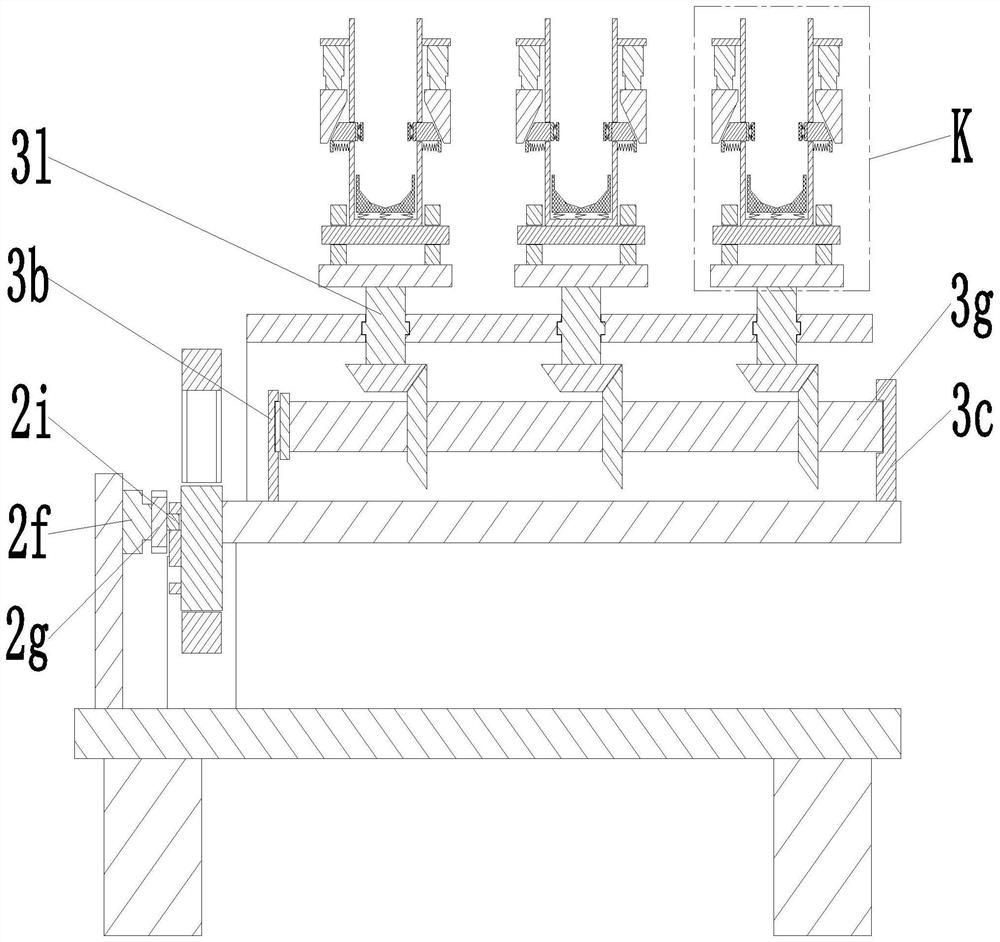

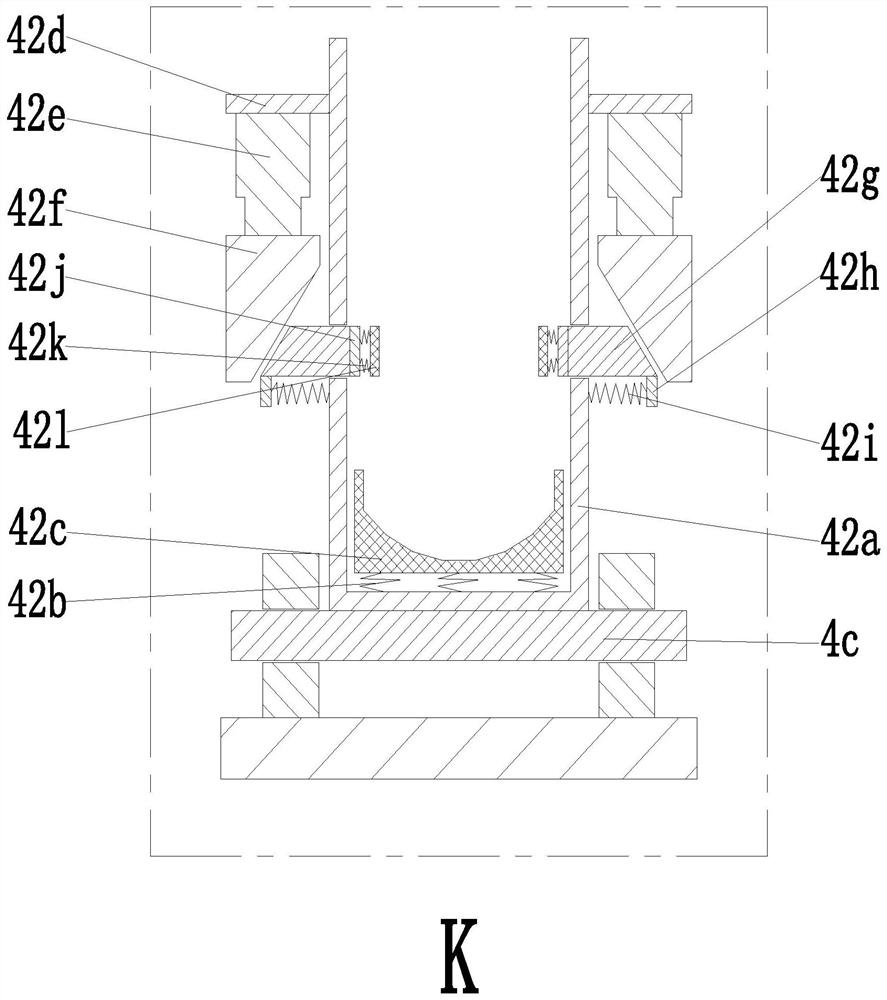

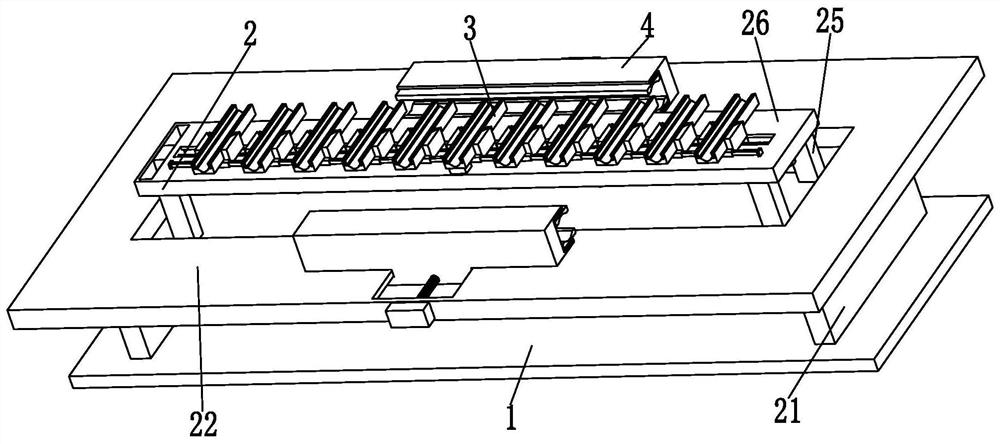

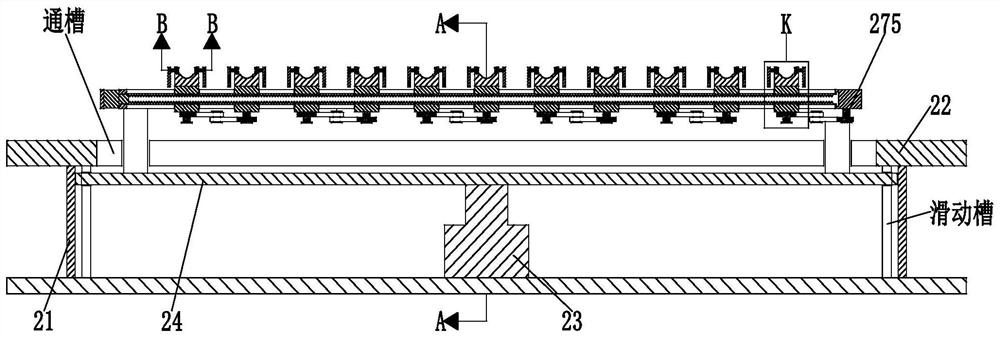

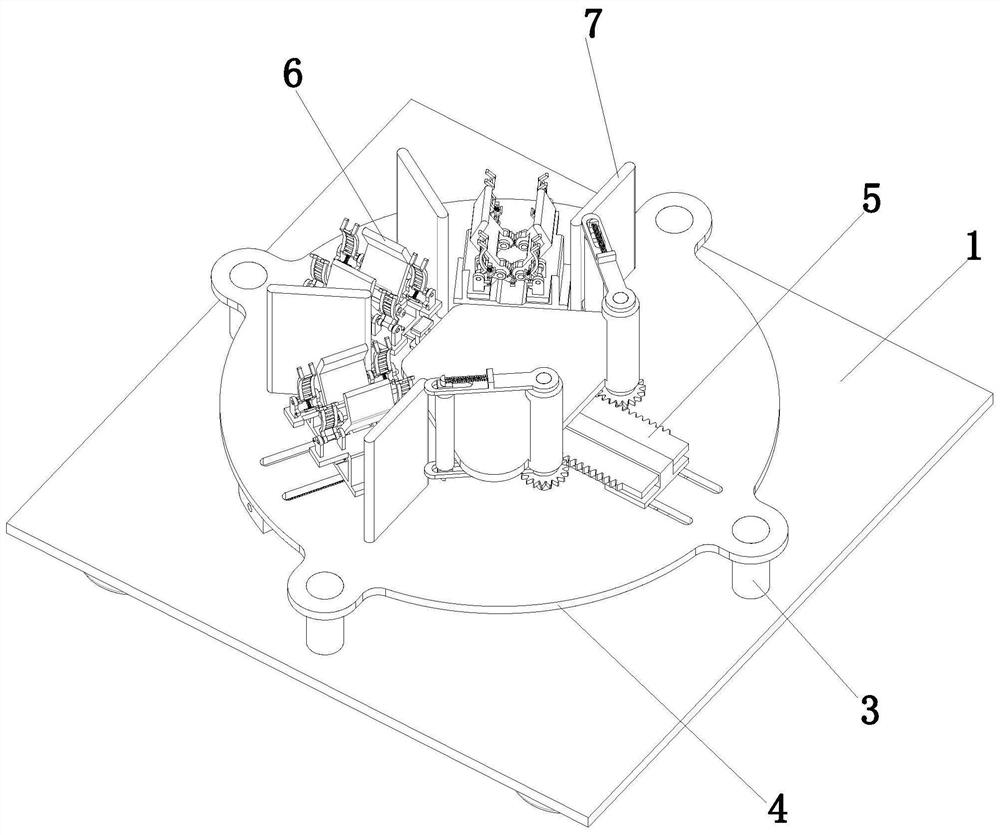

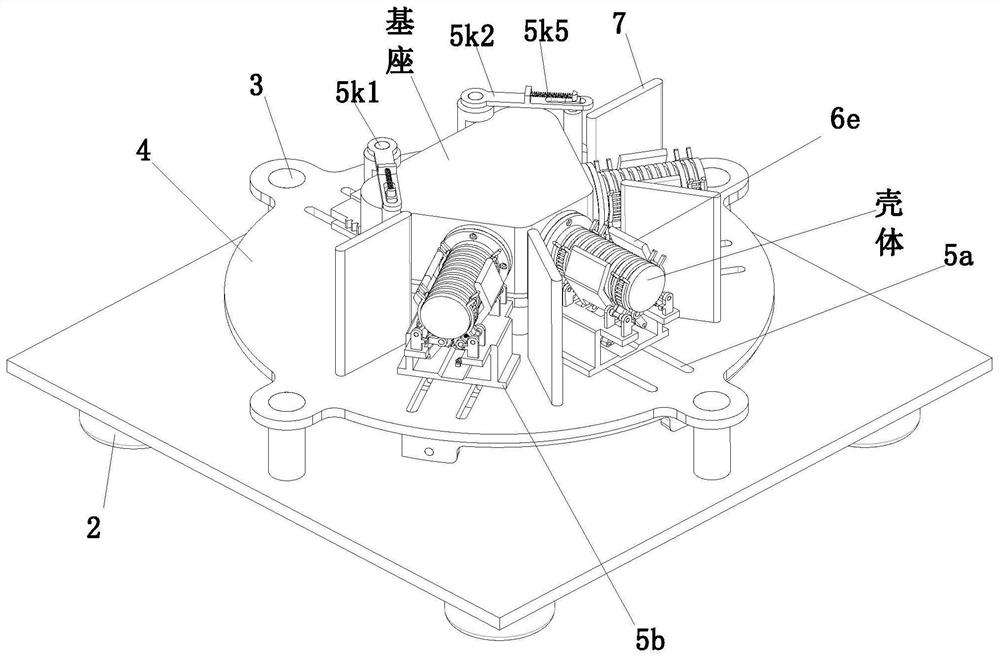

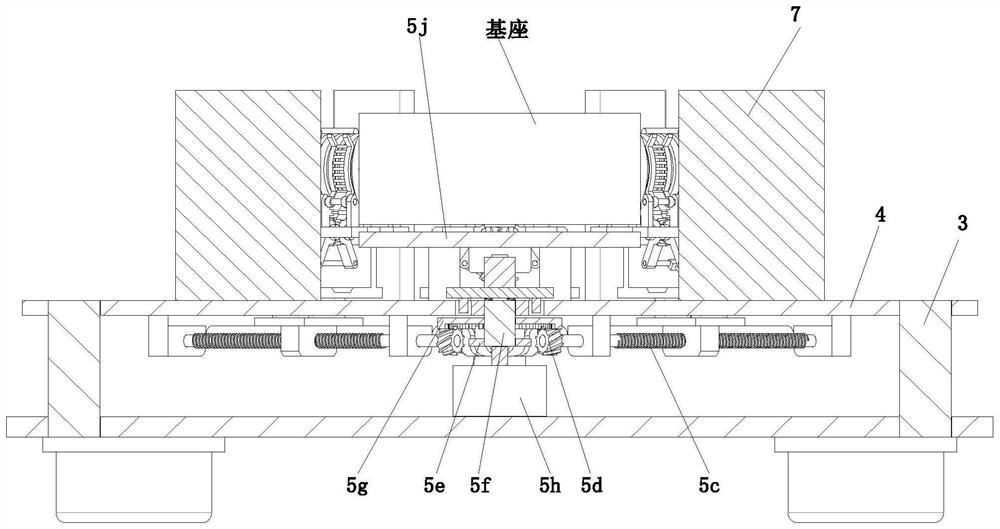

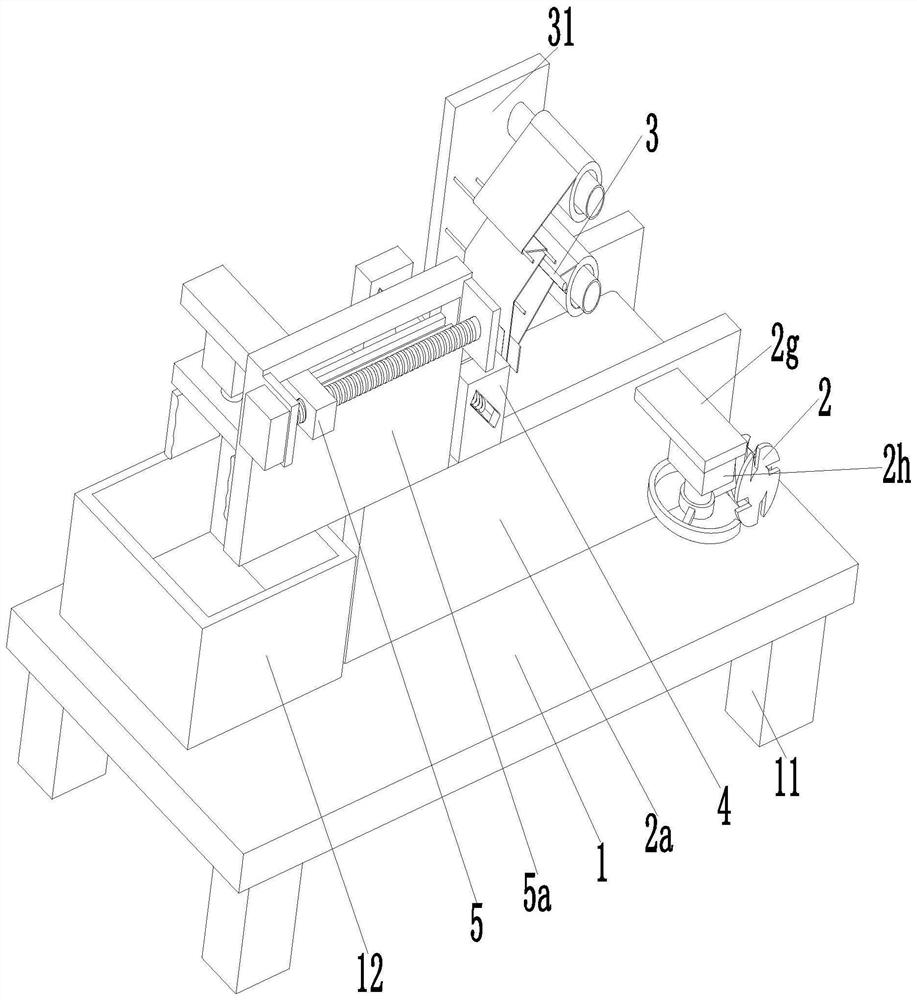

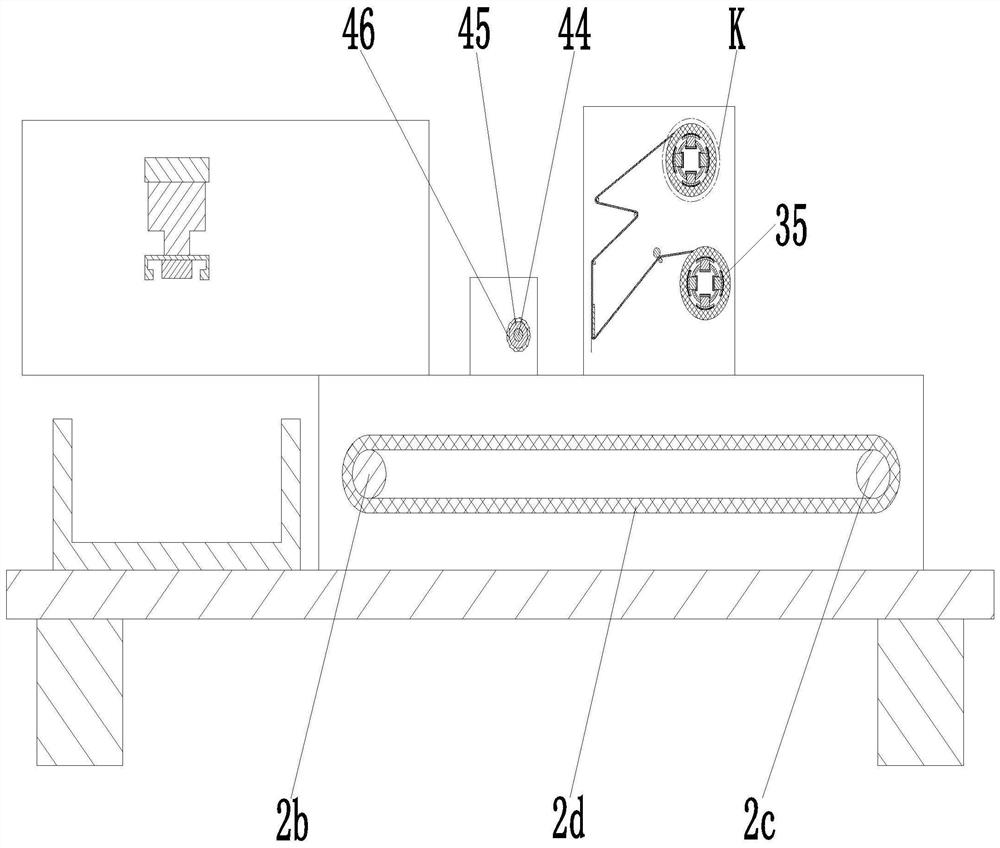

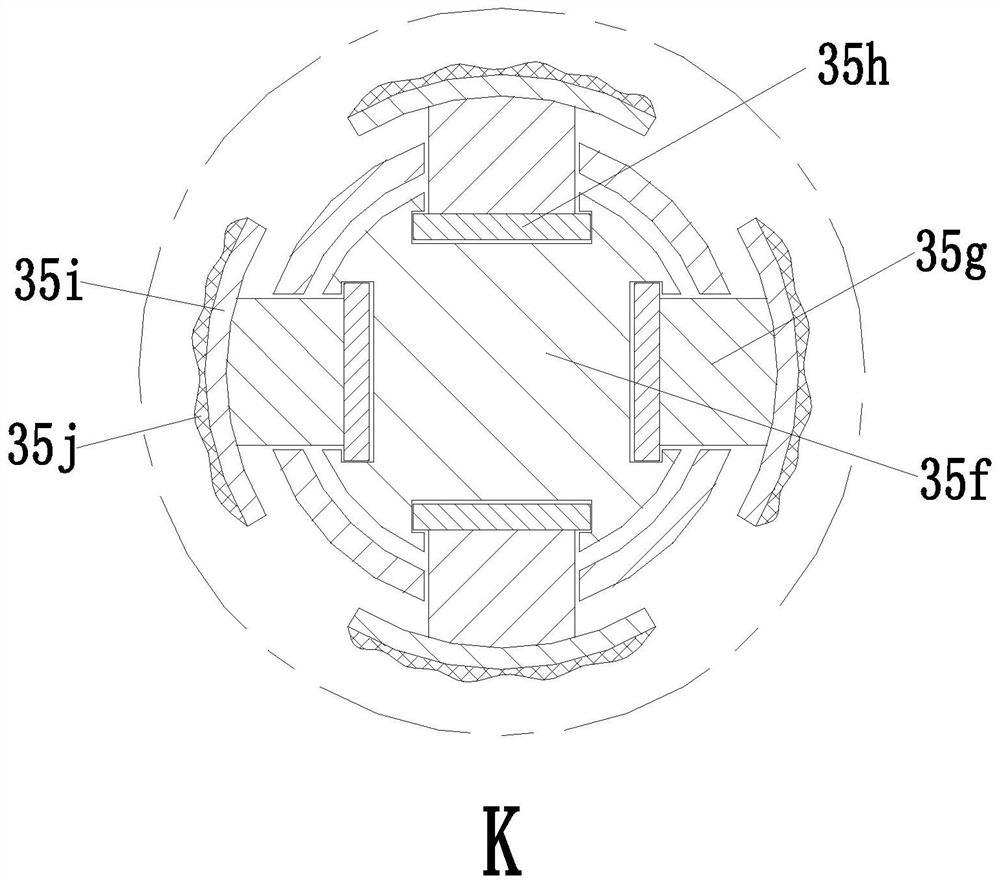

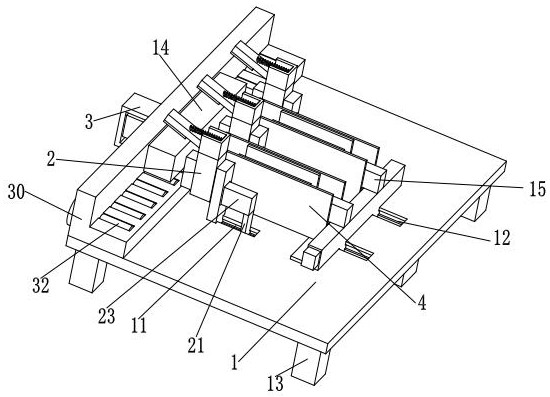

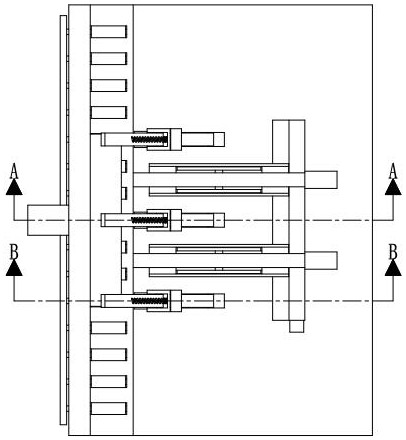

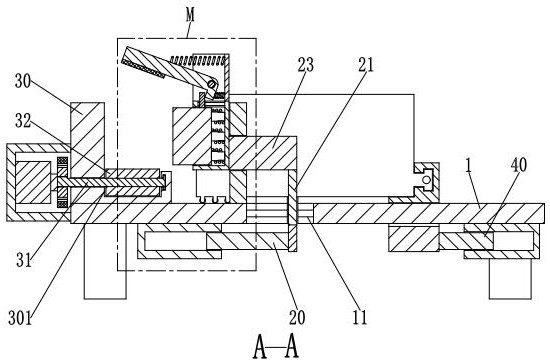

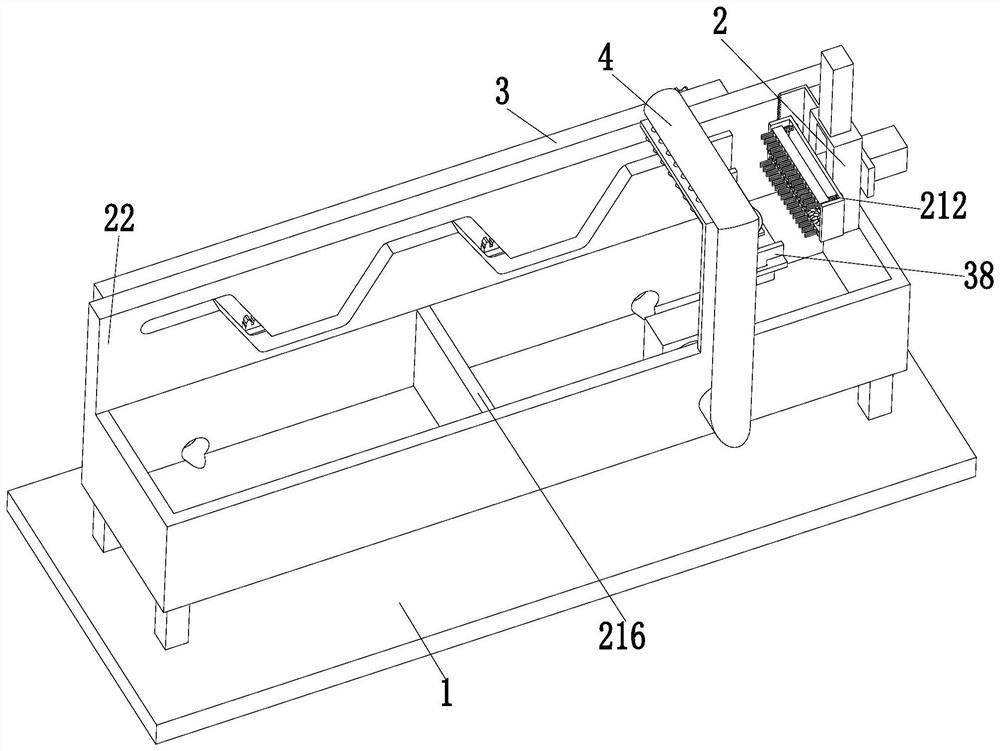

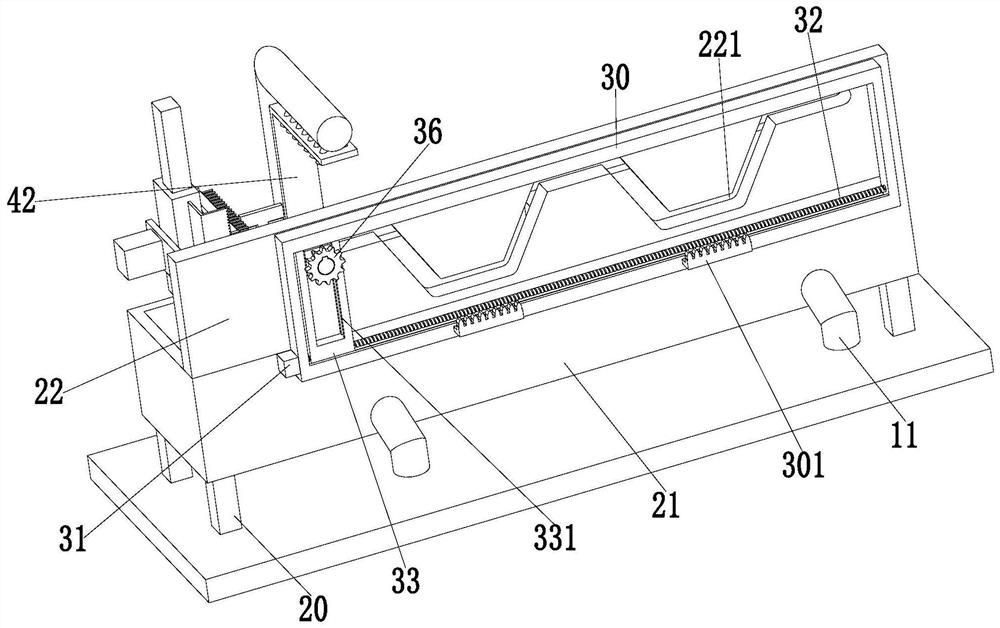

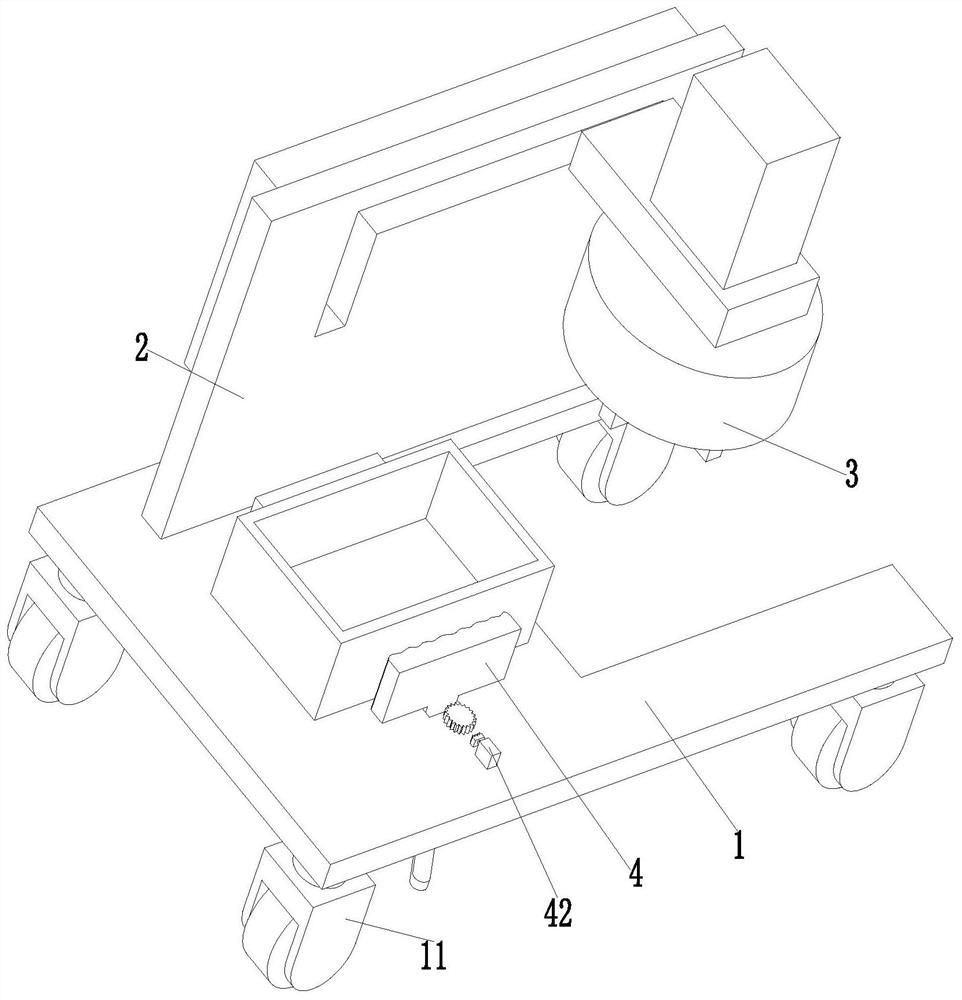

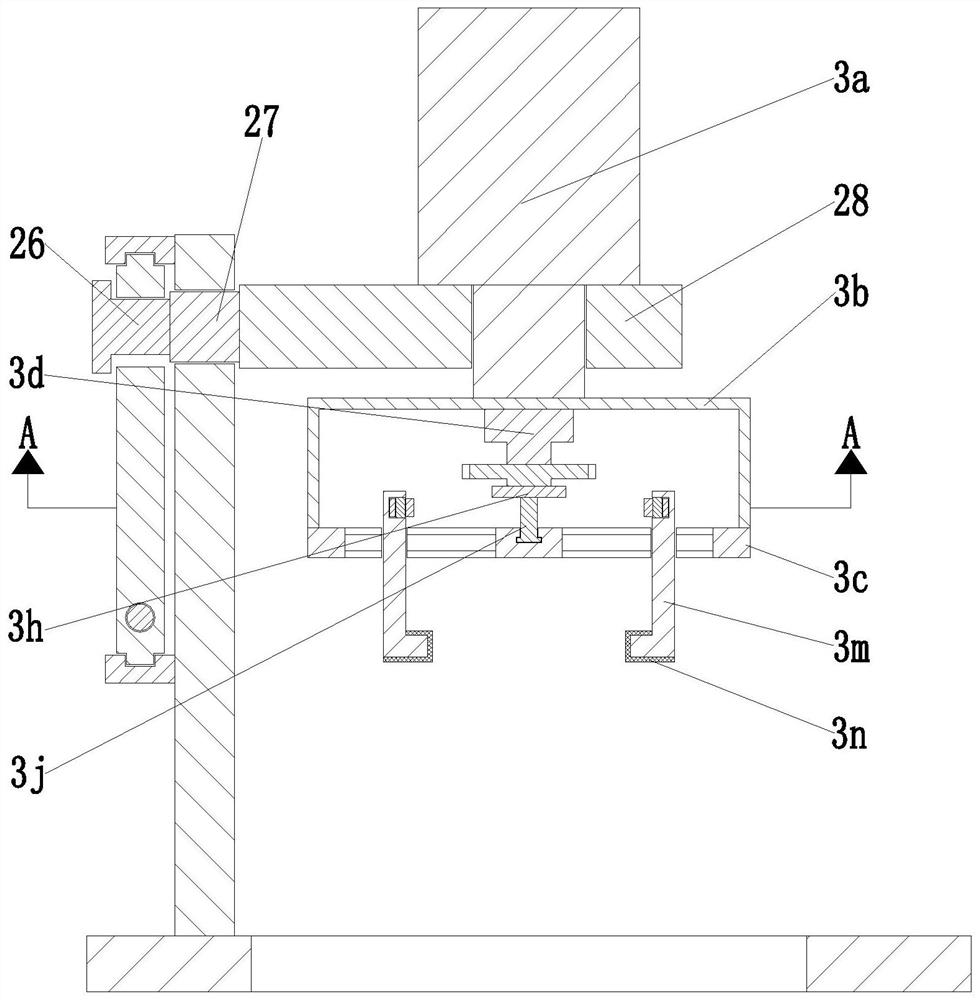

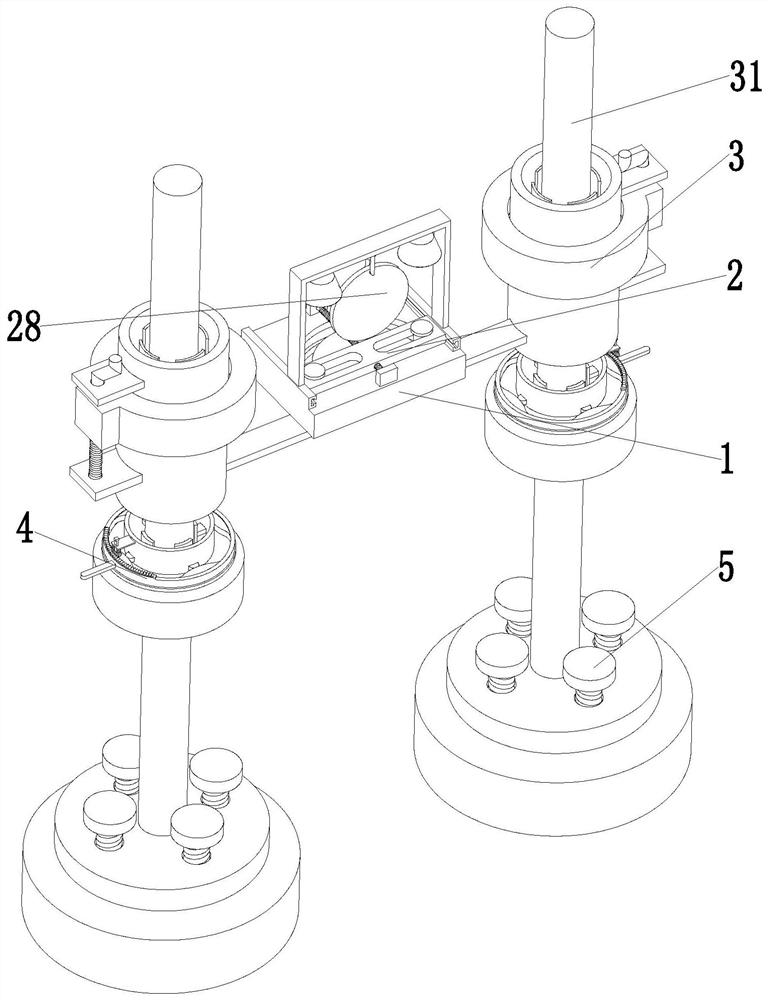

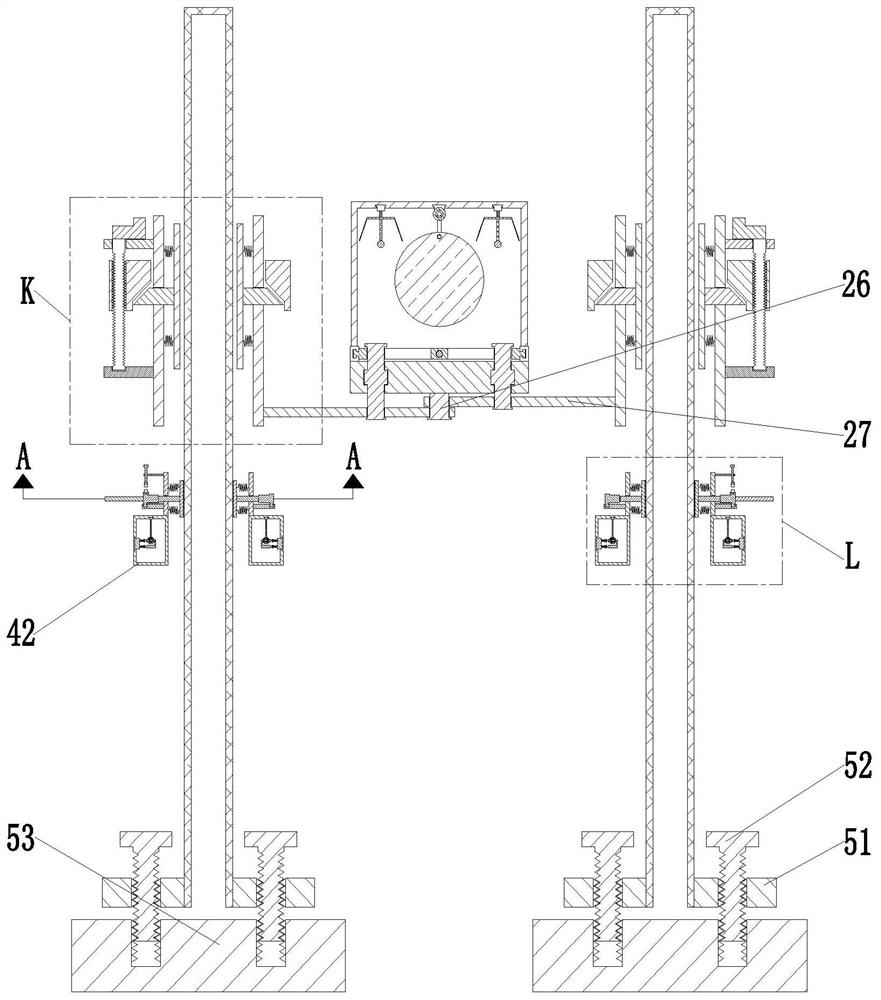

