Patents

Literature

30results about How to "Fully polished" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

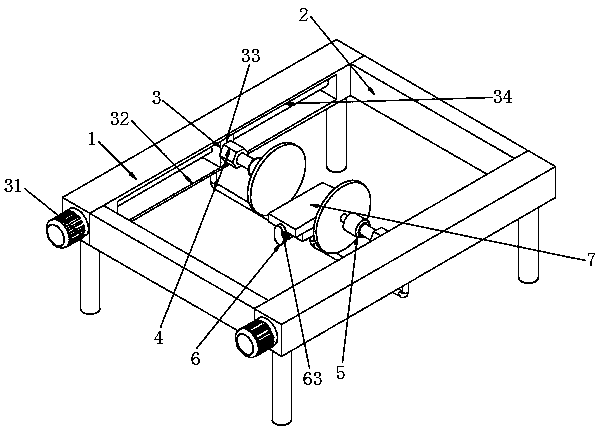

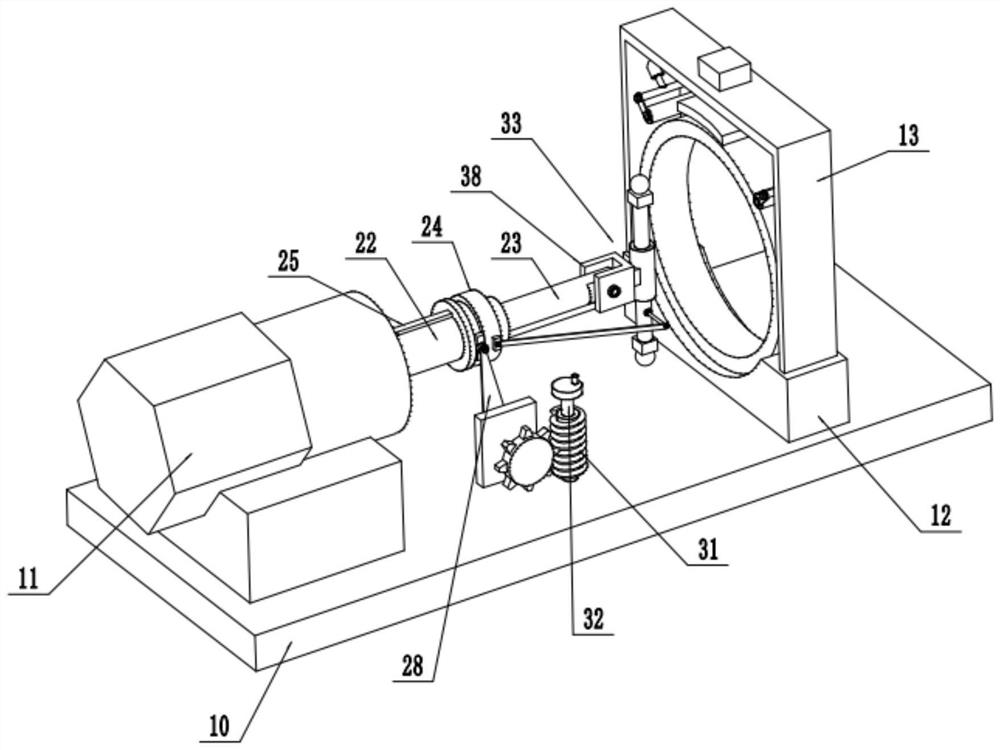

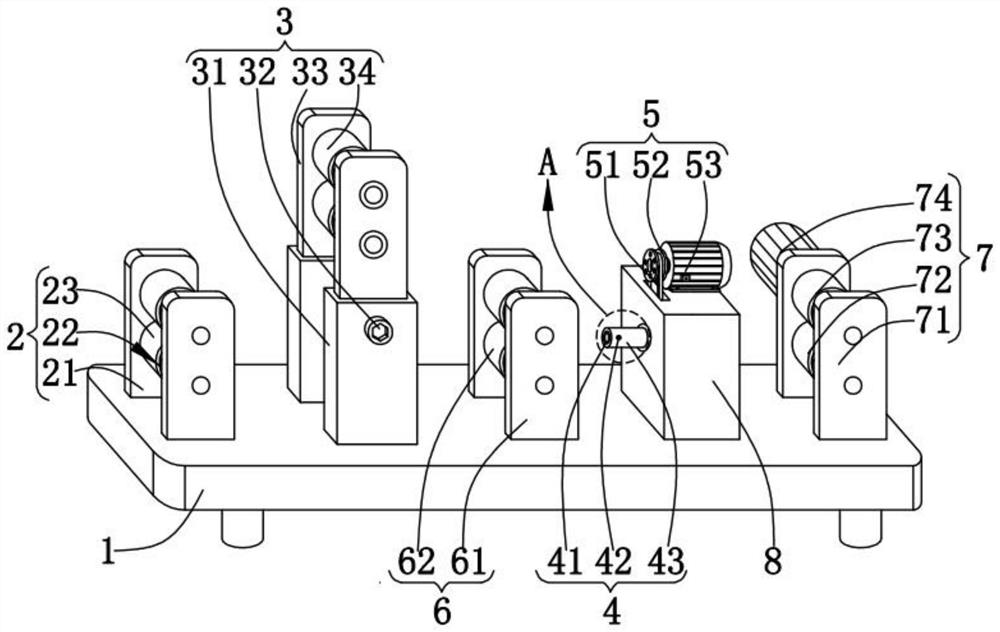

Polishing equipment for industrial steel pipe

InactiveCN106425818AHighly corrosiveStrong acid resistancePolishing machinesGrinding drivesIndustrial engineering

The invention relates to apolishingequipment, in particular to a polishing equipment for industrial steel pipes, and provides a polishing equipment for industrial steel pipes polishing uniformly, having less harm to people and saving both time and effort. In order to solve the technical problems, the invention provides the polishing equipment for industrial steel pipe. The polishing equipment for industrial steel pipes comprises a base plate, a first support plate, a second support plate, a first sliding rail, a first bearing pedestal, a second bearing pedestal, a positioning device, a steel pipe, a first gear and a first motor. The first support plate is welded at the left side of the base plate. The second support plate is welded at the right side of the base plate. The second support plate is arranged at the right of the first support plate. The polishing equipment for industrial steel pipes achieves the effect of uniform polishing, less harm to people and saving both time and labor during polishing through rotating steel pipes and moving polishing wheels.

Owner:南昌安润科技有限公司

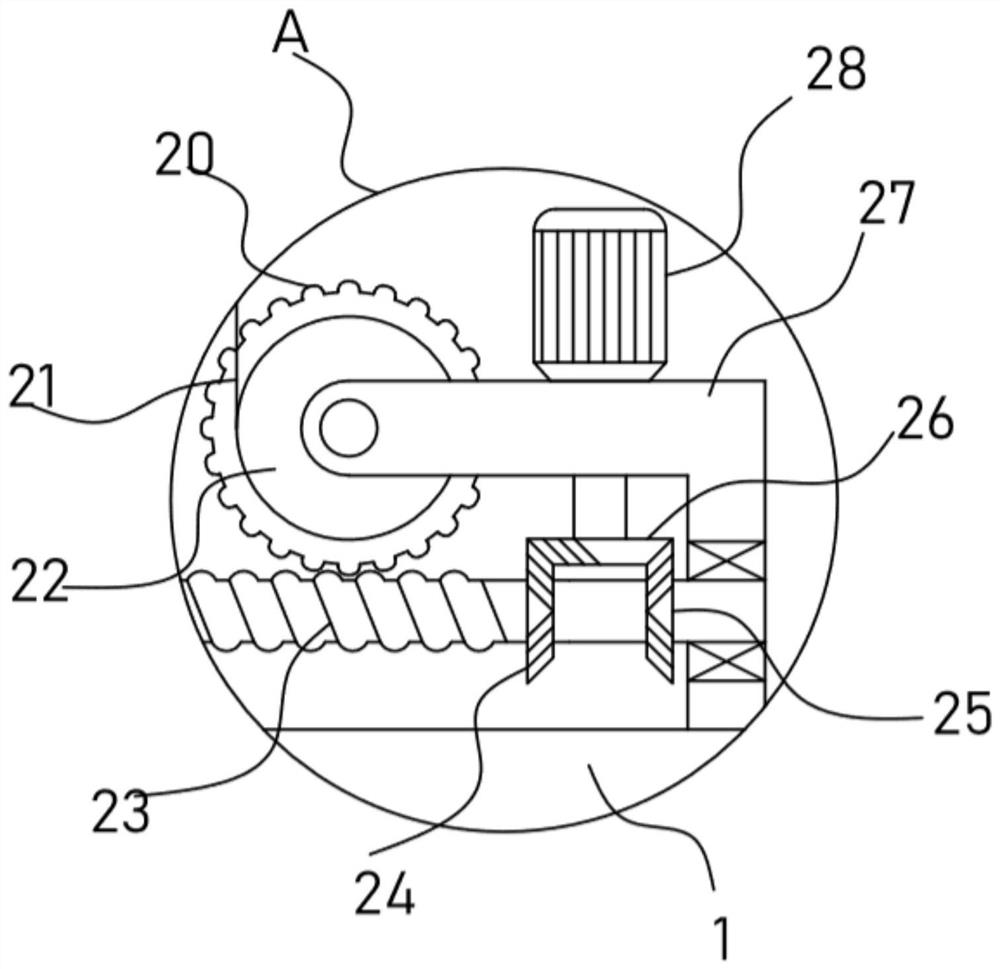

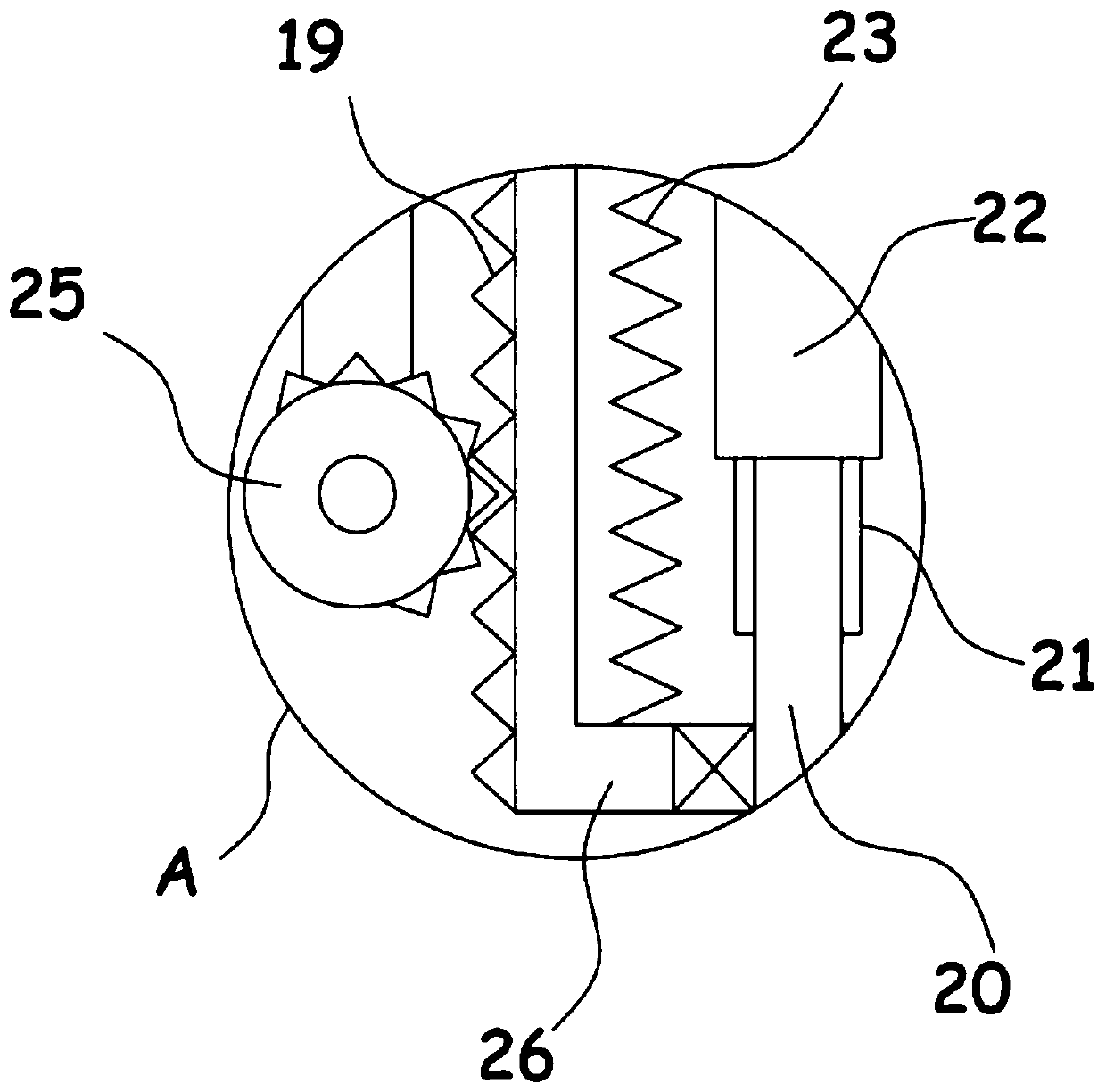

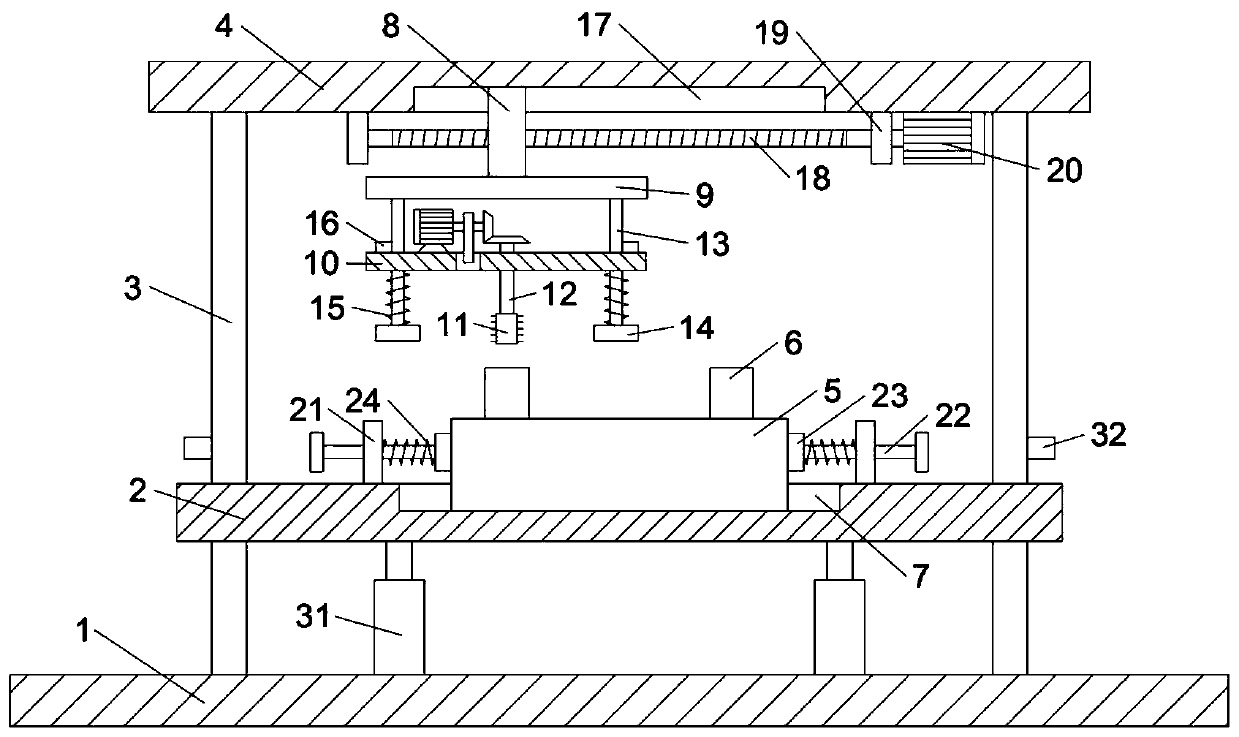

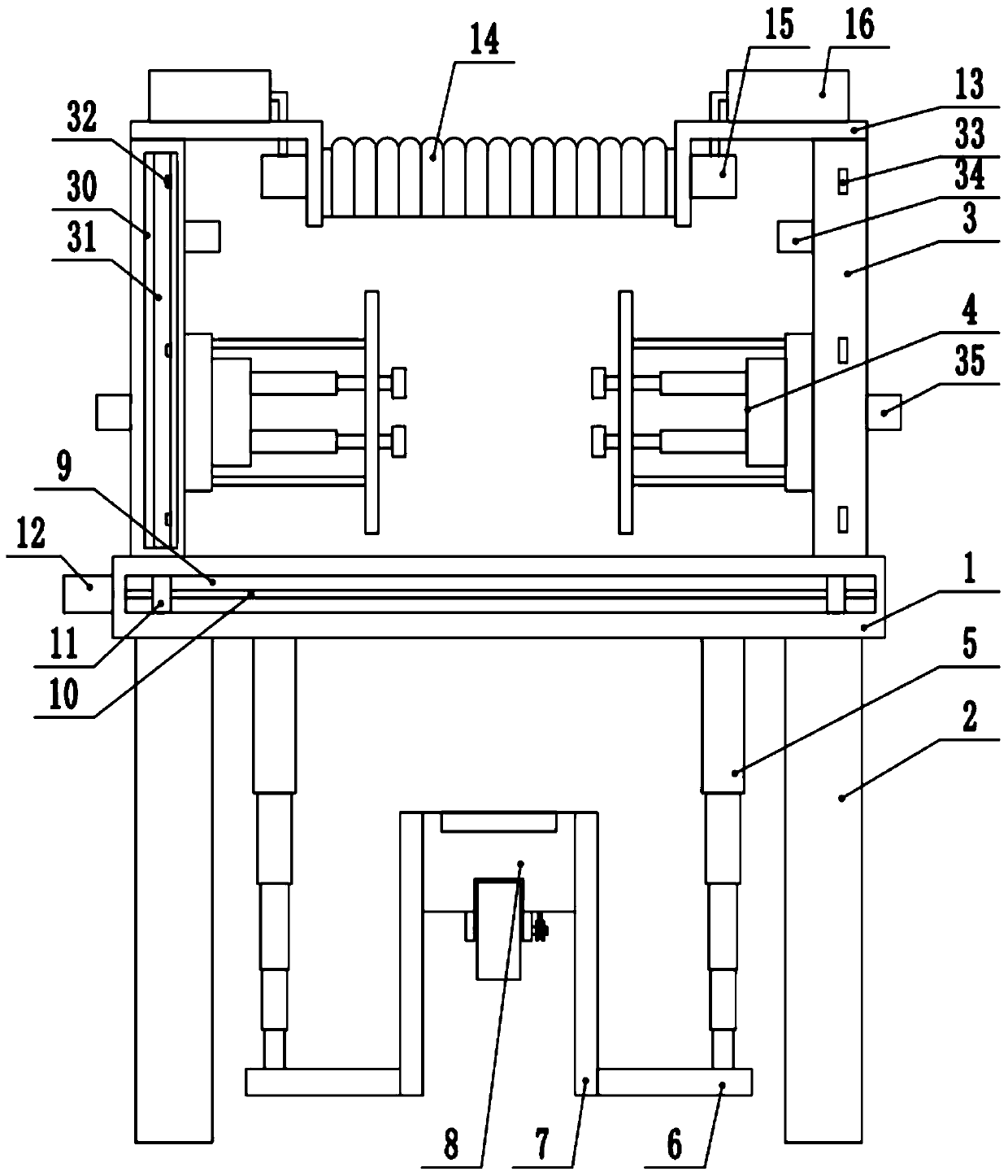

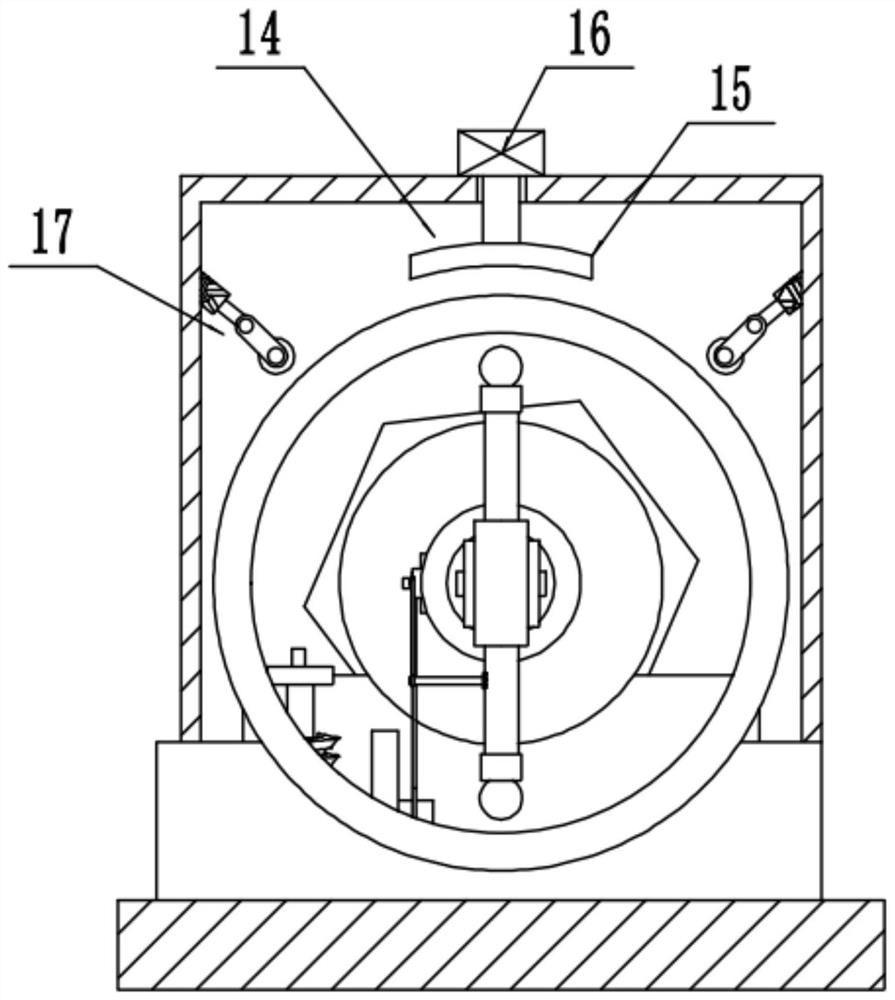

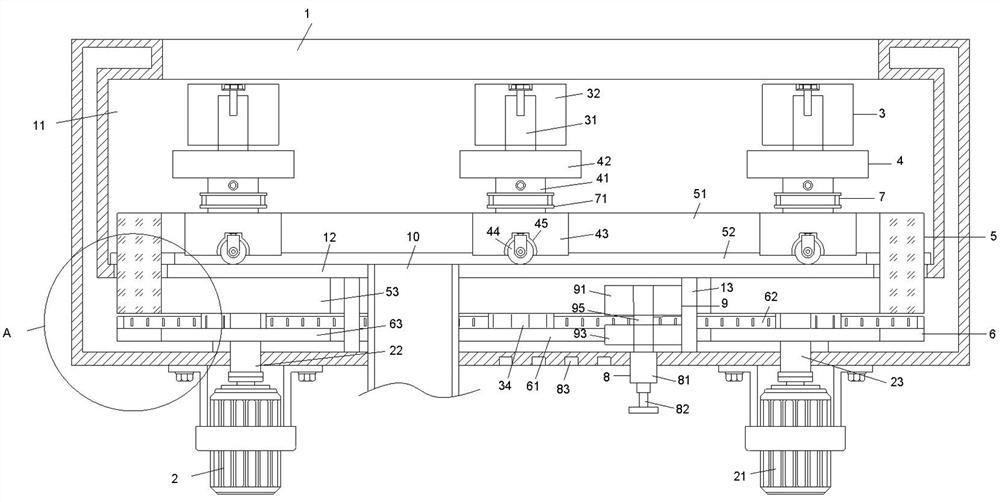

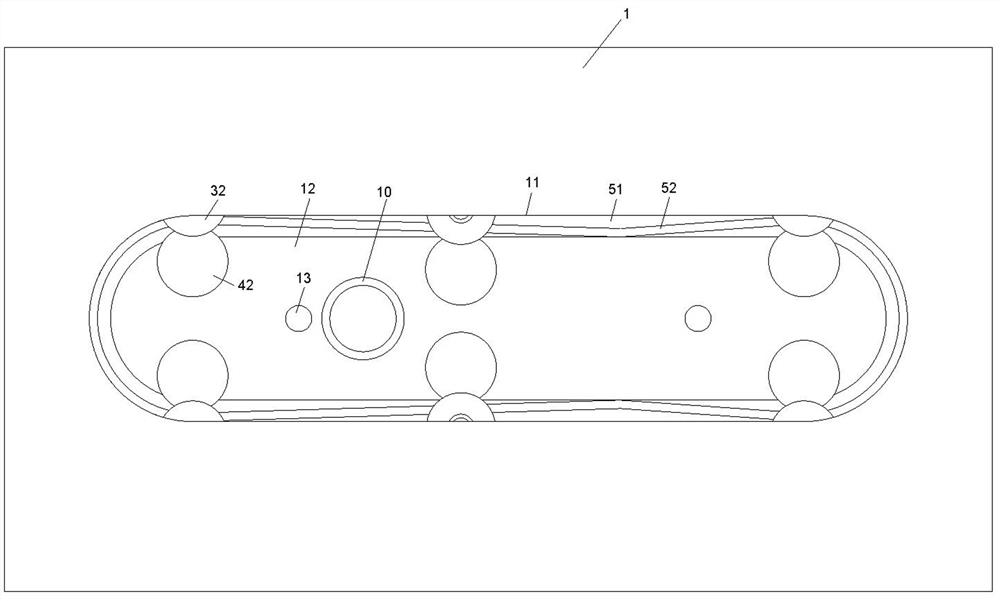

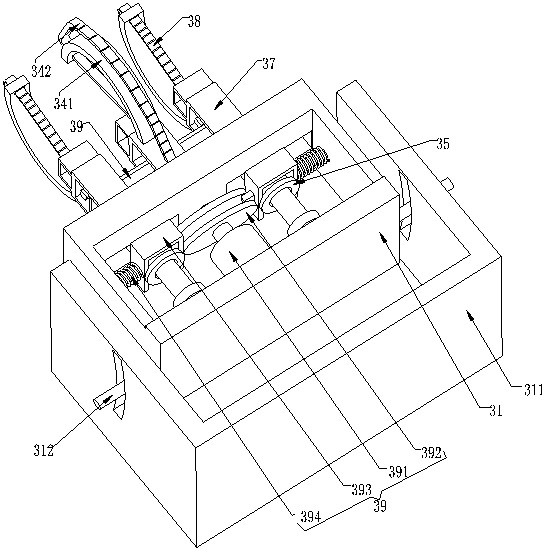

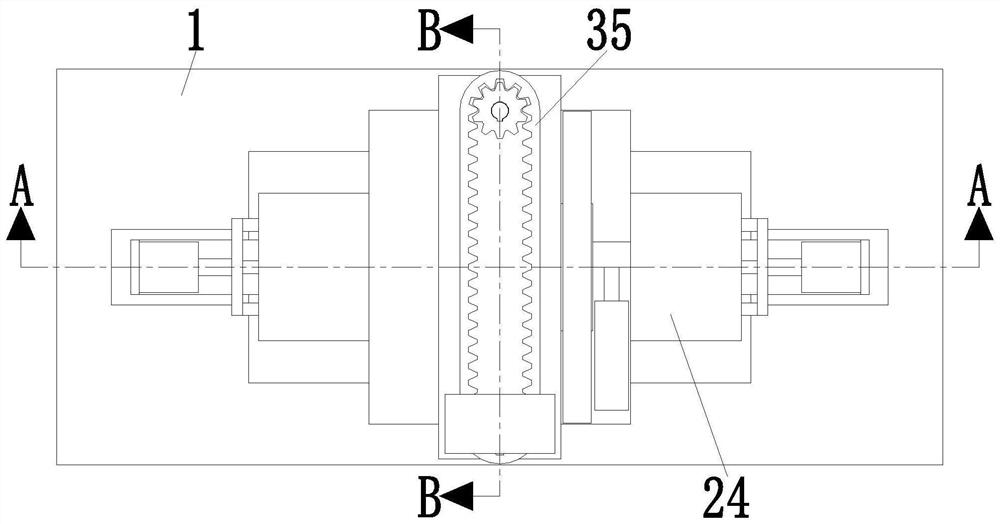

Plate surface polishing and flattening device for building construction

InactiveCN111872827AFully polishedGrinding stabilityGrinding carriagesPolishing machinesPolishingManufacturing engineering

The invention discloses a plate surface polishing and flattening device for building construction, and relates to the technical field of building construction machineries. The plate surface polishingand flattening device comprises a fixing frame, a polishing mechanism for polishing a plate is arranged on a guide sleeve block, a mounting frame is fixed on the fixing frame, a servo motor is fixed on the mounting frame, and a forward and reverse rotating mechanism is in driving connection with the servo motor; and the forward and reverse rotating mechanism is in driving connection with a translation mechanism for driving the guide sleeve block to vertically move; by means of a limiting mechanism, two clamping plates are used for clamping and fixing the plate, the stability of the plate grinding process is guaranteed, a grinding disc in the polishing mechanism rotates to achieve rotary polishing treatment on the surface of the plate, and the arranged forward and reverse rotating mechanismcan drive a winding wheel to rotate clockwise and anticlockwise alternately; and a steel wire rope can pull the guide sleeve block to do vertical reciprocating motion under the elastic effect of a spring ring, the rotating grinding disc can do vertical reciprocating motion relative to the plate, and efficient and sufficient grinding and polishing of the plate are achieved.

