Intelligent lamp panel frame production process

A production process and panel frame technology, which is used in manufacturing tools, metal processing equipment, grinding workpiece supports, etc., can solve the problems of low polishing efficiency, falling and damage of semi-finished panel frames, etc., to improve flame retardant performance and resistance to Effects of ageing properties, easy sanding treatment, high crack and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

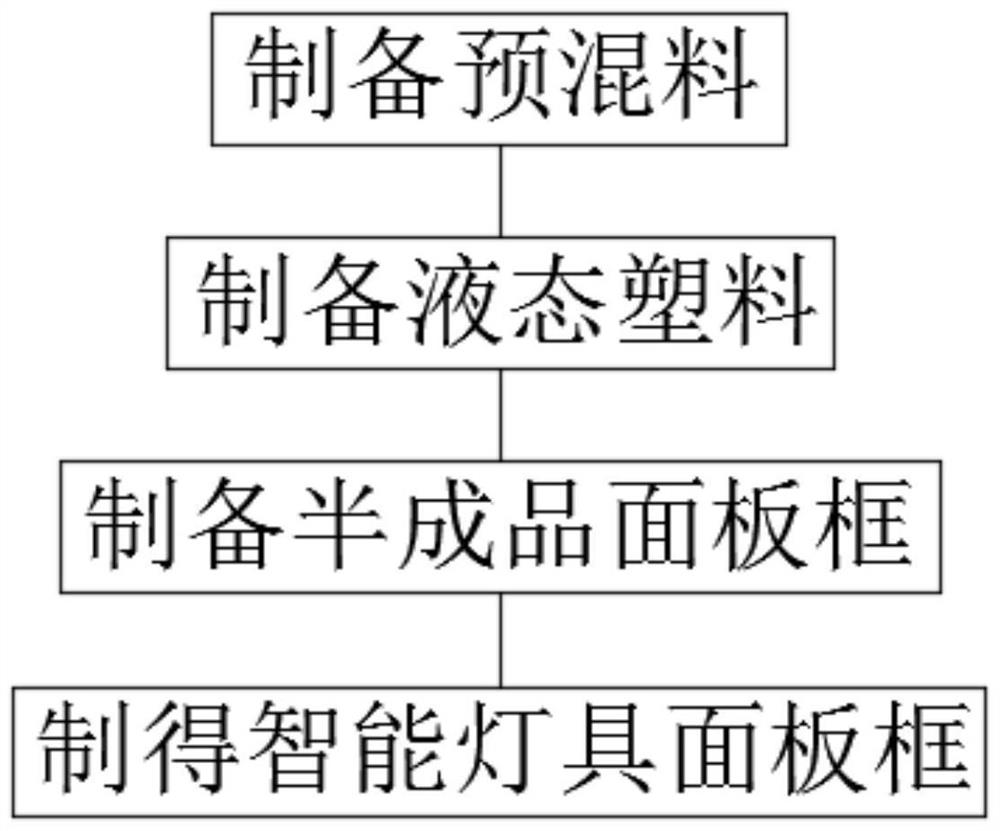

[0035] A production process of an intelligent lamp panel frame, comprising the following steps:

[0036] Step 1: Weigh 100 parts by weight of waste plastics, add the waste plastics into the reactor, add 3 parts by weight of silane coupling agent, 2 parts by weight of flame retardant, and 1 part by weight of antioxidant into the reactor, mix and stir to obtain premix;

[0037]Step 2: Keep the premix in a molten state, weigh 20 parts by weight of sorbitan monostearate, 10 parts by weight of nano silicon dioxide, 16 parts by weight of melamine cyanurate, and 5 parts by weight of styrene and add to the reaction In the container, mix and stir to obtain liquid plastic;

[0038] Step 3: Put liquid plastic, 3 parts by weight of anti-aging flame retardant blend, 2 parts by weight of weathering agent, and 3 parts by weight of plasticizer into a high-speed mixer for dry mixing, and then place them in injection molding equipment to extrude to obtain a semi-finished panel frame;

[0039...

Embodiment 2

[0047] A production process of an intelligent lamp panel frame, comprising the following steps:

[0048] Step 1: Weigh 110 parts by weight of waste plastics, add waste plastics into the reactor, add 5 parts by weight of silane coupling agent, 4 parts by weight of flame retardant, and 3 parts by weight of antioxidant into the reactor, mix and stir to obtain premix;

[0049] Step 2: Keep the premix in a molten state, weigh 25 parts by weight of sorbitan monostearate, 15 parts by weight of nano silicon dioxide, 18 parts by weight of melamine cyanurate, and 8 parts by weight of styrene and add to the reaction In the container, mix and stir to obtain liquid plastic;

[0050] Step 3: Put liquid plastic, 8 parts by weight of anti-aging flame retardant blend, 3 parts by weight of weathering agent, and 5 parts by weight of plasticizer into a high-speed mixer for dry mixing, and then place them in injection molding equipment to extrude to obtain a semi-finished panel frame;

[0051] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com