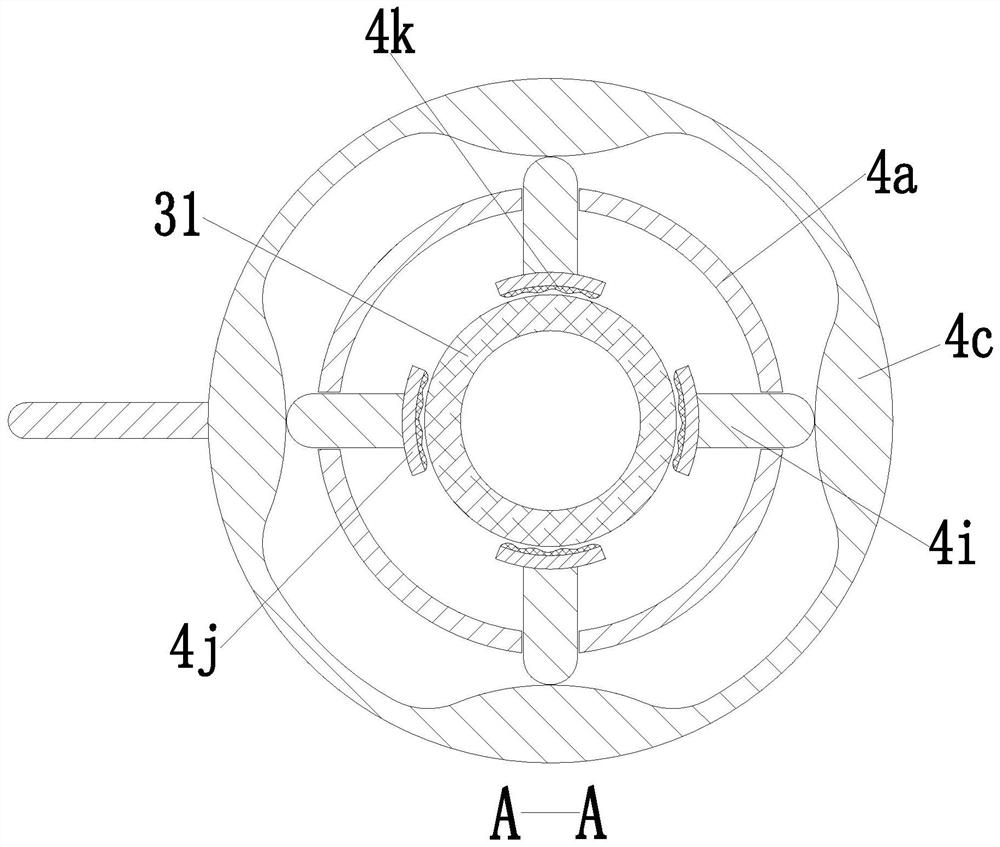

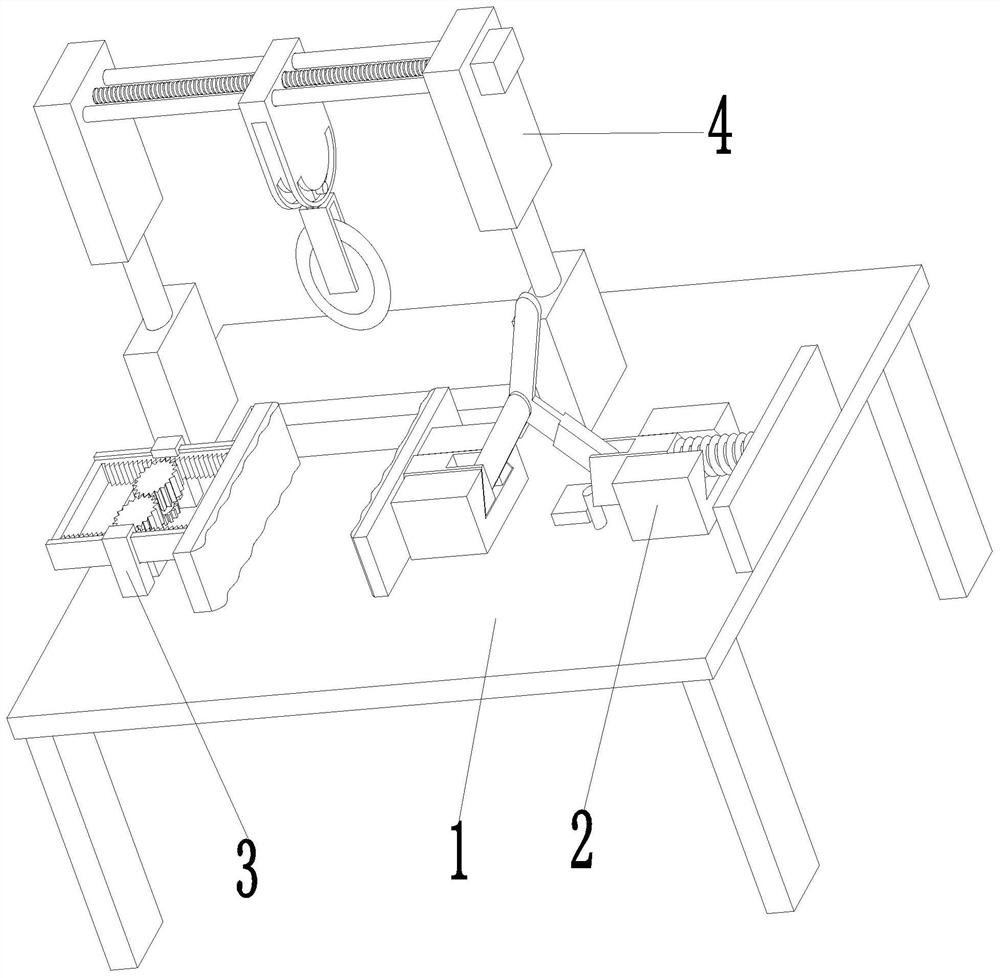

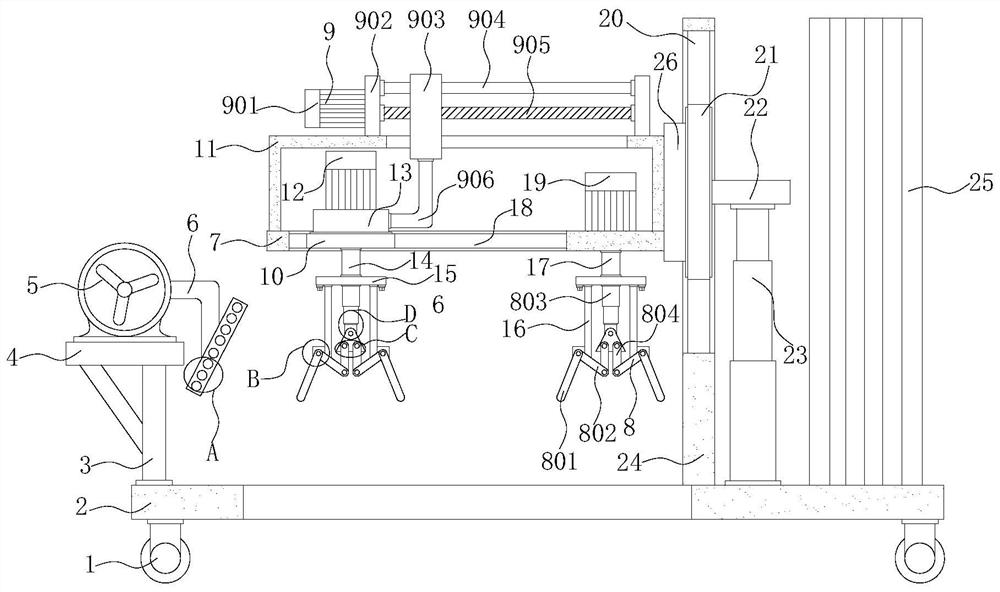

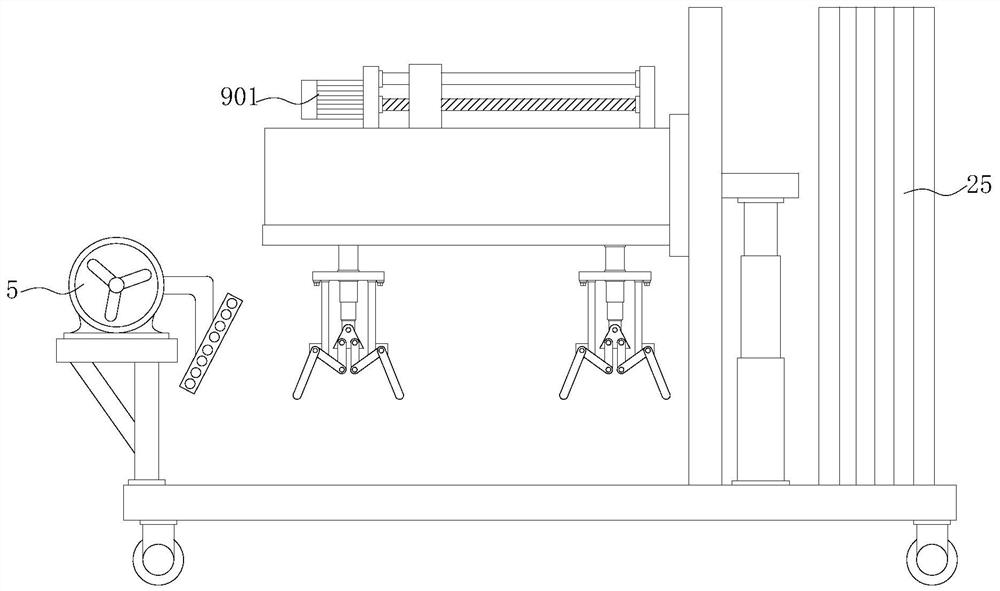

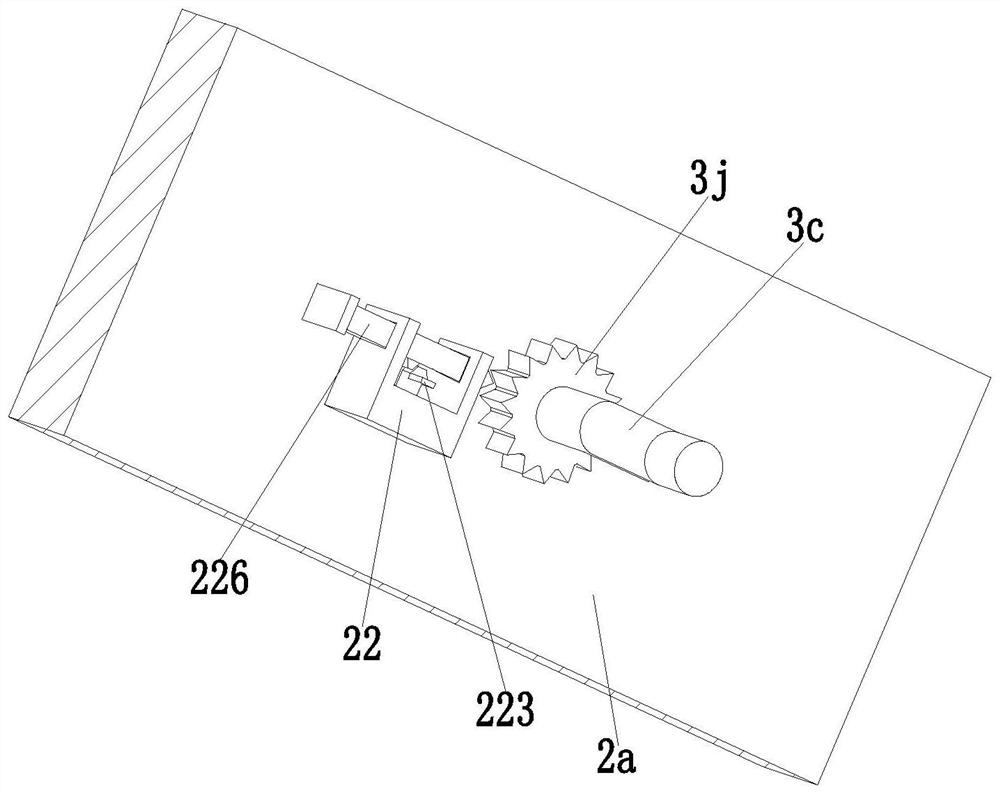

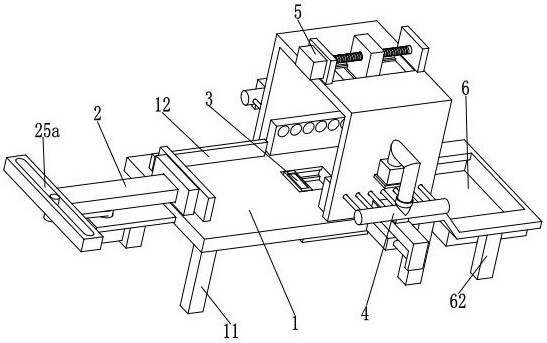

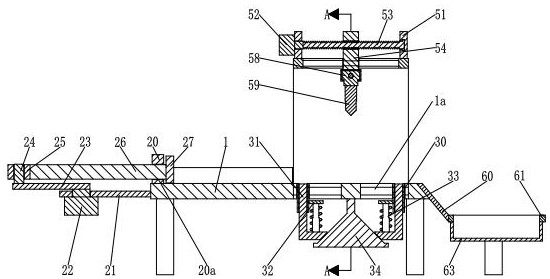

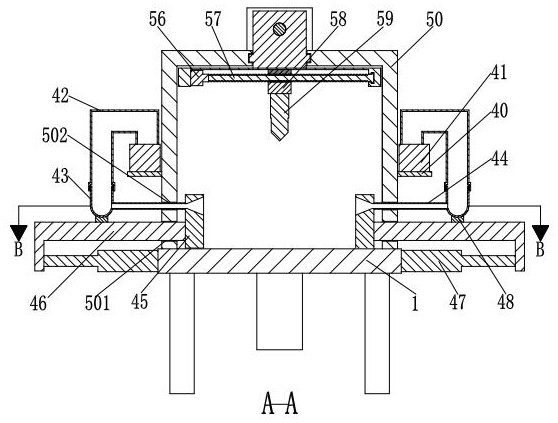

Clamping tool for automobile hub manufacturing and machining

InactiveCN113246022AImprove stabilityStable clamping workGrinding work supportsMachiningIndustrial engineering

The invention relates to a clamping tool for automobile hub manufacturing and machining. The clamping tool comprises a bottom plate, a clamping mechanism, a jacking mechanism and a clamping branched chain, the clamping mechanism is installed on the left side of the bottom plate, the jacking mechanism is installed on the right side of the bottom plate, and the clamping branched chain is installed on the jacking mechanism. The clamping tool is used for solving the following problems when an existing automobile hub is clamped: firstly, when the exterior of the traditional automobile hub is clamped, due to the fact that the outer wall of the automobile hub is smooth, the automobile hub is prone to sliding when being clamped, and manual grinding operation on the automobile hub is affected; and secondly, an existing automobile hub inner wall clamping device cannot stably clamp the interior of the automobile hub, the automobile hub can rotate during machining, and the grinding quality of the automobile hub is affected.