Owner:刘灿明

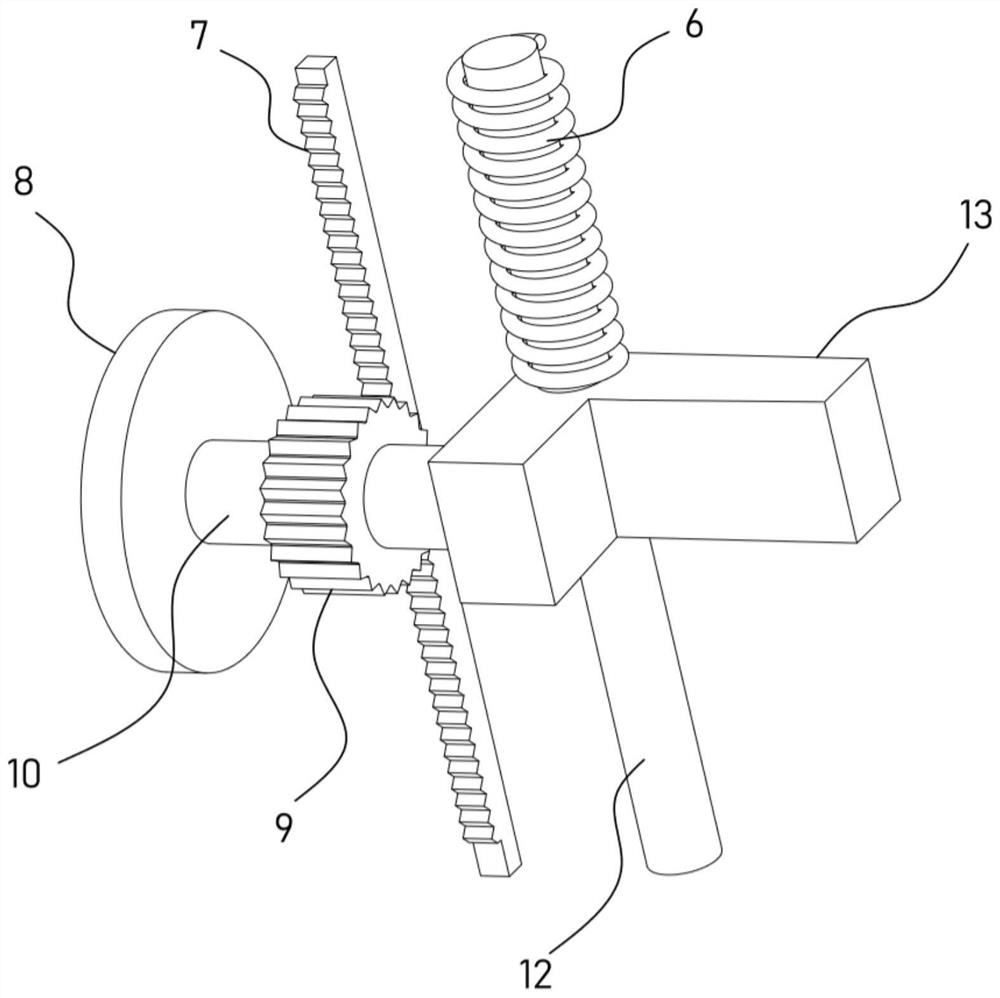

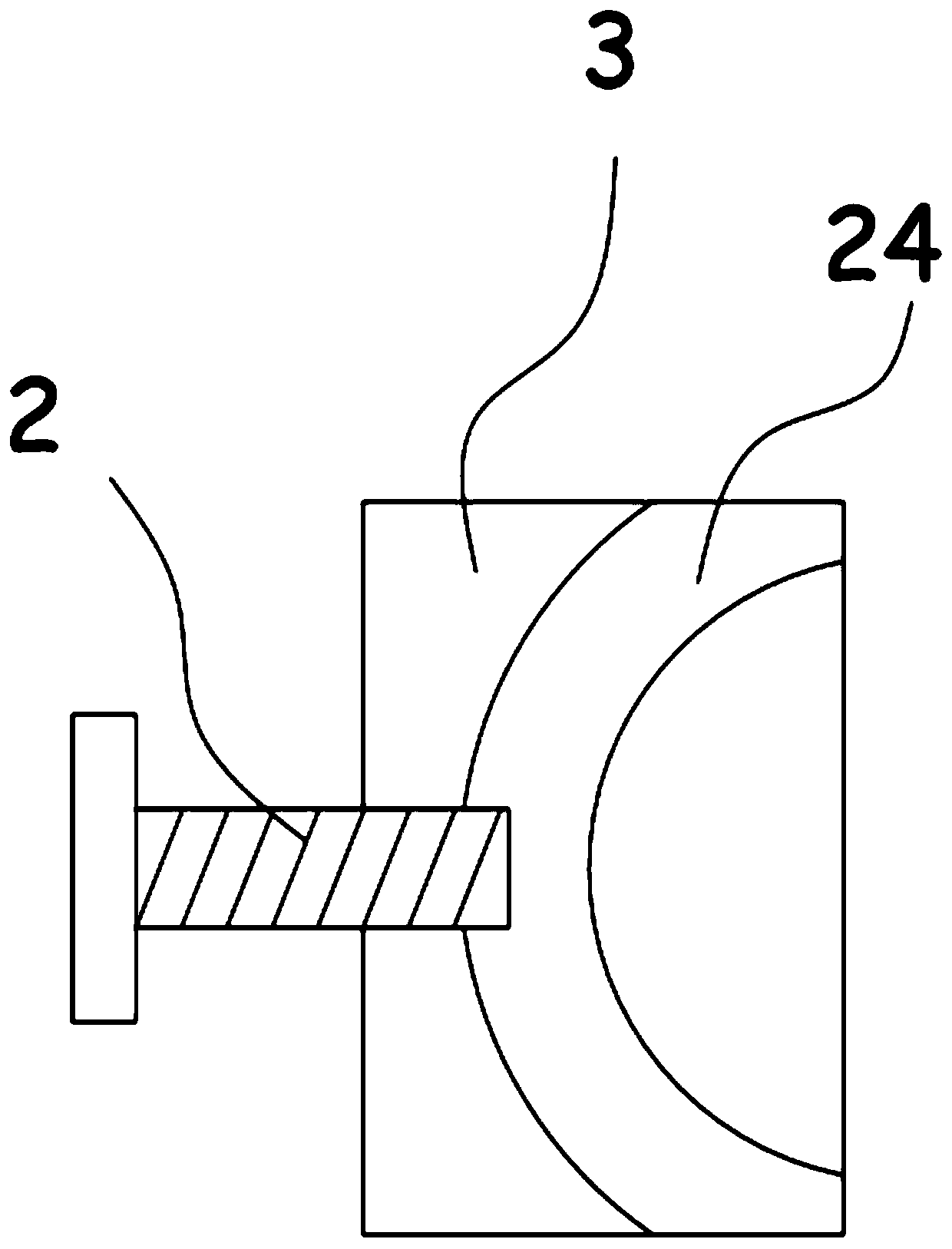

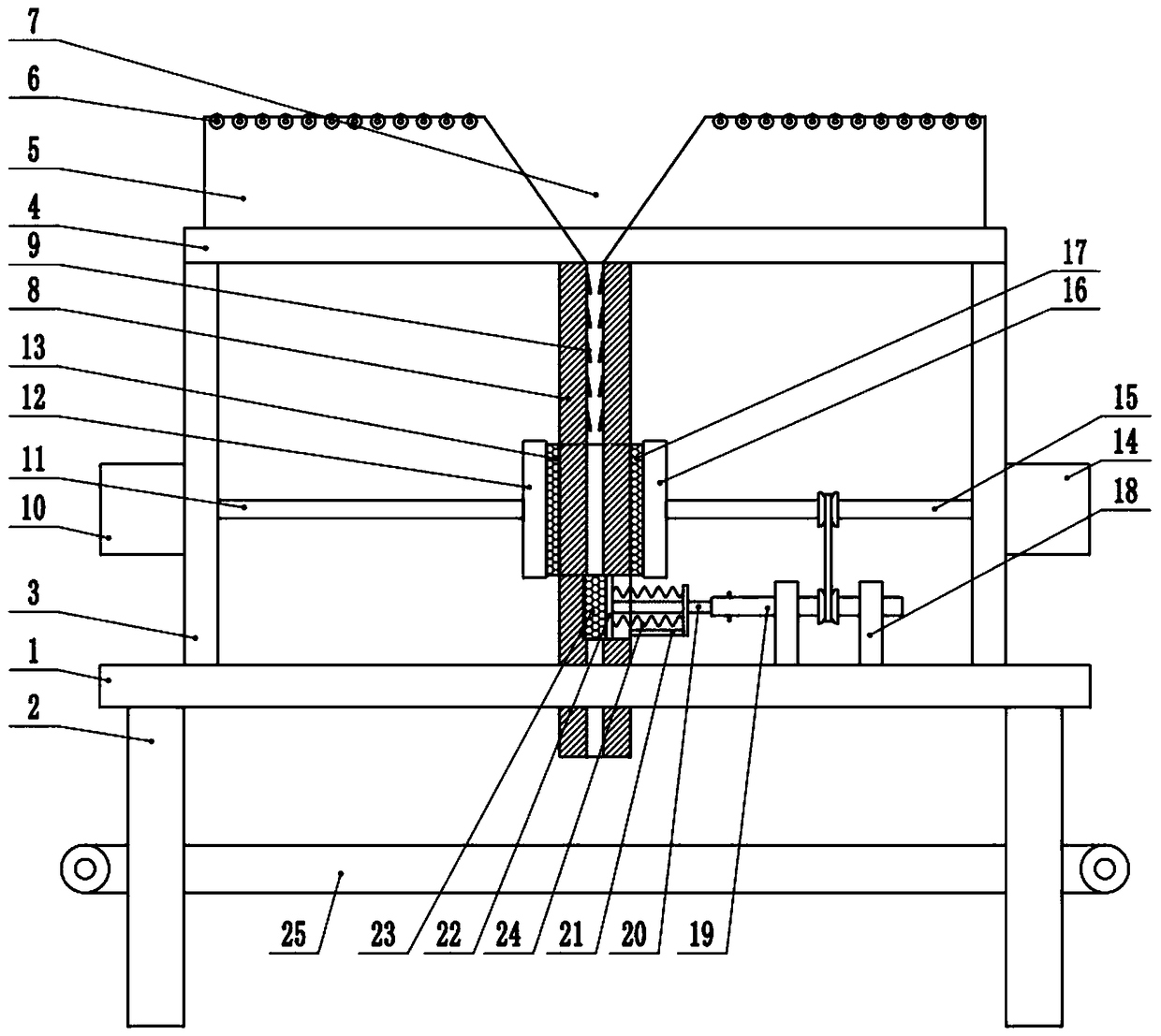

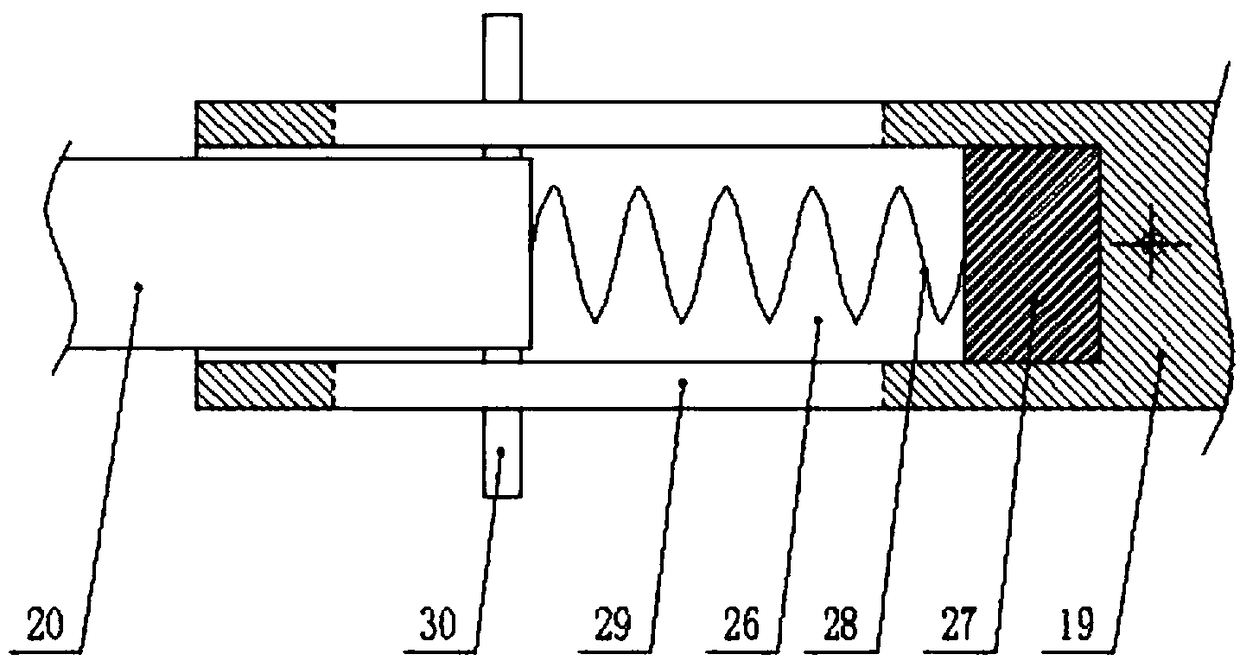

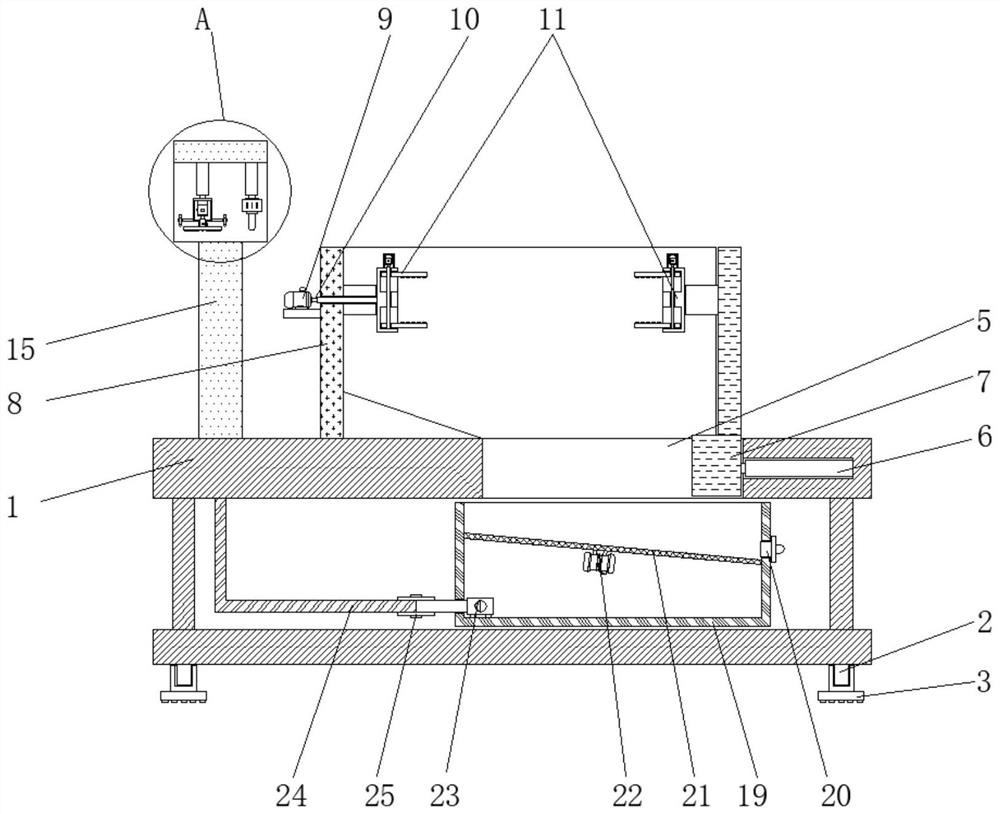

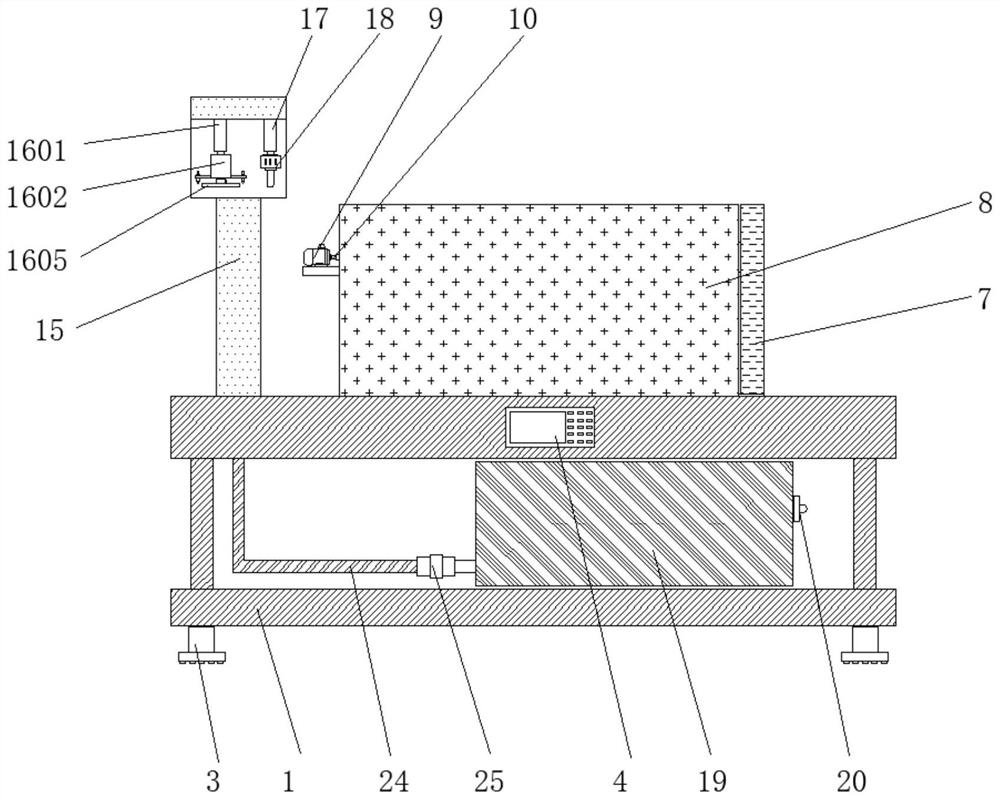

Electric kettle cover outer surface grinding device

InactiveCN110202431AEasy to holdFully polishedRevolution surface grinding machinesGrinding work supportsReciprocating motionSurface grinding

The invention discloses an electric kettle cover outer surface grinding device, and relates to the technical field of electric kettles. An operation frame is included. The servo motor is in driving connection with an adjusting mechanism for adjusting the distance between two limiting bases. The operation frame is in pin joint with a transmission sleeve, and the transmission sleeve is driven by a drive mechanism to rotate. The transmission sleeve is in transmission connection with a rotation shaft, and the operation frame is provided with a reciprocating mechanism driving the rotation shaft toreciprocate up and down. A clamping mechanism can be used for conducting the stable clamping effect on a kettle cover, the adjusting mechanism is used for conducting distance adjustment on the clamping mechanism, kettle covers different in size are clamped, the kettle cover grinding application range is enlarged, a grinding plate in a grinding assembly can achieve the kettle cover outer surface tight attachment effect in the rotating and grinding process, and the grinding effect is obviously improved; and meanwhile, under driving of the reciprocating mechanism, the grinding plate rotates and can move up and down and back and forth along the surface of the kettle cover, and kettle cover grinding is comprehensive and sufficient.

