Automatic chamfering mechanism for drill rod

A technology of chamfering mechanism and drill pipe, which is applied in the direction of repairing drilling, drilling tool accessories, boring/drilling, etc., can solve the problems of burrs, time-consuming and laborious, and heating of the grinding mechanism, and achieves the effect of strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] as attached figure 1 to attach Figure 6 Shown:

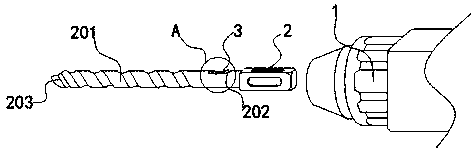

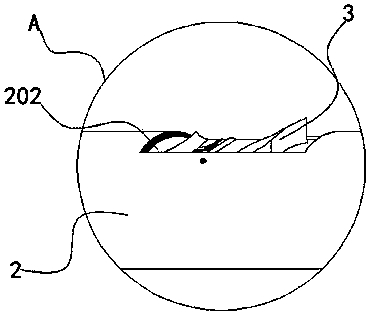

[0028] The present invention provides an automatic chamfering mechanism for drill rods. The automatic chamfering mechanism for drill rods includes a drilling rig 1 and a drill rod 2; one side of the drilling rig 1 is movably connected to a drill rod 2, and the other side of the drill rod 2 is sequentially integrated. There are connection grooves 202, guide rods 201, and cutting heads 203. The inside of the connection groove 202 is riveted with a chamfering mechanism 3, and the outside of the drill pipe 2 is movably connected with a material 4.

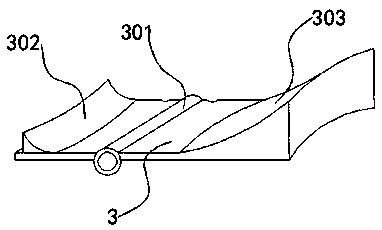

[0029] Among them, as attached figure 2 to attach image 3 As shown: the chamfering mechanism 3 includes a positioning shaft 301, a first convex plate 302, a second convex plate 303, a first diversion groove 3021, and a second diversion groove 3031. The connecting groove 202 is riveted with a positioning shaft 301 inside, The positioning shaft 301 is integrally provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com