Owner:杨小锋

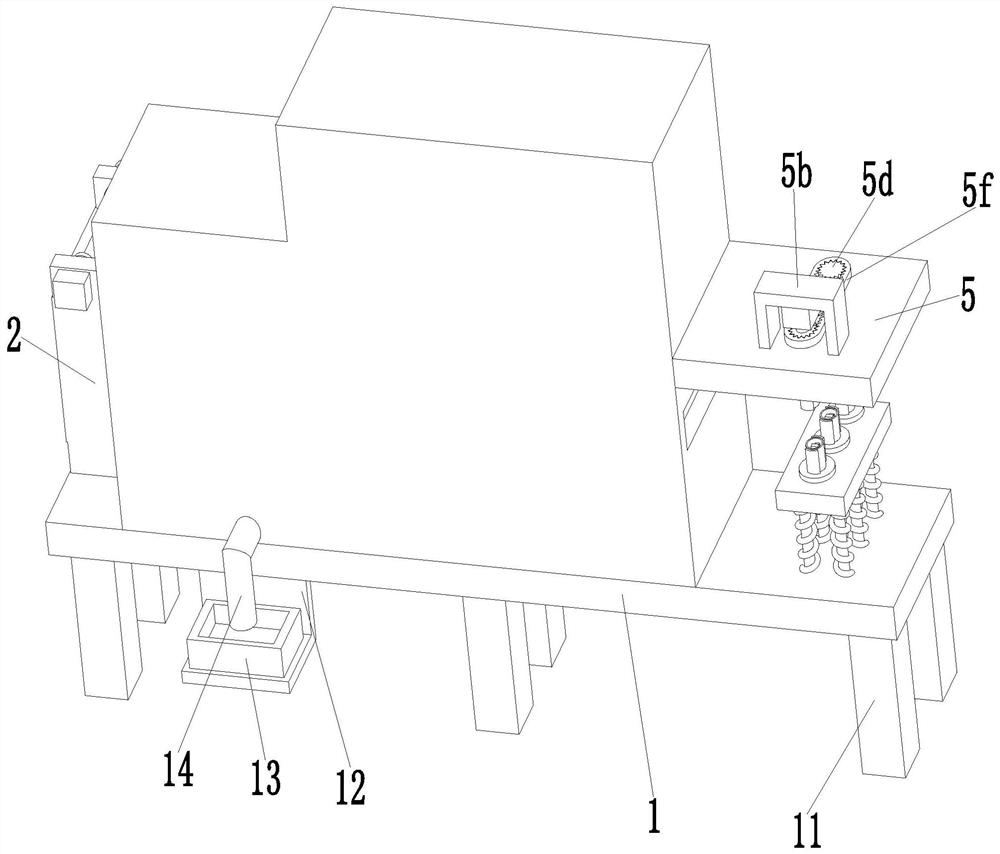

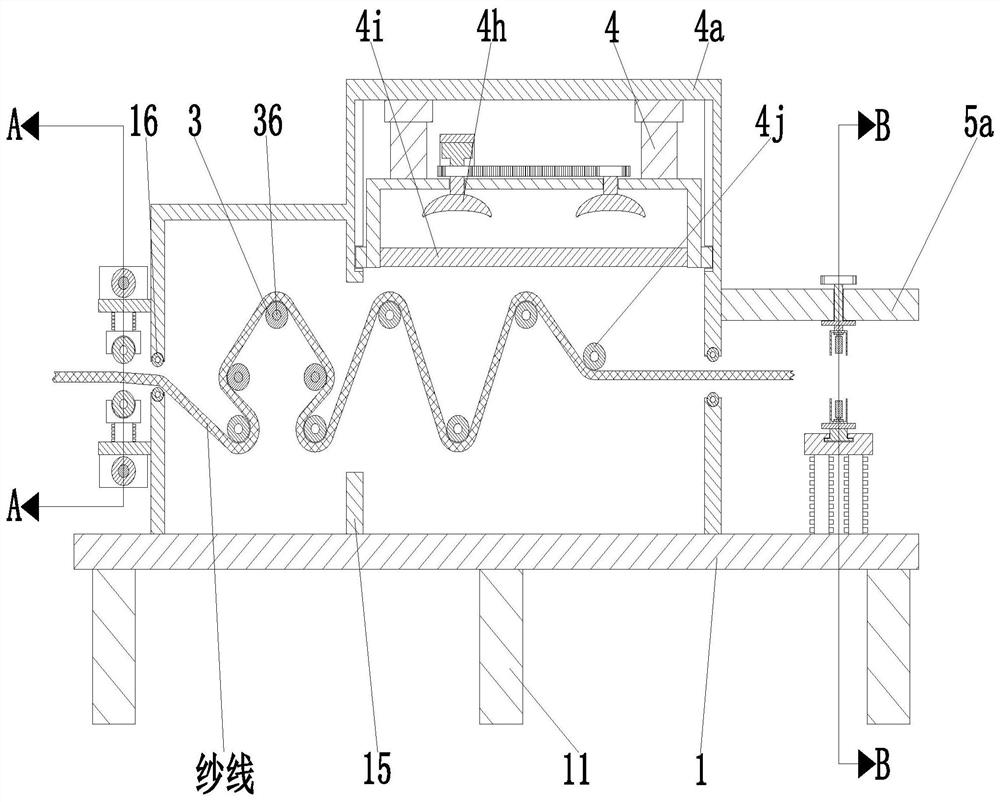

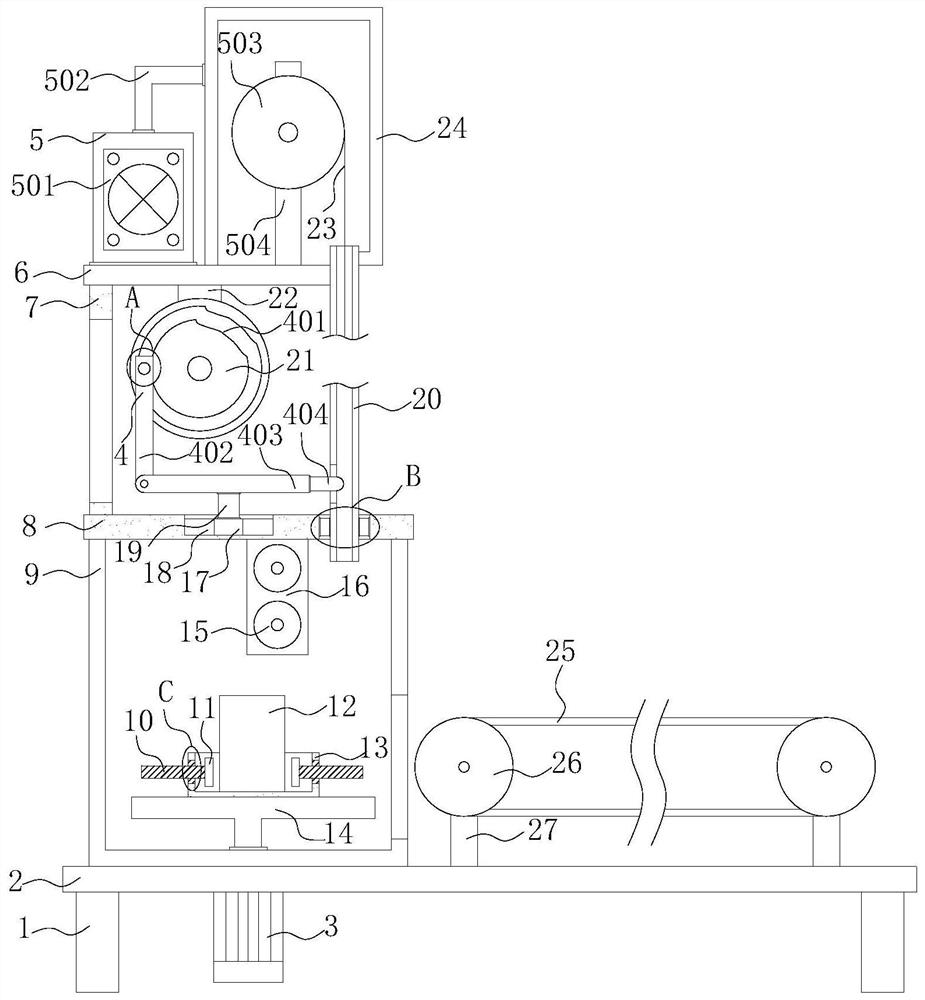

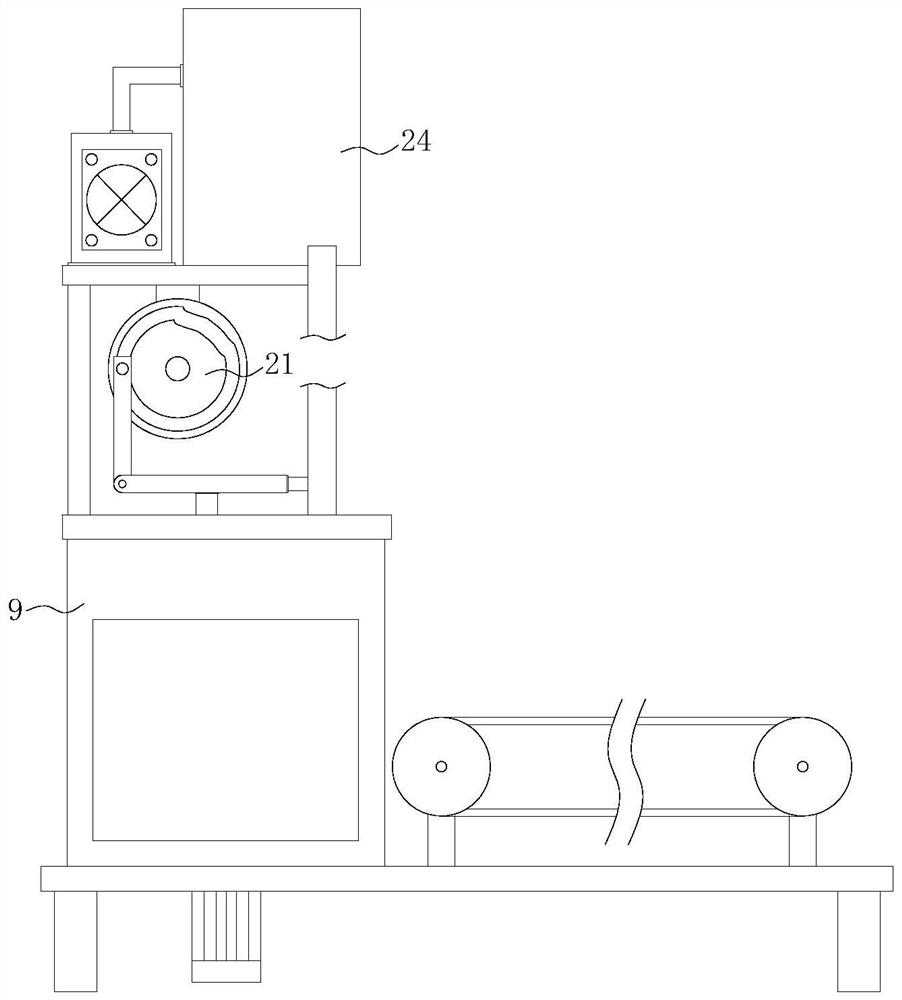

Drying and shaping system and drying and shaping process after yarn printing and dyeing

PendingCN111719268AIncrease labor intensityDecrease productivityLiquid/gas/vapor removal by squeezing rollersLiquid/gas/vapor removal by gas jetsProcess engineeringYarn

The invention relates to a drying and shaping system and drying and shaping process after yarn printing and dyeing. The system comprise a bottom plate, a wire inlet device, a dewatering device, a drying device and a wire take-up device, a drying device is arranged on the bottom plate, the wire inlet device is arranged at the left end of the drying device, the wire take-up device is arranged at theright end of the drying device, and the dewatering device is arranged in the drying device. The system and the process can solve the following problems when existing yarns are dried after printing and dyeing that firstly, traditional yarn drying needs to use a drying machine, and when the drying machine dries the yarns, materials of the yarns are uneven, and the deformation of the materials is prone to causing; and secondly, an existing drying device cannot quickly dry the cloth, the yarns can be wrinkled in the drying process, the collection and the attractiveness are not facilitated, the drying degree of the surface of the yarns is not uniform, the yarns need to be heated and dried twice by a user, the labor intensity of workers is enhanced, the working efficiency of yarn drying is reduced, and the efficiency and the effect of the yarn drying are improved.

Owner:黄远明

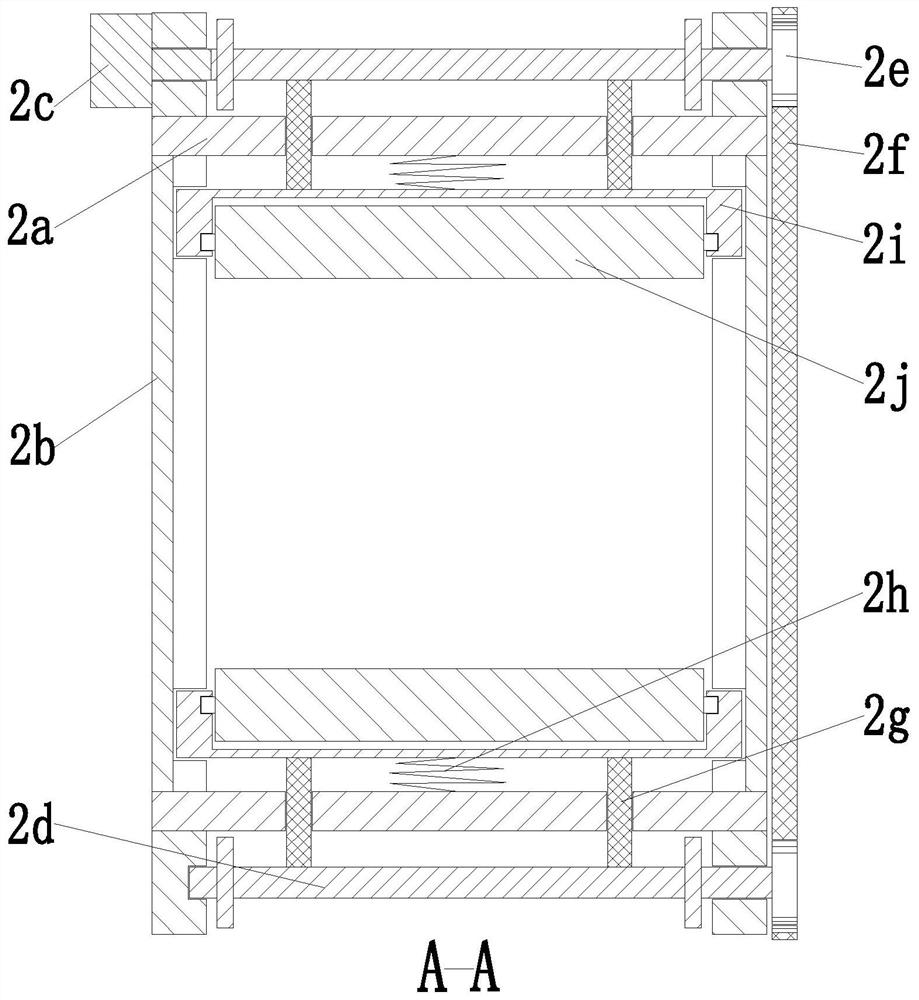

Grinding device and grinding process for formed metal product

ActiveCN113385993AStable clamping workNo movementRevolution surface grinding machinesGrinding drivesElectric machineryEngineering

The invention relates to the technical field of metal product grinding, in particular to a grinding device and a grinding process for a formed metal product, the grinding device comprises a supporting circular plate, a rotating mechanism, a grinding mechanism and a clamping mechanism, the rotating mechanism is mounted on the supporting circular plate, the grinding mechanism is mounted on the rotating mechanism, and the clamping mechanism is mounted on the outer wall of the left end of the supporting circular plate; according to the designed clamping mechanism, a transmission threaded rod is driven by a fourth motor to rotate, the transmission threaded rod drives a clamping arc plate through an L-face sliding plate so that a metal bent pipe can abut against a clamping plate, and under the abutting action of an abutting spring rod, the clamping plate and the clamping arc plate can stably clamp the metal bent pipe; and the phenomenon that the metal bent pipe moves during grinding is avoided, and convenience is provided for grinding of the inner wall of the metal bent pipe.