Owner:黄丽平

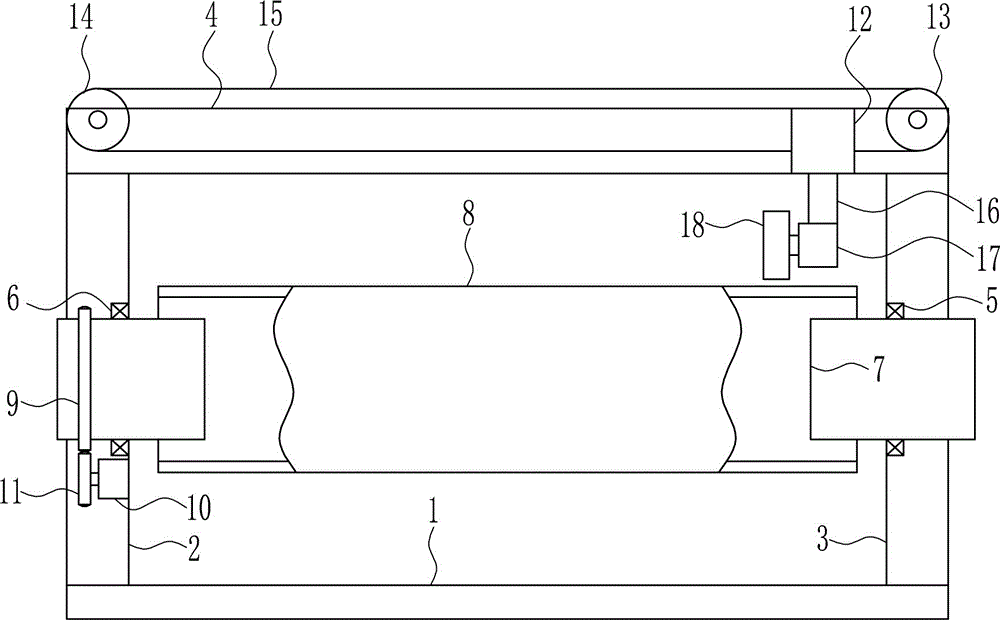

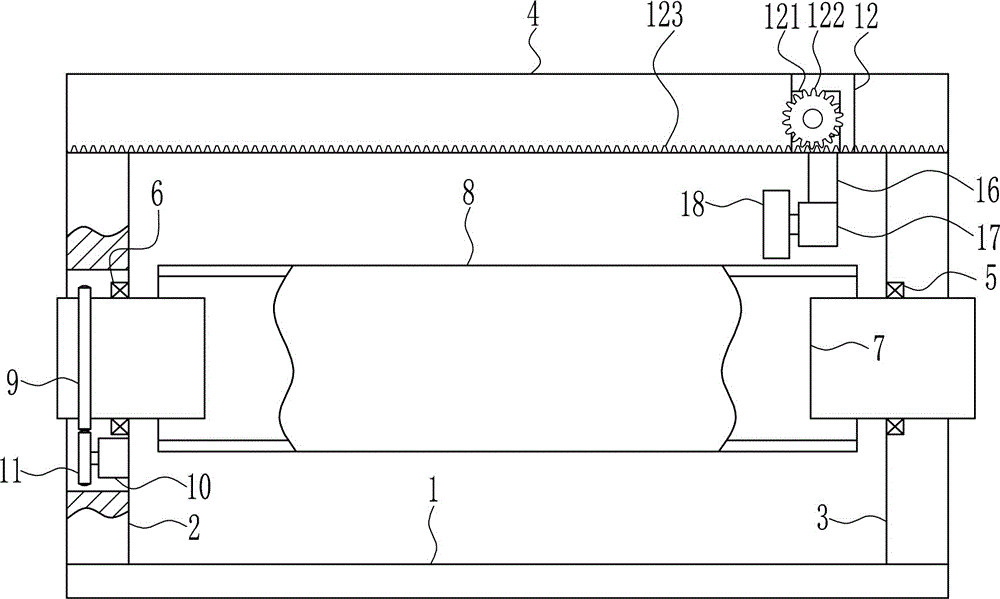

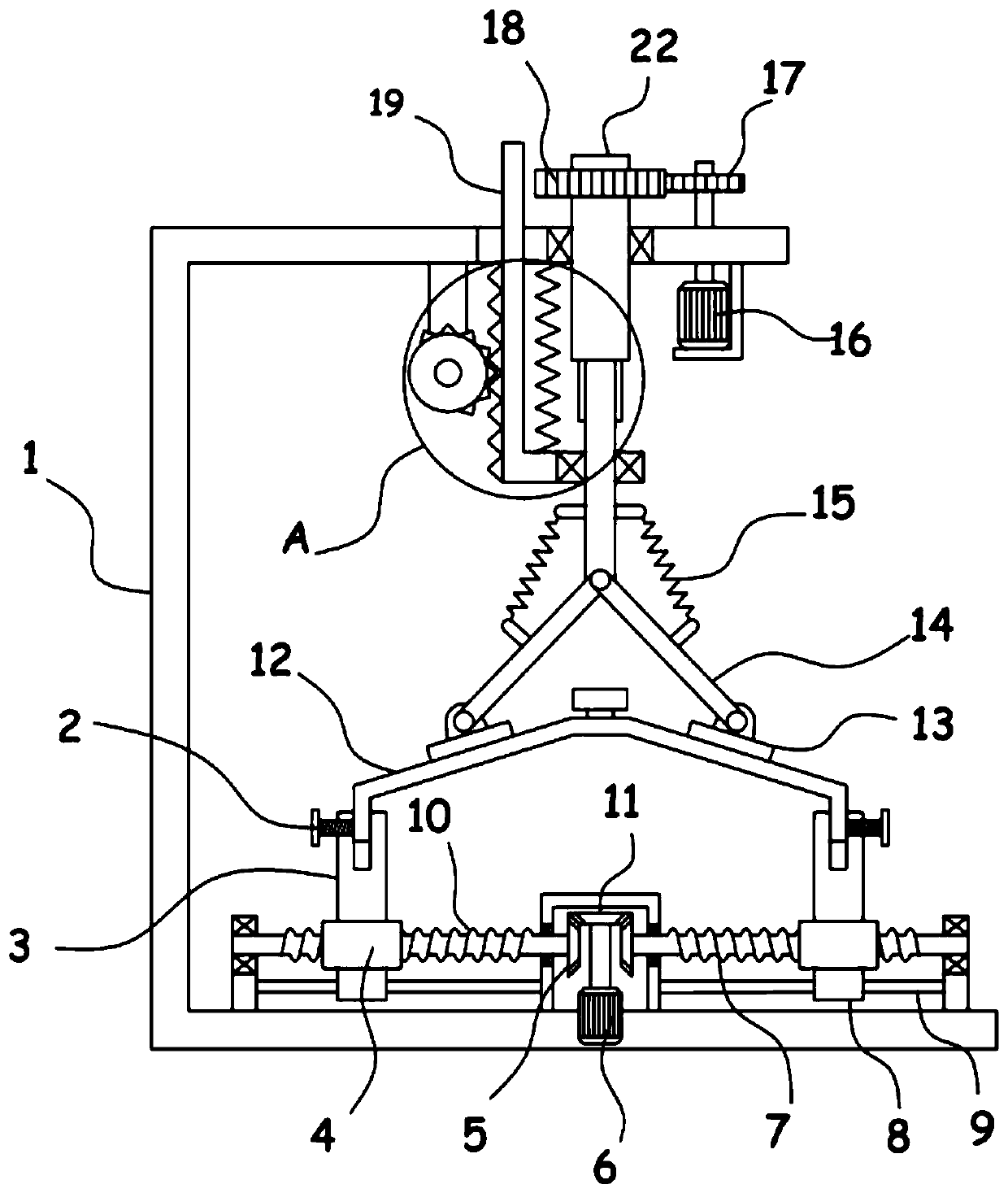

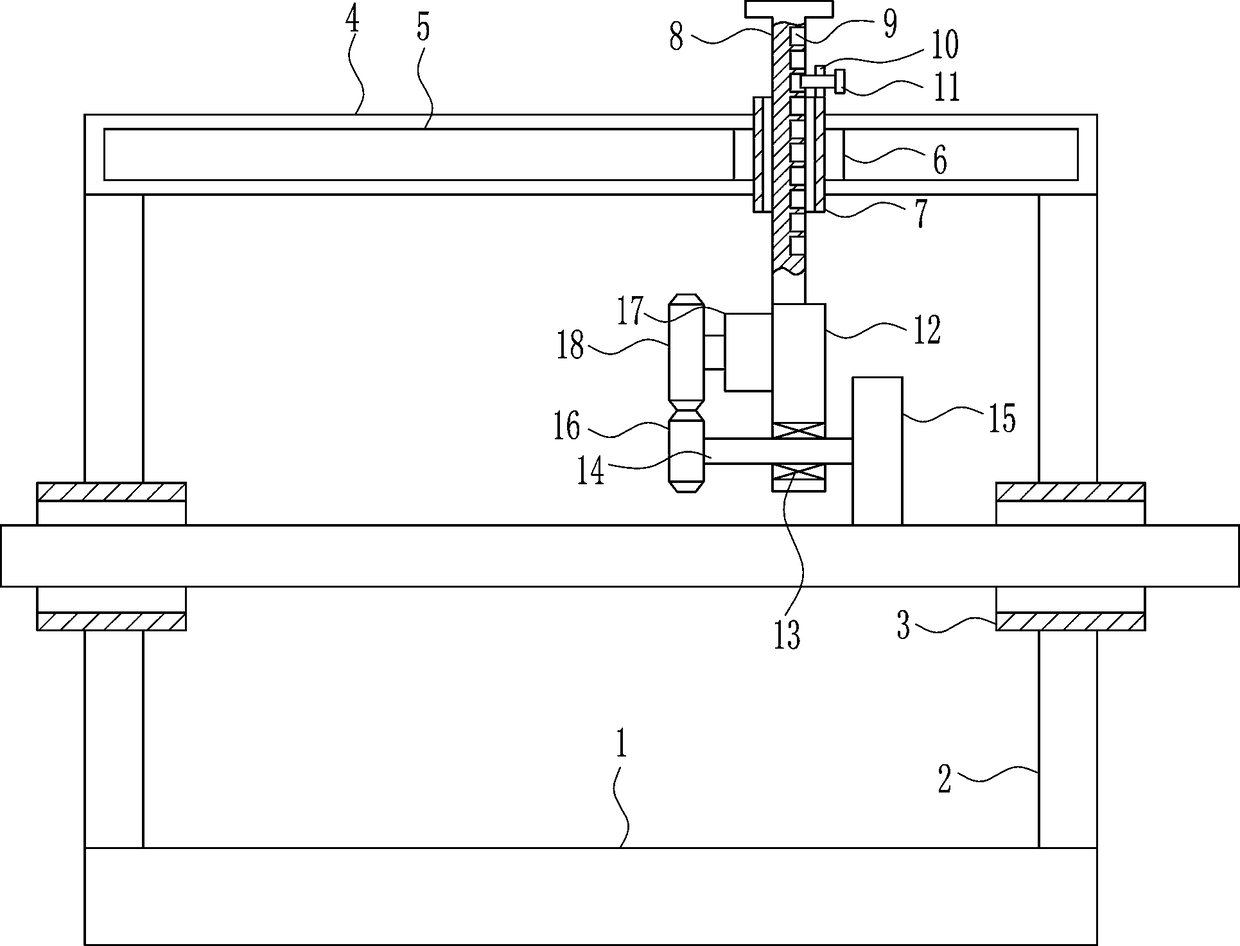

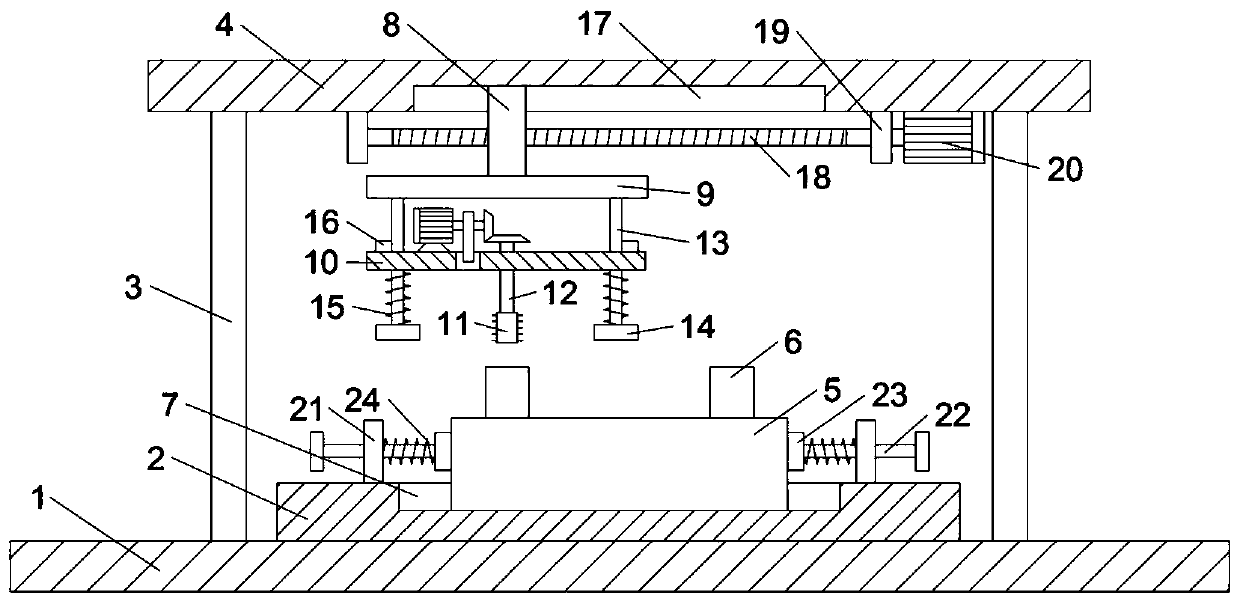

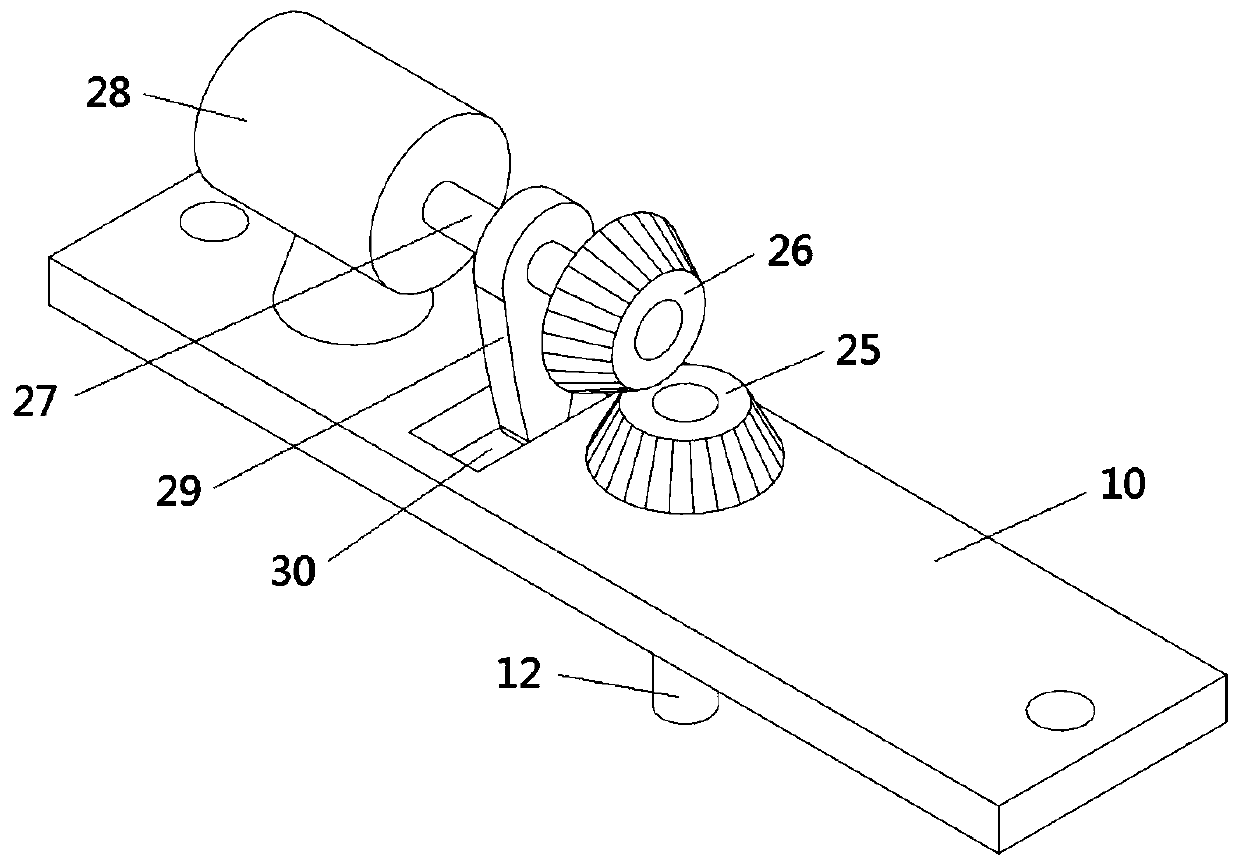

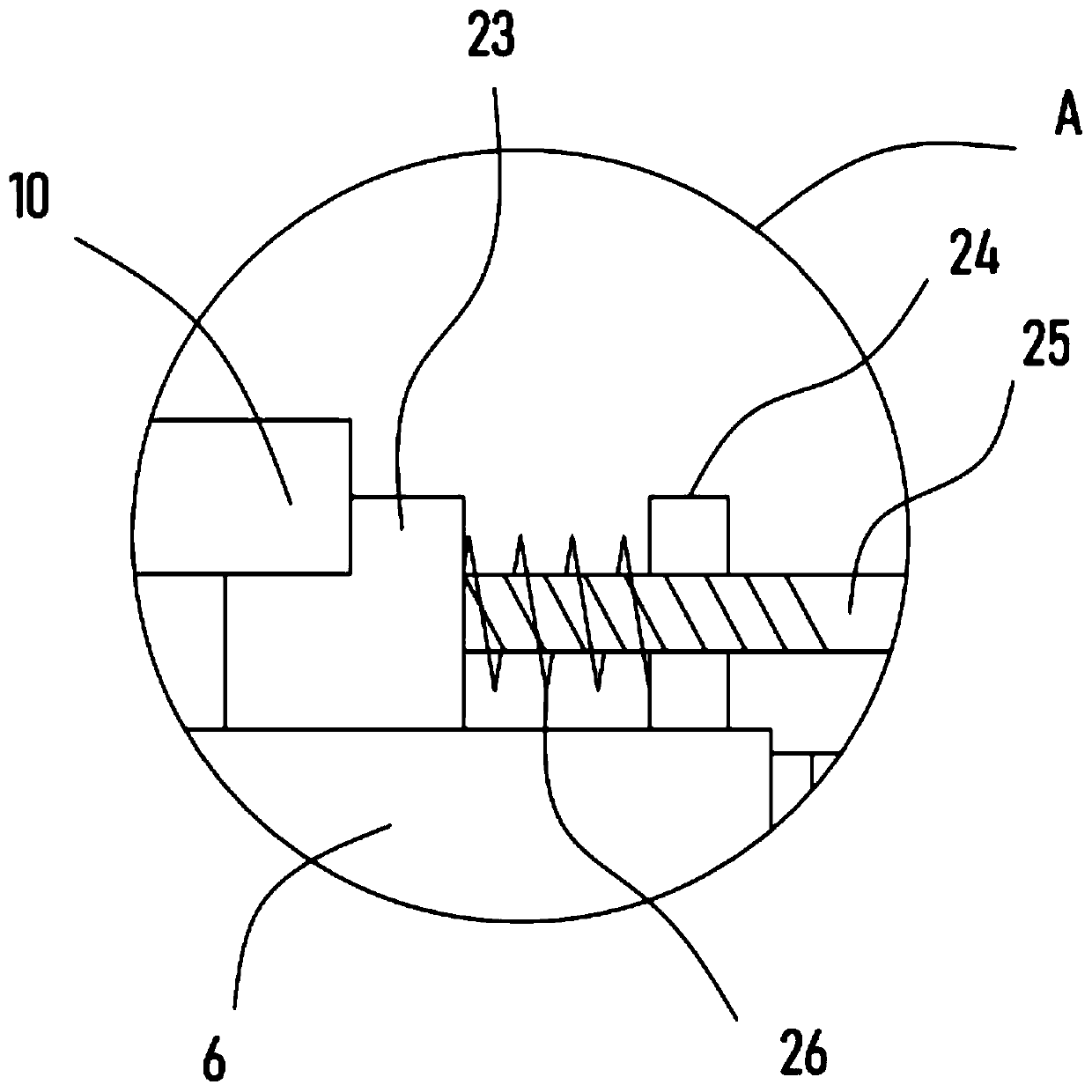

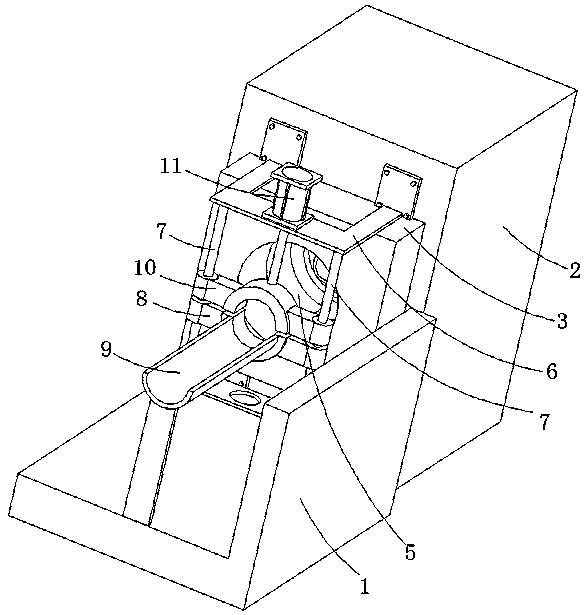

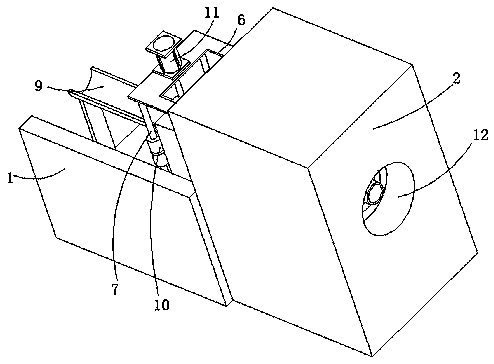

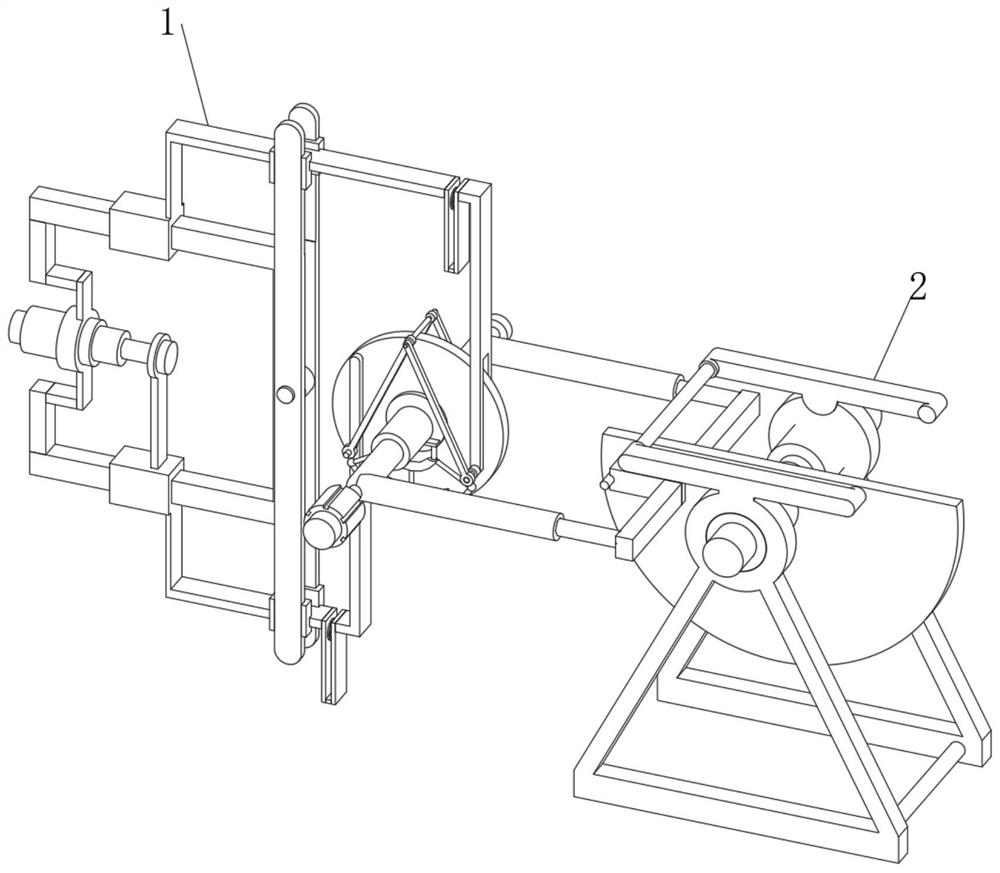

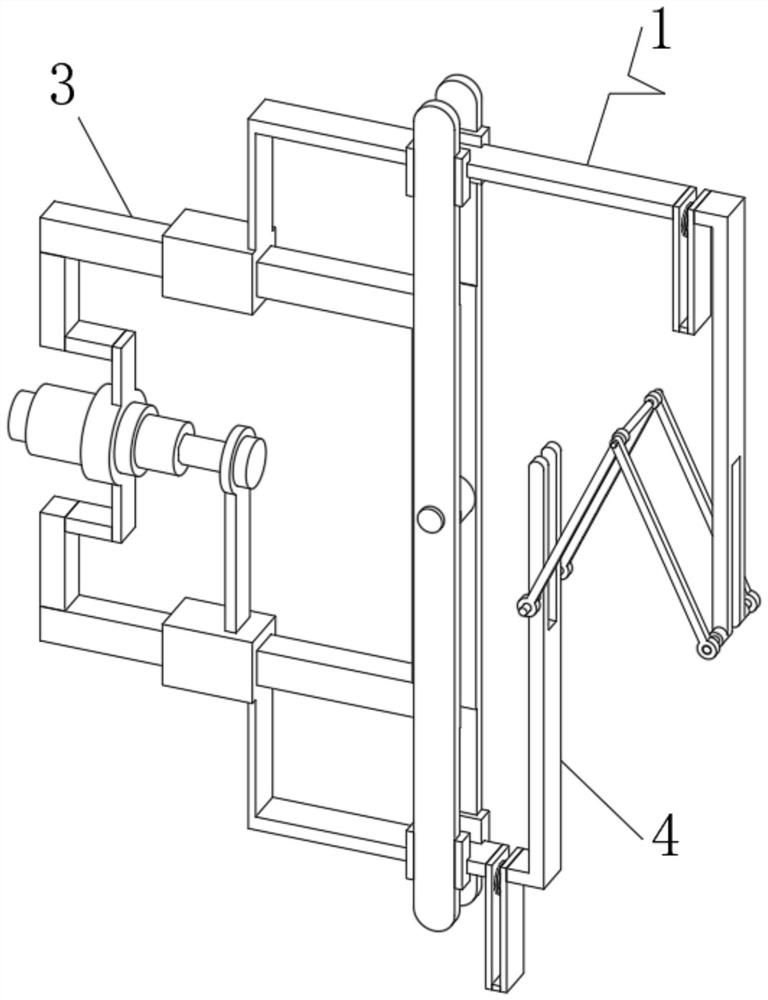

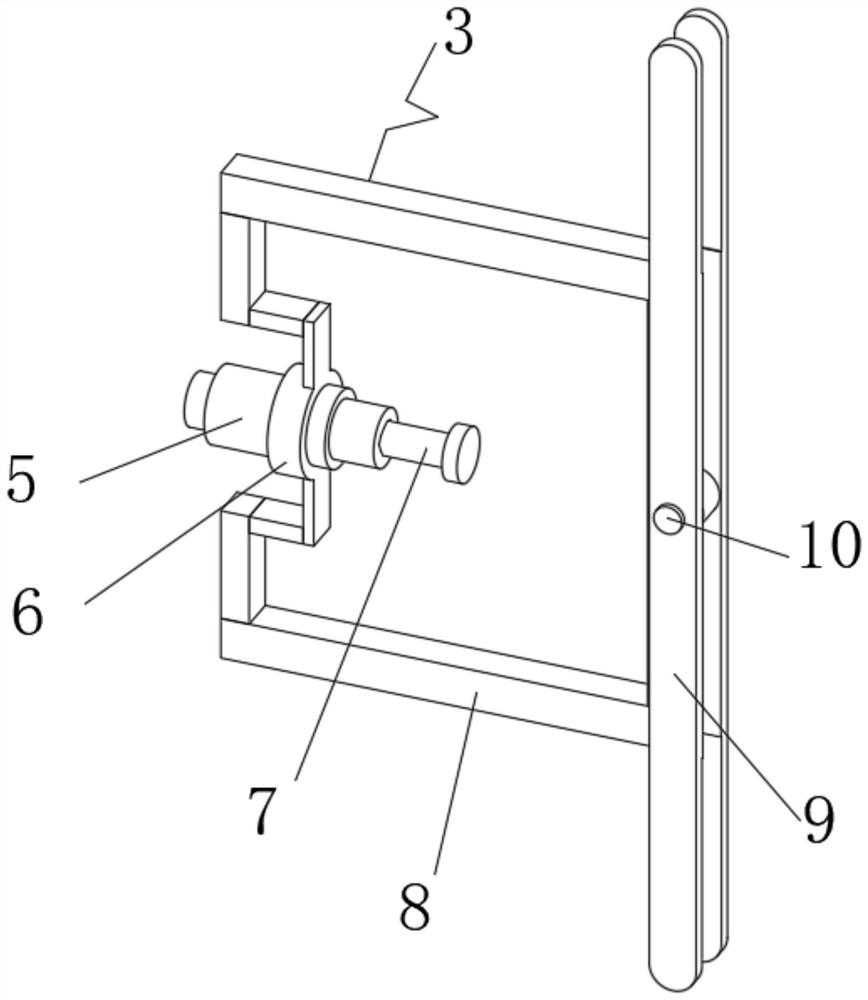

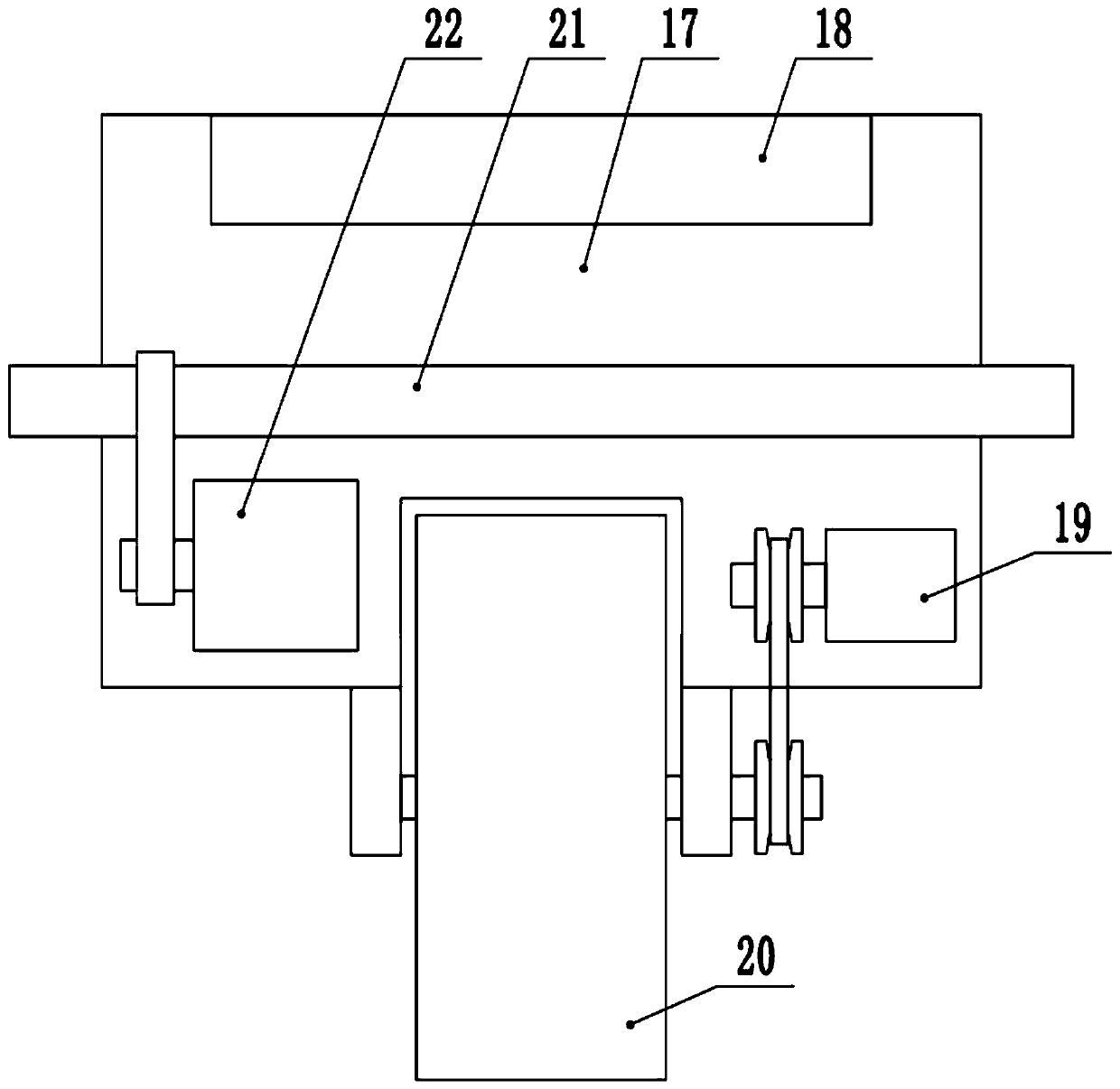

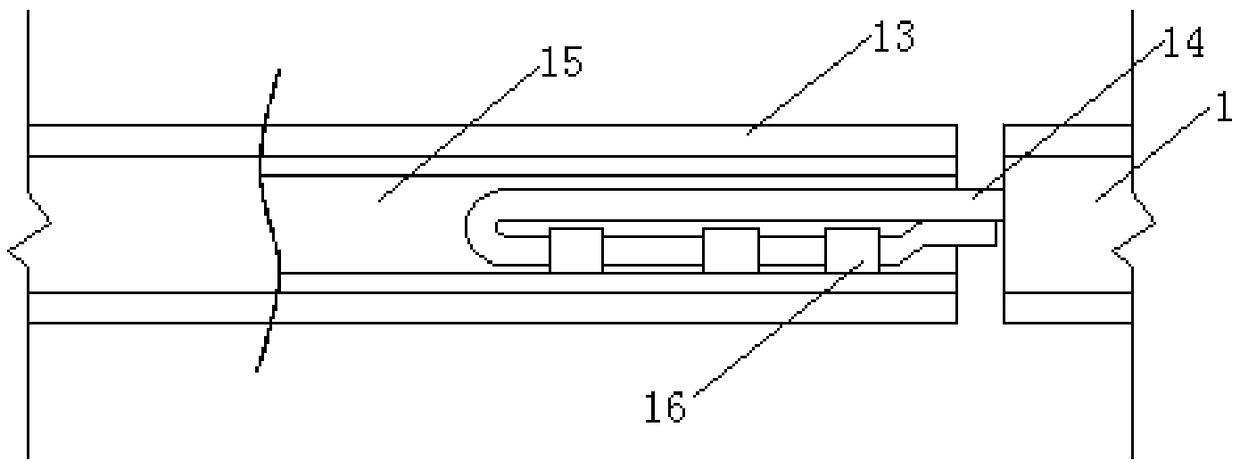

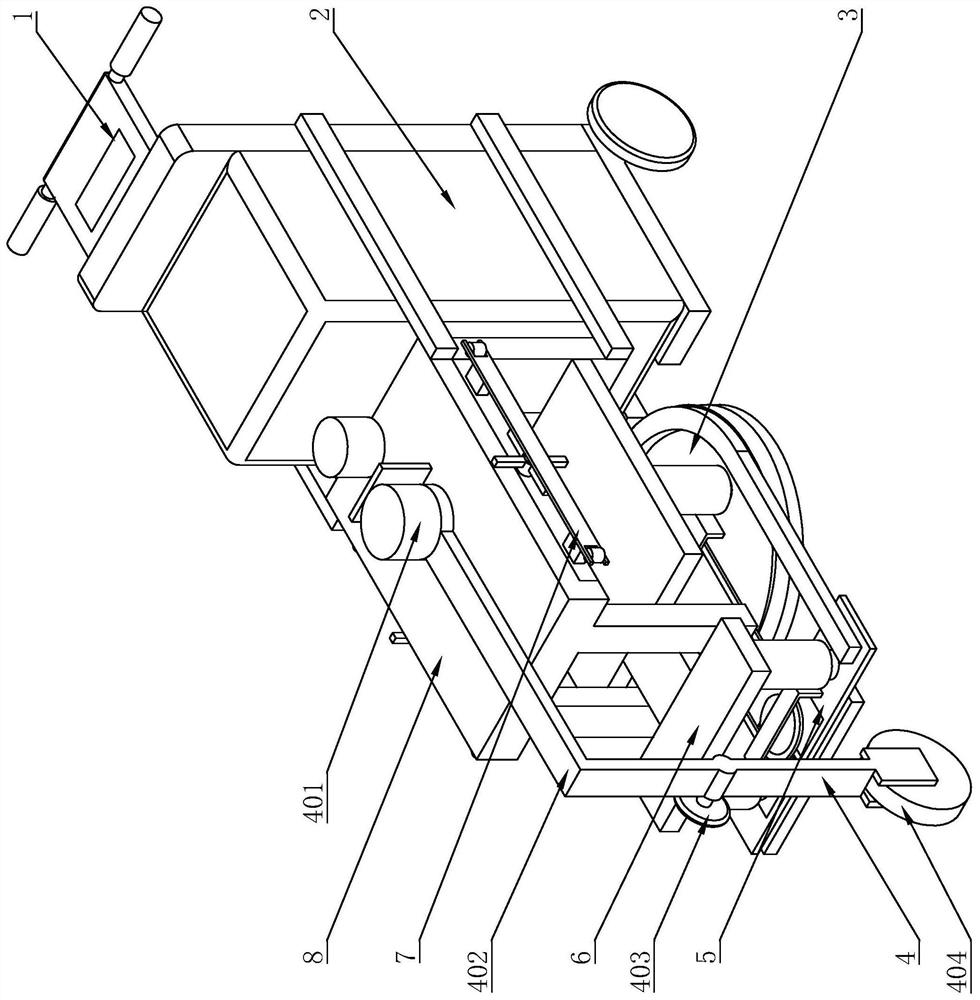

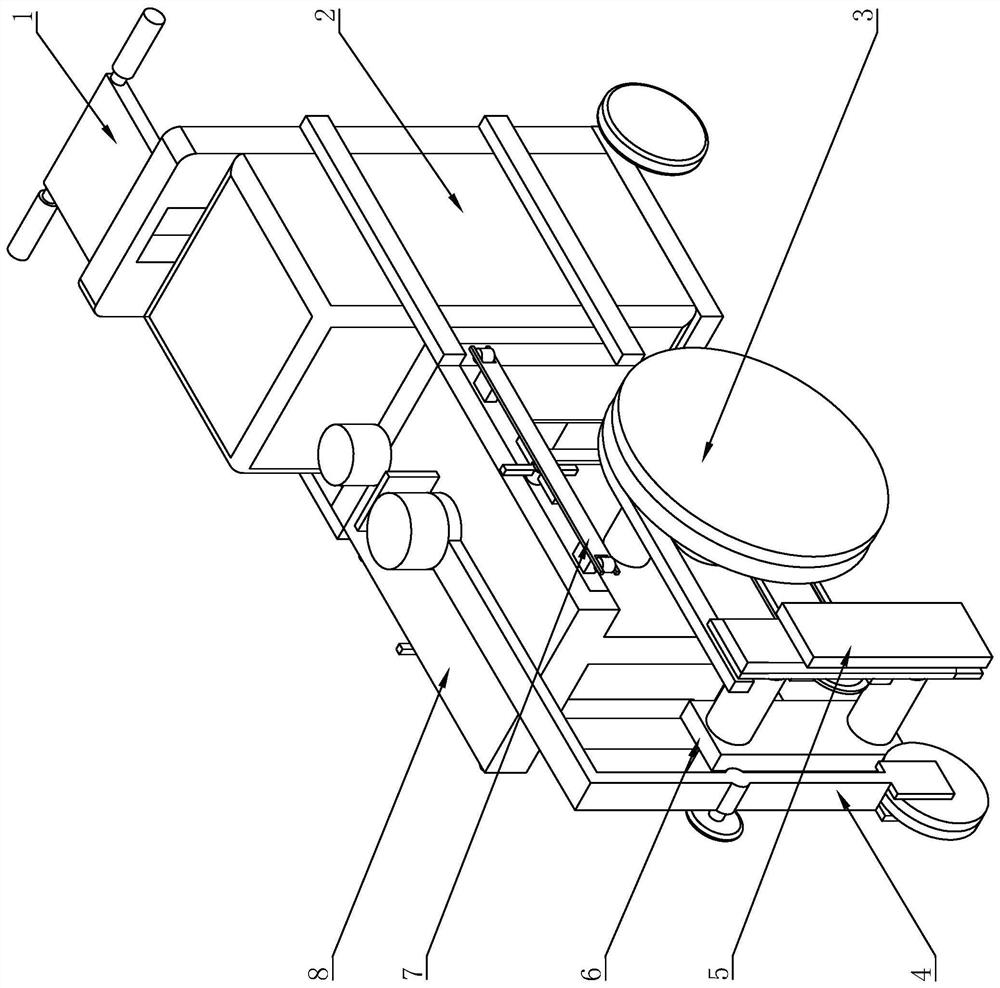

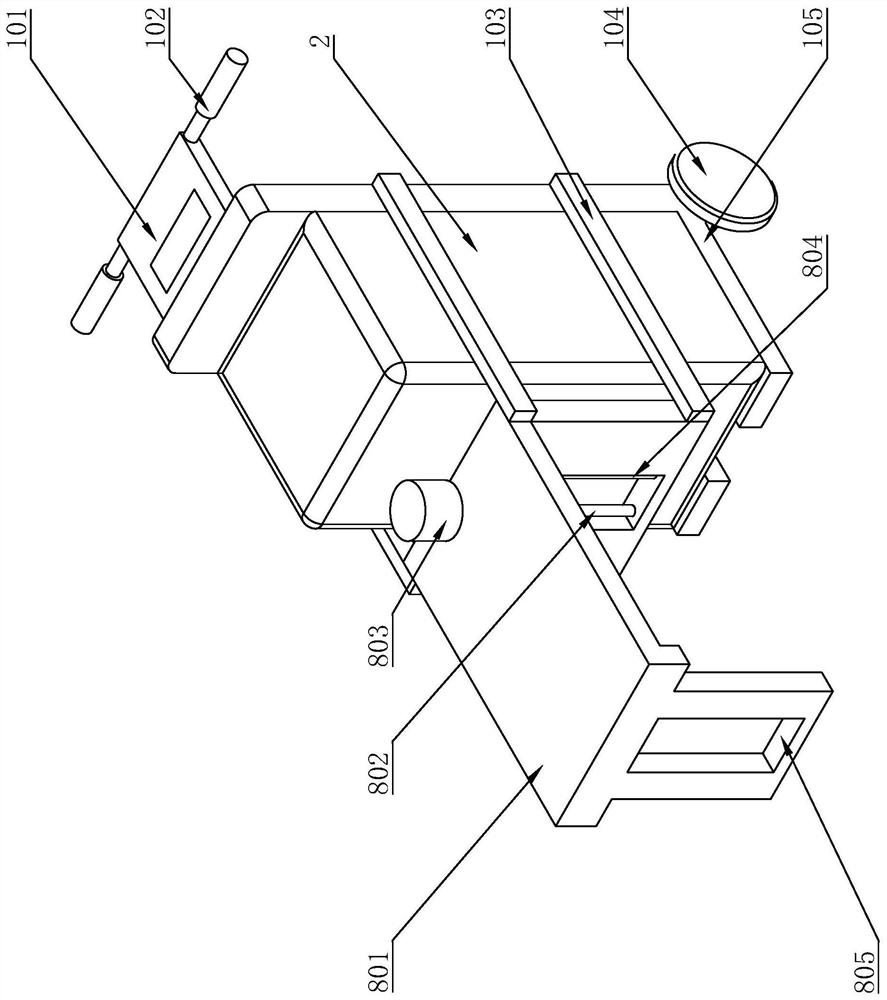

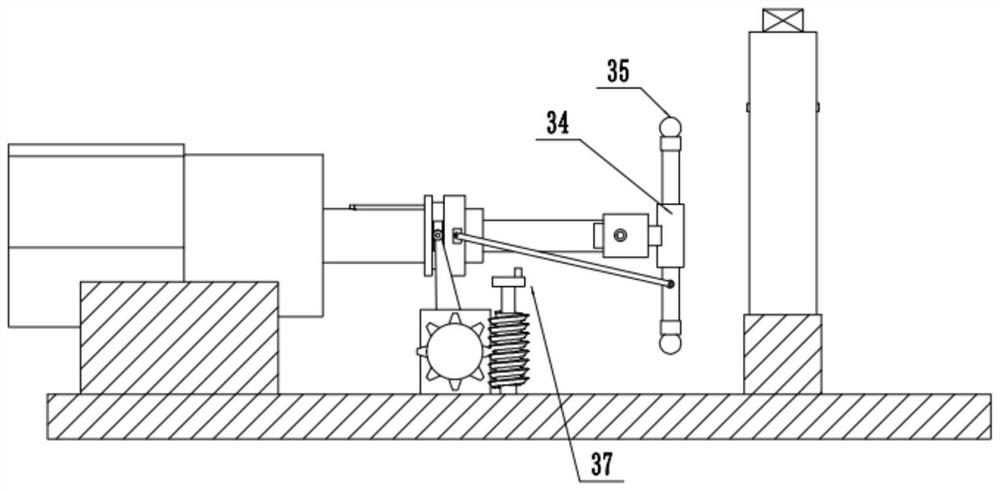

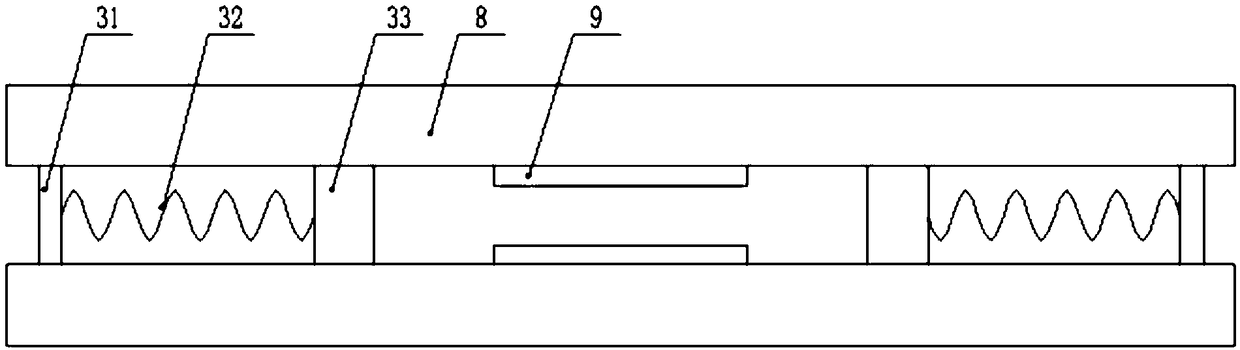

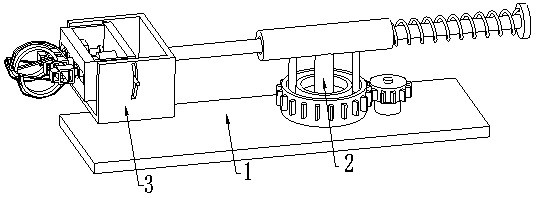

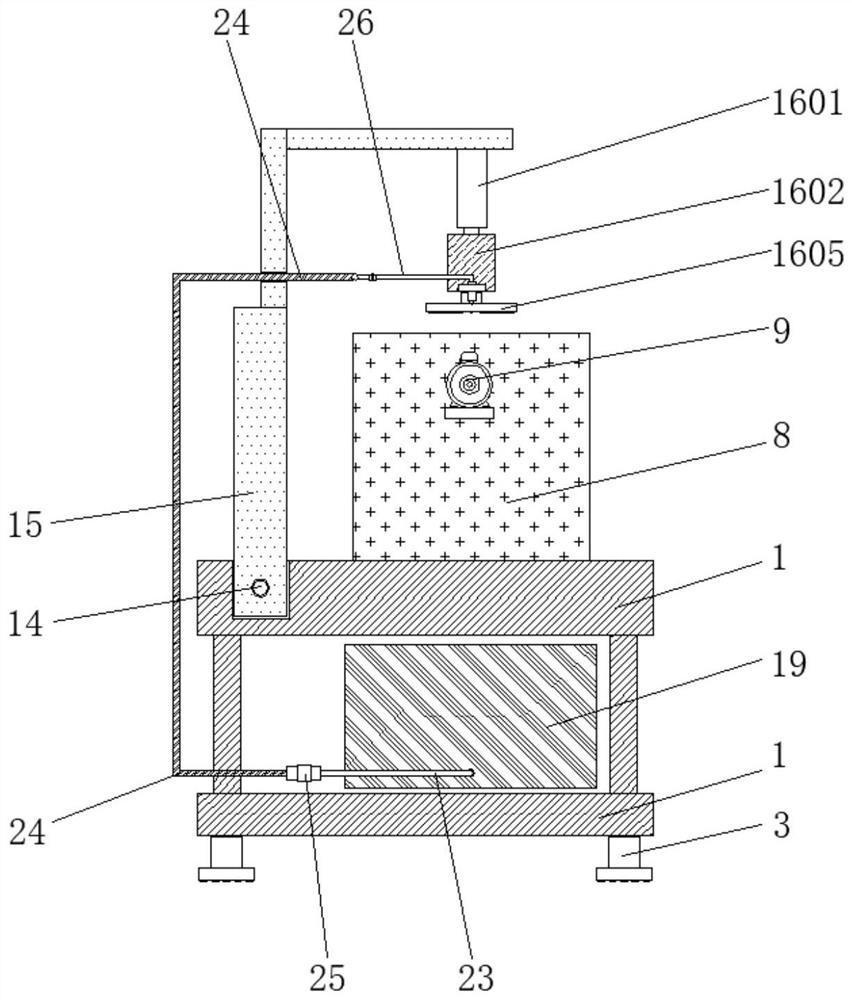

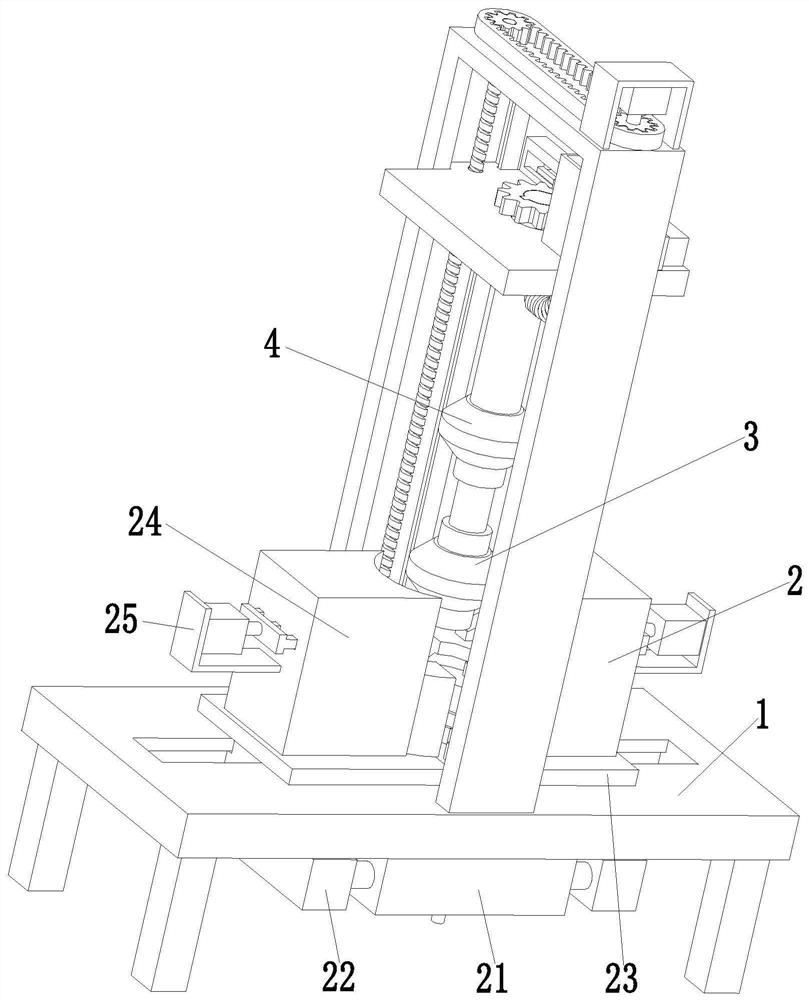

Surface bothway polishing rust removing equipment for mechanical steel tube parts

ActiveCN108177078AQuick polishFully polishedGrinding carriagesPolishing machinesMechanical componentsEngineering

The invention relates to mechanical part machining equipment, in particular to surface bothway polishing rust removing equipment for mechanical steel tube parts. The surface bothway polishing rust removing equipment for the mechanical steel tube parts can polish the surfaces of the steel tubes rapidly and comprehensively, and time and labor can be saved in the polishing process. The surface bothway polishing rust removing equipment for the mechanical steel tube parts comprises a base plate, supporting plates, sliding sleeves, a connecting plate, a sliding rail, a sliding block, a first guide sleeve and the like. The left side and the right side of the upper side of the base plate are both connected with the supporting plates. The lower portions of the front sides of the supporting plates are both connected with the corresponding sliding sleeves. By adoption of the surface bothway polishing rust removing equipment, the effects of being capable of polishing the surfaces of the steel tubes rapidly and comprehensively and further capable of saving the time and labor in the polishing process are achieved; and by adoption of the mode that a first polishing wheel and a second polishing wheel are used for polishing the upper sides and the lower sides of the steel tubes separately, the surfaces of the steel tubes can be polished quickly, and the danger caused due to the fact that usersdirectly operate a polishing machine can be avoided in the polishing process.

Owner:HANDAN HANGANG AFFILIATED ENTERPRISE CO LTD

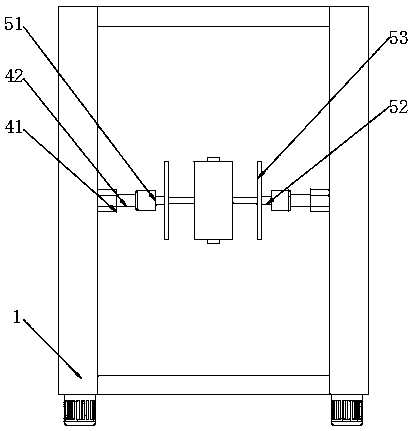

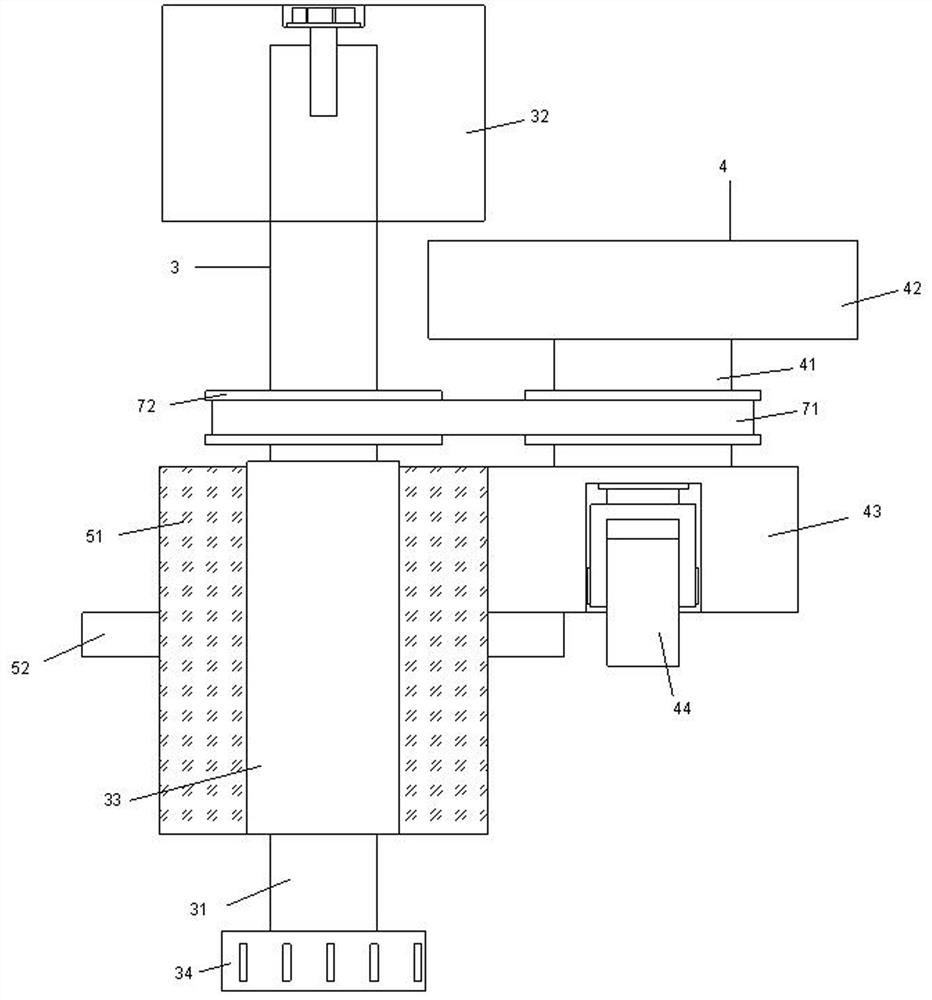

Machining device for automobile intercooler

InactiveCN110576354AGood sandingFully polishedEdge grinding machinesRevolution surface grinding machinesIntercoolerEngineering

The invention discloses a machining device for an automobile intercooler, and belongs to the field of intercooler machining. The machining device comprises a driving mechanism, a reciprocating assembly, an adjusting assembly and a positioning assembly, wherein the driving mechanism is used for driving a grinding assembly to rotate, the driving mechanism is connected with the grinding assembly, thereciprocating assembly is connected with the driving mechanism, when the driving mechanism drives the grinding assembly to rotate, the reciprocating assembly drives the grinding assembly to reciprocate linearly along the rotation axis of the grinding assembly, the adjusting assembly is used for driving the grinding assembly to linearly move on one side of a workbench, the positioning assembly isused for positioning and fixing a to-be-machined sample, and the positioning assembly is arranged on the workbench. According to the device, by means of the driving mechanism and the reciprocating assembly, a grinding roller can be driven to rotate and reciprocate up and down simultaneously, so that the inner wall of an oil pipe can be comprehensively and efficiently ground through the grinding roller to remove burrs in the oil pipe.

