Pottery clay blank treatment device

A processing device and pottery technology, which is applied in the direction of grinding drive device, grinding/polishing safety device, ceramic molding machine, etc., can solve the problem of not being able to finely handle pottery, and achieve the effect of preventing flying and ensuring cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

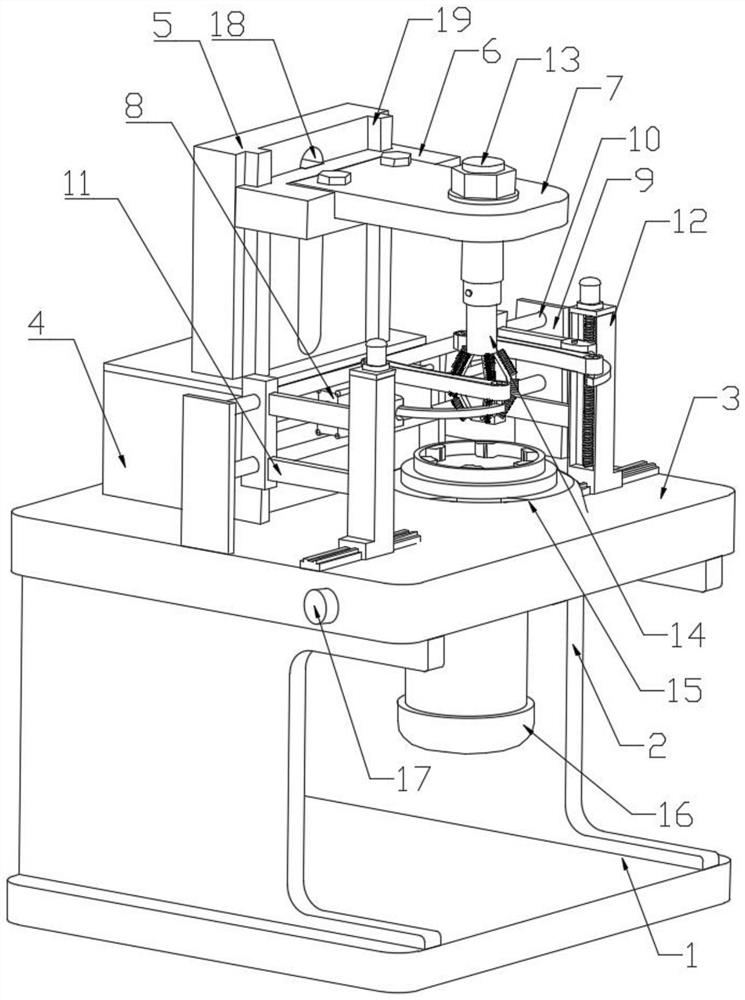

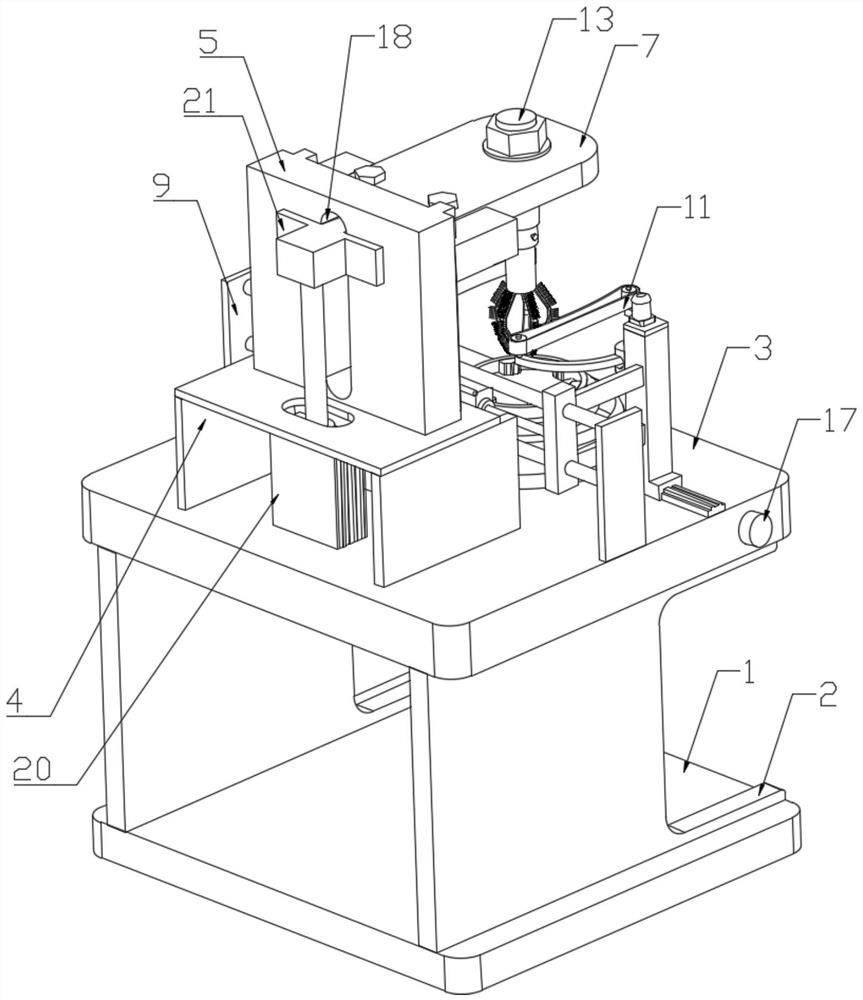

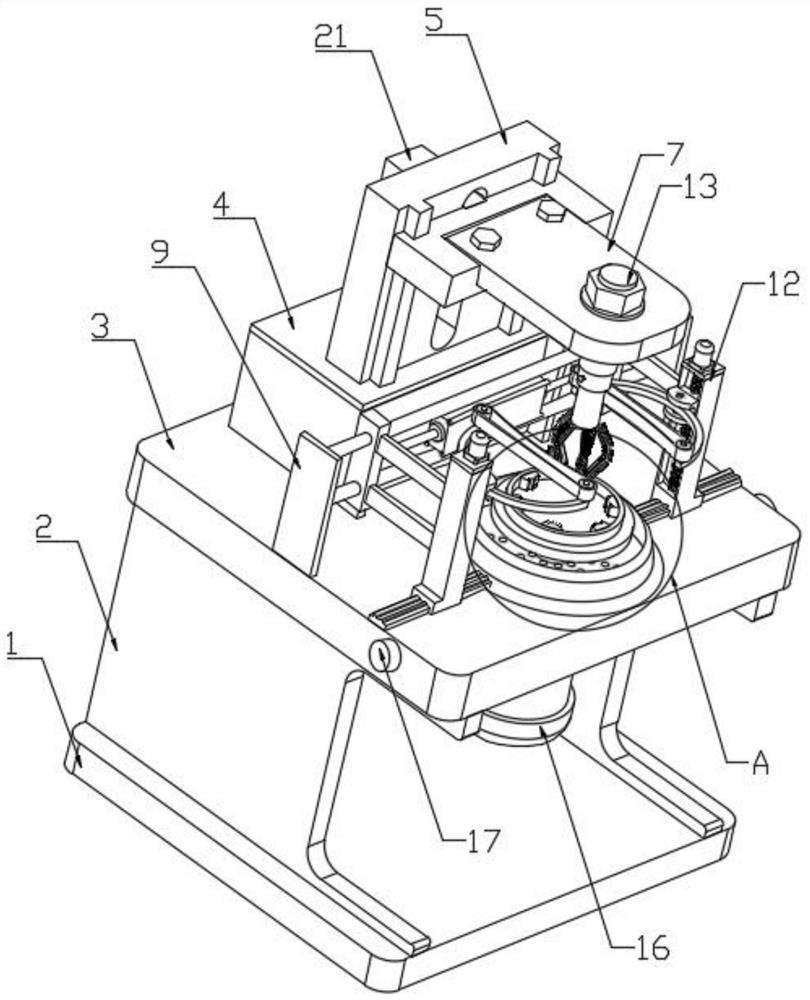

[0039] Attached below Figure 1-7 The present invention is further described with embodiment:

[0040] A pottery mud embryo processing device, comprising an installation base plate 1, two support seats 2 parallel to each other are fixed vertically above the installation base plate 1, and the top of the support base 2 is fixedly installed with a Workbench 3; the rear side of the top of the workbench 3 is fixedly equipped with a mounting frame 4, and the front side of the mounting frame 4 is provided with a ceramic mud embryo rotating clamping assembly 15; the described mounting frame 4 and the ceramic mud embryo rotate A side mounting plate 9 is arranged between the clamping components 15; two side mounting plates 9 are used, and the two side mounting plates 9 are arranged parallel to each other, and are fixedly installed on both sides of the top of the workbench 3 respectively; Two guide columns 10 parallel to each other are arranged between the two side mounting plates 9; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com