Owner:新沂市振港金属制品有限公司

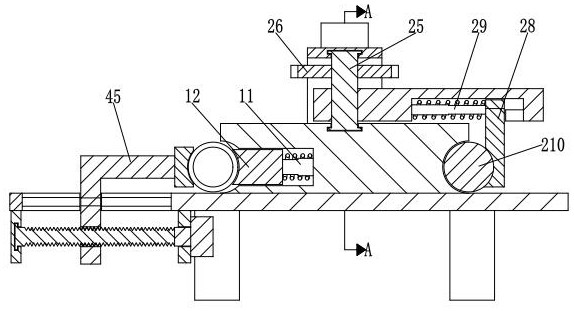

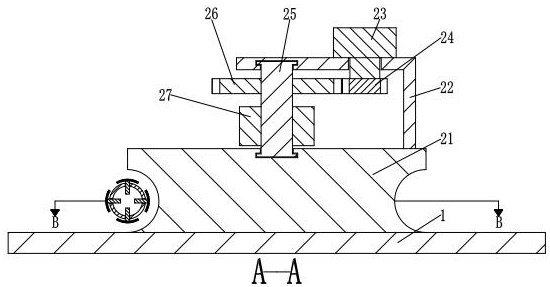

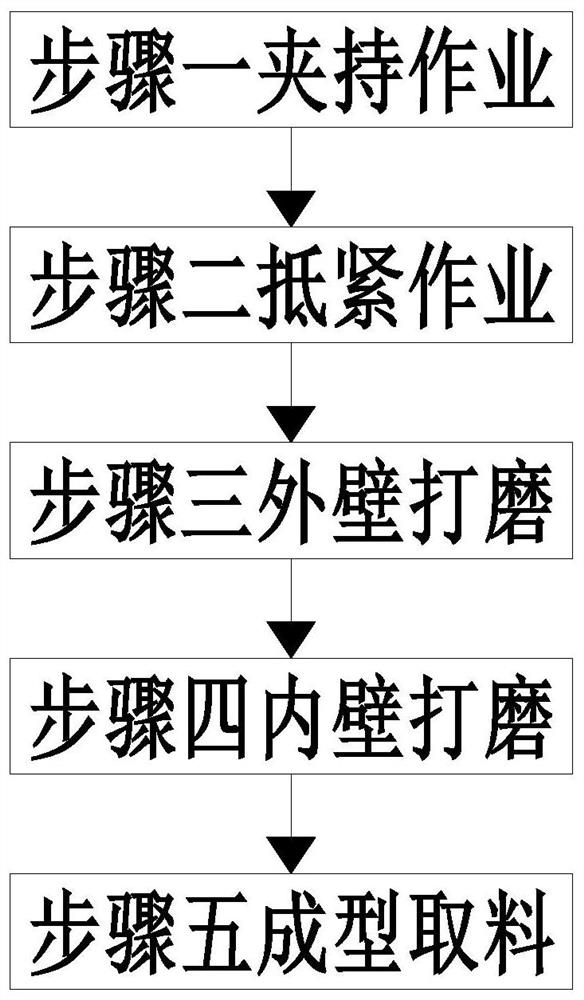

Manufacturing and machining method of micro engine

PendingCN113021088AReduce sanding qualityImprove stabilityRevolution surface grinding machinesGrinding work supportsMachiningIndustrial engineering

The invention relates to a manufacturing and machining method of a micro engine. The method mainly comprises the following steps of clamping operation, abutting operation, outer wall grinding, inner wall grinding, forming and material taking and the like, and used cylinder sleeve grinding equipment comprises a bottom plate, a propelling device, a clamping device and a grinding device. According to the method, the following problems existing during existing cylinder sleeve grinding can be solved: a, when a traditional cylinder sleeve is ground, the cylinder sleeve is mostly ground by manually holding a grinding tool, the grinding manner has relatively large potential safety hazards, the manual grinding efficiency is relatively low, the production efficiency of the cylinder sleeve is influenced, grinding errors are easily generated during manual grinding, and the use of the cylinder sleeve is influenced; and b, due to the fact that existing cylinder sleeve grinding equipment cannot conduct comprehensive grinding operation on the cylinder sleeve, flaws exist when the cylinder sleeve is ground, and the grinding quality of the cylinder sleeve is reduced.

Owner:张义

Food production bacterium content detector

ActiveCN112067763AImprove detection resultsEasy to detectShaking/oscillating/vibrating mixersTransportation and packagingBiotechnologyFood safety

The invention relates to a food production bacterium content detector which comprises a bottom plate, a vibrating device, a rotating device and an adjusting device, wherein the vibrating device is installed at the left end of the bottom plate, the rotating device is installed on the vibrating device, and the adjusting device is installed on the rotating device. The food production bacterium content detector can solve the following problems existing when an existing food production bacterium content detector conducts safety detection on food: 1, a traditional food production bacterium content detector cannot stably clamp a detection test tube, so that the detection test tube falls off during detection, the detection test tube is frequently broken by clamping, and the use of the detector isinfluenced; and 2, an existing food production bacterium content detector can only perform single detection operation on a detection test tube, is inconvenient to use and inaccurate in detection data,influences the detection result of food safety detection, and can improve the detection result of food safety detection.

Owner:GUANGDONG JIASHILI FOOD GRP CO LTD

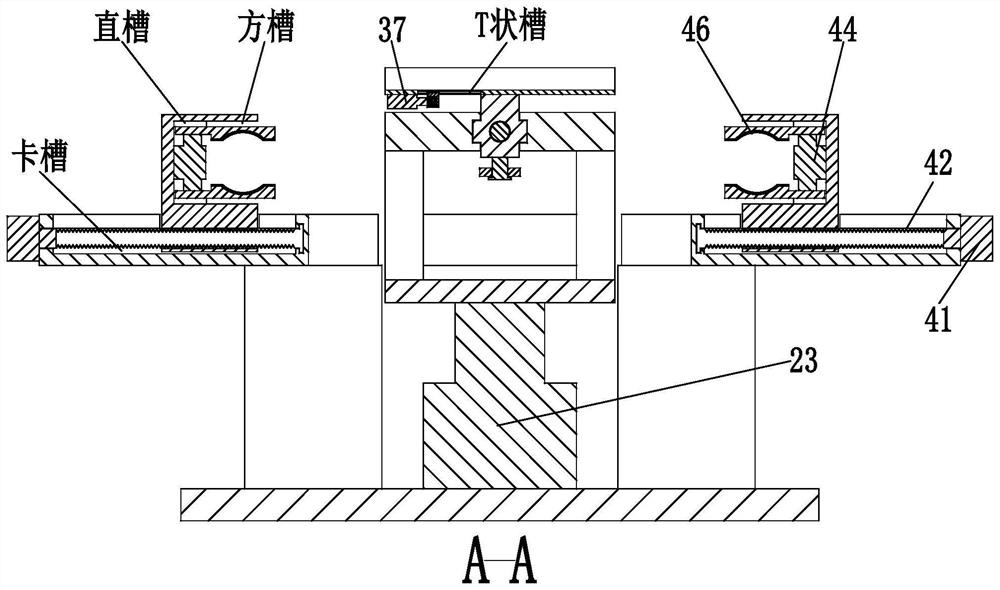

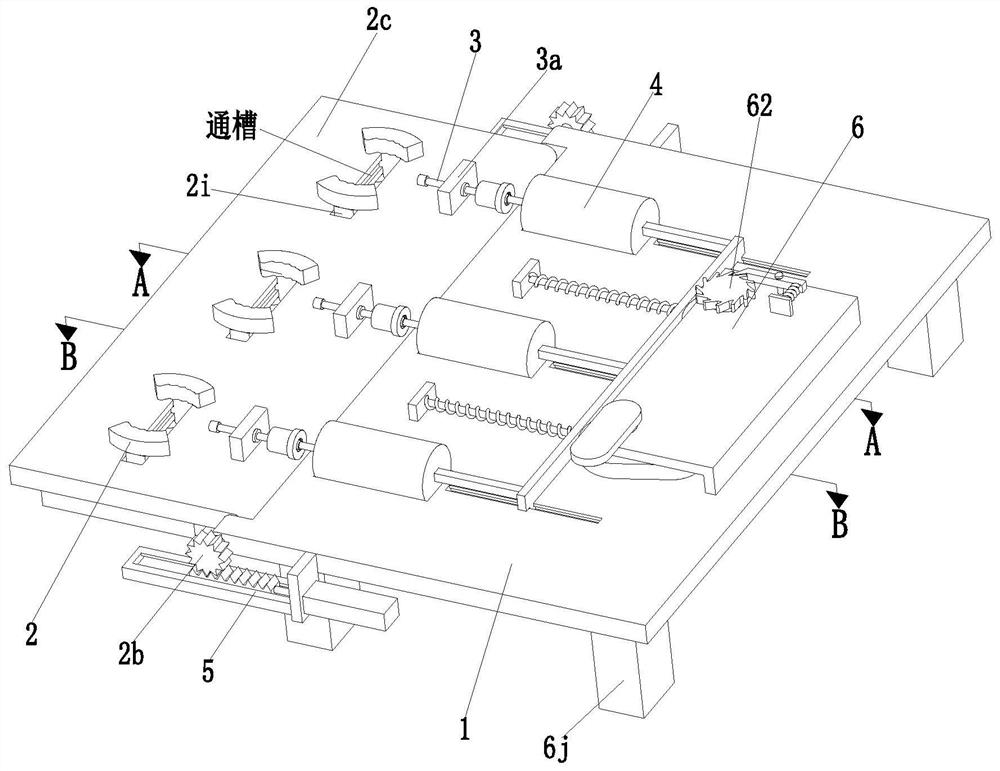

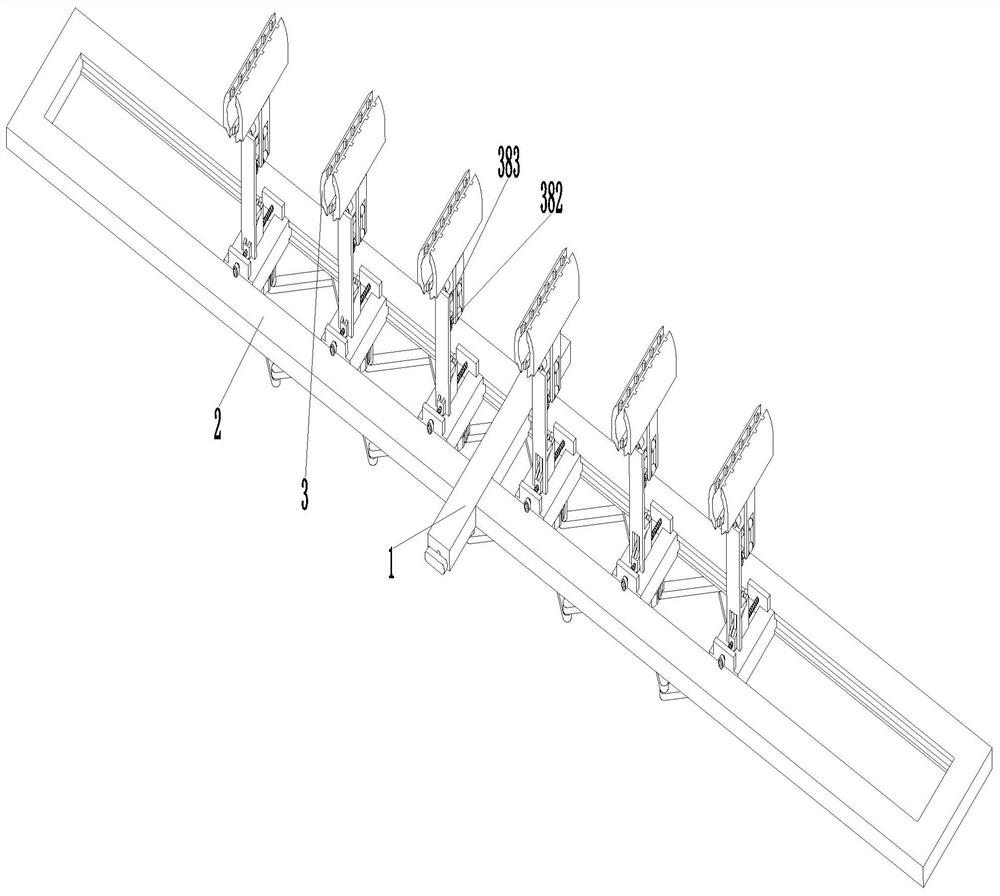

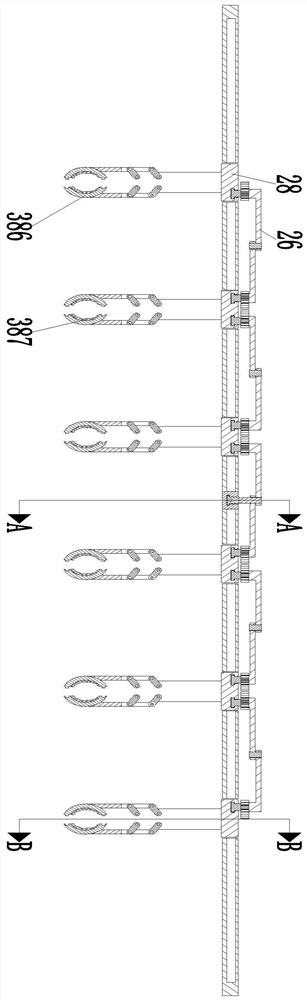

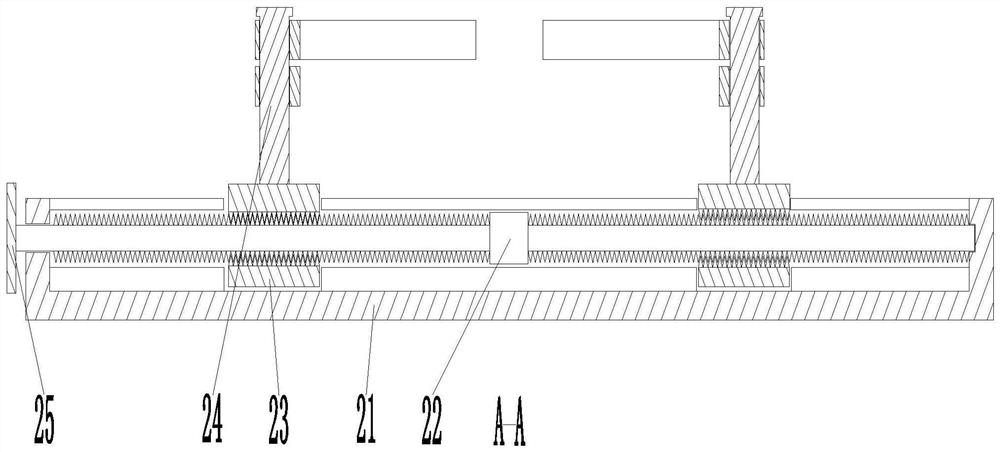

Municipal traffic isolation guardrail manufacturing and assembling auxiliary tool

ActiveCN113352045AImprove welding efficiency and qualityAvoid welding qualityWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringMechanical engineering

The invention relates to a municipal traffic isolation guardrail manufacturing and assembling auxiliary tool. The municipal traffic isolation guardrail manufacturing and assembling auxiliary tool comprises a bottom plate, an adjusting device, a clamping device and a positioning device. The adjusting device is installed on the bottom plate, and the clamping device and the positioning device are installed on the adjusting device. The municipal traffic isolation guardrail manufacturing and assembling auxiliary tool can solve the following problems existing when an existing traffic isolation guardrail is assembled and welded: firstly, when a traditional traffic isolation guardrail is assembled and welded, guardrail cross beams and guardrail vertical beams need to be assembled together by workers, one worker needs to hold connecting and welding positions, the other worker needs to conduct welding operation, and the welding and assembling mode is low in efficiency and wastes labor force; and secondly, when the existing traffic isolation guardrail is welded, due to the fact that manual positioning is unstable, the traffic isolation guardrail is dislocated in the welding process, and the welding quality of the traffic isolation guardrail is reduced.

Owner:CHUZHOU UNIV

Automatic processing and verifying device for measurement and detection standard meter assembly

InactiveCN113358278AReduce connection efficiencyReduce detection and verification efficiencyFluid pressure measurementAutomatic processingElectrical and Electronics engineering

The invention relates to an automatic processing verification device for a metering detection standard meter assembly, which comprises a bottom plate, a clamping mechanism, a connecting mechanism, an air inlet mechanism, rotating mechanisms and a pushing mechanism, the clamping mechanism is installed on the bottom plate, the connecting mechanism is installed on the clamping mechanism, the rotating mechanisms are installed on the outer walls of the front end and the rear end of the bottom plate, the pushing mechanism is installed at the right end of the bottom plate, and the air inlet mechanism is installed on the pushing mechanism. The automatic processing verification device can solve the following problems existing during detection and verification of an existing pressure gauge: 1, during detection and verification of a pressure gauge, the pressure gauge cannot be stably positioned, so that the pressure gauge moves during detection and verification, the connection between an air inlet pipe and a pressure gauge connector is relatively complicated and unstable, so that the reading of a pressure gauge is inaccurate, and the judgment of detection personnel is influenced; and 2, the existing pressure gauge detection and verification equipment can only detect and verify a single pressure gauge, so that the detection and verification efficiency of the pressure gauge is reduced.