Owner:湖北犇超有色金属铸造股份有限公司

Steel plate surface leveling and deburring device

InactiveCN109732429AFully polishedExcellent deburring effectEdge grinding machinesGrinding drivesSteel platesSheet steel

The invention discloses a steel plate surface leveling and deburring device, and relates to the technical field of steel plate processing. The steel plate surface leveling and deburring device comprises a support bottom plate, a support frame is fixed on the support bottom plate, a horizontal plate is fixed horizontally on the support frame, a rotary disc is rotationally arranged on the horizontalplate, a clamping mechanism for clamping a steel plate is mounted on the rotary disc, and a driven shaft which is vertically arranged is pivoted to the horizontal plate. By means of the steel plate surface leveling and deburring device, a polishing head rotates to achieve polishing on the surface of the steel plate on the rotary disc, the rotary disc can drive the steel plate to rotate, the surface of the steel plate is more fully polished, and the deburring effect is more excellent. The polishing head adjusts the lateral position by adjusting the rotation of a screw rod, so that the specificposition of the steel plate is polished, and the deburring process is more targeted; and by rotating a rotating sleeve, a threaded sleeve can be driven to rotate, height lifting of the steel plate isrealized, adjustment of the polishing strength of the polishing head on the surface of the steel plate is realized, adjustment according to actual needs is facilitated, and deburring is more thorough.

Owner:卢彭

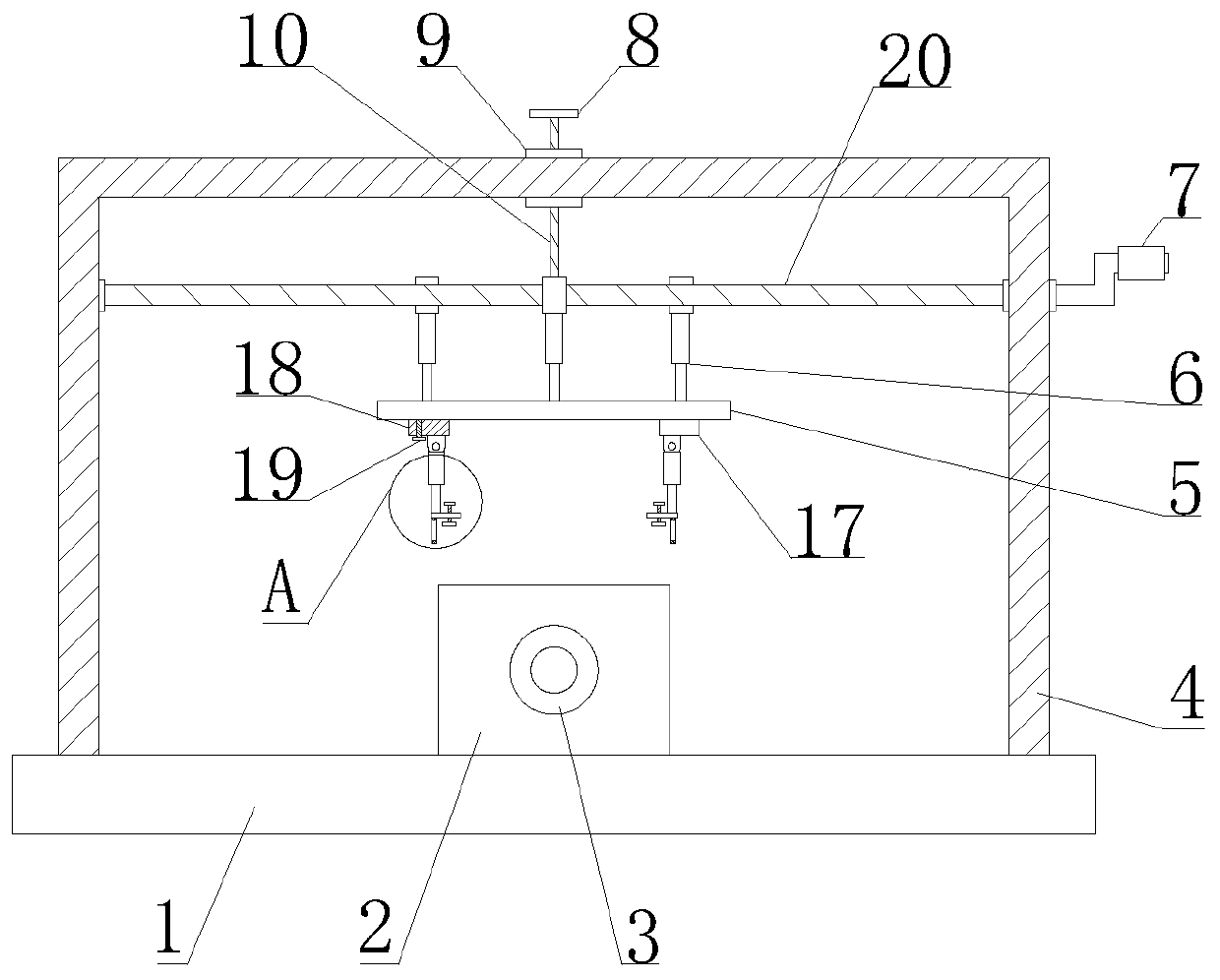

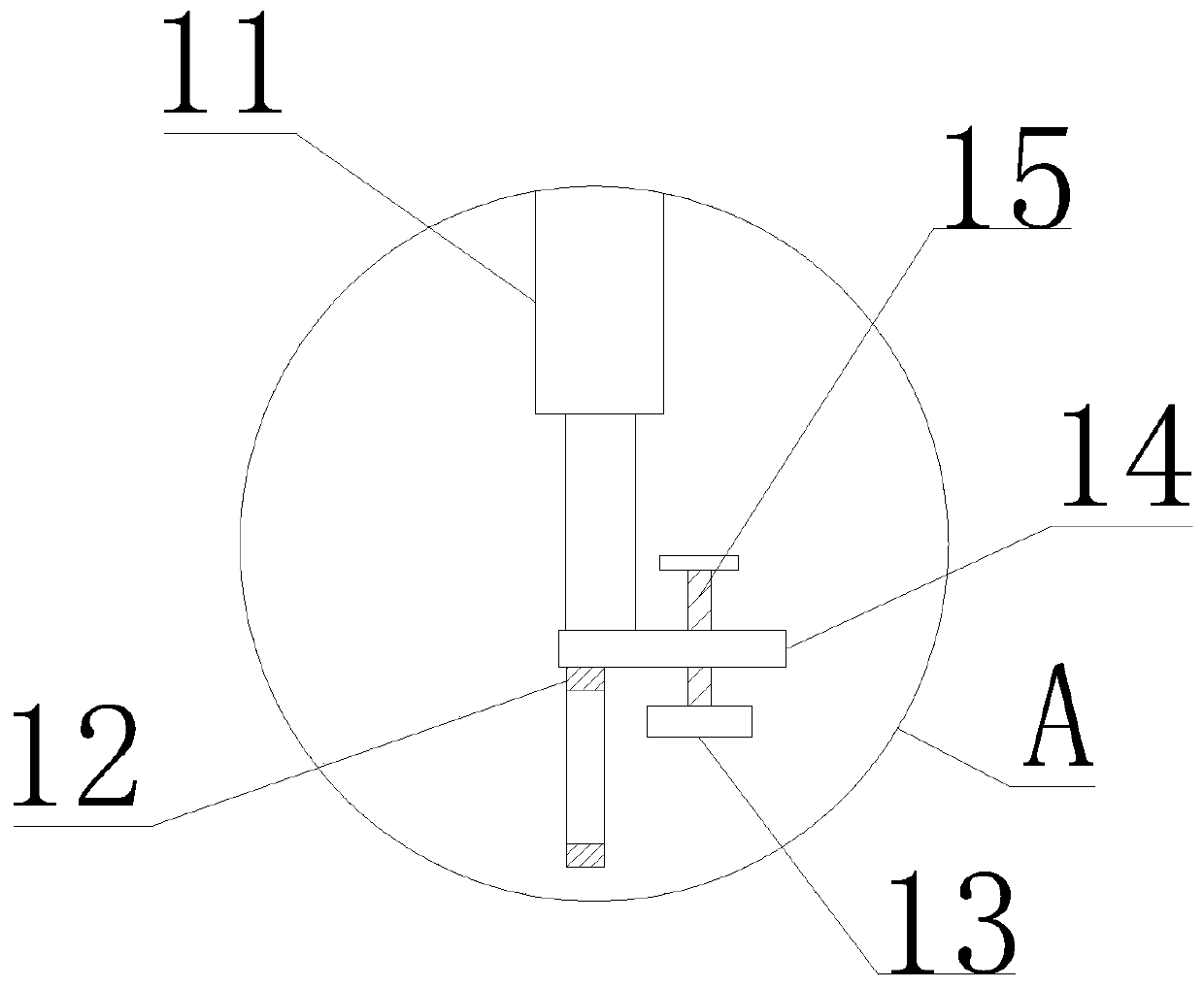

Improved motorcycle kick starter machining device and process

ActiveCN110497299AEasy to operateEasy to usePolishing machinesGrinding drivesEngineeringMachining process

The invention discloses an improved motorcycle kick starter machining device. A casing is arranged on a bottom plate; a first sliding member is slidably arranged at the top of the casing; the first sliding member is in threaded connection with a first threaded rod arranged vertically; the lower ends of a plurality of guide components are connected with a first mounting plate; the upper ends of theplurality of guide components are connected with a horizontal moving component; the upper end of the first mounting plate is rotationally connected with a first threaded rod; the upper ends of the two telescopic components are rotationally arranged on a second sliding member and a third sliding member which are arranged at the lower end of the first mounting plate; the lower ends of the two telescopic components are connected with a second mounting plate; a placing ring is arranged at the lower end of the second mounting plate; a second fixing member penetrates through the second mounting plate in a threaded mode and is rotationally connected with a clamping block; a polishing rod is located under the placing ring; the polishing rod is arranged on an output shaft of a driving device; andthe driving device is slidably arranged on the bottom plate. The invention also provides an improved motorcycle kick starter machining process. The machining device and process are simple in operationand convenient in use, and sand marks on the surface of a kick starter can be effectively polished.

Owner:重庆原创机械制造有限公司

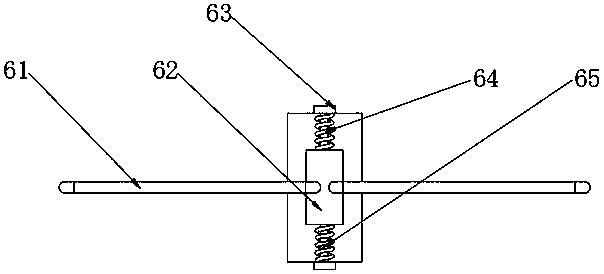

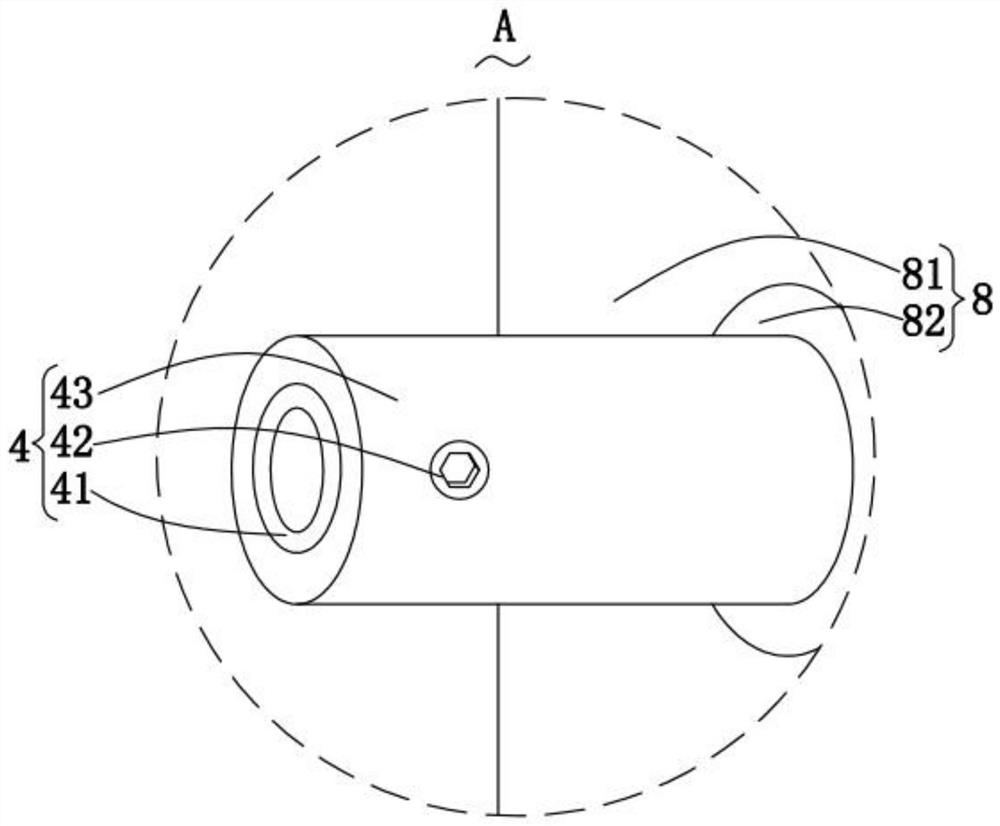

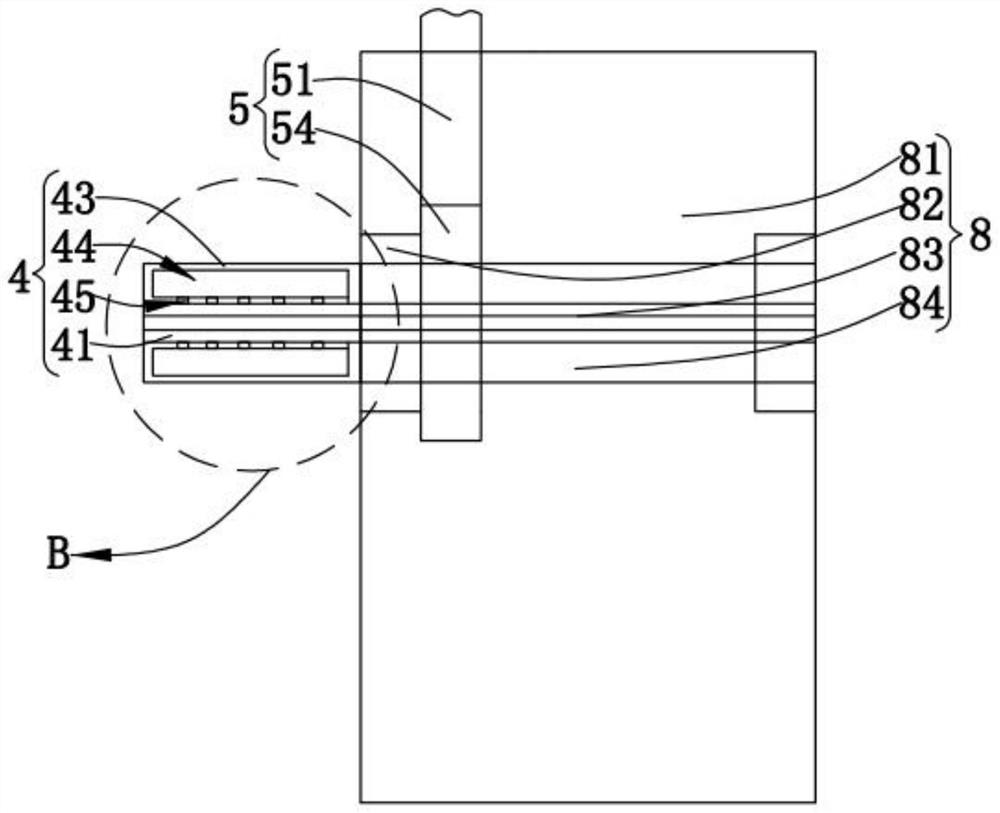

Intelligent grinding equipment for plastic pipe production

InactiveCN110900355AFully polishedAdjustable positionEdge grinding machinesGrinding carriagesStructural engineeringGrinding wheel

The invention discloses intelligent grinding equipment for plastic pipe production, and belongs to the technical field of intelligent plastic pipe production equipment. The equipment comprises a box body and a grinding shell fixedly arranged at an end part of the box body, wherein a mounting block is fixedly arranged on a side wall of the end, close to the box body, of the grinding shell, a through hole allowing a pipe to pass through is formed in the mounting block, mounting rods are fixedly arranged on an upper side wall and a lower side wall of the mounting block, a symmetrical sliding rodis fixedly arranged between the two mounting rods, a fixing block is fixedly arranged at a bottom end of the sliding rod, a conveying pipe allowing the pipe to be conveyed is fixedly arranged on the fixing block, and a sliding block is further slidably connected with a top end of the sliding rod. The equipment is advantaged in that the mounting shell capable of rotating along the pipe is arranged,a polishing grinding wheel capable of being attached to the pipe is arranged, so the mounting shell drives the polishing grinding wheel to rotate along the periphery of the pipe when rotating, and anend opening of the pipe can be conveniently polished in all directions.

Owner:南京丰濠网络科技有限公司

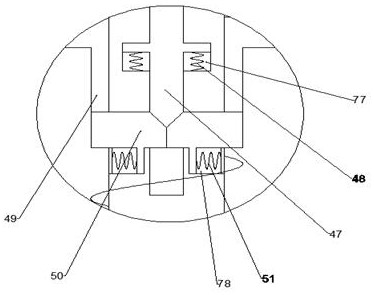

Disc type polishing device for machining

InactiveCN113276000AEasy connection and adjustment workEasy to grindPolishing machinesGrinding drivesPolishingEngineering

The invention discloses a disc type polishing device for machining. The disc type polishing device comprises a polishing device body, a driving device is arranged at the side end of the polishing device body, the polishing device body comprises a mounting part and a moving part, and the mounting part is arranged on one side of the inner end of the polishing device body. The side end of the mounting part is slidably connected with the moving part, the mounting part comprises a hydraulic elevator, a stable lantern ring, a push rod, a supporting rod frame, a hinge plate and a shaft sleeve, the hydraulic elevator is mounted in the center of the inner end of the mounting part, and the side end of the hydraulic elevator is fixedly connected with the stable lantern ring in a sleeving mode. The bottom end of the stabilizing lantern ring is fixedly connected with the supporting rod frame, and the center of the side end of the supporting rod frame is hinged to the hinge plate through the shaft sleeve. According to the disc type polishing device for machining, through the arrangement of the polishing device, the purpose of polishing the inner end is achieved.

Owner:新昌县云大农业有限公司

Automatic burr grinding device for mechanical accessories

ActiveCN111300200AAvoid bodily injuryFully polishedEdge grinding machinesGrinding feedersEngineeringWorkbench

The invention discloses an automatic burr grinding device for mechanical accessories, and relates to the technical field of mechanical accessory machining. The automatic burr grinding device comprisesa workbench, supporting legs are fixedly connected to the four corners of the bottom end of the workbench, side plates are arranged at the two ends of the top of the workbench correspondingly, the side plates are slidably connected with the workbench, and pressing and grinding devices are arranged on the adjacent sides of the two side plates correspondingly; an air purifying device is arranged atthe top end of the position between the two side plates, first telescopic rods are fixedly connected to the two ends of the bottom of the workbench, pull plates are fixedly connected to the bottom ends of the first telescopic rods, fixing plates are fixedly connected to the top ends of the pull plates, a feeding polishing device is arranged between the two fixing plates, and shielding mechanismsare arranged on the side edges of the side plates; and clamping driving mechanisms are arranged on the side edges of the workbench. According to the automatic burr grinding device, mechanical parts are polished comprehensively, the automation degree is high, and the protection performance on operators is good.

Owner:陈思涵

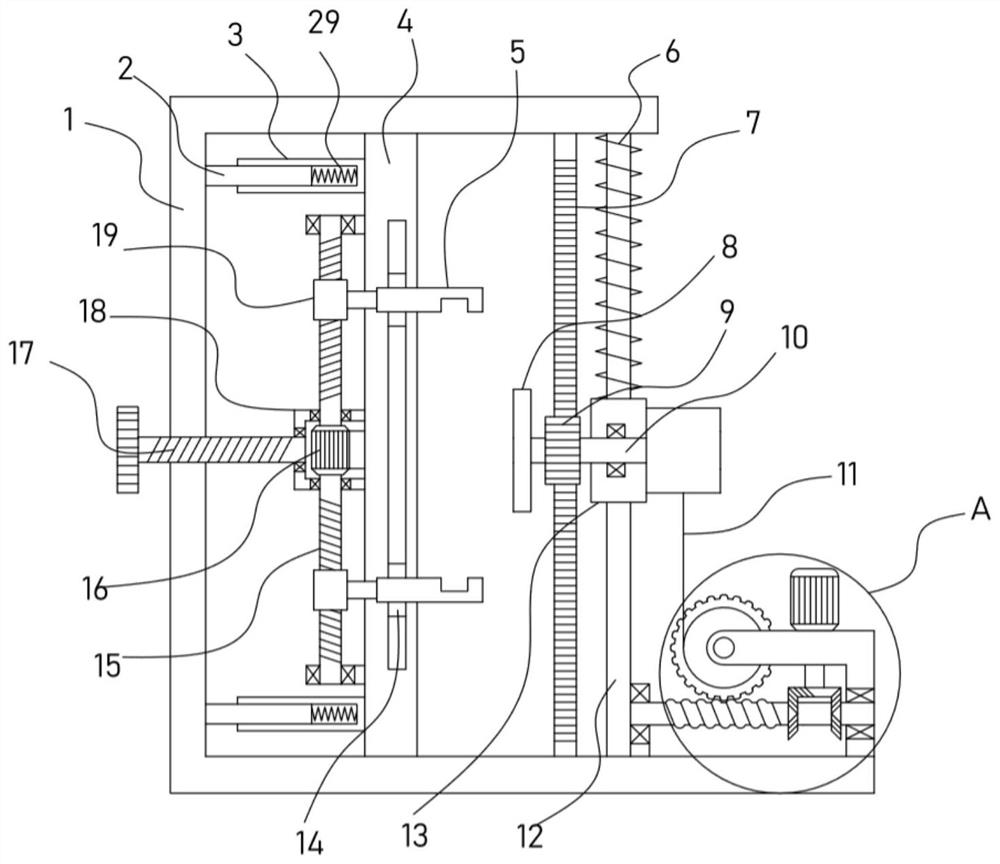

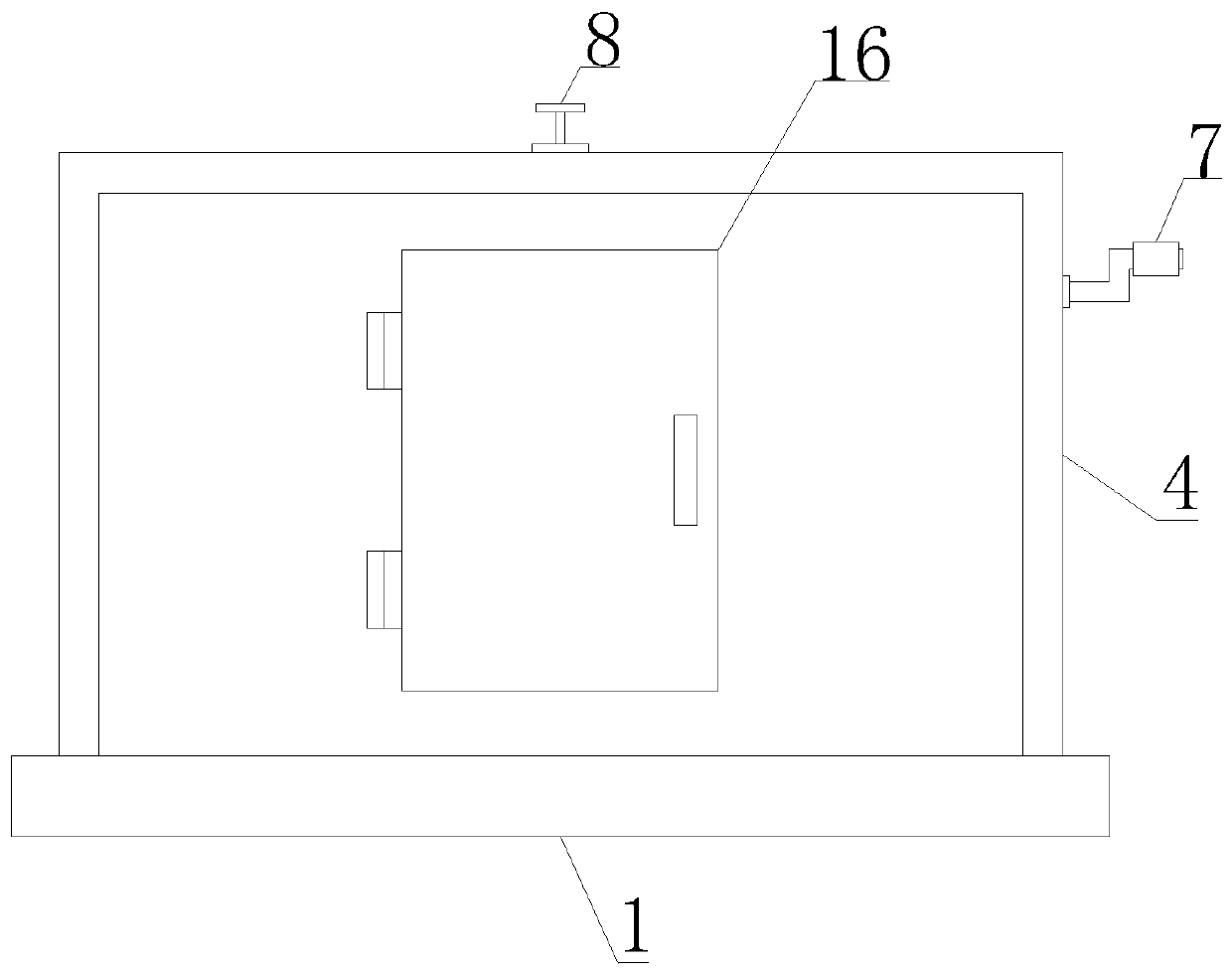

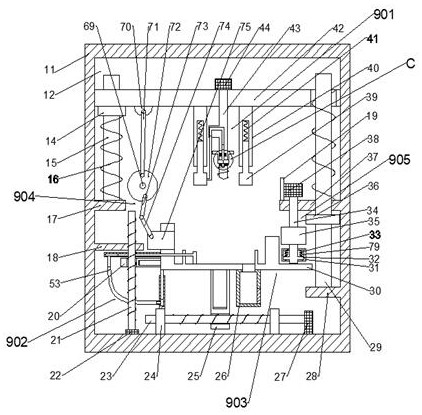

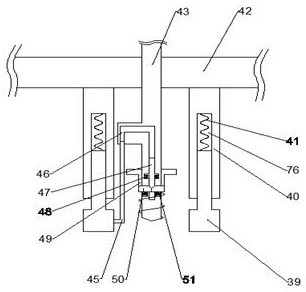

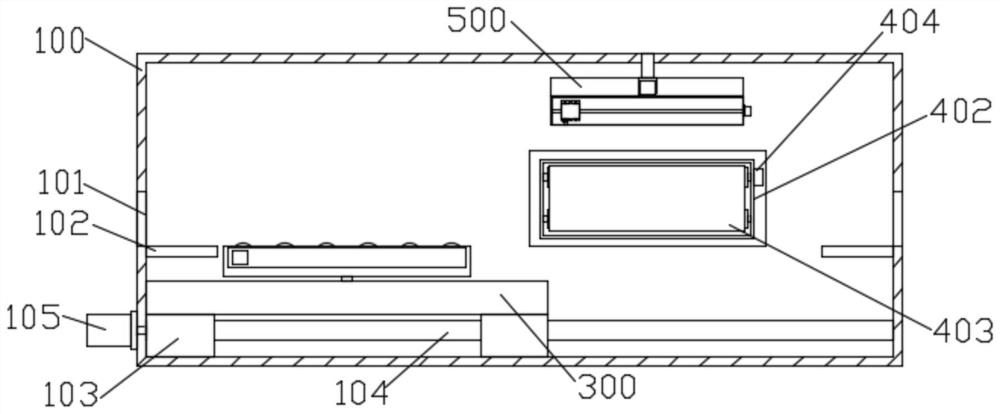

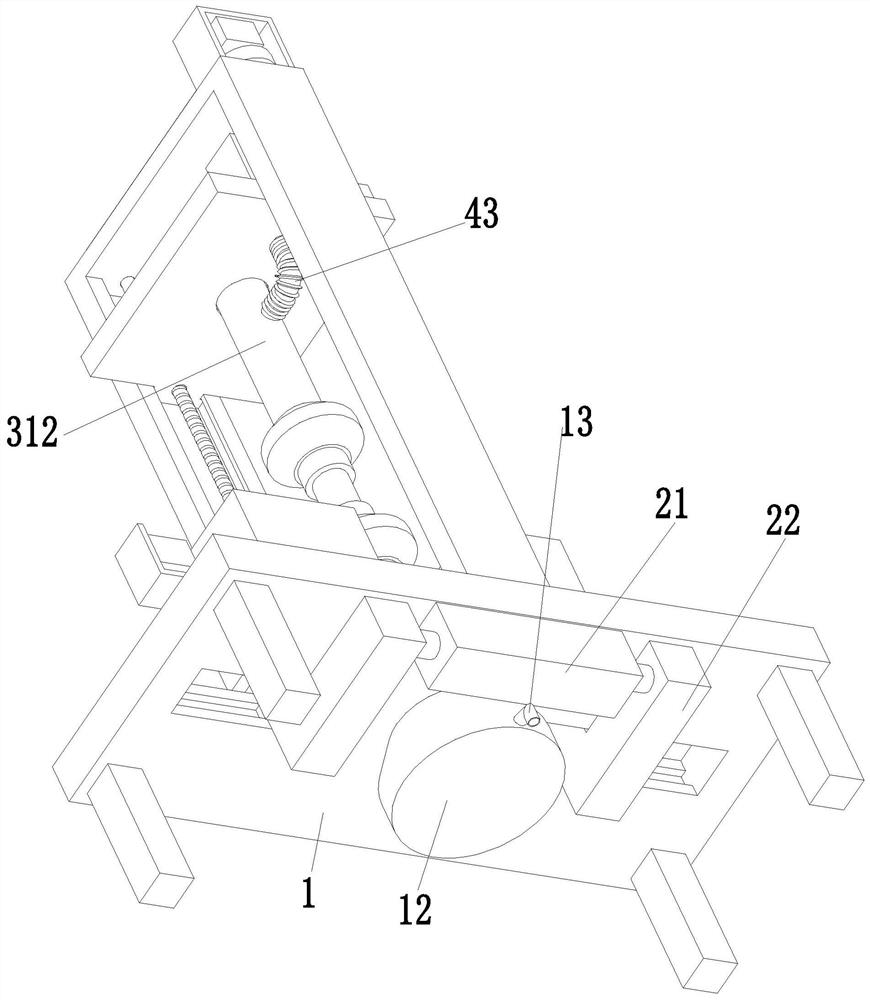

Device capable of freely drilling fine hole on same horizontal plane

InactiveCN111975031AFully polishedPrevent cracks on the edge of the hole, etc.Maintainance and safety accessoriesBoring/drilling machinesPhysicsDrill hole

The invention discloses a device capable of freely drilling a fine hole on a same horizontal plane. The device comprises a box body, the box body is provided with a cavity, and the cavity is providedwith an installation device which is located at the upper side of the bottom wall of the box body. The device realizes the function of freely punching holes on a workpiece by freely changing the position of a worktable, the drilled holes are comprehensively polished to make the punched holes finer, through the process of slowly moving down a screw rod, the amount of feeding of the punching can becontrolled to prevent cracks on the edge of the hole during the punching process; and after the drilling is completed, the surface of the worktable is cleaned to ensure that each drilling work is carried out smoothly and orderly.