Owner:郑大勇

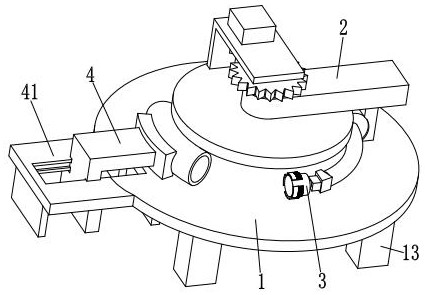

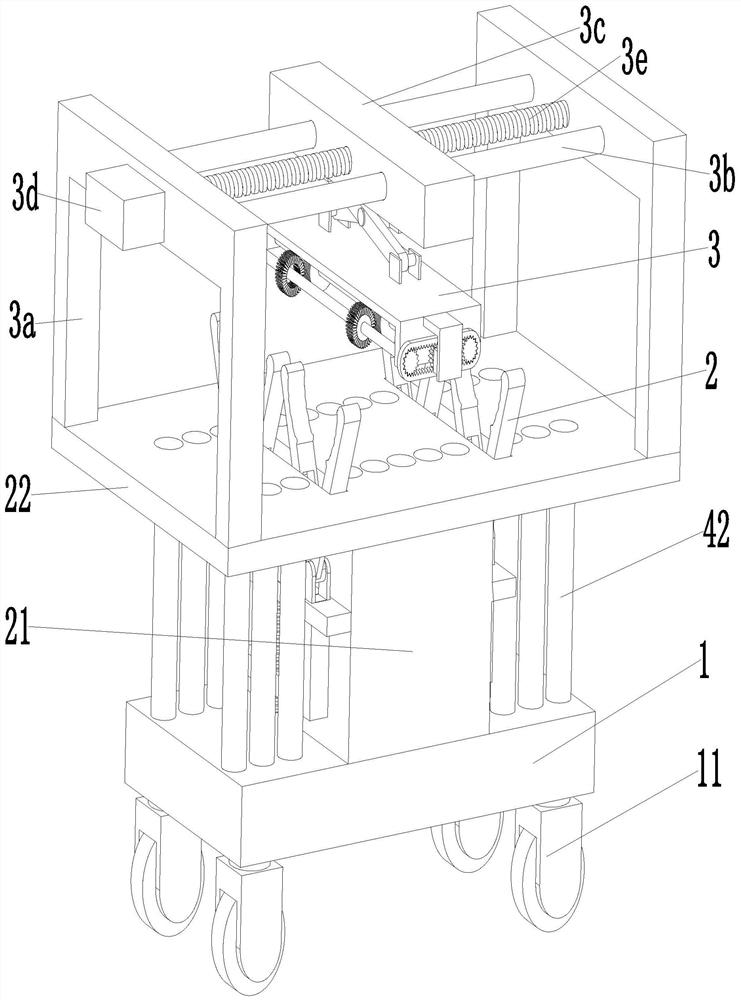

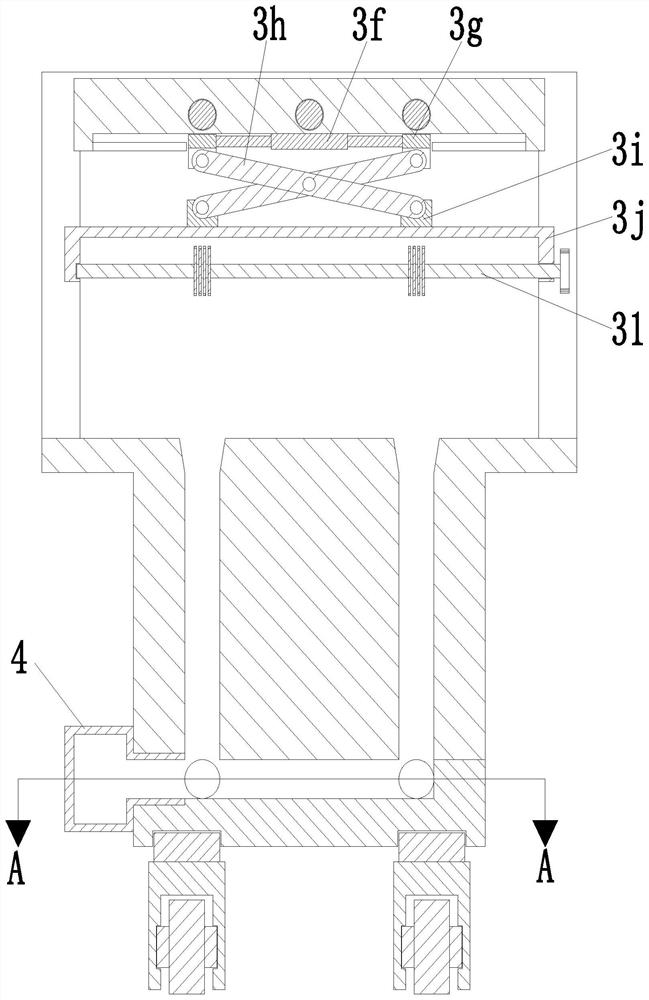

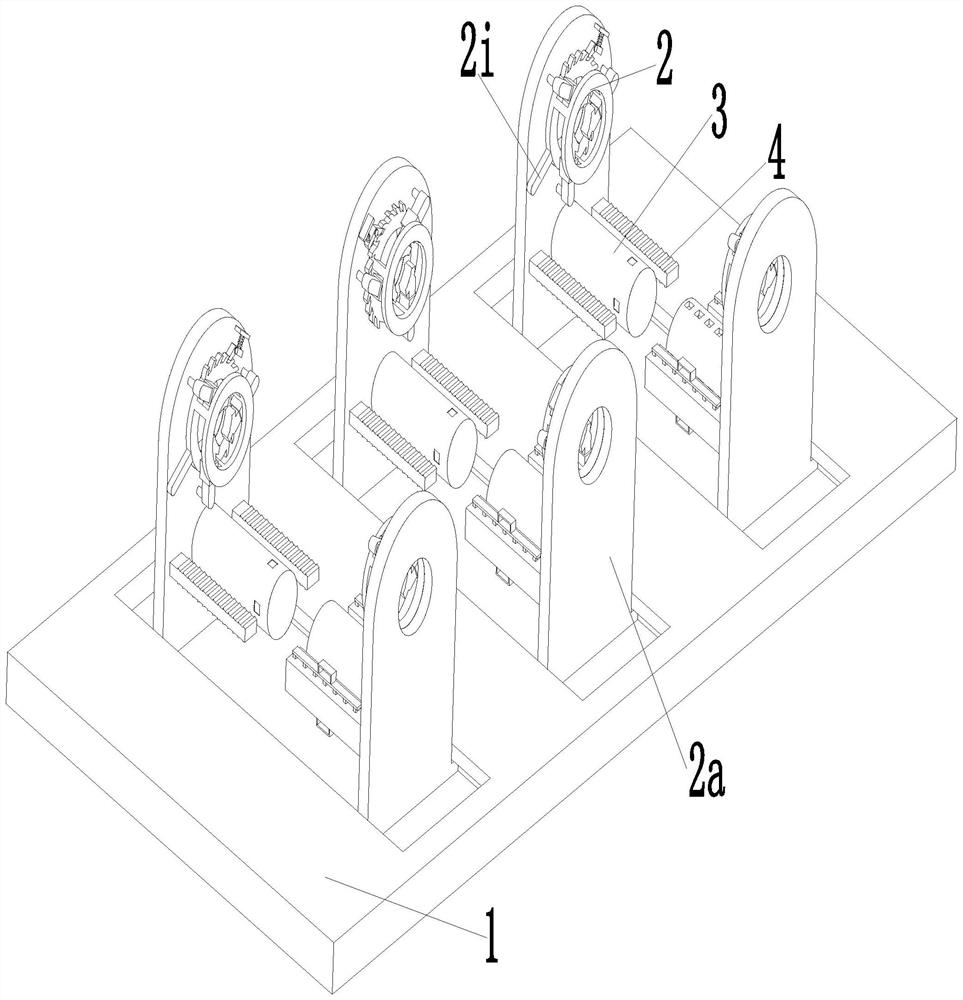

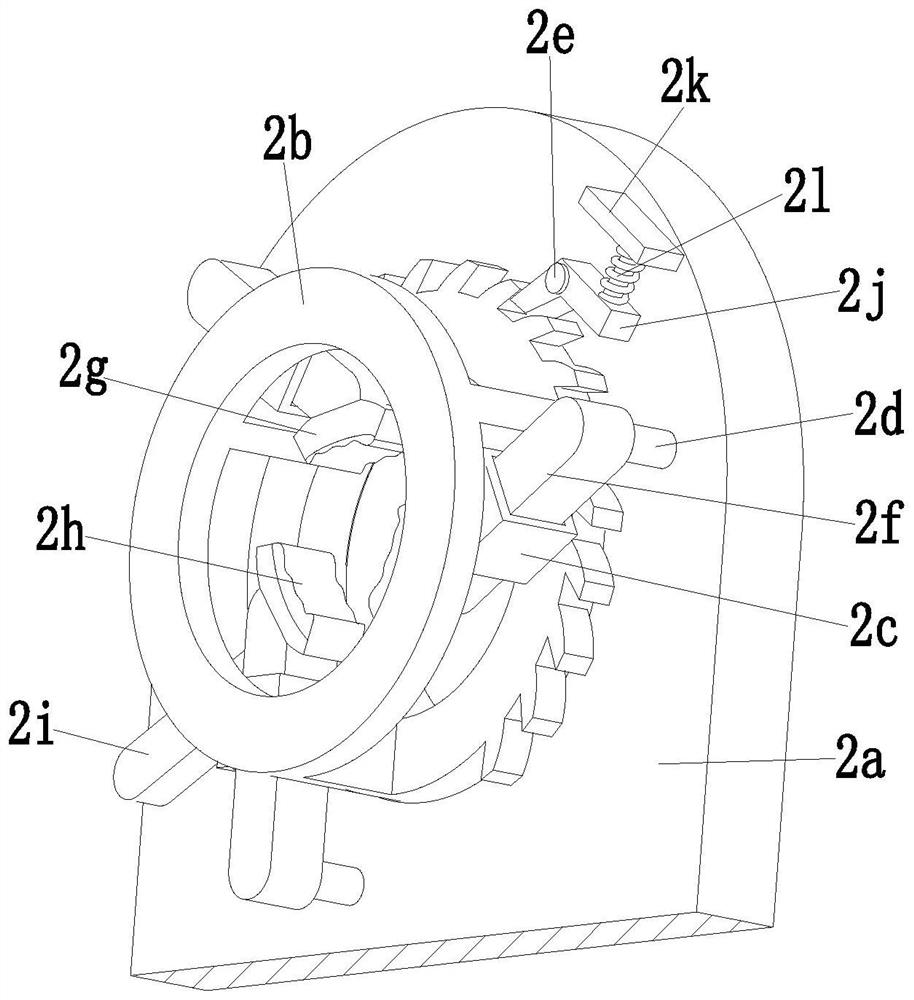

Piston air compressor pump head assembling machinery and assembling method

InactiveCN113263306AReduces the possibility of wobble deflectionHigh precisionWork holdersMetal working apparatusEngineeringPump head

The invention provides piston air compressor pump head assembling machinery and an assembling method. The piston air compressor pump head assembling machinery comprises a mounting bottom plate, supporting legs, supporting rods, a supporting disc, a positioning mechanism, clamping mechanisms and partition plates. By means of the piston air compressor pump head assembling machinery and the assembling method, the problems that piston air compressor pump head assembling operations are difficult to adapt to the radian change of the outer wall of a pump head base seat, and multi-station stable clamping operations can not be provided for the pump head base seat, the possibility that the pump head base seat shakes and deflects due to mechanical vibration is increased, the heights of the two ends of a pump head shell are also difficult to keep consistent while the pump head shell is stably clamped, mounting hole positions between the pump head base seat and the pump head shell are difficult to be quickly and accurately aligned and mounted, batch continuous operations are difficult to perform, and the operation difficulty of the positioning operations of the mounting hole positions is increased can be solved.

Owner:陈新海

Intelligent labeling system for logistics labels

InactiveCN112173329ALow efficiencyGood labeling effectLabelling machinesLogistics managementProcess engineering

The invention relates to an intelligent labeling system for logistics labels. The system involves a bottom plate, a conveying mechanism, a labeling mechanism, a smoothing mechanism and a material taking mechanism, wherein the conveying mechanism is arranged on the bottom plate, the labeling mechanism is arranged at the right end of the conveying mechanism, the smoothing mechanism is arranged in the middle of the conveying mechanism, and the material taking mechanism is arranged at the left end of the conveying mechanism. The system can solve the following problems existing in existing logistics packaging box labeling that firstly, traditional manual labeling needs label stripping, position approval, labeling and other procedures, so that the procedures are numerous, much time is consumed for manual labeling, and the labeling efficiency is reduced; and during manual labeling, many errors are caused by human factors, so that the positions of the labels of logistics packaging boxes are different, and the subsequent use is influenced; and secondly, during traditional machine labeling, the phenomenon of unstable labeling is prone to occur; and the system can realize an intelligent labeling function, and has the advantages that the labeling effect is good, the working efficiency is high and the like.