Owner:福州台江蓝晶灵科技有限公司

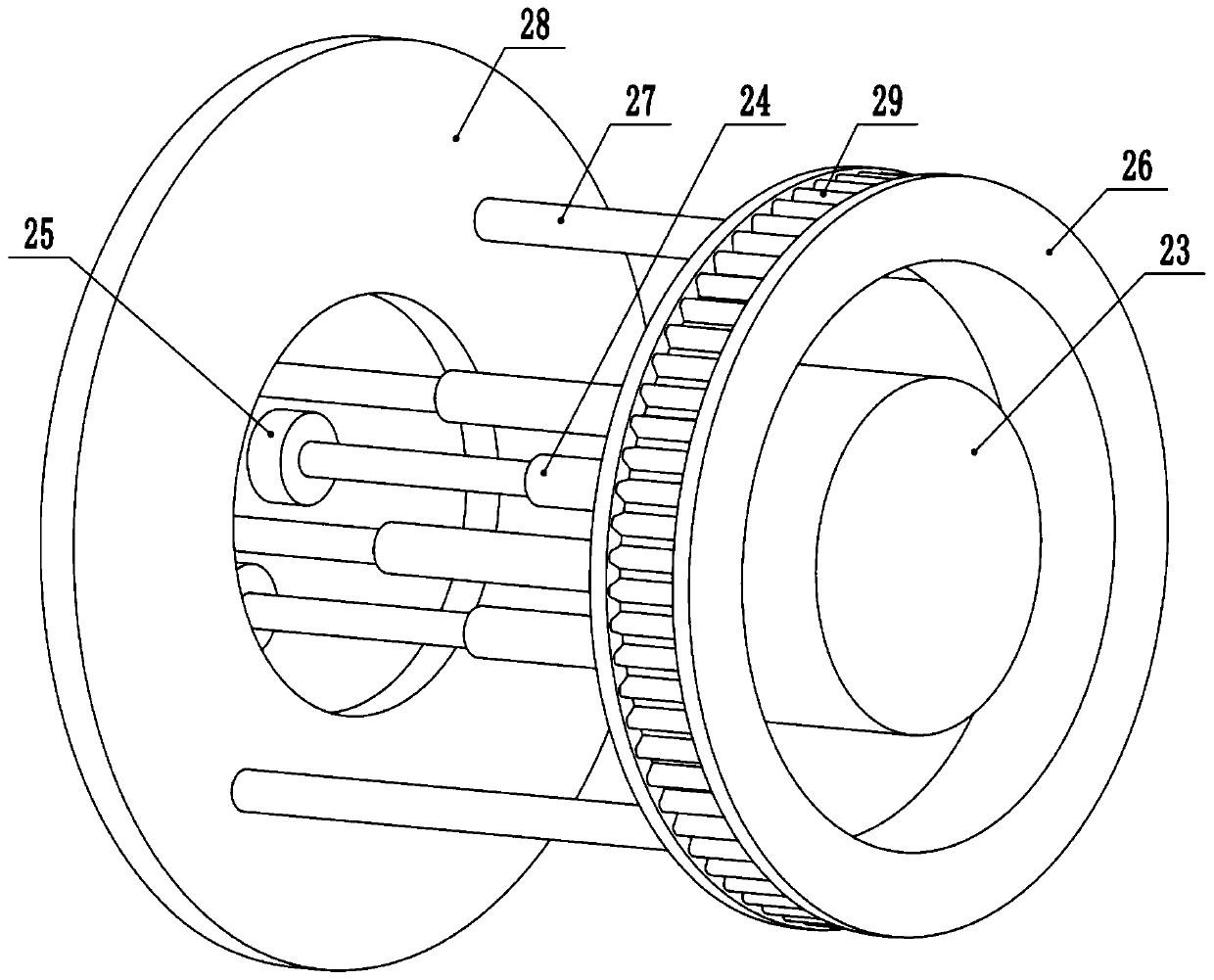

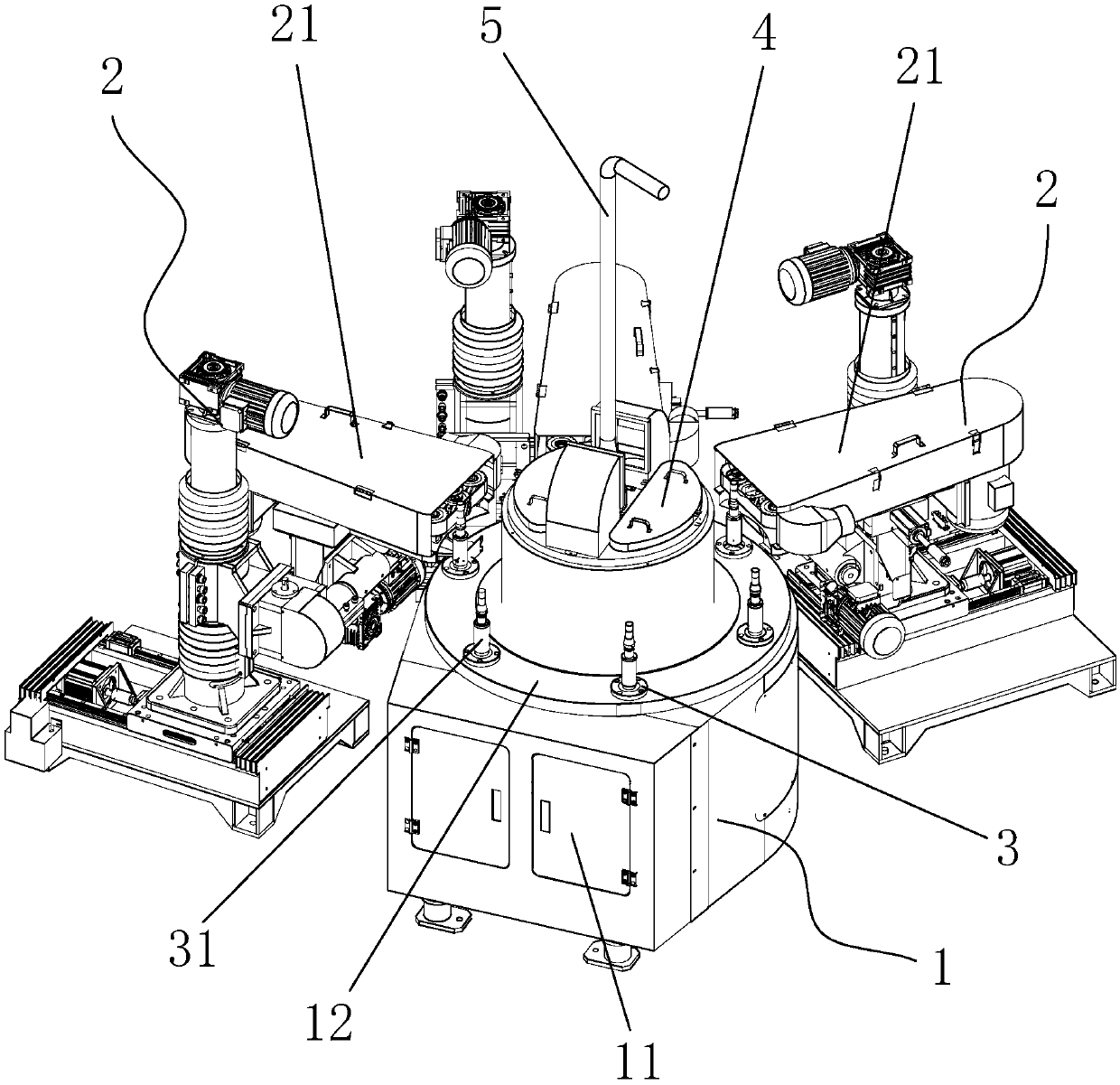

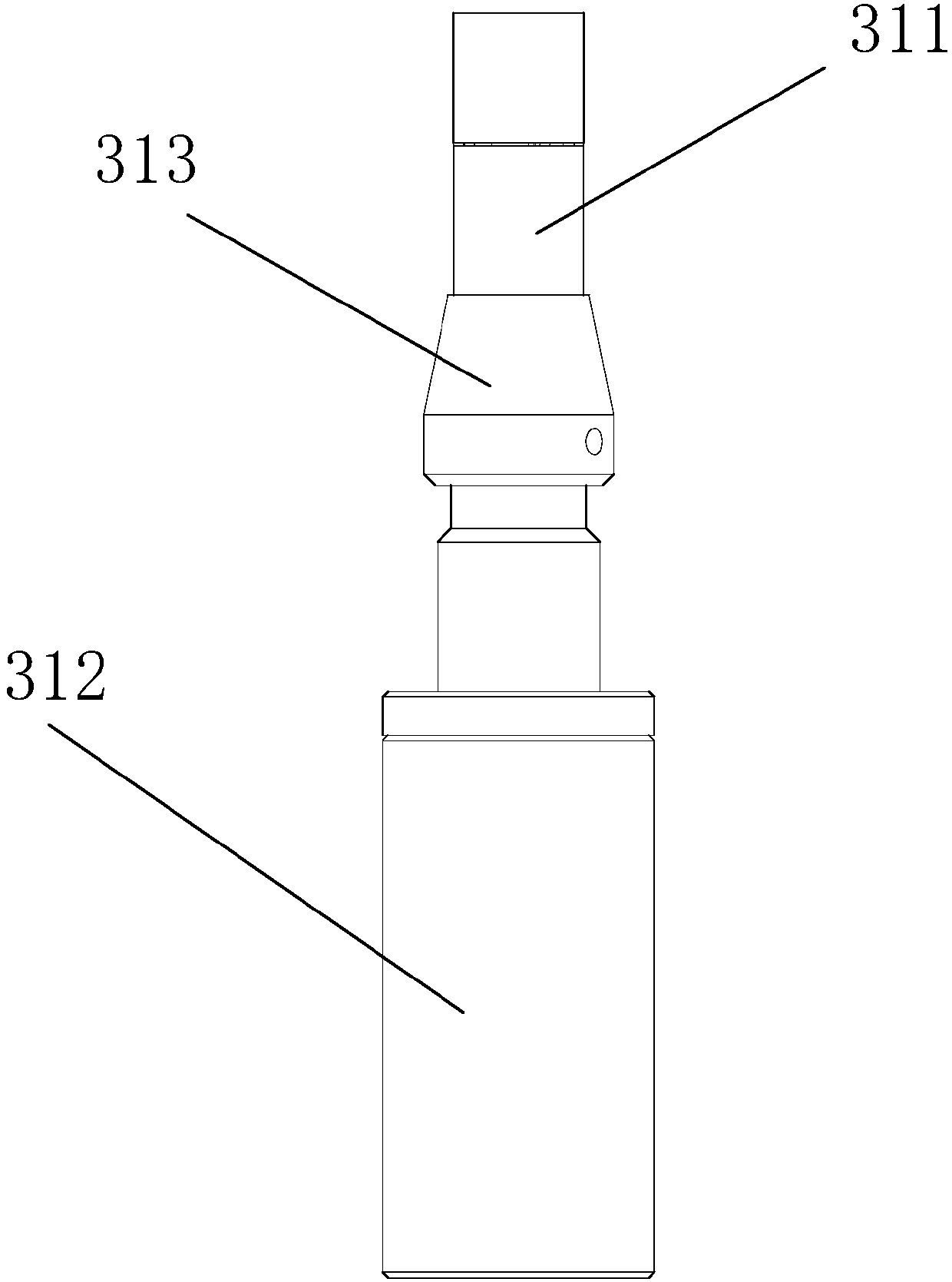

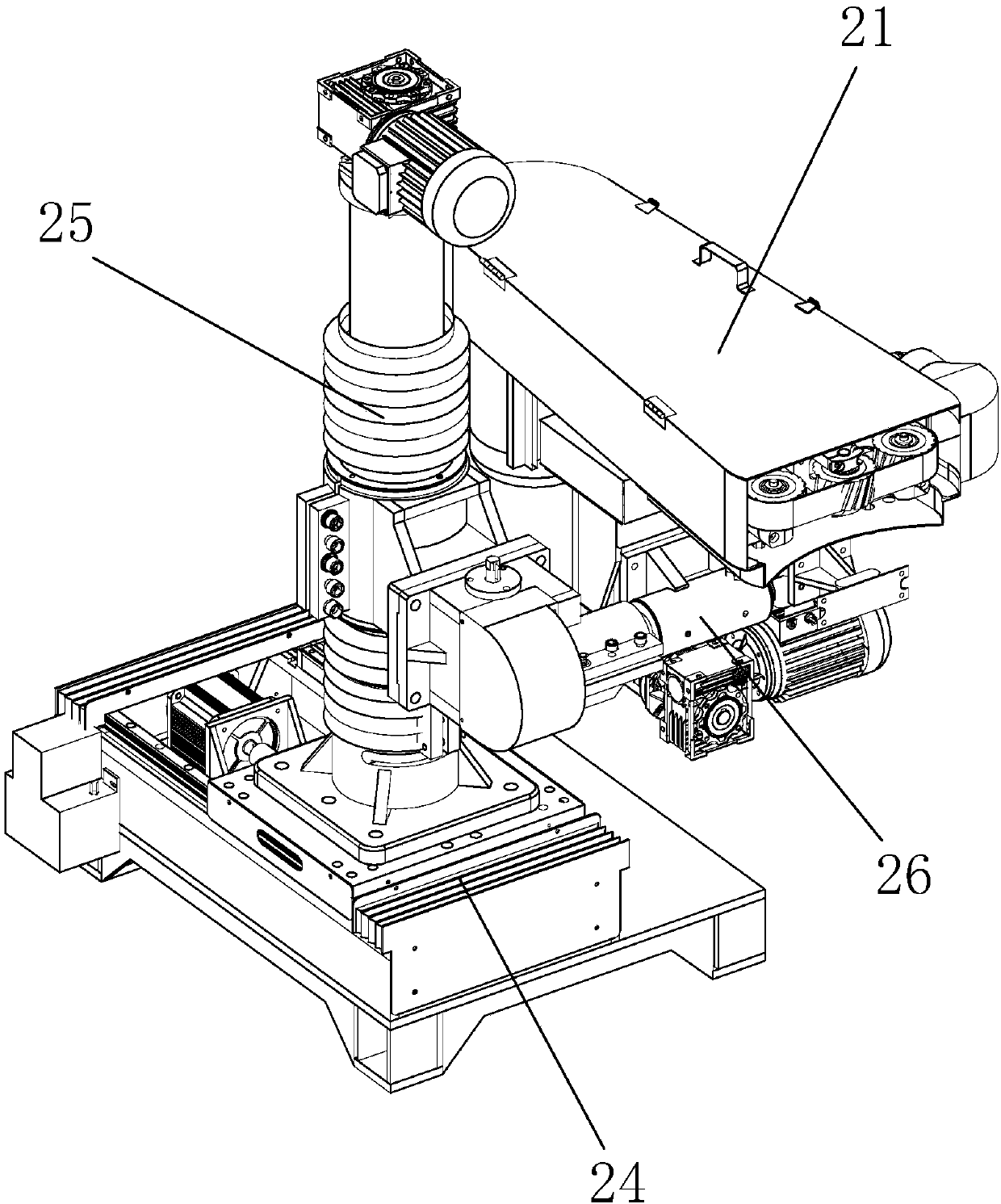

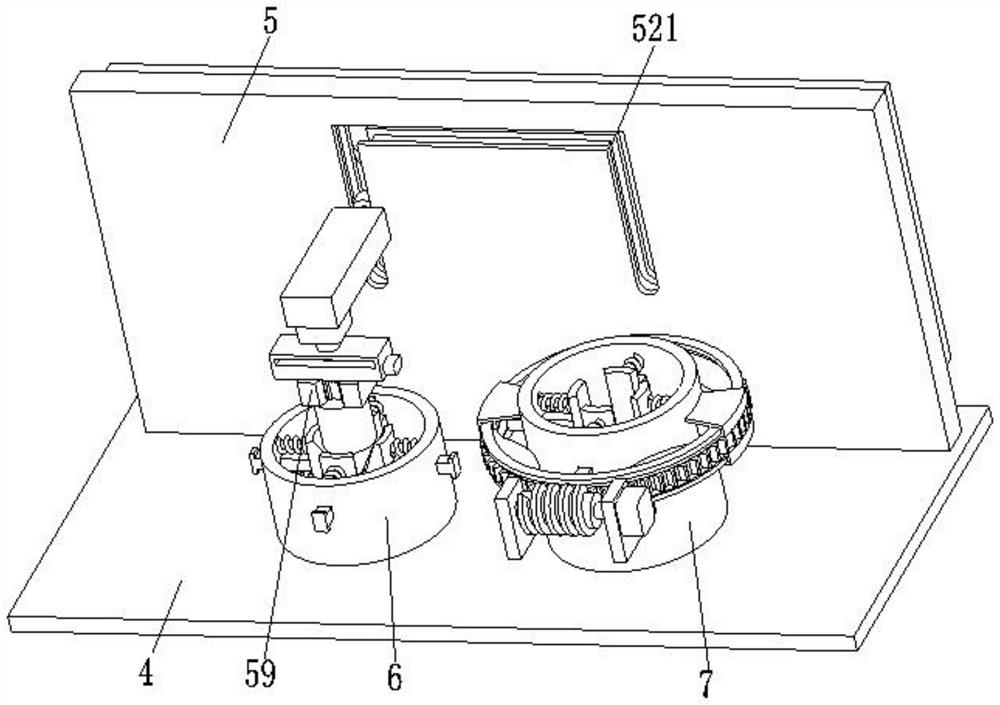

Five-axis polishing system

InactiveCN107932271AReduce labor burdenThere will be no problem of incomplete grindingGrinding drivesBelt grinding machinesCircular discDrive shaft

The invention discloses a five-axis grinding system, which includes a processing main platform and a grinding device; the processing main platform includes a central turntable, a processing disc and a bottom box, and the processing disc is arranged on the edge of the central turntable; There are S1 rotating shaft for supporting the product and driving the product to rotate and an S1 shaft motor for driving the S1 rotating shaft to rotate. The rotating shaft is connected; the grinding device includes an abrasive belt head and a moving mechanism that can drive the abrasive belt head to move along four axial directions; the grinding device is arranged along the edge of the central turntable, and the abrasive belt head is arranged above the processing disc. The five-axis grinding system can effectively polish various parts or surfaces of the product, thereby effectively improving the efficiency of grinding.

Owner:JIANGMEN SHUNZONG POLISHING EQUIP

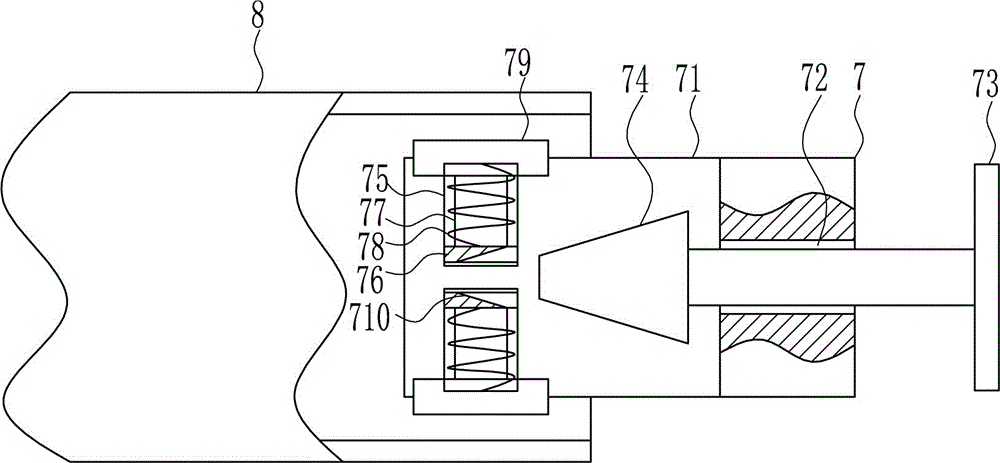

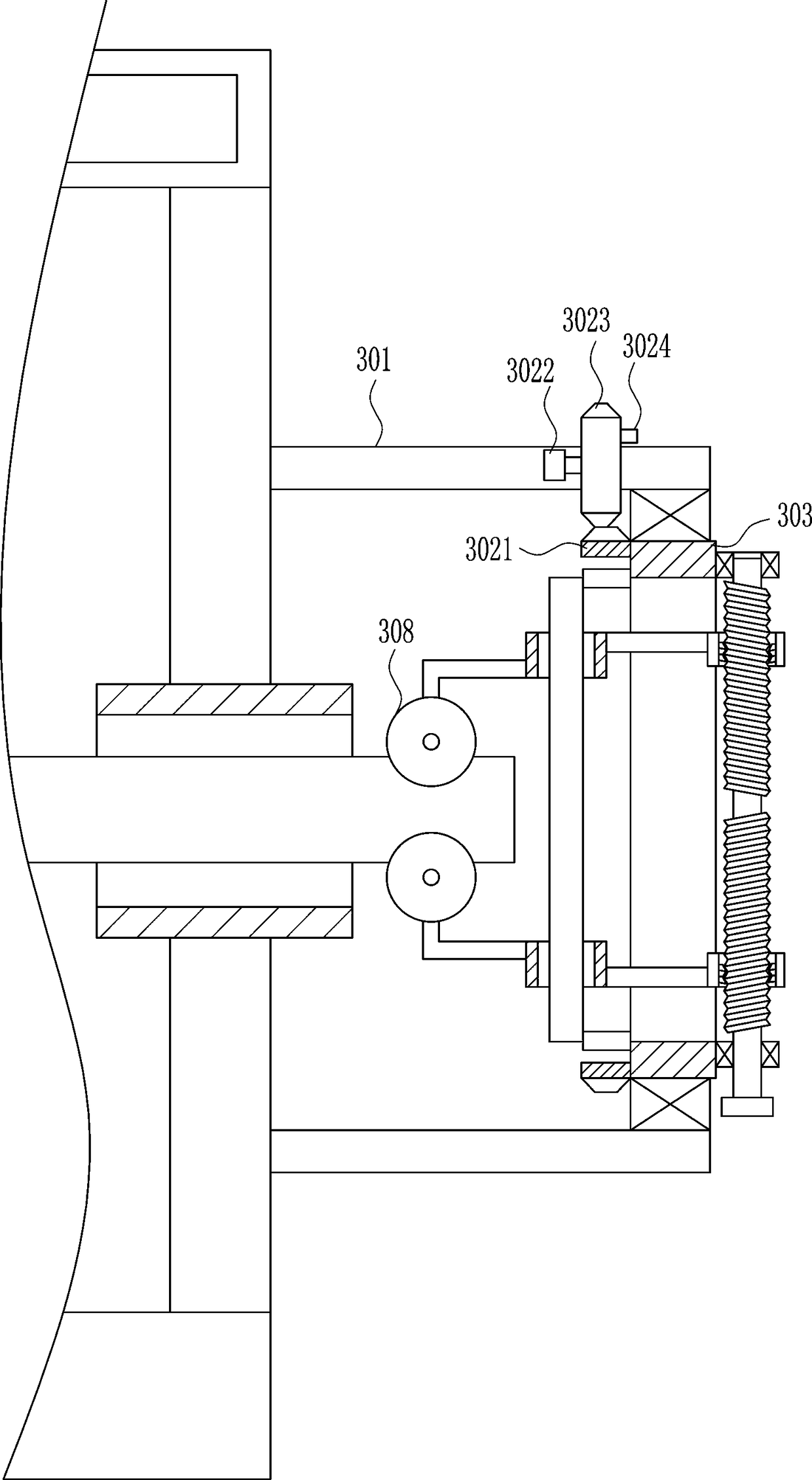

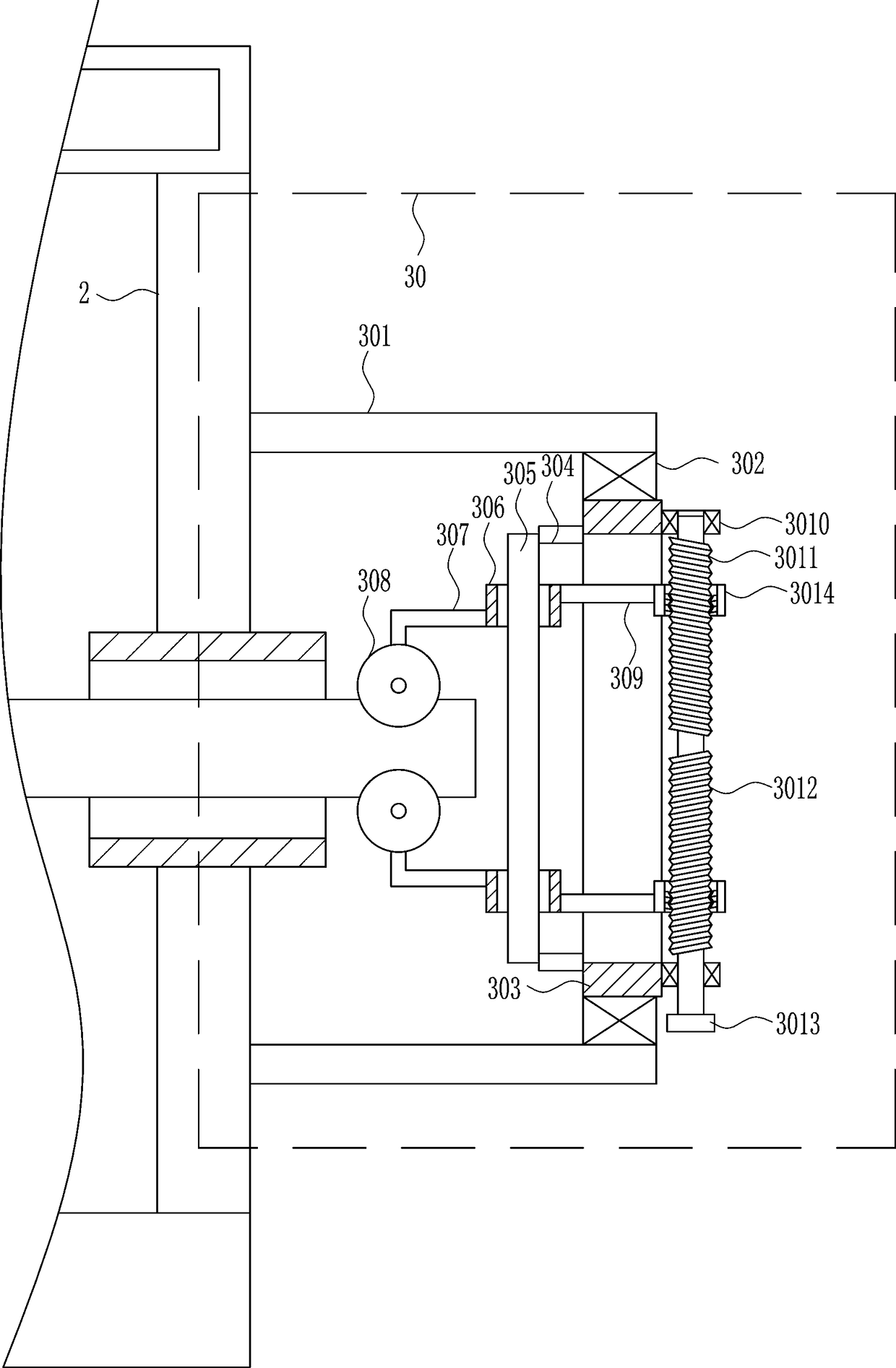

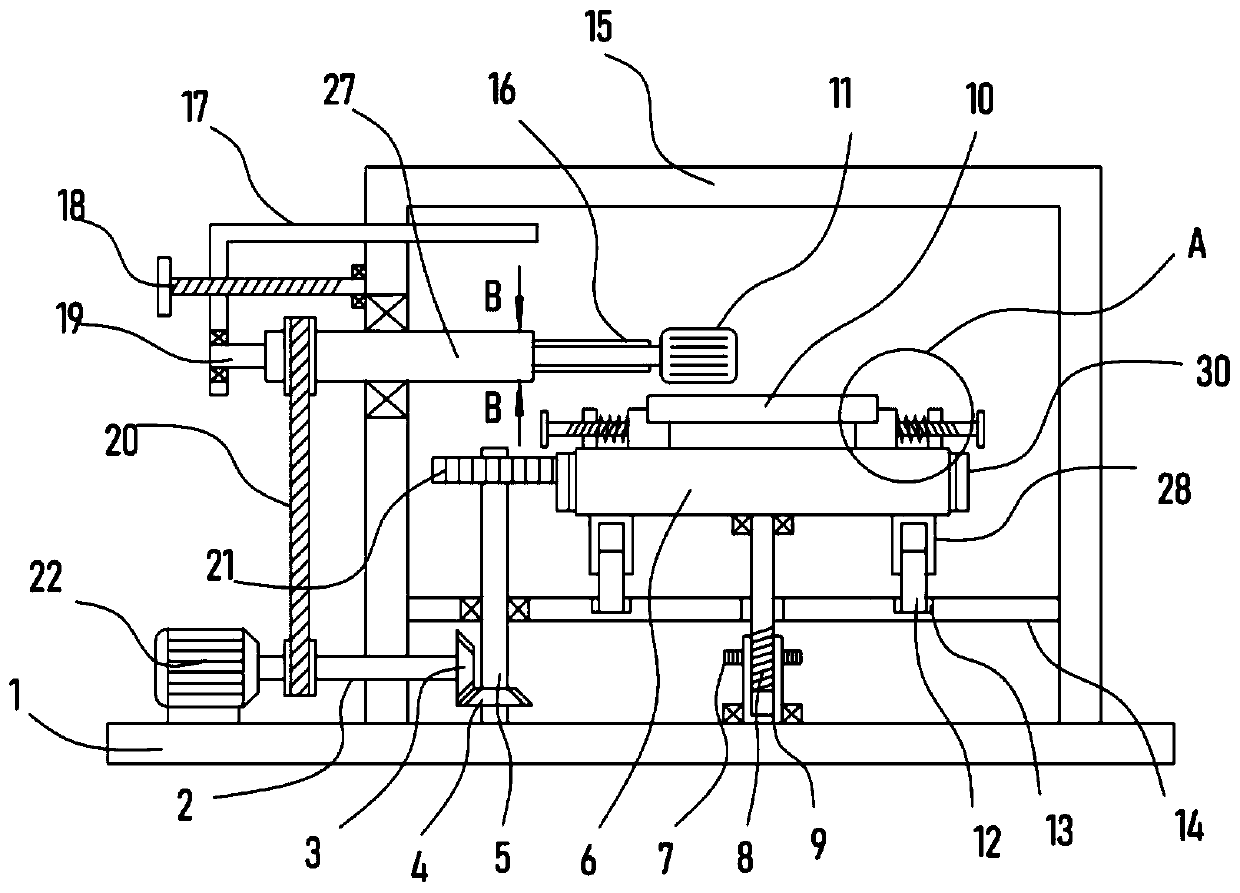

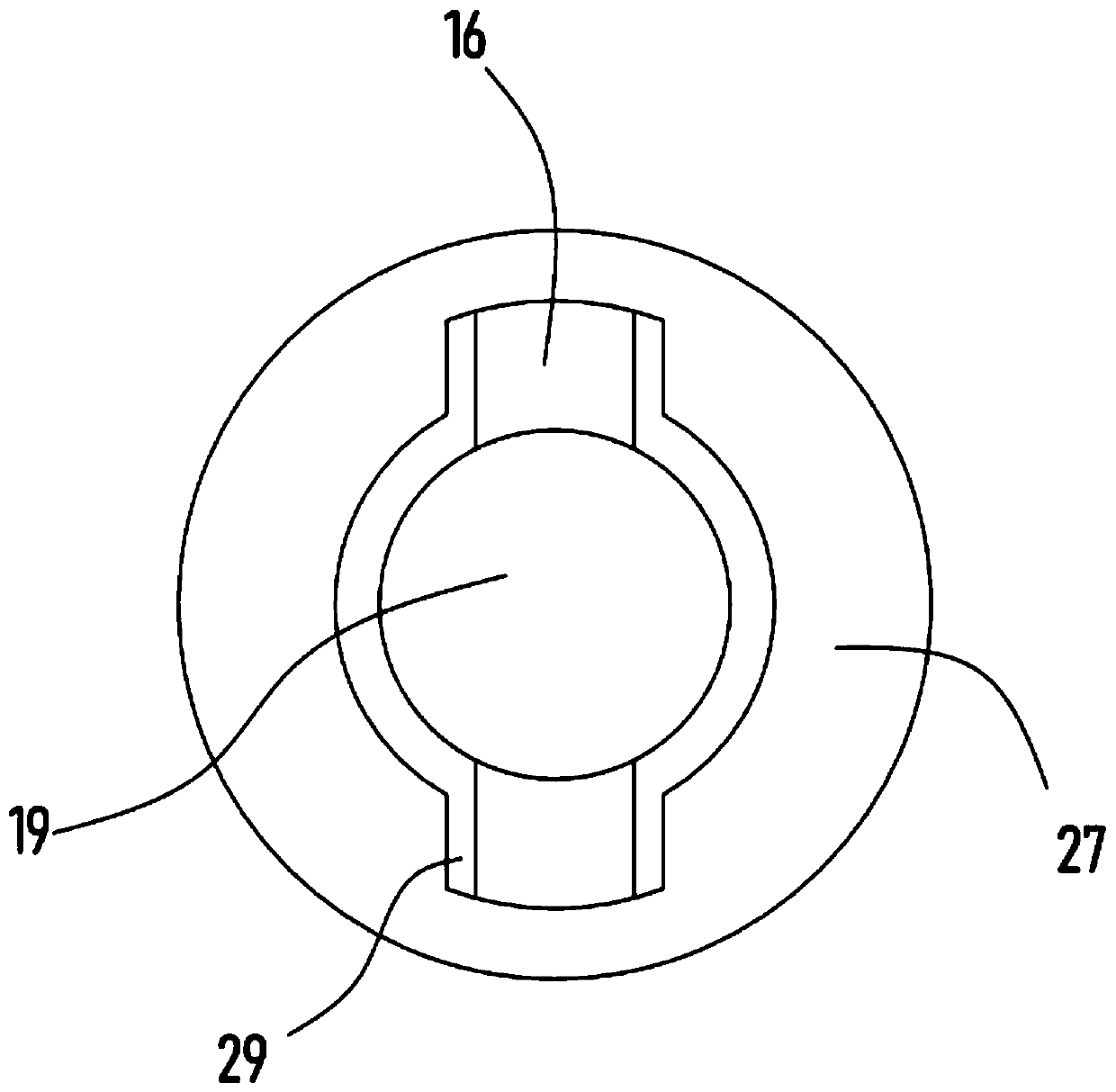

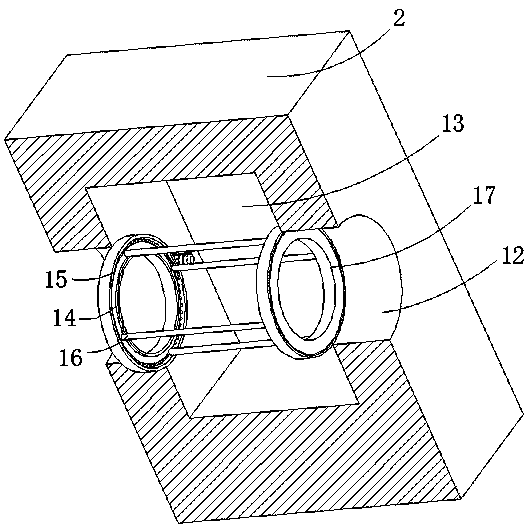

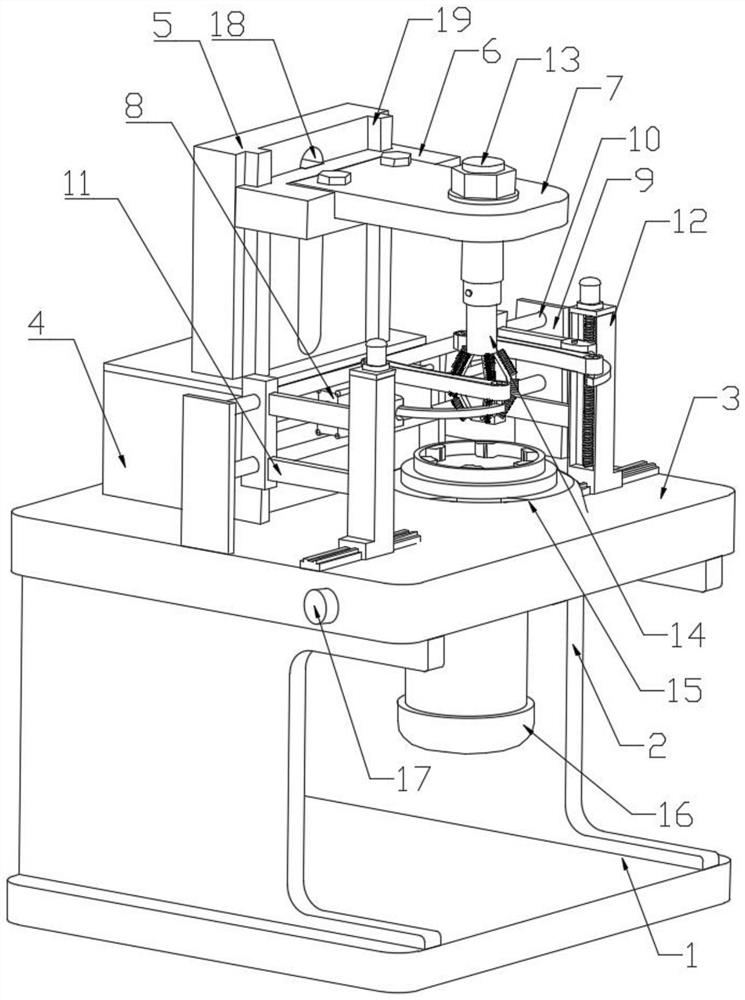

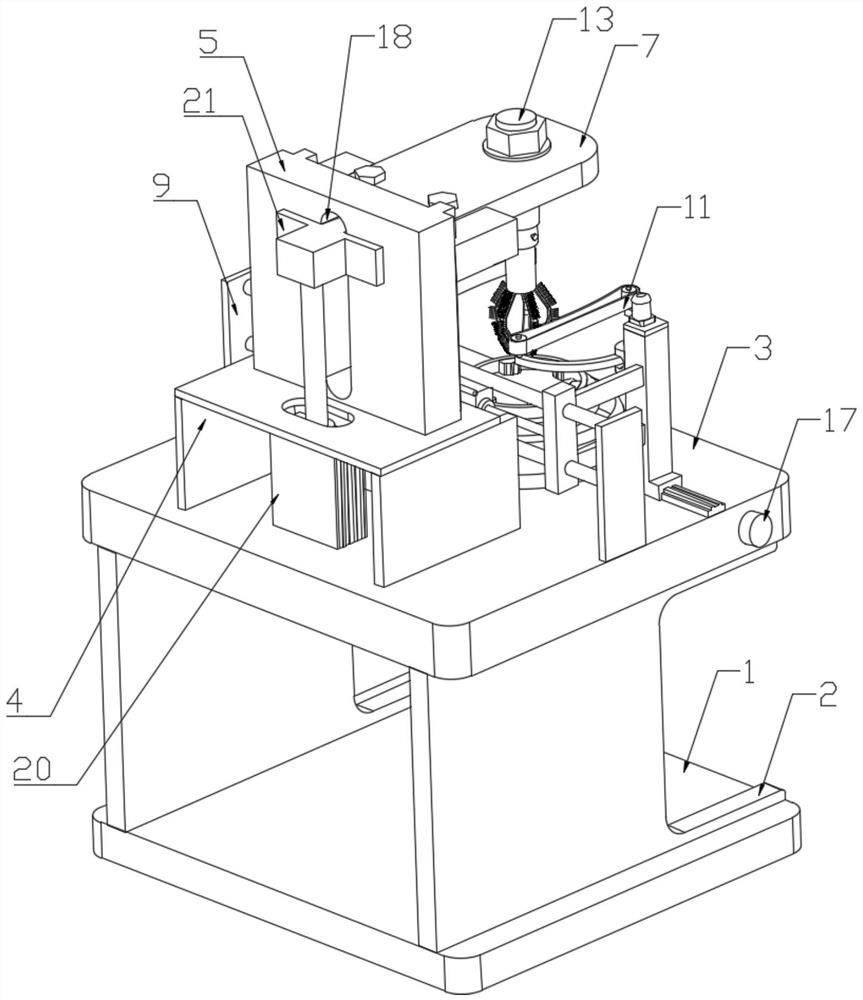

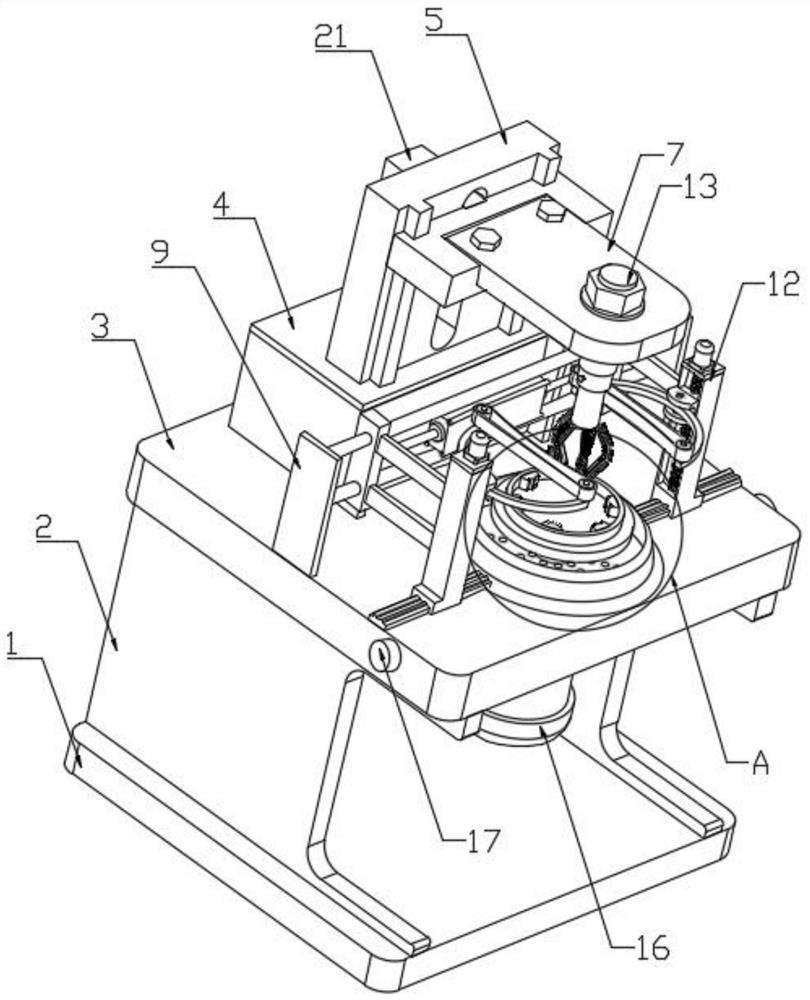

Finishing processing device for compressor bearing machining and working method

ActiveCN109773609AFully polishedGood polishingEdge grinding machinesGrinding carriagesMotor driveEngineering

Owner:MAANSHAN YUEMEI METAL PROD TECH IND

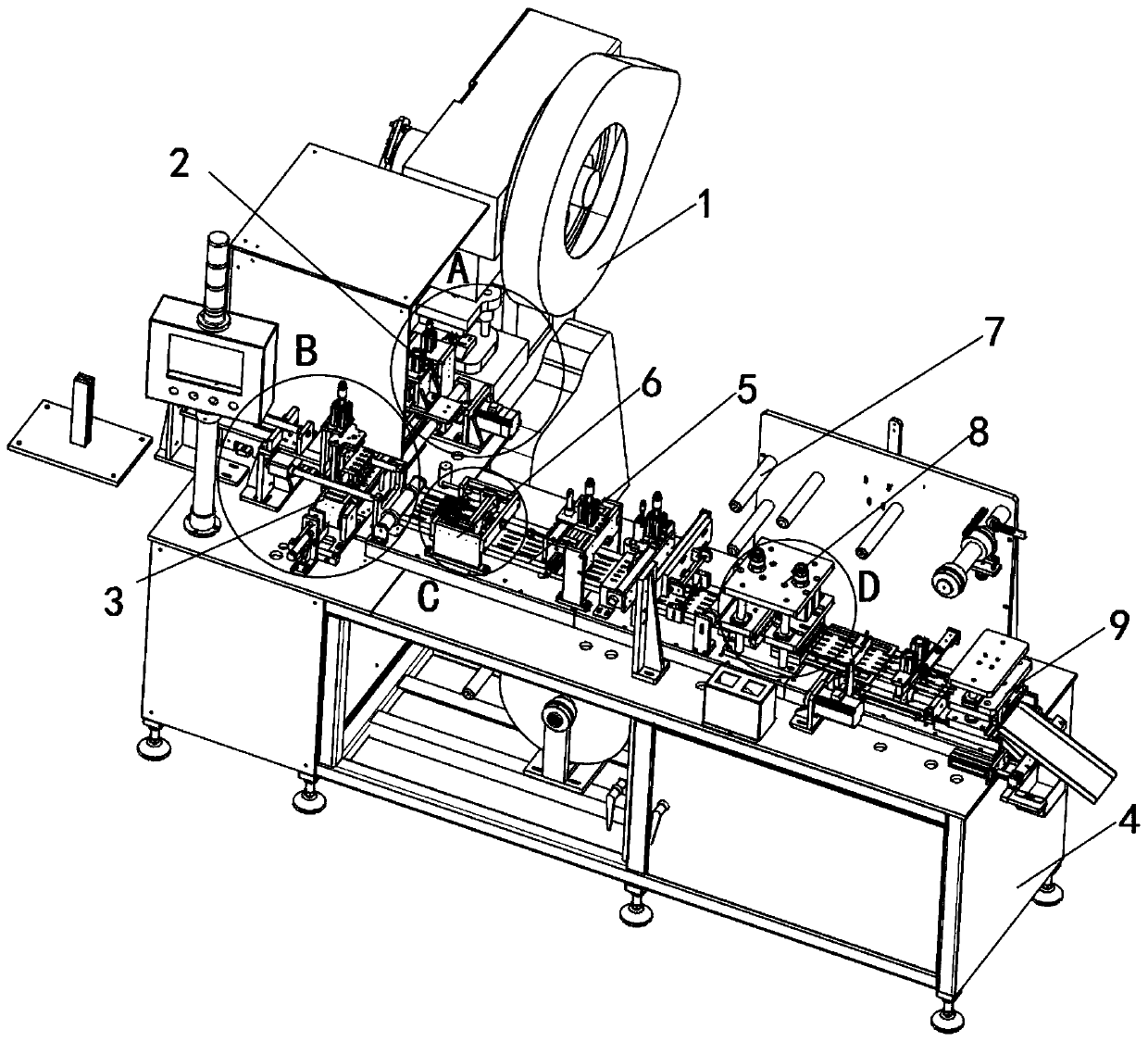

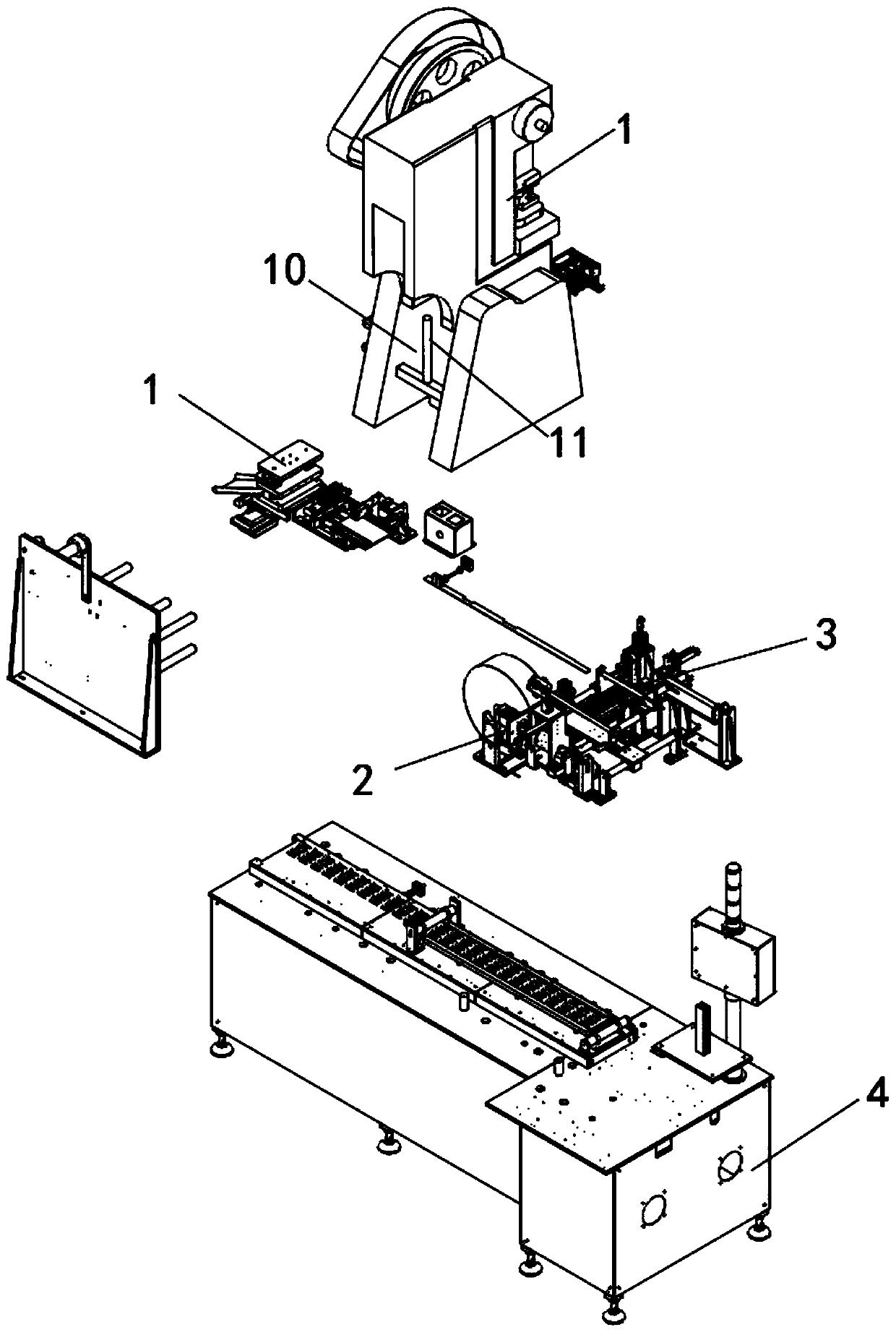

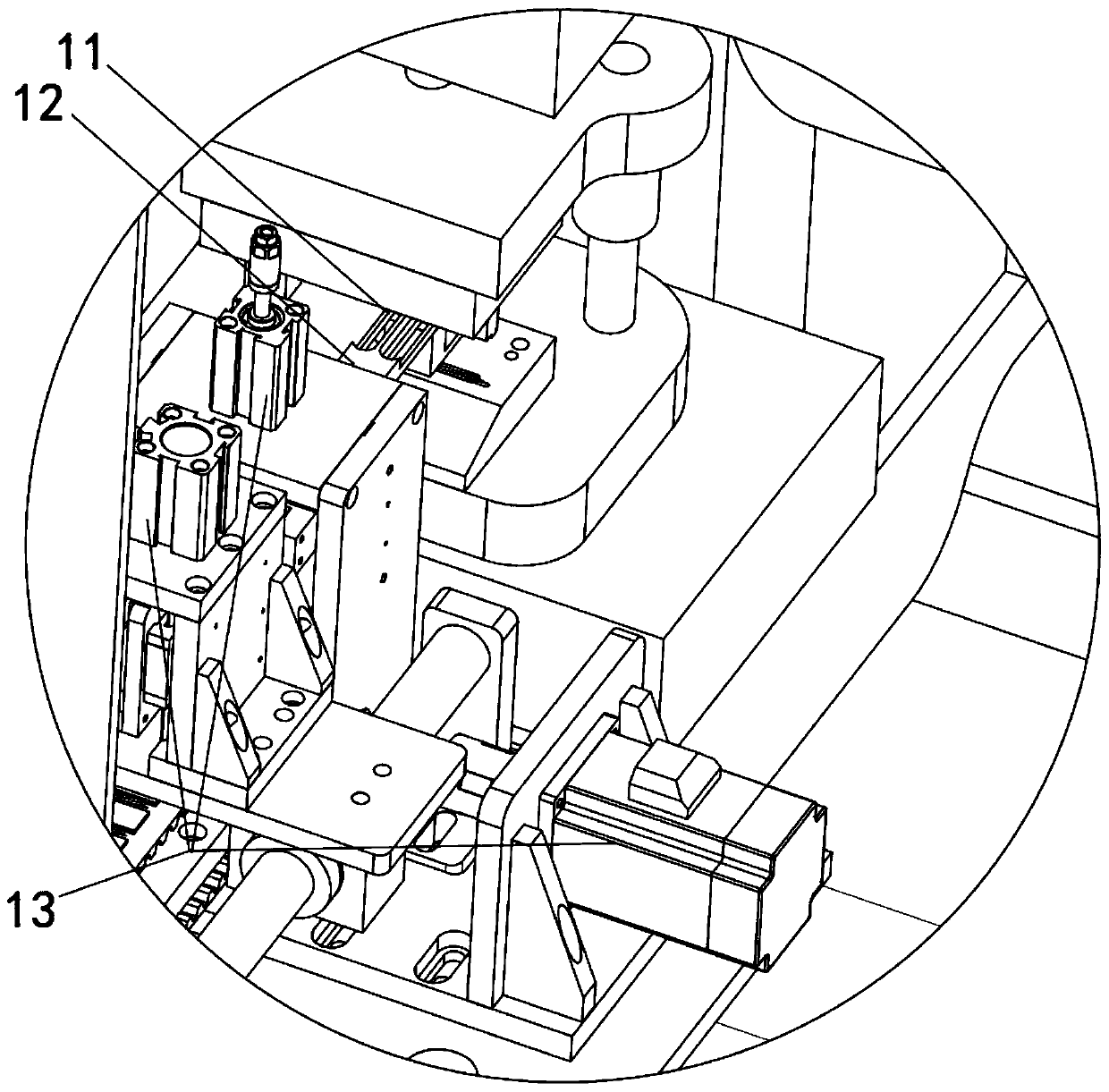

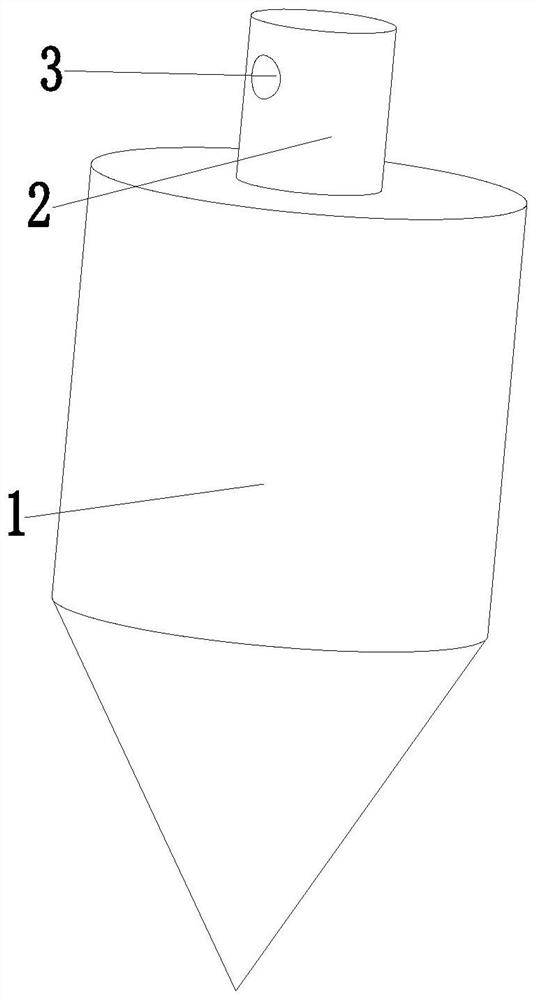

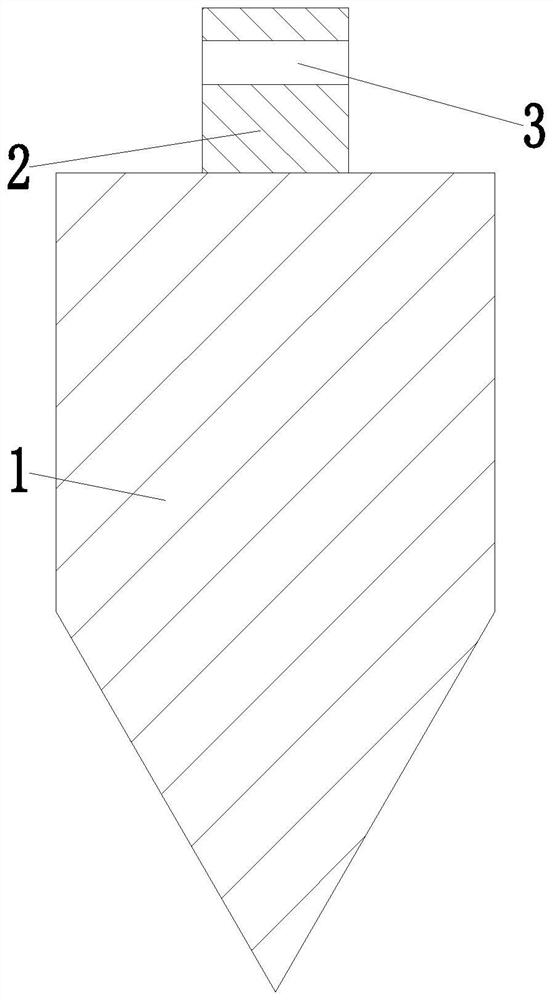

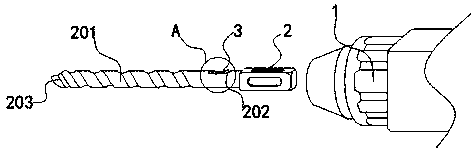

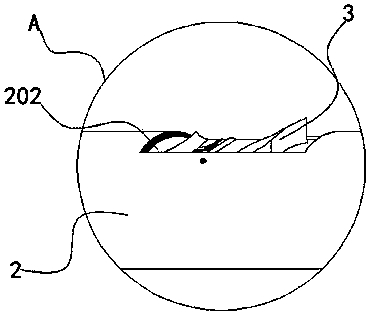

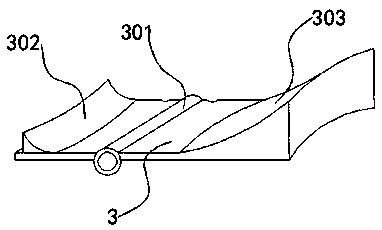

Projection point-to-point measurement plumb appliance and processing device thereof

ActiveCN114485597AImprove processing efficiencyFully polishedPolishing machinesRevolution surface grinding machinesPolishingMachining process

The invention relates to a projection point-to-point measurement plumb appliance and a machining device thereof.The projection point-to-point measurement plumb appliance comprises a plumb bob body, a wiring rod and a wiring hole, in the machining process of the plumb appliance, the special machining device needs to be used, and the machining device comprises an operation table, a conveying mechanism, a grinding mechanism and a polishing mechanism; the machining device comprises an operation table, a conveying mechanism is arranged at the rear end of the operation table, a grinding mechanism is installed at the left end of the operation table, and a polishing mechanism is installed at the left end of the operation table. And by adjusting the distance between the arc-shaped plates, the outer walls of the upper sides of the plumb bobs with different diameters can be polished, the application range is wide, and the machining efficiency of the plumb bobs is improved.

Owner:南通天正信息技术服务有限公司

A spike grinding device for processing agricultural spike harrows

ActiveCN106695467BConvenience for subsequent useFully polishedOther manufacturing equipments/toolsGear grindingTooth polishing

The invention relates to the technical field of agricultural machinery, in particular to a spike tooth polishing device for machining an agricultural tooth harrow. The device comprises a fixed base; multiple insertion holes are horizontally spaced in the fixed base; spike teeth are respectively inserted in all the insertion holes; one ends of the spike teeth are set as sharp ends, and one ends, far from the sharp ends, of the spike teeth are sleeved with sleeve shafts; the surfaces of the multiple sleeve shafts are respectively connected with an output shaft of a first motor through a first conveying belt; rotating shafts are horizontally arranged on two sides of one surface, near the sharp ends of the spike teeth, of the fixed base; and the externals of the two rotating shafts are respectively sleeved with rollers. The device has the advantages of simple structure and convenience to use, uses the circular moving conveying belt for driving a polishing layer to continuously polish the surfaces of the spike teeth, polishes the surfaces of the spike teeth more comprehensively, improves the overall polishing effect, and is convenient to use the tooth harrow in later period.

Owner:重庆和佳机械部件制造有限公司

Environment-friendly plate processing equipment

ActiveCN110421425AEasy to useFully polishedGrinding drivesGrinding work supportsUltimate tensile strengthPulp and paper industry

The invention discloses environment-friendly plate processing equipment. The equipment comprises mounting frames, connecting frames, movable assemblies, telescopic assemblies, polishing assemblies, aplatform assembly and a plate body, wherein the two mounting frames are parallel to each other, one ends of the two mounting frames are connected through one connecting frame, and the other ends of the two mounting frames are connected through the other connecting frame; the movable assembly is mounted on each mounting frame, the telescopic assembly is mounted on each movable assembly, and the polishing assembly is mounted on each telescopic assembly; and an unsealed cavity is formed between the two mounting frames and the two connecting frames, and the platform assembly is arranged at the middle position of the cavity. According to the equipment, the plate body is convenient to place arbitrarily and can be fixed, multi-surface polishing can be conveniently realized on the same machine, and the equipment is convenient to use; and the equipment is suitable for grinding of different size conditions, movable polishing is carried out, polishing is more comprehensive, the effect is better,manual polishing is replaced, and labor intensity is reduced.

Owner:徐州涌新环保科技有限公司

Corner polishing machine for building

InactiveCN113547448AFully polishedImprove work efficiencyGrinding carriagesGrinding drivesPolishingStructural engineering

The invention provides a corner polishing machine for a building, and belongs to the field of building machinery. The machine solves the problem that an existing corner polishing machine cannot be used for effectively and comprehensively polishing corners of the building. The machine comprises a pushing mechanism and a mounting mechanism, the pushing mechanism comprises an L-shaped bearing frame, a storage battery is arranged above the L-shaped bearing frame, two fixing rods are fixed to each of the two sides of the L-shaped bearing frame, the mounting mechanism comprises a placing plate, the end of the placing plate is fixed between the multiple fixing rods, two lifting grooves are formed in the placing plate, an extrusion mechanism is arranged above the placing plate, rotating mechanisms are arranged in the interiors of the two lifting grooves, a grinding mechanism and a polishing mechanism are arranged below each rotating mechanism, belts are arranged between the grinding mechanisms and the polishing mechanisms, and an adjusting mechanism is arranged below the placing plate. According to the machine, the ground at wall edges and wall corners and flat wall close to the ground can be polished, and therefore building corners can be effectively and comprehensively polished.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

Self-pressing type grinding device for brake disc machining

PendingCN114800125AEfficient grindingFully polishedEdge grinding machinesGrinding drivesBrakeStructural engineering

The invention belongs to the technical field of brake disc machining, and provides a brake disc machining self-pressing type grinding device which comprises a base. A supporting base of an arc-shaped structure is fixedly installed on one side of the top of the base, a pressing frame is arranged on the top of the supporting base, a self-pressing mechanism is arranged in the middle of the inner side of the pressing frame, and two static grinding mechanisms are symmetrically arranged on the portions, located on the two sides of the self-pressing mechanism, of the pressing frame. The static grinding mechanism is used for grinding the circumferential side wall of the rolling brake disc; a group of dynamic grinding mechanisms are movably arranged on the base on one side of the supporting seat, the dynamic grinding mechanisms are used for grinding the inner surface and the two outer side walls of the brake disc arranged on the supporting seat, and a driver fixed to the base is rotationally connected to the end, away from the supporting seat, of each dynamic grinding mechanism; a telescopic swing mechanism is arranged at the output end of the driver. The automatic polishing device has the advantages of automatic and comprehensive polishing, simple steps, low operation difficulty and high working efficiency.

Owner:徐州九阳机械制造有限公司

Oldness preventing polishing device for library book face shells

ActiveCN109108805AAchieve polishingRealize automatic dischargeGrinding carriagesPolishing machinesDrive motorSponge

The invention discloses an oldness preventing polishing device for library book face shells, and relates to the field of book processing. The oldness preventing polishing device comprises a workbench.Supporting legs are fixedly connected to the bottom end of the workbench. The top end of the workbench is fixedly connected with supporting plates. The top ends of the supporting plates are fixedly connected with a top plate. Two feeding tables are fixedly arranged at the top end of the top plate. A feeding port is formed between the two feeding tables. The bottom end of the top plate is fixedlyconnected with two clamping plates. A grinding channel is arranged between the two clamping plates. A first drive motor and a second drive motor are fixedly connected to the two supporting plates correspondingly. An output shaft of the first drive motor is fixedly connected with a first rotation rod. The first rotation rod is fixedly connected with a first rotation plate. According to the oldnesspreventing polishing device, the first drive motor and the second drive motor are arranged to drive first polishing sponge, second polishing sponge and third polishing sponge to rotate, the three faces of each book shell are polished and ground, grinding is comprehensive, and the grinding effect is good; and automatic discharging after book grinding can be achieved, and operation is simple and convenient.

Owner:LUOHE MEDICAL COLLEGE

Shoe sole polishing device for leather shoe production

InactiveCN112123147AQuick sandingFully polishedShoemaking devicesGrinding machinesPolishingEngineering

The invention discloses a shoe sole polishing device for leather shoe production. The shoe sole polishing device comprises a polishing box, a placing groove is arranged in the upper surface of the polishing box, a sealing plate is arranged in the placing groove, and two supporting columns are fixedly connected to the bottom of the sealing plate. The shoe sole polishing device has the beneficial effects that a side face polishing mechanism and a bottom polishing mechanism are connected through a third transmission mechanism, a first rotating rod rotates, side face polishing bars in the side face polishing mechanism can rotate at the same time, the side edges of a leather shoe sole can be polished at the same time, the upper surfaces of bottom polishing bars can polish the leather shoe sole,a second rotating rod rotates, the bottom polishing bars and the side face polishing bars can be driven to move on the periphery of the leather shoe sole along an annular track, the leather shoe solecan be rapidly and comprehensively polished, manual polishing is not needed, time and labor are saved, the polishing efficiency is high, and the effect of polishing the leather shoe sole is good.

Owner:孙国花

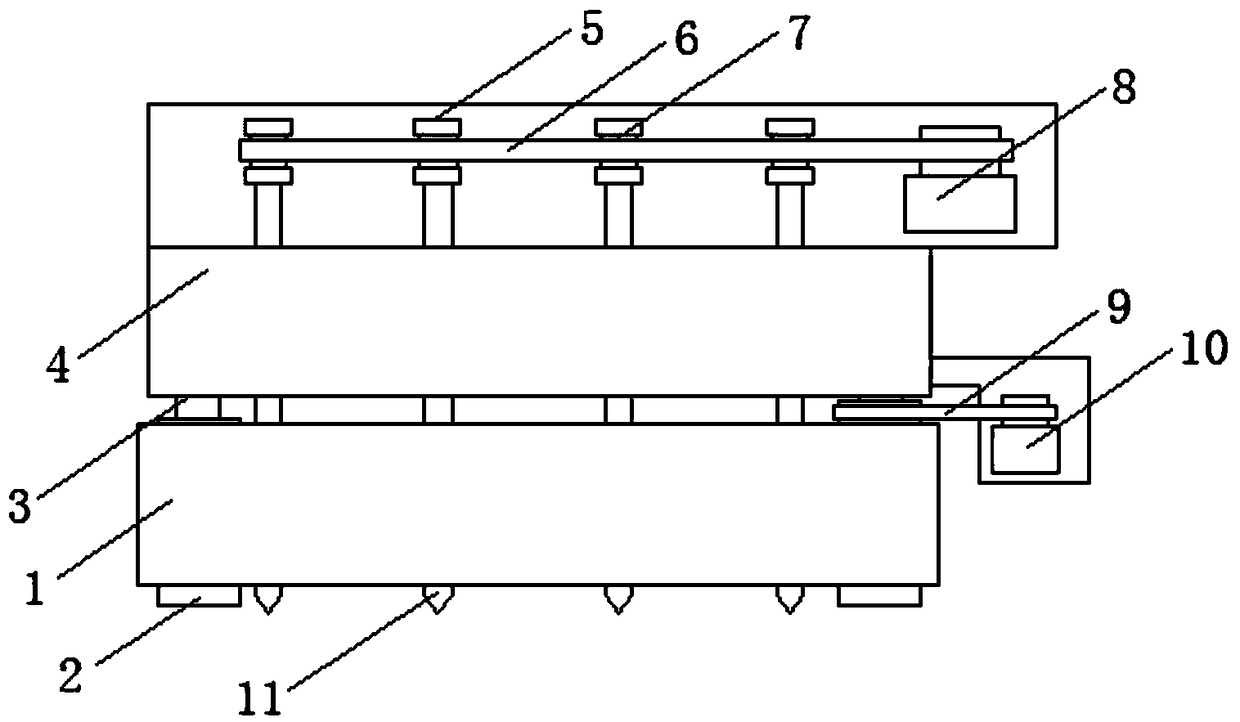

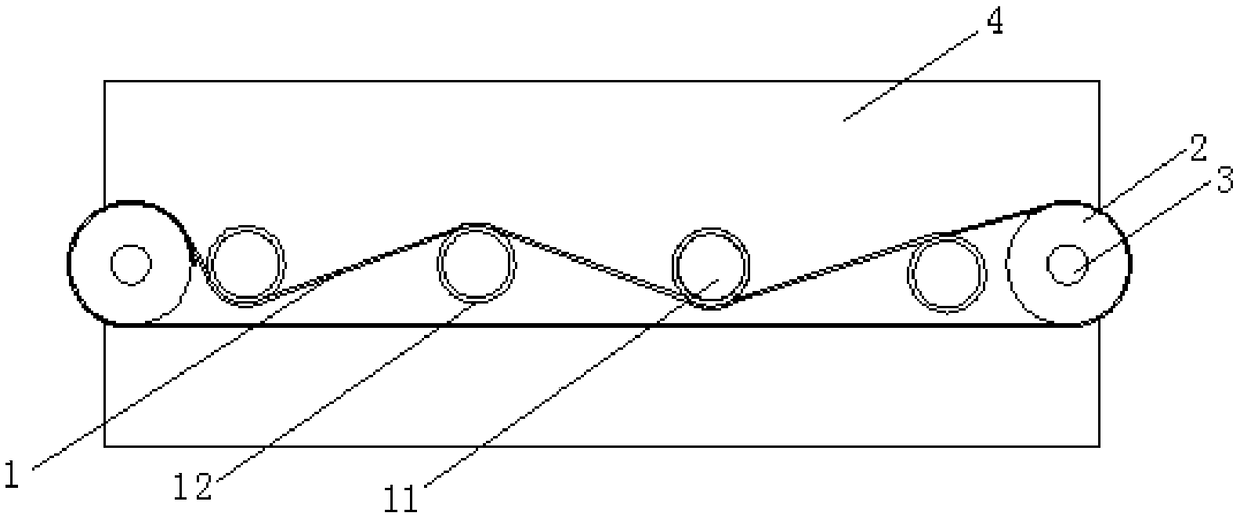

Polishing machine for steel belt

InactiveCN106564000AIncrease smoothnessFully polishedGrinding machine componentsPolishing machinesEngineeringSteel belt

The invention discloses a polishing machine for a steel belt. The polishing machine comprises a bottom plate, wherein a flattening device, a T-shaped plate and a polishing device are arranged on the upper surface of the bottom plate from left to right in sequence; the flattening device comprises two perpendicular plates; the bottoms of the perpendicular plates are fixedly connected with the upper surface of the bottom plate; the bottoms, at opposite sides, of the two perpendicular plates are connected through a first rotary rod; the first rotary rod is sleeved by a first rolling roller; one end of the first rotary rod gets to the outside of perpendicular plates, and is fixedly connected with the shaft center of a driven gear outside the perpendicular plates; and the driven gear is engaged with a drive gear. According to the polishing machine disclosed by the invention, by improving the flattening device, a distance between a second rolling roller and a first rolling roller can be regulated through a blocking slot and a telescopic pole, so that smoothness degree of the steel belt is improved; and the polishing device can be improved to carry out two-way polishing on the steel belt, and can be matched with an electric telescopic pole to polish the surface of the steel belt according to an actual situation, so that quality of products is improved.