Owner:深圳市兴耀扬科技有限公司

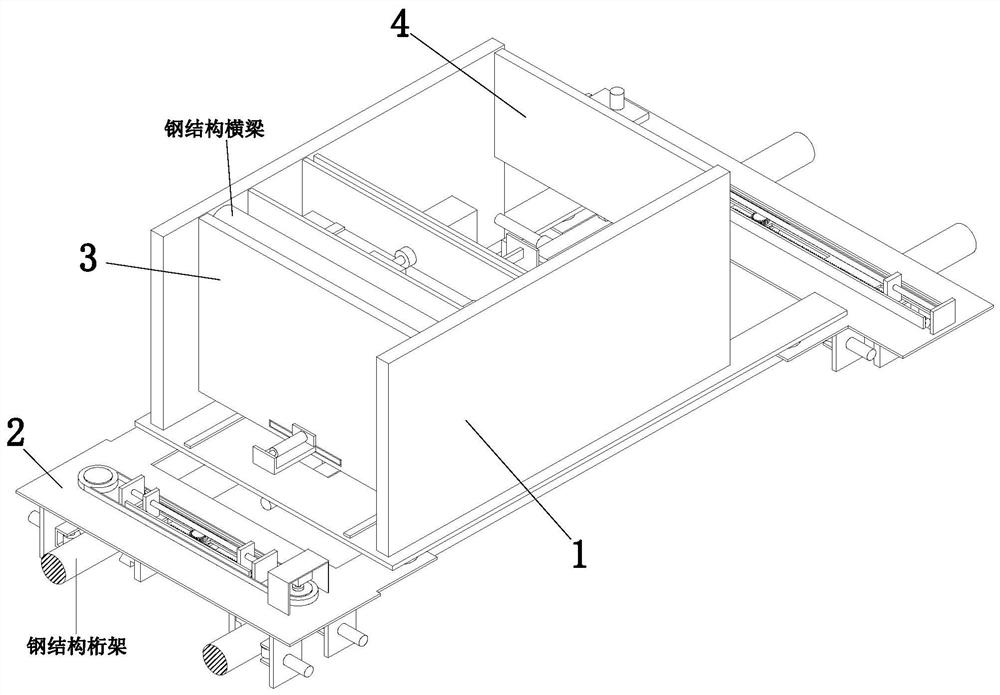

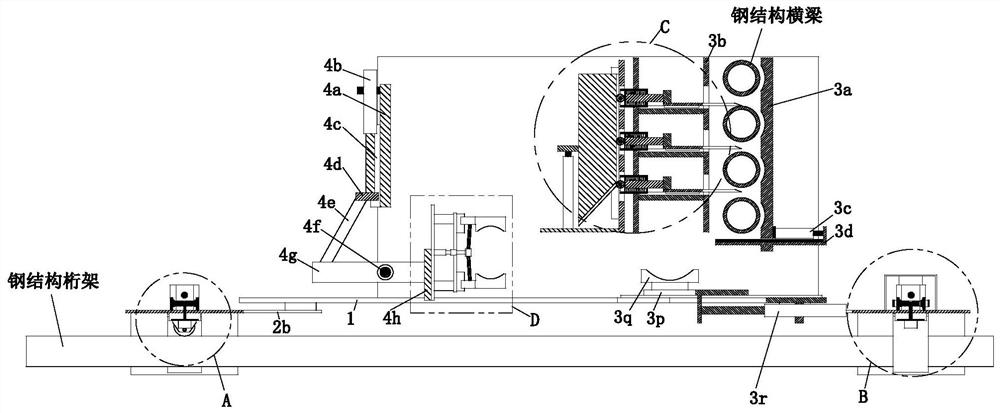

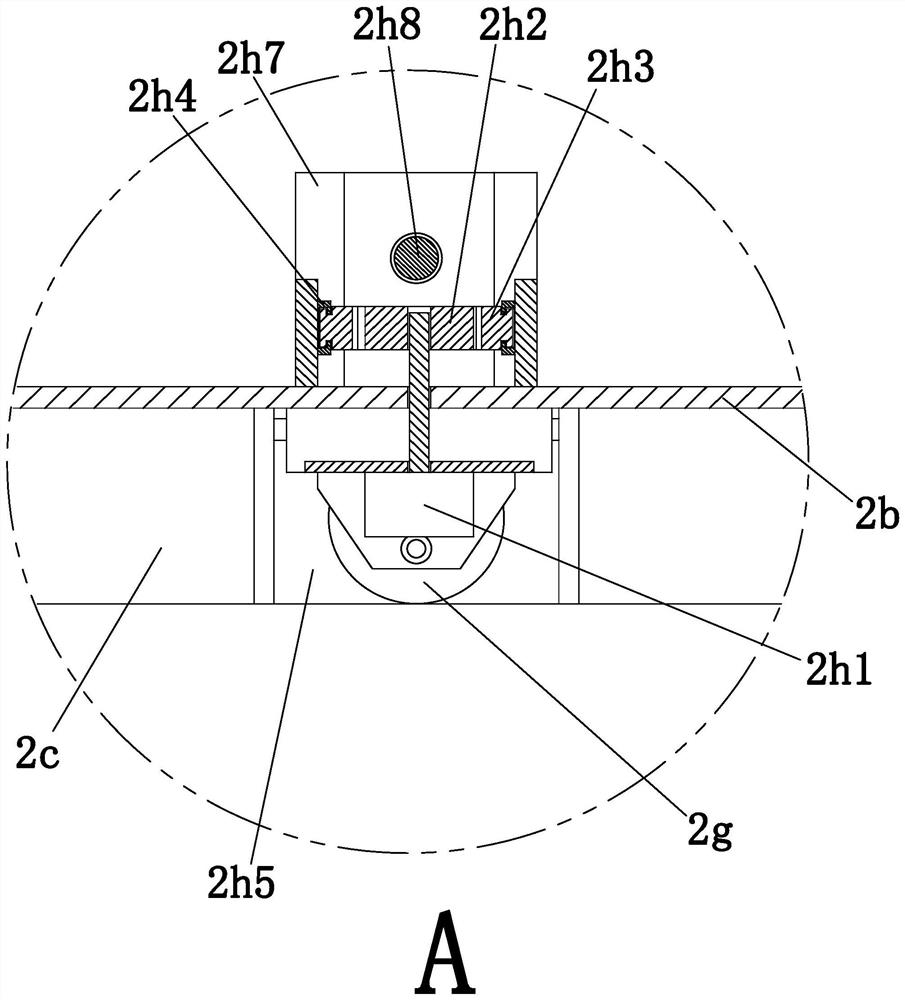

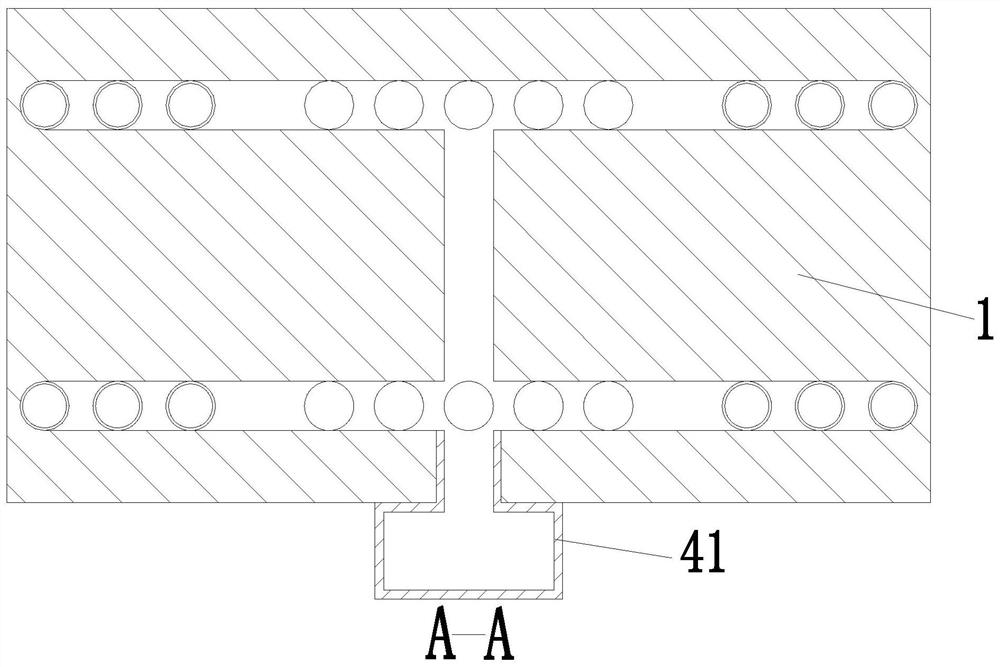

Steel structure cross beam splicing equipment and steel structure cross beam splicing process

ActiveCN111764513AImprove accuracyReduce labor intensityBuilding material handlingWork flowMechanical engineering

The invention provides steel structure cross beam splicing equipment and a steel structure cross beam splicing process. The equipment comprises a moving [-shaped bottom plate, an advancing mechanism,a falling mechanism and a clamping mechanism, according to the moving [-shaped bottom plate, an opening is upwards placed, the lower portion of the moving [-shaped bottom plate is provided with the advancing mechanism in a rotation fit manner, the falling mechanism is arranged between the inner walls of the two sides of the moving [-shaped bottom plate, the clamping mechanism is arranged between the inner walls of the two sides of the moving [-shaped bottom plate, the clamping mechanism is located behind the falling mechanism, according to the steel structure cross beam splicing equipment, a design theory of an adjusting type multi-station structure is adopted for splicing a steel structure cross beam, a mechanical integrated work structure is adopted, labor intensity of a worker is reduced, the work flow is simplified, meanwhile, a drive and positioning device is mounted, and accuracy of adjusting of the cross beam placing position during steel structure cross beam splicing is improved.

Owner:冠恒建设集团有限公司

A steel structure welding forming arrangement fixing fixture

ActiveCN113523696BConvenient welding workThere will be no welding misalignmentWelding/cutting auxillary devicesAuxillary welding devicesWeldingManufacturing engineering

The invention relates to a steel structure welding forming and arranging fixing fixture, which includes a placing plate, a clamping module, an adjusting module and an arranging module. The clamping module is equipped with an arrangement module at the right end of the placing plate; the present invention can solve the following problems in the welding and clamping of the steel structure. Temporary fixation and then welding operation reduces the welding efficiency of the steel structure, the labor cost is high, and the temperature is high during welding, which is likely to bring safety hazards to the workers; 2. Due to the unstable manual positioning of the steel structure, resulting in When the steel structure is welded manually, the steel structure moves, which makes the welding position of the steel structure deviate, which affects the welding quality of the steel structure.

Owner:徐州天元钢结构有限公司

Cleaning equipment for feces of pet cage

ActiveCN113617710AStable clamping workImprove cleaning efficiencyLavatory sanitoryAnimal housingFecesEnvironmental engineering

The invention relates to cleaning equipment for feces of a pet cage. The cleaning equipment comprises a base plate, a cleaning mechanism, a water passing mechanism and a spray washing mechanism, wherein the cleaning mechanism is installed on the base plate, the water passing mechanism is installed at the rear side of the cleaning mechanism, and the spray washing mechanism is installed in the cleaning mechanism. The cleaning equipment can solve the following problems during cleaning of the feces of the pet cage: firstly, the feces of a traditional pet cage needs to be cleaned manually through a small broom, and peculiar smell emitted by the feces of pets affects manual cleaning; and secondly, when the feces of the pet cage is manually cleaned, the phenomenon of incomplete cleaning often occurs, the subsequent use of the pet cage is influenced, the pet cage cannot be comprehensively disinfected, and bacteria remain in the pet cage, so that the health of pets is influenced.

Owner:JIANGSU AGRI ANIMAL HUSBANDRY VOCATIONAL COLLEGE

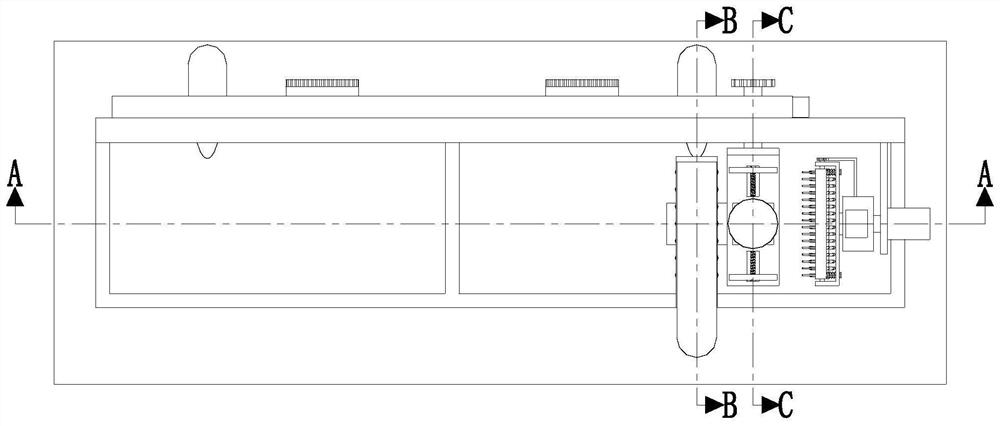

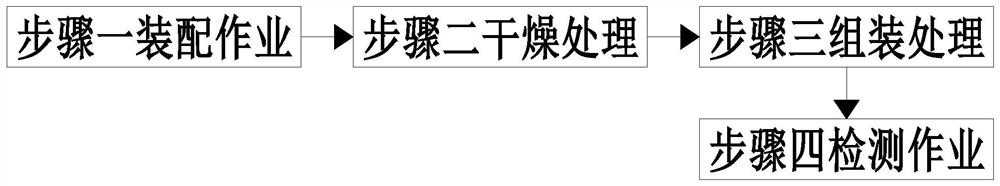

Manufacturing process of oil-immersed transformer

ActiveCN113035548AImprove stabilityImprove assembly quality and efficiencyInductances/transformers/magnets manufactureProcess engineeringTransformer

The invention relates to a manufacturing process of an oil-immersed transformer. The manufacturing process mainly comprises the following steps: assembling operation, drying treatment, assembling treatment, detection operation and the like. Used transformer assembling equipment comprises a bottom plate, a conveying device, a clamping device and a positioning device. The manufacturing process of the invention can solve the following problems existing when a traditional transformer and an oil tank are assembled: a, when the traditional transformer and the oil tank are assembled, the transformer needs to be manually lifted by using a tool and slowly conveyed into the oil tank, and due to the fact that the transformer is heavy, the labor intensity of manual assembling is large, and the phenomenon that the transformer is prone to falling off when being manually lifted and causes damage to the transformer and influence on subsequent use of the oil-immersed transformer occurs; and b, when an existing oil-immersed transformer is assembled, stable clamping and conveying operation cannot be carried out on the transformer, and due to the fact that the oil tank slides, assembly of the transformer is misplaced and the assembly quality and efficiency of the oil-immersed transformer are reduced.

Owner:中电变压器股份有限公司

Electric power grid overhead line high-voltage cement telegraph pole tower

ActiveCN113107256AEasy to installStable clamping workTowersAnimal repellantsPower gridControl theory

The invention relates to an electric power grid overhead line high-voltage cement telegraph pole tower. The electric power grid overhead line high-voltage cement telegraph pole tower comprises a connecting plate, an adjusting device, a clamping device, an alarm device and a fixing device, the adjusting device is installed on the connecting plate, the clamping device is installed on the adjusting device, and the alarm device and the fixing device are installed on the clamping device. The electric power grid overhead line high-voltage cement telegraph pole tower can solve the following problems in use of an existing telegraph pole tower that 1, the insulation combination gap of a high-voltage power transmission line is reduced, and the line tripping accident is caused due to the fact that birds often nest on a traditional telegraph pole tower, and materials such as grass and thin iron wires for nesting or excrement are extremely prone to falling on the power transmission line; and 2, when an existing telegraph pole tower inclines and shakes, an alarm cannot be given out in time, potential safety hazards exist, seriously, the pole tower collapses, the power transmission line is pulled to be broken, and power supply of a power grid is interrupted.

Owner:察右前旗恒达水泥制品有限责任公司

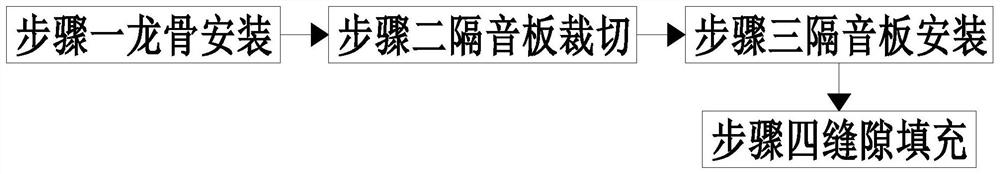

A cutting device for building sound insulation panels

InactiveCN111997213BReduce installation efficiencyImprove crop qualitySound proofingClassical mechanicsEngineering

The present invention relates to a cutting device for building sound insulation panels. The method for installing the sound insulation panels using the cutting equipment for building sound insulation panels mainly includes the following steps: keel installation, sound insulation panel cutting, and sound insulation panel installation As well as various processes such as gap filling, the sound insulation panel cutting equipment used includes a bottom plate, a positioning device, a pressing device and a cutting device. The present invention can solve the following problems existing in the existing sound insulation panel cutting, a. Traditional When cutting the sound insulation board, it is necessary to manually hold the cutting tool to cut the sound insulation board. The safety hazard of manual cutting of the sound insulation board is relatively large, and the labor intensity of manual cutting is high, and the cutting efficiency is low, which reduces the quality of the sound insulation board. For the efficiency of installation, the manually cut sound insulation panels often have burrs, which affects the use of the sound insulation panels.

Owner:安徽中南天开建设集团有限公司

A graphite carbon tube processing equipment

ActiveCN111890581BImprove slotting efficiencyImprove slotting effectWorking accessoriesStone-like material working toolsGraphite carbonWorking environment

The invention relates to a graphite carbon tube processing equipment, comprising a bottom plate, a clamping device, a slotting device and a dust suction device, the clamping device is installed on the bottom plate, and a slotting device and a dust suction device are installed on the clamping device , the present invention can solve the following problems that exist when the existing graphite carbon tubes are slotted. One, when the traditional graphite carbon tubes are slotted, they are generally polished by manual hand-held grinding equipment, and the efficiency of manual slotting of graphite carbon tubes is low , it is also difficult to ensure safety, and the operators work in an environment with powder and dust for a long time, which is harmful to health; 2. When the existing graphite carbon tube slotting equipment is slotting the graphite carbon tube, the slotting operation cost It is relatively high and has low efficiency. It cannot perform stable clamping operations on graphite carbon tubes, and cannot promptly absorb dust generated when graphite carbon tubes are slotted. It can also reduce the hazards of dust in the working environment to workers.

Owner:内蒙古京航特碳科技有限公司

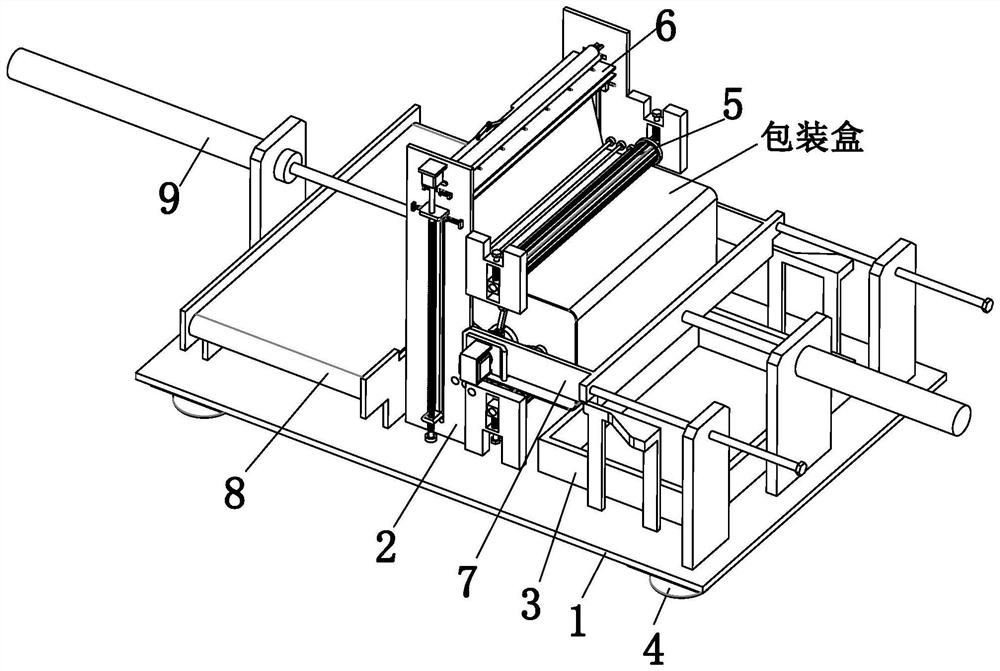

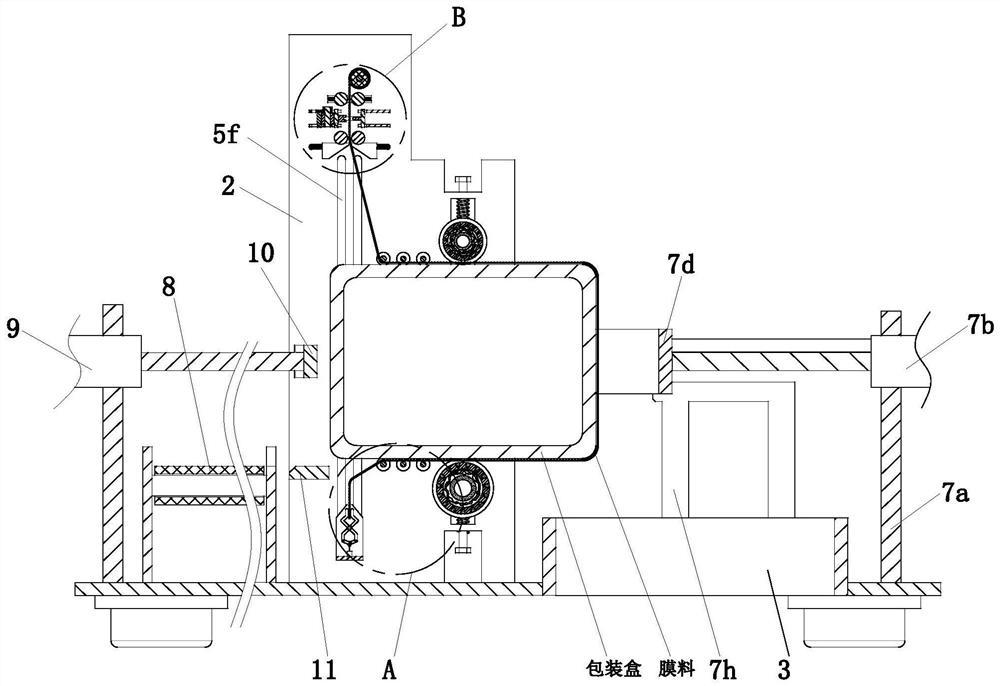

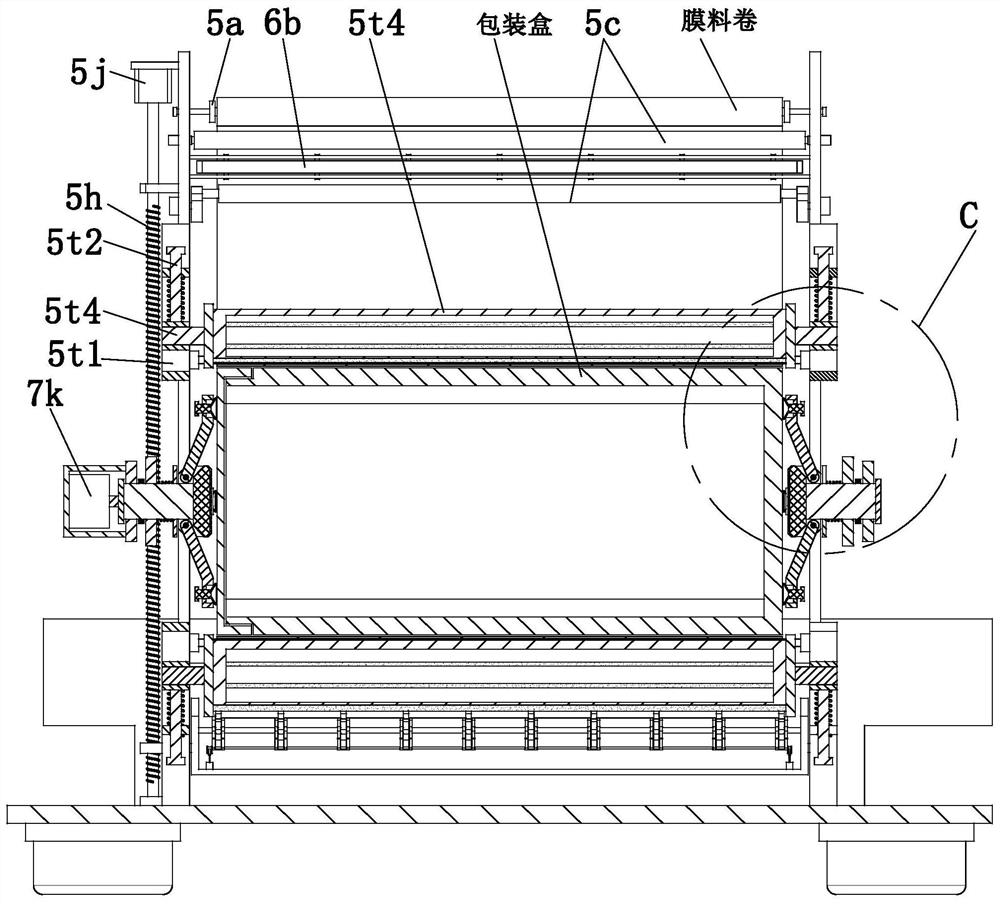

Metal packaging box manufacturing and processing machine and method

InactiveCN113071851AStable clamping workQuick installationConveyorsMetal working apparatusFilm materialFilm-coated tablet

The invention provides a metal packaging box manufacturing and processing machine and method. The metal packaging box manufacturing and processing machine comprises a mounting bottom plate, a supporting frame, a blanking groove, supporting legs, a film coating mechanism, a cutting mechanism, a positioning mechanism, a conveying belt, a conveying air cylinder, a conveying plate and a transition plate. According to the metal packaging box manufacturing and processing machine and method, the problems that manual film coating operation is usually carried out through manual work during metal packaging box manufacturing and processing operation, manual film coating operation is prone to causing wrinkling and deformation of film materials, then the protection effect on a packaging box is influenced, moreover, the thicknesses of the film materials on the outer surfaces of metal packaging boxes in different production batches are difficult to keep consistent, the attached film materials are more difficultly flatly cut off, and the film materials are more difficultly uniformly heated and softened in the circumferential direction can be solved, the bending capacity of the film materials is improved, meanwhile, the film materials are enabled to adapt to the radian change of the outer edge path of the metal packaging box, and then the attaching degree between the film materials and the metal packaging box is improved.

Owner:武汉苏藤贸易有限公司

Nursery site stacking device for vegetable planting

ActiveCN111924511AFast and stable clamping workReduce labor burdenLoading/unloadingConveyor partsAgricultural engineeringStructural engineering

The invention discloses a nursery site stacking device for vegetable planting, and relates to the technical field of vegetable planting. The nursery site stacking device for vegetable planting comprises a bottom plate. A hydraulic rod and a side rack are mounted on the outer surface of the top of the bottom plate in a welded manner. A second sliding groove is formed in the side rack. A second sliding block is mounted in the second sliding groove in a sliding manner. A locating block and a clamping plate are mounted on the outer walls of the two sides of the second sliding block correspondinglyin a welded manner. The free end of the hydraulic rod and the outer surface of the bottom of the clamping plate are mounted in a welded manner. A second top plate is mounted on the outer wall of oneside of the locating block in a welded manner. According to the nursery site stacking device, nursery sites of different sizes and widths can be subjected to stable clamping work, the transverse distance and angle of a stable clamping mechanism can be adjusted, the error-tolerant rate of clamping work is increased, height adjusting can be carried out on the stable clamping mechanism, stacking workafter workers clamp nursery sites is convenient, and in addition, surface dust removal work can be carried out on nursery sites.

Owner:江西百晟农业发展有限公司

Power transmission overhead line cable isolation rod

ActiveCN111864679AImprove stabilityGuaranteed stabilityMaintaining distance between parallel conductorsTelecommunicationsSevere weather

The invention relates to a power transmission overhead line cable isolation rod. The rod comprises a connecting plate, a telescopic device and a clamping device, the telescopic device is mounted on the connecting plate; the clamping device is mounted on the telescopic device; according to the invention, the following problems existing when a conventional cable isolation rod isolates a cable can besolved: firstly, a traditional cable isolation rod cannot stably clamp a cable, the clamping direction of the cable isolation rod to the cable is single, clamping force is insufficient, installationis inconvenient, the cable isolation rod cannot bear severe weather in the later period, the cable isolation rod is prone to loosening under the condition of large wind power, the cable isolation rodfalls off from the high altitude, and large potential safety hazards exist; and 2, the isolation distance of the existing cable isolation rod to the cables is fixed, and the interval length between the cables cannot be adjusted. Thus, according to the invention, the stability of cable isolation can be improved, and the isolation distance between the cables can be adjusted.

Owner:JIANGSU YONGXING ELECTRIC ENERGY EQUIP TECH CO LTD

Wire and cable connecting frame for overhead line of electric power tower

ActiveCN112152177BIncrease security risksStable clamping workSuspension arrangements for electric cablesTowerControl theory

The invention relates to a wire and cable connecting frame for an overhead line of an electric power tower, which includes a base plate, a clamping device, a positioning device and a docking device. The clamping device is installed on the base plate, and a positioning device and a docking device are installed on the clamping device. The present invention can solve the following difficult problems existing in the connection of existing wires and cables. 1. When docking traditional wires and cables, it is necessary to manually pull the wires and cables that need to be docked, and use tools to connect the wires and cables, and then Use cable connectors to connect and fix the processing, so the connected wires and cables are not firm; 2. The existing wire and cable connectors cannot perform stable clamping operations on the cables, and the phenomenon of broken cables often occurs. The clamping force of the cable is not enough, and it is not enough to withstand the bad weather in the later stage, and it is easy to loosen in the case of strong wind, which makes the wire and cable fall from a high altitude, and there is a big safety hazard.

Owner:ECONOMIC TECH RES INST OF STATE GRID ANHUI ELECTRIC POWER +1

A laser cutting machine

ActiveCN113263270BTimely cooling operationImprove efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringLaser cutting

The present invention relates to the technical field of cutting machines, in particular to a laser cutting machine, comprising a bottom plate, a feeding mechanism, a clamping mechanism, a dust suction mechanism, a cutting mechanism and a cooling mechanism. A cutting mechanism is installed on the right part of the upper end, a dust suction mechanism is installed on the cutting mechanism, a feeding mechanism is installed on the left end of the bottom plate, and a cooling mechanism is installed on the right end of the bottom plate. This invention can solve the following problems existing in the existing laser cutting machine when cutting products: Difficulties: 1. The laser cutting machine in traditional industrial manufacturing cannot automatically locate the material to be cut. It needs to manually move the material to carry out the cutting operation, which makes the cutting accuracy of the material poor; 2. The existing laser cutting cannot Cool the cut product in time, the waste heat of the laser will expand the cutting edge, resulting in a low yield rate and affecting the subsequent use of the product.

Owner:艾博特镭射科技徐州有限公司

A three-dimensional film packer with the function of removing internal air

ActiveCN112061470BQuality assuranceExtended service lifeWrapper supporting apparatusPackaging by pressurising/gasifyingElectric machineryEngineering

The invention discloses a three-dimensional film packing machine with the function of removing internal air, and relates to the technical field of film packing machines. The three-dimensional film packer with the function of excluding internal air includes a base plate, the bottom outer surface of the base plate is welded with supporting legs and a first motor, and the top outer surface of the base plate is welded with a U-shaped support box and a positioning plate, and the U-shaped support The top of the box is welded with a second top plate, the top outer surface of the second top plate is welded with a side frame, the side frame is provided with holes, and the top outer surface of the side frame is welded with a first top plate. The present invention can carry out air extraction work on the film located in a relatively closed space, avoiding the moisture contained in the internal air and causing corrosion to the film. It can perform stable clamping work on the objects, and can quickly transfer the coated items.

Owner:浙江霄腾智能科技有限公司

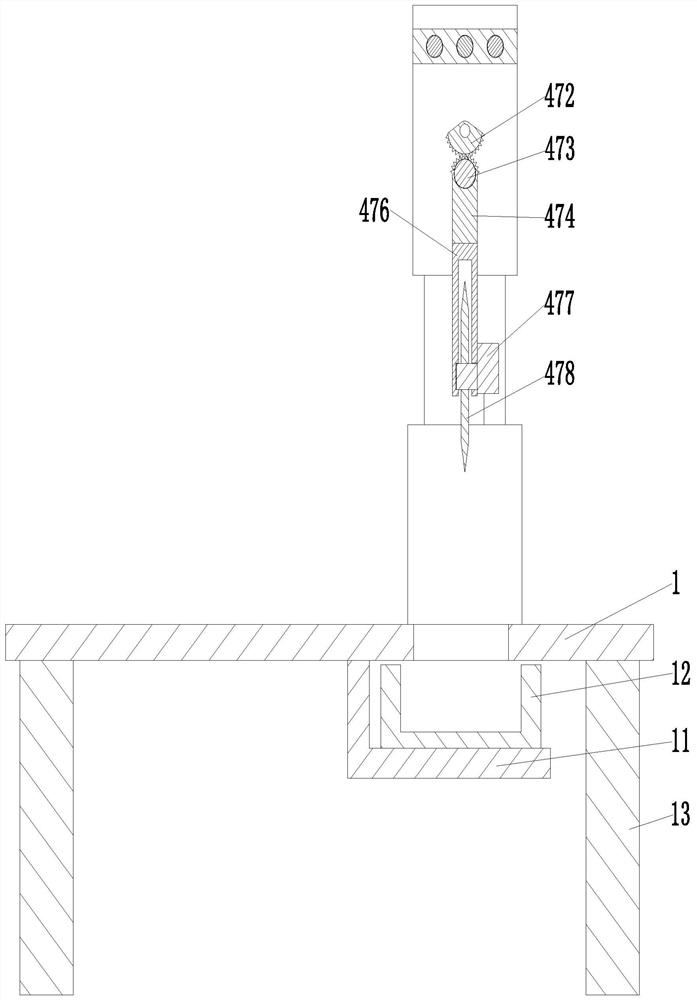

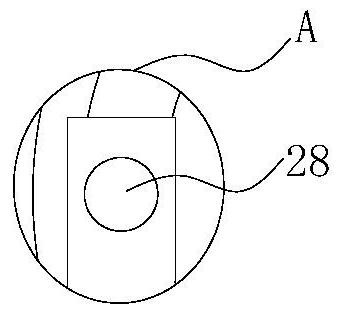

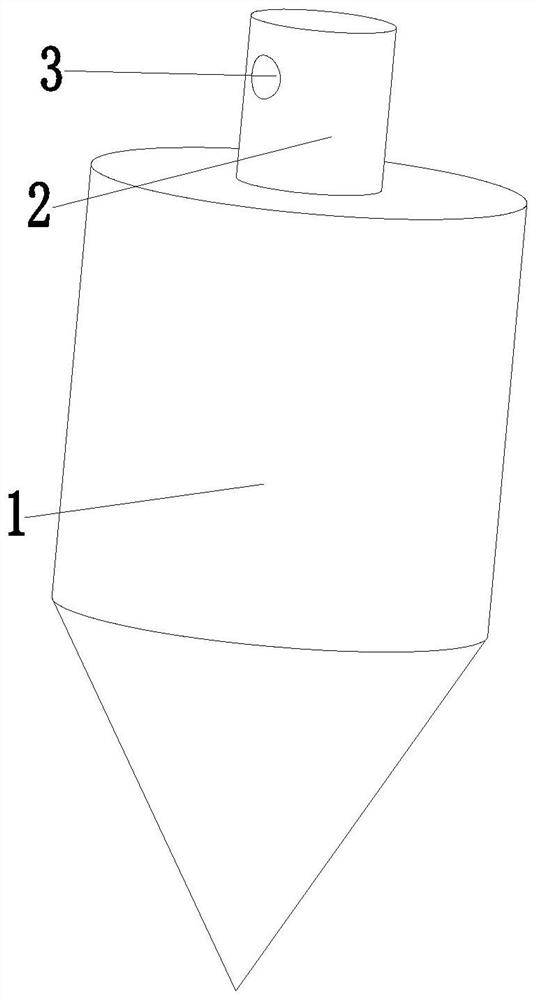

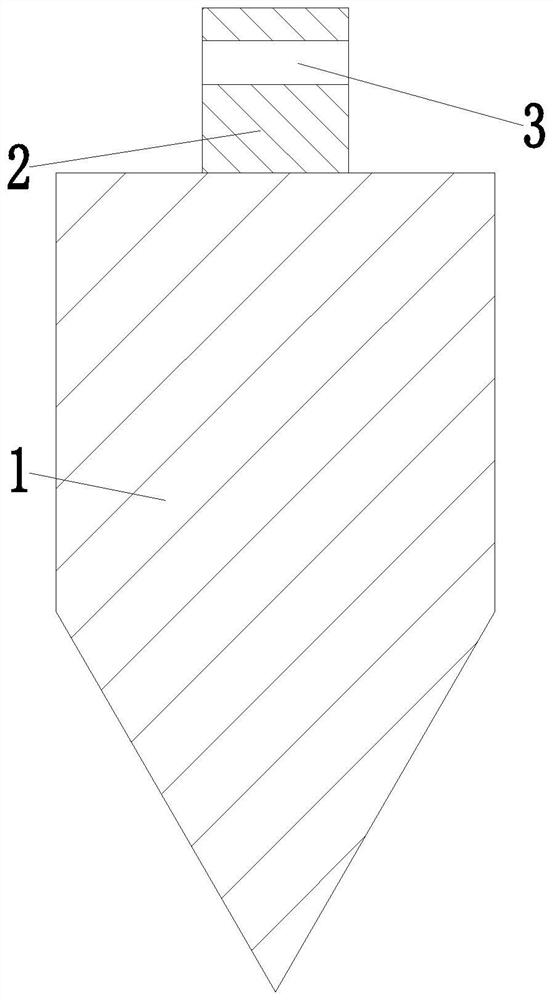

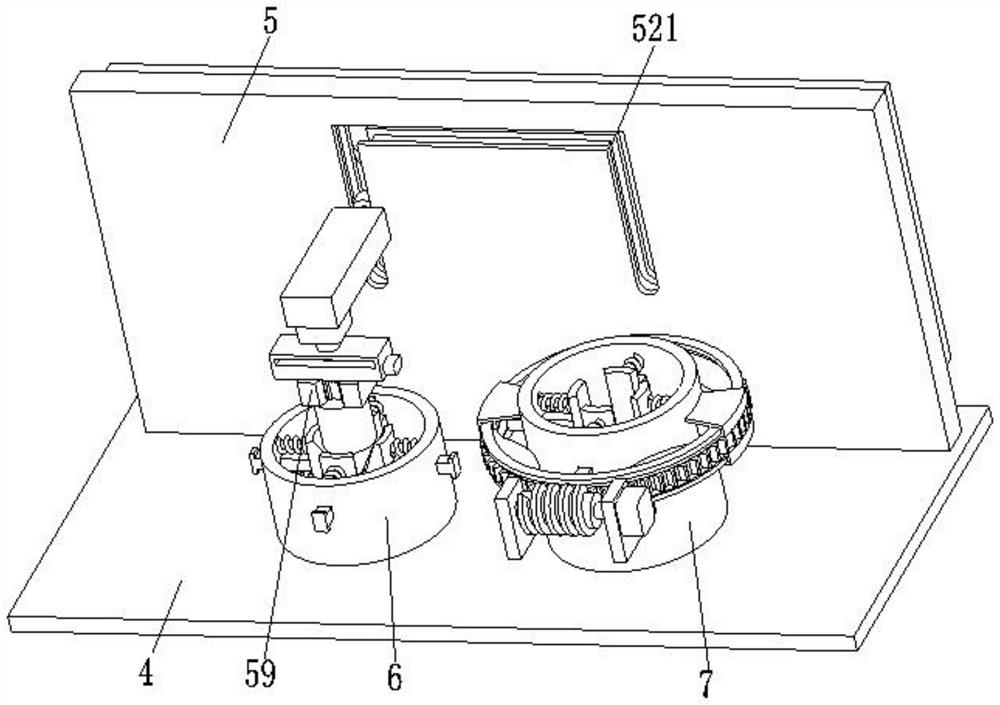

Projection point-to-point measurement plumb appliance and processing device thereof

ActiveCN114485597AImprove processing efficiencyFully polishedPolishing machinesRevolution surface grinding machinesPolishingMachining process

The invention relates to a projection point-to-point measurement plumb appliance and a machining device thereof.The projection point-to-point measurement plumb appliance comprises a plumb bob body, a wiring rod and a wiring hole, in the machining process of the plumb appliance, the special machining device needs to be used, and the machining device comprises an operation table, a conveying mechanism, a grinding mechanism and a polishing mechanism; the machining device comprises an operation table, a conveying mechanism is arranged at the rear end of the operation table, a grinding mechanism is installed at the left end of the operation table, and a polishing mechanism is installed at the left end of the operation table. And by adjusting the distance between the arc-shaped plates, the outer walls of the upper sides of the plumb bobs with different diameters can be polished, the application range is wide, and the machining efficiency of the plumb bobs is improved.

Owner:南通天正信息技术服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com