Owner:WUXI QIANTAI METAL COMPONENTS FACTORY

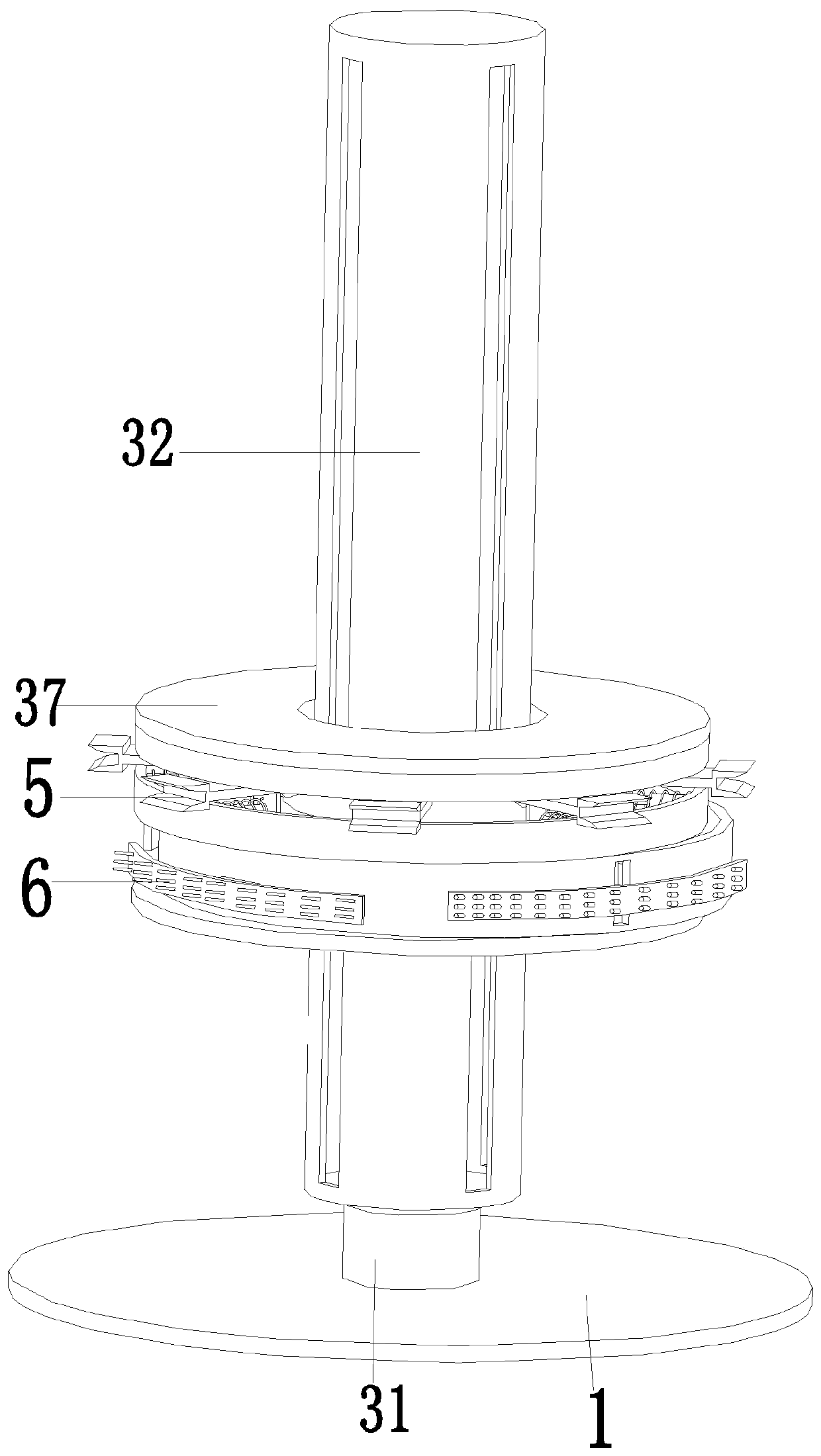

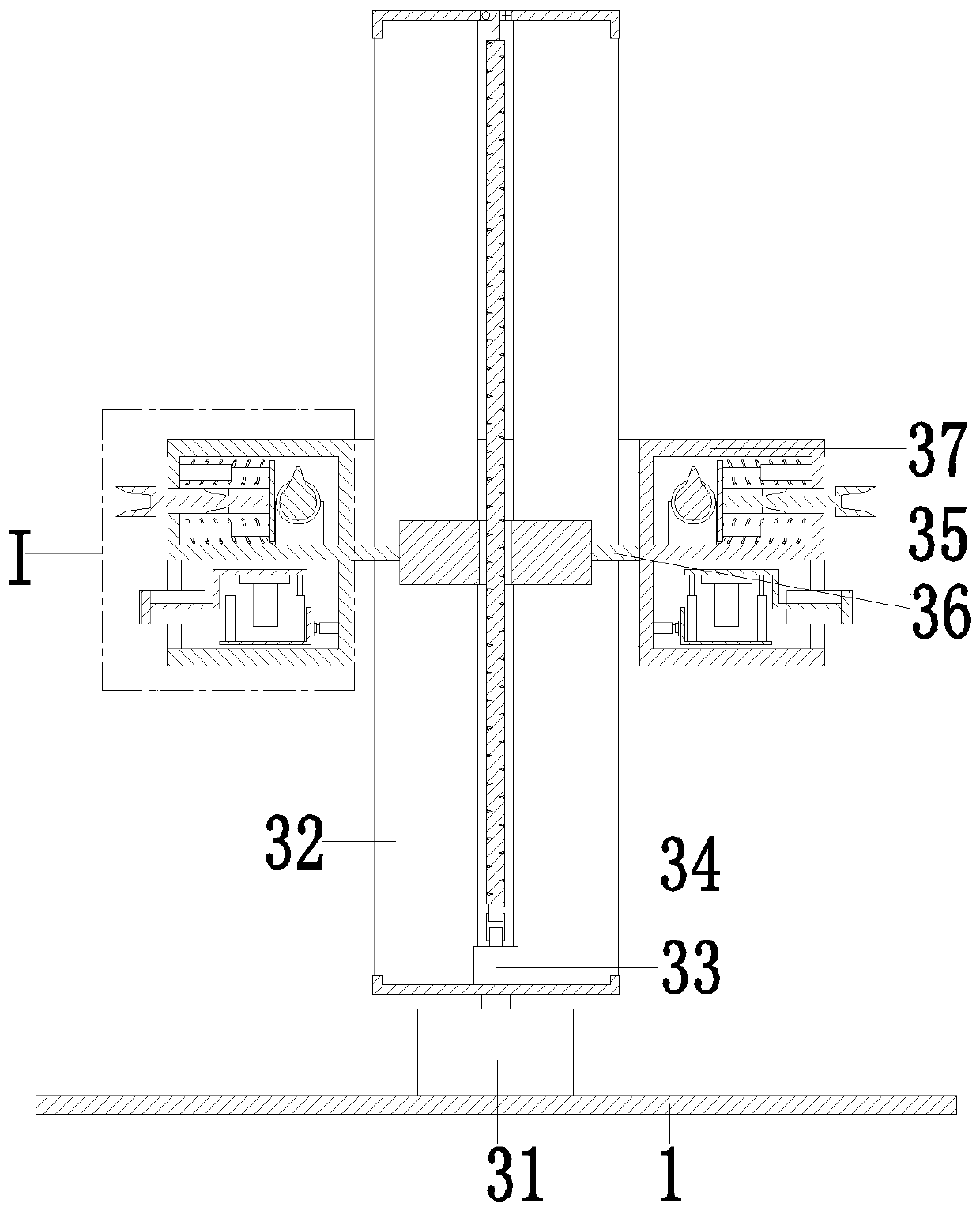

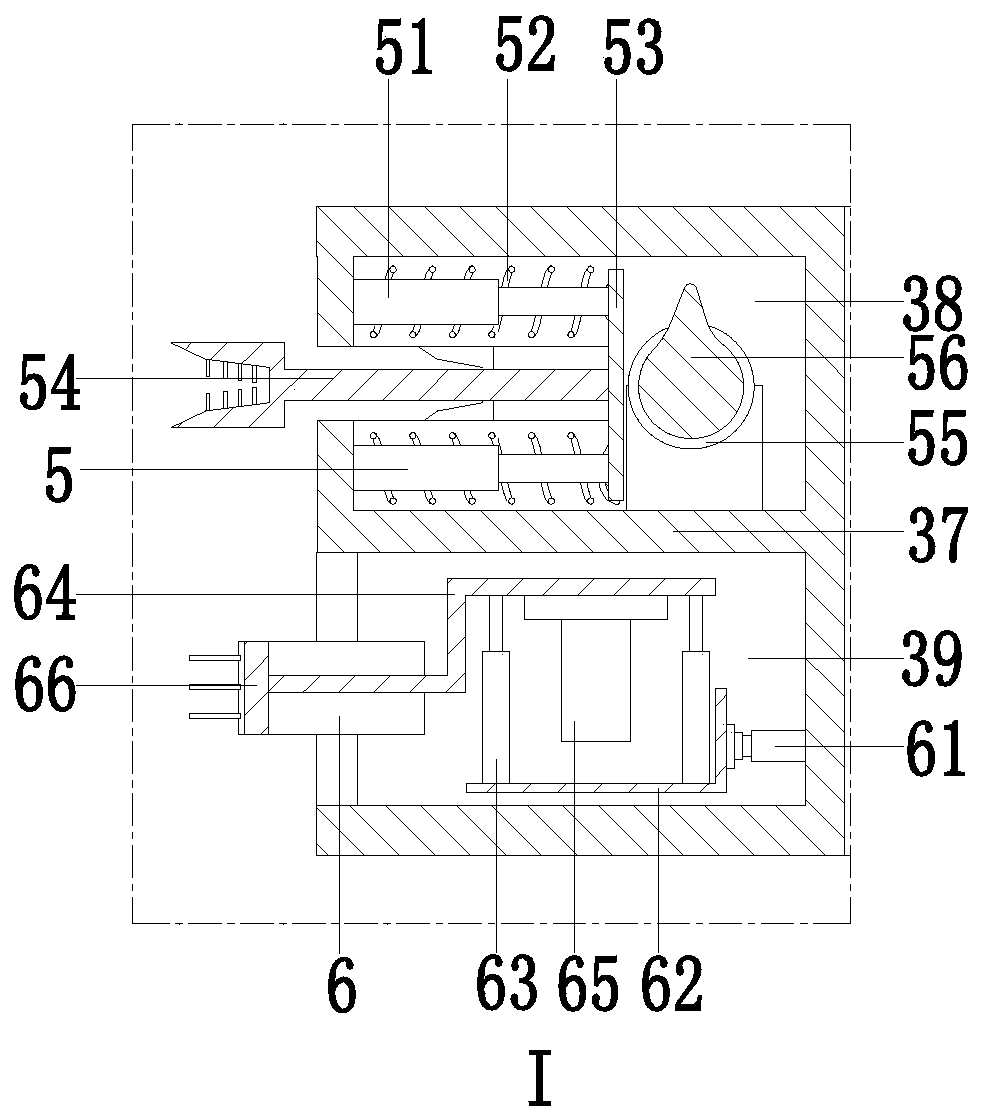

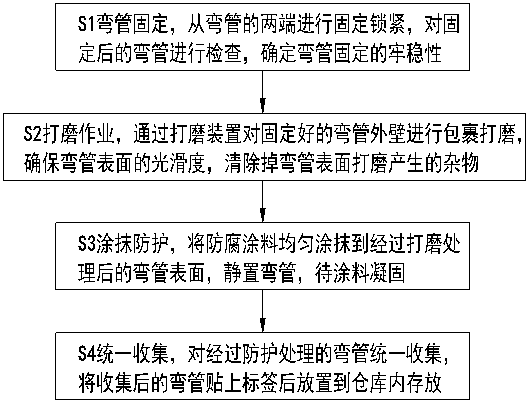

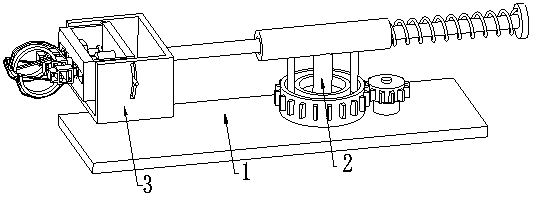

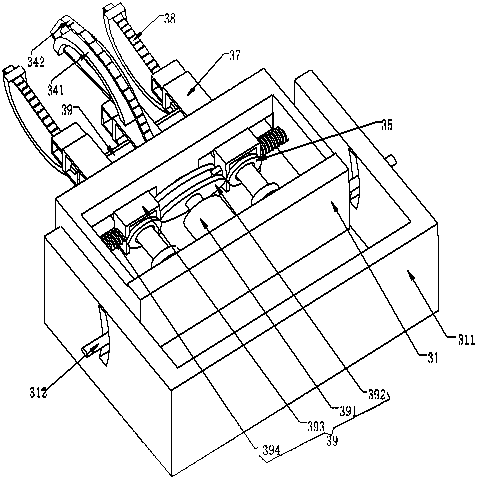

A method for surface treatment of municipal water supply PE pipes

ActiveCN111482853BFully polishedWide adaptabilityRevolution surface grinding machinesPolishingProcess engineering

The invention relates to a surface treatment method for municipal water supply PE pipes. The surface treatment method adopts the following grinding device to assist in the operation. The grinding device includes a bottom plate, a control mechanism arranged on the bottom plate, and an actuator connected to the control mechanism. The invention can solve the problem that the existing curved pipe needs to be manually polished during the grinding process. The dust generated during the manual grinding of the curved pipe affects human health, and the debris splashed during the grinding operation has potential safety hazards. The pipe is labor-intensive, and the existing bending pipe grinding equipment cannot be used for grinding pipes of different specifications. When grinding pipes of different specifications, it is necessary to prepare corresponding grinding equipment, which has disadvantages such as poor adaptability.

Owner:浙江地球管业有限公司

Kilometer-level deep sea laser cladding lathe equipment and method capable of conveniently adjusting angle of material

InactiveCN114045488AHeight adjustableEasy to adjust the angleMetallic material coating processesGrinding machinesWater storage tankElectric machinery

The invention discloses a kilometer-level deep sea laser cladding lathe equipment and method capable of conveniently adjusting angle of material. The kilometer-level deep sea laser cladding lathe equipment comprises a bearing table, a second motor, a grinding mechanism and a water storage tank, the water storage tank is placed at the inner bottom of the bearing table, a water pump is arranged at the inner bottom of the water storage tank, the tail end of a connecting pipeline is connected with spray heads, the spray heads are symmetrically fixed on two sides of a motor box. According to the kilometer-level deep sea laser cladding lathe equipment and the method capable of conveniently adjusting the angle of the material, after polishing treatment of the material is completed, a support returns to the original position, after the surface of the material is wrapped with a layer of specified coating material, a laser cladding machine moves rightwards along with the support, after the laser cladding machine moves downwards to a proper height, laser cladding operation can be carried out, a coating material can be conveniently melted, a coating is finally solidified and attached to the surface of the material, meanwhile, the material can rotate along with an electric clamp, the angle of the material can be conveniently adjusted, and comprehensive laser cladding operation can be conveniently completed.

Owner:中科联合航天科技(盐城)有限公司

A servo motor rotor intelligent processing system

ActiveCN108994670BEfficient grinding workImprove work efficiencyGrinding carriagesPolishing machinesElectric machineCoupling

The invention relates to an intelligent machining system for a servo motor rotor. The intelligent machining system comprises a bottom plate. An operation executing motor is mounted in the middle of the upper end of the bottom plate through a motor base, an rotating executing roll is mounted on an output shaft of the operation executing motor and is of a hollow structure, and lifting executing grooves are evenly formed in the rotating executing roll in the circumferential direction of the rotating executing roll. A rotating executing motor is mounted on the inner wall of the rotating executingroll through the motor base, and an output shaft of the rotating executing motor is connected with the lower end of an executing lead screw through a coupling. The upper end of the executing lead screw is mounted on the inner wall of the rotating executing roll through a bearing. According to the intelligent machining system, the problems that in the production and machining processes of an existing rotor sheet, the rotor sheet needs to be polished manually through existing equipment, manual polishing for the rotor sheet is not thorough, the service life of the rotor sheet is influenced, the consumed time is long, the labor intensity is large, operation is complex, and the working efficiency is low can be solved.

Owner:湖南德晟智能科技有限公司 +1

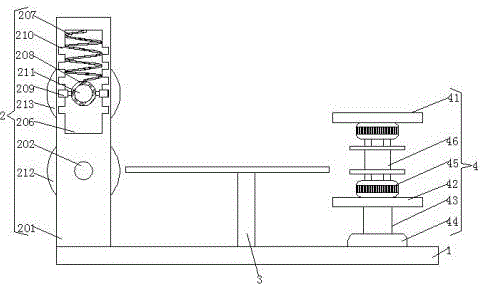

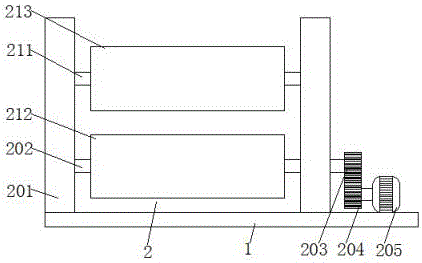

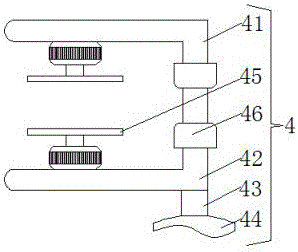

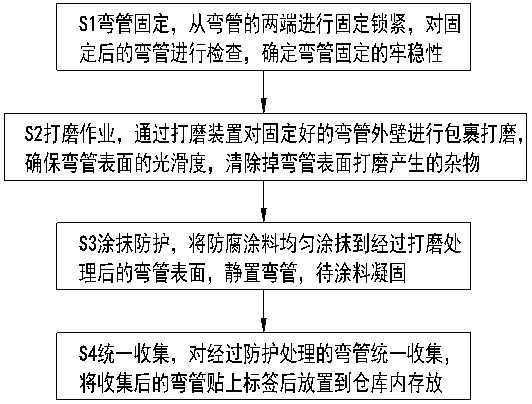

Surface treatment method for municipal water supply PE pipe

ActiveCN111482853AFully polishedWide adaptabilityRevolution surface grinding machinesHuman bodyProcess engineering

The invention relates to a surface treatment method for a municipal water supply PE pipe. The surface treatment method adopts a following grinding device for auxiliary operation; and the grinding device comprises a bottom plate, a control mechanism arranged on the bottom plate, and an execution mechanism connected in the control mechanism. The method can overcome the defects that in the elbow grinding process at present, an elbow needs to be ground manually, so that dust generated during manual elbow grinding affects the health of a human body, splashing chips generated during grinding operation have the potential safety hazard, and the labor intensity of manual elbow grinding is high; and existing elbow grinding equipment cannot perform grinding treatment for elbows with different specifications, and the corresponding grinding equipment needs to be prepared when the elbows with different specifications are ground, so that the adaptive range is narrow.

Owner:浙江地球管业有限公司

A metal wire deoxidation layer device

ActiveCN109746807BRealize automatic rotation grindingFully polishedGrinding machine componentsRevolution surface grinding machinesEngineeringEmery paper

Owner:浙江鸿铭材料科技有限公司

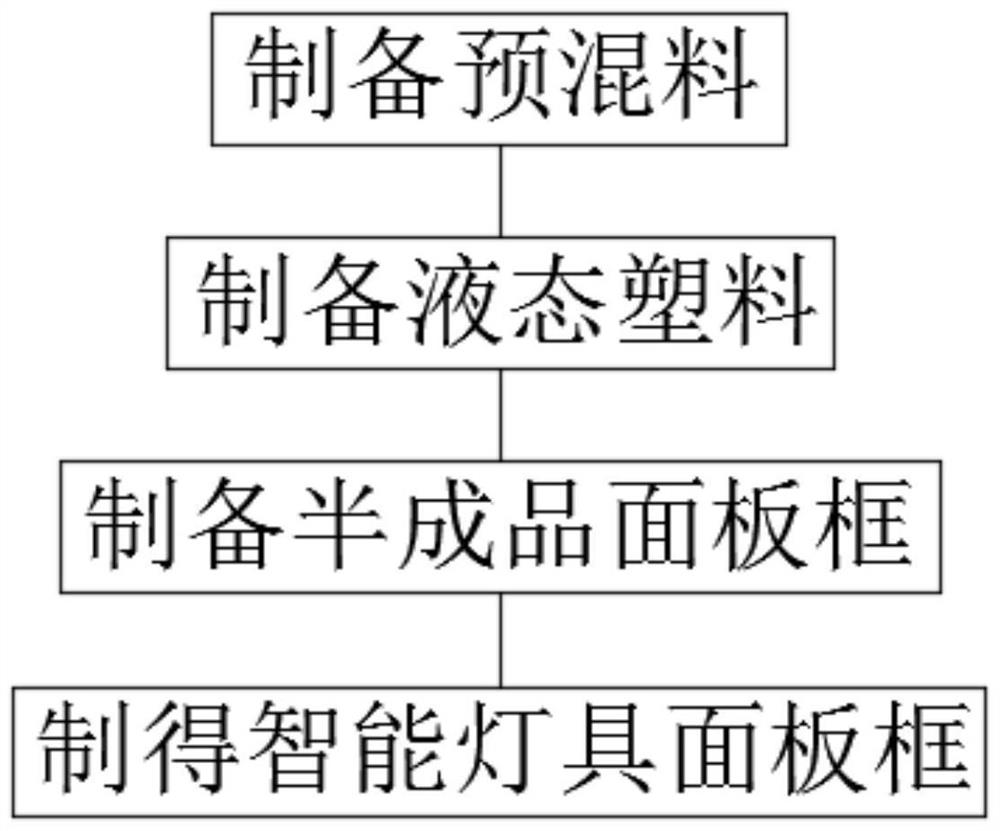

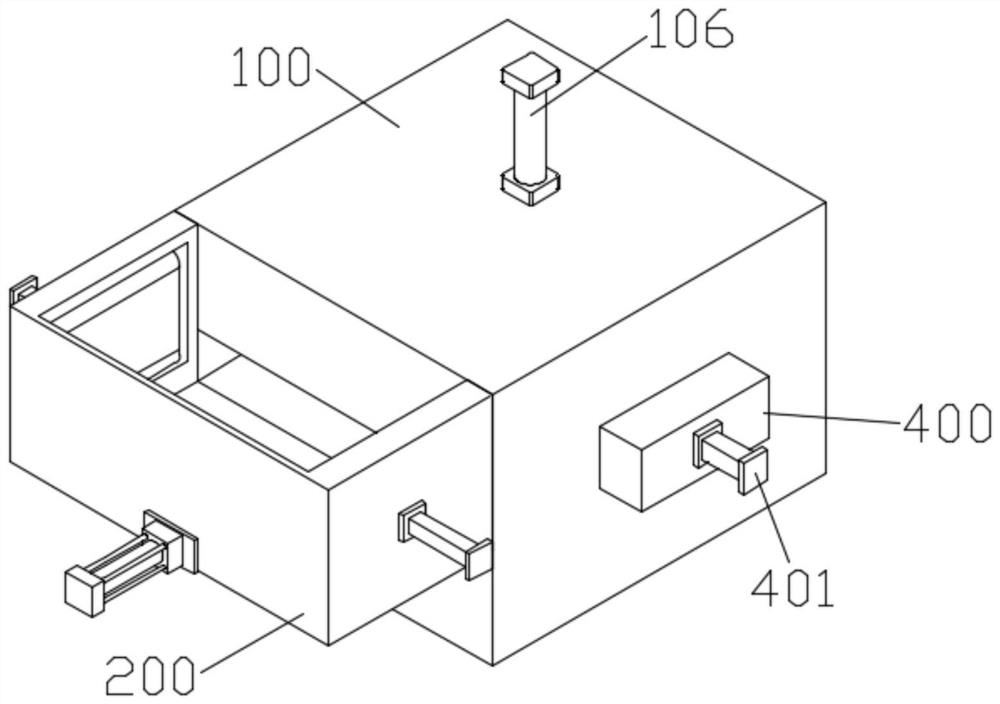

Intelligent lamp panel frame production process

ActiveCN114106578AEfficient recyclingImprove crack resistanceGrinding drivesBelt grinding machinesFiberSorbitan monostearate

According to the intelligent lamp panel frame production process, waste plastic can be effectively recycled through use of the waste plastic, and the anti-cracking and anti-impact performance of the material is improved by adding sorbitan monostearate, so that the prepared intelligent lamp panel frame has high anti-cracking and anti-impact performance, the service life of the intelligent lamp panel frame is prolonged, and the service life of the intelligent lamp panel frame is prolonged. A composite synergistic effect is formed through flame-retardant materials such as graphene, titanium dioxide and halloysite nanotubes in an anti-aging flame-retardant system and anti-aging materials such as wollastonite raphioid fibers, and the flame-retardant performance and the anti-aging performance of the intelligent lamp panel frame are greatly improved. And through cooperative arrangement of a connecting sleeve, a first lead screw and a fixing motor, the positioning mechanism can be driven to move in the polishing chamber, so that the positioning mechanism moves to the position below the inner wall polishing mechanism, and comprehensive polishing treatment can be conveniently conducted on the semi-finished panel frame.

Owner:ANHUI SHILIN LIGHTING

Automatic chamfering mechanism for drill rod

InactiveCN109434161AFully polishedPracticalTransportation and packagingMaintainance and safety accessoriesContact depthDrill

The invention provides an automatic chamfering mechanism for a drill rod. The automatic chamfering mechanism for the drill rod comprises a drill machine and a drill rod, wherein one side of the drillmachine is flexibly connected with the drill rod, and the other side of the drill machine is successively integrated with a connecting groove, a guide rod and a cutting head. A chamfering mechanism isconnected with the inner portion of the connecting groove in a riveting mode; materials are flexibly connected with the outer portion of the drill rod. According to the automatic chamfering mechanismfor the drill rod, when the contact depth between a second convex plate and the materials is increased, due to the side edge of the second convex plate is high and applying the lever principle of a locating shaft is the shaft, a first convex plate is subjected to move outside the connecting groove, and then polishes around a hole on the other side of the materials, making a device in the polishing process improve.

Owner:方陈

A metal fracturing head mold production equipment

ActiveCN113787423BIncrease the stress pointImprove stabilityGrinding drivesGrinding machinesEngineeringTraction unit

The invention relates to a metal fracturing head mold production equipment, comprising an operating table, a positioning unit, a grinding unit and a cleaning unit. The positioning unit is installed in the middle of the operating table, the grinding unit is installed on the operating table, and the grinding unit is installed with a Cleaning unit, a guiding unit and a drying unit are installed on the right side of the support plate, a traction unit is installed on the left side of the support plate, and a hair suction unit is installed at the lower end of the drying unit. The invention can solve the problem of the inner wall of the metal fracturing head mold. The following problems exist in grinding: 1. Now, the metal fracturing head mold is generally placed in the grinding equipment to grind its inner wall. Because the grinding equipment is not stable in clamping and fixing the metal fracturing head mold, it affects the metal fracturing head. The grinding quality of the mold; 2. After the grinding head grinds the metal fracturing head mold, the debris on the inner wall of the metal fracturing head mold cannot be cleaned in time, which affects the production efficiency of the metal fracturing head mold.

Owner:山东华恒智能装备有限公司

Pottery clay blank treatment device

ActiveCN113059667AFully polishedFlexibleGrinding drivesBelt grinding machinesMining engineeringElectric machinery

The invention relates to the technical field of pottery clay blank treatment, in particular to a pottery clay blank treatment device. According to the device, when push rods on the two sides of a double-outlet-rod air cylinder contract, a left-side polishing maintaining assembly and a right-side polishing maintaining assembly are driven to move relatively to clamp a pottery clay blank, so that the pottery clay blank can be stabilized during rotation, and fine treatment on the exterior of the pottery clay blank can be achieved; when a grinding belt makes contact with the pottery clay blank, the grinding belt is bent inwards and attached to the outer contour of a pottery, so that coating type attachment to the exterior of the pottery clay blank is achieved, and the treatment efficiency of the exterior of the pottery clay blank is effectively improved; and a driving motor drives a driving seat to move up and down through a screw rod, so that the polishing treatment of the pottery clay blank from top to bottom is realized.

Owner:GUANGXI POLYTECHNIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com